Submitted:

22 January 2024

Posted:

23 January 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

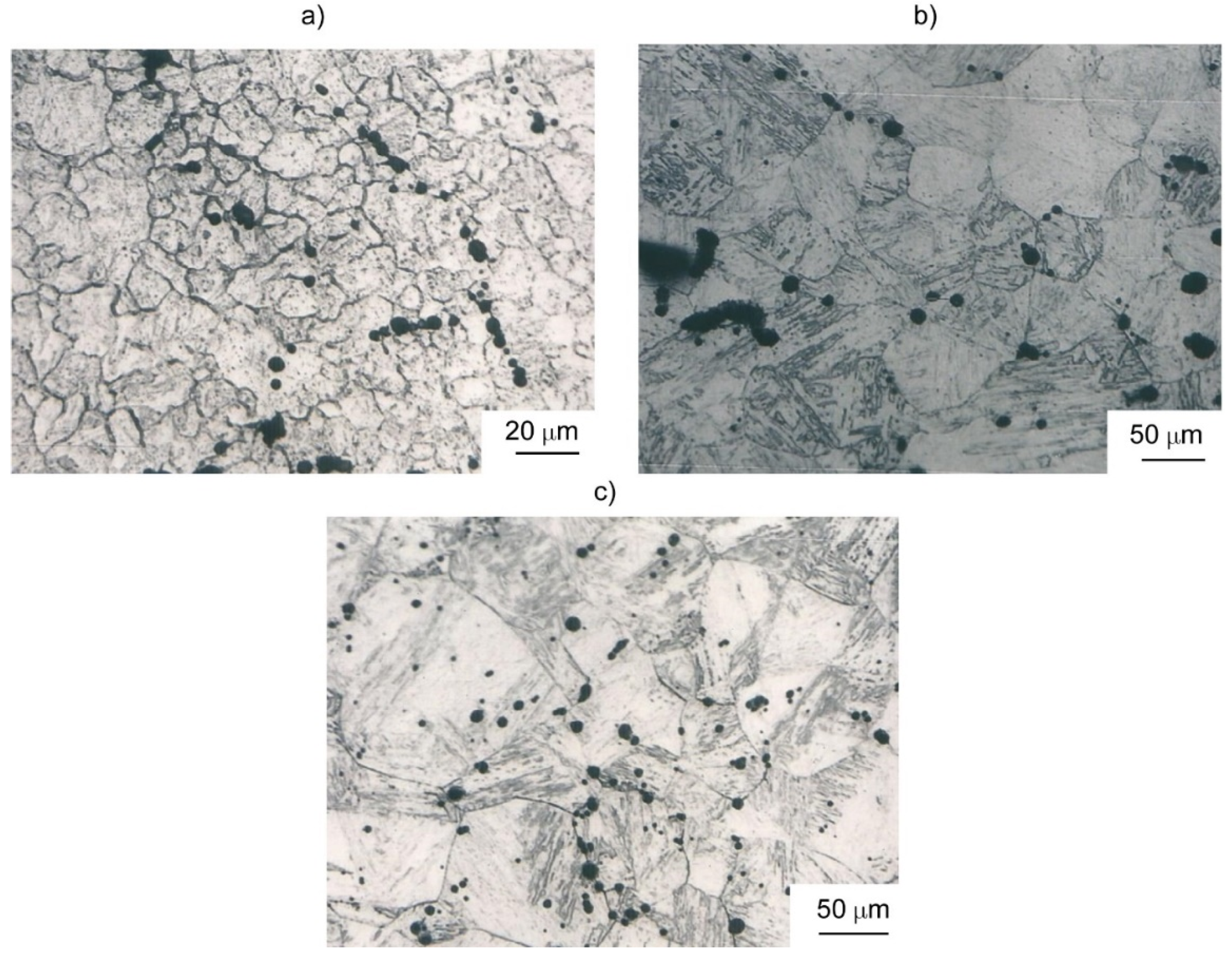

2. Experimental procedure

| Table I.- Chemical composition of the studied. |

| %C %Mn %Si %P %S %V %Ti %Al Nppm |

| 0,29 1,19 0,19 0,012 0,025 0,09 0,002 0,011 131 |

2.1. Experimental data

| Table II.- Experimental data of the experimental yield stress for different temperatures, strains and strain rates Microalloyed steel M-30 | |

| Tº (ºC) | Strain rates() (s-1) |

| 900º | 1E-4, 5E-4, 1E-3, 2E-3, 3E-3, 5E-3, 1E-2, 2E-2, 3E-2, 5E-2,7E-2 |

| 950º | 2E-4, 5E-4, 1E-3, 2E-3, 5E-3, 1E-2, 2E-2, 5E-2, 1E-1, 1, 3 |

| 1000º | 1E-4, 2E-4, 5E-4, 6E-4, 7E-4, 1E-3, 2E-3, 5E-3, 1E-2, 2E-2, 5E-2, 1E-1, 1, 3 |

| 1050º | 1E-4, 5E-4, 1E-3, 5E-3, 1E-2, 2E-2, 5E-2, 1E-1, 1, 3 |

| 1100º | 1E-4, 2E-4, 3E-4, 5E-4, 1E-3, 3E-3, 1E-2, 2E-2, 3E-2, 1E-1, 1,3 |

| 1150º | 1,3 |

3. Neural network model to obtain the processing maps

3.1. Data preparation

| Table III: Experimental data used from M-30 steel for ANN Training and Testing |

| (s-1) Training (M-30) Testing |

| 1E-4 900,1000,1100 ºC 1050 ºC |

| 1E-3 900,1000,1050,1100 ºC 950 ºC |

| 1E-2 900,950,1050,1100 ºC 1000 ºC |

| 1E-1 950,1000,1100 ºC |

| 1 950,1050,1100,1150 ºC 1000 ºC |

| 3 950,1000,1050,1150 ºC 1100 ºC |

| Table IV: Experimental data of the M-30 steel used for the ANN validation |

| (s-1) Validation |

| 3E-3 900 ºC |

| 5E-3 950 ºC |

| 5E-4 950 ºC, 1000 ºC,1050 ºC,1100 ºC |

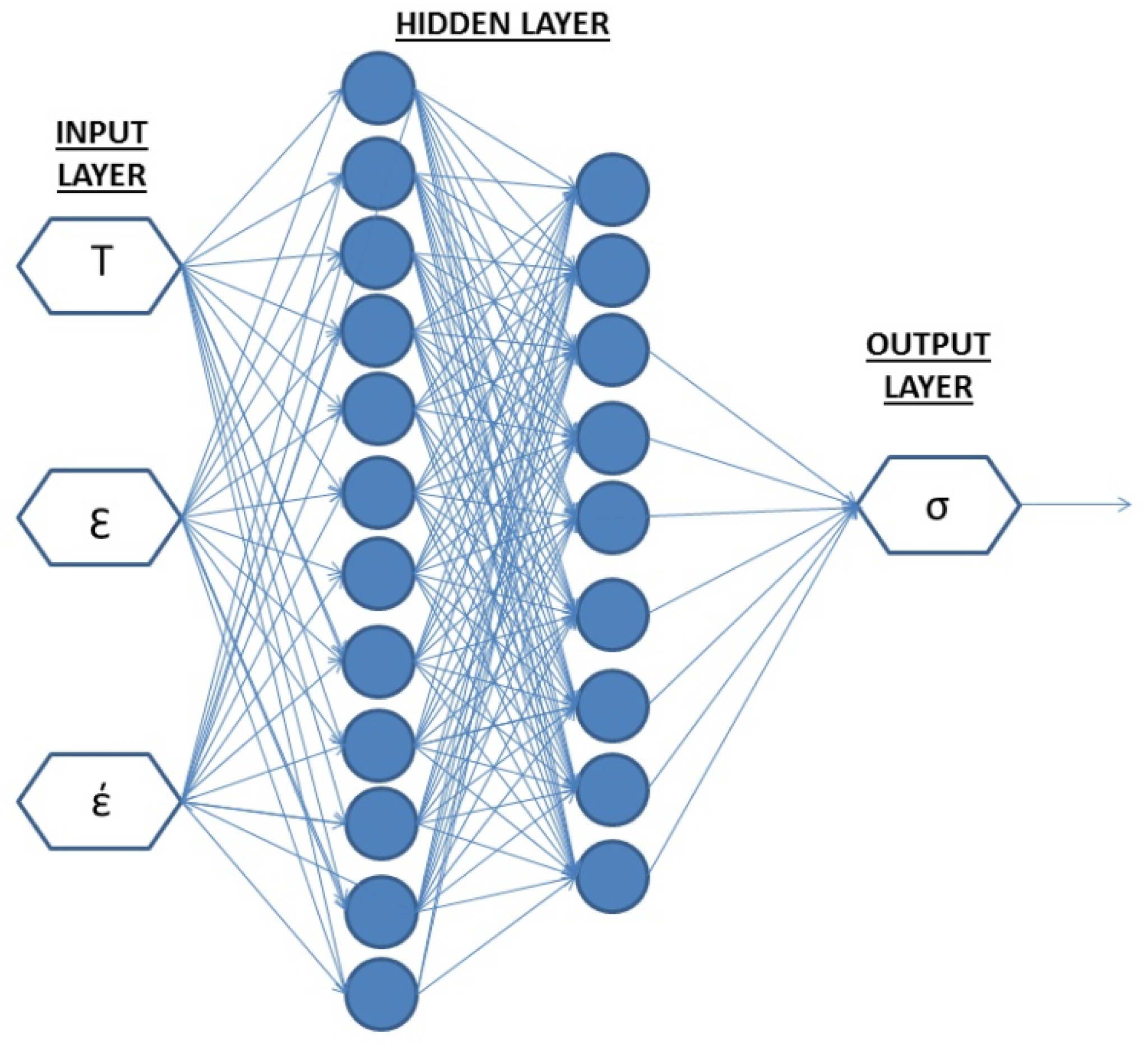

3.2.1. Neural network model

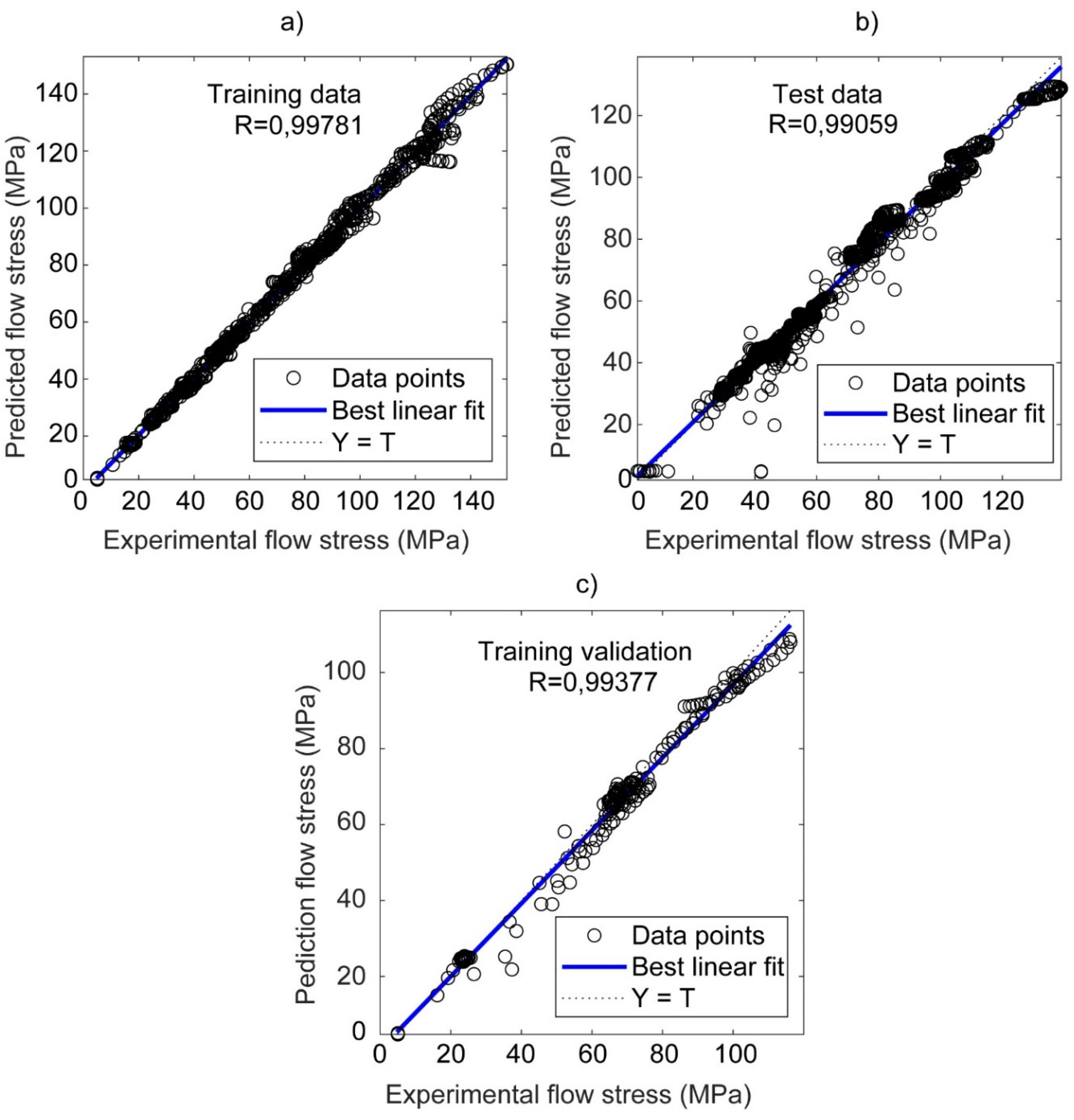

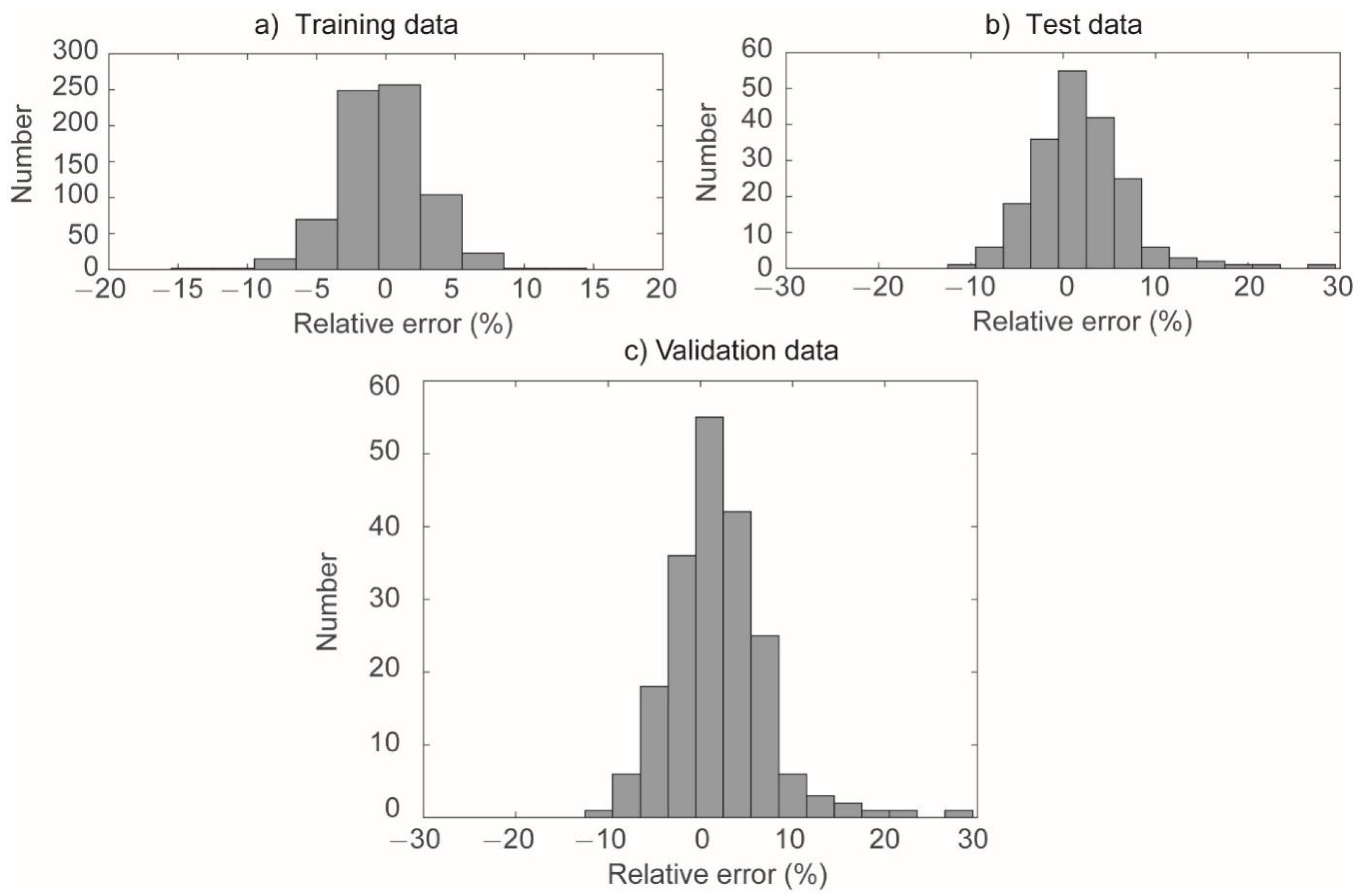

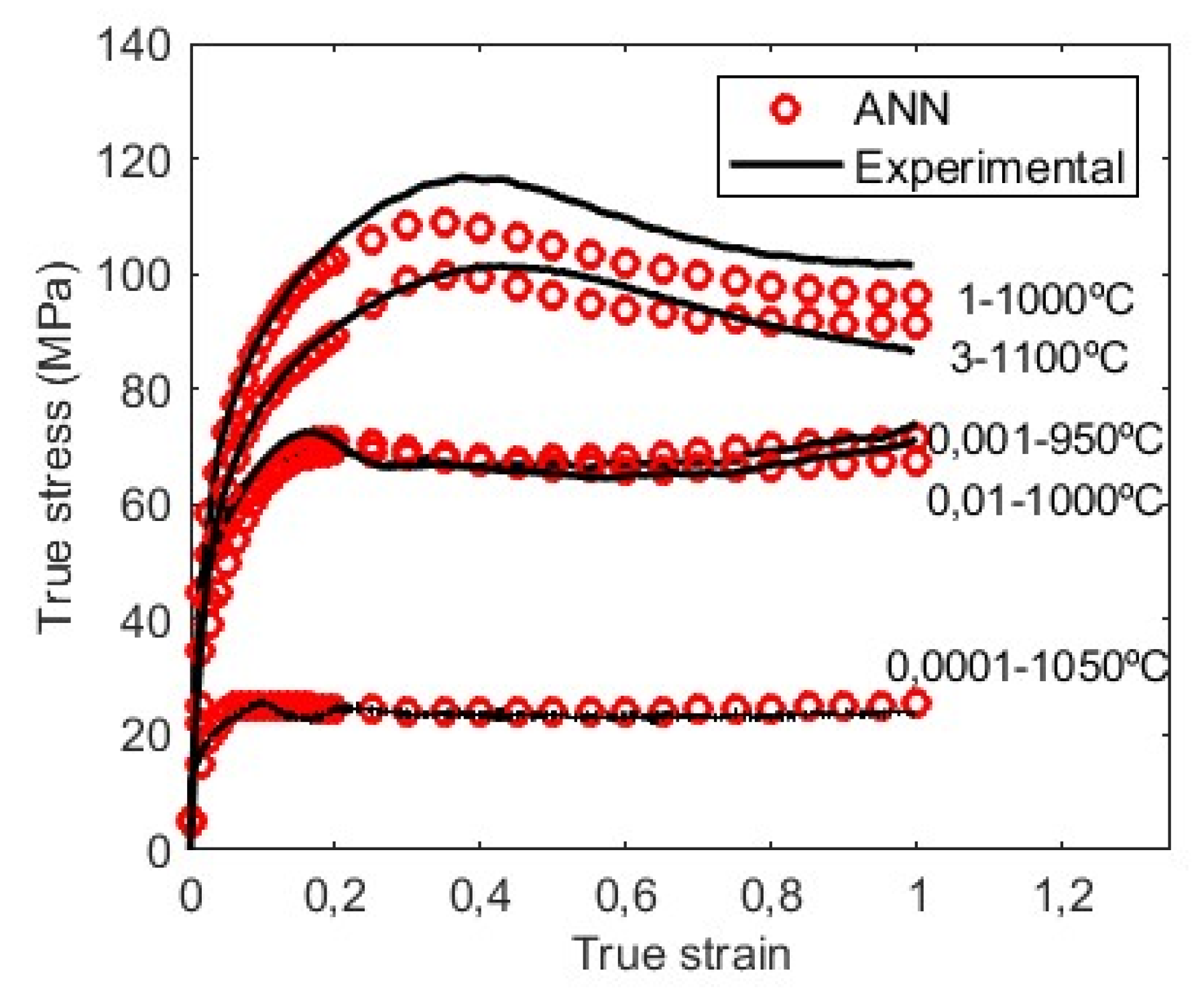

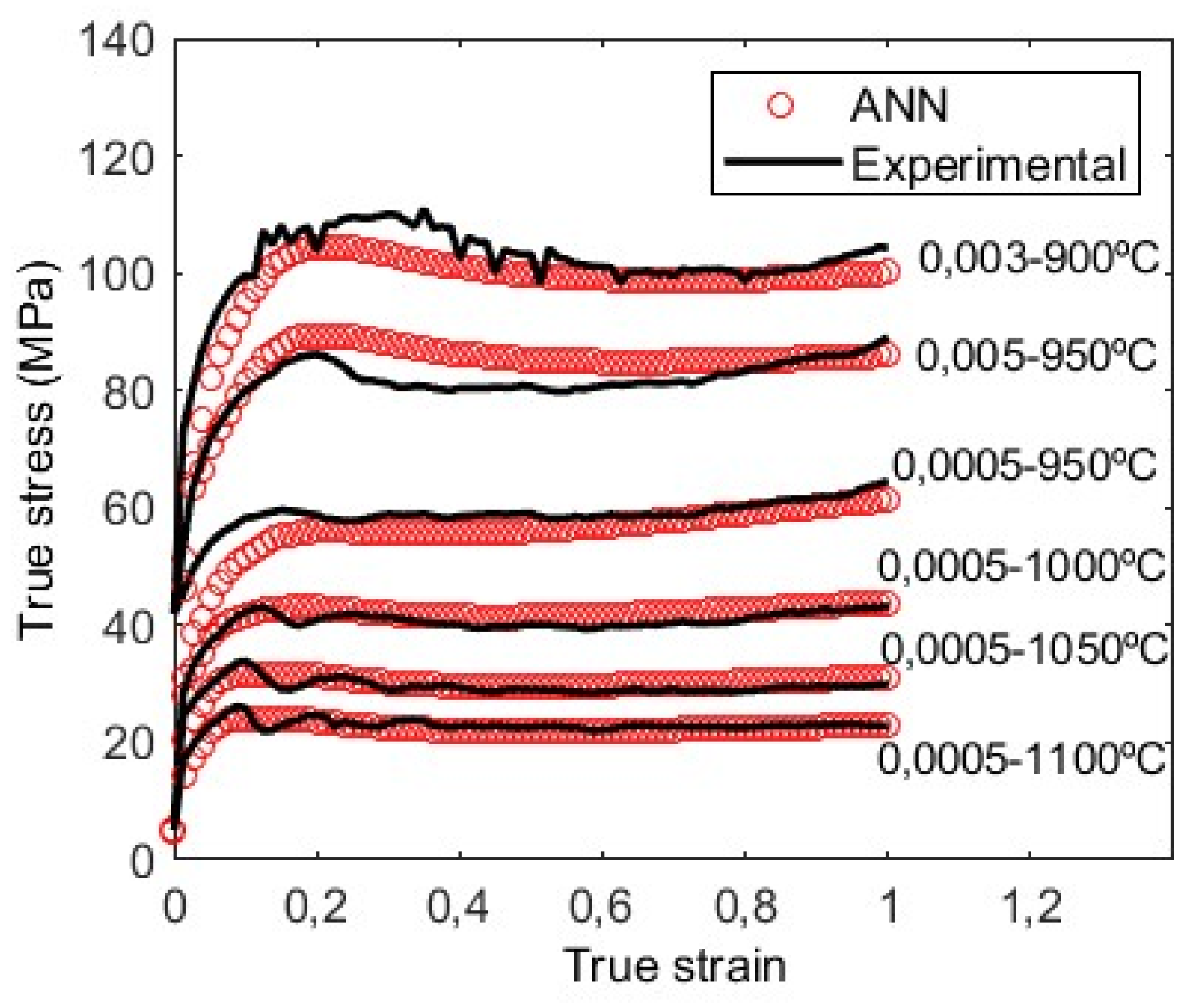

3.2.2. Standard validation of the results of the Neural Network

| Table V: RNA model performance for training, testing and validation |

| R RMSE(%) AARE(%) SI |

| Trainig 0,99781 2,8974 3,5978 0,0007 |

| Test 0,99059 3,5909 4,3209 0,0553 |

| Validation 0,99377 4,1508 4,7632 0,0637 |

3.3. Application of the dynamic model of materials

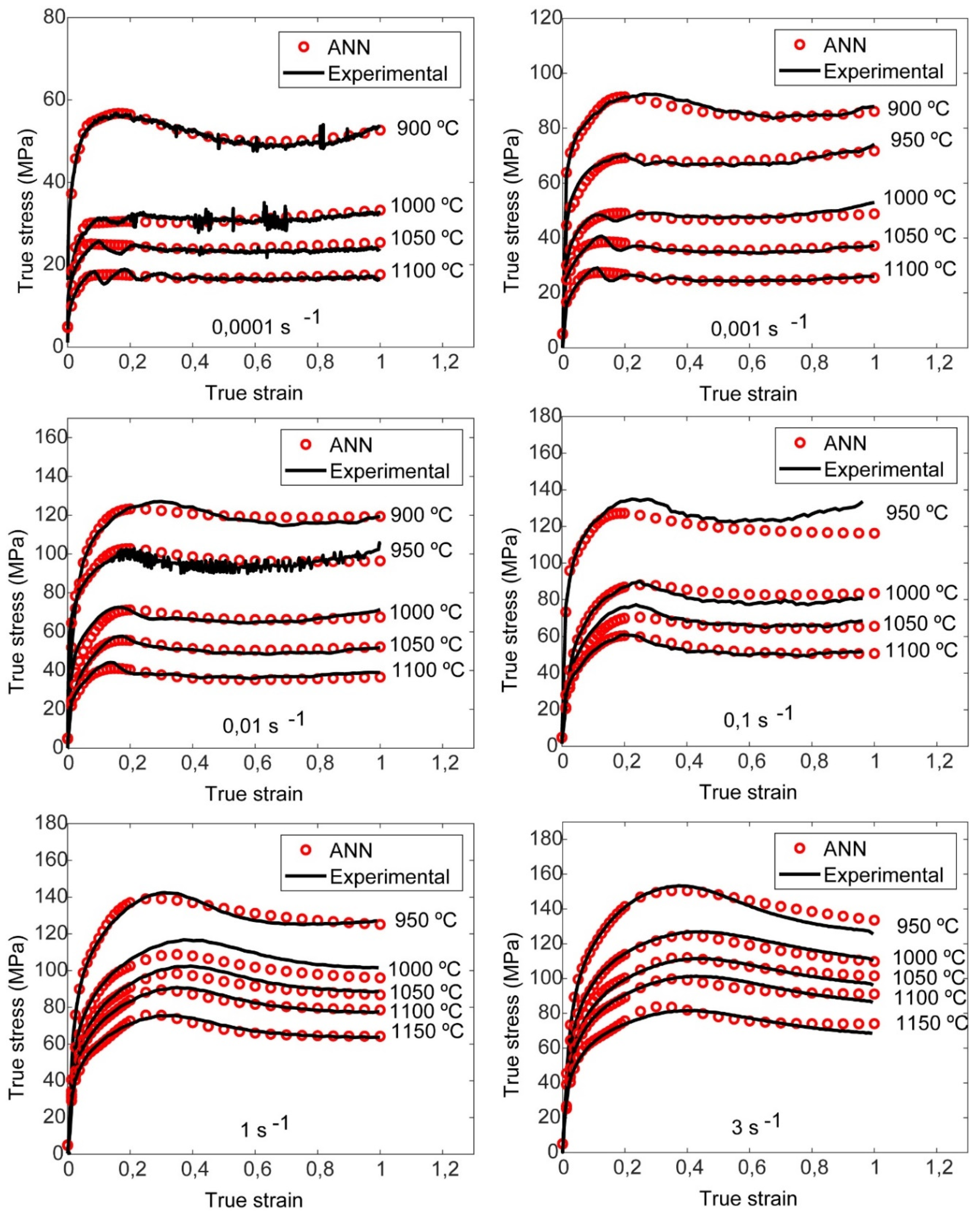

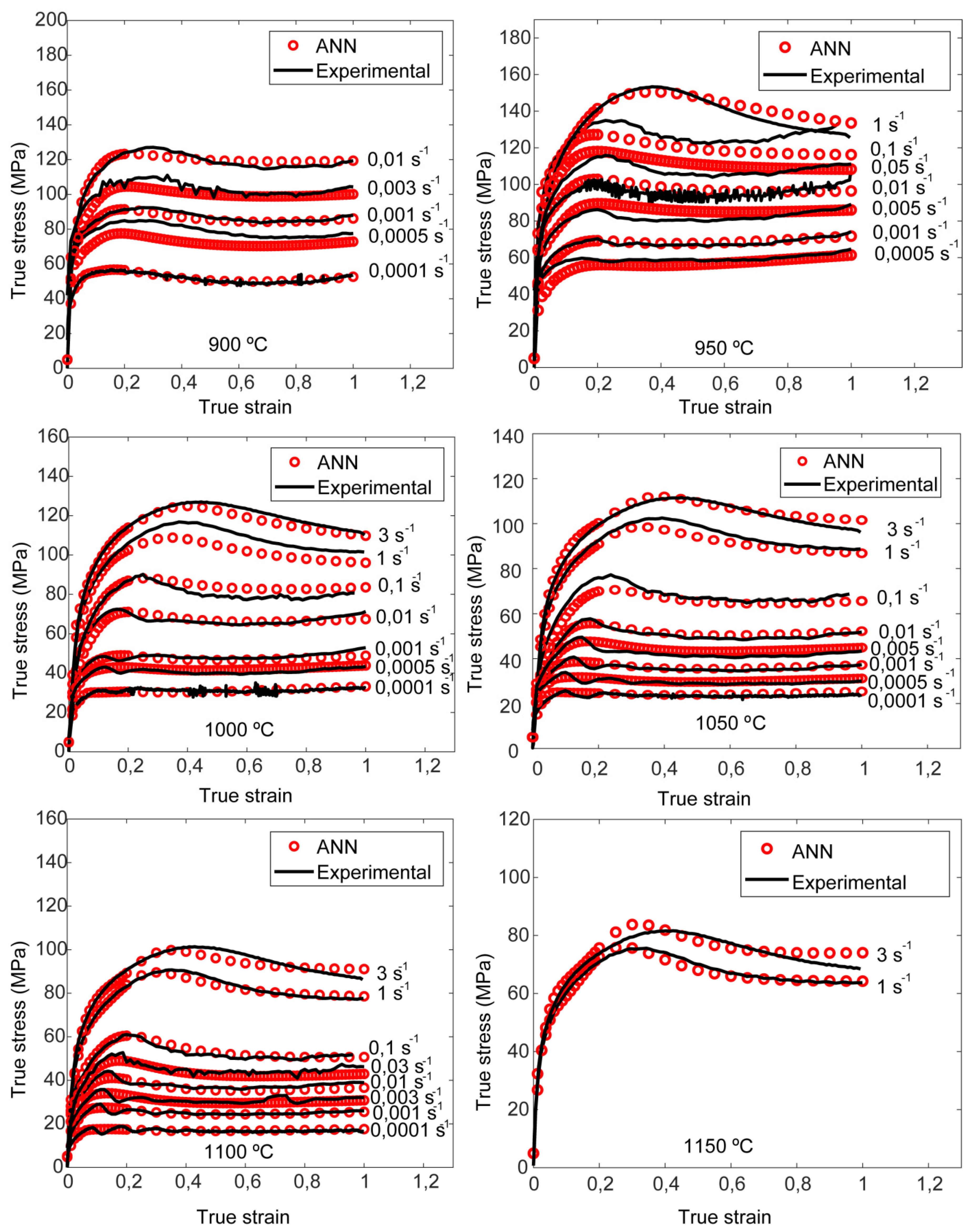

3.3.1. Flow curves

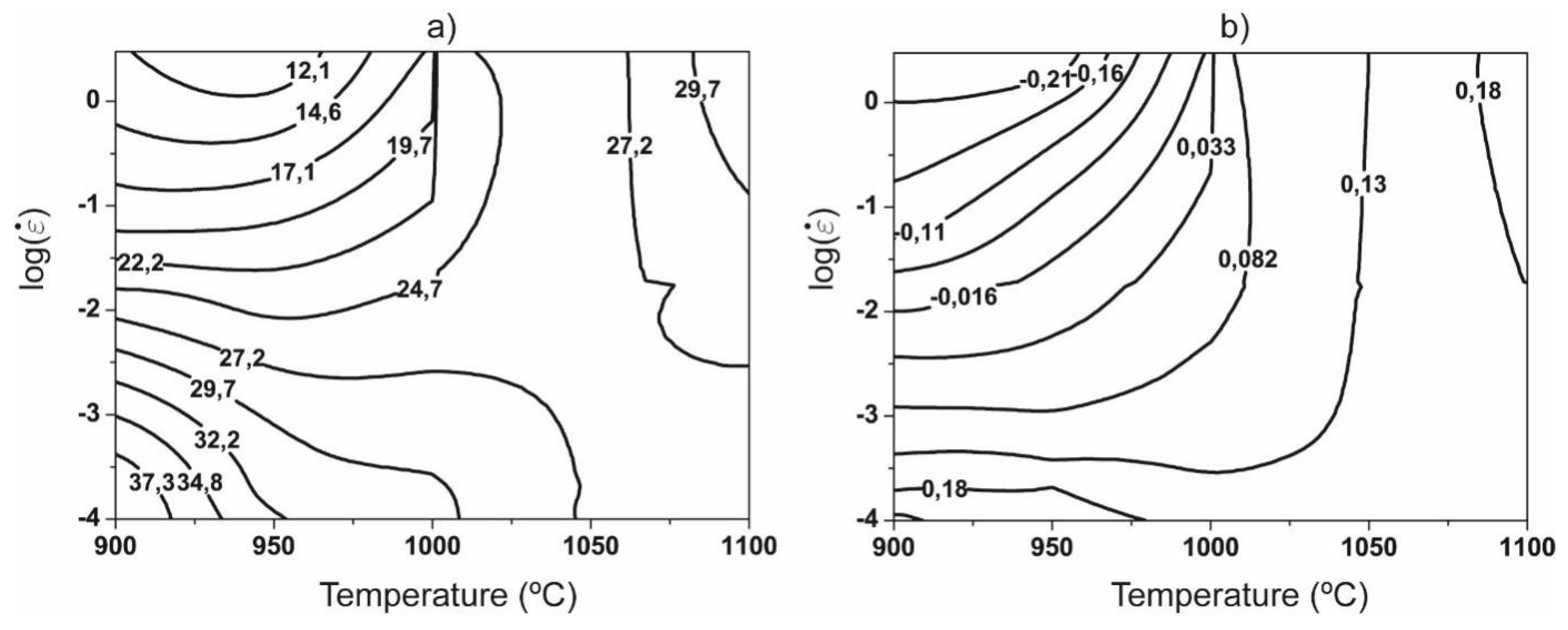

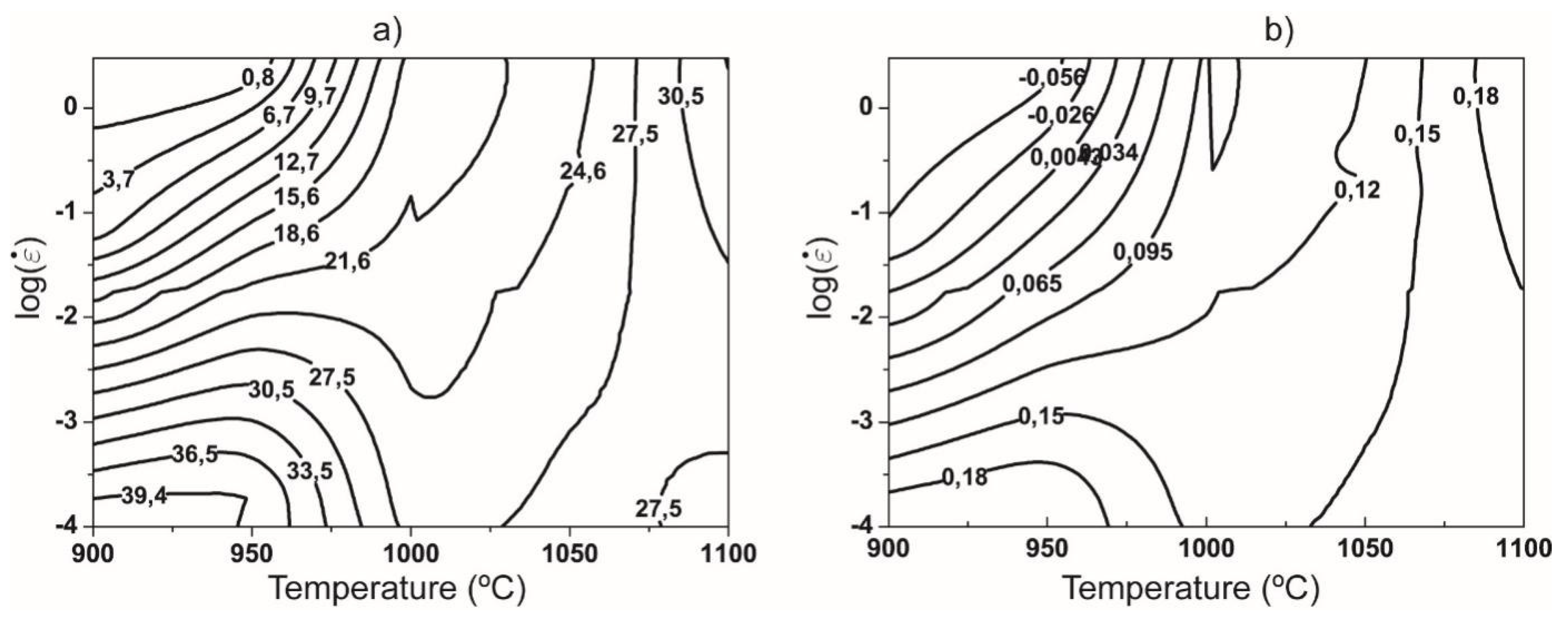

3.3.2. Experimental processing maps obtained by DMM and VDMM

3.4. Application of ANN to develop processing maps

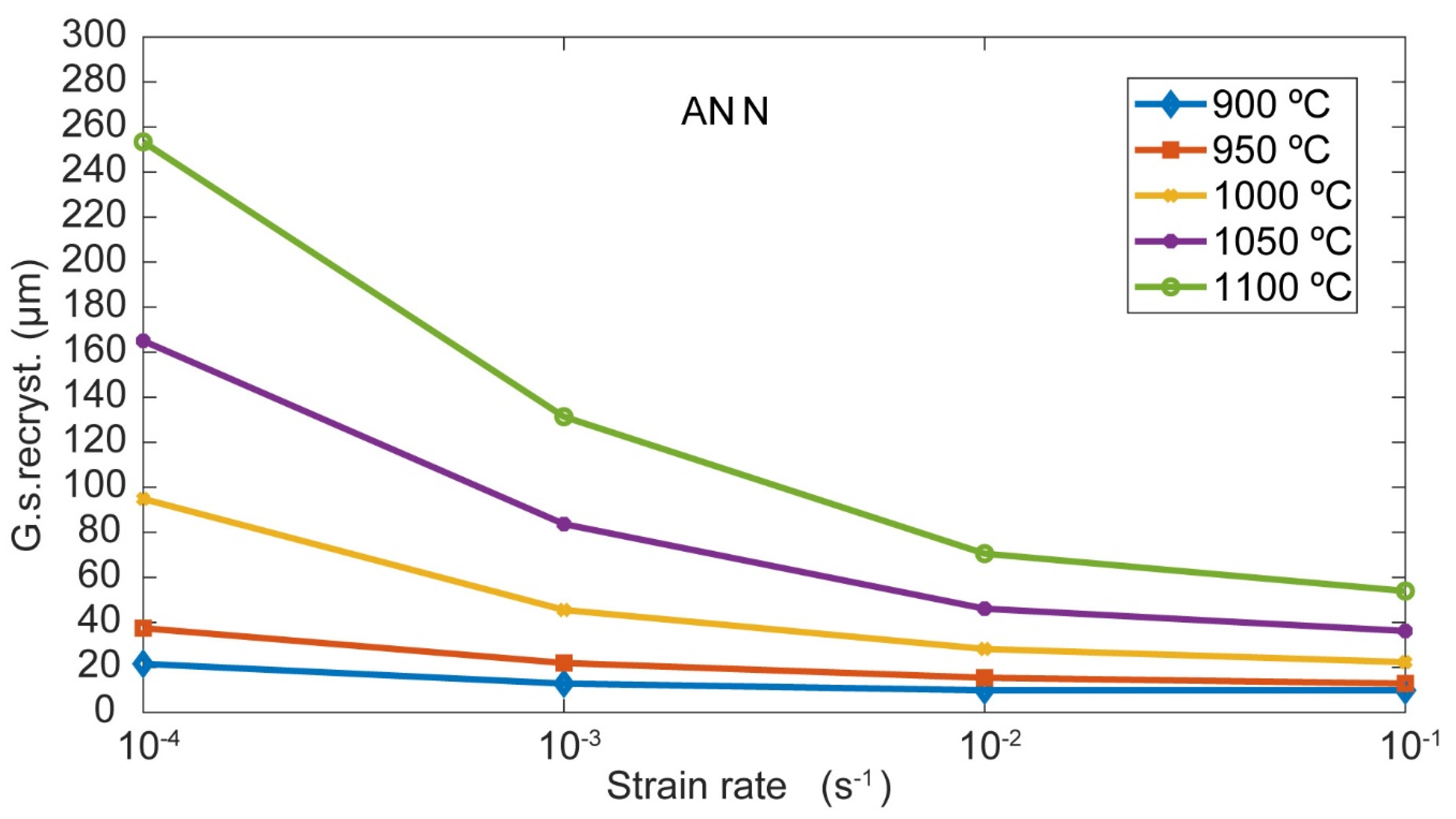

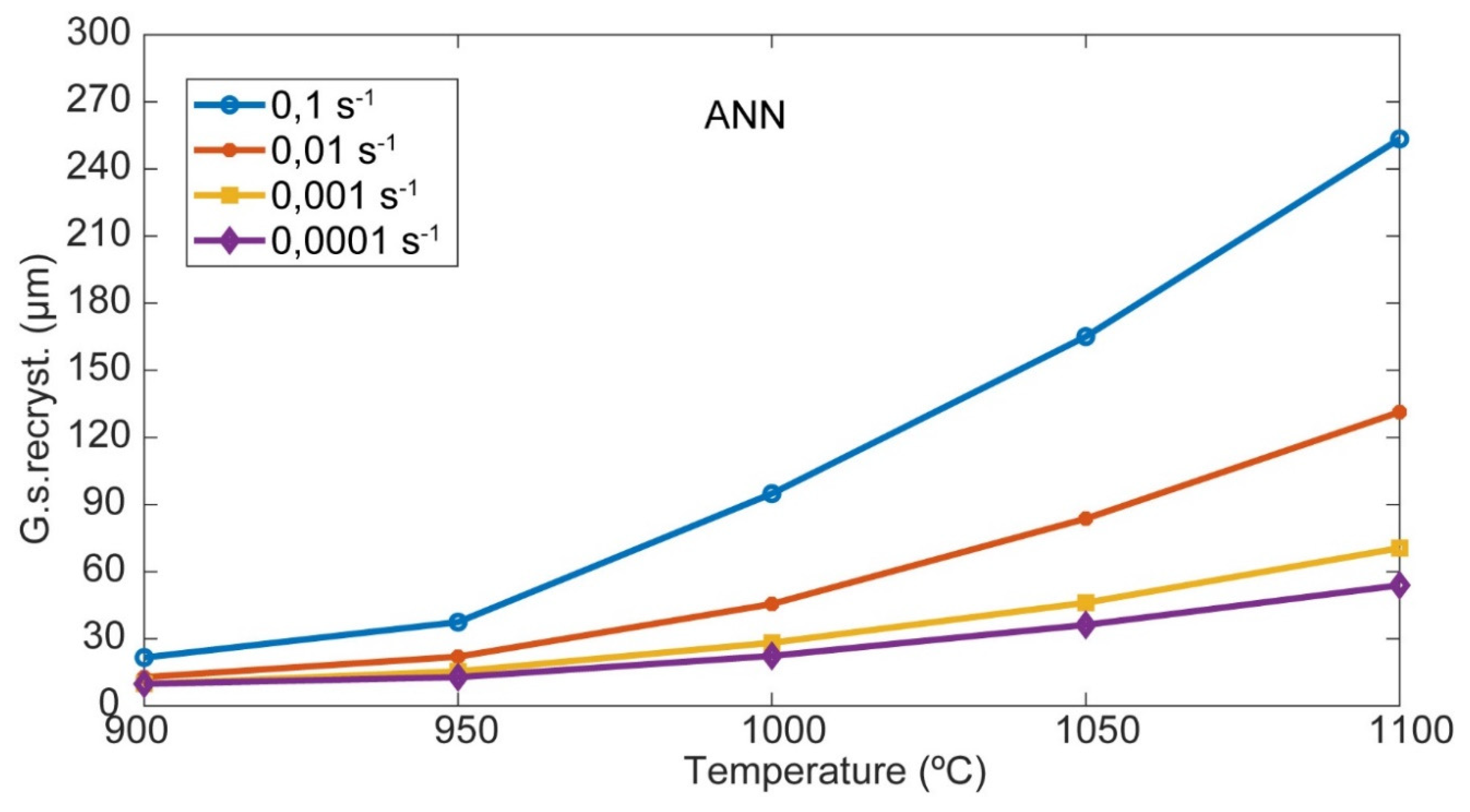

4. RNA to obtain the recrystallized grain size

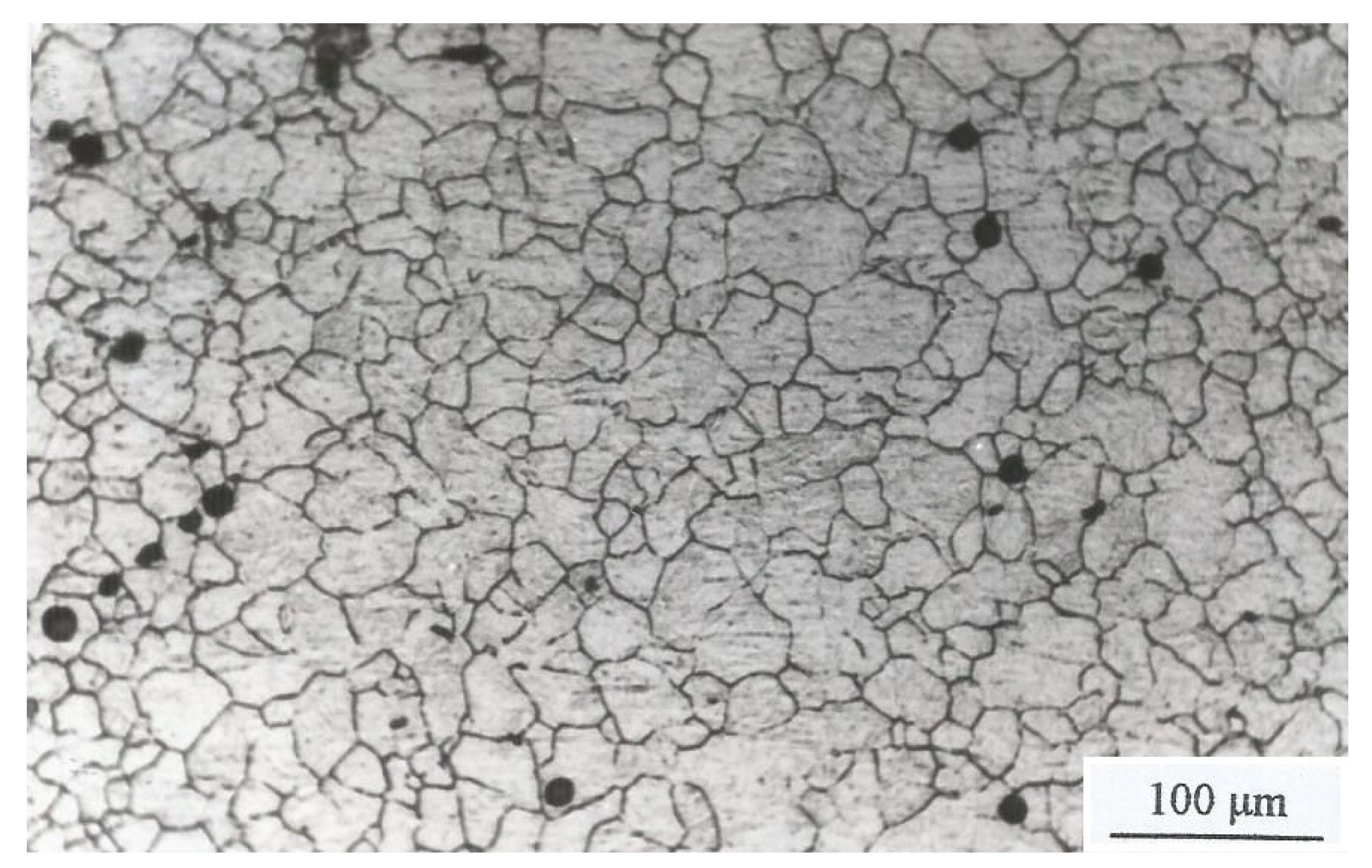

4.1. Experimental data on grain size

| Table VI. Experimental initial and final grain size for different temperatures and strain rates |

| T (ºC) (s-1) GS.INITIAL (μm) GS.FINAL (μm) |

| 900 0,0001 11,12 22,2557 |

| 900 0,0005 11,12 14,81 |

| 900 0,0020 11,12 12,9680 |

| 900 0,0100 11,12 11,3415 |

| 900 0,0500 11,12 9,799 |

| 900 0,3000 11,12 8,3298 |

| 950 0,0002 12,63 33,9160 |

| 950 0,0005 12,63 26,6486 |

| 950 0,0010 12,63 21,0201 |

| 950 0,0050 12,63 16,8403 |

| 950 0,0100 12,63 15,8876 |

| 950 0,0500 12,63 13,967 |

| 950 0,3000 12,63 12,3852 |

| 1000 0,0001 21,1 95 |

| 1000 0,0002 21,1 76 |

| 1000 0,0007 21,1 52,4296 |

| 1000 0,0020 21,1 37,7328 |

| 1000 0,0100 21,1 27,9388 |

| 1000 0,0500 21,1 23,9435 |

| 1000 0,1000 21,1 22,6202 |

| 1000 0,3000 21,1 21,3700 |

| 1050 0,0001 77,57 164,8713 |

| 1050 0,0100 77,57 46,0404 |

| 1050 0,0200 77,57 40,4298 |

| 1050 0,0500 77,57 37,4276 |

| 1050 0,1000 77,57 36,2312 |

| 1050 0,3000 77,57 33,9519 |

| 1100 0,0001 117,79 253,4429 |

| 1100 0,0010 117,79 131,3201 |

| 1100 0,0100 117,79 70,5940 |

| 1100 0,0300 117,79 61,9280 |

| 1100 0,1000 117,79 53,9414 |

| 1100 0,3000 117,79 49,1312 |

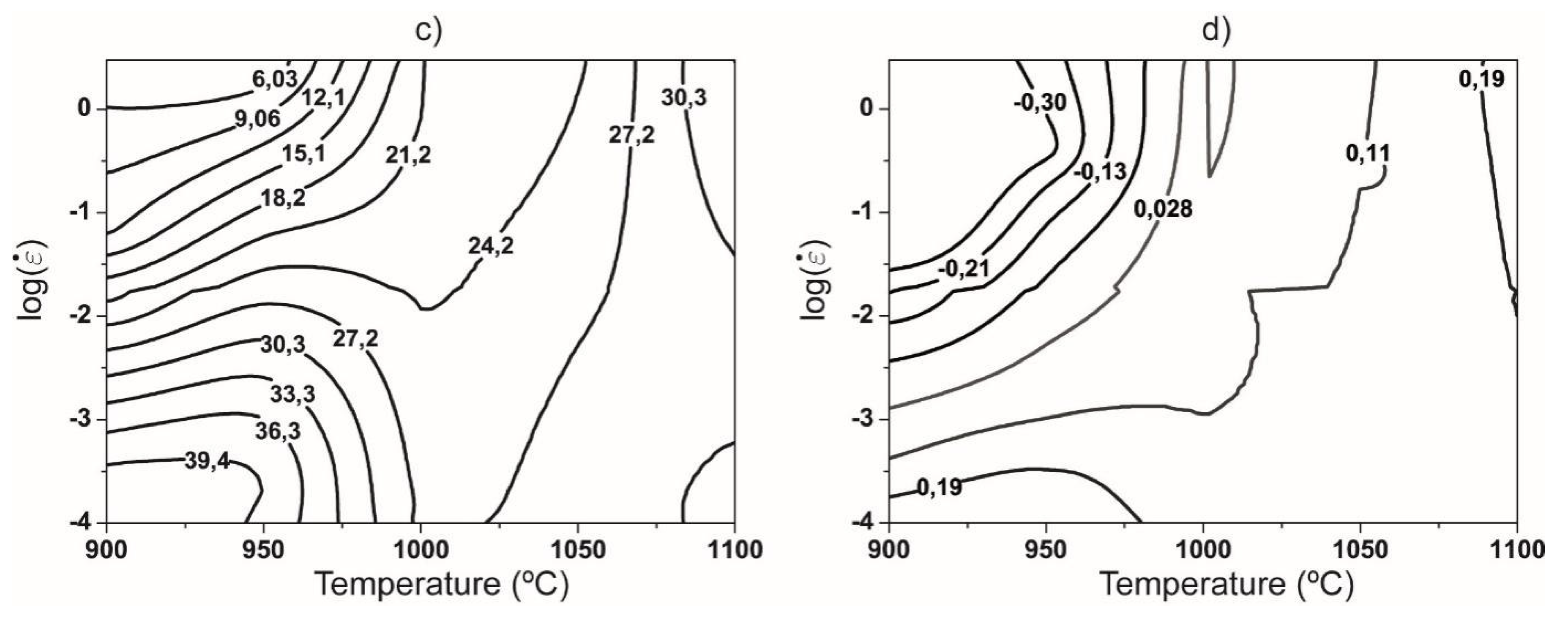

4.2. Construction of the neural network model to obtain the grain size

4.1. ANN results

| Table VII.- Data obtained through ANN in training |

| T (ºC) (s-1) GS.INITIAL (μm) GS.FINAL (μm) ANN(μm) |

| 900 0,0001 11,12 22,2557 21,6098 |

| 900 0,0005 11,12 14,81 15,4256 |

| 900 0,0020 11,12 12,9680 11,1386 |

| 900 0,0500 11,12 9,799 9,8309 |

| 900 0,3000 11,12 8,3298 9,7824 |

| 950 0,0002 12,63 33,9160 33,4308 |

| 950 0,0005 12,63 26,6486 26,5033 |

| 950 0,0050 12,63 16,8403 16,6861 |

| 950 0,0100 12,63 15,8876 15,4176 |

| 950 0,0500 12,63 13,967 14,0240 |

| 950 0,3000 12,63 12,3852 12,2633 |

| 1000 0,0001 21,1 95 94,8702 |

| 1000 0,0007 21,1 52,4296 52,3033 |

| 1000 0,0020 21,1 37,7328 37,5001 |

| 1000 0,0100 21,1 27,9388 28,2090 |

| 1000 0,0500 21,1 23,9435 23,9700 |

| 1000 0,1000 21,1 22,6202 22,3469 |

| 1000 0,3000 21,1 21,3700 21,4938 |

| 1050 0,0001 77,57 164,8713 165,0638 |

| 1050 0,0100 77,57 46,0404 46,0867 |

| 1050 0,0200 77,57 40,4298 40,5404 |

| 1050 0,0500 77,57 37,4276 37,3475 |

| 1050 0,1000 77,57 36,2312 36,1864 |

| 1100 0,0001 117,79 253,4429 253,4109 |

| 1100 0,0010 117,79 131,3201 131,3422 |

| 1100 0,0100 117,79 70,5940 70,5405 |

| 1100 0,0300 117,79 61,9280 61,9516 |

| 1100 0,1000 117,79 53,9414 53,9305 |

| 1100 0,3000 117,79 49,1312 49,1622 |

| Table VIII.- Results of the RNA test | ||||

| Tº(ºC) | (s-1) | GS.FINAL (μm) | ANN(μm) | ERROR(%) |

| 900 | 0,0100 | 11,3416 | 9,8553 | 1,4863 |

| 950 | 0,0010 | 21,0201 | 21,9764 | -0,9563 |

| 1000 | 0,0002 | 76,0000 | 82,6071 | -6,6071 |

| 1000 | 0,0500 | 23,9436 | 23,9700 | -0,0265 |

| 1050 | 0,3000 | 33,9519 | 32,3338 | 1,6181 |

| Table IX.-Results of the ANN validation | |||

| Tº(ºC) | (s-1) | GS.INITIAL (μm) | GS.FINAL(μm)ANN |

| 900 | 0,0001 | 11,12 | 21,6098 |

| 900 | 0,001 | 11,12 | 12,8276 |

| 900 | 0,01 | 11,12 | 9,8553 |

| 900 | 0,1 | 11,12 | 9,8426 |

| 950 | 0,0001 | 12,63 | 3,4371 |

| 950 | 0,001 | 12,63 | 21,9764 |

| 950 | 0,01 | 12,63 | 15,4176 |

| 950 | 0,1 | 12,63 | 12,848 |

| 1000 | 0,0001 | 21,1 | 94,8702 |

| 1000 | 0,001 | 21,1 | 45,5325 |

| 1000 | 0,01 | 21,1 | 28,209 |

| 1000 | 0,1 | 21,1 | 22,3469 |

| 1050 | 0,0001 | 77,57 | 165,0638 |

| 1050 | 0,001 | 77,57 | 83,6777 |

| 1050 | 0,01 | 77,57 | 46,0867 |

| 1050 | 0,1 | 77,57 | 36,1864 |

| 1100 | 0,0001 | 117,79 | 253,4109 |

| 1100 | 0,001 | 117,79 | 131,3422 |

| 1100 | 0,01 | 117,79 | 70,5405 |

| 1100 | 0,1 | 117,79 | 53,9305 |

5. Conclusions

References

- Y.V.R.K. Prasad, T. Seshacharyulu: Int. Mater. Rev. 43 (1998) 243. [CrossRef]

- S.V.S. Narayana Murty, B. Nageswara, B.P. Kash: Int. Mater. Rev. 45 (2000) 15. [CrossRef]

- A.H. Sheikhali, M. Morakkabati: Int. J. Mater. Res. 111 (2020) 1. [CrossRef]

- E. Ghasemi, A. Zarei-Hanzaki, E. Farabi, K. Tesar, A. Jäger, M. Rezaee: J. Alloys Compd. 695 (2017) 1706. [CrossRef]

- Y.V.R.K. Prasad, K.P. Rao, S. Sasidhar: Hot Working Guide, MaterialsPark, OH: ASM International (2015).

- S.V.S. Narayana Murty and B. Nageswara Rao: Mater. Sci. Lett.17 (1998) 1203. [CrossRef]

- S.V.S. Narayana Murty, B. Nageswara Rao, B.P. Kashyap: Modell.Simul. Mater. Eng. 10 (2002) 503. [CrossRef]

- S.V.S. Narayana Murty, B. Nageswara Rao, B.P. Kashyap: Comput. Sci. Technol. 63 (2003) 119. [CrossRef]

- S.V.S. Narayana Murty, B. Nageswara Rao, B.P. Kashyap: J. Mater. Process. Technol. 166 (2005) 279. [CrossRef]

- McCulloch, W. and Pitts, W., 1943, “A logical calculus of the ideas immanent in nervous activity,” Bulletin of Mathematical Biophysics, 5, p 115-133.

- McCulloch, W. and Pitts, W., 1943, “A logical calculus of the ideas immanent in nervous activity,” Bulletin of Mathematical Biophysics, 5, p 115-133.

- M.P. Phaniraj, A.Kumar, The applicability of neural network model to predict flow stress for carbon steels. Journal of Materials Processing Technology 141 (2003) 219-227.

- Y. Sun, W. Zeng, Y. Zhao,X. Zhang, X. Ma, Y. Han. Constructing processin map of Ti40 alloy using artificial neural network. Sciencie Direct. Trans. Nonferrous Met. Soc. China 21 (2011) 159-165.

- Alcelay, I., Peña, E., Al Omar, A. (2016) “Estudio del comportamiento termo-mecánico de un acero microaleado de medio carbono durante un proceso de conformado en caliente usando una red neuronal artificial”. Rev. Metal. 52(2): e066. [CrossRef]

- I. Alcelay, Anas Al Omar, J. Manuel Prado. Characterization of hot flow behaviour and deformation stability of medium carbon microalloyed steel using artificial neural networks and dynamic material model Int. J. Mater. Res. (formerly Z. Metallkd.) 105 (2014) 8; page 743– 754.

- A. Al Omar: Doctoral Thesis, Universidad Politécnica de Cataluña, Barcelona, Spain (1996).

- José Ignacio Alcelay Larrión: Doctoral Thesis, Universidad Politécnica de Cataluña, Barcelona, Spain (2015).

- S. Mandal,P.V. Sivaprasad, S. Vegunopal. Capability of a Feed-Forward Artificial Neural Network to predict the constitutive flow behavior of as cast 304 stainless steel under hot deformation. Materials Technology Division, Indira Gandhi Centre for Atomic Research. Vol. 129, 2007.

- Gouliand Ji, Fugou Li, Qinghua Li, Huiqu Li, Zhi Li. Prediction of the hot deformation behavior for Aermet100 steel using an artificial neural network. Computational Materials Sciencie 48 (2010) 626-632.252.

- Y. Sun, W. Zeng, Y. Zhao,X. Zhang, X. Ma, Y. Han. Constructing processin map of Ti40 alloy using artificial neural network. Sciencie Direct. Trans. Nonferrous Met. Soc. China 21 (2011) 159-165.

- M.T.Hagan, H.B.Demuth and M. Beale, Neural Network Design, Thomson Learning, Singapore, 2002. (Error relative menor Levenberg marquard).

- Prasad, Y.V.R.K., Sasidhara S. (1997). Hot Working Guide: A Compendium of Processing Maps, ASM International, Materials Park, Ohio, USA.

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).