1. Introduction

1.1. Coin Minting and Withdrawing

Coin minting is a manufacturing process which consists in pressing at high loads a coin blank with hardened steel obverse and reverse negative dies, which forms together with the collar a closed space to be filled by coin metal [

1,

2]. Usually, the relief figures on the negative dies are incused engraved; after the coin striking the figures result embossed engraved on the final metal coin [

3]. Of course, the coin model contains also the circulating nominal value and the issuing authority [

4].

Technical coin characteristics as diameter, weight, alloy content or represented figures are provided by adequate legal provisions [

5]. Also, the issuing terms are provided for the large public. Following the circulation period, the coin withdrawing is necessary and it is also provided by legal provisions, as terms and conditions [

5]. Valueless coins are retracted and, following the sustainable reuse of the metal alloy, are subjected to be melted.

But not all issued coins return to the issuer authority. Some remains at the public to be treasured by different reasons: to keep the metal piece, if valuable, as a memory from different times and places, as possible collecting items, or kept without any reason [

6]. Some other pieces could be lost in different circumstances and founded after many years.

During time, a valueless coin can acquire another value, as a collecting item: depending on its state, rarity or metal, its following price level can be lower or higher [

4,

7].

1.2. Coin Canceling

Countries around the world have been cancelling the metal coins withdrawn from circulation. Mainly done to prevent the returning into circulation, the metal coin cancelling (or metal coin defacing) consisted in destruction by pressing the coin between different patterns dies [

4]: lines, circles or other figures; a variety of this metal coin cancelling figures are also known in literature as waffle design [

8]. Some of metal coins were canceled by perforating holes. Usually, the cancelling was followed by the melting, in order to realize a sustainable recycle of the coin metal content, especially if the subjected metal was precious. But, for different reasons, some of these canceled coins had come to the collectors market: due to the piece state conservation, spectacularly aspect and rarity range, some are most valuable than other.

The literature indicates a lot of cancelled coins from different countries, as United Kingdom, Germany, United States, Malaysia, Philippine and others [

8,

9,

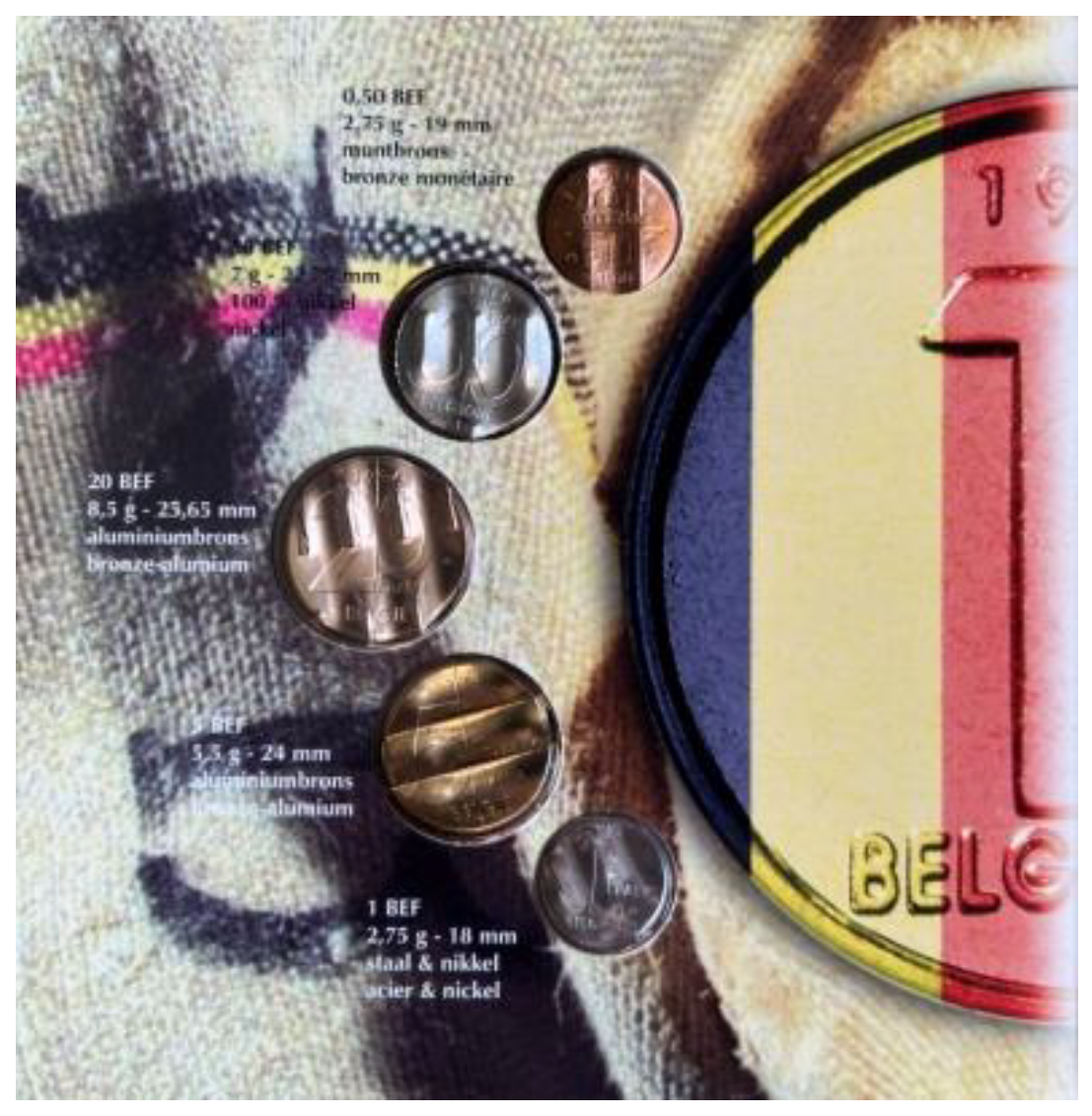

10]. In Europe, the introduction of euro currency generated a large hoard of cancelled coins, provided by the former currency of the involved countries. For commercial purpose, some of them are presented in lots or sealed numismatic sets and are highly appreciated by collectors; as example, in

Figure 1, there is presented a coin set containing the canceled coins of Belgium former franc. After the euro currency introduction, some of its metal coins were defaced because of their inconsistent manufacture or eventually deterioration; these pieces are also recorded by the specialty catalogues or internet sources [

10,

11].

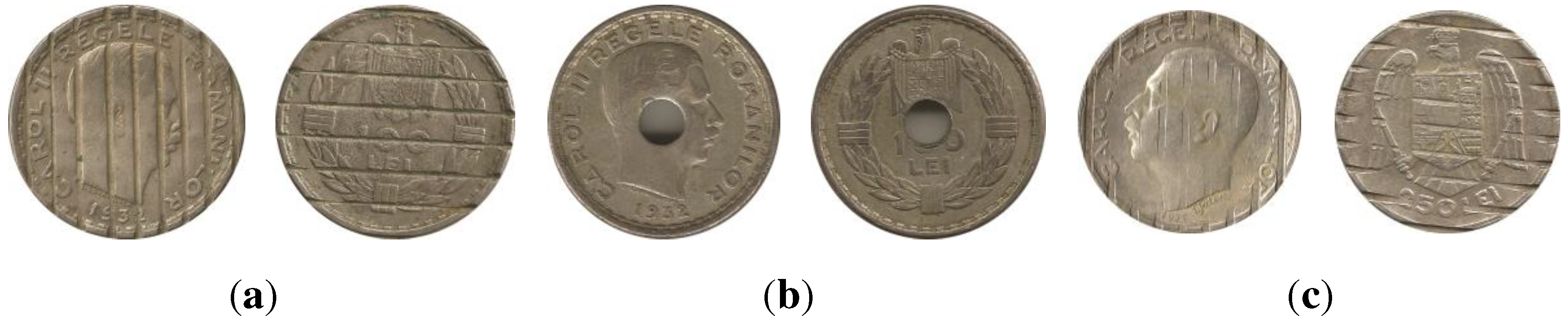

In Romania, the metal coin cancelling was introduced by authorities in the interwar period and was applied on some withdrawn coins in order to recycle the precious metal, but also on the discovered coin fakes, to prevent their reintroduction into circulation before melting [

5]. As example, in

Figure 2 there are presented some canceled Romanian coins from the interwar period.

The most known Romanian coins that have been massively canceled are the nickel coins of 50 and 100 lei, minted between the years 1936 – 1938. These coins, weighting 5.38, respectively 8.2 grams of fine nickel, were circulated until 1941 when, due to the country political changes and, also, the war out breaking, were withdrawn from circulation [

4,

5]. Their metal, fine nickel was considered important to supply the war industry needs and these obsolete coins had to be returned and replaced by other currency [

12]. In order to prevent the reintroduction into circulation, it was provided by the law their cancelling, supposed to be realized by those companies who indented to recycle the metal [

12]. As a result, for each nominal value, were retracted more than 80% of the initial mintage [

5], as is counted in

Table 1; the valueless remained pieces are also indicated. It has to be mentioned that, the remained undamaged pieces became valuable during decades on the collectors market [

4,

7]. Less appreciated in the past than their undamaged mates, now the canceled pieces reached also as valuable items the collector market [

4,

7]. But until today, is still unknown the exactly number of melted pieces from the withdrawn amount and what really was left on market as former canceled coins.

These may induce to the collector or interested customer, on one hand, the fear to achieve a valueless item that is not really needed [

6]; on the other hand, the tendency to buy the piece to be capitalized later at an increased price must be considered as well.

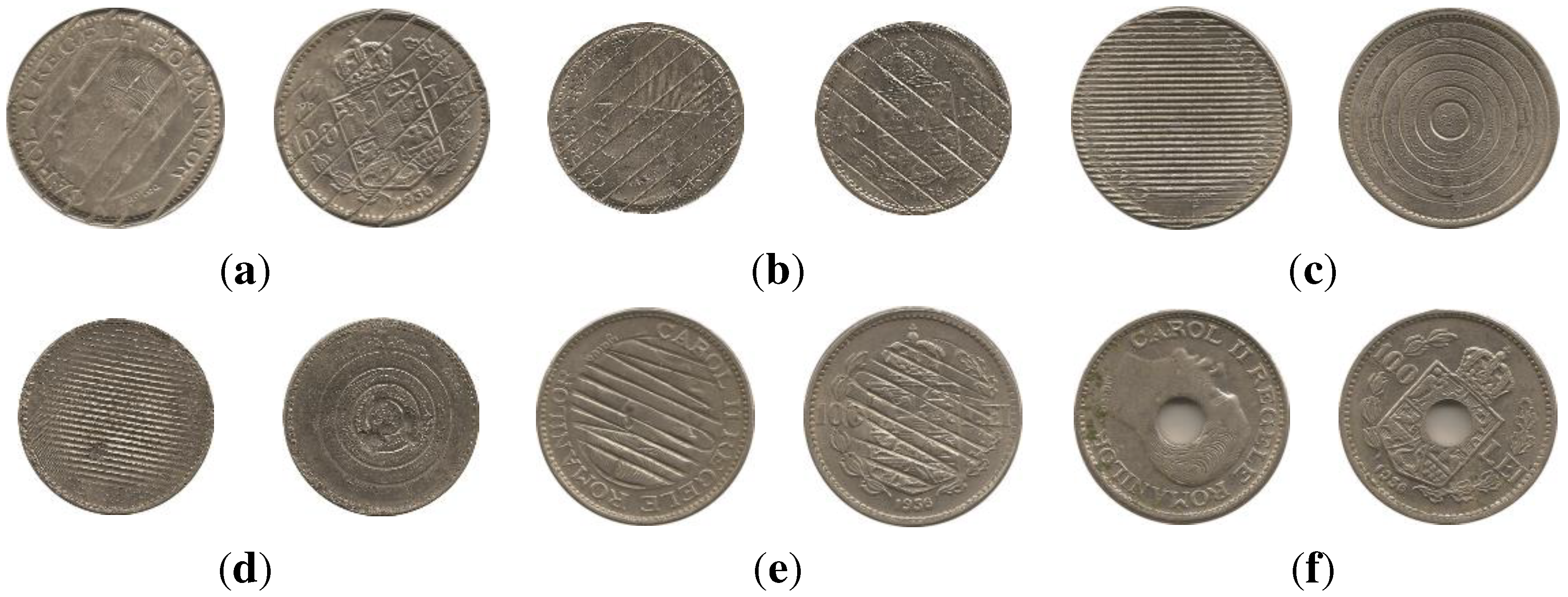

Today, the specialty literature [

4,

8,

13] records a large number of cancelled 50 and 100 lei nickel coins, as presented in

Figure 3. Some of those cancelling methods were previously used on other previous Romanian coins, as already presented in

Figure 2.

Following the cancelled coin needed rate to be melted and also the cost decreasing, it was observed that, the same cancelling design was more or less deep manufactured: since on the well cancelled coins the original model is hard recognizable, on the less cancelled, the coin model is almost unaffected by the applied canceling method. It has to be mentioned that the recorded cancelling pattern fits both coin sizes, 24 millimeters for the 50 lei coin, respectively 27 millimeters for the 100 lei coin [

4]. Also, the coin position between the cancelling dies was random. It’s also true that, the coins were canceled in different places, using different tools and pressing machines [

4,

12]. The mentioned manufacturing conditions led to some questions about what caused some particularities of a cancelling pattern or another and which was the most productive; so, the real motivation behind one or another used cancelling pattern may be revealed using modern study techniques.

2. Using of 3D Modeling and FEM Analysis in Coinage Field

The coinage industry is guided thru special regulations by most governments in the world [

1], so the specific studies about the coining process are quite rare in literature. Despite of these inconvenient the studied literature reveals important comprehensive contributions in the coining field that should be mentioned as follow.

Brekelmans et al. [

14] estimated in their work the predictions of coin material flow and also the coining pressure in order to realize a conical relief feature in the centre of a subjected piece. It was applied the finite element method, to obtain accurate information with respect to the corresponding stresses and strains. Also, was used the upper bound theorem which offered the possibility to determine more global results concerning the process; it was applied upon a quasi-static formulation with elasto-plastic constitutive equations, suitable for parameter research. Both methods were extensively described and evaluated and a quantitative comparison with experiments was used to verification; as a result, an excellent agreement was found. The work is considered by subsequent authors as the first application of the finite element method in the coin minting process.

Alexandrino et al. [

2] consider that, the research in science and technology of coin minting can be divided into three main periods that cover the previously passed five decades. In their work paper, the authors proposed a finite element method designing procedure to correct the coining die relief, in order to optimize the pressure distribution and also the alignment of the resultant vertical force at the end of the die stroke. This innovative design procedure for correcting the engraved die model, by tilting the obverse and also the reverse die reliefs, shows that the numerical simulation is able to be used to optimize the die model shapes, in order to reduce coin minting forces and extend the die life. The presented procedure was successfully applied at state mint of Portugal, to produce the collection coins dedicated to the age of iron and glass in Europe and, also, to the Portuguese ethnography. The coins were minted in 2017 [

15].

In their research, Zhong et al. [

1] studied the mechanism of flash line defect in coining process. Flash line is one of the most important surface failures which could appear on the manufactured coins. It is mostly unwanted on the silver commemorative coin. Usually, due to the lack of study on the defect causes, this failure requires a long time to be eliminated, through die tryouts which bring significant instabilities and development costs in subjected coin manufacture. In this study, the mechanism of flash line is studied by authors through the metal flow analysis using the finite element method. The authors concluded that, the radial components of friction between the die and also, the coin blank during striking are considered as the main reasons of the defect. The defects easily appear in the model field plane areas with metal flow state of compression and horizontal extrusion. The dies hardening effect and stress were also significant in the defect areas.

The mechanism of flash line defect in coining process was also studied by Xu et al. [

16]; they estimated that, the distribution of the flash-line surface defect is obtained by increasing the radial friction on the work model at the element level. The elasto-plastic large behavior of porous materials undergoing deformations is considered where the constitutive minimization level updates are the result of a local variation problem. It was studied the material flow at different die strokes, during the entire coining, and was observed that, the change in the flow direction of the material in the coin outer rim region may contribute the flash lines forming. It was proposed a new method of the rim geometry of the coin blank, to alleviate the flash-line defects which also led to good agreement with the experiments.

In other work [

3], Xu et al. developed commercial software called CoinForm in order to analyze the material flow during the coining process, including the prediction of the embossing force and the optimization for the geometry of the working dies.

Li et al. in their article [

17] proposed an 8-node hexahedral element based on multi-point integration in the dynamic explicit framework, with a new adopted adaptive subdivision method. Based on the several numerical examples, the locking-free and hourglass-free properties of the proposed hexahedral element are validated, and the accuracy of the coining simulation algorithm is also demonstrated. In authors’ opinion, this successful performance of the proposed element was validated by several numerical examples, without locking phenomenon and hourglass problem taking place. Two practical coining simulations were also presented. In the first example, was designed a simple round shape coin, made by 99.9% Ag. In the second example, a complex key-shaped commemorative coin (also made by 99.9% Ag), was designed for 2010 World Expo in Shanghai. In both practical coining examples, the simulation results agreed well with the experimental results, which led to the accuracy and, also, the stability of the developed algorithm with adaptive element subdivision.

Keran et al. [

18] work is focused on the accuracy of force prediction model in closed die coin striking process. The authors consider that, in micro-forming processes, such as coin striking, the microstructure of the subjected material and reduced dimension scale of the coined geometry can have a substantial influence on the of material deformation phenomenon. To determine the accuracy of proposed force prediction model, the experimental and modeled data were statistically analyzed and graphically presented.

Peng et al. [

19] article present adequate predictions of stress distribution and material flow in coining process, applied on the case of bimetallic commemorative coin, using a professional software, Deform 3D. The stress distribution and material flow in coining processes are studied, comparative for single and also bimetallic commemorative coins. The developed numerical examples demonstrate that, there are three main typical stages over the whole process, for the single or bimetallic coin. The stress concentrations appear at the corners of striking dies and the material interface in case of bimetallic coin. Since two materials with different hardness are adopted for the core and also the ring, the numerical results indicate that large strains occur at the coin edge and, also, at the interface between metals - in case of bimetallic coin with soft core. These led to the conclusion that, a deep adhesion occurs at the interface in case of that soft material is in the core. The authors suggest that hard material in the inner core and soft one in the outer ring may cause falling of the coin core.

It can be considered that the studied coinage specific literature is focused to use modern methods as 3D modeling and FEM analysis in few main directions: to create the theoretical support for the general real striking condition, to resolve some particular issues appeared on certain coin striking, or, respectively, to study and explain some coins manufacturing errors appearance. On each work, the obtained results are remarkable. In the same time, the studied literature is poor into the direction of approaching the coin cancelling and eventually the coin metal recycling issues. The literature is also poor in studying by mentioned modern methods some interesting valuable coins as collectible items from the past times. These highlights the necessity to use the available modern techniques to study the particularities of the canceling methods used on certain former coins, in order to ease the value estimation expertise of the subjected pieces as collecting item. On their turn, the collection items that have an adequate estimated catalogue value are able to increase the customer satisfaction [

20] and, also, to promote the sustainable consumption practices in this field [

6].

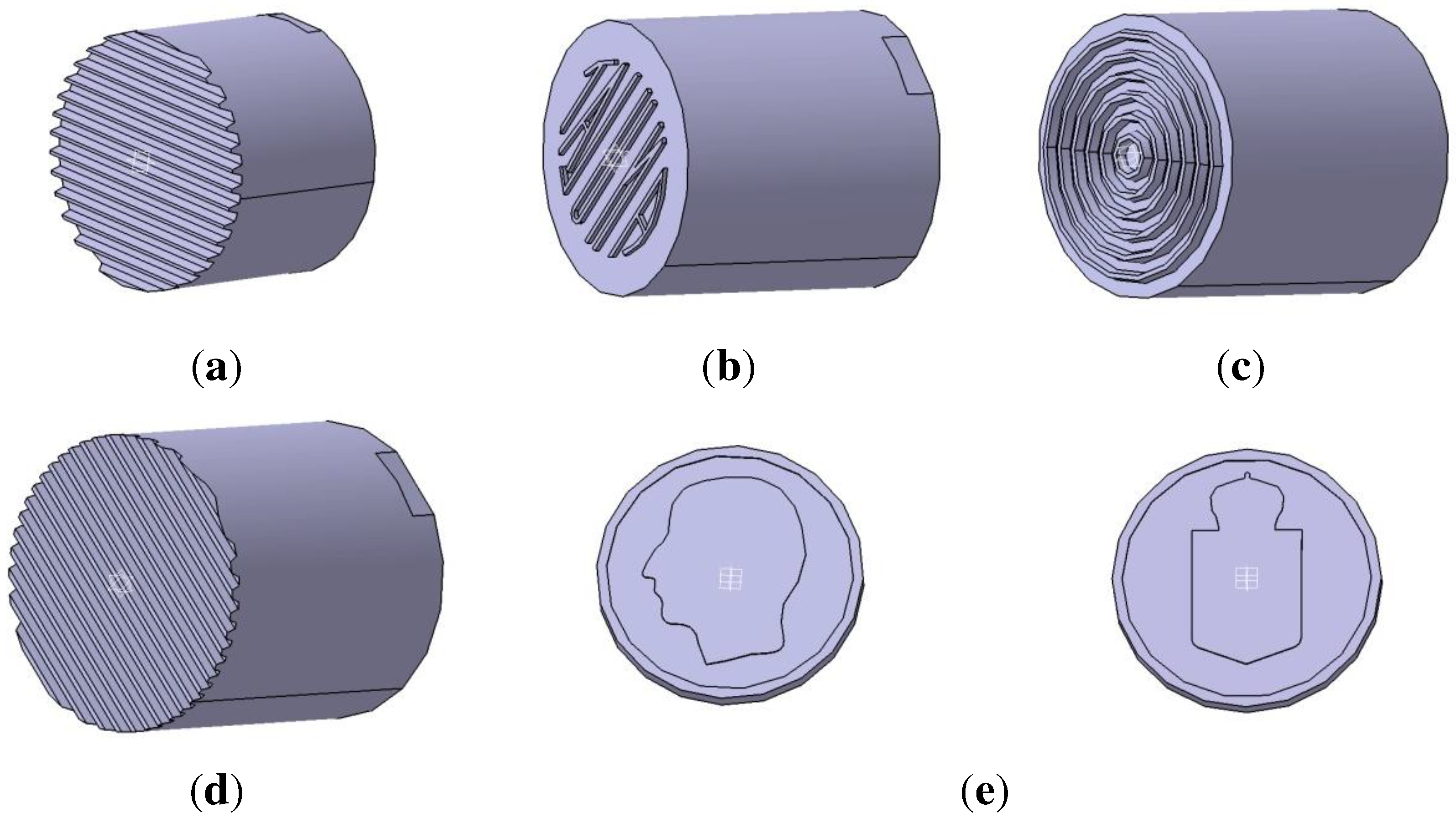

3. Computing the Virtual Model

As already presented, there are different types of patterns on cancelled 50 and 100 lei coins: the same parallel lines or inscription applied on both coin faces, respectively fine parallel lines applied on one face and concentric circles on the other face. The studied model will contain as parts, the both coin face cancelling dies and also the coin. Since the cancelling dies have a simple pattern to be computed, the subjected coins present some multiple complex details which cannot be faithfully reproduced on the virtual model [

21,

22]. So, a coin simplified model will be elaborated for the 100 lei piece, having represented on both faces just the main contour from the properly model. The coin angle between obverse-reverse figures, 180

0, is counted: while the obverse figure is placed in normal position, the reverse figure is placed upside down. Taking account of this it follows, for all needed parts, the virtual model computing, using the facilities offered by CATIA software, module Part Design [

23,

24]. Each cancelling die model consists in a cylinder having engraved the pattern negative contours, as presented in

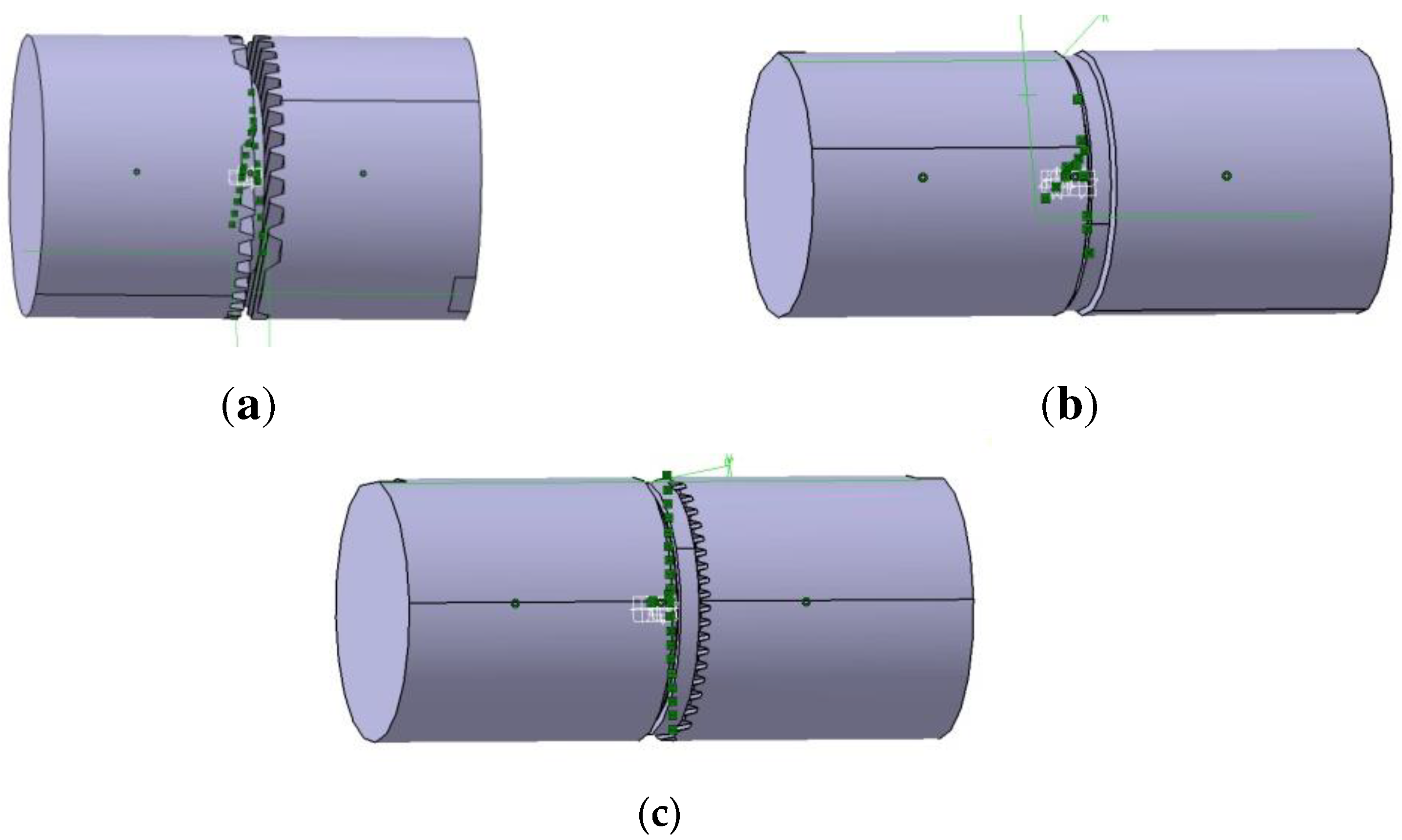

Figure 4.

To obtain the each subjected ensemble, the obtained individual parts must be combined: always two canceling dies having between the coins introduced. Using the CATIA software’s Assembly Design module [

23,

24], the devices assemblies are computed, as presented in

Figure 5.

Following the real first striking contact surface between the dies pattern and coin faces, the ensemble adequate constraints are defined. The defined contact area between the cancelling dies and coin covers the entire model highest common area, situation possible in the presumption when there are no the misalignments inside of the pressing machine and the relief is plan [

22,

25]. For the first and second ensemble models from

Figure 5, corresponding to the both faces parallel lines and, respectively, both faces inscription; the cancelling dies are positioned in the model to obtain the real pattern position, when the obverse-reverse angle between lines or inscription is 90

0. For the third ensemble model in

Figure 5, corresponding to the fine parallel lines on one face and concentric circles on the other face, the cancelling dies position in the model is not relevant.

4. Finite Element Model, Analysis and Simulation

For the analysis, the ANSYS software is used [

26]. The analysis objective is to determine the pressed cancelling dies on the coin ensemble behaviour under the load. For the analysis, the previous virtual assembled models are used. In following

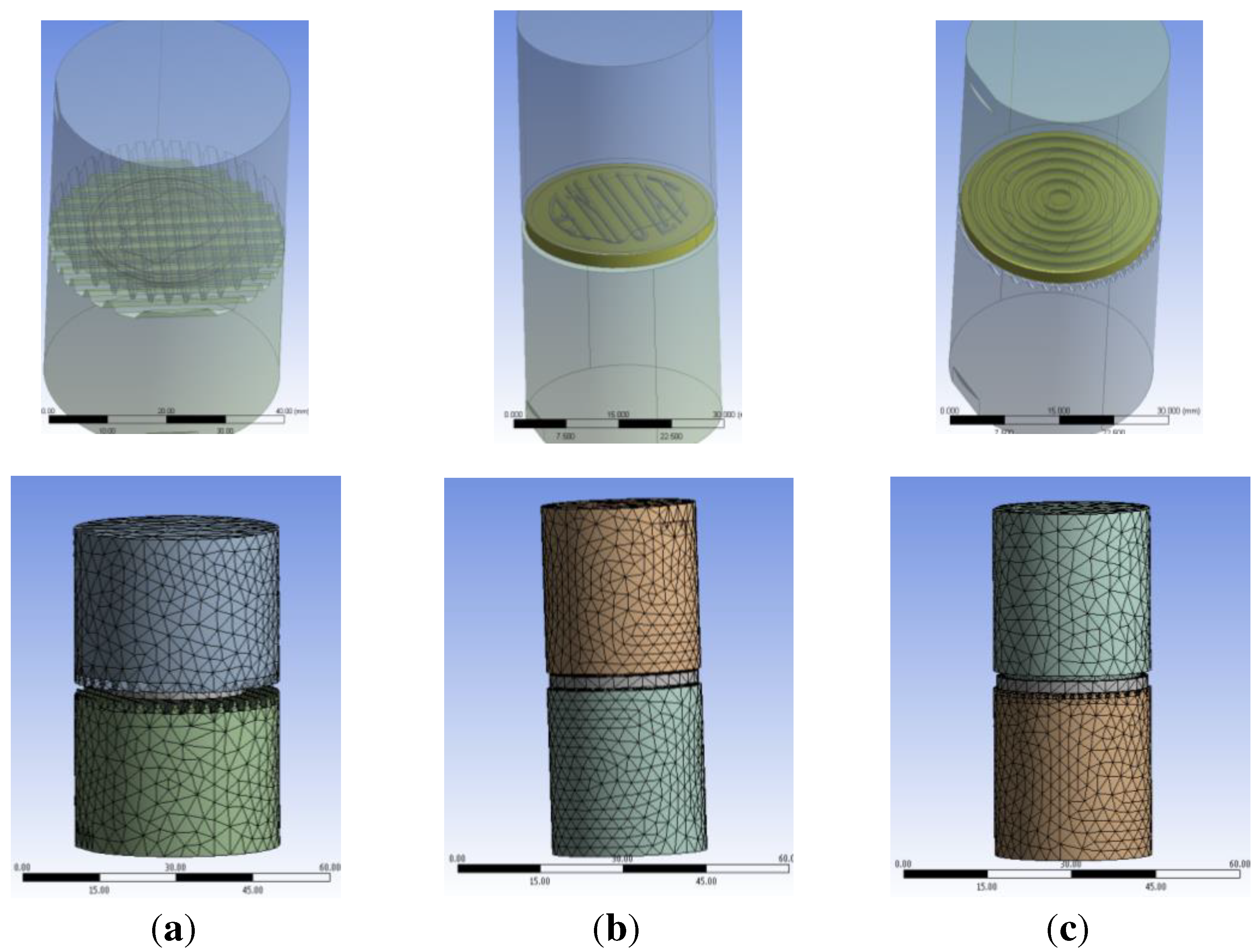

Figure 6, there are presented the obtained finite element model view and geometry, computed for all three studied cases: the model having on both faces parallel lines cancelling pattern, the model having on both faces inscription “ANULAT”, and, respectively, the model having as cancelling pattern fine parallel lines on one face and concentric circles on the other face.

The chosen material for cancelling dies is hardened steel; it has as mechanical properties: Density 7850 kg/m

3, Tensile Yield Stregth 250 MPa, Tensile Ultimate Strength 460 MPa, Young’s Modulus 200000 MPa and, respectively, Poisson’s Ratio 0.3. [

26,

27,

28]. The coin material is nickel, with the mechanical properties: Density 8900 kg/m

3, Tensile Yield Stregth 59 MPa, Tensile Ultimate Strength 317 MPa, Shear Modulus 76000 MPa and, respectively, Poisson’s Ratio 0.31 [

26,

27,

28]. In the contact area it is chosen a smooth mesh with the minimum edge length equal with 0.001 mm. Taking account that the cancelling dies doesn’t form a closed space around the pressed coin, the literature indicates that, the chosen coin material allowable stress should be decreased by 30-50%, related to the value corresponding to the closed space coin striking [

30]. The applied normal force is equal with 60KN, in order to obtain high contact pressures, over the coin blank material allowable stress, 1000 MPa [

5,

29,

30,

31].

5. Results and Discussion

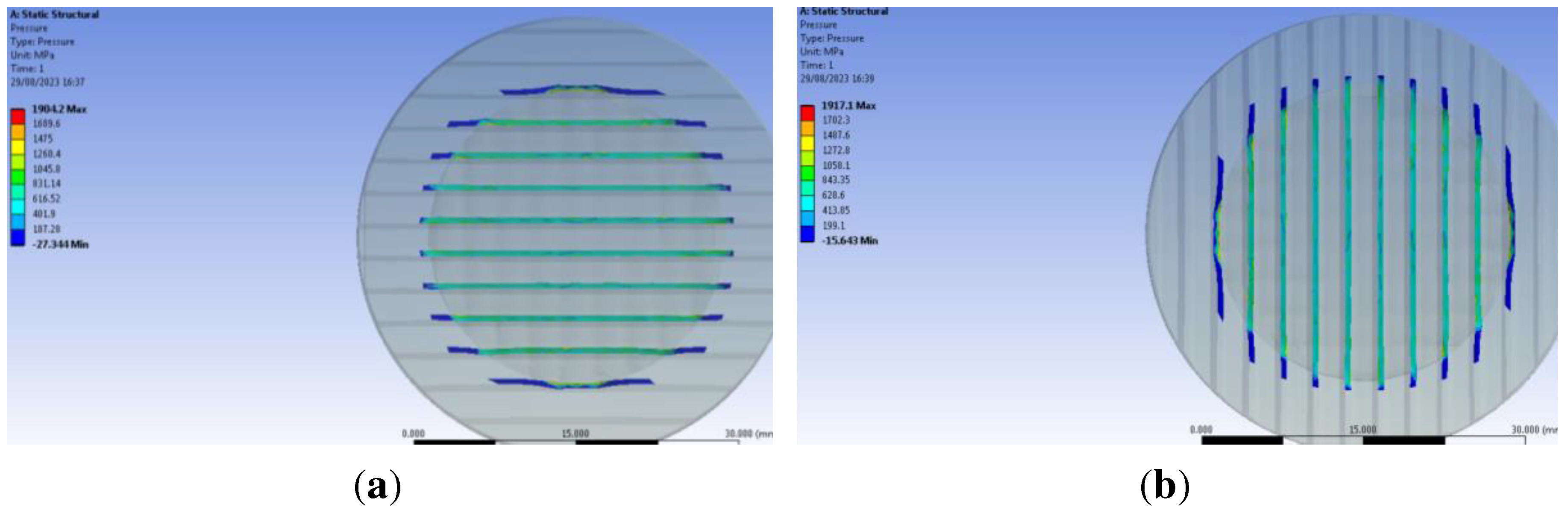

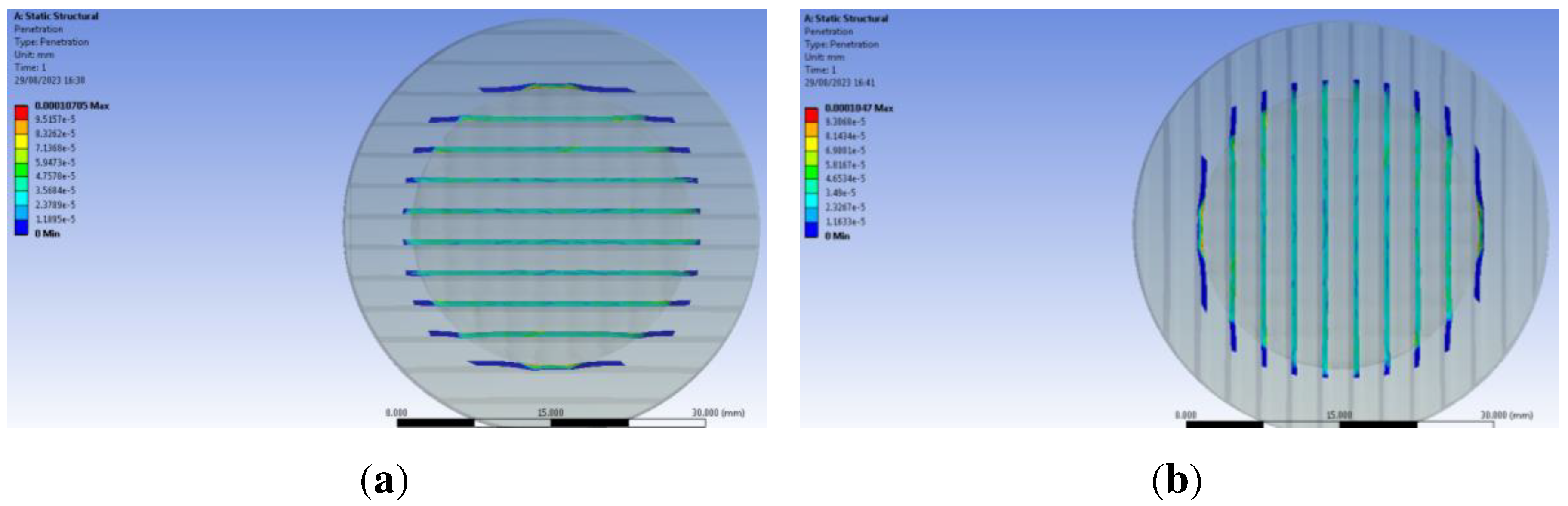

For all three studied cases, the results are presented in

Table 2 and, also, in to 12 and consist in the contact pressure maximum values and also the penetration maximum values on the each cancelling die material. The obtained values presented in

Table 2 should be considered as relative values, to be used to compare the different studied cases.

For the first studied model, having on both faces the similar parallel lines cancelling pattern, the related contact pressure maximum values are close each other; small differences are caused by different represented contours shape on the coin obverse and also reverse. For slightly increased contact area, the contact pressure maximum values are slightly decreasing. From

Figure 7 it can be observed that, those maximum values are recorded close to the coin outer edge. The other values appear in the main contact area and exceed the coin material allowable stress. The penetration maximum values are also recorded near the coin outer edge and are close for both obverse and reverse cancelling pattern dies, as presented in

Figure 8.

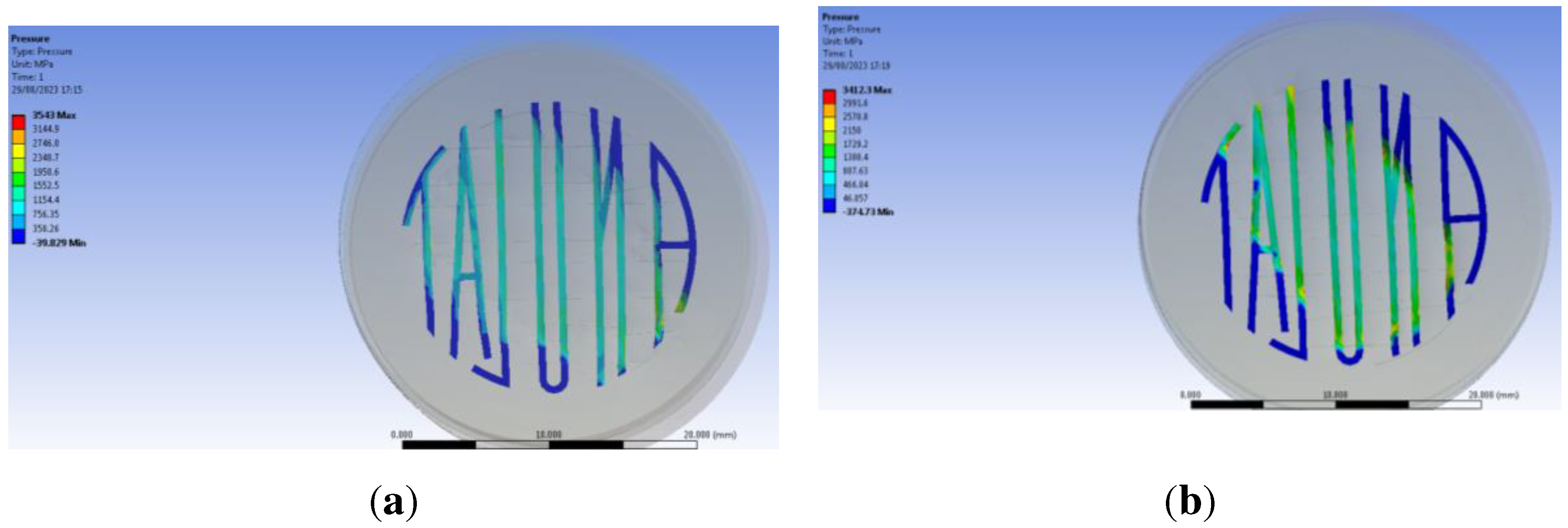

For the second model, having on both faces inscription “ANULAT”, the related contact pressure maximum values are close each other; also here, small differences are caused by different represented contours shape on the coin obverse and also reverse. Because the cancelling dies are smaller than the coin outer ring, from

Figure 9 it can be observed that, the maximum values are recorded close to the each face model edge contour; due to the coin material stiffness along the applied load direction, the faces contours are influencing each other the contact pressure in the contact area.

The other values appear in the main contact area and exceed the coin material allowable stress. But some of the contact pressure values exceed also the dies material allowable stress; so, the dies are damaged. This led to the conclusion that, this type of cancelling was applied on small pressing machines manually operated. The penetration maximum values are also recorded near the coin outer edge, and are close for both obverse and reverse cancelling pattern dies, as presented in

Figure 10.

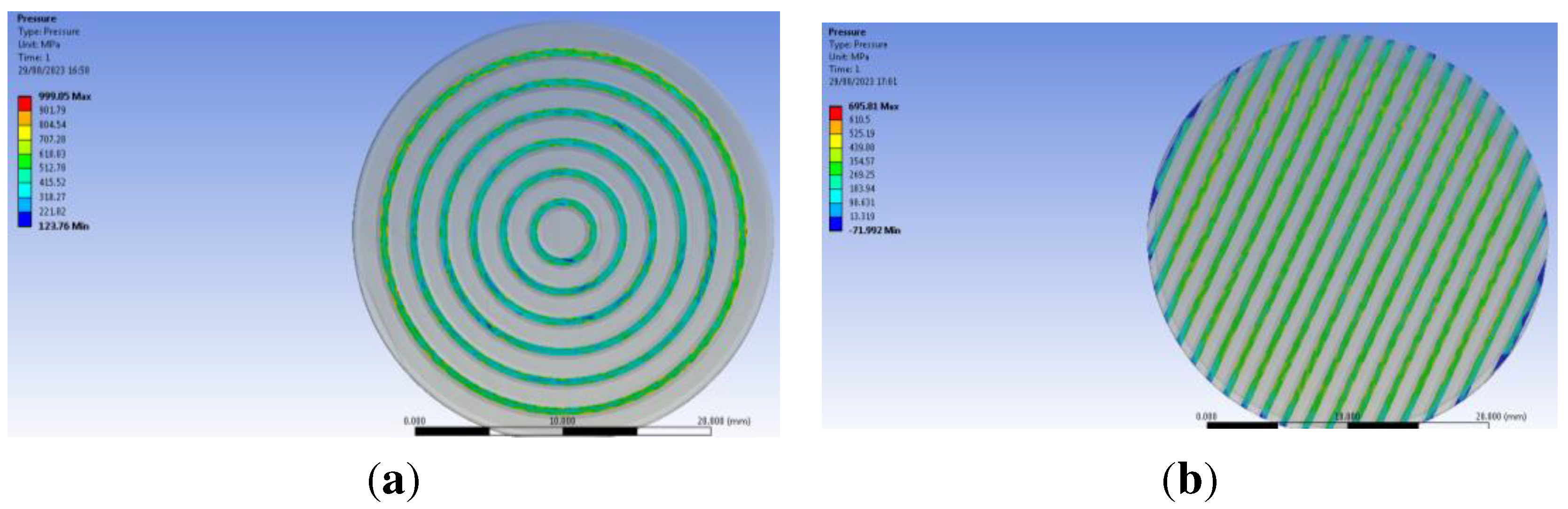

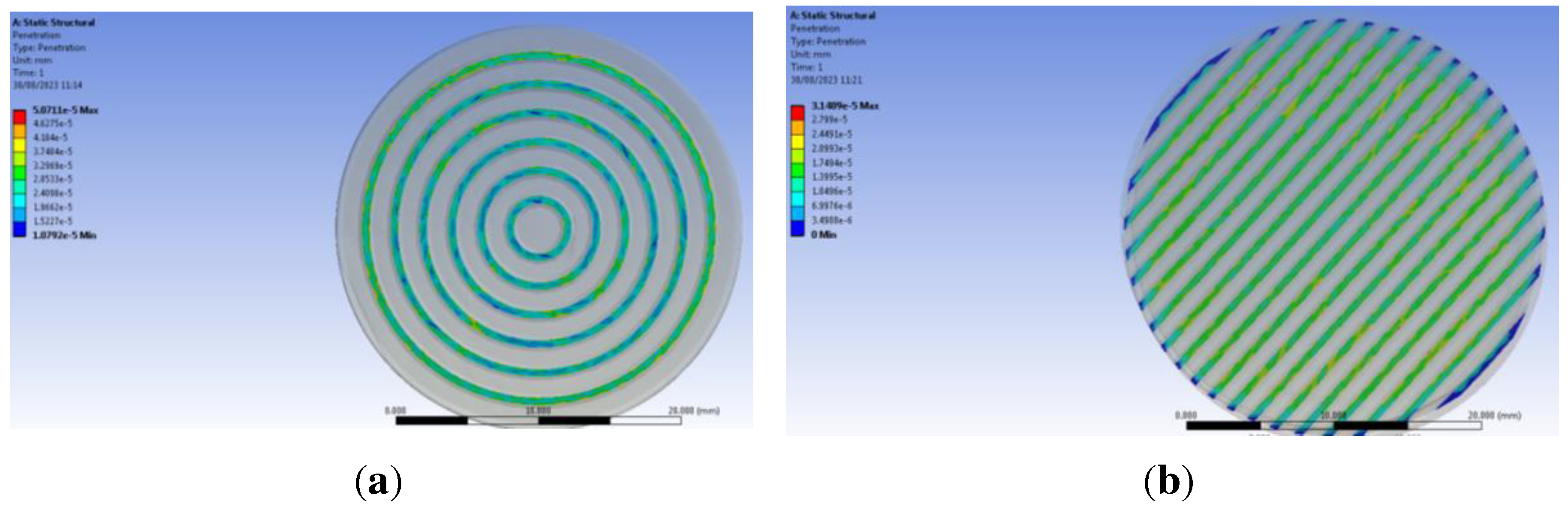

The third model has as cancelling pattern concentric circles applied on coin obverse and fine parallel lines applied on the coin reverse. The different pattern applied on coin faces has as main result important differences given by the contact area; in this case, the coin faces model differences are less important. The decreased area under the circles pattern led to increased contact pressure maximum values and, also, the increased area under the fine lines pattern led to decreased contact pressure maximum values, as presented in

Figure 11. Since the circles pattern is close to exceed the coin material allowable stress, the fine lines pattern is so far lower than this. The penetration maximum values, presented in

Figure 12 have the same trend: for circles pattern the value is higher than for fine lines pattern. It can be concluded that, the load value, 60 KN, was not adequate for this cancelling method. The needed load had to be obtained from a different bigger pressing machine.

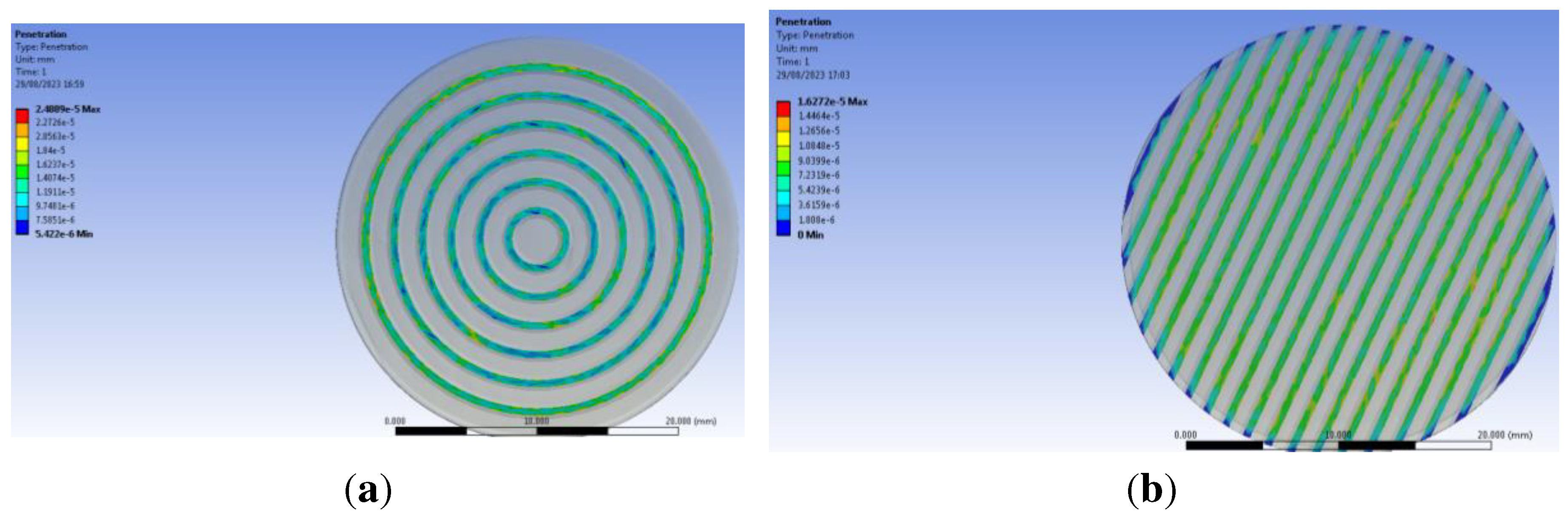

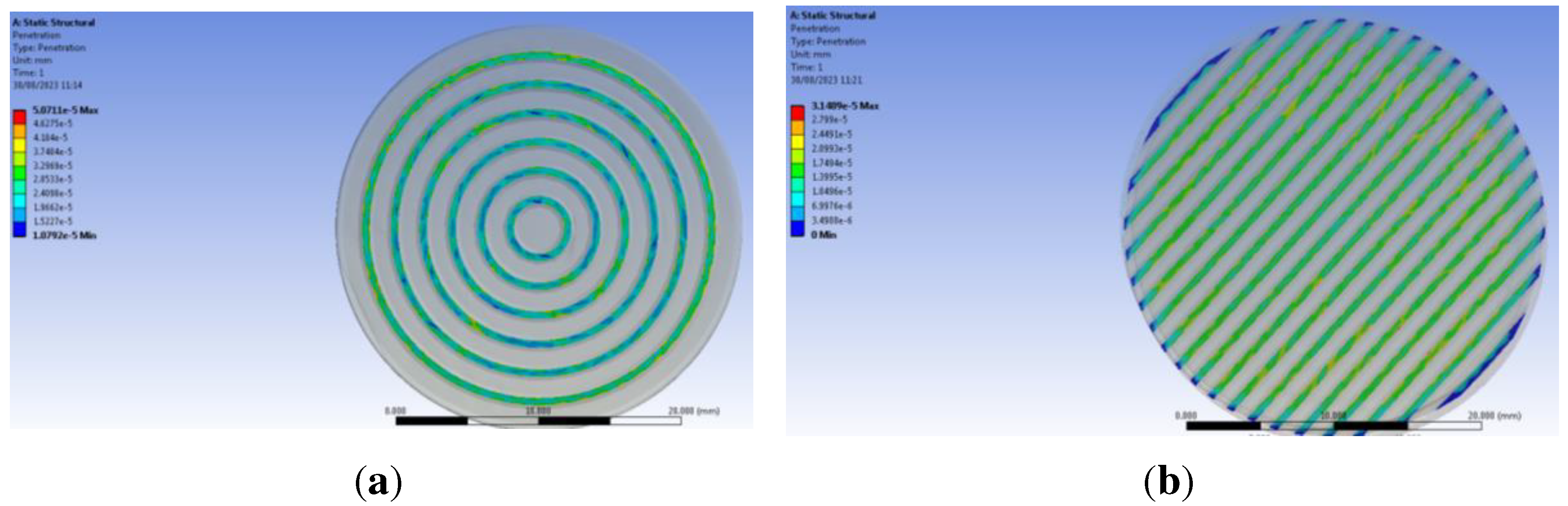

Consequently, this model was again simulated for an increased load, 120 KN [

5,

29,

30,

31]. The results are presented in

Table 3 and also in

Figure 13 and

Figure 14. The increased load led to increased contact pressure and penetration maximum values, but, due to the different contact area, the differences between the obverse and reverse values are maintained. The contact pressure on the fine line pattern finally reaches the level to exceed the coin material allowable stress. But in the same time, on the circular pattern die the values are more increased, over the dies material allowable stress. So, the circular pattern die is subjected to be damaged. This explains why some of the coins cancelled with this pattern type present die cracks on circles devaluated face.

6. Conclusions

Following the withdrawing of more than 80% issued nickel coins, the metal recycling, even in war condition, can be considered today as a sustainable procedure for that time.

As collecting issues, the remained coins, canceled or not, reached thru decades to a collectible value which depend by the conservation state or rarity. The canceled coins have added one more factor in their price estimation: the spectacular aspect of the applied procedure, which led to an increased value.

The three studied models indicate that, the coin cancelling was made on different pressing machines type. These generated different load, not necessarily well adapted to the used cancelling method. Since the similar used pattern used for both coin faces assured a longer dies lifetime, the different patterns used on the coin faces led to the destruction of the overloaded die. But, just before destruction, the canceling pattern has been impressed more spectacular, for example, added with damaged die cracks; so, for the resulted piece, the collecting value estimation could be easily increased.

By the proposed sustainable approach, the contribution of the paper is useful in further research on different metal coins, as well as for the market value establishing for the subjected pieces. A close to reality estimated catalogue value is able to increase the potential collector confidence and promote the good practices in the collecting issues field.

But not least, the remained former coins meet today their own highest sustainable mission: the belonging of the Romanian historical and cultural heritage, as part of the world heritage, ready to be revealed insight for the coming generations.

Supplementary Materials

Not applicable.

Author Contributions

Conceptualization, C.C.G.; methodology, C.C.G. and M.T.L.; software, C.C.G. and M.T.L.; validation, C.C.G., M.T.L. and G.G.; formal analysis, C.C.G. and M.T.L.; investigation, C.C.G.; resources, C.C.G., M.T.L. and G.G.; data curation, C.C.G. and M.T.L.; writing—original draft preparation, C.C.G.; writing—review and editing, C.C.G.; visualization, C.C.G. and M.T.L.; supervision, C.C.G., M.T.L. and G.G.. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Zhong, W.; Liu, Y.; Hu, Y.; Li, S.; Lai, M. Research on the Mechanism of Flash Line Defect in Coining Int. J. Adv. Manuf. Technol. 2012, 63, pp. 939–953.

- Alexandrino, P.; Leitão, P.J.; Alves, L.M.; Martins, P.A.F. Finite Element Design Procedure for Correcting the Coining Die Profiles, Manufacturing Rev. 2018, 5.

- Xu, J.P.; Liu, Y.Q.; Li, S.Q.; Wu, S.C. Fast Analysis System for Embossing Process Simulation of Commemorative Coin–CoinForm Comput. Model. Eng. Sci. 2008, 38, pp. 201–215.

- Buzdugan, G.; Luchian, O.; Oprescu, C. C. Romanian Coins and Banknotes Editura Sport Turism, Bucureşti, Romania, 1977; pp. 256 - 259.

- Finance Ministry, National Mint, Ten Years of Activity Monitorul oficial şi Imprimeriile statului; Bucureşti, Romania, 1945; pp. 81 - 87.

- Dabija, D.-C.; Csorba, L.M.; Isac, F.-L.; Rusu, S. Managing Sustainable Sharing Economy Platforms: A Stimulus–Organism– Response Based Structural Equation Modelling on an Emerging Market. Sustainability 2023, 15, 5583. [Google Scholar] [CrossRef]

- Krause, C.; Mishler, C.; Standard Catalog of World Coins Krause Publications, Iola, USA, 2001.

- Snyder B. World Mints Deface Coins with “Waffle Designs” Mint Errors News 2004, 5 Mike Byers, USA, p. 10.

- Euro 4, Monnaies et Billets, Edition Les Chevau-Lègers; Paris, France, 2007; p. 205.

- Coin World. Available online: https://www.coinworld.com/news/us-coins/canceled-coins-can-sometimes-return-to-the-co. html (accessed on 15 December 2023).

- Error-Ref. Available online: https://www.error-ref.com/canceled-waffled/ (accessed on 20 September 2023).

-

The Official Monitor of Romania, Monitorul oficial şi Imprimeriile statului, Bucureşti, Romania, 1941; no.189, part I., pp. 4708-4709.

- Romanian Coins. Available online: https://romaniancoins.org/ (accessed on 20 September2023).

- Brekelmans, W.A.M.; Mulders, L.H.G.; Ramaekers, J.A.H. The Coining Process: Analytical Simulations Evaluated CIRP Ann.Manuf. Techn. 1988, 37, pp. 235–238.

- Catalogue Euro. Coins and Banknotes,. Leuchtturm Albenverlag GmbH& Co.KG, Geesthacht, Germany, 2019; p. 529.

- Xu, J.P.; Khan, K.A.; Sayed, T.E. A Novel Method to Alleviate Flash-Line Defects in Coining Process Precision Engineering 2012, 37, pp.389–398.

- Li, Q.; Zhong, W.; Liu, Y.; Zhang, Z. A New Locking-Free Hexahedral Element With Adaptive Subdivision for Explicit Coining Simulation Int. J. Mech. Sci. 2017, 128–129, 105–115. [Google Scholar]

- Keran, Z.; Kondic, Z.; Piljec, P.; Runje, B. Accuracy of Model Force Prediction in Closed Die Coining Process Journal of Mechanical Engineering 2018, 64, pp.225-232.

- Peng, Y.; Xu, J.; Wang, Y. Predictions of Stress Distribution and Material Flow in Coining Process for Bi-Material Commemorative Coin Mater. Res. Express 2022, 9 066505.

- Huang, T.-C.; Ho, C.-T. Are Customers Always Right? The Importance of Sincerity and Keenness in Creating Retail Sustainable Development Sustainability 2023, 15, 5579. [Google Scholar]

- Arndt, C.; Crusenberry, C.; Heng, B.; Butler, R.; TerMaath, S. Reduced-Dimension Surrogate Modeling to Characterize the Damage Tolerance of Composite/Metal Structures Modelling 2023, 4, pp. 485–514.

- Gavrilă C. C.; and Lateş M. T. 3D Modelling and FEM Analysis on Die Clash Mint Error IOP Conf. Ser.: Mater. Sci. Eng. 2020, 898 012040 pp. 1 – 7.

- Ghionea, I. G. CATIA v5. Application in Mechanical Engineering Editura Bren Bucureşti, Romania, 2009.

- Ghionea I. G. CATIA v5. Parametric Design and Programming Applications, Editura Printech, Bucureşti, Romania, 2021.

- Hilbert, H. Stanzereitechnik Carl Hanser Verlag, Munchen, Germany, 1938; Volume I, p. 14, 196.

- Lee, H. H. Finite Element Simulations with ANSYS Workbench 14. Theory, Applications, Case Studies. Schroff Development Corporation, Kansas, USA, 2012.

- Lateş, M. T. Finite Elements Method. Applications Editura Universităţii Transilvania Braşov, Romania, 2008.

- Geru, N.; Chircă, D.; Bane, M.; Ripoşan, I.; Marin, M.; Coşmeleaţă, G.; Biolaru, T. Metallic Materials. Structure, Properties, Uses, Editura Tehnică, Bucureşti, Romania, 1985.

- Romanovski, V.P. Stamping and Cold Molding Editura Tehnica, Bucureşti, Romania, 1970; pp. 427 - 428.

- Iliescu, C.; Tureac, O. Cold Pressing Technology Editura Universităţii din Braşov Romania, 1987; pp. 262 - 267.

- Gavrilă, C. C.; Lateş, M. T. 3D Modelling and FEM Analysis on Holed Metal Coin Striking Die Mint Error, IOP Conf. Ser.: Mater. Sci. Eng. 2022, 1256 012001.

Figure 1.

Collectible numismatic set of canceled coins, obverse view

Figure 1.

Collectible numismatic set of canceled coins, obverse view

Figure 2.

Various cancelled Romanian metal coins: (a) a counterfeit 100 lei from 1932 which imitates the original made by silver, (b) perforated withdrawn silver 100 lei from 1932, (c) silver 250 lei from 1935.

Figure 2.

Various cancelled Romanian metal coins: (a) a counterfeit 100 lei from 1932 which imitates the original made by silver, (b) perforated withdrawn silver 100 lei from 1932, (c) silver 250 lei from 1935.

Figure 3.

Various cancelled Romanian nickel coins: (a) and (b) with parallel lines, (c) and (d) with circles and fine parallel lines, (e) with inscription and, respectively, (f), hole perforated.

Figure 3.

Various cancelled Romanian nickel coins: (a) and (b) with parallel lines, (c) and (d) with circles and fine parallel lines, (e) with inscription and, respectively, (f), hole perforated.

Figure 4.

The virtual model parts: (a), canceling die with parallel lines, (b), canceling die with inscription, (c), canceling die with circles, (d), canceling die with fine parallel lines and, respectively (e), the coin in two views.

Figure 4.

The virtual model parts: (a), canceling die with parallel lines, (b), canceling die with inscription, (c), canceling die with circles, (d), canceling die with fine parallel lines and, respectively (e), the coin in two views.

Figure 5.

The ensemble models having the cancelling die in contact with coin: (a), both canceling dies with parallel lines, (b), both canceling dies with inscription, and (c), one canceling die with circles and other with fine parallel lines.

Figure 5.

The ensemble models having the cancelling die in contact with coin: (a), both canceling dies with parallel lines, (b), both canceling dies with inscription, and (c), one canceling die with circles and other with fine parallel lines.

Figure 6.

The finite element model: (a), for both canceling dies with parallel lines, (b), for both canceling dies with inscription, and (c), for one canceling die with circles and other with fine parallel lines.

Figure 6.

The finite element model: (a), for both canceling dies with parallel lines, (b), for both canceling dies with inscription, and (c), for one canceling die with circles and other with fine parallel lines.

Figure 7.

The contact pressure on the parallel lines pattern cancelling dies: (a) obverse canceling die and (b) reverse canceling die.

Figure 7.

The contact pressure on the parallel lines pattern cancelling dies: (a) obverse canceling die and (b) reverse canceling die.

Figure 8.

The penetration on the parallel lines pattern cancelling dies: (a) obverse canceling die and (b) reverse canceling die.

Figure 8.

The penetration on the parallel lines pattern cancelling dies: (a) obverse canceling die and (b) reverse canceling die.

Figure 9.

The contact pressure on “ANULAT” pattern cancelling dies: (a) obverse canceling die and (b) reverse canceling die.

Figure 9.

The contact pressure on “ANULAT” pattern cancelling dies: (a) obverse canceling die and (b) reverse canceling die.

Figure 10.

The penetration on on “ANULAT” pattern pattern cancelling dies: (a) obverse canceling die and (b) reverse canceling die.

Figure 10.

The penetration on on “ANULAT” pattern pattern cancelling dies: (a) obverse canceling die and (b) reverse canceling die.

Figure 11.

The contact pressure on the concentric circles and fine parallel lines pattern cancelling dies: (a) obverse canceling die and (b) reverse canceling die.

Figure 11.

The contact pressure on the concentric circles and fine parallel lines pattern cancelling dies: (a) obverse canceling die and (b) reverse canceling die.

Figure 12.

The penetration on the concentric circles and fine parallel lines pattern cancelling dies: (a) obverse canceling die and (b) reverse canceling die.

Figure 12.

The penetration on the concentric circles and fine parallel lines pattern cancelling dies: (a) obverse canceling die and (b) reverse canceling die.

Figure 13.

The contact pressure for the increased load, on the concentric circles and fine parallel lines pattern cancelling dies: (a) obverse canceling die and (b) reverse canceling die.

Figure 13.

The contact pressure for the increased load, on the concentric circles and fine parallel lines pattern cancelling dies: (a) obverse canceling die and (b) reverse canceling die.

Figure 14.

The penetration for the increased load, on the concentric circles and fine parallel lines pattern cancelling dies: (a) obverse canceling die and (b) reverse canceling die.

Figure 14.

The penetration for the increased load, on the concentric circles and fine parallel lines pattern cancelling dies: (a) obverse canceling die and (b) reverse canceling die.

Table 1.

Issued, withdrawn and remained pieces of 50 and 100 lei nickel coins.

Table 1.

Issued, withdrawn and remained pieces of 50 and 100 lei nickel coins.

| Coin nominal value |

Year |

Issued pieces |

Withdrawn pieces |

Remained pieces1

|

| 50 lei |

1937 |

12,000,000 |

16,731,147 |

3,268,853 |

| 1938 |

8,000,000 |

| 100 lei |

1936 |

16,750,000 |

17,030,101 |

2,969,899 |

| 1938 |

3, 250,000 |

Table 2.

The contact pressure and the penetration on cancelling dies, maximum values, for loading case 60 KN

Table 2.

The contact pressure and the penetration on cancelling dies, maximum values, for loading case 60 KN

| The cancelling dies |

Contact pressure, MPa |

Penetration in the material, mm |

| Coin obverse cancelling die |

Coin reverse cancelling die |

Coin obverse cancelling die |

Coin reverse cancelling die |

| On both faces, parallel lines |

1904.2 |

1917.1 |

0.00010705 |

0.0001047 |

| On both faces, inscription “ANULAT” |

3543 |

3412.3 |

0.000079472 |

0.000075913 |

| Concentric circles on coin obverse combined with fine parallel lines on coin reverse |

999.05 |

695.81 |

0.000024889 |

0.000016272 |

Table 3.

The contact pressure and the penetration on cancelling dies, maximum values, for loading case 120 KN

Table 3.

The contact pressure and the penetration on cancelling dies, maximum values, for loading case 120 KN

| The cancelling dies |

Contact pressure, MPa |

Penetration in the material, mm |

| Coin obverse cancelling die |

Coin reverse cancelling die |

Coin obverse cancelling die |

Coin reverse cancelling die |

| Concentric circles on coin obverse combined with fine parallel lines on coin reverse |

2035.5 |

1347.5 |

0.000050711 |

0.000031489 |

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).