6.1. M219 Acoustic Cavity

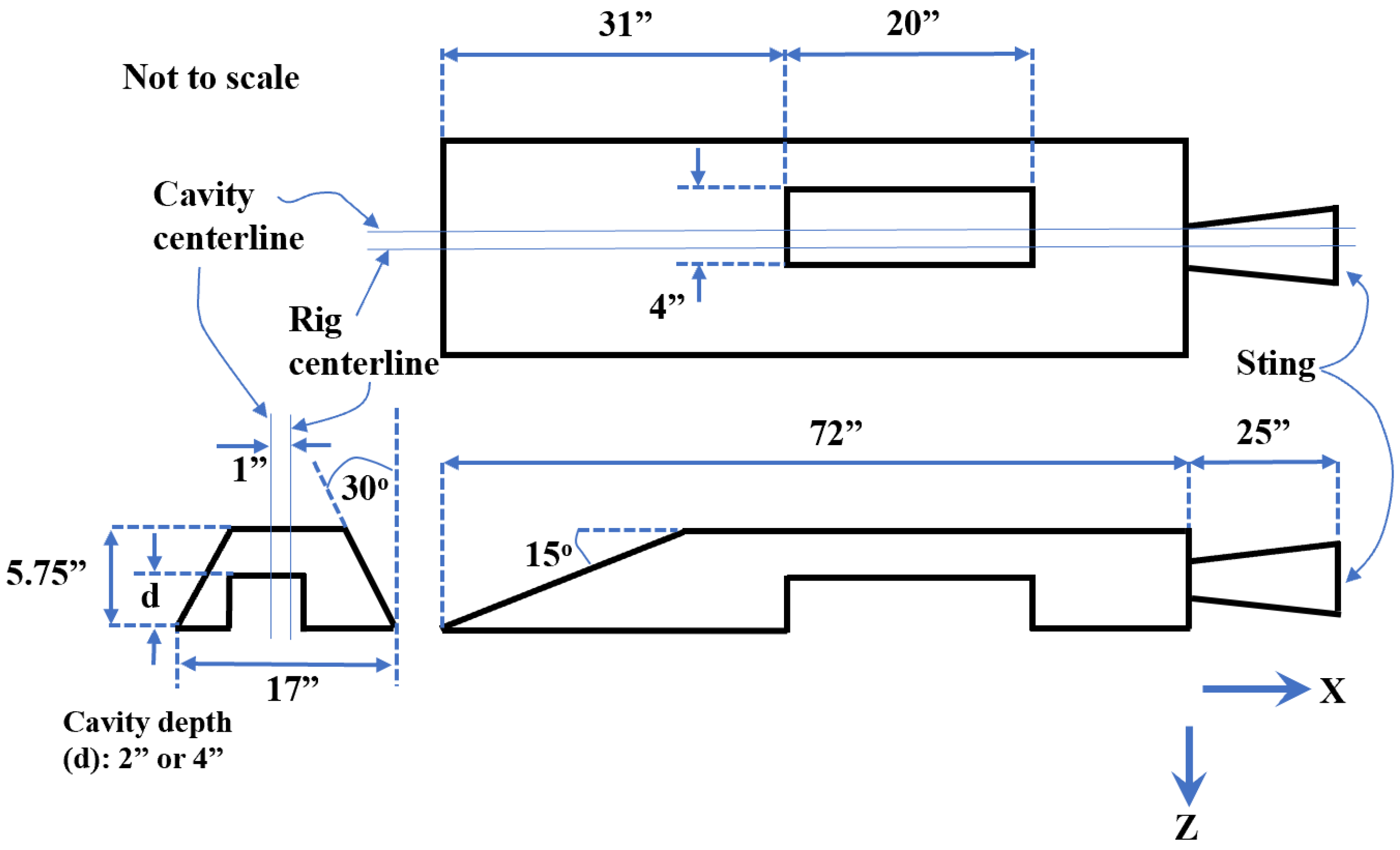

Numerical simulation of flow over a fully 3-D rectangular cavity are presented and discussed in this section. The vortex system and flow patterns inside a rectangular three-dimensional acoustic cavity consist of intricate fluid dynamics structures, highly dictated by the incoming flow regime and geometry dimensions. For the purpose of testing the Menter SST-SAS turbulence model, the cavity configuration is selected as the M219 experimental test case of Henshaw [

14] for a deep cavity (4 inches) at two different freestream Mach numbers,

(0.85 and 1.35). An schematic of the experimental model as done in [

14] is shown in

Figure 1. Static pressure was measured at the centerline and off-centerline (i.e., at the rig centerline) of the cavity via Kulite transducers. In the present study, only measured Root Mean Squared (RMS) of static pressure at the cavity centerline (

Y = 0) and ceiling was employed for numerical validation (K20 to K29 transducers).

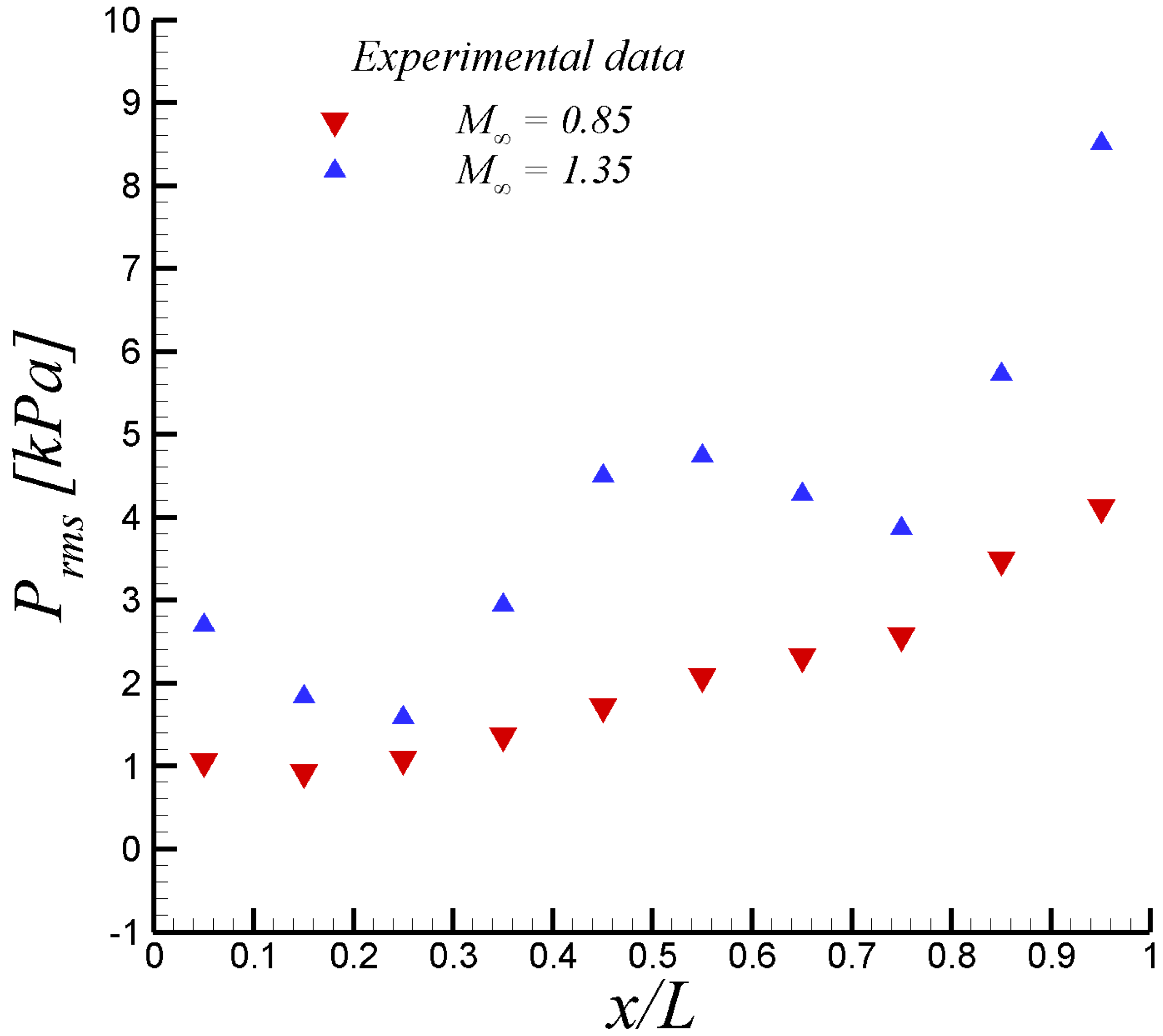

Figure 2 depicts the RMS static pressure distribution over the ceiling of the deep empty cavity. It is observed that incoming high subsonic Mach number induces a slightly increasing RMS distribution, with a growing factor of approximately four between the last (K29) and first (K20) Kulite transducer. However, the RMS distribution at Mach 1.35 exhibits a wavy trend with local minima at

0.25 and 0.75, respectively. The geometry dimensions of the M219 cavity in terms of the depth are

(length, width, and depth), with a depth

D of 4 inches. Since the width and depth of the cavity are the same, this configuration create a fully three-dimensional flow pattern. The Reynolds number spans 9.5

to 21

, based on the cavity depth. The incoming flat-plate boundary layer is turbulent, with the ratio of the upstream boundary layer thickness to the cavity depth, i.e.

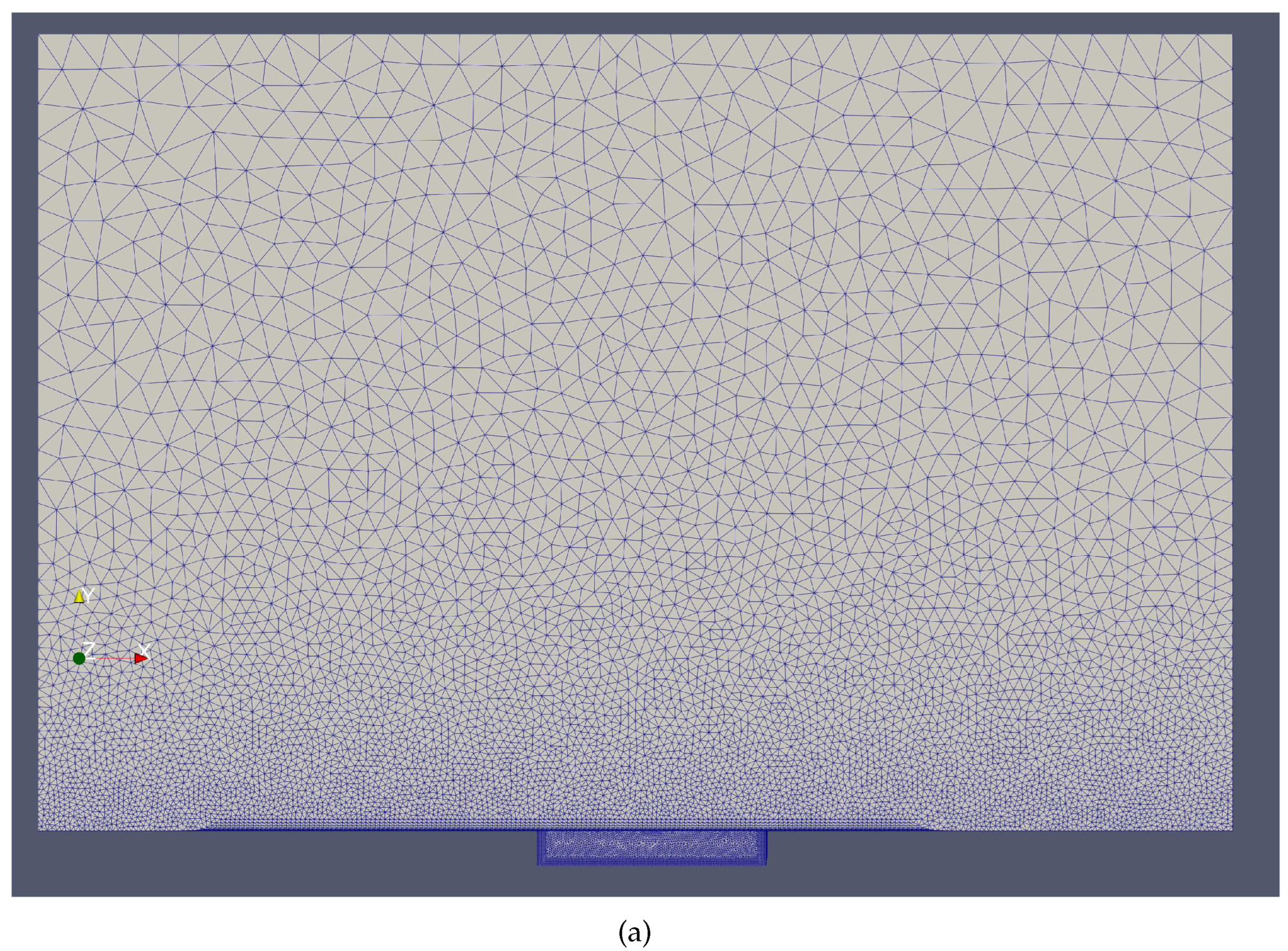

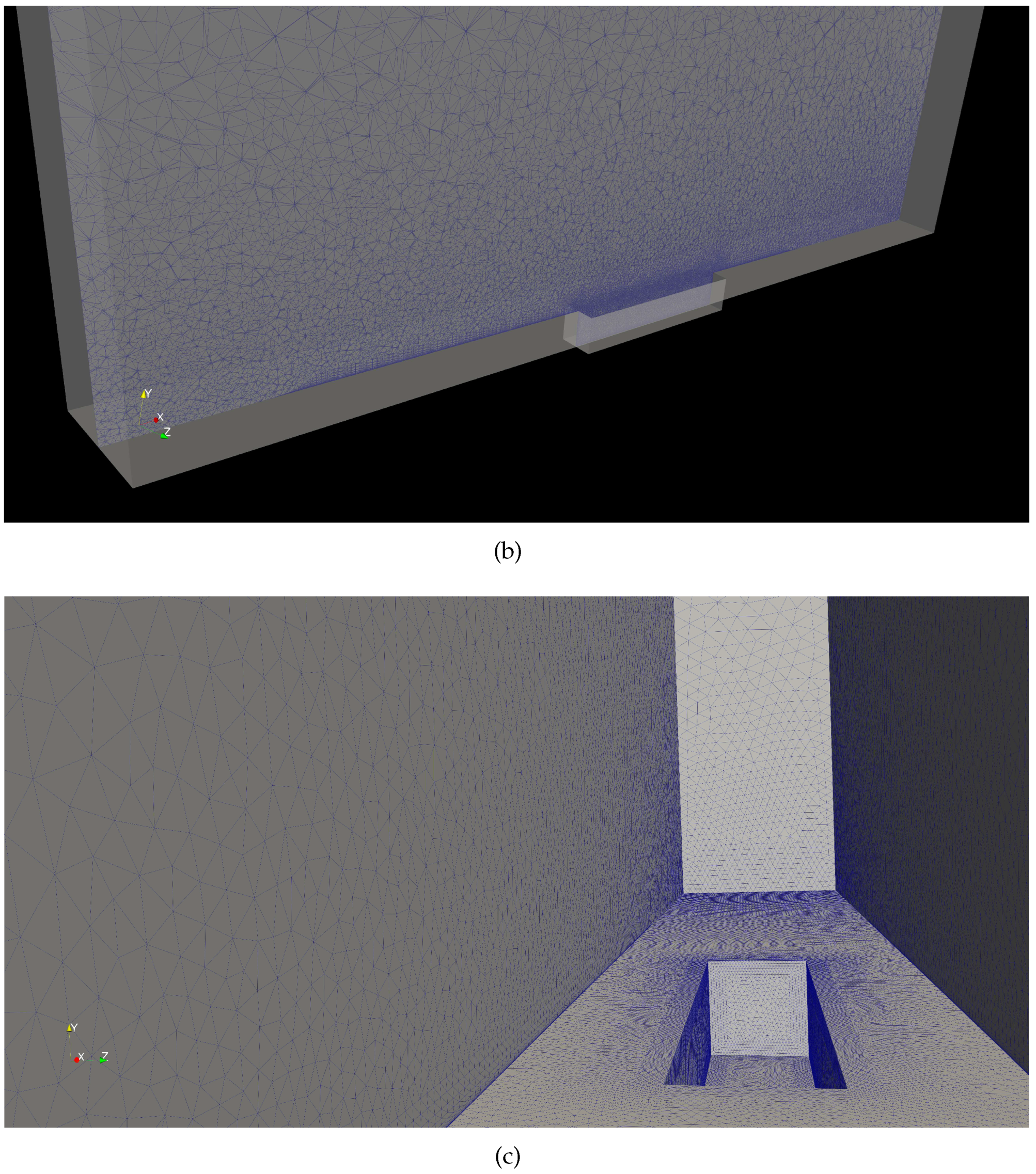

, approximately ranging from 0.1 to 0.25 for Mach numbers of 0.85 and 1.35, respectively. The unstructured hybrid mesh is composed by approximately 3.37 million tetrahedral elements, 4,472 prisms and 459 pyramids. The previously mentioned element distribution was determined to be deemed appropriate for the goals of this study and cavity representation based on the grid independent study performed. Some views of the computational domains and grid system are displayed in

Figure 3. Namely, a side view (plane Y-X) is shown in

Figure 3a. An schematic of the grid at the half-plane of the cavity is observed in

Figure 4b. Also, an interior cavity view is depicted by

Figure 4c. The mesh has 20 viscous layers for efficient boundary layer capturing with the first off-wall point located at

. This ensures that first off-wall point locations are within 0.2 to 0.4 wall or plus units, inside the viscous linear layer. The total dimensions of the computational domain are as follows:

along the streamwise, wall-normal and spanwise directions, respectively, and in terms of the cavity depth,

D. Therefore, the computational domain is tall and wide enough to eliminate any influence from the boundary faces on the flow statistics over the cavity. Moreover, the spanwise side walls are treated as symmetry (periodic) planes, the top boundary is a far-field boundary, and all bottom solid surfaces (including the cavity) are considered as adiabatic non-slip walls. Upstream of the cavity edge, a flat-plate with no-slip condition is prescribed (about 7.5

D in length). While a zone with slip condition (and inlet freestream flow parameters) is set up upstream of the flat plate (∼7.5

D in length).

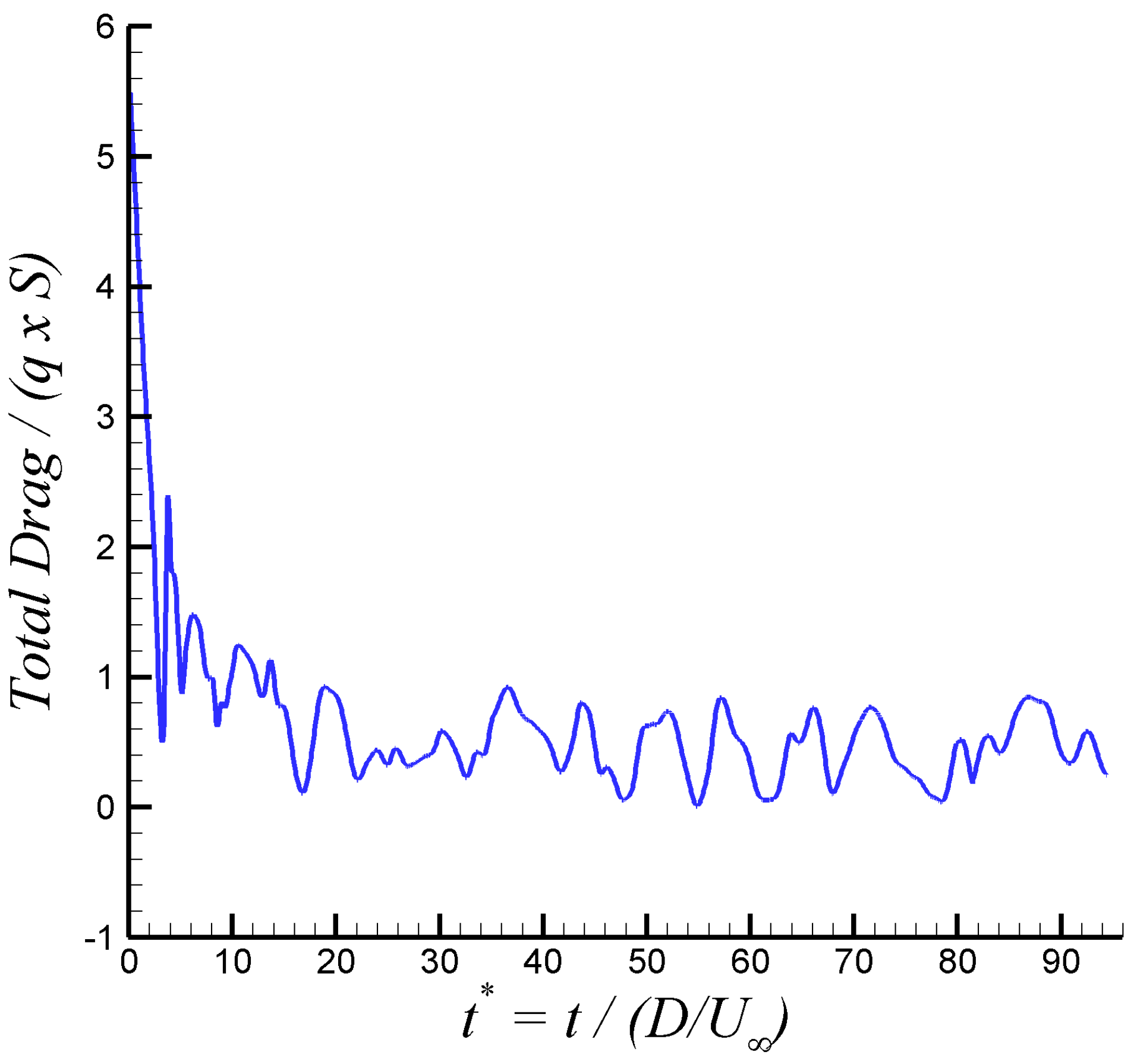

The selected normalized time step is

or approximately

seconds. The time variation of the total drag over the cavity at

= 0.85, normalized by the reference surface and freestream dynamic pressure, can be observed in

Figure 4. Furthermore, the transient stage took approximately 15 non-dimensional time units from the steady solution, as seen in

Figure 4. This transient part was discharged for flow statistics computation.

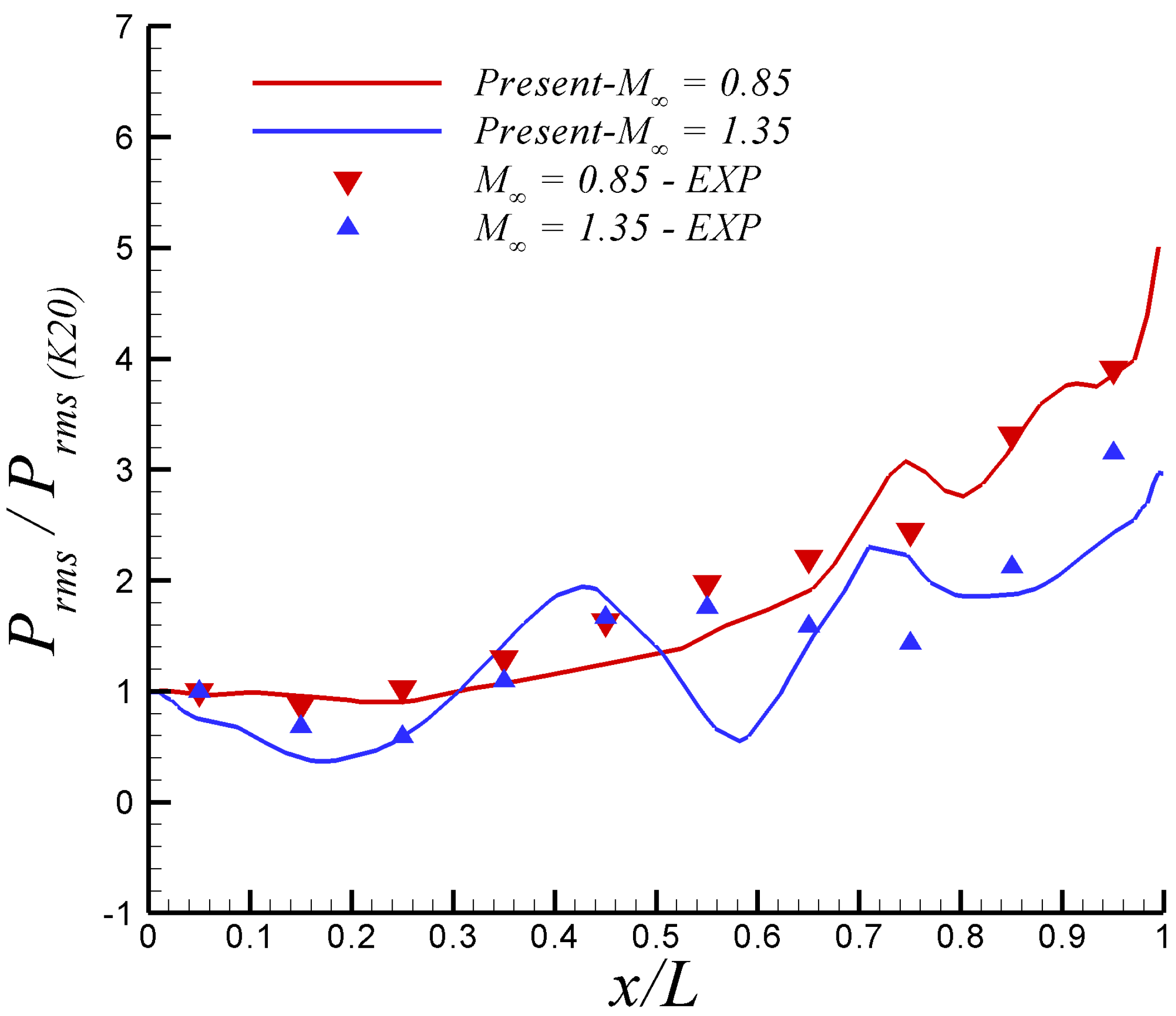

Figure 5 depicts the root mean square (RMS) of pressure fluctuations on the cavity ceiling at

0 (centerline) and both freestream Mach numbers. Approximately 500 flow fields were taken for computing

. Notice that in

Figure 6, the values of

were normalized by the value at the first transducer (i.e., K20) located 1 inch downstream of the front of the cavity in experiments by Henshaw [

14]. The comparison of present SST-SAS results at

= 0.85 with experimental data by [

14] is fairly good. The SAS model has been able to capture the increasing slope of

by the cavity end. On the other hand, the performance of the SAS-model at the supersonic regime (

= 1.35) is not as good as in the subsonic case. While the first inflexion point (around

= 0.35) is well captured, the second inflexion point in experimental

is improperly outlined by the SST-SAS model. This may be attributed to the presence of some important compressibility effect on the cavity flow, which is not taken into account in the SAS approach. The original SAS model was designed and mostly tested in incompressible and low-Mach wall-bounded flow applications [

7,

8]. Previous work done on turbulent coherent structures by [

9,

10] via Two-Point Correlations (TPC) and Lagrangian Coherent Structure (LCS) approach has revealed the moderate influence (but not negligible) of compressibility, as the Mach number increases at the supersonic regime level, on the coherent structure dimensions. Specifically, Lagares & Araya [

10] stated “coherent structures grow more isotropic proportional to the Mach number, and their inclination angle varies along the streamwise direction". Therefore, it can be inferred that the SAS turbulence model would be greatly enhanced by the addition of a Mach number dependency of the length scale computation of the flow, which is beyond the scope of present manuscript.

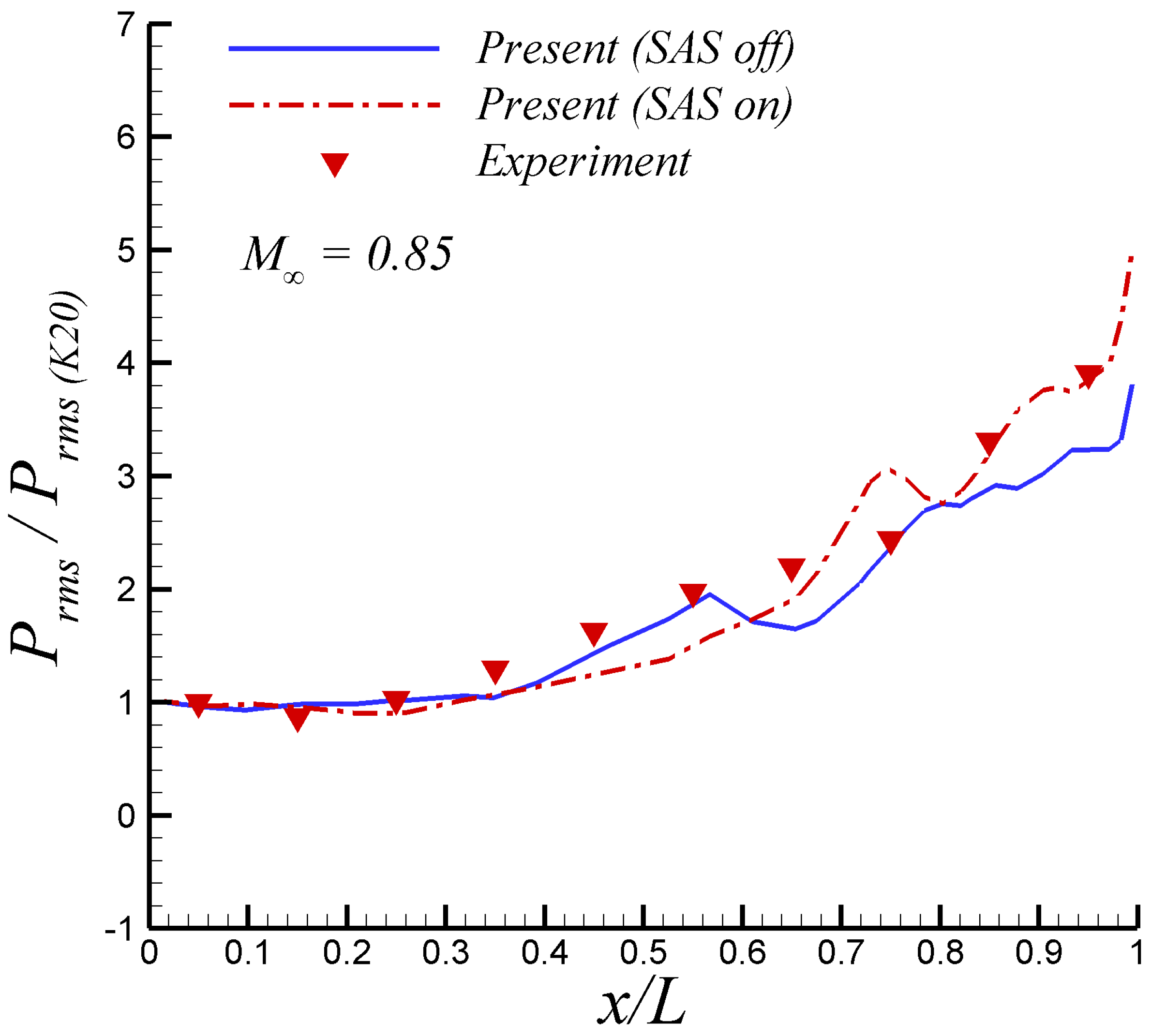

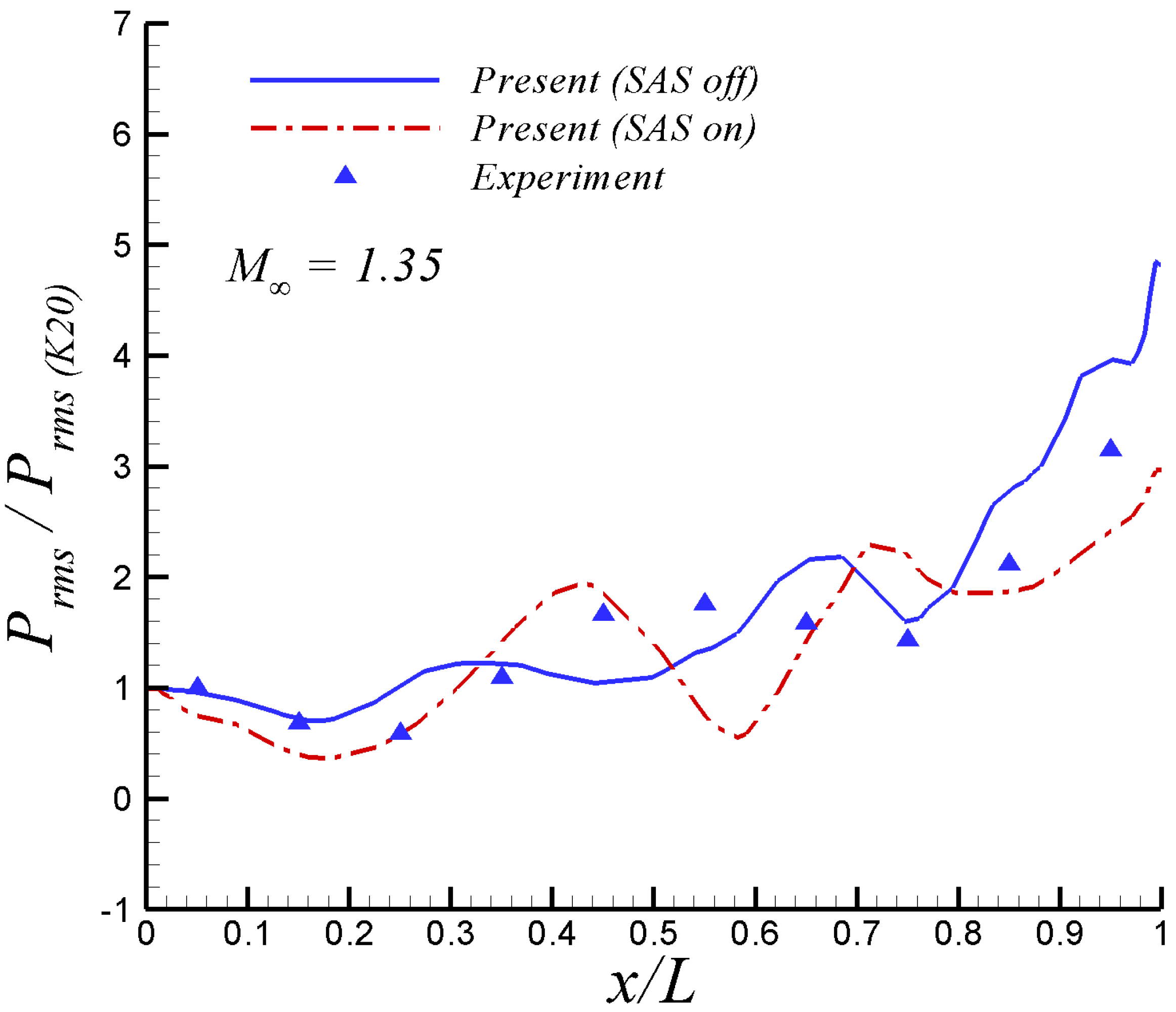

Results about the SAS model when switched on and off are shown in

Figure 6 and

Figure 7 at

= 0.85 and 1.35, respectively. The agreement of present URANS results exhibit a moderate better agreement with experiments by [

14] when the SAS model is active, particularly by the end of the cavity ceiling. It is hypothesized that the better performance of the SAS model when capturing experimental

in that rear cavity corner might be due to the presence of high turbulent kinetic energy,

k, and consequently large values of the turbulence length scale,

L, according to eq.

17 (as it will be visualized later on). The extra term

(see Equation (

16)) in the specific dissipation rate equation,

, is the sole adjustment to the SST model in equation

11 to account for the von Karman length-scale,

, allowing the simulations to dynamically accommodate to resolve the large scale motions (LSM). Notice that the term

is directly proportional to the square of the ratio

L/

.

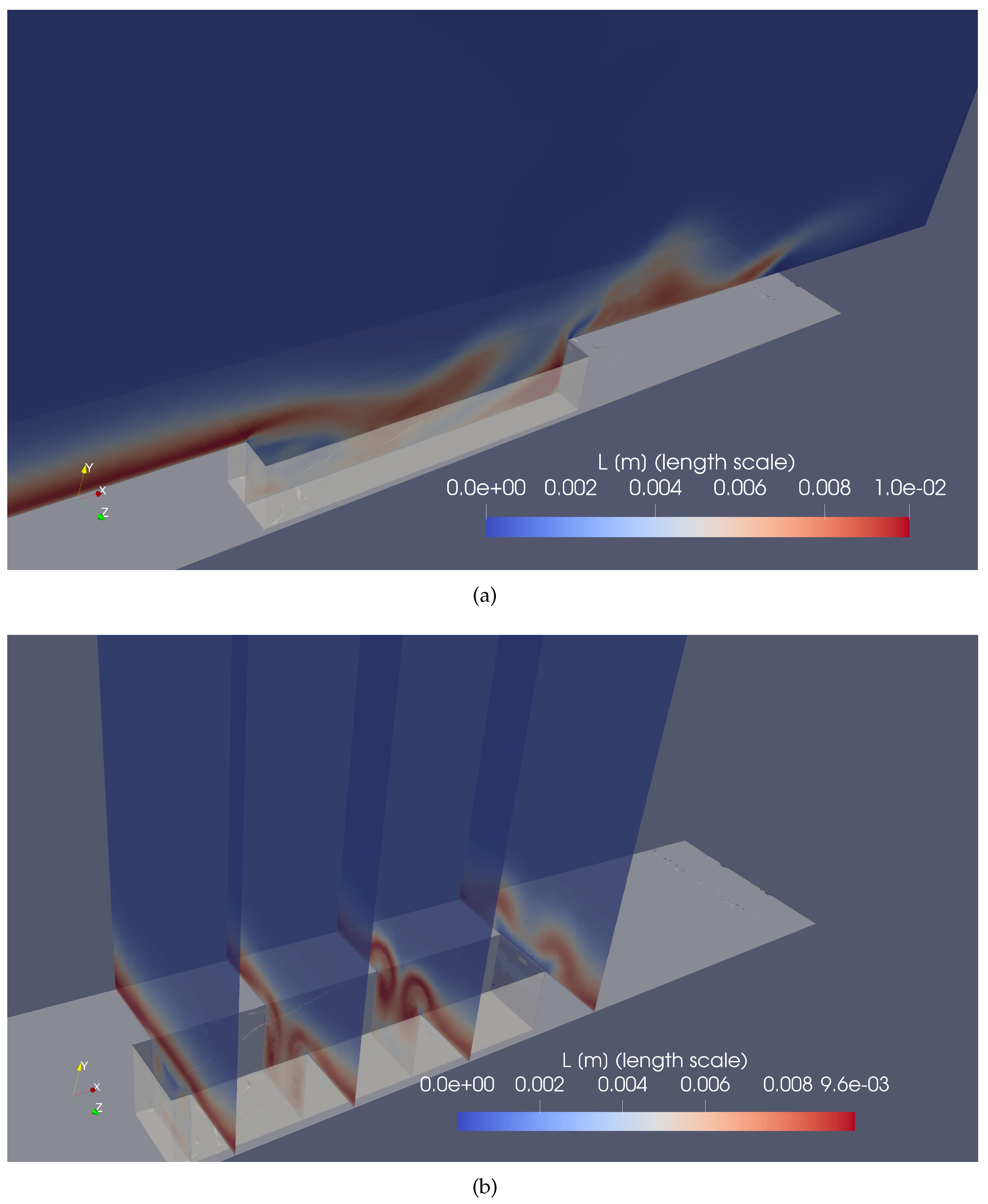

Furthermore, the corresponding iso-contours of instantaneous turbulence length scales,

L, are shown by

Figure 8a. The turbulence length scale is proportional to the square root of the turbulent kinetic energy,

k, and inversely proportional to the specific dissipation rate,

. As seen in the centerline longitudinal plane of the cavity (

Figure 8a), the maximum incoming length scale,

L, is in the order of 0.01m or

, reaching values

0.012m in the back bottom corner. These local large values of

L at the rear corner cause: (i) meaningful values for the

, and (ii) changes in

spatial distribution to better resolve LSM, which could be the physical explanation of better capturing wall pressure fluctuations in

Figure 6. Nevertheless, a deeper analysis should be carried out for shedding light on that aspect, which is outside the present manuscript’s scope. It is also clearly seen the formation of the front vortex, characterized by flow recirculation zone (with low values of momentum and turbulent kinetic energy) bounded by large values of

L (and turbulent kinetic energy, as well). A rear vortex system (highly energetic) is located by the end of the cavity at the bottom corner and characterized by significant turbulence length scale values.

Figure 8b exhibits four cross-sectional planes separated by a distance of approximately

with iso-contours of instantaneous turbulence length scales,

L. The spatial sequence of the major horseshoe vortex formation can be observed.

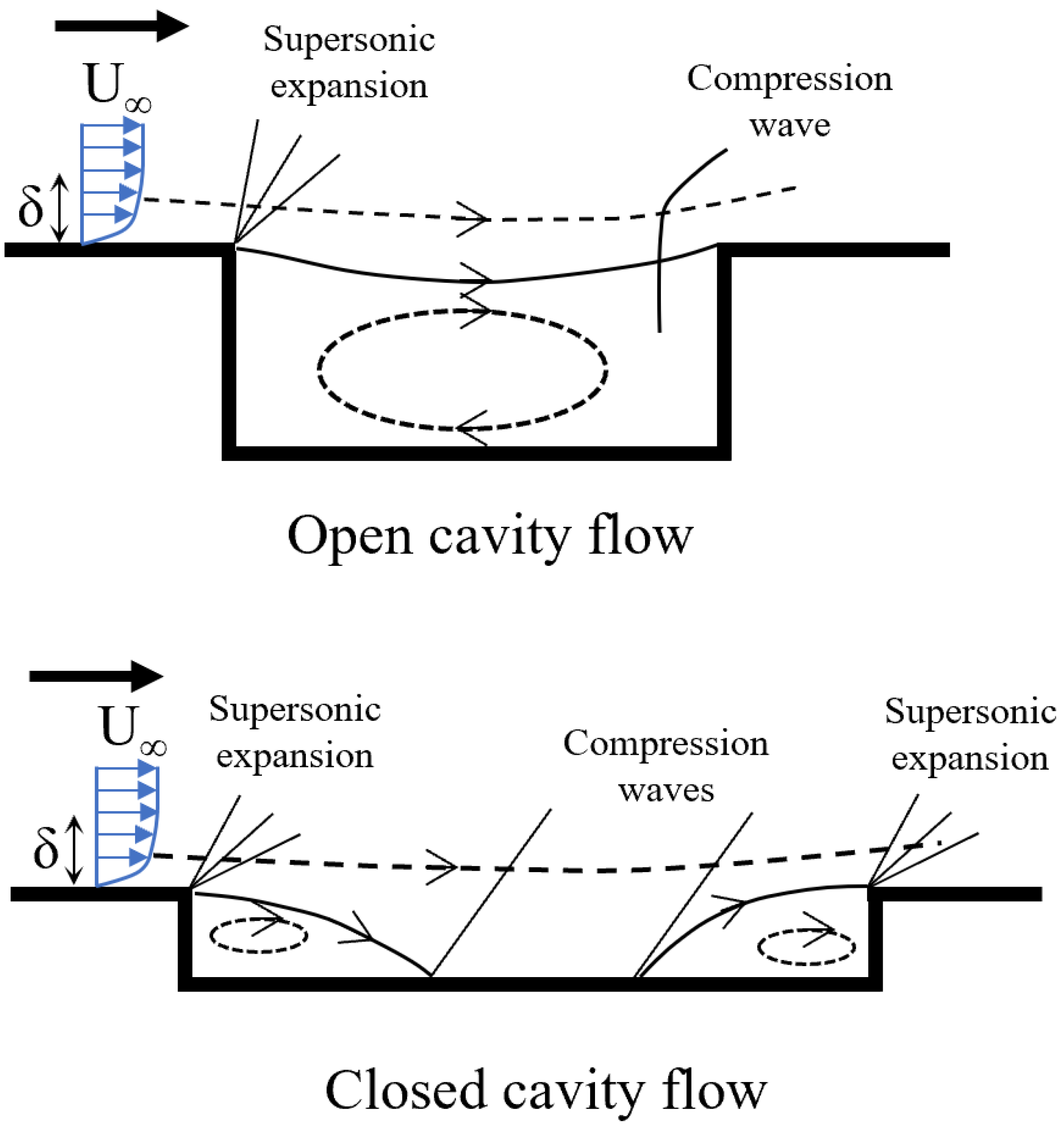

In order to describe the different vortical structures observed in the cavity, we should mention the following categories, as described in [

15]: open-type cavity flow and closed-type cavity flow, according to the ratio

. At subsonic flow regimes, an open-type cavity (

) is represented by a shear layer that spans the entire cavity opening, and by a large recirculation zone inside the cavity itself [

15]. On the other hand, closed-type cavities (

) are generally pictured by a shear layer generated at the front of the cavity that reattaches on the bottom of the cavity, without the presence of a large recirculation vortex in the centre of the cavity. A transitional regime for rectangular cavities takes place in between. This seems to be the most appropriate category to encase present cavity at

. The reasons are supplied hereafter. Also, it is worth highlighting that the cavity is narrow because of

; thus, a completely three-dimensional geometry generates a different set of vortices.

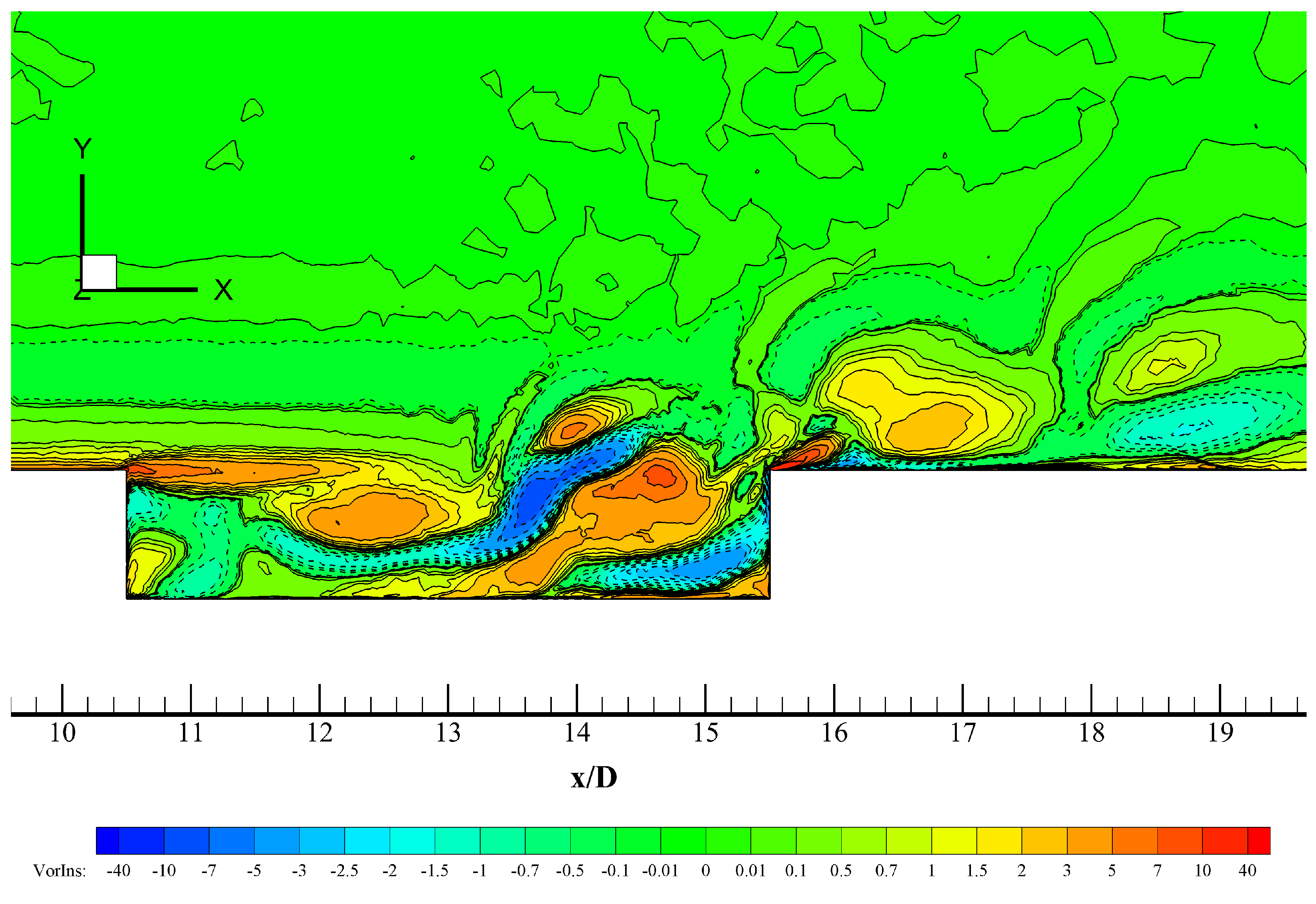

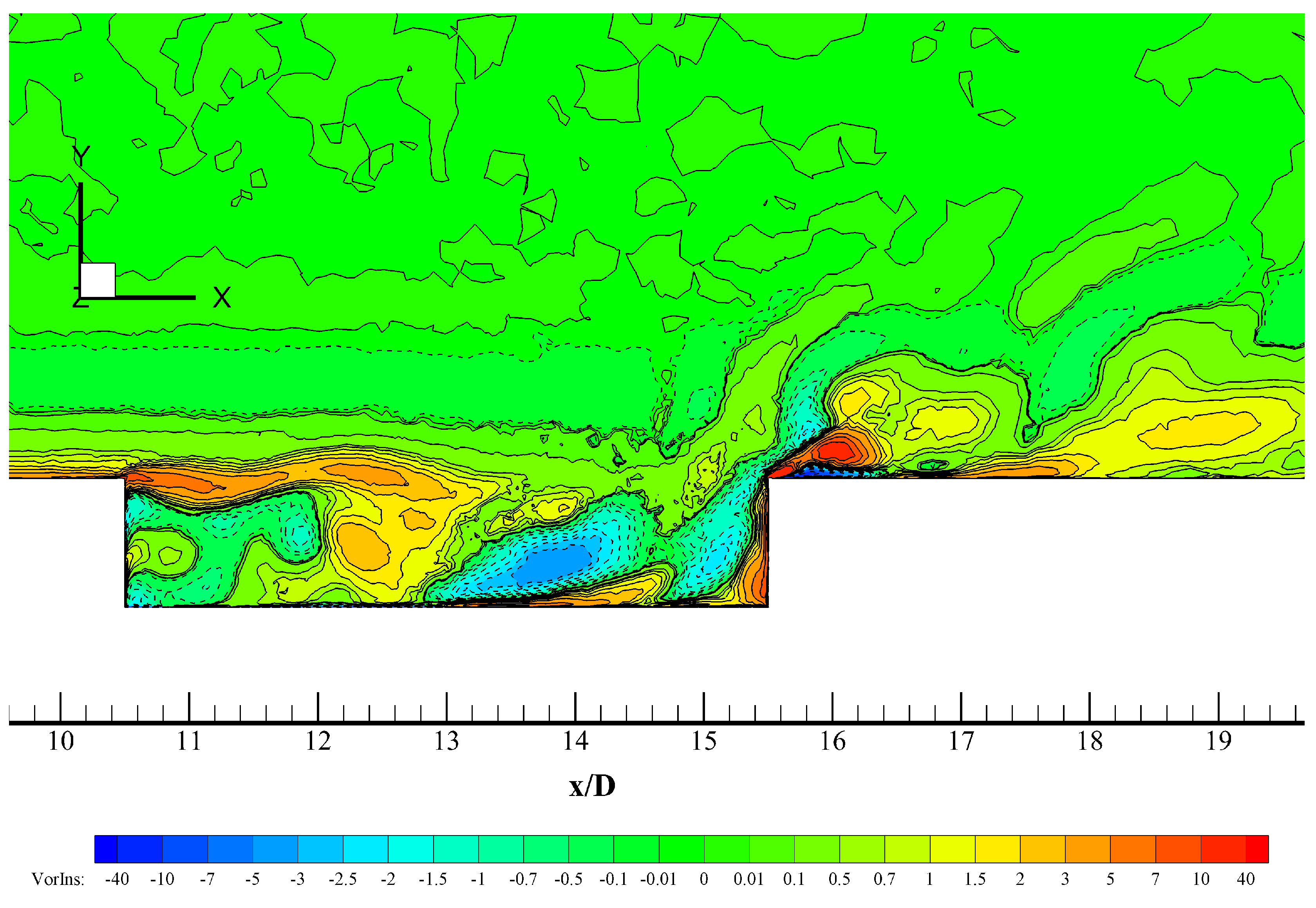

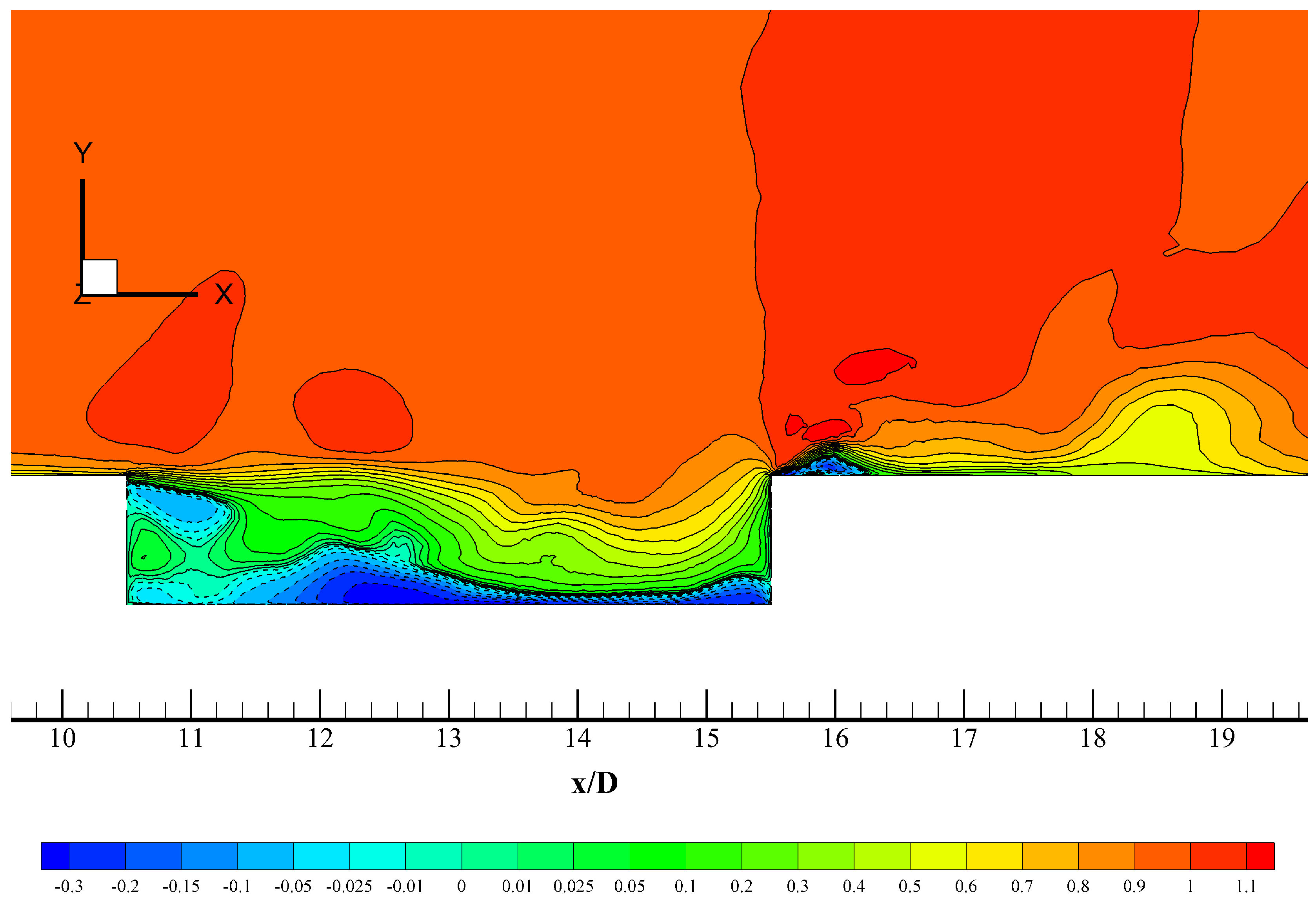

Figure 9 shows contours of instantaneous spanwise vorticity. Positive isolines (inward vorticity vector or clockwise spin) are represented by solid curves; whereas, negatives isolines (outward vorticity vector or counterclockwise spin) are represented by dashed curves. It can be seen in

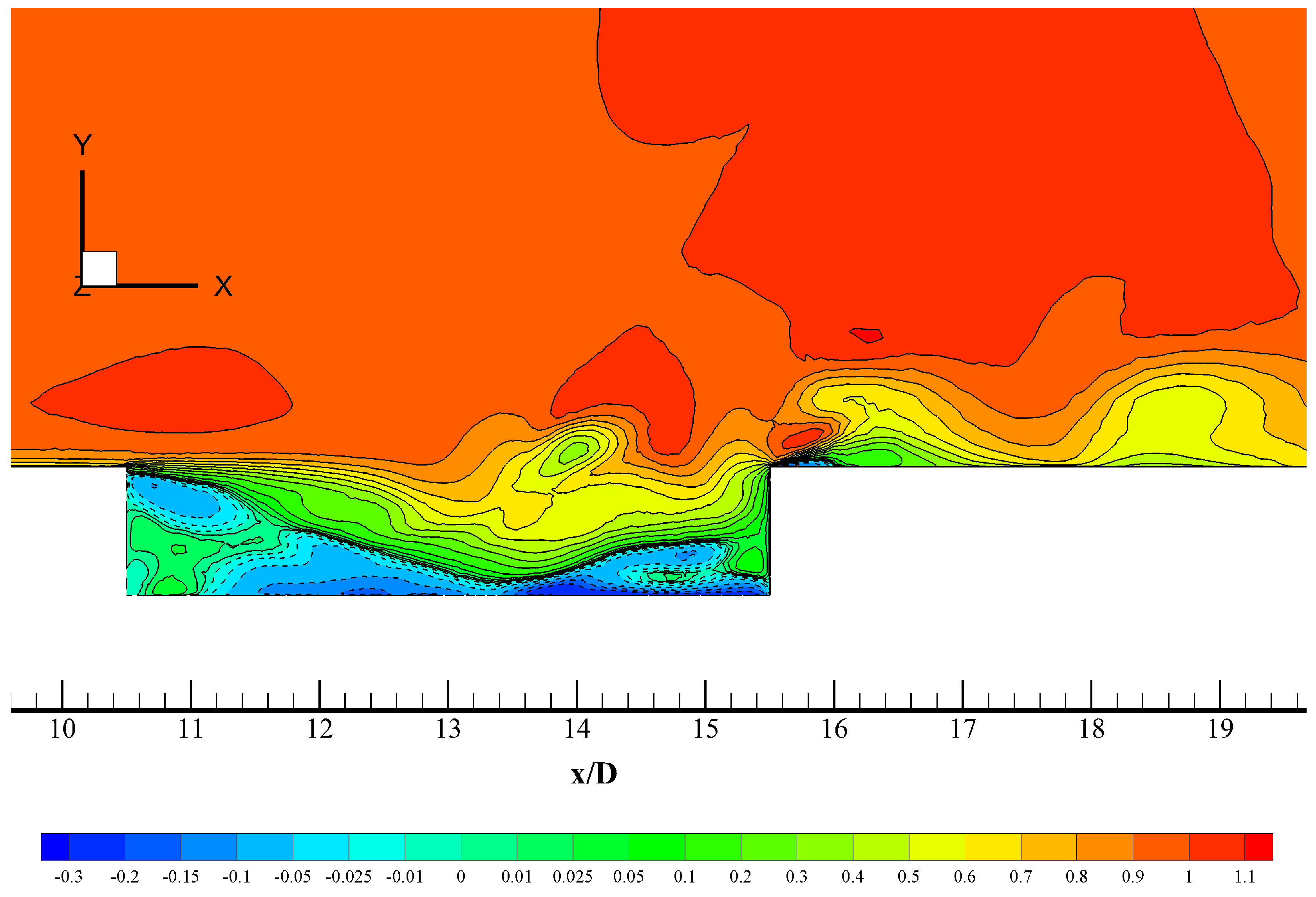

Figure 9 that the incoming turbulent boundary penetrates further into the cavity towards the ceiling. That incoming shear layer reattaches on the bottom of cavity, which is confirmed by

Figure 10 (contours of instantaneous streamwise velocity normalized by the freestream velocity). Two small recirculation zones with clockwise spins are observed in the front side (12 <

< 13) and in the back side (14 <

< 15) of the cavity. Particularly, the rear vortex transports fluid from the impinging shear layer on the cavity top downwards and towards the cavity bottom and viceversa, which is consistent with findings by [

15]. Those phenomena induce two “curved” and elongated counterclockwise vortices (or “banana-like” vortices) that contributes to the vertical mixing of turbulence inside the cavity. In particular, the vortex duplet located by the end of the cavity at the bottom corner is mainly responsible for turbulent kinetic energy generation, which in turns induces large local values of

L, as previously explained. The

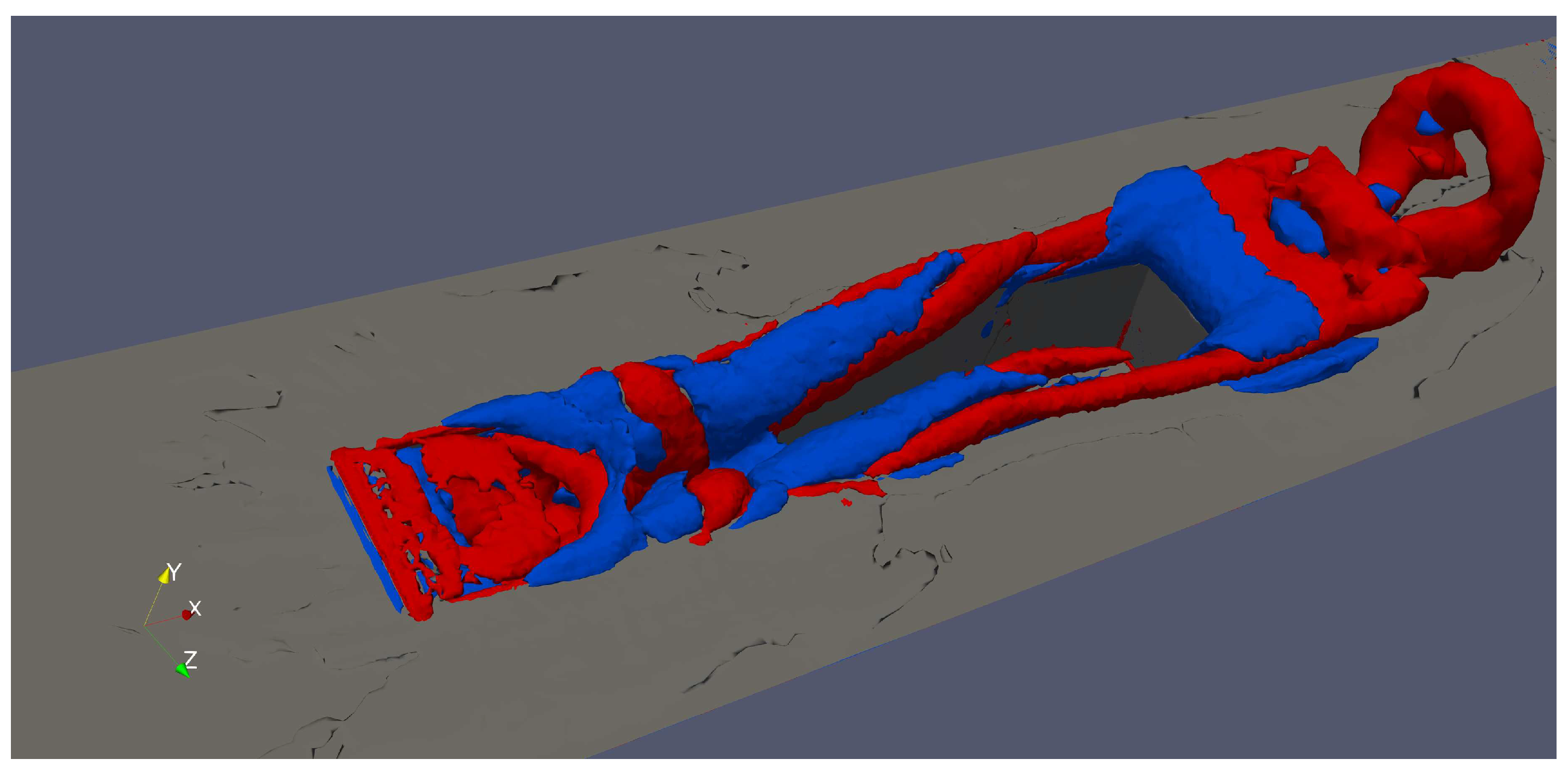

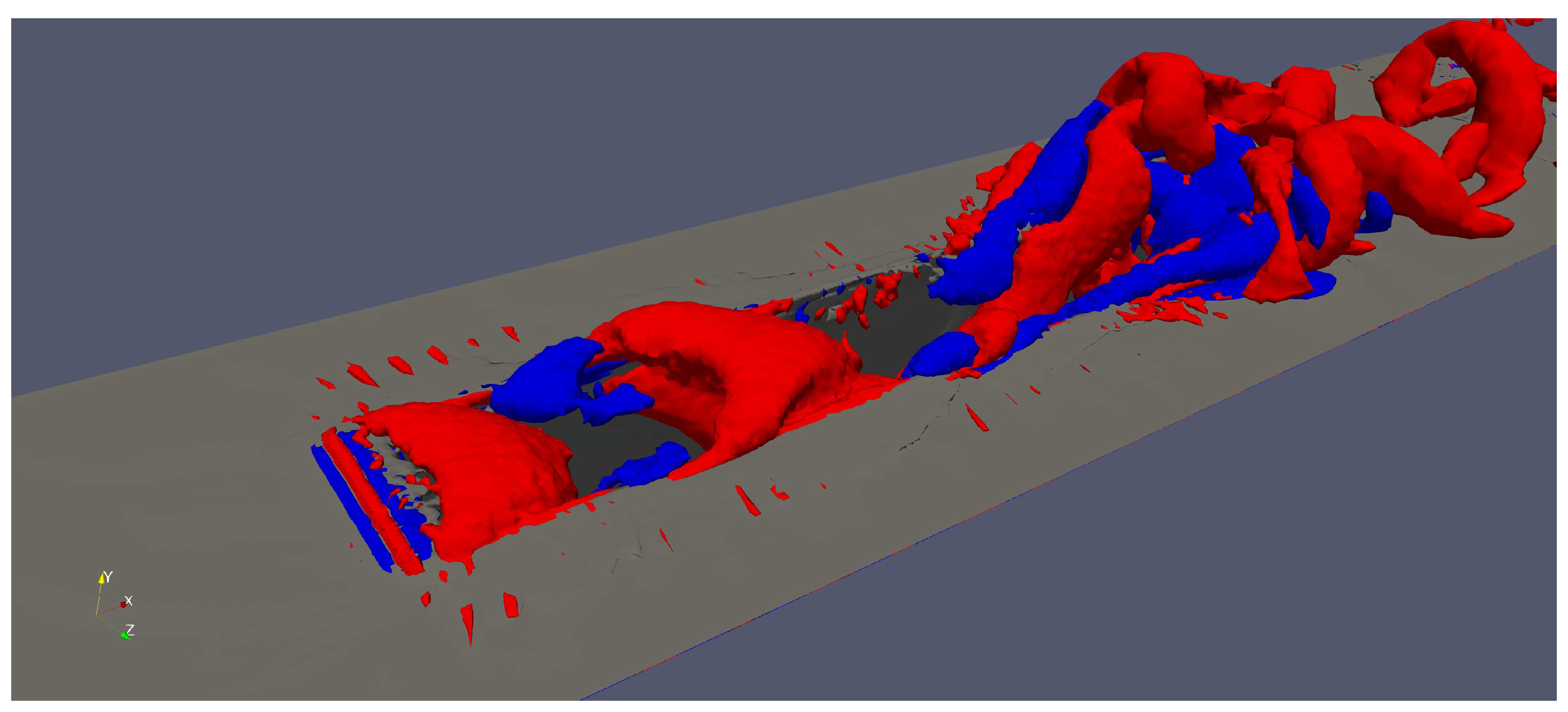

by [

16] is implemented in this study to extract and visualize vortex cores via positive values, which describe regions of the flow where rotation dominates over strain. On the other hand, negative iso-values of

represent highly deformed flow regions. Iso-surfaces of the

(positive values in red and negative values in blue) are exhibited in

Figure 11 at

= 0.85. Focusing exclusively on positive (red) iso-surfaces or vortex cores, the most energetic turbulent coherent structures emerge in three clearcut regions: (i) near the front region of the cavity, (ii) along the side cavity edges (see the presence of side vortices), and (iii) in the rear side of the cavity and downstream (vortex shedding). Highly energetic vortical coherent structures can also be observed in the cavity inside. Previously described phenomena related to coherent structure dynamics are consistent with findings and observations by [

17]. The streamwise counter-rotating vortex pair described in

Figure 8b is accurately captured by positive iso-surfaces of

. Interestingly, downstream the cavity, where flow separates, the vortex adopt a horseshoe or hairpin shape (or omega-shaped vortices) as described by [

18] with the typical leg, neck and head. These coherent structures are commonly found in turbulent boundary layers, particularly in the log-region, which are mainly responsible for the generation of Reynolds shear stresses and turbulence production [

18]. The vortex shedding downstream the cavity resembles the jet in a crossflow situation [

19], where horseshoe vortices are continuously created by the interaction of the incoming shear layer with the vertical jet. It is hypothesized that the streamwise counter-rotating vortex pair by the end of the cavity lifts-up low speed fluid, interacting with the incoming shear layer over the cavity and mimicking the crossflow jet problem. Highly strained flow (blue iso-surfaces) can be seen nearby vortex cores, predominantly in the cavity lateral sides and at the rear edge.

Turning to the Mach-1.35 case, it is important to emphasize the acoustic wave system generated when the incoming turbulent flow is supersonic.

Figure 12 illustrates idealized time-averaged situations of the incoming supersonic boundary layer facing a rectangular cavity (adapted from [

20]). According to Aradag & Knight [

20] (and similarly defined by [

15] for incoming subsonic flow in rectangular cavities), one can define two major cavity types based on the

ratio: open and closed cavity configurations. In the open or “deep" cavity system (i.e., at low values of

), the turbulent free shear layer reattaches on the rear part of the cavity (see top image in

Figure 12); therefore, creating a sole recirculation region in the mean flow. On the other hand, in the closed or “shallow" cavity (i.e., at large values of

), the shear layer reattaches on the cavity floor, and the vortex system resembles a combination of a backward and forward facing step. While the flow physics in terms of open and closed cavities is somehow similar for incoming subsonic and supersonic flow; there is no general consensus about the critical

values.

ratios greater than 13 indicate closed cavity flow, while

factors smaller than 10 mean open cavity flow [

20]. Furthermore, in Crook

et al.,Crook2013 it is reported 8 and 7 as those extreme

values previously mentioned. Clearly, one has to visualize the internal vortex system and the flow recirculation zone for better ascertaining if dealing with open or closed cavity flows. Furthermore, the most important aspect to highlight in supersonic cavities is the presence of compression and expansion waves according to the cavity type [

20], as depicted by

Figure 12.

Figure 13 depicts iso-surfaces of positive (vortex cores) and negative (highly deformed or strained flow) values of the

by [

16] for the supersonic incoming flow, i.e. at

= 1.35. The formation of horseshoe, hairpin shape or omega-shaped vortices downstream the cavity is evidently seen, as in the subsonic case of

Figure 11. However, the distribution of volumes with either highly rotational (in red) or strained (in blue) flow is clearly different at

= 0.85 and 1.35, respectively; which indicates that the vortex systems are rather distinctive in the supersonic case: most of the front side of the cavity is populated by vortex cores (rotational flow); whereas, by the rear cavity side and downstream, various zones coexist either with high level of rotation or deformation in a “twisted" fashion, not observed in the subsonic case. The presence of highly strained flow downstream of the rear cavity could be linked to the significant unsteady expansion, which will be further discussed in this manuscript. In

Figure 14, iso-contours of instantaneous spanwise vorticity is shown at

= 1.35 and at the centerline plane

of the cavity (i.e., at

Z = 0). As previously described, inward vorticity vector or clockwise spin is represented by positive solid isolines; while, outward vorticity vector or counterclockwise spin zones are represented by negative dashed curves. At this instant, two large vortical structures with opposite signs or spanwise counter-rotating vortex pair (clockwise and counter-clockwise, respectively) are observed in the cavity center (12 <

< 14.5). The incoming turbulent shear layer penetrates further almost to the cavity bottom, and this clockwise spanwise vortex induces the nearby counter-clockwise (by viscous effects and angular momentum conservation). At this point, the previously described instantaneous spanwise vortex pair leads to the generation of high levels of turbulent kinetic energy, wall-normal mixing and strong pressure gradients (with minimum pressure at vortex centers) inside the cavity. Additionally, the instantaneous vortex pair promotes the vortex formation (with opposite sign) in the vicinity of the cavity via viscous effects. It is worth highlighting that for this narrow cavity (

= 5) the turbulent flow generates highly unsteady three-dimensional vortical structures that significantly influences the cavity response.

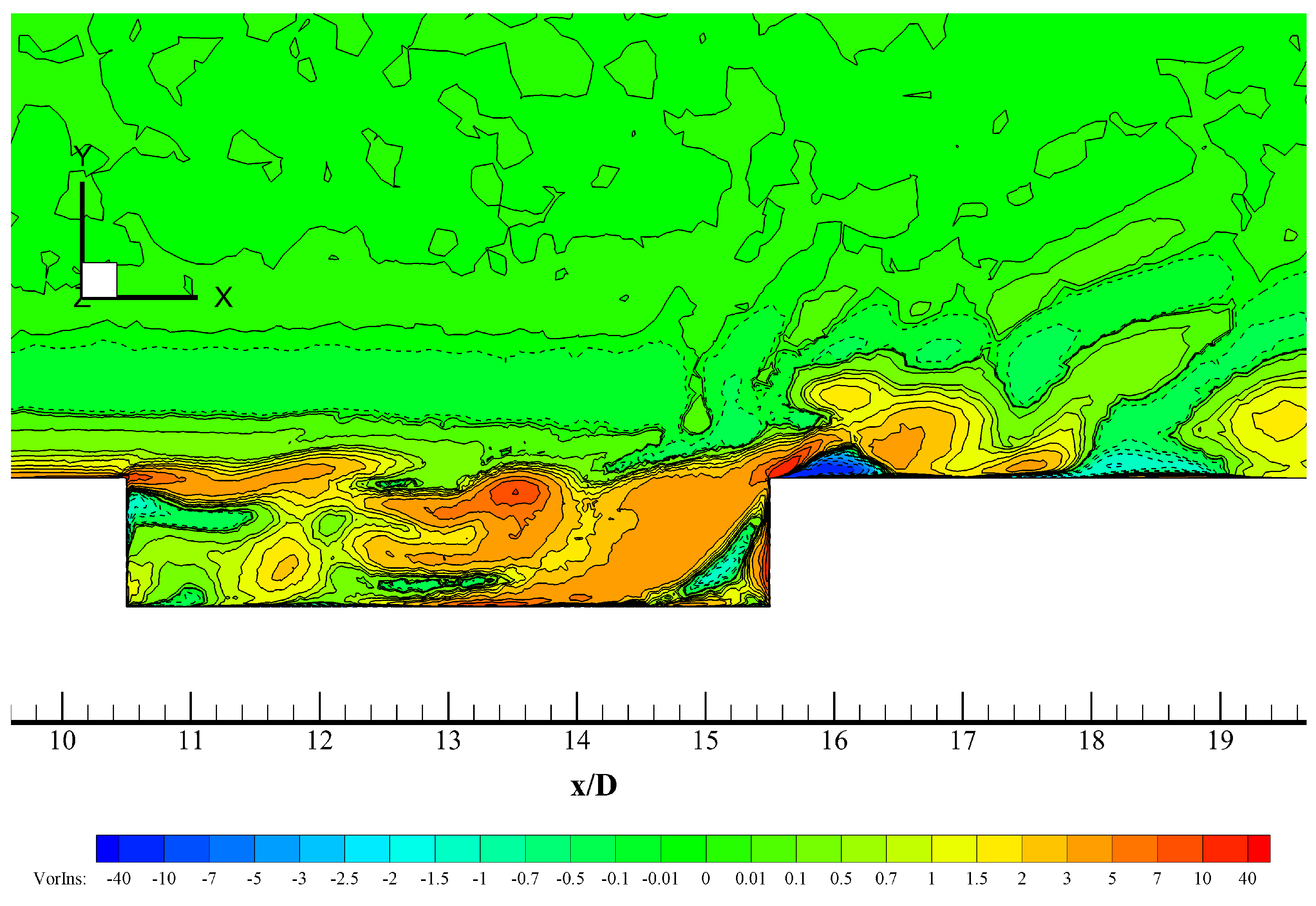

Figure 15 exhibits iso-contours of instantaneous spanwise vorticity at

= 1.35 and at an off-centerline plane

(i.e., at

Z = 0.25D). The strong differences on instantaneous spanwise vorticity distribution at

Z = 0.25D with respect to the cavity centerline plane (

Z = 0) evidences the non two-dimensionality nature for this cavity configuration. In

Figure 16, contours of instantaneous streamwise velocity normalized by the freestream velocity are shown for the supersonic incoming flow case. The incoming turbulent shear layer develops from the front cavity edge, bends down into the first half (10.4 <

< 13.4) due to pressure gradients and impinges on the bottom. A clear backflow region is observed (blue) with negative values of the streamwise velocity. The red region just above the cavity edge indicates the presence of moderate instantaneous supersonic expansion or favorable pressure gradient (FPG). In a similar manner, the flow strongly accelerates by the rear edge cavity. That strong supersonic expansion or FPG in the outer region and freestream might be the reason of the presence of extremely strained flow at the trailing edge, represented by iso-surfaces of

(in blue) in

Figure 13. In addition, the very strong adverse pressure gradient (APG) generated by the rear cavity edge in the near wall region is responsible for the downstream flow separation bubble. Outside of the rectangular cavity, the flow is supersonic, whereas subsonic flow recirculating volumes take place inside [

20]. Also, acoustic waves created due to the impingement of the turbulent shear layer at the rear wall of the cavity are able to propagate upstream through the subsonic region of the flow.