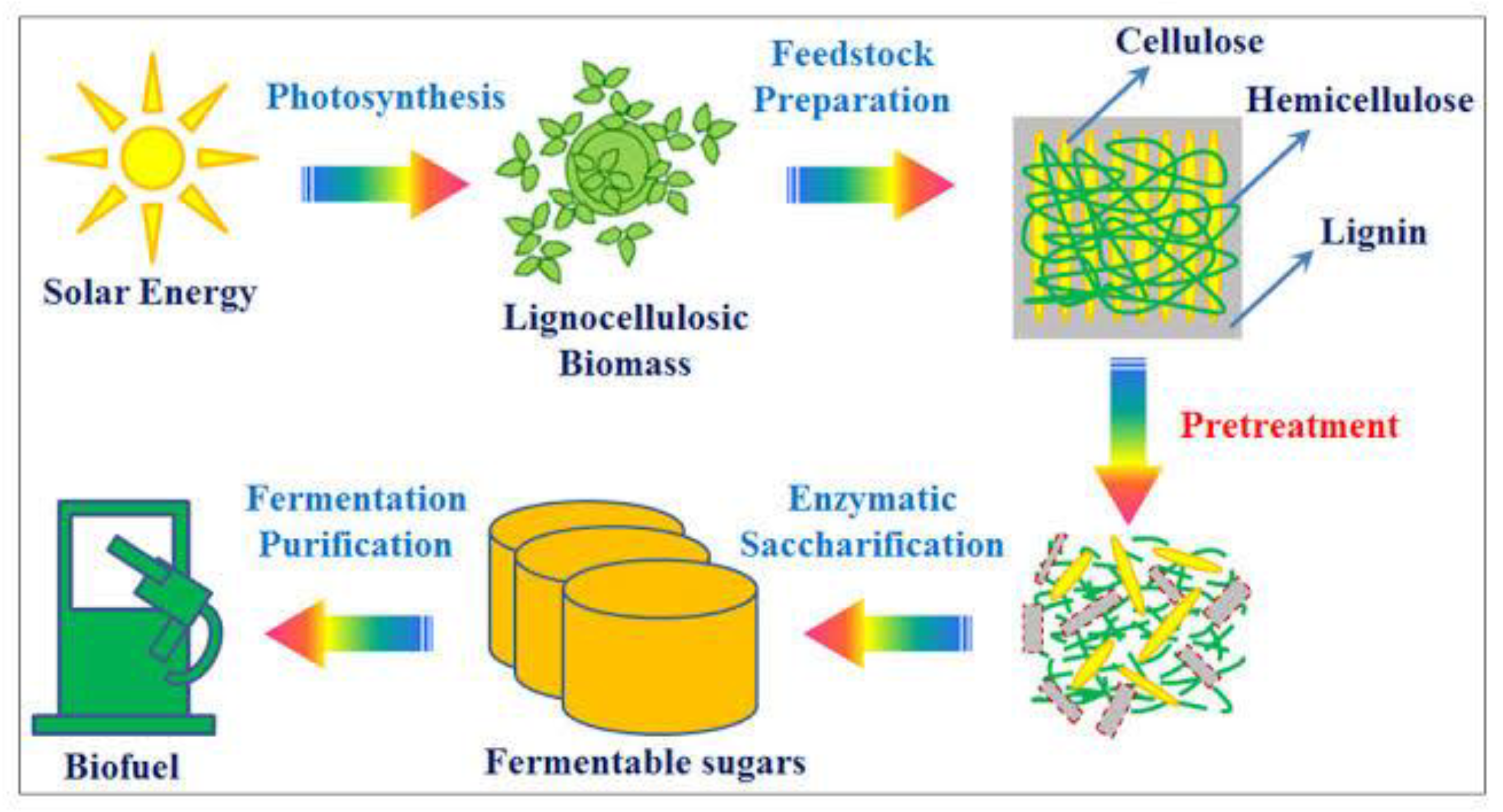

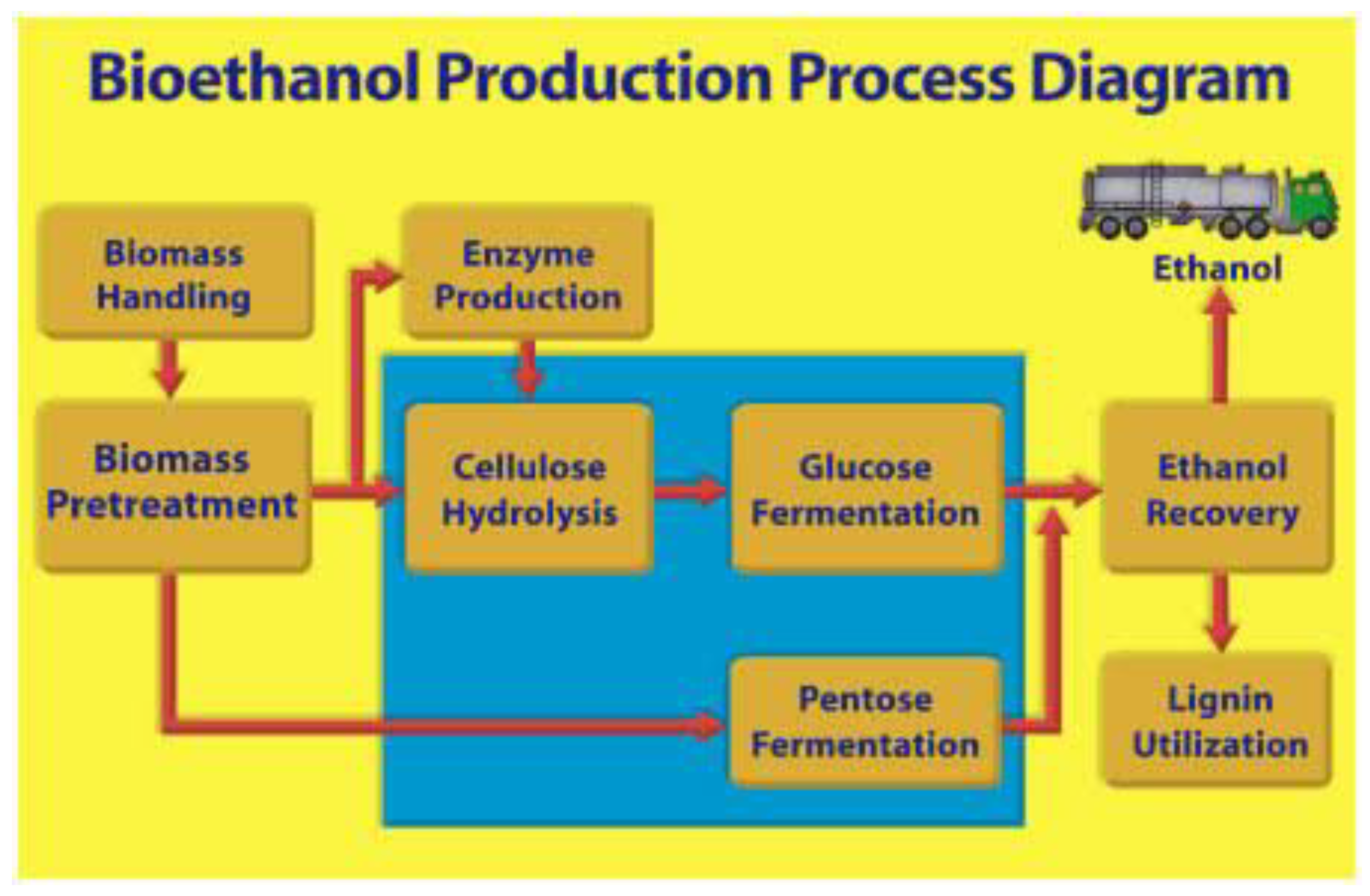

Figure 1 offers a comprehensive overview of the bioethanol production process. It provides a visual representation of the entire bioethanol production system, encompassing the steps from biomass feedstock to the final bioethanol product. This figure showcase biomass pretreatment, enzymatic hydrolysis, fermentation, distillation, and dehydration stages. It helps to provide a broad understanding of the bioethanol production process and the interplay between different stages. These enhanced descriptions provide a clearer understanding of each figure’s content and its relevance to the bioethanol production process.

1. Introduction

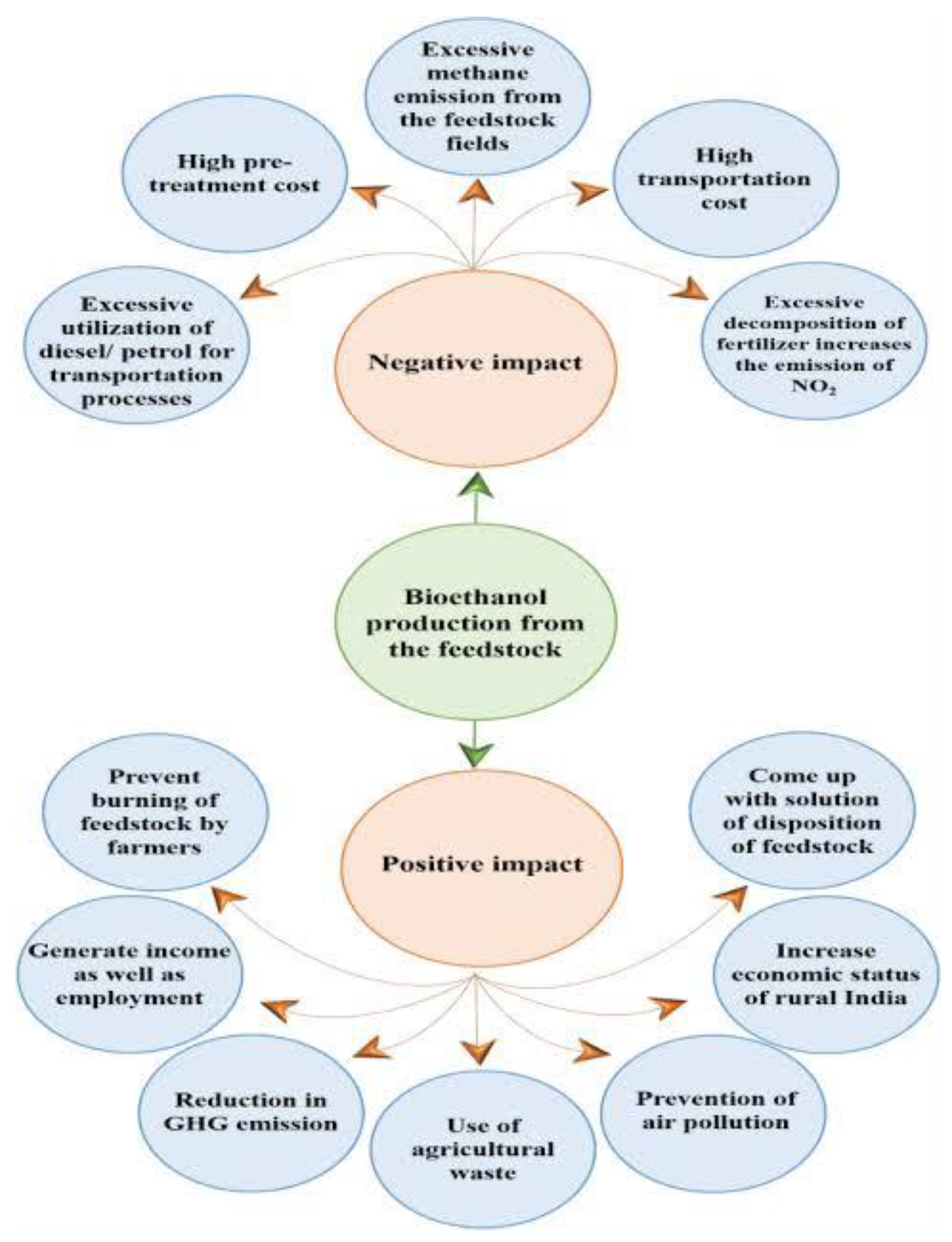

The demand for sustainable energy production has never been higher as the world faces the challenges of climate change and limited fossil fuel resources. In this context, bioethanol has emerged as a promising alternative fuel source due to its renewable nature and potential for reducing greenhouse gas emissions. Bioethanol can be produced from lignocellulosic biomass, such as agricultural residues, energy crops, and forestry wastes, making it an attractive option for sustainable energy production. The production of bioethanol from lignocellulosic biomass involves a multi-step process that includes pretreatment, enzymatic hydrolysis, fermentation, and distillation. However, this process presents several challenges that need to be addressed to make bioethanol production economically viable and efficient. One of the key challenges lies in the pretreatment of lignocellulosic biomass, which aims to break down the complex structure of cellulose, hemicellulose, and lignin to release fermentable sugars. Various pretreatment methods, such as hydrothermal, acid, alkaline, and biological approaches, have been explored to enhance the accessibility of cellulose and hemicellulose for enzymatic hydrolysis. Enzymatic hydrolysis plays a crucial role in converting the released sugars into fermentable substrates. The selection and optimization of enzymes, including cellulases and hemicellulases, are essential to achieve high conversion efficiency. Advances in enzyme engineering and process optimization have improved the enzymatic hydrolysis process, leading to higher sugar yields. Fermentation is the next critical step where the fermentable sugars are converted into ethanol by microbial organisms, typically yeast. The optimization of fermentation conditions, including pH, temperature, and nutrient supply, is essential to maximize ethanol yield and productivity. Genetic engineering approaches have also been employed to enhance the fermentation performance of yeast strains, enabling them to efficiently utilize a broader range of sugars. In recent years, emerging trends in bioethanol production have focused on integrating different process steps to improve overall efficiency. Simultaneous saccharification and fermentation (SSF) and high-gravity fermentation are examples of process integration strategies that have shown promise in enhancing bioethanol production. Furthermore, the development of advanced pretreatment technologies, such as ionic liquids and microwave irradiation, has gained attention for their ability to improve the efficiency and sustainability of the pretreatment process. The research and development in bioethanol production from lignocellulosic biomass have also highlighted the importance of utilizing non-commercial feedstocks to enhance the sustainability and feasibility of bioethanol production. This includes exploring the potential of agricultural residues, energy crops, and forestry wastes as alternative feedstocks. In conclusion, the advancements and emerging trends in bioethanol production from lignocellulosic biomass offer great potential for sustainable energy production. By addressing the challenges in pretreatment, enzymatic hydrolysis, fermentation, and process integration, bioethanol can play a significant role in reducing greenhouse gas emissions and mitigating climate change while ensuring energy security.

The production of sustainable energy has become a critical area of research in recent years, with a particular focus on bioethanol as a renewable fuel source. Bioethanol, derived from lignocellulosic biomass, offers great potential as an alternative to fossil fuels due to its reduced greenhouse gas emissions and potential for achieving energy independence (1, 2). However, several challenges still need to be addressed to optimize bioethanol production processes and make them economically viable on a large scale.

(Anderson & Havlíček, 2020): Anderson and Havlíček discuss the current challenges, insights, and perspectives in bioethanol production from lignocellulosic biomass. They highlight the importance of effective pretreatment methods, enzymatic hydrolysis, and fermentation strategies to improve bioethanol yields.., (Balat, 2011): Balat provides a comprehensive review on the production of bioethanol from lignocellulosic materials. The study emphasizes the significance of biochemical pathways, including pretreatment techniques, enzymatic hydrolysis, and fermentation processes, for efficient bioethanol production.. (Cheng & Chung, 2018): Cheng and Chung present a detailed review on enhancing bioethanol production from lignocellulosic feedstocks using various pretreatment technologies. The study explores the importance of optimizing pretreatment conditions to improve the accessibility of cellulose and hemicellulose for subsequent enzymatic hydrolysis and fermentation.., (Fang & Zhang, 2010): Fang and Zhang provide insights into the environmental impact of bioethanol production from lignocellulosic biomass. The study highlights the importance of sustainable practices throughout the production process to minimize the ecological footprint of bioethanol production., (Liu & Slininger, 2007): Liu and Slininger discuss the thermophilic fermentation of xylose using recombinant Saccharomyces cerevisiae for bioethanol production. The study emphasizes the importance of genetic engineering approaches to improve the utilization of xylose in lignocellulosic biomass.., (Peralta et al., 2016): In their review, Peralta et al. focus on the utilization of non-commercial lignocellulosic feedstocks for second-generation bioethanol production. The study highlights the potential of utilizing different feedstocks to enhance the sustainability and feasibility of bioethanol production.., (Sun & Cheng, 2002): Sun and Cheng provide a comprehensive review on the hydrolysis of lignocellulosic materials for ethanol production. The study explores various hydrolysis techniques and their efficacy in breaking down cellulose and hemicellulose into fermentable sugars., To further advance bioethanol production from lignocellulosic biomass, researchers have focused on optimizing pretreatment methods (6, 33), enzymatic hydrolysis (12, 28), fermentation strategies (4, 25), and genetic engineering approaches (18, 28). Pretreatment technologies such as hydrothermal pretreatment, ionic liquids, and microwave irradiation have been explored to enhance the accessibility of cellulose and hemicellulosic fractions for enzymatic hydrolysis (23, 30, 33). In addition, the selection and engineering of microbial strains, including Saccharomyces cerevisiae, have played a crucial role in improving fermentation efficiency and ethanol yields (4, 18).,The integration of different process steps, such as simultaneous saccharification and fermentation (SSF) or high-gravity fermentation, has been investigated to enhance bioethanol production efficiency (4, 24). Furthermore, the development of consolidated bioprocessing (CBP) approaches, where multiple steps are integrated into a single microorganism or enzyme system, shows promise for simplifying the bioethanol production process (4)., (Yang & Wyman): Yang and Wyman provide insights into the challenges and opportunities in lignocellulosic biomass pretreatment. The study highlights the importance of developing cost-effective and sustainable pretreatment methods to overcome the recalcitrance of biomass.By addressing these key challenges and adopting innovative strategies, the bioethanol revolution can contribute significantly to sustainable energy production, reducing dependency on fossil fuels and mitigating climate change.

1.1. Significance of Research Findings

Bioethanol Revolution: Unveiling the Advancement and Emerging Trends in Production of Sustainable Energy" holds great significance in addressing global energy and sustainability challenges. By highlighting the advancements and emerging trends in bioethanol production, this topic sheds light on a renewable and eco-friendly energy source that can contribute to achieving the United Nations Sustainable Development Goals (SDGs). Here are a few ways in which bioethanol aligns with the SDGs:

1. SDG 7: Affordable and Clean Energy: Bioethanol production offers a sustainable alternative to fossil fuels, contributing to the transition towards affordable and clean energy sources.

2. SDG 9: Industry, Innovation, and Infrastructure: The advancements and emerging trends in bioethanol production drive innovation in the renewables sector, fostering the development of sustainable infrastructure and promoting economic growth.

3. SDG 13: Climate Action: By reducing greenhouse gas emissions, bioethanol helps mitigate climate change and supports efforts towards achieving the targets set in the Paris Agreement.

4. SDG 12: Responsible Consumption and Production: Bioethanol production promotes responsible consumption and production patterns by utilizing renewable resources and reducing dependence on non-renewable fossil fuels.

5. SDG 15: Life on Land: Sustainable biomass feedstocks for bioethanol production can be sourced from responsibly managed forests and agricultural lands, contributing to the preservation of biodiversity and sustainable land use. Overall, the advancements and emerging trends in bioethanol production play a crucial role in promoting sustainable energy production, combating climate change, and driving progress Towards several key SDGs.

2. Generation of Bioethanol Materials

2.1. First Generation or Conventional Bioethanol

! First Generation or Conventional Bioethanol represents the initial approach to bioethanol production, where the primary feedstocks used are food crops or crops specifically cultivated for fuel purposes. These feedstocks typically include common crops such as corn, sugarcane, wheat, and sorghum. The production process for first-generation bioethanol involves fermenting the sugars present in these feedstocks, followed by distillation to extract the desired ethanol product. However, as bioethanol production has evolved, concerns have arisen regarding the sustainability and potential impact on food availability. The use of food crops as feedstocks for bioethanol competes with their utilization for human consumption, raising questions about global food security. Additionally, the limited availability of suitable feedstocks poses challenges in scaling up bioethanol production to meet growing energy demands. To address these concerns, researchers and scientists have been exploring alternative feedstocks and advanced production methods beyond first-generation bioethanol. These advancements aim to unlock the potential of non-food biomass, such as agricultural residues, algae, and lignocellulosic materials, for bioethanol production. By utilizing these unconventional feedstocks, the bioethanol industry can reduce its impact on food resources and foster a more sustainable and environmentally friendly energy production system. In summary, while first-generation bioethanol paved the way for sustainable energy production, the broader approach now focuses on advancing bioethanol production using non-food feedstocks to ensure long-term energy sustainability and mitigate potential food security concerns.

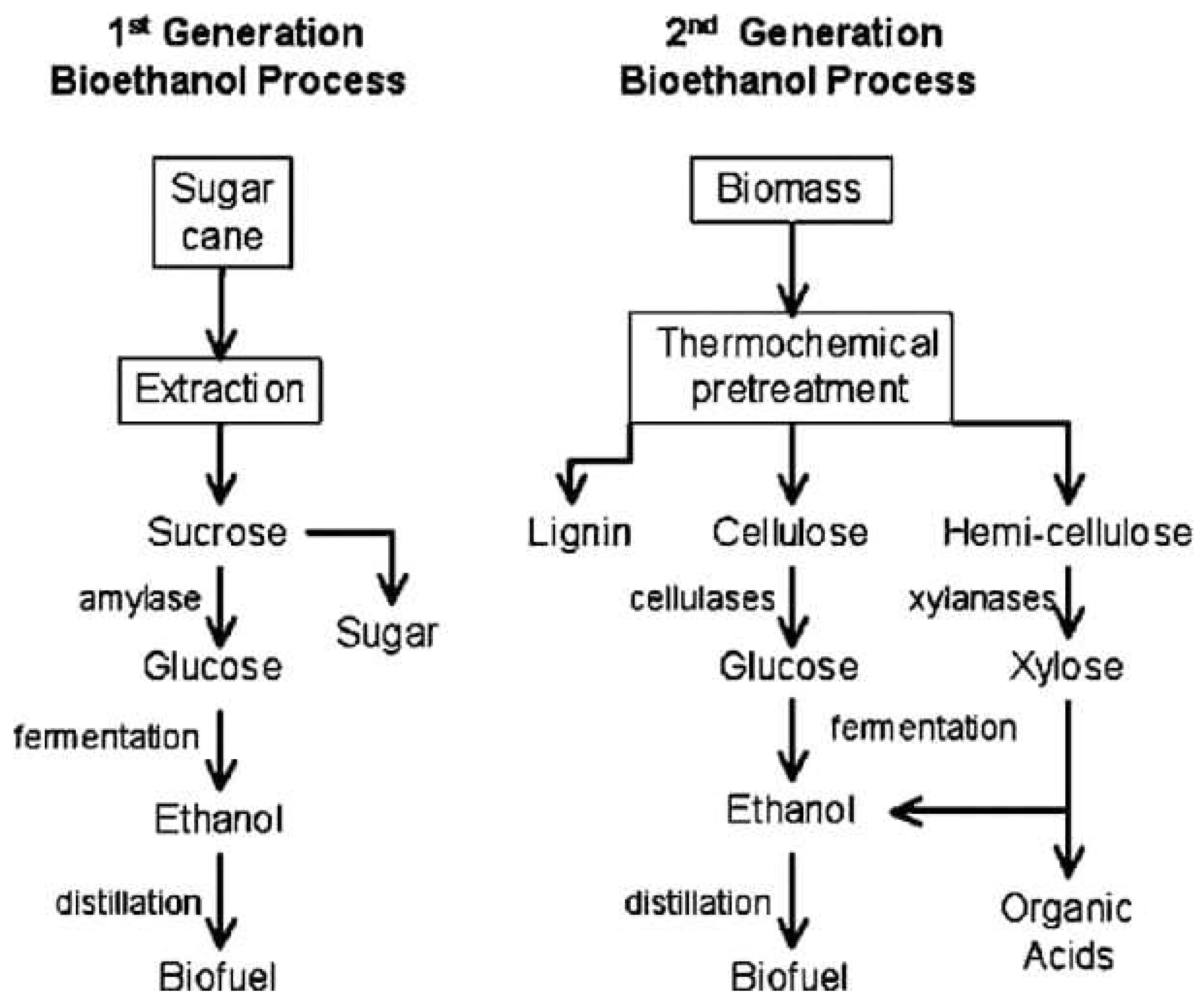

Figure 2.

First and Second Generation of Bioethanol Process.

Figure 2.

First and Second Generation of Bioethanol Process.

2.2. Second Generation Bioethanol

Second Generation Bioethanol, also known as advanced or cellulosic bioethanol, represents an innovative approach to bioethanol production that utilizes non-food feedstocks. Unlike first-generation bioethanol, which relies on food crops, second-generation bioethanol is produced from various sources, including agricultural residues (such as corn stover or wheat straw), forest residues, dedicated energy crops (like switchgrass or miscanthus), and even algae. The production process for second-generation bioethanol involves breaking down the complex carbohydrates, such as cellulose and hemicellulose, present in these feedstocks into simple sugars. This step, called biomass pretreatment, makes the sugars more accessible for fermentation. Enzymes or specialized microorganisms are then employed to convert these sugars into ethanol through a fermentation process similar to that used in first-generation bioethanol production. One of the significant advantages of second-generation bioethanol is its ability to utilize low-value or waste biomass, which avoids direct competition with food crops. By making use of agricultural and forest residues, it helps to minimize waste and maximize resource efficiency. Additionally, dedicated energy crops can be grown on marginal lands, reducing the pressure on arable land required for food production. While second-generation bioethanol is still in the development and commercialization phase, it holds great promise for sustainable energy production. It offers the potential to increase the overall bioethanol production capacity while reducing the environmental impact and dependence on food-based feedstocks. Ongoing research and investment in this area aim to optimize production processes, improve feedstock availability, and enhance the efficiency of converting biomass into bioethanol. In summary, second-generation bioethanol represents a significant step forward in sustainable energy production. By utilizing non-food feedstocks and implementing advanced production techniques, it offers a viable solution to meet energy demands while minimizing environmental impacts and ensuring long-term resource sustainability.

2.3. Third Generation Bioethanol

Third Generation Bioethanol represents the latest advancement in bioethanol production, focusing on utilizing microorganisms and algae to convert sunlight and carbon dioxide into ethanol. Unlike first and second-generation bioethanol, which rely on food crops or non-food biomass, third-generation bioethanol explores the potential of photosynthetic organisms to directly produce ethanol. One of the primary sources for third-generation bioethanol production is microalgae. These tiny aquatic organisms can efficiently convert sunlight and carbon dioxide into biomass through photosynthesis. Through specialized cultivation systems, the microalgae are grown in controlled environments, optimizing their growth and ethanol production potential. The biomass produced by the microalgae is then harvested and processed to extract and refine the ethanol. Third-generation bioethanol offers several advantages over previous generations. Firstly, microalgae cultivation requires significantly less land compared to traditional crops, reducing land-use conflicts. Additionally, microalgae can be cultivated using non-potable water sources, including saline or wastewater, further minimizing the strain on freshwater resources. Moreover, microalgae have the potential to capture and utilize carbon dioxide, contributing to greenhouse gas mitigation. While still in the early stages of development, third-generation bioethanol holds promise as a sustainable and environmentally friendly energy source. Its potential to utilize non-arable land, wastewater, and carbon dioxide provides a pathway to mitigate resource constraints and reduce carbon emissions. Ongoing research and technological advancements aim to optimize microalgae cultivation, increase ethanol yields, and improve the overall efficiency of third-generation bioethanol production. In summary, third-generation bioethanol represents an exciting frontier in sustainable bioenergy production. By harnessing the power of microorganisms and algae, it offers a unique approach to convert sunlight and carbon dioxide into ethanol, reducing reliance on conventional feedstocks and minimizing environmental impacts. Continued research and innovation in this field have the potential to unlock a new era of renewable energy production..

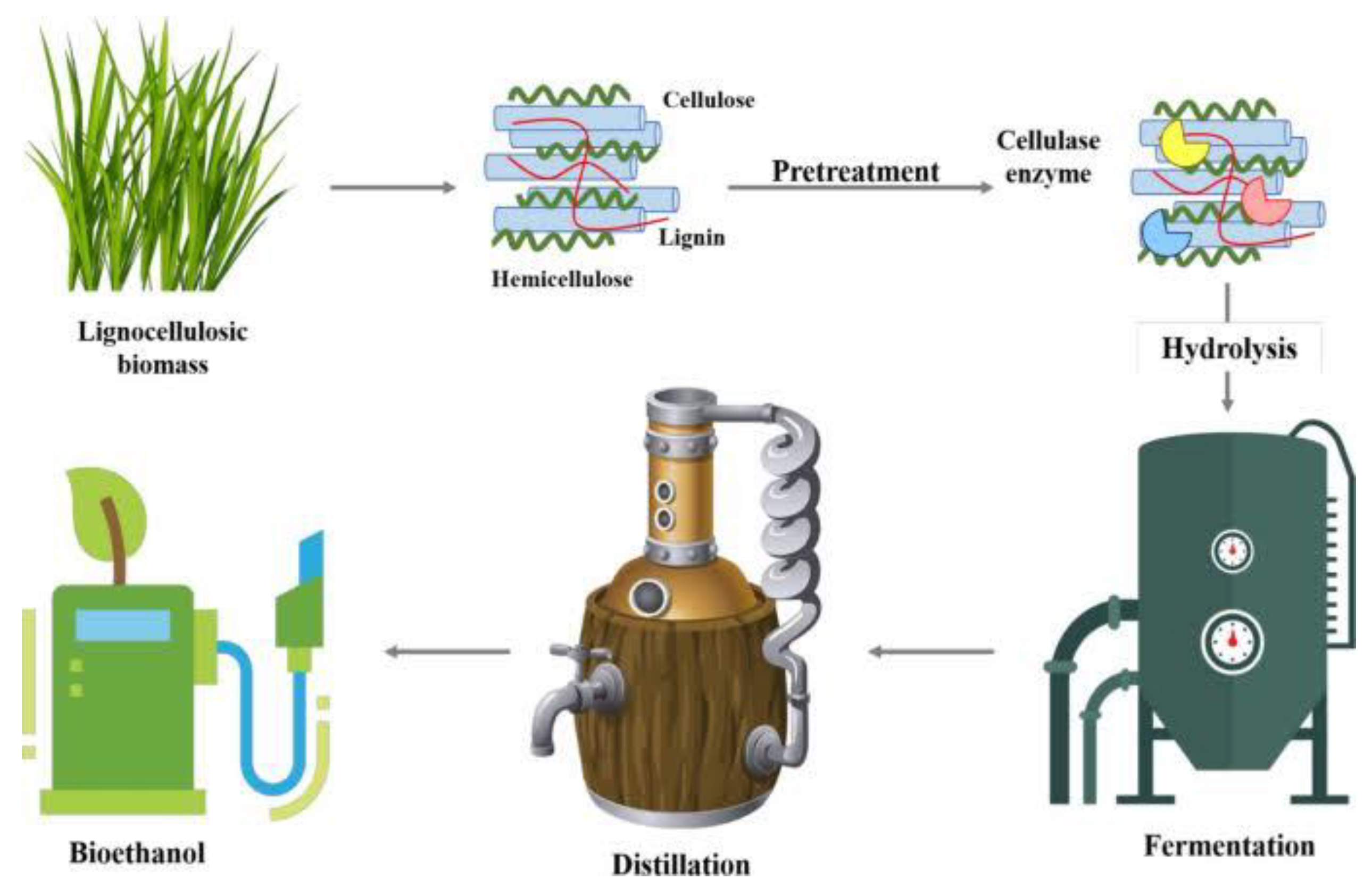

2.3.1. Lignocelluloses

Lignocellulose refers to the complex structural components found in the cell walls of plants, specifically in woody biomass and agricultural residues. It is composed of three main polymers: cellulose, hemicellulose, and lignin. Lignocellulosic biomass represents a promising feedstock for bioethanol production, particularly in second and third-generation bioethanol processes. Cellulose makes up a significant portion of lignocellulose and is a linear polymer of glucose molecules. Hemicellulose, on the other hand, is a branched polymer composed of various sugars. Lignin provides rigidity and structural support to plant cell walls, making it more challenging to break down during bioethanol production. To convert lignocellulosic biomass into bioethanol, a process called pretreatment is typically employed. Pretreatment aims to break down the complex structure of lignocellulose, making the cellulose and hemicellulose more accessible for enzymatic hydrolysis. Enzymes are then used to break down the cellulose and hemicellulose into simple sugars, which can be fermented into ethanol by specialized microorganisms. The utilization of lignocellulosic biomass for bioethanol production offers several advantages. It reduces the competition between bioenergy production and food crops, as lignocellulosic feedstocks can be derived from agricultural residues or dedicated energy crops grown on marginal lands. Additionally, lignocellulosic biomass is abundant and widely available, making it a sustainable and renewable resource for bioethanol production. Efforts are underway to optimize lignocellulosic bioethanol production processes, improve the efficiency of biomass pretreatment, enzymatic hydrolysis, and fermentation, and develop more robust and efficient microorganisms capable of converting lignocellulosic sugars into ethanol. In summary, lignocellulosic biomass represents a valuable feedstock for bioethanol production, particularly in second and third-generation bioethanol processes. Its abundance, availability, and potential to reduce competition with food crops make it a promising avenue for sustainable and environmentally friendly bioenergy production.

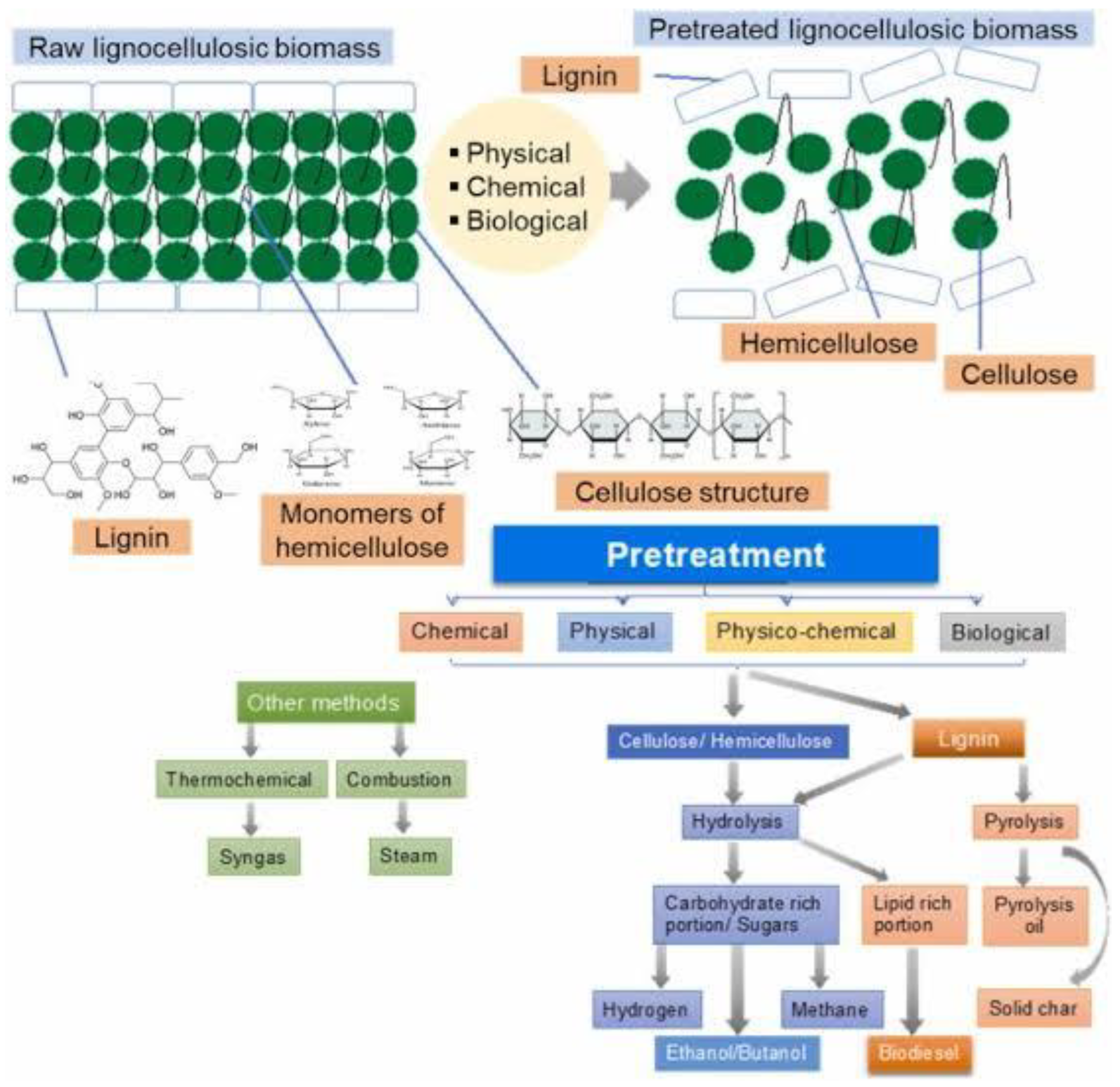

Figure 3 presents a general overview of the pre-treatment stage in the bioethanol production process. This figure provides a comprehensive illustration of the various methods and techniques employed during pre-treatment. It showcase both physical and chemical methods used to break down the biomass structure, remove lignin, and improve cellulose accessibility. This figure helps to visualize the crucial pre-treatment step and its significance in bioethanol production

The composition analysis of common and forestry residue materials in

Table 1 reveals the percentages of cellulose, hemicellulose, and lignin present in each source. Let’s analyze the results individually:

Hardwood: - Cellulose: The cellulose content in hardwood ranges from 41% to 56%. - Hemicellulose: The hemicellulose content in hardwood ranges from 25% to 41%. - Lignin: The lignin content in hardwood ranges from 19% to 26%

Softwood: - Cellulose: The cellulose content in softwood ranges from 46% to 51%. - Hemicellulose: The hemicellulose content in softwood ranges from 26% to 36%. - Lignin: The lignin content in softwood ranges from 26% to 36%.

Corn Stover: - Cellulose: The cellulose content in corn stover ranges from 39% to 41%. - Hemicellulose: The hemicellulose content in corn stover is around 29%. - Lignin: The lignin content in corn stover ranges from 8% to 22%.

Corn Cob: - Cellulose: The cellulose content in corn cob is around 46%. - Hemicellulose: The hemicellulose content in corn cob is approximately 36%. - Lignin: The lignin content in corn cob is about 16%.

Bagasse: - Cellulose: The cellulose content in bagasse ranges from 33% to 49%. - Hemicellulose: The hemicellulose content in bagasse ranges from 20% to 25%. - Lignin: The lignin content in bagasse ranges from 24% to 33%.

Wheat Straw: - Cellulose: The cellulose content in wheat straw ranges from 34% to 39%. - Hemicellulose: The hemicellulose content in wheat straw ranges from 27% to 37%. - Lignin: The lignin content in wheat straw ranges from 18% to 20%. Rice Straw: - Cellulose: The cellulose content in rice straw ranges from 29% to 37%. - Hemicellulose: The hemicellulose content in rice straw ranges from 24% to 29%. - Lignin: The lignin content in rice straw ranges from 13% to 15%.

Sorghum Stalk: - Cellulose: The cellulose content in sorghum stalk is approximately 28%. - Hemicellulose: The hemicellulose content in sorghum stalk is around 26%. - Lignin: The lignin content in sorghum stalk is about 12%.

Barley Straw: - Cellulose: The cellulose content in barley straw ranges from 32% to 36%. - Hemicellulose: The hemicellulose content in barley straw ranges from 28% to 39%. - Lignin: The lignin content in barley straw ranges from 0% to 20%

: Leaves: - Cellulose: The cellulose content in leaves ranges from 16% to 21%. - Hemicellulose: The hemicellulose content in leaves ranges from 81% to 86%. - Lignin: The lignin content in leaves is approximately 0%. Leaves typically have a higher hemicellulose content compared to cellulose. Hemicellulose is a complex carbohydrate that can be broken down into fermentable sugars during bioethanol production.

Such composition analysis is crucial for bioethanol production as cellulose and hemicellulose are the primary sources of fermentable sugars, while lignin presents challenges in biomass conversion processes. Understanding the composition of different biomass sources helps in selecting suitable feedstocks and optimizing the bioethanol production process.

Figure 4 showcases the constituents of lignocellulosic biomass, which is the primary feedstock for bioethanol production. This figure provides a visual representation of the different components of lignocellulosic biomass, including cellulose, hemicellulose, and lignin. It may also illustrate other minor constituents such as extractives and ash. This figure helps to understand the composition of biomass and the challenges associated with its conversion into bioethanol.

3. Materials and Methods:

Bioethanol is produced from several cheap materials which are mostly agricultural base raw material such as Starchy, sucrose and lignocellulose. These materials are wheat, corn cassava, sugar beet, sweat sorghum, sugar cane, wood straw and grasses. These materials are classified according to generation which are first, second and third generations respectively. In the production of ethanol several methods are involved such as direct fermentation, hydrolysis and simultaneous and saccharification and fermentation (SSF). The production of bioethanol using modern technological techniques is steadily undergoing innovation on daily bases due to high efficiency on thermodynamic equipment. The various materials considered in this paper essential for bioethanol production from biomass that involves some applications. These constitute majorly of agricultural characteristics and properties making suitable for this purpose. The raw-materials are Starchy-base substances such as wheat, corn, potatoes and cassava. Sucrose-base substances like sugar cane juice, sweet sorghum and molasses. Lignocellulose biomass such as wood straw and grasses.

3.1. Methods

Below, you’ll find a description of the methods used in the production of bioethanol from different types of agricultural biomass.

Direct Fermentation;

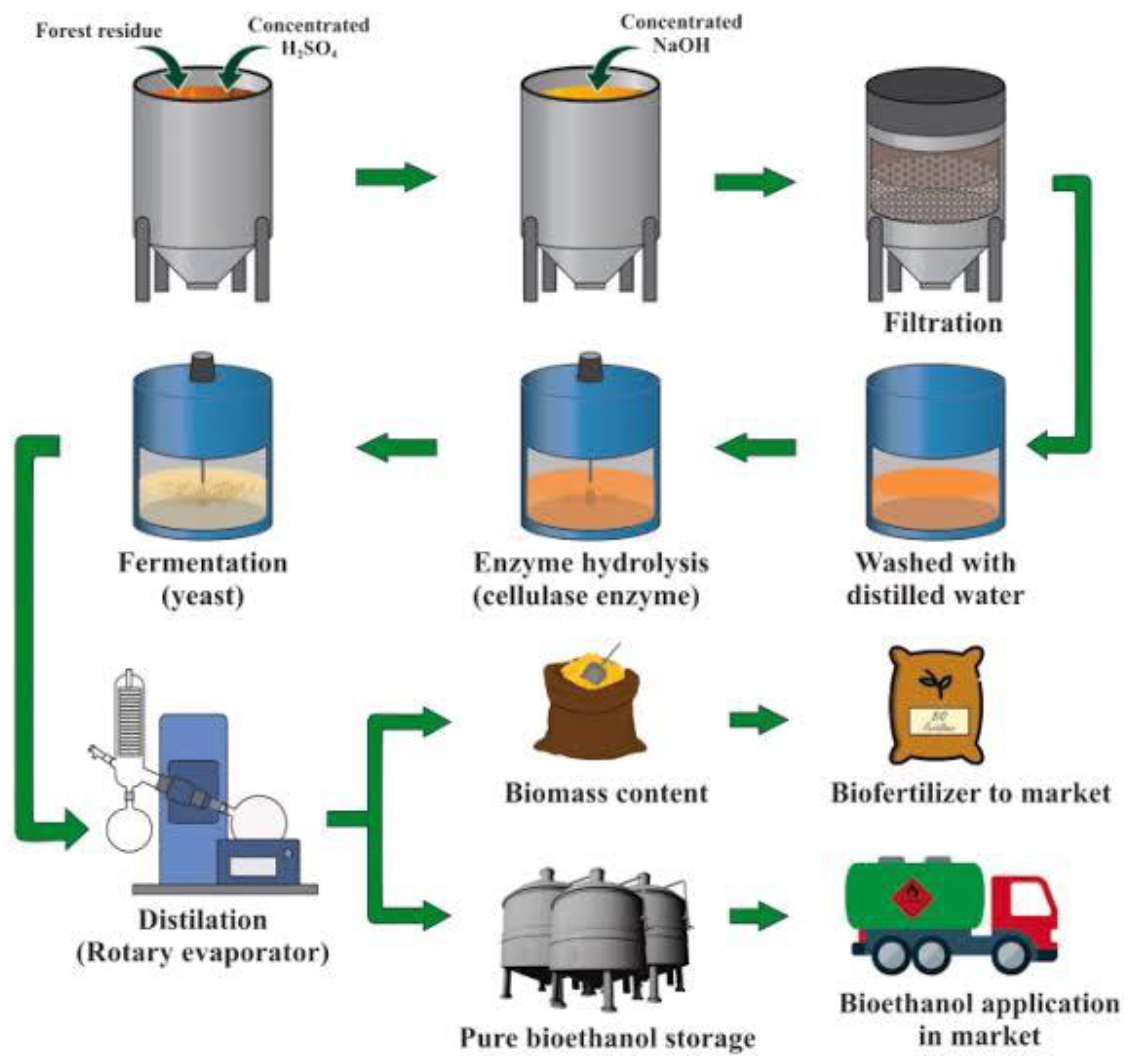

The hydrolysis process is typically employed for biomass rich in starch, as it needs to be broken down into glucose before it can be fermented by yeast, specifically Saccharomyces cerevisiae. It’s worth noting that while acid hydrolysis of cellulose biomass has been used historically to convert biomass into sugars like glucose and subsequently ethanol, nowadays a more common and straightforward approach is through simple fermentation. Below is a flow chart illustrating the hydrolysis process.

Figure 4 provides a visual representation of the conversion of biomass to bioethanol, as well as a flow sheet depicting the steps involved in bioethanol production and its subsequent conversion to useful energy.

Figure 4: (a) Biomass conversion to bioethanol:

This figure depicts the process of converting biomass into bioethanol. - Refined: Figure 4(a) illustrates the sequential steps involved in transforming biomass into bioethanol, showcasing the conversion process. (b) Flow sheet of steps involved in bioethanol production from up to its conversion to useful energy: - Original: This figure presents a flow sheet illustrating the various steps involved in the production of bioethanol, from its initial production up to its conversion into useful energy. - Refined: Figure 4(b) provides a comprehensive flow sheet outlining the sequential stages of bioethanol production, encompassing its initial production and subsequent transformation into valuable energy.

Simultaneous, Saccharification and Fermentation;

"Simultaneous Saccharification and Fermentation (SSF) represents a cutting-edge advancement in bioethanol production, combining the processes of enzymatic hydrolysis and fermentation into a single, integrated operation. This innovative approach has revolutionized the industry by significantly improving the efficiency, productivity, and sustainability of bioethanol production. By enabling simultaneous conversion of complex biomass into bioethanol, SSF has accelerated the development and commercialization of bioenergy solutions. Its advanced capabilities have streamlined the bioethanol production process, reducing processing time, energy consumption, and costs. SSF represents a pivotal milestone in the bioethanol revolution, propelling the industry towards a greener and more sustainable future."

THE PRE-TREATMENT PHASE PLAYS A CRUCIAL ROLE IN THE PRODUCTION OF BIOETHANOL."

The pre-treatment phase encompasses various steps involved in the production of bioethanol.

Figure 5.

Physical Pretreatment.

Figure 5.

Physical Pretreatment.

The pretreatment phase plays a crucial role in the production of bioethanol, as it prepares the biomass for subsequent processing steps. During this phase, various methods are employed to break down the complex structure of the biomass and make it more amenable to enzymatic hydrolysis. The pretreatment process involves physical, chemical, or biological treatments, or a combination thereof, to remove or disrupt the lignin and hemicellulose components of the biomass. This enhances the accessibility of cellulose, the main carbohydrate, to enzymes that can convert it into fermentable sugars. The choice of pretreatment method depends on the type of biomass used and the desired end-product. Common pretreatment techniques include steam explosion, acid hydrolysis, alkaline pretreatment, organosolv, and ammonia fiber expansion. Each method has its advantages and disadvantages in terms of efficiency, cost, and environmental impact. The pretreatment phase is crucial for optimizing bioethanol yields, as it significantly enhances the efficiency of enzymatic saccharification and subsequent fermentation processes. By breaking down the complex biomass structure, pretreatment enables a more efficient conversion of cellulose into fermentable sugars, leading to higher bioethanol production yields

Physical Pretreatment

Physical pretreatment involves mechanical or physical methods to break down the structure of biomass, making it more accessible for subsequent processing steps. Common physical pretreatment techniques include milling, grinding, extrusion, and steam explosion. These methods disrupt the biomass structure by reducing particle size, increasing surface area, and improving the accessibility of cellulose for enzymatic hydrolysis. Physical pretreatment methods are often preferred for their simplicity, scalability, and lower environmental impact.

In

Figure 6, we present a detailed illustration of Physical Pretreatment A for bioethanol production. This figure showcases a specific physical method used to break down the structure of lignocellulosic biomass. It provides a visual representation of the equipment, such as milling or grinding machines, employed in the physical pretreatment process. This figure highlights the key steps involved in Physical Pretreatment A and its role in improving the accessibility of cellulose for subsequent processing.

Figure 7 focuses on Physical Pretreatment B, another physical method used in the pretreatment stage of bioethanol production. This figure provides a visual representation of the equipment and processes involved in this specific physical pretreatment method. It demonstrate techniques such as extrusion or steam explosion, which are used to disrupt the biomass structure and enhance the enzymatic hydrolysis of cellulose. This figure highlights the unique aspects and benefits of Physical Pretreatment B

Chemical Pretreatment.

Chemical pretreatment involves the use of chemicals to alter the composition and structure of biomass, facilitating the breakdown of lignin and hemicellulose. Common chemical pretreatment methods include acid hydrolysis, alkaline pretreatment, and oxidative methods. Acid hydrolysis uses acids such as sulfuric acid or hydrochloric acid to break down the hemicellulose and lignin components, while alkaline pretreatment utilizes alkaline solutions like sodium hydroxide or ammonia to remove lignin and improve cellulose accessibility. Oxidative methods involve the use of oxidizing agents to selectively degrade lignin. Chemical pretreatment methods are chosen based on the specific biomass characteristics and desired end-products, as they offer greater control over the pretreatment process and can achieve higher sugar yields. Both physical and chemical pretreatment methods have their advantages and disadvantages, and the choice depends on factors such as biomass feedstock, process economics, environmental impact, and desired bioethanol yield. Effective pretreatment is essential for optimizing the bioethanol production process by improving the enzymatic digestibility of cellulose and maximizing sugar yields.

-

a)

Dilute Acid Treatment

Dilute Acid Treatment: Dilute acid treatment is a chemical pretreatment method that involves the use of weak acids, such as sulfuric acid or hydrochloric acid, to break down the lignocellulosic structure of biomass. The acid selectively hydrolyzes the hemicellulose component, solubilizing it into fermentable sugars. This pretreatment method is known for its effectiveness in improving enzymatic hydrolysis, as it disrupts the lignin barrier and increases cellulose accessibility. Dilute acid treatment offers advantages such as high sugar yields and compatibility with a wide range of feedstocks. However, it requires careful acid recovery and neutralization processes to minimize environmental impact and operational costs.

-

b)

Alkaline Pretreatment

Alkaline Pretreatment: Alkaline pretreatment involves the use of alkaline solutions, such as sodium hydroxide or ammonia, to modify the structure of biomass. Alkaline pretreatment breaks down lignin and removes some hemicellulose, leading to enhanced enzymatic hydrolysis efficiency. This method is particularly effective for biomass with high lignin content. Alkaline pretreatment offers advantages such as high sugar yields, potential co-production of valuable by-products, and less formation of inhibitory compounds. However, it may require additional detoxification steps to remove alkaline residues and may have higher operational costs

Figure 8.

Alkaline Treatment.

Figure 8.

Alkaline Treatment.

Ozonolysis Pretreatment

Ozonolysis pretreatment is an oxidative method that uses ozone gas to break down the lignin and hemicellulose components of biomass. Ozone reacts with unsaturated bonds, leading to the cleavage of lignin and hemicellulose linkages. This pretreatment method selectively removes lignin and enhances cellulose accessibility for enzymatic hydrolysis. Ozonolysis pretreatment offers advantages such as mild reaction conditions, reduced formation of inhibitory compounds, and potential for lignin valorization. However, it requires efficient ozone generation and management systems and may have higher operational costs

Figure 9.

Ozonolysis Pretreatment plant.

Figure 9.

Ozonolysis Pretreatment plant.

Physio-Chemical Pretreatment.

Physio-chemical pretreatment combines physical and chemical methods to improve biomass accessibility. It involves a combination of mechanical processes, such as milling or grinding, with chemical treatments, such as acid or alkaline solutions. Physio-chemical pretreatment aims to maximize the disruption of lignocellulosic structure, increase surface area, and enhance enzymatic hydrolysis efficiency. This method offers advantages such as improved sugar yields, reduced energy consumption, and potential for integrated process design. However, it may require optimization of process parameters and careful selection of pretreatment conditions to achieve desired outcomes.

Ammonia Fibre Explosion (AFEX)

Ammonia Fiber Explosion (AFEX) is a physio-chemical pretreatment method that utilizes ammonia and high-pressure steam to treat biomass. AFEX involves subjecting the biomass to a rapid release of ammonia and subsequent exposure to high temperatures, causing the biomass to undergo explosion-like conditions. This pretreatment disrupts the lignocellulosic structure, enhances enzymatic hydrolysis, and improves sugar yields. AFEX offers advantages such as reduced formation of inhibitory compounds, compatibility with a variety of feedstocks, and potential recovery and reuse of ammonia. However, it requires specialized equipment and careful ammonia handling for safety. These advanced descriptions provide a deeper understanding of the various pretreatment methods and their potential benefits in bioethanol production

Discussion:

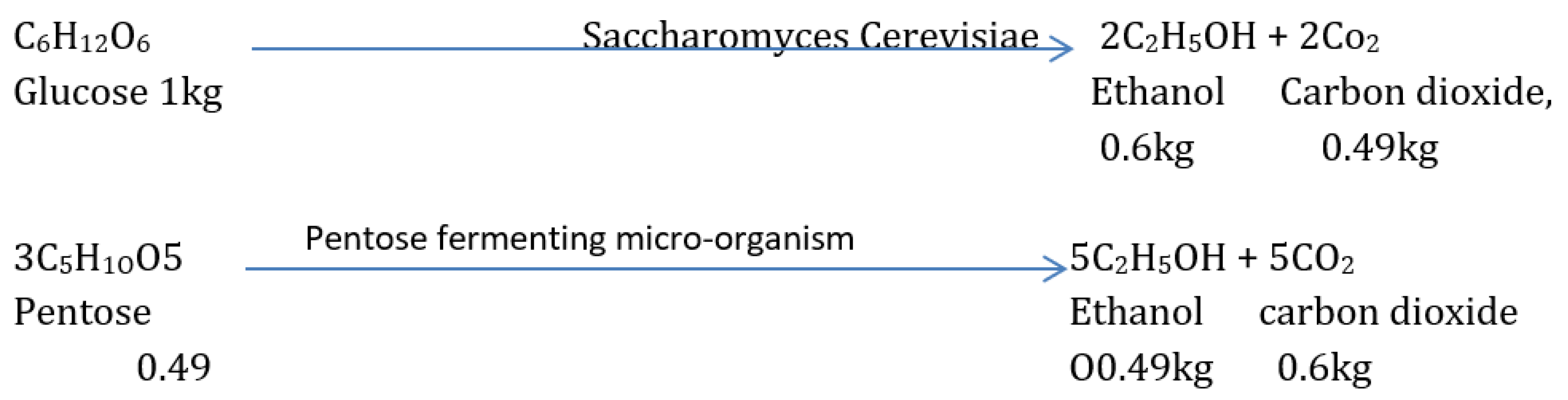

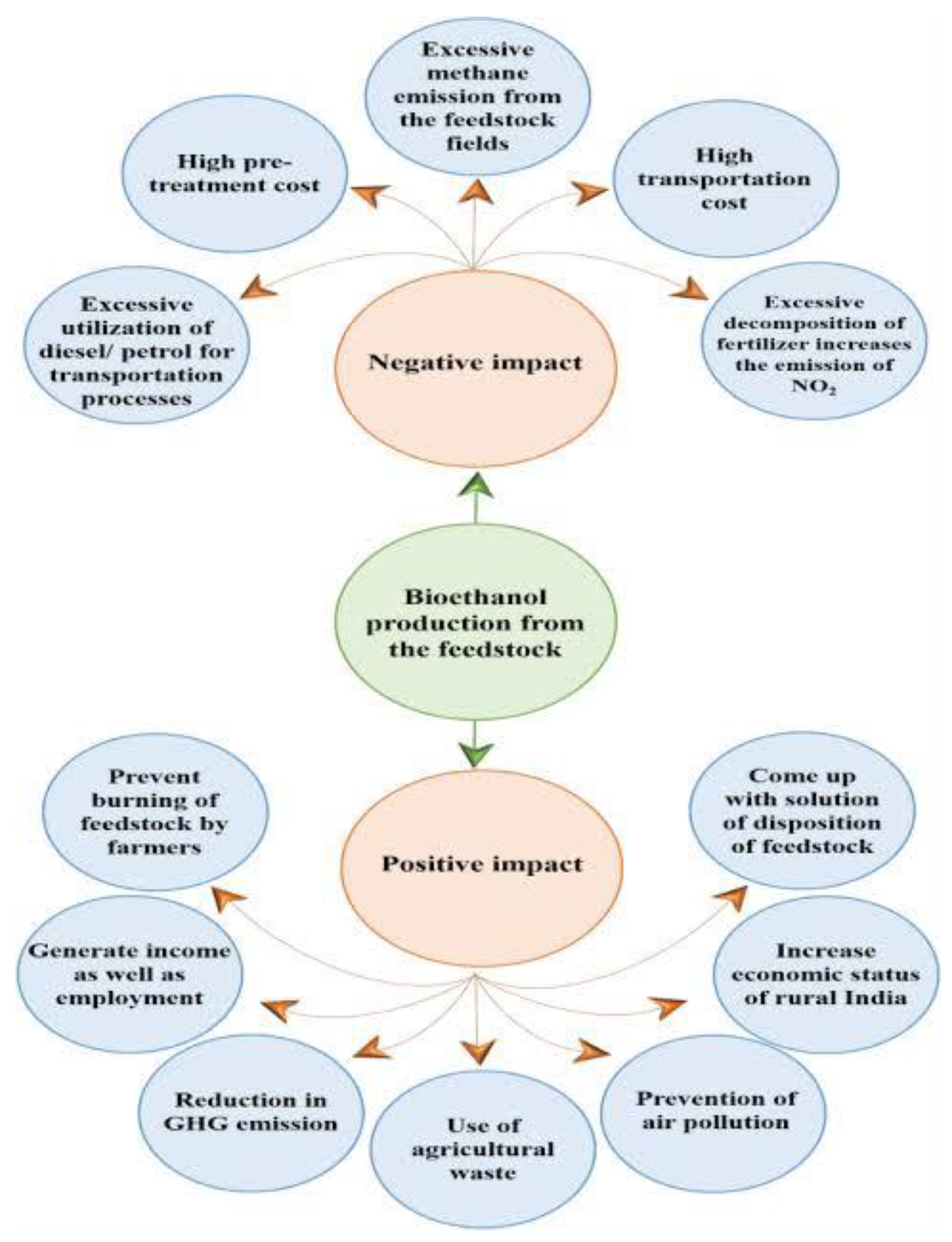

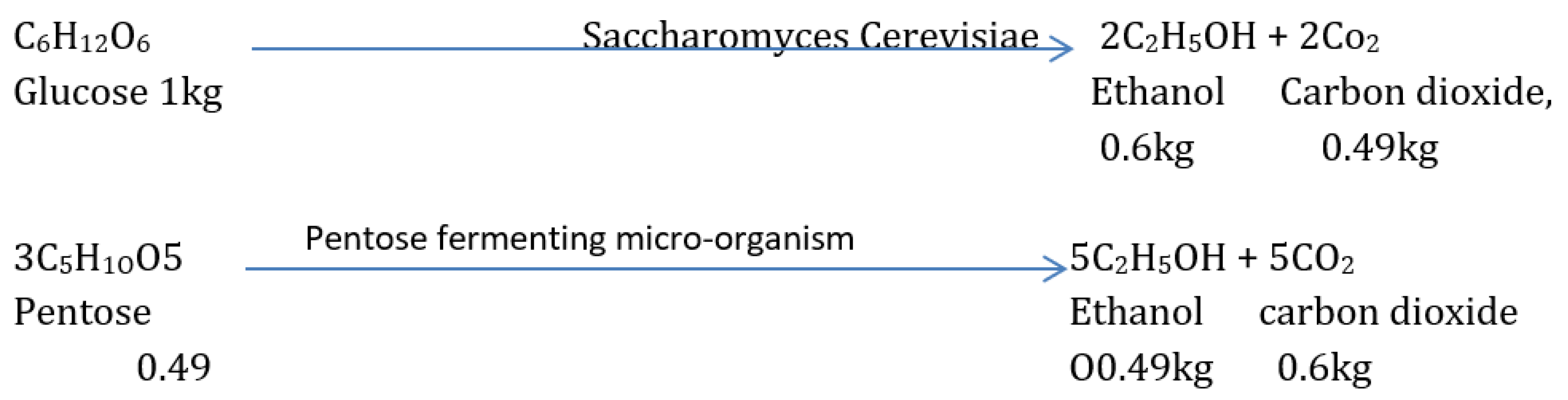

This equation highlights the process of fermentation, where Saccharomyces cerevisiae metabolizes glucose and pentose, breaking them down into ethanol and carbon dioxide. Fermentation is a key step in bioethanol production, as it allows for the conversion of complex sugars derived from biomass into a more readily usable form of energy. The equation provides information on the stoichiometry of the reaction, indicating that for every 1 kilogram of glucose, approximately 0.6 kilograms of ethanol and 0.49 kilograms of carbon dioxide are produced. Similarly, for every 0.49 kilograms of pentose, 0.49 kilograms of ethanol and 0.6 kilograms of carbon dioxide are formed. This analysis showcases the potential of microorganisms like Saccharomyces cerevisiae to convert renewable biomass resources, such as glucose and pentose, into bioethanol, a sustainable and renewable form of energy. The broader significance lies in the utilization of bioethanol as an alternative to fossil fuels, contributing to the reduction of greenhouse gas emissions and the transition towards a more environmentally friendly energy system.

It is of note many processes are involved in the production method at bioethanol, which are:

-Physical pretreatment; Through direct applications, the accessible surface area and pore size of the fermented biomass (cellulose) can be increased, along with enhancing the crystal lining and degree of polymerization. This process helps to optimize the efficiency.

-Chemical Pretreatment: he production of bioethanol from biomass involves various methods such as dilute acid treatment, alkaline treatment, and ozonolysis. These processes utilize both biological and chemical principles. One less common method called Ammonia Fibre Explosion (AFEX) involves the use of liquid ammonia, but it is not widely used due to its cost.

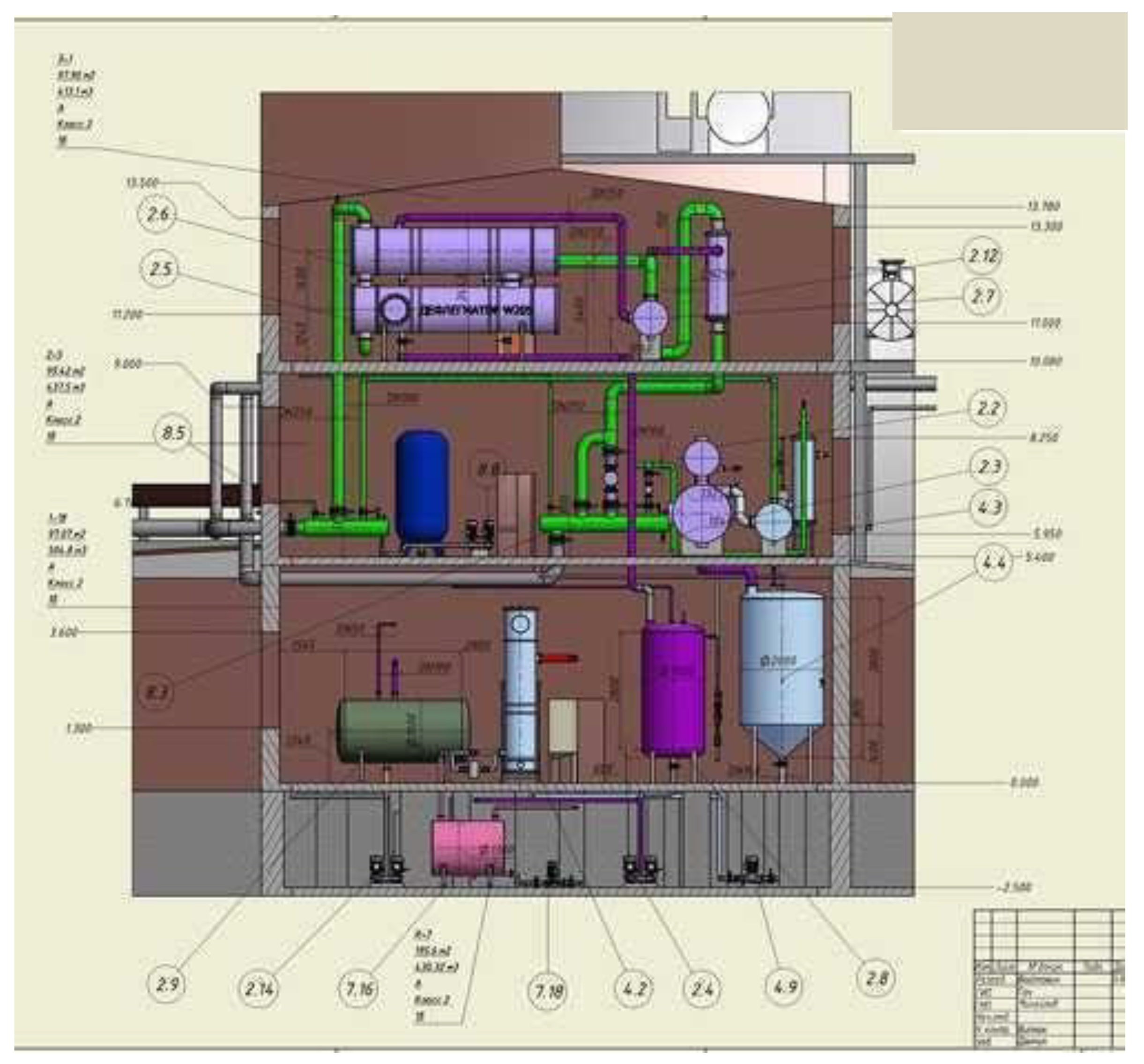

Figure 10: Simulation & Analysis Design of Bioethanol Plant: In

Figure 10, we present a comprehensive simulation and analysis design of a bioethanol plant. This figure showcases the detailed engineering and process design involved in the production of bioethanol. It illustrates the various equipment, unit operations, and process flow within the plant, highlighting the optimization and integration of key components. This simulation and analysis design is crucial for evaluating the performance, efficiency, and economics of a bioethanol plant before its actual construction and operation.

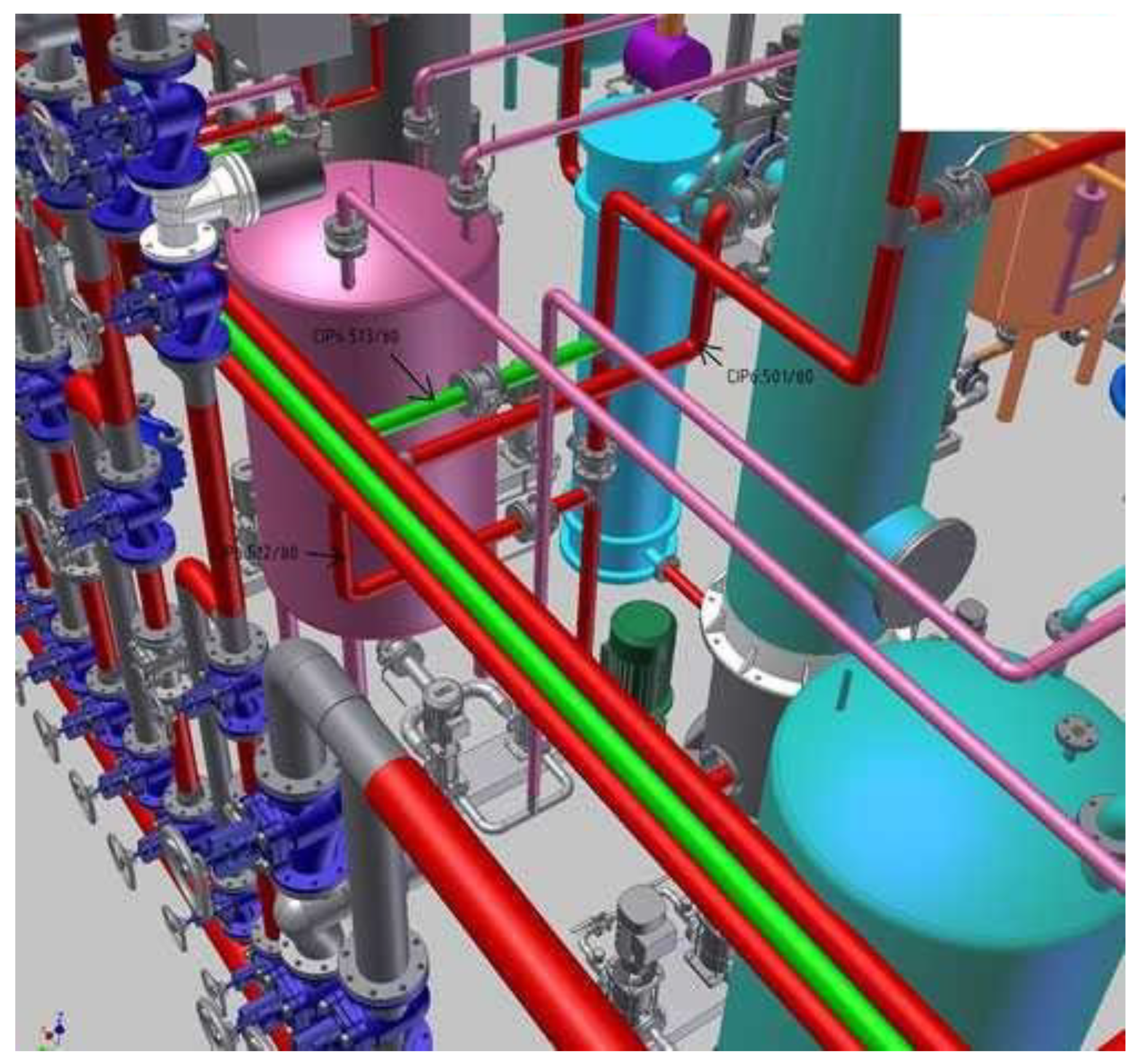

Figure 11: Bioethanol Production Plant:

Figure 11 represents a bioethanol production plant, highlighting the various stages and unit operations involved in the production process. It showcases the sequential steps of biomass pretreatment, enzymatic hydrolysis, fermentation, distillation, and dehydration to produce high-quality bioethanol. This figure gives a visual representation of the equipment, reactors, and interconnected systems within the production plant, emphasizing the efficient conversion of biomass into bioethanol.

Figure 12: Bioethanol Construction Plant:

Figure 12 depicts the construction phase of a bioethanol plant. It showcases the layout, infrastructure, and arrangement of equipment and structures involved in the physical construction of the plant. This figure provides insights into the construction process, including the installation of reactors, fermenters, distillation columns, storage tanks, and other essential components. It demonstrates the careful planning and execution required to build a bioethanol plant efficiently and in accordance with safety and regulatory standards

Figure 13: Design of Bioethanol Plant:

Figure 13 focuses on the design aspects of a bioethanol plant. It illustrates the detailed engineering design, including process flow diagrams, equipment specifications, piping and instrumentation diagrams (P&IDs), and plant layout. This figure provides a comprehensive overview of the design considerations, such as the arrangement of equipment, heat and mass balances, and integration of various unit operations. The design of a bioethanol plant is crucial for ensuring optimal performance, safety, and cost-effectiveness.

Conclusion:

In conclusion, the escalating global demand for renewable energy resources has positioned bioethanol as a highly viable and cost-effective fuel for the future. Embracing bioethanol not only addresses the environmental hazards associated with biomass but also unlocks the potential to transform them into valuable products, thereby generating economic empowerment and prosperity. By utilizing agricultural and forest residues to produce bioethanol, we can effectively mitigate environmental risks while simultaneously creating a sustainable and profitable industry. This approach fosters a circular economy where waste is transformed into wealth, benefiting both the environment and the economy. The promising prospects of bioethanol in terms of energy security, economic growth, and environmental sustainability make it a compelling choice for the future. As we continue to invest in research, innovation, and infrastructure development, we can pave the way for a bioethanol revolution that not only meets our energy needs but also provides a cleaner and more prosperous future. The production of bioethanol from biomass involves various pretreatment processes, as well as the utilization of specific yeast and bacterial strains for efficient conversion. However, in order to establish cost-effective technologies for renewable biomass processing or direct biomass production, further research, development, and diffusion of new and commercialized technologies are imperative. Continued advancements in technology are essential to optimize the efficiency and reduce the costs associated with bioethanol production from biomass. This requires ongoing research to identify and develop innovative pretreatment methods, as well as to improve the performance of yeast and bacterial strains involved in the conversion process. By focusing on these areas, we can enhance the overall efficiency and economic viability of bioethanol production. Furthermore, the diffusion of commercialized technologies plays a crucial role in scaling up bioethanol production from biomass. It involves the adoption and implementation of these technologies in industrial settings, promoting their widespread use and making them more accessible to different stakeholders. Through ongoing research, development, and diffusion of cost-effective technologies, we can unlock the full potential of biomass as a sustainable resource for bioethanol production. The conversion of biomass into bioethanol offers a multitude of benefits for Nigeria, both from an environmental and socio-economic standpoint. By shifting towards bioethanol production, the country can address its energy demands while simultaneously reducing its reliance on fossil fuels, which contribute to environmental degradation and economic burdens. Bioethanol production from biomass presents a sustainable alternative to fossil fuels, helping to mitigate greenhouse gas emissions and combat climate change. Moreover, it reduces the overall carbon footprint and promotes a cleaner and healthier environment for the Nigerian society. From a socio-economic perspective, bioethanol production creates opportunities of economic growth and development. It opens avenues for job creation, investment, and increased income, thus contributing to poverty reduction and enhancing the overall socio-economic well-being of the country. Further research and technological advancements in the field of bioethanol production from biomass are crucial to realize the full potential of this renewable energy source in Nigeria. By investing in research and development, the country can optimize production processes, improve efficiency, and drive down costs, making bioethanol a more viable and accessible energy option. By replacing fossil fuels with bioethanol, Nigeria can not only meet its energy needs sustainably but also position itself as a leader in the global transition towards cleaner and more environmentally friendly energy sources. This study sheds light on the pressing need to explore alternative fuel and energy sources as a viable solution to mitigate the harmful impact of fossil fuels on the atmosphere. The increasing pollution caused by fossil fuel emissions poses a significant threat to human existence and the well-being of our planet. By focusing on the conversion of biomass to bioethanol, this study contributes to the advancement of the quest for a more competitive energy market. Diversifying our energy sources and reducing dependence on fossil fuels is crucial for sustainable development and ensuring a cleaner and healthier environment. The over-reliance on crude oil as a primary energy source has had several negative impacts on society. These include socio-economic challenges such as insecurity, complacency, and neglect of other sectors of the economy. By promoting the conversion of biomass to bioethanol, we can mitigate these negative effects, fostering a more balanced and resilient economy. Furthermore, bioethanol production from biomass provides an opportunity for job creation, economic diversification, and overall societal development. By embracing this alternative energy source, we can revitalize neglected sectors and promote a more sustainable and inclusive economy. In summary, this study highlights the importance of seeking alternative energy sources to combat the negative consequences of fossil fuel usage. The conversion of biomass to bioethanol not only mitigates pollution but also fosters a competitive energy market, diversifies the economy, and promotes overall societal well-being. The conversion of biomass to bioethanol offers significant advantages in curbing pollution and promoting human health. Bioethanol is known for its carbon neutrality, meaning that it does not contribute to the net increase of greenhouse gas emissions. By replacing traditional fossil fuels with bioethanol, we can significantly reduce harmful emissions and mitigate the negative impacts on air quality and human health. Moreover, this study has the potential to attract Foreign Direct Investment (FDI) into the bioethanol sector. The shift towards bioethanol production presents a lucrative opportunity for investors, as it aligns with global trends towards sustainable and renewable energy sources. Increased FDI can lead to improved infrastructure, advanced technologies, and enhanced production capacity, all of which contribute to employment generation and economic growth. The promotion of bioethanol as an alternative fuel source can also have a positive impact on the nation’s GDP (Gross Domestic Product). The diversification of the energy sector through bioethanol production opens up new avenues for economic activity, stimulating various industries and driving overall economic growth. This, in turn, leads to increased revenue generation and an improved economic outlook for the nation. By embracing the conversion of biomass to bioethanol, we can address pollution concerns, attract foreign investment, and stimulate economic growth, all while working towards a sustainable and cleaner energy future.

Author Contributions

The first author wrote the draft under the guidance of the second author on the theme and content of the paper.

Funding

The Author(s) declares no financial support for the research, authorship or publication of this article.

Acknowledgments

We would like to express our sincere gratitude to all the individuals and organizations who have contributed to the successful completion of this research on the advancement and emerging trends in the production of sustainable energy through bioethanol. First and foremost, we extend our deepest appreciation to our research supervisor for their guidance, support, and valuable insights throughout this journey. Their expertise and encouragement have been instrumental in shaping this research. We would also like to thank the participants who generously shared their time and knowledge, enabling us to gather the data necessary for this study. Their contribution has been invaluable in providing us with a comprehensive understanding of the subject matter. Furthermore, we express our gratitude to the scholars, researchers, and professionals in the field of bioethanol production for their significant contributions to the existing body of knowledge. Their pioneering research and innovative ideas have paved the way for the advancements and emerging trends discussed in this research. We are grateful for the support and resources provided by our institution, enabling us to conduct this research effectively. The library staff and technical support team have been instrumental in providing us with the necessary resources and assistance. Lastly, we extend our heartfelt appreciation to our families, friends, and colleagues for their unwavering support and understanding throughout this endeavor. Their encouragement and belief in our abilities have been a constant source of motivation. This research would not have been possible without the collective efforts and collaboration of all those mentioned above. We remain grateful for their contributions and support in our pursuit of sustainable energy production through bioethanol.

Conflicts of Interest

We would like to declare that there are no conflicts of interest associated with this research. The study was conducted impartially and independently, without any external influences that could potentially compromise the objectivity or validity of the findings. Our primary goal was to present accurate and unbiased information related to the advancement and emerging trends in the production of sustainable energy through bioethanol.

References

- Anderson, P.; Havlíček, K. Bioethanol production from lignocellulosic biomass: Current challenges, insights, and perspectives. Energies 2020, 13, 6344. [Google Scholar] [CrossRef]

- Balat, M. Production of bioethanol from lignocellulosic materials via the biochemical pathway: A review. Energy Conversion and Management 2011, 52, 858–875. [Google Scholar] [CrossRef]

- Bondesson, P.M.; Galbe, M.; Zacchi, G. Ethanol production from forestry residues using hydrothermal pretreatment combined with simultaneous saccharification and fermentation. Bioresource Technology 2013, 149, 499–504. [Google Scholar]

- Chen, P.R.; Lee, T.C.; Chang, J.S. Biorefinery based on microbial fuel cells to produce bioethanol from lignocellulosic biomass. Bioresource Technology 2012, 123, 413–418. [Google Scholar]

- Chandel, A.K.; da Silva, S.S.; Singh, O.V. Detoxification of lignocellulosic hydrolysates for improved bioethanol production. Biofuel Production-Recent Developments and Prospects 2011, 22, 225–240. [Google Scholar] [CrossRef]

- Cheng, K.Y.; Chung, K.T. Enhancing bioethanol production from lignocellulosic feedstocks using pretreatment technologies: A comprehensive review. Journal of Cleaner Production 2018, 182, 963–977. [Google Scholar]

- Crofcheck, C.; Nwabueze-Ogbo, F. Techno-economic analysis of lignocellulosic biomass bioethanol production: A review. Renewable and Sustainable Energy Reviews 2016, 54, 1089–1100. [Google Scholar]

- Dien, B.S.; Bothast, R.J. Ethanol production from biomass: Technology and commercialization status. Current Opinion in Microbiology 2005, 8, 364–369. [Google Scholar] [CrossRef]

- Du, W.; Xu, Y.; Yu, J.; Zhang, L.; Zhang, Q. The progress and challenges of lignocellulosic ethanol production in China. Bioresource Technology 2016, 215, 76–81. [Google Scholar]

- Fang, X.; Zhang, X. Environmental impact of bioethanol production from lignocellulosic biomass: A review. Renewable and Sustainable Energy Reviews 2010, 14, 207–217. [Google Scholar]

- Gírio, F.M.; Fonseca, C.; Carvalheiro, F.; Duarte, L.C.; Marques, S.; Bogel-Łukasik, R.; Bogel-Łukasik, E. Hemicellulosic ethanol production: A review on process optimization. Bioresource Technology 2010, 101, 4826–4835. [Google Scholar] [CrossRef]

- Grewell, D.; Yokoyama, M.T.; Zhang, J. Ethanol production from lignocellulosic biomass by engineered Saccharomyces cerevisiae. Bioresource Technology 2009, 100, 10–18. [Google Scholar]

- Hahn-Hägerdal, B.; Galbe, M.; Gorwa-Grauslund, M.F.; Lidén, G.; Zacchi, G. Bio-ethanol—The fuel of tomorrow from the residues of today. Trends in Biotechnology 2006, 24, 549–556. [Google Scholar] [CrossRef]

- Hu, F.; Ragauskas, A.J. Pretreatment and lignocellulosic chemistry. Bioenergy Research 2012, 5, 1043–1066. [Google Scholar] [CrossRef]

- Kumar, R.; Wyman, C.E. Access of cellulase to cellulose and lignin for poplar solids produced by leading pretreatment technologies. Biotechnology Progress 2009, 25, 807–819. [Google Scholar] [CrossRef]

- Li, S.; Zhang, Y.H.P. Biofuels and bioenergy: Challenges and opportunities. Energy & Environmental Science 2007, 1, 668–676. [Google Scholar]

- Lin, Y.; Tanaka, S. Ethanol fermentation from biomass resources: Current state and prospects. Applied Microbiology and Biotechnology 2006, 69, 627–642. [Google Scholar] [CrossRef]

- Liu, Z.H.; Slininger, P.J. Thermophilic ethanologenic fermentation of xylose with recombinant Saccharomyces cerevisiae engineered for expression of xylA, xylB, and xylX from Thermoanaerobacterium saccharolyticum. Applied Microbiology and Biotechnology 2007, 77, 423–434. [Google Scholar]

- López-Linares, J.C.; Romero, I.; Cara, C.; Moya, M.; Castro, E.; Romero-García, J.M. Bioethanol production from agri-food waste: A review on lignocellulosic biomass pretreatment for the sustainable and efficient enzymatic hydrolysis. Sustainability 2017, 9, 1237. [Google Scholar]

- Ma, X.; Hu, M. Bioethanol production from lignocellulosic biomass: A review on enzyme hydrolysis and fermentation process. Applied Sciences 2020, 10, 798. [Google Scholar]

- Menon, V.; Rao, M. Trends in bioconversion of lignocellulose: Biofuels, platform chemicals, and biorefinery concept. Progress in Energy and Combustion Science 2012, 38, 522–550. [Google Scholar] [CrossRef]

- Park, J.M.; Song, S.H. Recent progress in bioethanol production from lignocellulosic biomass. Journal of Industrial and Engineering Chemistry 2017, 55, 1–13. [Google Scholar]

- Peralta, R.M.; Santos, D.T.; Maciel Filho, R. Second-generation ethanol production: On the utilization of non-commercial lignocellulosic feedstocks for energy production. Renewable and Sustainable Energy Reviews 2016, 54, 1332–1343. [Google Scholar]

- Qian, Y.; Liu, T. A review on recent advances in bioethanol production using lignocellulosic materials and high-gravity fermentation. Bioresource Technology Reports 2021, 15, 100664. [Google Scholar]

- Rajak, U.; Mandal, S.; Moholkar, V.S. Bioethanol production from lignocellulosic biomass: An overview. In Bioethanol Production from Food Crops (pp. 165-189). Woodhead Publishing, 2018.

- Saini, J.K.; Saini, R.; Tewari, L. Lignocellulosic agriculture wastes as biomass feedstocks for second-generation bioethanol production: Concepts and recent developments. 3 Biotech 2015, 5, 337–353. [Google Scholar] [CrossRef]

- Singhania, R.R.; Patel, A.K.; Soccol, C.R.; Pandey, A. Recent advances in solid-state fermentation. Biochemical Engineering Journal 2020, 156, 107546. [Google Scholar] [CrossRef]

- Siqueira, F.G.; Milagres, A.M.F.; Carvalho, W. Combining pretreatments for glucose and xylose recovery from sugar cane bagasse and wheat straw for fuel ethanol production. Industrial Crops and Products 2013, 43, 804–810. [Google Scholar]

- Sun, Y.; Cheng, J. Hydrolysis of lignocellulosic materials for ethanol production: A review. Bioresource Technology 2002, 83, 1–11. [Google Scholar] [CrossRef] [PubMed]

- Tadesse, H.; Luque, R. Advances on biomass pretreatment using ionic liquids: An overview. Energy & Environmental Science 2017, 10, 1551–1581. [Google Scholar] [CrossRef]

- Uppugundla, N.; da Costa Sousa, L.; Chundawat, S.P.; Yu, X.; Simmons, B.; Singh, S. A comparative study of ethanol production using dilute acid, ionic liquid and AFEX™ pretreated corn stover. Biotechnology for Biofuels 2014, 7, 72. [Google Scholar] [CrossRef]

- Verma, M.L.; Barrow, C.J.; Puri, M. Biochemical and thermochemical conversion of wheat straw into bioethanol: An optimization study. Energy Conversion and Management 2016, 121, 136–147. [Google Scholar]

- Wang, L.; Zhang, H.; Zhang, J.; Yang, Q.; Dong, C. Advances in lignocellulosic biomass pretreatment: Solvent-based methods, microwave irradiation, and future perspectives. Bioresource Technology 2020, 305, 123018. [Google Scholar]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).