Submitted:

06 January 2024

Posted:

08 January 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

1.1. Engineering aspect

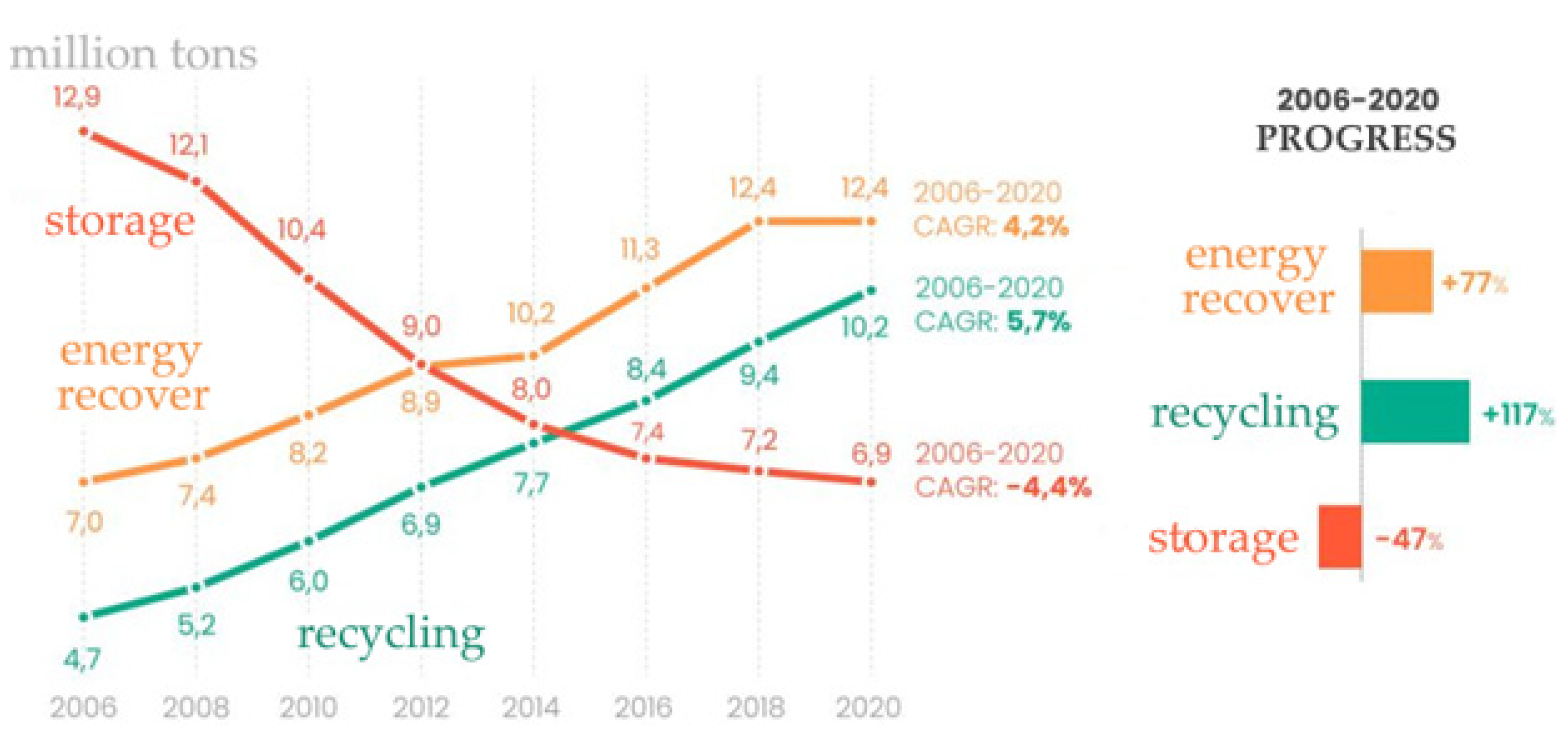

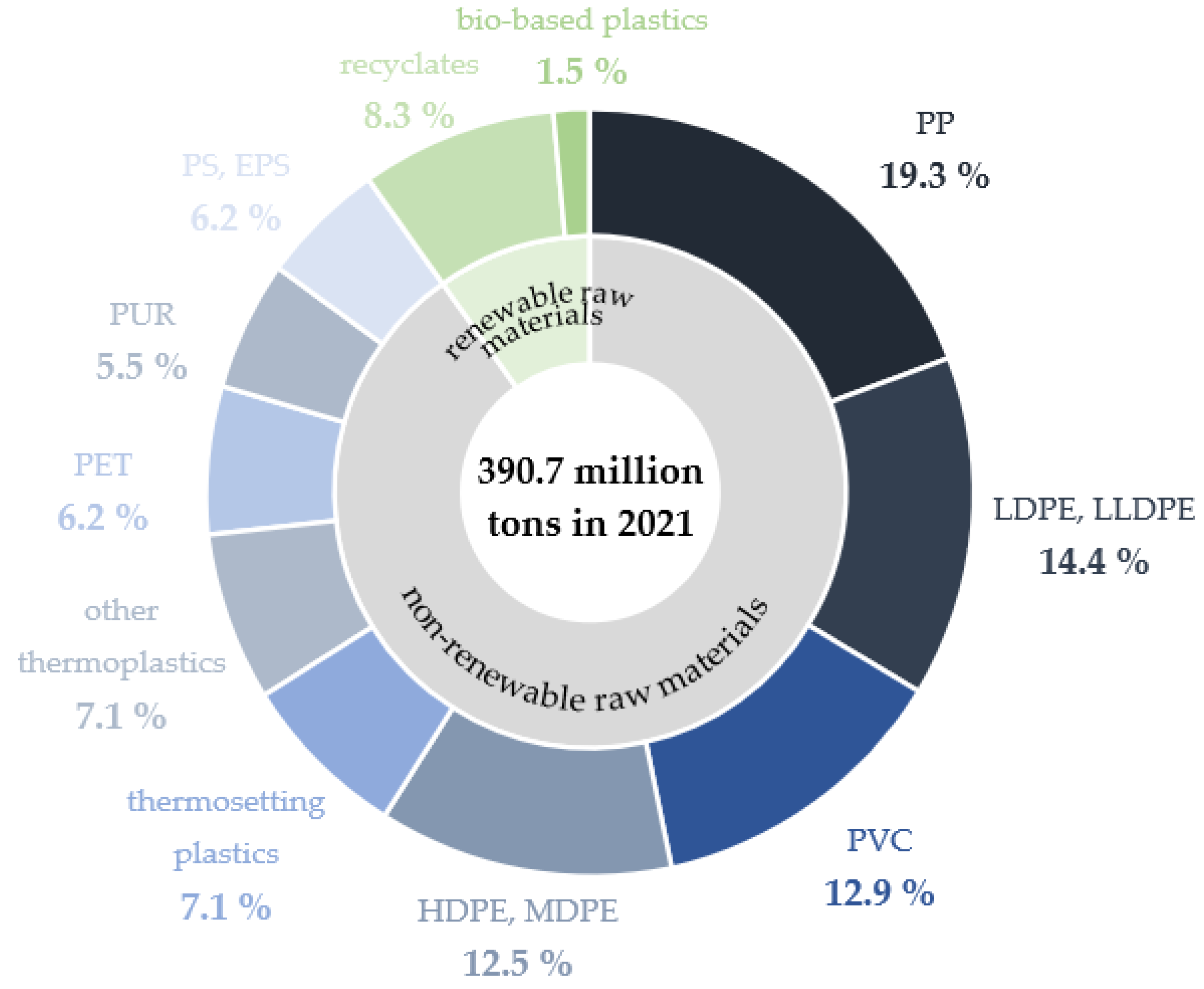

1.2. Environmental aspect

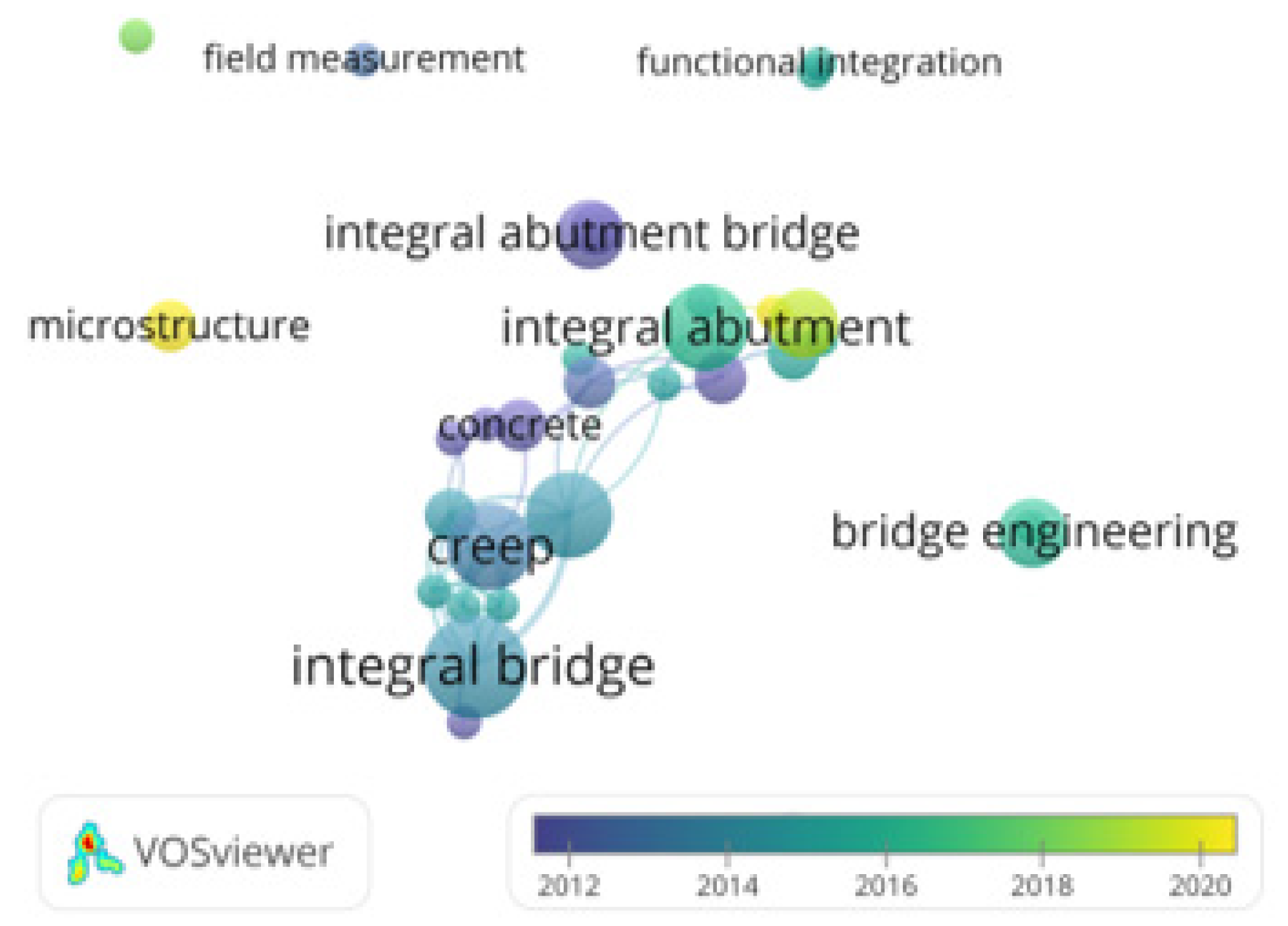

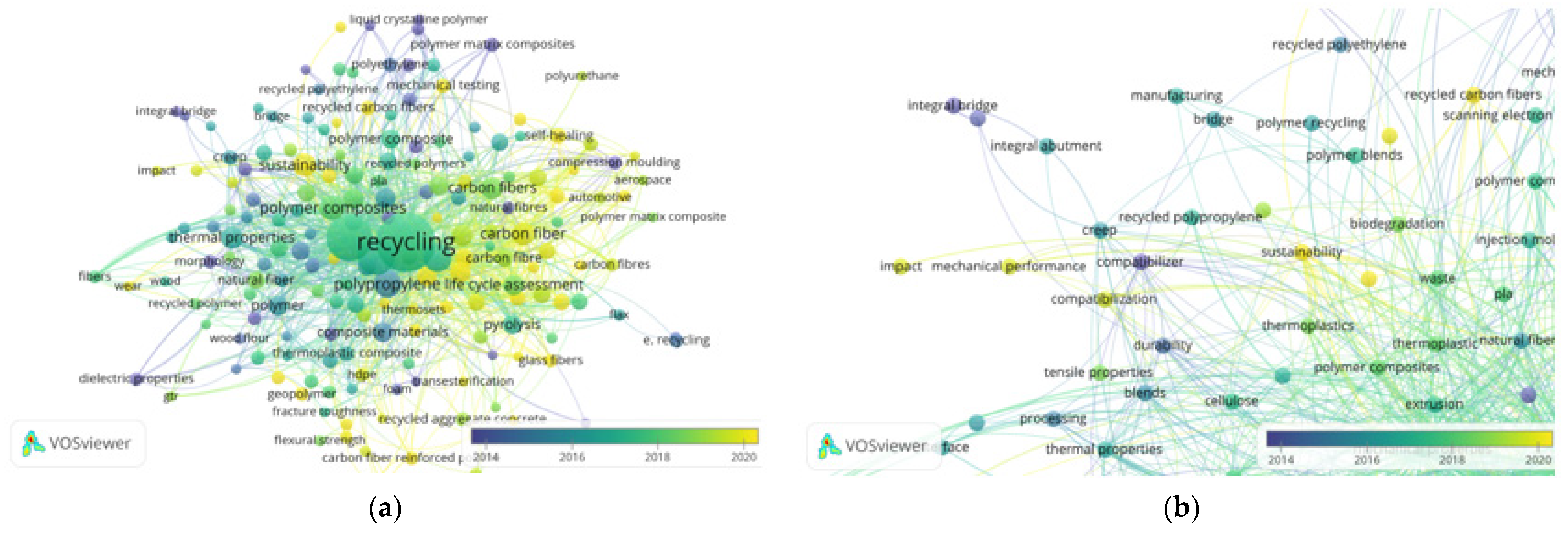

2. Keyword analysis

3. General purpose of research

4. Research area

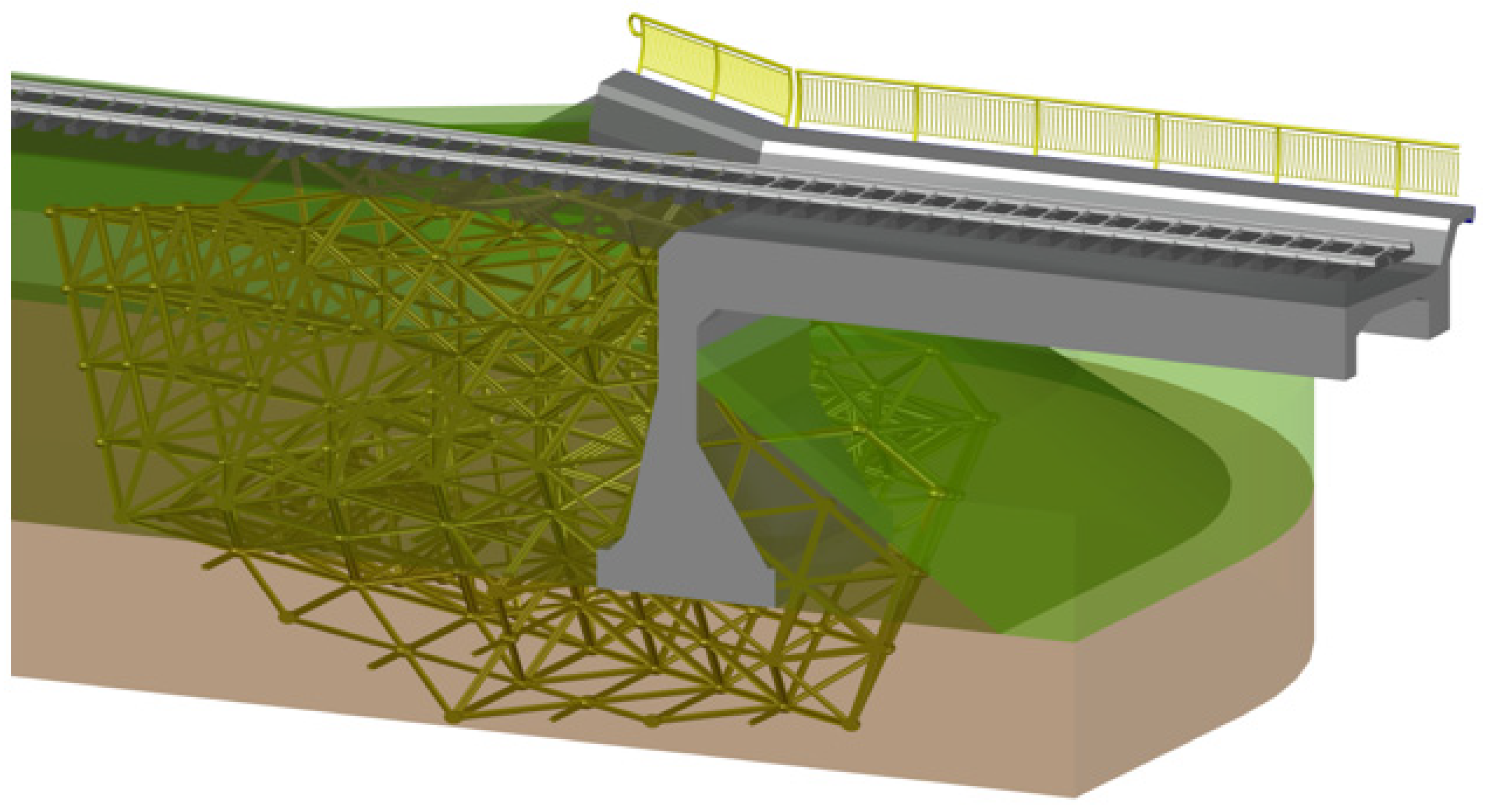

- Engineering Aspect: Current projects do not entirely solve the issue of stiffness discontinuity (flexibility) in the subgrade for linear structures approaching bridges. According to the authors, further progress supported by appropriately developed materials and the spatial structure of the joint construction will undoubtedly enrich contemporary bridge engineering with new design solutions that could reduce the transition effect. Introducing a new medium into the structure will affect the behavior of the structural abutment system and directly link it to the embankment. It will enhance load transfer through a complex structure onto different material centers and provide a smoother change in stiffness (flexibility) of the subgrade for linear structures.

- Environmental Aspect: The new material and its application area offer opportunities to utilize large amounts that accumulate in landfills or are incinerated. It is important to note that these materials could be reused (to be confirmed by planned future research). Due to their longevity anticipated in engineering constructions, the properties of processed waste will serve future generations. Pursuing the idea of sustainable development involves seeking applications for waste considered inefficient, difficult, or costly to process. This fact guarantees a constant demand for solutions enabling recycling.

5. Detailed overview related to the essence of the studies

5.1. Outline

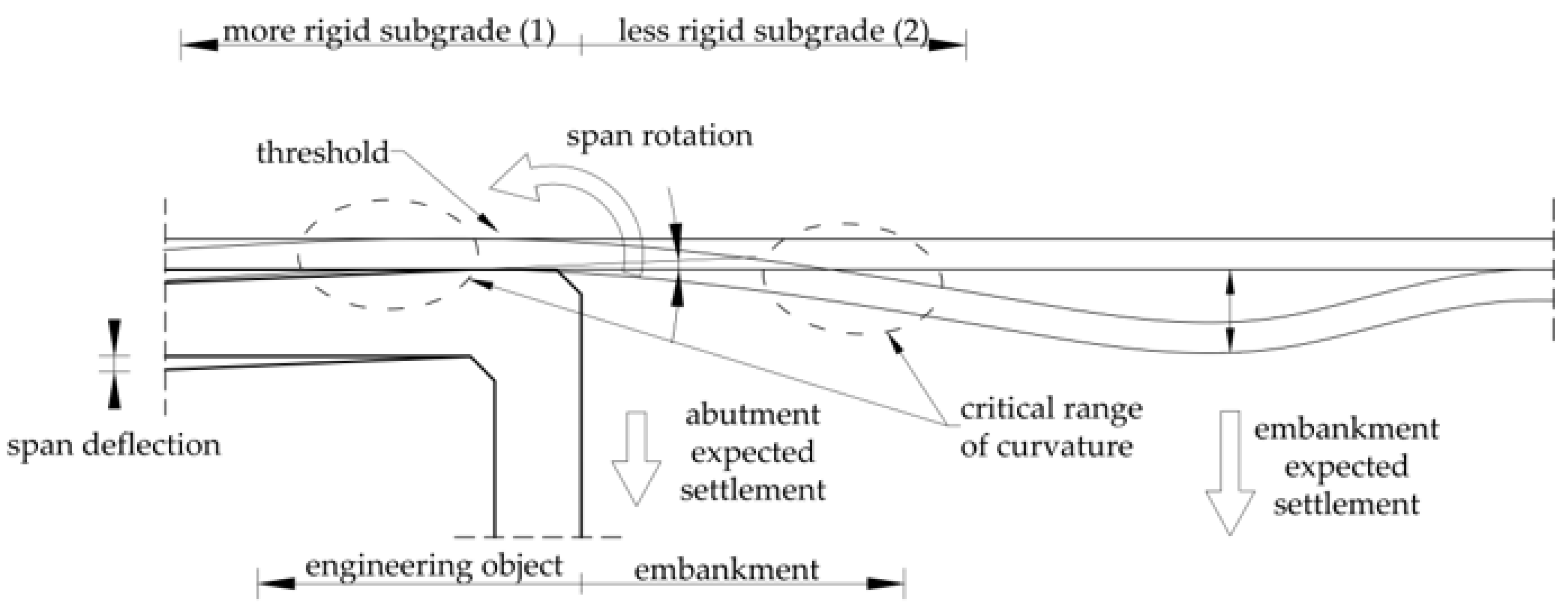

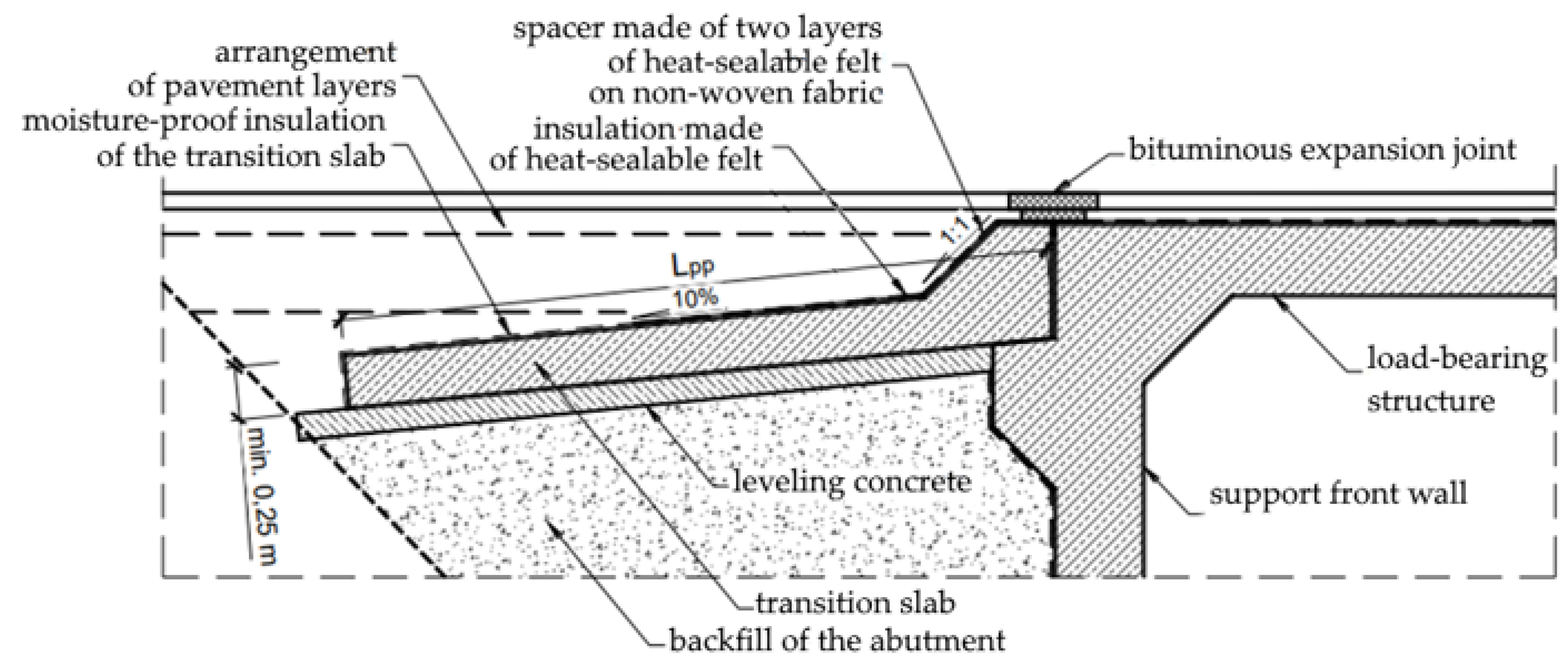

5.2. The importance of the connection between the abutment and the embankment in shaping the transition zone.

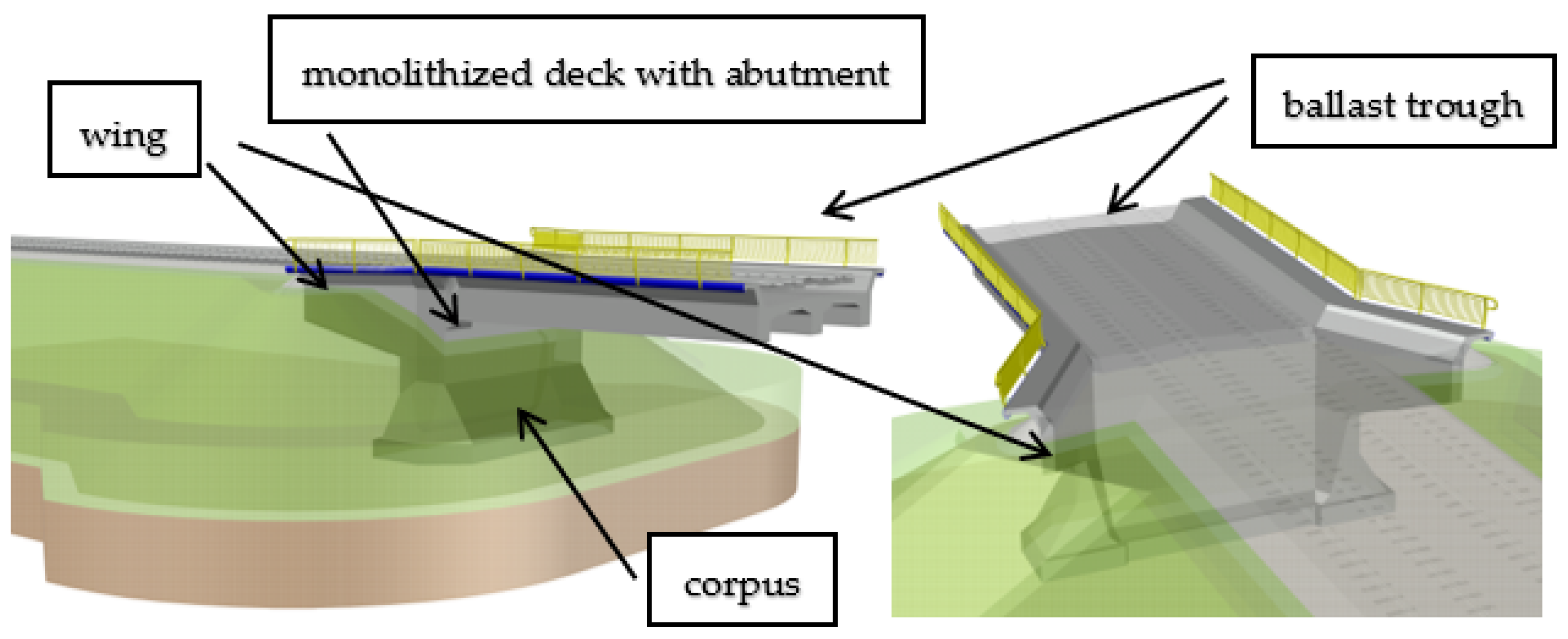

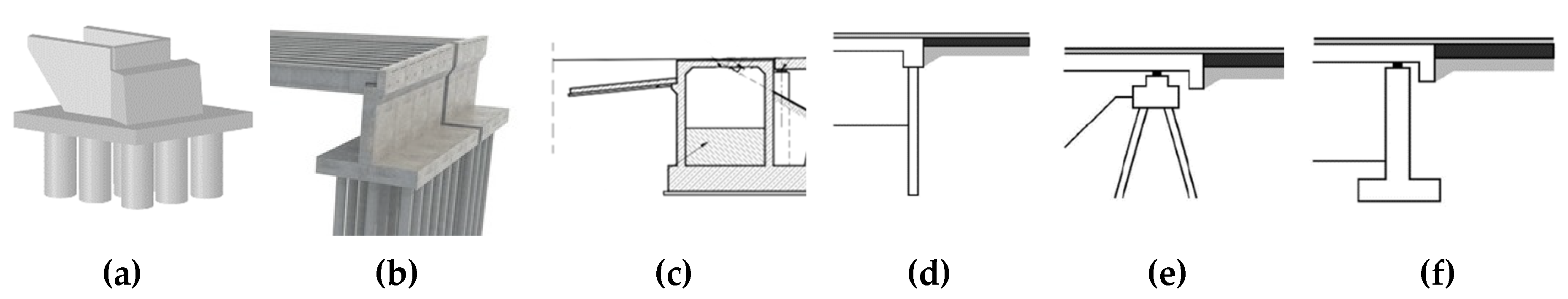

5.3. Integral bridges as a justified choice

5.4. Properties and use of polymers in bridge structures

5.4.1. Examples of polymers and their applications

5.4.2. Recycling polymers - use in bridge construction

5.4.3. Polymers in the construction of bridges and embankments

5.4.4. Polymers - use in reducing the transition effect

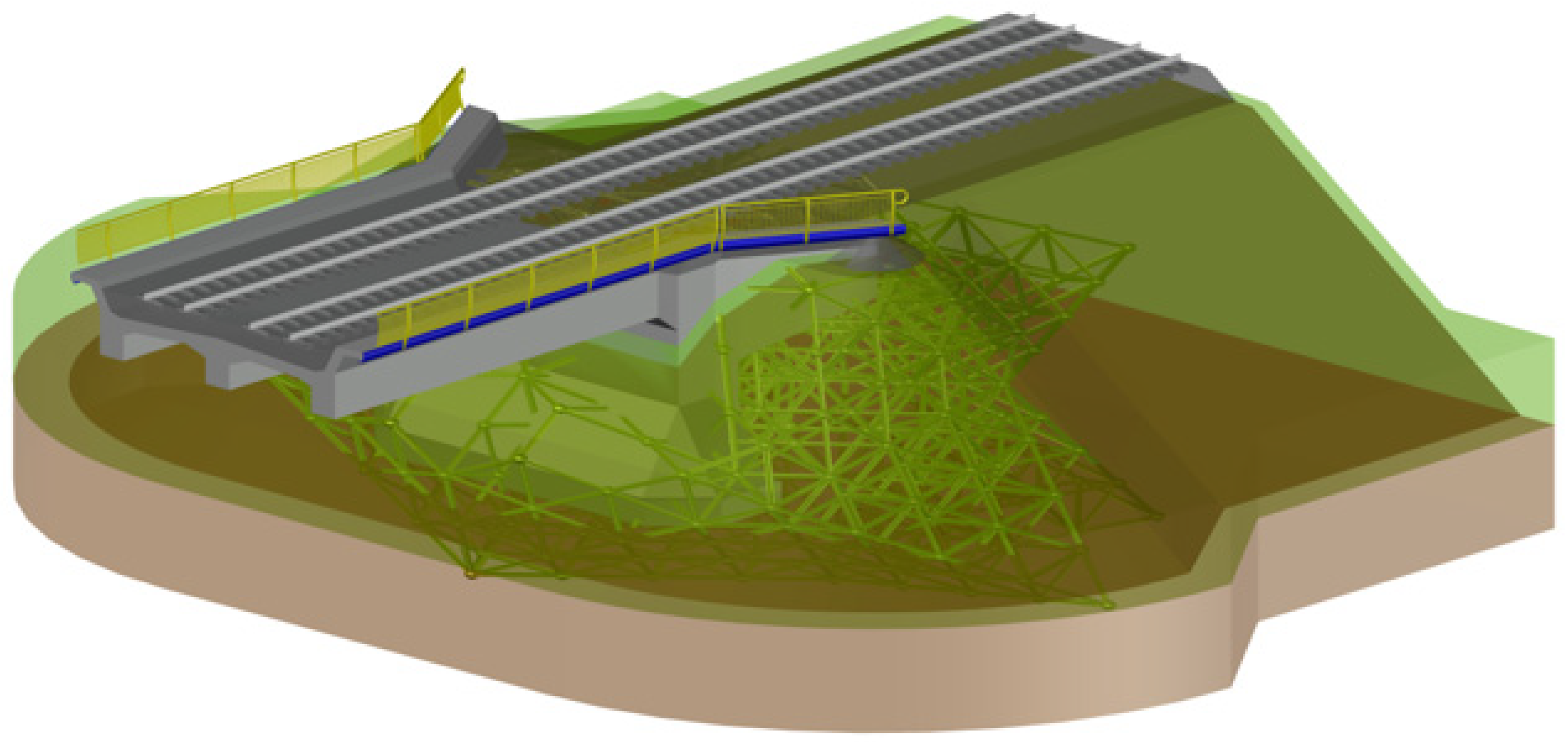

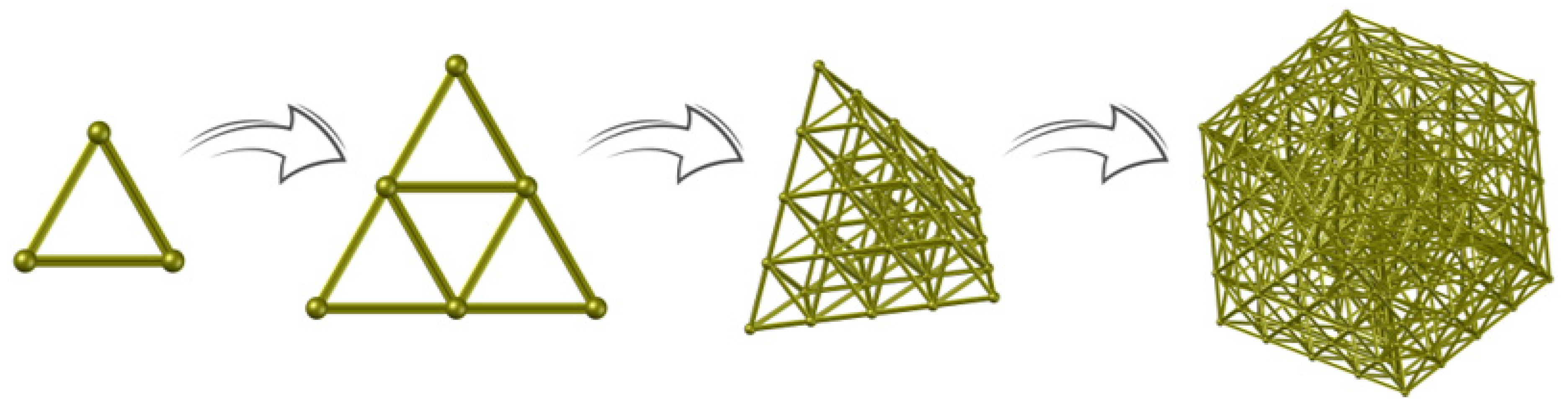

6. Description of the concept of reducing the transition effect using a spatial polymer bar structure

7. Future and perspectives

8. Research gaps

9. Summary

- It has been highlighted the relevance of the transition effect problem in bridge structures and the need for exploring new solutions. It has been proposed a solution related to integral bridges, allowing the avoidance of expansion joints and bearings, which positively impacts durability and maintenance costs. Transition slabs often do not completely eliminate this and may cause damage;

- It has been emphasized the importance of sustainable development, especially in the context of plastic waste management, drawing attention to the recycling potential in construction, the use of composite materials based on recyclables reinforced with fibers in bridge engineering, contributing to waste reduction and sustainable utilization of recycled materials;

- It has been Indicated that the possibility of using substitute materials, appropriately processed and shaped, might find application in bridge engineering, representing a cheaper and more ecological alternative to traditional solutions;

- It has been highlighted PET (polyethylene terephthalate) as having the best strength properties among waste plastics and exhibiting good capabilities for creating composites with fibers.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Sołkowski, J. Zarys analizy efektu progowego przy łączeniu nawierzchni podsypkowych z innymi typami nawierzchni. 2009; 12, 59–65. [Google Scholar]

- Sołkowski, J. Efekt progowy w nawierzchniach szynowych. Monografia 435. 2013. [Google Scholar]

- Cyunel, B.; Kulczycki, B. Kolejowe budowle ziemne, T. II–Technologia, organizacja budowy i modernizacji, 1987. [Google Scholar]

- Skrzyński, E. Osiadania podtorza gruntowego, Prace Instytutu Kolejnictwa, 2019, Zeszyt 161, 28–43.

- Bień, J. Uszkodzenia i diagnostyka obiektów mostowych, 2010.

- Vademecum Budownictwo Mostowe, 2016.

- Furtak, K.; Wrana, B. Mosty Zintegrowane, 2005.

- Musiał, T. Obiekty mostowe z przyczółkami zintegrowanymi, 2012.

- Steffen, M.; Chongjie, K. A new generation of integral high speed railway bridges, 2019, 11, 514–518.

- Capija, M.; Madaj, A. Mosty zintegrowane, 2008, 4, 81-83.

- Capija, M.; Madaj, A. Doświadczenia z projektowania i eksploatacji mostów zintegrowanych, 2010, 4, 50–53.

- Arsoy, S.; Barker, R. M.; Duncan, J. M. The behavior of integral abutment bridges, 1999.

- Burke, M. P Jr. Integral & Semi-Integral Bridges, 2009.

- Burke, M. P Jr. Integral Bridges, 1990.

- Jarosz, J. The effect of braking forces on displacement of integral bridges, 2013.

- Horvath, I.S. Integral-Abutment Bridges: Problems and Innovative Solutions Using EPS Geofoam and other Geosynthetics, 2000.

- Duszyńska, A. Zbrojenie geosyntetyczne podstawy nasypu, 2016.

- Jarosz, J. Experimental verification of numerical model of integral bridge, 2014, 3, 103–110.

- Sołkowski, J.; Kudła, D. Analiza niejednorodności mechanicznych nawierzchni i podtorza w obrębie obiektu mostowego. Zeszyty Naukowo-Techniczne SITK RP, Oddział w Krakowie 2016, 2, 165–175. [Google Scholar]

- Sasaoka, D. Track transition designs for heavy-axle-load service: analyses of track transition issues at bridge approaches, road crossings and special track work find ways to minimize track stiffness and maximize maintenance dollars. TTCI R&D. Railway Track and Structures, 1 April 2006. [Google Scholar]

- Kłosiński, B.; Niemierko, A. ERRI D 230.1/RP 3: Bridge Ends. Embankment Structure Transition, State of the Art Report, Utrecht. November 1999. [Google Scholar]

- Kłosiński, B.; Niemierko, A. Wzmacnianie stref przejściowych na dojazdach do mostów kolejowych. Archiwum Instytutu Inżynierii Lądowej 2012, 4. [Google Scholar]

- Alves, A.C.; Calcada, R.; Delgado, R. Dynamic effects induced by abrupt changes in track stiffness in high speed lines. Applications of Comp. Mech. in Geotechnical engineering - Sousa, 2007; 473–483. [Google Scholar]

- ČD S4 Železnični spodek - Přechodtělesażelezničního spodku na mostníobjekty, Příloha 24, 1998.

- Davis, D.D. Bridge approach performance in revenue service. Railway Track and Structures, Dec. 2003, pp. 18-20.

- Davis, D.; Plotkin, D. Track settlement at bridge approaches: what causestrack settlement at bridge approaches and how can railroad engineering departments deal with the problem safely and efficiently? Railway Track and Structures, February 1 2009.

- Diaz, A. La construcción de terraplenes y desmontes. Fundación de los Ferrocarriles Espanoles, 1993. [Google Scholar]

- Eisenmann, J. Dűrchfűrung von Dauerschwellversuchen an einer Űbergangkonstruktion. Technische UniversitatMűnchen, 1985-1990, (raport z badań).

- Raport Banku Światowego „What a Waste 2.0: A Global Snapshot of Solid Waste Management to 2050”.

- Dane statystyczne Eurostat 2021.

- Dane statystyczne GUS 2021.

- Dane statystyczne Organizacji UNESCO 2022.

- Dane statystyczne Fundacji PlasticsEurope 2022.

- Raport Fundacji Plastik Europe z 2022 „Reshaping Plastics: pathways to a circular, climate neutral plastics system in Europe”.

- Company research data Conversio Market & Strategy GmbH.

- Raport Fundacji Plastik Europe z 2021 „Tworzywa w obiegu zamkniętym”.

- Arkenbout, A. Hidden emissions: A story from the Netherlands Case Study, Zero Waste Europe, 2018.

- Dane statystyczne Organizacji Zero Waste Europe.

- Dane statystyczne Banku Światowego 2021.

- Geyer, R.; Jambeck, J.R.; Law, K.L. Production, use, and fate of all plastics ever made. Sci. Adv. 2017, 3, e170078. [Google Scholar] [CrossRef]

- Marine Pollution Bulletin, The Guardian, WWF, Santa Barbara Marine Conservancy.

- Ragaert, K.; Lauren, D.; Geem, K.V. Mechanical and chemical recycling of solid plastic waste. Waste Management, 2017, 69, 24–58. [Google Scholar] [CrossRef]

- European Parliament | Plastic waste and recycling in the EU: facts and figures. Available online: https://www.europarl.europa.eu/news/en/headlines/society/20181212STO21610/plastic-waste-and-recycling-in-the-eu-facts-and-figures (accessed on 20 November 2023).

- Raport końcowy: Badanie ewaluacyjne, pn. „Recykling wyeksploatowanych komponentów technicznych odnawialnych źródeł energii oraz akumulatorów pojazdów elektrycznych jako element transformacji w kierunku gospodarki o obiegu zamkniętym”, Wroconsult Sp. z o.o. oraz Ekovert Łukasz Szkudlarek na zlecenie Ministerstwa Energii.

- Drozdowski, W. Łopaty turbin wiatrowych najtrudniejsze do recyklingu, Centrum Informacji o Rynku Energii 2020. Available online: https://www.cire.pl/artykuly/opinie/155372-lopaty-turbin-wiatrowych-najtrudniejsze-do-recyklingu (accessed on 20 November 2023).

- Wronka, K. Pełny recykling łopat turbin wiatrowych - przyszłość czy złudna nadzieja?, Centrum Informacji o Rynku Energii 2022. Available online: https://www.cire.pl/artykuly/brak-kategorii/pelny-recykling-lopat-turbin-wiatrowych---przyszlosc-czy-zludna-nadzieja (accessed on 20 November 2023).

- Abdallah, R.; Juaidi, A. ; Savas ̧, M.A.; Çamur, H.; Albatayneh, A.; Abdala, S.; Manzano-Agugliaro, F. A Critical Review on Recycling Composite Waste Using Pyrolysis for Sustainable Development. Energies 2021, 14, 5748. [Google Scholar] [CrossRef]

- Albers, H. Recycling of wind turbine rotor blades–fact or fiction? DEWI Mag 2009, 34, 32–41. [Google Scholar]

- Dannemand Andersen, P.; Borup, M.; Krogh, T. Managing long-term environmental aspects of wind turbines: a prospective case study’, Int. J. Technology, Policy and Management 2007, 7, 339–354. [Google Scholar]

- Liu, P.; Barlow, C.Y. Wind turbine blade waste in 2050. Waste Manag 2017, 62, 229–240. [Google Scholar] [CrossRef] [PubMed]

- Liu, P.; Meng, F.; Barlow, C. Wind turbine blade end-of-life options: an eco-audit comparison. J. Clean. Prod. 2019, 212, 1268–1281. [Google Scholar] [CrossRef]

- Lefeuvre, A.; Garnier, S.; Jacquemin, L.; Pillain, B.; Sonnemann, G. Anticipating in-use stocks of carbon fibre reinforced polymers and related waste generated by the wind power sector until 2050. Resour. Conserv. Recycl. 2019, 141, 30–39. [Google Scholar] [CrossRef]

- Urząd Regulacji Energetyki | Moc zainstalowana MW stan na 31.12.2020. Available online: https://www.ure.gov.pl/pl/oze/potencjal-krajowy-oze/5753,Moc-zainstalowana-MW.html (accessed on 20 November 2023).

- WindEurope | Wind energy in Europe 2020 Statistics and the outlook for 2021-2025. Available online: https://windeurope.org/intelligence-platform/product/wind-energy-in-europe-in-2020-trends-and-statistics/ (accessed on 20 November 2023).

- Ziegler, L.; Gonzalez, E.; Rubert, T.; Smolka, U.; Melero, J.J. Lifetime extension of onshore wind turbines: a review covering Germany, Spain, Denmark, and the UK. Renew. Sustain. Energy Rev. 2018, 82, 1261–1271. [Google Scholar] [CrossRef]

- Ziegler, L.; Muskulus, M. In Proceedings of the Lifetime extension of offshore wind monopolies: Assessment process and relevance of fatigue crack inspection. EAWE PhD Seminar on Wind Energy in Europe, Location of DTU Lyngby, Denmark, May 2016. [Google Scholar]

- Perron, B.E.; Victor, B.G.; Hodge, D.R.; Salas-Wright, C.P.; Vaughn, M.G.; Taylor, R.J. Laying the foundations for scientometric research: A data science approach. Res. Soc. Work. Pract. 2017, 27, 802–812. [Google Scholar] [CrossRef]

- Zitt, M.; Bassecoulard, E. Challenges for scientometric indicators: Data demining, knowledge-flow measurements and diversity issues. Ethics Sci. Environ. Politics, 2008, 8, 49–60. [Google Scholar] [CrossRef]

- Singh, V.K.; Banshal, S.K.; Singhal, K.; Uddin, A. Scientometric mapping of research on ‘Big Data’. Scientometrics, 2015, 105, 727–741. [Google Scholar] [CrossRef]

- Gile, D. Analyzing translation studies with scientometric data: From CIRIN to citation analysis. Perspectives 2015, 23, 240–248. [Google Scholar] [CrossRef]

- Falagas, M.E.; Pitsouni, E.I.; Malietzis, G.A.; Pappas, G. Comparison of PubMed, Scopus, web of science, and Google scholar: Strengths and weaknesses. FASEB J. 2008, 22, 338–342. [Google Scholar] [CrossRef]

- Vieira, E.; Gomes, J. A comparison of Scopus and Web of Science for a typical university. Scientometrics 2009, 81, 587–600. [Google Scholar] [CrossRef]

- Scopus | Abstract and citation database. Available online: https://www.elsevier.com/products/scopus/ (accessed on 20 November 2023).

- Web of Science Coverage Details - Resources for Librarians. Available online: https://clarivate.libguides.com/librarianresources/coverage/ (accessed on 20 November 2023).

- Visualising Scientific Landscapes. Available online: https://www.vosviewer.com/ (accessed on 20 January 2023).

- Rymsza, J.; Biliszczuk, J.; Onysyk, J.; Toczkiewicz, R. Wytyczne projektowania elementów powiązania drogowych obiektów inżynierskich z terenem i drogą. Wzorce i standardy rekomendowane przez Ministra właściwego ds. transportu. 2020.

- Standardy techniczne–szczegółowe warunki techniczne dla modernizacji lub budowy linii kolejowych 2018-2023.

- Binder, K. Strefa przejściowa pomiędzy obiektem mostowym a nasypem drogowym. Mosty 2012, 4, 55–57. [Google Scholar]

- Hebda, M. Materiały dydaktyczne–Utrzymanie i remonty mostów. Politechnika Krakowska, Wydział Inżynierii Lądowej 2020.

- Krupka, J.; Sobala, D. Stan techniczny mostów zintegrowanych na przykładzie wybranych obiektów w Polsce. 2015.

- Germaniuk, K; Damage on the pavement of bridges and on the connection of the road to the bridge. Materiały Budowlane 2017, 4, 80–83.

- Dreier, D.; Burdet, O.; Muttonio, A. Transition Slabs of Integral Abutment Bridges. Structural Engineering International 2011, 2, 144–150. [Google Scholar] [CrossRef]

- Bukowski, M.; Łysiak, P.; Oleszek, R.; Trochymiak, W. Reasons of emergence of differences in soil settlement between the viaduct and the embankment on Siekierkowska route. Archiwum Instytutu Inżynierii Lądowej 2017, 24, 39–58. [Google Scholar] [CrossRef]

- Wang, H.; Chang, L.; Markine. V. Structural Health Monitoring of Railway Transition Zones Using Satellite Radar Data. Sensors (Basel) 2018, 18, 413. [Google Scholar] [CrossRef]

- Sołkowski, J.; Kudła, D. Wykonawstwo stref przejściowych do obiektów mostowych i aspekty modelowania numerycznego oddziaływania pojazd-nawierzchnia-podtorze. Konferencja Drogi Kolejowe 2013, Krynica, Poland, 23-25 października 2013.

- Sołkowski, J.; Jamka, M. Deformation of pavement and subgrade at the bridges - research and diagnostics. Przegląd Komunikacyjny 2016, 4, 39–47. [Google Scholar]

- Zuada Coelho B., Ph.D. Thesis. Delft University of Technology; Delft, The Netherlands: 2011. Dynamics of Railway Transition Zones in Soft Soils.

- Nicks, J.E. Ph.D. Thesis. Texas A&M University; College Station, TX, USA: 2009. The Bump at the End of the Railway Bridge.

- Li, D.; Davis, D. Transition of Railroad Bridge Approaches. J. Geotech. Geoenviron. Eng. 2005. [CrossRef]

- Esveld, C. Modern Railway Track. MRT-Productions; Zaltbommel, The Netherlands: 2001.

- Lundqvist, A.; Larsson, R.; Dahlberg, T. Influence of Railway Track Stiffness Variations on Wheel/Rail Contact Force. Track for High-Speed Railways; Porto, Portugal: 2006.

- Banimahd, M.; Woodward, P.K.; Kennedy, J.; Medero, G.M. ; Behaviour of train–track interaction in stiffness transitions. Proc. ICE Transp. 2012, 165, 205–214. [Google Scholar] [CrossRef]

- Gwizdała, K. Nowy Eurokod 7 w projektowaniu posadowień obiektów mostowych na palach. Mosty 2022, 3. [Google Scholar]

- Kerr, A.D.; Moroney, B.E. Track Transition Problems and Remedies. Volume 94. American Railway Engineering Association; Landover, MD, USA: 1993. p. 25.

- Sañudo, R.; dell’Olio, L. , Casado J.A., Carrascal I.A., Diego S. Track transitions in railways: A review. Constr. Build. Mater. 2016, 112, 140–157. [Google Scholar] [CrossRef]

- Sołkowski, J.; Lisowski, S.; Pawlak-Burakowska, A.; Jamka, M. Zarys metodyki badania sztywności nawierzchni i podtorza w strefach przejściowych do obiektów inżynierskich oraz na obiektach. Zeszyty Naukowo-Techniczne SITK RP, Oddział w Krakowie, 2012; 3, 285–309. [Google Scholar]

- Hunt, H.E.M. Settlement of railway track near bridge abutment. Proc. Instn Civ. Engrs, Transp., 1997, 123, 68–73. [Google Scholar]

- Jaup, A.; Kempfert, H.G. Setzungen in Hinterfüllungsbereich von Eisenbahn-brückenwiederlagern. Bautechnik 2001, 9, 635–640. [Google Scholar] [CrossRef]

- Indraratna, B.; Sajjad, M.B.; Ngo, T.; Correia, A.G.; Kelly, R. Improved performance of ballasted tracks at transition zones: A review of experimental and modelling approaches. Transportation Geotechnics 2019, 21. [Google Scholar] [CrossRef]

- Sakhare, A.; Farooq, H.; Nimbalkar, S.; Dodagoudar, G.R. Dynamic Behavior of the Transition Zone of an Integral Abutment Bridge. Sustainability (Switzerland) 2022, 14, 4118. [Google Scholar] [CrossRef]

- Frohling, R.D.; Scheffel, H.; Ebersöhn, W. The Vertical Dynamic Response of a Rail Vehicle Caused by Track Stiffness Variations along the Track. Veh. Syst. Dyn. 1996, 25 (Suppl. S1), 175–187. [Google Scholar] [CrossRef]

- Connolly, D.P.; Kouroussis, G.; Woodward, P.K.; Alves Costa, P.; Verlinden, O.; Forde, M.C. Field testing and analysis of high speed rail vibrations. Soil Dynamics and Earthquake Engineering 2014, 67, 102–118. [Google Scholar] [CrossRef]

- Connolly, D.P.; Kouroussis, G.; Fan, W.; Percival, M.; Giannopoulos, A.; Woodward, P.K.; Verlinden, O.; Forde, M.C. An experimental analysis of embankment vibrations due to high speed rail. 12th International Railway Engineering Conference (Railway Engineering 2013), London, United Kingdom, July 2013.

- Kouroussis, G.; Connolly, D.P.; O. ; Forde, M.C.; Verlinden, O. An experimental study of embankment conditions on high-speed railway ground vibrations. 20th International Congress on Sound and Vibration (ICSV20), Bangkok, Thailand, July 2013. Kouroussis, G.; Connolly, D.P.; Forde, M.C.; Verlinden, O. Train speed calculation using ground vibrations. Proceedings of the Institution of Mechanical Engineers Part F Journal of Rail and Rapid Transit 2015, 229, 466–483. [Google Scholar]

- Connolly, D.P.; Giannopoulos, A.; Forde, M.C. Numerical modelling of ground borne vibrations from high speed rail lines on embankments. Soil Dynamics and Earthquake Engineering 2013, 46, 13–19. [Google Scholar] [CrossRef]

- Grulkowski, S.; Kędra, Z.; Koc, W.; Nowakowski, M.J. Drogi szynowe. Wydawnictwo Politechniki gdańskiej 2016, Gdańsk, Poland.

- Bednarek, W. Static analysis of chosen imperfections of rail subgrade on additional rail deflection of jointless track. Przegląd komunikacyjny 2016, 11, 20–26.

- Kłosek, K.; Sołkowski, J.; Tondera, M. Ocena nośności i stateczności podtorza zgodnie z wymaganiami krajowymi oraz Eurokodu PN-EN 1991:2. Zeszyty Naukowo-Techniczne SITK RP, Oddział w Krakowie 2019, 2, 93–107. [Google Scholar]

- Rychlewski, P. Przemieszczenia fundamentów obiektów inżynierskich. Inżynier Budownictwa, 2017. [Google Scholar]

- Waniek, G.; Kwiecień, S. Analiza współpracy przyczółka mostowego z nasypem drogowym na podłożu gruntowym o małej sztywności. Drogownictwo 2015, 9, 302–305. [Google Scholar]

- England, G.; Tsang, N.; Bush, D. Integral bridges. A fundamental approach to the time-temperature loading problem. Imperial College. Highways Agency. Thomas Telford Ltd., February, 2000.

- Pisarczyk, S. Geoinżynieria. Metody modyfikacji podłoża gruntowego. Oficyna Wydawnicza Politechniki Warszawskiej 2005, Warsaw, Poland.

- Łęcki, P.; Różański, M. Wzmacnianie podłoża gruntowego budowli drogowych. Nowoczesne Budownictwo Inżynieryjne, 2015. [Google Scholar]

- Khayyer, F.; Esmaeili, M. ; Gharouni Nik; M. Static and Dynamic Analyses of Micropiles to Reinforce the High Railway Embankments on Loose Beds. 2016.

- Gajewska, B.; Kłosiński, B.; Rychlewski, P.; Grzegorzewicz, K. Zastosowanie geosyntetyków w budowlach ziemnych. Studium poznawczo-techniczne, Warszawa, 2003.

- Ajdukiewicz, J. Strome nasypy drogowe zbrojone geosyntetykami efektem wyspecjalizowanych prac inżynierskich. Zeszyty Naukowe Politechniki Śląskiej, z. 97, 2003.

- Wesołowski, A.; Krzywosz, Z.; Brandyk, T. Geosyntetyki w konstrukcjach inżynierskich. Wydawnictwo SGGW, Warszawa 2000.

- Wysokoński, L.; Kotlicki, W. Projektowanie konstrukcji oporowych, stromych skarp i nasypów z gruntu zbrojnego geosyntetykami. Wydawnictwo ITB. Instrukcja 429/2007.

- Holtz, R.; Christopher, B.; Berg, R. Geosynthetic Engineering, BiTech Publish Ltd, Canada, 1997.

- Jewell, R.A. Soil reinforcement with geotextiles, SP 123, CIRIA, 1996.

- Kawalec, J. ; Stabilizacja podłoża z wykorzystaniem georusztów. IMiG 2010, 4. [Google Scholar]

- Koerner, R. : Design with Geosythetics, Pretince Hall, USA, 1994.

- Duszyńska, A.; Bolt, A. F. Współpraca georusztu i gruntu w badaniu na wyciąganie. Monografia, Gdańsk 2004.

- Duszyńska, A. Co warto wiedzieć o geosyntetykach. Inżynieria Morska i Geotechnika 2010, 2. [Google Scholar]

- Duszyńska, A. , Szypulski P. (2012): Wymiarowanie wzmocnienia geosyntetycznego podstawy nasypu na słabym podłożu. Inżynieria Morska i Geotechnika 2012, 3. [Google Scholar]

- Duszyńska, A. , Makasewicz-Dzieciniak M. Nasyp z geosyntetycznym wzmocnieniem podstawy posadowiony na pionowych elementach nośnych. Inżynieria Morska i Geotechnika 2013, 3. [Google Scholar]

- Duszyńska, A.; Szypulski, P. Projektowanie nasypów komunikacyjnych ze zbrojeniem geosyntetycznym podstawy na słabym podłożu gruntowym. Przegląd Komunikacyjny 2014, 5. [Google Scholar]

- Duszyńska, A. , Sikora Z. (2014): Dobór wyrobów geosyntetycznych do zbrojenia gruntu. Inżynieria Morska i Geotechnika 2014, 5. [Google Scholar]

- Duszyńska, A. Stateczność nasypów drogowych ze wzmocnieniem geosyntetycznym. Inżynieria i Budownictwo 2014, 5. [Google Scholar]

- Nabochenko, O.; Sysyn, M.; Gerber, U.; Krumnow, N. Analysis of Track Bending Stiffness and Loading Distribution Effect in Rail Support by Application of Bending Reinforcement Methods. Urban Rail Transit 2023, 9, 73–91. [Google Scholar] [CrossRef]

- Shang, Y.; Nogal, M.; Teixeira, R.; Wolfert, A.R. (Rogier) M. Optimal design of rail level crossings and associated transition zones using adaptive surrogate-assisted optimization. Engineering Structures 2023, 282. [Google Scholar] [CrossRef]

- Brown, D. Bridges: Three Thousand Years of Defying Nature; Firefly Books, 2005; 1-208.

- Troyano, L.F. Bridge Engineering: A global perspective; Thomas Telford, 2003; 1-775.

- Leonhardt, F. Bridges: Aesthetics and Design, Bilingual Edition; Mit Pr, 1984; 1-308.

- Duan, L.; Chen, W.F. Bridge Engineering: Substructure Design (Principles and Applications in Engineering), 1st ed; 2007; 1-272.

- Bennett, D. Creation of Bridges: From Vision To Reality - The Ultimate Challenge Of Architecture, Design, and Distance, 1 st ed; Diane Pub Co, 1999; 1-232.

- National Research Council, Bridge Aesthetics Around the World, Transportation Research Board, 1991; 1-276.

- Arockiasamy, M.; Butrieng, N.; Sivakumar, M. State-of-the-art of integral abutment bridges: design and practice. J Bridge Eng 2004, 9, 497–506. [Google Scholar] [CrossRef]

- Madaj, A.; Wołowicki, W. Podstawy projektowania budowli mostowych. WKiŁ 2008, Warsaw, Poland.

- Gutkowski, R.M. Transportation infrastructure: environmental challenges in Poland and neighboring countries, 1st ed; Springer, 1996; Berlin, Heidelberg, Germany.

- Dicleli. M. Chapter 16 - Integral bridges. In Innovative Bridge Design Handbook; 2016; 429–450.

- Mitoulis, S.A. Challenges and opportunities for the application of integral abutment bridges in earthquake-prone areas: A review. Soil Dynamics and Earthquake Engineering 2020, 135. [Google Scholar] [CrossRef]

- Mitoulis, S.A.; Argyroudis, S.A.; Kowalsky, M. Evaluation of the stiffness and damping of abutments to extend direct displacement-based design to the design of integral bridges. In COMPDYN 2015, Kreta, Greece, May 2015.

- Naji, M.; Firoozi, A.A.; Firoozi, A.A. A Review: Study of Integral Abutment Bridge with Consideration of Soil-Structure Interaction. Lat. Am. j. solids struct. 2020, 17. [Google Scholar] [CrossRef]

- di Prisco, M.; Meda, A.; Balazs, G.L. Document details - A pushover method for seismic design of Integral Abutment Bridges. fib. The International Federation for Structural Concrete 2022, 449–457. [Google Scholar]

- Fiorentino, G.; Cengiz, C.; De Luca, F.; Mylonakis, G.; Karamitros, D.; Dietz, M.; Dihoru, L.; Lavorato, D.; Briseghella, B.; Isakovic, T.; Vrettos, C.; Topa Gomes, A.; Sextos, A.; Nuti, C. Integral abutment bridges: Investigation of seismic soil-structure interaction effects by shaking table testing. Earthquake Engng Struct Dyn. 2022, 1517–1538. [Google Scholar] [CrossRef]

- Shigeishi, M.; Colombo, S.; Broughton, K.J.; Rutledge, H.; Batchelor, A.J.; Forde, M.C. Acoustic emission to assess and monitor the integrity of bridges. Construction and Building Materials 2001, 15, 35–49. [Google Scholar] [CrossRef]

- Forde, M.C. Sonic and Radar Impulse Non-Destructive Testing of Railroad Bridges. Transportation Infrastructure 405-412.

- Forde, M. C. Non-destructive evaluation of bridges: research in progress. Proc of US-Europe Bridge Engineering Workshop Technical University of Catalonia Barcelona, 1996; 26. [Google Scholar]

- Zobel, H.; Karwowski, W.; Sarnowska, J.; Wróbel, M. Nowa generacja mostów, Mosty z kompozytów polimerowych, 2004, 4, 16-19.

- Szruba, M. Kompozyty w budownictwie, lipiec–sierpień 2020, 73-77.

- Zobel, H.; Karwowski, W. Kompozyty polimerowe w mostownictwie: pomosty wielowarstwowe, 2006, 2, 42-49.

- Kamyk-Wawryszuk, A.; Kamyk, Z. Kompozytowe mosty wojskowe, 2013, 2, 63-70.

- Sobczyk, B.; Pyrzowski, Ł.; Chróścielewski, J.; Miśkiewicz, M. FRP composite bridges - the future or the present? , 2022, 4, 31–35. [Google Scholar]

- Górski, M.; Kotala, B.; Białozor, R. Rodzaje i właściwości zbrojenia niemetalicznego. XXXIII Ogólnopolskie Warsztaty Pracy Projektanta Konstrukcji, Szczyrk, Poland, 6-9 March 2018.

- Florjańczyk, Z.; Penczek, S. Chemia polimerów, Wydawnictwo Politechniki Warszawskiej 2002, Warsaw, Poland.

- Pielichowski, J.; Puszyński, A. Chemia polimerów. Teza 2004, Kraków, Poland.

- Stevens, M.P. Polymer Chemistry: An Introduction. 3 rd ed; Oxford University Press, 1998; pp. 1–576.

- Modern Plastics Encyclopedia.

- Blicharski, M. Wstęp do inżynierii materiałowej, 1998.

- Furtak, K.; Śliwiński, J. Materiały budowlane w mostownictwie, 2004.

- Osiecka E., Materiały budowlane: Tworzywa sztuczne, Warszawa: Oficyna Wydawnicza Politechniki Warszawskiej, 2005.

- Monnerie, L. 2.5 - Mechanical properties of polymeric materials. In Statistical Models for the Fracture of Disordered Media Random Materials and Processes; 1990; 66-76.

- Deshmukh, K.; Kovářík, T.; Muzaffar, A. , Ahamed, M.B.; Khadheer Pasha, S.K. Chapter 4 - Mechanical analysis of polymers. In Polymer Science and Innovative Applications Materials, Techniques, and Future Developments 2020, 117–152.

- Gościański, M. Structure and physical as well as mechanical properties of the waste polymers PA6+PP mixture - ecological and applicational aspect. Journal of Research and Applications in Agricultural Engineering 2002, 47, 25–30. [Google Scholar]

- Grzesiczak, D.; Postawa, P. Mechanical and thermal properties of injecting samples after recycling of airbags made of PET plastic. Przetwórstwo Tworzyw 2017, 23, 535–542. [Google Scholar]

- Ratna, D. Recent Advances and Applications of Thermoset Resins, 2nd ed; Elsevier, 2022.

- Sukanto, H.; Raharjo, W.W.; Ariawan, D.; Triyono, J.; Kaavesina, M. Epoxy resins thermosetting for mechanical engineering. De Gruyter 2021, 11, 797–814. [Google Scholar] [CrossRef]

- Malek, A. Thermosetting polymer composites: Manufacturing and properties study. Reviews on Advanced Materials Science 2023, 62. [Google Scholar]

- Primachenko, B.M. Effect of Initial Materials and Uncertainty of Production Technology on the Structure and Mechanical Properties of a Thermosetting Polymer. Fibre Chemistry 2023, 55, 106–112. [Google Scholar] [CrossRef]

- Vaidya, U.K.; Britt, F. Structural applications of reinforced thermoplastics. NACE - International Corrosion Conference Series, 2007; 075461–075468. [Google Scholar]

- Moniruzzaman, M.; Christogianni, P.; Kister, G. Self-Healing in Epoxy Thermoset Polymer Films Triggered by UV Light. Procedia Engineering 2016. [CrossRef]

- Jankowiak, I. Materiały kompozytowe w budownictwie mostowym. Inżynier budownictwa, 2012. [Google Scholar]

- Siwowski, T. Wzmacnianie mostów materiałami kompozytowymi. Izbudujemy.pl 2016. [Google Scholar]

- Meier, U. Strengthening of structures using carbon fibre/epoxy composites. Construction and Building Materials 1995, 9. [Google Scholar] [CrossRef]

- ACI 440.2R-02. Guide for the Design and Construction of Externally Bonded FRP Systems for Strengthening Concrete Structures. Reported by ACI Committee 440, 2002.

- Jankowiak, Efektywność wzmacniania materiałami kompozytowymi żelbetowych belek mostowych, rozprawa doktorska, Politechnika Poznańska, 2010.

- Kamiński, M.; Wydra, W. Wzmacnianie konstrukcji żelbetowych za pomocą włókien węglowych z uwzględnieniem wymagań ochrony przeciwpożarowej, XIII Ogólnopolska Konferencja „Warsztaty pracy projektanta konstrukcji” 1998, Ustroń-Gliwice, Poland.

- Łagoda, M. Wzmacnianie mostów przy pomocy materiałów kompozytowych, realizacje i założenia do zaleceń stosowania, Konferencja Naukowo-Techniczna „Materiały kompozytowe w budownictwie mostowym” — Zeszyt pokonferencyjny 2000, Łódź, Poland.

- Meier, U. ; Kotynia., R.; Walendziak, R. Badania zmęczeniowe żelbetowych płyt wzmocnionych naprężonymi taśmami CFRP, monografia „Problemy naukowo-badawcze budownictwa” (praca zbiorowa pod redakcją M. Bronowicza i J.A. Prusiel), Wydawnictwo Politechniki Białostockiej, Białystok 2007.

- Radomski, W.; Trochymiak, W. Przegląd współczesnych metod wzmacniania mostów betonowych, VIII Seminarium „Współczesne metody wzmacniania i przebudowy mostów”, IIL Politechnika Poznańska, Poznań Kiekrz 1998.

- Siwowski, T.; Radomski, W. Pierwsze krajowe zastosowanie taśm kompozytowych do wzmocnienia mostu. Inżynieria i Budownictwo 1998, 7. [Google Scholar]

- Wołowicki, W. Projekt wykonawczy wzmocnienia mostu przez rzekę Wartę w Śremie, projekt zrealizowany przez PO.MOST ARS, Sp. z 0.0., Poznań 1997.

- Gallegos-Calderón, C.; Oliva-Quecedo, J.; Pulido, M. D.G.; Goicolea, J.M. Influence of the Properties of a Glass Fiber Reinforced Polymer Deck on the Dynamic Response of a Road Bridge. Revista Politecnica 2023, 52, 73–82. [Google Scholar] [CrossRef]

- Zhijun, C.; Shan, L.; Yiyan, L.; Weitao, L.; Zhenzhen, L. Dynamic compressive properties of lightweight engineered geopolymer composites containing ceramsite (LW-EGC). Construction and Building Materials 2023, 370, 130717. [Google Scholar]

- Mincigrucci, L.; Civera, M.; Lenticchia, E.; Ceravolo, R.; Rosano, M.; Russo, S. Comparative Structural Analysis of GFRP, Reinforced Concrete, and Steel Frames under Seismic Loads. Materials 2023, 16, 4908. [Google Scholar] [CrossRef]

- Qureshi, J. A Review of Fibre Reinforced Polymer Bridges. Fibers 2023, 11, 40. [Google Scholar] [CrossRef]

- Russell, J.M.; Wei, X.; Živanović, S.; Kruger, C. Vibration Serviceability of a GFRP Railway Crossing Due to Pedestrians and Train Excitation. Eng. Struct. 2020, 219, 110756. [Google Scholar] [CrossRef]

- Mayer, P.; Kaczmar, J. Właściwości i zastosowania włókien węglowych i szklanych, 2008, 6, 52–56.

- Mossakowski, P. Pręty z kompozytów polimerowych z włóknami do zbrojenia betonowych konstrukcji inżynierskich, 2006, 2, 63-85.

- Amalraj, E.F.P.; Ilangovan, P. Experimental Behavior of High-Strength Concrete Reinforced with Aramid Fiber and Polyurethane Resin. Buildings 2023, 13, 1713. [Google Scholar] [CrossRef]

- Rebeiz, K.S.; Fowler, D.W.; Paul, D.R. Recycling plastics in polymer concrete for construction applications. Journal of Materials in Civil Engineering 1993, 5, 237–248. [Google Scholar] [CrossRef]

- Rebeiz, K.S.; Fowler, D.W.; Paul, D.R. Recycling plastics in polymer concrete systems for engineering applications. Journal of Materials in Civil Engineering 1991, 30, 809–825. [Google Scholar] [CrossRef]

- Salimi, K.; Ghazavi, M. Soil reinforcement and slope stabilisation using recycled waste plastic sheets. Geomechanics and Geoengineering 2021, 16, 497–508. [Google Scholar] [CrossRef]

- Marusceac, V.; Vlad, M. A Different Approach to Classic Structural Reinforcements Using Recycled Synthetic Materials. Procedia Engineering 2017, 181, 273–279. [Google Scholar] [CrossRef]

- Łysoń, M. Przełom w budownictwie. Ten beton z biowłóknami przetrwa wszystko, November 2023. Available online: https://www.chip.pl/2023/11/przelom-budownictwo-beton-biowlokna (accessed on 28 November 2023).

- Khaneghahi, M.H.; Kamireddi, D.; Rahmaninezhad, S.A.; Sadighi, A.; Schauer, C.L.; Sales, C.M.; Najafi, A.R.; Cotton, A.; Street, R.; Farnam, Y.A. Development of a nature-inspired polymeric fiber (BioFiber) for advanced delivery of self-healing agents into concrete. Construction and Building Materials 2023, 408, 133765. [Google Scholar] [CrossRef]

- Mieczkowski, P. Hydroizolacja płyt pomostów na obiektach mostowych. Izbudujemy.pl 2015. [Google Scholar]

- Bichajło, L.; Siwowski, T. ; Nawierzchnie na obiektach mostowych - doświadczenia z nadzoru nad realizacją. Sympozjum: Nawierzchnie i izolacje na obiektach inżynieryjnych betonowych i stalowych. Konsekwencje i możliwości działań. XVII Międzynarodowe Targi Budownictwa Drogowego AUTOSTRADA-POLSKA, Kielce, Poland, 11-12 maja 2011.

- Kilarski, R. Analiza i ocena materiałów hydroizolacyjnych na pomosty obiektów mostowych. Prace IBDiM, Warszawa 1996.

- Abdullah, N.H.H.; Ng, K.S.; Jais, I.B.M.; Idrus, J. Use of geosynthetic reinforced soil-integrated bridge system to alleviate settlement problems at bridge approach: A review. Physics and Chemistry of the Earth, Parts A/B/C 2023, 129, 103304. [Google Scholar] [CrossRef]

- Bridge Enginiering Centre - Investigation and Evaluation of Iowa Department of Transportation Bridge Deck Epoxy Injection Process Final Report February 2019.

- Banaś, A.; Kuryłowicz, A.; Bałachowski, L.; Poteraj-Olesiak, A. Innowacyjna metoda wzmocnienia gruntu za przyczółkiem przy użyciu iniekcji geopolimerowych. Builder 2020, 9, 24–28. [Google Scholar] [CrossRef]

- Kokotkiewicz, P. Problemy geotechniczne na styku obiektów inżynierskich z nasypami drogowymi. MOSTY 2016, 1. [Google Scholar]

- Trojnar, K. Jak projektować nasypy na dojazdach do obiektów mostowych na słabym podłożu? MOSTY, 2016; 1. [Google Scholar]

- Gajewska, B.; Kłosiński, B.A. Rozwój metod wzmacniania podłoża gruntowego. Seminarium IBDiM i PZWFS: Wzmacnianie podłoża i fundamentów, Warszawa 2011.

- Jermołowicz, P. Wzmocnienie nasypów drogowych. Zasady projektowania i wykonawstwa. Opole-Pokrzywna, SITK, 2011.

- Poteraj-Oleksiak, A. Poziomowanie i stabilizacja gruntów–zalety metody iniekcji geopolimerowych, „Magazyn Autostrady”, 11–12/2018.

- Ostrowski, K.; Furtak, K. Influence of Carbon Fibre Reinforced Polymer and Recycled Carbon Fibres on the compressive behaviour of self-compacting high-performance fibre-reinforced concrete, 2022.

- Grzegorzewicz, K. Styropian w nasypach za przyczółkiem, V Seminariurn „Współczesne metody wzmacniania i przebudowy mostów”, Poznań 1995.

- Giraldi, A.L.F. de M.; Bártoli, J.R.; Velasco, J.I.; Innocentini-Mei, L.H. Innocentini-Mei, L.H. Glass fibre recycled poly(ethylene terephthalate) comp sites: Mechanical and thermal properties. Elsevier, 2005; Volume 24, pp. 507–512.

- Kracalik, M.; Pospíšil, L.; Slouf, M.; Fortelný, I. Recycled poly(ethylene terephthalate) reinforced with basalt fibres: Rheology, structure, and utility properties. Polymer Composites 2008, 29, 437–442. [Google Scholar] [CrossRef]

- Katalagarianakis, A.; de Voorde, B.V.; Pien, N.; Polyzos, E.; Duretek, I.; Holzer, C.; Cardon, L.; Bernaerts, K.V.; Van Hemelrijck, D.; Van Vlierberghe, S.; Pyl, L. The effect of carbon fiber content on physico-mechanical properties of recycled poly(ethylene terephthalate) composites additively manufactured with fused filament fabrication. Additive Manufacturing 2022, 60(A), 103246. [Google Scholar] [CrossRef]

- Zuodong, L.; et al. Glass fiber network reinforced polyethylene terephthalate composites for support insulators, 2023.

- Wei, Q.; Cheng-hui, L. Performance of Polyurethane Polymer in the Transition Zones of Ballasted and Ballastless Track. Sustainable Civil Infrastructures, 2018, 142-152.

- Zhao, C.; Wang, P. ; Qianga Yi, Meng, D. Application of polyurethane polymer and assistant rails to settling the abnormal vehicle-track dynamic effects in transition zone between ballastless and ballasted track. Shock and Vibration, 2015.

- Gałczyńska, M. Eko-asfalt z plastiku i piasku? Wynalazł go łodzianin, państwo nie było zainteresowane. Onet 2016. [Google Scholar]

- Spyrka, M. Evaluation of transition effects using composite material from polymer waste in integrated bridges. Nowoczesne Technologie i Systemy Zarządzania w Transporcie Szynowym NOVKOL 2023, Zakopane, Poland, 29 November–1 December 2023.

- AZO MATERIALS | Polyethylene Terephthalate - PET 55% Glass Fiber Reinforced, September 2001. Available online: https://www.azom.com/article.aspx?ArticleID=789/ (accessed on 20 November 2023).

- AKRO COMPOUNDS | Polyethylene Terephthalate - PET 30% Carbon Fiber Reinforced. Available online: https://akro-plastic.com/en/product/precite-e-icf-30-black-7429-en/ (accessed on 20 November 2023).

- Czarnecki, L. Betony polimerowe, 2010, 2, 63-85.

| height of the embankment [m] | narrow embankment for a single-track line [m3/mb] | narrow embankment for a double-track line [m3/mb] |

|---|---|---|

| 3 | 19.47 | 19.90 |

| 5 | 36.25 | 36.68 |

| 8 | 70.03 | 70.46 |

| 12 | 131.18 | 131.61 |

| 20 | 308.67 | 309.10 |

| selected keywords | number of searches by | ||

|---|---|---|---|

| Scopus | Web of Science | ||

| civil engineering | 1 | 1,748,102 | 1,057,904 |

| integral bridges | 6,195 | 5,314 | |

| transition zone | 75,613 | 65,590 | |

| transition effect | 593,443 | 476,006 | |

| reinforced polymer composite | 56,775 | 57,048 | |

| recycling | 245,488 | 240,686 | |

| civil engineering + integral bridges | 2 | 149 | 1,000 |

| integral bridges + transition zone | 9 | 10 | |

| integral bridges + transition effect | 50 | 64 | |

| reinforced polymer composite + recycling | 1,515 | 2,049 | |

| civil engineering + integral bridges + transition zone | 3 | 0 | 5 |

| civil engineering + integral bridges + transition effect | 0 | 7 | |

| transition zone + transition effect + reinforced polymer composite |

40 | 51 | |

| transition zone + reinforced polymer composite + recycling |

4 | 10 | |

| integral bridges + transition zone + transition effect + recycling |

4 | 0 | 0 |

| civil engineering + transition zone + transition effect + recycling |

5 | 320 | |

| integral bridges + transition zone + transition effect + reinforced polymer composite + recycling |

5 | 0 | 0 |

| civil engineering + integral bridges + transition zone + transition effect + reinforced polymer composite + recycling |

6 | 0 | 0 |

| material | tensile strength | density | real strength |

|---|---|---|---|

| [-] | [MPa] | [g/cm3] | [kNm/kg] |

| PET reinforced with glass fiber in a ratio of 55 % |

196 | 1,80 | 108,9 |

| PET reinforced with carbon fiber in a ratio of 30% |

220 | 1,45 | 151,7 |

| Steel S235JR | 360 - 510 | 7,85 | 45,9 - 65,0 |

| Steel S355 | 470 - 630 | 7,85 | 59,9 - 80,3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).