1. Introduction

In South Korea, the most common complaint from residents in multi-unit housing is floor impact noise from units upstairs and downstairs [

1,

2]. To address this acoustic problem, various stakeholders, including the government, construction companies, research institutions, and universities, are developing a range of technologies [

3,

4,

5,

6]. The products and solutions resulting from these research and development efforts are being applied to newly constructed multi-unit housing [

7,

8,

9]. Furthermore, construction companies use these technological developments as a promotional tool [

10,

11,

12]. The most active technology developed to solve the problem of floor impact noise is the development of floor structures [

13,

14]. Currently, developments include hollow slabs and techniques to increase the thickness and rigidity of the slab beyond the 210 mm bare slab [

15,

16,

17]. The main development is the installation of resilient structures on top of the bare slab [

18]. This involves installing a bare slab, resilient material, light-weight concrete, and a finishing mortar structure. However, there have been recent technological advancements that allow for the thickness and strength of the finishing mortar to be increased, resulting in a single structure of finishing mortar [

12]. This type of floor structure is currently being used in multi-unit housing. The materials used for resilient layer of the floating floor structure have evolved from single structures, such as EPS (Expandable Polystyrene) and EVA (Ethylene Vinyl Acetate), to composite structures that combine EPS, EVA, and other materials [

7,

12,

19,

20]. Additionally, cushioning materials are being developed using a wider range of materials beyond EPS and EVA, and various structures, not just flat types, are being applied to their development [

12].

The progress of developing ceiling structures in receiving rooms to reduce noise from floor impacts is also underway [

21,

22,

23,

24,

25,

26]. This involves using internal acoustic materials to minimize the amplification of impact noises to the room below due to the influence of the air layer within the ceiling, and a ceiling-less design to minimize the transmission of impact noises through the ceiling. Furthermore, there have been notable design alterations aimed at minimizing floor impact noises, such as changes in the placement of load-bearing walls and advancements in floor design to manage sound patterns [

25]. However, the application of such research and technology appears to be passive and insufficient from the perspective of apartment dwellers [

27,

28]. Residents of apartments, especially those with young children, are particularly sensitive to the problem of floor impact noise. To address this issue, the most effective solution is to install floor mats of a specific thickness [

29,

30,

31]. It has shown that floor mats are typically installed in living rooms and playrooms, with a minimum thickness of 10 mm and a maximum thickness of 50 mm [

32]. Furthermore, the primary outcomes of the research consist of the outcomes of a survey that asked apartment residents about the measures they take to prevent floor impact noise and preemptive actions they take [

31,

33]. The most frequent response was ‘educating children’, followed by ‘using floor mats or carpets’, and thirdly ‘wearing slippers’. In addition, the government has declared its intention to support apartment residents in purchasing floor mats to reduce floor impact noise, interest-free [

34]. Thus, apartment residents invest in floor mats to reduce inter-floor noise. However, there is an issue where residents are not receiving the expected impact sound reduction performance from the floor mats despite their financial investments.

The Korean standard code of KS F 2865 is a method for measuring and evaluating the impact sound reduction performance of floor surface finishing materials and floor mats in South Korea [

35]. This standard defines a method for measuring the level of reduction in light-weight and heavy impact sound of floor surface finishing materials, excluding floating floor layer constructed on a concrete slab, in a laboratory. The method is applicable to both single-layer and multi-layer floor finishing materials installed on a standard concrete floor. The scope of the test floor is defined as ‘a reinforced concrete flat plate with a rectangular planform and a thickness of 120 mm to 210 mm’. Some floor mat manufacturers and developers only present the impact sound reduction performance of light-weight impact sound, which is generally high, through the Korean standard code. The evaluation does not include the impact sound reduction performance of bang machine and rubber ball, which are heavy-weight impact sounds with relatively low impact sound reduction performance. Heavy-weight impact sound is created by simulating the behavior of children in apartment houses, which differs from the purpose of applying floor mats in apartment houses. The impact sound mentioned in the current Korean standard code is different from the impact source generated by children’s behavior. Therefore, even if floor mats are applied, the impact sound reduction performance caused by banging machines and rubber balls is insignificant. Additionally, the impact sound reduction performance of floor mats varies depending on the accurate information on the thickness of the floor structure mentioned in the Korean standard code.

This study evaluates light-weight and heavy-weight impact sound for various flooring mat materials at four different test-beds with a thickness range of 150 mm to 210 mm, as specified in KS F 2865. The evaluation method used is like the impact sound generated by children’s activities in previous studies. The reduction performance is evaluated by frequency band and as a single number quantity. Furthermore, a correlation analysis was carried out on various bare slab thicknesses of the floor structure to provide fundamental data on the reliability of the evaluation method, focusing on the sound reduction performance of the same floor mat.

2. Materials and Methods

2.1. Impact Sound Sources and Measurement Method

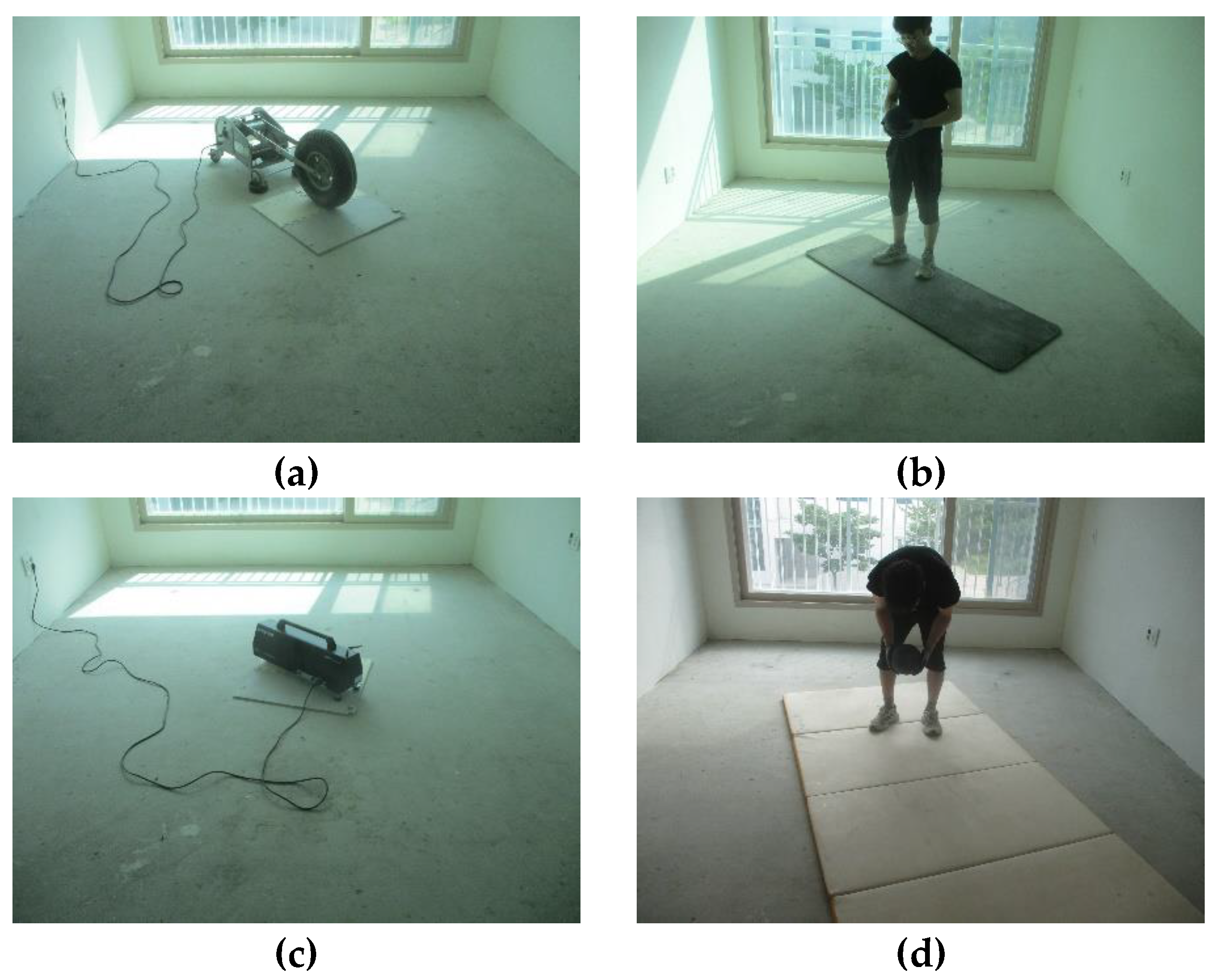

The impact sources used in this study are shown in

Figure 1. The heavy-weight impact sound was selected as Bang machine with standard weight impact characteristic 1 and Rubber ball with the standard weight impact force characteristic 2 as mentioned in KS F 2865, KS F 2810-1 and KS F 2810-2 [

35,

36,

37]. A tapping machine was used as the standard light-weight impact source. The purpose of using the floor mat is to reduce the impact sound generated by children’s behavior in apartment houses. Therefore, an impact source with a force similar to that of children’s behavior was selected. For the standard weight impact simulating children’s behavior, a rubber ball drop height of 0.4 m with a standard weight impact force characteristic 2 was selected based on existing papers. The drop height of the standard weight impact force characteristic 2 mentioned in ISO 16283-2 and KS F 2810-2 is 1 m [

38]. In this case, the impact force is about 1,800 N, and the impact force generated by the children’s behavior is about 1,100 N, which is similar to the rubber ball drop height of 0.4 m [

39,

40]. The experimental floor mat specimen was placed at the center of the living room of the sound source room, then a total of five exciting positions were considered. As shown in

Figure 2, a total of five microphones including center position were installed in the downstair sound receiving room. The floor impact sound insulation performance test was conducted according to KS F 2810-1 and KS F 2810-2 [

36,

37].

2.2. Test-Beds with Different Floor Plans and Slab Thickness

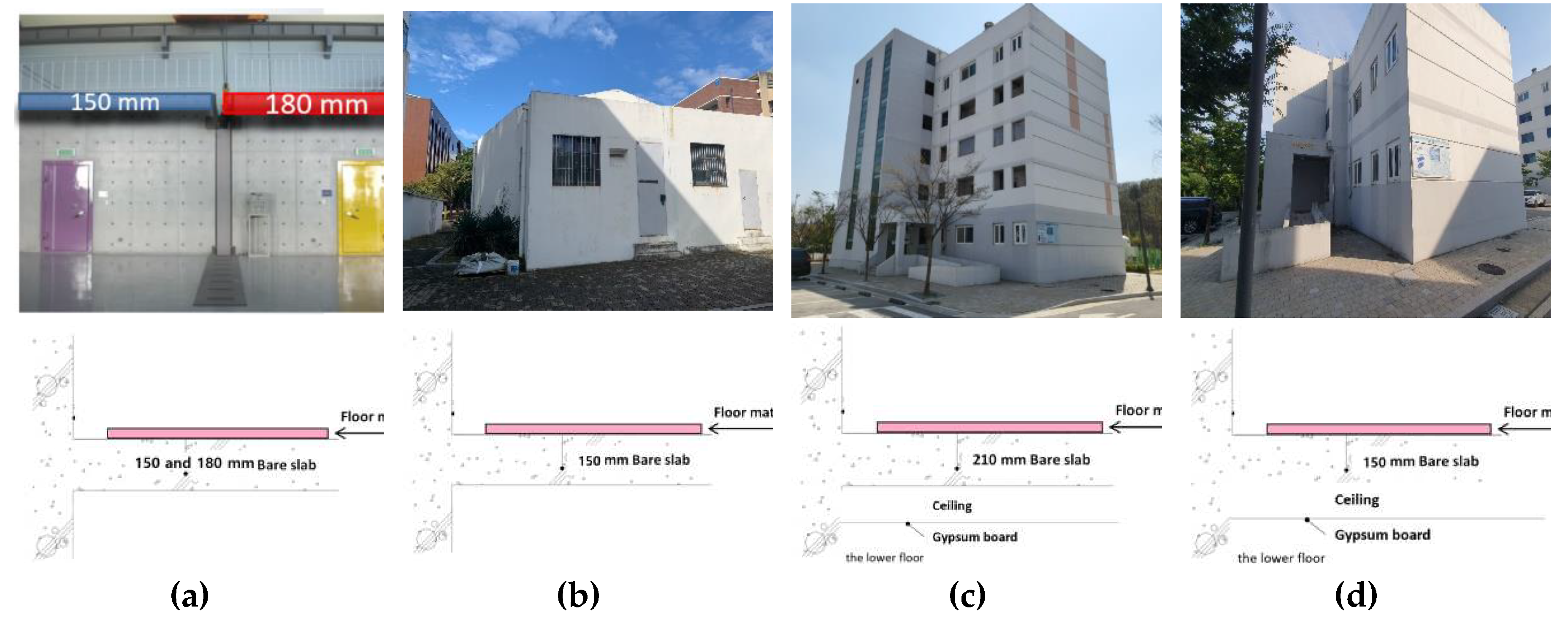

A total of four test-beds employed as shown in

Figure 3. As shown in

Figure 3a, the test-bed A is a box-type experimental building with wall-type concrete structure. It was divided into two rectangular rooms and the impact sound reduction performance was measured for each floor structure due to different slab thicknesses. The sound source room of the test-bed A is exposed to the outside. The floor structure is a bare slab with a thickness of 150 mm and 180 mm, respectively for left and right rooms.

Figure 3b shows the test-bed B which was originally designed as up-and-downside coupled reverberation chambers. In the test-bed B, an acoustic chamber is designed at the downside, and the floor structure is composed with a bare slab of 150 mm. The test-beds C and D as shown in

Figure 3c,d, respectively, were constructed as a standard apartment building with reflecting real-life style floor plan to evaluate floor impact sound performances [

3]. The floor structure of the test-bed C has a bare slab with a thickness of 210 mm as a wall-type concrete structure as shown in

Figure 3c. However, the floor structure of the test-bed D has a bare slab with a thickness of 150 mm as a Rahmen-type beam-column concrete structure as shown in

Figure 3d. All four testbeds are test facilities that meet the requirements of KS F 2865 [

35].

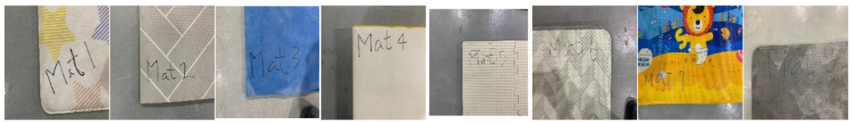

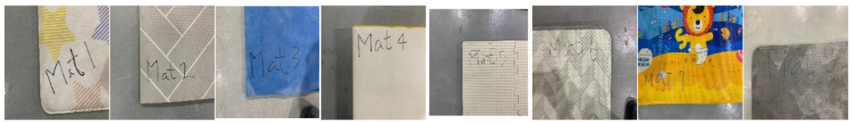

2.3. Floor Mats Samples

Table 1 shows the eight types of floor mat samples used in this study. The floor mat samples were selected based on their current availability on the market and frequent use by residents. Floor mat sample #1 is the thinnest among the eight types, made of polyurethane and with a thickness of 8 mm. Floor mat sample #2 is made of polyethylene and has a thickness of 13 mm, while floor mat sample #3 is made of polyurethane and has a thickness of approximately 12 mm. Floor mat sample #4 is characterized by a covering thin film of polyethylene on the inside and PVC on the outside. It is divided into three parts, making it foldable. It is the thickest of the eight types of floor mats, with a thickness of 36 mm. Floor mat sample #5 is a ‘fuzz mat’ made of ethylene-vinyl acetate copolymer. It can be assembled like a puzzle to achieve a desired size, measuring 300 mm wide and 300 mm long, and is approximately 11 mm thick. Floor mat samples #6 and #7 are both made of polyethylene and have similar thicknesses of 13 mm and 14 mm, respectively. Floor mat sample #8, which is 16 mm thick, is designed for physical exercise and yoga activities at home or in the gym. In this experiment, the impact sound reduction performance of the eight floor mat samples, five floor structures from the four test-beds was investigated.

2.4. Evaluation Method Including Single Number Quantity

The impact sound reduction performance evaluation method was based on the difference in sound pressure level (∆L) measured with and without the sample covering the bare slab, expressed in decibels (dB), as specified in KS F 2865 [

35]. Firstly, measurements were taken for both light and heavy-weight impact sound before the mat was installed on the bare slab, and then the same light and heavy-weight impact sound was evaluated after the mat was installed. The reduction level was calculated by subtracting the pre-installation value from the post-installation value. Additionally, the SNQ (single-number quantity) value was derived for each frequency band simultaneously with the reduction amount. The measurements were taken in 1/3 octave bands, ranging from 50 Hz to 630 Hz for heavy-weight impact sound and from 100 Hz to 3,150 Hz for light-weight impact sound.

3. Results

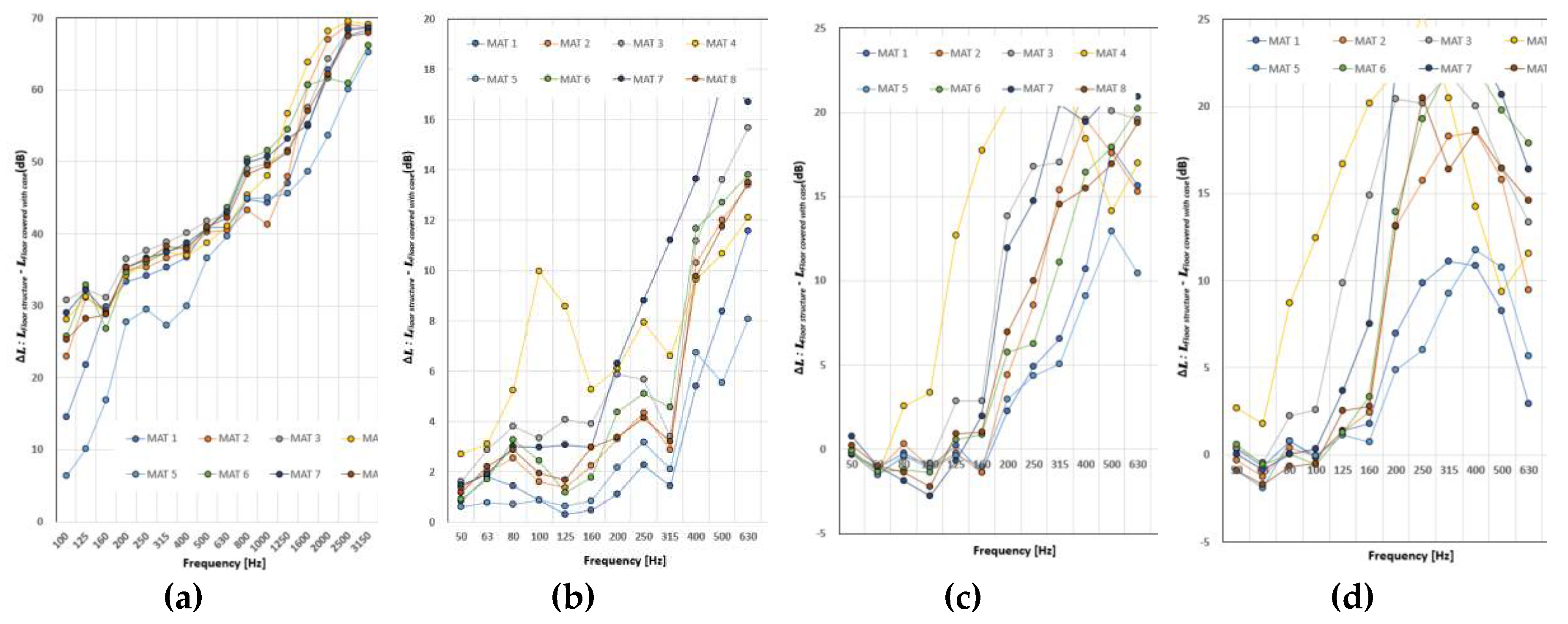

3.1. Test-Bed A with a Bare Slab Thickness of 150 mm

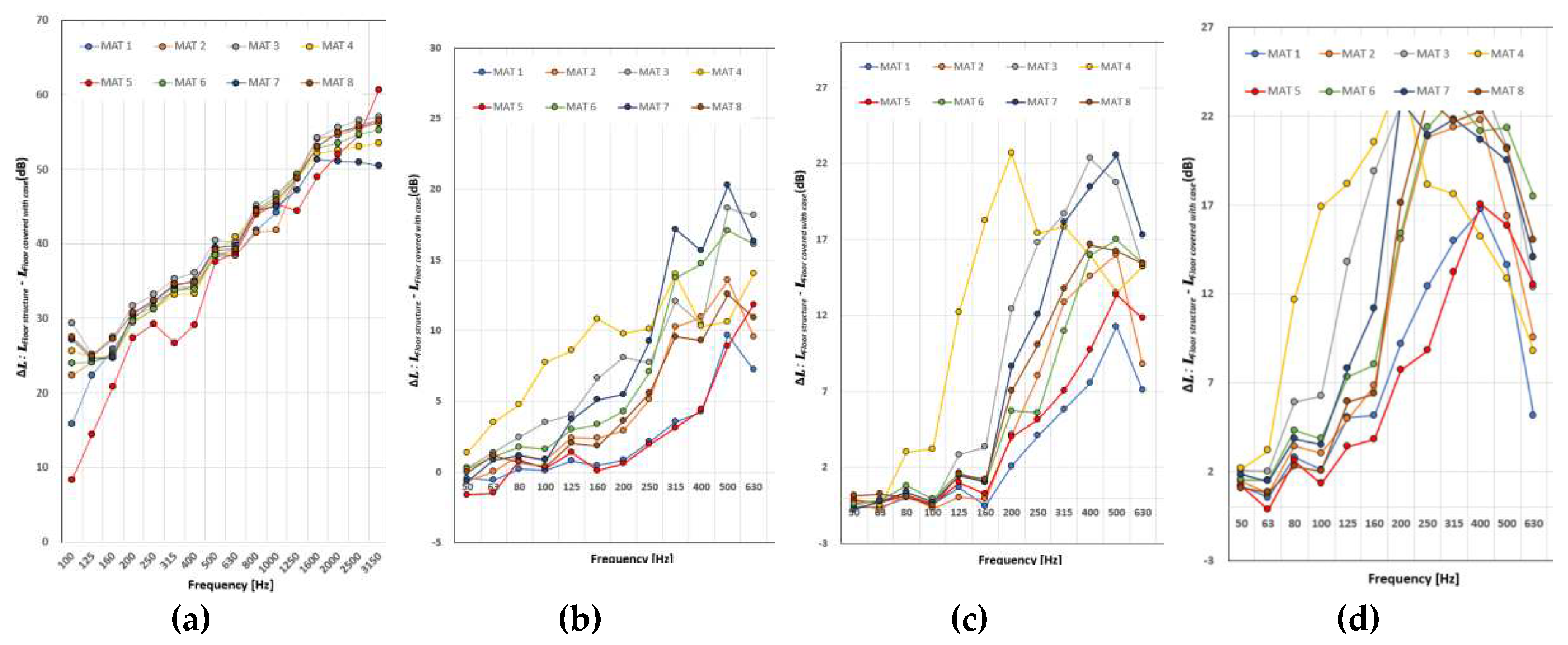

Figure 4 shows the impact sound reduction performance results for the bare slab thickness of 150 mm in the test-bed A as shown in

Figure 3a. The test room consisted of two floor structures with a total of eight floor mat samples. It was found that sufficient impact sound reduction was achieved for light-weight impact sound, regardless of the type of floor mat used. The study found that the reduction amount by frequency band increased as the reduction amount went to the high frequency band. For a single number quantity, a reduction amount of up to 38 dB and a reduction amount of up to 47 dB or more were secured. The impact sound reduction was similar up to a certain frequency band for the bang machine, but the impact sound reduction performance increased somewhat from 315 Hz and above. In the case of a single number quantity, the impact sound reduction performance ranged from 1 dB to 3 dB and from 4 dB to 10 dB, respectively.

Figure 4c shows the reduction performance of the floor mat samples for rubber ball drop height of 1 m. The reduction amount by frequency band indicates that the impact sound is amplified from the 50 Hz band to the 100 Hz band when some floor mats are installed. However, the impact sound reduction performance increased as the frequency band increased from 125 Hz and above.

Figure 4d shows the impact sound reduction performance of the floor mat for a rubber ball drop height of 0.4 m, simulating a child’s behavior. The impact sound reduction performance across frequency bands exhibited a similar reduction pattern to that of the rubber ball drop height of 1 m. A single number quantity can achieve a minimum of 3 dB and a maximum of 9 dB of impact sound reduction.

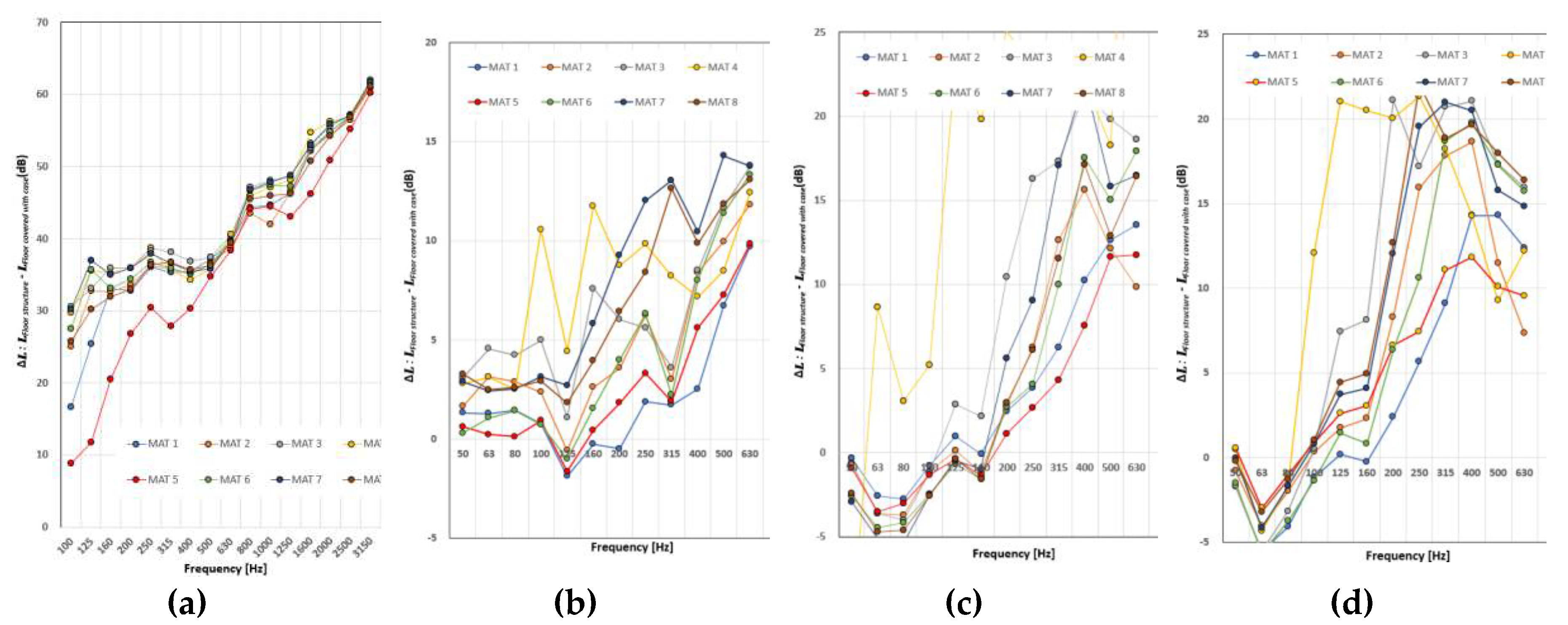

3.2. Test-Bed A with a Bare Slab Thickness of 180 mm

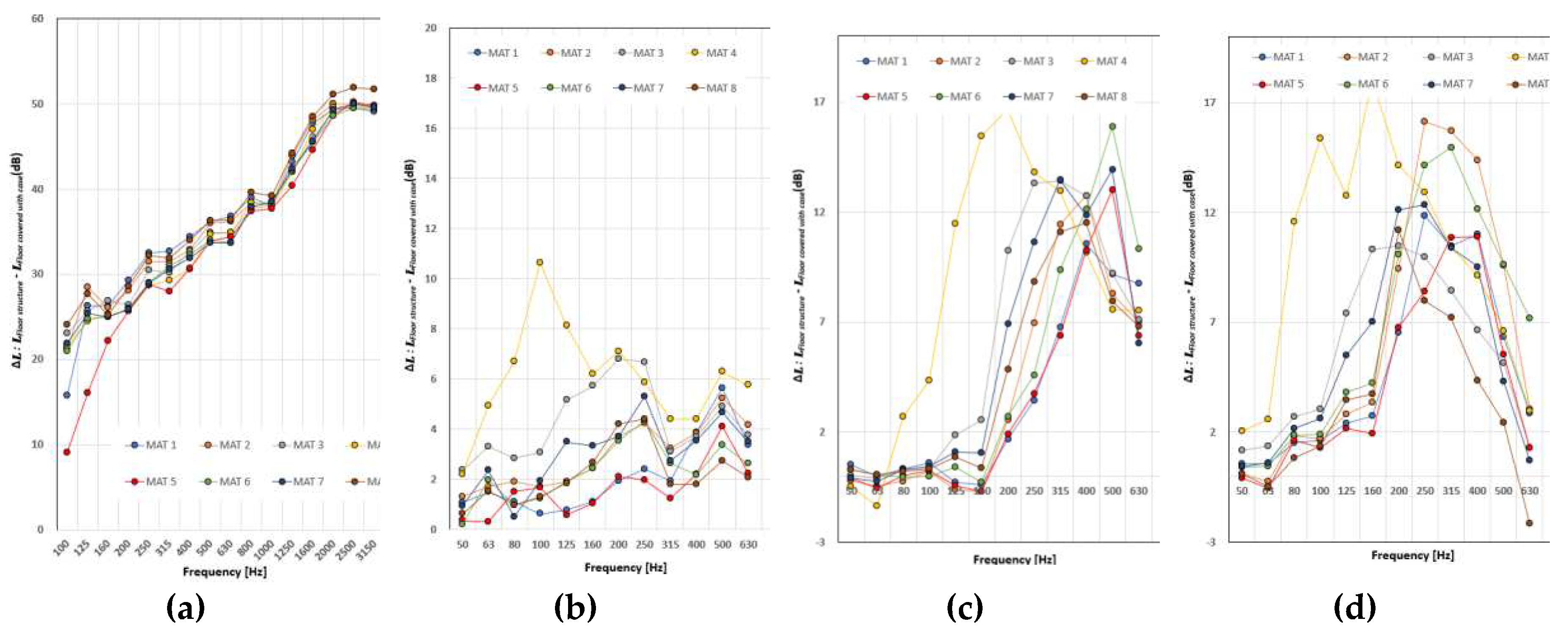

Figure 5 presents the results of the evaluation of impact sound reduction performance of floor mat samples for a bare slab with a thickness of 180 mm in test-bed A as shown in

Figure 3a. The impact sound reduction performance in the frequency band of lightweight impact sound increased from 100 Hz to 3,150 Hz. The single number quantity analysis showed that a reduction performance of at least 35 dB and up to 42 dB was achieved. In the measurement results from the bare slab thickness of 150 mm, the floor mat sample #5 exhibited the lowest impact sound reduction performance. This is because the light-weight impact sound was directly transmitted to the bottom due to the high density of floor mat sample #5. Bang machine demonstrated that it provided impact sound reduction performance throughout the frequency band. However, the analysis revealed that some floor mats slightly amplified the frequency band of 125 Hz. The single number quantity confirmed a minimum impact sound reduction performance of 1 dB and a maximum of 5 dB. A 1 dB improvement in impact sound reduction performance was observed in the floor mat sample #5. Rubber ball from the dropping height of 1 m was enhanced when most of the floor mats were installed in the frequency band below 100 Hz. However, it was determined that the impact sound reduction performance was adequate as it extended to the band above 125 Hz to 630 Hz. For single number quantities, the analysis showed that the impact sound reduction performance was secured at a minimum of 1 dB and up to 13 dB.

Figure 5d shows the impact sound reduction performance of a rubber ball dropped at 0.4 m, which mimics the impact force generated by children’s actions. The reduction performance was amplified in each frequency band from 50 Hz to 100 Hz. However, the impact sound reduction performance increased as the frequency band increased from 125 Hz to the 630 Hz high-frequency band. The single number quantity indicates a secured impact sound reduction performance of at least 2 dB and up to 13 dB. For the bare slab of 150 mm and 180 mm, as well as rubber ball drop heights of 1 m and 0.4 m, the performance increased at certain frequency bands. The installation of a floor mat is believed to increase the impact force of each impact source due to the matching of the impact sound of the rubber ball and the resonant frequency band of the floor structure.

3.3. Test-Bed B with a Bare Slab Thickness of 150 mm

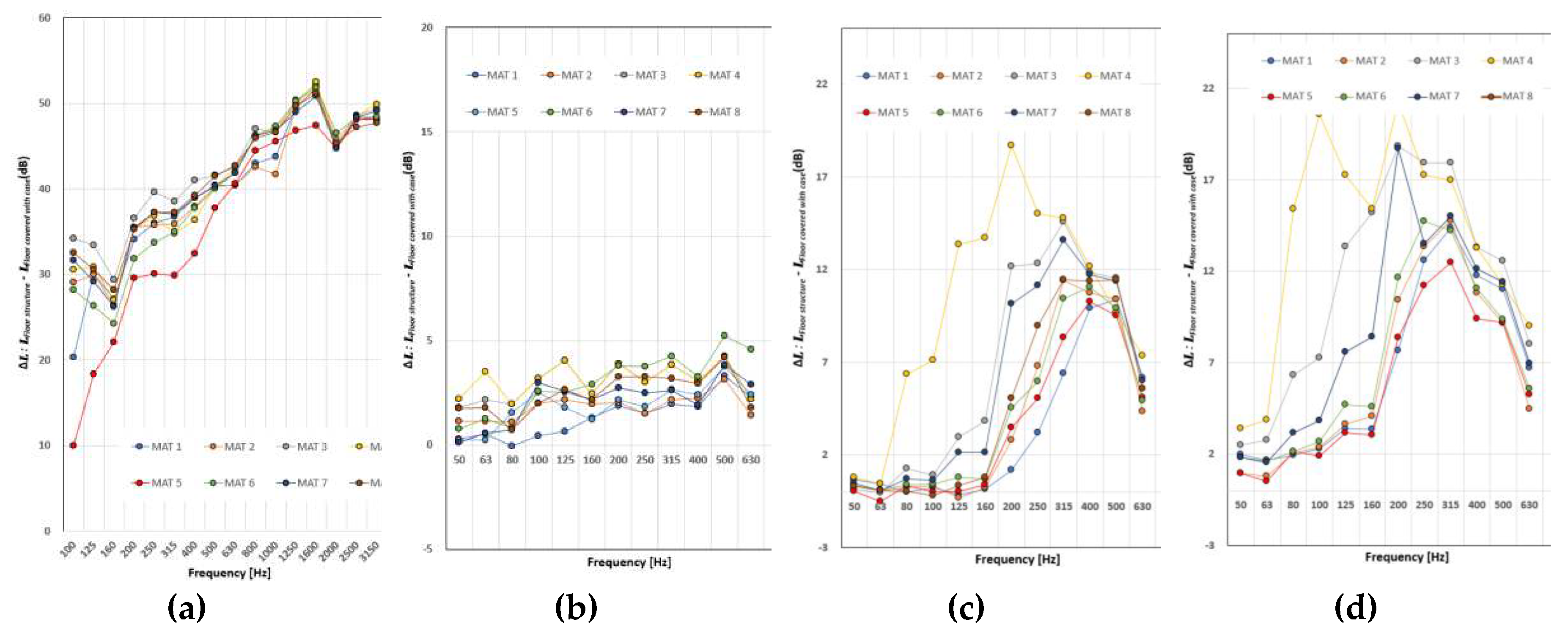

Figure 6 shows the results of evaluating the impact sound reduction performance of eight floor mat samples in the test-bed B as shown in

Figure 3b. The impact sound reduction performance increased from the 100 Hz band to the 3,150 Hz band for all types of floor mat samples, regardless of their weight differences. The study found that the single number quantity resulted in a minimum reduction of 38 dB and a maximum reduction of 44 dB. All evaluations, except for the floor mat sample #5, achieved a reduction performance of over 40 dB.

Figure 6b illustrates the impact sound reduction performance after being hit by a bang machine. It was found that the installation of certain floor mats led to a slight amplification of impact sound in the 50 Hz and 63 Hz bands. However, there was an increase in the impact sound reduction performance from 100 Hz to 630 Hz. Upon further analysis of the numerical values, it was observed that the floor mat samples #1 and #5 did not provide any impact sound reduction when placed on the floor. However, the floor mats that remained showed a minimum reduction of 1 dB and a maximum reduction of 3 dB.

Figure 6c shows the impact sound reduction performance of a rubber ball dropped from a height of 1 m. The reduction performance is insignificant from the 50 Hz band to the 100 Hz band. However, the analysis showed that the impact sound reduction performance from 125 Hz to 630 Hz was sufficiently secured. Furthermore, based on the single number quantity of impact sound reduction, the performance ranged from a minimum of 2 dB to a maximum of 7 dB. Additionally, the impact sound reduction performance was analyzed in relation to a rubber ball dropping from a height of 0.4 m, which simulates the impact force generated by a child, as shown in

Figure 6d. The impact sound reduction performance increased from the 50 Hz band to the 400 Hz band as the frequency band increased. However, from 500 Hz to 630 Hz, the attenuation decreased somewhat. The analysis aimed to achieve a minimum of 5 dB and a maximum of 11 dB of impact sound reduction, based on a single number quantity.

3.4. Test-Bed C with a Bare Slab Thickness of 210 mm

Figure 7 shows the impact sound reduction performance results of eight types of floor mat samples in the bare slab 210 mm living room of the wall-type test-bed C as shown in

Figure 3c. The impact sound reduction performance for light-weight impact sound increases from the 100 Hz band to the 3,150 Hz band when all floor mat samples are installed. For a single number quantity, it was found that the impact sound reduction performance ensures a minimum of 35 dB and a maximum of 40 dB.

Figure 7b shows the reduction performance of the bang machine by frequency band. The reduction performance was achieved in all frequency bands, although the impact sound reduction performance of each floor mat sample. Only two floor mat samples #5 and #6, did not reduce impact sound in the single number quantity. However, regarding the floor mat sample #4, it was analyzed to achieve a maximum reduction performance of 3 dB. The results of the impact sound reduction performance of the floor mat, with a rubber ball dropped from a height of 1 m, are presented in

Figure 7c. The impact sound reduction performance was insignificant from the 50 Hz to the 100 Hz band. However, it was secured from the 125 Hz band and above. Furthermore, in the case of a single number quantity, the impact sound reduction performance ranged from 1 dB to 2 dB. These single number quantities differed slightly from the results obtained in the test-beds A and B.

Figure 7d displays the impact sound reduction performance when a rubber ball is dropped from a height of 0.4 m. Furthermore, the impact sound reduction performance improved in the 50 Hz band to 250 Hz band range but decreased in the 315 Hz band to 630 Hz band range. The single number quantity indicates a minimum reduction of 1 dB and a maximum reduction of 5 dB.

3.5. Test-Bed D with a Bare Slab Thickness of 150 mm

Figure 8 shows the impact sound reduction performance results of eight floor mat samples in the bare slab 150 mm living room of the Rahmen-type test-bed D as shown in

Figure 3d. For light-weight impact sound, the reduction performance increases from the 100 Hz band to the 3150 Hz band for all floor mat samples. In a single number quantity, the analysis showed a minimum of 34 dB and a maximum of 44 dB of reduction performance.

Figure 8b shows the reduction performance of the bang machine by frequency band. Reduction performance was achieved in all frequency bands, with varying reduction performance for each floor mat sample. Only two floor mat samples #5 and #7 showed no reduction performance in a single number quantity. However, the floor mat sample #4 was found to have a maximum reduction performance of 3 dB.

Figure 8c displays the results when a rubber ball is dropped from a height of 1 m. The reduction performance was insignificant from the 50 Hz band to the 125 Hz band. However, it was secured from the 160 Hz band and above. Additionally, a minimum of 1 dB and a maximum of 6 dB of reduction performance was observed in terms of single number quantity. The single number quantity evaluation results differed from those of the test-bed A and B, but were similar to the impact sound reduction performance pattern of the test-bed C.

Figure 8d shows the reduction performance results when a rubber ball dropped from 0.4 m. Furthermore, the impact sound reduction performance improved in the 50 Hz band to 250 Hz band range but decreased in the 315 Hz band to 630 Hz band range. The single number quantity indicates a minimum reduction of 2 dB and a maximum reduction of 8 dB.

4. Discussion

4.1. Correlation Analysis of Impact Sound Reduction Performance according to Bare Slab Thickness

A correlation analysis was conducted on the reduction performance of the same floor mat with the same floor structure. To examine the reliability of the measurement and evaluation methods specified in KS F 2865, a correlation analysis was conducted on the impact sound reduction performance and single number quantity evaluation. The Korea standard code of KS F 2865 specifies a requirement for bare slab thickness in the range of 120 mm to 210 mm for measuring and evaluating floor covering materials [

35]. Analysis was conducted to determine the correlation between impact sound reduction performance and slab thickness. The evaluation was based on single number quantities derived at 150 mm, 180 mm, and 210 mm slab thicknesses. The impact sources analyzed are tapping machine, bang machine, and rubber ball.

4.1.1. Correlation Analysis between the Test-Beds with a Bare Slab Thickness of 150 mm

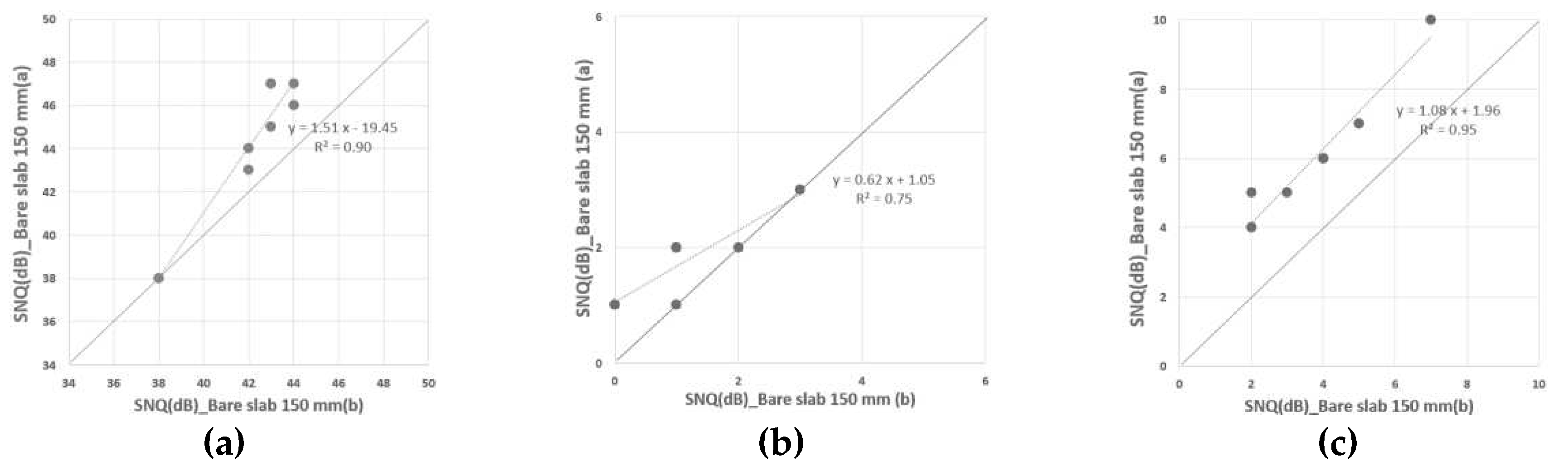

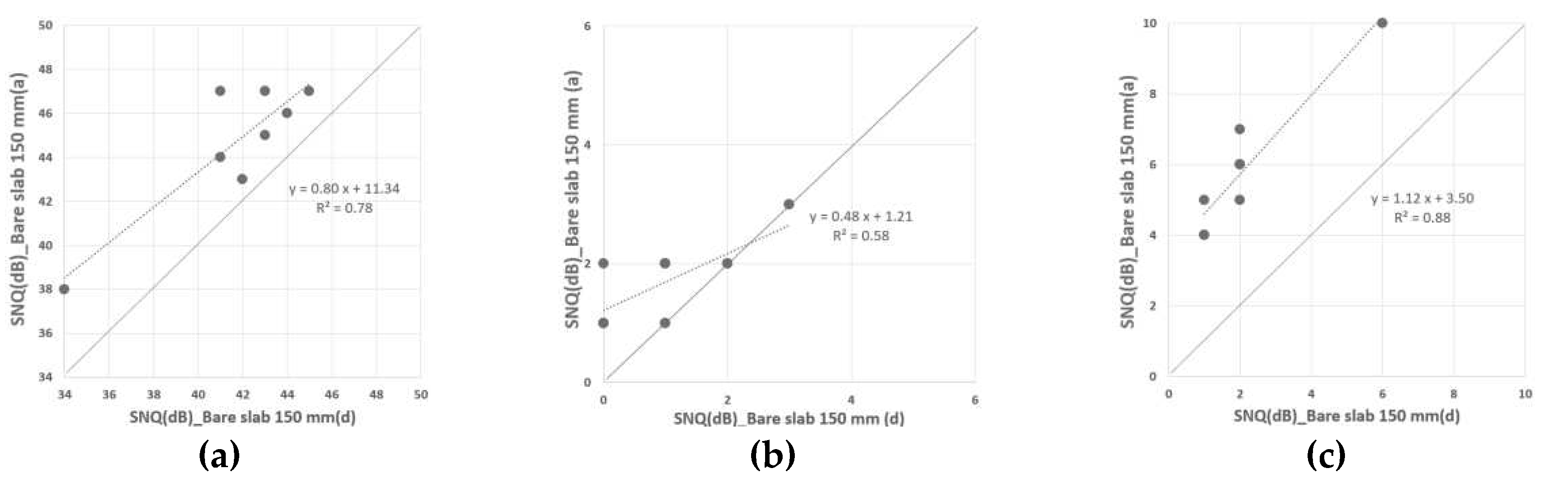

The study utilized four test-beds and tested two structures in test-bed A, resulting in a total of five floor structures. Three test-beds had a bare slab thickness of 150 mm. A correlation analysis was conducted on a single number quantity (SNQ) of the reduction performance of eight floor mat samples for the same impact source measured on a bare slab 150 mm in three test-beds.

First, the correlation between the test-bed A in

Figure 3a and the test-bed B in

Figure 3b of the bare slab 150 mm was analyzed as shown in

Figure 9. The correlation analysis of SNQ for light-weight impact sound reduction performance is shown in

Figure 9a, and the correlation

R2=0.90 (

y=1.51

x-19.45) was observed as very high. The coefficient of determination of the data obtained from the two floor structures of the bang machine is

R2=0.75 (

y=0.62

x+1.05) as shown in

Figure 9b, and the coefficient of determination of the rubber ball is

R2=0.95 (

y=1.08

x+1.96) as shown in

Figure 9c. Based on the results of the analysis, the evaluated values of light-weight impact sound and heavy-weight impact sound reduction performance in the test-beds A and B consisting of a bare slab thickness of 150 mm are at a reliable level for impact sound reduction. In addition, when measuring and evaluating the reduction performance of floor mats in the two test-beds, it is judged that the values can support the validity of the bare slab thickness range of 150 mm mentioned in KS F 2865.

Second, the correlation analysis of the test-bed with a bare slab thickness of 150 mm in

Figure 3a and the Rahmen-type test-bed D in

Figure 3d is shown in

Figure 10. The correlation analysis of SNQ for light-weight impact sound reduction performance showed that the coefficient of determination was very high with

R2=0.78 (

y=0.80

x+11.34) as shown in

Figure 10a. The coefficient of determination of the data obtained from the two test-beds using a bang machine is

R2=0.58 (

y=0.48

x+1.21) as shown in

Figure 10b, and the rubber ball is analyzed as

R2=0.88 (

y=1.12

x+3.50) as shown in

Figure 10c. Therefore, the evaluation values of the rubber ball reduction performance among light-weight impact sound and heavy-weight impact sound in the test-beds A and D consisting of a bare slab thickness of 150 mm are reliable as the amount of impact sound reduction. However, the correlation analysis results for the bang machine are somewhat lower than the correlation analysis results derived from the test-beds A and B. This is because the correlation analysis results are somewhat lower. The reason for the lower correlation is that the floor impact sound test-bed is a ramen structure rather than a wall structure, so when a large impact force of the bang machine is applied, the behavioral characteristics of the floor structure are different, and the impact sound transmitted to the lower part is different.

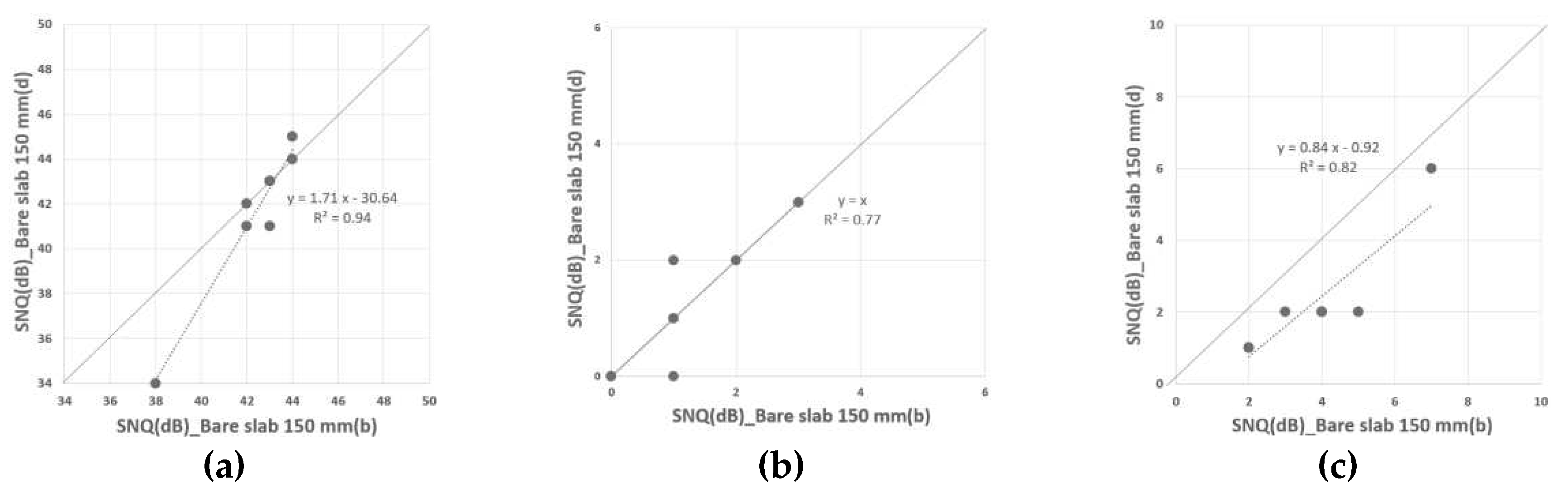

Third, the correlation analysis of the test-bed B in

Figure 3b, which is a bare slab 150 mm, and test-bed D in

Figure 3d, which is the Rahmen structure, was conducted as shown in

Figure 11. The correlation analysis of SNQ for light-weight impact sound reduction performance showed that the coefficient of determination was very high with

R2=0.94 (

y=1.71

x-30.64) as shown in

Figure 11a. The coefficient of determination of the data obtained from the two test-beds using bang machine is

R2=0.77 (

y=

x) as shown in

Figure 11b, and the coefficient of determination of the rubber ball is

R2=0.82 (

y=0.84

x-0.92) as shown in

Figure 11c. Therefore, the evaluation values of light-weight impact sound and heavy-weight impact sound reduction performance in the test-beds B and D consisting of a bare slab thickness of 150 mm are reliable in terms of impact sound reduction. In addition, when measuring and evaluating the reduction performance of floor mats in the two test-beds, it is judged that it is possible to secure the validity of the slab thickness range of 150 mm mentioned in KS F 2865.

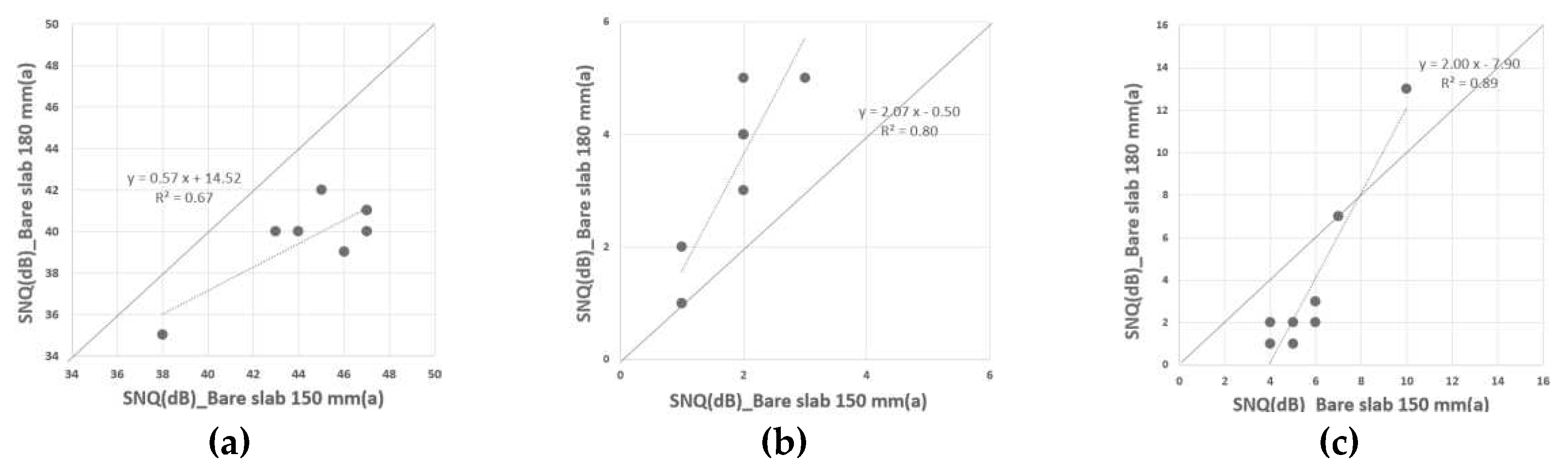

4.1.2. Correlation Analysis between the Bare Slab Thicknesses of 150 mm and 180 mm in the Test-Bed A

A correlation analysis was conducted on the SNQs of the impact sound reduction performance evaluated on the bare slab thickness of 150 mm and 180 mm of the test-bed A. The correlation analysis was conducted on the reduction performance. The results of the correlation analysis are shown in

Figure 12. As shown in

Figure 12a, the correlation analysis of SNQs with light-weight impact sound reduction performance was high with a correlation of

R2=0.67 (

y=0.57

x-14.52). The correlation of the data obtained from the two test-beds using the bang machine was

R2=0.80 (

y=2.07

x-0.50) as shown in

Figure 12b, and the correlation of the rubber ball was

R2=0.89 (

y=2.00

x-7.90) as shown in

Figure 12c. Based on the results of the analysis, the evaluated values of light-weight impact sound and heavy-weight impact sound reduction performance in test-bed A consisting of bare slab thickness 150 mm and 180 mm are reliable in terms of impact sound reduction.

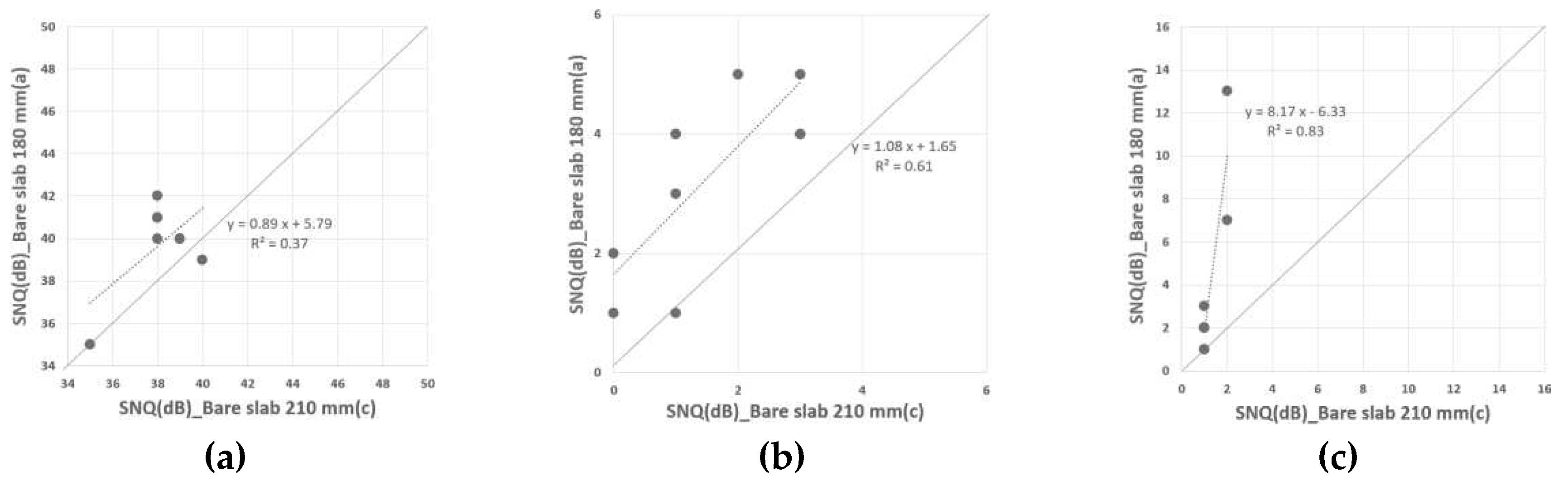

4.1.3. Correlation Analysis between the Test-Bed A with a Bare Slab Thickness of 180 mm and the Test-Bed C with a Bare Slab Thickness of 210 mm

A correlation analysis was conducted on the impact sound reduction performance SNQ evaluated on bare slab thicknesses of 180 mm and 210 mm. The thickness of the two floor structures differs by about 30 mm, but it is included in the floor thickness range specified in KS F 2865. The results of the correlation analysis of the impact sound reduction performance of the two floor structures are shown in

Figure 13. The correlation analysis of the SNQ for light-weight impact sound reduction performance was somewhat lower with a correlation

R2=0.37 (

y=0.89

x+5.79) as shown in

Figure 13(a). The correlation of the data obtained from the two floor structures of the bang machine is

R2=0.61 (

y=1.08

x+1.65) as shown in

Figure 13b, and the rubber ball is analyzed as high as

R2=0.83 (

y=8.17

x-6.33) as shown in

Figure 13c. Based on the results of the analysis, the correlation between light-weight impact sound and the SNQ of impact sound reduction performance was low. The factors that were analyzed for low correlation were the different structures of the two test-beds and the fact that the floor impact sound test-bed with a bare slab thickness of 210 mm had a ceiling structure, which had a higher reduction performance in the high frequency band when evaluating light-weight impact sound. In the case of bang machine, the correlation value of impact sound reduction performance was also somewhat lower than the correlation analysis results according to other floor thicknesses. However, the correlation value of the impact sound reduction performance of the rubber ball is at a level that can be trusted as the amount of impact sound reduction. In the future, it is necessary to change the conditions such as the acoustic chamber in the floor impact test room with a bare slab thickness of 210 mm. In addition, it is necessary to conduct additional floor mat tests in the changed test room to evaluate the impact sound reduction, and to correlate the results with other bare slab thicknesses and conditions. Based on the results, it is judged that it is necessary to consider whether the slab thickness range mentioned in KS F 2865 can be met.

4.2. Comparison of Single Number Quantities for the Same Impact Sound Sources

Table 2 through

Table 4 show the SNQ results of eight floor mat samples from different test-beds for the same impact source.

Table 2 shows the results for the tapping machine,

Table 3 shows the results for the bang machine, and

Table 4 shows the results for the rubber ball, respectively. Regardless of the type of floor mat, it was found that the light-weight impact sound blocking performance can be sufficiently reduced by showing consistent results when installed in an apartment house. In addition, the discriminating power of impact sound reduction performance by type of floor mat samples was analyzed. On the other hand, in the case of the bang machine, even if floor mats were installed, there were conditions where there was no impact sound reduction performance depending on the floor structure. However, the impact sound reduction performance of up to 5 dB was secured depending on the type of floor mat. The impact sound reduction performance of rubber ball was found to be at least 1 dB and up to 10 dB or more. However, the impact sound reduction performance was analyzed to be somewhat different depending on the test facility condition and bare slab thickness. Except for the test-bed D condition with a bare slab thickness of 150 mm and 180 mm, the impact sound reduction performance of rubber ball was analyzed similarly. In addition, in test-beds C and D, which were designed similarly to actual apartment houses, the bare slab thickness was 210 mm and 150 mm, respectively, and the impact sound reduction performance was analyzed somewhat lower than in test-beds A and B, which were laboratory test-beds.

5. Conclusions

This study examines the measurement and evaluation of impact sound reduction of floor mats used in apartment buildings. The evaluation method follows the guidelines outlined in KS F 2865, which specifies a bare slab thickness range of 120 mm to 210 mm. Thus, the impact sound reduction performance of floor mats applied in actual apartment houses was evaluated using various test facilities with different bare slab thicknesses. The standard impact sources include a tapping machine, a bang machine, a rubber ball, and a rubber ball falling from a height of 0.4 m, simulating the impact force generated by children’s behavior.

The experimental results indicate that the Tapping machine, a lightweight impact sound, provided sufficient impact sound reduction performance regardless of floor mats and test room conditions. Furthermore, the impact sound reduction performance increased from the low frequency band to the high frequency band. The bang machine produces heavier impact sounds than other sources, resulting in a lower impact sound reduction performance even with floor mats installed. In some cases, it may even amplify certain frequency bands. Similar to light-weight impact sounds, the impact sound reduction performance increases from low to high frequency bands. The results of the SNQ indicate that the installation of floor mats may not always reduce impact sound, with a maximum reduction of 5 dB. However, the effectiveness of floor mats varied depending on their type. Rubber balls amplified the impact sound from the 50 Hz band to the 125 Hz band for heavy-weight impacts, depending on the type of floor mat and the thickness of the bare slab. However, the study found that impact sound reduction performance was achieved from the 160 Hz band and above, with a tendency for the impact sound to decrease from the 315 Hz band to the 630 Hz band. The SNQ evaluation showed a minimum of 1 dB and a maximum of 10 dB or more of impact sound reduction performance. For a drop height of 0.4 m of a rubber ball, which simulates a child’s behavior, it is possible to secure impact sound reduction performance by installing a floor mat, regardless of the bare slab and floor structure. The impact sound reduction performance was somewhat amplified in certain frequency bands with certain floor mats. Similar to the rubber ball drop height of 1 m, the impact sound reduction performance increased up to a certain frequency band. However, above a certain frequency band, the impact sound reduction performance tended to decrease somewhat. In terms of a single numerical evaluation, the impact sound reduction performance ranged from a minimum of 1 dB to a maximum of 16 dB or more, depending on the type of floor mat and floor structure.

Finally, to assess the reliability of each floor mat’s impact sound reduction performance, a correlation analysis was conducted for each bare slab thickness to evaluate a SNQ value of impact sound reduction performance. The correlation analysis of light-weight and heavy-weight impact sounds showed a high correlation between the test-bed A and B, which consisted of a bare slab thickness of 150 mm. If the same floor matting is used to evaluate the impact sound reduction performance in both test-beds A and B, the figures can be considered reliable. Additionally, we analyzed the correlation of the bare slab 150 mm of the Rahmen structure, which is designed the same as the real apartment building, to ensure sufficient impact sound reduction performance reliability other than the bang machine. Furthermore, the correlation analysis between the impact sound SNQ in the laboratory and the bare slab 150 mm and 180 mm of the test-bed A indicates that the lightweight impact sound is lower than the heavyweight impact sound, bang machine, and rubber ball. However, the impact sound reduction performance is still reliable in both test-beds. The correlation analysis results for bare slab thicknesses of 180 mm and 210 mm show a weaker correlation. Therefore, further research is required.

It is expected that the results of this study will be used as a basis for improving the existing measurement standards. In the future, additional evaluations using the same floor mat and the same source at bare slab thicknesses of 180 mm and 210 mm will be required. It is also necessary to evaluate the impact sound reduction performance of floor mats according to changes in the conditions of the sound chamber to examine the effects of changes in test facility conditions.

Author Contributions

Conceptualization, J.O. and Y.H.; methodology, J.O. and S.S.; validation, J.O.; formal analysis, J.O. and S.S.; investigation, J.O.; resources, J.O. and S.S.; data curation, J.O.; writing—original draft preparation, J.O.; writing—review and editing, Y.H.; visualization, J.O. and Y.H.; supervision, Y.H.; project administration, J.O.; funding acquisition, J.O. and S.S. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by the National Research Foundation of Korea (NRF) grant funded by the Korea government (MSIT) (NRF-2022R1F1A1066636).

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Jeong, J.H.; Kim, Y.H.; Ryu, J.K.; Kim, K.H. Classification scheme of floor impact sound insulation by rubber ball, Proc. INTER-NOISE 2020, Seoul, Korea, 1139-1142.

- Lee, W.H.; Song, G.G.; Kim, Y.H.; Yoon, Y.J. Reduction performance of floor impact sound of the existing apartment buildings in Korea, J. Acoust. Soc. Am. 2017, 141, 3775. [CrossRef]

- Act No. 2023-494, Accreditation and Inspection Requirements for Floor Sound Insulation in Apartment Buildings, 2023, Ministry of Land, Infrastructure and Transport.

- Shin, H.K.; Park, S.H.; Kim, M.J.; Kim, K.W. A study on subjective response to heavy-weight impact sound through representative spectrum analysis: A case study in South Korea, Appl. Acoust. 2022, 188, 108562. [CrossRef]

- Im, J B; Chung, J.Y. A study to reduce heavy-weight floor impact noise in apartment building using stiffness reinforcement method on concrete slab, Proc. INTER-NOISE 2007, 2, 5027-5036.

- Kim, Y.H.; Song, G.G.; Lee, W.H.; Seo, J.B.; Kim, M.J.; Jeong, J.H.; Ryu, J.K.; Kim, K.H. A guideline of heavy-weight floor impact noise reduction for retrofitted apartment buildings in Korea, Proc. INTER-NOISE 2017, Hong Kong, 5471-5478.

- Kim, Y.H.; Song, G.G.; Bae, S.K. Application of ETPU materials for reducing floor impact noises, Proc. Euronoise 2018, Crete, Greece, 1723-1726.

- Yeon, J.O; Moon, S.S.; Kim, Y.H. Effects of Floor Impact Sound Reduction Performance according to Apartment Type, J. Kor. Inst. Arch. Sustainable Env. Build. Sys. 2023, 17(2), 110-126.

- Kim, K.W.; Shin, H.K.; Park, S.H.; Lee, J.W. Analysis of Floor Impact Sound Reduction Performance of Floor Structure with Damping Material. Trans. Korean Soc. Noise Vib. Eng. 2022, 32(6), 631-637. [CrossRef]

- Kim, T.M.; Kim, J.T.; Kim, T.H.; Park, I.S.; Shin, D.M. The Study of Floor Impact Noise for Apartment Complex using Statistical Energy Analysis : Coupling Loss Factor, Proc. Korean Soc. Noise Vib. Eng. 2016, 116-120.

- Yoon, C.Y.; Kang, C.G.; Lee, B.H. Influence of Floor Impact sound according to the composition change on the Aerated Concrete containing Lightweight Aggregate, Proc. Korean Soc. Noise Vib. Eng. 2018, 234.

- Koo, B.S. Construction companies’ response to reducing floor impact noise. Arch. Env. Facilities 2022, 16(4), 6-12.

- Bouttout, A. Experimental study of the impact noise through concrete floor with resilient layers, J. Acoust. Soc. Am. 2017, 142, 2517. [CrossRef]

- Act No. 2018-585, Structural criteria for floor impact sound insulation between floors to prevent noise, 2018, Ministry of Land, Infrastructure and Transport.

- Oliveira, M.D.; & Patricio, J.V. Impact noise of non-homogeneous floors: analysis of different input parameters for computational modeling predictions. J. Civil Eng. Arch. 2017, 11(3), 274-281.

- 16. Kim, T.M.; Kim, J.T.; Kim, J.S. Effect of structural vibration and room acoustic modes on low frequency impact noise in apartment house with floating floor. Appl. Acoust. 2018, 142, 59-69.

- Chun, Y.S; Lee, S.B. The Influence of the Shape of Slab on Heavyweight Impact Sound Reduction for an Apartment Building, Proc. INTER-NOISE 2016, 3234-3242.

- Song, G.G.; Lee, W.H.; Kim, Y.H.; Ryu, J.K. A Fundamental Study on the Field Measurement Method of Dynamic Stiffness of Resilient Materials used for Floor Impact Sound Insulation. J. Kor. Inst. Arch. Sustainable Env. Build. Sys. 2019, 13(1), 93-103. [CrossRef]

- 19. Ryu, J.K.; Jeong, G.H.; Jeon, I.A.; Go, J.C.; Lee, J.I.; Kim, H.B.; Kim, Y.S. Relationship between property of isolator for standardized floor structure and floor impact sound level. Proc. Korean Soc. Noise Vib. Eng. 2012, 278-279.

- Führ, G.; Masuero, A.B.; Pagnussat, D.T.; Barreto, M.F.F.M. Impact sound attenuation of subfloor mortars made with exfoliated vermiculite and chrome sawdust. Appl. Acoust. 2021, 174, 107725. [CrossRef]

- Kim, K.W.; Kang, J.S.; Lee, S.E.; Yang, K.S. Floor Impact Sound Isolation Performance by Composition of Ceiling and Wall, Trans. Korean Soc. Noise Vib. Eng. 2005, 15(4), 465-473.

- Kim, I.H.; Go, J.C. Effects of Finishing Materials in Wall and Ceiling on Floor Impact Sound, Proc. INTER-NOISE 2016, Hamburg, Germany 7512-7517.

- Ryu, J.K.; Song, H.S.; Kim, Y.H. Effect of the suspended ceiling with low-frequency resonant panel absorber on heavyweight floor impact sound in the building, Build. Environ. 2018, 139, 1-7. [CrossRef]

- Shin, H.K.; Kim, K.W. Floor Impact Sound Insulation Using Perforated Gypsum Board Ceiling, Proc. INTER-NOISE 2019, Madrid, Spain, 5848-5853.

- Kim, S.T.; Cho, H.M.; Kim, M.J. Effects of Wall-to-Wall Supported Ceilings on Impact Sound Insulation for Use in Residential Buildings, Buildings 2021, 11(12), 587. [CrossRef]

- Kim, Y.H. Acoustic Retrofit Approach of an Apartment Living Room Using Multi-Perforated Gypsum Boards in Terms of Heavy-Weight Impact Sounds, Sustainability 2022, 14(9), 5007. [CrossRef]

- Jeon, J.Y.; Ryu, J.K. Influence of noise sensitivity on annoyance of indoor and outdoor noises in residential buildings, Appl. Acoust. 2011, 72, 336-340. [CrossRef]

- Park, S.H.; Lee, P.J. Reaction to floor impact noise in multi-storey residential buildings: The effects of acoustic and non-acoustic factors, Appl. Acoust. 2019, 150, 268-278. [CrossRef]

- Kim, K.W.; Yeon, J.O.; Yang, K.S. Floor impact sound reduction properties of flooring mats, Proc. Korean Soc. Noise Vib. Eng. 2013, 190-192.

- Mun, D.H.; Song, G.G.; Lee, C.S.; Park, H.G. Reduction of Floor Impact Noise and Impact Force for PVC Floor Covering and Floor Mat, Trans. Korean Soc. Noise Vib. Eng. 2014, 24(7), 501-508. [CrossRef]

- 31. Yeon, J.O.; Kim, K.W.; Kim, H.S.; Kim, M.J. Evaluation of Impact Sound Reduction for Floor Mats Considering the Impact of Residents in Apartment Housing, J. Kor. Inst. Arch. Sustainable Env. Build. Sys. 2019, 13(5), 291-302.

- Chung, J.Y.; Song, H.S.; Song, G.G.; Yoon, Y.J. Improvement of evaluation method for impact sound reduction performance of floor coverings, J. Acoust. Soc. Kor. 2023, 42(2), 161-167. [CrossRef]

- Yeon, J.O.; Kim, K.W.; Kim, M.J. Evaluation of the Effect and the Perception Range on Impact Sound Reduction by Installing Floor Mats, J. Kor. Inst. Arch. Sustainable Env. Build. Sys. 2021, 15(6), 600-612.

- Korea Apartment News. https://www.hapt.co.kr/news/articleView.html?idxno=160369 (accessed on 10 January 2023).

- KS F 2865,Laboratory measurements of the reduction of transmitted impact sound by floor covering materials using standard light and heavy impact sources, 2015, Korean Agency for Technology and Standards.

- KS F 2810-1, Field measurements of impact sound insulation of floors—Part 1: Method using standard light impact source, 2015, Korean Agency for Technology and Standards.

- KS F 2810-2, Field measurements of floor impact sound insulation of buildings ― Part 2: Method using standard heavy impact sources, 2012, Korean Agency for Technology and Standards.

- ISO 16283-2, Acoustics — Field measurement of sound insulation in buildings and of building elements — Part 2: Impact sound insulation, 2018, International Organization for Standardization.

- Jeon, J.Y.; Lee, P.J.; Sato, S.I. Use of the standard rubber ball as an impact source with heavyweight concrete floors, J. Acoust. Soc, Am. 2009, 126(1), 167-178. [CrossRef]

- Yeon, J.O.; Kim, K.W.; Yang, K.S. A correlation between a single number quantity and noise level of real impact sources for floor impact sound, Appl. Acoust. 2017, 125, 20-33. [CrossRef]

Figure 1.

The employed impact sound sources in the sound source room. (a) Bang machine; (b) Rubber ball (drop height of 1 m); (c) Tapping machine; (d) Rubber ball (drop height of 0.4 m)

Figure 1.

The employed impact sound sources in the sound source room. (a) Bang machine; (b) Rubber ball (drop height of 1 m); (c) Tapping machine; (d) Rubber ball (drop height of 0.4 m)

Figure 2.

View of the sound receiving room with five microphones.

Figure 2.

View of the sound receiving room with five microphones.

Figure 3.

Picture and sectional plan of the bare slab structure with floor mat sample installed. (a) Test-bed A as a box-type building with two rooms of bare slab thickness of 150 and 180 mm; (b) Test-bed B as a up-and-downside coupled reverberation room with a bare slab thickness of 150 mm; (c) Test-bed C as a wall-type concrete apartment building with a real-life floor plan and bare slab thickness of 210 mm; (d) Test-bed D as a Rahmen-type beam-column concrete apartment building with a real-life floor plan and bare slab thickness of 150 mm.

Figure 3.

Picture and sectional plan of the bare slab structure with floor mat sample installed. (a) Test-bed A as a box-type building with two rooms of bare slab thickness of 150 and 180 mm; (b) Test-bed B as a up-and-downside coupled reverberation room with a bare slab thickness of 150 mm; (c) Test-bed C as a wall-type concrete apartment building with a real-life floor plan and bare slab thickness of 210 mm; (d) Test-bed D as a Rahmen-type beam-column concrete apartment building with a real-life floor plan and bare slab thickness of 150 mm.

Figure 4.

Frequency characteristics of floor impact sound reduction levels for each mat sample in the 150-mm-thick room of the test-bed A. (a) Tapping machine; (b) Bang machine; (c) Rubber ball (drop height of 1 m); (d) Rubber ball (drop height of 0.4 m).

Figure 4.

Frequency characteristics of floor impact sound reduction levels for each mat sample in the 150-mm-thick room of the test-bed A. (a) Tapping machine; (b) Bang machine; (c) Rubber ball (drop height of 1 m); (d) Rubber ball (drop height of 0.4 m).

Figure 5.

Frequency characteristics of floor impact sound reduction levels for each mat sample in the 180-mm-thick room of the test-bed A. (a) Tapping machine; (b) Bang machine; (c) Rubber ball (drop height of 1 m); (d) Rubber ball (drop height of 0.4 m).

Figure 5.

Frequency characteristics of floor impact sound reduction levels for each mat sample in the 180-mm-thick room of the test-bed A. (a) Tapping machine; (b) Bang machine; (c) Rubber ball (drop height of 1 m); (d) Rubber ball (drop height of 0.4 m).

Figure 6.

Frequency characteristics of floor impact sound reduction levels for each mat sample in the 150-mm-thick room of the test-bed B. (a) Tapping machine; (b) Bang machine; (c) Rubber ball (drop height of 1 m); (d) Rubber ball (drop height of 0.4 m).

Figure 6.

Frequency characteristics of floor impact sound reduction levels for each mat sample in the 150-mm-thick room of the test-bed B. (a) Tapping machine; (b) Bang machine; (c) Rubber ball (drop height of 1 m); (d) Rubber ball (drop height of 0.4 m).

Figure 7.

Frequency characteristics of floor impact sound reduction levels for each mat sample in the 210-mm-thick room of the test-bed C. (a) Tapping machine; (b) Bang machine; (c) Rubber ball (drop height of 1 m); (d) Rubber ball (drop height of 0.4 m).

Figure 7.

Frequency characteristics of floor impact sound reduction levels for each mat sample in the 210-mm-thick room of the test-bed C. (a) Tapping machine; (b) Bang machine; (c) Rubber ball (drop height of 1 m); (d) Rubber ball (drop height of 0.4 m).

Figure 8.

Frequency characteristics of floor impact sound reduction levels for each mat sample in the 150-mm-thick room of the test-bed D. (a) Tapping machine; (b) Bang machine; (c) Rubber ball (drop height of 1 m); (d) Rubber ball (drop height of 0.4 m).

Figure 8.

Frequency characteristics of floor impact sound reduction levels for each mat sample in the 150-mm-thick room of the test-bed D. (a) Tapping machine; (b) Bang machine; (c) Rubber ball (drop height of 1 m); (d) Rubber ball (drop height of 0.4 m).

Figure 9.

Correlation analysis between the test-beds A and B, both with a slab thickness of 150 mm. (a) Tapping machine; (b) Bang machine; (c) Rubber ball dropping at 1 m height.

Figure 9.

Correlation analysis between the test-beds A and B, both with a slab thickness of 150 mm. (a) Tapping machine; (b) Bang machine; (c) Rubber ball dropping at 1 m height.

Figure 10.

Correlation analysis between the test-beds A and D, both with a slab thickness of 150 mm. (a) Tapping machine; (b) Bang machine; (c) Rubber ball dropping at 1 m height.

Figure 10.

Correlation analysis between the test-beds A and D, both with a slab thickness of 150 mm. (a) Tapping machine; (b) Bang machine; (c) Rubber ball dropping at 1 m height.

Figure 11.

Correlation analysis between the test-beds B and D, both with a slab thickness of 150 mm. (a) Tapping machine; (b) Bang machine; (c) Rubber ball dropping at 1 m height.

Figure 11.

Correlation analysis between the test-beds B and D, both with a slab thickness of 150 mm. (a) Tapping machine; (b) Bang machine; (c) Rubber ball dropping at 1 m height.

Figure 12.

Correlation analysis between the slab thicknesses of 150 mm and 180 mm in the test-beds A. (a) Tapping machine; (b) Bang machine; (c) Rubber ball dropping at 1 m height.

Figure 12.

Correlation analysis between the slab thicknesses of 150 mm and 180 mm in the test-beds A. (a) Tapping machine; (b) Bang machine; (c) Rubber ball dropping at 1 m height.

Figure 13.

Correlation analysis between the test-bed A with a slab thickness of 180 mm and the test-bed C with a bare slab thickness of 210 mm. (a) Tapping machine; (b) Bang machine; (c) Rubber ball dropping at 1 m height.

Figure 13.

Correlation analysis between the test-bed A with a slab thickness of 180 mm and the test-bed C with a bare slab thickness of 210 mm. (a) Tapping machine; (b) Bang machine; (c) Rubber ball dropping at 1 m height.

Table 1.

Details of the floor mat samples.

Table 1.

Details of the floor mat samples.

| Sample No. |

Sample #1 |

Sample #2 |

Sample #3 |

Sample #4 |

Sample #5 |

Sample #6 |

Sample #7 |

Sample #8 |

| Picture |

|

| Thickness |

8 mm |

13 mm |

12 mm |

36 mm |

11 mm |

13 mm |

14 mm |

16 mm |

| Material type |

Polyurethane |

Polyurethane |

Polyurethane |

Polyurethane |

Ethylene vinyl acetate copolymer |

Polyethylene |

Polyethylene |

Polyurethane |

Table 2.

The SNQ measured for the floor mat samples using a tapping machine in different test-beds. Unit is dB.

Table 2.

The SNQ measured for the floor mat samples using a tapping machine in different test-beds. Unit is dB.

| Test-Bed with Bare Slab Thickness |

Sample No. |

| Sample #1 |

Sample #2 |

Sample #3 |

Sample #4 |

Sample #5 |

Sample #6 |

Sample #7 |

Sample #8 |

| Test-bed A (150 mm) |

44 |

43 |

47 |

45 |

38 |

47 |

47 |

46 |

| Test-bed A (180 mm) |

40 |

40 |

41 |

42 |

35 |

40 |

41 |

39 |

| Test-bed B (150 mm) |

42 |

42 |

44 |

43 |

38 |

43 |

43 |

44 |

| Test-bed C (210 mm) |

39 |

39 |

38 |

38 |

35 |

38 |

38 |

40 |

| Test-bed D (150 mm) |

41 |

42 |

45 |

43 |

34 |

41 |

43 |

44 |

| Average |

41.2 |

41.2 |

43 |

42.2 |

36 |

41.8 |

42.4 |

42.6 |

| Standard deviation |

1.9 |

1.6 |

3.5 |

2.6 |

1.9 |

3.4 |

3.3 |

3.0 |

Table 3.

The SNQ measured for the floor mat samples using a bang machine in different test-beds. Unit is dB.

Table 3.

The SNQ measured for the floor mat samples using a bang machine in different test-beds. Unit is dB.

| Test-Bed with Bare Slab Thickness |

Sample No. |

| Sample #1 |

Sample #2 |

Sample #3 |

Sample #4 |

Sample #5 |

Sample #6 |

Sample #7 |

Sample #8 |

| Test-bed A (150 mm) |

1 |

2 |

2 |

3 |

1 |

1 |

2 |

2 |

| Test-bed A (180 mm) |

1 |

3 |

5 |

5 |

1 |

2 |

4 |

4 |

| Test-bed B (150 mm) |

0 |

1 |

2 |

3 |

0 |

1 |

1 |

1 |

| Test-bed C (210 mm) |

1 |

1 |

2 |

3 |

0 |

0 |

1 |

3 |

| Test-bed D (150 mm) |

0 |

1 |

2 |

3 |

0 |

1 |

0 |

2 |

| Average |

0.6 |

1.6 |

2.6 |

3.4 |

0.4 |

1.0 |

1.6 |

2.4 |

| Standard deviation |

0.5 |

0.9 |

1.3 |

0.9 |

0.5 |

0.7 |

1.5 |

1.1 |

Table 4.

The SNQ measured for the floor mat samples using a rubber ball dropping at 1 m height in different test-beds. Unit is dB.

Table 4.

The SNQ measured for the floor mat samples using a rubber ball dropping at 1 m height in different test-beds. Unit is dB.

| Test-Bed with Bare Slab Thickness |

Sample No. |

| Sample #1 |

Sample #2 |

Sample #3 |

Sample #4 |

Sample #5 |

Sample #6 |

Sample #7 |

Sample #8 |

| Test-bed A (150 mm) |

4 |

5 |

7 |

10 |

4 |

5 |

6 |

6 |

| Test-bed A (180 mm) |

2 |

2 |

7 |

13 |

1 |

1 |

3 |

2 |

| Test-bed B (150 mm) |

2 |

2 |

5 |

7 |

2 |

3 |

4 |

4 |

| Test-bed C (210 mm) |

1 |

1 |

2 |

2 |

1 |

1 |

1 |

1 |

| Test-bed D (150 mm) |

1 |

1 |

2 |

6 |

1 |

2 |

2 |

2 |

| Average |

2 |

2.2 |

4.6 |

7.6 |

1.8 |

2.4 |

3.2 |

3.0 |

| Standard deviation |

1.2 |

1.6 |

2.5 |

4.2 |

1.3 |

1.7 |

1.9 |

2.0 |

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).