1. Introduction

Internal combustion engines, essential components of automobiles, motorbikes, ships, and industrial generators, transform chemical energy into mechanical energy with an average efficiency of approximately 25%. The efficiency varies between 20% and 45%, depending on the engine's internal structure and operating condition. This significant energy loss as heat presents a critical challenge and opportunity in energy recovery and sustainability. This indicates that a significant portion, ranging from 55% to 80%, of the chemical energy derived primarily from fossil fuels is lost as heat through engine and cooling system emissions [

1]. In the broader context of waste heat recovery, technologies like Organic Rankine Cycle (ORC) systems, heat pumps, and advanced heat exchangers have been developed to capture and utilize this lost energy, representing a pivotal shift towards more efficient energy use.

Hendricks and Choate [

2] observed that in the industrial sector, over one-third of the energy used in U.S. manufacturing is released into the atmosphere or cooling systems as waste heat. Nagaraj Nandihalli and others [

3] have suggested that the bulk chemical industry is the largest energy consumer, followed by the refining and mining industries. Although the utilization rate of waste heat has increased significantly in recent years, a large amount of waste heat is still discharged into the atmosphere. This widespread presence of waste heat in industrial processes underscores the pressing need for innovative solutions to harness this otherwise lost energy.

Thermoelectric generators (TEGs) are well-suited for efficient waste heat recovery in limited areas such as aircraft, ships, and vehicles due to their straightforward design, compact size, lightweight, silent operation, longevity, reliability, and minimal maintenance needs [

4]. However, the evolution of TEGs has faced challenges such as material optimization, device integration, and durability, necessitating ongoing research and development.

The exploration of thermoelectric materials has been diverse, with bismuth telluride being one of the earliest to be widely studied and utilized. Over time, research has branched out to various materials, including but not limited to skutterudites and half-Heuslers. These materials have been recognized for their unique properties that potentially offer enhanced performance and efficiency in various applications, reflecting thermoelectric material research's evolving and multifaceted nature. Most commercially available waste heat recovery devices are designed specifically for flat plate thermoelectric generators (FTEGs) using flat plate heat exchangers or square-shaped thermoelectric elements(figure 1) [

5,

6,

7], From analyzing energy fluxes and heat transfer to system development, research on TEGs is still being actively pursued in various aspects [

8,

9,

10]. Nevertheless, the quest for more efficient TEGs continues, with current research focusing on nanostructured materials and novel geometries to enhance thermoelectric performance.

Recent research has focused on enhancing the thermoelectric performance of materials through nanostructuring and novel geometries. Kanatzidis [

11] and Vaqueiro [

12] both highlight the role of nanostructuring in reducing lattice thermal conductivity, a key factor in improving thermoelectric performance. This is further supported by Zhao [

13], who discusses the use of solution-based chemistry approaches to prepare thermoelectric nanomaterials with reduced thermal conductivity. Nam [

14] and Jaldurgam [

15] both emphasize the importance of using eco-friendly and low-cost elements in nanostructured thermoelectric materials. Mori [

16] and Mohanraman [

17] discuss novel nanostructuring methods, such as phonon-selective scattering and the use of nanocomposite materials, to enhance thermoelectric performance.

Tae Young Kim [

18,

19] and colleagues extensively examined heat exchangers used in thermoelectric waste heat recovery systems, focusing specifically on hexagonal and compact heat exchangers in typical automotive settings [

20]. Their analysis demonstrated the successful conversion of heat into electricity, illustrating the potential of TEGs in automotive applications. This underscores the broader relevance of TEGs in various sectors, including industrial and residential energy recovery, where their adaptability to different heat sources can be leveraged.

Improving thermoelectric materials and device construction is necessary to enhance waste heat recovery devices' total thermoelectric conversion efficiency [

21]. Ugur Erturun et al. [

22] found that optimizing the structure of a device is very important. The evolution of thermoelectric materials from traditional bismuth telluride to more advanced compounds has opened up new possibilities in device efficiency and application. They saw that increasing the thermal contact area and decreasing the height of the thermoelectric element led to significant improvements in power production and heat conversion. This highlights the critical role of material science and engineering in optimizing TEGs for higher performance and broader applicability.

Yohann Thimont et al. [

23] simulated thermoelectric elements with various shapes. They found that even basic hollow and layered structures could generate more considerable temperature differences and more power compared to conventional cuboid structures. These findings point to the need for continued innovation in TEG design, exploring different geometries and configurations to maximize efficiency. Lingen Chen et al. [

24] performed comprehensive numerical investigations on the influence of thermoelectric element configuration and heat transfer surface area in cooling modules, determining the most favorable operating currents to achieve maximum cooling capacity and performance under different conditions. Such studies are pivotal in guiding the design and optimization of next-generation thermoelectric devices.

Samson Shitt et al. [

25] highlighted that annular thermoelectric generators can potentially reduce thermal contact resistance from geometric mismatches with circular sources/sinks. This suggests a significant direction for TEG development, focusing on minimizing energy losses and maximizing compatibility with various heat sources. In a comparison of flat-plate and annular thermoelectric generators (ATEG), Zhang et al. [

26] discovered that ATEGs outperformed FTEGs when exposed to cylindrical heat sources with higher inlet temperatures and heat transfer coefficients. The superior performance of ATEGs in such scenarios underlines their potential in specific industrial applications where cylindrical heat sources are prevalent.

Xiao-Xiao Tian et al. [

27] utilized ATEGs in air coolers, suggesting ATEGs are more suitable than FTEGs for fluid operations. This adaptability of ATEGs in diverse applications further reinforces the need for targeted research in TEGs to exploit their full potential in waste heat recovery. Akihiro Sakai et al. [

28] fabricated tubular thermoelectric components via melt-spinning and spark plasma sintering to validate these discoveries, achieving substantial power generation. Their work signifies a critical step in transitioning TEG technology from laboratory settings to real-world applications.

Andreas Schmitz et al. [

29] manufactured ring-shaped components for tubular structures using a current-assisted sintering technique with a custom mold and diffusion barrier. Innovation in manufacturing processes such as these is crucial for the practical deployment of advanced TEGs. Wenlong Yang et al. [

30] researched concentric heat exchangers to enhance overall heat transfer and reduce pressure drop in ATEGs, increasing net power production by 65%. This research contributes to the efficiency of TEGs and economic viability by enhancing their power output.

A range of studies have explored the performance of tubular or annular thermoelectric generators (TEGs) in various applications. Kishore [

31] and Jang [

32] both highlight the importance of environmental factors and thermal contact quality in TEG performance, with Jang [

32] specifically focusing on the fabrication of tubular TEGs. Huang [

33] and Chen [

34] propose design improvements for TEGs, with Huang [

33] introducing a novel concentric cylindrical TEG system and Chen [

34] using the Taguchi method to optimize TEG performance. Wu [

35] and Yang [

36]delve into the technical aspects of TEGs, with Wu [

35] analyzing the influence of various factors on TEG performance and Yang [

36]discussing the potential of high-temperature thermoelectric materials. Hatzikraniotis [

37] and Temizer [

38] both investigate the long-term performance and stability of TEGs, with Hatzikraniotis (2010) [

37] focusing on a commercially available TEG and Temizer [

38] examining a TEG system used in diesel engines.

Finally, A. Faddouli et al. [

39] focused solar energy 20-fold onto combined FTEG/ATEG systems, achieving 161.68W power output, 86.5% thermal efficiency, and 1345 liters of heated water per day. Integrating solar energy with TEGs opens new avenues for sustainable energy solutions, combining renewable energy sources with waste heat recovery.

This research significantly contributes to enhancing the efficiency of thermoelectric waste heat exchangers. By incorporating advancements in materials science, design, and application-specific innovations, our study presents a novel module for efficient fluid heat recovery. This module, which integrates full-ring elements within a tubular thermoelectric generator (TTEG), combines the advantages of form and contact area found in annular thermoelectric generators (ATEGs). The design offers a compact, practical solution for thermal energy recovery from fluids, contributing to the ongoing efforts in sustainable energy technologies.

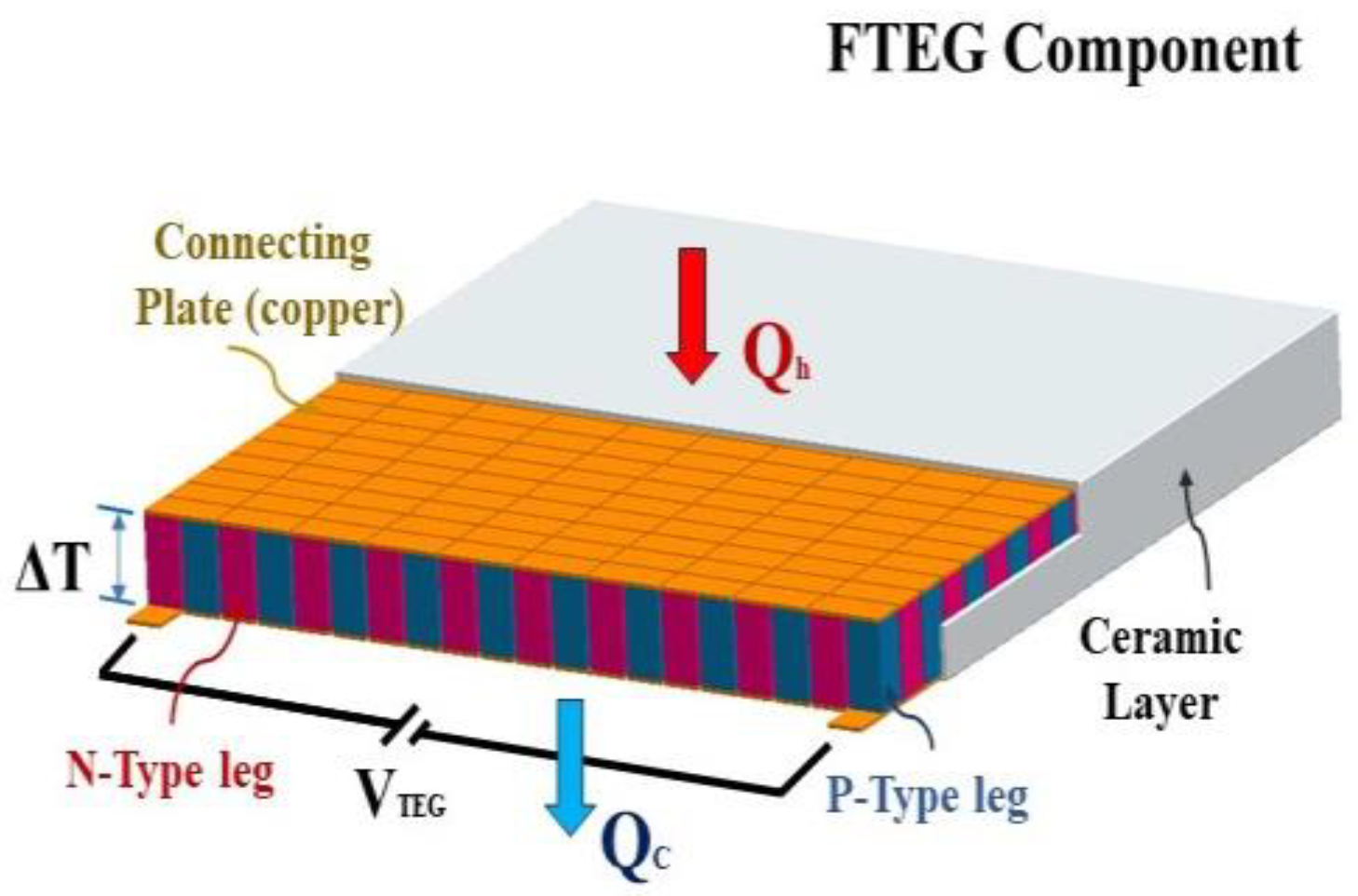

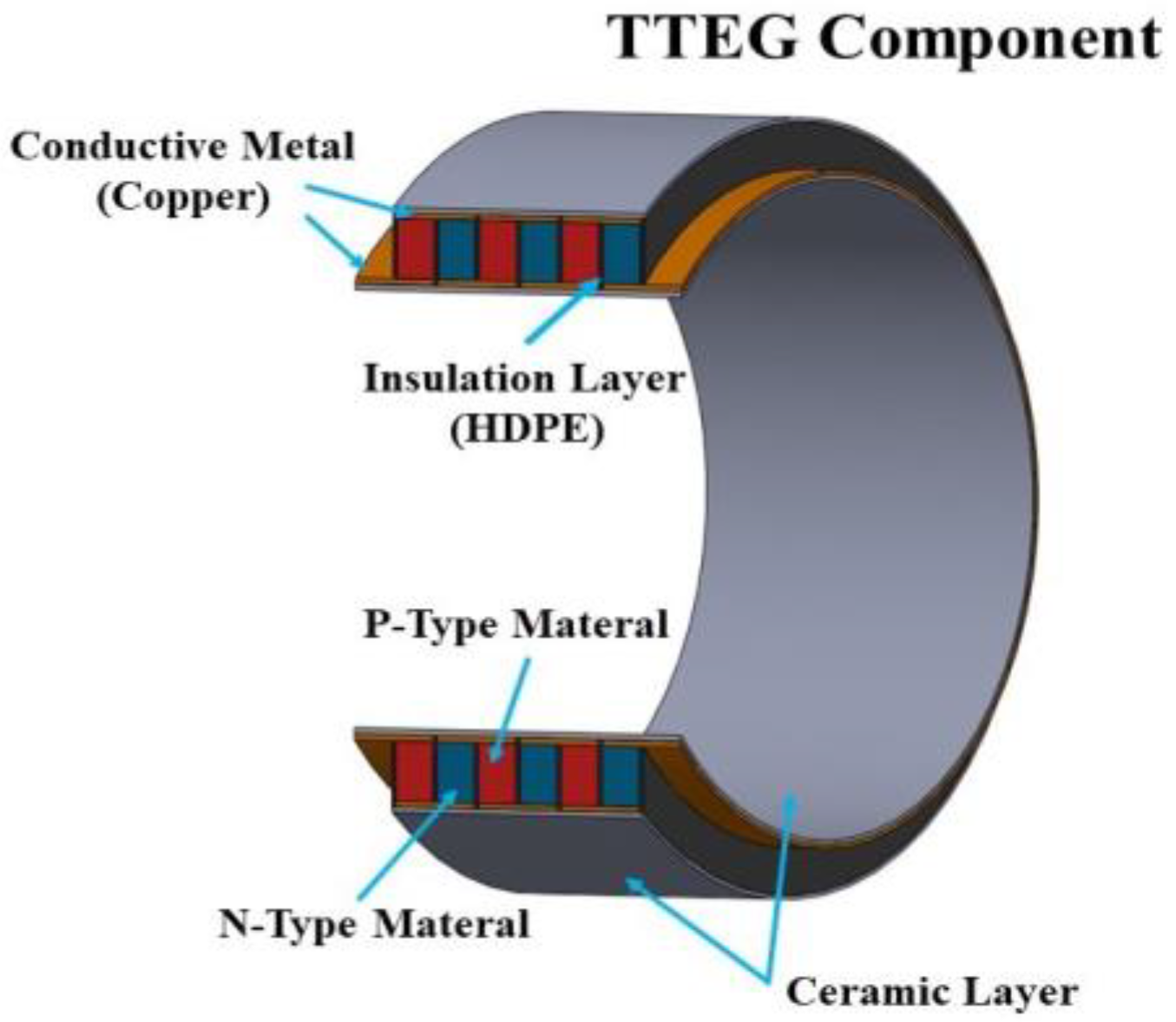

Figure 1.

This diagram provides a detailed representation of the architecture and component layout of a thermoelectric chip, illustrating its functional and structural elements.

Figure 1.

This diagram provides a detailed representation of the architecture and component layout of a thermoelectric chip, illustrating its functional and structural elements.

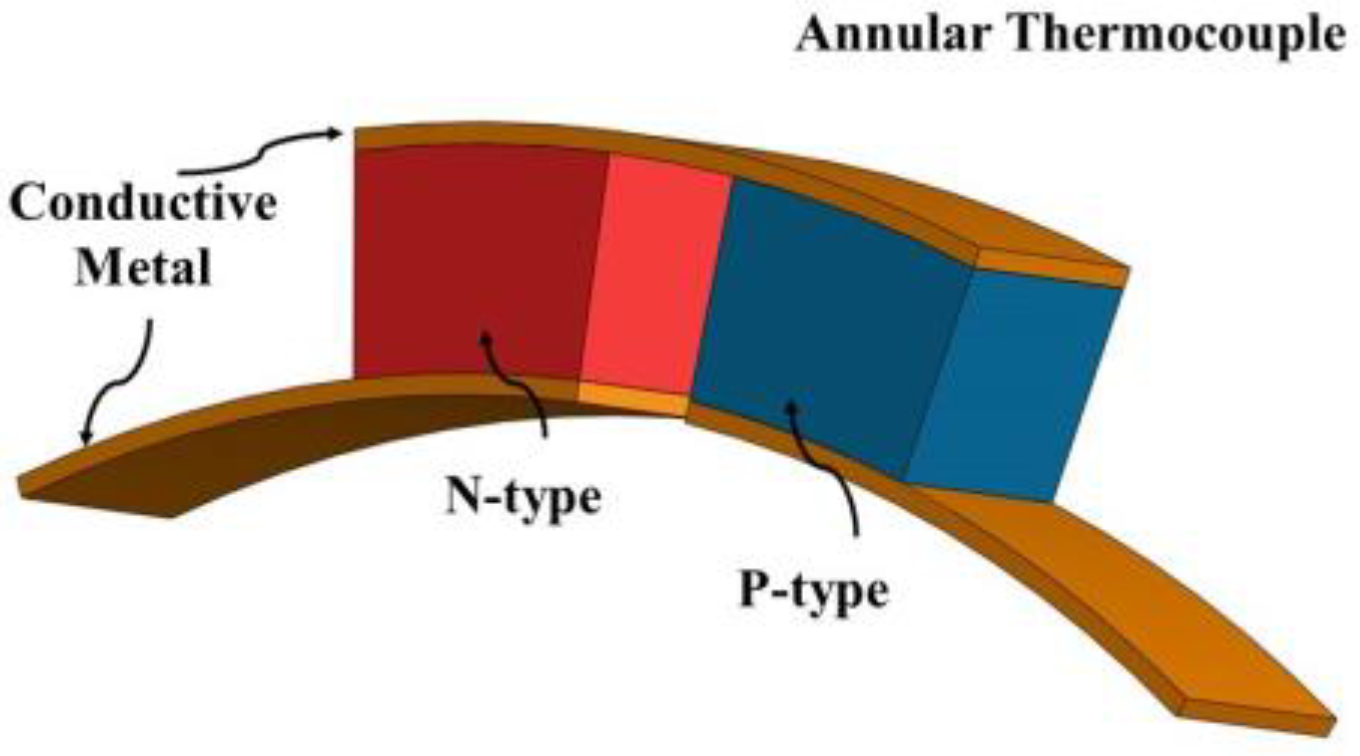

Figure 2.

This diagram illustrates the structure of a thermocouple within an Annular thermoelectric generators (ATEG).

Figure 2.

This diagram illustrates the structure of a thermocouple within an Annular thermoelectric generators (ATEG).

2. Module Configuration

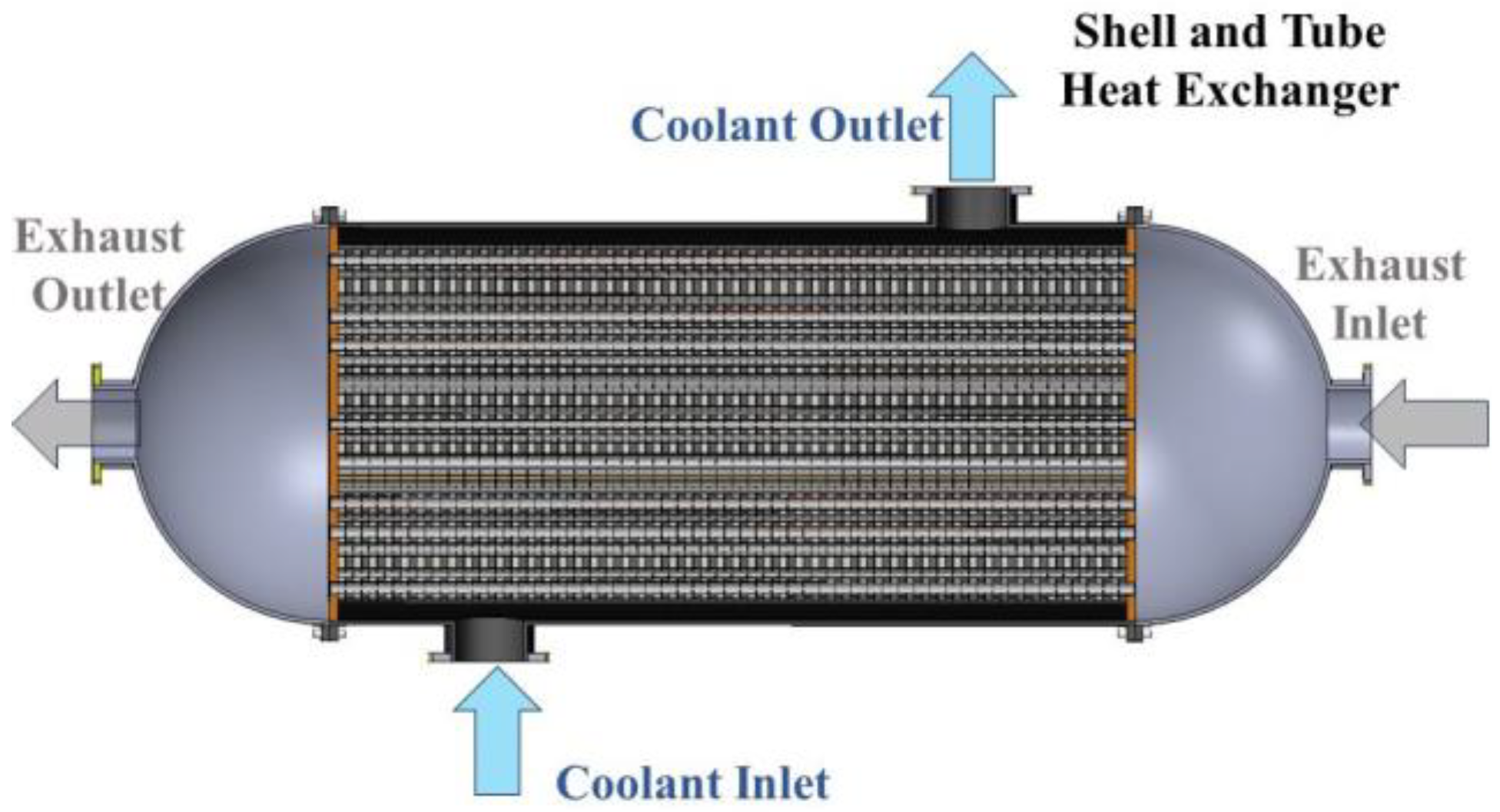

Shell and tube heat exchangers, commonly used in cooling systems of large internal combustion engines, facilitate heat transfer from engine coolant, lubricating oil, and exhaust gases. Our investigation expands on this by simulating the integration of thermoelectric elements on the tube bundle's exterior in such an exchanger.

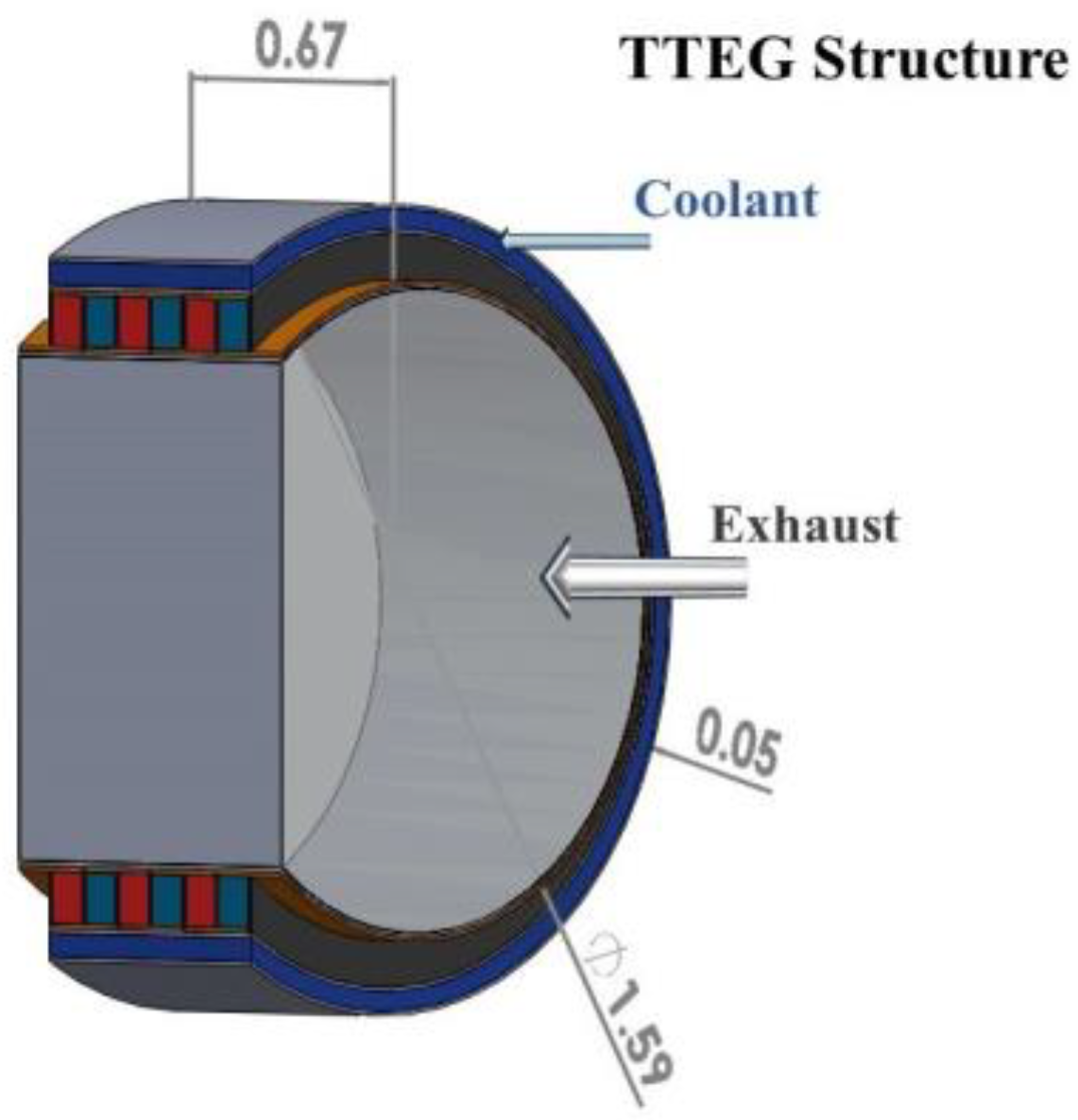

Figure 3 and

Figure 4 illustrate the exchanger's interior structure from a cross-sectional and a longitudinal view, respectively. This enhanced TTEG design, depicted in

Figure 5, incorporates full-ring thermoelectric elements (

Figure 6) for improved heat capture efficiency.

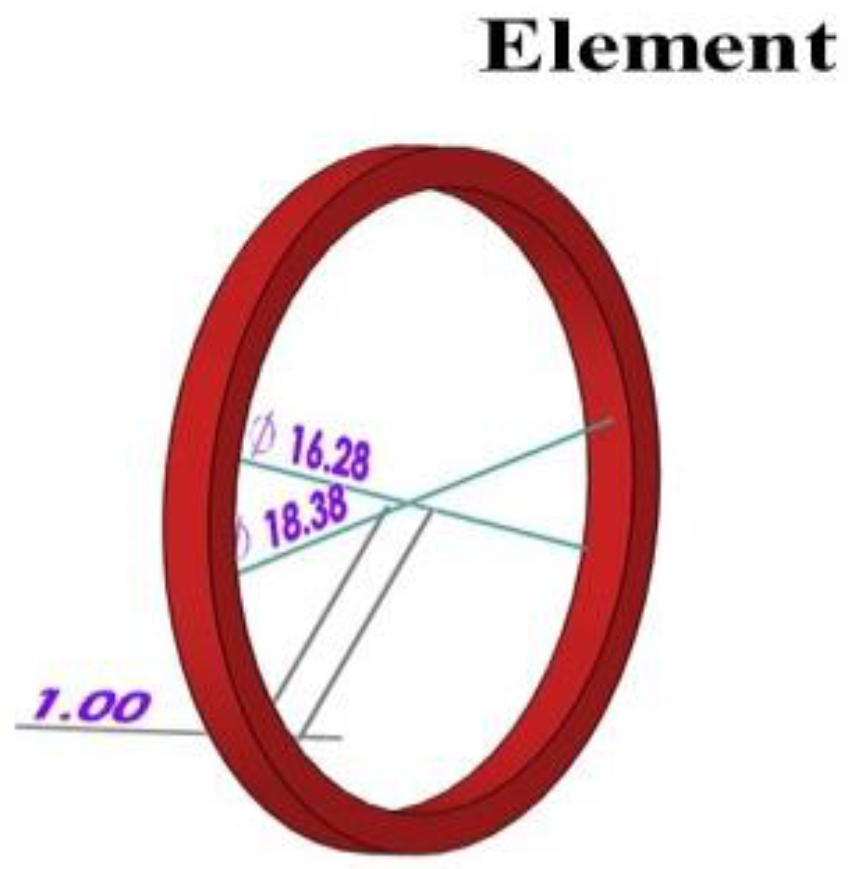

Our study focuses on the TGM1-127-1.0-0.8 thermoelectric chip from KRYOTHERM, Saint Petersburg, Russia. We use its specifications and material properties [

40], as listed in

Table 1, to model a TTEG with equivalent thermoelectric material. The simulated thermoelectric element mirrors the TGM1-127-1.0-0.8 chip in dimensions, ensuring design compatibility with standard shell and tube exchangers. The outer diameter of the tube bundle (1/2 inch or 15.88mm) is matched by the complete ring thermoelectric element, which has dimensions: an inner diameter of 16.28mm, an outer diameter of 18.38mm, and a height of 1.05mm. A 0.1-mm-thick copper conductor, covered by a 0.1-mm-thick ceramic layer, connects the thermoelectric element, offering protection and insulation from the fluid streams. High-density polyethylene (HDPE) is placed between the thermoelectric parts to shield them from fluid flow and engine vibration, serving as shock absorbers and insulators. Our design also includes three thermocouples made from material akin to the TGM1-127-1.0-0.8, covering a contact heat source area of 306.87 mm

2. Due to the absence of gaps between each thermoelectric element, our modeling tests can disregard heat radiation and the Thomson effect.

This TTEG design was chosen for its potential to harness waste heat more efficiently than conventional systems. The full-ring structure offers enhanced thermal contact with the heat source, improving energy conversion. This design was favored over other potential configurations for its simplicity and ease of integration with existing heat exchanger systems.

3. Boundary Conditions and Governing Equations

The study involved simulations using COMSOL 5.5, employing the finite element analysis technique. In order to get significant outcomes by solving equations, the following criteria were established:

Simulations were conducted under steady-state conditions.

All thermoelectric elements are of identical dimensions.

Heat transfer in the thermoelectric elements is maintained radially, with lateral parts remaining thermally insulated.

Electrical and thermal contact resistances, including those of the welding layers, are negligible.

Maximum output power from the thermoelectric module is achieved when the external resistance equals the internal resistance.

∙ The thermal and electrical properties of the thermoelectric materials are assumed to be constant and do not vary with temperature changes.

For calculating the internal resistance within the tubular thermoelectric module, the following governing equations were used (as referenced in [

41]):

In the governing equations mentioned above, various parameters and their relationships within the TTEG are defined as follows:

Rpn represents the internal resistance of a single thermocouple pair (consisting of one P-type and one N-type thermoelectric element). Rc is the internal resistance of the connecting copper tube. RTEG is the total internal resistance of the TTEG. Rp and Rn respectively denote the internal resistances of the P-type and N-type thermoelectric elements. ρp、ρn and ρc are the electrical conductivities of the P-type and N-type thermoelectric elements and the connecting copper tube, respectively. r1 and r2 represent the inner and outer radii of the thermoelectric element. W is the width of the thermoelectric element. Δθis the angle of the annular thermoelectric element. Lc is the length of the connecting copper tube.AI and AO are the contact areas between the inner and outer connecting copper tubes and the thermoelectric element. N is the number of thermocouple pairs in the TTEG.

Using the following control program, we can calculate the output power of the TTEG [

26]:

In the control equations previously mentioned, the parameters are defined as follows:

V represents the voltage across the thermoelectric module. I is the current flowing through the circuit. RL denotes the external load resistance. P is the output power of the TTEG.

To determine the efficiency of the TTEG, the following control equations can be used [

40]:

In the control equations for the TTEG, the terms are defined as follows:

Qh is the heat input at the hot side of the TTEG. Qc is the heat output at the cold side of the TTEG. Qh and Qc are measured in watts (W). mh and mc represent the mass flow rates of the fluid at the hot and cold sides, respectively. Cph.side and Cpc.side are the specific heat capacities of the fluid at the hot and cold sides.Th.in and Th.out are the inlet and outlet temperatures of the fluid at the hot side.Tc.in and Tc.out are the inlet and outlet temperatures of the fluid at the cold side. ηTEG is the thermal efficiency of the TTEG.N is the number of thermoelectric elements in the TTEG.αis the Seebeck coefficient of the thermoelectric elements, measured in volts per kelvin (V/K). Th and Tc are the average temperatures at the hot and cold sides of the TTEG, measured in Kelvin (K). κTEG is the thermal conductivity of the thermoelectric element, measured in watts per kelvin (W/K). ηTEG is the thermal efficiency of the TTEG.

Most reference studies utilize determined parameters, but the variables listed above (italicized) indeed have uncertain factors (such as manufacturing, measurement) [

42]. This study will identify differences between experimental and simulation results before proceeding with model validation and analysis.

4. Model verification and analysis

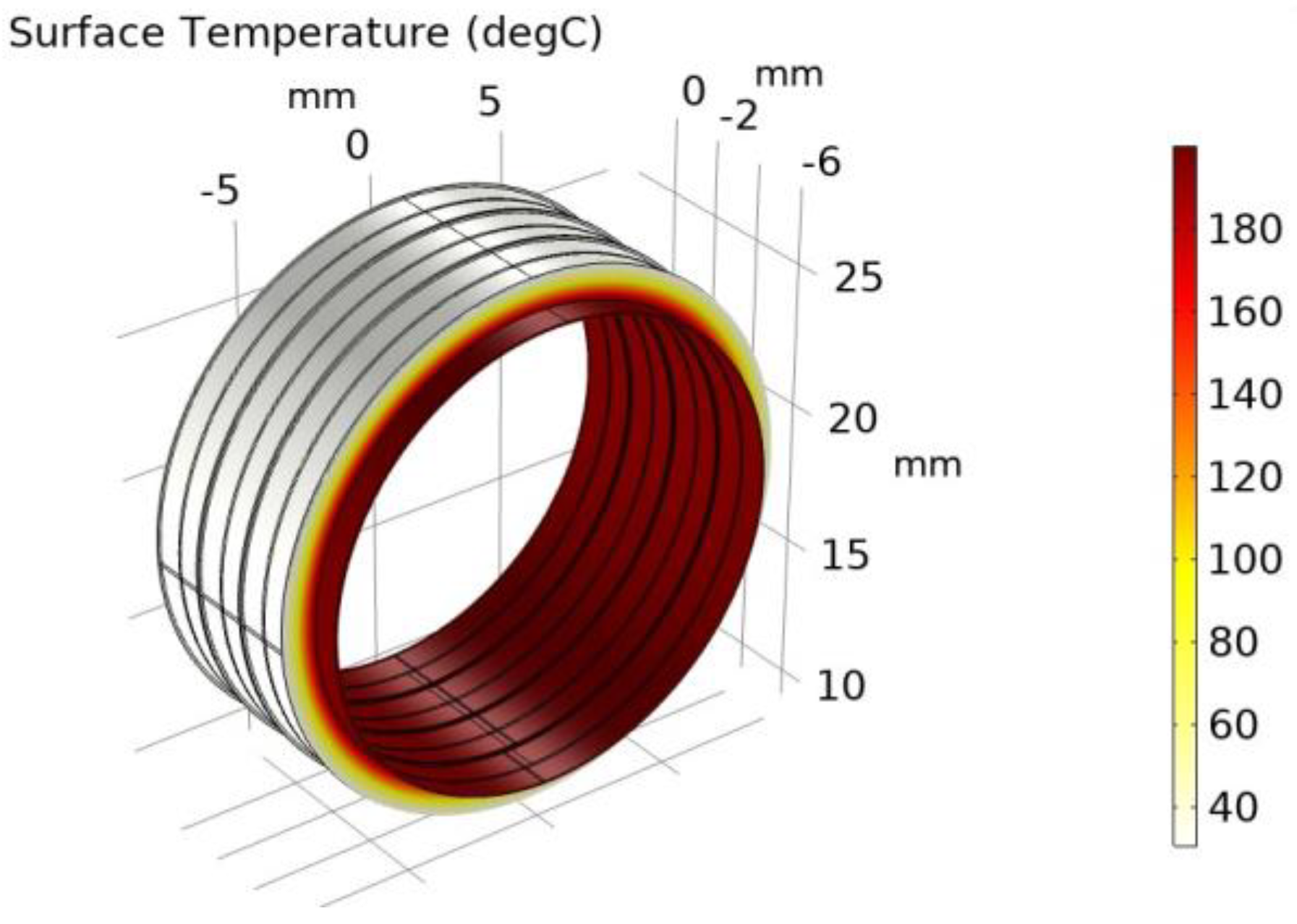

In order to assess the disparity in output power between the TTEG and the FTEG, the study initially examines the test parameters specified by the manufacturer of the TGM1-127-1.0-0.8 thermoelectric chip. At a hot side temperature (Th) of 200°C and a cold side temperature (Tc) of 30°C, the FTEG chip generates a maximum power output of 5.1W [

40]. Furthermore, to compare the simulated values of the FTEG with the test values provided by the manufacturer, a replica of the TGM1-127-1.0-0.8 thermoelectric chip module was created and tested under identical temperature conditions. This test yielded an open-circuit voltage of 13.42V and an output power of 5.81W. Although there is a 0.12% discrepancy between the actual data and simulation results of the TGM1-127-1.0-0.8 thermoelectric chip, this study will base subsequent validations on the simulation results to highlight the achievements in developing the TTEG model. The simulation experiment for the TTEG reveals that by altering the shape of the thermoelectric element (leg) within the TTEG, increasing the contact area with the heat source, and reducing the length of the thermoelectric element, the TTEG produces an open-circuit voltage of 0.32V and an output power of 9.44W (as depicted in

Figure 7). The inner and outer ceramic layers are maintained at constant temperatures of 200°C and 30°C, respectively. This signifies a 62.5% surge in output power about the TGM1-127-1.0-0.8 thermoelectric chip module. In order to verify the accuracy of these simulation findings, the temperature on the cold side of the TTEG was maintained at a constant 30°C.

Qimin Cao and colleagues [

43] improved the thermoelectric performance of FTEG modules by using heat pipes for enhanced cooling, resulting in a 15.49% increase in maximum power density. However, ATEG and TTEG still outperform FTEG in efficiency [

44]. Our study's TTEG prototype, the first to apply full-ring thermoelectric elements in fluid waste heat recovery, is still in the experimental phase due to manufacturing limitations. Optimizing the thermoelectric module under the same volume conditions of thermoelectric materials, TTEG showed a 62.5% increase in maximum output power. This suggests that a complete ring structure enhances thermal contact and conversion efficiency, and improvements in heat exchanger design can yield greater thermoelectric performance gains than local system enhancements.

In comparison, the temperature on the hot side was systematically adjusted between 200°C and 350°C to monitor the corresponding alterations in the thermoelectric module's output power. The output power generated by annular thermoelectric elements, as computed by S. Manikandan et al. [

41], was compared with the output power values derived from this simulation experiment. According to

Figure 8, The estimated maximum power values derived from the thermoelectric material properties in the literature are slightly higher than the calculated values obtained through simulation experiments in this study. This comparison result is consistent with the findings of Xiao-Xiao Tian and others [

27].there was a variance of around 4% between the two, which suggests a substantial similarity and confirms the accuracy of the simulation results. This error margin also aligns with the findings of Faisal Albatati et al. [

40], who tested the performance of the TEC1-12706 thermoelectric chip through experiments involving varying load resistances and compared it to the research results of Alaa Attar and others [

45].

5. Results and Discussion

We present a comprehensive analysis of our findings, highlighting several vital aspects. These aspects include a detailed comparison with traditional flat plate thermoelectric generators, outcomes from simulation experiments, and an evaluation of the TTEG's performance under various conditions. The section aims to elucidate the enhanced capabilities of the TTEG and potential applications in energy recovery. Here are the main findings:

Comparison of TTEG with FTEG: The study compares the performance of the TTEG with traditional Flat Plate Thermoelectric Generators (FTEGs), demonstrating a 62.5% increase in output power for the TTEG under similar conditions.

Simulation Experiment Outcomes: The simulation experiments for the TTEG show significant increases in output power due to altered thermoelectric element shapes and increased contact area with the heat source.

Temperature Variation Analysis: The study assesses the TTEG's performance under varying temperatures at the hot and cold sides, identifying optimal operating conditions.

Analysis of Thermoelectric Elements: The research investigates the effect of varying the number of thermocouples in the TTEG, leading to insights into the optimal number for maximum power output.

Real-World Application Potential: The results suggest the TTEG's high effectiveness in practical applications, particularly in automotive and industrial environments for waste heat recovery.

For analysis, it is assumed that every TTEG within the shell and tube heat exchanger undergoes equal heating. Therefore, the approach examines explicitly a solitary TTEG. This section initially examines the impact of different external loads on the output power of the TTEG. Subsequently, the study investigates the correlation between external load, output power, and thermal efficiency by modifying the inlet temperatures of the hot and cold sides of the TTEG under varying temperature circumstances. In addition, by maintaining consistent fluid temperatures and mass flow rates at both the hot and cold ends, the research expands the number of thermocouples within the TTEG. This is achieved using simulation and statistical analysis to identify the ideal number of thermocouple pairs for achieving the highest possible output power.

5.1. Analysis of TTEG Performance Under Varying External Loads

In order to simulate real-life situations more accurately, the study utilizes the identical testing settings employed by Faisal Albatati et al. [

40] for the FTEG. The TTEG utilizes the engine exhaust of a semi-truck as its heat source, which has a temperature of 550°C and a mass flow rate of 0.032 kg/s. The coolant employed is ethylene glycol (C₂H₆O₂) at a temperature of 90°C, with a mass flow rate of 0.237 kg/s. The cooling water flow path is established by calculating the difference between the height of the TTEG and the spacing between the tube bundles in the shell and tube heat exchanger, as illustrated in

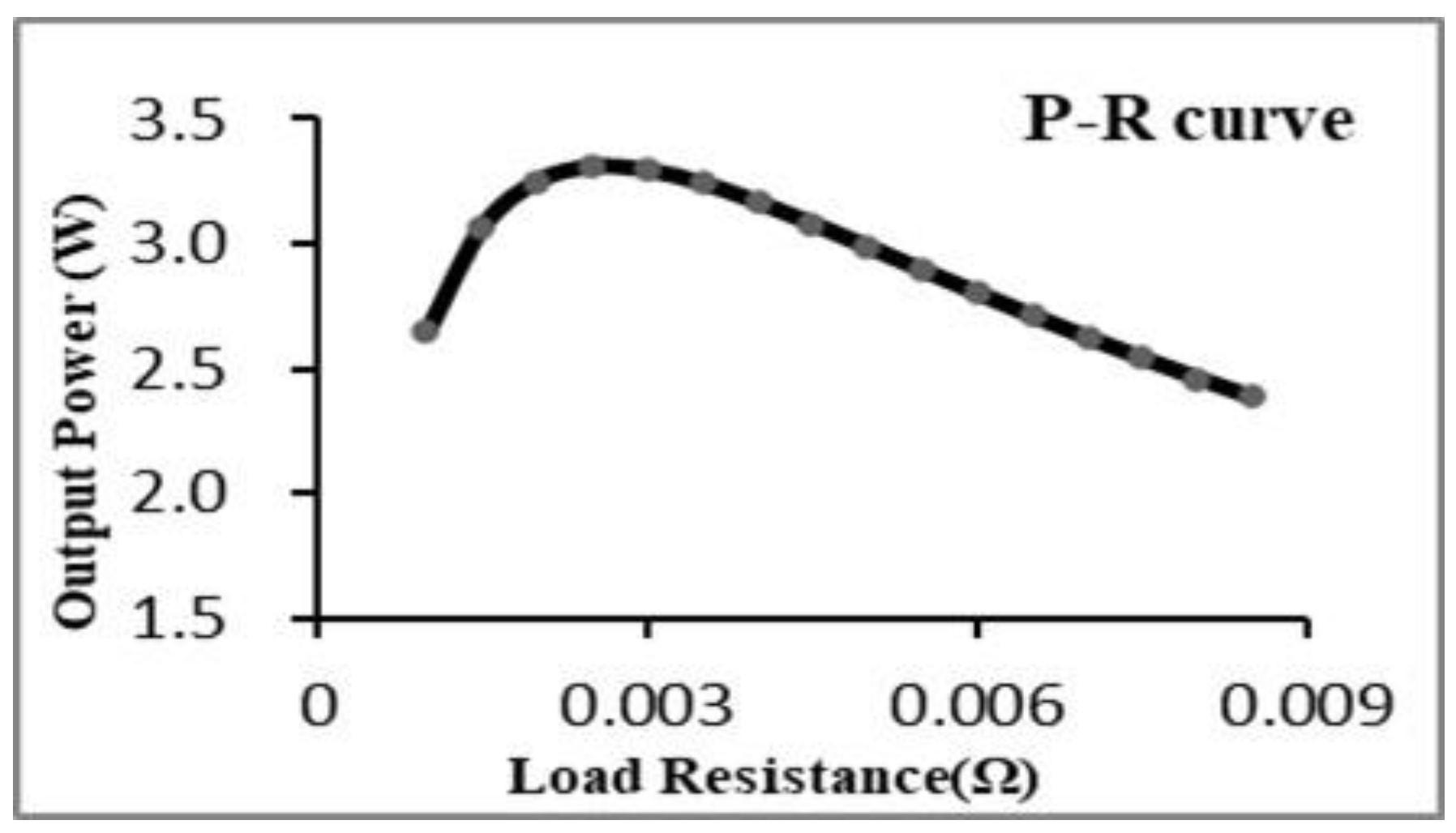

Figure 9. Given the specified test conditions, figure 10 illustrates the correlation between the external load (Load Resistance) and the output power. The data demonstrates that as the external load is steadily raised, the output power of the TTEG experiences a sharp increase until it reaches its maximum value, gradually decreasing. When the external load is the same as the internal resistance (0.00262Ω), the TTEG generates an open-circuit voltage of 0.19V and a maximum output power of 3.31W. As the external load increases, causing the total resistance to rise, the output current drops, decreasing output power. The pressure differential between the engine exhaust inlet and outflow is 25.45Pa, far below the recommended back-pressure threshold of 812 Pa proposed by Sumeet Kumar et al. [

46]

The results suggest that TTEGs can significantly be highly effective in real-world applications when waste heat is recovered from vehicle exhaust systems. The potential to generate significant power outputs with minimal pressure drops encourages the use of TTEGs in automotive and industrial environments.

5.2. Relationship Between Load Resistance Values and Heat Source Inlet Temperatures on Output Power and Thermal Efficiency

The study's methodical and comprehensive approach involves setting a wide range of engine exhaust temperatures (ranging from 100 to 625°C) and coolant temperatures (between 80 and 100°C), considering the variability caused by different engine types, output powers, and fuel types. The specified range covers most situations in internal combustion engines, where exhaust temperatures typically range from 150 to 600 degrees Celsius, and coolant temperatures generally vary from 80 to 100 degrees Celsius.

To maintain regulated and consistent circumstances in the investigation, the engine exhaust mass flow rate is constant at 0.032 kg/s, while the coolant (ethylene glycol) mass flow rate is set at 0.237 kg/s. This configuration is advantageous for efficiently monitoring and evaluating the TTEG operation under different temperature circumstances at both the high and low ends. The study may assess the impact of temperature variations on the external load, output power, and thermal efficiency of the TTEG.

The study seeks insights into ideal TTEG operating parameters by modeling diverse situations to maximize efficiency and waste heat recovery application efficacy. This analysis is essential for determining TTEG integration feasibility in various engine systems, which would enhance energy efficiency and minimize the environmental footprint of internal combustion engines.

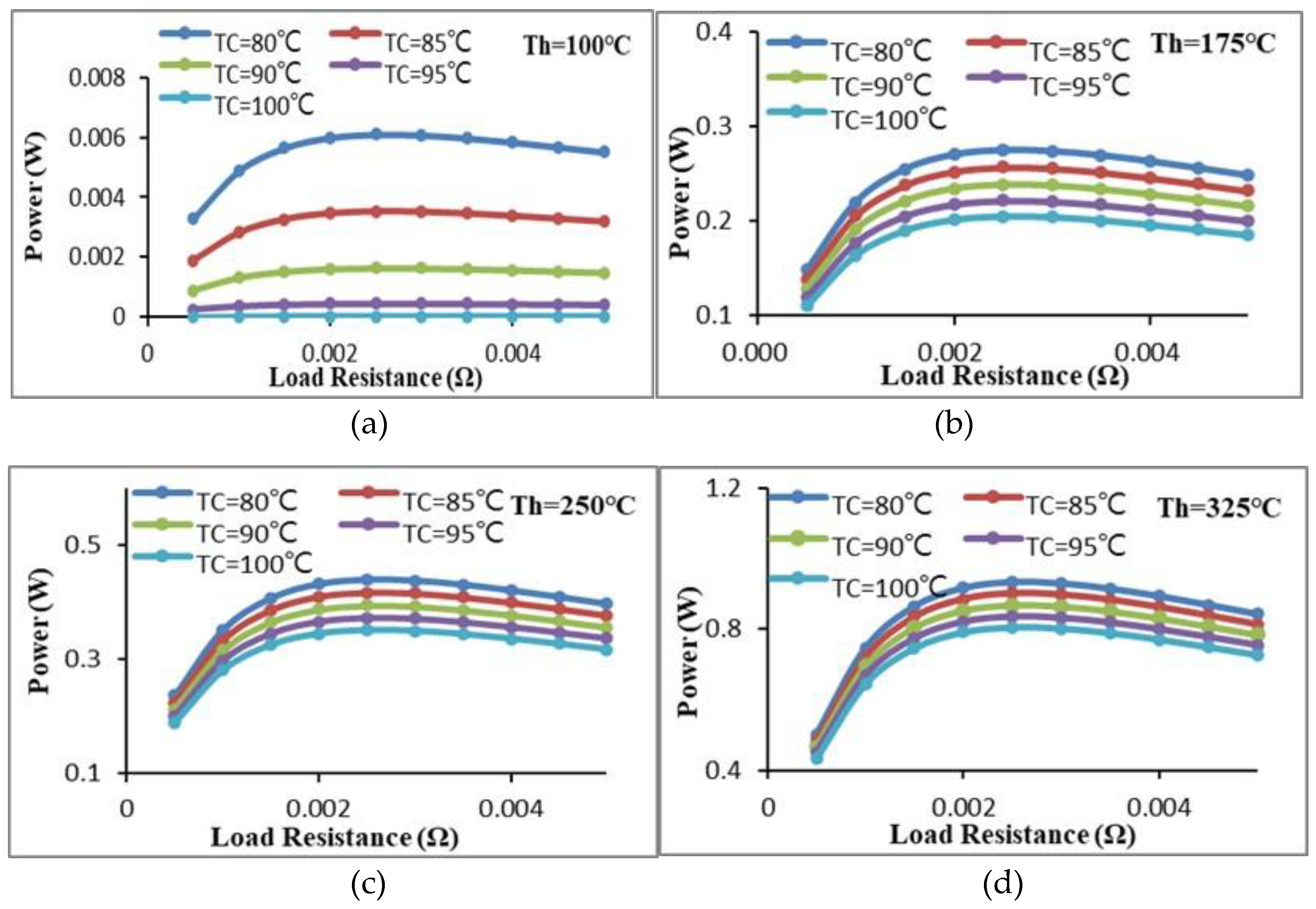

The analysis of

Figure 11a–h reveals that the Tubular thermoelectric generators (TTEGs) consistently provide a more significant amount of power when the cooling water input temperature is set at 80°C, regardless of the exhaust temperature variations. The improved performance of this output is mainly due to the substantial temperature difference between the high and low ends of the TTEGs. Moreover, the TTEGs exhibit a significant rise in power output when the external resistance increases. The power output of the TTEGs reaches its maximum when the external resistance matches the internal resistance. After reaching this point, any further rise in external load leads to a progressive decrease in power production, which follows a linear pattern.

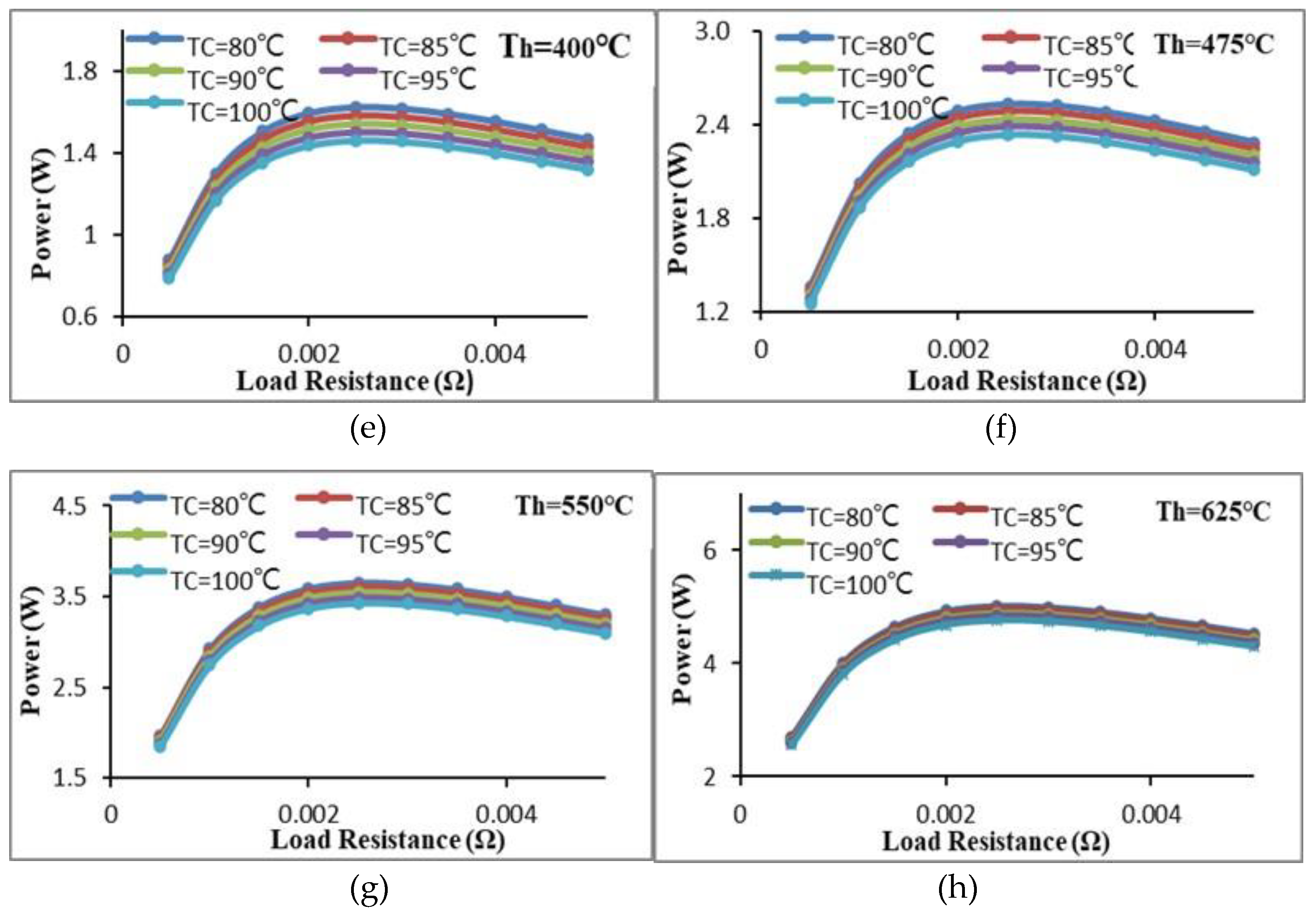

Additionally, an examination of

Figure 12a,h reveals a similar linear relationship between the thermal efficiency of the TTEGs and the external load, mirroring the trend observed in the power output versus the external load graph. Furthermore, it is noted that when the temperature of the engine exhaust rises, both the highest possible efficiency of thermoelectric conversion and the external load at which the TTEGs generate the most power also increases. Furthermore, when the cooling water temperature is lower at a consistent exhaust temperature, there is a higher temperature difference across the thermocouple, which leads to an enhanced thermoelectric conversion efficiency of the TTEGs.

5.3. Optimization of Thermocouple Numbers

As the length of the TTEG increases, there are corresponding changes in the temperature distribution at both the cold and hot ends, the internal resistance, and the module's output power. This study brings engine exhaust at a temperature of 550°C and a rate of 0.032 kg/s into the hot end of the TTEG. Simultaneously, ethylene glycol coolant at a temperature of 90°C and a rate of 0.237 kg/s is introduced at the cold end. The study examines how the output power of the TTEG changes when the number of thermocouples is varied while keeping the cold and hot end inlet temperatures and mass flow rates constant. The goal is to identify the ideal number of thermocouples resulting in the highest output power.

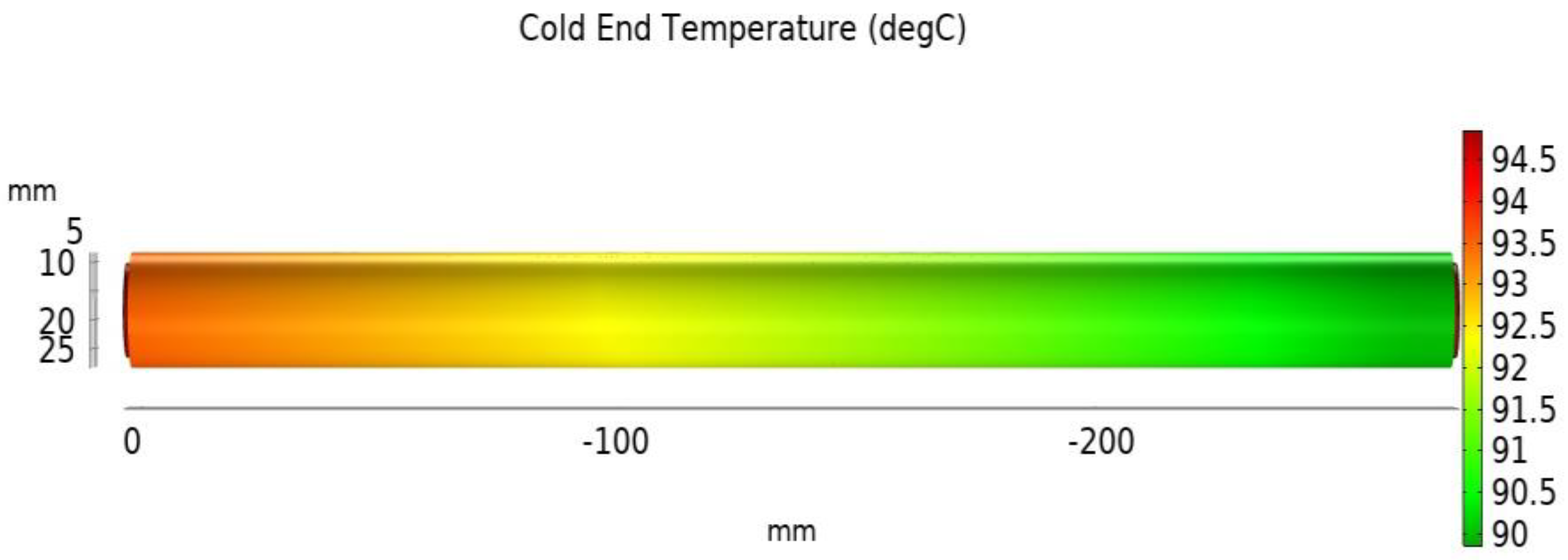

Figure 13 and

Figure 14 illustrate the temperature changes at the cold and hot ends of a TTEG with 125 thermocouple pairs.

Figure 13 demonstrates that the temperature at the cold end of the TTEG is variable rather than constant. The module's temperature rises progressively as the number of thermocouples increases due to heat absorption from the hot engine exhaust through the thermocouples, with coolant arriving from the right.

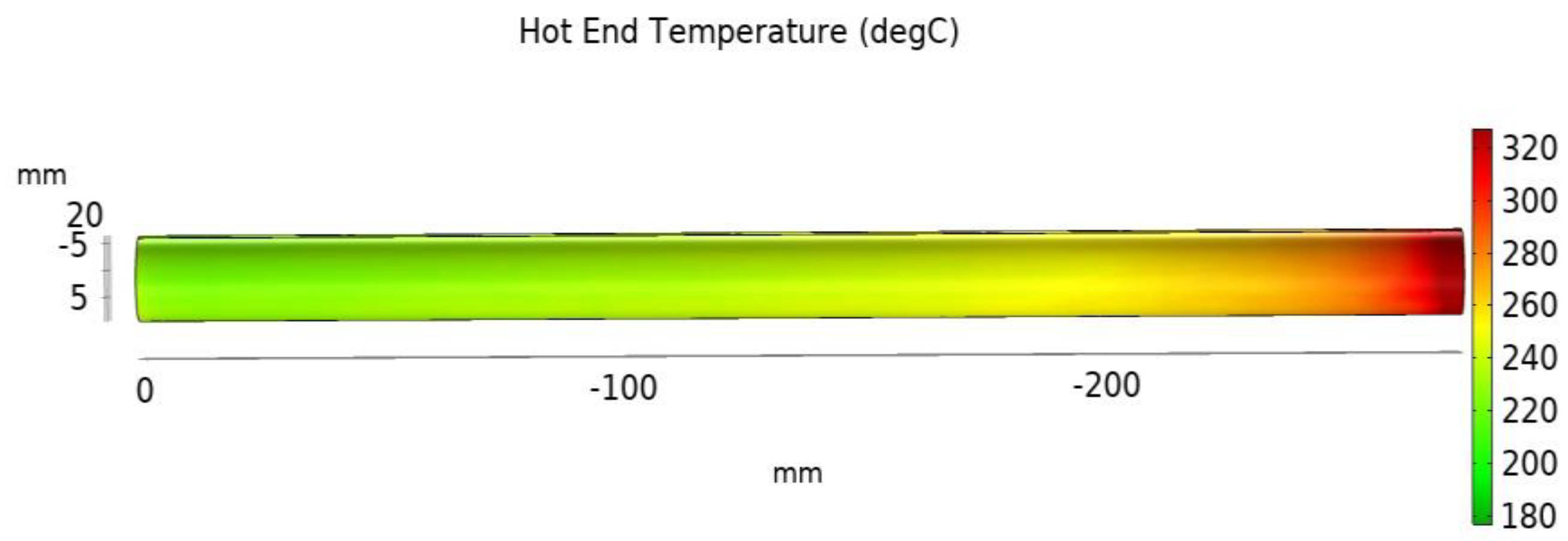

In contrast,

Figure 14 illustrates a decline in temperature near the high-temperature end of the TTEG. In this scenario, the engine exhaust enters from the right side, and as the module extends, the thermocouples convert more heat, resulting in a progressive decline in temperature. Increasing the number of thermocouples from 125 to 750 pairs results in a rise in the output temperature of the coolant from 93.71°C to 103.89°C. Similarly, the exhaust gas's temperature at the TTEG's exit reduces from 477.62°C for 125 pairs of thermocouples to 293.02°C for 750 pairs. These data emphasize the intricate relationship between the quantity of thermocouples, temperature distribution, and heat transport in a TTEG. Comprehending these interactions is essential for maximizing the efficiency and functionality of TTEGs, especially in cases where they are used to recover waste heat from high-temperature sources such as engine exhausts. The study offers valuable insights into optimizing the design of TTEGs by altering the number of thermocouples to get the appropriate equilibrium between heat absorption and conversion efficiency.

According to Ohm's Law,

V=

I×

R, where

V is voltage,

I is current, and

R is resistance. Ohm's Law states that voltage (

V) is equal to the product of current (

I) and resistance (

R), expressed as

V = I × R. The internal resistance of a thermoelectric module grows linearly as the number of thermocouples within the module increases. While adding more thermocouples can expand the surface area that absorbs heat and raises the open-circuit voltage [

41], it is worth noting that the temperature differential between the cold and hot ends of the TTEG is inconsistent, as evidenced by

Figure 13 and

Figure 14. Hence, the TTEG's voltage does not correlate directly with the module's length. Nevertheless, the current tends to diminish when the internal resistance increases in direct proportion. The power output formula,

P =

I2 *

RL (where

RL =

RI, the load resistance equals internal resistance), states that if the increase in internal resistance (caused by an increased number of thermocouples) is smaller than the square of the decrease in current, the maximum output power of the thermoelectric module will decrease. The optimal length for achieving maximum power output is the point at which the rise in internal resistance matches the square of the reduction in current for the TTEG. Conducting this research is of utmost importance to enhance the design of TTEGs, specifically in establishing the optimal quantity of thermocouples and the length of the module. The objective is to achieve equilibrium between the expanded surface area that absorbs heat (and thus leads to a potential rise in voltage) and the rise in internal resistance, affecting the current and power output. Attaining this equilibrium is crucial for optimizing the effectiveness of the TTEG, particularly in scenarios that involve the transformation of wasted heat into electrical power.

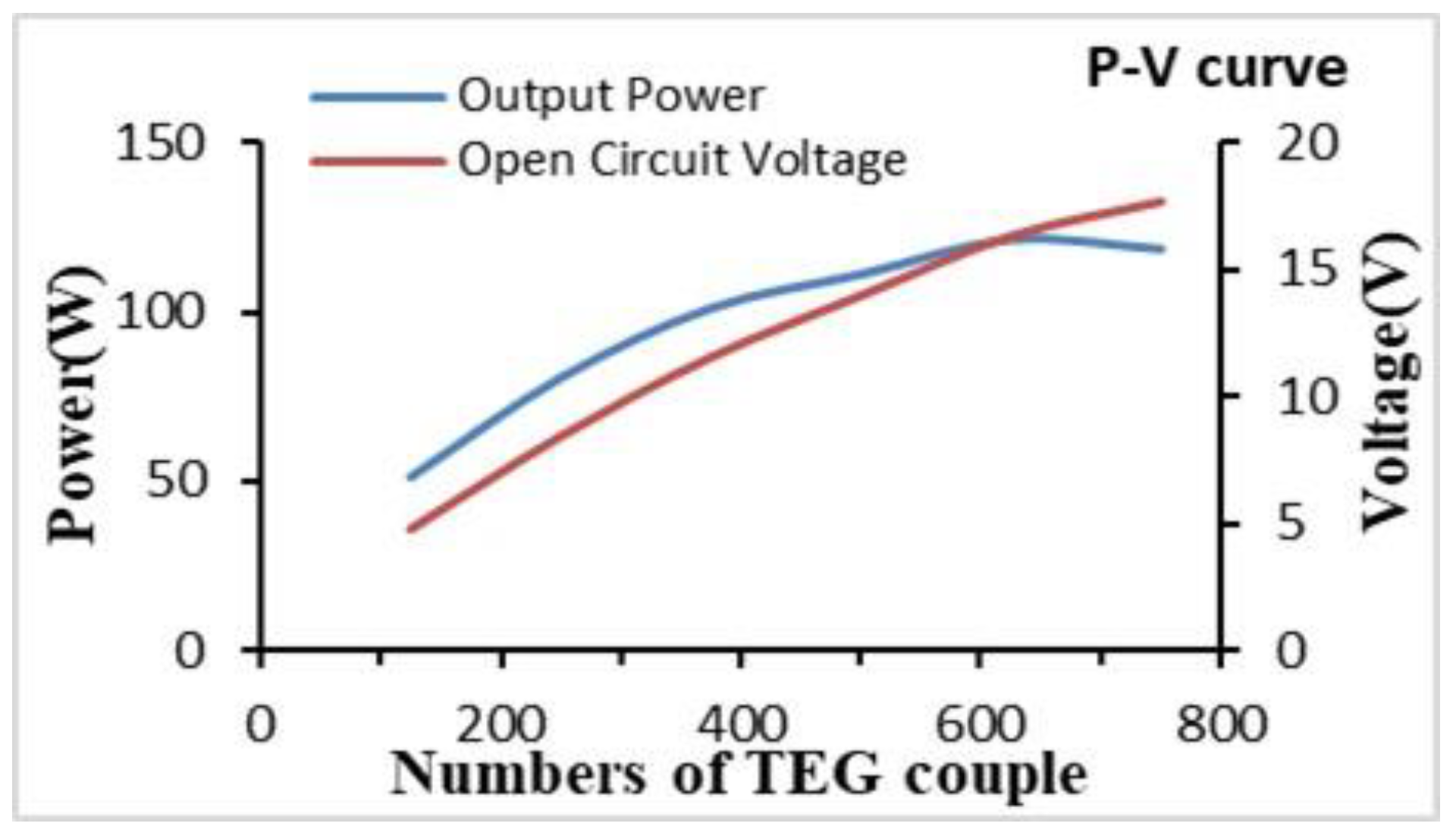

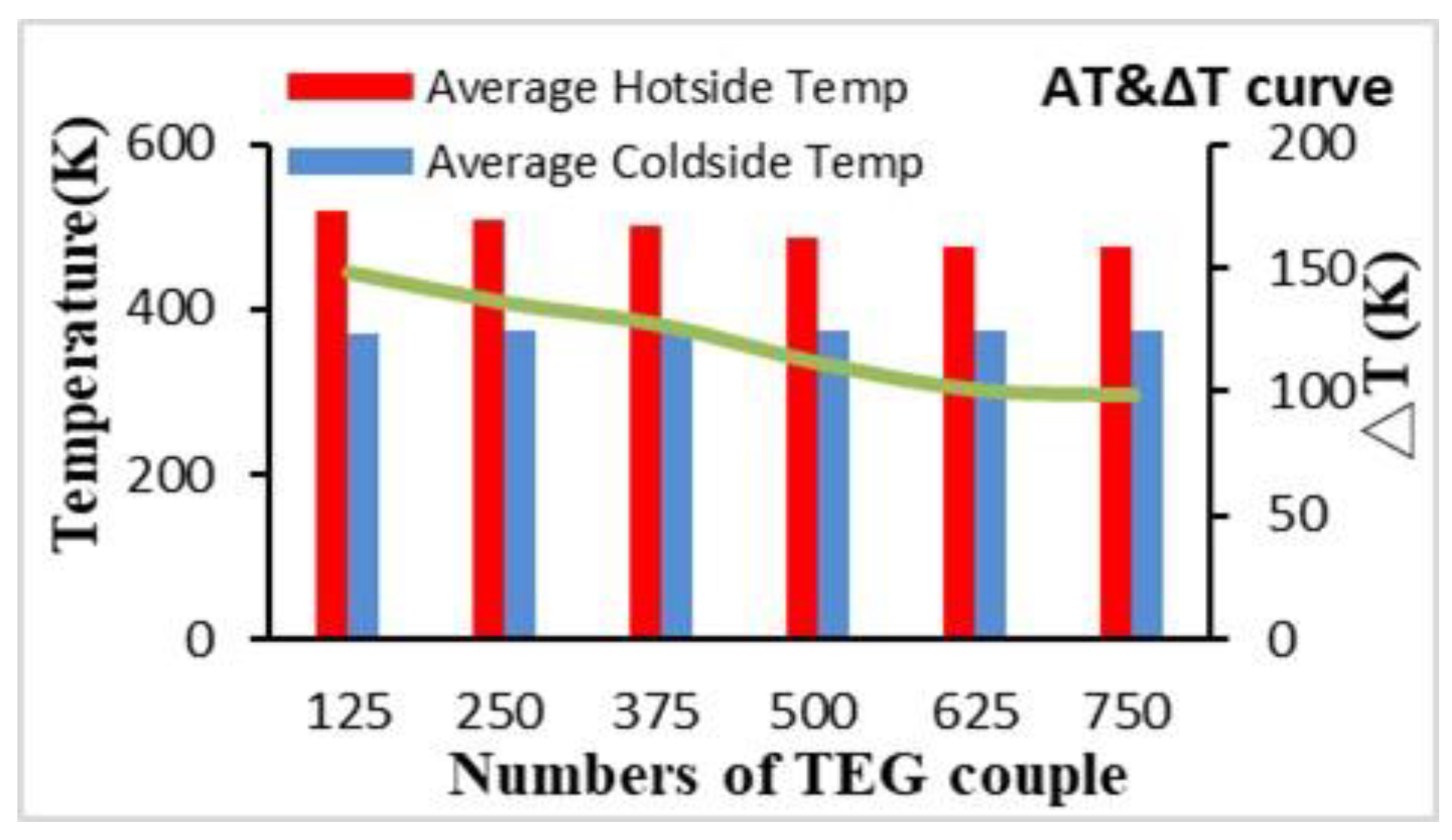

Figure 15 and

Figure 16 demonstrate that the open-circuit voltage of the TTEG rises in correlation with the quantity of thermocouples. Simultaneously, there is a rise in the average temperature at the cold end and a decline at the hot end. As the number of thermocouples rises, the temperature difference between the hot and cold ends decreases. The TTEG reaches its maximum output power of 121.63 W with 625 thermocouple pairs. Nevertheless, exceeding this threshold by adding more thermocouples results in a decline in output power. The observed phenomenon, in which the output power of the TTEG reaches its maximum at a specific number of thermocouples and then falls as more pairs are added, is consistent with the results reported by Sakthivadivel Duraisamy and colleagues [

47]. The study emphasizes a crucial element of thermoelectric module design: an optimum quantity of thermocouples exists that maximizes the output power. Once the ideal number is exceeded, the overall power production is negatively affected by the diminishing temperature differential and higher internal resistance despite the possible increase in voltage generation resulting from a bigger heat-absorbing surface. These insights are vital for implementing TTEGs, particularly in systems where optimizing energy recuperation from waste heat is imperative. By adjusting the number of thermocouples, designers may guarantee that TTEGs function at their maximum efficiency, offering a more efficient alternative for turning waste heat into usable electrical energy. Achieving this equilibrium is crucial for improving the efficiency and usefulness of thermoelectric generators in a wide range of industrial and automotive applications.

Figure 3.

This diagram provides a longitudinal sectional view of a shell and tube heat exchanger, detailing its internal configuration. Key elements include tube arrangements, shell structure, and flow paths.

Figure 3.

This diagram provides a longitudinal sectional view of a shell and tube heat exchanger, detailing its internal configuration. Key elements include tube arrangements, shell structure, and flow paths.

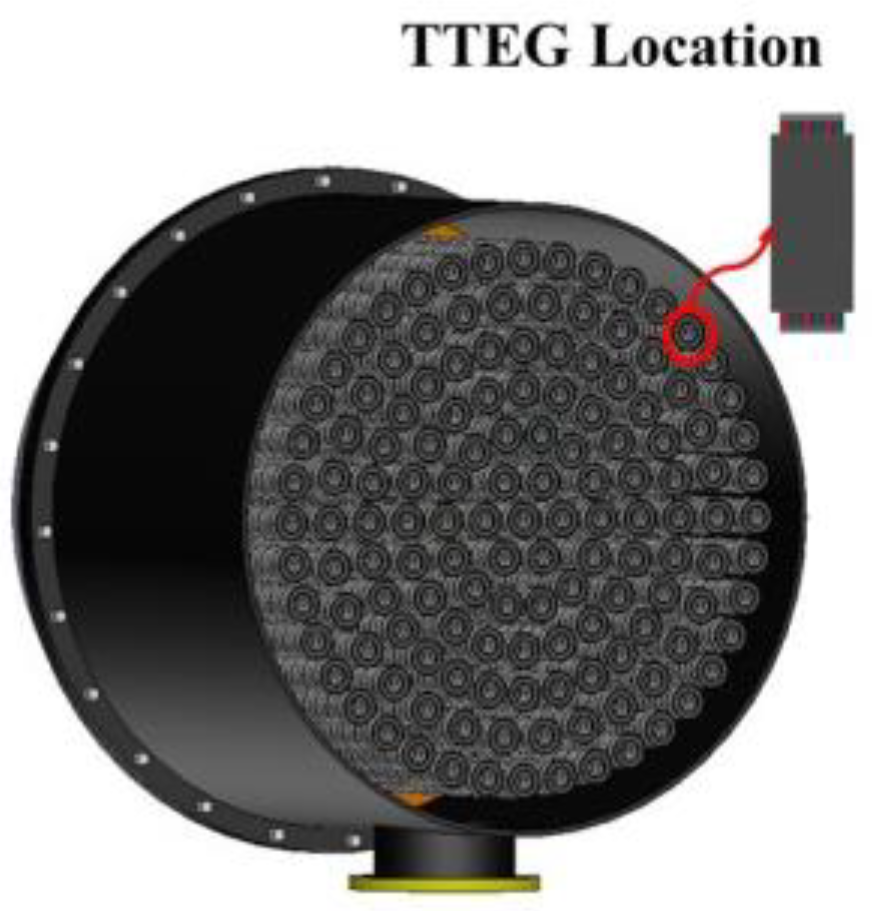

Figure 4.

This diagram exhibits a cross-sectional view of a shell and tube heat exchanger, illustrating its internal architecture.

Figure 4.

This diagram exhibits a cross-sectional view of a shell and tube heat exchanger, illustrating its internal architecture.

Figure 5.

This diagram provides an in-depth view of the Tubular Thermoelectric Module (TTEG), outlining its comprehensive structure. It details the arrangement and alignment of key components within the module.

Figure 5.

This diagram provides an in-depth view of the Tubular Thermoelectric Module (TTEG), outlining its comprehensive structure. It details the arrangement and alignment of key components within the module.

Figure 6.

Figure 6. This illustration details the structure of an Annular Thermoelectric element, highlighting its unique circular configuration.

Figure 6.

Figure 6. This illustration details the structure of an Annular Thermoelectric element, highlighting its unique circular configuration.

Figure 7.

Figure 7. This diagram depicts the temperature distribution across a Tubular Thermoelectric Module (TTEG). It illustrates the spatial variation in temperature within the module, highlighting areas of heat concentration and dispersion, which are vital for assessing the module's thermal efficiency and performance characteristics.

Figure 7.

Figure 7. This diagram depicts the temperature distribution across a Tubular Thermoelectric Module (TTEG). It illustrates the spatial variation in temperature within the module, highlighting areas of heat concentration and dispersion, which are vital for assessing the module's thermal efficiency and performance characteristics.

Figure 8.

This diagram presents a comparative analysis between the performance metrics of a Tubular Thermoelectric Module (TTEG) and the research findings published by S. Manikandan et al. [

41].

Figure 8.

This diagram presents a comparative analysis between the performance metrics of a Tubular Thermoelectric Module (TTEG) and the research findings published by S. Manikandan et al. [

41].

Figure 9.

This diagram provides a schematic illustration of fluid flow simulation within a Tubular Thermal Energy Module.

Figure 9.

This diagram provides a schematic illustration of fluid flow simulation within a Tubular Thermal Energy Module.

Figure 10.

This diagram illustrates the relationship between the external load applied to a Tubular Thermoelectric Module and its resultant output power. It graphically represents how changes in the load affect the module's power output, highlighting the operational efficiency and performance characteristics under varying load conditions.

Figure 10.

This diagram illustrates the relationship between the external load applied to a Tubular Thermoelectric Module and its resultant output power. It graphically represents how changes in the load affect the module's power output, highlighting the operational efficiency and performance characteristics under varying load conditions.

Figure 11.

These diagrams (a to h) depict the relationship between the external load and output power of thermoelectric tubular modules under various temperature conditions.

Figure 11.

These diagrams (a to h) depict the relationship between the external load and output power of thermoelectric tubular modules under various temperature conditions.

Figure 12.

comprising subfigures (a) to (h), showcases the correlation between the external load and the thermal efficiency of a Tubular Thermoelectric Module (TTEG) under various temperature conditions.

Figure 12.

comprising subfigures (a) to (h), showcases the correlation between the external load and the thermal efficiency of a Tubular Thermoelectric Module (TTEG) under various temperature conditions.

Figure 13.

This diagram presents the temperature distribution observed at the cold ends of 125 thermocouple pairs. It provides a comprehensive visualization of temperature variations across these points, highlighting the differential cooling patterns within the thermocouple array.

Figure 13.

This diagram presents the temperature distribution observed at the cold ends of 125 thermocouple pairs. It provides a comprehensive visualization of temperature variations across these points, highlighting the differential cooling patterns within the thermocouple array.

Figure 14.

This diagram illustrates the temperature distribution at the hot ends of 125 thermocouple pairs. It effectively visualizes the temperature gradients and variations present at these points, providing insights into the heat distribution of thermocouples.

Figure 14.

This diagram illustrates the temperature distribution at the hot ends of 125 thermocouple pairs. It effectively visualizes the temperature gradients and variations present at these points, providing insights into the heat distribution of thermocouples.

Figure 15.

This diagram depicts the relationship between the length of a Tubular Thermoelectric Module (TTEG) and its output power. It illustrates how variations in the length of the module influence its power generation capabilities, providing a crucial understanding of the module's performance characteristics in relation to its physical dimensions.

Figure 15.

This diagram depicts the relationship between the length of a Tubular Thermoelectric Module (TTEG) and its output power. It illustrates how variations in the length of the module influence its power generation capabilities, providing a crucial understanding of the module's performance characteristics in relation to its physical dimensions.

Figure 16.

This diagram showcases the trends in temperature gradients within a Tubular Thermoelectric Module (TTEG). It graphically represents the variations in temperature difference across the module.

Figure 16.

This diagram showcases the trends in temperature gradients within a Tubular Thermoelectric Module (TTEG). It graphically represents the variations in temperature difference across the module.

Table 1.

The results of effective material properties for (TMG-127-1.0-0.8) at Th = 200 ℃, Tc = 30℃,n = 127,Ae = 1 mm2,and Le = 1.35 mm.

Table 1.

The results of effective material properties for (TMG-127-1.0-0.8) at Th = 200 ℃, Tc = 30℃,n = 127,Ae = 1 mm2,and Le = 1.35 mm.

| Effective Material Properties |

|---|

|

α*=314.96 μ‧V/K |

k*=0.03 W/cm‧K |

ρ*=2.23*10-3 Ω‧cm |

z*=1.492*10-3 1/K |