Submitted:

05 January 2024

Posted:

08 January 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Materials and Methods

2.1. Renewable Materials Selection for Racking: Wood

2.2. Material Properties

2.3. PV Racking Basic Design Parameters

| System Type | System | Reference |

|---|---|---|

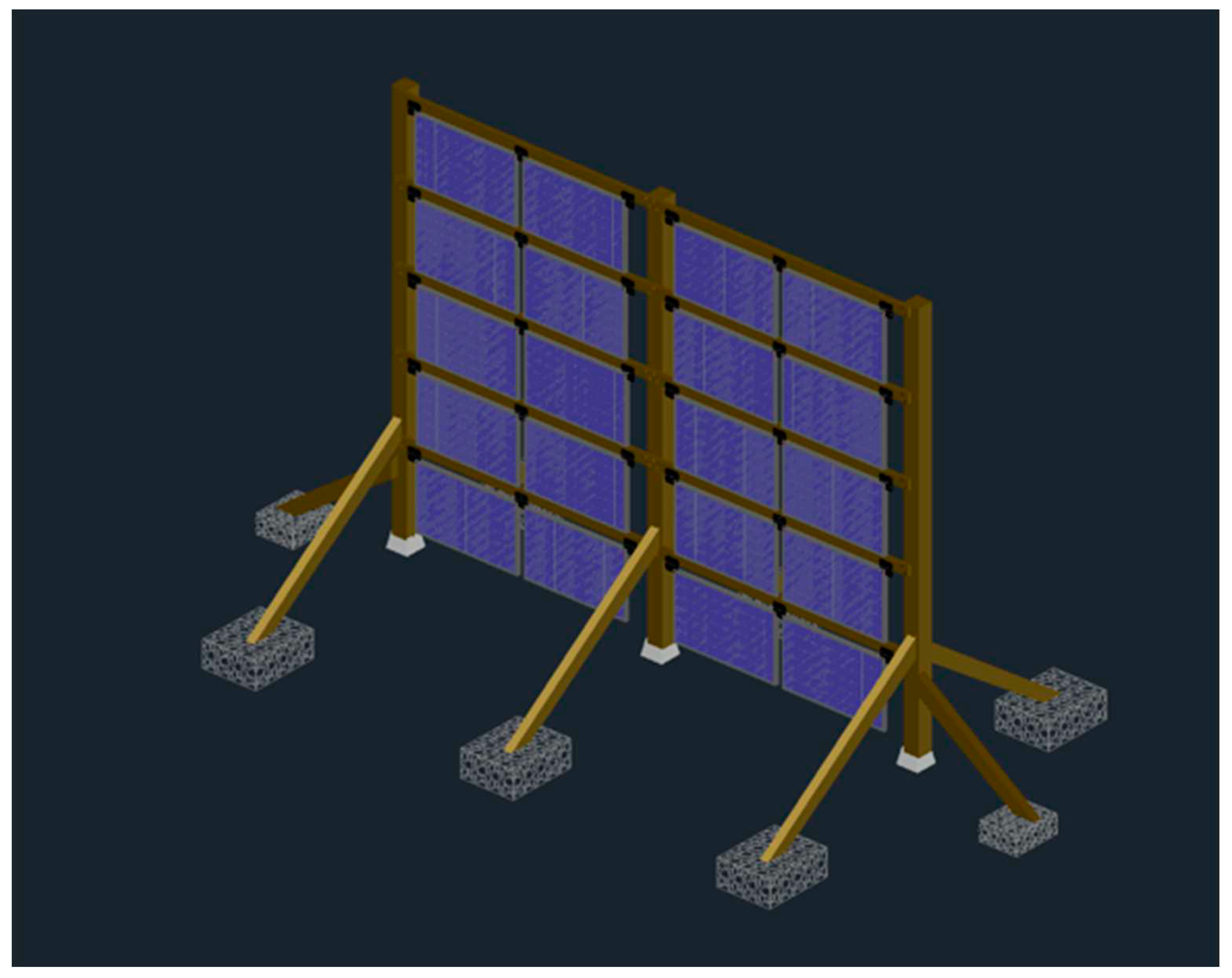

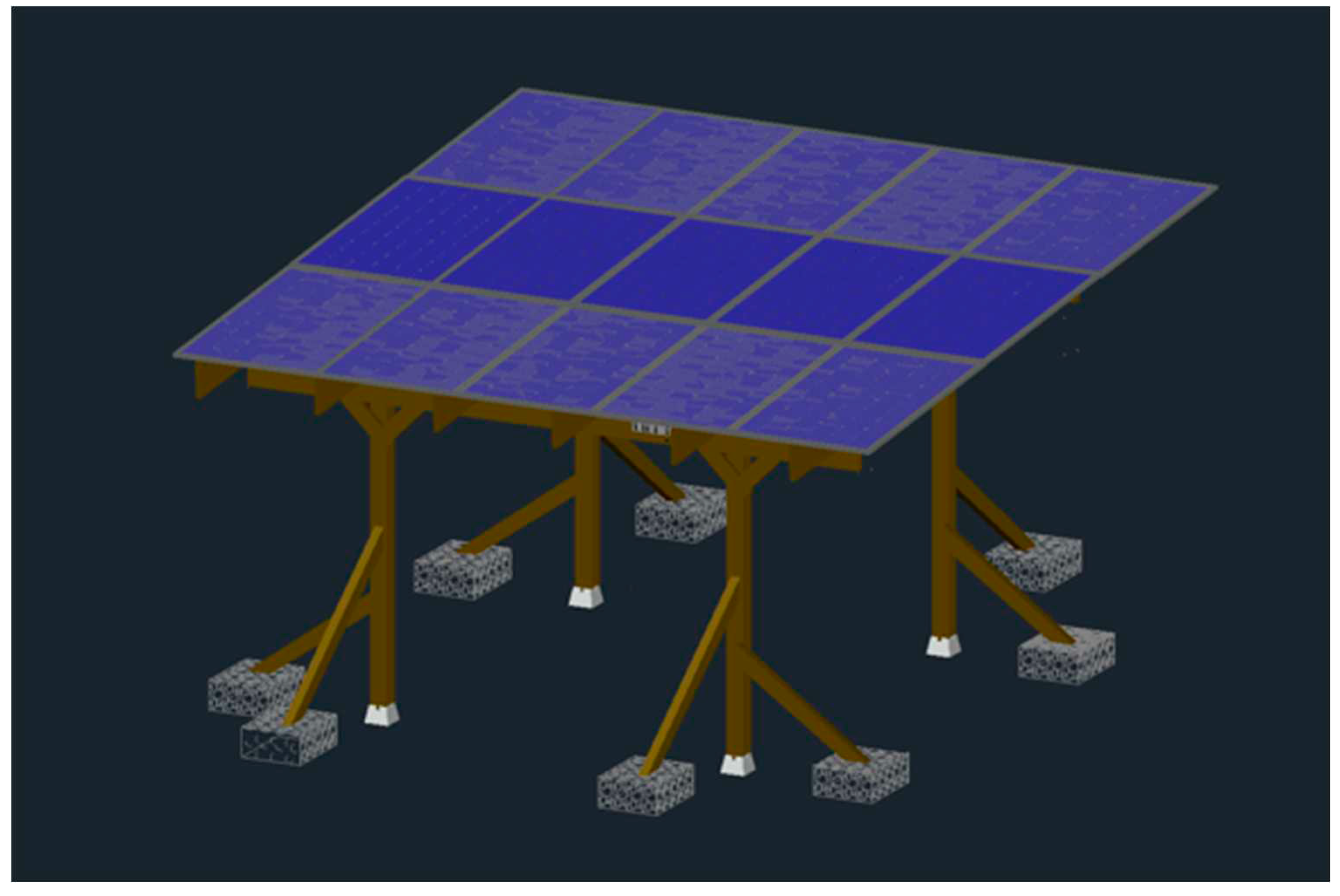

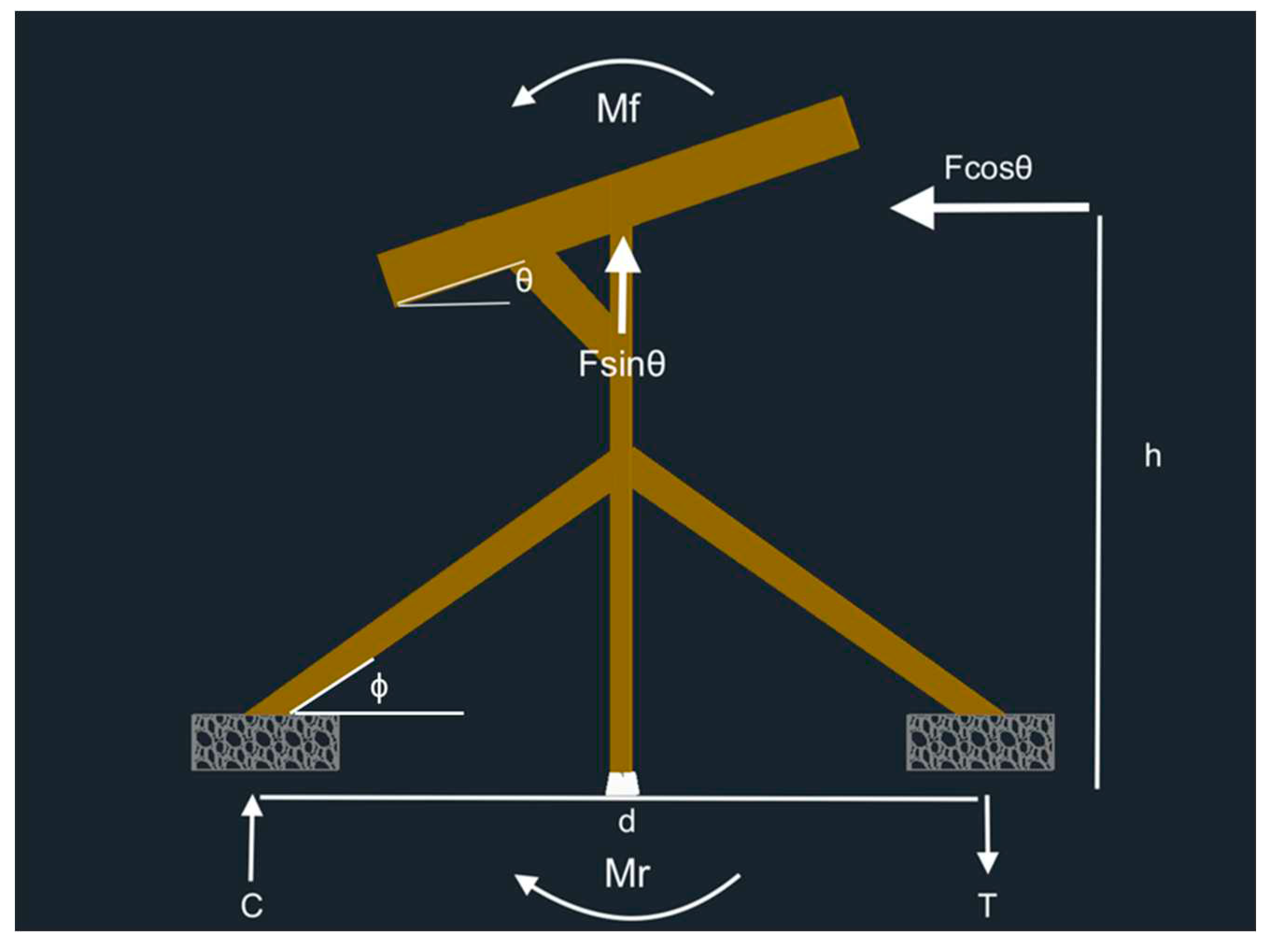

| Single Line of Posts | Sloped T-Shaped System | Figure 1 [47] |

| Inverse Y System | Figure 2 [47] | |

| T-Shaped System | Figure 3 [47] | |

| Swinging Vertical System | Figure 4 [44] | |

| Wire Rope System1 | Figure 5 [49] | |

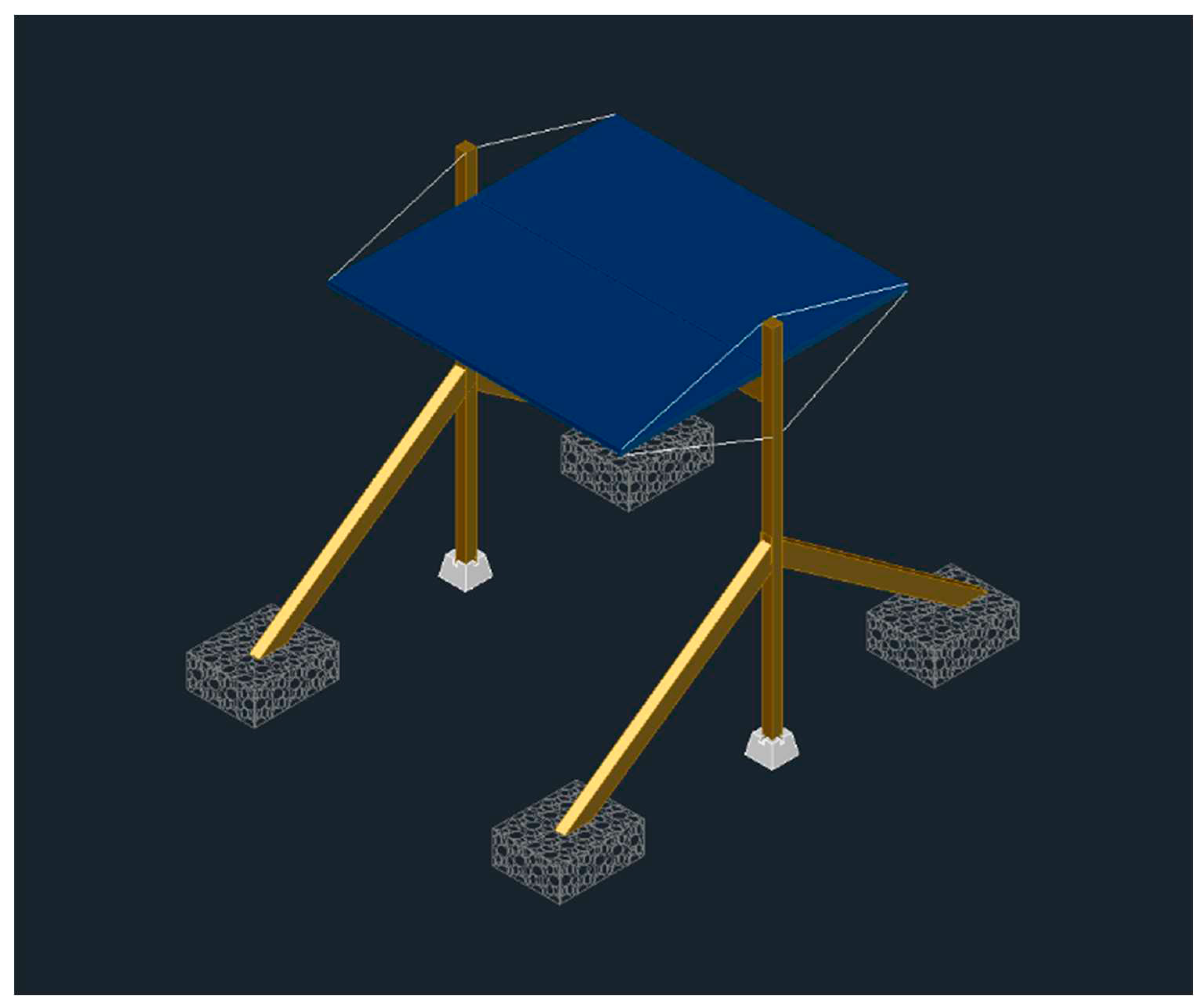

| Single-Spot Carport System2 | Figure 6 [75] | |

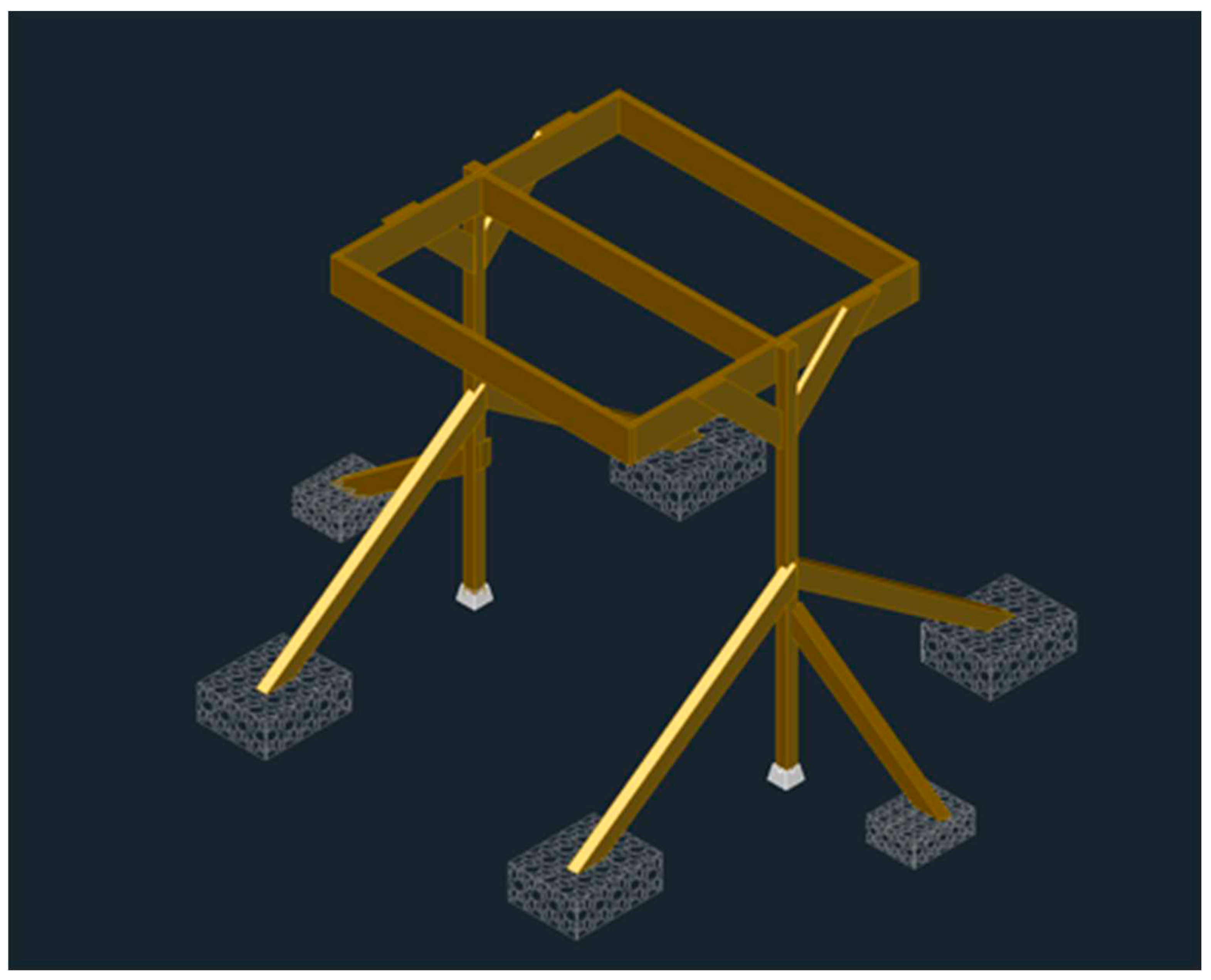

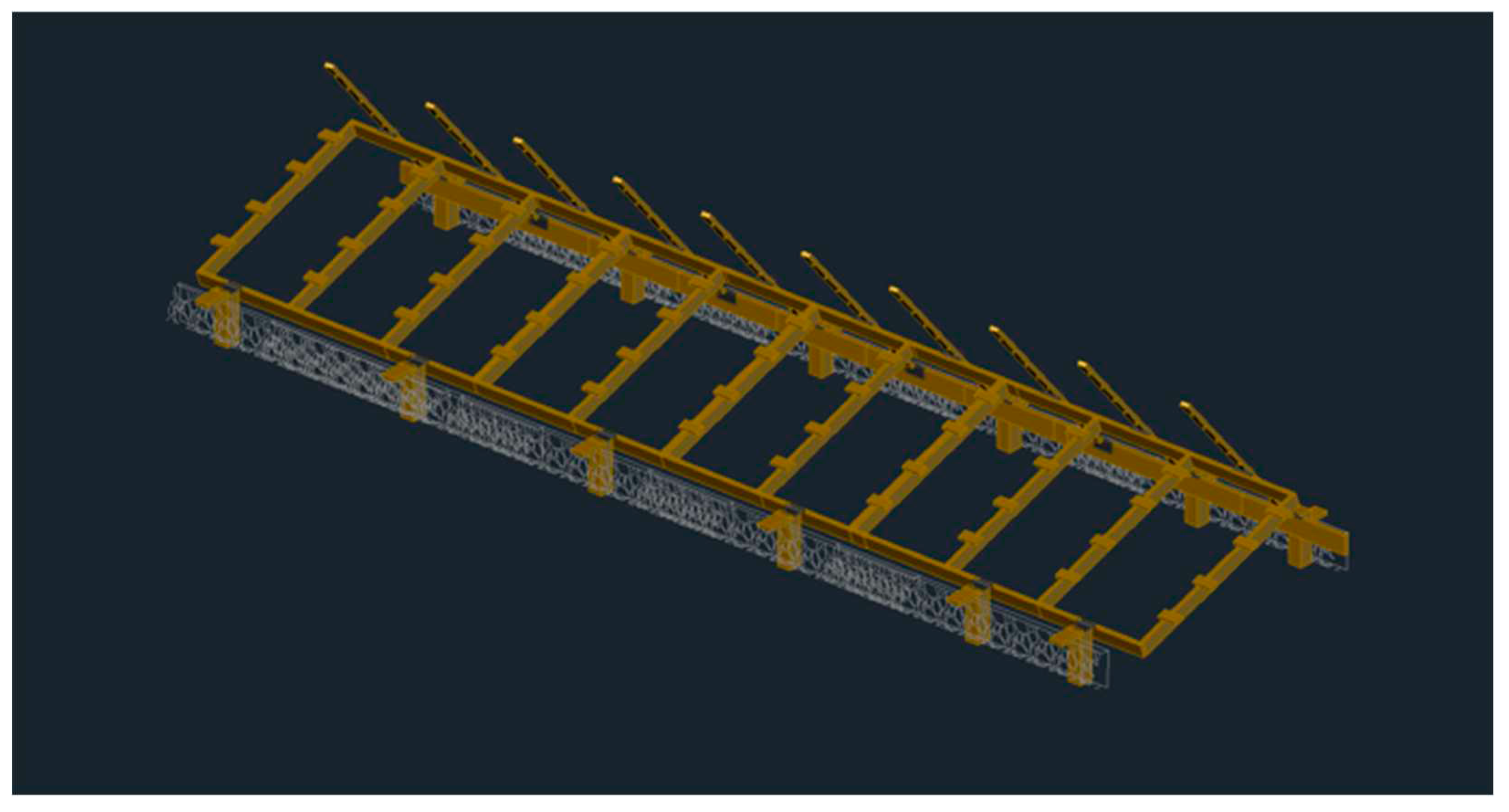

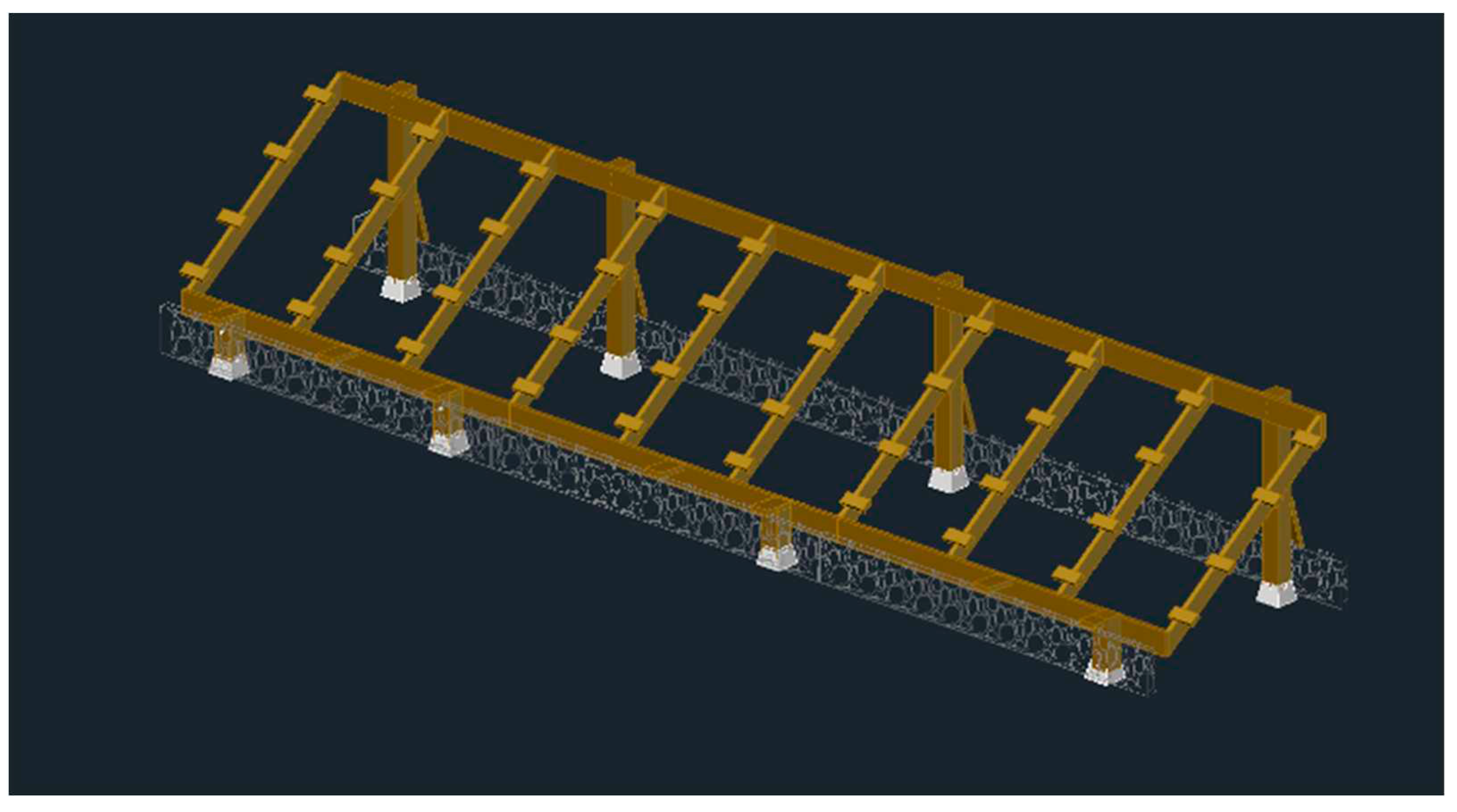

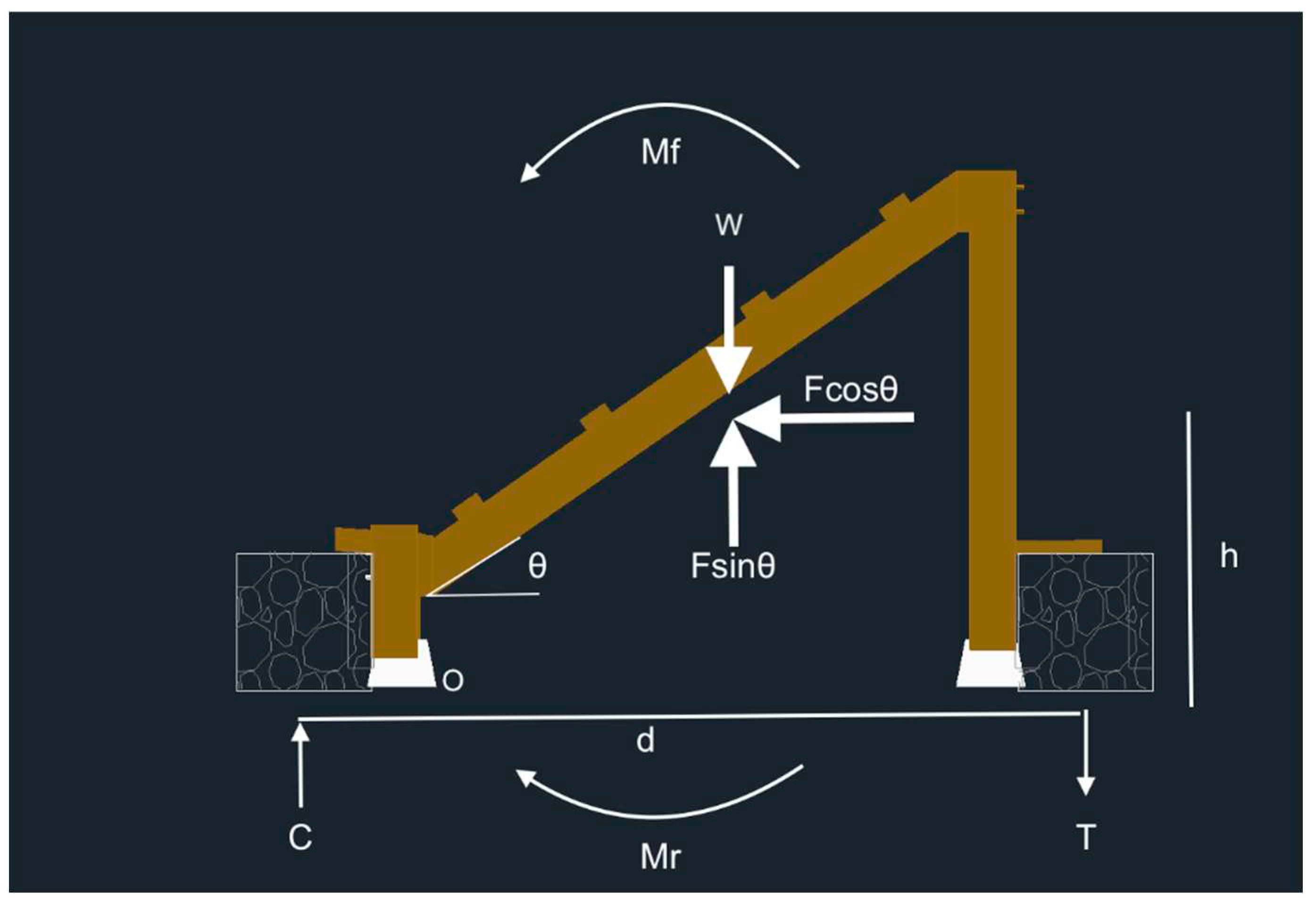

| Double Line of Posts | Variable Tilt System1 | Figure 7 [42] |

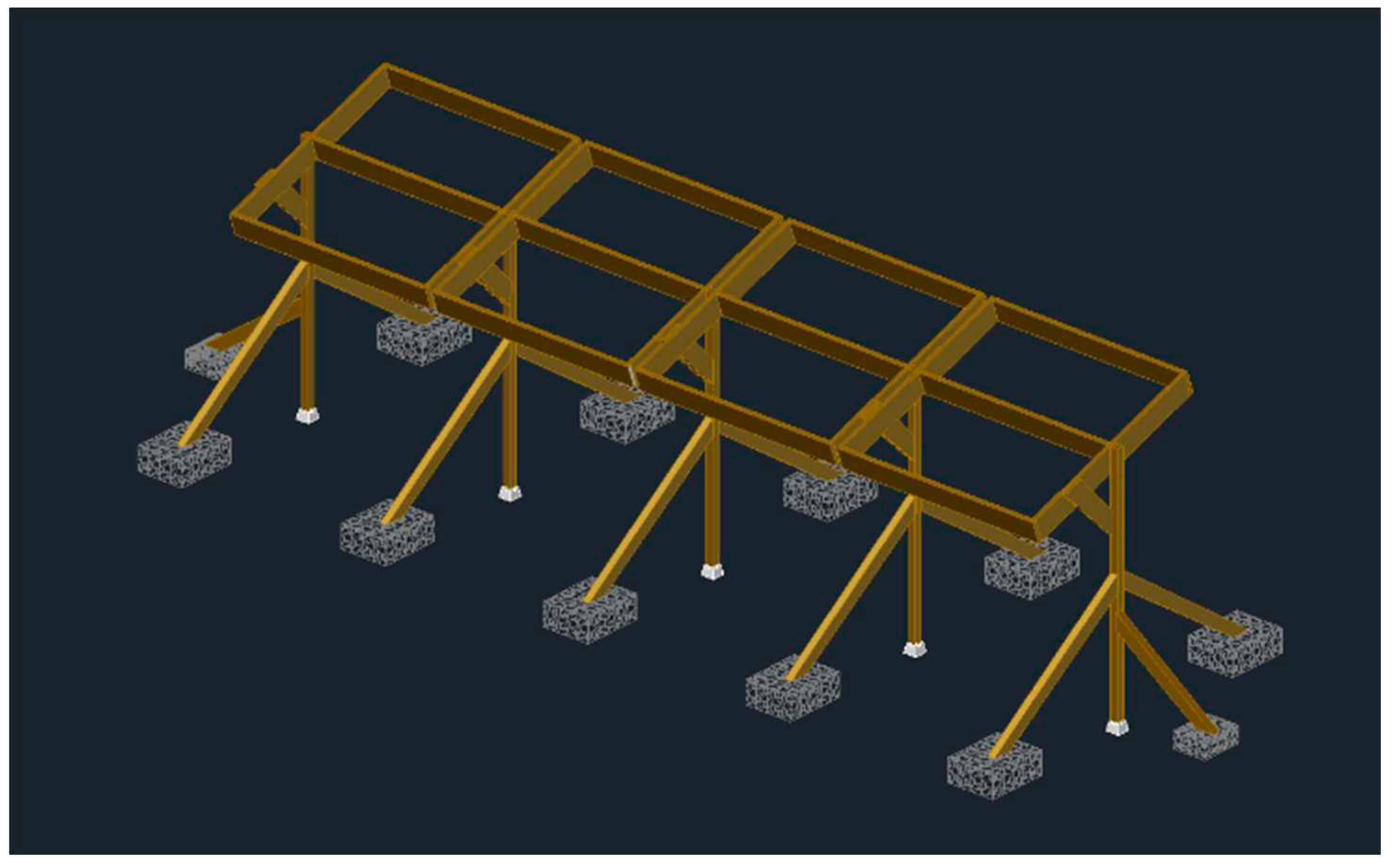

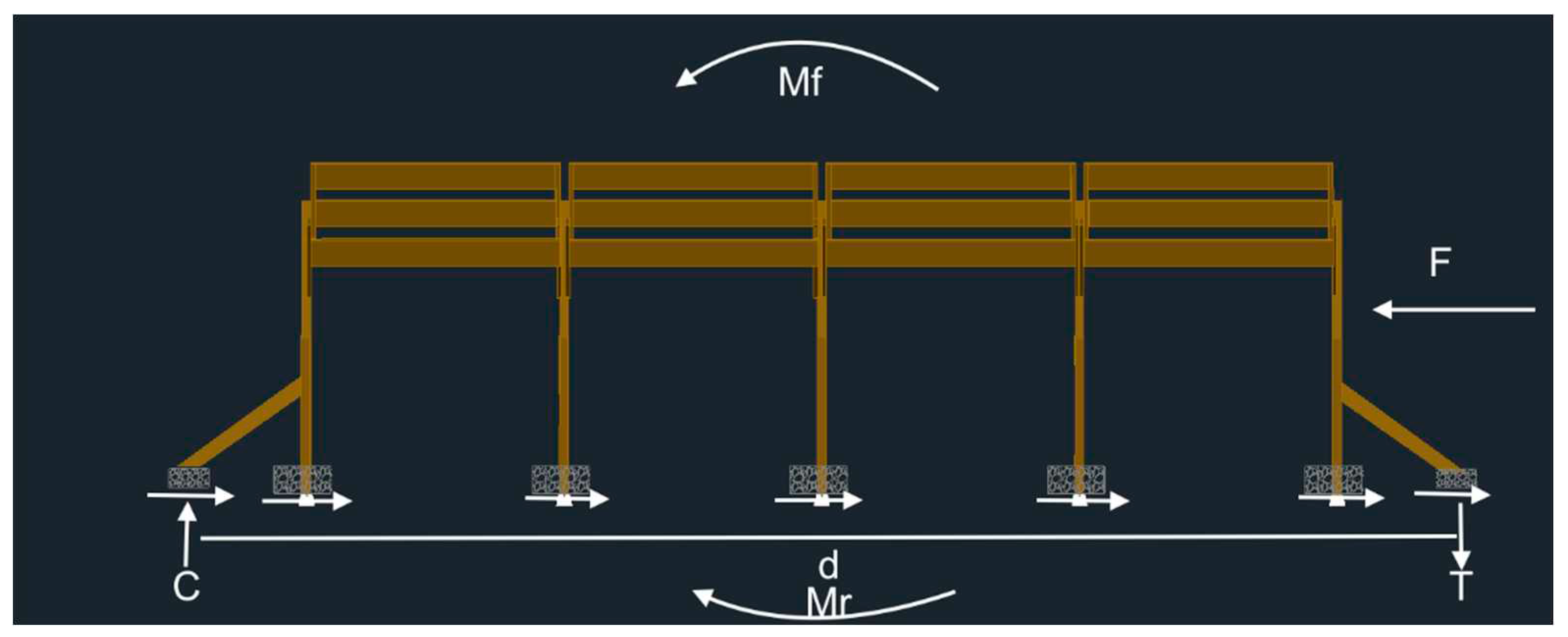

| Fixed Tilt System | Figure 8 [41] |

2.4. Design Analysis Assumptions

2.5. Economic Analysis

3. Results

3.1. Foundation Weight Requirements

3.2. T-Shaped Fixed-Tilt Rack

3.2.1. Bill of Materials (BOM)

| Member Name | Piece1 | Cost per Piece2 | Quantity | Cost [$CAD] | |

|---|---|---|---|---|---|

| Joists | 2x10x8 | $24.92 | 15 | $373.80 | |

| Beams | 2x10x8 | $24.92 | 10 | $249.20 | |

| Cross Braces | 2x10x8 | $24.92 | 2 | $49.84 | |

| Posts | 4x4x8 | $16.78 | 6 | $100.68 | |

| Outside Joist Connection | 2x4 Fence Bracket | $0.43 | 20 | $8.60 | |

| Cross Braces Connection | 2x4 Fence Bracket | $0.43 | 20 | $8.60 | |

| Middle Joist Connection | 2x6 Joist Hanger | $1.82 | 10 | $18.20 | |

| Beam to Post Connection | ½” Carriage Bolt (10”) | $5.37 | 6 | $32.22 | |

| Beam to Post Connection | ½” Nut | $0.79 | 6 | $4.74 | |

| Beam to Post Connection | ½” Washer | $0.80 | 6 | $4.80 | |

| Tension Based Connections | 2-1/2” Brown Deck Screws | $49.99 | 1 | $49.99 | |

| Shear Based Connections | 1-1/2” Joist Hanger Nails | $4.19 | 3 lbs | $12.57 | |

| Diagonal From Post to Basket | 2x6x8 | $12.60 | 6 | $75.60 | |

| Superstructure Cost | $988.84 | ||||

| Post Block | 4x4 Deck Block | $10.45 | 6 | $62.70 | |

| Gabion Wire Basket | 1” x 36” x 25′ Chicken Wire | $37.99 | 2 | $75.98 | |

| Plywood on Gabion Basket | 4x8x1/2” Plywood | $71.95 | 1 | $71.95 | |

| Gabion Rocks | Large Riverstone (2+”) | $172.083 | 1 | $172.08 | |

| Foundation Cost | $382.71 | ||||

| Total Cost | $1,371.55 | ||||

| Cost/W | $0.3429 | ||||

3.2.2. Sloped T-Shaped Fixed Tilt Assembly Instructions

3.3. Variable Tilt Rack

3.3.1. Bill of Materials

3.3.2. Variable Tilt Ballast System Assembly Instructions

3.4. Economic Analysis

| System Type | Location | q [kPa] | Weight of Rocks per Basket [lbs] | Percentage Difference |

|---|---|---|---|---|

| Single Line of Posts | London, ON | 0.47 | 590 | - |

| Toronto, ON | 0.44 | 552 | -6.4% | |

| Vancouver, BC | 0.45 | 565 | -4.2% | |

| Halifax, NS | 0.58 | 728 | +23.4% | |

| Fort Nelson, BC | 0.30 | 376 | -36.3% | |

| Cape Race, NL | 1.05 | 1300 | +120.3% |

| System Type | Location | q [kPa] | Weight of Rocks per basket [lbs] | Percentage Difference |

|---|---|---|---|---|

| Double Line of Posts | London, ON | 0.47 | 1939 | |

| Toronto, ON | 0.44 | 1777 | -8.3% | |

| Vancouver, BC | 0.45 | 1820 | -6.1% | |

| Halifax, NS | 0.58 | 2514 | +29.6% | |

| Fort Nelson, BC | 0.30 | 1027 | -47.0% | |

| Cape Race, NL | 1.05 | 5033 | +259.5% |

| System Type | Clearance [m] | Weight of Rocks per Basket [lbs] | Percentage Difference |

|---|---|---|---|

| Single Line of Posts | 2.0 | 590 | - |

| 1.0 | 295 | -50% | |

| 1.5 | 442 | -25% | |

| 2.5 | 738 | +25% | |

| 3.0 | 885 | +50% |

| System Type | Clearance [m] | Weight of Rocks per end [lbs] | Percentage Difference |

|---|---|---|---|

| Double Line of Posts | 0.75 | 1939 | - |

| 1.5 | 3385 | +74.5% | |

| 2.0 | 4349 | +124.3% | |

| 2.5 | 5312 | +173.9% | |

| 3.0 | 6276 | +223.7% |

| System Type | Distance between baskets [m] | Weight of Rocks per Basket [lbs] | Percentage Difference |

|---|---|---|---|

| Single Line of Posts | 1.5 | 590 | - |

| 1.0 | 944 | -50.0% | |

| 2.0 | 472 | -25.0% | |

| 2.5 | 378 | +25.0% | |

| 3.0 | 314 | +50.0% |

| System Type | Distance between baskets [m] | Weight of Rocks per Basket [lbs] | Percentage Difference |

|---|---|---|---|

| Double Line of Posts | 2.0 | 1939 | - |

| 1.0 | 2552 | +31.2% | |

| 1.5 | 2184 | +12.6% | |

| 2.5 | 1776 | -8.4% | |

| 3.0 | 1636 | -15.6% |

4. Discussion

4.1. Limitations

4.1.1. Preservatives

4.1.2. Wood Species Alternatives

4.1.3. Soil Conditions

4.1.4. Uneven Land

4.1.5. Construction Staging

4.2. Wood price sensitivity

5. Future Work

6. Conclusions

7. OSHWA Certification in Place of Patents

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

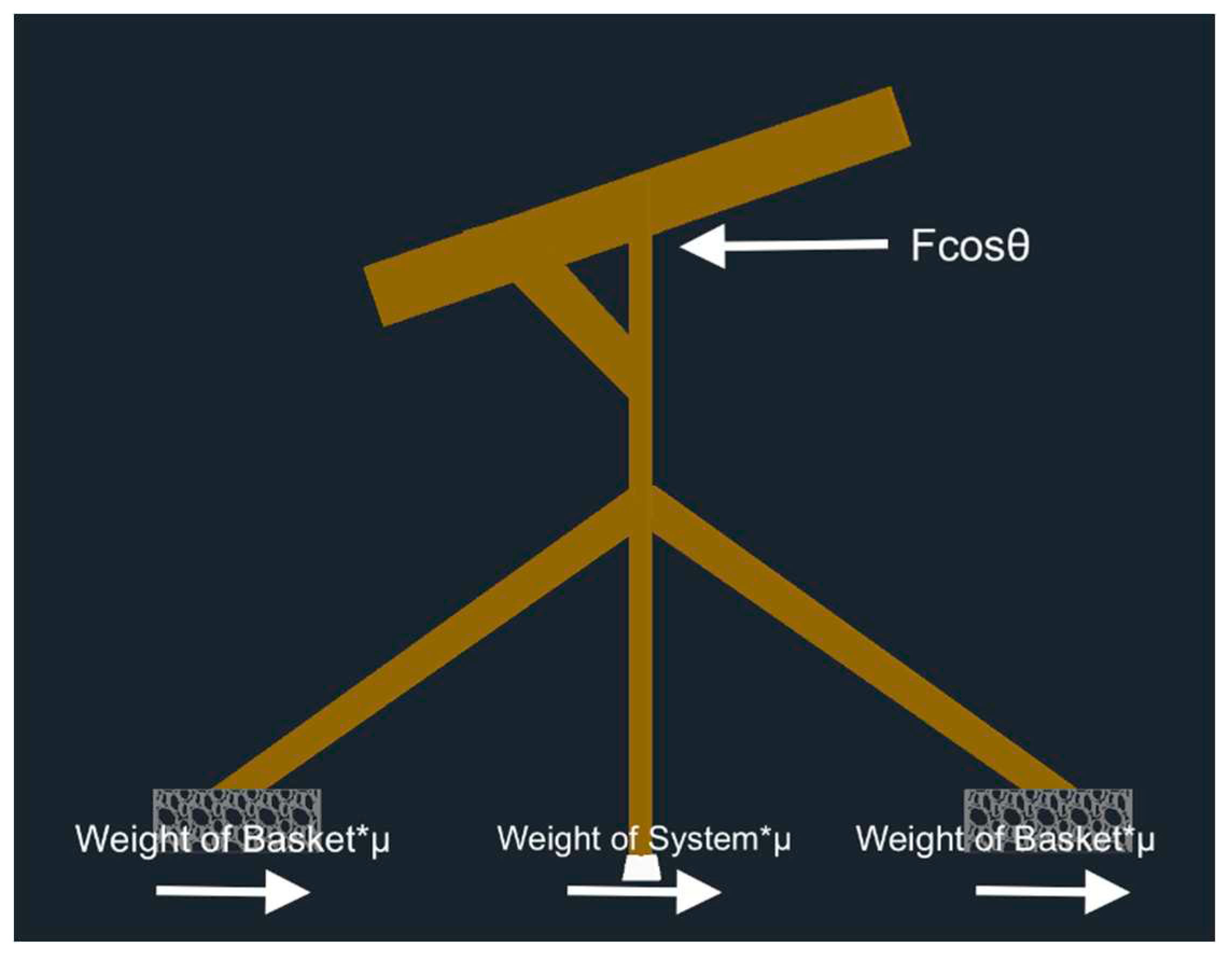

Appendix A. Foundation Design Load Calculations

Appendix B. Single Line of Post Foundation Design Weight Calculations

Sliding

Overturning

Diagonal Design

Global-Lateral Foundation Design

Appendix C. Double Line of Posts Foundation Design Calculations

References

- Karakaya, E.; Sriwannawit, P. Barriers to the Adoption of Photovoltaic Systems: The State of the Art. Renew. Sustain. Energy Rev. 2015, 49, 60–66. [Google Scholar] [CrossRef]

- Fu, R.; Feldman, D.J.; Margolis, R.M. US Solar Photovoltaic System Cost Benchmark: Q1 2018 2018.

- Matasci, S. Solar Panel Cost: Avg. Solar Panel Prices by State in 2019: EnergySage. Sol. News EnergySage 2019.

- Dudley, D. Renewable Energy Will Be Consistently Cheaper Than Fossil Fuels By 2020; Forbes, 2019.

- Solar Industry Research Data | SEIA. Available online: https://www.seia.org/solar-industry-research-data (accessed on 2 January 2024).

- Solar Industry Research Data Available Online.

- Vaughan, A. Time to Shine: Solar Power Is Fastest-Growing Source of New Energy. The Guardian 2017. [Google Scholar]

- Barbose, G.L.; Darghouth, N.R.; LaCommare, K.H.; Millstein, D.; Rand, J. Tracking the Sun: Installed Price Trends for Distributed Photovoltaic Systems in the United States-2018 Edition 2018.

- IEA Solar PV – Renewables 2020 – Analysis. Available online: https://www.iea.org/reports/renewables-2020/solar-pv (accessed on 18 October 2023).

- Levin, T.; Thomas, V.M. Can Developing Countries Leapfrog the Centralized Electrification Paradigm? Energy Sustain. Dev. 2016, 31, 97–107. [Google Scholar] [CrossRef]

- Chakrabarty, S.; Islam, T. Financial Viability and Eco-Efficiency of the Solar Home Systems (SHS) in Bangladesh. Energy 2011, 36, 4821–4827. [Google Scholar] [CrossRef]

- Lang, T.; Ammann, D.; Girod, B. Profitability in Absence of Subsidies: A Techno-Economic Analysis of Rooftop Photovoltaic Self-Consumption in Residential and Commercial Buildings. Renew. Energy 2016, 87, 77–87. [Google Scholar] [CrossRef]

- Roy, R.; Pearce, J.M. Is Small or Big Solar Better for the Environment? Comparative Life Cycle Assessment of Solar Photovoltaic Rooftop vs. Ground-Mounted Systems. Int. J. Life Cycle Assess. 2023. [Google Scholar] [CrossRef]

- Agenbroad, J.; Carlin, K.; Ernst, K.; Doig, S. Minigrids in the Money: Six Ways to Reduce Minigrid Costs by 60% for Rural Electrification. Rocky Mt. Inst. 2018. [Google Scholar]

- Szabó, S.; Pinedo Pascua, I.; Puig, D.; Moner-Girona, M.; Negre, M.; Huld, T.; Mulugetta, Y.; Kougias, I.; Szabó, L.; Kammen, D. Mapping of Affordability Levels for Photovoltaic-Based Electricity Generation in the Solar Belt of Sub-Saharan Africa, East Asia and South Asia. Sci. Rep. 2021, 11, 3226. [Google Scholar] [CrossRef] [PubMed]

- Awan, A.B. Optimization and Techno-Economic Assessment of Rooftop Photovoltaic System. J. Renew. Sustain. Energy 2019, 11, 033501. [Google Scholar] [CrossRef]

- Wang, P.; Yu, P.; Huang, L.; Zhang, Y. An Integrated Technical, Economic, and Environmental Framework for Evaluating the Rooftop Photovoltaic Potential of Old Residential Buildings. J. Environ. Manage. 2022, 317, 115296. [Google Scholar] [CrossRef]

- Fthenakis, V.; Alsema, E. Photovoltaics Energy Payback Times, Greenhouse Gas Emissions and External Costs: 2004–Early 2005 Status. Prog. Photovolt. Res. Appl. 2006, 14, 275–280. [Google Scholar] [CrossRef]

- Feldman, D.; Barbose, G.; Margolis, R.; Bolinger, M.; Chung, D.; Fu, R.; Seel, J.; Davidson, C.; Darghouth, N.; Wiser, R. Photovoltaic System Pricing Trends: Historical, Recent, and Near-Term Projections 2015 Edition 2015.

- Feldman, D.; Barbose, G.; Margolis, R.; Wiser, R.; Darghout, N.; Goodrich, A. Photovoltaic (PV) Pricing Trends: Historical, Recent, and Near-Term Projections, Sunshot 2012.

- PVinsights PVinsights. Available online: http://pvinsights.com/.

- Tamarack Solar Products Tamarack Solar Top of Pole Mounts. Available online: https://www.altestore.com/store/solar-panel-mounts/top-of-pole-mounts-for-solar-panels/tamarack-solar-top-of-pole-mounts-6072-cell-solar-panels-p40745/ (accessed on 29 June 2023).

- TPM3 Pole Mount for Three 60/72 Cell Solar Modules - Modern Outpost. Available online: https://www.modernoutpost.com/product/tpm3-pole-mount-for-three-60-72-cell-solar-modules/ (accessed on 2 January 2024).

- Precedence Research Agrivoltaics Market Is Expected to Increase at a 12.15% of CAGR by 2030. Available online: https://www.precedenceresearch.com/press-release/agrivoltaics-market (accessed on 23 August 2023).

- International Energy Agency Solar. Available online: https://www.iea.org/energy-system/renewables/solar-pv (accessed on 23 August 2023).

- Mahto, R.; Sharma, D.; John, R.; Putcha, C. Agrivoltaics: A Climate-Smart Agriculture Approach for Indian Farmers. Land 2021, 10, 1277. [Google Scholar] [CrossRef]

- Feuerbacher, A.; Herrmann, T.; Neuenfeldt, S.; Laub, M.; Gocht, A. Estimating the Economics and Adoption Potential of Agrivoltaics in Germany Using a Farm-Level Bottom-up Approach. Renew. Sustain. Energy Rev. 2022, 168, 112784. [Google Scholar] [CrossRef]

- Dupraz, C.; Marrou, H.; Talbot, G.; Dufour, L.; Nogier, A.; Ferard, Y. Combining Solar Photovoltaic Panels and Food Crops for Optimising Land Use: Towards New Agrivoltaic Schemes. Renew Energy 2011, 36, 2725–2732. [Google Scholar] [CrossRef]

- Guerin, T.F. Impacts and Opportunities from Large-Scale Solar Photovoltaic (PV) Electricity Generation on Agricultural Production. Environ. Qual. Manag. 2019, 28, 7–14. [Google Scholar] [CrossRef]

- Valle, B.; Simonneau, T.; Sourd, F.; Pechier, P.; Hamard, P.; Frisson, T.; Ryckewaert, M.; Christophe, A. Increasing the Total Productivity of a Land by Combining Mobile Photovoltaic Panels and Food Crops. Appl. Energy 2017, 206, 1495–1507. [Google Scholar] [CrossRef]

- Mavani, D.D.; Chauhan, P.M.; Joshi, V. Beauty of Agrivoltaic System Regarding Double Utilization of Same Piece of Land for Generation of Electricity & Food Production. 2019, 10.

- Sekiyama, T.; Nagashima, A. Solar Sharing for Both Food and Clean Energy Production: Performance of Agrivoltaic Systems for Corn, A Typical Shade-Intolerant Crop. Environments 2019, 6, 65. [Google Scholar] [CrossRef]

- Agostini, A.; Colauzzi, M.; Amaducci, S. Innovative Agrivoltaic Systems to Produce Sustainable Energy: An Economic and Environmental Assessment. Appl. Energy 2021, 281, 116102. [Google Scholar] [CrossRef]

- Daniels, T.L. The Development of Utility-Scale Solar Projects on US Agricultural Land: Opportunities and Obstacles. Socio-Ecol. Pract. Res. 2023. [Google Scholar] [CrossRef]

- Grafman, L. To Catch the Sun: Inspiring Stories of Communities Coming Together to Harness Their Own Solar Energy, and How You Can Do It Too! Humboldt State University Press: Arcata, 2021; ISBN 978-1-947112-62-9. [Google Scholar]

- Wittbrodt, B.; Laureto, J.; Tymrak, B.; Pearce, J.M. Distributed Manufacturing with 3-D Printing: A Case Study of Recreational Vehicle Solar Photovoltaic Mounting Systems. J. Frugal Innov. 2015, 1, 1. [Google Scholar] [CrossRef]

- Wittbrodt, B.T.; Pearce, J.M. Total U.S. Cost Evaluation of Low-Weight Tension-Based Photovoltaic Flat-Roof Mounted Racking. Sol. Energy 2015, 117, 89–98. [Google Scholar] [CrossRef]

- Wittbrodt, B.; Pearce, J.M. 3-D Printing Solar Photovoltaic Racking in Developing World. Energy Sustain. Dev. 2017, 36, 1–5. [Google Scholar] [CrossRef]

- Arefeen, S.; Dallas, T. Low-Cost Racking for Solar Photovoltaic Systems with Renewable Tensegrity Structures. Sol. Energy 2021, 224, 798–807. [Google Scholar] [CrossRef]

- Pearce, J.M.; Meldrum, J.; Osborne, N. Design of Post-Consumer Modification of Standard Solar Modules to Form Large-Area Building-Integrated Photovoltaic Roof Slates. Designs 2017, 1, 9. [Google Scholar] [CrossRef]

- Vandewetering, N.; Hayibo, K.S.; Pearce, J.M. Impacts of Location on Designs and Economics of DIY Low-Cost Fixed-Tilt Open Source Wood Solar Photovoltaic Racking. Designs 2022, 6, 41. [Google Scholar] [CrossRef]

- Vandewetering, N.; Hayibo, K.S.; Pearce, J.M. Open-Source Design and Economics of Manual Variable-Tilt Angle DIY Wood-Based Solar Photovoltaic Racking System. Designs 2022, 6, 54. [Google Scholar] [CrossRef]

- nlinventor Ground Mounted Solar Panels With Adjustable Angles. Available online: https://www.instructables.com/Ground-Mounted-Solar-Panels-With-Adjustable-Angles/ (accessed on 2 January 2024).

- Vandewetering, N.; Hayibo, K.S.; Pearce, J.M. Open-Source Vertical Swinging Wood-Based Solar Photovoltaic Racking Systems. Designs 2023, 7, 34. [Google Scholar] [CrossRef]

- Masna, S.; Morse, S.M.; Hayibo, K.S.; Pearce, J.M. The Potential for Fencing to Be Used as Low-Cost Solar Photovoltaic Racking. Sol. Energy 2023, 253, 30–46. [Google Scholar] [CrossRef]

- Mayville, P.; Patil, N.V.; Pearce, J.M. Distributed Manufacturing of after Market Flexible Floating Photovoltaic Modules. Sustain. Energy Technol. Assess. 2020, 42, 100830. [Google Scholar] [CrossRef]

- Jamil, U.; Vandewetering, N.; Pearce, J.M. Solar Photovoltaic Wood Racking Mechanical Design for Trellis-Based Agrivoltaics. PLOS ONE 2023, 18, e0294682. [Google Scholar] [CrossRef]

- Franz, J.; Morse, S.; Pearce, J.M. Low-Cost Pole and Wire Photovoltaic Racking. Energy Sustain. Dev. 2022, 68, 501–511. [Google Scholar] [CrossRef]

- Wood and Cable-Based Variable Tilt Stilt-Mounted Solar Photovoltaic Racking System[v1] | Preprints.Org. Available online: https://www.preprints.org/manuscript/202312.0086/v1 (accessed on 27 December 2023).

- Hollman, M.R.; Pearce, J.M. Geographic Potential of Shotcrete Photovoltaic Racking: Direct and Low-Concentration Cases. Sol. Energy 2021, 216, 386–395. [Google Scholar] [CrossRef]

- DIY Ground Mounted Solar Array. Available online: https://www.mobile-solarpower.com/ground-mount-solar-array.html (accessed on 2 January 2024).

- UnpluggedTexan How to Build a DIY Ground Mount Solar Panel Rack. Available online: https://www.youtube.com/watch?v=BKYSW4zRyVg (accessed on 2 January 2024).

- DIY SOLAR PANEL GROUND MOUNTING. Available online: https://signaturesolar.com/solar-news/diy-solar-panel-ground-mounting/ (accessed on 2 January 2024).

- Country View Acres Building Our First Solar Array. Easy, Low Cost Solar Ground Mount. Available online: https://www.youtube.com/watch?v=EZEq7Hdoz_E (accessed on 2 January 2024).

- Martin Johnson - Off Grid Living How to Build the Ultimate DIY Solar Panel Ground Mount. Available online: https://www.youtube.com/watch?v=7t4hGBWLtxM (accessed on 2 January 2024).

- BuilditSolar DIY PV System -- Building the Mounts. Available online: https://www.builditsolar.com/Projects/PV/EnphasePV/Mounts.htm (accessed on 2 January 2024).

- Everyday Solar Best DIY Solar Ground Mount | Complete Assembly. Available online: https://www.youtube.com/watch?v=IgeaQs1OUtE (accessed on 2 January 2024).

- Country Living Experience: A Homesteading Journey Finally An Affordable Solar Panel Ground Mount! Installation DIY EG4. Available online: https://www.youtube.com/watch?v=RX6kdvptl6s (accessed on 2 January 2024).

- Solano, E. How to Build a DIY Solar Panel Ground Mount - Tinktube. Available online: https://tinktube.com/free-plans/diy-solar-panel-ground-mount/ (accessed on 2 January 2024).

- Poz, D. Building A DIY Solar Array Ground Mount (Part 1). Available online: https://www.youtube.com/watch?app=desktop&v=tc-wgpGfbtA (accessed on 2 January 2024).

- Iduna’s Orchard DIY Solar Ground Mount (Simple, Cheap!). Available online: https://www.youtube.com/watch?v=6R8_HE2xt8g (accessed on 2 January 2024).

- Sirois, É. 10 DIY Solar Panel Rack Ideas - Tinktube. Available online: https://tinktube.com/diy-ideas/diy-solar-panel-rack-ideas/ (accessed on 2 January 2024).

- 30 Solar Panel Ground Mounting Kit IronRidge. Available online: https://sunwatts.com/30-solar-panel-ground-mounting-kit-ironridge/ (accessed on 5 January 2024).

- Solar Panels Ground Mount - DIY KIT- 4.62kW. Prairie Sun Sol.

- Ground Mount Solar Panel Kits for Sale | GoGreenSolar. Available online: https://www.gogreensolar.com/collections/ground-mount-solar-panel-kits (accessed on 5 January 2024).

- Canada, N.R.C. National Building Code of Canada 2015. Available online: https://nrc.canada.ca/en/certifications-evaluations-standards/codes-canada/codes-canada-publications/national-building-code-canada-2015 (accessed on 17 February 2022).

- 2 Man Auger Rental | The Home Depot Canada. Available online: https://www.homedepot.ca/en/home/tool-and-vehicle-rental/p.2-man-auger.08822.html (accessed on 27 December 2023).

- Concrete Compressive Strength Variation with Time. Available online: https://theconstructor.org/concrete/concrete-compressive-strength-variation-with-time/5933/ (accessed on 27 December 2023).

- Mamun, M.A.A.; Dargusch, P.; Wadley, D.; Zulkarnain, N.A.; Aziz, A.A. A Review of Research on Agrivoltaic Systems. Renew. Sustain. Energy Rev. 2022, 161, 112351. [Google Scholar] [CrossRef]

- Lehmann, S. Sustainable Construction for Urban Infill Development Using Engineered Massive Wood Panel Systems. Sustainability 2012, 4, 2707–2742. [Google Scholar] [CrossRef]

- Embodied Carbon Footprint Database. Available online: https://circularecology.com/embodied-carbon-footprint-database.html (accessed on 2 January 2024).

- Hildebrandt, J.; Hagemann, N.; Thrän, D. The Contribution of Wood-Based Construction Materials for Leveraging a Low Carbon Building Sector in Europe. Sustain. Cities Soc. 2017, 34, 405–418. [Google Scholar] [CrossRef]

- Salazar, J.; Meil, J. Prospects for Carbon-Neutral Housing: The Influence of Greater Wood Use on the Carbon Footprint of a Single-Family Residence. J. Clean. Prod. 2009, 17, 1563–1571. [Google Scholar] [CrossRef]

- 2018 NDS. Available online: https://awc.org/publications/2018-nds/ (accessed on 8 March 2022).

- Vandewetering, N.; Hayibo, K.S.; Pearce, J.M. Open-Source Photovoltaic—Electrical Vehicle Carport Designs. Technologies 2022, 10, 114. [Google Scholar] [CrossRef]

- Rana, S.; Vandewetering, N.; Powell, J.; Ariza, J.Á.; Pearce, J.M. Geographical Dependence of Open Hardware Optimization: Case Study of Solar Photovoltaic Racking. Technologies 2023, 11, 62. [Google Scholar] [CrossRef]

- SiteOne Stone Centre — Delivering Landscape Supplies in London, Ontario. Available online: https://www.east.siteone.ca/ (accessed on 14 December 2023).

- Copp’s Buildall - London’s Local Hardware & Building Supply Specialists. Available online: https://www.coppsbuildall.com/?store=4 (accessed on 14 December 2023).

- Adpearance, I. What You Need to Know About Pressure Treated Wood | AIFP | PDX, OR. Available online: https://www.lumber.com/blog/what-you-need-to-know-about-pressure-treated-wood (accessed on 17 February 2022).

- Setliff, E.C. Wood Decay Hazard in Canada Based on Scheffer’s Climate Index Formula. For. Chron. 1986, 62, 456–459. [Google Scholar] [CrossRef]

- Helsen, L.; Bulck, E.; Hery, J.-S. Total Recycling of CCA Treated Wood Waste by Low-Temperature Pyrolysis. Waste Manag. 1998, 18, 571–578. [Google Scholar] [CrossRef]

- Frost Heave Prevention or How to Stop Frost Heaving. Available online: https://www.ecohome.net/guides/3628/what-causes-frost-heave-read-here-how-to-prevent-and-fix-frost-heaving/ (accessed on 27 December 2023).

- Lumber - 2022 Data - 1978-2021 Historical - 2023 Forecast - Price - Quote - Chart. Available online: https://tradingeconomics.com/commodity/lumber (accessed on 26 July 2022).

- Municipal Climate Change Action Centre in Alberta. Available online: https://mccac.ca/ (accessed on 2 January 2024).

- Toronto, C. of Solar Permitting & Regulations. Available online: https://www.toronto.ca/services-payments/water-environment/net-zero-homes-buildings/solar-to/solar/ (accessed on 27 November 2023).

- Solar Panels. Available online: https://www.waterloo.ca/en/living/solar-panels.aspx (accessed on 27 November 2023).

- Building Permits | City of London. Available online: https://london.ca/living-london/building-renovating/building-permits (accessed on 29 November 2023).

- US EPA, O. Overview of Wood Preservative Chemicals. Available online: https://www.epa.gov/ingredients-used-pesticide-products/overview-wood-preservative-chemicals (accessed on 28 May 2022).

- Haywood, S. The Effect of Excess Dietary Copper on the Liver and Kidney of the Male Rat. J. Comp. Pathol. 1980, 90, 217–232. [Google Scholar] [CrossRef] [PubMed]

- Rasmussen, T.; Fraser, R.; Lemberg, D.S.; Regis, R. Mapping Stamp Sand Dynamics: Gay, Michigan. J. Gt. Lakes Res. 2002, 28, 276–284. [Google Scholar] [CrossRef]

- Kumi-Larbi Jnr, A.; Galpin, R.; Manjula, S.; Lenkiewicz, Z.; Cheeseman, C. Reuse of Waste Plastics in Developing Countries: Properties of Waste Plastic-Sand Composites. Waste Biomass Valorization 2022, 13, 3821–3834. [Google Scholar] [CrossRef]

- Seghiri, M.; Boutoutaou, D.; Kriker, A.; Hachani, M.I. The Possibility of Making a Composite Material from Waste Plastic. Energy Procedia 2017, 119, 163–169. [Google Scholar] [CrossRef]

- Kern, E.C. Ballast-Mounted PV Arrays: Phase 2 Final Report; Ascension Technology, Inc.: Lincoln, MA (US), 2000. [Google Scholar]

- Fanney, A.H.; Weise, E.R.; Henderson, K.R. Measured Impact of a Rooftop Photovoltaic System. J. Sol. Energy Eng. 2003, 125, 245–250. [Google Scholar] [CrossRef]

- Peek, R.T. Innovative Ballasted Flat Roof Solar PV Racking System; Cascade Engineering, Grand Rapids, MI (United States), 2014.

- Wills, R.; Milke, J.A.; Royle, S.; Steranka, K. Best Practices for Commercial Roof-Mounted Photovoltaic System Installation; Springer, 2015; ISBN 978-1-4939-2883-5. [Google Scholar]

- Franklin, D.E. Mounting Your Solar Photovoltaic (PV) System.

- Peek, R.T. Innovative Ballasted Flat Roof Solar PV Racking System; Cascade Engineering, Grand Rapids, MI (United States), 2014.

- Roecker, C. NEW MOUNTING SYSTEMS FOR PV ON BUILDINGS. 2000.

- Alrawashdeh, H.; Stathopoulos, T. Wind Loads on Solar Panels Mounted on Flat Roofs: Effect of Geometric Scale. J. Wind Eng. Ind. Aerodyn. 2020, 206, 104339. [Google Scholar] [CrossRef]

- P.Eng Stamped Structural Roof Assessment - Structural Roof Load Assessment | Solar Roof Installation Permitting Service. Available online: https://solarpowerstore.ca/products/p-eng-stamped-structural-roof-assessment (accessed on 4 January 2024).

- Friction Coefficients - Slab on Grade. Available online: https://structx.com/Material_Properties_007.html (accessed on 27 December 2023).

| Basket Type | Weight of Rocks Required per Basket [lbs] | Number of Baskets | Cost of Rocks per Basket [$CAD] | Total Cost of Rocks [$CAD] |

|---|---|---|---|---|

| Inside | 590 | 6 | 14.16 | 113.28 |

| Outside | 295 | 4 | 7.08 | 56.64 |

| Lateral | 45 | 2 | 1.08 | 2.16 |

| Total Cost of Rocks | $172.08 |

| Basket Type | Weight of Rocks Required [lbs] | Number of Baskets | Cost of Rocks per Basket [$CAD] | Total Cost of Rocks [$CAD] |

|---|---|---|---|---|

| Continuous | 1939 | 2 | 46.54 | 93.07 |

| Lateral | 45 | 2 | 1.08 | 2.16 |

| Total Cost of Rocks | 95.23 |

| Member Name | Piece1 | Cost per Piece2 | Quantity | Cost |

|---|---|---|---|---|

| Outside Joists | 2x6x8 | $12.60 | 2 | $25.20 |

| Inside Joists | 2x8x8 | $18.87 | 9 | $169.83 |

| Beams | 2x8x10 | $23.58 | 8 | $188.64 |

| Front Posts | 4x4x10 | $20.99 | 4 | $83.96 |

| Joist to Beam Connection | 2x4 Fence Bracket | $0.43 | 22 | $9.46 |

| Back Supports | 2x4x8 | $7.47 | 10 | $74.70 |

| 2x4 Hinges | 8” Gate Hinges | $16.99 | 10 | $169.70 |

| 4x4 to Beam Hinges | 6” Gate Hinges | $11.99 | 6 | $71.94 |

| Beam to Post Connection | ½” Carriage Bolt (6”) | $4.44 | 6 | $26.64 |

| Beam to Post Connection | ½” Nut | $0.79 | 6 | $4.74 |

| Beam to Post Connection | ½” Washer | $0.80 | 6 | $4.80 |

| Tension Based Connections | 2-1/2” Brown Deck Screws | $49.99 | 1 | $49.99 |

| Shear Based Connections | 1-1/2” Joist Hanger Nails | $4.19 | 3 lb | $4.19 |

| Superstructure Cost | $883.79 | |||

| Post Block | 4x4 Deck Block | $10.45 | 12 | $125.40 |

| Gabion Wire Basket | 1” x 36” x 25′ Chicken Wire | $37.99 | 3 | $113.97 |

| Plywood on Gabion Basket | 4x8x1/2” Plywood | $71.95 | 1 | $71.95 |

| Gabion Rocks | Large Riverstone (2+”) | $95.233 | 1 | $95.23 |

| Foundation Cost | $406.55 | |||

| Total Cost | $1290.34 | |||

| Cost/W | $0.3226 |

| System | Number of Bags | Cost per Bag | Total Concrete Cost |

|---|---|---|---|

| T-shaped Fixed Tilt System | 15 | $6.39 | $95.85 |

| Variable Tilt System | 24 | $6.39 | $153.36 |

| System | With Ballast Foundation [$/W] | With Concrete Foundation [$/W] | Percentage Difference |

|---|---|---|---|

| T-shaped Fixed Tilt System | 0.3429 | 0.2712 | 26.4% |

| Variable Tilt System | 0.3226 | 0.2593 | 24.4% |

| System | With Purchased Rocks [$/W] | With Free Rocks [$/W] | Percentage Difference |

|---|---|---|---|

| T-shaped Fixed Tilt System | 0.3429 | 0.2999 | 14.3% |

| Variable Tilt System | 0.3226 | 0.2988 | 7.9% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).