1. Introduction

Currently, microelectromechanical systems (MEMS) are an integral part of most electronic and optical devices [

1]. The specificity of MEMS elements lies in their spatial scale, which can be of the order of several microns or less [

2,

3]. The deformation of elastic elements at such a scale significantly depends on factors that are usually neglected in the conventional design [

4,

5]. These include the influence of incompatibility of strains, surface tension, the non-linear mutual effect of in plane tensions on bending stress-strain state, and a significant variation of the elements geometric shapes due to their high flexibility [

6,

7,

8,

9]. To take into account these factors, it is necessary to go beyond the limits of the classical theory of elastic plates and shells [

10,

11], considering them from the standpoint of non-linear continuum mechanics [

12] as elastic systems with a small parameter, corresponding to their thickness.

Despite the relevance of the issue and the fact that a huge amount of literature is devoted to the linear theory of plates and shells, for example [

10,

13], modeling for finite deformation of thin-walled structures is not widely represented [

14,

15,

16].

Recall that the conventional approach to the mathematical modeling of deformations in thin-walled solids is based on three main provisions: 1. Representation of the displacements in the form of fairly simple approximations with respect to the spatial coordinate, along which the body is assumed to be thin-walled. 2. Averaging of kinetic and strain energy along the directions transverse to some reduction surface. 3. Derivation of the equations of motion and boundary conditions from the principle of least action with respect to extended set of kinematic functions defined on the reduction surface. This strategy, which was founded in the works of L. Euler [

17,

18] and G. Kirchhoff [

19], gave excellent results for small deformation modeling in elastic plates and shells. In subsequent studies considerable attention was paid to the issue of reducing the error associated with the approximate nature of the displacements along the transversal direction. Different variants of linear and polynomial (with respect to transversal coordinate) approximations were proposed by Uflyand [

20], Mindlin [

21], Kil’chevskiy [

22]. This made it possible to clarify the effect of shear and elongation in transverse direction, which gave significant corrections in the simulation of high-frequency plates and shells oscillations [

23]. Note that the extension of the polynomial approximation to the power series raises the question of its convergence, which was discussed even in the works of Cauchy [

24] and Poisson [

25]. The proof of convergence (under certain restrictions) was obtained by Lauricella [

26], which made it possible to construct an analytic theory of shells [

22,

27]. However, all these models assume small strains and a linear (anisotropic, in general [

28]) relationship between stresses and strains. Such restrictions do not allow adequate description of the deformation for flexible thin-walled structures, the deflections of which significantly exceed the thickness.

There are two main problems in modeling thin-walled flexible structures. The first one, which can be characterized as a geometric non-linearity, is that the geometric shape of a flexible structure before deformation differs significantly from its deformed shape. Particularly in plates, this leads to bending and plane deformations becoming coupled. The first models that take into account geometric non-linearity were proposed by Föppl [

29], and somewhat later by von Kármán [

30]. Despite the fact that the relationship between stresses and strains in these models was assumed to be linear, and the non-linear terms characterizing the relationship between the plane stress state and bending were determined semi-empirically, their use in engineering calculations showed results close to those observed in experiments [

31]. This, of course, does not solve the issue of their justification, which is discussed in detail, for example, in [

32]. The second problem is to take into account the physical non-linearity and is relevant for materials that allow hyperelastic deformation [

12]. To solve this problem, it is necessary to obtain equations for thin-walled structures directly from the non-linear hyperelasticity equations, distinguishing between the reference and deformed shapes, and determining the response from the hyperelastic potential, which is more complicated than the quadratic one. The results in this direction were obtained mainly only for membranes, that is, for thin-walled structures, in which the bending stiffness can be ignored at all [

33,

34,

35,

36,

37].

In this paper, we represent the further developing of completely (geometrically and physically) non-linear theory of thin-walled structures and its application to such of them, which in the reference shape can be projected onto an averaging plane. This explains the fact that the title of the paper contains the term ”hyperelastic plate”. A feature of the developed approach is that incompatible finite deformations can be taken into account within its framework.

We obtain the field equations and conservation laws in a general form without accounting of the specific expression for the elastic potential, but with explicit allowance for the fields that characterize the measures of strain incompatibility. We pay special attention to the material conservation laws and configurational forces, since they characterize the self-stressed state (residual stresses), caused by deformation incompatibility and surface effects.

2. Kinematics

Within the general geometrical approach, adopted in non-linear mechanics of continuum [

38,

39,

40,

41,

42], we formalize deformation as an embedding of material manifold

into physical space

[

43]. The latter is considered to be a 3-dimensional smooth manifold endowed with affine-Euclidean geometry,

i.e. point set

E and translation vector space

[

44]. We refer to an image of such embedding as a shape of the body, materially represented by

. For simplicity hereinafter we assume that all appropriate shapes are bounded connected regions of

E, which are regular in the sense of Kellogg [

45].

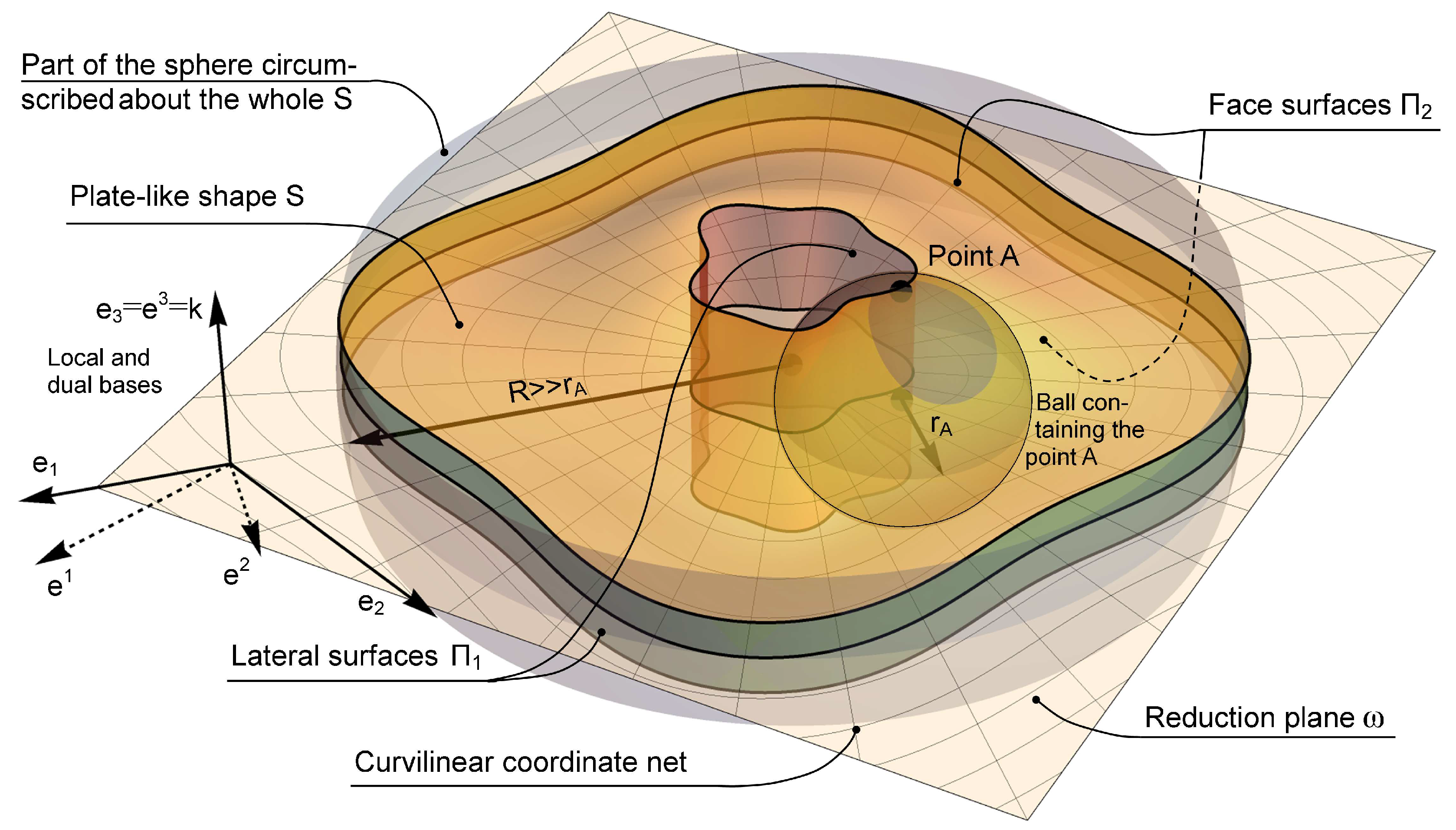

In the paper we will use the concept of a plate-like shape, which can be formalized as a shape

, which boundary

can be decomposed into two parts:

and meets the following conditions: i) There exists a plane

such that for each point

A on

there is a ball containing this point, with center lies on

; ii) The radius of this ball

is much less than the radius

R of the sphere circumscribed about the whole

(

Figure 1). We will refer to

as plane of reduction, to connected parts of

as face surfaces, and to connected parts of

as lateral surfaces. The intersection of reduction plane and lateral surfaces,

i.e. , defines the contour of the plate-like shape.

Suppose that certain shape

can be considered as the reference one. Let

be right orhonormal (Cartesian) frame in

E such that

are parallel to the reduction plane

. Thus at least part

can be covered with appropriate curvilinear coordinates

as follows:

Hereinafter symbols

,

,

denote Cartesian coordinates, related with chosen frame in

E.

For simplicity, we will assume that the contour

entirely lies in

, and connected subsets of

are surfaces without self-intersections. Consequently, the shape

, as a region in

E, can be defined in coordinate manner by the following extension of the chart

onto the neighbourhood of the

:

In the region

, that is open subset of the reduction plane

(

i.e. subspace of

E, spanned over

), one can define the field of frames with local (oblique in general) basis

as follows:

Reciprocal bases

can be obtained as solution of linear inhomogeneous equations

. The field of frames and its dual can be expanded on

with bases

and

. So defined frames allow to determine plane and spatial Hamilton operators in

and

correspondingly as follows:

Note that hereinafter we, follow [

12], define gradient operator as the transpose of formal dyadic product of appropriate Hamilton operator and a field

, which gradient is sought,

i.e. . For the sake of brevity, we denote

as

(without dyadic product sign). So,

and, consequently, if

is a vector field, then:

where

are Christoffel symbols, related with curvilinear coordinates on

.

Define deformation as a diffeomorphism

[

43] that maps the region

onto region

,

i.e.

This map induces deformation

of reduction plane as the restriction of

to

:

Here

denotes the image of the reduction plane,

, that can be referred as reduction surface.

Because both sets,

and

, are regular regions in

, they inherit affine-Euclidean structure, that makes it possible to define vector field of displacements:

Recall now that reference shape is plate-like, so we can take advantage of expansion over small parameter, related with the thickness of the plate. To this end consider the displacement field (

1) as power expansion:

with coefficients, which can be (under well-known analytical assumptions) derived directly as derivatives of

:

Thus, instead of 3D problem with respect to

, one can consider 2D problem with respect to the sequence of unknowns

, which is much simpler than the former. In this instance deformation gradient can be evaluated in terms of

:

With only a finite number of items we arrive at the asymptotic representation. If we take into account the items of the degree not higher than one, then, formally:

The appearance of

in the expression for deformation gradient is asymptotically consistent, but leads to discrepancy with conventional approach in shell theory. To avoid this discrepancy we can either neglect this term, or change the approach to the deformation, considering (

2) as an exact expression for 2D Cosserat continuum deformation. In present paper, we take the latter approach and rewrite formulae (

2) as follows:

and consider the displacements (in accordance with the Euler – Chasles theorem) as a composition of displacements of points in

and rotations of line elements, which are transversal to

,

i.e.

where

is proper orthogonal tensor (

,

). For small values of

the approximation

, where

is an asymmetric tensor, is valid, so we arrive at Uflyand – Mindlin representation for displacements.

3. Classical Formulation

For the modeling of the elastic plate response we use the least action principle and variational symmetries. With this approach the field equations and natural boundary conditions can be derived from the stationary-action condition, while the conservation laws follow from the invariance of the action with respect to coordinate and field variations. Thus, the main attention should be paid to the formulation of the action functional, while everything else may be obtained with formal derivation. This approach is useful for the analysis of elastic systems with additional degrees of freedom, which geometric interpretation may not be so obvious, such as generalized models of plates and shells. At the same time, this formal derivation can lead to cumbersome equations with unclear geometric meaning, and when using it, it is useful to make comparisons with similar models derived within the conventional 3D elasticity. With this in mind, we first analyze the variational formulation for the plate-like solid, regarding it as a 3D simple isotropic hyperelastic body. Along the way, we stipulate conditions on the material properties, which we assume in both 3D and 2D formulations. They are the following:

- (1)

The material is hyperelastic, i.e. a stored-energy function exists and does not depend on the deformation history.

- (2)

The material is simple, i.e. the values of stored-energy function at a point depend only on deformation within infinitesimal neighborhood of the point.

Under these assumptions one can formulate action functional

as iterated integral over time interval

and the region

in physical space, which coincides with the reference shape of plate-like solid:

Here

denote the instants of starting and finishing of the deformation process,

is the density of the action (Lagrangian) which, according to the assumptions above, depends on position vector

, current instant

t, and first derivatives over spatial and time variables (dot denotes time derivative). The last item in the integrand stands for Jacobian that is the square root of the determinant of the metric form, related with adopted curvilinear coordinates:

The standard reasoning carried out within the framework of the Lagrangian formalism assumes separate transformations for spatial and time derivatives, which makes the derivation of the field equations and conservation laws rather cumbersome. To avoid this cumbersomeness, it is proposed to use a (3+1)D formulation, which allows to derive the equations in a more concise form. To this end we introduce (3+1)D event vector and (3+1)D nabla operator:

where

is a formal unit vector, orthogonal to all elements of local spatial basis (one can regard

as the basis in direct sum

).

Remark 1. (3+1)D representations make it possible to combine differentiation with respect to spatial variables and time within one differential operation . However, we do not use the specifics of the four-dimensional frame decomposition on time-like line and spatial platform with respect to observer, adopted in the special theory of relativity [46], since we assume the velocities of material points to be sufficiently small. So, we suppose that such decomposition is fixed and (3+1)D Minkowski space has trivial global structure of direct sum . In this regard, one can identify (3+1)D space with Galilean space-time.

Within this formalism the action (

3) for (3+1)D event (

4) and displacements (

1) can be written as follows:

where

is (3+1)D representation for Lagrangian, adopted in (

3),

is the projector onto

,

denotes identity over

, while

, is a (3+1)D cylindrical region (world-tube of the shape

), and

denotes (3+1)D volume element in coordinate space which is simply the product of spatial and time increments:

. The use of such an elementary volume implies that the Jacobian, related with curvilinear coordinates used, is accounted within

.

One can define (3+1)D metric tensor in as . The negative sign in front of the time-like unit vector is needed only so that d’Alembert-type operators can be represented in the simplest form in terms of four-divergences. Then the Lagrangian will be supplied with metric multiplier instead of . This notation is commonly used in relativity, but in the paper for brevity we will not explicitly indicate this in the notation. At the same time, one should keep in mind the (3+1)D metric for a correct understanding of the scalar product, denoted with . Although the dot product symbols in 3D and (3+1)D are typographically indistinguishable, the difference is always clear from the context.

Within conventional non-linear elasticity the density of the action,

i.e. Lagrangian, can be split into three items:

The first item,

, defines kinetic energy, the second,

, determines stored elastic energy, and the last,

, denotes the work, done by external fields.

In accordance with constraints, adopted in classical continuum mechanics, the expression for the stored elastic energy must satisfy the principle of material indifference [

12]:

Here

is an arbitrary proper orthogonal tensor in

,

i.e. ,

(

denotes identity in

). Thus the stored elastic energy has to be defined as following composition

where

stands for symmetrizing operator,

for arbitrary second rank tensor

this operator

returns the self-conjugate (symmetric) part of

. Writing deformation gradient in the form of Cauchy polar decomposition,

,

, where

is symmetric,

, and

is proper orthogonal,

, we arrive at specific form for functional

, that depends on right Cauchy – Green strain tensor

:

To define a particular form of functional

it is necessary to account stretches relative to some uniform (for example, stress-free) state. Generally, solids can’t be transformed entirely into uniform state due to incompatible deformations and residual stresses, occurring in them. These factors turn out to be especially important in micron-scale elastic bodies, particularly in the elements of MEMS structures. Thus, the uniform state can be achieved only locally by local deformation

, which is in general does not meet any compatibility conditions, i.e.

[

47,

48]. Consequently, on the whole solid

can not be represented as gradient of some vector field and this is its the main difference from the conventional deformation gradient

. To take such local deformations into account, one has to rewrite the functional

in the form:

related with total distortion:

Note that even in the case when

does not explicitly depend on

and is an isotropic function with respect to second argument (which corresponds to a homogeneous and isotropic material),

depends on

via

and remains an isotropic function only for particular values of

. Thus, a locally homogeneous and isotropic material turns out to be inhomogeneous and anisotropic as part of a self-stressed body. This fact is characterized by the concepts of material uniformity and inhomogeneity [

49,

50].

Further reasoning is grounded on the the least action principle

A feature of the variational approach used below is that the variation of the functional is calculated with respect to the total variation of coordinates and fields [

49,

51]. In doing so, firstly define families for coordinates

, and fields

, which depend on scalar parameter

such that

Then total variation can be defined as follows:

where

denotes arbitrary sufficiently small increment of the parameter

. These variations cause the variations of action functional, which, after obvious transformations involving chain rule and Stokes theorem, can be represented in following equivalent forms:

Here

denotes total variation of Noether current,

stands for Euler – Lagrange differential expression, and

for energy-momentum tensor:

while

denotes Lagrangian explicit gradient,

i.e.

The detailed derivation of above formulae one can find in [

52] (one just need to keep in mind that in the paper [

52] the Gibbs notation was used for the nabla operator).

From partial variations, in which the fields vary, while the coordinates remain fixed, follow field equations and natural boundary conditions:

Another type of partial variations, with fixed fields and varying coordinates, gives conservation laws:

According to Noether theorem, specific forms of conservation laws can be derived from general relation (

7), if a particular group of variations (translations and rotations) are specified. Corresponding conservation laws are given in the

Table 1. The "strong" column shows the conservation laws that hold regardless of the field equations (

6). The column "weak" contains the conservation laws provided that the field equations are satisfied. In the table

is arbitrary vector in (3+1)D, guiding the translation;

denotes the finite rotations about arbitrary axis in (3+1)D;

is corresponding antisymmetric tensor, that represents infinitesimal rotations, and

denotes energy momentum – momentum tensor,

.

Even though the (3+1)D formulation leads to concise equations, it is useful to show at least once their transformation to the conventional form. For field equations and boundary conditions (

6) this transformation has the form:

where

is the lateral part of (3+1)D volume

, instants

,

define corresponding bases of this volumes,

denotes Piola stresses,

stands for linear momentum and

is the volume force:

All these fields are related with the (3+1)D fields as follows:

Obviously,

and among with the Piola stresses

one can derive the Cauchy stresses with the Piola transformation

. Of course, the right-hand sides in the boundary conditions (

8) may be inhomogeneous. In this case they can be converted to homogeneous ones using standardization procedure. A more drastic difference between this formulation of the boundary-value problem and the classical one is that the time-like boundary conditions are specified for the initial and final instants, instead of the field values and their time derivative in initial instant only. Meanwhile this feature is characteristic of the Lagrangian approach and it is possible to obtain the usual conditions for functions and their derivatives at the initial instant only by fundamentally changing the structure of the action functional, for example, by constructing it on the basis of the convolutive principle [

53]. Here we will not do this and reconcile ourselves with some difference in the formulation of the initial-boundary value problem.

A more nutty object that contains information about incompatible deformations in energetic format is the energy-momentum tensor

. It can be decomposed as follows:

where

is Eshelby stress tensor,

denotes canonical momentum,

is the Hamiltonian density, and

stands for Umov-Poynting vector:

Conservation law for energy-momentum tensor, that can be rewritten as balance law with non-zero RHS, procreates balance equations for canonical momentum and energy flux:

Here

denotes configurational force, while

stands for dissipative force:

Emphasize that it is the configurational and dissipative forces that determine the nontrivial self-stress state caused by incompatible deformations and their evolution. Indeed, these forces arise due to spatial and temporal inhomogeneity, which, in turn, arises due to the inhomogeneous field of the implant

and its evolution in time. In this case, surface effects can be represented by some special distribution of the implant field on the front surfaces of the plate, which formally leads to the same mathematical formalism.

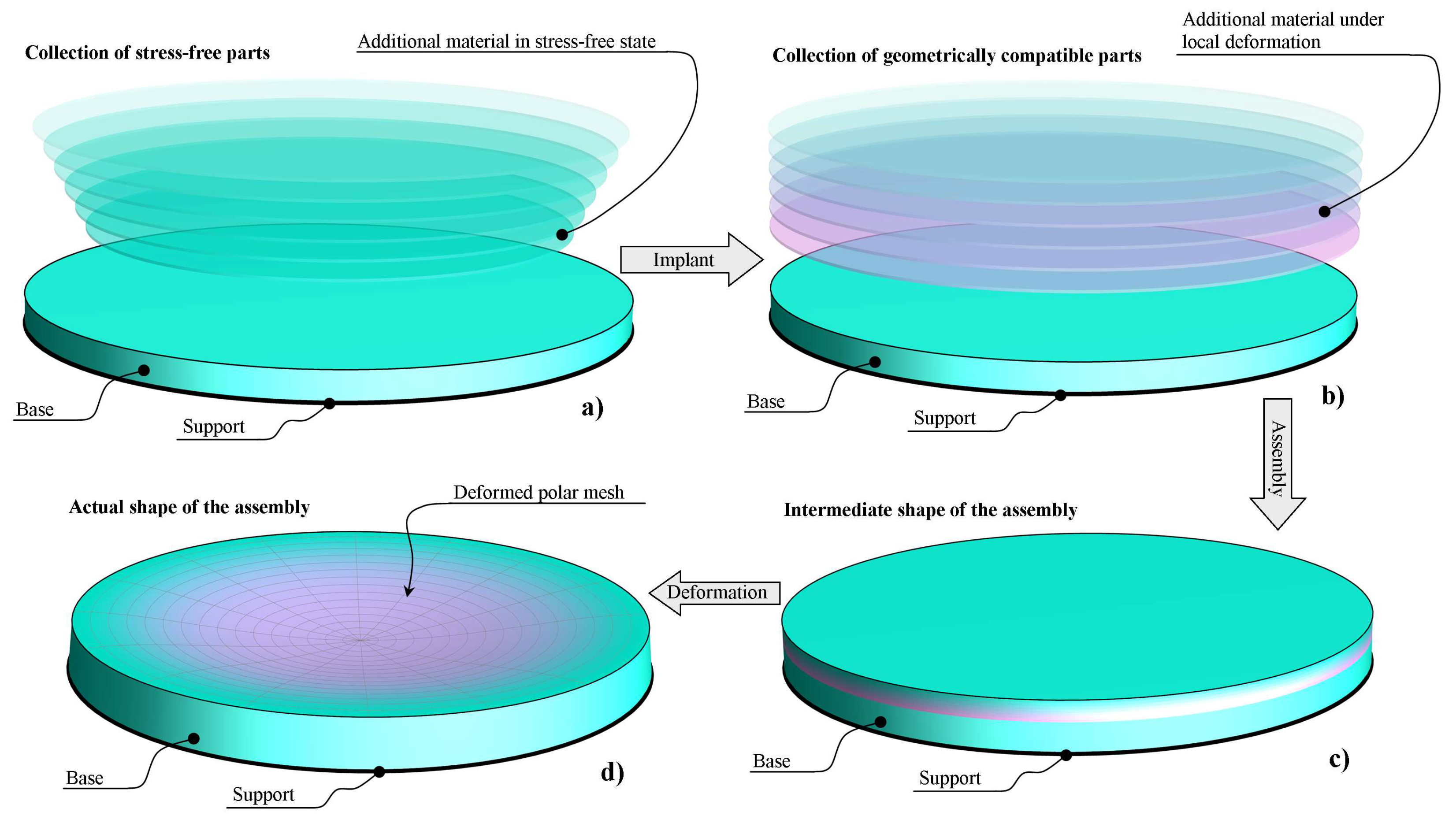

To illustrate the obtained relations, consider the model problem for self-stressed hyperelastic circular plate (

Figure 2). The displacements of the plate are constrained in transversal (vertical) direction along circular support which is shown in the

Figure 2 with black thick line. The plate can be brought into stress-free state by being divided into disjoint parts (

Figure 2 a)). As a result of assembling these parts, all of which were subjected to local deformation, a certain self-stressed shape can be obtained. Of all the possible shapes, it is advisable to choose the shape with the simplest geometry as a reference one (

Figure 2 b)). This shape is in equilibrium only under the action of specific volume forces that balance it (

Figure 2 c)). In the absence of external fields, the entire assembly is deformed into some distorted shape (

Figure 2 d)).

To fill out a more comprehensive description of the stressed state, we assume that the elastic potential is of Saint-Venant – Kirchhoff type,

i.e.

where

,

are material constants which correspond to Lamé elastic moduli in linear approach, and

denotes Green – Saint-Venant strain. Here, of course, we understand the stress tensor in the local sense. This potential corresponds to the constitutive equation, that expresses the second Piola-Kirchhoff stress tensor

with

as follows:

Note that we specifically chose a potential that gives constitutive equation close in form to Hooke’s law. At the same time, these relations are more general than their counterparts in linear approach.

To illustrate the effects caused by incompatible local deformations, it is enough to set them in the form of some law, without relating it to a specific technological process. For simplicity, we assume that the implant (tensor inverse to local deformations of a geometrically incompatible part of the assembly) is spherical and linearly depends on the transversal coordinate:

where

a,

b are some constants (we will refer to particular value of multiplier

as implant factor). Thus, we consider a certain model assembly process, during which infinitely thin stretched layers are attached to the substrate, the measure of stretching of which changes during the process. This process generally corresponds to the technology of layer-by-layer deposition, during which the implant factor changes due to changes in the temperature field and the evolution of incompatible thermomechanical deformations. Of course, for a more detailed description, the law of change in the implant field should not be specified, but found from the solution of the evolutionary problem. However, a discussion of these issues is beyond the scope of this article. We only mention that evolutionary problems are described in more detail in [

42,

48,

54].

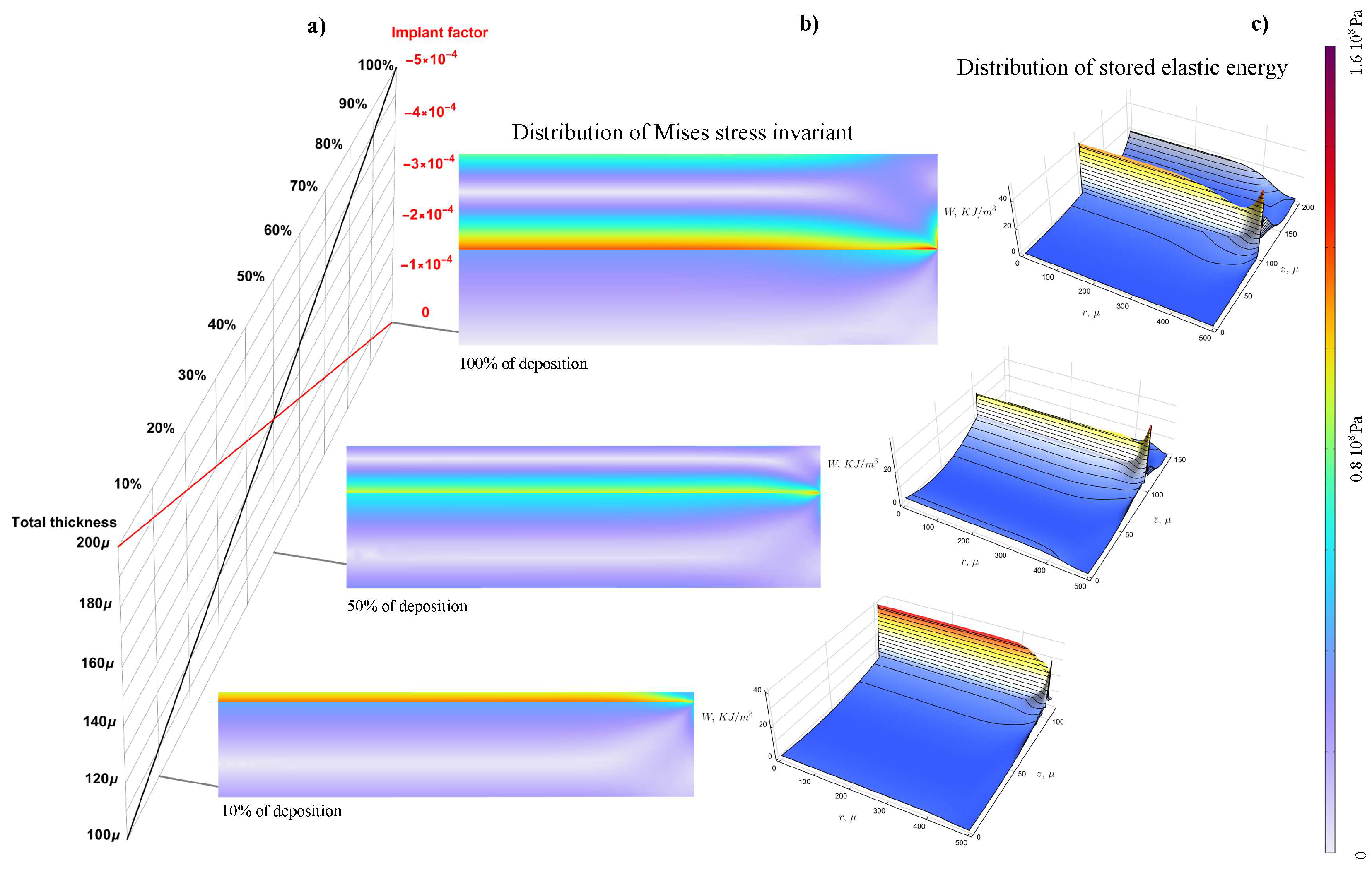

Computational modeling was performed by finite element method with the following data:

Elastic moduli (silicon) GPa, GPa;

Diameter of the plate 1 mm;

Initial thickness of the plate mm;

Final thickness of the plate mm;

Initial implant factor ;

Final implant factor 0.

The results of computer simulation is given in

Figure 3. The figure shows a diagram that compares the dependences of the thickness of the assembly and the implant factor of the upper layer depending on the time-like variable (

Figure 3 a)). For three moments corresponding to 10%, 50%, 100% of the assembly process, the distributions of the von Mises stress intensity (

Figure 3 b)) and stored elastic energy (

Figure 3 c)) are given. Note that non-zero distributions of stored energy in the absence of external force fields precisely characterize the inhomogeneity caused by incompatible deformations. By differentiating with respect to spatial variables, one can find configurational force

, and by differentiating with respect to a time-like variable, the dissipative force

(

9). The latter characterizes that part of the mechanical work that was performed during the assembly of the intermediate shape, but was not returned when this shape was deformed into the actual one.

4. Micropolar Formulation

Imagine now that instead of a 3D body, we observe only the surface of reduction

, which is a part of the plane, embedded in

(generally it does not necessarily lie inside the reference shape

). All we can observe is the bending and stretching of this surface. The stretching are characterized by 2D deformations, similar to those in 3D, only when one spatial dimension is ignored. However, the bending,

i.e. the change of the curvature and transversal displacements, has to be characterized in a fundamentally new way. From the various ways, we choose the Cosserat approach [

12,

55,

56]. This approach allows extra degrees of freedom to be taken into account, which may be interpreted either as internal deformations, for example, micro-deformations of individual grains in polycrystalline solid, or external deformations, related with bending, that can’t be directly observed within 2D geometry of reduction surface [

12,

21,

56,

57].

Within this approach the action

is defined on

can be written as follows

Here

denotes the density of action with respect to area element

,

stands for a tuple of surface coordinates for a material points on

, while

is a second-rank tensor field, that describes local extra deformation of specific kind. It can be interpreted as a linear transformation of hidden geometric parameters associated with elementary volume, that, in its turn, is identified by the material point of the deformed body. Within general Cosserat approach the components of

are considered to be independent from each other and not depend on conventional deformations, represented by the field

. In such a case

are referred to as micromorphic deformations [

55] and can be represented by means of a set of vectors

,

(possibly not related in any way to translational vectors from

), referred to as directors:

. Generally, the directors can be defined in some abstract vector space with dimension

n, differ from 2 and 3. Meanwhile, for modeling of plates and shells deformations within the framework of the conventional approach, such a generality is redundant, since the additional degrees of freedom are associated with rotations of a normal element,

i.e. a material fiber that is oriented transversal to the surface of reduction

in the reference shape. This means that the tensor field

acts in

(so

) and its components are coupled by the orthogonality relation

. Thus, the components of

can’t be considered as independent functions, and in order to apply variational technique, it is important to express them via independent ones. We can get such expression with Rodrigues’ formula:

where

is a vector field, which components do not related to each other. Geometrically, the vector

can be expressed with unit vector

that defines the axis of rotation and the angle

of rotation as follows:

. Straightforward calculations shows that

where

denotes vectorial invariant (Gibbs cross) of the tensor

.

As for 3D solid, we will use space-time formalism in order to obtain equations in concise form and represent the action as:

Here

is the (2+1)D cylindrical space-time domain with base

, while

denotes action density with respect to (2+1)D space-time coordinate volume

,

i.e.

and

is (2+1)D event vector, which first component is time-like and last two components are space-like. The symbol

denotes 3D space-time nabla operator:

In above formula

is the projector onto

, and

denotes identity over

. Symbol

g stands for the determinant of metric tensor defined on

. Generally we should distinguish it from metric determinant in (

3). Meanwhile, because of the specific form of decomposition (

3), their numerical values coincide, so we will not use different designations for them.

Repeating the reasoning given above for the 3D solid, we believe that the Lagrangian can be represented as the following splitting:

where

is kinetic energy density,

determines stored elastic energy density, and

defines the specific work, exerted by external fields. Obviously, all densities are defined in relation to the area element

.

As for 3D solids, we adopt the principle of material frame-indefference. Thus, the functional

shall satisfy the condition

where

is an arbitrary proper orthogonal tensor in

. Note that, despite the fact that the density of stored elastic energy

is determined on the 2D plane

, the orthogonal tensor

is defined in the ambient 3D physical space. Furthermore, the orthogonal transformations that acts on conventional deformation gradient

and orthogonal transformations of microdeformations

are carried out in a consistent manner, by means of the same tensor

. Note this difference between the Cosserat shell theory and the abstract theory for micromorphic continuum, within which the transformation of microdeformation

, associated with a material point, is independent of the transformation of the affine space, containing the point.

The condition (

11) will be satisfied if one defines

in a particular form, replacing the arguments

,

,

with their combinations, that are invariant under the 3D transformation

(

5). Since

itself defines orthogonal transformation,

, hence

does not explicitly depend on

. Two other arguments may be taken as

,

. These combinations are invariant with respect to

and in the linear approximation correspond to conventional kinematic hypotheses of the classical linear theory of shells. To eliminate the mutual dependence between the components of these fields (arising in view of the orthogonality of

), following [

56,

57], we introduce strain measures

and

via the relations

From the last relation, one can explicitly express

as

Here denotes Levi-Civita tensor.

Consequently, the arguments of functional

can be specified as follows:

To take local incompatible deformations into account one can define the functional

with respect to uniform state as

where

is the local 2D deformation (generally incompatible), similar to the one defined above for the 3D solid,

is the local orthogonal transformation that brings directors into uniform state.

With (

10), (

14), (

15) one can consider Lagrangian either as explicit function on

,

,

or as following compositions:

The explicit form via

gives the field equations and conservation laws in most simple form that reflects only first order character of the theory and the structure of the collection of fields. The form with composition of

,

, and

results to the field equations, stress resultants and boundary conditions like those used in conventional shell theory. The last form, written in terms of

,

,

,

, and

makes it possible to use in the Lagrangian an expression for elastic energy coinciding with the standard expression, which is usually measured in mechanical tests on standard samples deformed from a uniform state. It is

that represents the initial information about the physical and mechanical properties of the material, which can be obtained as a result of testing standard samples. On the other hand,

represents an explicit dependence on kinematic functions for a self-stressed body whose inhomogeneity and anisotropy are induced by incompatible deformations of its constituent elementary volumes.

Assuming that the Lagrangian depends on coordinates and fields

,

, which components do not depend each on other, we arrive at the expression for variation of the action in the following equivalent forms:

Here the variation of Noether current,

, Euler – Lagrange equations,

,

, and Eshelby stress tensor

take the forms:

while

denotes Lagrangian explicit gradient with account of microrotation fields:

As above, from partial variations, in which the fields vary, while the coordinates remain fixed, follow field equations:

and natural boundary conditions:

The partial variations with fixed fields and varying coordinates give conservation laws in the

Table 2,

denotes arbitrary vector in (2+1)D, which spatial part belongs to

,

stands for arbitrary rotations also in (2+1)D (spatial rotations are exhausted by rotations about axis

),

is asymmetric tensor that is infinitesimal counterpart of

, and

is (2+1)D energy momentum-momentum tensor.

The field equations (

16) can be transformed to a more familiar form if the stored elastic energy functional

is presented as an explicit dependence on strain measures (

12), (

13). In this case, taking into account the expressions for partial variations of strain measures:

where for brevity the following notation is used:

and, consequently, for the density of stored elastic energy:

we arrive at field equations in the following well recognizable form:

Here

are conventional quantities related with stress and momentum resultants.

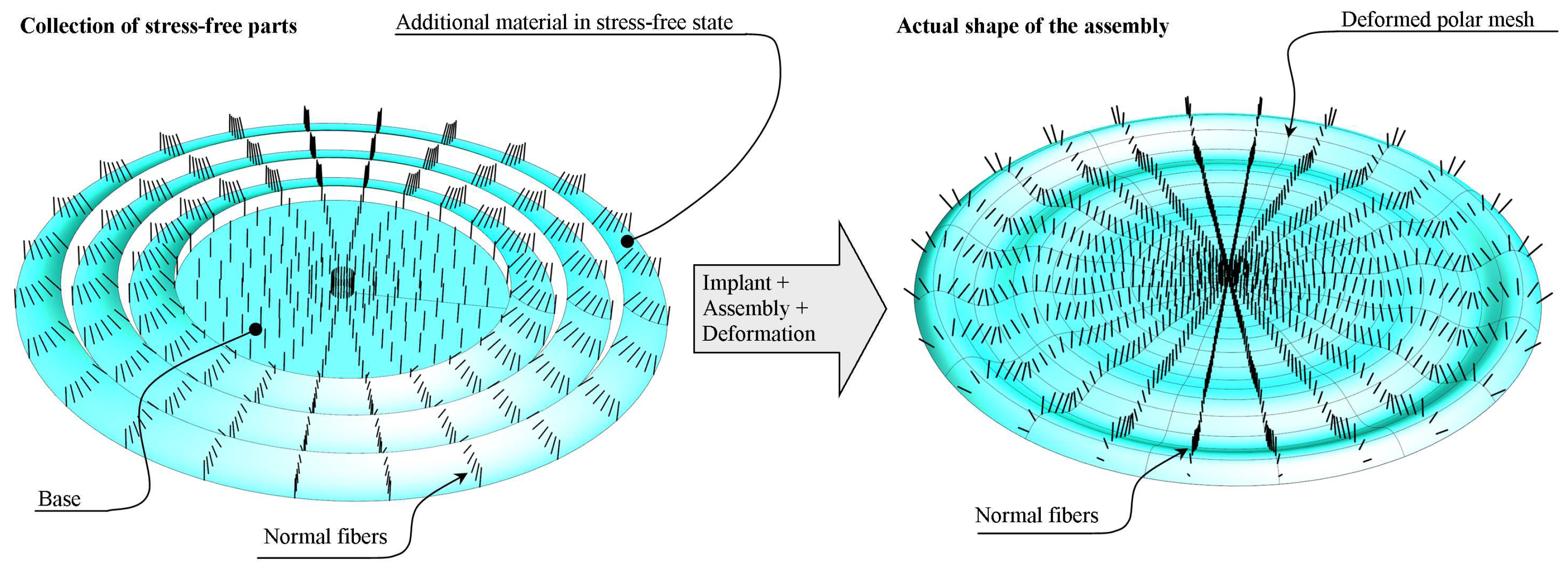

An illustration similar to that shown in

Figure 2, but adapted to the case of the Cosserat continuum and two implant fields, is shown in

Figure 4. For brevity, it skips the stages of assembling the intermediate shape, but along with the geometric images of the shape themselves, the fields of directors are shown, whose role is played by the fibers (normal elements) of the plate. Figuratively speaking, to assemble a collection of geometrically incompatible Cosserat-like shapes, it is necessary not only to coordinate the geometric regions they occupy, but also the orientation of their fibers. This fact clearly interprets the need for two implant fields.