1. Introduction

Wood, being a natural resource and valuable building material, has been used in countless structural applications since ancient times. The continuous population growth and increase in wood demands, result in the constantly increasing woody biomass residues generation derived mainly from logging, timber mechanical processing, demolitions, old furniture/structures wood recovery etc. Various industries appear to have a strong interest in the utilization of this raw material, such as those of paper and pulp, wood-based composite materials, bioenergy and biofuels (pellets, briquettes) etc. Nevertheless, the most beneficial use among these options, are the one that maintain the carbon content absorbed in the material mass for as long as possible, such as the long service-life duration building materials and their structures (De ligne et al. 2022). Furthermore, the substitution of plastic or other energy-consuming materials by wooden elements is in the truck of eco-friendly building materials with low environmental impact. Currently, several types of synthetic fibres are used to transform a brittle cement matrix into a ductile and tougher one (Sierra Beltran and Schlangen, 2009): flexible fibres, such as polyvinyl alcohol, polypropylene, and polyethylene, and stiff fibres, such as glass or steel, are mainly used. On the other hand, artificial fibres require considerable amounts of energy and could be economically replaced with natural fibres (Sierra Beltran and Schlangen, 2010). Natural fibres, such as those of wood, reed and straw, have been utilized for thousands of years as reinforcement material of inorganic materials in bricks and mortars (Han et al. 2017). Since wood fibres, of both hardwood and softwood species, are abundant, lightweight, low-cost and less energy-intensive alternative to synthetic fibres, they are becoming more and more popular in the fibre-cement building product market (Shao et al. 2000). In particular, wood fibres incorporated in mortars could provide good indoor air quality (acting as moisture-buffering materials), good thermal insulation and acoustical absorbency (Da silva Bertolini et al. 2014, Vo and Navard, 2016, De ligne et al. 2022, Stefanidou et al. 2023). Flexural strength, fracture toughness, and dimensional stability all tend to improve with increasing wood fibre length and decreasing the fibre diameter for a range of fibre contents (Badejo 1988). Fibre content higher than 3% results in low density mortars, of improved insulating properties, though as well of lower mean static bending strength (Frybort et al. 2008, Soares Del Menez et al. 2007, Zakaria et al. 2016).

In general, the moisture content, density, chemical composition and morphological characteristics/geometry of fibres, fibres content, the matrix cohesion, the interface between the reinforcing fibre and matrix (Coutts and Cambell, 1980), as well as the water-to-cement ratio in the matrix, curing conditions and age, among others, constitute critical factors affecting the strength and almost all properties of the wood-cement composites (Shao et al. 2000).

Unfortunately, wood fibres demonstrate as well lower density and comparatively worse mechanical properties compared to the synthetic fibres, which also refers to the resultant composites (Campbell and Coutts, 1980). As an organic, hygroscopic material, wood fibres are prone to dimensional instability and micro-organisms catastrophic action. Their hydrophilic nature increases the water demand during mortar-mixtures preparation, affecting adversely the workability and homogeneity of the fibre dispersion (De ligne et al. 2022) and decreases their adhesion to the matrix (Moslemi 2008, Sierra Beltran and Schlangen 2008). Additionally, the natural fibres appear to be susceptible to degradation when exposed to alkaline environments conditions, such as those of cement mortars, restricting their utilization in construction industry (Morjene et al. 2020).

It is well known that wood consists of lignin, cellulose, hemicelluloses, extractives, and ash. Hemicelluloses are mostly made up of glucose, mannose, galactose, xylose, and arabinose as well as a few water-soluble monosaccharides (Han et al. 2017, Kamperidou 2019). When cement hydrates, these molecules tend to combine to create calglucon, which is covered in cement surface and blocks both cement and water. The cement hydration reaction rate slows down, the film gradually thickens, and the cement hardening rate gradually prolongs as the reaction goes on (Han et al. 2017). Effective approaches for resolving the incompatibility of wood fibres and cement are critical to their successful utilization as mortars reinforcement.

Treatments of wood fibres also focus on the increase of fibres dimensional stability against the changes of relative humidity that tend to cause swelling and shrinkage of the wood fibres and the prevention of this phenomenon subsequent micro-fracturing of the matrix during the cement hydration (Lin et al. 1994). In this direction, three methods have been mainly used so far for wood fibre modification, i.e., aqueous extraction, alkaline hydrolysis and coating with some substances on the fibre surface (retention treatment) (Han et al. 2017). Although these treatments effectively improve the performance of cement setting on wood surfaces, each one acts in a very different way. Aqueous extraction, mainly in hot water, removes inhibitory water -soluble compounds though demonstrates relatively low leaching efficiency and improvement (Han et al. 2017). The commonly used method of alkaline hydrolysis degrades hemicelluloses and sugars into non-inhibitory substances, by exposing the wood fibres to NaOH solution, in order to dissolve out the monosaccharides, though it is considered an intensive treatment that causes the destruction of both hemicelluloses and cellulose, highly deteriorating in this way the wood fibres mechanical strength (De ligne et al. 2022). In the retention treatment, a thin coating is formed on the wood surface and inhibitory substances are not released to the setting medium, nevertheless, the final mechanical properties of the resulting composites do not appear to be satisfying (Han et al. 2017).

Hydro-thermal modification constitutes a non-biocidal, environmentally friendly and low-cost wood protection method applied to enhance the behavior of wood and wood fibres and some properties critical for its service life expectancy and utilization perspectives. In the presence of steam, heat induces changes to the chemical constituents of wood, altering as well its physical, hygroscopic and mechanical properties. This treatment may cause a decrease in the density and therefore, in mechanical strength of wood fibres, especially when intense conditions are applied (high temperature, pressure, duration), though it seems to limit the hygroscopic nature of the material, because of the gradual thermal degradation of hemicelluloses and amorphous parts of cellulose (Cai et al. 2020), and enhances the natural durability of wood (Kamperidou 2019), providing the chance, (especially to species characterized by low water resistance, dimensional stability and high susceptibility to bio-degradation factors), to be adequately utilized, participating in a much wider range of applications (Stefanidou et al. 2021). Additionally, by restricting the hygroscopicity of the wood fibres, the workability of these fibres in cementitious matrices is being improved (Lin et al. 1994, De Ligne et al. 2022, Stefanidou et al. 2022). The depolymerization of wood fibres hemicelluloses could also effectively improve the cement curing properties of the wood-cement mortar, to some extent (Han et al. 2017). During the treatment, some volatile extractives that demonstrate retarding effect on cement hydration are being released in the atmosphere. Additionally, the thermal degradation of chemical components may slightly increase the surface roughness of the wood fibres, contributing to higher adherence and affinity to the matrix (Cai et al., 2020).

Although, lignocellulosic fibres have been employed so far in several experimental studies involving cement matrix, a great lack of information has been detected in the literature concerning the potential utilization and performance of wood fibres treated under a mild hydrothermal modification process in cement matrix and cementitious mortars. Therefore, in the present contribution, residual wood fibres of black pine and beech wood species (two commonly used and abundant species) were incorporated in wood-cement composites (applying the proportion of 1.5% v/v fibres in mortar) to assess their performance as reinforcement materials, after their exposure to a mild hydrothermal modification. The mortars workability (at fresh state), physical, hygroscopic, thermal and mechanical characteristics at the age of 28, 90 and 365 days and weathering performance by subjecting them at different artificial ageing environments (freeze-thaw cycles or outdoor exposure) were examined.

2. Materials and methods

2.1. Materials

2.1.1. Wood fibres and hydrothermal treatment

For the purposes of this study, two forest species of Greek origin were used, those of black pine (Pinus nigra L.) and beech (Fagus sylvatica), grown in Kalambaka region. The wood material was transported to the laboratory in the form of boards, where it was cut and crushed into small pieces of fibrous particles (1-2 cm long) using a hammer mill, to let their moisture content easily reduce and incorporate them into cement mortars. The wood fibres remained for about 2 months in an air-conditioned chamber under stable conditions (temperature 20 ± 2 °C, 60 ± 5% relative humidity) till constant weight. Their equilibrium moisture content (EMC) was measured to be 10.73% for beech and 11.44% for black pine wood.

Then the wood fibres were subjected to a mild hydrothermal treatment at 140 °C in an atmosphere of saturated steam at the low pressure of 1.5 atm in a closed chamber system with a steam generating unit, in a laboratory custom-made device, for the duration of 2 hours from the moment of the final conditions stabilization in the chamber (temperature and pressure). At the end of the treatment, the wood fibres were cooled in glass desiccators and then weighed and stored in a conditioning chamber (20 ± 2 °C, 65 ± 3% relative humidity).

Fourier Transform Infrared Spectroscopy - Attenuated Total Reflectance (FTIR ATR) was performed at room temperature to the surface of treated and untreated wood fibres of the two studied wood species, to detect any potential chemical changes induced to these lignocellulose materials by the mild hydrothermal treatment. The measurements were implemented in the range of 500-4000 cm-1 in the respective FTIR-ATR device (Agilent technologies, Cary 630 FTIR ATR) and the software of FTIR “MicroLab” was used for the spectra processing and visualization.

2.1.2. Chemical analysis of fibres

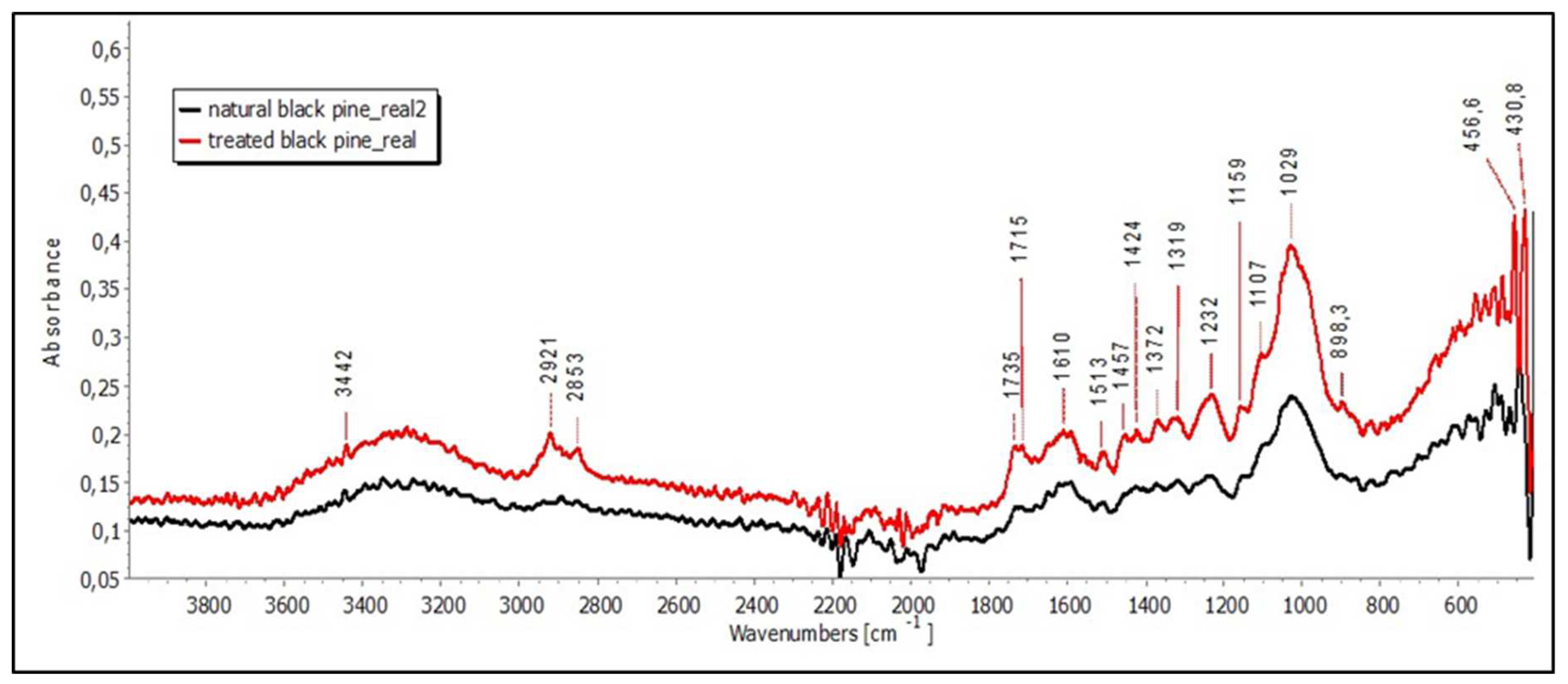

Even though in this paper there is no reference to untreated wood fibres, a comparative analysis was performed to understand the role of the hydrothermal treatment on their properties. According to the spectra of untreated and thermally treated black pine and beech wood fibres, derived from FTIR ATR spectroscopy, intense differences in anatomy, chemical compounds, chemical bonds and the structure between the untreated and treated black pine (

Figure 1) and beech (

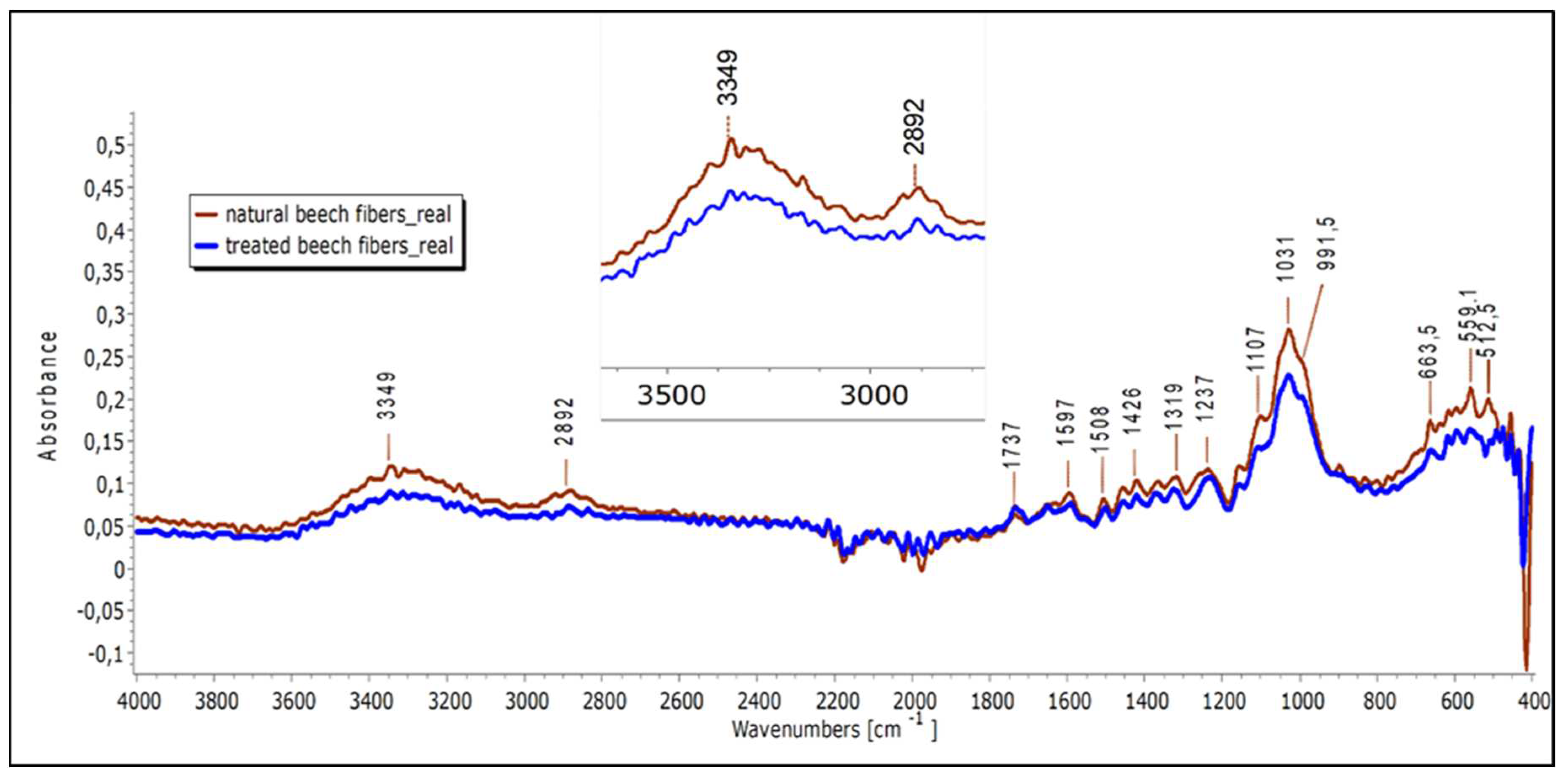

Figure 2) wood fibres were not detected (neither because of the treatment, nor between the two different wood species). The spectral line and peaks were found quite common indicating that wood bears the same functional groups and wood bond types among species, which result in various vibrations when the light bundle contacts the sample. Although the different bands that correspond to different characteristics of wood groups (hydroxyl groups, carbon chains, carbonyls, double bonds and absorbed water, aromatic rings, etc.) were examined, differences between spectra of treated and untreated wood are difficult to be identified, and complicated to be evaluated, since in wood mass a large number of reactions occur simultaneously during the thermal treatment process (Garcia et al., 2010).

According to the spectra of both species, a slight increase in carbonyls (C=O) of hemicelluloses has been identified in the spectrum band of 1700 - 1730 cm-1, which applies to both species of wood fibres examined. The mild hydrothermal treatment appeared to induce changes of low intensity and shifts of the spectral lines in the areas that correspond to wood components. There is a slight difference between the untreated and treated samples in the range of 1462 - 1425 cm-1 and 1384 - 1346 cm-1, where the key structural wood components, of cellulose and hemicelluloses are depicted, supporting the hypothesis that even such a mild hydro-thermal treatment may affect the level of wood components.

In case of black pine, the data reveal that there was no major change in the 3430 cm-1 band, which corresponds to O-H stretching vibrations of alcohols (3600 – 3300 cm-1) and carboxylic acids (3300 - 2500 cm-1) and concerns equally polysaccharides and lignin, while in the case of beech wood slight changes have been detected, corresponding to O-H stretch vibrations revealing a decrease of polysaccharides in the mass of wood. Concerning both species of wood fibres, the hydroxyl groups were found slightly decreased by the hydrothermal treatment. The two bands at 2900 cm-1 and 2800 cm-1 consist of the overlapping of the stretch asymmetric vibrations of the -CH2- (the band around 2921 - 2853 cm-1) and -CH3 (the band around the 2970 - 2950 cm-1), as well as of the overlapping of stretch symmetric vibrations of the -CH2- (band about 2865 - 2845 cm-1) and -CH3 (2880- 2860 cm-1). In these bands, a slight shift is detected. According to the literature, it is expected that thermally treated wood presents a decrease in this band especially in mild treatments (Esteves et al. 2013, Kamperidou 2021). Beech recorded an increase and shifting in the band of 1735 cm-1.

In addition, a significant variation was found in the spectra for peaks at 1460 cm-1 and 1420 cm-1. Based on the literature, it is expected, the absorption peaks located at 1460 cm-1 and 1420 cm-1 to increase with thermal treatment (Kotilainen et al. 2000).

As regards the black pine wood fibres, the spectra band of 1600 - 1750 cm-1 revealed some slight differences between the C=O bonds of carbonyls and C=C bonds of alkenes of thermally treated and untreated fibres.

In the range of 1457 - 1424 cm-1 and 1372 -1345 cm-1, where the basic structural components of wood are depicted, a small difference is found between untreated and treated pine fibres, as in the case of beech wood, which strengthens the belief that the thermal treatment slightly affected the levels of these components, mainly the hemicelluloses which were slightly degraded due to hydrothermal treatment. In the bands of 1505 – 1512 cm-1, a slight reduction in methoxyl groups was detected, with the subsequent increase in mass loss during the treatment. In the area of 3600 – 3300 cm-1, which corresponds to O-H stretching vibrations of alcohols slight variations were detected in the spectra of treated and untreated fibres, as well as in the area of 3300 - 2500 cm-1 which corresponds to carboxylic acids, concerning mainly polysaccharides.

Therefore, several slight changes and shifts in the FT-IR ATR spectra lines of both species treated wood fibres revealed that the wood components have been slightly affected by even such a mild thermal treatment. The free hydroxyl groups were decreased, because of the slight and gradual thermal depolymerization of hemicelluloses. The extracts of pine and beech wood fibres exhibited a decrease, since the volatile ones have been evaporated, while some new extracts were formed by the hemicelluloses degradation products. In general, according to FTIR ATR findings, the fibres were found to be of enhanced properties compared to untreated fibres, without being intensively thermo-degraded by the treatment, which increases their utilization potential as raw materials in cement-based mortars and composites, enhancing these products properties and performance as well.

2.1.3. Preparation of mortars

In the context of the current research, three cement mortars (C’-) were produced including a reference-unreinforced mixture (R) and two wood-reinforced compositions. For the enhancement of the cement (type CEM I42.5) mortars, dry hydrothermally treated black pine (pn) and beech (fs) fibres, of 1-2 cm length, were applied in proportion of 1.5% v/v (fibres volume per mortar volume). This specific percentage was selected based on previous experience and study of old mortars, where often the amount of fibres included was not exceeding this value (Stefanidou et al. 2012). Concerning the rest mortars components, natural siliceous sand (0-4 mm) of river origin was utilized as aggregates and the water/binder ratio remained stable at 0.45. The binder/aggregate ratio was stable (1/ 2.5 by weight) in all cases. It should be mentioned that a small portion (% w/w: weight of additive per weight of binder) of superplasticizer (aqueous polycarboxylate solution) was added at the bio-reinforced mortars, seeking to achieve the expected workability (11±1 cm) based on EN 1015-3. The detailed mortars composition together with their succeeded workability are displayed in

Table 1. Evaluating these results, it seems that the mild hydrothermal treatment minimizes the hydrophilic nature of wood fibres, as with the provision of a small superplasticizer portion similar workability with the reference sample is accomplished.

For the implementation of the experimental tests, prismatic (4 x 4 x 16 cm3) and slab (20 x 20 x 2.5 cm3) specimens were prepared. After demolding, all samples (except those intended to be employed for the determination of volume stability and water vapor permeability) were placed in a climatic chamber under stable conditions of 20 ± 2 oC and 95% ± 5% relative humidity and remained at these curing conditions till testing process (namely after 28, 90 and 365 days of hardening).

2.2. Methods

Physical, mechanical and artificial ageing tests were performed to the prismatic specimens, while hygroscopic and thermal properties measurements were performed to the slab specimens, respectively. Analytically, at all ages experiments were conducted involving the determination of the mortars apparent specific gravity, absorption and open porosity values (according to RILEM CPC11.3), capillary absorption (based on EN 1015-18), drying rate indicating the first 24 drying hours (according to EN 16322), mechanical properties referring to the compressive and flexural strength (based on EN 1015-11) and dynamic modulus of elasticity (based on AN 12504-4). The investigation on the compositions physical behavior completed with the evaluation of their volume stability. The specific assess was achieved by keeping the prismatic mortars (after demolding) at a climate chamber of stable conditions of 20 ± 2 oC and 50 ± 5% rh and measuring their dimensions, at a daily basis, with a digital vernier caliper until volume stabilization, this usually occurs during the first 28 ageing days in cement mortars (Kesikidou and Stefanidou 2019).

Regarding the mortars thermal aspect, the thermal conductivity coefficient (λ) was detected applying the heat flow meter apparatus. More precisely, the λ values were determined with the utilization of the device HFM 100 Series-Thermtest (conforming with EN 12667), at all maturing times (previously mentioned), at two mean heating temperatures (10 oC and 20 oC). To achieve these temperatures, a difference of 10 oC was required between the two heating-cooling plates of the instrument. Hence, to perform the test at 10 oC (mean temperature) the lower plate was set at 15 oC and the upper at 5 oC, while for the 20 oC (mean temperature) the lower plate was set at 25 oC and the upper at 15 oC. Prior to the measurements, the specimens were subjected to a drying-smoothing procedure to restrict the moisture content influence and meet the surface requirements of the device manufacturer. This included their placement to a climate chamber under the conditions of 20 ± 2oC and 50 ± 5% rh till constant mass (the determination of the mass changes was carried out applying successive weight measurements) and then, sanding the slabs surfaces until smooth and parallel sides were formed. For each composition, three slabs were assessed.

As for the hygroscopic investigation of the specimens, water vapor permeability tests were performed based on the principals of EN 1015-19 and EN ISO 12572. This included the storage of the slab samples (after demolding) for 2 days at moist conditions (climatic chamber with 20 ± 2

oC and 95 ± 5% rh) and for 26 days at dry conditions (20 ± 2

oC and 50 ± 5% rh) as a primarily step prior to testing. Afterwards, the test set ups were formed by sealing with hot glue silicone the mortars over cylindrical test cups, which contained an air gap of 2.5 cm and a saturated solution of potassium nitrate (KNO

3). This solution provided within the set up 97% rh at 21

oC. Aluminum foil was used for the mortars peripheric covering. After that, the set ups were placed in the climatic chamber at 20 ± 2

oC and 50 ± 5% rh and daily weighted until a steady state vapor transmission rate was achieved. The calculation of the mortars water vapor permeability Wvp involved the multiplication of the water vapor permeance Λ (described below) with the slab thickness. Then the water vapor diffusion resistance factor μ (dimensionless quantity) was defined as a ratio of the air water vapor permeability to the mortar water vapor permeability. Water vapor permeance equation in [kg/m

2*s*Pa]:

where A describes the area through which the water vapor diffusion occurs (m

2), Δ

P is the partial water vapor pressure difference of the set-up air and the climate chamber air (Pa) and, finally, R

A defines the set-up air gap water vapor resistance (0.048*10

9 Pa*m

2*s/kg per 10 mm air gap).

Finally, the mortars weathering performance was evaluated by subjecting the 90 days prismatic samples to different artificial ageing environments including exposure to freeze-thaw cycles and outdoor conditions. In correlation with the first case, the mortars were submitted to 60 freeze-thaw cycles based on ASTM C666/ C666M – 03 incorporating freezing in air (-18 ± 2 oC) for 4.5 hours (h) ± 0.5 h and thawing in water (specimens immersed in water) at 4 ± 2 oC for 19.5 hours ± 0.5 h. During this durability procedure, the wet mortars dimensions (utilizing a digital vernier caliper) and dynamic modulus of elasticity (based on EN 12504-4) were recorded. The choice of the specific cycles number (which usually in literature is over 300 for cement compositions) was taken in the frames of avoiding the mortars visible deterioration and achieving their mechanical properties measurement (Çavdar 2014). According to the outdoor exposure environment, the specimens remained for 8 months at exterior conditions. During this experiment, the volume changes and the dynamic modulus of elasticity of the specimens were evaluated. For each ageing technique, 3 samples of every composition were tested. In the end of the weathering exposure, the mortars porosity, dynamic modulus of elasticity (in dry state), compressive and flexural strength were assessed (according to standards mentioned previously).

3. Results and discussion

3.1. Physical properties

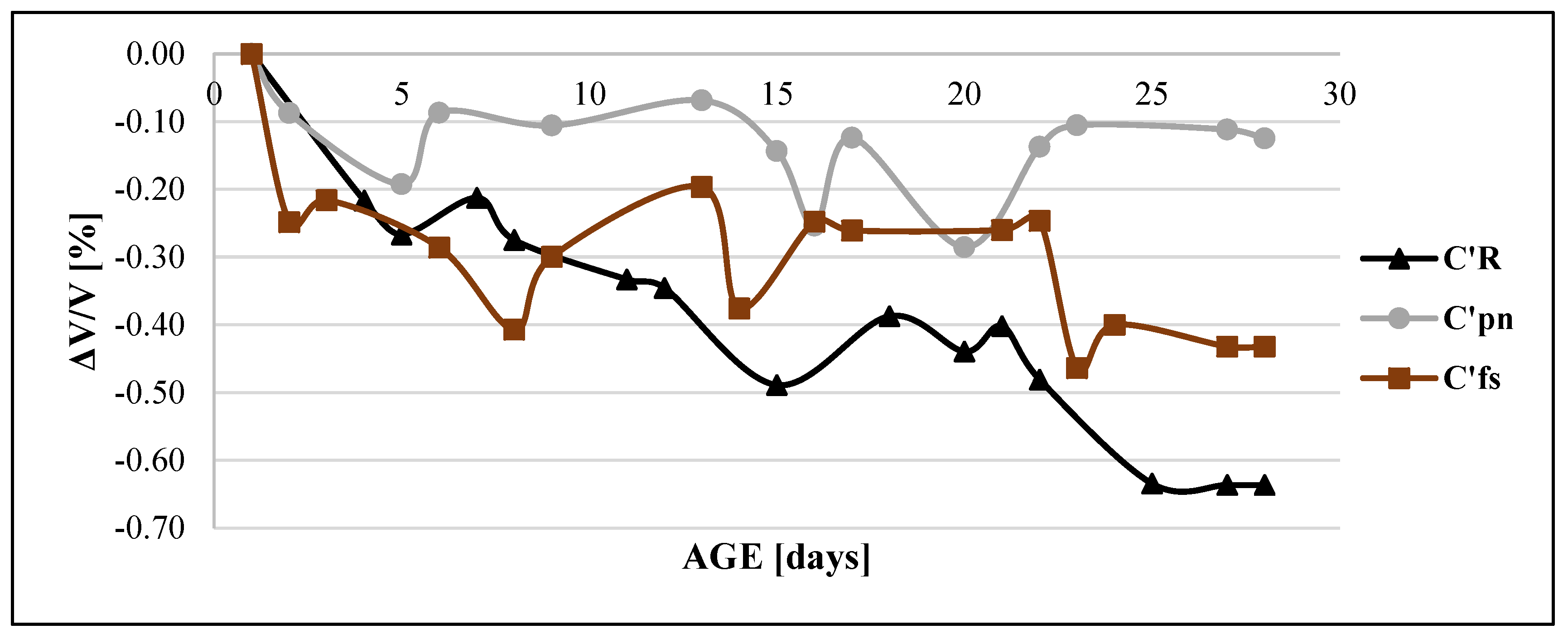

Evaluating the mortars volume deformations, presented in

Figure 3, it seems that the addition of treated wood fibres in cement mortars improved their volume stability. This observation could be justified by the decreased volume changes of the reinforced compositions in comparison with the reference samples. In general, during hardening, cement materials tended to shrink due to moisture loss. This water movement originated from the chemical reactions occurring inside the cement structure (hydration process) or the interactions with the exposure environment conditions (drying-water evaporation). Considering these, the volume stabilization of the bio-reinforced cement mortars is probably affected by the fibres water absorbency, which led to moisture release in the cement matrix (Markovski et al. 2012, Ajouguim et al. 2022). Considering the different wood fibres performance, the black pine fibres indicated the most stable behavior during maturing, which is in accordance with their higher mechanical strength, higher lignin content and higher release of moisture in the cement matrix compared to the beech fibres (Kamperidou 2021, Stefanidou et al. 2023). In all cases, the mortars dimensions tended to stabilize after the age of 24 days.

As regards the characterization of the mortars’ physical properties, presented in

Table 2, the presence of the bio-fibres enhanced the water absorbency and the porosity values of the specimens, while the samples became slightly lighter. The wood fibres low density influenced the specific gravity of the final-reinforced cementitious composites (Zobel 2004). Comparing the two wood species fibres impact, the highest differences from the reference samples properties levels were recorded by beech fibres (97% absorption increase at the age of 28 days or 37% after 365 hardening days and 89% porosity increase at the age of 28 days or 32% after 365 hardening days). Although, the fibre-reinforced mortars displayed similar specific gravity values over time, with the difference from the reference composition to extend about -4.1% at the age of 365 days. Evaluating the mortars physical properties over time, the unreinforced samples presented an increase in the water absorption capacity from 28 to 90 days of ageing and then, stabilized values were recorded till 365 days, while pn enhanced mortars showed stable physical properties through maturing process (with low variations) and finally, the fs-reinforced specimens displayed a decline in porosity-absorption values from 28 to 90 hardening days and then a stabilization process till the age of 1 year. In addition, the compositions preserved their specific gravity rates during hardening (with low variations). A possible explanation of the above phenomenon lies in the formation of micro shrinkage cracks due to ageing in the pure cement structure and their avoidance at the fibre reinforced cases due the fibres swelling (this is in accordance with the mortars volume deformations from the

Figure 3). Also, the moisture release from the fibres promoted the hydration process of the non-hydrated calcium silicate compounds (Esteves 2011) with their products to fill the existing voids.

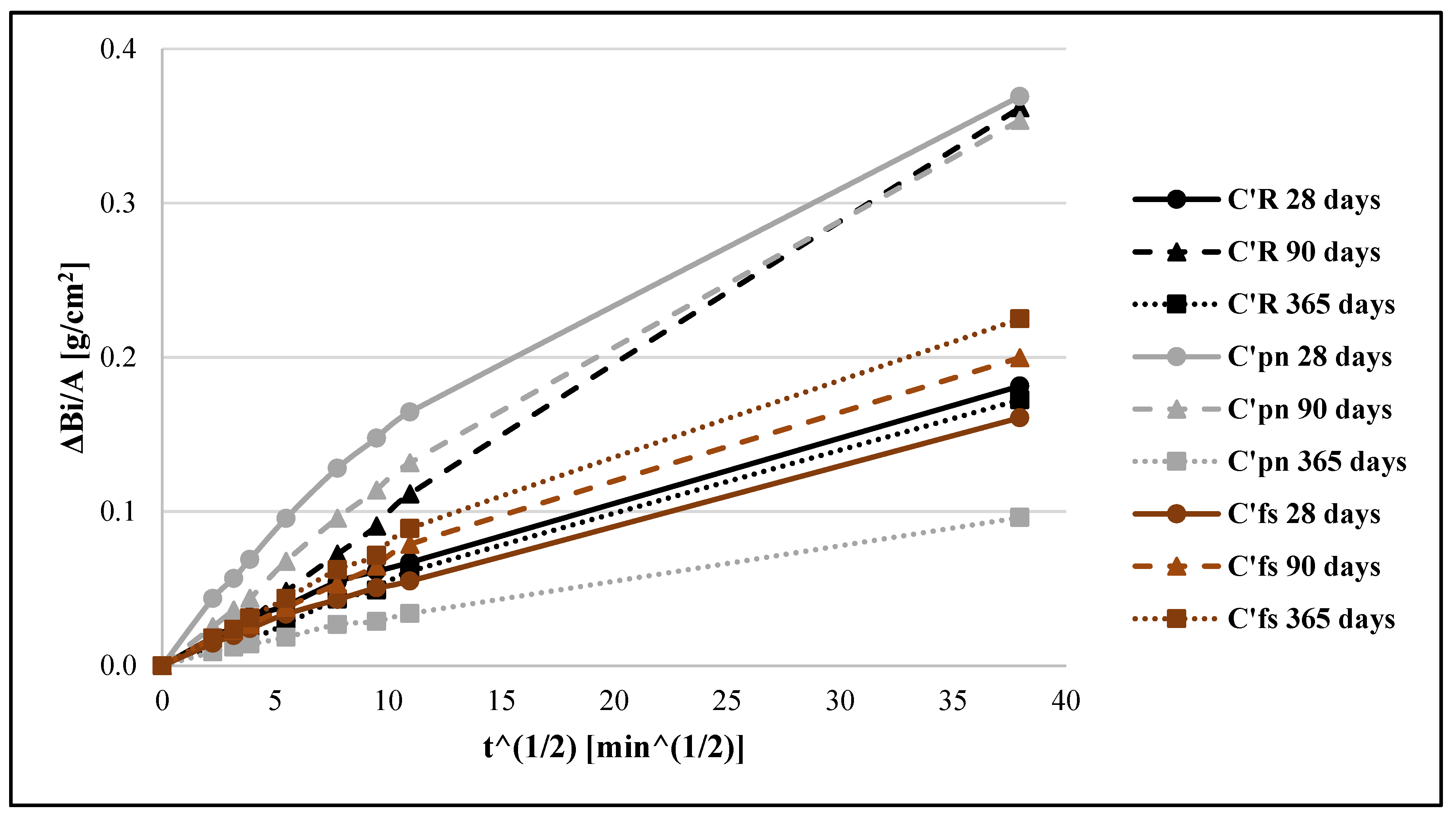

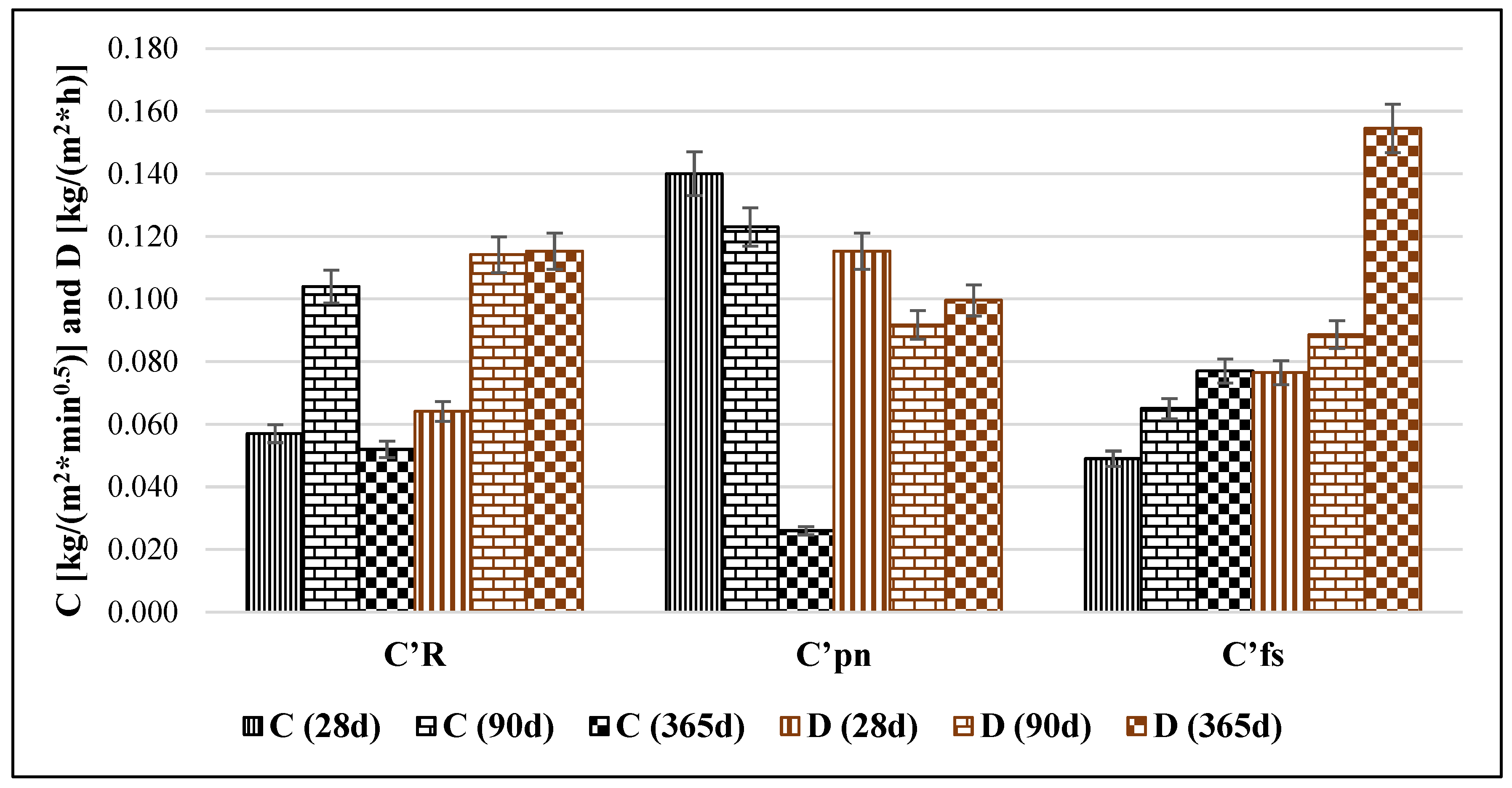

The capillary absorption of the specimens is affected both by the addition of bio-fibres (depending on the wood species) and their hardening time. According to

Figure 4 and

Figure 5, it appears that the reference mortars maintained stable their tendency for capillary absorption over time (referring to the first and final recording), although from 28 to 90 days there was an increase of about 82% at the capillary water absorption coefficient (C). This increase probably relates to the porosity increase and the formation of shrinkage cracks mentioned previously, which amplifies the communication of the internal micropores. This behavior was normalized during maturing, when the hardening products reduced the voids and diminished their interconnection (De Azevedo 2021). Examining the fibres performance, the two reinforced mortars behaved differently. As it is presented in

Figure 4 and

Figure 5, the C’pn case displayed a decreasing absorption inclination through ageing, with lower water absorption values from the reference case at the age of 365 days (-50% variation of C value). In contrast, the C’fs case presented an increasing corresponding tendency through maturing, recording shorter capillary curves than the reference composition between 28 and 90 hardening days. Apparently, the pores connection system was affected by the mortars porosity and hydration process of cement, since their interaction was impaired in pn-case (porosity remained stable, but the hydration products minimized the pores connection) and improved in fs-type (porosity was decreased, but interconnected micro-pores may be formed). A rational explanation arises probably from the fibres structure, which affects the interaction zone of fibres-cement matrix and contributes to the formation of the mortars capillary systems.

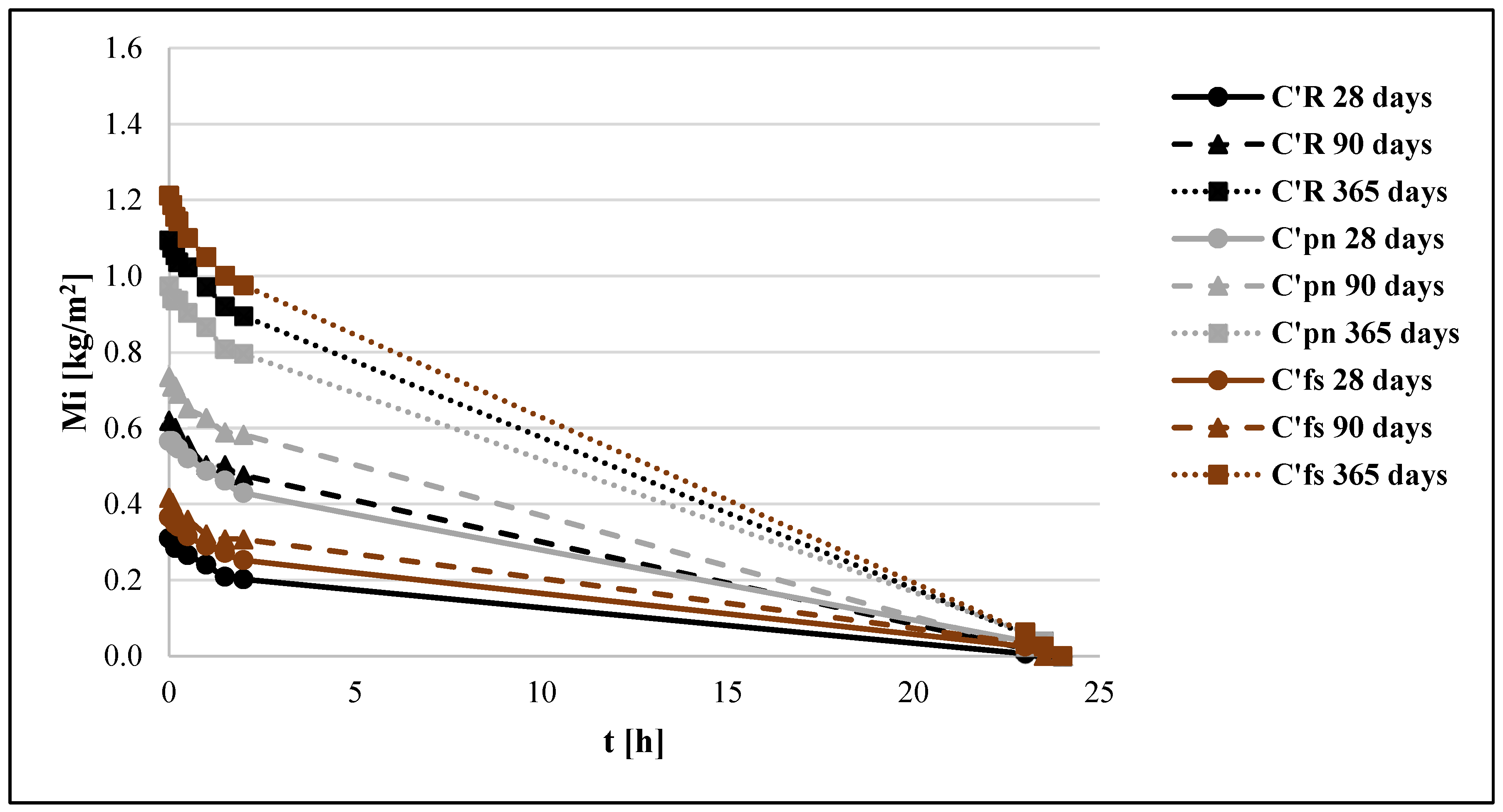

Finally, analyzing the specimens drying curves (

Figure 6), it was observed that all compositions became less dense during maturing, as the drying phases became longer. The specific behavior related to the porosity values of the C’R and C’pn cases and to the capillary absorption tendency of the C’fs composition. Concerning the effect of the wood fibres in the mortars drying procedure, it appeared that at early ages (28 days) the presence of fibres boosted the drying action of the cement mortars (with the reference case to be the densest), while after 365 hardening days the C’pn mortars became the most dense (which displayed the lowest capillary absorption coefficient at this age). On the other hand, after 365 maturing days, the C’fs case showed the highest drying rate that corresponded to an increase of about 34% from the reference composition (

Figure 5).

3.2. Mechanical properties

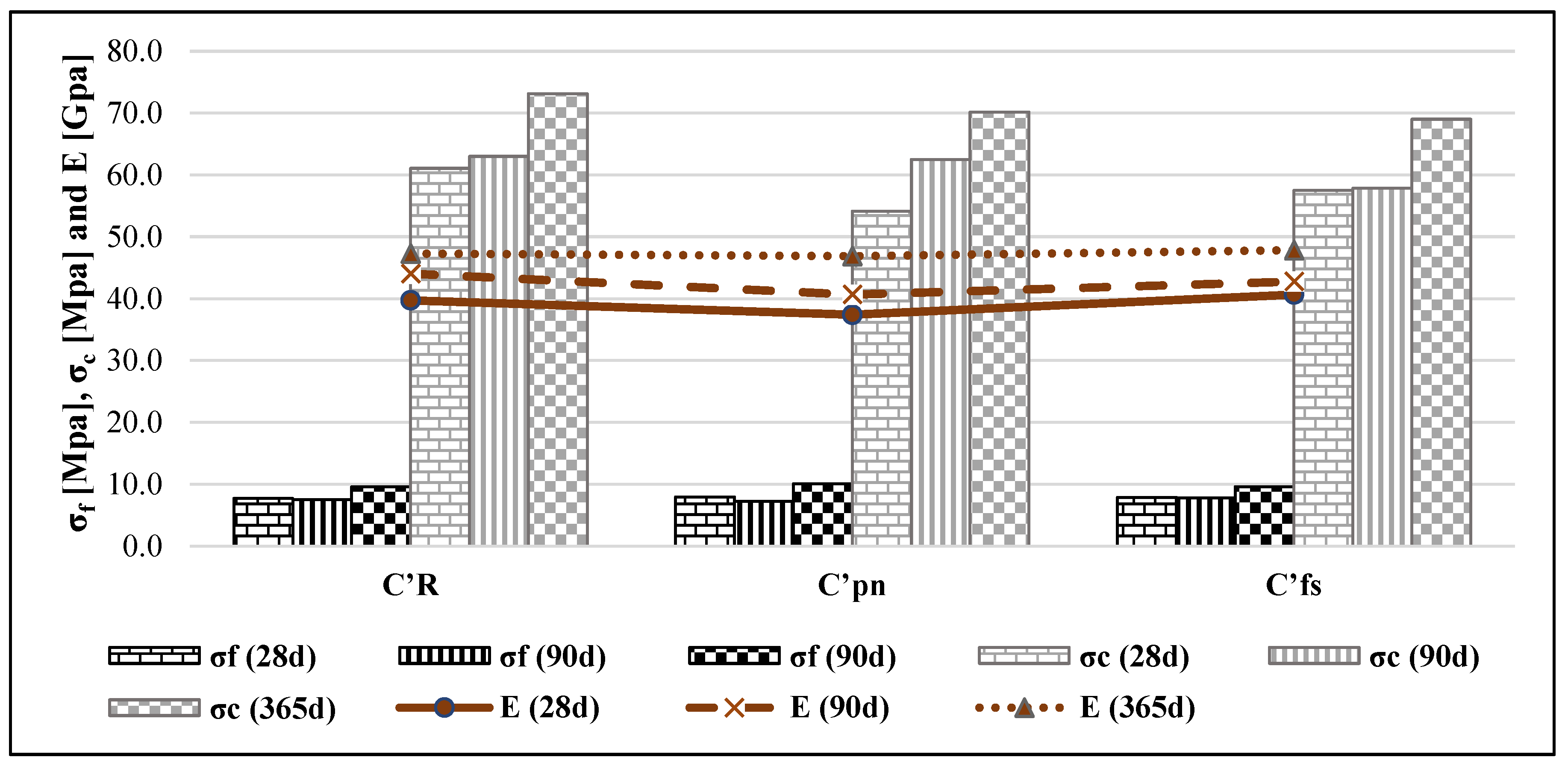

While maturing, the mechanical properties of all compositions were enhanced marking a gradual improvement (

Figure 7). More specifically, regarding the strength improvement of the mortars from 28 to 365 days, the flexural strength was enhanced about 25%, 27% and 22%, and the compressive strength was improned about 20%, 30% and 20% for the C'R, C'pn and C'fs sample cases, respectively. However, this uniform behavior was interrupted concerning the flexural strength of all samples categories from 28 to 90 ageing days, when a decrease about 3%, 9% and 1% was observed (for C’R, C’pn and C’fs mortars respectively). The specific improvement of the mortars mechanical characteristics could be attributed to the hydration process of cement and the curing conditions, as the wet environment provided the humidity required for the hydration of the non-hydrated compounds (Seyam and Nemes 2023, Caronge et al. 2017). Moreover, the flexural strength reduction from 28 to 90 days is probably related to the corresponding porosity increase of the samples (

Table 2).

The treated wood fibres incorporated in cement matrix, provided enhanced flexural strength and slightly lower compressive strength (

Figure 7), during hardening, in comparison to the unreinforced specimens. The most beneficial effect on the cement mortars flexural behavior for each hardening time (28, 90 and 365 days) was about 3.3% (pn fibres), 3.6% (fs fibres) and 5.4% (pn fibres) increase respectively. On the other hand, concerning the compressive strength, the lowest reduction was about 5.8% (with fs fibres), 0.8% (with pn fibres) and 4.0% (with pn fibres) for the previous hardening ages, which could be justified by the higher porosity values of the bio-enhanced samples. The performance of treated wood fibres in cement mortars mechanical properties confirmed the results presented in literature, revealing that bio-fibres tend to reinforce the low flexural strength of cement compositions by bridging the cracks through the pull-out procedure (Lin et al. 2023). Meanwhile, the presence of bio-fibres usually adversely affects the compressive strength of cement mortars due to the destruction of hydrogen bonds (formed between matrix and fibres) caused by the water absorption during hardening in wet environment (Kesikidou and Stefanidou 2019, Tolêdo Filho et al. 2000). High differences in the response of the samples reinforced with different wood species fibres were not detected.

Finally,

Figure 7 displays the samples dynamic modulus of elasticity (E) throughout one year of ageing. The results indicated the improvement of the mortars rigidity during hardening, which responded to the compressive strength evolution (Chavhan and Vyawahare 2015). The specific increase was equivalent to 19%, 25% and 16% from 28 to 365 days for the cases of C’R, C’pn and C’fs, respectively. Furthermore, the addition of black pine fibres contributed to the reduction of the mortars E values, while as time was passing by, this differentiation was normalized till the 0.8% decrease at the age of 365 days. In contrast, the beech fibres-reinforced samples presented similar values to the reference composition through all maturing times. This bio-reinforced mortars behavior was probably affected by the fibres E value and the composition structure. More specifically, it has been proved that the saturated bio-additive E value is a scale lower from the corresponding at dry state, which negatively affected the mortars modulus of elasticity. Moreover, the existence of flaws, namely voids and microcracking, in the mortars structure also reduces their stiffness (Jongvisuttisun and Kurtis 2015).

The fibres performance through 365 days of ageing designated their durability and satisfactory functionality in alkaline environments. This statement can be documented by the fact that the weakening of the bio-additives would lead to a mechanical strength impair, as mechanisms like fibres mineralization or cellulose alkaline hydrolysis could act (Tolêdo Filho et al. 2000, Wei and Meyer 2014).

3.3. Hygrothermal properties

According to the compositions thermal behavior, displayed in table 3, it seems that cement mortars maintained their high thermal conductivity values during ageing. There was a slight decrease of about 0.8-4.3% between 28 and 90 hardening days and a higher reduction of about 2.8%-14.9% for all samples at both temperatures tested, probably due to the porosity rise and the micro-cracking formation (Smith et al. 2013). Furthermore, the presence of wood fibres in cement matrix induced a reduction in λ values about 32.7-36.2% for the C’pn samples case (compared to the reference at all ages) and a corresponding decrease of about 10.1-27.5% for the C’fs specimens. The explanation of this behavior lies on the higher porosity and lighter structure records of the reinforced samples compared to the reference (

Table 2) and to the thermal insulation nature of the bio-fibres. According to the Technical Guideline T.O.T.E.E. 20701-2/2017 of the Technical Chamber of Greece (TGG) (Androutsopoulos et al. 2017) the pine wood λ value is 0.14 W/(m*K) and the beech wood value is 0.17 W/(m*K), which are an order of magnitude lower than the pure cement matrix material (C’R case).

Proceeding with the samples’ hygroscopic characteristics (

Table 3), the water vapour permeability of the cement mortars was improved through the bio-additions, especially in terms of the buildings good indoor air quality (Vo and Navard, 2016, De ligne et al. 2022). More specifically, the pn fibres contributed to a 22.8% decrease in the water vapour resistance factor (μ) compared to the reference case, while fs fibres were conducive to a corresponding 10.5% decline, attributed to the pores’ tortuosity (Romano et al. 2021). Hence, the bio-reinforced mortars, with higher porosity values than the reference composition, were found to demonstrate an advanced ability for moisture transfer inside their structure leading to a regulation of the living conditions in the case of inhabited edifices in accordance to the literature (Zhang et al. 2012).

3.4. Weathering performance

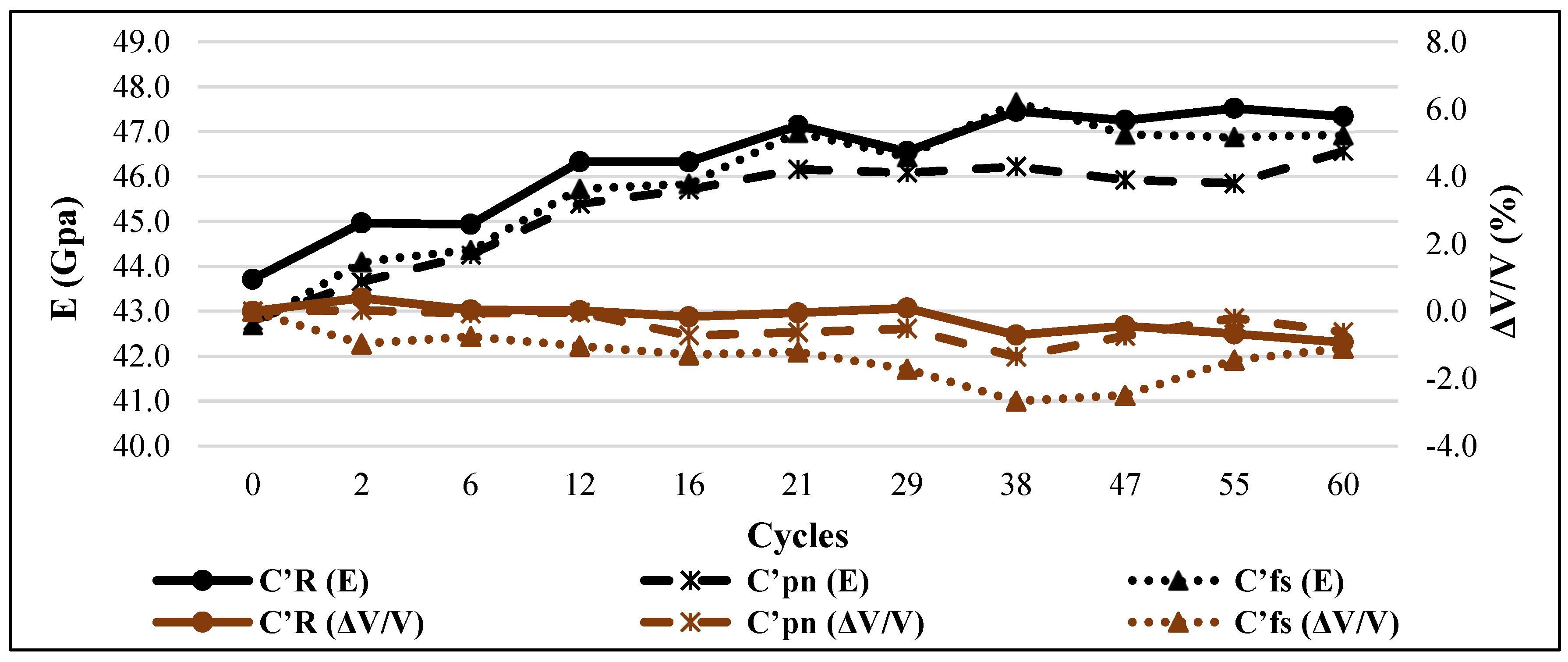

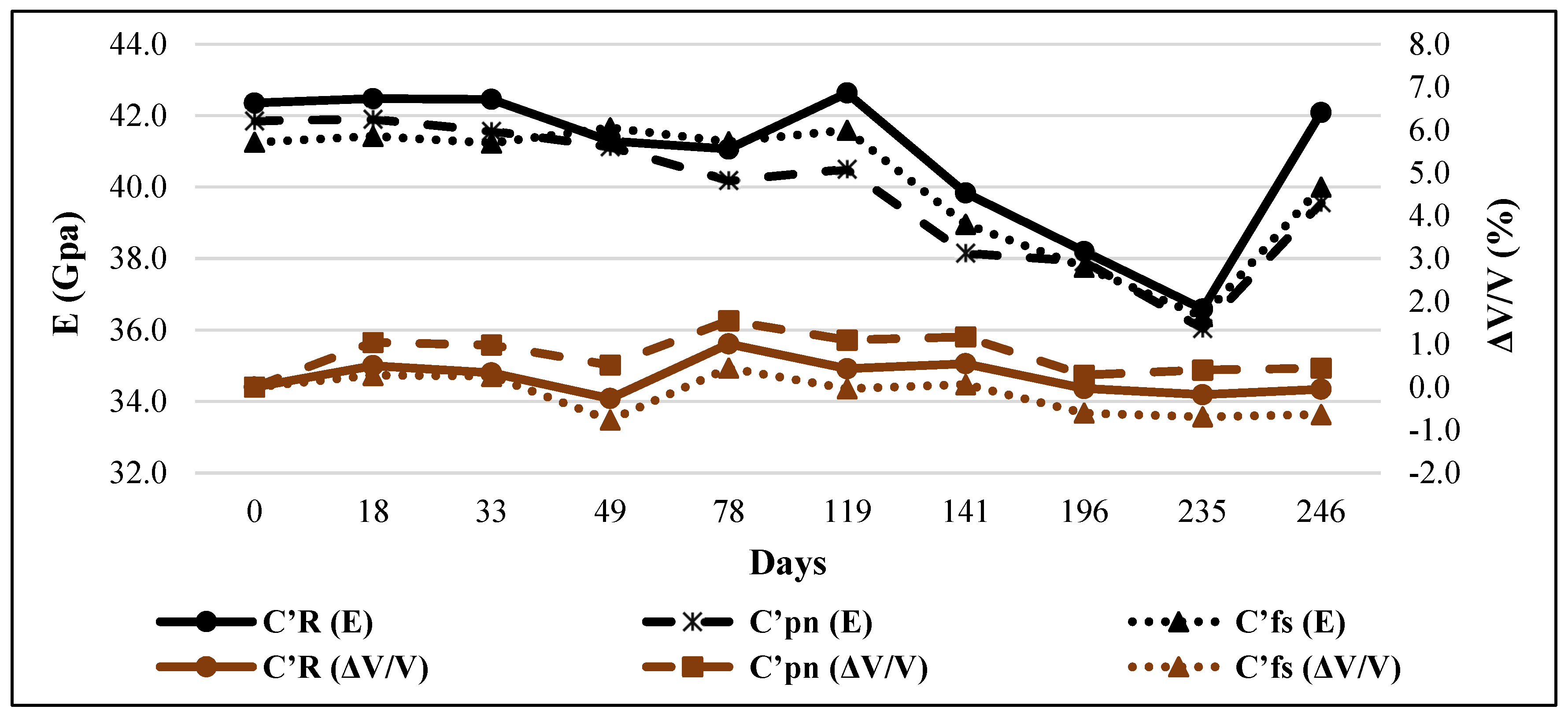

Evaluating the E and volume deformations curves of the cement mortars during artificial ageing (

Figure 8 and

Figure 9), similar modification patterns of the slope were observed between the reference and the reinforced compositions under both weathering conditions. In a more detailed observation, at the freeze-thaw cycles the C’R and C’fs samples presented similar E values, with the C’pn values to be the lowest one. Nevertheless, in relation to the volume deformation, the C’R and C’pn compositions displayed the most stable dimensional stability. The gradual increase of the specimens’ dynamic modulus of elasticity indicated the evolution of cement hydration process at these first stage of freeze-thaw cycles, which overcame the freeze-thaw effect due to the phase change of the water inside the materials voids (Zhang et al. 2022). Moreover, the fibres role was probably not significant yet, since the deterioration process was not fully developed (Çavdar 2014). According to the curves of the mortars for the outdoor exposure, the fs reinforced samples case displayed the most stable E behavior, regarding to the changes between successive timing moments. Furthermore, in correlation to the dimension deformations the C’R and C’fs presented higher volume stability than the C’pn. At the specific severe exposure conditions, where constant temperature, humidity, ultraviolet (UV) radiation, CO

2 subjection and air changes interact (Soroushian et al. 2012, Tolêdo Filho et al. 2000), it seemed that the porosity values and the voids connection affected the materials properties. Hence, the fs fibres reinforced mortars, with similar porosity of the R samples case and the lowest capillary absorption at the age of 90 days (the beginning of the cycles), improved the cement mortars behavior, while the humidity absorption and movement were probably minimized.

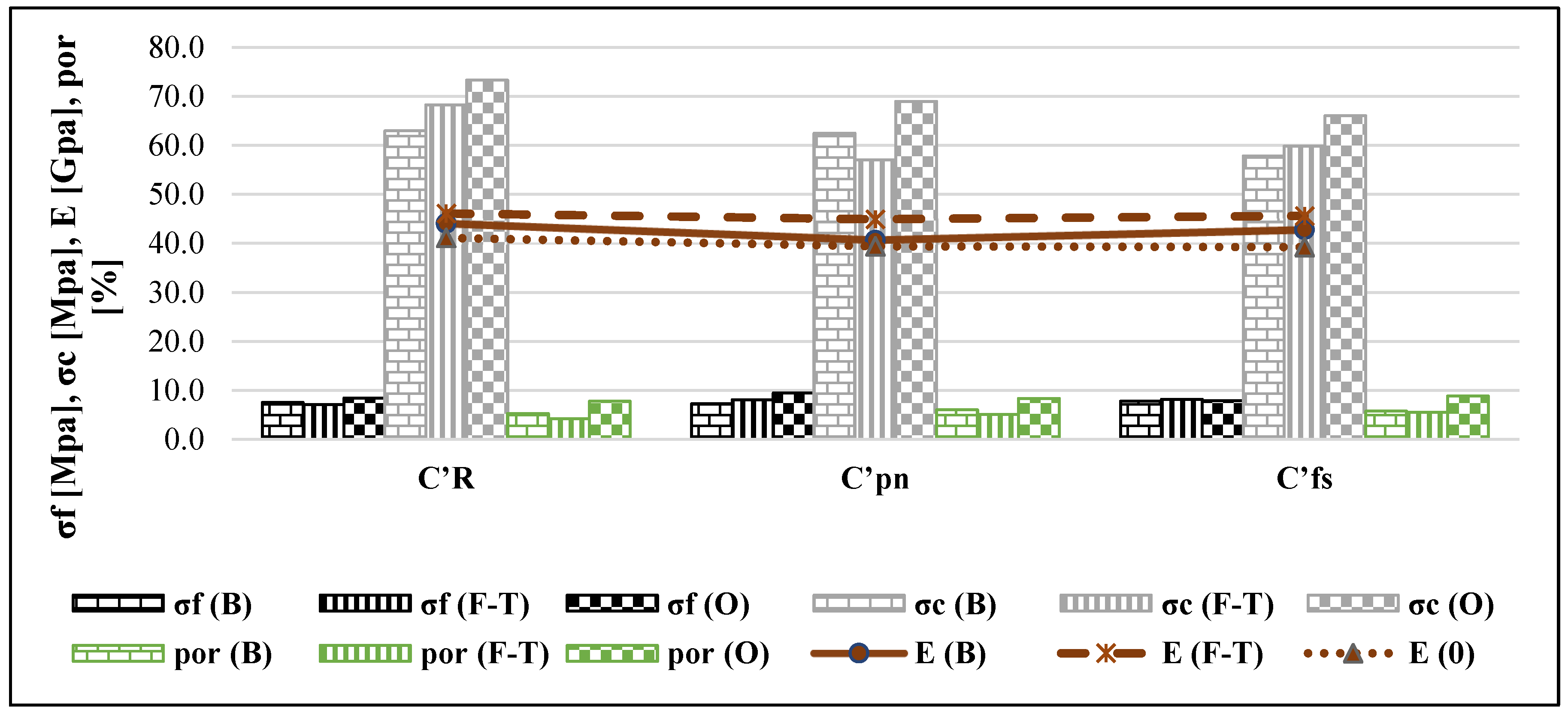

Τhe confirmation of the above formulations was achieved by evaluating the mechanical properties results presented in

Figure 10. The mortars subjected to freeze-thaw cycles displayed in most cases advanced E and mechanical properties at the end of the experiment (due to cement hydration), while the porosity decreased due to the reduction of pores/voids (Zhang et al. 2022). On the other hand, the outdoor exposure led to a porosity increment and E reduction likely on account of microcracks formation. Nevertheless, the mechanical properties were improved probably due to the chemical reactions continued. The moisture enhanced from rains during that period probably contributed to that direction. The highest flexural enhance was found in C’pn sample case (30.6%). In relation to the fibres impact, in the end of the freeze-thaw cycles, both reinforced compositions displayed advanced flexural strength compared to the C’R composite case, in contrast to the outdoor exposure where only the pn-enhanced samples showed a corresponding improvement. Furthermore, in the end of both weathering exposures, the reinforced samples showed a lower compressive strength compared to the reference case, which could be attributed to their higher porosity values. Overall, the performance of the fibres through extreme weathering conditions at long term testing, indicated their durability and suitability for their utilization as cement mortar reinforcements.

4. Conclusions

In the current study, black pine and beech wood fibres were exposed to mild hydrothermal treatment and incorporated in cement mortars. The evaluation of their performance at different ages (after 28, 90 and 365 hardening days) indicated their beneficial role in dimensional stability, with the black pine fibres to present the lowest dimensional change, specific gravity and weight. Although, in terms of water absorbency and porosity values, the wood fibres promoted the tendency for voids formation, with the pn reinforced samples to maintain stable its porosity during ageing (in contrast to the other two compositions). Furthermore, through maturing, the capillary absorption tendency of the mortars differed, with the most beneficial composition to be the C’pn at the age of 365 days. In correlation with the drying curves, it seems that all samples became less dense through ageing and the R or C’pn samples were the densest after 28 or 365 hardening days respectively.

Concerning the mechanical characteristics of the mortars, all specimens presented advanced flexural and compressive strength through ageing and their rigidity was improved. As regards the fibres impact, they provided advanced flexural strength and contributed to a slightly decreased compressive strength. The pn fibres indicated the best flexural strength improvement about 5.4% at the age of 365 days and the lowest compressive reduction from 90 to 365 hardening days. Moreover, the modulus of elasticity of all specimens was found similar after one year.

The specimens preserved their high thermal conductivity values through ageing and the presence of bio-materials induces a λ decrease about 35% (at all maturing times) for the black pine samples and 19% for the beech samples. Furthermore, the wood fibres improved the water vapor permeability of the cement mortars considering the breathability of the material, with the C’pn composition to display the highest μ reduction (about 22.8%).

Under artificial ageing, the wood reinforced samples displayed similar modification of E and volume deformation patterns with the reference mortars, with the black pine fibres (and the beech fibres) to improve the volume stability of the cement mortars under freeze-thaw cycles (and outdoor exposure respectively). In most cases, in the end of artificial ageing, the mechanical properties of the mortars were enhanced, and their porosity values were decreased in freeze-thaw cycles and increased under outdoor conditions. Meanwhile, the reinforced mortars presented advanced flexural strength (except the fs case at outdoor exposure) and slightly declined compressive one, compared to the reference.

To sum up, the treated wood fibres-composites seem to remain integrated and the fibres to behave satisfactory in alkaline environments through all hardening conditions. Considering the minimization of the building energy consumption and the breathability boost of the structures, the black pine fibres were proved to be the most beneficial choice among the two wood species examined in the current study. The FTIR spectra of the fibres revealed a slight decrease in extracts, hemicelluloses and hydroxyl groups that have been induced by the mild hydrothermal treatment, which were proven to be favorable to the fibres performance in cementitious mortars.

Hence, their utilization in the construction sector could provide green, sustainable, and low-cost solutions for mortars reinforcements. Further investigation on the microstructure of the final wood-cement composites and the mortar-substratum adhesion could contribute to a thorough understanding of the treated wood fibres’ role and impact on cement mortars.

Acknowledgments

The authors would like to express their gratitude to Dr. Tsardaka Eirini for the support in FTIR ATR spectra generation and visualization and Prof. Barboutis Ioannis for the assistance in sawn wood processing and cutting processes.

References

- Ajouguim, S., Stefanidou, M., Abdelouahdi, K., Waqif, M., & Saâdi, L. (2022). Influence of treated bio-fibers on the mechanical and physical properties of cement mortars. European Journal of Environmental and Civil Engineering, 26(8), 3120–3135. [CrossRef]

- Androutsopoulos, A., Aptalidou, F., Aravantinos, D., et.al, (2017). EBPD 20701-2/2017. Detailed National Performance Specifications for the Thermophysical properties of building materials and control of the thermal insulation adequacy of buildings, 1st edition, 2017 Athens (Greece).

- Badejo, S O O 1988. Effect of flake geometry on properties of cement-bonded particle board from mixed tropical hardwoods Wood Sci. Technol. 22 357-69. [CrossRef]

- Cai, C., Javed, M. A., Komulainen, S., Telkki, V.-V., Haapala, A., and Heräjärvi, H. (2020). Effect of natural weathering on water absorption and pore size distribution in thermally modified wood determined by nuclear magnetic resonance. Cellulose 27, 4235–4247. [CrossRef]

- Campbell, M.D., Coutts, R.S.P. Wood fibre-reinforced cement composites. J Mater Sci 15, 1962–1970 (1980). [CrossRef]

- Caronge, M. A., Tjaronge, M. W., Hamada, H., & Irmawaty, R. (2017). Effect of water curing duration on strength behaviour of portland composite cement (Pcc) mortar. IOP Conference Series: Materials Science and Engineering, 271, 012018. [CrossRef]

- Çavdar, A. (2014). Investigation of freeze–thaw effects on mechanical properties of fiber reinforced cement mortars. Composites Part B: Engineering, 58, 463–472. [CrossRef]

- Chavhan, P.P., & Vyawahare, M.R. (2015). Correlation of Compressive strength and Dynamic modulus of Elasticity for high strength SCC Mixes. Int. J. Eng. Tech. Res., 3, 42–46.

- Coutts P and Ni P 1995 The relationship between wood pulp fibre properties and fibre cement composite performance Proc. 49th Appita Conf. 1995 (Hobart, Tasmania, Australia) pp 411-7.

- Da Silva Bertolini M, Inácio de Campos C, de Souza A M, Hallak Panzera T, Christoforo A Land Rocco Lahr F A 2014 Wood-cement composites from wastes of Pinus Sp. wood: effect of particles treatment Int. J. Compos. Mater. 4 146-9. [CrossRef]

- De Azevedo, A. R. G., Marvila, M. T., Tayeh, B. A., Cecchin, D., Pereira, A. C., & Monteiro, S. N. (2021). Technological performance of açaí natural fibre reinforced cement-based mortars. Journal of Building Engineering, 33, 101675. [CrossRef]

- De Ligne L., Van Acker J., Baetens J.M., Omar S., De Baets B., Thygesen L.G., Van den Bulcke J., Thybring E., 2022. Moisture Dynamics of Wood-Based Panels and Wood Fibre Insulation Materials. Front. Plant Sci., 2022, Sec. Plant Biophysics and Modeling, Vol. 13 (2022). [CrossRef]

- Esteves, B.; Velez Marques, A.; Domingos, I.; Pereira, H., 2013: Chemical changes of heat treated pine and eucalypt wood monitored by FTIR. Maderas Ciencia y Tecnologia, 15 (2): 245-258. [CrossRef]

- Esteves, L. P. (2011). On the hydration of water-entrained cement–silica systems: Combined SEM, XRD and thermal analysis in cement pastes. Thermochimica Acta, 518(1–2), 27–35. [CrossRef]

- Frybort S, Mauritz R, Teischinger A, Muller U 2008 Cement bonded composites: a mechanical review BioResources 3 602-26.

- Garcia, R. A.; de Carvalho, A. M.; Latorraca, J. V.; de Matos, J. M.; Santos, W. A.; De Medeiros Silva, R. F., 2010: Nondestructive evaluation of heat-treated Eucalyptus grandis Hill ex Maiden wood using stress wave method. Wood Science and Technology, 46: 41-52. [CrossRef]

- Han F.Q., Tan X., Zhao F.Q., 2017. Modification of Wood Fibre for Use in Cement Board. IOP Conf. Series: Materials Science and Engineering 281 (2017) 012020. [CrossRef]

- Jongvisuttisun, P., & Kurtis, K. E. (2015). The role of hardwood pulp fibers in mitigation of early-age cracking. Cement and Concrete Composites, 57, 84–93. [CrossRef]

- Kamperidou V. 2021. Chemical and Structural Characterization of Poplar and Black Pine Wood Exposed to Short Thermal Modification. Drvna industrija 72(2):155-167. [CrossRef]

- Kamperidou, V. The Biological Durability of Thermally- and Chemically-Modified Black Pine and Poplar Wood Against Basidiomycetes and Mold Action. Forests 2019, 10, 1111. [CrossRef]

- Kesikidou, F., & Stefanidou, M. (2019). Natural fiber-reinforced mortars. Journal of Building Engineering, 25, 100786. [CrossRef]

- Kotilainen, R.; Toivannen, T.; Alén, R., 2000: FTIR monitoring of chemical changes in softwood during heating. Journal of Wood Chemistry and Technology, 20 (3): 307-320. [CrossRef]

- Lin, C., Kanstad, T., Jacobsen, S., & Ji, G. (2023). Bonding property between fiber and cementitious matrix: A critical review. Construction and Building Materials, 378, 131169. [CrossRef]

- Markovski, G., Ćećez, M., Šahinagić-Isović, M. (2012). Shrinkage strain of concrete - causes and types. GRAĐEVINAR, 64 (9).

- Morjène L, Aloulou F and Seffen M 2020 Effect of organoclay and wood fibre inclusion on the mechanical properties and thermal conductivity of cement-based mortars Comptes Rendus.Chimie 23 733-46.

- Moslemi A 2008 Technology and market considerations for fibre cement composites 11th Int.Inorganic-Bonded Fibre Composites Conf. (Madrid) pp.113-29.

- Romano, Grammatikos, S., Riley, M., & Bras, A. (2021). Analysis of dynamic moisture movement within bio-based earth mortars. Construction and Building Materials, 306, 124862. [CrossRef]

- Seyam, A. M., & Nemes, R. (2023). Age influence on compressive strength for concrete made with different types of aggregates after exposed to high temperatures. Materials Today: Proceedings, S2214785323037975. [CrossRef]

- Shao Y., Moras S., Ulkem N., Kubes G. 2000. Wood fibre - cement composites by extrusion. Canadian Journal of Civil Engineering 27 (3). [CrossRef]

- Sierra Beltran M G and Schlangen E 2008 Wood fibre reinforced cement matrix: a micromechanical based approach Key Eng. Mater. 385-7 445-8.

- Sierra Beltran M.G., Schlangen E., 2009. Interface bond characteristics between wood fibres and a cement matrix. Brittle Matrix Composites 9, (2009) 43-51. [CrossRef]

- Sierra Beltran M.G., Schlangen E., 2010. Fibre-matrix interface properties in a wood fibre reinforced cement matrix. Fracture Mechanics of Concrete and Concrete Structures-High Performance, Fibre Reinforced Concrete, Special Loadings and Structural Applications- B. H. Oh, et al. 2010 Korea Concrete Institute, ISBN 978-89-5708-182-2. Proceedings of FraMCoS-7, May 23-28, 2010, 1425-1430. https://www.framcos.org/FraMCoS-7/12-07.pdf.

- Smith, D. S., Alzina, A., Bourret, J., Nait-Ali, B., Pennec, F., Tessier-Doyen, N., Otsu, K., Matsubara, H., Elser, P., & Gonzenbach, U. T. (2013). Thermal conductivity of porous materials. Journal of Materials Research, 28(17), 2260–2272. [CrossRef]

- Soares Del Menez C H, de Castro V G and de Souza M R 2007 Production and properties of amedium density wood-cement boards produced with oriented strands and silica fume Maderas. Cienc. Tecnol. 9 105-15.

- Soroushian, P., Won, J.-P., & Hassan, M. (2012). Durability characteristics of CO2-cured cellulose fiber reinforced cement composites. Construction and Building Materials, 34, 44–53. [CrossRef]

- Stefanidou M., Kamperidou V., Konstantinidis A., Koltsou P., Papadopoulos S., 2021. Use of Posidonia oceanica fibres in lime mortars. Construction and Building Materials 298 (2021): 123881. [CrossRef]

- Stefanidou M., Kamperidou V., Konstantinidis A., Koltsou P., Papadopoulos S., 2022. 24 - Rheological properties of biofibres in cementitious composite matrix. In book: Advances in Bio-Based Fibre. 2022, 553-573. [CrossRef]

- Stefanidou M., Kampragkou P., Kamperidou V., 2023. Wood fibres as additives in mortars: a sustainable reinforcement. IOP Conf. Series: Earth and Environmental Science 1196 (2023) 012067. [CrossRef]

- Stefanidou, M., Papayianni, I., & Pachta, V. (2012). Evaluation of inclusions in mortars of different historical periods from greek monuments. Archaeometry, 54(4), 737–751. [CrossRef]

- Tolêdo Filho, R. D., Scrivener, K., England, G. L., & Ghavami, K. (2000). Durability of alkali-sensitive sisal and coconut fibres in cement mortar composites. Cement and Concrete Composites, 22(2), 127–143. [CrossRef]

- Vo L T and Navard P 2016 Treatments of plant biomass for cementitious building materials – A review Constr. Build. Mater. 121 161-76.

- Wang, X.P., Pang, Y.X., Yang, D.J., Lou, H.M., Qiu, X.Q., 2012. Effect of Composition of Calcium Lignosulfonate on Setting of Portland Cement with Anhydrite. AMR. [CrossRef]

- Wei, J., & Meyer, C. (2014). Degradation rate of natural fiber in cement composites exposed to various accelerated aging environment conditions. Corrosion Science, 88, 118–132. [CrossRef]

- Zakaria M, Ahmed M, Hoque M and Islam S 2016. Scope of using jute fibre for the reinforcement of concrete material Text. Cloth. Sustain. 2 11.

- Zhang, C., Liu, T., Jiang, C., Chen, Z., Zhou, K., & Chen, L. (2022). The freeze-thaw strength evolution of fiber-reinforced cement mortar based on NMR and fractal theory: Considering porosity and pore distribution. Materials, 15(20), 7316. [CrossRef]

- Zhang, H., Yoshino, H., & Hasegawa, K. (2012). Assessing the moisture buffering performance of hygroscopic material by using experimental method. Building and Environment, 48, 27–34. [CrossRef]

- Zobel, B. (2004). Tree breeding, practices | biological improvement of wood properties. Encyclopedia of Forest Sciences, 1458–1466. [CrossRef]

Figure 1.

FTIR ATR chemical analysis spectra of untreated and thermally treated black pine fibres over a range of 4000 cm-1 – 500 cm-1.

Figure 1.

FTIR ATR chemical analysis spectra of untreated and thermally treated black pine fibres over a range of 4000 cm-1 – 500 cm-1.

Figure 2.

FTIR ATR chemical analysis spectra of untreated and thermally treated beech fibres over a range of 4000 cm-1 – 400 cm-1.

Figure 2.

FTIR ATR chemical analysis spectra of untreated and thermally treated beech fibres over a range of 4000 cm-1 – 400 cm-1.

Figure 3.

Volume deformations of the produced mortars (C’R: reference / unreinforced mixture, C’pn: reinforced with black pine fibres, C’fs: reinforced with beech fibres).

Figure 3.

Volume deformations of the produced mortars (C’R: reference / unreinforced mixture, C’pn: reinforced with black pine fibres, C’fs: reinforced with beech fibres).

Figure 4.

Capillary absorption of the cement mortars at the age of 28, 90 and 365 days.

Figure 4.

Capillary absorption of the cement mortars at the age of 28, 90 and 365 days.

Figure 5.

Capillary water absorption coefficient (C) and drying rate for the first 24 hours of drying(D) of the cement mortars at the age of 28, 90 and 365 days (28d, 90d and 365d).

Figure 5.

Capillary water absorption coefficient (C) and drying rate for the first 24 hours of drying(D) of the cement mortars at the age of 28, 90 and 365 days (28d, 90d and 365d).

Figure 6.

Drying curves of the produced mortars after 28, 90 and 365 hardening days.

Figure 6.

Drying curves of the produced mortars after 28, 90 and 365 hardening days.

Figure 7.

Flexural strength (σf), compressive strength (σc) and dynamic modulus of elasticity (E) of the produced mortars at the age of 28, 90 and 365 days (28d, 90d and 365d).

Figure 7.

Flexural strength (σf), compressive strength (σc) and dynamic modulus of elasticity (E) of the produced mortars at the age of 28, 90 and 365 days (28d, 90d and 365d).

Figure 8.

Dynamic modulus of elasticity (E) and volume deformations (ΔV/V) of the produced mortars during freeze-thaw cycles.

Figure 8.

Dynamic modulus of elasticity (E) and volume deformations (ΔV/V) of the produced mortars during freeze-thaw cycles.

Figure 9.

Dynamic modulus of elasticity (E) and volume deformations (ΔV/V) of the produced mortars at days of exposure to outdoor conditions.

Figure 9.

Dynamic modulus of elasticity (E) and volume deformations (ΔV/V) of the produced mortars at days of exposure to outdoor conditions.

Figure 10.

Flexural strength (σf), compressive strength (σc), dynamic modulus of elasticity (E) and porosity (por) of the produced mortars before the start of cycles (B) and at the end of the freeze-thaw cycles (F-T) or the outdoor exposure (O).

Figure 10.

Flexural strength (σf), compressive strength (σc), dynamic modulus of elasticity (E) and porosity (por) of the produced mortars before the start of cycles (B) and at the end of the freeze-thaw cycles (F-T) or the outdoor exposure (O).

Table 1.

Composition of cement mortars (in proportion by weight).

Table 1.

Composition of cement mortars (in proportion by weight).

| Mortars |

Cement |

Aggregates |

Wood fibres (% v/v) |

w/c |

Superplasticizer (% w/w) |

Workability (cm) |

| C’R |

1 |

2.5 |

- |

0.45 |

- |

12.0 |

| C’pn |

1 |

2.5 |

1.5 |

0.45 |

0.25 |

12.0 |

| C’fs |

1 |

2.5 |

1.5 |

0.45 |

0.25 |

12.0 |

Table 2.

Absorption, porosity and specific gravity of the produced mortars at the age of 28, 90 and 365 days (28d, 90d and 365d).

Table 2.

Absorption, porosity and specific gravity of the produced mortars at the age of 28, 90 and 365 days (28d, 90d and 365d).

| Sample |

Absorption (%) |

Open Porosity (%) |

Specific gravity [g/cm3] |

| 28d |

90d |

365d |

28d |

90d |

365d |

28d |

90d |

365d |

| C’R |

1.77 |

2.43 |

2.33 |

3.91 |

5.29 |

5.20 |

2.21 |

2.18 |

2.20 |

| C’pn |

2.74 |

2.79 |

2.80 |

5.93 |

6.04 |

6.18 |

2.16 |

2.16 |

2.14 |

| C’fs |

3.48 |

2.65 |

3.19 |

7.38 |

5.78 |

6.85 |

2.12 |

2.16 |

2.15 |

Table 3.

Thermal conductivity coefficient (λ) at the age of 28, 90 and 365 days and water vapour resistance factor (μ) of the produced mortars.

Table 3.

Thermal conductivity coefficient (λ) at the age of 28, 90 and 365 days and water vapour resistance factor (μ) of the produced mortars.

| Samples |

λ [W/(m*K)] |

μ |

| 28 days |

90 days |

365 days |

| 10 oC |

20 oC |

10 oC |

20 oC |

10 oC |

20 oC |

| C’R |

1.2597 |

1.3008 |

1.2050 |

1.2586 |

1.1101 |

1.0723 |

57 |

| C’pn |

0.8093 |

0.8302 |

0.8032 |

0.8474 |

0.7440 |

0.7210 |

44 |

| C’fs |

0.9251 |

0.9426 |

0.9164 |

0.9158 |

0.9421 |

0.9635 |

51 |

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).