1. Introduction

In recent decades, a significant increase in sudden deaths caused by non-communicable chronic diseases, mainly cardiovascular issues, and arterial hypertension, has been observed [

1]. In this context, excessive sodium consumption is considered a contributing factor [

2]. As a result, reducing sodium intake has become a global concern.

Most sodium intake in the population is in the form of sodium chloride (NaCl) and comes from processed products, such as meat products, which represent about 20 to 30% of daily intake [

3]. Fresh sausage is a popular meat product with unique sensory characteristics [

4], but its high NaCl content makes it a significant source of sodium in the human diet. Consequently, seeking technological strategies to promote sodium reduction in fresh sausages without altering the original traits is essential and challenging.

Many scientific studies on meat products aim to reduce or replace sodium chloride (NaCl) with alternative ingredients like non-sodium salts, flavor enhancers, or by modifying crystal size[

5,

9]. However, strategies to reduce sodium in food, such as non-sodium salt substitutes, alternative ingredients, and flavor enhancers, face regulatory challenges in many countries. Furthermore, physiologically, the salty flavor is favored by the sodium ion and the smaller size of the chloride anion compared to sodium and non-sodium NaCl substitutes [

10]. In this context, the best alternative (and clean label) is the use of NaCl with reduced particle size.

In this scenario, industries can reformulate products, adjusting to the original formulation and aiming for products with lower sodium content. However, it is important to ensure that modifications align with the consumer's sensory expectations. As [

11] has observed, consumers often hesitate to compromise on sensory quality for health reasons. It is also worth noting that reformulating a product can introduce complex sensory changes. Hence, relying solely on static sensory tests may not provide a complete perception recording but only a picture. Studying the dynamic sensory profile of low-sodium fresh sausages seems imperative to comprehensively understand the sensory phenomenon [

12].

Dynamic sensory tests can provide more realistic insights than static tests as they capture responses often concealed during food consumption. The act of consuming a particular food involves multisensory experiences. Therefore, the choice of sensory test should not be limited to a fixed set of sensory attributes statically. Instead, it should be dynamic and aim to obtain detailed consumer opinion results [

13,

14].

In this context, Temporal Check-All-That-Apply (TCATA) is a new dynamic method that aims to identify all sensory attributes perceived during tasting. TCATA has been shown to be effective in studying how sensory attributes of food products can be applied [

15]. Additionally, these attributes have been linked to the overall liking, which allows for identifying drivers of liking, i.e., when present in the sensory description, can modify the product's liking. In this framework, the study examines the effect of micronized salt on the sensory, technological, chemical, and textural characteristics of fresh sausages.

2. Materials and Methods

The experiment was conducted at the Meat Quality and Processing Laboratory of Departamento de Agroindútria, Alimentos e Nutrição (LAN) of the Escola Superior de Agricultura ‘’Luiz de Queiroz’’ (ESALQ), Universidade de São Paulo (USP).

2.1. Raw materials and ingredients

The Materials and Meth The pork meat and fat were acquired from a local slaughterhouse in Capivari – SP and transported in thermal boxes to the laboratory. They were kept frozen (-18°C) until the production of fresh sausages. The micronized salt (MS) was obtained by sieving regular salt (RS) using a stainless-steel sieve with a 60-mesh size, resulting in a particle size of 168.86±1.66 μm, yielding micronized salt (MS), according to [

16]. The remaining ingredients were provided by Ibrac (Rio Claro, SP, Brazil).

2.2. Manufacture of fresh sausages

Four treatments were processed: control (C) with 2.0% regular salt, M2.0% with 2.0% micronized salt, M1.5% with 1.5% micronized salt, and M1.0% with 1.0% micronized salt, as shown in

Table 1. The entire experiment was conducted Randomized Complete Block Design (RCBD) considering two independent processing batches as blocks (n=40 fresh sausages/treatment/batch). In manufacturing the fresh sausages, pork meat (Semimembranosus) and pork backfat were ground using 8 mm and 6 mm grinding discs, respectively. For the treatments using micronized salt (M2.0%, M1.5%, and M1.0%), half of the MS was mixed with the fat, and the other half was combined with the meat batter and other ingredients. The mixture was homogenized for 2 minutes before being stuffed into natural pork casings (Canova, 32 mm caliber) soaked in a 1% saline solution. In the control treatment (C), regular salt was mixed with the meat and fat before homogenization. Subsequently, the fresh sausages were vacuum-packed (-73 cm Hg, Selovac 300 B vacuum packer, Brazil) and stored at -18°C for subsequent analyses.

2.3. Characterization of fresh sausages

2.3.1. Moisture and ashes

We determined the moisture and ashes content of the fresh sausages according to AOAC guidelines [

17].

2.3.2. pH and Aw

The pH values were determined in the cooked fresh sausages, with measurements taken in triplicate using a properly calibrated pH meter (buffer solutions 4.0, 7.0, and 10.0) equipped with a temperature sensor electrode (Lucadema model, LUCA-210, São José do Rio Preto, Brazil). The water activity (Aw) was determined at 25°C in raw fresh sausage samples using an AquaLab® 4TEV water activity instrument (Decagon, USA).

2.3.3. Instrumental color

The MiniScan®XE Plus spectrophotometer (Hunter Associates Laboratory Inc., Reston, VA) was used to determine the lightness (L*), redness (a*), yellowness (b*), chroma (C*), and hue angle (H*) of raw fresh sausages exposed on Petri dishes. Before taking color measurements, the equipment underwent calibration using a white ceramic tile set to Y = 93.7, x = 0.3160, and y = 0.3323. The measurement area was 8mm in diameter, the viewing angle was 10 degrees, and A10 illuminant was used. Each sample was measured in triplicate.

2.3.4. Relative myoglobin content

The relative content of myoglobin (oxymyoglobin OMb and metmyoglobin MMb) was determined according to [

18]. Raw fresh sausage samples were exposed on Petri dishes and using a calibrated MiniScan®XE Plus portable spectrophotometer (Hunter Associates Laboratory Inc., Reston, VA), reflectance spectra were obtained from 400 to 700 nm in 10 nm increments. Linear interpolation was used to calculate the reflectance at 473, 525, and 572 nm, subsequently converted into absorbance (A = log (1/R)). The absorbance values were used in equations provided by [

18] to quantify the relative myoglobin content.

2.3.5. Cooking loss

Cooking loss was determined following the methodology described by [

19], and calculated according to Equation 1.

2.3.6. Instrumental texture

The textural properties of the fresh sausages were analyzed through Texture Profile Analysis (TPA) following [

20] in a TA-XT texture analyzer (Stable Micro Systems, Godalming, United Kingdom). For each treatment, six cylinders were sampled using a stainless-steel cutter with a height of 2 cm. Then, cooked samples were compressed twice axially to 50% of their original height at a pre-test speed of 1 mm/s and 5 mm/s, using a P/35 probe (Stable Micro Systems, Godalming, United Kingdom). The parameters considered were hardness (N), springiness (mm), cohesiveness (dimensionless), and chewiness (N).

2.3.7. Sodium content

The quantification of sodium content in sausage samples was performed following the methodology described by [

17] and [

21]. Initially, 5g of samples were incinerated at 550°C (Jung, Brazil). The resulting ashes were cooled to room temperature and then solubilized in 15 mL of 25% nitric acid solution (250 mL of HNO3 in 750 mL of distilled water). The samples were analyzed in triplicate using a flame photometer (Digimed, model DM63, São Paulo, Brazil). For calculation, a blank sample was used as a control.

2.3.8. Microbiological analysis

Before conducting sensory analysis of fresh sausages, the microbiological quality of samples was assessed considering the examination of

Escherichia coli, mesophilic aerobic bacteria,

and Salmonella spp. following the American Public Health Association [

20].

2.3.9. Sensory analysis

Consumers

For the sensory analysis, we recruited 109 regular consumers of fresh pork sausages from the campus community, including students, staff, and visitors, all over 18 years old. Initially, the participants read and signed the Informed Consent Form, previously approved by the Ethics Committee for Human Research at ESALQ/USP (protocol number 6.087.327).

Procedure

The sensory tests were conducted at the Sensory Laboratory of Departamento de Agroindútria, Alimentos e Nutrição (LAN) at ESALQ/USP. The samples (~10g) were served monadically to consumers with three-digit codes following the Williams Latin Square design. Initially, the consumers performed the TCATA test, followed by the overall liking test. Water and unsalted crackers were provided to cleanse the palate between the samples. The data was collected in the Compusense Cloud software (Compusense Inc., Guelph, Canada) via tablets with the Android operating system.

Temporal-Check-All-That-Apply

The TCATA test followed previous research protocols [

8,

23]. The participants were given specific instructions to choose from a list of predetermined sensory attributes, which included salty, juicy, firm, off-flavor, dry, and tender, to describe the sensory profile of each sample they were given. They could check as many attributes as they felt were necessary while tasting.

Overall liking

Immediately after the TCATA test, consumers were instructed to rate their overall liking using a 9-point hedonic scale ranging from 1 = extremely dislike to 9 = extremely like.

2.4. Data analysis

The experiment was implemented in an RCBD, considering each processing as a block. The instrumental results underwent a mixed analysis of variance (ANOVA), with treatment as a fixed factor and processing as a random factor. When treatment was significant, the Tukey test was applied for pairwise comparison.

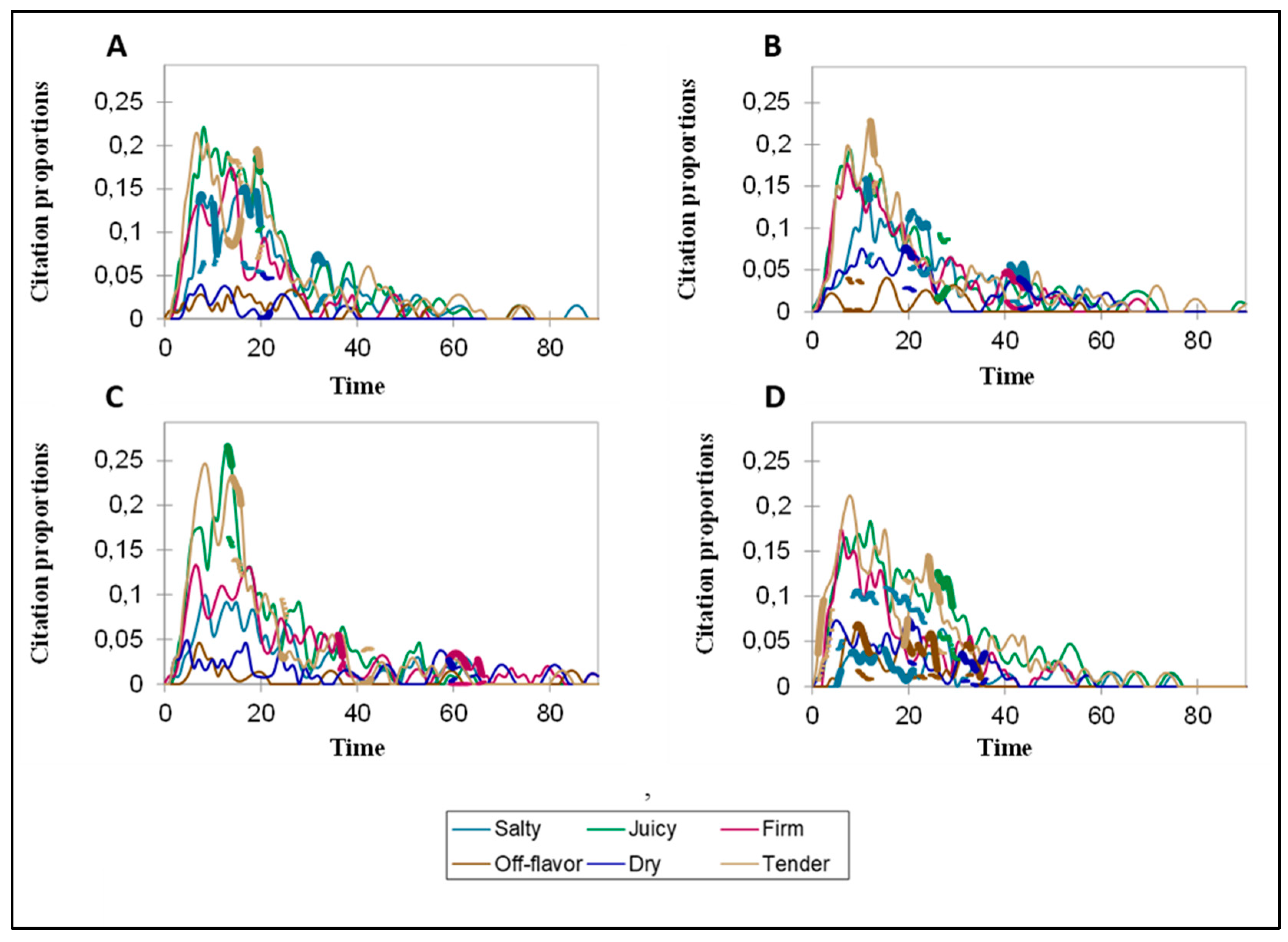

The proportions of citations for attributes and products over time were represented in curve plots. Thick solid lines represent significant reference curves for sensory attributes [

24]. The overall liking of pork sausage was submitted to ANOVA considering treatments, consumers, and presentation order as factors. When applicable, the Tukey test was employed was used to explore the differences among treatments. All inferential tests were conducted at 5% of significance.

3. Results and Discussion

3.1. Physicochemical analysis, yield properties, texture profile, and sodium content

The decrease in sodium levels in the formulations did not affect the moisture, pH, Aw, cooking loss, and springiness values, as shown in

Table 2. The moisture content remained within the guidelines of Brazilian regulations for fresh sausages, which stipulate that values should not exceed 70% [

25].

It was observed that the sodium content in sample M2.0% was not significantly different from the control sample. This was expected because both samples contained the same amount of added salt, although the salt used in M2.0% was micronized. As the amount of NaCl decreased in the formulations, the ash and sodium content showed similar behavior.

The treatment with 1% NaCl (M1.0%) resulted in a significant reduction of 52.3% in sodium levels compared to the control. This makes it a promising candidate to obtain the "low sodium" label as per Regulation (EC) nº 1924/2006 [

24]. This outcome is particularly beneficial for consumers of fresh sausages as it can help reduce their exposure to high sodium levels, lowering the risk of developing cardiovascular diseases, as suggested by [

25].

Regarding TPA, the springiness of the burgers was not affected by the decrease in sodium content. However, the samples' hardness, cohesiveness, and chewiness showed a significant reduction (as shown in

Table 2). The importance of salt in meat products has been extensively discussed in the literature. Sodium chloride (NaCl) dissolves myofibril proteins in the meat matrix, which enhances the bonding capacity between water and fat, resulting in a firmer texture profile [

26]. The salt content reduction in the formulations may have led to decreased extraction of myofibril proteins, resulting in reduced hardness, cohesiveness, and chewiness. These findings are consistent with a previous study that observed similar results in fresh sausages with reduced sodium content [

27]. On the other hand, when comparing sausages with equal salt content (treatments C and M2.0%), it is possible to observe that using micronized salt leads to a decrease of eight units in chewiness. This decrease may be attributed to the mixture of micronized salt with fat, which could hinder the interaction between salt and myofibrillar proteins and ultimately affect the texture of the sausage, as previously explained.

3.2. Instrumental color and relative myoglobin content

Table 3 displays the instrumental color characteristics such as L*, a*, b*, C*, and H* and the relative myoglobin content of fresh sausages with different concentrations of micronized NaCl. Replacing regular salt (RS) with micronized salt (MS) and reducing salt content did not affect the color responses a*, b*, C*, and H*. These findings are like those of a study conducted by [

27], that examined the reduction of encapsulated salt in carnauba wax in fresh sausages over 90 days of vacuum packaging and refrigerated storage.

The study found no differences in instrumental color, indicating that reducing sodium or using non-sodium salt in meat products does not hurt the final product's color [

28,

29]. Conversely, the M1.0% treatment showed a lower L* value and a higher percentage of metmyoglobin, as shown in

Table 3, when compared to the other treatments (P < 0.05). The lower L* values observed in this treatment are related to a higher concentration of metmyoglobin. This change imparts a brown color to the meat product, reducing L* values [

30]. A previous study by [

31] found that the decrease in L* values could be associated with the oxidative process of lipids and proteins responsible for color deterioration in meat products. In addition, sodium reduction is responsible for altering the water holding capacity, impairing color development due to changes in light dispersion by the meat matrix [

32].

3.3. Microbiological characterization

The microbiological quality of the fresh sausages formulated in this paper is safe for human consumption according to the Brazilian regulations RDC No. 724, dated July 1, 2022, and IN No. 161, dated July 1, 2022 [

33]. The samples exhibited average values of <3.0 MPN for

Escherichia coli, mean counts of mesophilic aerobic bacteria at 2.4 x 103 CFU/g, and the absence of

Salmonella spp. in 25 g of sample.

3.4. Temporal sensory profile and overall liking

Figure 1 displays the TCATA citation curves for the fresh sausage samples. All treatments exhibited a similar pattern in the initial 20 seconds of tasting. Attributes such as juicy, tender, and firmness received the highest citation proportions. However, differences among the treatments became apparent when assessing the line thickness for each attribute.

According to [

24], an increase in line thickness indicates that a specific attribute is more cited in one treatment than others. Treatments C and M2.0% exhibit the highest proportions of salty flavor, as they contain the most NaCl. However, it is noteworthy that micronized salt (M2.0%) increased tenderness compared to regular salt (C). This phenomenon can be attributed to the improved penetration of salt into the meat matrix and an increase in the extraction of myofibrillar proteins. Similarly, [

34] observed great NaCl penetration in dry-cured pork when using NaCl crystals of 0.55 mm.

In treatment M1.0%, the salty attribute had the lowest proportions. However, the other attributes exhibited behavior like samples C and M2.0%, indicating that the reduction in salty taste did not significantly impact the consumers' perceptions of the other attributes. Among all the treatments, treatment M1.5% stood out, showing the highest citations for juicy and tender.

As mentioned by [

8], reducing NaCl in beef burgers increased the proportions of negative attributes. However, in contrast to this scenario, our study reduces 50% of NaCl without a high proportion of negative sensory attributes. These results suggest that the use of micronized salt may be more effective in fresh sausages than in burgers.

Figure 2 illustrates the overall liking scores, revealing no statistically significant differences among the treatments. The assessments conducted on a 9-point hedonic scale converged to values close to 7 (Like moderately). Even with a 50% reduction in sodium content in the fresh sausages, consumers could not detect a difference compared to the control treatment (C). Micronized salt appears to have played a significant role in this outcome, intensifying the salty flavor in the low-sodium treatments.

4. Conclusions

The use of micronized salt (MS) enclosed within the fat layer has enabled a reduction of sodium content of up to 50% in fresh sausages (M1.0%) without any significant changes in technological, chemical, textural, and microbiological characteristics. When MS was combined with fat, the chewiness of the product decreased in comparison to the control treatment at the same concentration. As far as the sensory aspect is concerned, the TCATA attribute mentions were similar for all the treatments, and consumers did not notice any differences in overall liking. Additional research is needed to assess the oxidative behavior of proteins and lipids in fresh sausages with reduced sodium content through micronization.

Author Contributions

Chimenes D. L. de Araújo: Methodology; Validation; Formal analysis; Investigation; Resouces; Data curation; Writing - original draft preparation; Writing - review and editing. Monique M. Krauskopf: Methodology; Investigation; Writing - original draft preparation. João A. S. Manzi: Methodology; Investigation; Data curation. José A. L. Barbosa: Methodology; Data curation. Cecylyana L. Cavalcante: Methodology. Gabriela Feltre: Writing - review and editing. Juan D. Rios-Mera: Writing - review and editing. Erick Saldaña: Supervision; Data curation; Writing - original draft preparation; Writing - review and editing. Carmen J. Contreras-Castillo Writing - review and editing; Visualization; Supervision; Administration; Funding acquisition.

Data Availability Statement

Data is contained within the article.

Acknowledgments

Coordination for the Improvement of Higher Education Personnel (CAPES), which awarded the Doctorate scholarship (grant number 88887.637004/2021-00), to the Unified Scholarship Program (PUB) at ESALQ/USP. The authors would like to thank Frigodeliss Ltda, Sealed Air Brazil and Ibrac Additives for the donation raw meat, packaging, and additives respectively.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Grillo, Salvi, Coruzzi, Salvi, and Parati, “Sodium Intake and Hypertension,” Nutrients, vol. 11, no. 9, p. 1970, Aug. 2019. [CrossRef]

- F. J. He, M. Tan, Y. Ma, and G. A. MacGregor, “Salt Reduction to Prevent Hypertension and Cardiovascular Disease,” J Am Coll Cardiol, vol. 75, no. 6, pp. 632–647, Feb. 2020. [CrossRef]

- P. Gullón, G. Astray, B. Gullón, D. Franco, P. C. B. Campagnol, and J. M. Lorenzo, “Inclusion of seaweeds as healthy approach to formulate new low-salt meat products,” Curr Opin Food Sci, vol. 40, pp. 20–25, Aug. 2021. [CrossRef]

- ABIPECS, “SUÍNA-ABIPECS, A. C. (2013). Relatório anual, 2012.”.

- M. C. Cruz-Romero, C. C. O’Flynn, D. Troy, A. M. Mullen, and J. P. Kerry, “The Use of Potassium Chloride and Tapioca Starch to Enhance the Flavour and Texture of Phosphate- and Sodium-Reduced Low Fat Breakfast Sausages Manufactured Using High Pressure-Treated Meat,” Foods, vol. 11, no. 1, p. 17, Dec. 2021. [CrossRef]

- J. L. da Rosa et al., “High-power ultrasound, micronized salt, and low KCl level: An effective strategy to reduce the NaCl content of Bologna-type sausages by 50%,” Meat Sci, vol. 195, p. 109012, Jan. 2023. [CrossRef]

- E. S. Inguglia, Z. Zhang, B. K. Tiwari, J. P. Kerry, and C. M. Burgess, “Salt reduction strategies in processed meat products – A review,” Trends Food Sci Technol, vol. 59, pp. 70–78, Jan. 2017. [CrossRef]

- J. D. Rios-Mera et al., “Impact of the content and size of NaCl on dynamic sensory profile and instrumental texture of beef burgers,” Meat Sci, vol. 161, p. 107992, Mar. 2020. [CrossRef]

- M. M. Selani et al., “Consumer’s perception and expected liking of labels of burgers with sodium reduction and addition of mushroom flavor enhancer,” Meat Sci, vol. 185, p. 108720, Mar. 2022. [CrossRef]

- J. D. Rios-Mera, E. Saldaña, I. Patinho, M. M. Selani, and C. J. Contreras-Castillo, “Enrichment of NaCl-reduced burger with long-chain polyunsaturated fatty acids: Effects on physicochemical, technological, nutritional, and sensory characteristics,” Meat Sci, vol. 177, p. 108497, Jul. 2021. [CrossRef]

- D. Oliveira, L. Antúnez, A. Giménez, J. C. Castura, R. Deliza, and G. Ares, “Sugar reduction in probiotic chocolate-flavored milk: Impact on dynamic sensory profile and liking,” Food Research International, vol. 75, pp. 148–156, Sep. 2015. [CrossRef]

- M. Visalli, M. V Galmarini, and P. Schlich, “Use of temporal sensory evaluation methods with consumers: a position paper,” Curr Opin Food Sci, vol. 54, p. 101102, Dec. 2023. [CrossRef]

- C. de S. Paglarini et al., “Using dynamic sensory techniques to determine drivers of liking in sodium and fat-reduced Bologna sausage containing functional emulsion gels,” Food Research International, vol. 132, p. 109066, Jun. 2020. [CrossRef]

- B. E. Auriema et al., “Fat replacement by green banana biomass: Impact on the technological, nutritional and dynamic sensory profiling of chicken mortadella,” Food Research International, vol. 152, p. 110890, Feb. 2022. [CrossRef]

- G. Ares, F. Alcaire, L. Antúnez, L. Vidal, A. Giménez, and J. C. Castura, “Identification of drivers of (dis)liking based on dynamic sensory profiles: Comparison of Temporal Dominance of Sensations and Temporal Check-all-that-apply,” Food Research International, vol. 92, pp. 79–87, Feb. 2017. [CrossRef]

- J. D. Rios-Mera et al., “Reducing the sodium content without modifying the quality of beef burgers by adding micronized salt,” Food Research International, vol. 121, pp. 288–295, Jul. 2019. [CrossRef]

- V. Paez et al., “AOAC SMPR® 2016.002,” J AOAC Int, vol. 99, no. 4, pp. 1122–1124, jul. 2016. [CrossRef]

- AMSA. 2012., “AMSA Meat Color Measurement Guidelines. American Meat Science Association. Champaign, IL, USA.”.

- K. O. Honikel, “Reference methods for the assessment of physical characteristics of meat,” Meat Sci, vol. 49, no. 4, pp. 447–457, Aug. 1998. [CrossRef]

- Bourne MC, “Texture profile analysis,” Food Technology, vol. 32, pp. 62–66, 1978.

- M. A. de Almeida, N. D. M. Villanueva, J. S. da S. Pinto, E. Saldaña, and C. J. Contreras-Castillo, “Sensory and physicochemical characteristics of low sodium salami,” Sci Agric, vol. 73, no. 4, pp. 347–355, Aug. 2016. [CrossRef]

- Y., & T. M. L. Salfinger, Salfinger, Compendium of methods for the microbiological examination of foods. American Public Health Association. 2015. [CrossRef]

- G. Ares et al., “Comparison of two TCATA variants for dynamic sensory characterization of food products,” Food Qual Prefer, vol. 54, pp. 160–172, Dec. 2016. [CrossRef]

- J. C. Castura, A. K. Baker, and C. F. Ross, “Using contrails and animated sequences to visualize uncertainty in dynamic sensory profiles obtained from temporal check-all-that-apply (TCATA) data,” Food Qual Prefer, vol. 54, pp. 90–100, Dec. 2016. [CrossRef]

- BRASIL, BRASIL. Ministério da Agricultura, Pecuária e Abastecimento - MAPA. Instrução Normativa no 4. Anexo III - Regulamento Técnico de Identidade e Qualidade de linguiça. Diário Oficial da União, Brasília, April 05, 2000.

- E. Desmond, “Reducing salt: A challenge for the meat industry,” Meat Sci, vol. 74, no. 1, pp. 188–196, Sep. 2006. [CrossRef]

- P. H. B. Beck, M. A. Matiucci, A. A. M. Neto, and A. C. Feihrmann, “Sodium chloride reduction in fresh sausages using salt encapsulated in carnauba wax,” Meat Sci, vol. 175, p. 108462, May 2021. [CrossRef]

- D. H. da Silva Araujo et al., “Reduction of sodium content in frozen goat sausage using different types of salt,” LWT, vol. 135, p. 110272, jan. 2021. [CrossRef]

- M. A. Pires et al., “The effect of sodium reduction on the microstructure, texture and sensory acceptance of Bologna sausage,” Food Structure, vol. 14, pp. 1–7, Oct. 2017. [CrossRef]

- R. F. de Oliveira et al., “Effect of the fruit aqueous extract of Brazilian pepper tree (Schinus terebinthifolius, Raddi) on selected quality parameters of frozen fresh pork sausage,” J Agric Food Res, vol. 2, p. 100055, Dec. 2020. [CrossRef]

- B. AMARAL, M. V. da SILVA, and S. C. da S. LANNES, “Lipid oxidation in meat: mechanisms and protective factors – a review,” Food Science and Technology, vol. 38, no. suppl 1, pp. 1–15, Dec. 2018. [CrossRef]

- M. Ruusunen and E. Puolanne, “Reducing sodium intake from meat products,” Meat Sci, vol. 70, no. 3, pp. 531–541, jul. 2005. [CrossRef]

- Brasil, Brasil. (2022). Agência Nacional de Vigilância Sanitária. Resolução de Diretoria Colegiada No. 724, de 1 de julho de 2022.

- J. H. Aheto et al., “Investigation into crystal size effect on sodium chloride uptake and water activity of pork meat using hyperspectral imaging,” J Food Process Preserv, vol. 43, no. 11, nov. 2019. [CrossRef]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).