1. Introduction

In the prevailing digitization zeitgeist within the maritime industry, digital twins assume a pivotal position. The domain of marine commerce is considerably impacted by burgeoning globalization tendencies, and in this context, solutions stemming from digital twins emerge as significant pillars of support. These solutions enable shipbuilding and shipping enterprises to proficiently grapple with sundry challenges, including but not limited to escalating delivery expenses and political compulsion towards decarbonization [

2]. These tools serve as significant assets bolstering digitization initiatives. Structural health monitoring (SHM) is a multidisciplinary technical field offering reliable insights into the mechanical behavior of structures under load via measurement data from sensor systems, thus facilitating decision support for structural safety evaluation. Existing stress monitoring of hull structures mainly utilizes limited and discrete strain sensors placed precisely at monitoring points, thereby presenting challenges in securing comprehensive field information of the hull structure [

2,

3,

4,

5,

6,

7,

8].

With the advent of digital twins, a concept that has rapidly risen to prominence, conducting health and safety evaluations rooted in twin models is gradually gaining traction as a focal point of research. In the recent chronological sphere, initial applications of digital twins within the maritime domain have surfaced [

9,

10,

11,

12]. Literature evidences the usage of digital twins in the realm of shipping, bifurcating it into two primary classifications [

13]. The first category pertains to observation, calibration, and decision support integral to ship operation and modulation. For instance, Coraddu et al. [

14] established a numerical model anchored in machine learning to quantify the velocity of damage caused by marine fouling. However, the paradigm necessitated an ample corpus of sample data for efficient training of the model. The second category is applicable to system integration testing and training. Tofte et al. [

15] delineated a simulation system encapsulating virtual humans in the ship pipe installation process, touted for its efficacy in hardware testing and operational training. Utilization of digital twin technology in evaluating structural safety remains in the nascent stages. Bernasconi et al. amalgamated finite element analysis with augmented reality, proffering a twin model dedicated to monitoring fatigue crack evolution in metal composite bonded connections founded on measured strain data [

16]. Schirmann et al. [

17] instituted a digital twin system for estimating hull structure fatigue, predicated on measured wave response data, serving as an evaluation tool for cumulative impairment endured by the ship.

Leveraging a strain sensor network measurement system to mirror the displacement field of a structure in real time, colloquially known as shape-sensing, constitutes an integral research tactic in SHM. In 2004, LR [

18]. proffered a scheme for sensor configuration specifically crafted for typical hull structure surveillance in bulk carriers or oil tankers Classification societies such as ABS and DNV have established protocols for sensor types, measurement precision, and data retention requisite in hull monitoring systems [

19]. Majewska et al. [

20] conferred a methodology for contemporaneous strain/stress monitoring of a sailing ship’s foremast employing Fiber Bragg Grating (FBG) sensors. In a notable innovation, Tessler and Spangler [

21,

22] at NASA Langley Research Centre germinated a groundbreaking shape- and stress-sensing algorithm, christened as iFEM. The utility and precision of the iFEM framework in assessing structural deformation fields have been duly validated [

23,

27]. Kefal et al. [

25] employed the strain data obtained by finite element analysis as input data procured through finite element analysis as input data within the iFEM algorithm, actualizing deformation surveillance in a typical chemical tanker.

One of the main purposes of employing digital twin models for ship structural health monitoring is to extract and exploit efficacious data to the maximum possible extent. Commercial software platforms such as CEI Ensight [

28] and GLView VTFx [

29] intensify the demand for visual interaction of FEA data in virtual reality environments to a certain extent. However, limited interdisciplinary interfaces and non-open source features limit the application of user innovation scenarios. With the development of VR technology, it is possible to reproduce the real process of mechanical phenomena. Song et al. developed the middleware CAE2VR [

30], a tool adept at transmuting FEA data into virtual visualization files, subsequently crafting a system to disseminate limited heterogeneous FEA data within a virtual reality milieu. Cho et al. [

31] proposed a scheme for FEA data conversion and lightweight representation, thereby augmenting the dissemination of FEA outcomes. Taking advantage of the superior memory capacity inherent in supercomputers, Liu et al. [

32] transformed the ODB result file, computed by the Abaqus software, into a .vtk visualization file via a Python script, thereby facilitating the parallel visualization of large-scale FEA results in the Paraview commercial software. Through the application of neural networks, Hambli et al. [

33] forecasted real-time deformation of tennis balls and rackets during the collision process, in which users can feel the impact load of the racket through haptic glove in a virtual reality environment. Although the above-mentioned research has achieved rapid response to prediction results by training surrogate models, it is still limited by the scale of the finite element model, which may produce unreliable results for untrained inputs. Deciphering ways to streamline interaction and disseminate FEA data in pragmatic applications continues to pose a formidable challenge [

33,

34,

35,

37].

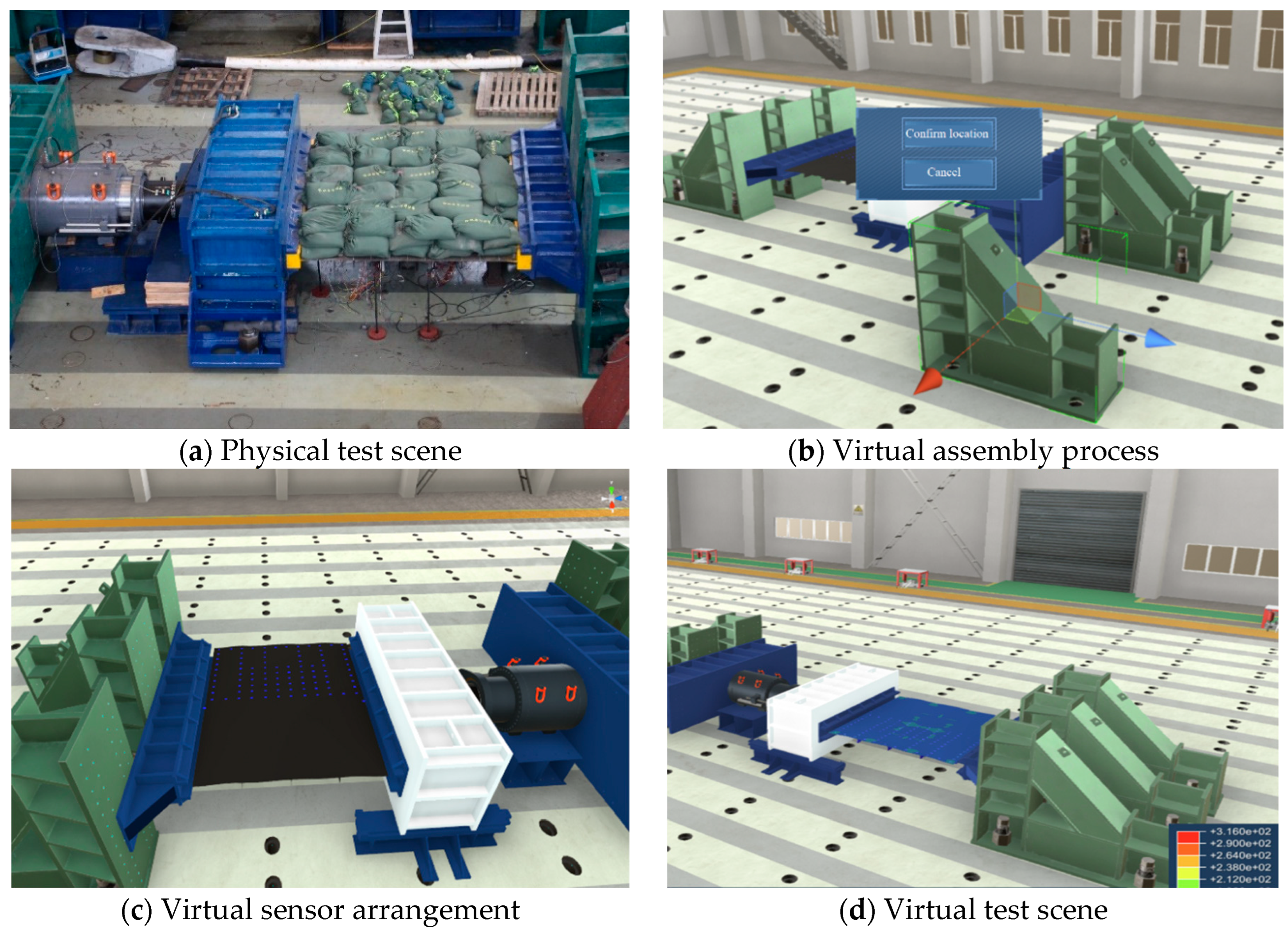

On the whole, when tasked with assessing and overseeing the safety status of a structure through the examination of mechanical traits inherent in the ship structure, it typically necessitates the development of a finite element model of the target edifice, a reduced-order variant, or the deployment of deep learning methods. The unwieldy nature of finite element simulations often falls short of meeting the exigencies for swift response in the monitoring sequence. The adoption of a reduced-order model necessitates a considerable amount of preparation work, demanding repetition when the target structure varies. Deep learning methods require training with an extensive volume of samples, yet they may yield unreliable outcomes for untrained inputs. A common feature amongst these three methods is the disjunction between numerical computations and physical scenes. This paper aims to explore the feasibility of employing limited discrete strain measurement data within physical scenes to effectuate the reconstruction of the structural deformation field, ultimately actualizing the potential of a virtual-real fusion digital twin monitoring system. The primary and innovative objective of this work is to combine iFEM methods, digital twins, and VR approach for the first time in the literature. The self-developed digital twin tool commences with the values gathered from strain gauges on the investigated structures, proceeding with an analysis based upon the iFEM framework. Following the reconstruction of the deformation field, the data is subsequently provided to the VR system to achieve an integration of monitoring, analysis, and visualization.

The remaining sections of this paper is organized as follows. In

Section 2, the fundamental concepts and overview of the extant digital twin system are explained, and a digital twin framework of virtual-real fusion, a deformation field reconstruction algorithm based on inverse finite element, and a visualization strategy in virtual scenes are established.

Section 3 introduces the real-time virtual-real interactive platform for ship structure mechanics testing, constructed using the digital twin methodology, validated through comparative verification via physical model test case studies. This section incorporates discussions on various technical issues related to the monitoring of structural mechanical properties, such as analysis of deformation fields, fusion of physical and virtual data, and virtual visualization of deformation fields. Finally,

Section 4 draws the primary conclusions and encapsulates the observations gleaned from this study.

2. Methodology

2.1. Real-time digital twin of ship structure deformation field

Digital twins, utilized for real-time assessment of ship structure deformation fields, require the following basic elements: fusion of physical measurement and virtual data, reconstruction of the deformation field, and a virtual-real fusion visual interactive platform. These components can interlink and bolster a variety of complementary functions, such as data analysis, monitoring and decision-making. All analysis, simulation, and visualization must be executed in real-time to undergird the expeditious assessment of the ship structure deformation field. This novel digital twin system harbors the potential to aid operators' decision-making processes concerning hull structure safety assessments. It focuses on deterministic identification of the structural deformation state under specified loads, as opposed to statistical values predicated on marine environmental factors or labor-intensive numerical simulation computations. The system can proffer more granular information on the entire field of the ship structure, thereby mitigating the risk of structural failure induced by excessive operation of the vessel. As current circumstances dictate, extant digital services are not without their flaws [

38]. In the future, the completed system should incorporate assessments of potential large deformations of ship structures under severe sea conditions.

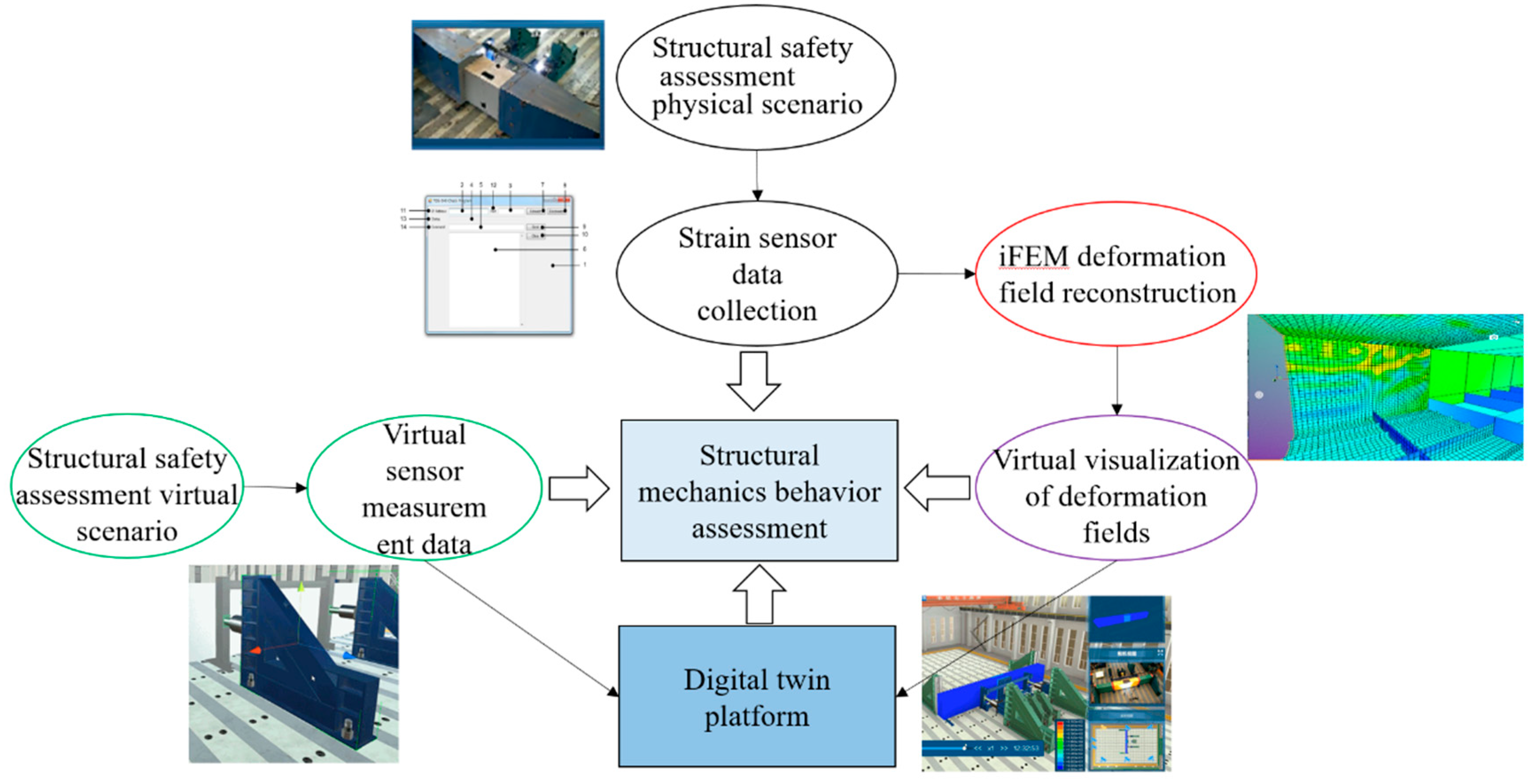

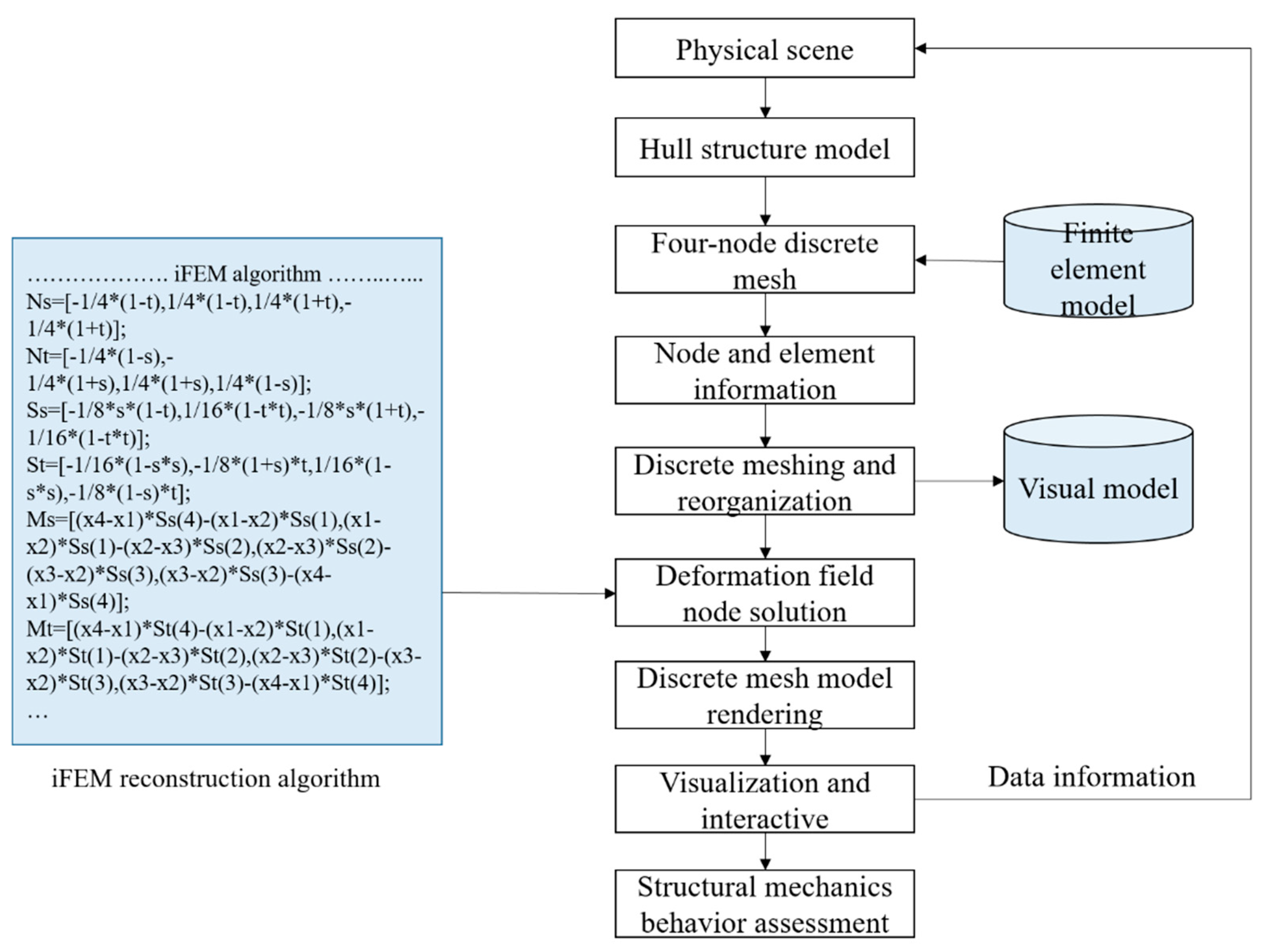

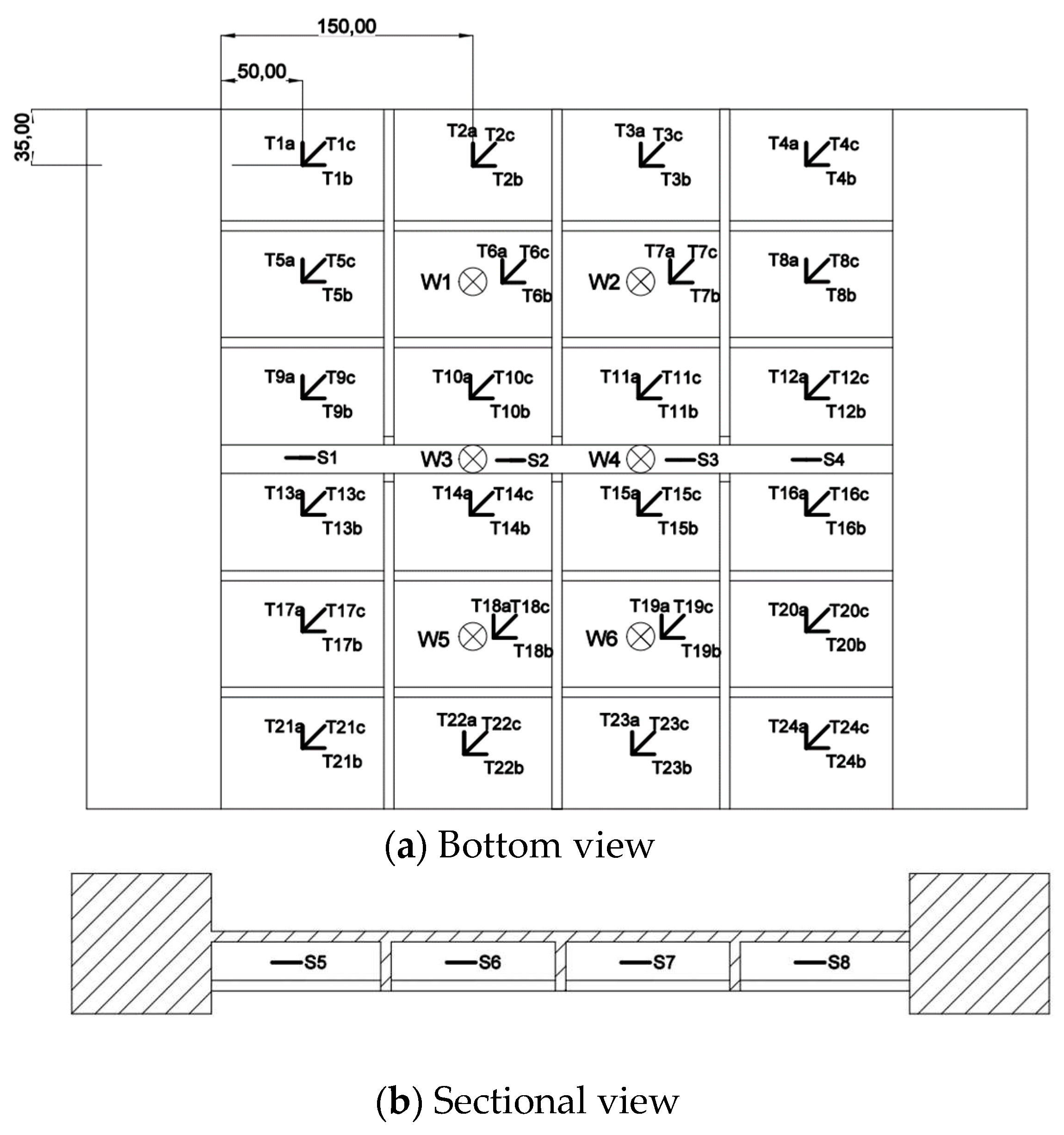

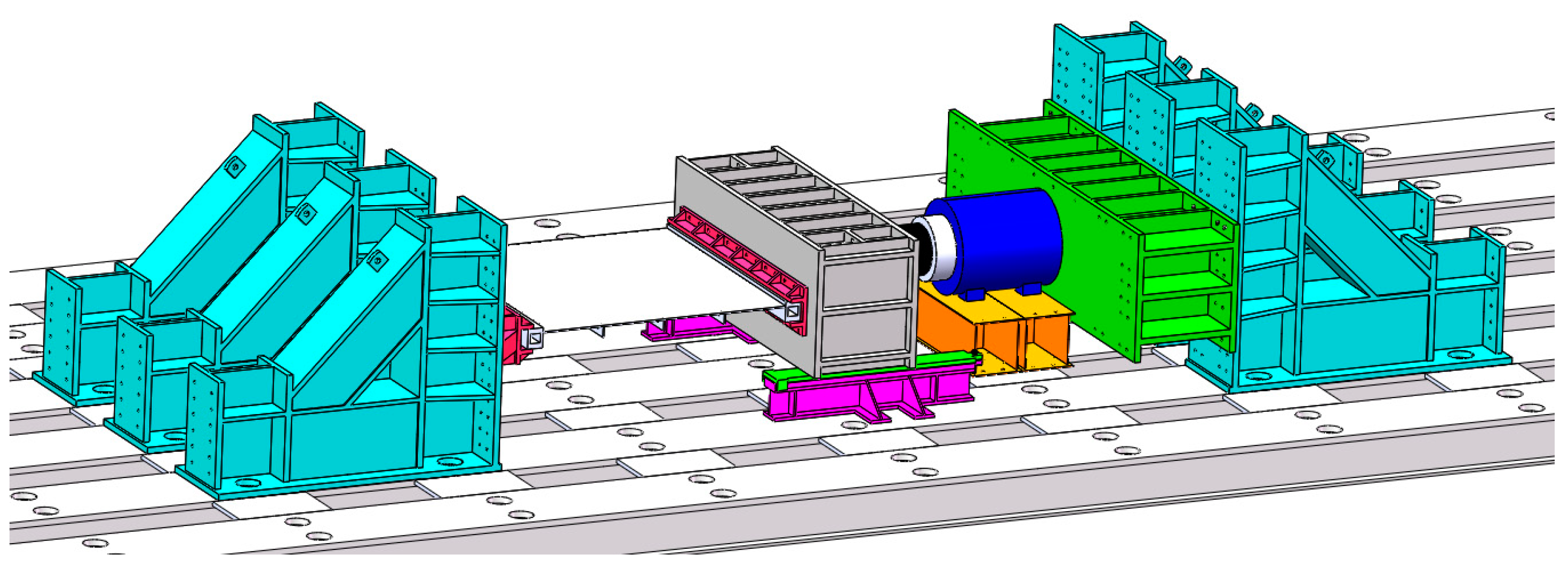

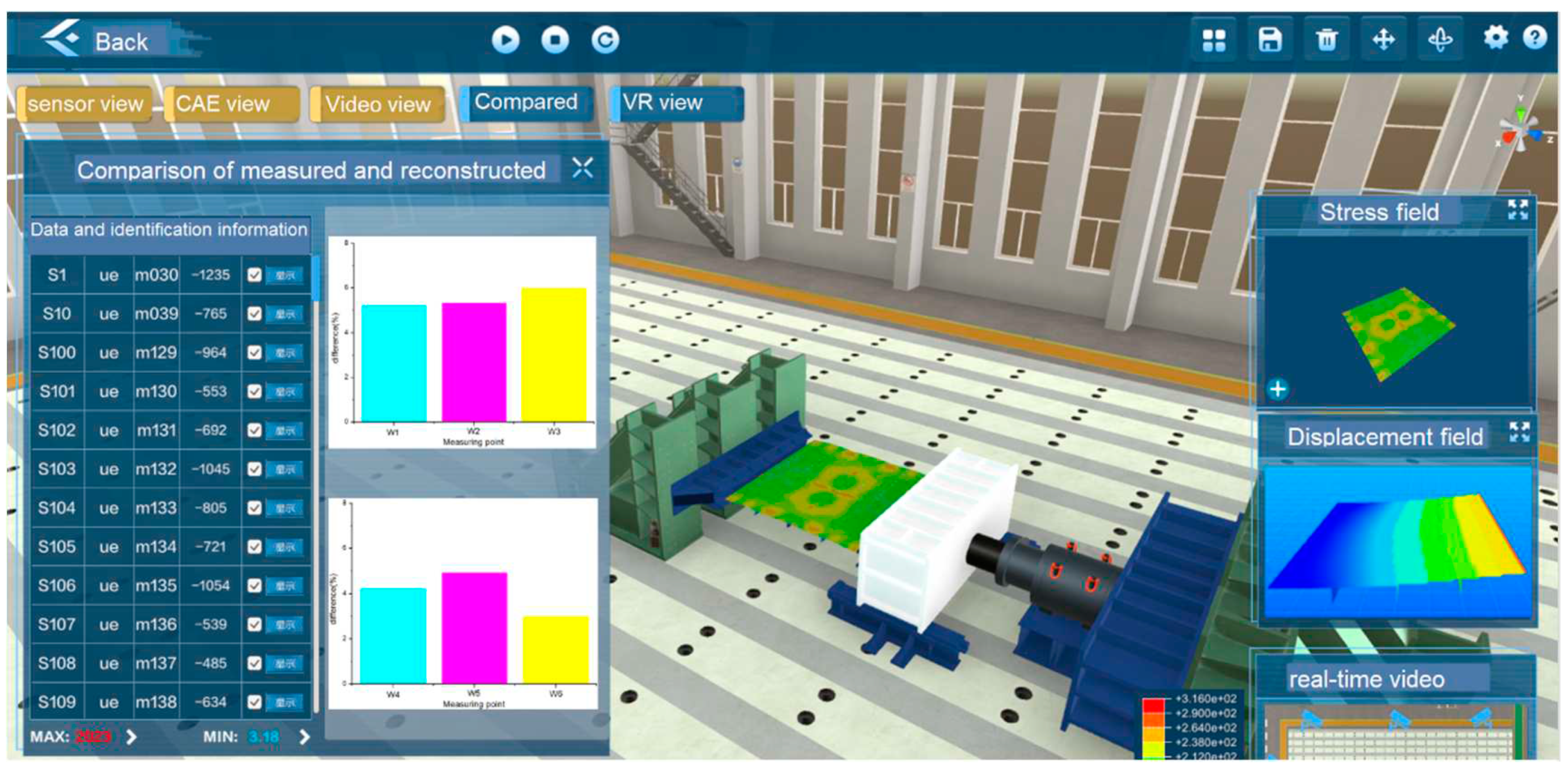

The composition of the digital twin platform for real-time assessment of ship structure deformation fields is depicted in

Figure 1. It encompasses a physical scene and strain data measurement module, an iFEM-based deformation field reconstruction module, a virtual scene construction and data fusion module, a deformation field visualization module, and a digital twin integration platform. The bottom layer of the deformation field reconstruction module integrates the iFEM algorithm to derive global field deformation information about the structure via measured strain data. The virtual sensor measurement module prompts the model within the virtual scene to mimic motion responses consistent with the physical scene, using displacement data derived from the loading device in the physical scene. The deformation field virtual visualization module offers users immersive interactive functionalities within virtual scenes to facilitate exploration of structural mechanical properties. The digital twin platform amalgamates these diverse functional modules, thereby constructing a digital twin software system for real-time assessment of ship structural deformation fields through its deployment.

2.2. Digital twin architecture

Assani et.al. [

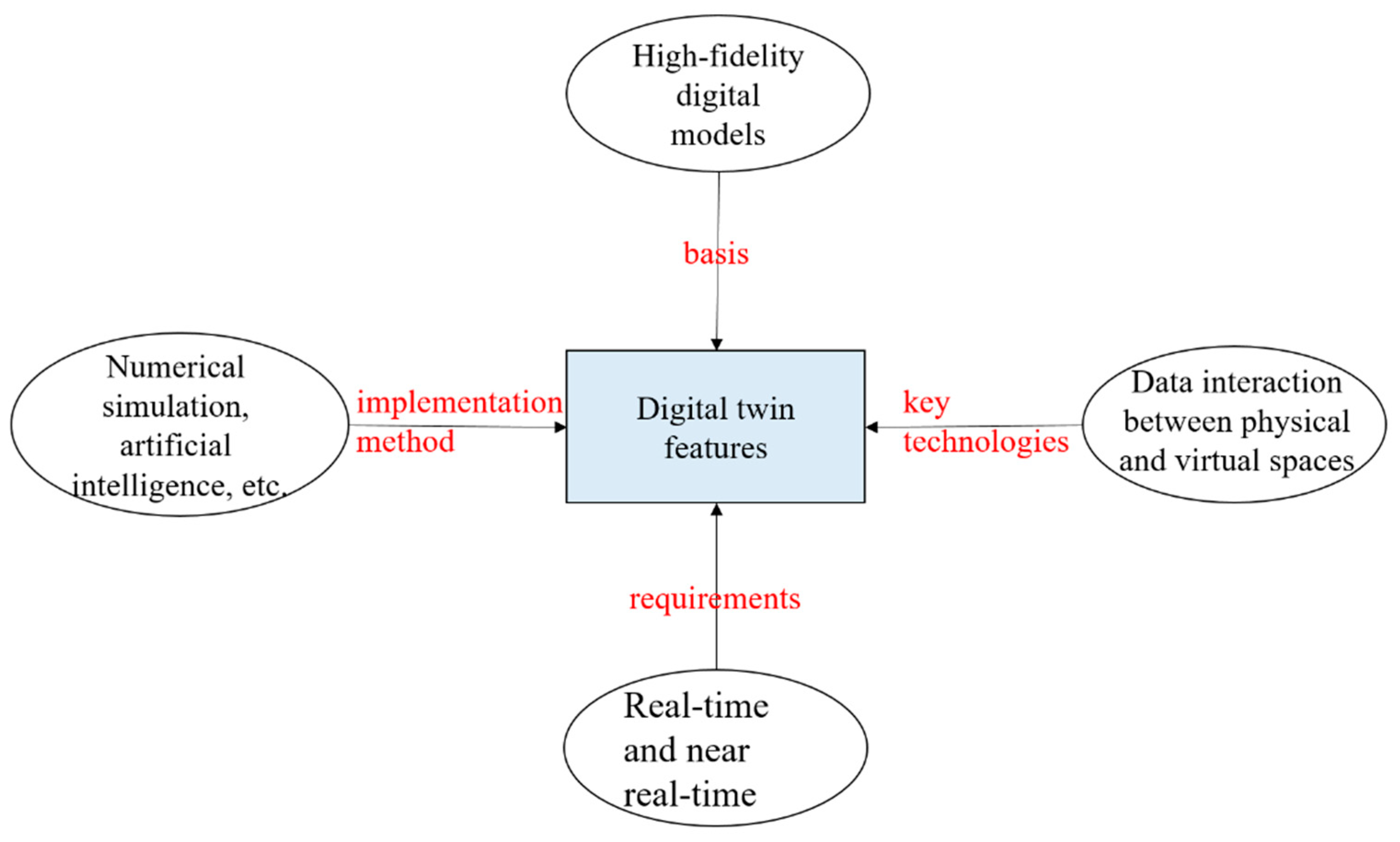

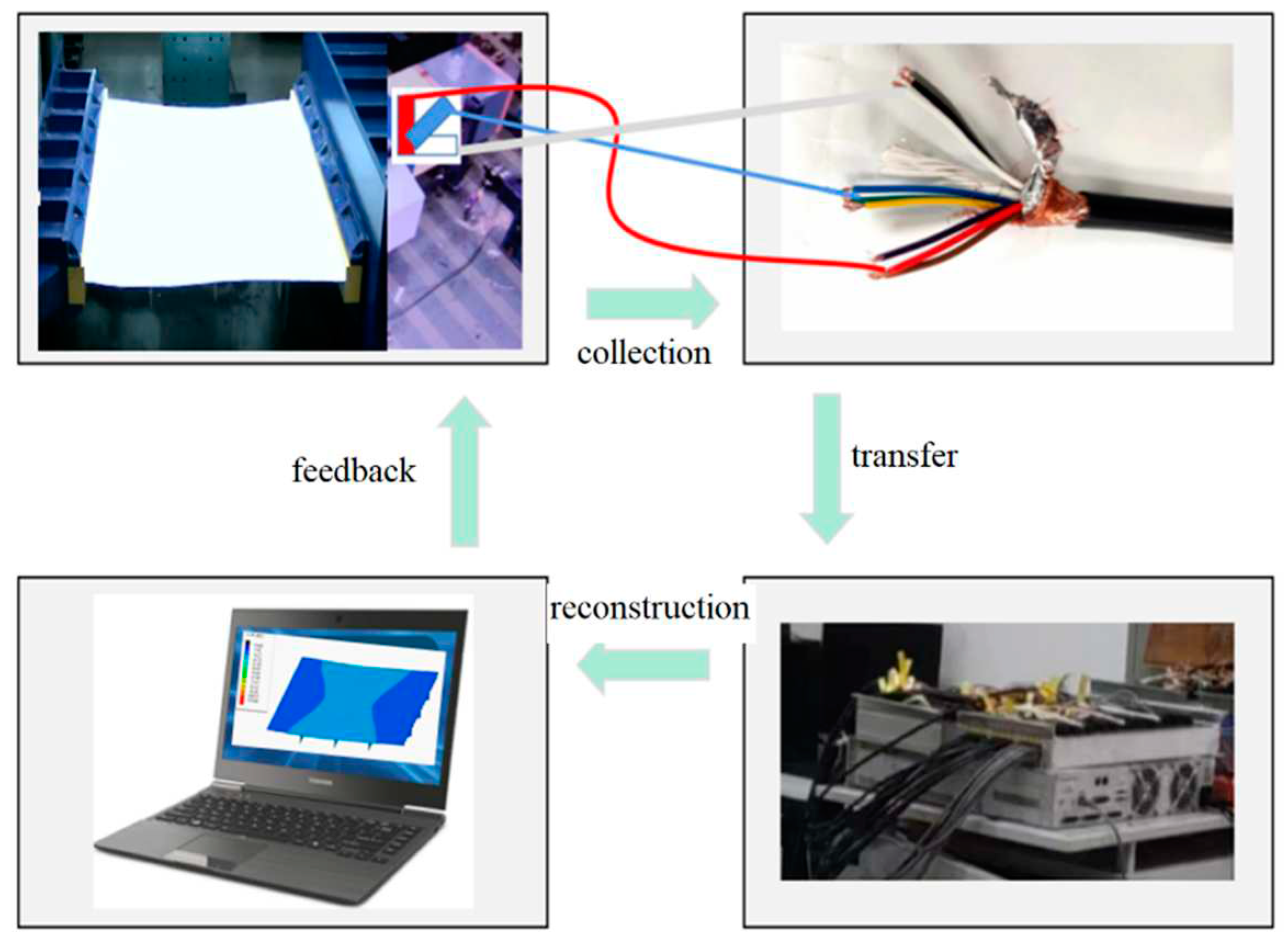

39] described the application of digital twins within the sphere of marine engineering Upon perusal of extant literature, it can be observed that digital twins have varying degrees of integration in imitating physical objects. The first layer is referred to as the digital model, encompassing the digital simulation of the physical entity where the communication between the digital and physical object is wholly manual. The second layer, also known as the digital shadow, ensures the one-way flow of data wherein alterations in the physical model’s state are mirrored within the digital copy. The third layer, known as the digital twin, exhibits seamless bi-directional information transmission between the physical and digital objects. The theoretical concept of the digital twin encompasses procuring load data and hull response readings through environmental monitoring to formulate a simulation model. The intersection of virtuality and reality facilitates the conversion of environmental monitoring outcomes into structural stress results, with the digital model guiding and forecasting for the physical model. As illustrated in

Figure 2, the characteristics of digital twins can be described as follows:

(1) The transition from physical space to virtual space rests on the premise that the digital model possesses high fidelity.

(2) The implementation approach is numerical simulation technology and artificial intelligence.

(3) The key technology lies in facilitating data interaction between physical and virtual spaces.

(4) The implementation requirement is to meet real-time performance as much as possible.

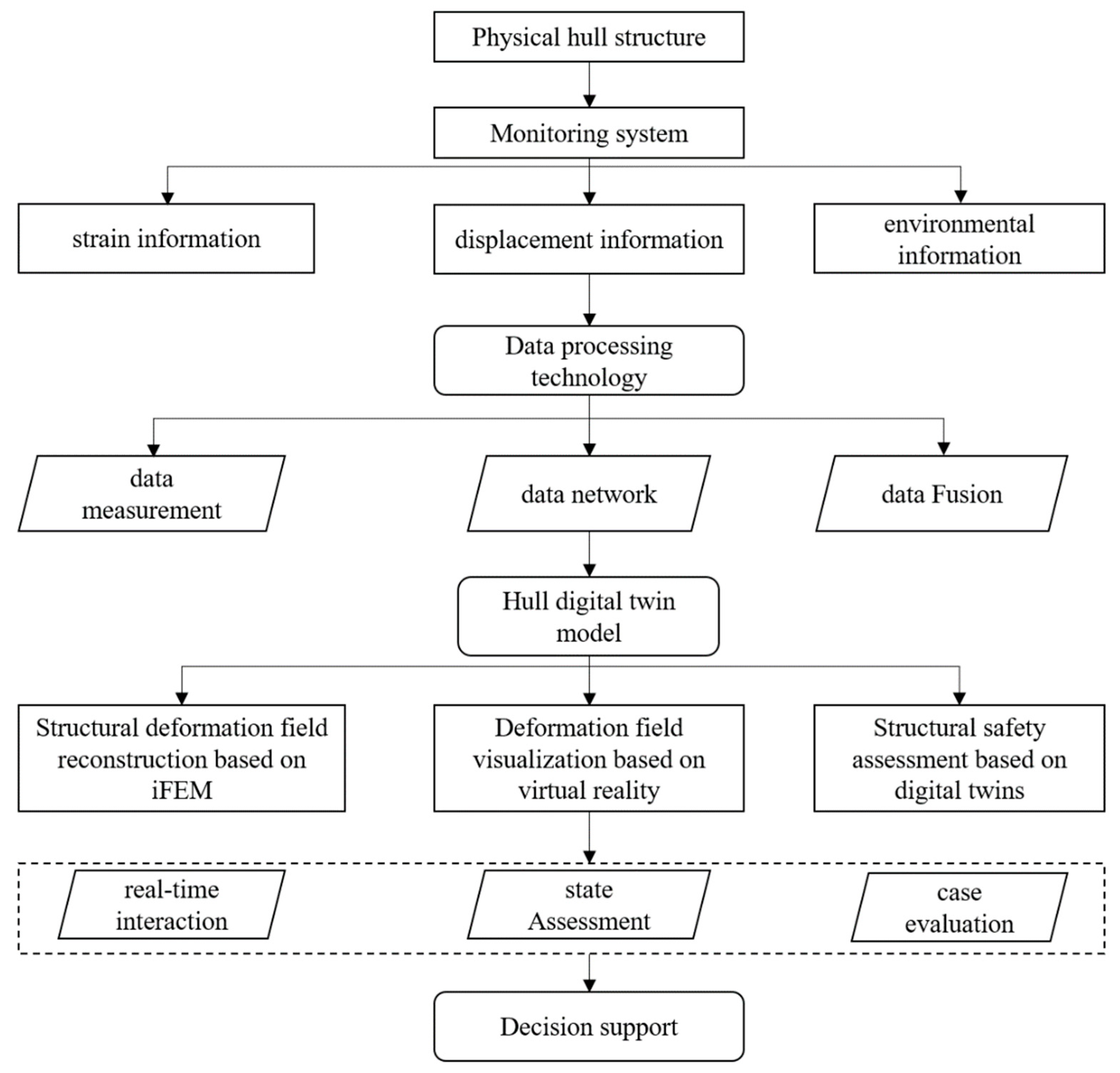

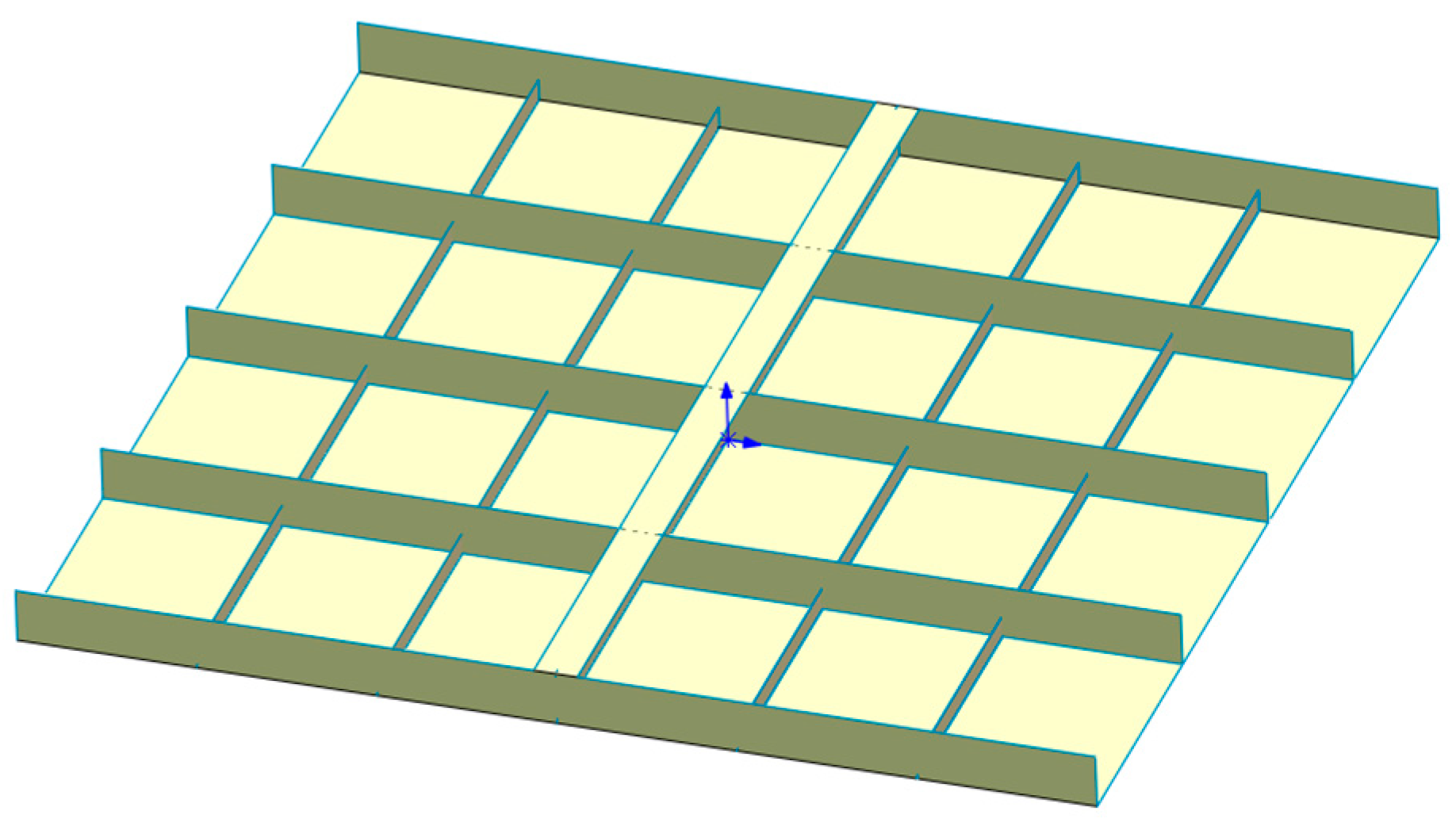

For hull structures, traditional beam theory coupled with finite element and other technologies have offered varying degrees of fidelity in virtual models and numerical simulation results, aligning with the first two characteristics referenced above. The key to realizing the digital twin of ship hull structures currently lies in enhancing the fidelity of virtual models and simulation results, and ensuring rapid response. Though monitoring the external environment of hull structures is still in its infancy, stress monitoring is relatively mature. Consequently, strain measurements can serve as the data source for the digital twin system dedicated to ship structure safety monitoring. Given the impracticality of installing strain sensors at all points in the ship structure, particularly within narrow and enclosed spaces, utilizing limited strain measurement locations to procure global field information of the structure poses a significant technical challenge. Additionally, the finer the numerical model, the higher the computational cost, which contradicts the real-time nature of digital twins. Hence, resolving the swift response within the digital twin platform remains an important issue. In this research, the conceptual implementation of the digital twin for ship hull structure safety assessment (

Figure 3) envisages using partial stress monitoring points to effectuate deformation field reconstruction, supplemented with displacement monitoring data in the physical environment. Such data are incorporated into the construction and simulation technology of the digital hull structure model, and the structural state of the ship’s global field is obtained through efficient computation of deformation field reconstruction. In the meanwhile, relevant measured data and reconstruction results are relayed back to engineering and experimental designers via virtual reality technology.

Digital twin epitomizes the cutting-edge evolution in implementing digital modeling, simulation, and industrial internet of things (IoT) technology, encompassing all digital models of the physical system to simulate, predict, and assess key activities interrelated with physical measurement data. The content of the digital twin is organized here as: embodiment of the physical entity, interconnectedness of states and data harvested from the entity, and simulation or scrutiny of behavior. Digital twin includes all entities and virtual models shared in the simulation. Sensor measurement data collected from the system serves the analysis and simulation of the structural mechanical behavior. The digital twin developed in this research facilitates a bidirectional flow of data information between the actual hull structure and its virtual model. Additionally, for a digital twin platform of high-fidelity simulation models across multiple domains, it is prudent to adopt a phased progression in development. Functional modules are independently developed and then associated with the digital twin platform to strike the necessary equilibrium between fidelity and simplification.

2.3. Inverse finite element formulation for shells

Real-time, rapid, and accurate acquisition of structural state information is crucial for early warning mechanisms and bolstering ship safety. Most SHM methods do not take into account the structure’s topology and boundary conditions. The iFEM reconstructs the overall displacement field of the structure in real-time from strain data gathered from a network of sensors stationed at various points on the structure. Unlike other developed SHM system, the iFEM method possesses broad applicability to intricate structures influenced by complex boundary conditions in real-time [

22]. Given that the strain measurements represent the sole input in the iFEM formulation and the constructed strain-displacement relationship does not involve the structure's material properties and load information, there is no requirement for prior knowledge of material characteristics and load information, making it well-suited for complex structures. The four-node inverse quadrilateral shell (iQS4) element formulation is established under the assumption of Mindlin’s first-order plate theory. Considering the practical application in marine structures, the measured strain data in this study serve as the input for the iFEM algorithm, with the structure’s deformation field as the output data.

2.3.1. Inverse quadrilateral shell element

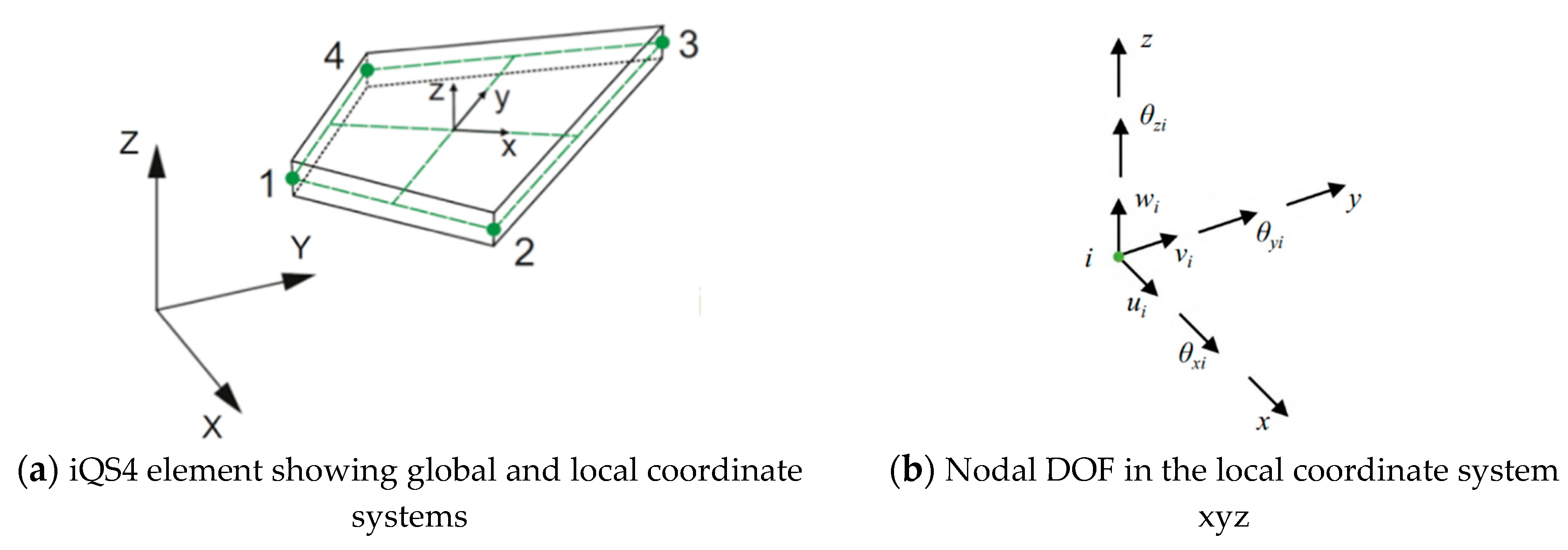

This section employs the four-node inverse quadrilateral shell (iQS4) element to demonstrate the derivation process of the iFEM formula. As depicted in

Figure 4(a), the iQS4 element, global coordinate system XYZ and local coordinate system xyz are illustrated. The origin of the xyz system is located at the centroid of the element middle surface quadrilateral. Nestles at the centroid of the middle surface quadrilateral of the element. Furnished with six degrees-of-freedom (DOF) per node, as highlighted in

Figure 4(b), the iQS4 element encompasses translations

in addition to rotations

. The theoretical strain of the structural element is divided into plane strain

, bending curvature

and transverse shear strain

, where

symbolizes the displacement exhibited by the four nodes. The formulation of the iQS4 element is actualized initially by composing the membrane and bending curvature matrices separately, ultimately amalgamating them for exportation. The relevant calculations of iQS4 is procured relying on Mindlin’s plate theory, considering the influence of shear deformation. According to the assumptions of Mindlin’s first-order plate theory, the relevant derivatives of the three components of the displacement vector are calculated. Subsequently, the strain-displacement relationship of linear elastic theory is deduced as follows:

Where,

matrix stands for the derivatives of the shape functions associated with the membrane behavior. Conversely,

matrices manifest the corresponding derivatives of shape functions designed to delineate the bending behavior of the element.

Figure 4.

Four-node inverse shell element.

Figure 4.

Four-node inverse shell element.

2.3.2. Input data from in-situ strain sensors

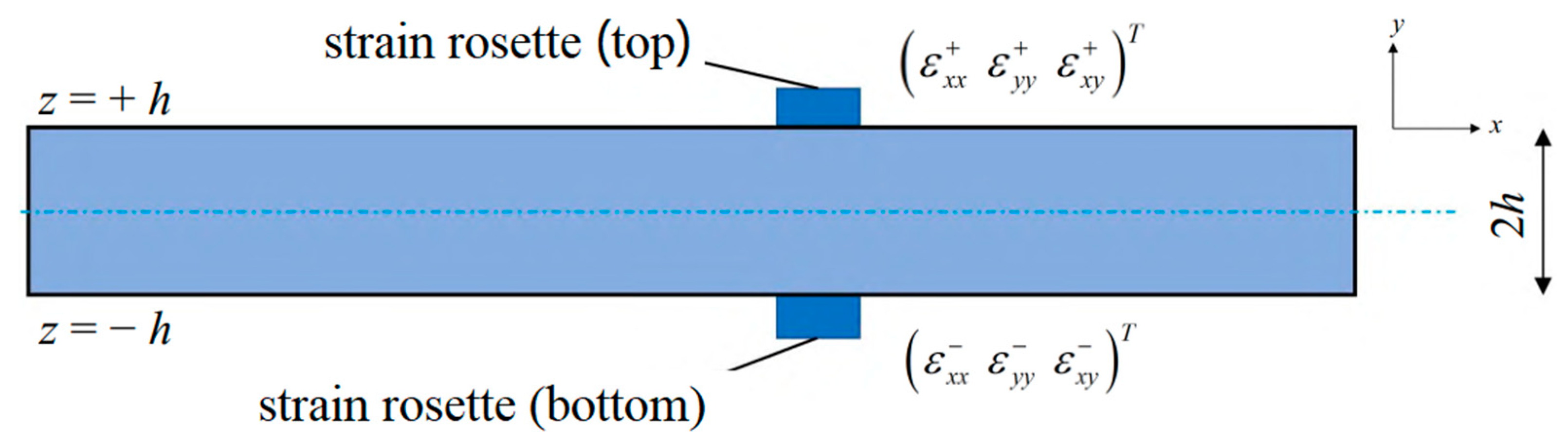

The input for the IFEM is the measured strains at the center points on the top and bottom surfaces of each inverse element, as illustrated in

Figure 5. Commonly used strain sensors incorporate strain rosettes or FBG sensor networks. The distinct attributes of an FBG system include its lightweight nature, swift operation, immunity to electromagnetic interference, and a lack of necessity for recalibration post-installation. Tessler and Spangler (2005) pointed out that reference plane strains

and curvatures

could be calculated utilizing measured surface strains [

40]. In Equations 2 and 3,

denotes the measured strain on the upper surface of the element,

represent the measured strain on the lower surface of the element, and h is the distance from the middle surface to the surface. Transverse shear strain

cannot be measured directly through strain rosette sensors. However, in the context of plate and shell structures, the value of transverse shear strain is much smaller than plane strain and bending curvature, thereby rendering the influence of transverse shear strain negligible in the iFEM formulation.

2.3.3. Weighted least-squares functional

At the core of iFEM lies the construction of a least-squares function

between the measured strains of an element and the theoretical strains. By considering the membrane, bending and transverse shear deformation of the element, the least-squares function is minimized with respect to the nodal displacements using the variational principle. Subsequently, an estimated value for the node displacement is procured and deemed reflective of the measured displacement.

In formula (3),

are weighting constants. The correct use of the weighting constant is especially critical for problems involving a relatively small number of strain measurement points. Setting the weighting constant at 1 is recommended when the element possesses a corresponding strain measurement value. The square norm depicted in equation (3) can be rephrased in the context of a normalized Euclidean norm as follows:

In the formula,

is the area of the element. For inverse elements without strain sensors, the weighting constant is set to 10^-5. These weighting constants guarantee satisfactory regularization of equation (3), even under circumstances where the iFEM model presents scant measurement strain data. This allows for necessary interpolation linkages between inverse shell elements equipped with strain rosettes. Nonetheless, augmenting the quantity of elements for strain-free measurements has the potential to impair the precision of the deformation field reconstruction. With these assumptions, the least-squares function is minimized using the variational principle, i.e., through the extraction of partial derivatives relative to nodal displacements:

Where,

are the inverse stiffness matrix and load column matrix of element respectively. The overall displacement of the structure can be calculated from both the overall inverse stiffness matrix and the corresponding inverse load column matrix. Once the local matrix equations are defined, the element contributions to the global linear equation system of the discretized structure can be obtained as:

Where, K is correlated with the measured strain value, U embodies the global nodal displacement vector, and F represents a global function of the measured strain value.

2.4. Visualization and visual interaction

The use of VR technology in the evaluation of engineering analysis results has attracted increasing attention [

41]. Some existing shared formats can indeed enhance the exchangeability of deformation field data in VR scenarios. However, they are still relatively inefficient. Therefore, the concept of a new practical shareable neutral data architecture is proposed for effective sharing of multidisciplinary data in collaborative environments. The most critical requirements are summarized below:

(1) Improve access to data sources and automation level.

(2) Provide higher data processing efficiency and facilitate verification by design and engineering personnel.

(3) Enhance immersive exploration of data results.

(4) Enhance the interactivity of simulation results.

(5) Traceability and consistency of data result conversion.

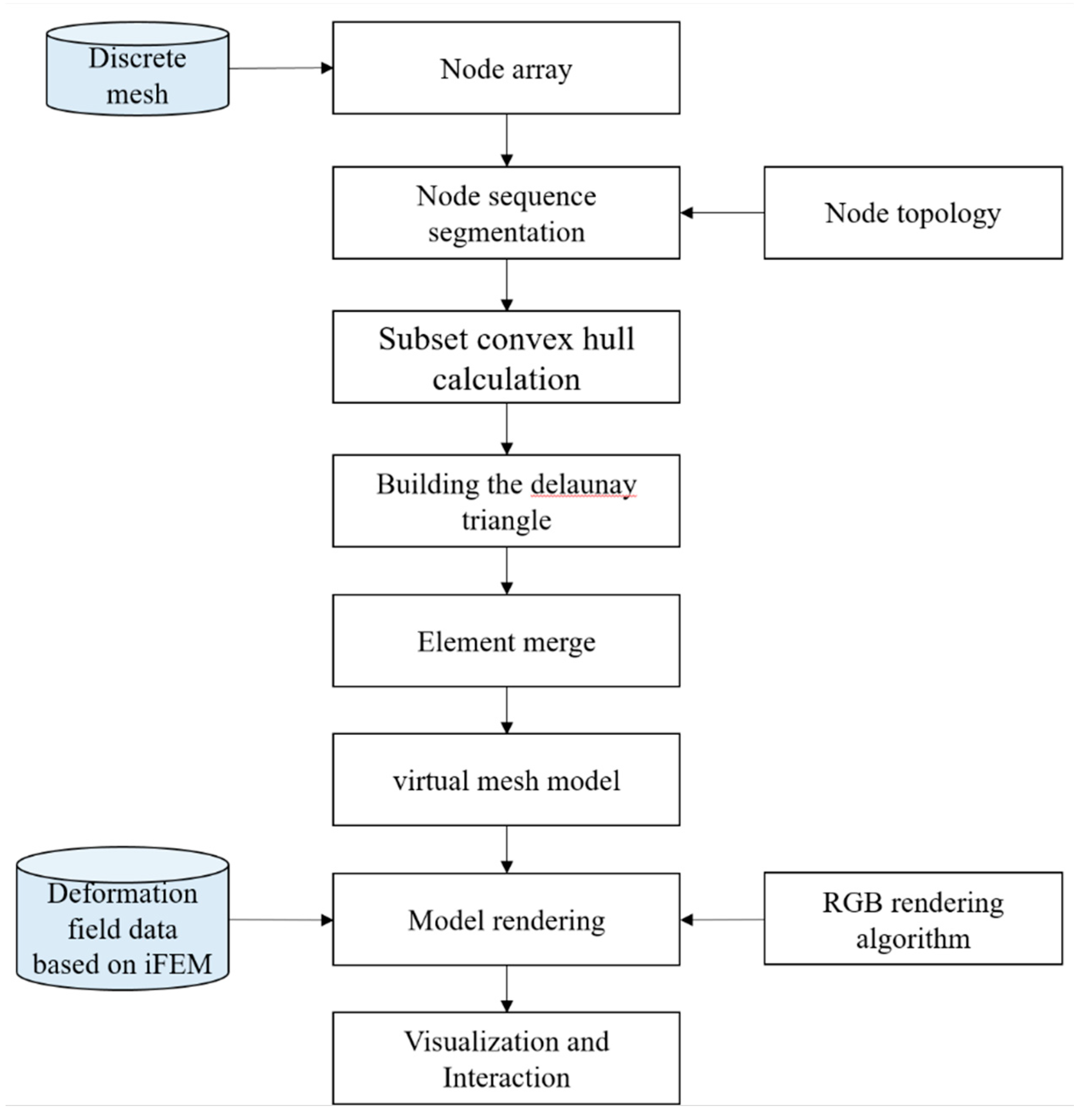

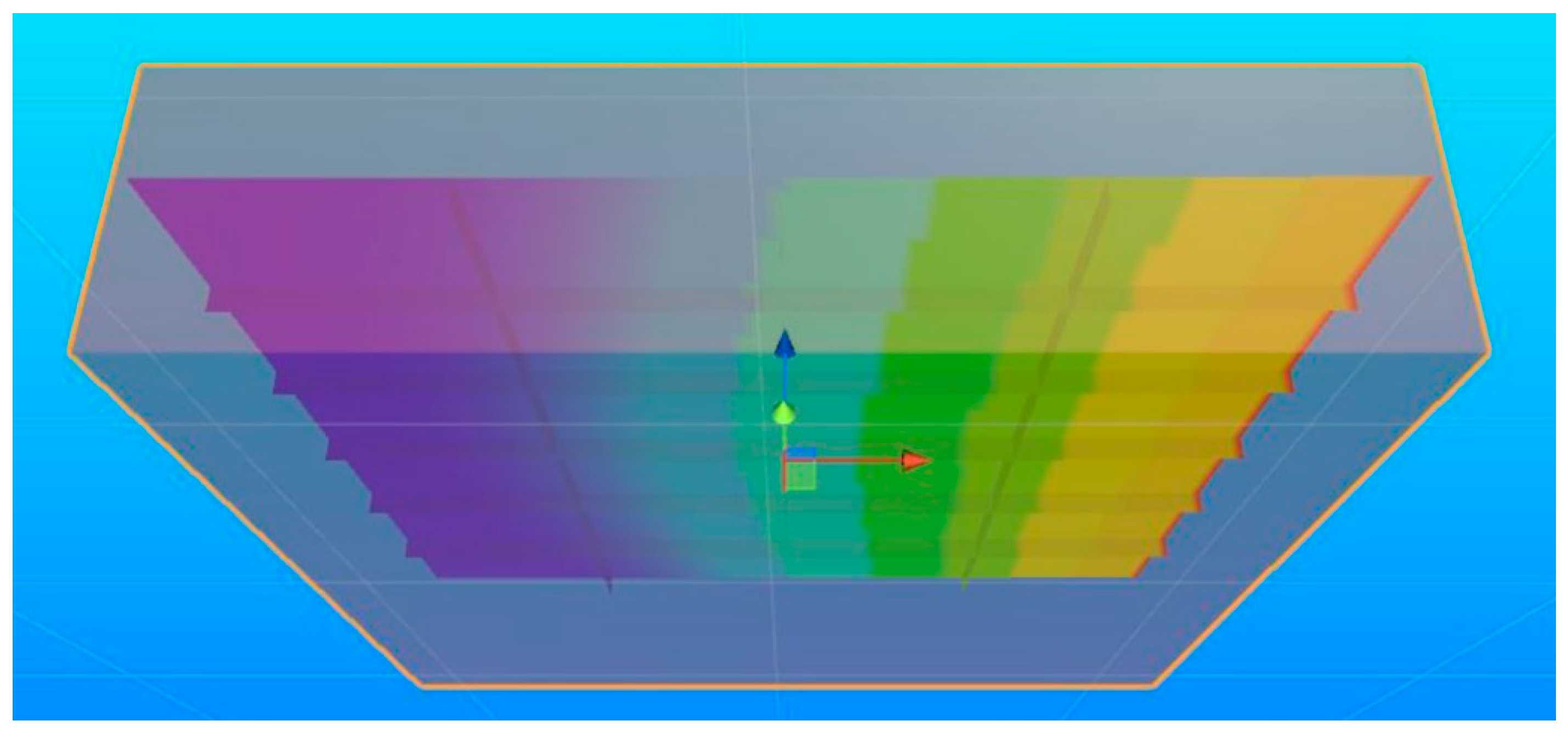

This study attempts to propose a VR-based visualization post-processing system for virtual visualization of strain field data, thereby enhancing the attention of engineering designers and managers to the structural change results. Among them, the developed workflows range from reading raw data to displaying visualizations in a virtual environment (VE). Hence, a virtual visualization framework is established, as shown in

Figure 6. The virtual visualization system consists of three modules, which are discrete mesh model reconstruction module, deformation field data processing module, and virtual interaction module. Through customized data interfaces between different modules, data interaction and management during system integration can be realized. The discrete mesh model reconstruction module primarily completes the reconstruction of the target structure in the virtual scene, laying the foundation for the visualization of the deformation field cloud diagram. The deformation field data processing module mainly completes reading and node assignment for deformation field data obtained by the IFEM algorithm. The virtual interaction module renders and interacts with the deformation field, and observes and evaluates the structure through various interactive methods such as segmentation, rotation, slicing, and extraction.

The process of visualizing discrete mesh model and deformation field data involves nodes, elements, vertex sequences, normal sequences, edge sequences, and texture sequences. Shareable models must minimize files while retaining necessary information. Since the Unity 3D platform does not support quad-mesh rendering, the meshing and reorganization algorithms are also embedded. Delaunay triangulation (DT) is the most common unstructured triangulation method in many applications [

42], which maximizes the minimum angle of any triangle [

43]. For large-scale models, the subdivision and reorganization algorithm is designed in parallel, and Python’s multi-processing module is used to call multiple processes to achieve full utilization of system resources. In the division, elements are evenly distributed among different processes, and their array intervals are calculated. During the reorganization process, data blocks are evenly distributed to different processes for sub-model reorganization, where each process reads the shared data without writing.

4. Conclusions

Powerful online monitoring technology serves as a pivotal catalyst for remote control centers, particularly when integrated with dynamic perception algorithms. Practical case studies demonstrate the potential of digital twins in augmenting the monitoring of ship structural mechanics characteristics. The utilization of immersive visualization simplifies the conveyance of the mechanical behavior and state of a structure, superseding traditional methods such as the exhibition of logs and diagrams or the triggering of alarms. The responsive interaction employed in this paper is actualized through a high-frequency data exchange communication system interfacing with the physical setup. A modular methodology is employed to link the deformation field monitoring system to the digital twin. The iFEM approach is used to acquire real-time, global field deformation information of the target structure, eschewing reliance solely on independent data from key discrete measurement points. On one hand, the integration of the iFEM algorithm facilitates rapid response to strain data, offering more flexibility compared to traditional time-consuming numerical simulations and enhancing the capabilities of the digital twin as a unified integrated system. On the other hand, the proposed immersive virtual visualization interaction scheme revolutionizes the exploration of structural mechanical behavior and enhances the workflow of virtual reality-supported decision-making. Unforeseen interactions may surface during the operation of distributed subsystems.

Drawing on our experience, promoting data exchange and interoperability has facilitated the construction of a synchronized motion response of the virtual assembly scene relative to the physical testing process. Effective communication of assumptions between test engineers, either through written software documentation or verbal directives, empowers operators to respond adeptly and diminish the likelihood of test failures. A significant theme for subsequent research involves investigating how to execute more complex application scenarios within the digital twin, with an ultimate aim to widen its scope to a more extensive digital architecture.