Preprint

Article

Feasibility Study on a Black Paper Base Film Coated with Cooked Tung Oil

Altmetrics

Downloads

109

Views

22

Comments

0

A peer-reviewed article of this preprint also exists.

This version is not peer-reviewed

Submitted:

30 December 2023

Posted:

03 January 2024

You are already at the latest version

Alerts

Abstract

A new biodegradable paper-based film is a hot research topic in the development of green agriculture. In this paper, a black paper base film coated with cooked tung oil with excellent mechanical properties, hydrophobic surface, high heat transfer and strong weather resistance was prepared by spraying high pigment carbon black solution on the surface of base paper. The results showed that the surface solidified oil film with rough structure was made by the brush coating process of cooked tung oil, and the base film of black paper was given hydrophobic structure, and the contact angle reached 98.9 °. Cooked tung oil permeates into the inside of the paper base, and after curing, it forms a multi-dimensional network film structure. The maximum tensile stress of the black paper base film is about 123% higher than that of the original paper base film. The coloring of carbon black makes the black paper base film have heat conduction effect, and the average heat transfer rate reaches 15.12 °C/s. Cooked tung oil is combined with the paper-based fiber high-toughness layer to form a stable system. The existence of the cured film improves the basic mechanics and hydrophobicity, and the resistance to ultraviolet radiation and hot air is greatly improved. This study provides a feasible scheme for the application of a black paper base film coated with cooked tung oil.

Keywords:

Subject: Chemistry and Materials Science - Surfaces, Coatings and Films

1. Introduction

Plastic film mulching can effectively improve soil temperature, reduce soil mechanical resistance, increase microbial biomass, maintain soil organic components, maintain the nutrients needed by crops, etc., and can efficiently increase the yield [1,2,3,4]. Population growth has increased competition for soil, food and water resources. Especially in some arid and semi-arid areas, furrow and ridge mulching with plastic film is an important way to improve grain yield [5]. However, the insufficient recovery of traditional plastic mulch film leads to its becoming the main source of residual plastic pollution [6]. Since the mass production of plastic products began in 1950 s, plastic residues have forced many countries around the world to spend a lot of manpower and financial resources to reduce the pollution caused by plastics [7,8]. To solve this problem, biodegradable film is used as a research and development role to replace traditional plastic film [9]. Nowadays, there are many raw materials for the production of biodegradable films, such as polysaccharides, starch, cellulose, biological derivative monomers, microorganisms and so on [10]. Julio Harada[11] et al. used PBAT, polylactic acid and natural fillers (carbon black, organic fertilizer and silica rice ash) to prepare biodegradable mulch film, and studied its biodegradability in simulated soil. The results show that the biodegradable film with natural filler is superior to the biodegradable film with pure mixture.

The color of plastic film is diverse, among which the black plastic film has excellent water retention ability. And its low light transmittance leads to insufficient light in the soil under the film, thus inhibiting the growth of weeds. James E. Brown et al [12] compared the growth and yield of sweet pepper under four conditions: bare soil (BS), bare soil-drip irrigation (BS-DI), black plastic film (BPM) and black plastic film-drip irrigation (BMP-DI). The results showed that the yield of sweet pepper increased by 57.1% and 63.1% respectively under BMP and BMP-DI conditions. M.J. Kasperbauer [13] found a way to increase the yield of strawberry in the seedbed cultivation of strawberry with black plastic film. The yield of strawberry covered with red plastic and standard black plastic was compared. The results showed that the far-red light and red light reflected by red plastic affected the distribution of photosynthate mediated by photosensitivity, making strawberry larger on red plastic film, and photosensitivity directly acted on fruit development, showing yield advantage. A. Anzalone [14] et al. conducted a three-year field experiment on tomato using several different biodegradable plastic film materials, such as rice straw, barley straw, corn residue, wormwood, black biodegradable plastic, kraft paper, PE, herbicide, artificial weeding and no weeding. The weed control effect of them instead of black polyethylene mulch film was studied. Experiments show that the best weed control effect is paper. For most crops, weeds will seize soil, oxygen, organic matter, etc. in the early growth process [15]. Therefore, the use of black plastic film undoubtedly reduces the production cost of crops and improves weeding efficiency.

As a reinforcing raw material, carbon black has low cost, can be used as a dye, and has good stability and high thermal conductivity [16]. Widely used in lithium batteries, capacitors, composite rubber, etc [17,18,19,20]. Amit Kumar Mishra [21] et al. added 2.5% low-load carbon black nano powder (CBNP) to improve the thermal conductivity and photothermal conversion efficiency of organic phase change materials (PCM) by 135% and 84%. Chia-Kenleong [22] et al. used carbon black dispersion based on polyethylene glycol (PEG) or di (ethylene glycol) butyl ether, and dissolved ethyl cellulose to provide a thermal interface materials superior to solder. The results show that carbon black is superior to materials with higher thermal conductivity (graphite, diamond and nickel particles and carbon filaments) in providing high performance thermal paste, and superior to solder in providing high thermal contact conductivity.

Pure tung oil is processed from tung oil. Compared with raw tung oil, pure tung oil is easier to solidify and form a smooth film, which has good heat resistance and corrosion resistance [23,24,25]. It can be used for color fixing, furniture maintenance, machine repair instead of clear oil, etc. [26]. Tung oil is widely used to modify materials. Yugang Huang [27] et al. used tung oil to react with maleic anhydride (MA), and then reacted with hydroxyethyl acrylate (HEA) or triacrylate (PETA) and methacrylate (GMA) to synthesize UV curable resin. The results show that the successful preparation of the target resin depends on the feed ratio of MA, tung oil and HEA (or PETA). The higher the carbon bond content of acrylate, the faster the curing rate and the lower the carbon bond conversion rate. All cured films have good thermal stability, and the transformation range is 40-52 °C. Shan Wei Wang [28] et al. prepared 9 kinds of mixtures by adding hemp fiber into tung oil lime mud. The basic mechanical properties, pore structure, surface morphology and characterization of cured and aged slurry were tested. The results show that the fiber addition reaction will strengthen the composite and accelerate the carbonation process of lime. The curing process enhances the compressive strength of the cured pulp. The composite with 1.0% fiber and 5% tung oil has good frost-resistance cycle and salt resistance.

The research progress of degradable mulch film tends to be mature gradually, but it is difficult to find a paper-based film that can realize real application in current research. In this paper, black paper base film covered with cooked tung oil was prepared by using degradable base paper film, spraying carbon black solution and brushing with cooked tung oil. The basic mechanics, hydrophobicity test, heat conduction, ultraviolet weatherability, dry heat weatherability and so on were studied. Fill the research gap of black paper base film in degradable mulch film. In addition, carbon black is skillfully used to improve the heat transfer efficiency of mulch film, which makes up for the defect of insufficient soil temperature caused by low light transmittance of black mulch film. A practical black paper base film with excellent comprehensive performance was prepared by cheap raw materials and simple process, which provided a feasible scheme for the promotion of global green agriculture.

2. Materials and Methods

2.1. experimental materials and equipment

High pigment carbon black, Zhengzhou Hengnan Chemical Products Co., Ltd.; High-quality cooked tung oil, Fangji Tung Oil Processing Factory in Gushi County; Fully biodegradable paper-based film (BM), developed by Tottori Prefecture, Japan, specifications; Deionized water, self-made in laboratory; Anhydrous ethanol: 95% purity, Fuyu Chemical Co., Ltd. Table 1 gives the experimental equipment.

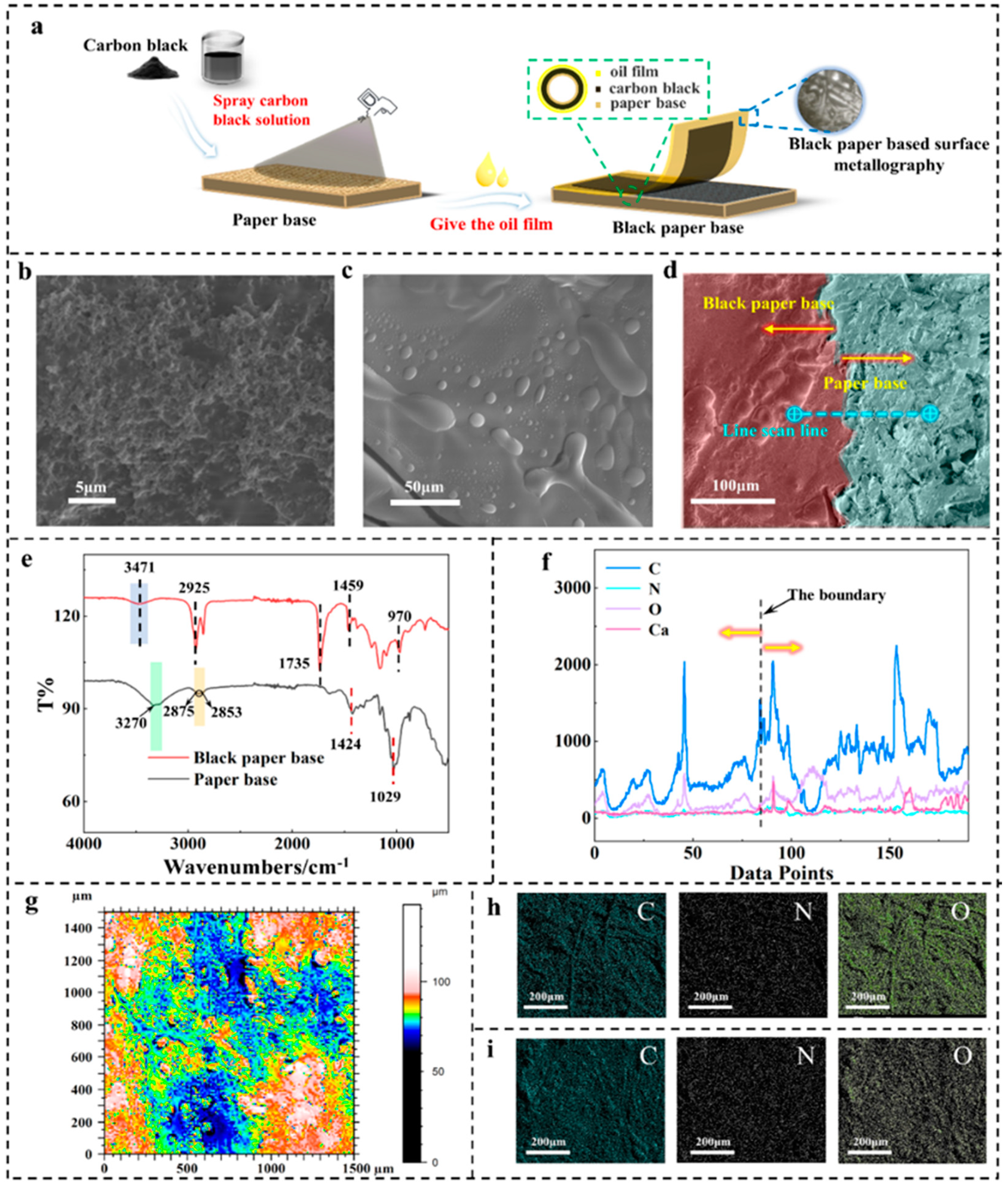

Figure 1a shows the preparation process of black paper base. Measure 150 ml of deionized water in a beaker. Weigh 1.5 g of water-soluble high pigment carbon black. Add the carbon black into deionized water and stir to prepare 1% g/ml carbon black solution. Spray the carbon black solution evenly on the front and back surfaces of the base paper with an oil-free compressor, and air-dry at room temperature for 20 min. After that, the cooked tung oil was brushed on the surface of the sample sprayed with carbon black solution. Brush evenly on both sides. Drying in a drying oven at 100 °C for 4 h, and curing the cooked tung oil on the surface of the paper base. Realize the surface fixation of black paper base film. Finally, the black paper base film covered with cooked tung oil was prepared.

2.2. characterization and testing

Basic mechanical test: The WDW-10M microcomputer-controlled electronic universal testing machine (Jinan Zhongluchang Testing Machine Manufacturing Co., Ltd.)was used to test the basic mechanics of film samples of base paper and black paper. The samples were cut into dumbbell-shaped tensile specimens of 115 mm×25 mm and right-angle tear specimens of 100 mm×20 mm, and the tensile and tear tests were carried out respectively. The test speed was 100 mm/min, and the test was repeated for 5 times.

Hydrophobicity test: The contact angle weighing instrument (Theta Flex, Ou Lin Company, Sweden) was used to test the hydrophobicity of the base paper and black paper films. Cut the paper base to a width of 1 cm and place it on a glass slide. Measure the static contact angle. Select 5 points randomly on the surface of the paper base. Drop 4 μl of deionized water on the surface of the paper-based sample. The change characteristics of static contact angle were measured.

Heat transfer performance test: Measure the thermal conductivity of the base paper and black paper film. Heat the heating plate (self-made in the laboratory) to 60 °C. The paper sample is cut to 5 cm×5 cm and placed on the heating plate. Use infrared thermal imager (Tis60+, USA) to monitor the temperature rise of paper surface to 60 °C. Due to the low thickness of the paper film itself, a small cylinder of silicone rubber was placed on the surface of the paper film sample, and a small cylinder of silica gel was placed on the paper base. The time of heating up to 60 °C was monitored by infrared thermal imager, and the heat transfer effects of different paper base films were compared.

Anti-aging test: The anti-aging performance of base paper film and black paper film was analyzed. Firstly, it is subjected to hot air aging and ultraviolet accelerated weathering treatment. Under the national standard 《GB/T 464-2008》, it is undergoing hot air aging. Set the temperature at 150 °C for 24 hours. The ultraviolet accelerated weathering test chamber (MU3089, moujing industrial co., ltd., China) set the radiation intensity of fluorescent ultraviolet lamp at 0.76 w m-2 nm-1 @ 340 nm and uvat (60±3) °C. After that, the tensile, tearing, hydrophobic and thermal conductivity of the aged paper-based samples were tested. By comparing the basic properties of aged base paper and black paper mulch film. Further explain the weather resistance of black paper base film.

And characterization mechanism analysis: The paper-based film was characterized by Fourier transform infrared spectroscopy(IRTracer-100, Japan) and Raman spectroscopy. SEM and EDS(Octane Super EDAX, USA) were used to analyze the surface of different kinds of paper-based films. Three-dimensional surface topography instrument (NANOVEA ST400, USA) was used to measure the surface roughness of paper base film and reveal the microstructure of paper base surface.

3. Results and Discussions

3.1. Surface morphology analysis

Figure 1b, c SEM analysis of water-soluble high pigment carbon black and cooked tung oil. The carbon black powder aggregates, and the particles are aggregated. This characteristic makes it show a good effect in the coloring stage of paper-based film. There are some bubbles on the surface of the cooked tung oil. After the surface of the sample is brushed and dried, the air inside the bubbles is released during the drying process. Therefore, during the curing process, the cooked tung oil will form a rough surface structure of the black paper base film, as shown in Figure 1g. Figure 1d and f characterize the cross section of black paper base film by SEM and EDS. The left side of the section boundary is black paper base, and the right side is base paper base. With the dividing line as the center line, sweep the left and right collinear length by 950 mm. Figure 1f shows the surface element changes of different paper base surfaces. On both sides of the dividing line, compared with the black paper covered with oil film, the base paper on the right side has a larger change range of Ca element and a higher change frequency of C element. According to the difference of the change range of elements around the dividing line and the distribution of three elements C, O and N in the base film of base paper and black paper in Figure 1h and i, it shows that the production process of black paper base film covered with oil film is feasible. Figure 1e fourier transform infrared spectrum analysis of base paper and black paper. In the base paper, there is a characteristic peak of stretching vibration of -OH associated group in the infrared spectrum near 3270 cm-1, and there is a broad peak of symmetric stretching vibration of -CH3 and -CH2 groups between 2853 cm-1 and 2875 cm-1. There is a strong absorption peak of =C-O-C at 1029 cm-1. However, in the black paper base film, there is an antisymmetric stretching peak of -NH2 near 3471cm-1. There is a characteristic peak of -CH2- antisymmetric stretching vibration at 925 cm-1. There are -CH3, -CH2- antisymmetric stretching and symmetric bending vibration peaks near 459 cm-1.

3.2. Mechanical properties

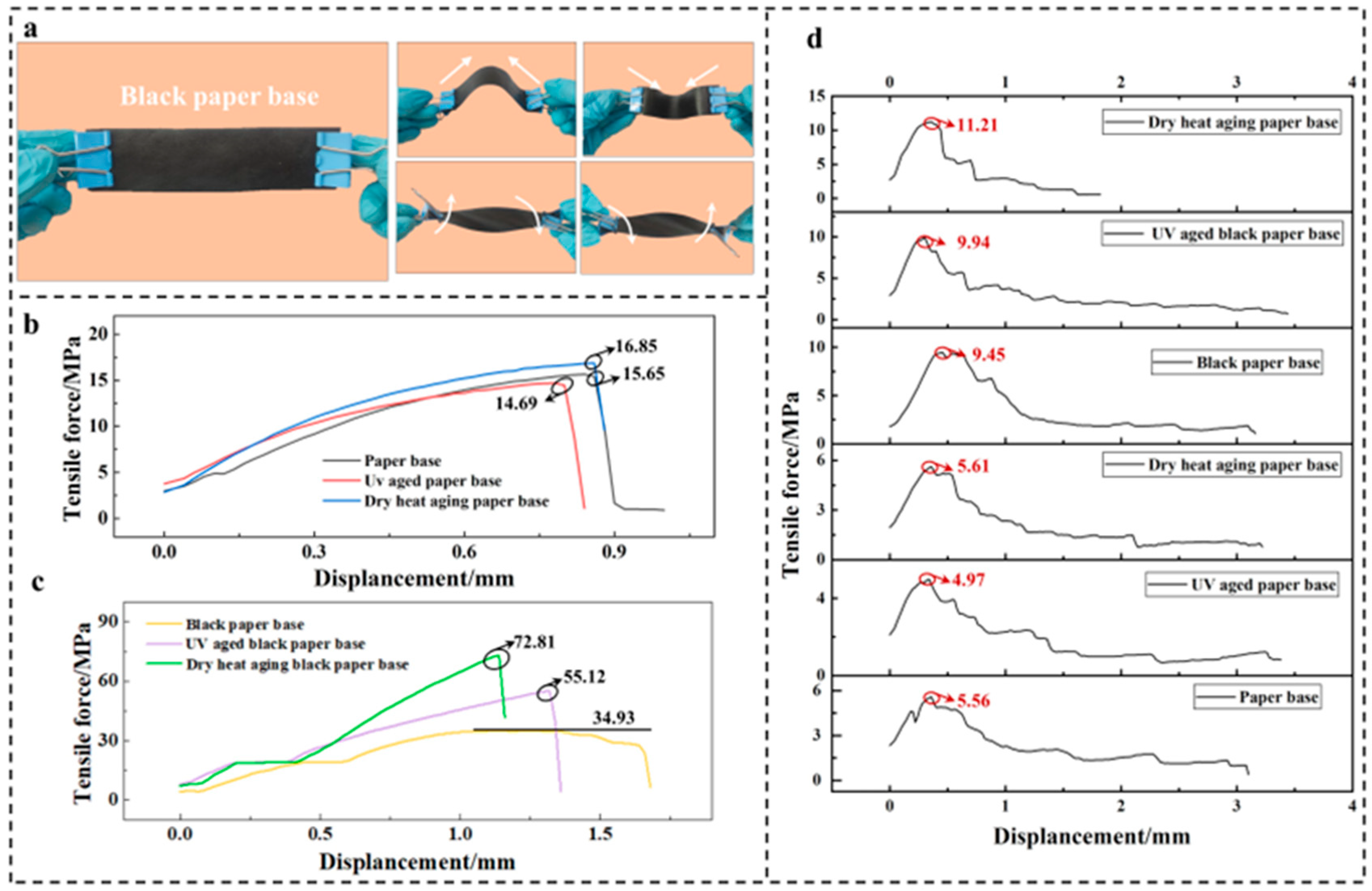

In the practical application of plastic film, its mechanical strength is a key content. In the process of spreading and using plastic film, it will be affected by wind, rain, weeds and some destructive forces caused by external people. Therefore, the mechanical strength of mulch film determines whether mulch film can be applied. Figure 2b and c clearly show that there is an oil film attached to the surface of the black paper base film, which tightly covers and wraps the base paper fibers. Paper fiber itself is a network structure which is cross-linked by wood fibers. It is a combination of fibers formed by glue adhesion. In the basic mechanical test of paper base film, as shown in Figure 2d and e, the maximum tensile and tearing force of black paper base film is greatly improved compared with that of original paper base film. The maximum tensile force increased by 123.2%. The maximum tearing force is increased by 69.59%. From Figure 2f as a whole, the mechanical strength of the black paper base film is larger than that of the original paper base film, whether in tensile test or tear test. This is mainly due to the solidified oil film formed by cooked tung oil on the surface of black paper base film. With the curing process of cooked tung oil in drying oven, its oil molecules cross-link with each other to form a dense complex structure. It adheres to the surface of paper base, and improves the mechanical endurance of black paper base film [30]. Figure 2g and h show more clearly that the fibers of the base paper crisscross each other and the tightness of the solidified oil film on the surface of the paper coated with cooked tung oil. Figure 2i, the paper base will be soaked in oil during the brushing process of cooked tung oil. The cooked tung oil permeates between the paper fibers, and after drying and curing, the fibers-cooked tung oil-fibers interweave with each other to produce a strong pulling force. Compared with the fiber-fiber structure of the base paper, the existence of cooked tung oil undoubtedly endows the black paper base film with excellent mechanical strength, and the mechanical mechanics is higher than that of the base paper.

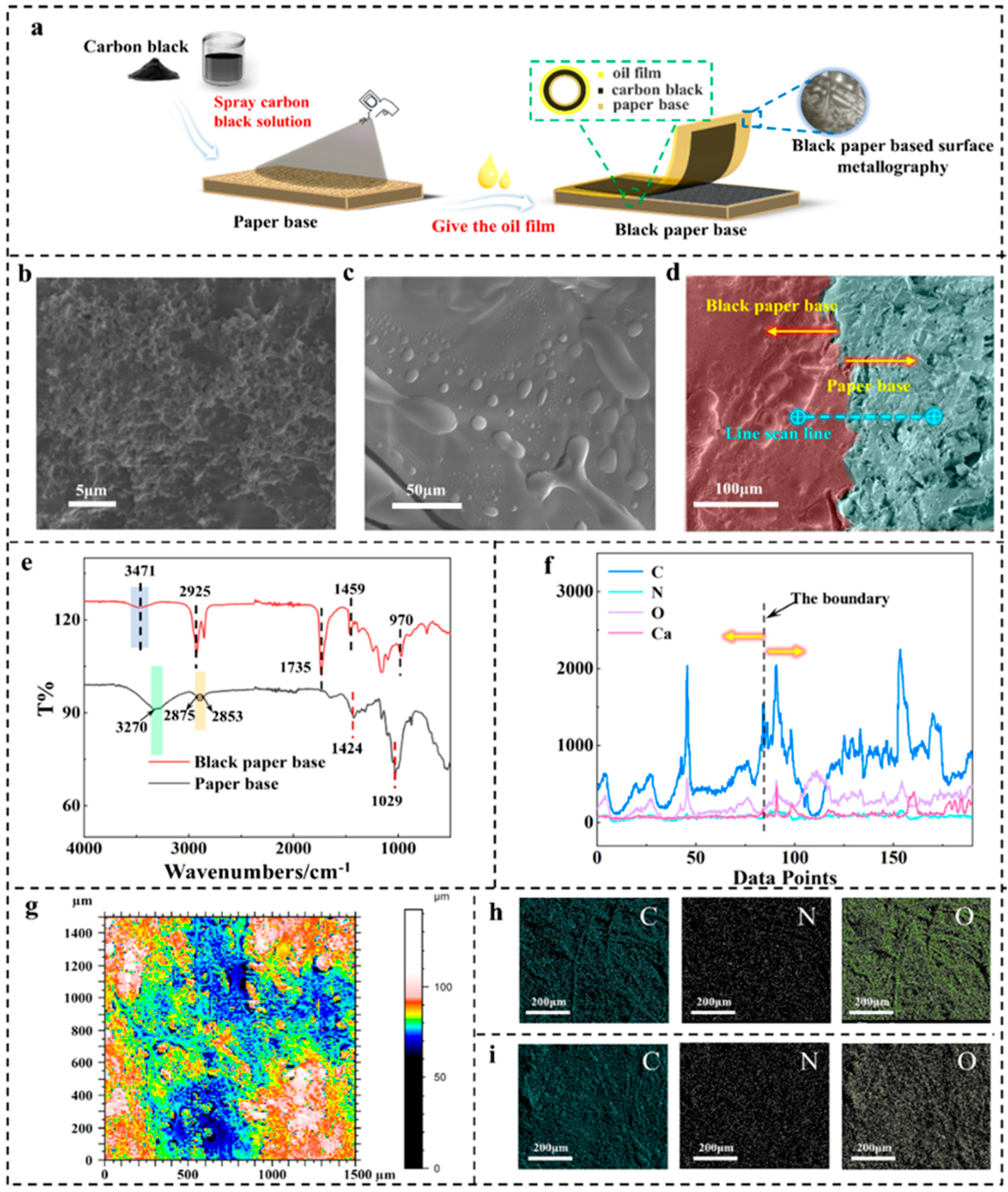

3.3. Hydrophobic property

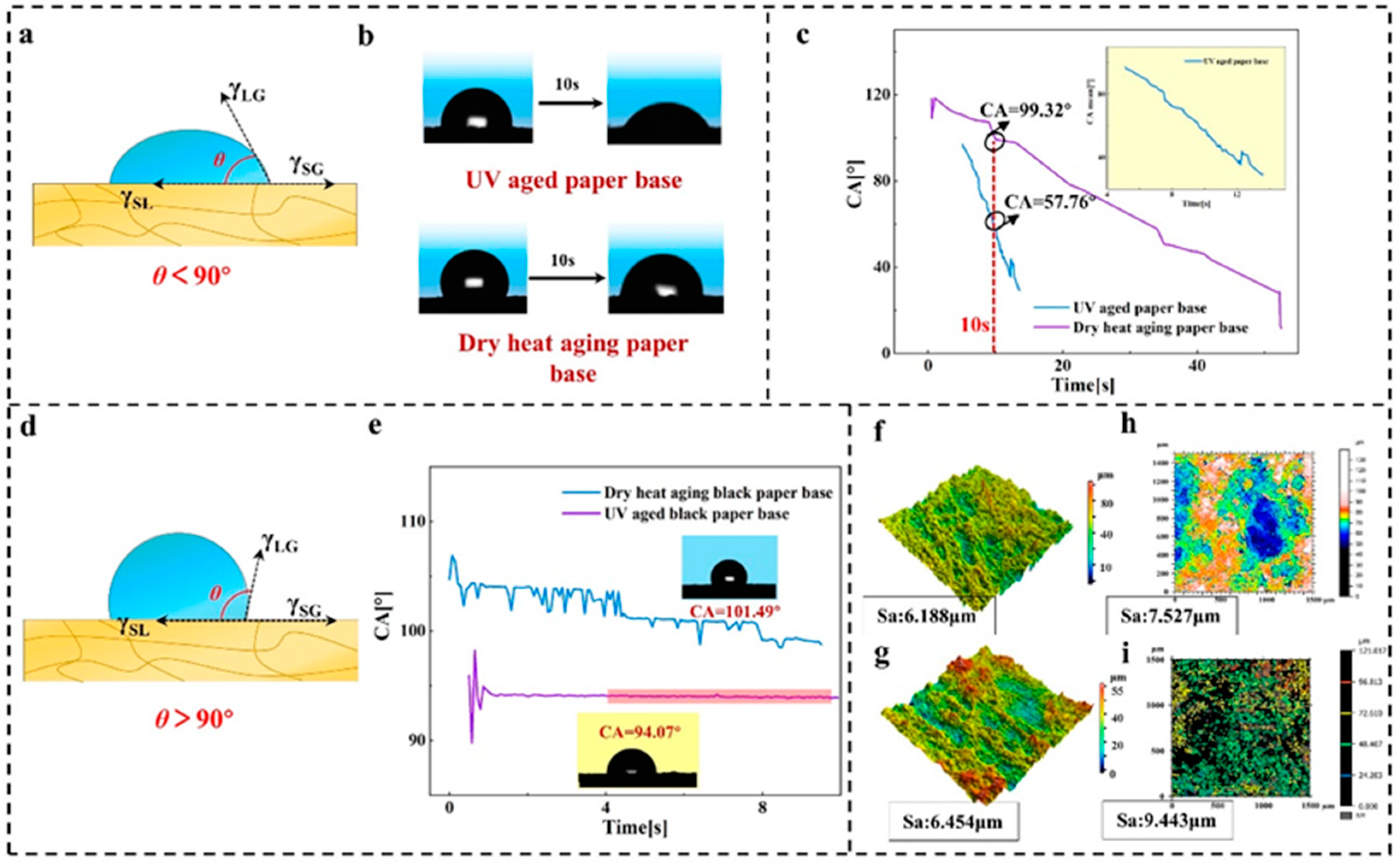

The environmental changes that crops have to cope with in the process of production are changeable. Among them, rainwater is an important environmental condition in the early growth of crops. There are many gaps in the fibers in the paper forming stage. Drops of water drop on the surface of the paper base and soon infiltrate. Rotten in water is a disadvantage of paper-based film. Figure 3a shows the manufacturing process of black paper base film coated with cooked tung oil. Brush coating of cooked tung oil on the surface of base paper is equivalent to a protective layer, which makes the hydrophilic base paper base film transition to hydrophobic black paper base film. Figure 3d, e, the surface of base film of base paper is extremely hydrophilic. In the static contact angle test, when the liquid drops are on the film surface of the base paper, they gradually wet the base paper. As can be seen from Figure 3e, within 20 s, the droplet volume gradually decreases, and the paper fibers absorb water and expand. Finally, the base paper is completely soaked by liquid droplets. Figure 3f, g, after the water droplets drop on the surface of black paper base film, the contact angle is stable around 97.9 ° (> 90 °), showing hydrophobicity. The water drops are still on its surface, and the black paper base is not soaked, keeping its original state.

The main factor to realize the hydrophilicity of base paper to hydrophobicity of black paper base film is the solidification of cooked tung oil. After spraying carbon black solution on the surface of the base paper and brushing a layer of cooked tung oil, the surface of the base paper is obviously hydrophobic. Figure 3b and Figure e show the rough surface morphology of base paper and black paper film, respectively. The arithmetic average height sa of the base paper surface is 6.939 μm. The surface roughness of black paper base Sa=7.765 μm, which is 11.9% higher than that of base film of base paper. As a kind of drying oil, cooked tung oil can cross-link with oxygen during curing. Brush the surface of black paper base with cooked tung oil. During the curing process, the cooked tung oil on the surface of black paper base separates from the paper base sprayed with carbon black, and some wrinkles appear in the oil film, resulting in the surface of black paper base becoming rough and losing its original luster [31]. Figure 3h and i compare the SEM of two kinds of paper-based films. The surface wrinkles of black paper-based films are obvious, and the appearance of micro-rough structure realizes the surface hydrophobicity of black paper-based films.

3.4. Efficient heat transfer performance

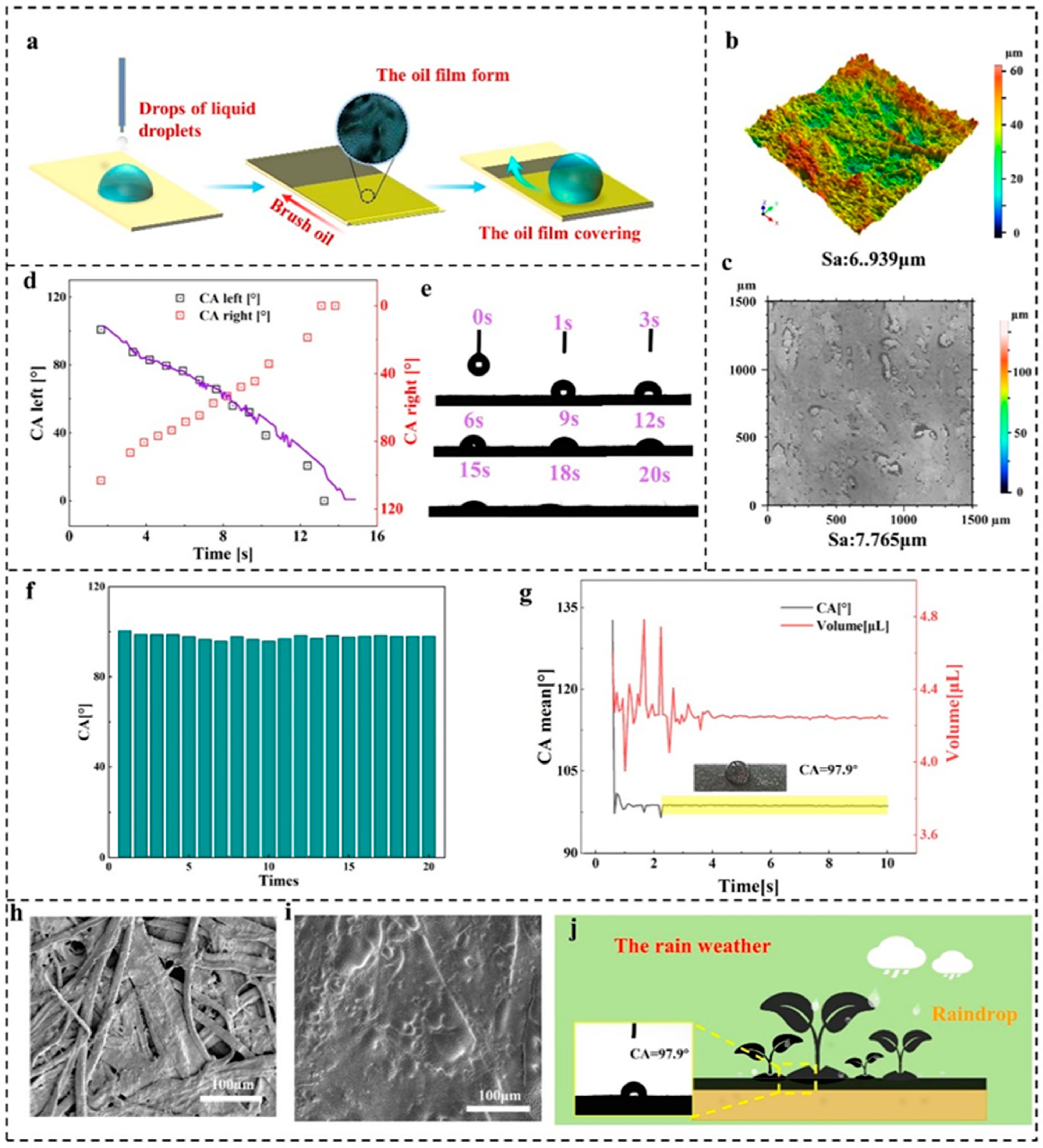

The thermal conductivity of black paper-based film was studied. The sample of paper-based film was used as a medium at room temperature. By monitoring the time of silicone rubber rising from room temperature to 60 °C, the heat transfer effect of paper base can be judged. Figure 4a, after the heating plate is heated to 60 °C, the paper-based sample is placed. When the thermometer detects that the surface temperature of the paper-based sample reaches 60 °C, place a silica gel block to monitor its temperature change. Figure 4b, when the silica gel block on the surface of the base paper is initially placed, the temperature is 32.42 °C, and the time point is 22 s. After that, the time points of the silica gel block at about 40 °C, 45 °C, 55 °C and 60 °C were recorded, and the heat transfer rate was calculated. When the base paper is the heat transfer medium. The time for the silica gel block to rise to 45.08 °C and 60.05 °C is 35 s and 220 s, respectively. Heat transfer rates are 36.17 °C/s and 12.6 °C/s respectively. Obviously, the temperature rise rate decreases obviously in the stage of 45 °C~60 °C

Figure 4 c, the black paper base film rises to 60 °C within the initial 10 s after being placed on the heating plate. After that, the instantaneous temperature of the silica gel block was 31.57 °C. At the subsequent 29 s, 41 s, 119 s and 195 s, the temperature of the silica gel block was 40.30 °C, 45.03 °C, 55.05 °C and 60.11 °C, respectively. Similarly, the rising rates of rubber blocks from around 30 °C to around 45 °C and 60 °C are 70.8 °C/s and 15.42 °C/s, respectively. It is observed that the temperature of rubber block rises rapidly before it rises from the initial temperature to 45 °C. Between 45 °C and 60 °C, the temperature rises slowly. However, compared with the base paper as the heat transfer medium, the heat transfer efficiency of black paper is obviously higher. The excellent thermal conductivity of carbon black endows the black paper base film with high thermal conductivity. Paper-based film can increase the soil temperature in a short time, inhibit the growth of weeds and meet the temperature requirements of crop growth.

3.5. Weather resistance (UV aging resistance, dry heat aging resistance)

In the actual agricultural production, the direct ultraviolet rays and the high temperature brought by sunlight are two important roles that make the plastic film naturally age, and then affect its service life. Rainfall, direct sunlight, pulling, etc. are all natural and man-made influences that need to be considered during the use of plastic film. Therefore, the key to examine whether the paper base has weatherability is to compare whether its mechanical and hydrophobic effects have changed. Under laboratory conditions, ultraviolet aging box and hot air aging box are used to simulate the natural environment. And paper-based samples are subjected to ultraviolet and dry-heat aging. By comparing the mechanical and hydrophobic properties of the film of base paper and black paper before and after paper aging. It is concluded that the black paper base film has excellent weather resistance. Further prove the practicability of the black paper base film coated with cooked tung oil[32].

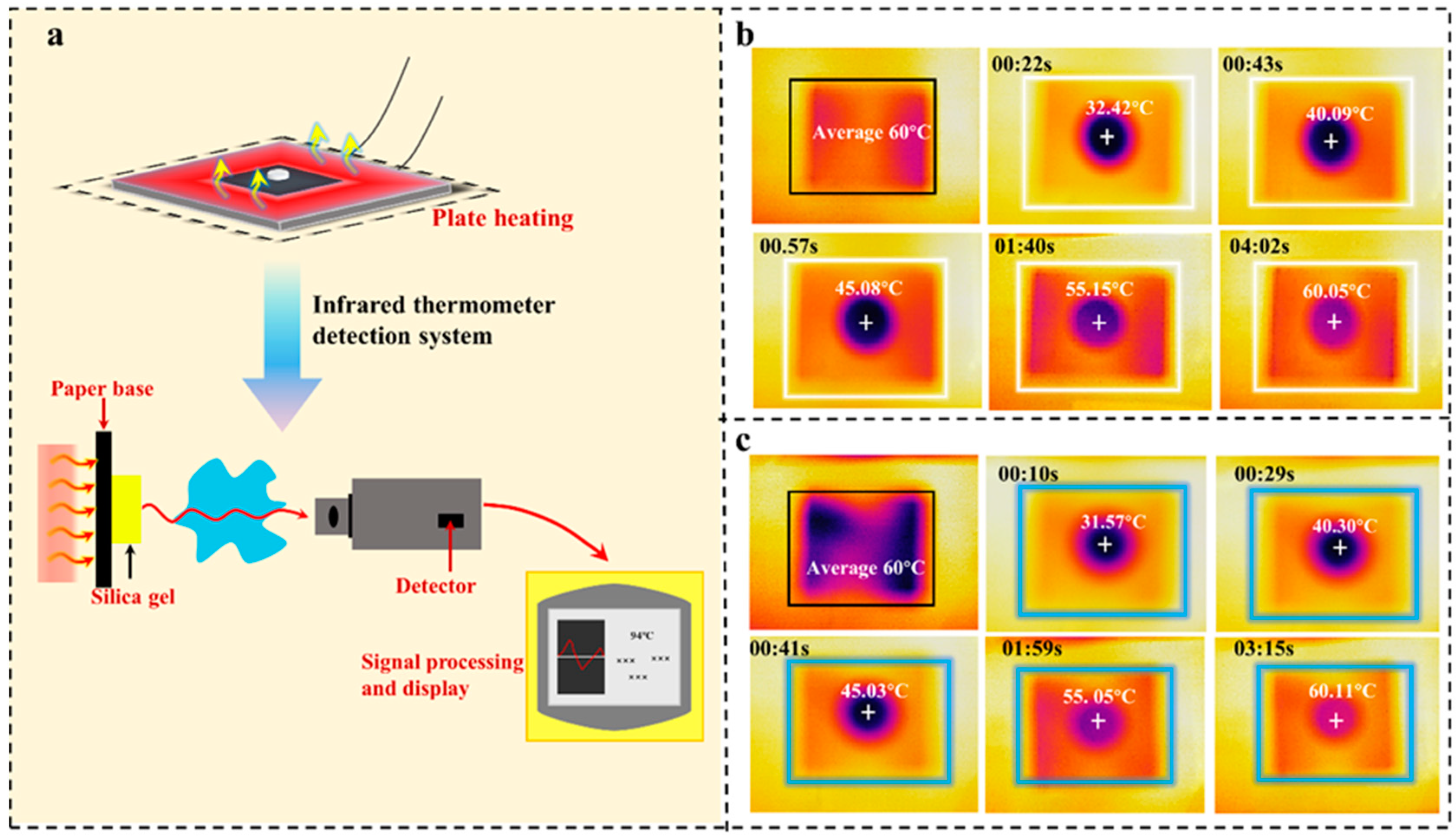

3.5.1. Mechanical analysis of weather resistance

In Figure 5 a, the black paper base film is bent upward and downward, and twisted clockwise and counterclockwise to simulate the actual use and destruction scene in farmland. Finally, the macroscopic surface of the black paper base film remains the same. Figure 5b, c, d, mechanical test of base paper and black paper film after ultraviolet and dry heat aging. After ultraviolet light aging, the mechanical strength of the base paper decreased slightly. Compared with the base paper without ultraviolet aging, the maximum tensile and tearing forces of the base paper have a downward trend. On the contrary, the maximum tensile stress of black paper-based film increased by 57.8% after ultraviolet aging. Under the irradiation of ultraviolet light, the ultraviolet light directly shines on the surface of paper mulch film, destroying the paper fiber structure and breaking the molecular chemical bond, which leads to the obvious decline of the mechanical properties of the base paper after ultraviolet aging.

Figure 5 b, c, d, the mechanical strength (tensile strength, tear strength) of raw paper base and black paper base films are improved after dry heat aging. After dry-heat aging, the maximum tensile force and tearing stress of black base film increased by 108.5% and 18.6%, and the mechanical strength of black base film increased even more. Different from ultraviolet light breaking molecular bond structure. The aging forces the paper-based fibers to dehydrate rapidly, and the crosslinked fiber network becomes stiff, which leads to the larger external force needed to destroy the structure. In the mechanical test after dry heat aging, the mechanical strength of the black paper base film did not decrease, but showed better performance. Part of the reason is the dehydration and hardening of paper-based fibers after high temperature. The other part comes from the blessing of the oil film of cooked tung oil. Mature tung oil permeates into the inner layer of paper base, forms an organic combination with paper fibers, and the film-forming system is more stable. Compared with the original paper base, the black paper base film can effectively maintain its mechanical properties after dry and ultraviolet aging, and the small increase after ultraviolet aging and the large increase after dry and hot aging can show the excellent weatherability of the black paper base film from the side.

3.5.2. Analysis of weatherability and hydrophobicity

The weatherability and hydrophobicity of paper-based film were tested. The experiment shows that the hydrophobic properties of base film of base paper are different after ultraviolet aging and dry-heat aging. The base paper aged under ultraviolet and dry heat conditions is also hydrophilic[33,34,35,36,37,38,39,40]. In the hydrophilic model of Figure 6a, the solid-liquid-gas medium θ is less than 90 °, and the sample surface is wetted by droplets. When the droplets fall on the film surface of the base paper after ultraviolet and dry heat aging, the droplets will soak the base paper in a short time. Figure 6b and Figure c, the droplets are hydrophobic when they drop on the surface of the aged paper base, and then there is a big difference in the rate at which the droplets soak into the paper base. In the same time (10 s), the UV-aged base paper was quickly soaked by droplets, and the contact angle became 57.76 °. However, the dry-hot aged base paper was still hydrophobic at 10 s (CA=99.32 °). This shows that UV aging and dry-heat aging have different effects on the surface of paper mulch film, and the three-dimensional rough structure of hydrophilic paper base aged by dry heat (Figure 6g) is obviously rougher than the original paper base aged by UV (Figure 6f).

In the hydrophobic structure of Figure 6d, θ is greater than 90 °, and the sample surface is not wetted. Figure 6e, the contact angle of the black paper base film after high temperature treatment is 101.5 °, which is higher than that of the unaged black paper base film by 98.9 °. After ultraviolet aging, the contact angle of black paper base is 94.0 °, which still shows hydrophobic Figure 6h, i. Similar to the performance of the original paper base, the surface roughness of the black paper base after dry heat aging is larger than that after ultraviolet aging, and its hydrophobic performance is excellent. To sum up, the hydrophobic property of black paper base film did not decrease obviously after ultraviolet and dry heat aging, but it still showed hydrophobicity. The coating of cooked tung oil gives the black paper base film excellent weather resistance.

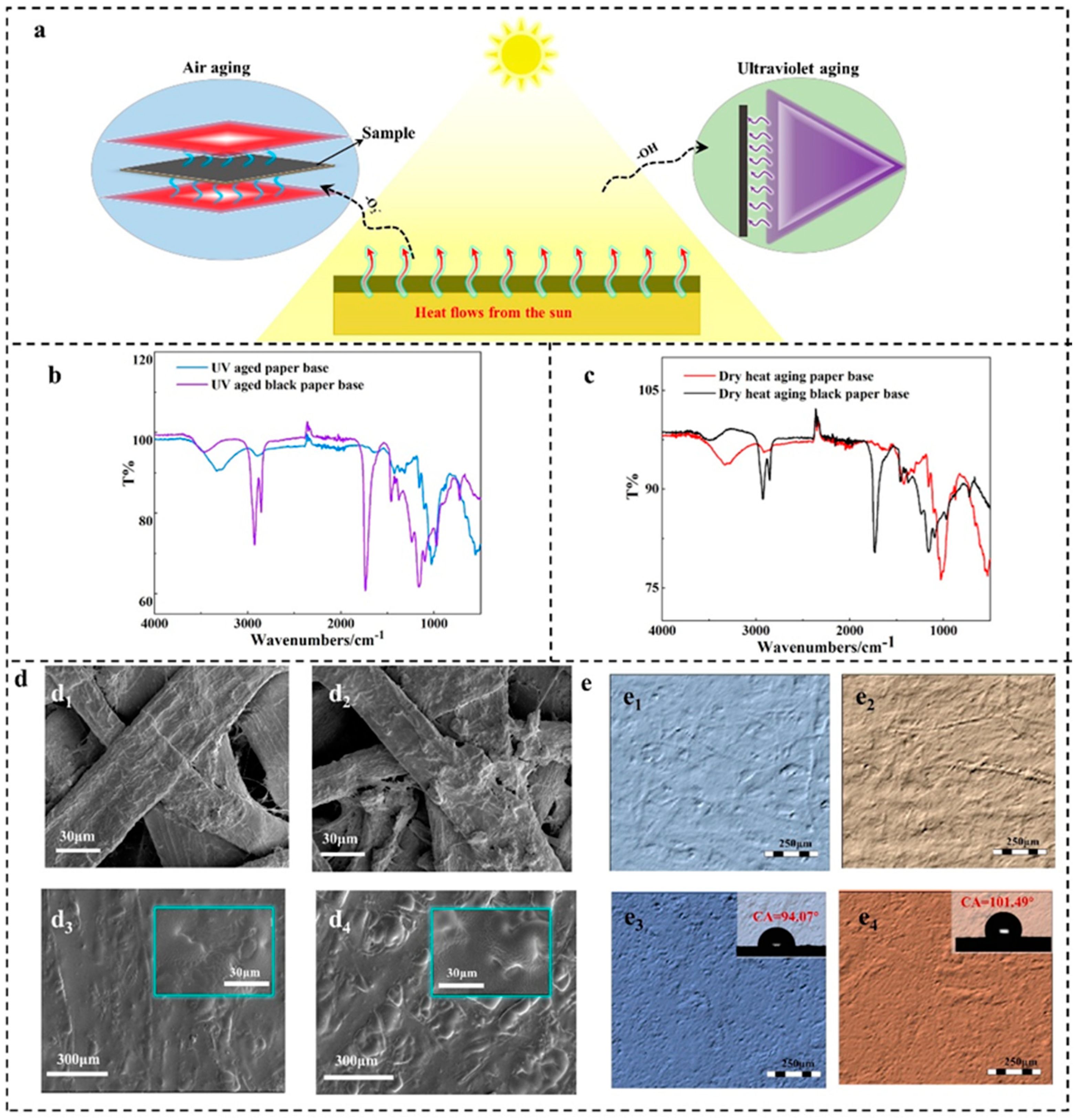

3.5.3. Analysis of weather resistance mechanism

Figure 7 shows the effect mechanism of ultraviolet and dry-heat aging on base paper and black paper, and explains the weather resistance mechanism of black paper base film. In the treatment process of black paper base, cooked tung oil mainly affects the mechanical and hydrophobic properties of black paper base film. Carbon black solution enhances its heat transfer efficiency. The paper base film coated with carbon black solution is soaked with ripe tung oil, which on the one hand has a color fixing effect, on the other hand, enhances the mechanical strength, hydrophobicity and aging resistance of the black paper base film, and then prolongs its service life. Ultraviolet light is irradiated on the surface of the black paper base film. Compared with the original paper base film, the infrared spectrum of the black paper base film after ultraviolet aging in Figure 7b has a strong amplitude peak at -CO- (lipid) (1735cm-1) and an antisymmetric stretching peak at -CH2-(2927cm-1), and the peak is obvious. It can be seen that ripe tung oil plays an important role in maintaining the properties of paper mulch film during ultraviolet aging. Under the irradiation of ultraviolet rays, there are oxidative polymerization and free radical polymerization reactions on the surface of black paper base, which leads to some prominent wrinkles on the surface of black paper base after the irradiation of ultraviolet rays (Figure 7d3, e3), showing a wrinkled membrane structure as a whole. The prominent wrinkles caused by light aging and the non-hydrophilicity of oil itself make the black paper base after ultraviolet aging still appear hydrophobic. Compare the prominent fiber profile of the base paper surface (Figure 7d1, e1) after UV aging. The oil film on the surface of the black paper tightly wraps the paper fiber structure, protecting the black paper base from ultraviolet light erosion.

Figure 7d4, e4, the cooked tung oil is dried at high temperature after the surface of the paper base is solidified, and many wrinkles are produced on the surface of the black paper base during the high temperature treatment. Cause its surface to become rougher and maintain its hydrophobic structure. The process of high heat aging is a complex oxidative polymerization reaction. Figure 7c shows that the expansion peaks of -CO- (lipid) and -CH2- groups of black paper base after dry heat aging are more prominent. At high temperature, the mature tung oil and oxygen molecules form more free fatty acids and a wider range of hydroxyl compounds. After accelerated aging by dry heat, trans double bonds (~972-975cm-1) are preserved in the cured structure of the cooked tung oil, and the cured structure soaked by the cooked tung oil has better mechanics and stronger resistance to dry heat aging after high temperature treatment.

Under normal circumstances, the substance of paper will turn yellow and become brittle when exposed to sunlight for a long time. Accelerate the aging of paper and shorten its service life. Obviously, conventional paper is not suitable for agricultural use. As a kind of dry oil, the black paper base film coated with cooked tung oil can still maintain its own properties and basic performance under ultraviolet irradiation and dry heat treatment, and the cooked tung oil has played a great role.

4. Conclusions

Through a simple process of spraying carbon black solution on the surface of base paper and smearing cooked tung oil on the surface, we prepared a black paper base film covered with cooked tung oil with excellent mechanical properties, hydrophobicity, high heat transfer and excellent weather resistance. The cured film of black paper base film soaked with cooked tung oil forms a multi-dimensional network film structure, and its mechanical strength is far superior to that of base paper film, and the maximum tensile force is increased by 123% compared with that of base paper. Curing the rough structure of the oil film on the surface gives the black paper a hydrophobic structure, and the contact angle reaches 97.9 °. The coloring of carbon black makes the black paper base film have heat conduction effect, and the average heat transfer rate reaches 15.12 °C/s. The oil film stability system formed by the penetration of cooked tung oil into the paper base makes the black paper base film resistant to ultraviolet light and hot air. It provides a reliable basis for the feasibility of a black paper base film coated with cooked tung oil.

Author Contributions

Conceptualization, Y.W. and Y.S.; methodology, Y.W.; software, Y.Y.; validation, Y.Z., Y.Y. ; formal analysis, Y.S.; investigation, Y.S.; resources, Y.W.; data curation, Y.S.; writing—original draft preparation, Y.S.; writing—review and editing, Y.W.,Y.Z.,Y.Y.; visualization, Y.Z.,Y.Y.; validation, Y.S.; supervision, Y.W.; project administration, Y.W.; funding acquisition, Y.W. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Wang X, Fan J, Xing Y, et al. The Effects of Mulch and Nitrogen Fertilizer on the Soil Environment of Crop Plants. Advances in Agronomy, 2019, 153:121-173. [CrossRef]

- Arora V K, Singh C B, Sidhu A S, et al. Irrigation, tillage and mulching effects on soybean yield and water productivity in relation to soil texture. Agricultural Water Management, 2011, 98(4):563-568. [CrossRef]

- Qiang He, Jiwen Wang, Guangfei Wang, et al. Construction of a durable superhydrophobic flame-retardant coating on the PET fabrics, Materials and Design,233(2023)112258. [CrossRef]

- Wang Y, Xie Z, Malhi S S, et al. Effects of gravel–sand mulch, plastic mulch and ridge and furrow rainfall harvesting system combinations on water use efficiency, soil temperature and watermelon yield in a semi-arid Loess Plateau of northwestern China. Agricultural Water Management, 2011, 101(1):88-92. [CrossRef]

- Zhou L, Zhang F, Liu C. Improved yield by harvesting water with ridges and subgrooves using buried and surface plastic mulchs in a semiarid area of China. Soil & Tillage Research, 2015, 150:21-29. [CrossRef]

- Qi Y, Beriot N, Gort G, et al. Impact of plastic mulch film debris on soil physicochemical and hydrological properties. Environmental Pollution, 2020, 266(Pt 3):115097. [CrossRef]

- Gao H, Yan C, Liu Q, et al. Effects of plastic mulching and plastic residue on agricultural production: A meta-analysis. Science of The Total Environment, 2018, 651:484-492. [CrossRef]

- Barnes D, Galgani F, Thompson R C, et al. Accumulation and fragmentation of plastic debris in global environments. Philos Trans R Soc Lond B Biol, 2009, 364(1526):1985-1998. [CrossRef]

- Brodhagen M, Goldberger J R, Hayes D G, et al. Policy considerations for limiting unintended residual plastic in agricultural soils. Environmental Science & Policy, 2017. [CrossRef]

- Miles, Carol, DeVetter, et al. Suitability of Biodegradable Plastic Mulches for Organic and Sustainable Agricultural Production Systems.. HortScience, 2017. [CrossRef]

- Harada J, Souza A G D, José R.N. de Macedo, et al. Soil culture: Influence of different natural fillers incorporated in biodegradable mulching film. Journal of Molecular Liquids, 2019,273:33-36. [CrossRef]

- Brown J E, Channell-Butcher C. Black Plastic Mulch and Drip Irrigation Affect Growth and Performance of Bell Pepper. Journal of Vegetable Crop Production, 2001, 7(2):109-112. [CrossRef]

- Kasperbauer, M. Strawberry Yield over Red versus Black Plastic Mulch. OAI, 2000.

- Anzalone A, Cirujeda A, Aibar J, et al. Effect of Biodegradable Mulch Materials on Weed Control in Processing Tomatoes. Weed Technology, 2010, 24(3):369-377. [CrossRef]

- Melo, C. Soil microorganisms and their role in the interactions between weeds and crops/Microorganismos do solo e suas funções nas interações entre plantas daninhas e culturas.

- Portet C, Yushin G, Gogotsi Y. Electrochemical performance of carbon onions, nanodiamonds, carbon black and multiwalled nanotubes in electrical double layer capacitors. Carbon, 2007, 45(13):2511-2518. [CrossRef]

- Wang Y, Chen J, Cao J, et al. Graphene/carbon black hybrid film for flexible and high rate performance supercapacitor. Journal of Power Sources, 2014, 271(dec.20):269-277. [CrossRef]

- Nadakatti S, Tendulkar M, Kadam M. Use of mesoporous conductive carbon black to enhance performance of activated carbon electrodes in capacitive deionization technology. Desalination, 2011, 268(1-3):182-188. [CrossRef]

- Kossyrev, P. Carbon black supercapacitors employing thin electrodes - ScienceDirect. Journal of Power Sources, 2012, 201(3):347-352. [CrossRef]

- Song J P, Tian K Y, Ma L X, et al. The effect of carbon black morphology to the thermal conductivity of natural rubber composites. International Journal of Heat & Mass Transfer, 2019, 137:184-191. [CrossRef]

- Mishra A K, Lahiri B B, Philip J. Superior thermal conductivity and photo-thermal conversion efficiency of carbon black loaded organic phase change material. Journal of Molecular Liquids, 2019. [CrossRef]

- Leong C K, Chung D. Carbon black dispersions as thermal pastes that surpass solder in providing high thermal contact conductance. Carbon, 2003, 41(13):2459-2469. [CrossRef]

- Huang J, Yuan T, Ye X, et al. Study on the UV curing behavior of tung oil: Mechanism, curing activity and film-forming property. Industrial Crops and Products, 2018, 112:61-69. [CrossRef]

- Zhang C, Garrison T F, Madbouly S A, et al. Recent advances in vegetable oil-based polymers and their composites. Progress in Polymer Science, 2017:S0079670016301198. [CrossRef]

- He Z, Chapital D C, Cheng H N, et al. Application of tung oil to improve adhesion strength and water resistance of cottonseed meal and protein adhesives on maple veneer. Industrial Crops and Products, 2014, 61:398–402. [CrossRef]

- Xin Y L, Timar M C, Varodi A M, et al. TUNG OIL AND LINSEED OIL AS TRADITIONAL FINISHING MATERIALS IMPORTANT FOR FURNITURE CONSERVATION. Pro Ligno, 2015.

- Huang Y, Pang L, Wang H, et al. Synthesis and properties of UV-curable tung oil based resins via modification of Diels–Alder reaction, nonisocyanate polyurethane and acrylates. Progress in Organic Coatings, 2013, 76(4):654-661. [CrossRef]

- Huang Y, Pang L, Wang H, et al. Synthesis and properties of UV-curable tung oil based resins via modification of Diels–Alder reaction, nonisocyanate polyurethane and acrylates. Progress in Organic Coatings, 2013, 76(4):654-661. [CrossRef]

- Wang S, Yao W, Lu Z, et al. Characterization and durability assessment of fibre-reinforced tung oil lime putties for restoration. Journal of Building Engineering, 2021, 38(6):102241. [CrossRef]

- Samadzadeh M, Boura S H, Peikari M, et al. Tung oil: An autonomous repairing agent for self-healing epoxy coatings. Progress in Organic Coatings, 2011, 70(4):383-387. [CrossRef]

- Hu Songxi, LI Pu. New Chemical Materials, 2019, 047(003):116-118.

- Xin Y L, Timar M C, Varodi A M, et al. TUNG OIL AND LINSEED OIL AS TRADITIONAL FINISHING MATERIALS IMPORTANT FOR FURNITURE CONSERVATION. Pro Ligno, 2015.

- Qiang He, Jiwen Wang, Guangfei Wang, et al. Construction of a durable superhydrophobic flame-retardant coating on the PET fabrics, Materials and Design,233(2023)112258. [CrossRef]

- Jiwen Wang, Yanbin Zhang, Qiang He *Stretchable superhydrophobic fluororubber fabricated by transferring mesh microstructures, Soft Matter,2023,19,1560. [CrossRef]

- Qiang He*, Yongwei Ma, Xiaosen Wang, et al. Superhydrophobic flexible silicone rubber with stable performance, anti-icing and multi-level rough structure,ACS Applied Polymer Materials,2023,6,3c00273. [CrossRef]

- Anling Li, Zhen Wei, Fangyuan Zhang, et al. A high reliability super hydrophobic silicone rubber,Colloids and Surfaces A: Physicochemical and Engineering Aspects,671(2023)131639. [CrossRef]

- Qiang He*, Yangyang Jia, Haoyu Wan, et al. Triple conversion strategy to build anti-de-icing sheets for the leading edge of the rotor blade,Materials & Design,237(2024)112516. [CrossRef]

- Qiang He, Kangshuai LI, Zehua XU, et al. Research progress on construction strategy and technical evaluation of aircraft icing accretion protection system, Chinese Journal of Aeronautics,2023,36(10):1-23. [CrossRef]

- Zehua Xu, Yanbin Zhang, Anling Li, et al. Research progress on compounding agent and mechanical test method of fluororubber, J Appl Polym Sci. 2021;e50913. [CrossRef]

- Qiang He, Xu Yuan, Fanghyuan Zhang, Yangyang Jia, et al. Preparation methods and research progress of super-hydrophobic anti-icing surface. Advances in Colloid and Interface Science, 2023: 103069. [CrossRef]

Figure 1.

Schemes follow the same formatting. Surface analysis (a) Preparation process of black paper mulch film; (b) Water-soluble pigment carbon black SEM; (c) SEM of cooked tung oil; (d) SEM of black paper mulch film section; (e) Infrared spectrum analysis of base paper and black paper film; (f) EDS of black paper mulch film section; (g) False color view of black paper base film surface; (h) EDS on the film surface of base paper; (i) EDS on the surface of black paper base film.

Figure 1.

Schemes follow the same formatting. Surface analysis (a) Preparation process of black paper mulch film; (b) Water-soluble pigment carbon black SEM; (c) SEM of cooked tung oil; (d) SEM of black paper mulch film section; (e) Infrared spectrum analysis of base paper and black paper film; (f) EDS of black paper mulch film section; (g) False color view of black paper base film surface; (h) EDS on the film surface of base paper; (i) EDS on the surface of black paper base film.

Figure 2.

Mechanical test and mechanism analysis (a) Simulates the use of plastic film in natural environment; (b) Metallographic image of base film of base paper; (c) Metallographic image of black paper base film; (d) Stretching-displacement curves of film on base paper and black paper; (e)Tear-displacement curve of film on base paper and black paper; (f) Maximum tensile and tearing force of paper base film; (g) Base paper SEM; (h) Black paper-based SEM; (i) Schematic diagram of action mechanism of cooked tung oil.

Figure 2.

Mechanical test and mechanism analysis (a) Simulates the use of plastic film in natural environment; (b) Metallographic image of base film of base paper; (c) Metallographic image of black paper base film; (d) Stretching-displacement curves of film on base paper and black paper; (e)Tear-displacement curve of film on base paper and black paper; (f) Maximum tensile and tearing force of paper base film; (g) Base paper SEM; (h) Black paper-based SEM; (i) Schematic diagram of action mechanism of cooked tung oil.

Figure 3.

Discussion on hydrophobic properties of paper base film (a) Schematic diagram of the process from hydrophilic base paper base film to hydrophobic black paper base film; (b) 3D view of the film surface of base paper; (c) Black paper base film step height view; (d) Change of static contact angle of base paper film droplets during infiltration; (e) Actual change of contact angle of liquid droplets on the surface of base paper; (f) Contact angle test of black paper base film; (g) Change of static contact angle of black paper base film; (h) Base paper SEM; (i) SEM of black paper base film; (j) Simulation of practical application of black paper base film.

Figure 3.

Discussion on hydrophobic properties of paper base film (a) Schematic diagram of the process from hydrophilic base paper base film to hydrophobic black paper base film; (b) 3D view of the film surface of base paper; (c) Black paper base film step height view; (d) Change of static contact angle of base paper film droplets during infiltration; (e) Actual change of contact angle of liquid droplets on the surface of base paper; (f) Contact angle test of black paper base film; (g) Change of static contact angle of black paper base film; (h) Base paper SEM; (i) SEM of black paper base film; (j) Simulation of practical application of black paper base film.

Figure 4.

Study on thermal conductivity of paper base film (a) Thermal conductivity experiment and schematic diagram of infrared temperature measuring gun principle; (b) Temperature change of base film heat conduction experiment of base paper; (c)Temperature change of heat conduction experiment of black paper base film.

Figure 4.

Study on thermal conductivity of paper base film (a) Thermal conductivity experiment and schematic diagram of infrared temperature measuring gun principle; (b) Temperature change of base film heat conduction experiment of base paper; (c)Temperature change of heat conduction experiment of black paper base film.

Figure 5.

Weather resistance mechanical test of paper base film (a) Distortion test of black paper base film; (b) The tensile-displacement curve of base film of base paper before and after aging; (c) The tensile-displacement curve of black paper base film before and after aging; (d) Tear-displacement curves of base film of base paper and black paper before and after aging.

Figure 5.

Weather resistance mechanical test of paper base film (a) Distortion test of black paper base film; (b) The tensile-displacement curve of base film of base paper before and after aging; (c) The tensile-displacement curve of black paper base film before and after aging; (d) Tear-displacement curves of base film of base paper and black paper before and after aging.

Figure 6.

(a) Hydrophilic (CA < 90 °) model; (b) Hydrophilic infiltration process of base film of base paper after ultraviolet and dry heat aging; (c) Contact angle curve of the base film of the base paper after ultraviolet and dry heat aging; (d) Hydrophobic (CA > 90 °) model; (e) Contact angle of black paper base film after ultraviolet and dry heat aging; (f), (g) Three-dimensional morphology of base film surface of base paper after ultraviolet and dry heat aging; (h), (i) Contour lines of black paper base film surface after ultraviolet and dry heat aging.

Figure 6.

(a) Hydrophilic (CA < 90 °) model; (b) Hydrophilic infiltration process of base film of base paper after ultraviolet and dry heat aging; (c) Contact angle curve of the base film of the base paper after ultraviolet and dry heat aging; (d) Hydrophobic (CA > 90 °) model; (e) Contact angle of black paper base film after ultraviolet and dry heat aging; (f), (g) Three-dimensional morphology of base film surface of base paper after ultraviolet and dry heat aging; (h), (i) Contour lines of black paper base film surface after ultraviolet and dry heat aging.

Figure 7.

Analysis of weather resistance mechanism of paper base film (a) Ultraviolet and dry heat aging experimental model; (b) Infrared spectra of base paper and black paper film after ultraviolet aging; (c) Infrared spectra of base paper and black paper film after dry heat aging; (d) SEM of base paper and black paper after UV and dry heat aging (d1 and d3 UV aging base paper and black paper base film, d2 and d4 dry heat aging base paper and black paper base film); (e) Photo simulation of the surface of base paper and black paper after ultraviolet and dry-heat aging (e1 and e3 ultraviolet aging base paper and black paper base film, e2 and e4 dry-heat aging base paper and black paper base film).

Figure 7.

Analysis of weather resistance mechanism of paper base film (a) Ultraviolet and dry heat aging experimental model; (b) Infrared spectra of base paper and black paper film after ultraviolet aging; (c) Infrared spectra of base paper and black paper film after dry heat aging; (d) SEM of base paper and black paper after UV and dry heat aging (d1 and d3 UV aging base paper and black paper base film, d2 and d4 dry heat aging base paper and black paper base film); (e) Photo simulation of the surface of base paper and black paper after ultraviolet and dry-heat aging (e1 and e3 ultraviolet aging base paper and black paper base film, e2 and e4 dry-heat aging base paper and black paper base film).

Table 1.

Experimental equipment.

| Device name | Model | Manufacture factory |

|---|---|---|

| Bending tester | SMT-5000 | China Yangzhou Saisi Testing Equipment Co.,LTD |

| Contact Angle tester | HKCA-15 | China Beijing Hake Test Instrument Factory |

| Ultraviolet accelerated weathering test chamber | MU3089 | China Shanghai Moujing Industrial Co.,LTD |

| Interferometric three-dimensional surface topography instrument | ZeGage | ZYGO,Inc |

| Raman instrument | LabRAM HR Evolution | HORIBA Jobin Yvon,France |

| SEM | SEM450 | American NOVANANO Company |

| Hot air aging testing machine | MU3040C | Shanghai Moujing Industrial Co.,LTD |

| FTIR | IRTracer-100 | Japan |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Copyright: This open access article is published under a Creative Commons CC BY 4.0 license, which permit the free download, distribution, and reuse, provided that the author and preprint are cited in any reuse.

MDPI Initiatives

Important Links

© 2024 MDPI (Basel, Switzerland) unless otherwise stated