1. Introduction

Weighing lysimeters, a particular type of scale system, are widely used in agricultural and hydrological research to measure crop evapotranspiration (ET). ET is the combined process of water evaporation from the soil surface and transpiration from plants, which is an essential component of the water cycle and plays a crucial role in the overall water balance of an ecosystem. Although many other ways exist to measure or estimate ET [

1,

2,

3,

4,

5,

6,

7,

8,

9], lysimeters are considered the most accurate method for crop water use measurements [

10]. A weighing lysimeter typically consists of a container with a known area, which is equipped with electronic load cells or other weighing devices to measure changes in weight over time. The container is typically buried in the ground, maintaining the soil and vegetation inside the container to simulate natural conditions as closely as possible. Weighing lysimeters are utilized under the working principle that changes in the lysimeter mass predominantly reflect the amount of water lost through evapotranspiration. By continuously monitoring the lysimeter mass, the water loss and evapotranspiration rate during a given time can be calculated. This method provides a direct and accurate measurement of evapotranspiration, considering both the soil evaporation and plant transpiration processes.

Over the years, many lysimeters have been installed worldwide using various designs and installation systems [

11,

12,

13,

14,

15,

16,

17,

18,

19,

20,

21,

22]. ET data derived from lysimeter experiments have been used for many applications, such as studying the water requirements of different crops, evaluating the effectiveness of irrigation strategies, assessing the impact of climate change on evapotranspiration patterns, and calibrating other methods and techniques for measuring and estimating ET [

10,

23]. However, one of the primary purposes of utilizing weighing lysimeters in agriculture has been to derive the crop coefficients needed to estimate ET from weather data [

2,

24,

25].

Although there is a long history of using weighing lysimeters for measuring ET, the electronics for reading the lysimeter load cells consist typically of a data logger [

21] that collects and stores the data onsite, requiring researchers to visit the site to download and visualize the data. This system tends to be expensive and suffers from many disadvantages. New developments in open-source microelectronics and data communication systems (i.e., radio, cellular, Wi-Fi) provide new opportunities for enhancing lysimetry. The availability of internet-connected devices via developing and applying Internet of Things (IoT) systems can make lysimetry more affordable and convenient [

26,

27]. IoT systems enable the collection and transmission of real-time information accessible from anywhere in the world via the Internet using a computer or smartphone. In previous studies, we have used open-source electronics to develop IoT systems for monitoring and making real-time data available online. Three IoT systems were designed for soil moisture monitoring [

28,

29,

30] to assist growers in making more accurate and timely irrigation scheduling decisions based on real-time sensor data. Another IoT system was developed to monitor agricultural runoff from an agricultural field [

31]. Therefore, building on our previous experience, this study aimed to create an affordable Internet of Things (IoT) scale system to measure crop evapotranspiration.

2. Materials and Methods

2.1. Electronic Components

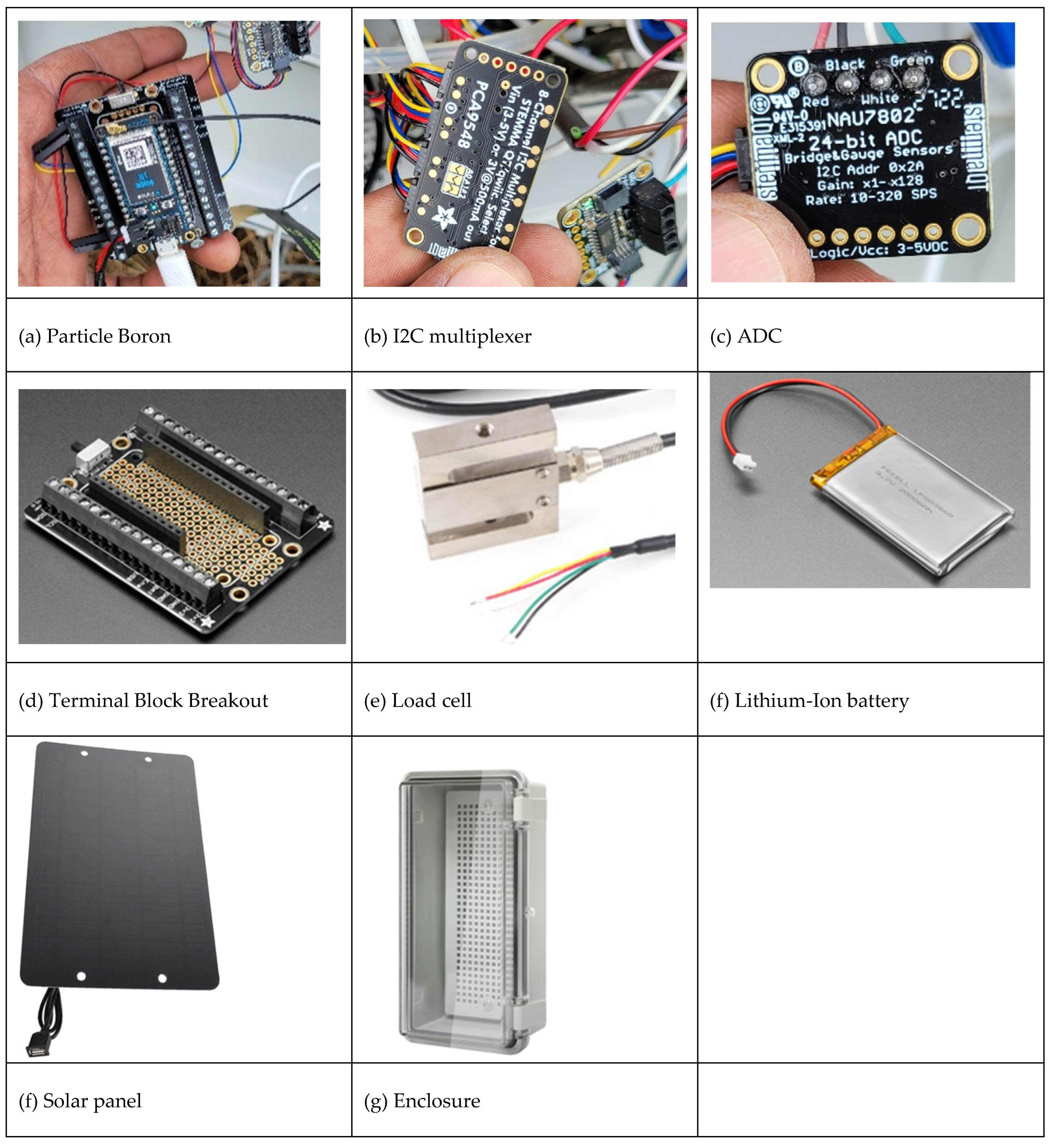

The essential electronic components for the IoT scale system consisted of four electronic load cells, a microcontroller, an Inter-Integrated Circuit (I2C) multiplexer, and four analog-to-digital converters (ADC). A Particle Boron LTE CAT-M1 (BRN404X) device was used as the microcontroller to collect and transmit the data from the load cells to the Internet. The Boron device combines a microcontroller (ARM Cortex-M4F 32-bit processor @ 64MHz) with embedded cellular (LTE) and Bluetooth communication capabilities. The Boron device also features, among other specifications, 20 mixed signal GPIO pins (6 x Analog, 8 x PWM), UART, I2C, SPI, and an integrated Li-Po battery charging circuity and connector. The Boron device was mounted on an Adafruit terminal block breakout (Adafruit.com, Assembled Terminal Block Breakout FeatherWing for all Feathers) to facilitate connection to the GPIO, power, and data communication pins.

Four 100 kg capacity S-Type Load Cells (Phidgets.com) with the technical specifications shown in

Table 1 were used to measure changes in the mass of the scale system. The load cells convert changes in the mass of the scale into an analog voltage signal using a bridge circuit. There is usually an excellent linear relationship between the mass and the combined voltage output of the load cells [

16]. Free-standing scale systems are typically designed using several load cells to account for imbalances and differences in load cell outputs resulting from differences in mass placement.

An Adafruit NAU7802 24-Bit ADC-STEMMA QT/Qwiic was used for each load cell (

www.adafruit.com) to provide a regulated voltage excitation to the load cell and accurately convert the analog voltage output of the load cell into a digital output. STEMMA QT/Qwiic refers to a particular type of connector the ADC and other electronics use to facilitate connecting to external devices, like a microcontroller. The accuracy of conversion from the analog to digital signal is greatly affected by the number of bits of the ADC; the higher the number of bits, the higher the accuracy. The 24-bit ADC used here is accurate since it can divide the analog signal into 224 = 16,777,216 divisions. The digital output was transmitted to the microcontroller using an I2C serial communication protocol. The I2C protocol allows connecting multiple slave devices (i.e., the NAU7802 24-Bit ADC) to a single master device (i.e., a microcontroller), and multiple masters can control a single or multiple slave devices. But, connecting multiple slaves to a single master depends on each slave having a unique address. However, all the NAU7802 ADCs were manufactured with the same default I2C address (0x2A), which could not be changed, and the Boron device had only one I2C channel.

This setup would only allow connecting one NAU7802 ADC to the single I2C channel of the Boron device. Therefore, an I2C multiplexer was used to expand the number of I2C channels on the Boron device from 1 to 8 (Adafruit PCA9548 8-Channel STEMMA QT/Qwiic I2C Multiplexer - TCA9548A Compatible). This arrangement allows reading up to 8 ADCs sequentially with the same I2C address. Power to the electronic components was supplied using a 3.7 V and 2500mAh, Lithium-ion polymer (Li-Po) battery (Adafruit.com). The battery was charged using a monocrystalline mini solar panel (5 volts, 6 Watts). All the electronic components, except for the load cells and the solar panel, were housed in a plastic IP65 waterproof enclosure with dimensions of 200 x 100 x 70 mm (LMioEtool ABS). Images of the different components of the IoT scale system are shown in

Figure 1, and web links to additional information are shown in

Table 2. The quantities required and the cost of the components, based on the current list prices and excluding taxes, and shipping & handling, are shown in

Table 3. The multiplexer and ADC require special STEMMA QT/Qwiic connectors (not included in Fig.1 or

Table 3), which must be purchased separately.

2.2. Internet of Things (IoT) System

The Particle Boron device was programmed using Particle Workbench, a professional tool built into Visual Studio Code to facilitate IoT development (

https://www.particle.io/blog/particle-workbench-ga/). The code for the Particle Boron device included several external library files such as "Particle.h," "Wire.h," "Adafruit_NAU7802.h," and "ThingSpeak.h." The first three library files were needed for the Boron to communicate with and control the I2C multiplexer and the ADC. The "ThingSpeak.h" library was needed to send the data to ThingSpeak™ (ThingSpeak.com), an IoT analytics platform service allowing users to aggregate, visualize, and analyze live data streams in The Cloud. The Particle Boron was programmed to sample the four load cells and send the data to ThingSpeak.com every minute during the indoor part of the experiment and every ten minutes during the outdoor experiment.

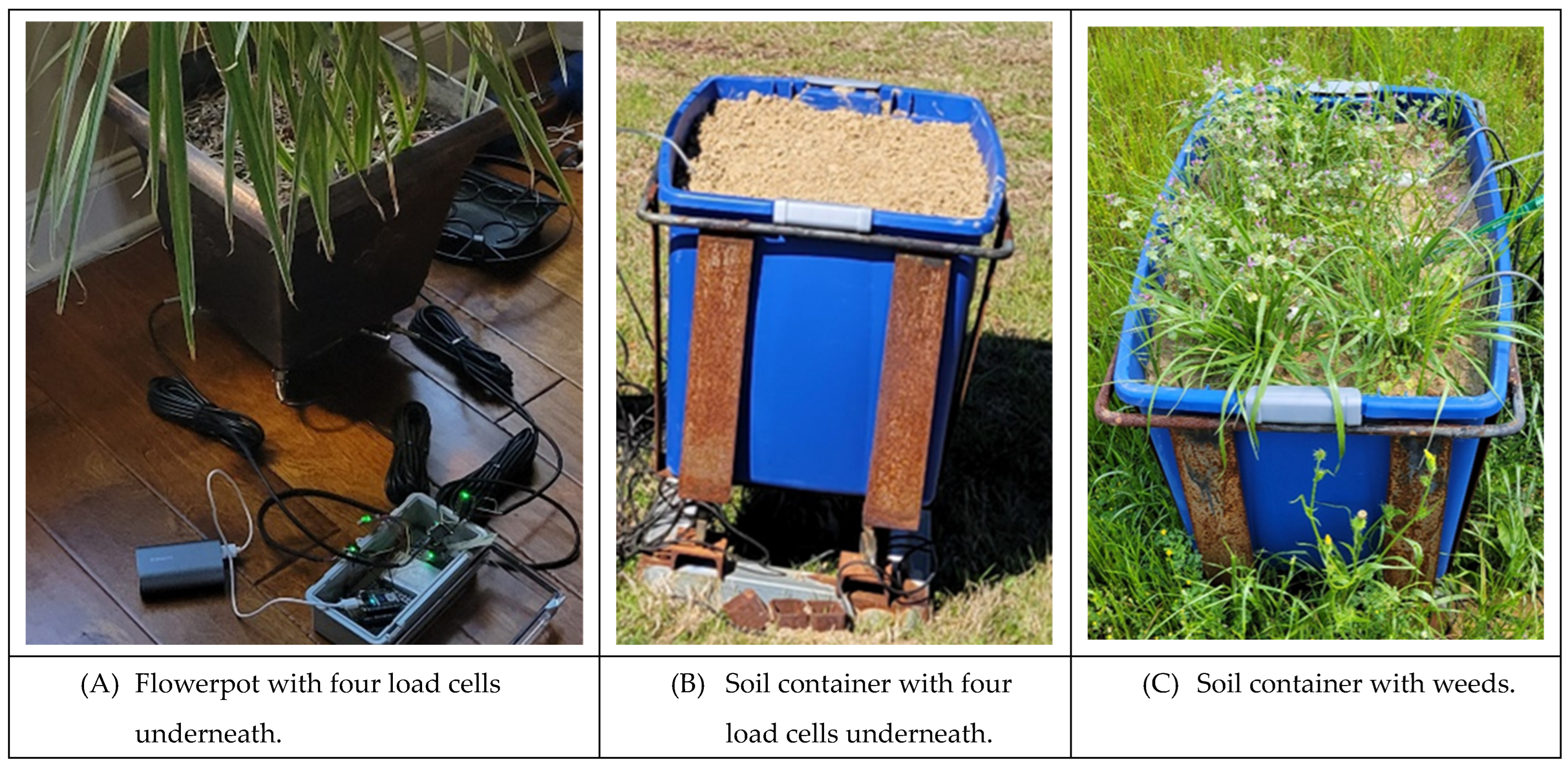

2.3. Indoor and Outdoor Experiments

The performance of the IoT scale system was initially tested during an indoor experiment by placing the four load cells in each corner underneath a flowerpot (

Figure 2A). The IoT system was used to measure the mass of the flowerpot every minute for two days. The indoor experiment was conducted to test the hardware, software, and data communication. Another purpose was to evaluate if the scale system responded adequately to changes in mass by performing a calibration experiment and collecting data from the flowerpot. Once the indoor experiment proved successful, a scale system was built to be deployed outdoors (

Figure 2B) to continuously monitor soil water evaporation, simulating a weighing lysimeter's operation. The system consisted of a steel frame supported by four load cells (one underneath each corner) containing a soil-filled plastic storage bin. The outdoor experiment was installed on 1/21/2023 in a grassy area at the edge of an agricultural field at the Clemson University Edisto Research and Education Center, Blackville, South Carolina. The IoT scale system was programmed to collect data every ten minutes and send the data to ThingSpeak.com. The collected data included the output of each load cell, the total output (summing the output of the four load cells), and the total mass of the soil container (kg). The soil in the container was initially bare (

Figure 2B), but weeds were allowed to grow inside the container (

Figure 2C).

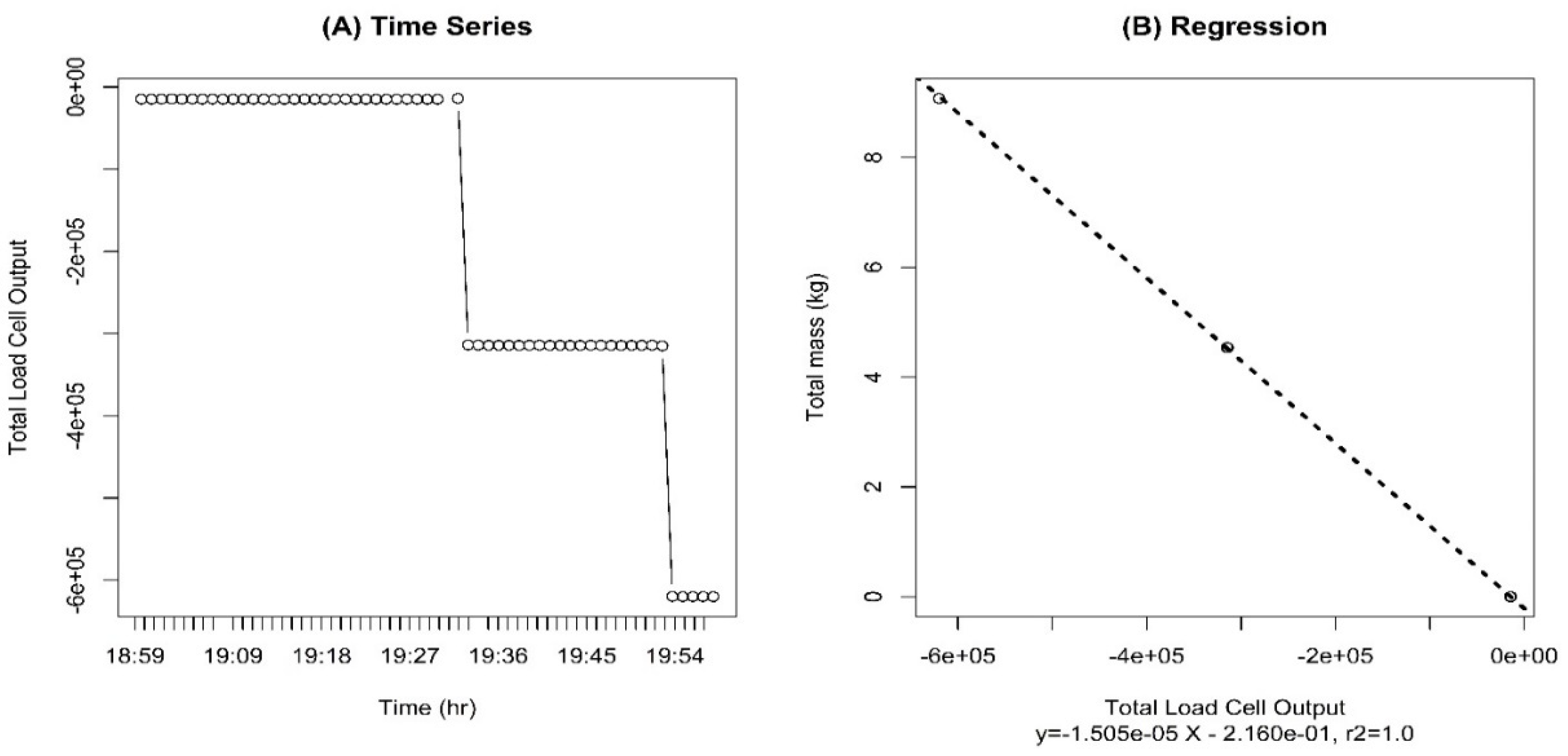

2.4. System Calibration

The load cells produce a very small voltage output that the ADC converts into an integer value. In this application, this integer had no intrinsic meaning and needed to be converted into mass (kg) to be useful. A calibration was conducted to convert the output of the ADC to mass (kg). The calibration consisted of sequentially adding objects of known mass (kg) to the scale system and recording the corresponding ADC output. The aim was to empirically develop an equation to convert the output into mass (kg). The initial calibration was conducted during the indoor experiment phase on 1/15/2023. A similar calibration was also performed during the outdoor experiment on 2/24/2023 (

Figure 3). For the indoor calibration, the objects of known mass were books previously weighed using an electronic kitchen scale (Model EK9710, 5 kg capacity). For the outdoor calibration, sealed plastic containers were filled with dry sand and weighed using an electronic compact bench scale (Ohaus, Model Ranger 3000, 30 kg capacity). Each container was filled to weigh around 5 kg. The linear regression equation resulting from the calibration was used to convert the load cell output to mass (kg). The lysimeter mass was converted into its equivalent depth of evapotranspiration water (mm) based on the surface area of the lysimeter container (

Figure 3) (mm of water = kg of water/m

2).

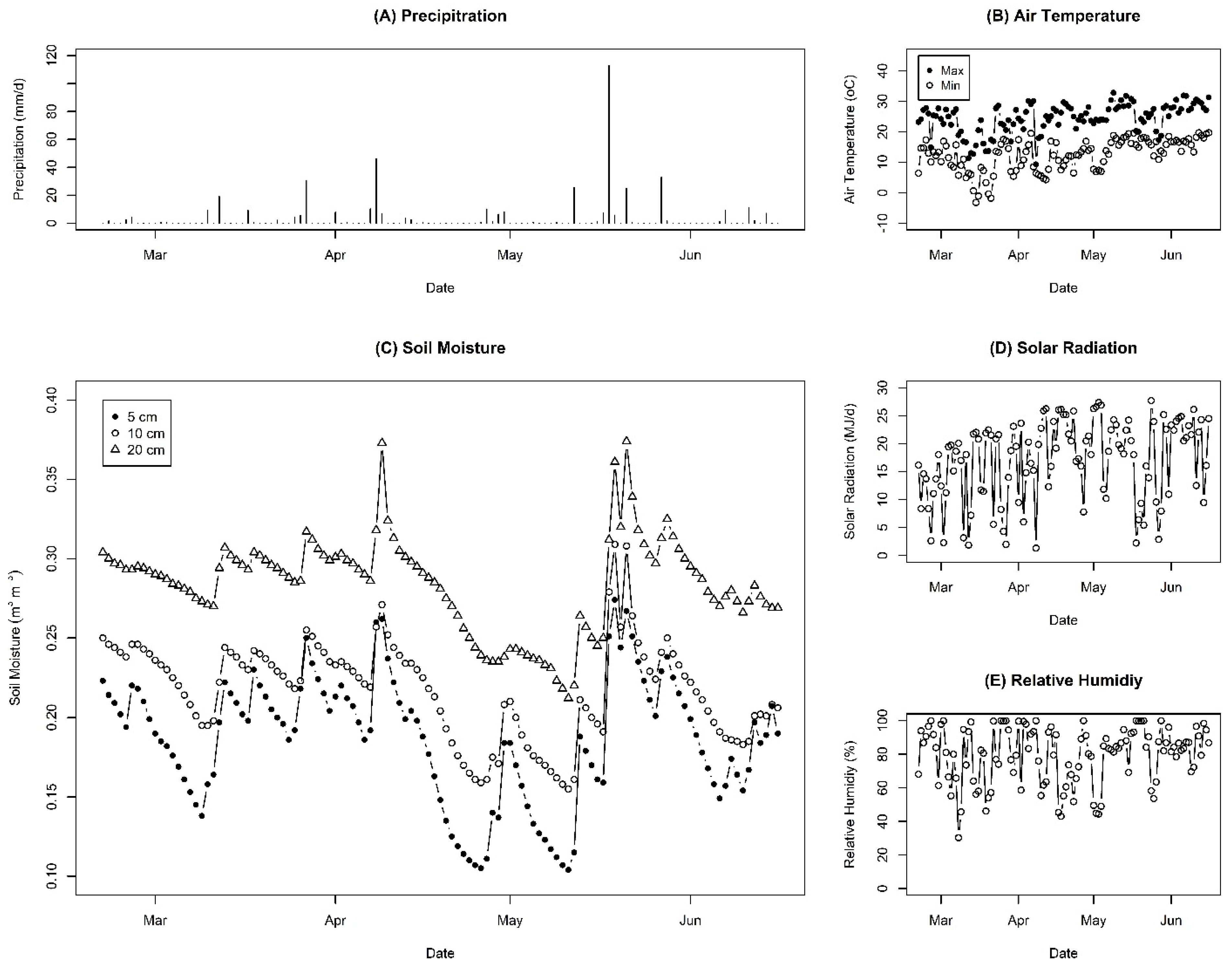

2.5. Weather and Soil Moisture Data

Daily weather and soil moisture data for the research site was obtained from a weather station at the Edisto Research and Education Center. The station is part of the National Oceanic and Atmospheric Administration (NOAA) National Weather Service. It is located at a linear distance of around 800 m from where the outdoor experiment was conducted. The data obtained from the weather station for this study included precipitation, air temperature (maximum and minimum), mean relative humidity, solar radiation, and soil moisture at three soil depths (5, 10, and 20 cm).

3. Results and Discussion

3.1. Calibration Results

The results of the indoor calibration are shown in

Figure 4.

Figure 4A shows the changes through time in the total load cell output from adding three masses to the scale system. The output collected every minute for each mass indicates that the signal was very stable, with no noticeable noise. The regression analysis (

Figure 4B) yielded a perfect correlation (r

2 = 1.0) between the total load cell output and the mass.

Figure 4B shows a negative relationship, which could result from the type of load cell used in this study, which can operate in tension or compression modes. The negative relationship also depends on how the two signal wires of the load cell are connected to the ADC positive and negative pins, which will result in either a positive or negative output. The results of the outdoor calibration were similar to the indoor calibration (data not shown).

3.2. Weather and Soil Moisture

Information on daily precipitation, Maximum (Max) and Minimum (Min) air temperature, soil moisture at three soil depths, solar radiation, and relative humidity from February to June 2023 at the study site are shown in

Figure 5. The daily precipitation data (

Figure 5A) shows frequent precipitation events, typical in the study area during Spring. The soil moisture data in

Figure 5D reflects various wetting and drying cycles in response to the recurring rainfall events.

3.3. Results of the Outdoor Experiment

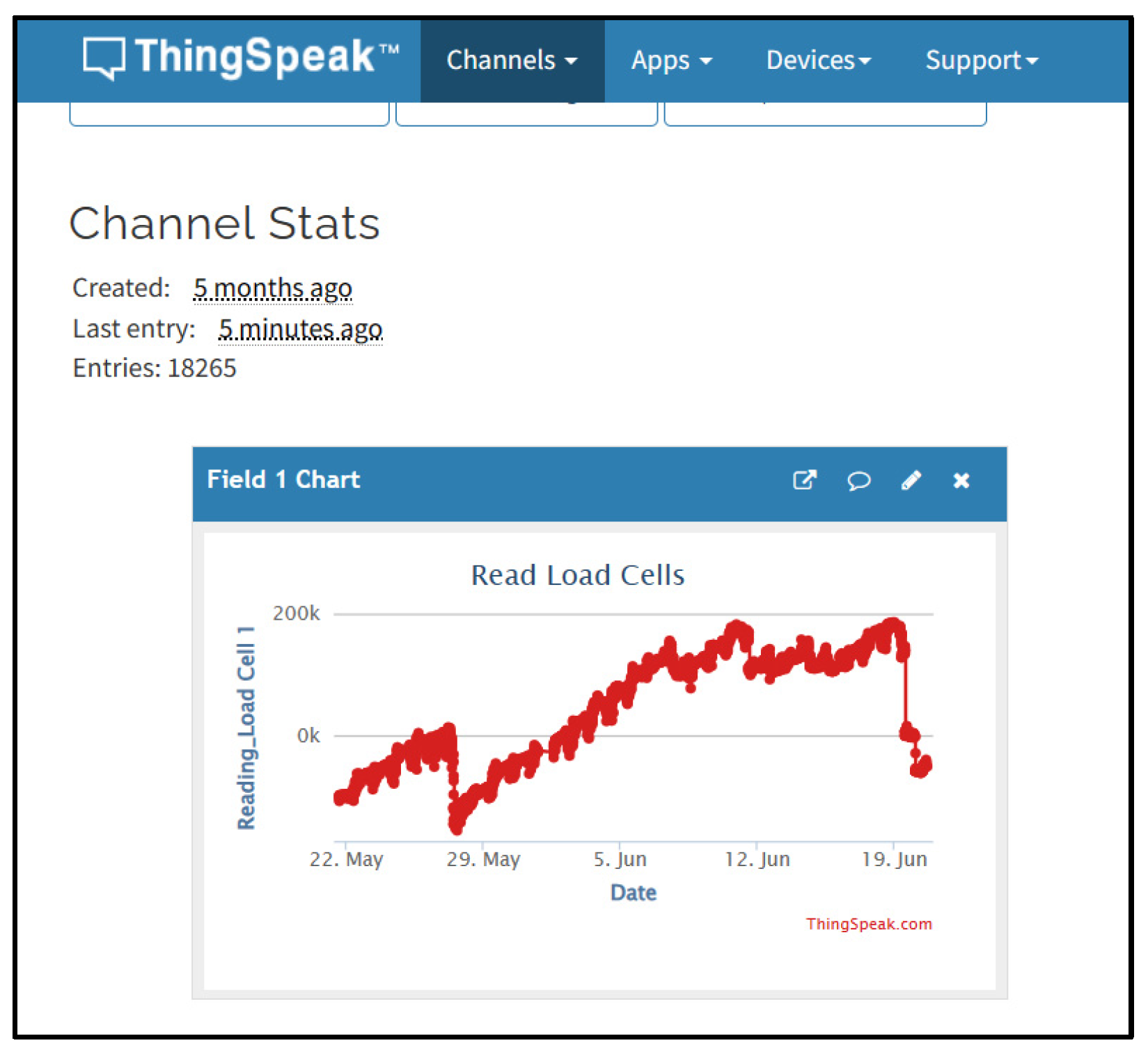

Figure 6 shows an example of the output of one of the load cells displayed in ThingSpeak.com from May 22 to June 19, 2023, during the outdoor experiment. The ThingSpeak.com tool allows displaying up to eight charts per channel, and the data can be visualized using a computer or cell phone. The data on ThinkSpeak.com can be made private, shared with specific people, or made public for anyone to see. The data sent to ThingSpeak.com gets a timestamp when received, gets stored in a database, and can be downloaded as a CSV file.

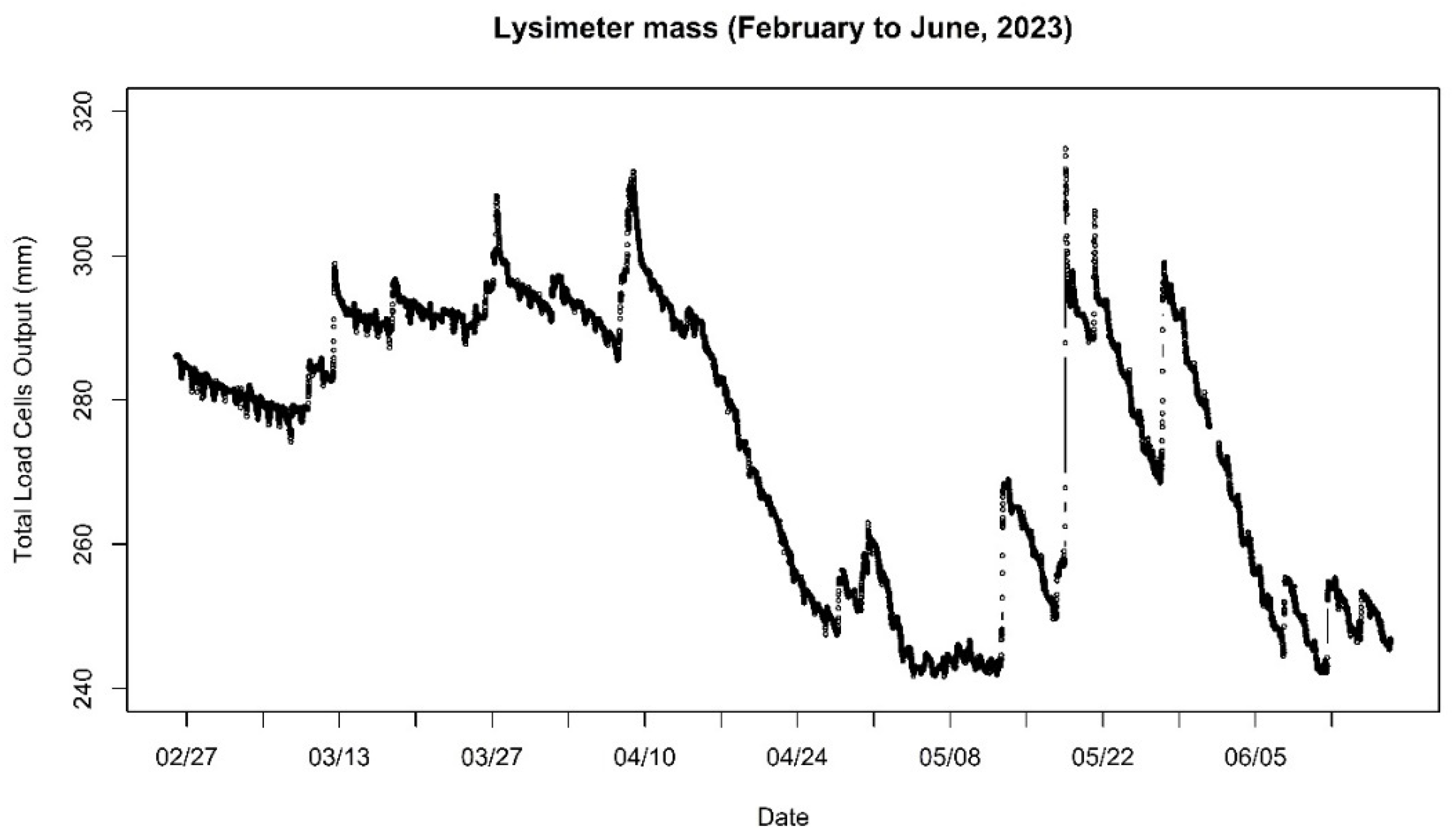

The data collected every ten minutes during the outdoor experiment is shown in

Figure 7 for the entire study period from February to June 2023. The data collection and communication system did not fail during this period, indicating that the IoT scale system was reliable. However, the reliability of the communication system depends on cell phone coverage and quality of coverage, which vary by site and local conditions. It should be noted that the lysimeter mass data shown in

Figure 7 followed the same pattern as the soil moisture data previously shown in

Figure 5D, indicating that the IoT scale system accurately responded to the local changes in soil wetting and drying cycles.

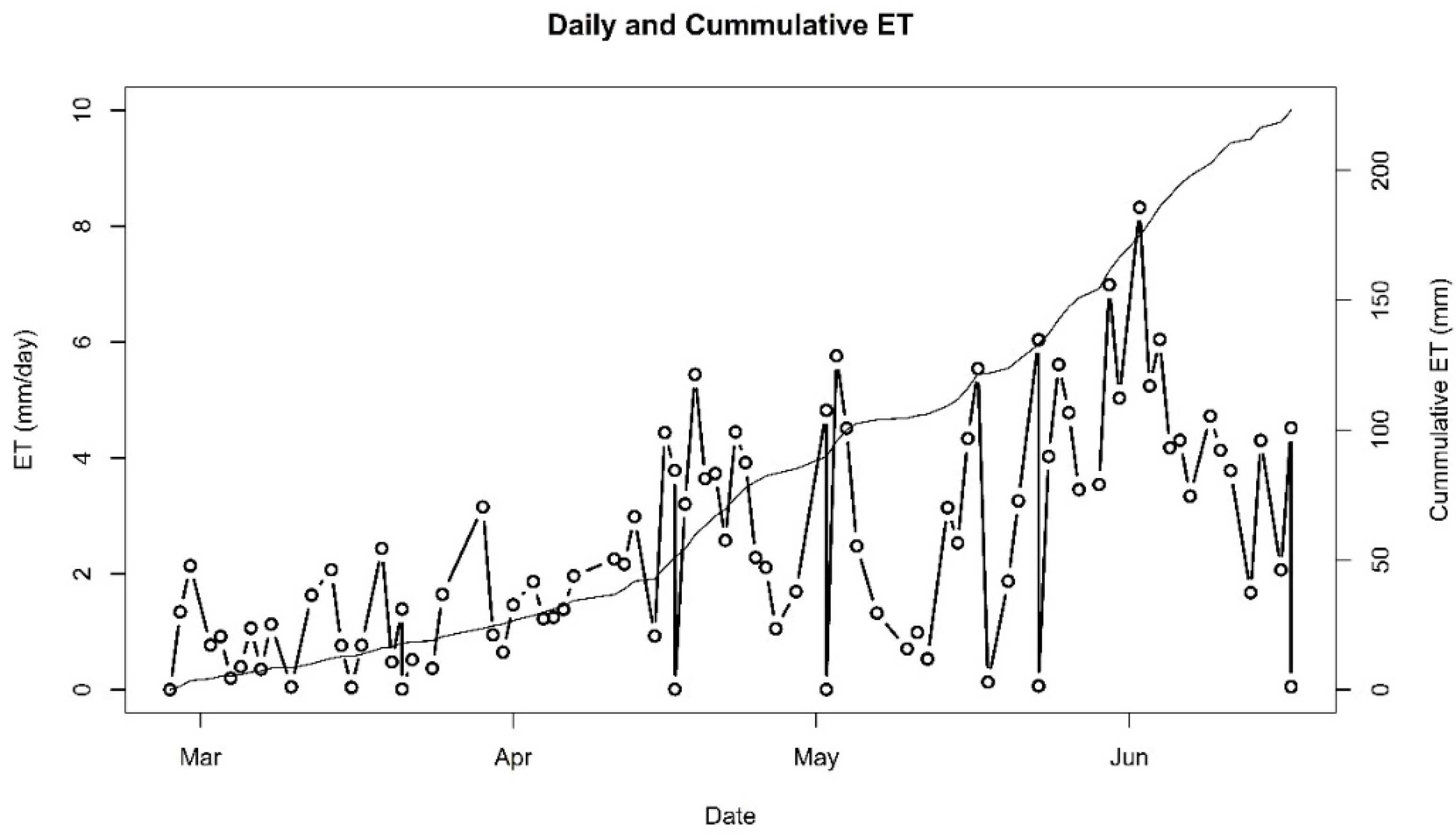

The 10-minute data in

Figure 7 was filtered to retain only the values measured at midnight each day. The midnight lysimeter mass values were used to calculate the daily evapotranspiration by subtracting the midnight value for the current day from that of the previous day. Since rainy days would result in negative ET values, the negative values were removed. The resulting daily and cumulative ET values for the study period are shown in

Figure 8. As expected, the daily ET values were variable, reflecting the normal day-to-day variability in weather and soil moisture conditions. The daily ET rate depends on several weather variables, such as solar radiation, temperature, relative humidity, and wind speed. For a cropped surface, crop type, crop development stage, percent crop cover, and level of water stress also play an essential role. Despite the variability in daily ET, the tendency was for the daily ET values to increase with time as the weather got warmer as Spring moved towards Summer.

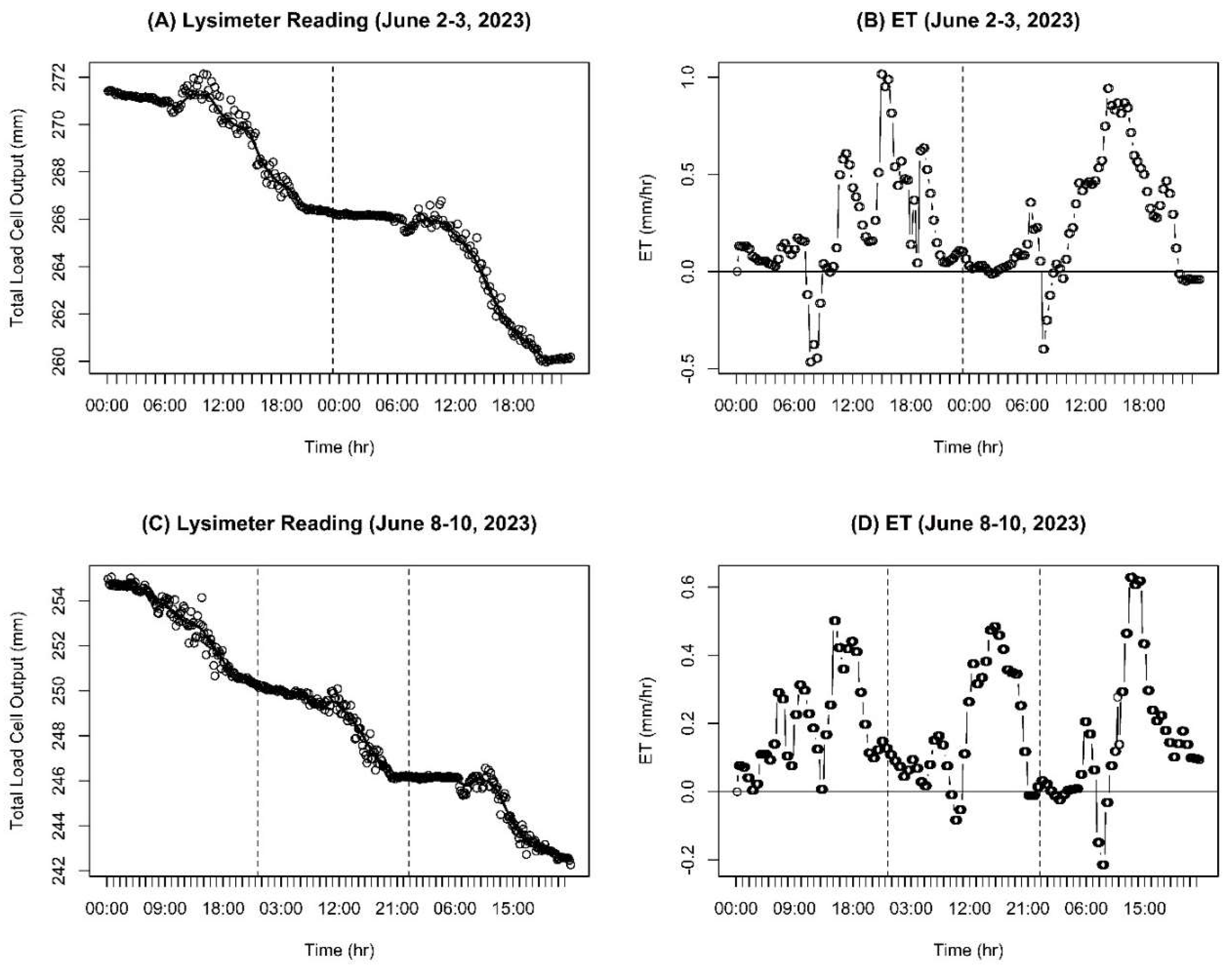

Figure 9 shows the lysimeter mass and evapotranspiration measured every ten minutes during June 2-3 and June 8-10, 2023, which provides a closer look to appreciate the accuracy of the IoT scale system. It shows the daily pattern of crop water use, with the rate of water use increasing during the daytime compared to nighttime hours. In general, more noise in the signal is observed during the day compared to nighttime. During the daytime, more noise could result from the effect of clouds on solar radiation and the usual tendency of wind speed to increase during the day [

32]. It is possible that our field experiment setup, with the soil container above ground, could have been more severely impacted by changes in wind speed than a normal lysimeter, which is typically buried. An interesting observation from

Figure 9A is that there was a mass increase during the morning hours for June 2 and 3 instead of the expected decrease. The rise in mass could be due to dew accumulation in the morning, a common occurrence in the study area.

Figure 9C shows that considerable nighttime evaporation occurred from June 8 to June 9, but evaporation was minimal during the night of June 9 to June 10. These results show that the IoT scale system was accurate enough to detect both the daily evapotranspiration and even evapotranspiration rates during shorter periods (i.e., 10 min). However, for periods shorter than daily, it would be advisable to remove noise by smoothing the data before calculating evapotranspiration. Some of the short-term noise could be removed by programming the microcontroller to oversample and time-average during data collection. Additional smoothing can be applied in post-processing using various data smoothing techniques that can be applied to time series (i.e., moving average, lowess). The data in

Figure 9A and

Figure 9C were first smoothed using the lowess () function in R (using f = 0.05) before the ET values in

Figure 9B and

Figure 9D were calculated. As indicated earlier,

Figure 9B and

Figure 9D show that negative ET values resulted during the morning hours in most of the five days shown, probably due to dew formation.

3.4. Cost of the IoT Scale System

Electronic supplies to build the IoT scale system (

Table 3) cost

$338.57, excluding taxes and shipping & handling. But the four load cells represented 53% (

$180) of the total cost, and all the other electronic supplies were purchased for

$159. However, this work focused on building and testing the electronics for the scale or lysimeter system. The cost of building a field lysimeter for actual evapotranspiration monitoring can be significant. Under their current pricing policy, non-commercial users have no ongoing monthly cost or data plan for using the Particle Boron to transmit data using the cellular network. Also, there is no cost for non-commercial users to use the ThingSpeak.com IoT platform.

3.5. Advantages and Disadvantages of the IoT Scale System

The IoT scale system has many advantages. For example, it can be built using open-source electronics and an existing IoT platform. The system has low power requirements and can operate with a small battery and solar panel, which is especially important in remote agricultural locations. Lysimeters are typically installed in the middle of an agricultural field; therefore, a bulky solar panel and battery system often obstruct farming operations. The system offers connectivity to the Internet, allowing users to see the data in real-time. Internet connectivity enables users to monitor the system remotely to ensure that the lysimeter is working correctly without needing to visit the site to download and visualize the data manually. The system has a 24-bit ADC, which is the same accuracy as the flagship Campbell Scientific data loggers (i.e., models CR1000X or CR6), commonly used for lysimeter applications in agriculture, but at a small fraction of the cost.

On the other hand, one of the main disadvantages of the IoT scale system is that it is not equipped to timestamp and save the data locally. It relies on timestamping and saving the data in The Cloud, which depends on the availability and reliability of the cellular network. Our field experiment did not have problems with the cellular network. Still, our experience with other applications is that cellular communication could fail, depending on the site and weather conditions.

4. Conclusions

In this study, an affordable IoT scale system was developed using open-source electronics and an IoT platform. The system was tested during a several-month field experiment to measure evapotranspiration using an above-ground lysimeter. The system proved to be reliable both in data collection and data communication under the conditions of the study. It also accurately measured changes in the lysimeter mass that enabled determining evapotranspiration during daily and shorter periods. The system can be built at a fraction of the cost of popular data logging systems typically used for lysimeter applications.

Funding

Technical Contribution No. XXX of the Clemson University Experiment Station. This material is based upon work supported by NIFA/USDA under projects SC-1700593 and SC-170539. Additional funding was provided by USDA-NRCS Project number 69-3A75-17-274. Names of commercial products are solely provided as information to the reader and do not imply an endorsement or recommendation by the authors or their organizations.

Data Availability Statement

The data presented in this study are available on request from the corresponding author. The data are not publicly available since some of the datasets presented (i.e., soil and weather data) were obtained from a third party.

Acknowledgments

the author acknowledges the technical support provided by Dana Turner, Anna Sara Hill, and Ali Mirzakhani Nafchi.

Conflicts of Interest

The author declares no conflict of interest.

References

- Allen, R.G.; Jensen, M.E.; Wright, J.L.; Burman, R.D. Operational estimates of reference evapotranspiration. Agron. J. 1989, 81, 650–662. [Google Scholar] [CrossRef]

- Allen, R.G.; Pereira, L.S.; Raes, D.; Smith, M. Crop evapotranspiration-guidelines for computing crop water requirements-FAO Irrigation and drainage paper 56. FAO, Rome, Italy, 1998, 300, D05109.

- Castellvi, F.; Snyder, R.L.; Baldocchi, D.D. Surface energy-balance closure over rangeland grass using the eddy covariance method and surface renewal analysis. Agric. For. Meteorol. 2008, 148, 1147–1160. [Google Scholar] [CrossRef]

- Holmes, J.W. Measuring evapotranspiration by hydrological methods. Agric. Water Manag. 1984, 8, 29–40. [Google Scholar] [CrossRef]

- Kizer, M.A.; Elliot, R.L. Eddy correlation systems for measuring evapotranspiration. Trans. ASAE 1991, 34, 387–392. [Google Scholar] [CrossRef]

- Payero, J.O.; Neale, C.M.U.; Wright, J.L.; Allen, R.G. Guidelines for validating Bowen ratio data. Trans. ASAE 2003, 46, 1051–1060. [Google Scholar] [CrossRef]

- Paw U, K.T.; Qiu, J.; Su, H.; Watanabe, T.; Brunet, Y. Surface renewal analysis: a new method to obtain scalar fluxes. Agric. For. Meteorol. 1995, 74, 119–137. [Google Scholar] [CrossRef]

- Todd, R.W.; Evett, S.R.; Howell, T.A. The Bowen ratio-energy balance method for estimating latent heat flux of irrigated alfalfa evaluated in a semi-arid, advective environment. Agric. For. Meteorol. 2000, 103, 335–348. [Google Scholar] [CrossRef]

- Niu, H.; Hollenbeck, D.; Zhao, T.; Wang, D.; Chen, Y. Evapotranspiration estimation with small UAVs in precision agriculture. Sensors 2020, 22, 6427. [Google Scholar] [CrossRef]

- Moorhead, J.; Marek, G.; Gowda, P.; Lin, X.; Colaizzi, P.; Evett, S.; Kutikoff, S. Evaluation of evapotranspiration from eddy covariance using large weighing lysimeters. Agronomy 2019, 2, 99. [Google Scholar] [CrossRef]

- Pruitt, W.O.; Angus, D.E. Large weighing lysimeter for measuring evapotranspiration. Trans. ASAE 1960, 3, 13–18. [Google Scholar] [CrossRef]

- McFarland, M.J.; Worthington, J.W.; Newman, J.S. Design, installation, and operation of a twin weighing lysimeter for fruit trees. Trans. ASAE 1983, 26, 1717–1721. [Google Scholar] [CrossRef]

- Howell, T.A.; McCormick, R.L.; Phene, C.J. Design and installation of large weighing lysimeters. Trans. ASAE 1985, 28, 106–112. [Google Scholar] [CrossRef]

- Allen, R.G.; Fisher, D.K. Low-cost electronic weighing lysimeters. Trans. ASAE 1990, 33, 1823–1832. [Google Scholar] [CrossRef]

- Schneider, A.D.; Howell, T.A.; Moustafa, A.T.A.; Evett, S.R.; Abou-Zeid, W. A simplified weighing lysimeter for monolithic or reconstructed soils. Appl. Eng. Agric. 1998, 14, 267–274. [Google Scholar] [CrossRef]

- Payero, J.O.; Irmak, S. Construction, installation, and performance of two repacked weighing lysimeters. Irrig. Sci. 2008, 26, 191–202. [Google Scholar] [CrossRef]

- Evett, S.R.; Mazahrih, N.T.; Jitan, M.A.; Sawalha, M.H.; Colaizzi, P.D.; Ayars, J.E. A weighing lysimeter for crop water use determination in the Jordan Valley, Jordan. Trans. ASABE 2009, 52, 155–169. [Google Scholar] [CrossRef]

- Fisher, D.K. Simple weighing lysimeters for measuring evapotranspiration and developing crop coefficients. Int. J. Agric. Biol. Eng. 2012, 5, 35–43. [Google Scholar]

- Mariano, D.D.C.; Faria, R.T.D.; Freitas, P.S.L.D.; Lena, B.P.; Johann, A.L. Construction and calibration of a bar weighing lysimeter. Acta Sci. Agron. 2015, 37, 271–278. [Google Scholar] [CrossRef]

- Fenner, W.; Dallacort, R.; Junior, C.; Freitas, P.; Queiroz, T.; Santi, A. Development, calibration and validation of weighing lysimeters for measurement of evapotranspiration of crops. Rev. Bras. De Eng. Agrícola E Ambient. 2019, 4, 297–302. [Google Scholar] [CrossRef]

- Nicolás-Cuevas, J.; Parras-Burgos, D.; Soler-Méndez, M.; Ruiz-Canales, A.; Martínez, J. Removable weighing lysimeter for use in horticultural crops. Appl. Sci. 2020, 14, 4865. [Google Scholar] [CrossRef]

- Clark, J.; Tape, K.; Young-Robertson, J. Quantifying evapotranspiration from dominant arctic vegetation types using lysimeters. Ecohydrology 2022, 1. [Google Scholar] [CrossRef]

- Karam, F.; Mounzer, O.; Sarkis, F.; Lahoud, R.; Amara, T.; Karam, F. Yield and nitrogen recovery of lettuce under different irrigation regimes. J. Appl. Hortic. 2002, 2, 70–76. [Google Scholar] [CrossRef]

- Wright, J.L. New evapotranspiration crop coefficients. J. Irrig. Drain. Div. ASCE 1982, 108, 57–74. [Google Scholar] [CrossRef]

- Oke, A.; Omotosho, O.; Ogedengbe, K. Determination of crop coefficient and water use of SUWAN-1-SR with a mini lysimeter in Ibadan, Nigeria. FUOYE J. Eng. Technol. 2019, 4, 116–121. [Google Scholar] [CrossRef]

- Oliveira, G.; Almeida, C.; Santos, J.; Martins, J.; Caeiro, J. IoT Lysimeter system with enhanced data security. APCA International Conference on Automatic Control and Soft Computing, CONTROLO 2022, pp 119-129. [CrossRef]

- Goyal, P.; Sharda, R.; Siag, M.; Singh, K. Development of an IoT based weighing type micro-lysimeter for soilless cultivation. Indian J. Agric. Sci. 2020, 10, 1980–1987. [Google Scholar] [CrossRef]

- Payero, J.O.; Mirzakhani Nafchi, A.; Davis, R.; Khalilian, A. An Arduino-based wireless sensor network for soil moisture monitoring using Decagon EC-5 sensors. Open J. Soil Sci. 2017, 7, 288–300. [Google Scholar] [CrossRef]

- Payero, J.O.; Mirzakhani-Nafchi, A.; Khalilian, A.; Qiao, X.; Davis, R. Development of a low-cost Internet-Of-Things (IoT) system for monitoring soil water potential using Watermark 200SS sensors. Adv. Internet Things 2017, 7, 71–86. [Google Scholar] [CrossRef]

- Payero, J.O.; Marshall, M.W.; Davis, R.; Nafchi, A.M. Development and application of cell-phone-based Internet of Things (IoT) systems for soil moisture monitoring. Agric. Sci. 2021, 12, 549–564. [Google Scholar] [CrossRef]

- Payero, J.O.; Marshall, M.W.; Nafchi, A.M.; Khalilian, A.; Farmaha, B.S.; Davis, R.; Porter, W.; Vellidis, G. Development of an Internet of Things (IoT) system for measuring agricultural runoff quantity and quality. Agric. Sci. 2021, 12, 584–601. [Google Scholar] [CrossRef]

- Nolz, R.; Kammerer, G.; Cepuder, P. Interpretation of lysimeter weighing data affected by wind. J. Plant Nutr. Soil Sci. 2013, 176, 200–208. [Google Scholar] [CrossRef]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).