2.1. Circular Economy Supply Chain (CESC)

The CESC is mainly employed to carry out comprehensive innovation of the supply chain functions by reducing the consumption of resources and energy, lessening pollutant discharge, systematically storing materials, regenerating biomaterials, and constructing an ecosystem responsible for society. Ultimately, productivity and profitability is enhanced, in order to achieve the vision of zero waste and reach an optimal balance among economic, social and environmental benefits [

19,

35]. Remanufacturing is a key factor of the CE. It can slow down resource consumption, reduce pollution and solid waste, and further lower carbon emissions. Then, the CE can be formed by high-quality remanufacturing [

25,

46]. Mhatre et al. (2021) pointed out that implementing the CE in the supply chain is conducive to remanufacturing. Therefore, when waste products are input as production materials and enter the supply chain to conduct remanufacturing [

25], the CESC can be realized, and the goal of zero waste can be achieved as well. When the industry can carry out value recycling across different supply chains as well as integrate and coordinate supply chains to realize material recycling, then it can exhibit a higher level of CESC and raise its competitiveness and performance [

45].

Adopting a CE in the supply chain can keep the products and materials use in the production line at a higher efficiency, so that materials and products can be kept in the longest time of circulation [

43]. Additionally, the use of resources can be minimized, carbon dioxide emissions can be lessened, social benefits can be leveled up with more eco-friendly products, and finally the environment can be better protected [

35]. Ansari et al. (2020) also proposed that adopting the CESC is an approach to sustainable development, which can help generate economic, social, and environmental benefits, save energy, lessen emissions, and ultimately enhance profitability. When companies adopt CESC, they can decrease carbon emissions in the production process as well as offer environmental benefits [

45]. Alternatively, they can cooperate with other organizations to gain more value from waste recycling [

5], and waste can also be used as an alternative resource for making new products as well as create new business opportunities while protecting the environment [

29].

Recent studies have indicated that insufficient shared data in the supply chain restricts taking CE. However, in the long-term perspective, the CE is the main key to carrying out sustainability programs. Unfortunately, the current literature lacks specific strategies for the effective promotion of data sharing and sharing data in a timely manner [

13]. This study believes that this is a key factor in urging CESC in remanufactured products. Chen and Huang (2021) also proposed that the uncertainty of the current CESC mainly comes from the information asymmetry between companies, which make it difficult for companies to make decisions. Nonetheless, most of the methods proposed by other studies are at the theoretical stage and not systematic enough, so it is difficult to carry them out. Zhang et al. (2021) addressed that to effectively manage the CE, appropriate circularity indicators must be developed at product and supply chain levels. Therefore, this study incorporated past literature and integrated the CE and the supply chain into a framework applicable to remanufactured products. Besides, this study provided detailed definitions and proposed aspects and criteria of implementation.

2.2 Proposed Methods

The FDM was developed by Murray et al., combining the fuzzy theory with the Delphi method to conduct analysis [

34]. Compared with the traditional Delphi method, the strength of the FDM is that it can reduce the number of expert investigations, explicitly reveal expert opinions, and consider the uncertainty of the collected data [

9,

34]. FDM can verify the indicators with the level of judgment through experts’ language preferences, which can not only reduce the ambiguity of expert evaluation but also ensure the quality of the results [

38]. Additionally, Chen et al. (2021) propose that the FDM strength is that it can shorten the time for experts to make decisions as well as eliminate less important qualitative information and subjective preferences at the same time.

The Geneva Research Center put forward the DEMATEL method, which was helpful to discover the relationship between standards. However, only using DEMATEL was not enough to control the uncertainty of the data, so the fuzzy set theory was suggested to help explain and judge the uncertain environment related to fuzziness [

44]. The fuzzy DEMATEL expounds the causal relationships between attributes by computing the weight of each attribute [

37]. Consequently, this study first used FDM to select the key factors, determined the key factors, and then used fuzzy DEMATEL so as to determine the cause-and-effect relationships between indicators and their importance ranking.

2.2 Proposed measures s

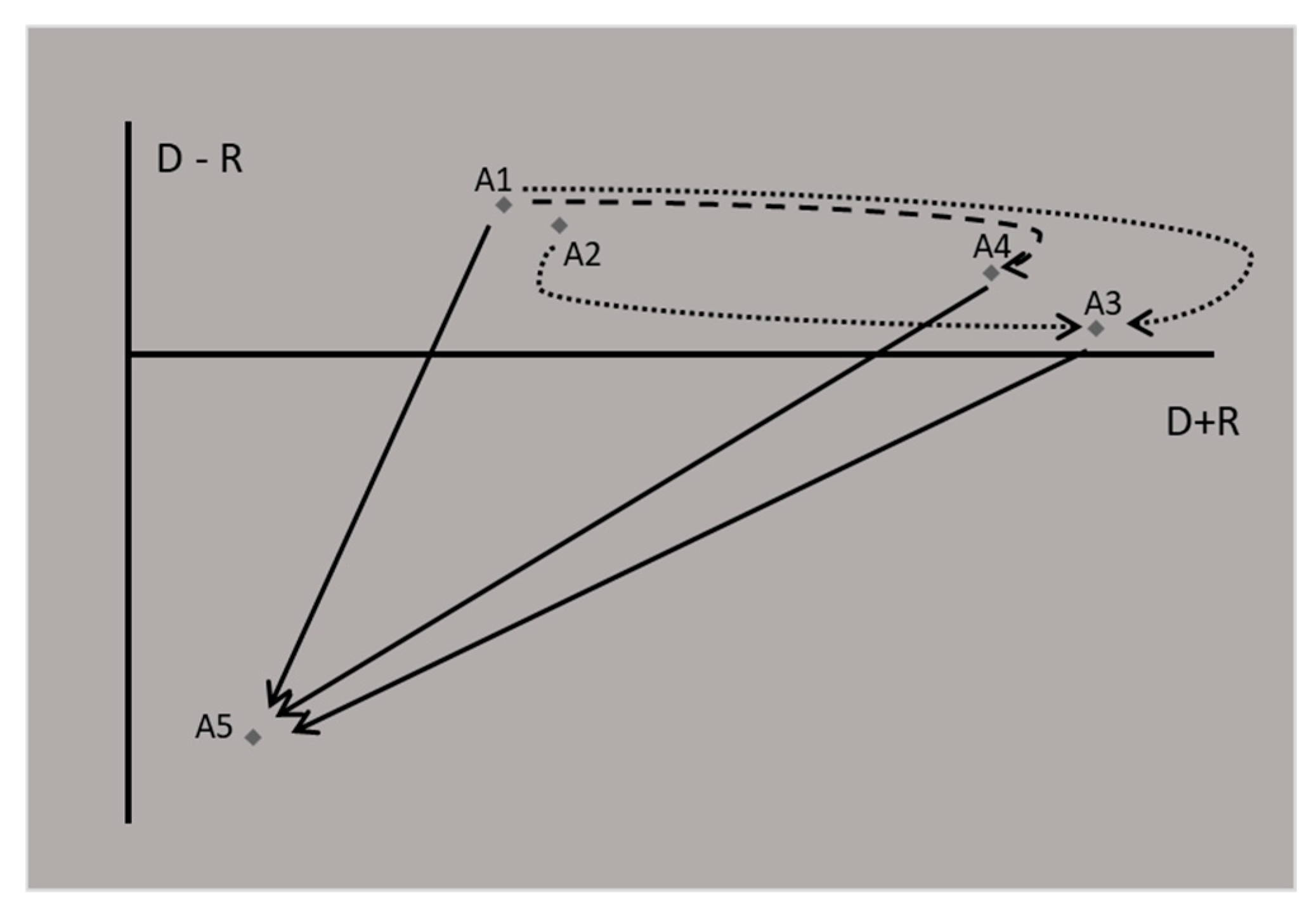

In the remanufacturing process, information sharing (A1) is an important part, because waste cannot be ordered like ordinary materials. If real-time information cannot be obtained, the cost of remanufacturing increases [

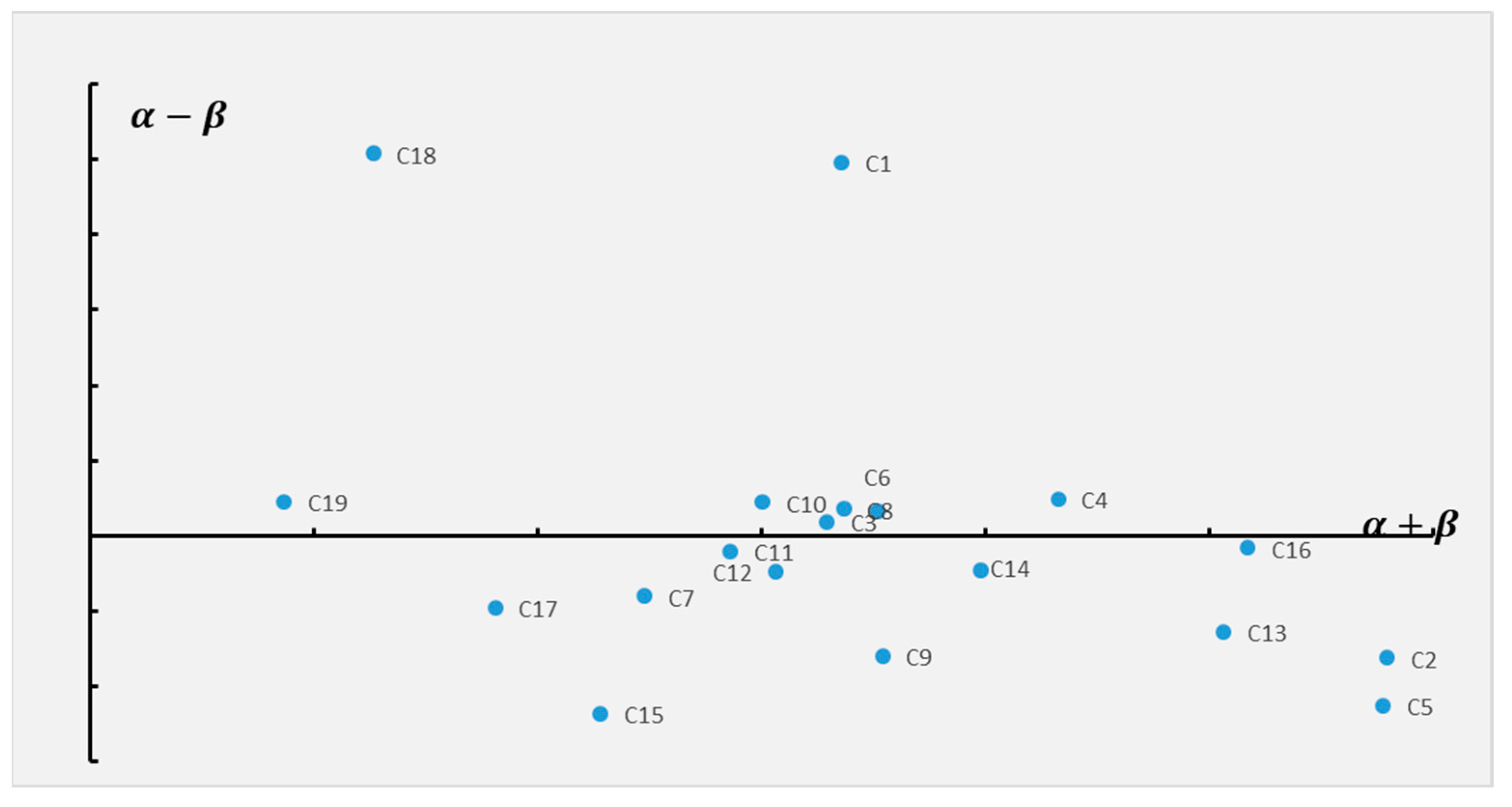

10]. Therefore, digital twins (C1) can be used as a solution to information asymmetry. When the company can establish a database for data integration (C4), the company can analyze the data according to its own needs as well as optimize the production process (C3) [

8]. In addition, the company can carry out effective tracking and recycling of products during the remanufacturing process (C6). Companies can also apply big data to handle large and rapidly generated data (C2), and share data in the product lifecycle (C5), which is a promising remanufacturing model that can manage the remanufacturing process more meticulously [

41]. From an operational perspective, although remanufacturing can preserve product value, it complicates inventory management and makes shared information uncertain. Hence, optimizing inventory strategies (C7) can lift the flexibility of the CESC to prevent the supply chain from being disrupted [

1].

The original components which make remanufactured products are repeatedly used. If customers have doubts about the condition of the components, they avoid risks when purchasing. In order to better sell remanufactured products (A2), information about product quality can be disclosed to customers (C11), so that customers can understand the service record of remanufactured products (C10). When customers’ willingness to pay for green responsibility is high (C9), they are willing to buy greener products. Information about tracking and recording components’ lifecycles (C8) can help resolve customers’ mistrust of the quality of remanufactured products. When customer demand shifts from conventional products to remanufactured products, members participating in the CESC can make more flexible pricing decisions (C12) to strengthen the cooperative relationship between members as well as soften downstream competition [

32]. To better sell products, remanufacturers conduct business strategies driven based on material usage efficiency in the CESC, which can keep materials and outputs in the chain for a longer circulation time (C13) while simultaneously maintain their value [

6,

43].

Although the CESC has many environmental and economic benefits, there are still many obstacles posed by risks to prevent it from functioning normally. The CESC risk management (A3) aims to ensure that the supply chain is not destroyed by obstacles. Nevertheless, the critical challenges of remanufacturing are the stability of output and supply (C14) and the maintenance of product quality (C15). These risks make the CESC unstable and cause many problems related to quality and performance [

16,

39]. Therefore, companies can offset these loopholes by selecting the most acceptable risk solutions, through appropriate de-risking measures, risk assessment, or risk control, such as carbon reduction programs, and enabling managers to quickly deploy resources. (C16), and exploring the possibility of alternative raw materials (C17), all of which can prevent or mitigate the likelihood of supply chain disruption. Furthermore, the different companies' cooperation can boost the effectiveness of implementing CE, make reuse and remanufacturing a feasible solution, and then effectively manage supply chain risks [

15,

32,

36].

The circular business model (A4) mainly focuses on creating value by slowing down, strengthening and closing material loops. In order to better develop recycled and remanufactured products, companies must develop capabilities specific to CESC (C18), such as recycling energy from waste products through new waste treatment technologies [

14]. New capabilities can create a new sustainability culture (C20) for companies, build a suitable environment, and develop approaches to circular manufacturing-oriented decision-making and governance. When a company redesigns a remanufactured product (C22), it needs to adopt CE principles and turn to a more sustainable direction. In the meantime, the correct implementation of life cycle assessment (C21) can reduce the materials' consumption or decrease toxic materials during the production process, or standardize it, which can provide a new framework or action plan for subsequent remanufacturing [

6,

14]. However, consumer acceptance (C19) is a key factor in the remanufactured products. Consumers’ willingness to purchase remanufactured products is relatively important. If companies can instill the manufacturing process and history of products to customers, it can contribute to the follow-up marketing and also build positive attitudes towards potential customers [

1,

6].

In addition to reducing waste generation, the CE can also reuse and recycle waste [

14]. There are many benefits to accepting the CESC, one of which is that it can better improve the resource value in the supply chain (A5). Strategies of the supply chain are considered to encourage remanufacturing and increase resource efficiency (C26) and to optimize the use of materials by reducing waste and using cost-effective waste products. Before entering the CESC, manufacturers need to identify waste composition and separate materials (C23) since harmful components in rubber are likely to increase environmental burdens; thus, this preliminary task is also relatively important [

6,

24,

38]. Besides, the supply chain also plays a crucial role in curbing waste flow into the environment. Not only can it establish an infrastructure which supplements logistics (C24), but it can also restore the value of returned products (C25). Consequently, apart from meeting economic and social goals, efficient CESC can also decrease the effect on the environment. Meanwhile, integrating collaboration and competition (C27) into the remanufacturing system can optimize the system and help decision makers maximize benefits. Moreover, better strategies of adjusting organizations can also satisfy customer demand [

33,

39].

With the development towards a CE, the recycling of products, components, and materials has also received much attention. Reverse logistics of remanufactured products (A6) is the main driving force for material circulation flow, facilitating the return of remanufactured products to the CESC and carrying out value extraction many times. In particular, the material composition (C28) of the product is one of the most primary characteristics in the reverse logistics. When company can becomes easier use this components in their next product. Both the value chain analysis (C29) and the cost-benefit analysis (C30) can improve the process of reverse logistics, rethink the value chain to prolong product lifetime, or reduce costs and create value via re-evaluating the value of remanufactured products. When the company monitors and evaluates the performance of the remanufacturing reverse logistics (C31), this may lead to an increase in profitability (C32), thereby constituting a competitive economy and market advantages for manufacturers [

23,

26].