Submitted:

23 January 2024

Posted:

24 January 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

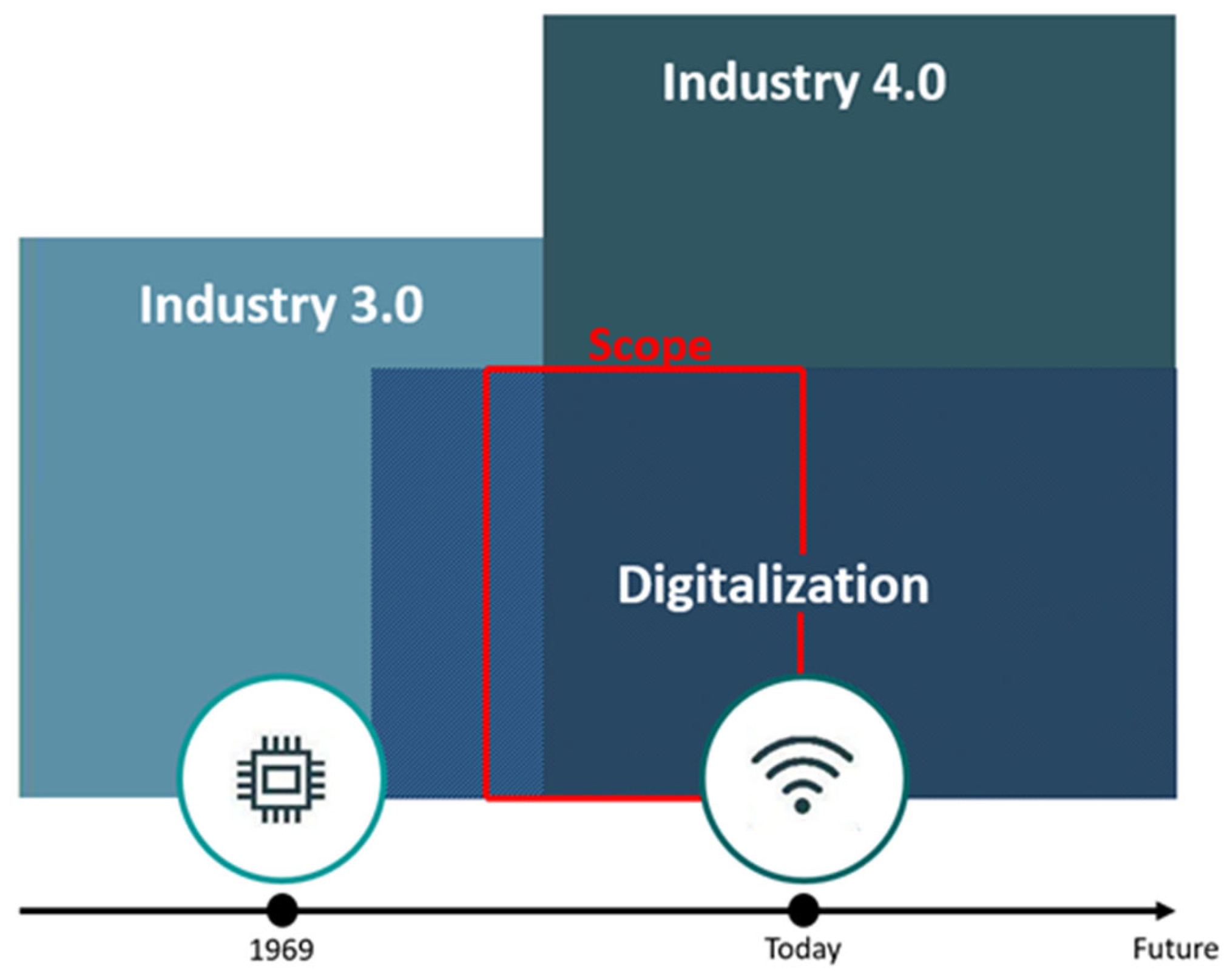

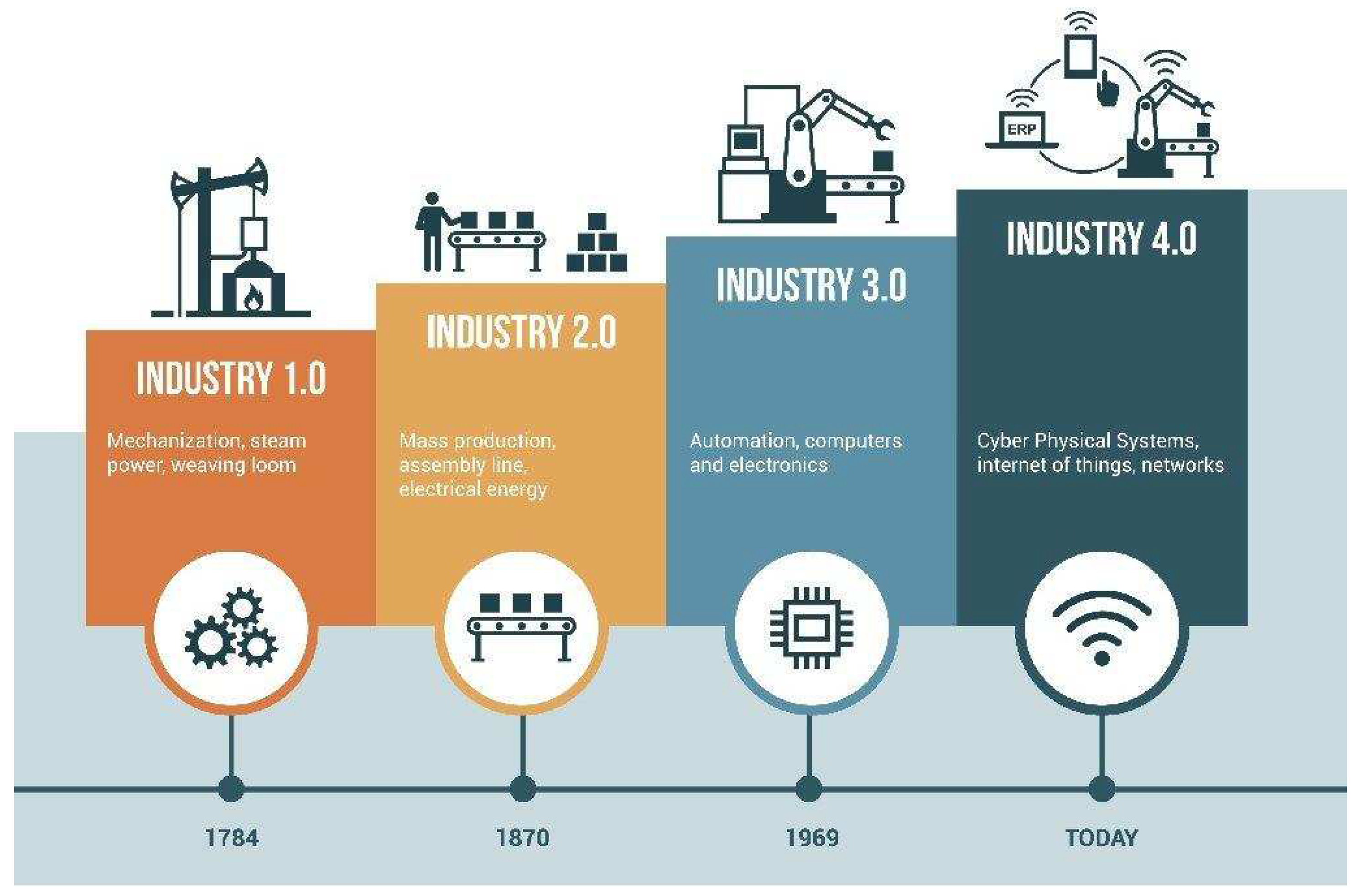

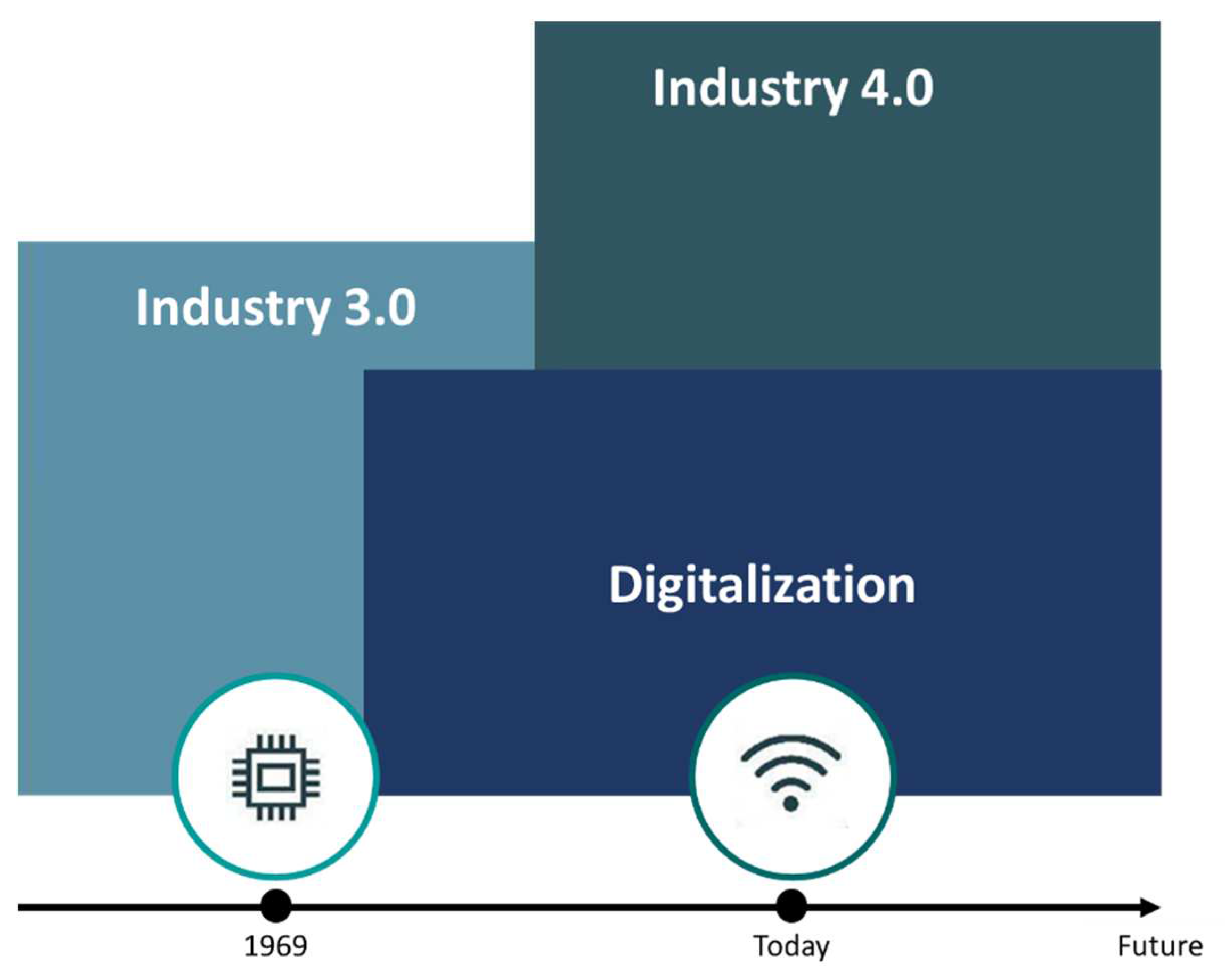

2. Digitalization and Industry 4.0

3. Paper Scope

4. Technologies

- A.

- Hardware in the transition between Industry 3.0 and Industry 4.0

- B.

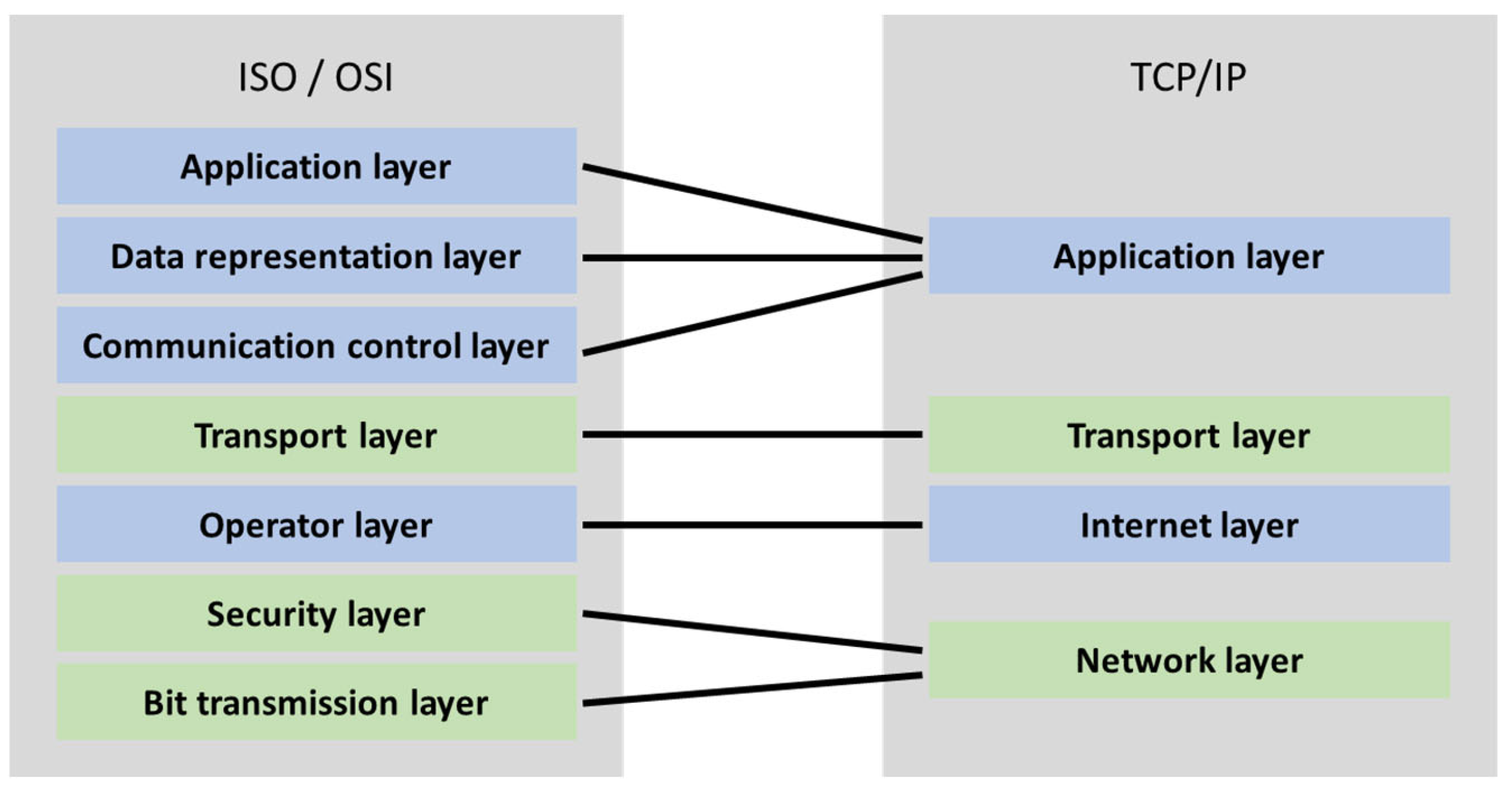

- Communication standards between Industry 3.0 and Industry 4.0

- C.

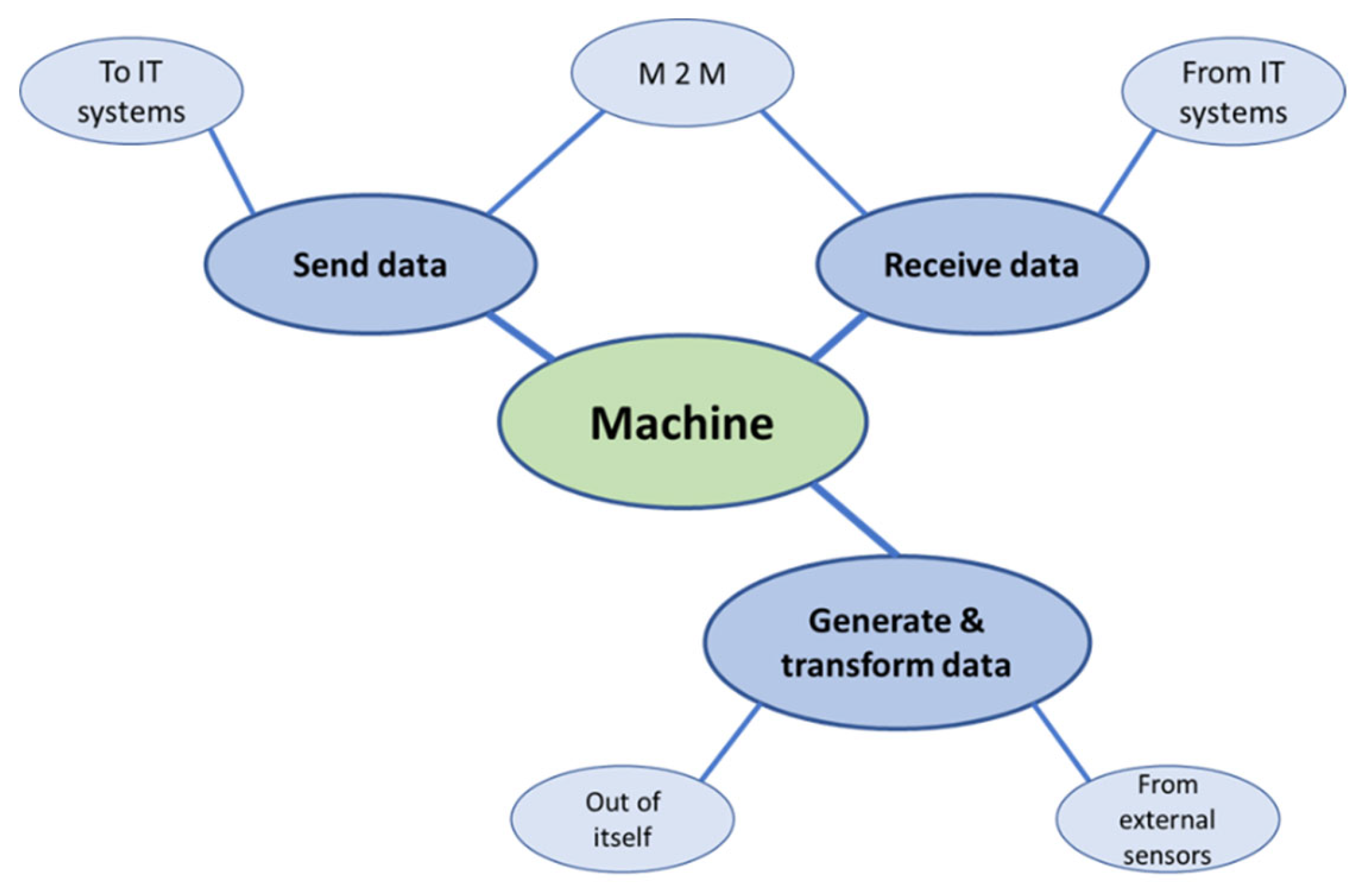

- Machine communication in the transition from Industry 3.0 to Industry 4.0

- D.

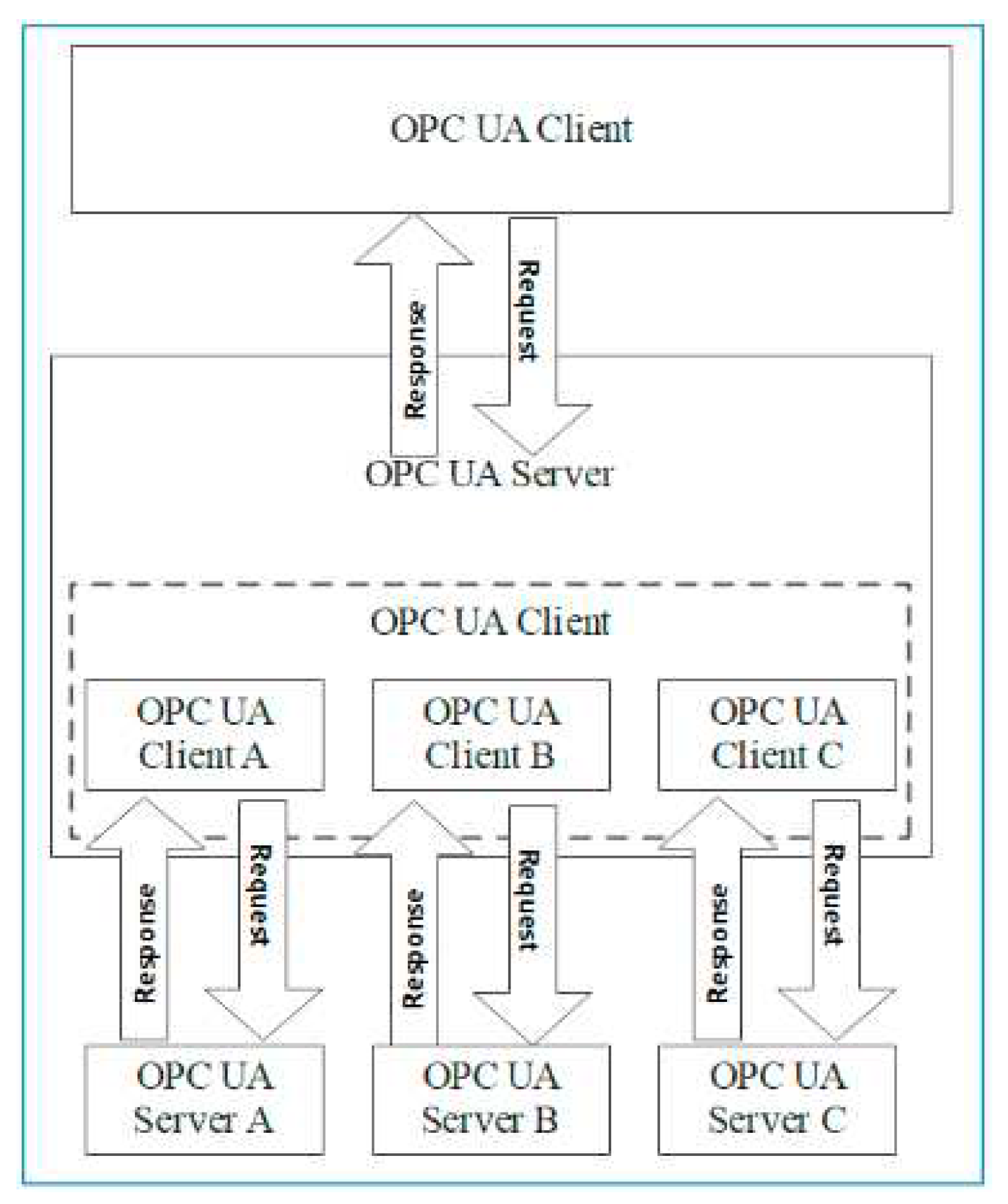

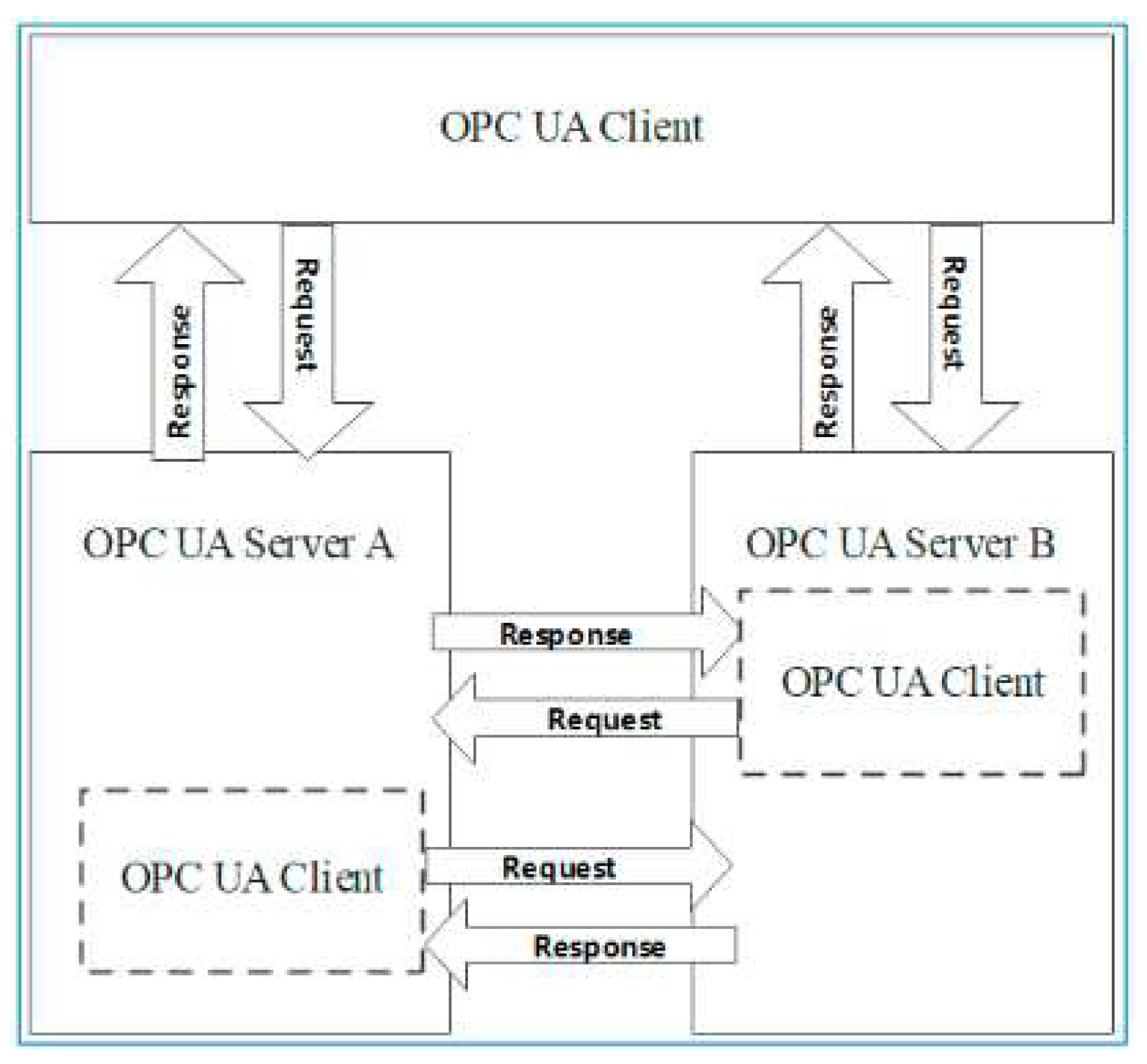

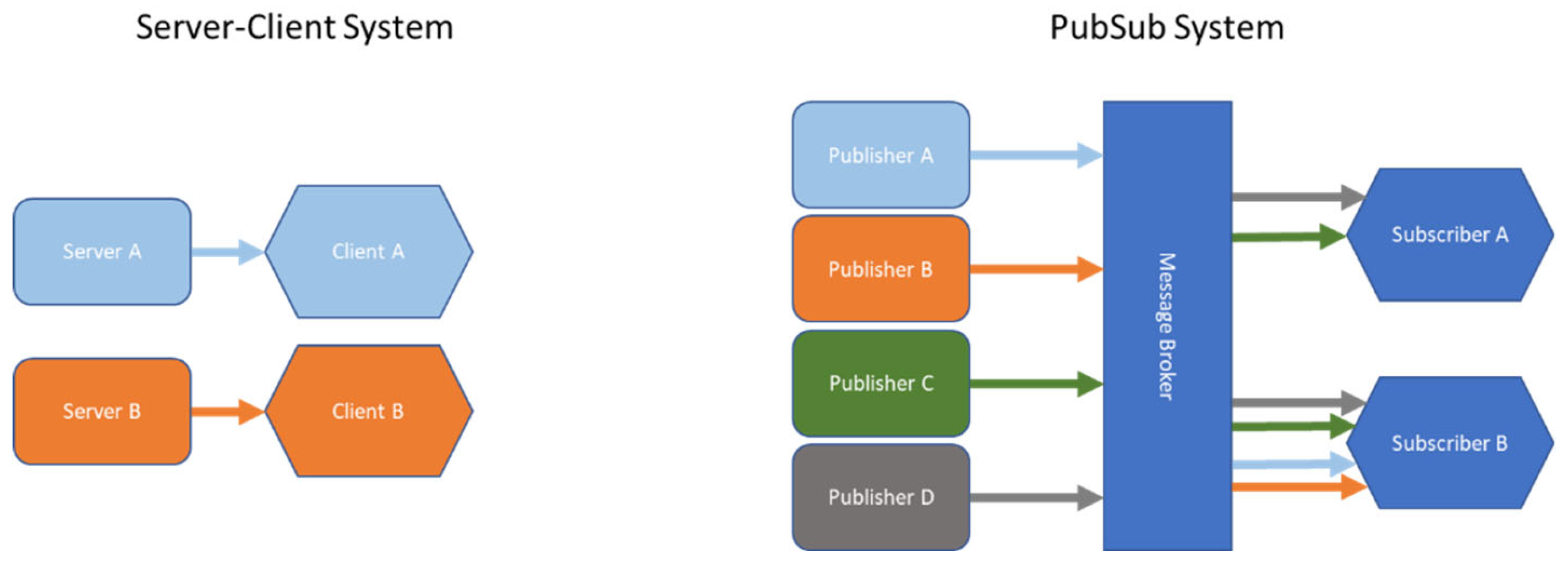

- Industry 4.0 communication standard OPC UA

- 1)

- OPC UA machine communication

- 2)

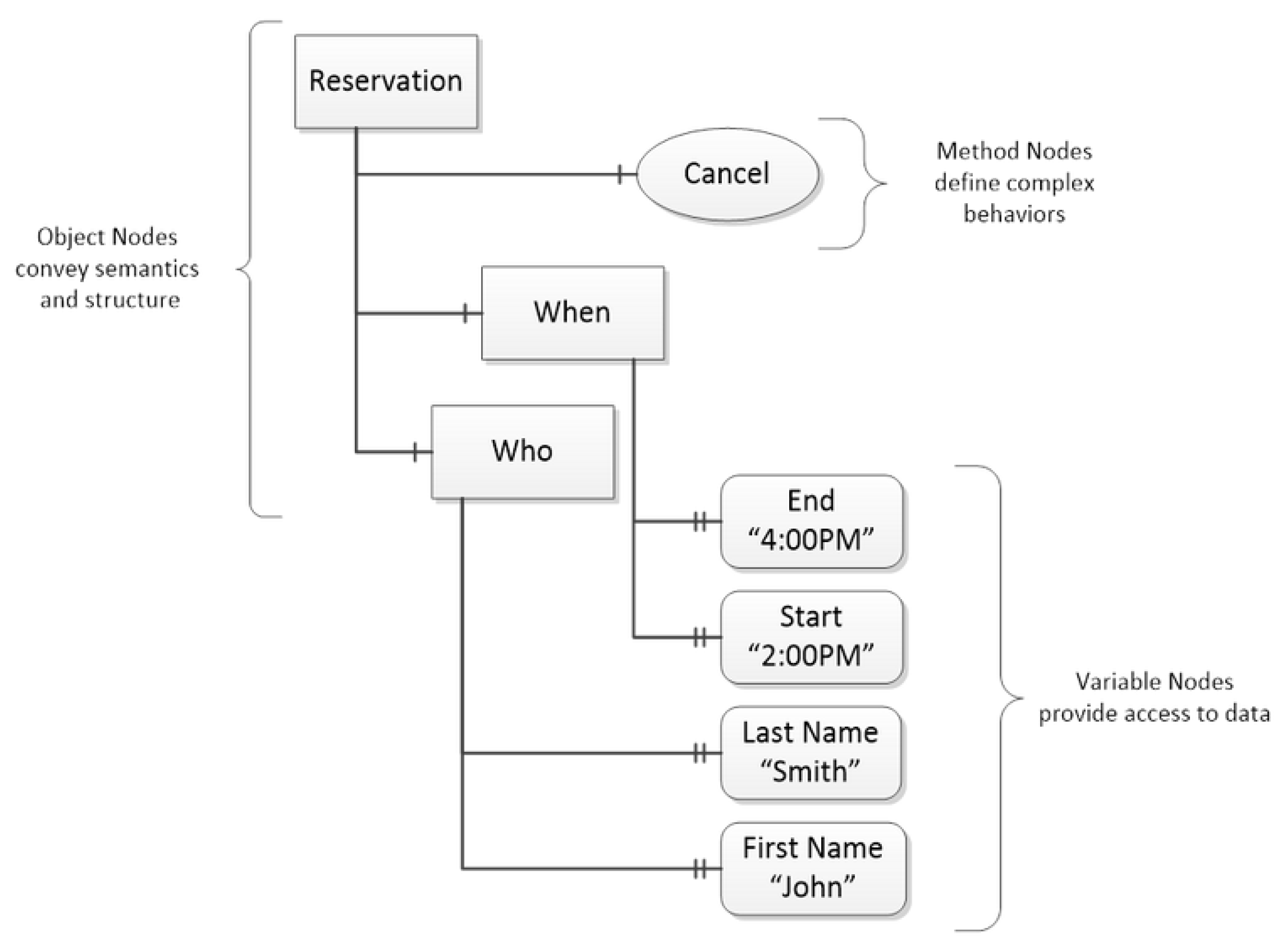

- Data structures in OPC UA

- 3)

- Advantages and added value of OPC UA for mechanical engineering

- Spread and increasing acceptance of OPC UA as a communication standard between machines and higher-level software systems

- Generally defined structures for creating models for processing and transferring data from machines to higher-level systems

- Expandability of the structure due to modularity and object-orientation

- Industry-specific company specifications (CS) are provided for special cases in the respective industry sector

- Independence of the overall OPC UA concept for hardware and software

- 4)

- Limitation of OPC UA

5. IT Functionalities in the Field of Mechanical Engineering

- A.

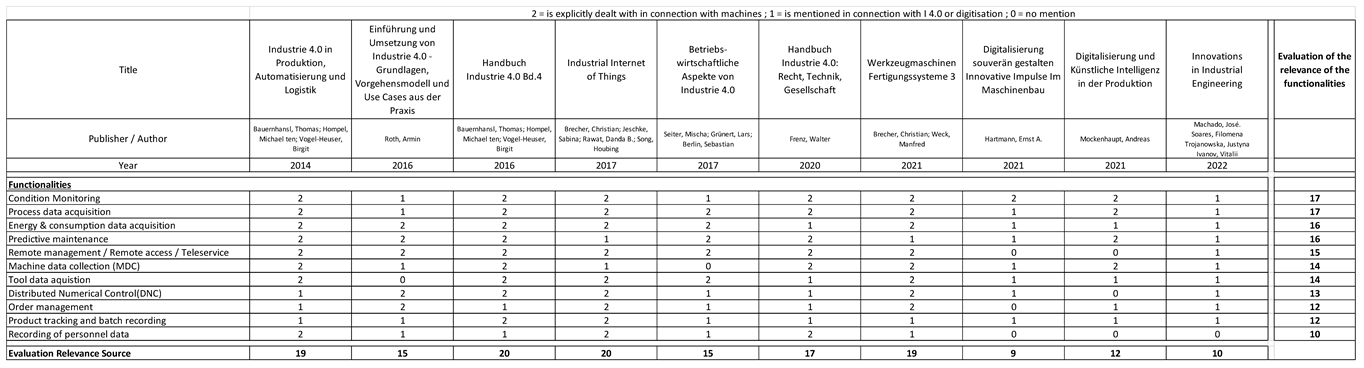

- Determination of relevant IT functionalities

- B.

- Functional description

- 1)

- Remote management / Remote access / Teleservice

- 2)

- Machine data collection (MDC)

- 3)

- Energy & consumption data acquisition

- 4)

- Process data acquisition

- 5)

- Condition Monitoring

- 6)

- Predictive maintenance

- 7)

- Order management

- 8)

- Distributed Numerical Control (DNC)

- 9)

- Product tracking and batch recording

- 10)

- Tool data acquisition

- 11)

- Recording of personnel data

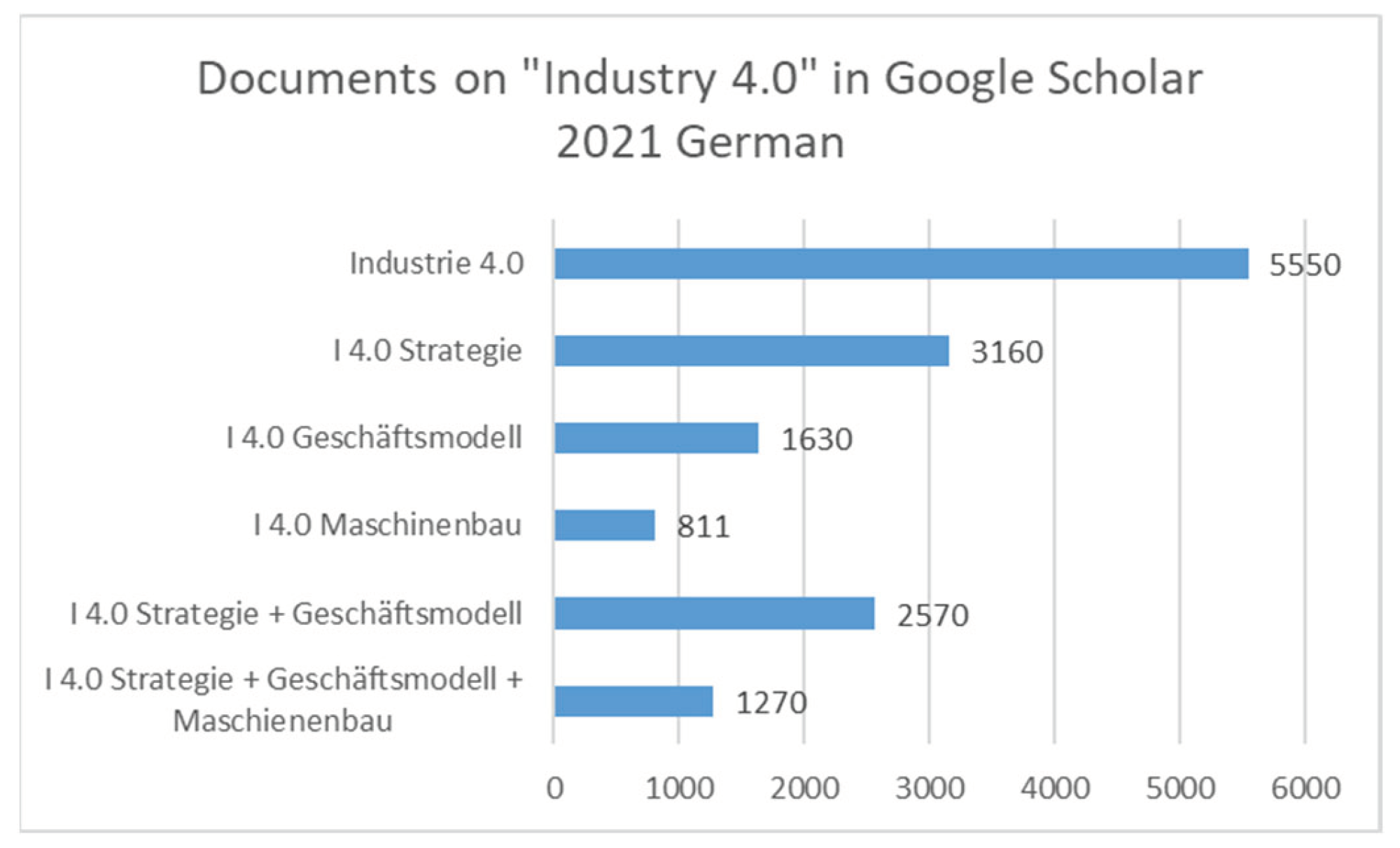

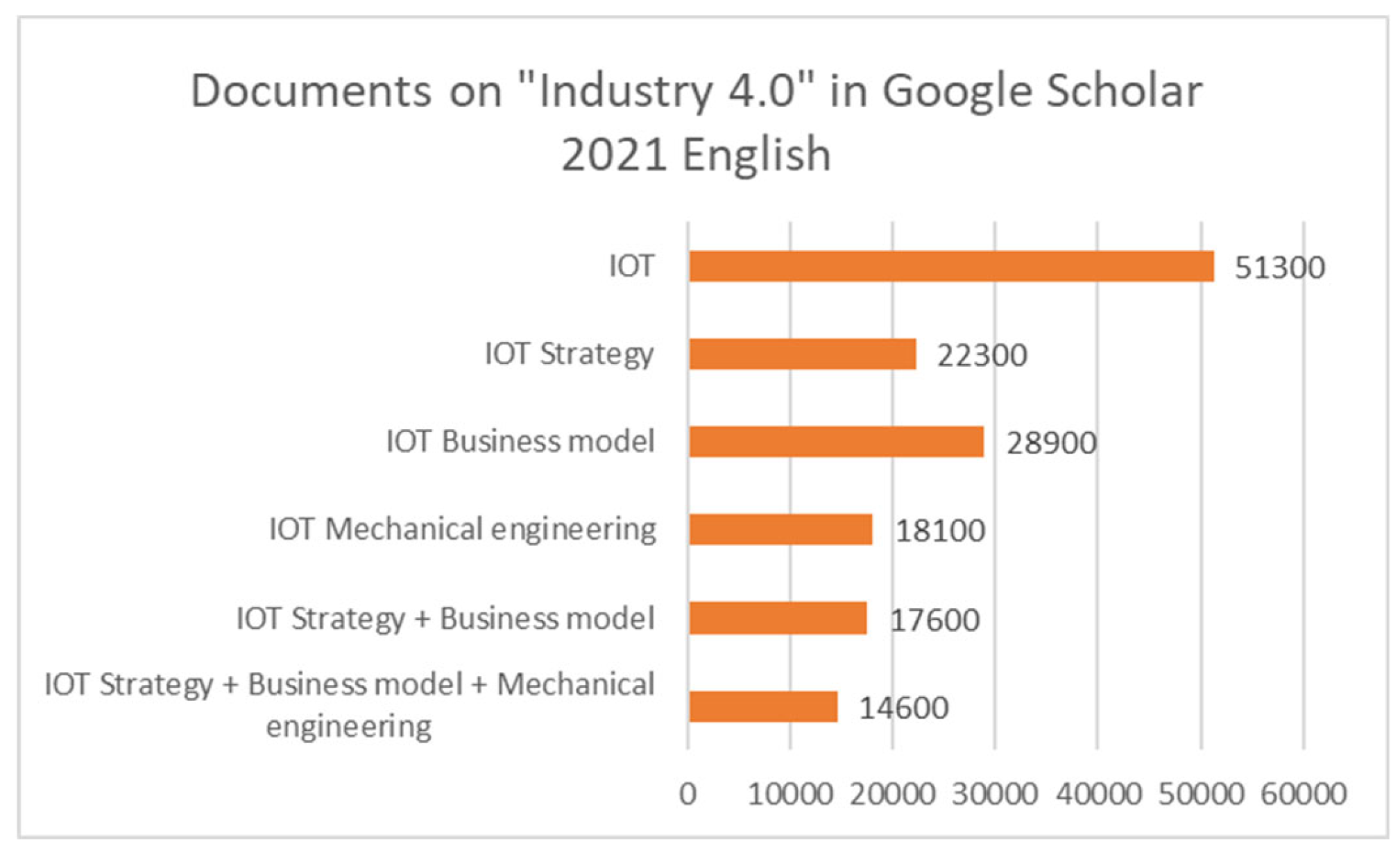

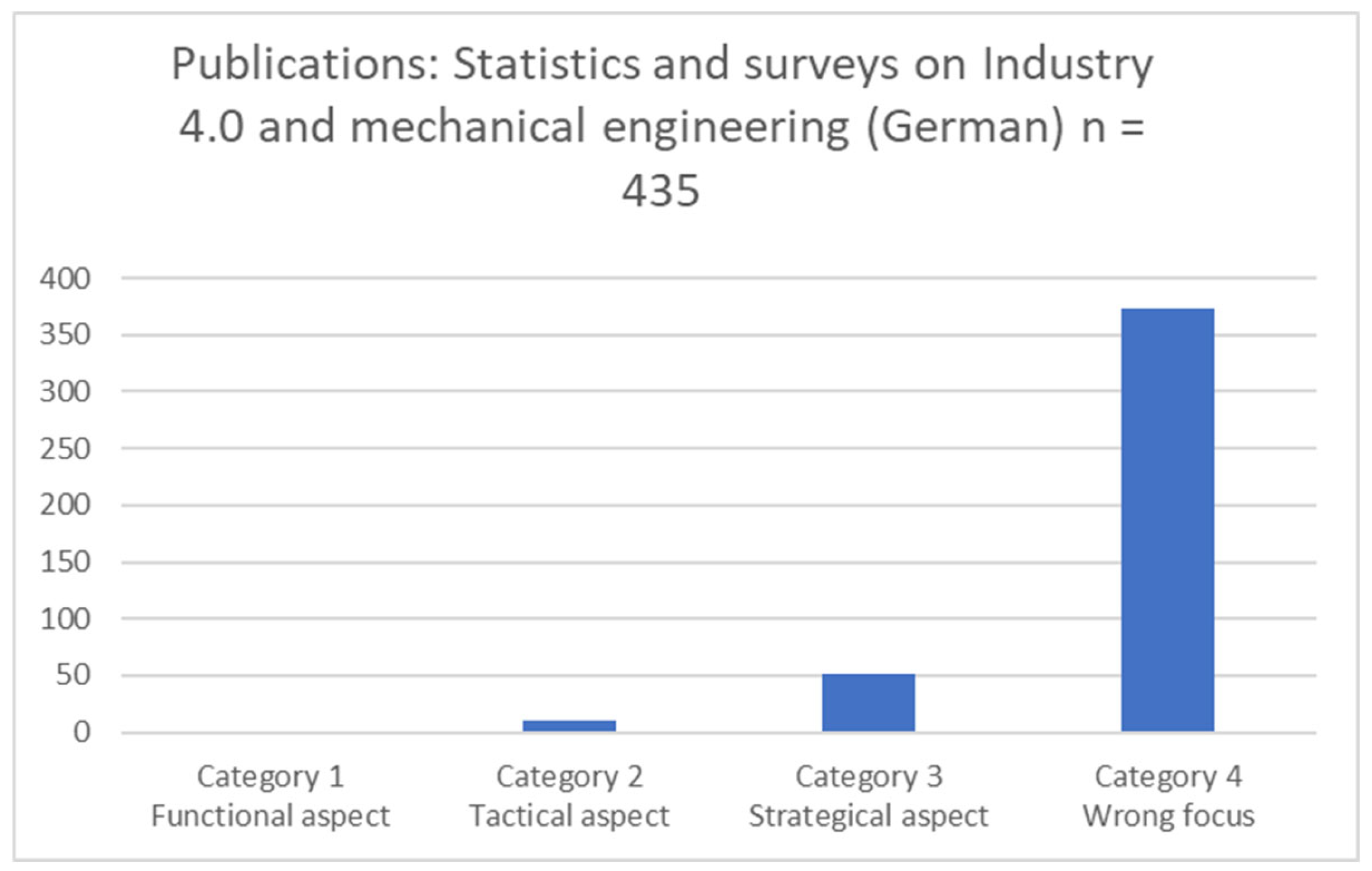

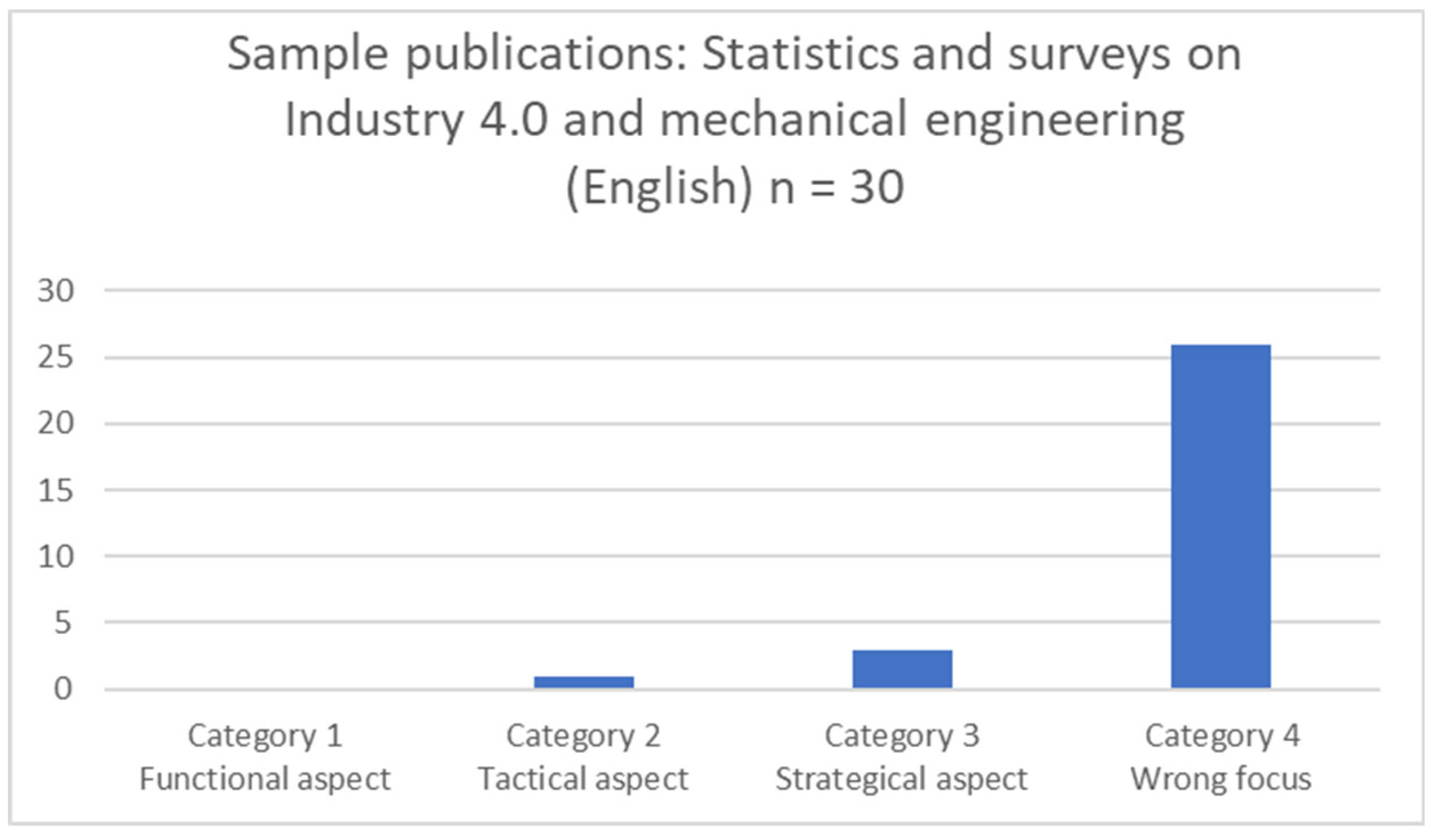

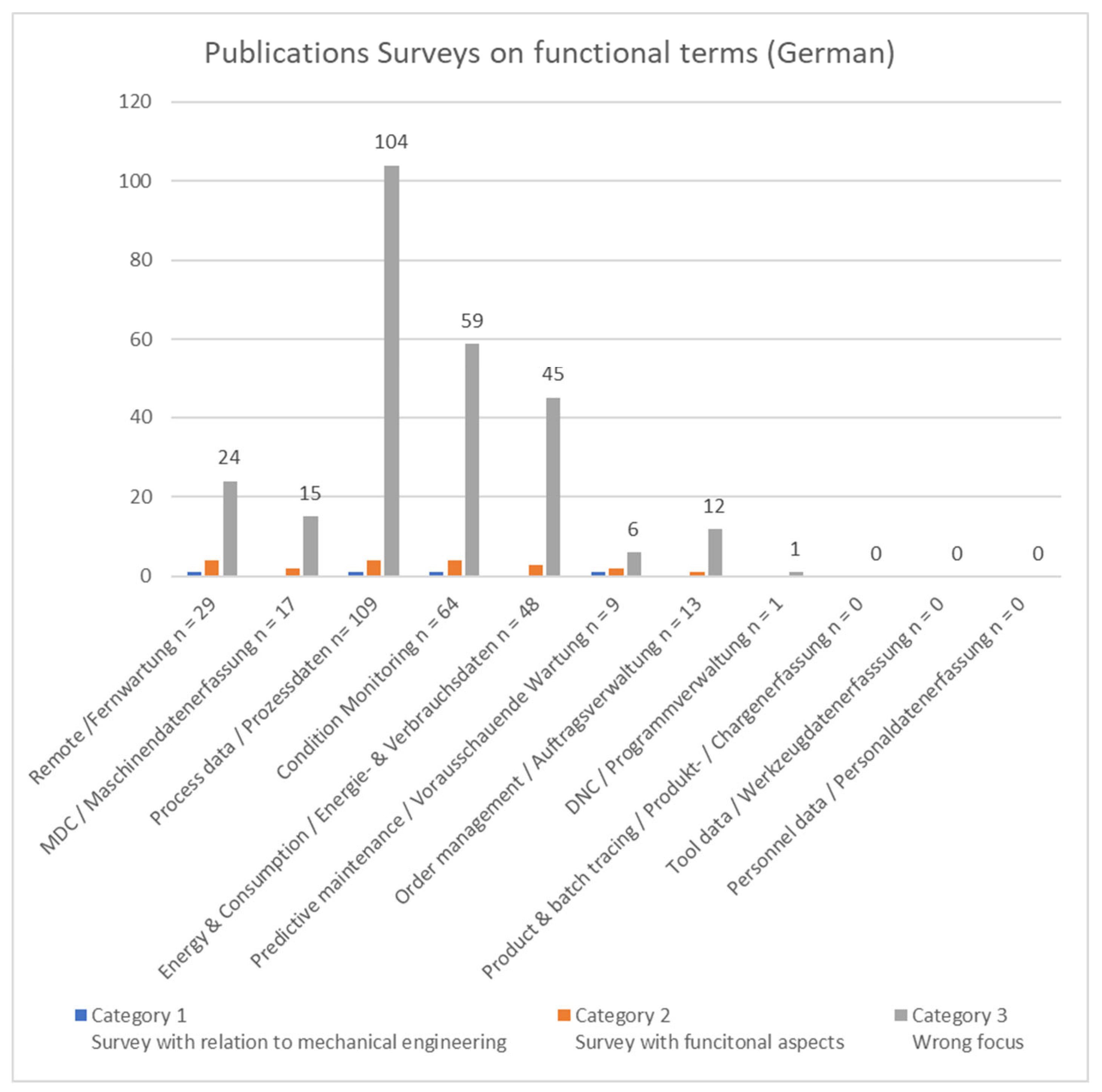

6. Research for Industry Transfer

- A.

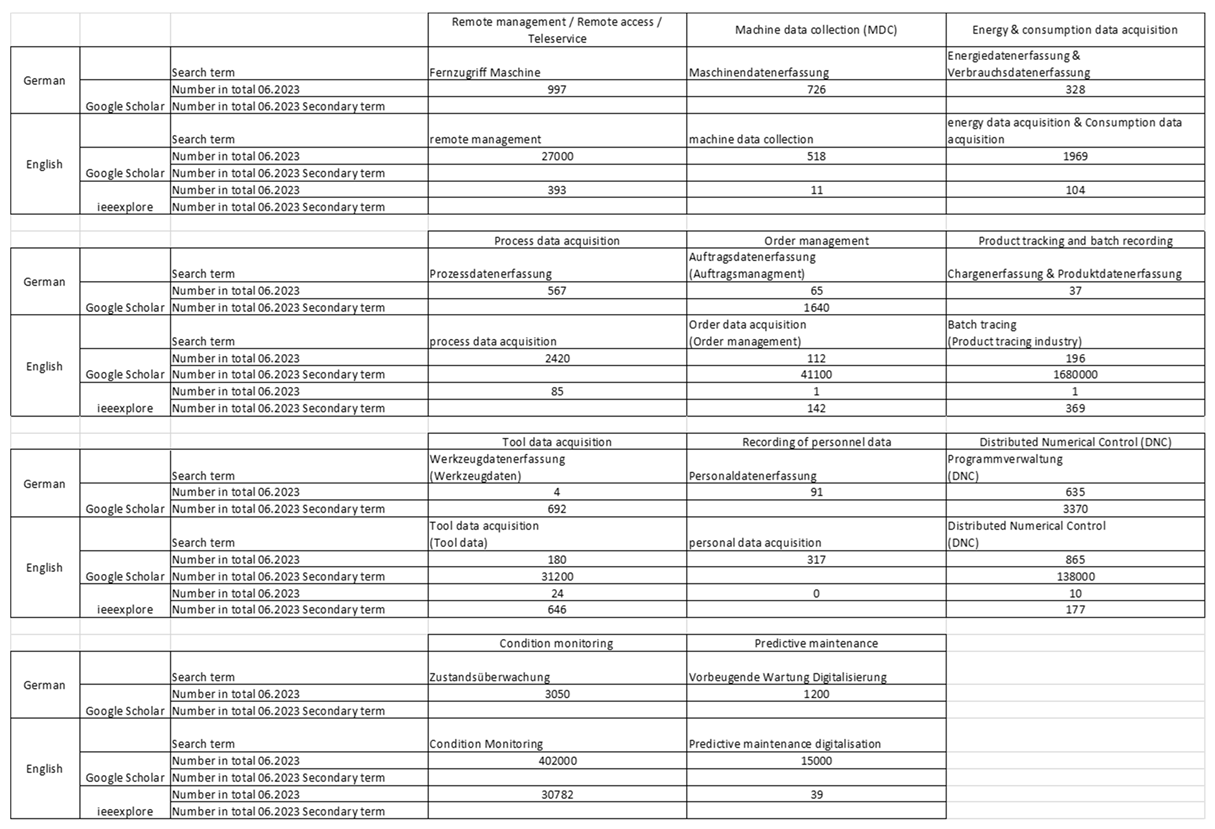

- Procedure

- Category 1: Publications on the topic of Industry 4.0 in which the areas of mechanical engineering and production are explicitly considered

- Category 4: Publications that focus on topics outside of mechanical engineering or where no statistically usable data is available. [175]

- Category 1: Publications in which the survey explicitly considers the functionality aspects of the field in relation to mechanical engineering or production

- Category 2: Publications in which the survey considers functionality aspects

- Category 3: Publications with the wrong thematic focus or no statistically usable data available

- B.

- Result

7. Conclusions

Appendix A

Appendix B

References

- Mertens, P.; Barbian, D.; Baier, S. Digitalisierung,“ in Digitalisierung und Industrie 4.0 - eine Relativierung, Wiesbaden, Springer Vieweg, 2017, pp. 34-36.

- Bendel, O. Definition: Digitalisierung,“ 13 07 2021. [Online]. Available: https://wirtschaftslexikon.gabler.de/definition/digitalisierung-54195/version-384620. [Access on 27 12 2022].

- BMWK. Bundesministerium für Wirtschaft und Klimaschutz,“ 2016. [Online]. Available: https://www.plattform-i40.de/IP/Navigation/DE/Industrie40/WasIndustrie40/was-ist-industrie-40.html. [Access on 27 12 2022].

- BMBF. Bundesministerium für Bildung und Forschung,“ 2016. [Online]. Available: https://www.bmbf.de/bmbf/de/forschung/digitale-wirtschaft-und-gesellschaft/industrie-4-0/industrie-4-0. [Access on 27 12 2022].

- Tan, Y.; Yang, W.; Yoshida, K.; Takakuwa, S. Application of IoT-Aided Simulation to Manufacturing Systems in Cyber-Physical System. Machines 2019, 7, 2. [Google Scholar] [CrossRef]

- K. Al-Gumaei, Schuba, K.; Friesen, A.; Heymann, S.; Pieper, C.; Pethig, F.; Schriegel, S. A Survey of Internet of Things and Big Data integrated Solutions for Industrie 4.0,“ in 2018 IEEE 23rd International Conference 92018, 2018.

- Bendel, O. Definition: Industrie 4.0,“ 13 07 2021. [Online]. Available: https://wirtschaftslexikon.gabler.de/definition/industrie-40-54032. [Access on 27 12 2022].

- Jara, A.J.; Parra, M.C.; Skarmeta, A.F. Marketing 4.0: A New Value Added to the Marketing through the Internet of Things,“ in 2012 Sixth International Conference 072012, 2012.

- Viorel, P. Status and trends in the global manufacturing sector,“ IIoT World OPTIMO LLC, 26 09 2018.

- Roth, A. Industrie 4.0 – Hype oder Revolution?,“ in Einführung und Umsetzung von Industrie 4.0, Leinfelden-Echterdingen, Deutschland, Springer Gabler, 2016, p. 6.

- Mockenhaupt, A. Grundlagen der Digitalisierung und Industrie 4.0,“ in Digitalisierung und Künstliche Intelligenz in der Produktion, Wiesbaden, Springer Vieweg, 2021, p. 35.

- Siepmann, D. Industrie 4.0 – Grundlagen und Gesamtzusammenhang,“ in Einführung und Umsetzung von Industrie 4.0, Leinfelden-Echterdingen, Deutschland, Springer Gabler, 2016, pp. 19-21.

- Kleinemeier, M. Von der Automatisierungspyramide zu Unternehmenssteuerungs-,“ in Industrie 4.0 in Produktion, Automatisierung und Logistik, Wiesbaden, Springer Vieweg, 2014, pp. 571 - 579.

- Kropik, M.; Produktionsleitsysteme für die Automobilindustrie, 2 Hrsg., Wien: Springer Gabler, 2021, p. 426.

- Dorst, W. Fabrik- und Produktionsprozesse der Industrie 4.0 im Jahr 2020,“ in Industrie 4.0 – Wie sehen Produktionsprozesse im Jahr 2020 aus?, Saarbrücken, IMC AG, 2013, p. 25.

- H.-J. Born, Geschäftsmodell-Innovation im Zeitalter der vierten industriellen Revolution, München: Springer Vieweg, 2018, p. 51.

- Petrik, D.; Management der Zufriedenheit der Wertschöpfungspartner auf Basis der Boundary Resources im IIoT, Wiesbaden: Springer Gabler, 2022.

- Dispan, J. Digitale Transformation im Maschinen- und Anlagenbau. Digitalisierungsstrategien und Gestaltung von Arbeit 4.0,“ in Digitalisierung souverän gestalten - Innovative Impulse im Maschinenbau, Berlin, Springer Vieweg, 2021, p. 121.

- Bauernhansl, T. Die Vierte Industrielle Revolution – Der Weg in ein wertschaffendes Produktionsparadigma,“ in Industrie 4.0 in Produktion, Automatisierung und Logistik, Wiesbaden, Springer Vieweg, 2014, pp. 26 - 30.

- Statista, 07 12 2023. [Online]. Available: https://de.statista.com/statistik/daten/studie/154143/umfrage/umsatz-im-maschinenbau-2009-nach-laendern/.

- Müller. Digitale Technologien,“ 19 02 2018. [Online]. Available: https://wirtschaftslexikon.gabler.de/definition/digitale-technologien-54127/version-277181.

- Netzer, M.; Begemann, E.; Gönnheimer, P.; Fleischer, J. Digitalisierung im deutschen Maschinen- und Anlagenbau/Study on Digitalization in the German Mechanical Engineering Sector. wt Werkstattstech. Online 2021, 111, 526–530. [CrossRef]

- FORCAM GmbH. Maschineneanbindung: Die Globale Fabriksteuerung steht und fällt mit der richtigen Maschinenanbindung,“ 15 07 2022. [Online]. Available: http://docplayer.org/76874123-Maschinenanbindung-die-globale-fabriksteuerung-steht-und-faellt-mit-der-richtigen-maschinenanbindung-forcam-we-deliver-results-in-productivity.html.

- B.-A. Behrens, Krimm, R.; Koß, J.; Höber, A. Bauteilbezogene Speicherung prozessrelevanter Daten - Eine flexible Nachrüstlösung zur Prozessdatenakquise,“ Zeitschrift für wirtschaftlichen Fabrikbetrieb, pp. 66-70, 2022.

- Meinel, C.; Asjoma, M. Wie verständigen sich Maschinen im Internet?,“ in Die neue digitale Welt verstehen, Berlin; Heidelberg, Springer, 2021, pp. 189 - 192.

- Bauernhansl, T.; Krüger, J.; Reinhart, G.; Schuh, G. WGP-Standpunkt Industrie 4.0,“ Wissenschaftliche gesellschaft für produktionstechnik Wgp e. V, darmstadt, 2016.

- Hering, E.; Vogt, A.; Bressler, K. Steuerungen und Regelungen,“ in Handbuch der elektrischen Anlagen und Maschinen, Berlin, Heidelberg, Springer, 1999, pp. 455 - 459.

- Schumny, H. Die "klassischen" Standardschnittstellen,“ in Meßtechnik Mit Dem Personal Computer - Meßdatenerfassung und -Verarbeitung, Berlin / Heidelberg, Springer, 1993, pp. 28 - 32.

- Siemens. Was müssen Sie bei den PPI/MPI/DP-Schnittstellen beachten, wenn Sie den CP 5711 / PC Adapter USB A2 mit einer SIMATIC S7-200 verwenden wollen?,“ 23 04 2014. [Online]. Available: https://support.industry.siemens.com/cs/document/85669627/was-m%C3%BCssen-sie-bei-den-ppi-mpi-dp-schnittstellen-beachten-wenn-sie-den-cp-5711-pc-adapter-usb-a2-mit-einer-simatic-s7-200-verwenden-wollen-?dti=0&lc=de-DE.

- J.-Thomesse, P. Fieldbus Technology in Industrial Automation,“ Proc. IEEE (Proceedings of the IEEE), Nr. 6, pp. 1073 - 1101, 2005.

- Rasmussen, M. Twisted pair based ethernet,“ 21 08 2016. [Online]. Available: https://www.thingiverse.com/thing:1730415. [Access on 28 09 2022].

- Schiffmann, W.; Bähring, H.; Hönig, U. PC im Netzwerk,“ in Grundlagen der PC-Technologie, Berlin; Heidelberg, Springer, 2011, pp. 321 - 322.

- George, A.; S.Sagayarajan. Exploring the Potential and Limitations of 5G Technology: A Unique Perspective,“ PUIIJ, pp. 160 -174, 03 2023.

- Maulani, E.; C.Johansyah, A. The Development of 5G Technology and Its Implications For The Industry,“ Devotion, pp. 631 - 635, 02 2023.

- Jondral, F.K. Industrie 4.0 – Funk in der Fabrik,“ Zeitschrift für wirtschaftlichen Fabrikbetrieb, Nr. 1-2, p. 59–62, 2016.

- H.-W. Faßbender, Jensch, W.; Kranz, H.R.; Lorenz, R.; Stöbe, K.; Voskuhl, J.; Weinen, S.; Wöppel, K. Praxiswissen Digitale Gebäudeautomation - Planen, Konfigurieren, Betreiben,“ Wiesbaden, Springer Vieweg, 1997.

- Babel, W. Feldbusse, Kommunikationsprotokolle, Bedienoberflächen, Hardware ASIC’s - IO-Link,“ in Industrie 4.0, China 2025, IoT - Der Hype um die Welt der Automatisierung, Wiesbaden; Heidelberg, Springer Vieweg, 2021, pp. 305 - 311.

- Leßmann, G.; et al. Skalierbarkeit von PROFINET over TSN für ressourcenbeschränkte Geräte,“ in Kommunikation und Bildverarbeitung in der Automation - Ausgewählte Beiträge der Jahreskolloquien KommA und BVAu 2020, Berlin, Springer Vieweg, 2020, pp. 160 - 169.

- Gehring, H.; Gabriel, R. Branchenspezifische operative Anwendungssysteme,“ in Wirtschaftsinformatik, Wiesbaden, Springer Gabler, 2022, pp. 275 - 281 .

- Meinel, C.; Asjoma, M. TCP/IP-Protokoll – Betriebssystem des Internets,“ in Die neue digitale Welt verstehen, Berlin; Heidelberg, Springer, 2021, pp. 79 -83.

- Weber, P.; Gabriel, R.; Lux, T.; Menke, K. Referenzmodelle der Datenübertragung,“ in Basiswissen Wirtschaftsinformatik, Wiesbaden, Spinger Vieweg, 2022, pp. 83 - 84.

- AL-Dhief, F.T.; Sabri, N.; Latiff, N.M.A.; Malik, N.N.N.A.; Musatafa Abbas, A.A.; Mohammed, M.A.; AL-Haddad, R.N.; Salman, Y.D.; Ghani, M.K.A.; Obaid, O.I. Performance Comparison between TCP and UDP Protocols in Different Simulation Scenarios,“ International Journal of Engineering & Technology, pp. 172 - 176, 2018.

- R. A. P. u. K. O. T. Dominik Appius. Edge Computing und Industrie 4.0,“ in Digital Business - Analysen und Handlungsfelder in der Praxis, Wiesbaden, Springer Gabler, 2021, p. 316.

- Hoppe, S. Standardisierte horizontale und vertikale Kommunikation,“ in Handbuch Industrie 4.0 Bd.2 - Automatisierung, Berlin, Heidelberg, Springer Berlin Heidelberg, 2017, pp. 371 - 374.

- Kletti, J. Einführung eines MES im Unternehmen - Euromap E63,“ in Konzeption und Einführung von MES-Systemen - Zielorientierte Einführungsstrategie mit Wirtschaftlichkeitsbetrachtungen, Fallbeispielen und Checklisten, Berlin, Heidelberg, Springer-Verlag, 2007, p. 230.

- Euromap. EUROMAP 63 - Data Exchange Interface,“ 07 2000. [Online]. Available: https://www.euromap.org/media/recommendations/63/2000/eu63.pdf. [Access on 30 08 2022].

- Bärnreuther, B.; Ein Beitrag zur Bewertung des Kommunikationsverhaltens von Automatisierungsgeräten in flexiblen Produktionszellen, München; Wien: Hanser, 1992.

- Baumann, C. Visualisierung von Maschinendaten im Intranet,“ Zeitschrift für wirtschaftlichen Fabrikbetrieb, pp. 64 - 66, 1997.

- Turau, V Techniken zur Realisierung Web-basierter Anwendungen. Inform. Spektrum 1999, 22, 3–12. [CrossRef]

- Rohr, M. Design-Entscheidungen des HTTP-Protokolls,“ in Sicherheit Von Webanwendungen in der Praxis - Wie Sich Unternehmen Schützen Können - Hintergründe, Maßnahmen, Prüfverfahren und Prozesse, Wiesbaden, Vieweg, 2015, pp. 6 - 11.

- Vrana, J. Die vierte Revolution der zerstörungsfreien Prüfung: Vernetzung, Feedback, Digitalisierung und Einbindung in die Digitale Fabrik,“ in DACH-Jahrestagung, 2019.

- Wegener, K.; Kunz, A.; L. Bochmann und Bänziger, T. Industrie 4.0 für den Maschinen und Anlagenbau,“ in 3. Wiener Produktionstechnik Kongress Adaptive & Smart Manufacturing, Vienna, Austria, 2016.

- OPC Foundation. History - OPC Foundation,“ [Online]. Available: https://opcfoundation.org/about/opc-foundation/history/. [Access on 04 01 2023].

- U. Enste, Mahnke, W. OPC Unified Architecture,“ Automatisierungstechnik, pp. 397 -404, 2011.

- Farnham, B.; Barillere, R. MIGRATION FROM OPC-DA TO OPC-UA,“ in 13th International Conference on Accelerator and Large Experimental Physics Control Systems, Grenoble, France, 2011.

- OPC Foundation. What is OPC?,“ [Online]. Available: https://opcfoundation.org/about/what-is-opc/. [Access on 04 01 2023].

- OPC Foudation. pcfoundatio,“ [Online]. Available: https://opcfoundation.org/about/opc-foundation/mission-statement/. [Access on 31 08 2022].

- Pauker, F.; Frühwirth, T.; Kittl, B.; Kastner, W. A Systematic Approach to OPC UA Information Model Design. Procedia CIRP 2016, 57, 321–326. [CrossRef]

- OPC Foundation, OPC 40001-1 - OPC UA for Machinery, 2022.

- Euromap. https://www.euromap.org/euromap77,“ 2020. [Online]. Available: https://www.euromap.org/euromap77. [Access on 31 08 2022].

- OPC Foundation. OPC 40083 UA for Plastics and Rubber Machinery,“ 08 08 2022. [Online]. Available: https://reference.opcfoundation.org/v104/PlasticsRubber/GeneralTypes/v103/docs/4.2.3/. [Access on 22 08 2022].

- Technische Universität München. weihenstephanstandards,“ [Online]. Available: https://www.weihenstephan-standards.com/de/technik/kommunikationsschnittstellen/ws-opc-ua/. [Access on 31 08 2022].

- Siemens. OPC UA – Open Platform Communications Unified Architecture,“ [Online]. Available: https://new.siemens.com/de/de/produkte/automatisierung/industrielle-kommunikation/opc-ua.html. [Access on 31 08 2022].

- Beckhoff. TF6100 | TwinCAT 3 OPC UA,“ [Online]. Available: https://www.beckhoff.com/de-de/produkte/automation/twincat/tfxxxx-twincat-3-functions/tf6xxx-tc3-connectivity/tf6100.html. [Access on 31 08 2022].

- Bosch Rexroth. OPC UA Server App OPC UA Server for ctrlX CORE,“ 2022. [Online]. Available: https://www.boschrexroth.com/en/xc/myrexroth/media-directory-download?object_nr=R911403778.. [Access on 31 08 2022].

- Mitsubishi Electric. MELSEC iQ-R Series,“ [Online]. Available: https://www.mitsubishielectric.com/fa/products/cnt/plcr/pmerit/it_connect/opc.html. [Access on 31 08 2022].

- Martins, J. ̃. Lucasc, Costelha, H.; Nevesa, C. Developing an OPC UA Server for CNC Machines,“ in International Conference on Industry 4.0 and Smart Manufacturing, 2021.

- Ayatollahi, Kittl, Pauker, Hackhofer. Prototype OPC UA Server for Remote Control of Machine Tools,“ in International Conference on Innovative Technologies, Budapest, 2013.

- Schleipen, M.; Gilani, S.-S.; Bischoff, T.; Pfrommer, J. OPC UA & Industrie 4.0 - Enabling Technology with High Diversity and Variability. Procedia CIRP 2016, 57, 315–320. [CrossRef]

- Mahnke, W.; S.-H. Leitner, Damm, M.; OPC unified architecture, Berlin; Heidelberg: Springer, 2009.

- Happ, D.; Karowski, N.; Menzel, T.; Handziski, V.; Wolisz, A. Meeting IoT platform requirements with open pub/sub solutions. Ann. Telecommun. 2016, 72, 41–52. [CrossRef]

- OPC Foundation. OPC unified architecture - Interoperabilität für Industrie 4.0 und das Internet der Dinge,“ 2017. [Online]. Available: https://opcfoundation.org/wp-content/uploads/2017/11/OPC-UA-Interoperability-For-Industrie4-and-IoT-DE.pdf. [Access on 22 03 2023].

- Pfrommer, J.; Ebner, A.; S. Ravikumar und Karunakaran, B. Open Source OPC UA PubSub Over TSN for Realtime Industrial Communication,“ in 2018 IEEE 23rd International Conference 92018, 2018.

- OPC Foundation. OPC 40083 UA for Plastics and Rubber Machinery,“ 08 08 2022. [Online]. Available: https://reference.opcfoundation.org/v104/PlasticsRubber/GeneralTypes/v103/docs/18.1/. [Access on 30 08 2022].

- Spinnarke, S. OPC UA wird (neben anderen) Industrie 4.0-Standard,“ Produktion Online, 13 07 2016.

- Hoppe, S. Von Kommunikation zu Information: OPC UA überall!,“ digital-process-industry, 08 04 2021.

- VDMA Verlag GmbH. Studie zur Interoperabilität im Maschinen- und Anlagenbau - Die Weltsprache der Produktion als Grundlage für Industrie 4.0,“ VDMA Verlag GmbH, Frankfurt am Main, 2021.

- Pott, A.; Dietz, T. Steuerungstechnik,“ in Industrielle Robotersysteme, Wiesbaden, Springer Vieweg, 2019, pp. 51 - 63.

- Nakutis, Z.; Deksnys, V.; Jarusevicius, I.; Dambrauskas, V.; Cincikas, G.; Kriauceliunas, A. Round-Trip Delay Estimation in OPC UA Server-Client Communication Channel. Elektronika ir Elektrotechnika 2016, 22, 80–84. [CrossRef]

- Gamper, S.; Poudel, B.K.; Schriegel, S.; Pethig, F.; Jasperneite, J. Untersuchung der Netzlastrobustheit von OPC UA -Standard, Profile, Geräte und Testmethoden,“ in Kommunikation und Bildverarbeitung in der Automation, Berlin, Heidelberg, Springer , 2020, pp. 63 -76.

- Bruckner, D.; Stanica, M.-P.; Blair, R.; Schriegel, S.; Kehrer, S.; Seewald, M.; Sauter, T. An Introduction to OPC UA TSN for Industrial Communication Systems. Proc. IEEE 2019, 107, 1121–1131. [CrossRef]

- Pfrommer, J.; Usländer, T. Open-Source Implementierung von OPC UA PubSub für echtzeitfähige Kommunikation mit Time-Sensitive Networking,“ in Kommunikation und Bildverarbeitung in der Automation - Ausgewählte Beiträge der Jahreskolloquien KommA und BVAu 2018, Lemgo, Springer Vieweg, 2018, pp. 78 -87.

- Oxford University Press. functionality noun - Definition, pictures, pronunciation and usage notes,“ 21 11 2023. [Online]. Available: https://www.oxfordlearnersdictionaries.com/us/definition/english/functionality.

- Jazdi, N. Universelle Fernservice-Infrastruktur für eingebettete Systeme,“ Shaker, Aachen, 2003.

- Lay, G.; Nippa, M.; Konzepte und Praxisbeispiele für Technik, Organisation und Personal in serviceorientierten Industriebetrieben, Heidelberg: Physica-Verlag HD, 2005, pp. 20-21.

- Dreher, C.; Lay, G.; Michler, T. Teleservice in Deutschland,“ Karlsruhe, 1997.

- Stotz, I. Auf die SPS aus der Ferne zugreifen – und programmieren,“ elektrotechnik, 2020.

- Siemens. Höchstmaß an Sicherheit im Produktionsnetzwerk,“ Siemens, Nürnberg, 2017.

- P. Langreder, F. Schmidt und K.-H. Niemann. Fernwartung und OT-Security,“ atp, 09 2022.

- K.-I. Voigt, Bauer, J.; Dremel, A. researchgate.net,“ 2013. [Online]. Available: https://www.researchgate.net/profile/Florian-Steinmann/publication/259339758_Condition_monitoring_as_a_key_technology_-_An_analysis_of_requirements_for_new_business_models_for_remote_services/links/543293320cf22395f29c2965/Condition-monitoring-as-a-key-te. [Access on 01 09 2022].

- BSI. Bundesamt für Sicherheit in der Informationstechnik,“ 02 2021. [Online]. Available: https://www.bsi.bund.de/SharedDocs/Downloads/DE/BSI/Grundschutz/Kompendium_Einzel_PDFs_2021/04_OPS_Betrieb/OPS_1_2_5_Fernwartung_Edition_2021.pdf?__blob=publicationFile&v=2.

- Wonnemann, C. Cyber-Security entlang der IoT-Lieferkette,“ Datenschutz Datensich (Datenschutz und Datensicherheit - DuD), 2022.

- Markt und Mittelstand, 23 08 2022. [Online]. Available: https://www.marktundmittelstand.de/zukunftsmaerkte/seit-kriegsausbruch-hacker-legen-deutsche-windkraftwerke-massenweise-lahm-1301841/.

- Dachs, B.; Simon, N. Dienstleistungsinnovationen im Kontext von Industrie 4.0,“ AIT Austrian Institute of Technology GmbH, Wien, 2016.

- Echterhoff, B.; Gausemeier, J.; Koldewey, C.; Mittag, T.; Schneider, M.; Seif, H. Geschäftsmodelle für Industrie 4.0 Digitalisierung als große Chance für zukünftigen Unternehmenserfolg,“ in Digital vernetzt. Transformation der Wertschöpfung., München, Carl Hanser Verlag GmbH & Co. KG, 2017, pp. 35 - 56.

- Storm, M.; Werkstattinformationssysteme, Berlin: Springer, 1993.

- Kayar, A.; Öztürk, F. Machine Data Collection and Analysis in Industry 4.0 Applications,“ in 2nd International Conference on Life and Engineering Scciences, Istambul, 2019.

- Breiing, M. STAND DER TECHNIK,“ in Potenzialanalyse zum Einsatz minimalinvasiver Datenerfassung und maschineller Lernverfahren für die Identifizierung von SMC-Prozessschritten, Aachen, 2023, p. 6.

- Kletti, J.; Rieger, J. Die Bausteine für die perfekte Produktion,“ in Die perfekte Produktion - Manufacturing Excellence in der Smart Factory, Wiesbaden, Springer Vieweg, 2022, pp. 102 -103.

- H.-G. Kemper , Baar, H.; Mehanna, W. Operational BI in der Nutzfahrzeugproduktion,“ in Business Intelligence – Grundlagen und praktische Anwendungen, Wiesbaden, Vieweg+Teubner, 2010, p. 239.

- Fastec. Fokus auf Transparenz – die MES Module MDE, BDE, Monitoring, Alarmierung etc.,“ [Online]. Available: https://www.fastec.de/wp-content/uploads/2021/05/FASTEC-Whitepaper-04-Industrie40-Software-for-production.pdf. [Access on 02 09 2022].

- Large, M. Remote-I/Os sind das Rückgrat der Industrie 4.0,“ all-electronics, 2017.

- Schuh, G.; et al. Steigerung der Kollaborationsproduktivität durch cyber-physische Systeme,“ in Handbuch Industrie 4.0 Bd. 2, 2. Auflage Hrsg., B. Vogel-Heuser, T. Bauernhansl und Hompel, Hrsg., 2017, pp. 88 -89.

- DIN EN 415-11, 2021.

- Kletti, J. Erfassen und Verarbeiten von Maschinendaten (MDE),“ in MES – Manufacturing Execution System, Berlin, Springer Vieweg, 2015, pp. 82 - 88.

- Stoltenberg, U.; Funke, M. Praxisorientierte Einführung eines Ökocontrolling-Systems,“ in Betriebliches Ökocontrolling , Wiesbaden, Gabler Verlag, 1996, p. 173.

- Schmelzle, F.; Institute for Advanced Sustainability Studies IASS; Kunkel, S.; Matthess, M.; Beier, G. Digitalisierte Industrie und Nachhaltigkeit - Zwischen Synergie und Dissonanz. Ind. 4.0 Manag. 2022, 2022, 7–11. [CrossRef]

- Funk, B.; Niemeyer, P. Abbildung von Umweltwirkungen in betrieblichen Informationssystemen. HMD Prax. der Wirtsch. 2010, 47, 37–46. [CrossRef]

- Richtlinie 2012/27/EU zur Energieeffizienz, 2012.

- Richtlinie 2010/75/EU über Industrieemissionen, 2010.

- DIN EN ISO 50001, 2018.

- Müller, J.; Müller, J.; Michos, G.; Koch, L.; Hermann, M.; Hubert, M.; Franke, J. Process and Energy Data Acquisition on Machining Center and Individual Machine Components. Appl. Mech. Mater. 2016, 856, 123–130. [CrossRef]

- Bitburger-Braugruppe. nachhaltigkeit bitburger braugruppe,“ 09 08 2023. [Online]. Available: https://nachhaltigkeit.bitburger-braugruppe.de/2022/klima-ressourcen.

- Wago. Energiemanagement,“ [Online]. Available: https://www.wago.com/de/energiemanagement/modulare-datenerfassung. [Access on 05 09 2022].

- Raspberry Pi Ltd. Raspberry Pi for industry – Raspberry Pi,“ [Online]. Available: https://www.raspberrypi.com/for-industry/. [Access on 20 02 2023].

- BMWK. Bundesministerium für Wirtschaft und Klimaschutz,“ 2023. [Online]. Available: https://www.bmwk.de/Redaktion/DE/Downloads/Energie/04_EEG_2023.pdf?__blob=publicationFile&v=1.

- FANUC. roboshot,“ [Online]. Available: https://www.fanuc.eu/de/de/roboshot/roboshot-zubeh%c3%b6r. [Access on 05 09 2022].

- Witt, E.; Anton, C. Additive Fertigung - Entwicklungen, Möglichkeiten und Herausforderungen,“ Deutsche Akademie der Naturforscher Leopoldina e.V. - Nationale Akademie der Wissenschaften; Union der deutschen Akademien der Wissenschaften e. V; acatech - Deutsche Akademie der Technikwissenschaften e. V, Halle (Saale); Mainz; München, 2020.

- Denkena, B.; Bergmann, B.; Becker, J.; Reimer, S.; Stiehl, T. Maschinen fehlerlos einfahren - Ausreißererkennung für Einzelteil- und Kleinserien,“ IT&Production online, p. 4, 22 04 2021.

- Güney, S. Alles unter Kontrolle - Prozessüberwachungssystem sichert Qualität beim Fertigen komplexer Teile auf Bearbeitungszentren.,“ maschinenmarkt, 28 09 2006.

- VDW. Verein Deutscher Werkzeugmaschinenfabriken e.V.,“ 2017. [Online]. Available: https://vdw.de/prozessautomatisierung-auf-dem-weg-in-die-wolken-3/.

- Moker, A.; Brosi, P. Digitalisierung in der Wartung - PredictiveMaintenance,“ in Systematische Entwicklung von Dienstleistungsinnovationen - Augmented Reality für Pflege und industrielle Wartung, Wiesbaden; Heidelberg, Springer Gabler, 2021, p. 94.

- Maier, D.; Sensorlose online Zustandserfassung von Vorschubantriebskomponenten in Werkzeugmaschinen, Stuttgart: IMA, 2015.

- ISO 13379-1, 2012.

- ISO 17359, 2018.

- Wolf, P. Schadensdedektion,“ in Messsystem zur Überwachung von Faserkunststoffverbunden, Chemnitz, 2012, pp. 58 -59.

- Czichos, H. Zustandsüberwachung von Maschinen,“ in Mechatronik - Grundlagen und Anwendungen technischer Systeme, Wiesbaden, Springer Vieweg, 2015, pp. 203 - 206.

- Wang, W. An Intelligent System for Machinery Condition Monitoring. IEEE Trans. Fuzzy Syst. 2008, 2, 110–122. [Google Scholar] [CrossRef]

- Yang, S.; Kearney, T.; Mo, J.; Boland, P. Machine GP – a new concept in signal-based machine condition monitoring and diagnostics,“ in 9th International Conference on Manufacturing Excellence 2003, Melbourne, Australia, 2003.

- AiSight GmbH. Plug & Predict - Proaktive Maschinenwartung für die Textilindustrie,“ Berlin, 2020.

- Uhlmann, E.; Röhner, M. Turbomaschinenforschung in Berlin-Brandenburg,“ in Turbomaschinen in Berlin-Brandenburg, Berlin, TSB Technologiestiftung Innovationszentrum Berlin, 2010, pp. 64 -65.

- Moker, A.; Brosi, P. Digitalisierung in der Wartung - PredictiveMaintenance,“ in Systematische Entwicklung von Dienstleistungsinnovationen - Augmented Reality für Pflege und industrielle Wartung, Wiesbaden, Heidelberg, Springer Gabler, 2021, p. 95.

- Babel, W. Prädiktive Wartung oder ‚Predictive Maintenance‘,“ in Industrie 4.0, China 2025, IoT - Der Hype um die Welt der Automatisierung, Wiesbaden; Heidelberg, Springer Vieweg, 2021, pp. 33-37.

- Holzer, P.; Pölzlbauer, G. Data Mining im Online Condition Monitoring: Vergleich gängiger statistischer Methoden,“ Institut für Maschinentechnik der Rohstoffindustrie, RWTH, Aachen, 2014.

- Lehmann, C.; Balun, R. Integrierte Geschäftsmodelle – Industrie 4.0-basierte Dienste in der Windkraftbranche,“ in Abschlussveröffentlichung: S-CPS: Ressourcen-Cockpit für Sozio-Cyber-Physische Systeme, Chemnitz, aw&I - Wissenschaft und Praxis, 2017, p. 197.

- Stefanie, M.; B. Van Leeuwen. Wegbereiter für die digitale Zukunft in der Industrie,“ Maschinenmarkt, 31 07 2017.

- Bruhn, M.; Hadwich, K.; Automatisierung und Personalisierung von Dienstleistungen - Konzepte - Kundeninteraktionen - Geschäftsmodelle, Wiesbaden: Springer Gabler, 2020, pp. 49 -67.

- Dombrowski, U.; Richter, T. Ganzheitliche Produktionssysteme und Industrie 4.0. 2016, 111, 771–774. [CrossRef]

- Königs, M.; Zeller, V. Schlussbericht: DigiKMU - Entwicklung einer Methode zur Unterstützung von KMU im Maschinen- und Anlagenbau bei der Umsetzung von Industrie 4.0 im Bereich der CAD-CAM-NC-Verfahrenskette,“ Aachen, 2017.

- Büscher, C.; Meisen, T.; Jeschke, S. ONTOLOGIEBASIERTES INFORMATIONSMANAGEMENT FÜR DIE FABRIKPLANUNG,“ in Digitales Engineering zum Planen, Testen und Betreiben technischer Systeme, Magdeburg, 2015, pp. 28 - 36.

- Parasuraman, R.; T.Sheridan, B.; C.Wickens, D. A model for types and levels of human interaction with automation,“ IEEE Transactions on Systems, Man, and Cybernetics - Part A:, pp. 286 - 297, 2000.

- Schneider, T. Trumpf: „So verändern Künstliche Intelligenz und Industrie 4.0 die Arbeitswelt“,“ automationspraxis., 4 3 2021.

- Osterhage, W.W. Stammdaten,“ in ERP-Kompendium - Eine Evaluierung von Enterprise Resource Planning Systemen, Berlin, Springer, 2014, pp. 85 -86.

- Bauer, J. Grundlagen der Produktionslogistik,“ in Handbuch Maschinenbau - Grundlagen und Anwendungen der Maschinenbau-Technik, Wiesbaden, Springer Fachmedien Wiesbaden, 2021, pp. 1702 - 1704.

- ISA. ISA95, Enterprise-Control System Integration- ISA,“ ISA, 2023.

- Kletti, J.; Deisenroth, R. Verwaltung der NC-Programme und Einstelldatensätze,“ in MES-Kompendium, Berlin, Springer, 2019, p. 160.

- Kletti, J. DNC und Einstelldaten,“ in MES - Manufacturing Execution System - Moderne Informationstechnologie unterstützt die Wertschöpfung, Berlin; Heidelberg, Springer Vieweg, 2015, p. 94.

- Hehenberger, P. Fertigungsleitsysteme,“ in Computerunterstützte Fertigung - Eine kompakte Einführung, Berlin, Heidelberg, Springer, 2011, pp. 187 - 192.

- K.-Büttner, H.; Brück, U. Use Case Industrie 4.0-Fertigung im Siemens Elektronikwerk Amberg,“ in Handbuch Industrie 4.0 Bd.4 - Allgemeine Grundlagen, Berlin, Heidelberg, Springer, 2016, pp. 53, 59.

- Wölfle, R.; Matter, P. Logistikketten für Lebensmittel,“ in Prozessexzellenz mit Business Software, München; Wien, Hanser, 2006, pp. 212 - 213.

- J. Van der Vorst. Performance levels in food traceability and the impact on chain designe: Results of an international benchmark study,“ in Dynamics in chains and networks, Wageningen, Wageningen Academic Publishers, 2004, pp. 175 -176.

- Lichtenberger, S. Abgrenzung zu Traceability eines ERP-Systems,“ in Konzeption und Realisierung eines standardisierten Erfassungs- und Auswertesystems zur Chargenrückverfolgung in der Serienproduktion, Wien, Technische Universität Wien, 2016, p. 78.

- Hippenmeyer, H.; Moosmann, T.; Automatische Identifikation für Industrie 4.0, Berlin: Springer Vieweg, 2016.

- Voigt, T.; Neue Methoden für den Einsatz der Informationstechnologie bei Getränkeabfüllanlagen, München: Technischen Universität München, 2004.

- Brauckmann, O. Integration von BDE und CAQ - Eingabe von Chargen am BDE-Terminal,“ in Integriertes Betriebsdaten-Management - Wie Sie Ihre Wertschöpfung in IT-Regelkreisen optimieren, Wiesbaden, Gabler Verlag, 2002, p. 138.

- Martin, E.; Morris, A.; Papazoglou, M.; Kiparissides, C. Batch process monitoring for consistent production. Comput. Chem. Eng. 1996, 20, S599–S604. [CrossRef]

- Streicher, D. Digitaler Zwilling in der Fertigung,“ Zeitschrift für wirtschaftlichen Fabrikbetrieb, p. 36–37, 2020.

- Schmid, D. Herstellen,“ in RFID im Mobile Supply Chain Event Management, Wiesbaden, Gabler Verlag, 2006, p. 66.

- Röschinger, M.; Stockenberger, D.; W.Günthner, A. Werkzeugmanagement in der Cloud - Potenziale einer unternehmensübergreifenden Cloud-Lösung für ein digitales und automatisiertes Werkzeugmanagement,“ Industrie Managment, Nr. 1, pp. 52 -56, 2014.

- Pohl, M.; Schreiber, P.; Tengg, G. Werkzeugeinlagerungshelfer - Assistenz-system für Zerspanungsunternehmen,“ Mittelstand-Digital Magazin Wissenschaft trifft Praxis, Nr. 13, pp. 36 -41, 2020.

- J. Aurich, C.; Faltin, M.; Kempf, F.A.; G. RFID für ein effizientes Werkzeugmanagement,“ Zeitschrift für wirtschaftlichen Fabrikbetrieb, Nr. 7-9, pp. 642 - 647, 2009.

- D. v. Geerenstein. Maschinengenerierte Daten,“ in Handbuch Industrie 4.0: Recht, Technik, Gesellschaft, Berlin; Heidelberg, Springer, 2020, pp. 640 - 649.

- D. v. Geerenstein. Gesetzliche Haftung: Produkt- und Produzentenhaftung,“ in Handbuch Industrie 4.0: Recht, Technik, Gesellschaft, Berlin; Heidelberg, Springer, 2020, pp. 649 - 652.

- Schimmelpfeng, K. Personalcontrolling,“ in Lebenszyklusorientiertes Produktionssystemcontrolling - Konzeption zur Verfügbarkeitssicherung hochautomatisierter Produktionssysteme, Wiesbaden, Deutscher Universitätsverlag, 2001, pp. 81 - 83.

- Wienkamp, H. Der Weg zum Personalkennzahlensystem,“ in Der Weg zum Personalkennzahlensystem, Berlin, Heidelberg, Springer Berlin Heidelberg, 2020, pp. 21 - 52.

- Wojak, S. Intelligente Kollektiv-Algorithmen in der Personalverwaltung - Betrachtung ausgewählter Problemfelder zweier fiktiver Szenarien nach Art. 22 DS-GVO,“ Datenschutz und Datensicherheit, pp. 553 - 557, 9 2018.

- thyssenkrupp Materials IoT GmbH. Maschinendatenerfassung,“ [Online]. Available: https://www.thyssenkrupp-materials-iot.com/de/glossar/maschinendatenerfassung. [Access on 02 02 2023].

- Jagusch, K.; Beuß, F.; Sender, J.; Flügge, W. Intelligente Montageassistenz - Durch Identifikation und Bauteilmanipulation zum flexiblen Arbeitsplatzsystem,“ Zeitschrift für wirtschaftlichen Fabrikbetrieb, 6 2018.

- Kletti, J.; Deisenroth, R. Manuelle Datenerfassung und Information der Mitarbeiter,“ in Lehrbuch für digitales Fertigungsmanagement, Berlin; Heidelberg, Springer Vieweg, 2021, pp. 61 - 62.

- Lanza, G.; Nyhuis, P.; Ansari, S.M.; Kuprat, T.; Liebrecht, C. Befähigungs- und Einführungsstrategien für Industrie 4.0,“ Zeitschrift für wirtschaftlichen Fabrikbetrieb, pp. 76 - 79, 2016.

- Vogt, H.; Ehrat, M.; Fuchs, R.; Holler, M. Welche datenbasierten Servicemodelle sind erfolgsversprechend für KMU der Maschinen , Anlagen , Elektro- und Metallindustrie?,“ HMD (HMD Praxis der Wirtschaftsinformatik), p. 521–536, 16 04 2021.

- Brumby, L. Digitale Transformation in der Instandhaltung,“ in Services Management und digitale Transformation - Impulse und Beispiele für die erfolgreiche Umsetzung digitaler Services, Wiesbaden; Heidelberg, Springer Gabler, 2021, pp. 379 - 396.

- Lüder, A.; Steininger, H.; Goltz, D. Quo vadis Automation?,“ at - Automatisierungstechnik, p. 6–15, 2023.

- Sauer, O.; M.Haller, L.; S. Wagner-Sardesai, Henke, J.; Schmelting, J.; Meyer, T.; Kujath, M.; Seidel, H.; Kuhn, T.; Schnicke, F.; Harst, S.; Wenzel, K. Manufacturing-X: Die Branche der Fabrikausrüster,“ Fraunhofer-Gesellschaft, 2023.

- Thorade, N.; Vernetzte Produktion - Computer Integrated Manufacturing (CIM) als Vorgeschichte von Industrie 4.0, Bonn: Friedrich-Ebert-Stiftung, 2020.

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).