1. Introduction

Mechanical contacts that are subject to small oscillations often suffer from various forms of damage, which are summarized under the term "fretting", and which can significantly decrease the lifetime or performance of the contacting materials and bodies. Depending on the characteristic extent of the stick and slip zones in the contact during the oscillation, it is common to distinguish different "fretting regimes" [

1], mainly the partial slip and the sliding regime.

The two main damage phenomena associated with fretting are fretting wear and fretting fatigue. While the dominant damage mode in the partial slip regime often is fretting fatigue, the sliding regime mostly suffers from fretting wear. Nevertheless, both phenomena interact with each, and a numerical routine for the life prediction of a fretting contact should account for both wear and fatigue ([

2,

3,

4]). However, doing so in a rigorous way – especially considering that, in the partial slip regime, the wear debris material will act as a "third body" in the contact – has proven to be extremely difficult [

5].

The amount of influencing mechanisms and governing parameters in fretting is vast. Some of these have a contact mechanical origin, while others are of a more general tribological (physico-chemical) nature. One of the almost strictly contact mechanical aspects of fretting is the fatigue crack initiation due to the intricate, multiaxial, and rapidly changing stress field beneath the frictional contact under complex cyclic loading [

6]. For the prediction of fatigue crack nucleation, there are different well-established mechanical frameworks [

7]. One of the most common approaches are critical plane parameters [

8], like the Smith-Watson-Topper (SWT, [

9]) parameter.

Based on the SWT parameter (or similar critical plane approaches), different aspects of the fatigue crack initiation problem in fretting have already been analyzed numerically and experimentally in the literature. In that regard, especially in the past decade, a lot of research interest was dedicated to the impact of the loading protocol and the contact profile geometry on crack initiation, as these are influence factors that can be controlled more or less easily in design and construction of fretting contacts. With respect to the loading protocol, the influences of out-of-phase loading [

10] and phase difference ([

11,

12]), as well as more complex cyclic loading paths ([

13,

14]) were studied. On the other hand, regarding the influence of the surface geometry on crack initiation, the overall contact geometry [

15] and macroscopically worn profiles [

16], as well as the surface microgeometry [

17], surface pit treatment [

18] and machined surface texture [

19] have been considered.

Most of the aforementioned numerical studies are based on the Finite-Element-Method (FEM). While the FEM, due to its flexibility with respect to the physical modelling, can account for a wide variety of mechanisms and phenomena in a specific fretting contact – und thus achieves good predictive power under sufficiently well-defined circumstances – its demands for computational power and calculation time often make large parameter studies for the comprehensive analysis of different influencing factors unfeasible.

One solution to this problem consists in the application of data science and machine learning approaches, e.g., artificial neural networks [

20]. These, however, sacrifice the aspiration of a physical description and understanding of the system, for the purpose of a robust prediction of only a few concrete output variables, e.g., the fatigue life.

Another approach may be the reduction and simplification of the physical modelling: If the model description of the system is simple enough – so that the numerical solution of the resulting system of equations can be executed sufficiently fast to allow for a comprehensive analysis of a large parameter space – one is able to get a broad and deep physical understanding of the reduced model. While the results of such a reduced model, in most cases, won’t achieve a very high quantitatively predictive power, they can provide a broad, physically-based set of ideas, which parameter combinations can be worthwhile to analyze deeper with a more elaborate modelling, e.g., based on the FEM.

The latter approach shall be pursued in the present work. As was pointed out above, fretting fatigue crack initiation is mainly due to the complex oscillating mechanical stress field beneath a frictional contact under cyclic tangential (or multimodal) loading. For the elastic frictional contact of smooth, convex, axisymmetric bodies (this characterization constitutes the aforementioned model reduction), very recently an extremely efficient procedure has been suggested for the determination of the subsurface stress state beneath the frictional contact under arbitrary 2D oblique loading [

21], which reduces the problem of calculating the subsurface stresses to the evaluation of elementary one-dimensional integrals. Once the subsurface stress state is known, the critical plane parameters for the prediction of fatigue crack initiation can be determined easily, allowing for the very fast analysis of a specific set of geometrical and loading parameters.

Based on this procedure, in the present manuscript, the influence of the loading protocol and the contact profile geometry on the SWT parameter in partial slip bimodal oscillations of axisymmetric elastic contacts is theoretically studied. That shall provide general insights into the coupled (contact mechanical) dependencies of fretting fatigue life on these two classes of input parameters, i.e., load and geometry.

The remainder of the manuscript is structured as follows: In

Section 2, the analyzed problem is formulated in a physically rigorous form. After that, in

Section 3, the semi-analytical and numerical procedures for the solution of the contact problem and the determination of the subsurface stress state, as well as the fatigue crack initiation criterion, are described in detail.

Section 4 presents the obtained numerical results with respect for the influence of load and profile geoemtry on the SWT parameter. A discussion of the results finishes the manuscript.

2. Problem Statement

Let us consider the contact of axisymmetric elastic bodies, made of linear, isotropic, homogeneous materials that are elastically similar to each other (to avoid elastic coupling between the normal and tangential contact problems), i.e., whose shear moduli

and Poisson ratios

(at least, approximately) satisfy the relation

Moreover, the bodies shall also obey the restrictions of the half-space approximation; in that case, the contact between the two elastic bodies is equivalent to the one between an elastic half-space, having the effective moduli

and a rigid indenter having the axisymmetric profile

, with the polar radius

r in the contact plane and the contact normal direction

z;

f is given by the gap between the contacting surfaces in the instant of first contact. Microscopic surface roughness is neglected

We will consider different profile functions

f; specifically, the paraboloid (i.e., the axisymmetric Hertzian contact),

with the curvature radius

R; the cylindrical rounded flat punch,

with the radius

b of the flat face of the punch, the curvature radius

R of the rounded edge, and the Heaviside step function H; the truncated paraboloid

and the paraboloid with superimposed small waviness,

with the amplitude

h and wave length

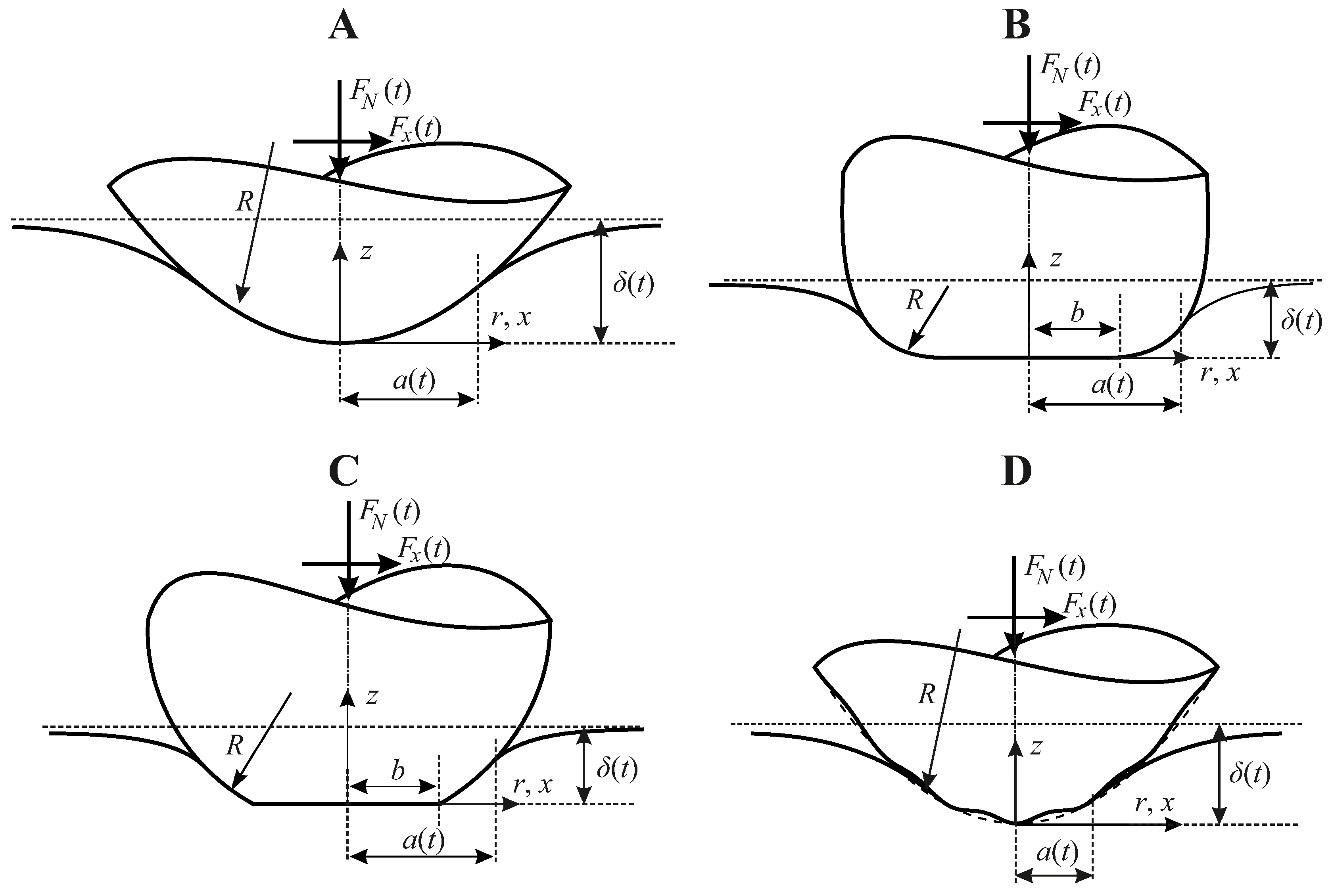

of the waviness. The analyzed contact problems are shown schematicallyin

Figure 1.

The contacts shall be subject to displacement-controlled bimodal harmonic oscillations; that is to say, the indentation depth

as a function of the time

t shall be

with the average indentation depth

, the amplitude

and angular frequency

of the normal oscillation, and a phase angle

; moreover, for the macroscopic relative tangential displacement between the contacting bodies,

u,

with the amplitude

and angular frequency

of the tangential oscillation.

Note that in the literature recently also variable amplitude fretting oscillations have been considered ([

22,

23]). This would in principle be possible to analyze within the framework described in the present manuscript, but would too significantly extent the relevant parameter space.

The tangential contact problem with friction shall be solved within the framework of the Cattaneo-Mindlin approximation ([

24,

25]), specifically:

validity of a local Amontons-Coulomb friction law between normal and frictional surface tractions, with a globally constant coefficient of friction

neglect of the lateral (i.e., orthogonal to the loading plane) elastic surface displacements – which would slightly violate the isotropy of the friction law

Munisamy

et al. [

26] compared the Cattaneo-Mindlin approximate theory to a rigorous numerical contact solution for the frictional Hertzian contact under shear load, and found that the error of the approximation in terms of the contact tractions is generally small.

We are interested in the Smith-Watson-Topper (SWT, [

9]) multiaxial fatigue crack initiation parameter due to the oscillating subsurface stress and deformation fields. It belongs to the group of critical plane criteria of (fretting) fatigue crack initiation [

7]; that is to say, it evaluates a certain characteristic scalar quantity of the intricate time-evolution of the subsurface stress and deformation fields in each material plane at a specific material point. The plane with the highest value of the scalar quantity is deemed critical, i.e., most prone to crack nucleation.

In the case of the SWT parameter, the scalar quantity is given by the product of the maximum normal stress

and the normal strain amplitude

in the specific plane,

where the upper index "max" of the stress and the strain amplitude are to be understood over one (stationary) oscillation cycle; the lower index "max" indicates maximizing with respect to the orientation of the plane [

27]. The SWT parameter is thus defined for every material point with the cartesian coordinates

; we will be interested only in the maximum value of the field,

which can be connected to the specimen lifetime (measured in oscillation cycles to initiate a crack of given length) [

8]. In that regard, it has to be kept in mind, that, because of the highly localized character of the contact stress fields – and therefore, too, the SWT parameter – such a strictly local version of the crack initiation criterion will provide very conservative lifetime estimates [

6]. To obtain better lifetime predictions, the local field of the parameter can either be averaged over a certain volume [

28], or evaluated at a certain critical distance [

29] from the strictly local maximum. Both the averaging volume and the critical distance depend on the specifics of the fretting contact, e.g., the material pairing. As the present work doesn’t aim for concrete lifetime predictions – but rather aspires to analyze the behavior of the criterion (

9) under different contact mechanical conditions – and therefore chracteristics like the concrete material pairing aren’t specified, we will use a local formulation of the SWT parameter. However, theoretically speaking, the averaged or critical distance formulations can easily be obtained from the local field, as well.

Final it should be noted, that very recently also the crack orientation prediction within the SWT framework has been significantly improved, based on the critical direction method [

30].

4. Results

4.1. Scaling Laws

The characteristic scale of the SWT parameter is the scale of the elastic energy density,

with the characteristic deformation scale in an axisymmetric Hertzian contact,

.

Dimensional analysis and numerical solutions of the problem stated in

Section 2 show that the SWT parameter, normalized for its characteristic scale (

19), will only depend on a few non-dimensional parameters, specifically

Here,

denote the non-dimensional parameters for the characterization of the profile geometry, which wil be detailed in

Section 4.3.

It should be noted that the dependencies of the non-dimensional SWT parameter on the friction coefficient and the non-dimensional tangential oscillation amplitude, , are rather elementary (increasing these parameters with all others held constant increases s), and shall not occupy us further. The dependence on Poisson’s ratio is intricate, but very weak. Therefore, the remaining dependencies, that will be analyzed in the following, are the ones on the normalized normal oscillation amplitude, , the frequency ratio between tangential and normal oscillation, , the (initial) phase difference , and the profile parameters .

Unless stated otherwise explicitly, the simulations used the fixed non-dimensional parameters listed in

Table 1.

It should be pointed out, that for basically all simulations the critical point (with the maximum SWT parameter) was in the contact surface, in the plane

, and well outside the region of permanent stick. The orientation of the critical plane was always close to perpendicular into the material (i.e., the normal vector of the critical plane pointed in the tangential

x-direction). This is in agreement with respective experimental data in the literature [

7].

4.2. Influence of Load Parameters in Parabolic Contact

First, let us analyze in-detail the influence of the bimodal loading protocol parameters (normalized amplitude of normal oscillation), (frequency ratio between tangential and normal oscillation) and (phase angle between normal and tangential oscillation at the beginning of the stationary cycle), on the non-dimensional SWT parameter in a parabolic contact.

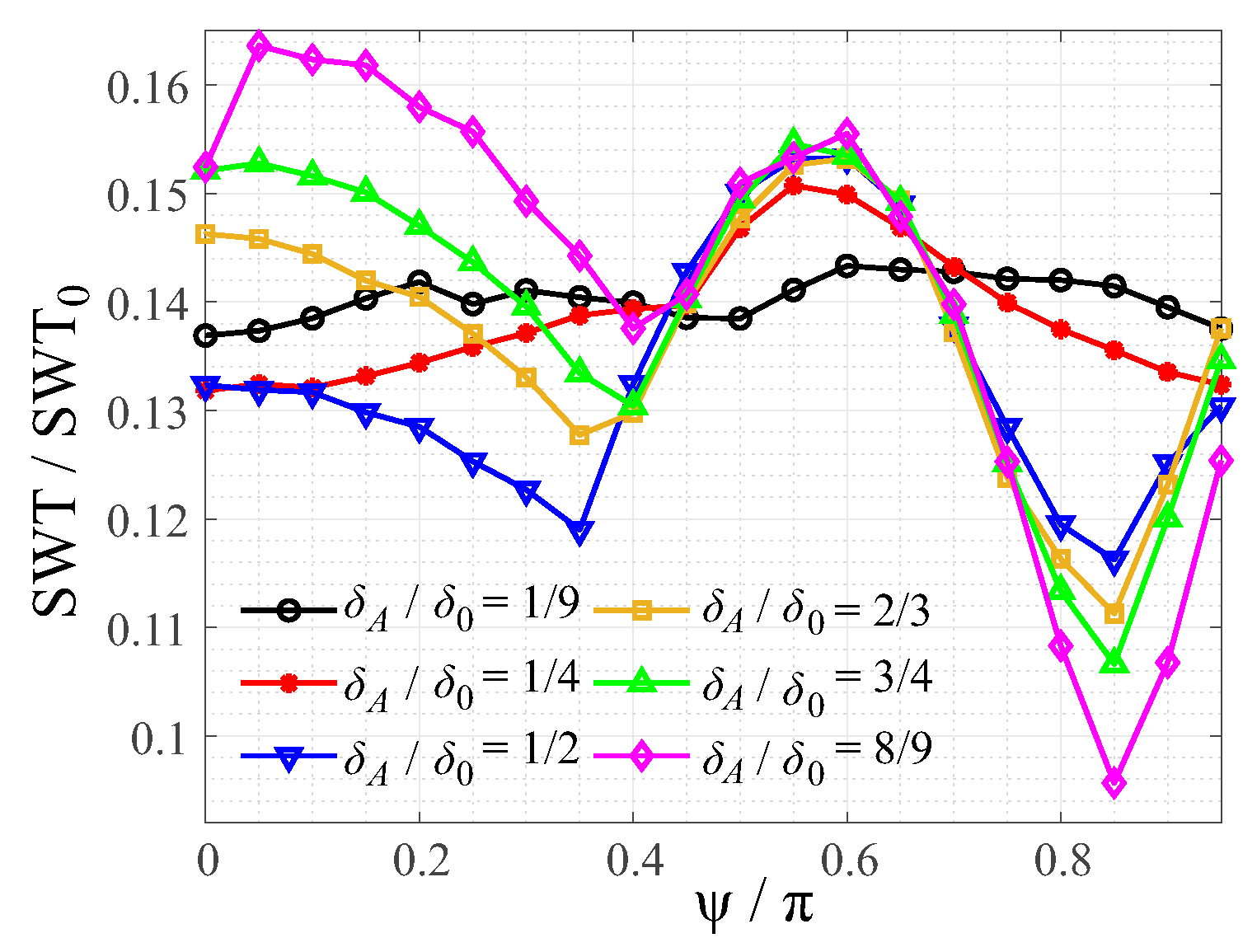

In the case of oscillations with the same frequency (

), the remaining function

could, in theory, be demonstrated comprehensively in a countour diagram. However, this presentation would be hard to read; therefore, in

Figure 3, the normalized SWT parameter is shown as a function of the phase angle

for different values of the normal oscillation amplitude.

Without normal oscillation, there would, of course, be no dependence on the phase angle. Therefore, for small normal oscillation amplitudes, the curves in

Figure 3 are almost constant. Expectedly, for large normal oscillations, the dependence on the phase angle increases, and turns out to be actually very relevant, as for

, the maximum and minimum values of the SWT parameter, as a function of the phase angle, differ by almost the factor of Two!

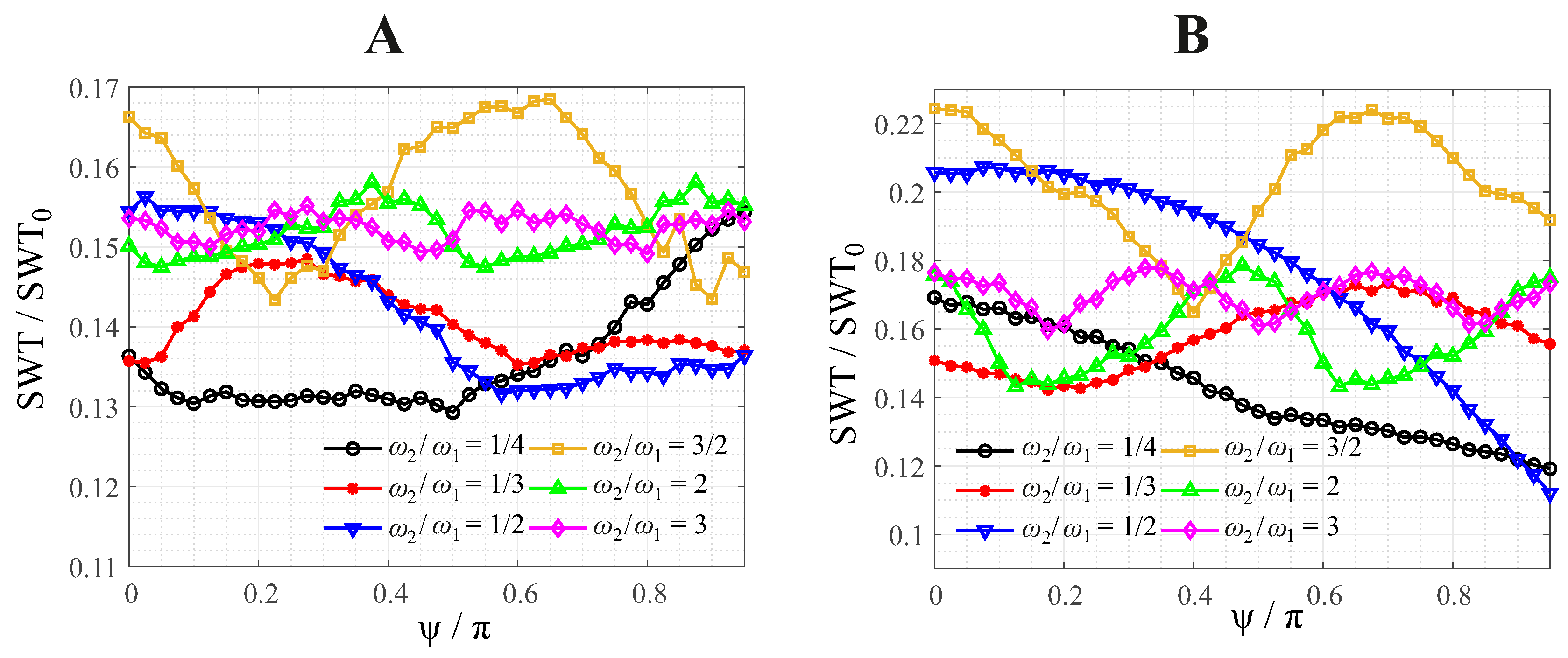

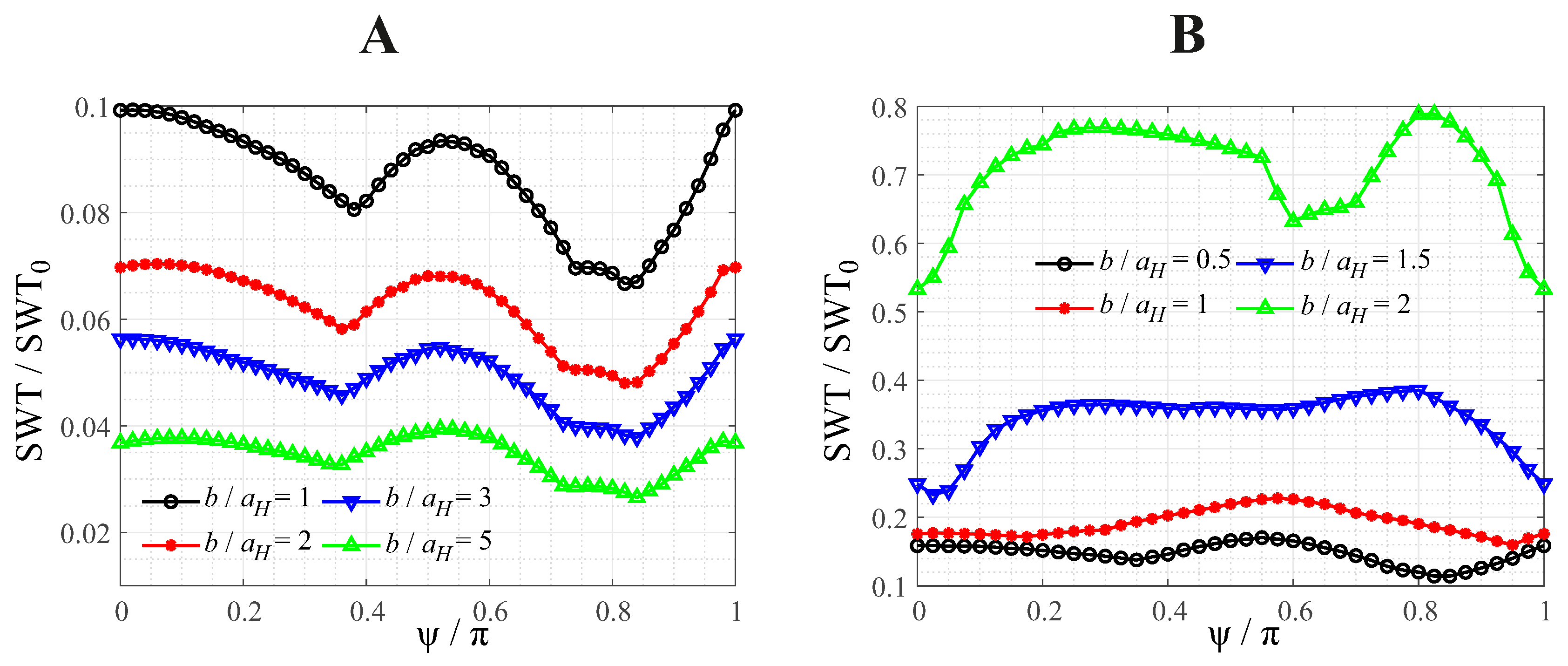

Moreover, there is a very interesting effect with regard to the coupled dependencies on the frequency ratio and the phase angle, which is shown in

Figure 4. There, the normalized SWT parameter is shown as a function of the phase angle for different frequency ratios, and small (A, left) or large normal oscillations (B, right).

The variation of the crack initiation criterion with the phase angle seems to be most prominent for frequency ratios of 1/4, 1/2 and 3/2; other values were tested, but showed little influence on the SWT parameter; probably, because the cycle duration of the full stationary cycle is very long for less commensurate frequencies, and thus the precise form of the loading protocol becomes less relevant, as normal and tangential contact configurations become statistically less correlated. Also, there seems to be a periodicity in the function , whose period length decreases with increasing frequency of the tangential oscillation.

Once again, all effects are amplified for larger amplitudes of the normal oscillation.

4.3. Influence of Profile Geometry

Let us now turn our attention to the influence of the contact profile geometry on the crack initiation criterion.

4.3.1. Rounded Flat Punch and Truncated Paraboloid

In the popular case of the cylindrical flat punch with rounded corners – the contact profile was given in Eq. (

4) – the only governing profile parameter in the non-dimensional formulation (

20) is the ratio between the radius

b of the flat face of the punch, and the Hertzian contact radius

. Note that the curvature radius

R of the rounded corners also enters the scale

of the SWT parameter in Eq. (

19); that is to say, if the curvature radius is reduced, the scale of the crack initiation criterion (and accordingly, the criterion itself) increases; the limit

corresponds to the sharp flat punch, which will be extremely prone to crack nucleation, due to the oscillating stress singularity at the edge of the punch.

For the truncated paraboloid with the profile given in Eq. (

5), once again, the only influencing profile parameter in the non-dimensional formulation is the ratio between the radius

b of the indenter’s flat face, and the Hertzian contact radius

In

Figure 5, the normalized maximum SWT parameter is shown for the same-frequency bimodal contact oscillation, as a function of the phase angle

, for different values of the normalized radius of the punch face,

, for the rounded flat punch (A, left) and the truncated paraboloid (B, right).

Obviously, in these cases, the dependence on the profile geometry is rather simple: For increasing values of , the normalized SWT parameter globally and monotonously decreases for the rounded flat punch, and increases for the truncated paraboloid.

Also there seems to be only a very weak coupling between the profile geometry as an influencing factor, and the loading protocol – especially for the rounded punch, for which this coupling is basically negligible – as the curves for different profile parameters differ only slightly in their dependence on the loading protocol (i.e., in the case of

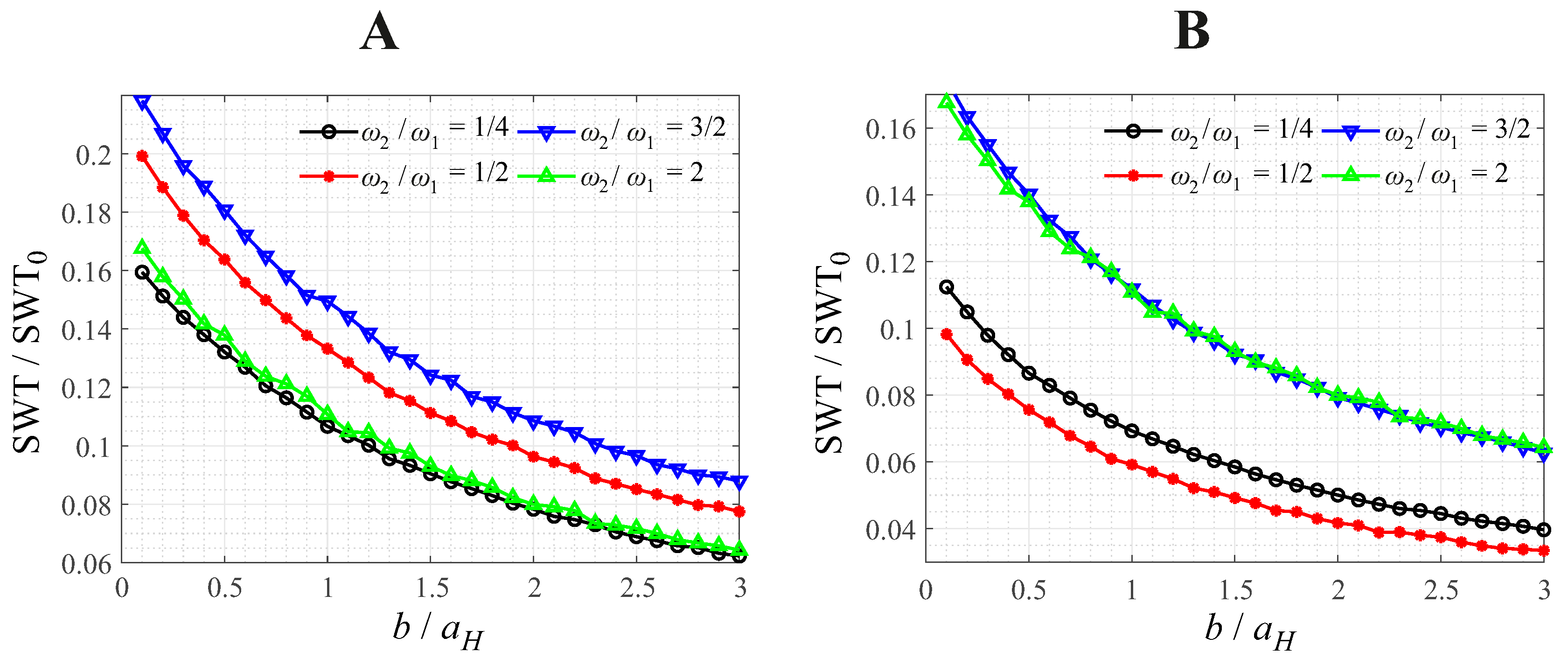

Figure 5, the phase angle). This phenomenon is highlighted again in

Figure 6, showing the normalized SWT parameter for the different-frequency oscillation of a rounded flat punch, as a function of the normalized radius of the punch face

, for different values of the frequency ratio between tangential and normal oscillation, for a phase angle

(A, left) and a phase angle

(B, right).

Interestingly, no coupling between profile and loading influences can be detected in

Figure 6, as all curves exhibit exactly the same decreasing behavior; the influence of the loading protocol on the crack initiation criterion for the rounded flat punch seems to be the same as for the paraboloid, which was discussed in-detail in

Section 4.2.

4.3.2. Paraboloid with Small Waviness

An intriguing problem is the question, whether a small waviness influences the crack initiation criterion. As it turns out, there are two non-dimensional parameters to characterize the waviness, as given in the profile function (

6): the normalized waviness amplitude

, and the normalized wave length

. Note that for the contact area to remain compact (which is a necessary prerequisite for the contact solution within the MDR), the wave length has to be large enough; this has been checked in the simulations.

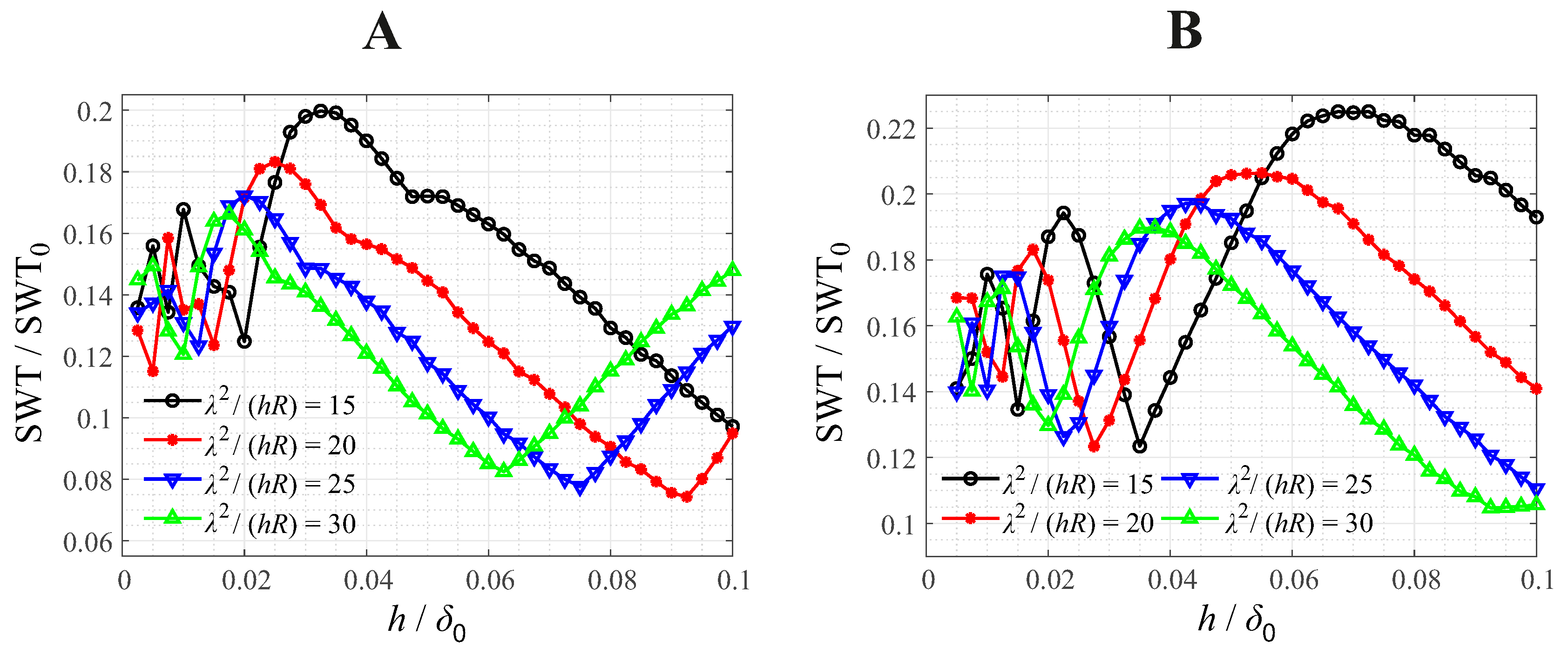

In

Figure 7, the normalized maximum SWT parameter for the same-frequency bimodal contact oscillation are shown as a function of the waviness amplitude, for different values of the normalized wave length; for small (A, left), or large (B, right) normal oscillations.

It is apparent that even a very small waviness can have a significant impact, especially the waviness amplitude. In that regard, it is interesting that this impact is only slightly affected by the normal oscillation, as both diagrams in

Figure 7, qualitatively and quantitatively, show quite similar behavior. Another notheworthy effect are the oscillations of the crack initiation parameter for small waviness amplitudes, which decrease in period length and amplitude, as the waviness amplitude decreases.

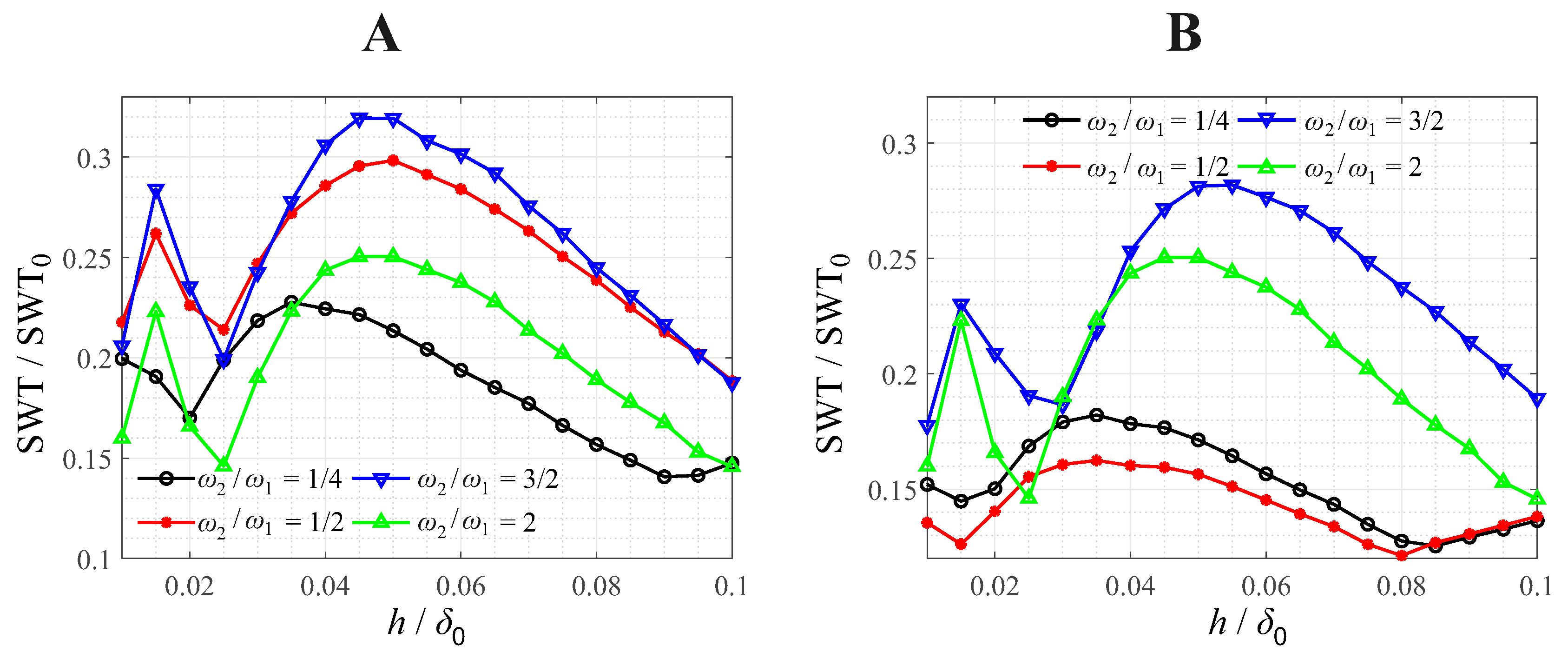

To analyze the coupling between the influencing variables of contact profile and load protocol for this indenter type, in

Figure 8 the normalized SWT parameter for the different-frequency oscillation is shown, as a function of the normalized waviness amplitude

, for different values of the frequency ratio between tangential and normal oscillation, for a phase angle

(A, left) and a phase angle

(B, right).

As was the case also for the paraboloid without waviness, the most significant difference in the SWT parameter for different phase angles appears for a frequency ratio of

. Moreover, there seems to be weak coupling between the profile and load influences, as all curves in

Figure 8 quantitatively are quite distinct from each other, but qualitatively all exhibit similar trends.

5. Discussion

As was laid out in the Introduction, the obtained results are not necessarily intended as quantitative predictions of fretting fatigue life, but shall give a comprehensive understanding of the coupled contact mechanical influences of loading and profile geometry on the SWT parameter – which is a very valid indicator for possible fatigue crack initiation – in elastic fretting contacts. Various interesting trends and ideas have been identified, which are worthwhile to analyze deeper with physically more flexible numerical procedures, e.g., the FEM.

The calculations have been performed within the framework of several simplifying model assumptions, that should be kept in mind when applying the results to real engineering contacts, most prominently linear elasticity, the validity of a local-global Amontons-Coulomb friction law and the neglect of microscopic surface roughness. In that regard, it should be noted that the influences of both plasticity [

38] and an unstable friction law [

39] on fretting fatigue crack initiation have already been considered in the literature.

A very desirable extension of the proposed formalism, which remains for future work, is the inclusion of bulk stress (which is also necessary to propagate nucleated fatigue cracks from the vicinity of the contact into the bulk material) into the calculation of the subsurface stress fields, as was already done successfully very recently for plane fretting contacts [

40].

Figure 1.

Schematic representation of the considered contact profiles. A: Paraboloid B: Flat punch with rounded corners C: Truncated paraboloid D: Paraboloid with small waviness

Figure 1.

Schematic representation of the considered contact profiles. A: Paraboloid B: Flat punch with rounded corners C: Truncated paraboloid D: Paraboloid with small waviness

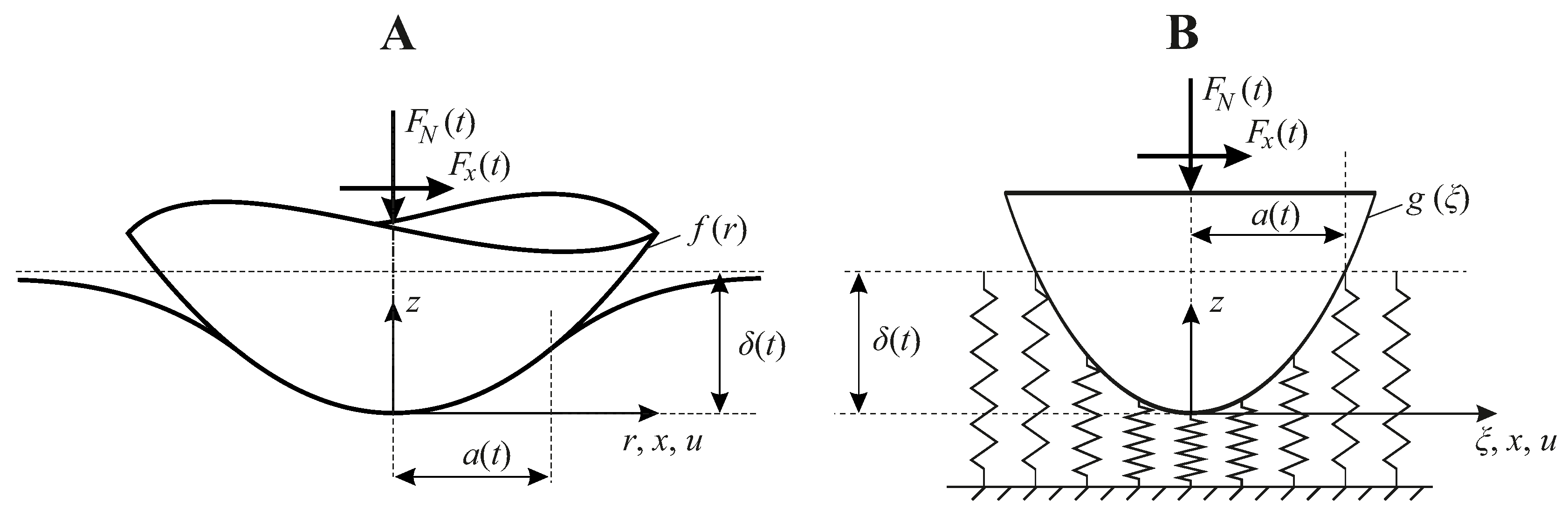

Figure 2.

A: Original axially symmetric tangential contact problem between a rigid indenter with the profile and an elastic half-space B: Equivalent problem within the MDR.

Figure 2.

A: Original axially symmetric tangential contact problem between a rigid indenter with the profile and an elastic half-space B: Equivalent problem within the MDR.

Figure 3.

Normalized maximum SWT parameter for the same-frequency bimodal contact oscillation between a paraboloid and a flat, as a function of the phase angle , for different values of the normal oscillation amplitude.

Figure 3.

Normalized maximum SWT parameter for the same-frequency bimodal contact oscillation between a paraboloid and a flat, as a function of the phase angle , for different values of the normal oscillation amplitude.

Figure 4.

Normalized maximum SWT parameter for the different-frequency bimodal contact oscillation between a paraboloid and a flat, as a function of the phase angle , for different values of the frequency ratio. A: B: .

Figure 4.

Normalized maximum SWT parameter for the different-frequency bimodal contact oscillation between a paraboloid and a flat, as a function of the phase angle , for different values of the frequency ratio. A: B: .

Figure 5.

Normalized maximum SWT parameter for the same-frequency bimodal contact oscillation between a flat face indenter and a flat, as a function of the phase angle , for different values of the radius of the punch face. A: rounded flat punch B: truncated paraboloid

Figure 5.

Normalized maximum SWT parameter for the same-frequency bimodal contact oscillation between a flat face indenter and a flat, as a function of the phase angle , for different values of the radius of the punch face. A: rounded flat punch B: truncated paraboloid

Figure 6.

Normalized maximum SWT parameter for the different-frequency bimodal contact oscillation between a rounded flat punch and a flat, as a function of the normalized radius of the punch face , for different values of the frequency ratio between tangential and normal oscillation. A: phase angle B: phase angle .

Figure 6.

Normalized maximum SWT parameter for the different-frequency bimodal contact oscillation between a rounded flat punch and a flat, as a function of the normalized radius of the punch face , for different values of the frequency ratio between tangential and normal oscillation. A: phase angle B: phase angle .

Figure 7.

Normalized maximum SWT parameter for the same-frequency bimodal contact oscillation between a paraboloid with small waviness and a flat, as a function of the normalized waviness amplitude, for different values of the normalized wave length; A: for B: for

Figure 7.

Normalized maximum SWT parameter for the same-frequency bimodal contact oscillation between a paraboloid with small waviness and a flat, as a function of the normalized waviness amplitude, for different values of the normalized wave length; A: for B: for

Figure 8.

Normalized maximum SWT parameter for the different-frequency bimodal contact oscillation between a paraboloid with small waviness with and a flat, as a function of the normalized waviness amplitude, for different values of the frequency ratio between tangential and normal oscillation. A: phase angle B: phase angle

Figure 8.

Normalized maximum SWT parameter for the different-frequency bimodal contact oscillation between a paraboloid with small waviness with and a flat, as a function of the normalized waviness amplitude, for different values of the frequency ratio between tangential and normal oscillation. A: phase angle B: phase angle

Table 1.

List of used fixed non-dimensional parameters for the simulations (unless stated otherwise in the text).

Table 1.

List of used fixed non-dimensional parameters for the simulations (unless stated otherwise in the text).

| Parameter |

|

|

|

|

|

|

| Value |

0.3 |

0.3 |

3/4 |

1 |

5/6 |

0 |