1. Introduction

As per the 2018 United Nations report, more than 82% of the population in North America resides in metropolitan regions. Forecasts indicate that this might potentially rise to 90% by the mid-point of the current century [

1]. Consequently, Roads are crucial for the establishment of an efficient transportation network [

2]. Due to its low noise, good wear resistance, abundant raw materials, great strength, low fuel consumption, and excellent comfort, asphalt pavement is the predominant choice for roadways [

3]. Approximately 94% of roadways in the United States of America are surfaced with asphalt mixtures. According to comparable data, the proportion of roads in Canada made of asphalt pavement is above 90%, while in Mexico it is 96% [

4].

Most pavements in humid and wet regions experience failures such as rutting and stripping [

5]. These failures are caused by factors such as traffic stress, hot temperature and water [

6,

7,

8]. The greater affinity of the aggregate surface for water, as compared to asphalt, is regarded as the primary catalyst for the stripping phenomenon in asphalt mixtures [

9]. The adhesion between bitumen and aggregates plays a crucial role in determining the stability of flexible pavement. The problem of stripping, which varies depending on the kind of aggregates, can be attributed to the ionic nature of the aggregates [

10]. The chemical affinity between asphalt and aggregate can be enhanced by introducing minute amounts of chemicals that alter the properties of either the asphalt or the aggregate, thus increasing their mutual attraction. These substances are commonly referred to as "Anti-stripping Agents" or "adhesion promoters" [

11,

12].

From a technical perspective, various forms of anti-stripping agents have been proposed to mitigate pavement stripping. Two particularly noteworthy solutions are chemical modification, which involves adding liquid anti-stripping materials or using hydrated lime filler, and physical modification, which involves polymer modification of aggregates [

13,

14]. The majority of the liquid additives demonstrated enhanced unconditioned properties, however, they failed to sustain the improvement following moisture conditioning. There is a new type of nanotechnology called organo-silicon-based anti-stripping additives that is gaining popularity. This technology makes use of the strong chemical link between silicon atoms, which is known to be the strongest bond found in nature [

15,

16,

17]. Zycotherm and Zycosoil are liquid silane-based additives that effectively enhance the resistance of asphalt mixtures to moisture damage. These additives act as silane coupling agents, forming covalent bonds between the organic and inorganic phases. This results in the formation of durable adhesive bonds that remain intact even under unfavorable environmental conditions [

18,

19,

20,

21].

Choosing the appropriate type and dose of anti-stripping additives is no doubt vital to the intended performance. Therefore, it is critically important to determine the dose of the additives used in the modification of asphalt binders. In practice, the quantity of the additives should be precisely controlled and managed. Currently, no effective methods have been developed yet to measure the dose of siloxane-based anti-stripping liquid agents, thus making the quality administration (QA) and quality control (QC) of the modified binders extremely difficult. As a result, the applications of these promising, beneficial, innovative technologies have been seriously hindered, considering that asphalt mixture pavement has been increasingly adopted in millions of miles of Georgia highways.

The objective of this research is to exam the feasibility of detecting the dose of siloxane-based anti-stripping liquid agents, i.e., Zycotherm in their modified asphalt binders by combustion-based method. Commonly used equipment for quantitative analysis of asphalt binders will be examined thoroughly and compared with each other in terms of their feasibility in terms of repeatability, accuracy, and time of measurement. The method concentrates on the selection of suitable equipment, sample preparation, and calculation formulas to achieve the highest accuracy, repeatability, and reproducibility.

2. Materials and Methods

2.1. Materials

2.1.1. Asphalt

In this study, PG 64-22 Asphalt binder was used as a base binder which was later modified by Zycotherm.

Table 1 displays the precise technical specifications of the base asphalt binder.

2.1.2. Zychotherm

ZycoTherm was utilized as an additive to enhance the characteristics of asphalt. ZycoTherm is essentially an upgraded version of Zycosoil, with improved specifications in all aspects. Zycosoil is an organosilane compound derived from Silanol groups (Si–OH). Silanol groups exhibit reactivity and establish a siloxane linkage (Si–O–Si) with the silanol groups present on mineral surfaces, including minerals found on the surface, soil, and gravel. The hydrophobic siloxane linkages are not easily removed by washing, as they form a strong chemical bond with the surface materials.

The physical and chemical characteristics of ZycoTherm, which were utilized in this investigation, are outlined in

Table 2.

2.1.3. Mixing Process of ZycoTherm in Asphalt Binder

The wet method involved the employment of a low-speed mixer to mix Zycotherm into the base binder PG 64-22. Zycotherm was introduced into the binder by the weight of asphalt binder in four distinct proportions (0%, 0.05%, and 0.1%). The Zychotherm was mixed with Asphalt binder at a low shear mixing speed of 700 rpm for a duration of 45 minutes. The entire mixing procedure was carried out at a temperature of 135°C. To get the desired outcome, ZaycoTherm should be introduced gradually and continuously stirred.

2.2. Test Methods

2.2.1. Oxygen Bomb Calorimeter

2.2.1.1. Experimental Apparatus

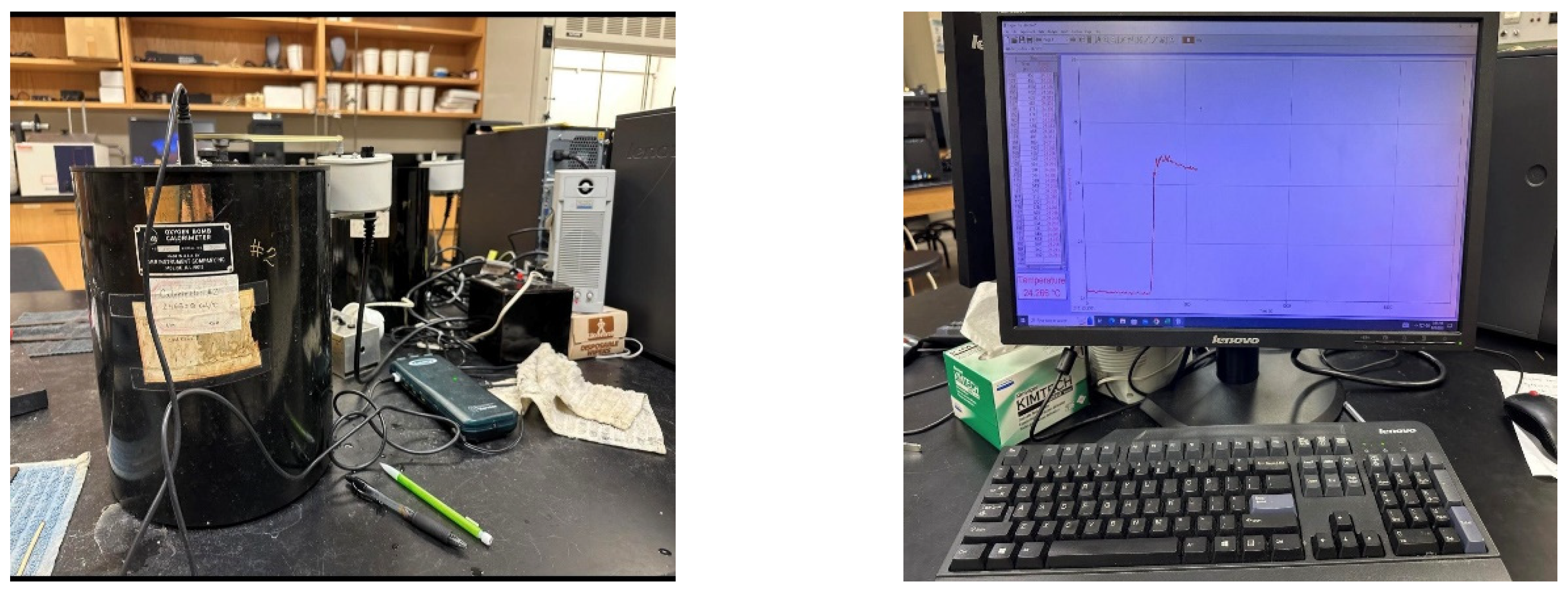

This study utilized an oxygen bomb calorimeter manufactured by PARR Instrument Company INC. The interior chamber of the calorimeter was filled with deionized water. The temperature of the water was monitored with a high precision of 10-4 K at 30-second intervals using a SWC-II digital Beckmann thermometer. Furthermore, the Zychotherm mixed Asphalt binder samples were compressed using a tablet machine at a laboratory size. The samples were weighed using an Ohaus PX224 Pioneer Analytical Balance, which has a minimum sensitivity of ±0.1 mg.

Figure 1.

Oxygen Calorimeter Setup.

Figure 1.

Oxygen Calorimeter Setup.

2.2.1.2. Experimental Procedure

To reliably assess the heat combustion value of binder samples, it is necessary to strictly adhere to the experimental techniques. The primary experimental protocols were presented as follows.

Initially, the combination of Zychotherm and asphalt binder was measured using the Ohaus PX224 Pioneer Analytical Balance. Subsequently, it was compressed into slices using a laboratory-scale tablet machine. Subsequently, the ignition wire was linked to the ignition electrodes, before the attachment of the oxygen bomb's cover. Later, the lid was securely fastened, and oxygen was introduced into the oxygen bomb until the gauge pressure reached the predetermined value of 4 MPa. Subsequently, the testing circuit was linked. Eventually, around 2 kilograms of water were put into the inner barrel, and the measurement process began. The collected data were examined using the methodology suggested in the relevant literature. It is important to note that each mixed sample condition involved five repetitions of the measurement.

2.2.2. Ignition oven

2.2.2.1. Experimental Apparatus

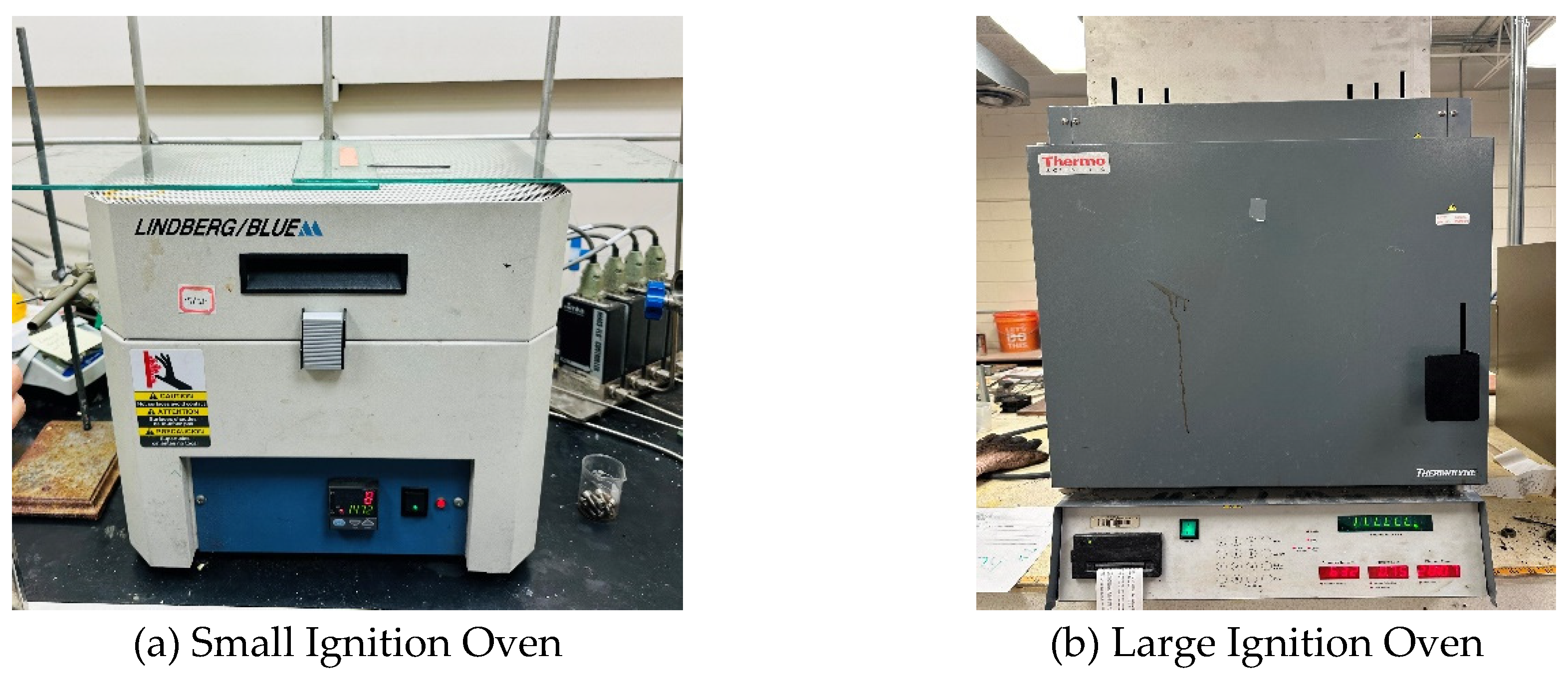

This study included two distinct sizes of NCAT Asphalt Content Furnace manufactured by Thermo Fisher Scientific business. Due to spatial constraints, the small oven was unable to oxidize the 20g large sample. Consequently, the ignition process for the larger sample was conducted in two separate stages. First, incinerate the sample in the larger oven, then subject it to oxidation in the smaller oven. The 10g sample was completely burned by the tiny oven oxidation alone.

2.2.2.2 Experimental Procedure

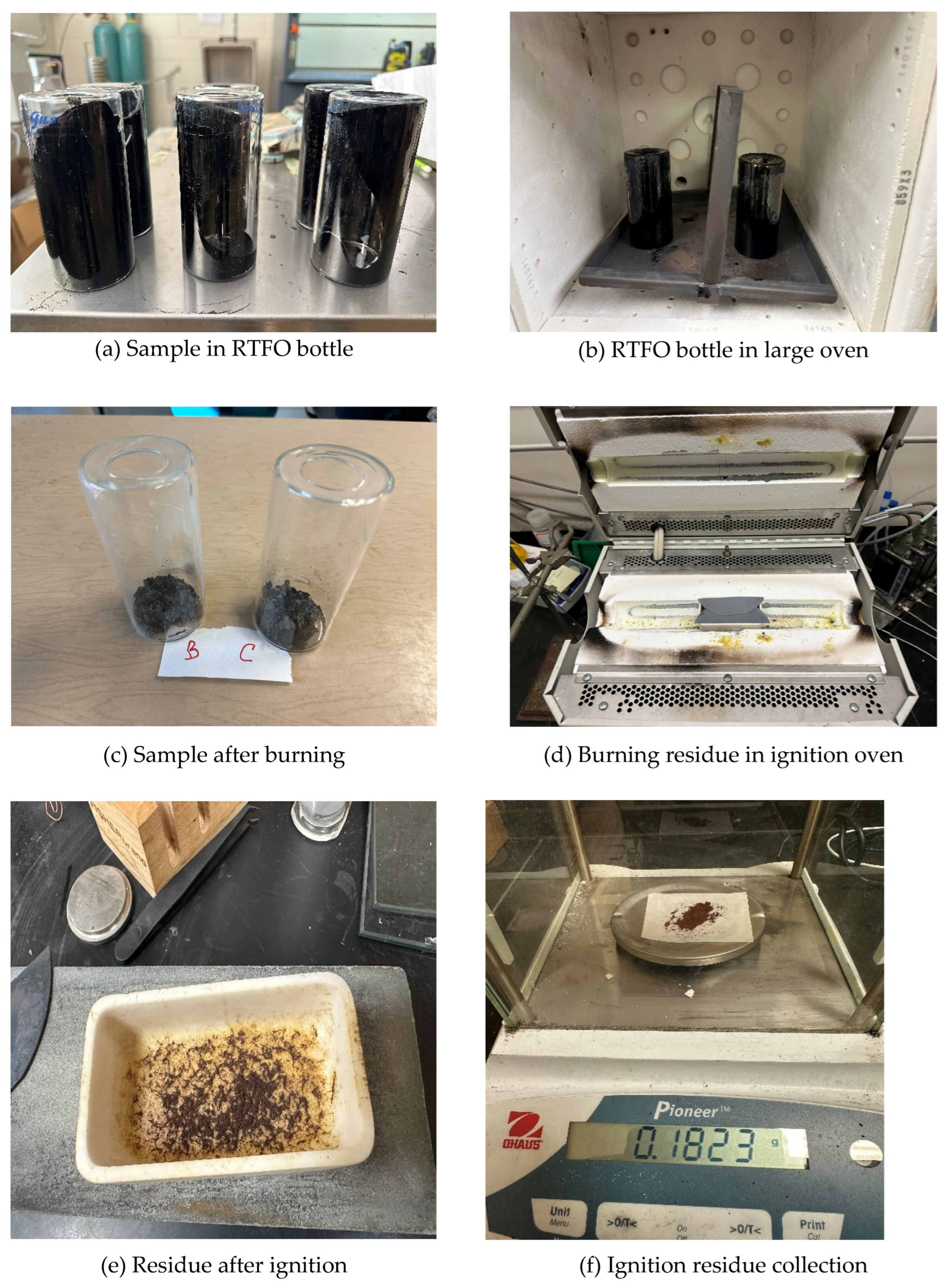

The 20g sample was initially weighed using the Ohaus PX224 Pioneer Analytical Balance and then transferred into the Rolling Thin Film Oven container. Subsequently, the RTFO bottles were positioned within the expansive Furnace oven to undergo combustion. Following the combustion procedure, charred specimens were gathered and subsequently relocated to the compact furnace for ignition. Once the ignition residue samples were gathered, they were measured using a balance.

Figure 3.

Burning and Ignition of a Large Sample. (a) Weighed sample in RTFO bottle (b) RTFO bottle placed in large oven for burning (c) Samples after burning (d) Burned sample placed in small oven for ignition (e) Residue after ignition (f) Ignition residue.

Figure 3.

Burning and Ignition of a Large Sample. (a) Weighed sample in RTFO bottle (b) RTFO bottle placed in large oven for burning (c) Samples after burning (d) Burned sample placed in small oven for ignition (e) Residue after ignition (f) Ignition residue.

For the 10 g samples, the sample was directly placed in the tiny furnace for ignition, and the residue collected after ignition was weighed.

2.2.3. Scanning electron microscopy (SEM)

The microstructure characteristics of siloxane-modified asphalt were examined using the SEM EPMA (S-570) equipment developed by the Hitachi Group. This analysis aimed to observe the change and existence of silicon in asphalt binder.

3. Results

3.1. Oxygen Bomb Calorimeter Test

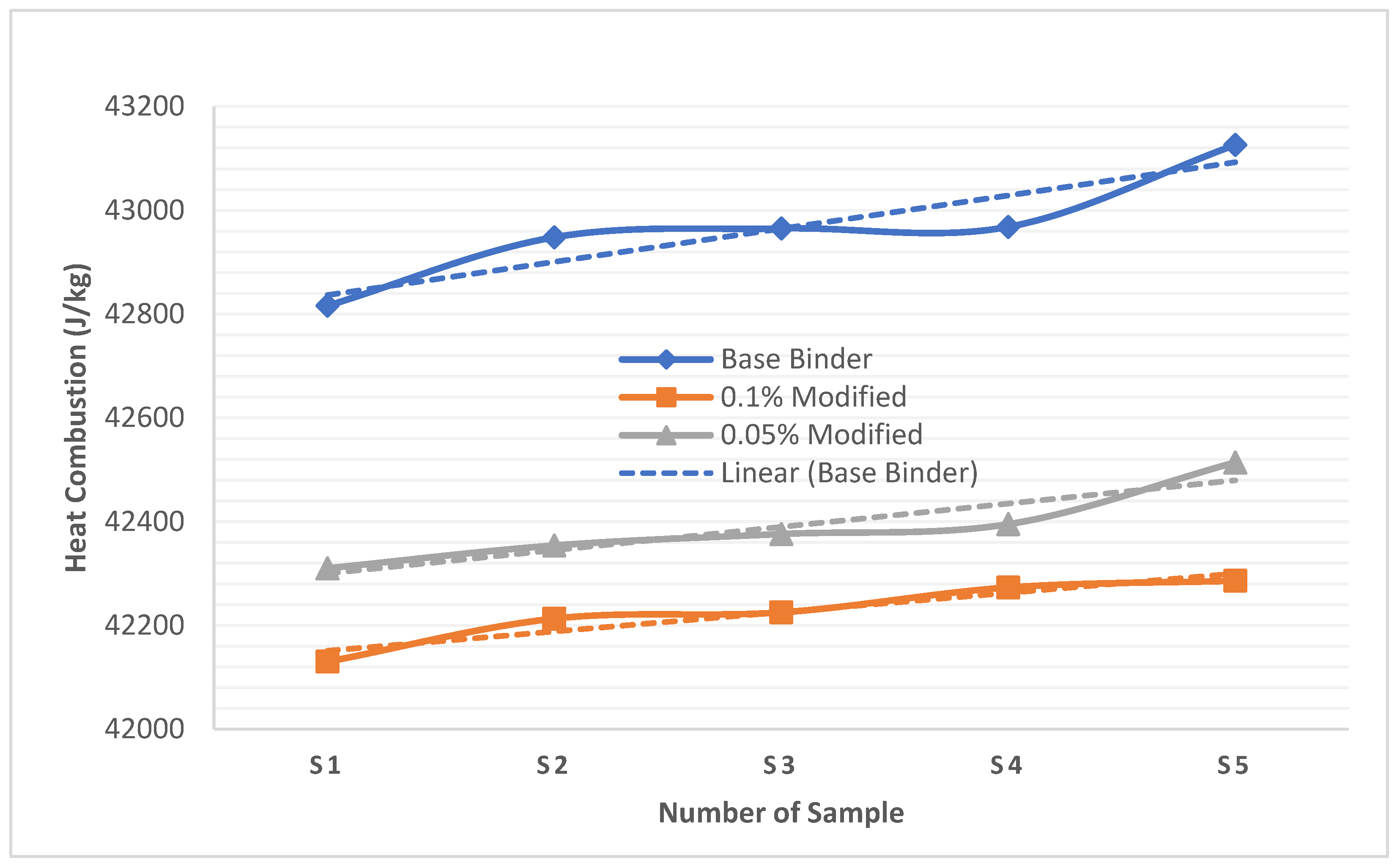

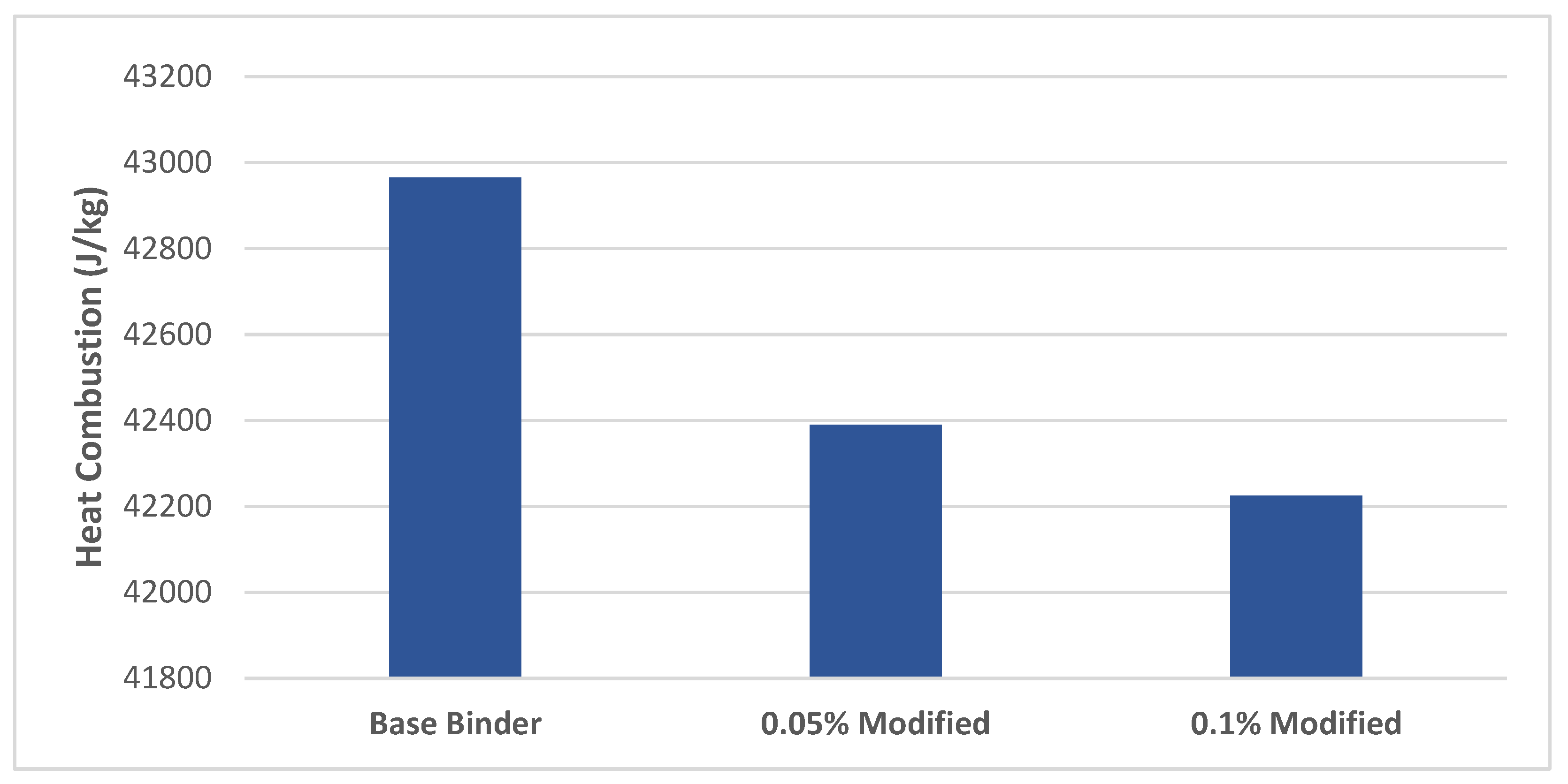

The results from the oxygen Bomb Calorimeter (

Figure 4) demonstrate that the inclusion of Zychotherm additives generally leads to a decrease in the heat combustion value. An explanation for the decrease in heat combustion value can be provided. When siloxane-based additives undergo oxidation in oxygen, siloxanes are transformed into silicon dioxide (SiO

2), along with the formation of volatile carbon dioxide and water [

21,

22]. The following is an example of the oxidation reaction of materials containing siloxane:

Upon analyzing the five repetitions for each sample of heat combustion, it is evident that the heat combustion value of the 0.05% modified and 0.1% modified binder fell by 1.18% and 1.61% respectively compared to the basic binder, resulting in the lowest heat combustion value. For optimal combustion efficiency, these values decrease by 1.34% and 1.72% correspondingly.

Heat combustion value differs from 42816 J/g - 43126 J/g, 42130 J/g - 42286 J/g and 42310 J/g – 42514 J/g respectively for unmodified, 0.05% modified, and 0.1% modified asphalt binder. We believe that the less flammable siloxanes added to the flammable asphalt matrix can retard the oxidation process and thus result in lower combustion heat values as showcased in

Figure 5.

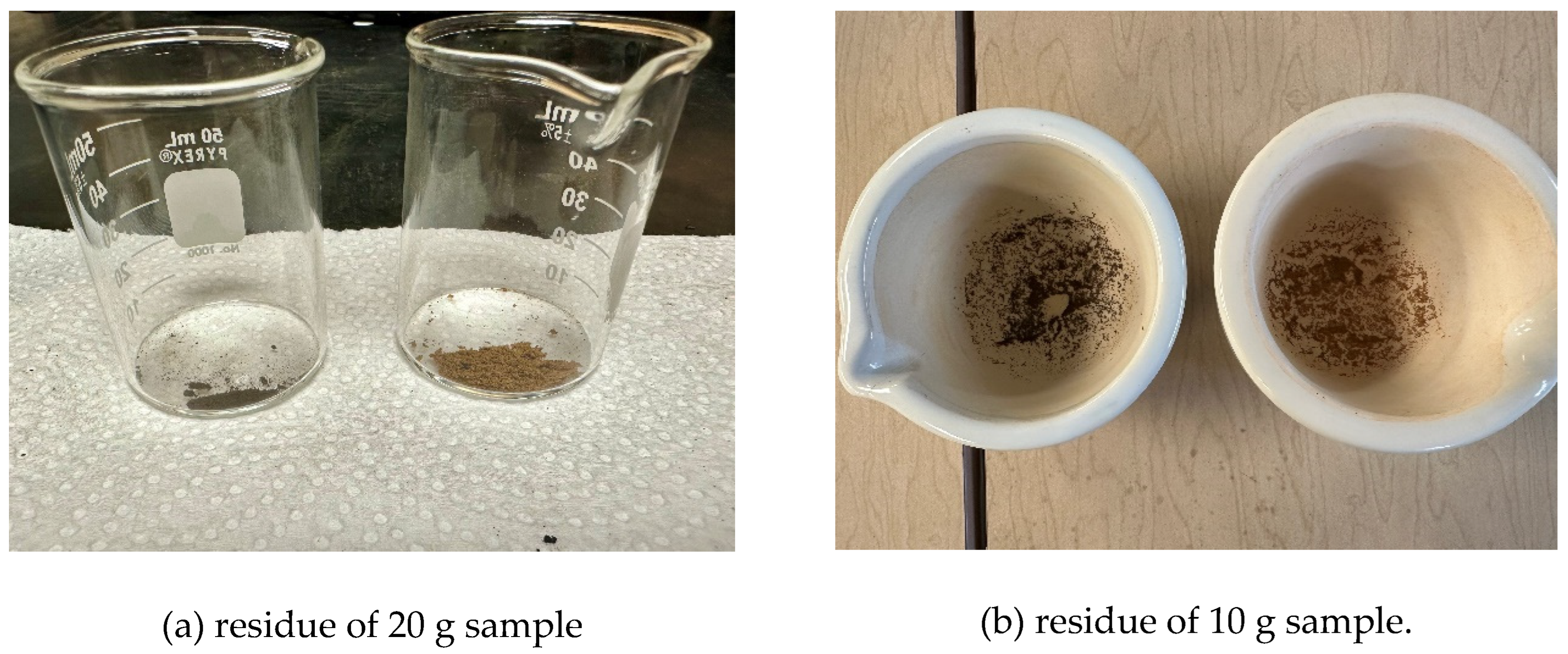

3.2. Detection by residue visualization

Zychotherm can be readily identified by observing the residue left behind following the ignition of the samples. The residue of Zychotherm-modified asphalt was yellowish, while the residue of untreated binder appeared as a dark black color. This phenomenon can be elucidated. Despite being colorless, Silica exhibited color in the residue. The primary factor is that the majority of asphalt binders consist of Vanadium Oxide (V

2O

5), which imparts a dark brown hue. Additionally, the presence of silica mixed with Vanadium Oxide (V

2O

5), results in a yellowish appearance in samples containing siloxanes.

Figure 6 displays the color of both unmodified and modified residues.

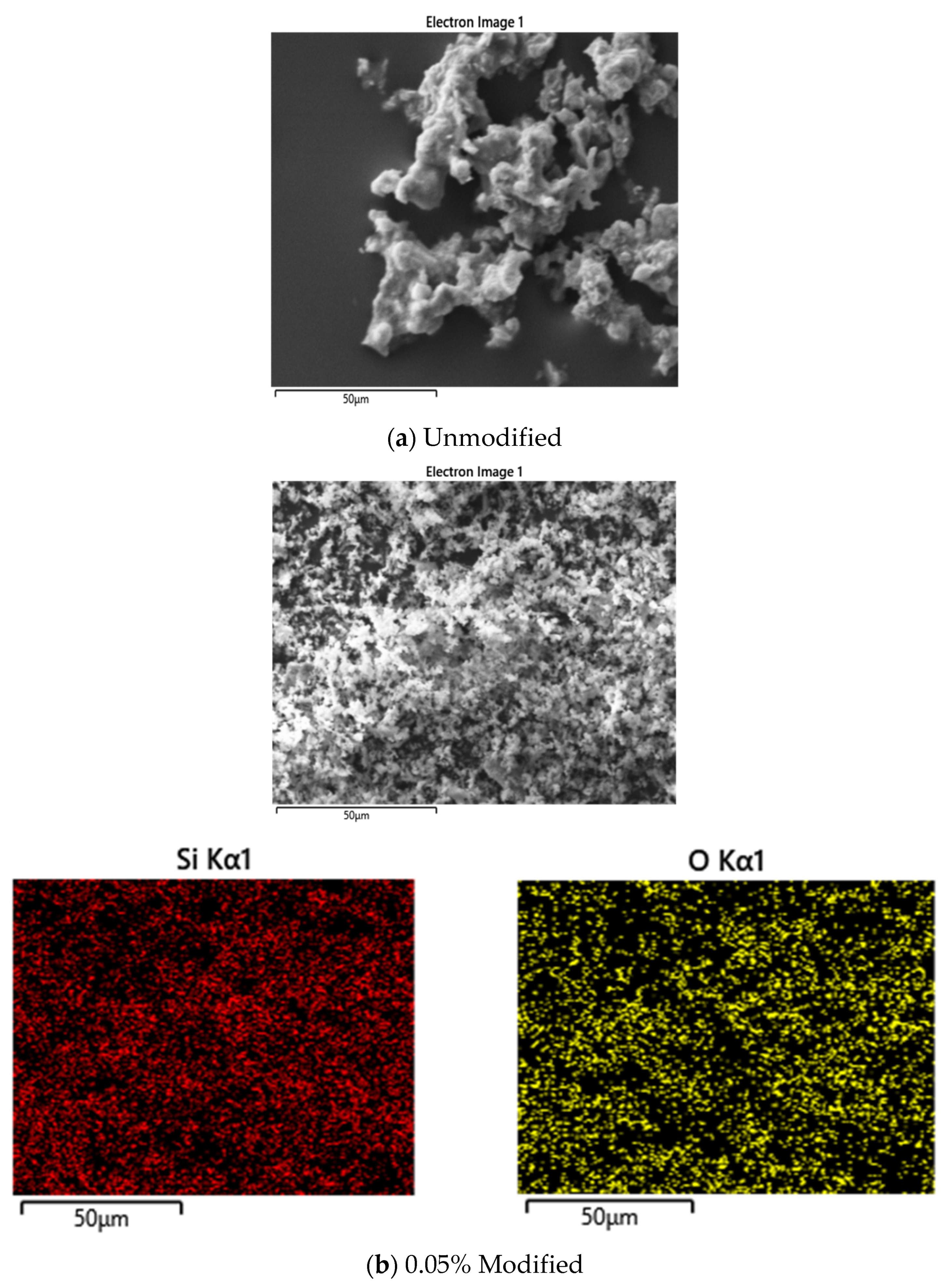

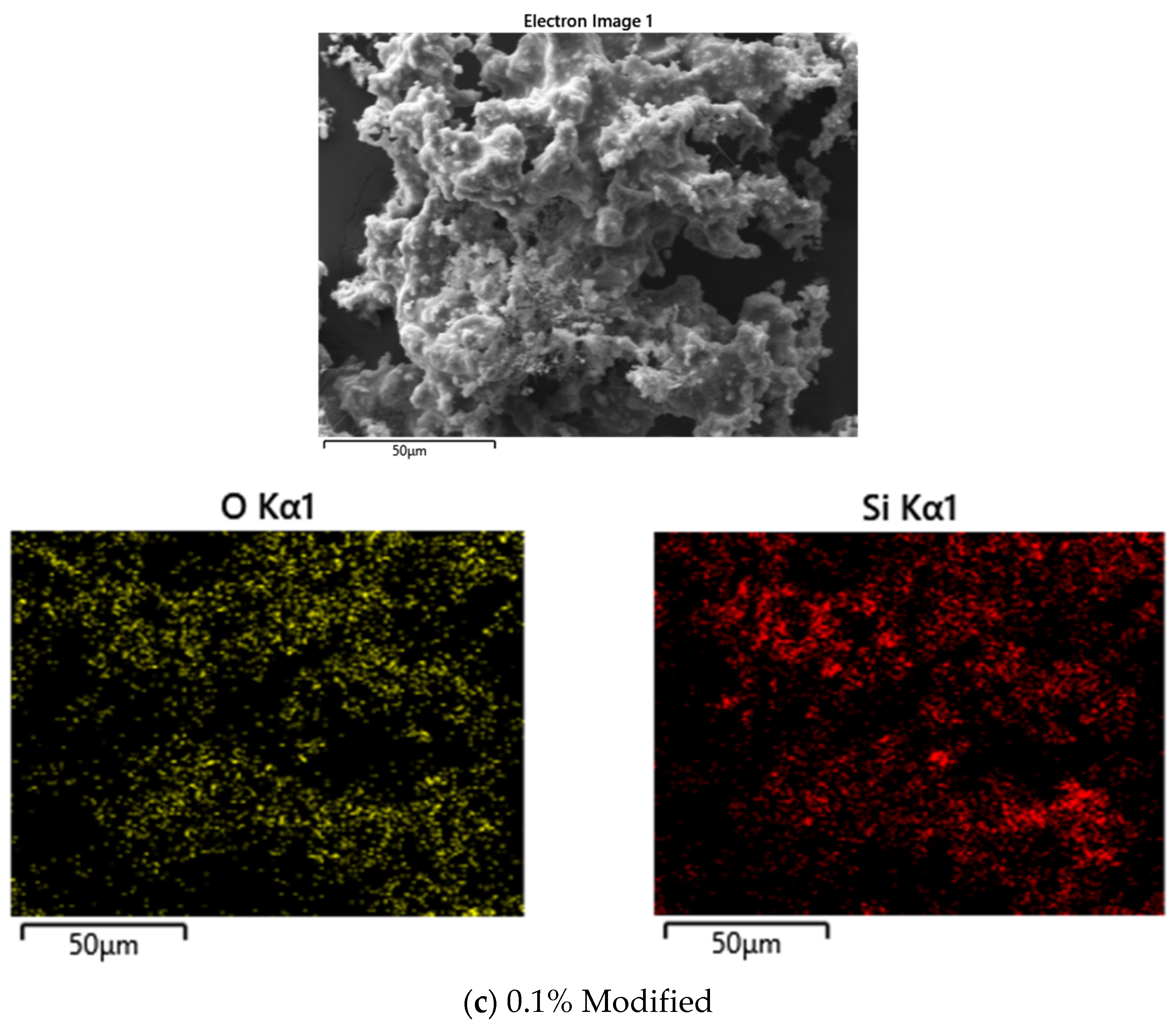

3.3. Scanning electron microscopy (SEM) analysis

Figure 7 shows the SEM images of the modified and unmodified asphalt binder.

All the above images were collected using a field-emission scanning electron microscope attached to an EDX analyzer.

Figure 7 (b &c) has a medium concentration of siloxanes;

Figure 7(a) has a low or zero concentration of siloxanes.

3.4. Sample size effect

Although it is possible to detect Zychotherm-modified asphalt binder by visualizing their residue color it is not possible to quantify the amount of Zychotherm.

For quantifying the amount of Zychotherm, the residue for each sample was carefully weighed by Ohaus PX224 Pioneer Analytical Balance.

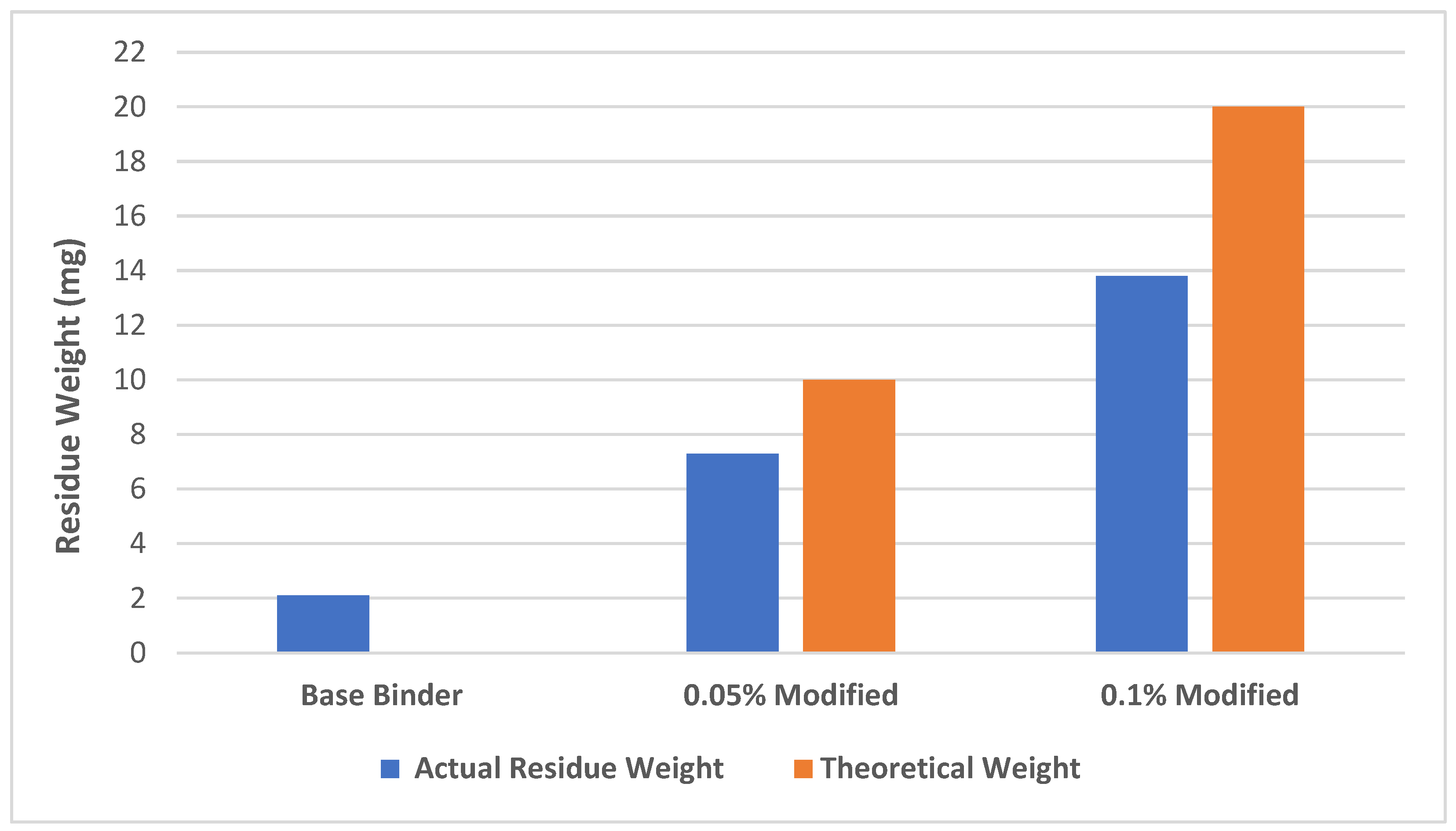

Figure 8 shows the actual residue weight and the theoretical residue weight for the 20 g sample. The actual residue weight is lower than the theoretical residue weight by 27% and 31% for 0.05% Zychotherm-modified and 0.1% Zychotherm-modified samples respectively. The error is quite high because when the 20g sample burnt in the large oven some of the sample overflowed from the RTFO bottle due to the volume expansion of the samples. It may cause the loss of some portion of Zychotherm with the sample. To avoid the loss of sample due to volume expansion, in the next step sample weight reduces to 10g from 20g.

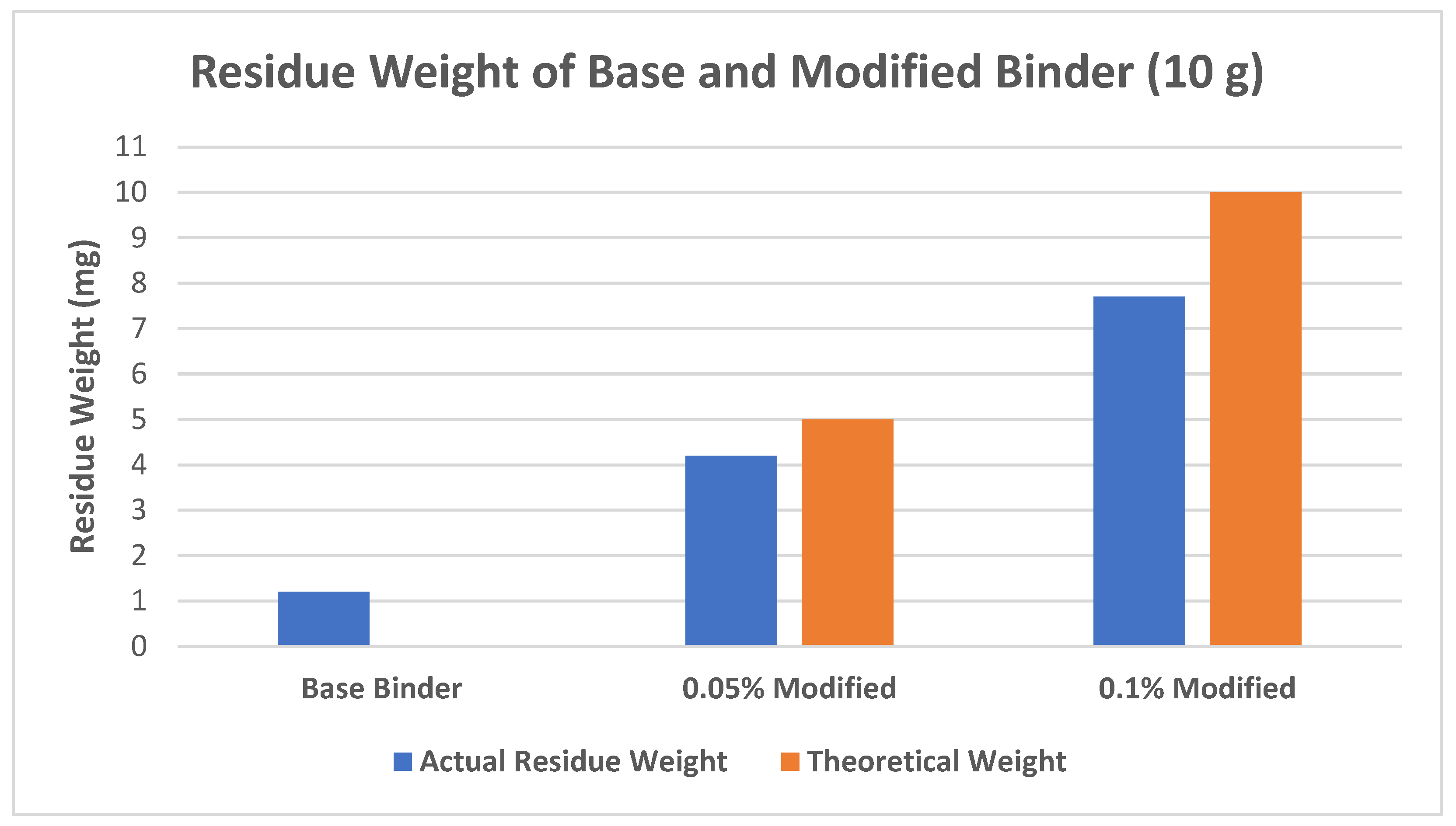

By reducing the weight of the sample result precession is increased.

Figure 9 depicts the residue weight for both modified and unmodified binders, where the difference between the actual and theoretical residue weight is much lower than the 20g sample. The actual residue weight is lower than the theoretical residue weight by 16% and 23% for 0.05% Zychotherm-modified and 0.1% Zychotherm-modified samples respectively.

4. Discussion

The objective of this study was to examine the feasibility of developing a detection technique capable of quantifying the concentration of siloxane-based anti-stripping liquid agents, specifically Zycotherm, in modified asphalt binders. Based on the diverse testing outcomes, the subsequent conclusions can be inferred:

By visualizing the residue after ignition, it was true for all the samples that Zychotherm-modified binder leaves yellowish substances. The SEM-EDX data also supports this statement.

All testing results from heat combustion results showed that with the addition of Zychotherm anti-stripping additive, heat combustion value decreased appreciably. As fewer flammable siloxanes were added to the flammable asphalt matrix can retard the oxidation process and thus result in lower combustion heat values.

Residue from 10 g of modified binders showed better results than 20 g of modified binders for every percentage of Zychotherm mixing.

The mass of silica residue is nearly in direct proportion to the concentration of siloxanes present in the asphalt.

This study tried to make the result as precise as possible yet there is more scope to improve the result through advanced techniques. For further studies, Gel Permeation Chromatography (GPC), and Fourier Transform Infrared Spectroscopy (FTIR) can be examined together as a combined microanalysis tool for better results.

Author Contributions

Conceptualization, J.S. and J.W.; methodology, J.S. and J.W.; software, R.H.R.; validation, J.S. and J.W.; formal analysis, R.H.R.; investigation, R.H.R.; resources, J.S. and J.W.; data curation, R.H.R.; writing—original draft preparation, R.H.R.; writing—review and editing, J.S. and J.W.; visualization, R.H.R.; supervision, J.S. and J.W.; project administration, J.S. and J.W.; All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data provided in this study can be obtained from the respective authors upon a reasonable request.

Acknowledgments

Thanks are extended to Dr. Peter Wu, Bureau Chief, Georgia Department of Transportation for his technique discussion and the samples tested, and to Dr. Jim Lobue from the Department of Biochemistry, Chemistry, and Physics for his assistance in the use of the Oxygen bomb calorimeter.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- 2018 Revision of World Urbanization Prospects | Multimedia Library - United Nations Department of Economic and Social Affairs. (2018). https://www.un.org/development/desa/publications/2018-revision-of-world-urbanizationprospects.html.

- Ma, B., Chen, S. S., Wei, K., Liu, F. W., & Zhou, X. Y. (2019). Analysis of thermoregulation indices on microencapsulated phase change materials for asphalt pavement. Construction and Building Materials, 208, 402-412. [CrossRef]

- Zheng, S., Zhu, J., Wu, Y., & He, J. (2023). Analysis of Asphalt Concrete Highway Construction Technology in Highway Engineering. Journal of Theory and Practice of Engineering Science, 3(11), 27-33. [CrossRef]

- Virginia Asphalt Association. (2020). https://vaasphalt.org/asphalt-facts/why-choose-asphalt-2/.

- Kerh T, Wang Y-M, Lin Y. Experimental evaluation of anti-stripping additives mixing in road surface pavement materials. Am J Appl Sci 2005;2(10):1427–33. [CrossRef]

- Xie, Z., & Shen, J. (2016). Fatigue performance of rubberized stone matrix asphalt by a simplified viscoelastic continuum damage model. Journal of Materials in Civil Engineering, 28(4), 04015162. [CrossRef]

- Xie, Z., Shen, J., Fan, W., & Wang, L. (2014). Laboratory investigation of the effect of warm mix asphalt (WMA) additives on the properties of WMA used in China. Journal of testing and Evaluation, 42(5), 1-8.Kiggundu BM, Roberts FL. Stripping of in HMA mixtures: state of art and critical review of test methods. NCAT Report no. 88-2; 1998. [CrossRef]

- F., Amirkhanian, S., Putman, B., & Shen, J. (2010). Laboratory investigation of engineering properties of rubberized asphalt mixtures containing reclaimed asphalt pavement. Canadian Journal of Civil Engineering, 37(11), 1414-1422. [CrossRef]

- Chauhan, G. S., & Tripathy, S. (2019). Influence of Zycotherm on Properties of Bituminous Concrete Mix.

- Ghabchi, R., Rani, S., Zaman, M., & Ali, S. A. (2021). Effect of WMA additive on properties of PPA-modified asphalt binders containing anti-stripping agent. International Journal of Pavement Engineering, 22(4), 418-431. [CrossRef]

- Nazirizad, M., Kavussi, A., & Abdi, A. (2015). Evaluation of the effects of anti-stripping agents on the performance of asphalt mixtures. Construction and Building Materials, 84, 348-353. [CrossRef]

- Guha, S., & Kumar, A. (2018). A literature review on anti-strip additives in asphalt mixture. International Journal of Science and Research, 2. [CrossRef]

- Mirzababaei, P., Moghadas Nejad, F., & Naderi, K. (2020). Effect of liquid silane-based anti-stripping additives on rheological properties of asphalt binder and hot mix asphalt moisture sensitivity. Road Materials and Pavement Design, 21(2), 570-585. [CrossRef]

- Fakhri, M., Vanaei, V., & Rahi, M. (2014). “Rheological evaluation of the effect of nano-liquid additives on bitumen properties.” In 8th national congress on civil engineering. Nooshirvani Babol university of technology.

- Dai, Z., Shen, J., Shi, P., Zhu, H., & Li, X. (2018). Nano-sized morphology of asphalt components separated from weathered asphalt binders. Construction and Building Materials, 182, 588-596. [CrossRef]

- Shen, J., Huang, B., Shu, X., & Tang, B. (2011). Size effect of sub nano-scaled hydrated lime on selected properties of HMA. International Journal of Pavement Research and Technology, 4(4), 252.

- Arabani, M., & Hamedi, G. H.Using the surface free energy method to evaluate the effects of polymeric aggregate treatment on moisture damage in hot-mix asphalt. Journal of Materials in Civil Engineering 2010, 23, 802–811. [CrossRef]

- Buechler, S., Wistuba, M. P., & Falchetto, A. C. (2016). “Mixing and compacting asphalt mixtures modified with silane molecules.” In 6th Eurasphalt & Eurobitume Congress. Prague, Czech Republic.

- Sybilski, D., Wistuba, M. P., Bankowski, W., Buechler, S., & Heinrich, P. (2015). Investigation on binder-aggregate adhesivity using a nanotechnology chemically reactive silane additives based agent. Bituminous Mixtures and Pavements VI, 447.

- Vanaei, V. (2013). Evaluation of the moisture susceptibility of asphalt mixtures in cold regions. Tehran: University of K.N.Toosi.

- Chagger, H. K., Hainsworth, D., Patterson, P. M., Pourkashanian, M., & Williams, A. (1996, January). The formation of SiO2 from hexamethyldisiloxane combustion in counterflow methane-air flames. In Symposium (International) on Combustion (Vol. 26, No. 2, pp. 1859-1865). Elsevier. [CrossRef]

- Panda, S. S.; Mishra, D. P.; Upadhyaya, A. (2009). Effect of varying gas-flow conditions on the characteristics of the diffusion flame and silica powders prepared using flame combustion synthesis. Powder technology 191(1-2), 164–169. [CrossRef]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).