1. Introduction

Coastal Infrastructure assets play an important role in modern society [

1]. Ports are especially vulnerable to several risks and represent a critical and strategic asset for the development of any country as they handle a large part of economic exchanges [

2]. Hence, understanding the deterioration processes affecting these infrastructures is crucial for determining service life and developing effective maintenance solutions. Reinforced Concrete (RC) is one of the most used materials in the world for this kind of asset because of the availability of its components and its ease of construction [

3].

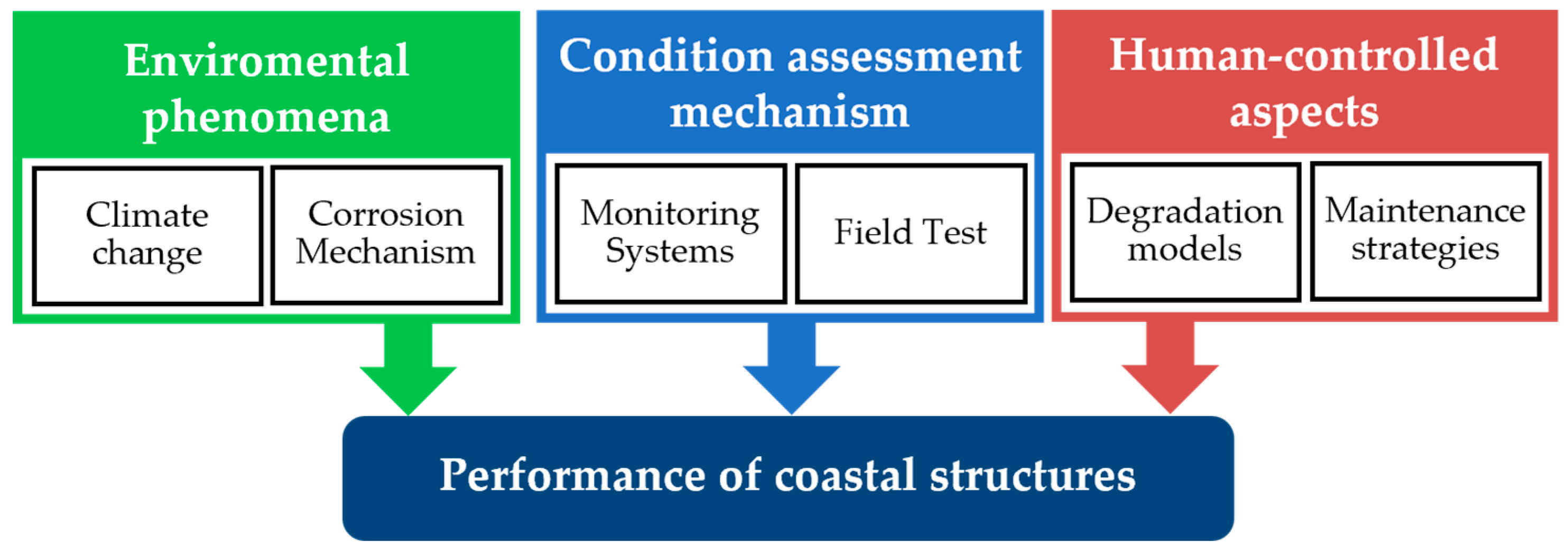

Figure 1 shows the main aspects that have an impact on the performance of coastal structures, where climate change and corrosion mechanisms are the main environmental factors; degradation patterns and maintenance strategies are the main human-controlled aspects; and monitoring and testing are the main mechanisms to assess the condition of structures.

The main problem for RC structures in coastal environments is damage caused by reinforcement corrosion, which manifests in the form of steel cross-section decrease, loss of concrete-to-steel connection, cracking, and spalling of concrete cover [

4,

5]. The corrosion initiation and propagation process highly depend on environmental conditions. Therefore, the scientific challenge for the long-term infrastructure behavior is to comprehend the influences of climate change on the dynamics of many coastal ecosystems, and water quality. According to [

6], a 0.5 m rise in sea level by 2050 might result in the value of vulnerable assets in 136 port megacities reaching USD 28 trillion. While researchers are concentrating their efforts on the fundamental process of climate change, there appears to be a knowledge deficit regarding the interaction of the environment with concrete structures [

7,

8].

Hence, the maintenance of harbor assets has become a major economic and tourism concern, and the challenge of the owners and administrators is to ensure that the aging structures continue to operate in a safe, cost-effective, and timely manner [

9,

10], even with the unforeseen modifications that climate change can bring. Therefore, decision-making represents another crucial role for the administration. However, decisions are generally based on budgetary, operation, and safety constraints, and, most of the time, maintenance is curative (after unforeseen events) or preventive, with a high cost (anticipation of predictable events) and more rarely, predictive (evolutionary predictions) [

11]. Due to the importance of infrastructure maintenance, it is not surprising that fifty percent of the construction industry expenses in most European countries are associated with repairs, maintenance, and rehabilitation of existing structures, and are expected to increase in the future [

12,

13].

Establishing maintenance schedules that extend the structure’s lifespans considering environmental, social, and economic impact, is essential for modern society. These maintenance processes should consider current needs, and uncertain and complex future risks in a changing climate. For this reason, hard maintenance policies are required now to address effects in the mid and long-term, which difficult the decision-making process. Thus, degradation models represent a crucial role in determining the long-term performance of the asset and have been widely implemented mainly in bridges and railway transport infrastructure maintenance systems [

14,

15]. These models can contribute to determine the type and timing of essential maintenance actions, necessary for the implementation of a scheduled maintenance strategy ensuring good working of the system and preventing breakdowns. Consequently, the implementation of degradation models in coastal infrastructure represents an opportunity for the best use of resources and guarantees an adequate lifespan of the structures.

Finally, for optimal asset management is crucial to quantify the condition of the structure from in-situ measured data [

16]. Monitoring and field testing is a key piece that provides information on the current situation of the structure. The location, frequency, and type of monitoring can influence the understanding of deterioration. Lecieux et al. [

17], found that monitoring has been largely devoted to following up the behavior of forces, strains, and displacements; but very rarely to the identification of parameters. Additionally, the literature mentioned that the research in the material properties area has been focusing on soil-structure interaction or partially on the effect of the environment on concrete properties [

18,

19]. Additionally, the number of procedures and research regarding the testing and measurement of RC corrosion using NDT methods are considered limited [

20].

The objective of this paper is to make a critical analysis of the 5 fundamental aspects that most influence the long-term behavior of coastal infrastructures. A critical review of the latest research in degradation models and corrosion processes in port infrastructure is presented. Finally, the future challenges for lifespan assessment and maintenance of coastal assets under a changing climate context are addressed. The paper is structured as follows.

Section 2 presents the review methodology.

Section 3 presents a summary of corrosion in RC structures and the effects of chloride presence on RC durability.

Section 4 describes the main models used for assessing the degradation of coastal infrastructures.

Section 5 emphasizes the importance of maintenance strategies and presents the main advances in this subject.

Section 6 points out the influences of monitoring for quantifying the condition of the structure and establishing degradation and maintenance strategies. After,

Section 7 explains the repercussions that climate change will have on marine environments and its impacts on RC coastal infrastructures. Finally,

Section 8 provides the discussion and conclusions of this study.

2. Review Methodology

The scope of this article is centered on comprehending deterioration caused by chloride-induced corrosion in reinforced concrete structures situated in coastal zones, particularly ports. It excludes deterioration resulting from factors like damage, mishandling, extreme events, fatigue, among others. The authors have also excluded carbonation-induced corrosion, as chloride penetration stands as the primary cause of corrosion in coastal regions.

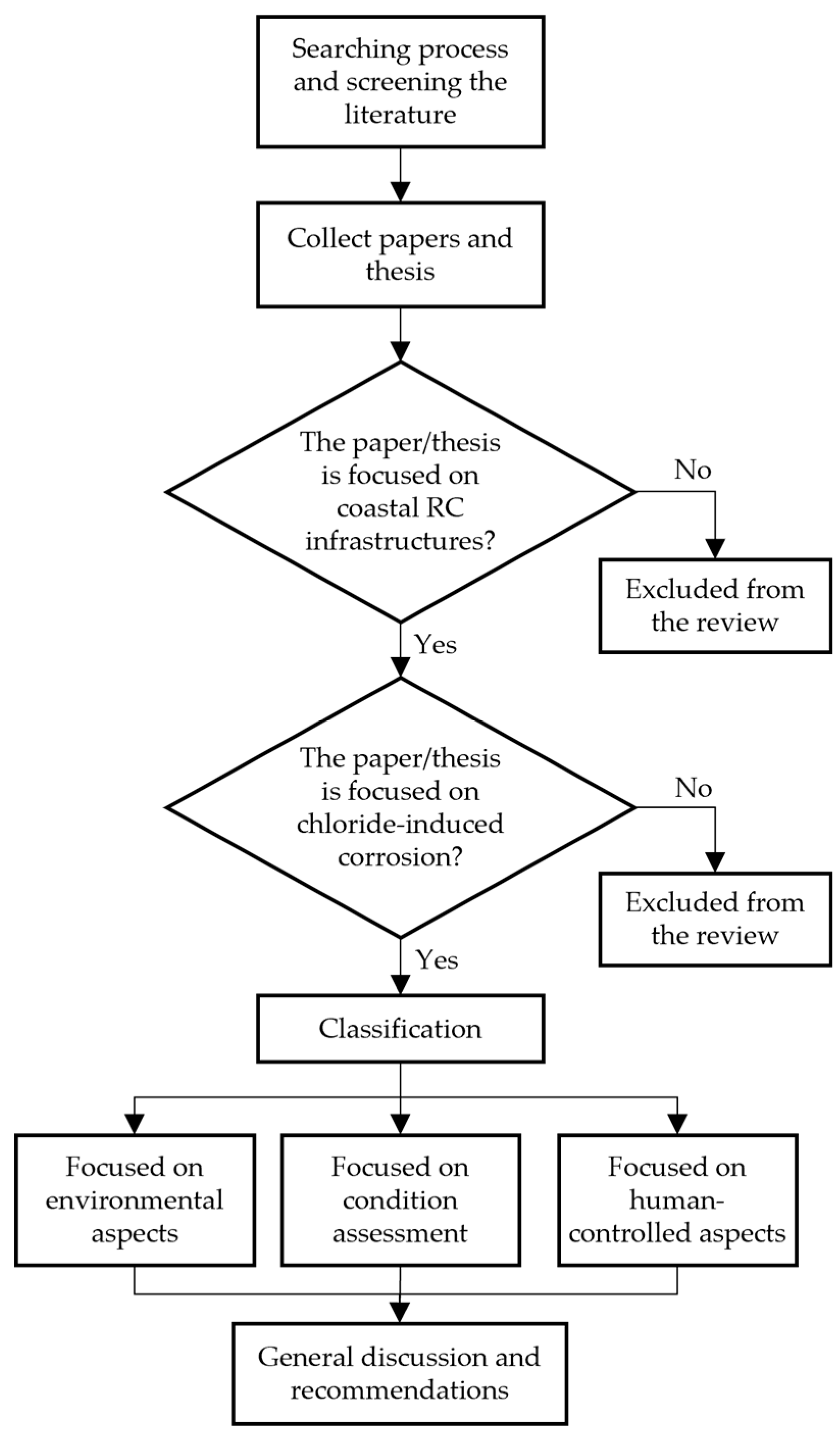

Figure 2 depicts the review methodology. The papers were categorized based on the specific subtopics they addressed. The employed methodology or procedure, along with their main outcomes were highlighted. An exploration of the advantages, drawbacks, and applicability of the articles is also provided, incorporating suggestions for potential investigations in subsequent research.

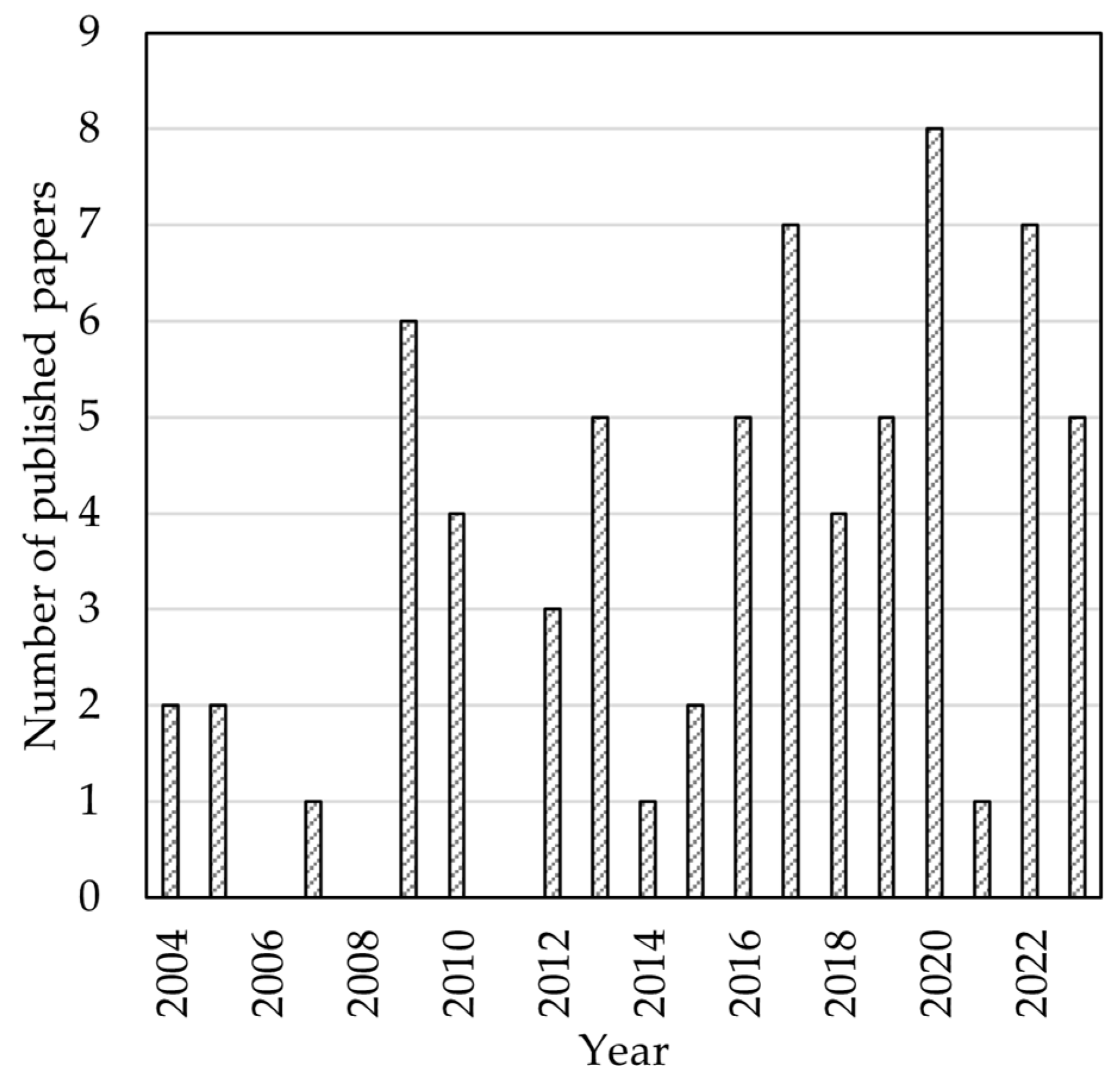

Figure 3 presents studies of the main axes of port or coastal infrastructures. About 69 papers were included in this review. The figure shows that the number of published papers progressively increased over time. The number of articles in the last four years is equal to the number of articles published before 2012. This trend implies a growing concern in the deterioration and future maintenance of coastal structures, especially for ports.

3. Chloride-Induced Corrosion, a Critical Issue

3.1. Relevance

Reinforced concrete is the most common building material in the world, and it is used in construction due to its design flexibility and comparatively low cost [

21]. Every year, an estimated 25 billion metric tons of concrete are produced [

22]. Reinforced concrete has very good durability performance when properly used. The main mechanism to prevent corrosion is the use of a concrete cover on the reinforcing bars, which serves as a physical barrier and through its high pH serves as an inhibitor of the phenomenon [

23].

However, many structures show early deterioration, namely those exposed to aggressive environments such as coastal areas [

24,

25]. Hence, deterioration may occur and significantly affect the service life of the structures [

25], and in some cases cause the collapse of the structure [

26].

Nowadays, it is well known that the durability of materials and structures depends on the surrounding environmental conditions and the material resistance to the action of aggressive substances [

24,

27,

28]. Chloride-induced reinforcement corrosion is one of the main causes affecting the long-term behavior of RC structures [

24,

29]. Therefore, coastal and maritime infrastructure assets are subjected to this kind of damage due to their exposure to aggressive chloride environments present in the seawater [

30]. Under these conditions, high rates of chloride penetration and chloride-induced reinforcement corrosion often lead to a reduced service life [

24,

31,

32,

33,

34].

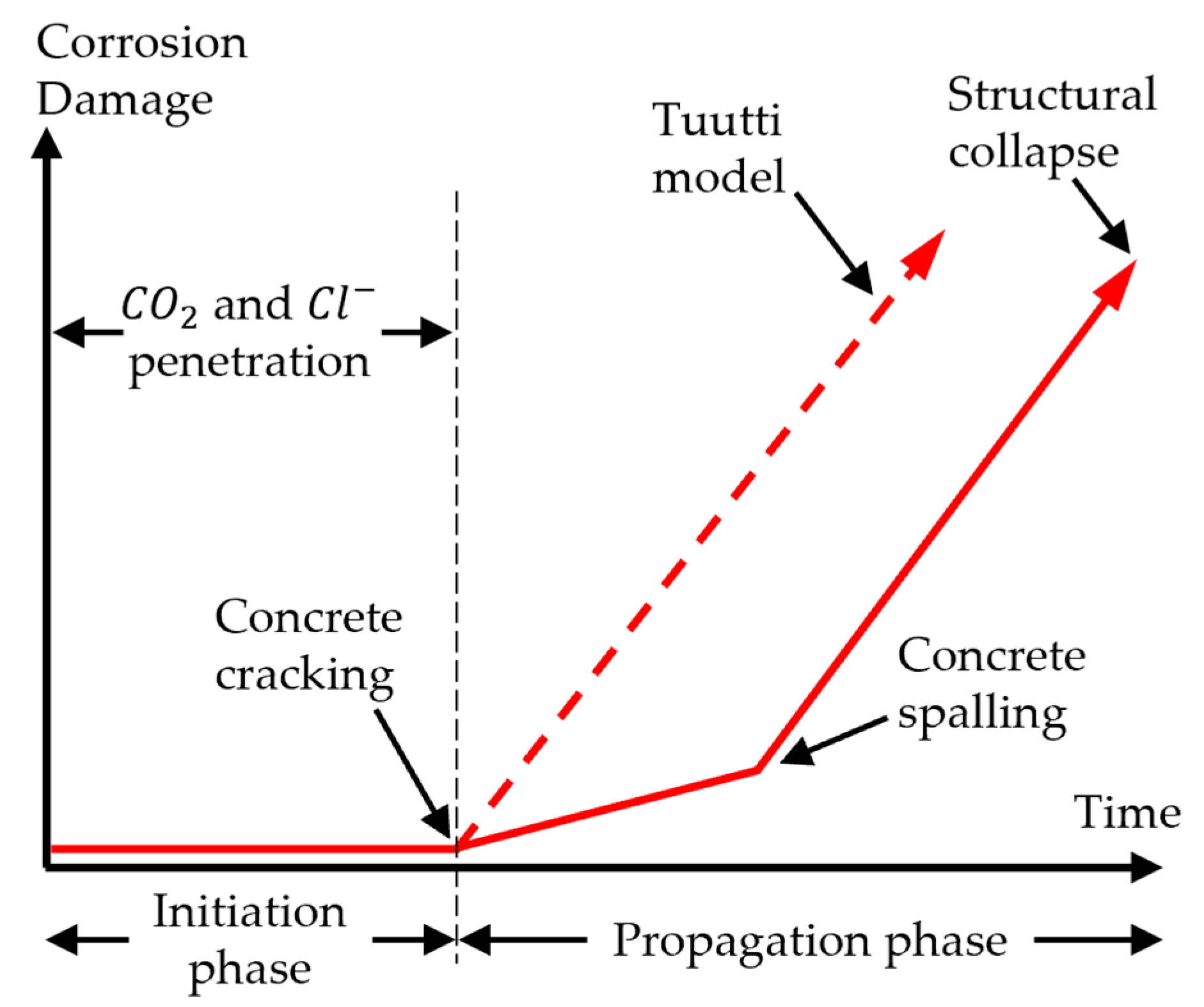

The corrosion process in RC structures is commonly divided into two main phases. During the chloride transport process, part of the chloride is dissolved in pore water (Free chloride) and the rest is bound by cement hydrates (Bound chloride) [

35]. When the free chloride ion reaches the surface of rebars, it destroys the passive layer of steel and initiates its corrosion [

36]. This process is known as the initiation phase [

37].

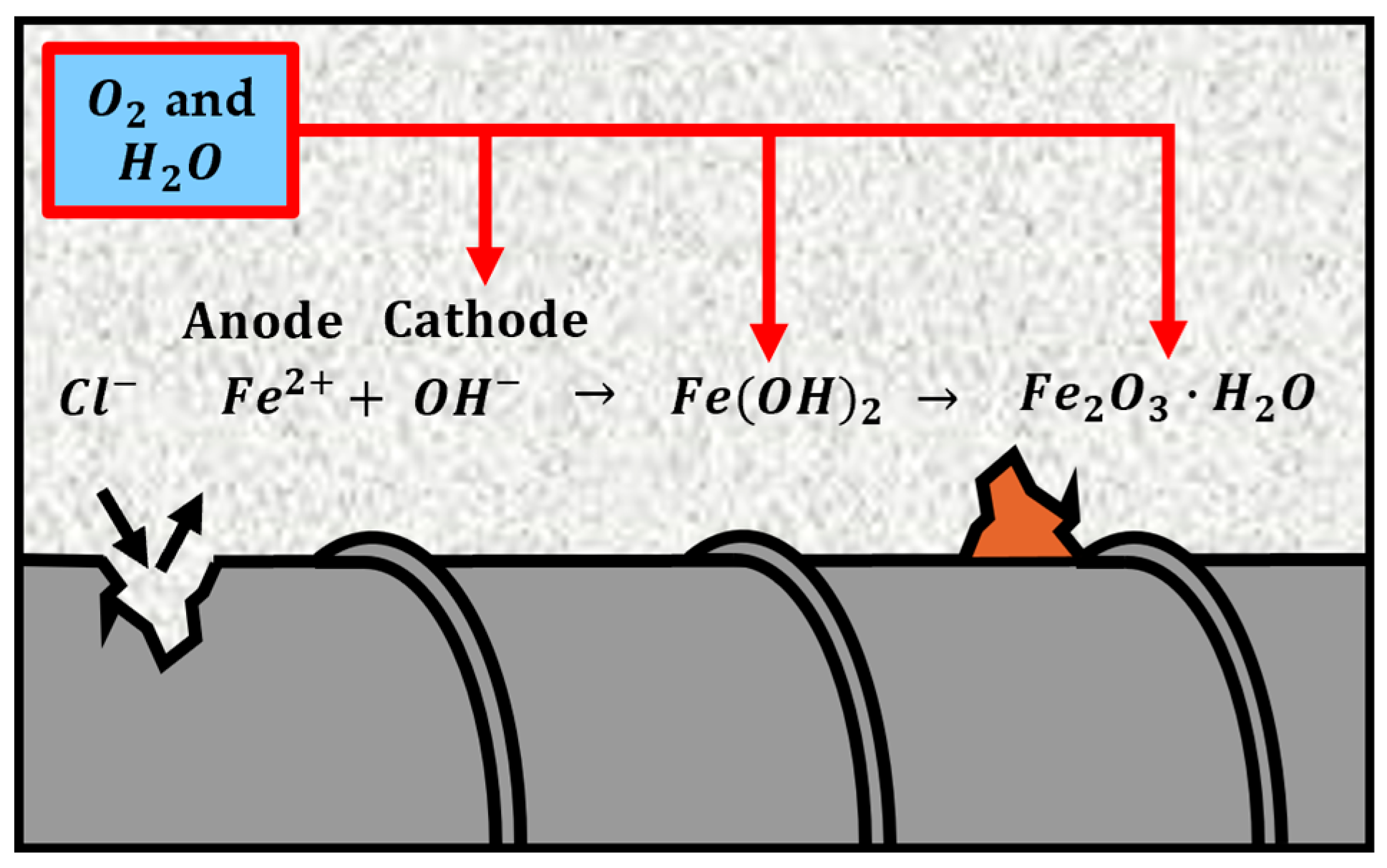

In the second phase, or propagation phase, corrosion produces a cross-sectional reduction in the reinforcement and an accumulation of corrosion products at the interface between concrete and steel, which leads to tensile stresses that initiate cracks, delamination, and spalling of concrete cover [

3] (See

Figure 4).

In general, steel corrosion is produced by an electrochemical process that involves both anodic and cathodic reactions, which are accelerated by chloride due to depolarization effects and ion channels [

35]. The product at the anode,

, get combine with the hydroxyl ion in the concrete pore solution to generate ferrous hydroxide,

, which is then oxidized to form ferric hydroxide,

and finally convert into hydrated ferric oxide or rust,

(See

Figure 5).

Other products of the chemical reaction are the lepidocrocite

and the akageneite

, produced during the dehydration of ferrous hydroxide and in a chloride-contaminated environment through the unstable phase of green rust

. These products favored pitting corrosion, which accelerated reinforcement corrosion [

41,

42].

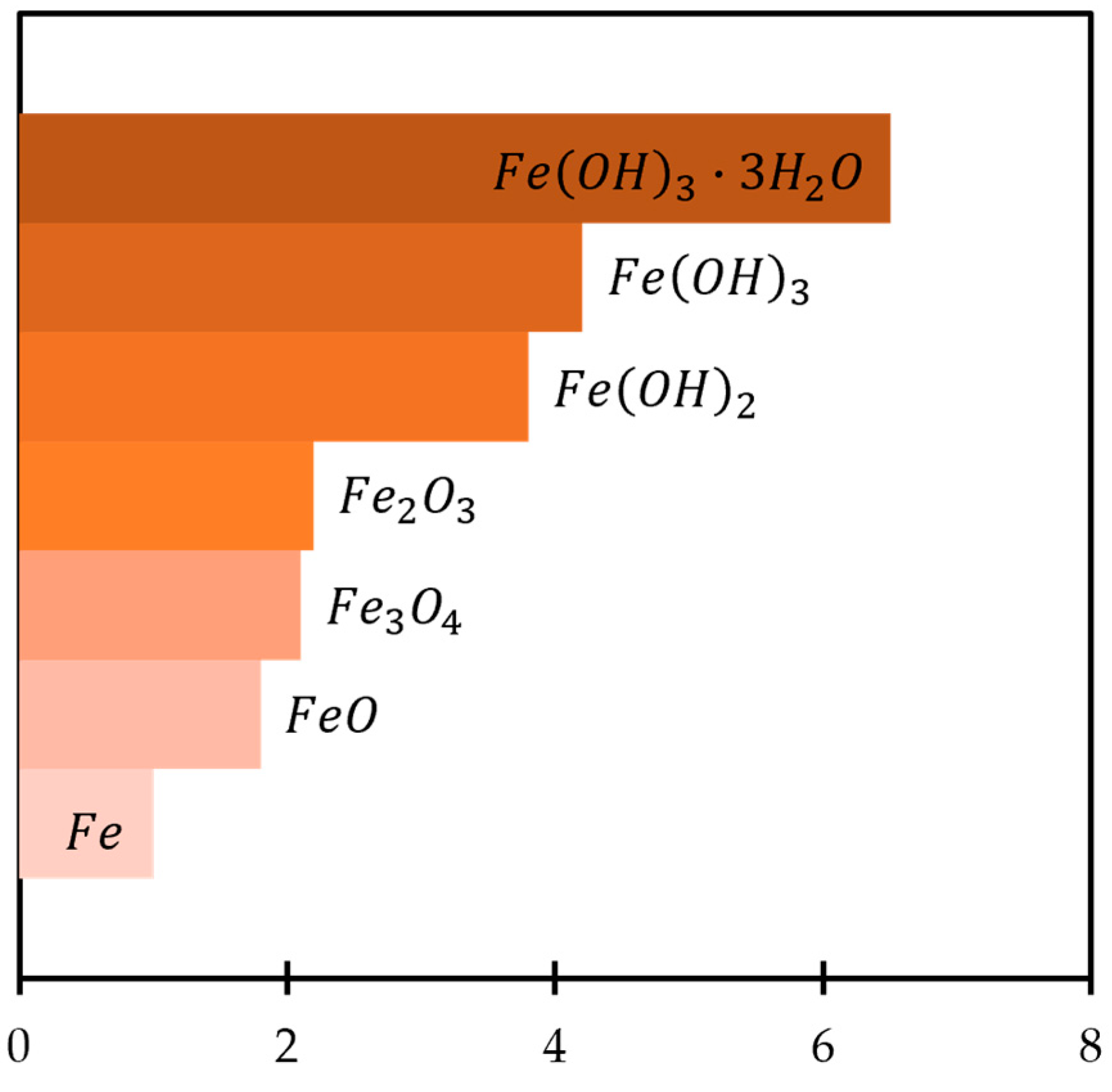

Overall, corrosion products are composed of different oxides and oxyhydroxides with higher volumes than iron (See

Figure 6). The expansion due to the conversion of iron to corrosion products can lead to the cracking of concrete cover due to the steel-to-concrete bond deterioration and eventually spalling [

35,

43].

However, the consequences of chloride-induced corrosion damage in terms of serviceability and safety that define inspection and maintenance strategies are different for each type of asset due to differences in failure modes for ports, buildings, bridges, coastal defenses, etc. [

45,

46,

47,

48]. Therefore, RC structures, generally designed for a lifetime of 50 to 100 years, could begin to deteriorate after 15 to 30 years when are in contact with chloride ions [

31,

49,

50,

51].

3.2. Modelling

Capillary absorption, hydrostatic pressure, and convection are mechanisms by which chloride can penetrate into concrete [

21]. However, the principal process of chloride ingress is diffusion, which is the movement of chloride ions from a location where they are more concentrated to others with lower concentration [

52].

Therefore, chloride-induced corrosion initiation is generally considered to be a diffusion-based phenomenon [

29]. According to Tuutti [

36], and implemented recently by Naito et al. [

21], the diffusion problem can be modeled with a probabilistic implementation of Fick’s second law considering some assumptions such as concrete homogeneity, constant chloride diffusion coefficient (in time and space), chloride flow in saturated conditions, and constant chloride concentration at the exposed concrete surface. From that, Pang and Li [

53], developed probability models for surface chloride content and chloride diffusion coefficient calibrated using the results of field investigations of seventeen high-pile wharf structures located at the south coast of China.

Although closed-form solutions to Fick’s second law can be found, they do not correctly represent real-world structural deterioration processes, resulting in inaccurate predictions [

54]. Chloride binding, concrete aging, temperature and humidity interactions, and other factors all play a role in the chloride ingress phenomenon. To account for such factors, authors like Martín-Pérez et al. [

55], presented four partial differential equations to describe chloride ingress into concrete, moisture and heat diffusion through concrete, and oxygen transport to the reinforcement. The model correlated successfully with closed-form solutions.

Studies like the one conducted by Nguyen et al. [

56], go beyond by predicting the chloride penetration into the concrete using a coupled thermo-hydro-chemical model that considers multiple factors affecting the phenomena including diffusion, convection, chloride binding, ionic interaction, and concrete aging. Similar to this, Cherif et al. [

57], studied the effect of the cementitious material composition on that of its interstitial solution. They demonstrated that the effect of the composition change during the chloride transfer is related to the dissolution/precipitation phenomena of the solid matrix compounds. They also highlighted the effect of the use of some mineral additions on the reduction of free chlorides in the pore solution. Later, Cherif et al. [

58], proposed a multispecies transfer model based on Nernst-Plank (N-P) flux, a model extension of Fick’s laws of diffusion, and considering the thermodynamic equilibria induced by the dissolution/precipitation phenomena of the solid matrix compounds. They consider seven species of the pore solution (

,

,

,

,

,

and

). The proposed model simulates real chloride transfer conditions considering sea water and pore solution for boundary and initial conditions.

Many of these research studies and proposed models are based on and have served as the foundation for globally accepted design codes. The most noticeable is the Duracrete model, developed in the 1990s as a European research project, suggests that the failure of the structure is considered to occur when the chloride content on the reinforcing bars’ surface exceeds the critical chloride threshold. Therefore, corrosion initiation is determined by the balance between the actual chloride content at the steel surface and the critical chloride content [

59]. The code presents a fully probabilistic concept, and the model requires experts to select appropriate statistical values for the model parameters, making it less accessible for general use [

60]. Another globally accepted standard is the fib Model Code for Service Life Design (fib bulletin 34), which presents a comprehensive performance-based concept for durability design regarding reinforcement corrosion [

61]. Similar to the aforementioned code, it introduces a fully probabilistic concept that considers durability in a reliability-based manner. However, the concept can only be applied by a few experts due to the necessity of appropriate statistical values for the model parameters [

62].

In summary, many researchers have analyzed the phenomenon of chloride-induced corrosion in the initiation stage. Authors like Cherif et al. [

58] and Nguyen et al. [

56] have studied in detail the specific relationships between materials and the transfer phenomenon. However, other authors such as Pang and Li [

53] continue to develop relatively simple models based on Tuutti approach [

36], which is calibrated using experimental data. Therefore, experimental campaigns also play an important role in understanding this phenomenon.

3.3. Experimental Characterization

Many laboratory studies on chloride-induced corrosion of steel bars embedded in concrete have been conducted under controlled environmental conditions, allowing a systematic investigation of the impact of various parameters on corrosion [

63,

64,

65,

66]. However, the mechanism of chloride-induced corrosion in the field may differ, and it is necessary to understand the corrosion process in situ [

67,

68].

Field surveys are crucial for the improvement of our understanding of corrosion processes under in-situ conditions [

35]. Several efforts have been carried out to investigate the long-term corrosion behavior of RC structures in the field, and different corrosion mechanisms have been analyzed. Moradi-Marani et al. [

69], analyzed an RC jetty after 15 years of service and determined that the main cause of the deterioration was reinforcement corrosion which was initiated within a few years after the completion of the jetty structure. Despite rehabilitation after 7 years of service, inadequate cover thickness and concrete transport properties make the problem reappear. Later, Touil et al. [

70], applied a similar methodology to assess the oldest Algerian concrete structure exposed to the Mediterranean Sea and found extensive chloride penetration and deterioration of the surfaces due to the long-term exposure to seawater.

Castro-Borges and Mendoza-Rangel [

71], used 47 years of data on temperature, relative humidity, precipitation, and evaporation recorded in a tropical microclimate of a port in Mexico to detect climatic patterns and combined chloride profiles analyzed in 15 years old concretes of different quality exposed to the same microclimate. The results show that seasonal and multiannual climatic cycles influenced the behavior of the chloride profile of the studied concretes and thus their durability. Yokota et al. [

72], presented the main results of the analysis of the RC members of a Port of 30 to 40 years old. The paper places special emphasis on the high variability of corrosion even in elements under almost the same conditions.

Otieno, Beushausen, and Alexander [

73], compared chloride-induced corrosion of cracked RC beam specimens exposed to accelerated laboratory conditions (impressed current and cyclic wetting and drying) and a filed marine tidal environment. The research focused on corrosion performance under certain material parameters, depth of cover, and crack width. The results indicated that the relationship between the above factors and corrosion rate is not straightforward. No relationship was found in the effect of crack width on corrosion rate between laboratory and field samples. This highlights the importance of field testing in understanding this complex phenomenon.

Other authors, like Pang and Li [

53], used the data from seventeen high-pile wharf RC structures constructed between 1970 and 2000 and located on the south coast of China to develop adjusted models for surface chloride content and chloride diffusion coefficient. Balestra et al. [

74], used a database of RC structures built between 1958 and 1978 in the Arvoredos Island (Brazil), to formulate a new empirical chloride profile model, based on the Modified Holliday equation. The model presented a similar correlation with Fick’s Law solution in the diffusion zone, but in the convection zone, the new model was able to represent better the chloride concentration.

Wu, Li, and Yu [

75] focused on the influence of different exposure conditions (atmospheric, tidal, and splash zones), on the chloride ingress and chloride diffusivity of concrete samples obtained from two RC ports located in the Beibu Gulf. The results show a better fit with the DuraCrete model [

59], compared to the LNEC E465 [

76], and Life365 models [

77]. A similar analysis was recently published by Xu et al. [

78], where the authors focused on the apparent chloride diffusion coefficient and its time-dependent constant of concrete exposed in tidal zone based on a large number of natural exposure test data. The service life was calculated using the DuraCrete model [

59], the Life365 model [

77], and the ChaDuraLife model [

79], with the latter proving to be the most cost-effective and reliable for prediction.

Other studies such as Imounga et al. [

3], used a Bayesian network approach for the probabilistic characterization of the input parameters of the corrosion initiation model taking into account the effects of loading from experimental data. The results indicate the high capabilities of the methodology to integrate the loading and chloride test information for the determination of the probabilistic parameters of the corrosion initiation model.

Liu et al. [

34], used a large body of experimental results collected from various sources including a 30-year-old concrete bridge in a marine environment in Shenzhen, China, to present a new statistical analysis-based model to predict chloride diffusion in offshore concrete structures and compared it with other existing prediction models to demonstrate its suitability and enhancing the understanding of chloride-induced steel corrosion under natural conditions. More recently, Tian et al. [

67], analyzed a database of RC corrosion focusing on corrosion rate, microstructure at the steel-concrete interface, rust composition, accelerated techniques to reproduce natural corrosion characteristics, and corrosion repair technology. The study concluded that a gap exists in establishing the relationship between laboratory acceleration techniques and steel corrosion in specific natural environments, as well as in developing a post-repair durability behavior assessment system for existing technologies.

In summary, the long-term impact of chloride-induced corrosion initiation on RC structures is potentially high, especially with structures in more aggressive exposure conditions for concrete such as marine environments. Despite several publications on the modeling of the phenomenon, the difference between laboratory and field data has highlighted the complexity of the problem. Moreover, the significant variability observed in the timeframe for corrosion manifestation in coastal structures underscores the critical role of field data collection and highlights the intricate nature of the phenomenon. Therefore, this mechanism can significantly affect the service life of the structures.

4. Degradation Models for Lifetime Assessment

Establishing maintenance schedules that preserve and/or extend the structure’s lifespans considering environmental, social, and economic impact, is essential for modern society. In this field, degradation models contribute to understanding the deterioration process and determining the long-term performance of the asset. Therefore, they are essential in defining the type and timing of maintenance actions which is crucial for ensuring the good operation of the system.

This chapter presents the main research in this field applied especially to the corrosion propagation phase, where the corrosion produces a cross-sectional reduction in the reinforcement and an accumulation of corrosion products at the interface between concrete and steel, which leads to tensile stresses that initiate cracks, delamination, and spalling of concrete cover [

3] (See

Figure 4).

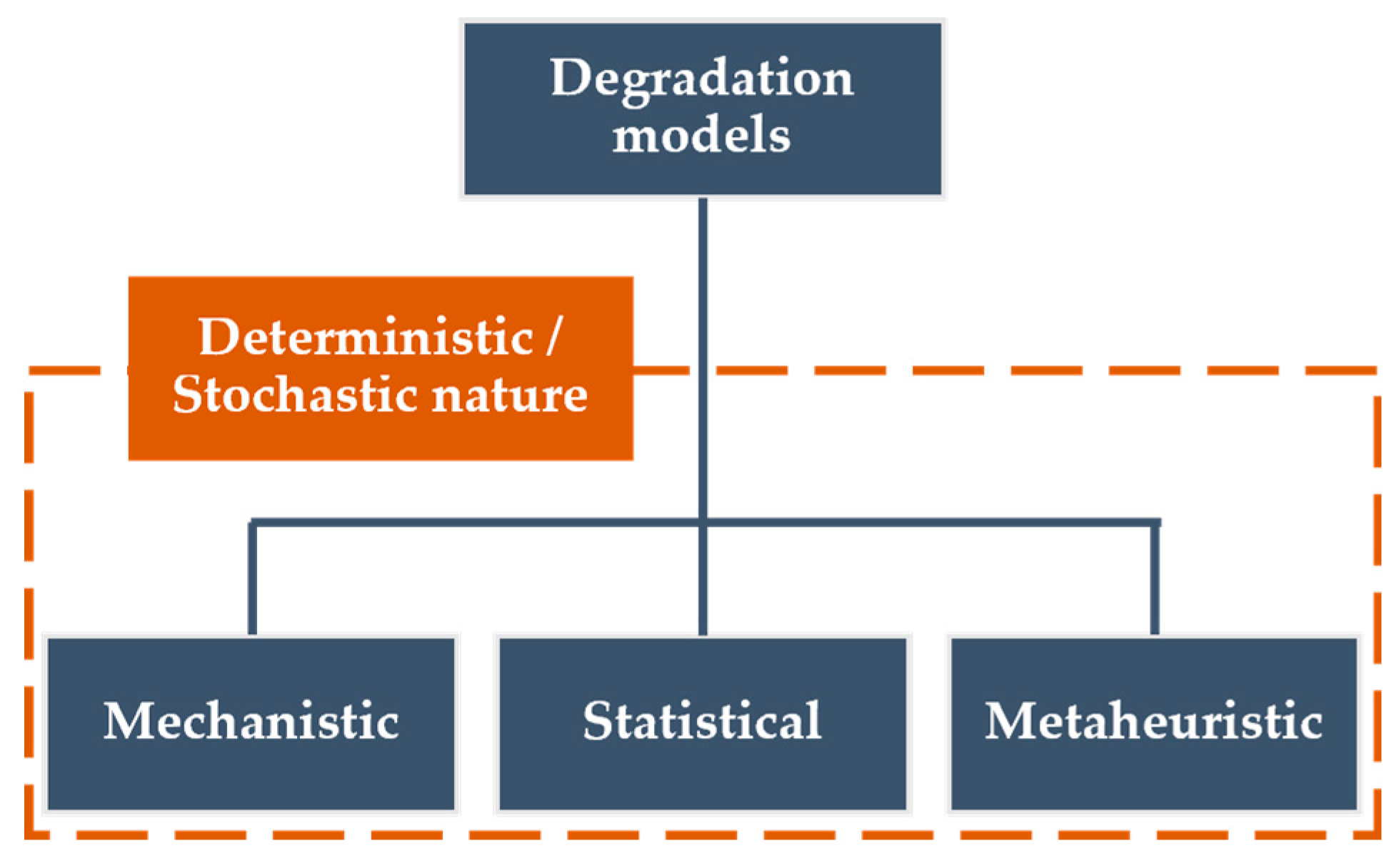

Once corrosion produces visible signs of deterioration, some degradation models make use of visual inspections to determine the future deterioration of the element or structure. Other degradation models focus on specific deterioration phenomena, such as corrosion, and consider the propagation phase, or even from the initiation phase. Therefore, the nature of the degradation models can be deterministic or stochastic. In this context, the models published to date can be separated into 3 categories, as shown in

Figure 7.

4.1. Mechanistic Models

Mechanistic models aim to establish the relationship between the variables that influence the phenomenon and the observed outcomes. In general, mechanistic models are based on parameters with a high impact on the structural capacity and reliability such as material properties or stress conditions [

80].

Villain et al. [

81], developed a 3D cross-correlation model to perform a durability diagnosis to analyze a wharf of the Nantes–Saint-Nazaire Port, using laboratory tests and non-destructive techniques. Ožbolt et al. [

82], present a three-dimensional fully coupled chemo-hygro-thermo-mechanical model to simulate the effects of corrosion of steel in concrete and evaluate the damage to the structure. More recently, Bui and Tan [

83], presented a finite element model to simulate nonuniform corrosion-induced concrete cracking considering microcell and microcell mechanisms to determine the total corrosion rate. The results evidence that vertical cracks accelerated the spread of the corroded area and created a more rounded corrode depth.

A similar work was presented by Nguyen et al. [

56], who predicted the chloride penetration into the concrete using a coupled thermo-hydro-chemical model but went beyond by considering multiple factors affecting the phenomena including diffusion, convection, chloride binding, ionic interaction, and concrete aging. Additionally, the researchers propose a model simplification to reduce the computational cost, proving a good efficient and accurate for long-term chloride ingress modeling and reducing the need for larger climate databases. In general, mechanistic models provide a reliable lifetime assessment. However, the main disadvantage of their implementation, is the high cost in terms of data requirement and modeling, making it inefficient on a wider scale.

4.2. Probabilistic Models

Probabilistic models take into account the variability of the different components of the phenomenon and establish that a deterministic analysis may provide more inaccurate results. Kwon et al. [

25], used field data from two wharves of 8 and 11 years of service in South Korea, for the probabilistic prediction of the service life of RC structures exposed to the marine environment conditions considering the crack effect on chloride penetration through the relationship between diffusion coefficients and crack widths. The results predict a shorter service life than that calculated using deterministic methods.

Bastidas-Arteaga et al. [

84], developed a probabilistic lifetime prediction model for RC structures under the coupled effect of corrosion and fatigue, and the results show that the coupled effect strongly affects performance, leading to a large reduction in the expected lifespan. Imounga et al. [

3], analyzed a similar situation, where they considered the effects of chloride-induced corrosion and load-induced concrete cracking on the serviceability and safety of RC structures. This research obtains comprehensive results by integrating the loading and chlorination test data for the determination of the probabilistic parameters using a Bayesian network approach. However, the study used a simple chlorination model and not considered mechanics-based cracking models.

Bastidas-Arteaga et al. [

54], presented a stochastic model that considered the effects of convection, chloride binding, concrete aging, temperature, and humidity, to study the influence of weather conditions and global warming on chloride ingress and the evaluation of the corrosion initiation time. The results show a lifetime reduction ranging from 2 to 18% on RC structures located in oceanic environments due to climate change and the importance of the implementation of countermeasures directed to reduce and/or mitigate the action of global warming on weather and minimize the impact of climate change on RC structures.

Molyneaux et al. [

39], developed a probabilistic model for the deterioration of RC elements of Australian port infrastructure due to corrosion, cracking, and spalling. The study performed a parametric analysis of the influence of the variation of the concrete cover, the surface chloride concentration, and the diffusion coefficient, finding in the latter the largest variation observed in the field and its high sensitivity in the model. The model estimates the onset of corrosion of the analyzed elements, assuming a normal distribution of the input variables. Later, Homer, Law, and Molyneaux [

85] extended the study by analyzing the statistical distribution of specified cover, element type, and method of construction.

Other studies such as [

53], developed a model to predict the service life of high-pile wharf structures in China, by considering a probabilistic model for surface chloride content and chloride diffusion. The research was based on exposure trials and field data of seventeen high-pile wharf structures located on the south coast of China and presented reasonable results for concrete in the splash zone but significantly smaller chloride content results for the semi-splash zone.

Yu et al. [

86], developed a time-dependent probabilistic model to describe chloride ingress for durability assessment of RC structures. The model with a reliability index is highly dependent on characteristics such as the apparent chloride diffusion coefficient, the water-to-cement ratio, curing periods, and the depth of concrete cover. This model is less reliable for tidal zones than for splash and submerged zones.

Pereira et al. [

87], used data from a 50-years-old bridge on a port in Portugal to establish the structure deterioration models with a deterministic nature, based on the Model Code 2010 and a semi-probabilistic based on the E465 specification from the Portuguese National Laboratory for Civil Engineering (LNEC). The results show that these models are too conservative and alluded to information not considered for the models such as cracks in the structure.

More recently, Pang et al. [

88], analyzed the relationship between flexural strength, temperature, relative humidity, geometric parameters, and corrosion probability. The results showed high variability in corrosion probabilities depending on the exposure zone. The authors remarked that the randomness of temperature and humidity should be considered in the analysis of chloride ingress for RC beams on offshore atmospheric zones.

Due to the high uncertainty of the main factors influencing corrosion deterioration of coastal structures, a large number of models have been proposed. These models vary in complexity and applicability and have been implemented locally, so their adaptability to different climatic conditions has not been studied extensively.

4.3. Statistical Models

Statistical models are based on the interpretation of a database of existing knowledge of failures or historical data to estimate future deteriorations. These models are often used for estimating the long-term performance of structures like bridges and are based on deterministic or stochastic approaches.

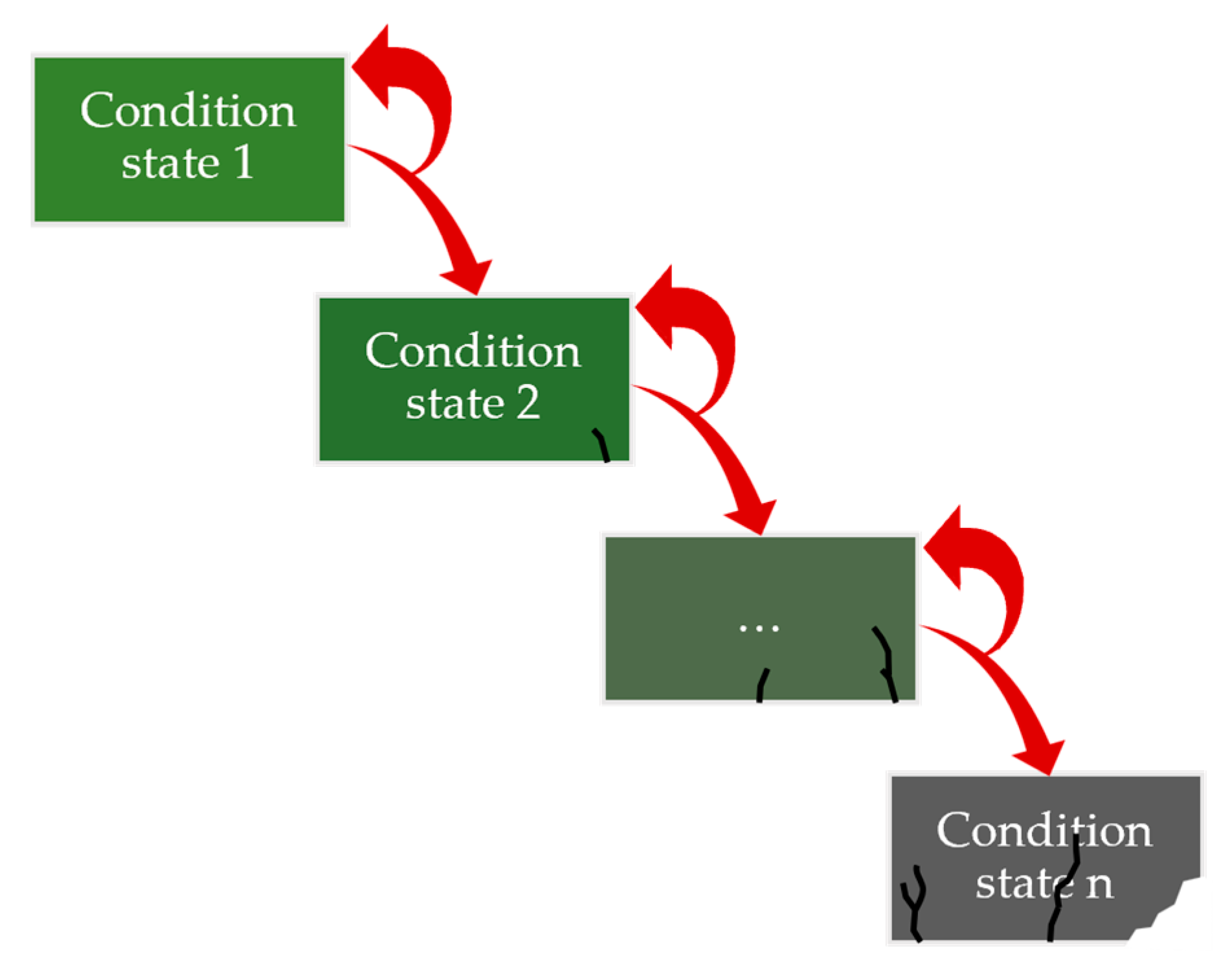

Markov Chain (MC) models stand out in this section because they are based on the discretization of the condition of the structural elements or systems and estimate a probability that the analyzed element deteriorates to the following state in a period (See

Figure 8) [

89]. These probabilities can be established from expert opinions and/or monitoring data available [

90].

MC models have been applied to different types of structures and materials [

91,

92,

93,

94,

95]. Considering the marine environment, Bastidas-Arteaga and Schoefs [

96], presented a methodology that combines a numerical model of chloride penetration, the Markov degradation process, and decision theory. The research is based on the discussion with stakeholders on the integration of inspection data and chloride penetration models, however, further research is suggested on the factors influencing the corrosion initiation such as environmental and characteristics of the concrete and repair material.

A similar work was presented by Zhang et al. [

97], where a structural degradation model was developed for a wharf in Tokyo. The formulation was based on a randomized MC model to describe the port infrastructural deteriorations and works as a more flexible tool to quantify the uncertainties associated with the deterioration process than a deterministic approach.

Statistical models in general have great advantages such as their simplest approach and practicality at a network level. However, they ignore the interaction between degradation and the different components of the structures. Additionally, they provide qualitative results due to their basis on qualitative damage scales, therefore the safety and reliability of the structure in terms of resistance are questionable [

80]. Finally, the outputs of the models depend strongly on the information available. Models like the one by Mauch and Madanat [

98] need at least 20 years of data, therefore, they are specific cases where they can be applied.

4.4. Metaheuristic Models for Prediction

Metaheuristic algorithms are gradient-free, iterative, and frequently population-based approaches that start with a set of initial random solutions [

99]. These models use searching tactics, such as exploration and exploitation, to steadily enhance the quality of solutions. They are specially designed to solve highly complex Nondeterministic Polynomial (NP) hard problems and have been applied for the solution for a variety of engineering problems.

Metaheuristic models include:

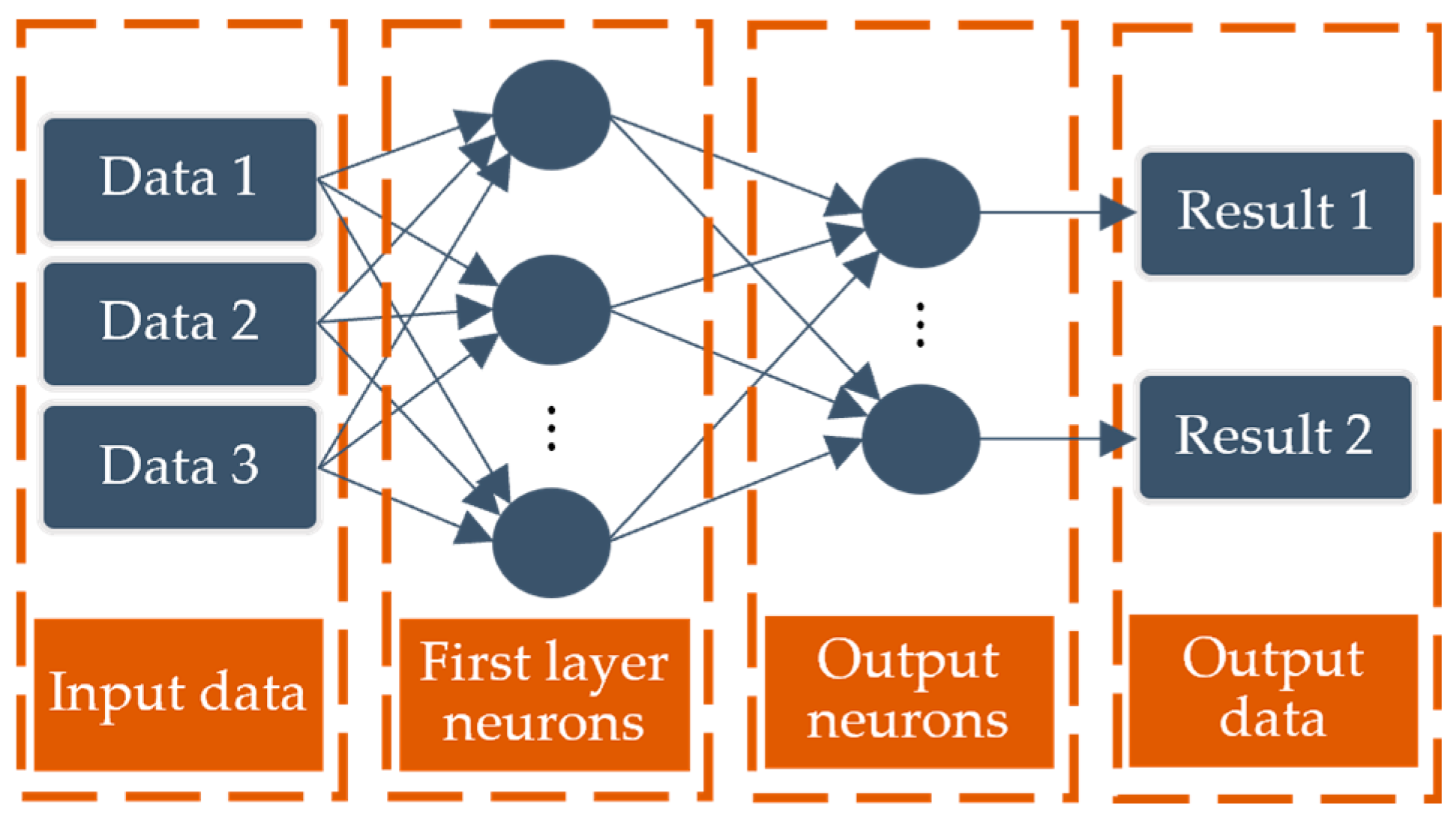

Among these, ANNs have become popular as they overcome the deficiencies of current mechanistic, probabilistic and statistical models in degradation prediction. ANN concept is an artificial intelligence method which is originated from the human brain’s understanding [

105]. It consists of each neuron processing information separately and simultaneously, mimicking the brain’s functioning. ANN obtains knowledge through the training phase that is established by using a set of training data, where the system identifies the relationship between the input and output parameters. The concept of synaptic weights is determined to store the knowledge from training and to use it to solve problems for an unknown dataset [

106].

Figure 9 presents an example of a neural network.

In the context of coastal infrastructure, Ukrainczyk, Banjad, and Ukrainczyk [

108], applied an ANN in the prediction of the expected future degree of damage considering a damage classification of steel corrosion gathered in three concrete structures in a marine environment, two bridges and a torpedo factory in Croatia. The authors classified the damage caused by corrosion into five categories, which correspond to the types of work that would be required to repair the damage and corresponded to information obtained by testing and visual inspections (See

Table 1). The results show that the ANN model developed can predict damage degree accurately and was able to analyze the influence of the main parameters on the damage. However, the model depends on the available data, so its reliability in predicting damage may vary depending on the structure and historical data.

Asghshahr, Rahai, and Ashrafi [

109], used laboratory data on chloride penetration to develop classification and regression trees (CARTs) and ANN models to predict chloride concentration considering environmental conditions, penetration depth, water-to-cementitious material ratio and silica fume mass as input parameters. The results showed a good ability and accuracy of the models for predicting the chloride concentration in concrete under marine environment conditions, with the best accuracy shown by the ANN model.

Lyne C and Lejano [

110], present an ANN model for estimating the microcell current density of steel in mortar mixed with seawater, where several variables were considered as input variables and the results consists of 8 input variable, 8 neurons in the hidden layer, and one output variable. The resulting neural network model satisfactorily predicted the corrosion current density with high correlation coefficients. Other studies, such as [

111], evaluate five metaheuristic models in the prediction of pitting corrosion risk and marine corrosion rate. The results were compared with two real-world datasets and a hybrid model combining support vector regression (SVR) with a smart nature-inspired metaheuristic optimization algorithm presented the lowest errors.

More recently, Mohammadi et al. [

112], proposed the use of ANN optimized by four marine creatures-based metaheuristic algorithms to model the apparent chloride diffusion of concrete exposed to atmosphere, tidal, splash, and submerged environments. The models were evaluated with 216 data from relevant field experiments from the literature and the Wilcoxon rank-sum test shows that the ANN-JSO (Jellyfish Search Optimizer) algorithm shows better results. In the same year, Rincon et al. [

113] developed MC models and ANN models to describe the degradation process of a marine exposed and repaired structure using data from corrosion sensors from 2006 to 2020. The results demonstrate the potential applicability of these models due to the lower errors obtained.

Therefore, it is possible to say that metaheuristic models could capture complex phenomena without prior knowledge. Within the metaheuristic models, ANN models are highlighted due to the possibility of generating estimations with higher accuracy. Additionally, ANN-based techniques can generate missing data to fill gaps. However, there are some disadvantages, such as a lack of transparency in their decision-making process, and the high inaccuracy of the results when sufficient data is not available.

5. Maintenance of Infrastructure

5.1. Relevance

Currently, in most European countries, approximately half of the construction industry expenses are associated with repairs, maintenance, and rehabilitation of existing structures, and are expected to increase in the future [

12,

13]. It is estimated that the public budget for rehabilitation will grow approaching the volume of the expenditure on new structures [

13].

The objective of the degradation prediction over time is to provide crucial information to develop maintenance strategies [

114]. Therefore, the next step after the development of degradation models is to establish maintenance schedules, that extend the structure’s lifespans under cost-effective and efficient restrictions that benefit modern society [

14].

Currently, maintenance decisions are frequently made without a comprehensive understanding of the risks involved, resulting in extensive and challenging meetings amongst managers with a variety of technical, strategic, financial priorities, and most of the time, maintenance is either curative, after unanticipated events, or preventative, anticipation of predictable events, and rarely, predictive before unforeseen events [

11]. Preventative maintenance includes proactive efforts aimed at preventing or delaying a deteriorating process that could lead to failure [

115]. This type of maintenance can be justified on economic grounds since it can extend the life of structures avoiding the need for unplanned curative maintenance.

Additionally, the discussion of the maintenance action forces the managers to face budgetary, operational, and safety limitations, factors that influence decisions, and structures that are sometimes operated in more severe service circumstances than anticipated [

115]. This could lead to uncontrolled maintenance expenses or uncontrolled safety and unavailability costs. For that reason, Zen [

116], considers that systematic planning of maintenance works is necessary as early as possible in the structural design phase; otherwise, a huge expense can be generated due to unexpected deterioration of structural performances.

5.2. Maintenance Modeling and Optimization

Effective integration of preventative maintenance measures and strategies is considered highly important. Researchers like Val [

117], investigated the impact of maintenance interval, design specification, environmental conditions and discount rates on the maintenance cost of corroding RC structures. The proposed approach has the advantage of providing conservative results and overestimating the probabilities of failure, which can be beneficial for ensuring structural safety. However, the use of lognormal distributions to model loads and the assumption of independence between structural failures in different years may limit the accuracy of the results and lead to an excessively conservative assessment for repairs. A similar approach was presented by Chiu, Noguchi, and Kanematsu [

118], focused on the probabilistic assessment method of service life and life-cycle maintenance strategies for buildings in corrosive environments with high seismic hazards considering the impact of repair and retrofit.

Later, Yang, Li, and Pang [

119], investigated the maintenance planning of the RC structure applied to a marine wharf in Shanghai, China built in 2002. Deterioration models and life cycle management models were first established for the maintenance operations of the RC elements in the wharf. Later, the same authors, include the consideration of the impact of crack width in the control of flexural RC elements on the maintenance costs in the same port [

120].

Authors like Kurth et al. [

121], affirmed that the adoption of corrosion management techniques and procedures for civil and maritime infrastructure is still in its early stages. The research presented and discussed the common types of techniques, methods, and documents available for inspecting maritime assets, evaluating exposures, and calculating the service life of maritime infrastructure. The maintenance strategies analyzed by the authors for RC elements include surface coatings and sealers, crack repair materials, and galvanic systems or impressed current systems.

In the same research line James et al. [

122], provided a categorization of solution methods for protection, maintenance, and repair, based on standards and codes culled from around the world. The study contemplated five primary methods to treat RC corroded structures:

The study presented the limitations and advantages of 27 methods used for the protection, maintenance, and repair of RC structures, gathered from standard codes and studies; and proposed a flowchart for corrosion detection, assessment, and rehabilitation. Recently, Peng et al. [

123], applied an alternative reinforcement of geopolymer-bonded small-diameter carbon fiber-reinforced polymer in strengthening the concrete superstructure at The Port of Zhanjiang (China) and improved the crack control capacity.

In addition to the type of action, the consideration of multiple constraints imposed by economic, social, and environmental factors leads maintenance planning optimization to a major challenge for designers, owners, and users of infrastructures. Studies such as [

96], focused on the management optimization of RC structures placed in chloride-contaminated atmospheres, considering preventive maintenance. The study considered patch repair and the inspection/maintenance strategy chosen is modeled using decision theory and Markov processes.

Farahani [

124], developed an optimized-based life-cycle-cost analysis of corroded structures in marine environments that considers repair and maintenance scenarios applied during the lifespan of these structures. Eleven different scenarios were considered, and the solution was optimized by a Genetic Algorithm (GA) based on minimum LCC cost and 40 years of failure time in terms of corrosion.

Schrecker et al. [

125], described the rehabilitation performed on a jetty in the Northern Cape, built in the late 1940s. The structure was in an advanced deterioration stage, with high chloride contamination, larges cracks, and spalling of concrete, and previous repairs were found to generally have failed. The research proposed and applied a series of actions that included a patch repair, sectional casting, and reinforcement replacement; however, it is affirmed that regular monitoring and occasional maintenance will be required.

Recently, Rakotovao Ravahatra et al. [

114], focused on a procedure to help infrastructure managers in the process of selecting appropriate models for predicting corrosion by combining the costs of input parameters, their relative importance, and the benefits brought through obtaining parameters, and the maintenance strategy of the manager.

5.3. Sustainable Maintenance

In general, many studies have been conducted on infrastructure maintenance systems that have been focused on life-cycle cost minimization only and the solution does not necessarily result in satisfactory long-term structural performance [

97,

126]. To achieve an appropriate solution, the economic evaluation is usually integrated with structural performance measures such as reliability, redundancy, and risks [

127,

128]. However, few works can be found in maintenance strategies specifically focusing on sustainable development [

13,

97].

Researchers such as Losada and Benedicto [

129], analyzed the limit state in terms of failure probability for marine structures considering not only economic but also social and environmental consequence indicators. The study gives recommendations for values of a structure’s minimum useful life, joint probability of failure against the principal failure modes, ascribed to ultimate and serviceability limit states, minimum operationality, average number of admissible technical breakdowns, and maximum allowed duration of a stoppage mode.

Årskog, Fossdal, and Gjørv [

130], present a methodology for quantifying the ecological effects and impacts of various methods and systems for repairs and maintenance of concrete structures, including materials and energy consumption, waste generation, emission to the environment, and health risk. Similar research was presented by Bastidas-Arteaga and Schoefs [

13], where a methodology is proposed for evaluating, comparing, and/or improving the sustainability of maintenance strategies based on probabilistic modeling of deterioration and repair, and the sustainability assessment considering cost,

emissions and waste generation.

Zhang et al. [

97], considered the environmental loss on developed a reliable structural deterioration model using a randomized Markov chain model to analyze port infrastructure and used a utility function to find the optimal maintenance strategy considering the cost due to retrofitting, operation loss, and environmental impact. More recently, Truong et al. [

131], evaluated different maintenance strategies in terms of durability, cost and environmental impact. The research analyzed the cover replacement technique for square cross-section RC columns exposed to chloride-induced corrosion and determined that circular repairs achieve higher cost-effectiveness and sustainability results.

In general, stakeholders of coastal structures are interested in the current state of their structures, their capacities and service life. Hence, the thorough analysis of maintenance becomes a fundamental and indispensable component within the broader scope of corrosion analysis in RC ports. A large number of maintenance analyses of concrete structures exposed to corrosion have been proposed around the world. This highlights the concern that disruptions or collapses in structures such as ports represent a major economic, social, and ecological risk.

6. The Influence of Field Testing and Monitoring Corrosion

6.1. Relevance

Visual inspection allows the assessment and identification of the degradation status of a structure. These inspections may identify corroded areas and could generate information about the cause and extension, but provide information after corrosion initiation and heavily depend on the inspector’s experience [

132]. Therefore, preventive maintenance should not be planned only with visual inspection. A monitoring plan must be presented in parallel to provide more precise information about the phenomena.

Therefore, quantifying the condition of the structure from in-situ measured data is requisite for optimal asset management [

16]. For that reason, monitoring and field tests are the key pieces that provide information on the current situation of the structure. The location, frequency, and type of monitoring and testing can influence the understanding of deterioration. Lecieux et al. [

17] found that monitoring is largely devoted to controlling behavior concentrated on forces, strain, and displacement measurements, and very rarely to the identification of parameters. Additionally, they mentioned that the research in the material properties area has been focusing on soil-structure interaction or partially on the effect of the environment on concrete properties [

18,

19].

6.2. Monitoring Systems

Monitoring systems, commonly called health monitoring systems, are a set of embedded sensors generally installed during construction or after repair maintenance to record information about specific characteristics of the structure. For long-term deterioration of RC structures due to corrosion, the embedded sensors emphasize on measuring two factors:

Environmental factors: Temperature, pH, water content, and oxygen transport.

Corrosion factors: Polarization resistance, Galvanic current, concrete resistivity and open circuit potential.

Environmental factors, as described in Chapter 3, are key to determining corrosion and its rate. Corrosion factors are based on the identification of electrochemical variations of reinforcement and concrete during the development of corrosion. Figueira [

132], recently presented a review of the different types of electrochemical sensors. The study concluded that corrosion monitoring systems should not be seen as a generic procedure but focused on structures located in particularly aggressive environments; in structural elements that are difficult to access; in structures where damage has already been detected; or in structures that have been repaired and is of interest to follow the performance of the repair.

Martínez & Andrade [

133], evidence more than a decade ago the difficulty for the correct interpretation of sensor data due to external factors such as temperature and moisture that influence the deterioration process. The authors provided examples of corrosion monitoring using three types of electrochemical sensors: corrosion potential sensors, electrical resistance sensors, and corrosion rate sensors. These three techniques, often used in combination, focus on analyzing the electrical disturbances of electrodes embedded in the concrete. In the same year, Pereira et al. [

134], developed a system for permanent evaluation of the performance of repair mechanisms in the field. Later, Rincon et al. [

113], used the data from this system to establish the long-term degradation of a structure located in a marine environment. The study evidenced that the loss of information from these systems can affect long-term predictions and recently presented a methodology for estimating the missing data from the system [

135].

The monitoring of port structures becomes particularly valuable in cases of potentially severe consequences of failure, innovative construction methods, or complex and expensive maintenance. A review within EC COST Action 14021 revealed that monitoring efforts primarily focus on behavior control, such as forces and strain/displacement measurement, with limited emphasis on enhancing structural models or identifying parameters, and a few papers address material properties with a focus on soil-structure interaction or the environment’s impact on concrete properties [

18,

19,

136]. Lecieux et al. [

17], present a structural health monitoring system for a port wharf in Saint-Nazaire, France. The multi-sensor system is designed to measure temperature, strain, and resistivity to detect chloride penetration ions and quantify the risk of corrosion. The results show that a monitoring system could provide useful information as a long-term framework and for validating the quality of the construction.

Andrade & Izquierdo [

137], recently discussed the scarce research on the systematic and statistical treatment of parameters such as degree of saturation or corrosion levels. Therefore, the study presented a preliminary analysis of five bridges, seven marine exposed structures, and one power plant. The authors identified an annual average corrosion rate despite seasonal and daily climate variation; and considered that a detailed analysis of the data could produce a tool for enhancing future designs.

In general, the monitoring sensors and techniques have not varied recently. However, future performance and repairs have led owners and managers of coastal structures to increasingly implement these, which has led to a significant increase in experience with monitoring systems. The major constraints are linked to the durability, sensitivity to electromagnetic interference and stability of the sensors over time [

132]. Problems in system reliability due to environmental factors, durability, or power supply problems can lead to loss of information and generate greater uncertainty in the assessment of corrosion progress [

135].

6.3. Field Testing

The field testing of RC can be performed by destructive and non-destructive techniques (NDT), being the last one widely studied due to its cost-effectiveness and ease of implementation [

138]. In general, destructive methods are limited to sampling, while NDT could provide useful information in space and time about the state of the structure and the corrosion phenomena [

139]. NDT methods use ultrasonic, radiographic, magnetic, electromagnetic, eddy-current, acoustic emission, half-cell potential, and others, to gather different types of information about the structures [

140]. In general, there are three techniques used to evaluate the corrosion condition of a structure:

Overall, corrosion monitoring techniques have not changed in the last 10 years. The most used NDT for analysis of the corrosion process in RC structures is the Wenner Four-Electrode which focuses on the measurement of the electrical resistivity of the concrete cover [

141,

142,

143], and the half-cell potential method [

144]. These electrical-based methods, commonly called concrete resistivity and corrosion potential, are easy to operate for an in-situ test with a simple detection facility but are unable to quantify the corrosion-induced damage [

20].

Another method used ultrasonic waves to estimate the mechanical properties of concrete and was not sufficiently used in the prediction of corrosion level [

145,

146,

147]. Xu & Jin [

20], recently applied ultrasonic-based NDT and ANN to diagnose and predict rebar’s non-uniform corrosion-induced damage within reinforced concrete members. By using this technique to extract the signal information and perform inversion analysis, the data on mechanical properties and defect distribution of materials and structures can be obtained. However, the ultrasonic velocity can vary depending on the water content in the concrete and the results are limited by the data sample size.

Acoustic emission-based is another method for RC corrosion monitoring. Verstrynge et al. [

148], recently performed a review of the protocols for RC corrosion monitoring based on this specific NDT method. The research analyzed the AC method results on accelerated corrosion tests, corroded RC elements under load testing, and on-site testing of RC structures. The authors highlighted the importance of the well-informed use of the technique to avoid erroneous results, the absence of standard procedures, and the need of more studies.

Other studies have focused on the combined use of techniques to provide more reliable information. Oktavianus et al. [

138], proposed a methodology condition assessment of existing critical infrastructure using several types of NDT methods. The authors measured the thickness, air permeability, and electrical resistivity of the concrete cover, on four RC bridges located in coastal areas in Indonesia. The results show first, adequate cover thickness values in the structures, second, that maintenance solution, in this case painting, lower currently the air permeability and, third, low corrosion rates on the structures product of suitable construction procedures.

Schrecker et al. [

125], described the rehabilitation performed on a jetty in the Northern Cape, built in the late 1940s. Ferro-scanning, core samples, NDT, and visual inspection were combined to correctly assess the piles, beams, deck, and surfaces of the jetty. Delamination and extensive cracking were detected in various locations indicating high corrosion-related deterioration and failed repairment processes.

Touil et al. [

70], conducted in-situ tests on a 100-year-old port in Algeria. The results evidence the significant influence of chloride penetration as the main catalyst for the structure’s deterioration after prolonged exposure. A similar result was obtained by Torres Martín et al. [

149], in the analysis of a 22-year-old breakwater’s crow wall. Were chloride concentrations exceeded the critical values given by the regulations up to a depth of 150 mm and advised for an immediate repair and protection of the structure. The authors used several tests which ultrasonic pulse velocity, concrete resistivity, corrosion potential, among others.

Another important factor to consider for the monitoring and testing procedures is the randomness of the results. Schoefs et al. [

16], have addressed the task of characterizing the randomness and spatial variability of material properties, load conditions, or deterioration processes to optimize the number and location of NDT measurements. The results of the methodology reduce the number of samples needed in the example presented, which can help improve the efficiency and accuracy of NDT. However, the study only considered one NDT method to establish water content in the concrete.

On the whole, monitoring and field testing of RC structures has been focusing on behavioral control for structural analysis, leaving parameter identification aside for long-term monitoring. Despite the number of procedures and research regarding the testing, the measurement of RC corrosion using NDT methods is considered limited [

20]. Finally, corrosion monitoring techniques have not changed in the last 10 years but optimization of the number of NDT measures, sensors, multi-sensor systems, and data analysis have been proposed that have added additional value to the data collected.

Table 2 presents the main highlights of the articles mentioned in this chapter.

7. Climate Change and Its Future Consequences

7.1. Relevance

The Paris Agreement attempted to restrict the increase in the Earth’s average temperature to 2°C above pre-industrial levels, to mitigate climate change risks and impacts [

150]. However, there is an 88 percent risk that the average temperature would exceed this threshold, with a 50 percent chance that it will happen between 2035 and 2055 [

151]. Furthermore, there are previous studies that showed that, if the planet’s mean temperature surpasses 2º C, there will be an increase of 27 million people at risk related to climate change [

152].

Climate change is already affecting built environment worldwide [

153]. Nonetheless, awareness of the effects has only recently emerged, particularly concerning the build-up of greenhouse gases caused by the combustion of fossil fuels. The greenhouse effect plays an important role in regulating the world’s temperature, and its principal concern about climate change is its incremental trend. By the year 2100, a 1.5°C global temperature increase is projected to cause a sea level rise between 0.26 and 0.77 meters, and reducing it by 0.1 meters could mitigate exposure risks for up to 10 million people, not factoring in adaptation measures [

154]. These increases promote the elevation of the Earth’s atmosphere and ocean temperature, threatening the existence of many ecosystems. The shrinking cryosphere can negatively impact food security, water resources, health, infrastructure, transportation, tourism, and recreation [

155].

Recently, it has been observed months with prolonged heatwaves, sudden cloudbursts, severe lightning, extensive wildfires, and long drought periods [

156]. However, climate change impacts in a different way each region of the planet. For instance, the Europe forecast shows for northern Europe the largest warming in winter, with an increase in mean and extreme precipitation. Whereas, in the Mediterranean area, with the largest temperatures in summer, the mean precipitation decreases and increases the risk of droughts. Also, in southern Europe, the highest average temperatures will increase especially in summer [

157]. Extreme weather events (e.g. coastal and urban floods) and gradual changes (e.g. temperature, winds, and rainfall variations) are examples of climate change dangers to transportation infrastructure [

158,

159,

160,

161,

162].

7.2. Impact on Port Infrastructure

Ports are essential infrastructure for economic activities that are susceptible to impacts from climate change-driven processes, like sea-level rise, in wave patterns, among others [

163]. Therefore, the maintenance of marine assets is a major economic stake. The challenge of the owners consists of guaranteeing the operation of the aging structures at reasonable costs and availability conditions [

9,

164].

Ports are on the front lines of climate change due to their location on coasts that are vulnerable to sea-level rise and storms, or on rivers that are prone to flooding and drought. As a result, ports provide an enthralling example of the dangers posed by climate change [

165].

The effects of climate change will be diverse. Bastidas-Arteaga [

166], divided the influence of climate change on infrastructure into three axes involving two types of events:

Extreme events: changes in intensity and frequency

Progressive events: changes in the kinetics of deterioration rates

Combination of effects on extreme events and progressive deterioration

The most visibly apparent challenge port authorities experienced during natural disasters was dealing with damaged infrastructure, due to extreme events. However, progressive deterioration may have a larger impact in the long term. Lenton, Foottit, and Dlugoglecki [

6] showed that a basis scenario of a sea-level rise of 0.5 m by 2050 may make the value of exposed assets in 136 port megacities account for USD 28 trillion. Therefore, studies such as Becker et al. [

167], evaluated port administrators’ knowledge, attitudes, and planning activities to analyze the effects of climate change on international seaports. The research showed that capital planning at port typically 5 to 10 years making it very difficult to address the complex issue of climate change. The authors concluded that the world port community is very concerned with the impact of climate change but the lack of specific information from the scientific community makes it challenging to make good decisions.

Sierra et al. [

163], focused on the risk level and productivity of ports due to the changes in the wave agitation in the port of Barcelona. The study considered the RCP8.5 scenario to estimate changes in the wave fields and sea level rise and the results suggested a minimal variation in the trend and agitation. However, the rise in the sea level will increase the water deep and penetration of waves within the harbor, leading to a reduction in port operability.

Another aspect often overlooked by the infrastructure administrators is the variation of ocean chemistry due to climate change. A research on the effects of the acidification of sea on marine organism, determined that the ocean acidification due to the absorption of the carbon dioxide emitted by human activities has reduced the pH by 0.47 units since the pre-industrial period [

168,

169]. These chemical process also influences the ionic composition of seawater by changing the organic and inorganic speciation of trace metals with changes expected to have impacts although they are currently poorly documented and understood [

170]. Hunting et al. [

171], determined a clear correlation between climate change, the increase in salinity, and the rate at which chloride ingress occurs in RC on Australian Seaport Infrastructure. The results suggest that faster corrosion initiation and more frequent operational downtime will affect the stakeholders in the future. A similar conclusion was obtained by Bastidas-Arteaga et al. [

54], where the authors highlighted the necessity of the implementation of countermeasures to minimize the impact of climate change on RC structures.

Bastidas-Arteaga and Stewart [

27], performed deeper research by analyzing the adaption of existing RC structures built in different years considering different durability standards and construction codes. The study focused on two different types of climates on the coast of France but only considered two types of concrete cover thickness as possible adaptation strategies. The benefit-cost ratio proposed by the authors demonstrates the framework’s adequacy in evaluating the cost-effectiveness of climate adaptation strategies and could be extended to other adaptation approaches but not address the potential social or environmental impacts of the adaptation strategies. The same authors [

172], also analyzed the risk and main potential of climate change effects and the consequences in terms of cost and vulnerability. The review evident the increasing human vulnerability to climate change and stated that worldwide income and GDP would be significantly reduced if mitigation or adaptation measures are not implemented.

Focusing on policymakers, Nogal, Bastidas-Arteaga, and dos Santos Gervásio [

173] discuss the potential strategies to be addressed by structural codes to tackle the problem of climate change-induced corrosion. The document focused on the process of standardization of adaptation measures in future generations of Eurocodes and highlighted the uncertainty related to climate change as the main challenge.

In conclusion, the studies mentioned emphasize the expected effects of climate change on the infrastructure and its influences becoming more evident and extreme, increasing the pressure on authorities to ensure the resilience of the assets. However, research efforts in this area have focused principally on the impact of climate change on adaptation measurement for extreme events or bridge infrastructures and findings suggest that, while through different angles research has highlighted the importance of barriers to climate change in the adaptation measurement, it is still in the inception stage [

174].

Table 3 presents the main highlights of the articles mentioned in this chapter.

8. Discussion and Conclusions

The present review portrays an analysis of the state of the art in the field of degradation models and maintenance of port and coastal infrastructures. The potentially disastrous implications for society of port infrastructure failure due to poor maintenance can be significant. It is important to remember that a port disruption might result in not just a loss at the port, but also a complete shutdown of the supply chain [

175]. In general, most port infrastructure assets must be used for an extended period and structural deterioration can occur at any point during this lifespan. For this reason, degradation models represent a significant role in the forecast of the long-term performance of the asset and the deterioration process. Some authors emphasized that slightly attention has been devoted to the research on the modeling of the deterioration process for port infrastructures, and more effort is demanded to further understand this research topic [

97].

Corrosion of reinforcing steel is a major problem for concrete structures, particularly those exposed to a chloride environment [

38], and coastal RC structures will be affected by chloride ingress, resulting in the decline of capacity [

88]. Numerous research indicated that different corrosion patterns cause variable corrosion rates and compositions of corrosion products [

35]. Despite decades of laboratory and field research, the influence of different zones in the marine environment on chloride-induced corrosion mechanisms and the subsequent possible structural damage has not been understood thoroughly [

23].

Experimental evidence indicates that chloride ingress is highly influenced by the weather conditions in the surrounding environment [

34]. Bastidas-Arteaga et al. [

176], found that the time-variant nature of humidity and temperature has a significant influence on the corrosion initiation process. Therefore, the several possible variations in the environment due to climate change will have an important impact on structural reliability and should be considered in design and maintenance processes. While research efforts have focused principally on the impact of climate change on adaptation measurement for extreme events or bridge infrastructures, the adaptation measurement for long-term events is still in the inception stage [

174].

Field tests and monitoring is the other fundamental piece that provides information to understand the deterioration of a structure. However, monitoring is principally focused on control behavior (forces, strains, and displacements), and very rarely on the identification of key corrosion/durability indicators [

17]. The number of procedures and research regarding the field testing and measurement of RC corrosion using NDT methods is considered limited and has not changed in the last 10 years [

20]. Lately, research efforts have focused on the optimization of the number of sensors, multi-sensor systems, and data analysis that have added additional value to the data collected.

Currently, several structures are being evaluated for possible repair and continue in service despite their deteriorated condition due to the economically unfeasible that implies their replacement [

96]. In addition, port infrastructure is typically located along coastlines, demanding constant repairs and retrofit works [

97]. These structures are exposed to harsh environmental conditions that accelerate the deterioration mechanism. Therefore, the is a need for managers and owners to implement effective and economic maintenance planning and should consider the variability and uncertainties present in both deterioration processes and maintenance actions. Being the properties of materials, the environmental conditions, and the effectiveness of inspection and repair actions, the main sources of uncertainty [

96]. Due to the need to establish maintenance schedules that preserve/extend the structure’s lifespans in scenarios where multiple constraints are imposed by economic, social, and environmental considerations to optimize resources and decrease the impact, researchers consider that there is a gap in assessing the port infrastructure maintenance problem from a sustainable point of view [

97].

Author Contributions

Conceptualization, L. F. Rincon; methodology, L. F. Rincon; validation, L. F. Rincon and E. Bastidas-Arteaga; formal analysis, L. F. Rincon; investigation, L. F. Rincon; data curation, L. F. Rincon; writing—original draft preparation, L. F. Rincon; writing—review and editing, L. F. Rincon, E. Bastidas-Arteaga and A. Hamami; visualization, L. F. Rincon.; supervision, Y. M. Moscoso, J. C. Matos, and E. Bastidas-Arteaga; project administration, J.C. Matos and E. Bastidas-Arteaga; funding acquisition, J. C. Matos, Y. M. Moscoso and E. Bastidas-Arteaga. All authors have read and agreed to the published version of the manuscript.

Funding

This work is financed by national funds through FCT - Foundation for Science and Technology, under grant agreement 2021.05862.BD attributed to the first author.

Data Availability Statement

No new data were created or analyzed in this study. Data sharing is not applicable to this article.

Acknowledgments

This work is financed by national funds through FCT - Foundation for Science and Technology, under grant agreement 2021.05862.BD attributed to the first author. This work was partly financed by FCT / MCTES through national funds (PIDDAC) under the R&D Unit Institute for Sustainability and Innovation in Structural Engineering (ISISE), under reference UIDB / 04029/2020 (doi.org/10.54499/UIDB/04029/2020), and under the Associate Laboratory Advanced Production and Intelligent Systems ARISE under reference LA/P/0112/2020.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Alcaraz, C.; Zeadally, S. Critical Infrastructure Protection: Requirements and Challenges for the 21st Century. Int. J. Crit. Infrastruct. Prot. 2015, 8, 53–66. [Google Scholar] [CrossRef]

- Yang, Z.; Barroca, B.; Laffréchine, K.; Weppe, A.; Bony-Dandrieux, A.; Daclin, N. A Multi-Criteria Framework for Critical Infrastructure Systems Resilience. Int. J. Crit. Infrastruct. Prot. 2023, 42, 100616. [Google Scholar] [CrossRef]

- Imounga, H.M.; Bastidas-Arteaga, E.; Moutou Pitti, R.; Ekomy Ango, S.; Wang, X.-H. Bayesian Assessment of the Effects of Cyclic Loads on the Chloride Ingress Process into Reinforced Concrete. Appl. Sci. 2020, 10, 2040. [Google Scholar] [CrossRef]

- Fang, C.; Lundgren, K.; Chen, L.; Zhu, C. Corrosion Influence on Bond in Reinforced Concrete. Cem. Concr. Res. 2004, 34, 2159–2167. [Google Scholar] [CrossRef]

- Pommersheim, J.; Clifton, J. Prediction of Concrete Service-Life. Mater. Struct. 1985, 18, 21–30. [Google Scholar] [CrossRef]

- Lenton, T.M.; Foottit, A.; Dlugoglecki, A. Major Tipping Points in the Earth’s Climate System and Consequences for the Insurance Sector; 2009.

- Shen, X. han; Jiang, W. qiang; Hou, D.; Hu, Z.; Yang, J.; Liu, Q. feng Numerical Study of Carbonation and Its Effect on Chloride Binding in Concrete. Cem. Concr. Compos. 2019, 104, 103402. [Google Scholar] [CrossRef]

- Shen, X.; Liu, Q.; Hu, Z.; Jiang, W.; Lin, X.; Hou, D.; Hao, P. Combine Ingress of Chloride and Carbonation in Marine-Exposed Concrete under Unsaturated Environment: A Numerical Study. Ocean Eng. 2019, 189, 106350. [Google Scholar] [CrossRef]

- AIPCN Implementation Manual for Life Cycle Management of Port Structures; 2008.

- Permanent Technical Committee II. Working Group 31 Life Cycle Management of Port Structures: General Principles; 1998.

- Boero, J.; Schoefs, F.; Capra, B.; Rouxel, N. Technical Management of French Harbour Structures - Part 1: Description of Built Assets. Rev. Paralia 2009, 2, 6.1–6.11. [Google Scholar] [CrossRef]

- Pereira, D.D. Lifetime Evaluation of Maritime Structures: Application to the Bridge Pier at the Leixões Seaport (In Portugueses), Universidade do Minho, 2017.

- Bastidas-Arteaga, E.; Schoefs, F. Sustainable Maintenance and Repair of RC Coastal Structures. Proc. Inst. Civ. Eng. Eng. 2015, 168, 162–173. [Google Scholar] [CrossRef]

- Denysiuk, R.; Fernandes, J.; Matos, J.C.; Neves, L.C.; Berardinelli, U. A Computational Framework for Infrastructure Asset Maintenance Scheduling. Struct. Eng. Int. 2016, 26, 94–102. [Google Scholar] [CrossRef]

- Falamarzi, A.; Moridpour, S.; Nazem, M. A Review of Rail Track Degradation Prediction Models. Aust. J. Civ. Eng. 2019, 17, 152–166. [Google Scholar] [CrossRef]

- Schoefs, F.; Bastidas-Arteaga, E.; Tran, T.V.; Villain, G.; Derobert, X. Characterization of Random Fields from NDT Measurements: A Two Stages Procedure. Eng. Struct. 2016, 111, 312–322. [Google Scholar] [CrossRef]

- Lecieux, Y.; Rozière, E.; Gaillard, V.; Lupi, C.; Leduc, D.; Priou, J.; Guyard, R.; Chevreuil, M.; Schoefs, F. Monitoring of a Reinforced Concrete Wharf Using Structural Health Monitoring System and Material Testing. J. Mar. Sci. Eng. 2019, 7, 84. [Google Scholar] [CrossRef]

- Del Grosso, A.; Lanata, F.; Brunetti, G.; Pieracci, A. Structural Health Monitoring of Harbour Piers. In Proceedings of the 3rd International Conference on Structural Health Monitoring of Intelligent Infrastructure, Vancouver, Canada; 2007. [Google Scholar]

- Finno, R.J.; Roboski, J.F. Three-Dimensional Responses of a Tied-Back Excavation through Clay. J. Geotech. Geoenvironmental Eng. 2005, 131, 273–282. [Google Scholar] [CrossRef]

- Xu, Y.; Jin, R. Measurement of Reinforcement Corrosion in Concrete Adopting Ultrasonic Tests and Artificial Neural Network. Constr. Build. Mater. 2018, 177, 125–133. [Google Scholar] [CrossRef]

- Naito, C.; Fox, J.; Bocchini, P.; Khazaali, M. Chloride Migration Characteristics and Reliability of Reinforced Concrete Highway Structures in Pennsylvania. Constr. Build. Mater. 2020, 231, 117045. [Google Scholar] [CrossRef]

- Klee, H. The Cement Sustainability Initiative: Recycling Concrete. World Bus. Counc. Sustain. Dev. Geneva, Switz. 2009. [Google Scholar]

- Melchers, R.E. Long-Term Durability of Marine Reinforced Concrete Structures. J. Mar. Sci. Eng. 2020, 8, 290. [Google Scholar] [CrossRef]

- Costa, A.; Appleton, J. Case Studies of Concrete Deterioration in a Marine Environment in Portugal. Cem. Concr. Compos. 2002, 24, 169–179. [Google Scholar] [CrossRef]