1. Introduction

Transportation activities have been in the last century major contributors of air pollution and greenhouse gases emissions caused from the combustion of fossil fuels. The unsustainability of such situation is nowadays largely recognized, and substantial efforts are being perfused by the governments and institutions to reduce the emissions of polluting substances and greenhouse gases through the establishment of suitable decarbonization strategies. In this regard, in 2011, the European Commission put forward a first decarbonization plan, which in 2020 became part the “green deal”: a new growth strategy for Europe to become the world’s first climate-neutral continent by 2050. For transport, which accounts for a quarter of the EU’s total greenhouse gas emissions, achieving the climate neutrality objectives will require a 90% reduction of the sector’s emissions by 2050, compared to 1990 levels. Such objective is extremely challenging, considering the transport demand is expected to increase in the future and that the transport sector, including land air and maritime routes, is still largely dependent on fossil fuels. The adoption of EU Directive 2014/94 on alternative fuels marks the opening to the construction of infrastructures for the distribution of fuels to replace petrol and diesel and recognizes compressed natural gas (CNG) liquefied petroleum gas (LPG) and liquefied natural gas (LNG) as alternative fuels.

While fossil fuels are seen as a short-term solution, electricity and hydrogen are generally considered the only valid solutions for complete decarbonization on the long run, as long as their production involves only renewable sources. Such condition is however hardly viable due to several technical shortcomings related to the intermittency of renewable sources in relation to the variability of energy demand. The storage of electric electricity in electrochemical accumulators (i.e. batteries) which could be a valid solution to such problem has indeed several disadvantages, related to the availability of rare and expensive metals used in their production, and to their questionable lifecycle environmental effectiveness considering the significant pollutions during the production and disposal phases. In addition, batteries can be useful for compensating daily fluctuations in supply and demand (e.g. day and night cycle of solar panels), but compensating the seasonal cycles is much more difficult due to the self-discharge effect. A definitive solution to such problems might actually derive from the employment of hydrogen, which is the most abundant element in the universe and an excellent energy carrier. Considering a single kilogram of H2 is capable of developing 142 MJ of energy, compared to 56MJ for natural gas, 45-46 MJ for petrol, diesel or kerosene. In addition, hydrogen can be transported along pipelines without any production of CO2 or pollutants and can be produced from renewable sources by means of electrolysers by decomposing the H2O molecules, while chemical energy can be transformed back into electricity in a fuel cell. Among the advantages of hydrogen there is also the conversion efficiency, in fact a current fuel cell reaches an efficiency of 60% compared to 45% for a modern coal-fired thermoelectric plant. Nowadays, however, the cost of green hydrogen is too high compared to more traditional production technologies, although the situation is evolving and the International Energy Agency (IEA, 2019) predicts that in 2030 the price of H2 will decrease by 30%, thanks to the increase in production and to the improvement of renewable technologies.

In such context, logistics and transportation operators are currently facing the problem of converting their fleet of vehicles through the adoption of more sustainable technologies in order to reduce their overall carbon footprint in compliance with the aforementioned green deal program. Considering the operating period of a transportation vehicle can be of some decades, the strategic industrial relevance and complexity of the fleet renewal decisions are related to the substantial economic investment involved and to the high level of uncertainty characterizing possible future scenarios. The consequences of such decision also significantly affect the management of operations, considering that the conversion of a fossil fuel propelled vehicle to an electric or hydrogen vehicle substantially impacts its endurance, the payload and the recharging time, therefore requiring a substantial revision of the fleet management policies. Based on the considerations above, logistic operators are nowadays challenged with the problem of establishing a strategy for phasing out fossil fueled vehicles with two possible alternatives in the medium-long term, represented by battery electric vehicles (BEVs) and fuel cell electric vehicles (FCEVs). While the literature increasingly confirms technical possibility of introducing of heavy-duty battery-electric trucks (BET) and several manufacturers already launched their commercial proposals. The real-world application of such technologies is however currently being questioned by researchers and professionals, based on several technical and economic issues. In such uncertain context, some fleet managers may adopt conservative decisions according to their perceived risks and individual beliefs, while others are delaying their decisions until price parity for trucks with alternative powertrain is reached. This condition however might still take some years, considering that the average price of a heavy-duty diesel truck is currently less than half the market price of an electric truck with similar features. According to many researchers [

1,

2], however, relaying on the parity of the acquisition cost might lead to wrong and dangerous decisions, because when the cost over the lifetime is considered, electric trucks might achieve a substantial reduction in energy costs due to the significant lower cost of electricity per kilometer compared to diesel fuel. Further considerations involve the current inadequacy of the electric charging infrastructure and the technological turmoil which affects the market of electrochemical accumulators. The market of Lithium-ion batteries (LIBs) is in fact projected to reach a value of US

$53.8 billion by 2024, with a compound annual growth rate (CAGR) of 11% during 2019–2024 [

3], while the global electric truck market is projected to reach over 3.86 billion U.S. dollars in size by 2030, with a CAGR of 26.4 percent between 2021 and 2030. An additional source of market uncertainty is represented the establishment of innovative startups such as the Nikola Motor Company, which is partnering with Bosch, Mahle, and Iveco to produce next generation vehicles. The experience of the traditional truck manufacturers can be a key success factor on the market, considering the reliability issues of vehicles travelling million miles. In such complex scenery, decision makers are charged with high responsibilities, since adopting a tardive or wrong decision may substantially affect the performance of logistic companies, while over-cautious approaches aiming at meeting the short-term decarbonization targets with a combination of evolutionary improvements to the Internal Combustion Engines (ICEs) and limited adoption of hybrid or full electric systems only where tight regulations hold (i.e. city delivery), might result in sub-optimal solutions. This paper addresses the research gap related to the absence of appropriately structured approaches to the vehicle renewal decision problem taking into account the multiple objectives involved. The methodology proposed focuses on the tradeoff between costs and long-term environmental sustainability (and related regulatory compliance) considering also the main technical limitations of the different technologies and taking into account the substantial scenario uncertainty which affects the decision problem. From a methodological point of view, the novelty of the approach proposed lays in combining multi criteria decision making methods with lifecycle analysis by considering two fundamental parameters such as the Total Cost of Ownership (TCO) and the Well to Wheel (WTW) emissions. This approach also demonstrates how different fleet operating conditions (e.g. annual kilometers travelled by the vehicles) may affect the optimum choice and highlights the importance of the attitude of the decision maker towards risk and his perception about the future scenarios.

In the reminder of the paper, after reviewing of the relevant literature in the following section, the methodology proposed is discussed in section 3 while a validation based on a case study is given in section 4. The results will finally be discussed, and conclusions drawn up in section 5.

2. Literature Review

The recent establishment of the “green deal” by the European Community (Massaro et al. 2021) as an overall strategy for reaching the climate neutrality within year 2050 involves the spread of green propulsion systems and promotes the development of hydrogen as the definitive solution to achieve full decarbonization. In particular, the green deal foresees an increase in the production volume of green hydrogen to 10 million tonnes/year through the installation of an additional 40 GW electrolyzer capacity by 2030, while by 2050, the expected share of hydrogen in the European energy mix by 2050 should reach 14%. According to the green deal, the European program and investments are thus divided into 3 sequential phases:

• Phase 1 (from 2020 to 2024): birth of the hydrogen market and definition of an ad hoc legislative-regulatory framework.

• Phase 2 (from 2025 to 2030): development of the hydrogen market, creation of the first localized applications and construction of the transport infrastructure.

• Phase 3 (from 2031 to 2050): large-scale diffusion of hydrogen with a massive penetration of the vector into the energy mix of final consumption.

The roadmap of the green deal poses some fundamental challenges for the operators of transport and logistic services, considering the growing demand for transport and the strong dependence on traditional (fossil) fuels. In particular, as pointed out by many authors [

4,

5,

6,

7], the compliance with the long-term objectives of the green deal requires the conversion of the fleet to electric powered or hydrogen propelled vehicles as the only viable possibility to achieve full decarbonization. Clearly, the green deal relies on some fundamental assumptions about the evolution of the propulsion technologies in the next 25 years, however, the technological landscape is currently evolving, therefore the reliability of the plan is questionable. Nevertheless, the compliance to the green deal is currently a hot topic in the transportation sector, which involves strategic decisions related to the renewal of the fleets of vehicles. In order to clarify the different technological alternatives to consider in the decision problem, a detailed review of the technological landscape is provided in the next section, while the decision methodologies are discussed in section 2.2.

2.1. Transportation technologies

The category of electric vehicles can be broadly subdivided into All-Electric Vehicles (AEV), which run entirely on a battery and an electric drive, and Hybrid Electric Vehicles (HEV) equipped with both an electric and an ICE. Hydrogen based propulsion systems can be sub-classified into Hydrogen Internal Combustion Engine Vehicles (HICEVs), generating kinetic energy form the combustion of hydrogen and Fuel Cell Electric Vehicles (FCEVs) exploiting the reaction of hydrogen and oxygen in a fuel cell. As many authors [

2,

8] pointed out, green vehicles have some relevant advantages compared to traditional combustion engines powered by fossil fuels, related to their weight, space, and, above all, environmental sustainability. In particular, as long as the electric energy produced for powering the electric vehicles or for producing hydrogen derives from renewable sources, the absence of life cycle emissions [

6,

7] makes them a most promising possibility to achieve full decarbonization. Although the benefits of zero emission vehicles (ZEV) have been widely discussed in the literature [

9,

10], their superiority compared to traditional vehicles in logistic operations is questionable, as their limited diffusion in long haul distribution evidences. A critical element in such regard is represented by their related costs, which are an important element of strategic decision making in a sector where economic competitiveness is paramount [

11,

12]. The establishment of appropriate cost models to evaluate the efficiency of ZEV and to compare them with traditional fossil fueled vehicles has thus become a relevant research topic in the last decade. Al-Alawi and Bradley [

1], for example, investigating the cost of hydrogen electric vehicles came to the conclusion that they were less expensive than traditional combustion vehicles, at least under some favorable conditions. Similarly, Offer et al. [

2] demonstrated that electric and hydrogen vehicles have higher capital costs than traditional vehicles, however, when fuel costs over the entire life of the vehicle, are considered ZEVs become cheaper than fossil fueled vehicles. Overall, such studies demonstrate that both hydrogen and traditional combustion vehicles are highly sensitive to fuel costs, therefore accurate estimates over a long period are not possible considering the unpredictable dynamics of the market. Contestabile et al. [

13] compared electric vehicles to hydrogen vehicles concluding that smaller electric vehicles offer cost benefits when operating in an energy efficient driving cycle. Wu et al. [

14] also produced a probabilistic model to simulate the costs of electric and combustion vehicles, concluding that electric vehicles have a good chance of becoming the most cost effective choice for small vehicles operating in urban settings. Davis [

15] focused on the study of electric and traditional combustion trucks for deliveries in urban environments, concluding that electric trucks are more expensive in almost all cases, but referred to the uncertainties in technological evolutions, considering that an increase in energy costs and the development of battery technology could make electric trucks more competitive in most cases. Finally, an additional 176 element that should be considered is the effect of incentives which might have a relevant impact on strategic decisions [

16].

The above reported scientific literature confirms that a reliable representation of the cost implications related to the substitution of a traditional transport vehicle with a ZEV should take into account the overall lifecycle, through a comprehensive indicator such as the Total Cost of Ownership (TCO). The concept of TCO is used since the late 90’s in strategic procurement since it allows to perform asset 182 acquisition analyses taking into account both the cost of purchase and the costs of operations (maintenance, consumables, etc.) which are generally itemized separately in traditional cost models, since they belong to different cost classes. Clearly, the concept of aggregating the cost elements of different categories distributed over the lifecycle, derives from the adoption of a value-chain [

2,

16] and lifecycle-oriented approach [

6,

11], therefore implying several 187 assumptions related to the usage conditions of the vehicle. Different computational models have thus been employed by researchers and practitioners in different application scenarios, therefore a standardized procedure does not actually exist. However the notion of TCO is well-established in the scientific literature and widely employed in the acquisition process of transportation vehicles comparing different propulsion technologies [

17,

18]. Burke [

19] conducted a TCO analysis on diesel, electric, and fuel cell electric trucks and concluded that full electric trucks equipped with large batteries cannot be cost competitive with diesel trucks until the battery pack price drops below

$100/kWh for long haulers.

Other researches [

20] report in order to outperform diesel trucks the cost BEV long haulers with a high mileage of 104,000 miles annually (approx. 170,000 km), and should decrease of 12%. Clearly, in the context of strategic decision making, the condition of indifference is reached when the TCO parity is achieved, which according to recent studies could be by the end of this decade [

21]. Wolff et al. [

22] clearly state that BETs will suffer a significant payload penalty exceeding 20%, which will significantly impact their TCO parity with diesel trucks. In the last decade, the issues related to the long-term sustainability of transport operations have become paramount in the choice among different propulsion systems for transport vehicles, therefore a decision approach based only on cost efficiency can be inadequate and somehow misleading, since different vehicles may have substantially different environmental performance. In such regard it must be pointed out that until now, the environmental impact of transportation vehicles has been measured referring to their tailpipe emissions in terms of CO2 and air pollutants. This approach, which can be appropriate for fossil fuels powered vehicles, cannot be applied to electric and hydrogen vehicles that do not produce any emission during their usage. The assessment of environmental sustainability of ZEV thus requires different methodological approach considering the entire life cycle of the energy source, and the impacts of the production and distribution of an energy carrier in addition to its use for vehicle propulsion. According to the European Commission (2016) a suitable approach for such purpose is the Well-to-Wheels (WTW) analysis, which can be used to determine the 218 environmental impact of a fuel in terms of greenhouse gas emissions (GHG) and energy efficiency. Similarly to the TCO, the well-to-wheel analysis is a non-standardized indicator, although it is frequently employed to quantify the impact of transportation fuels and vehicles regarding energy and climate change. The WTW analysis can be divided into a Well-to-Tank (WTT) and Tank- to-Wheels (TTW). The WTT part of the analysis begins with the extraction of the 223 primary energy source before being refined to a transportation fuel and sold to distributers and end-users. The TTW part of the study determines the fuel consumption in the engine and the tailpipe emissions during its usage. In other words, the first stage (WTT) involves the extraction or production of fuel, and the “upstream” section, while the second (TTW) is the “downstream” part related to how it is consumed and burned. Several researchers have applied this methodology in assessments of GHG emissions of electric cars. Liu et al. [

23] discussed the influence of regional electricity grids on the WTW GHG emissions of battery-electric heavy-duty trucks in the US. Li et al. [

24] employed the WTW analysis for the assessment of battery and fuel cell vehicles and suggested cleaner hydrogen production pathways and cleaner electricity power generation. Gupta et al. [

25] established the WTW cycle for heavy-duty vehicles, evaluated the 20% hydrogen and compressed natural gas mixture fuel engine, and suggested that a cleaner hydrogen feedstock was essential.

2.2. Strategic decision-making approaches

The problem of choosing the right type of vehicle for the needs of a logistic operator is a complex decision problem involving several objectives and requiring an appropriate decision-making approach. Multi-criteria decision making (MCDM) methods are methodologies developed in the general context of decision science to structure and formalize complex decision-making processes. The context of decision-making methods can be broadly subdivided into two categories, the Multi-Attribute Utility Theory (MAUT) methods [

26,

27], the methods based on the outranking concept [

28]. The application of either multi criteria decision approaches in ranking or selecting the most suitable vehicle among a set of different technological alternatives is a topic frequently discussed in the literature [

29,

30]. Recently MCDM have been successfully employed in conjunction with Life Cycle Analysis (LCA) [

31,

32,

33,

34], in the transportation sector where MCDA methods have Been employed to rank the alternatives, by means of weighted sums and additive value functions [

35,

36,

37], the Analytic Hierarchy Process [

38], PROMETHEE and SMAA-LCA [

39,

40,

41], compromise programming [

42]. Such methodologies have been extensively used in the context of sustainability decisions related to transport. Kolak et al. [

43] applied the Technique for Order of Preference by Similarity to Ideal Solution (TOPSIS) method to assess the sustainability of the transport networks in 15 European countries. Awasthi and Chauhan [

44] presented a composite indicator of transport sustainability using the AHP method and Dempster-Shafer theory to assess the impact of sustainable transport solutions, Haghshenas and Vaziri [

45] compared the transport sustainability of 100 cities around the 257 world considering nine transport indicators.

In this research the TOPSIS method has been employed the decision problem related to the renewal of a fleet of vehicles. The TOPSIS method is based on the concept that the ranking of alternatives results from their distances from the (positive) ideal solution (PIS) and from the negative ideal solution (NIS) or nadir. With such features, the TOPSIS method has the merits of providing a robust result with a simple decision-making approach which limits the occurrence of rank reversals. Finally, the complexity of the decision-making problem considered is linked to the substantial uncertainty that characterizes the decision-making context. In general, uncertainty can be classified into three categories [

46]: scenario uncertainty, parameter uncertainty and model uncertainty. While model and parameter uncertainty typically refer to performance measurement errors and a misinterpretation of correlations and uncertainty, respectively, scenario uncertainties include descriptive errors and incomplete information about the decision context that are typically present in problems long-term decision making [

47,

48]. In this context, scenario analysis is often used to analyze and demonstrate the implications of alternative policy options or to explore the impacts of uncertainties on strategic policies. Based on the above literature, this research proposes an original integrated decision-making framework in which the TOPSIS method is used to classify different vehicle propulsion technologies taking into account the inherent life cycle environmental and economic implications as well as the uncertainty of the long-term scenario. The employment of the TOPSIS methodology in decision making problems involving the choice of vehicles with different propulsion alternatives is well established in the literature [

49,

50], since the simplicity of this method makes it preferable in the application in practical contexts. However, this research proposed an original implementation of such methodology in a generalized lifecycle approach, involving economic and environmental objectives and considering the inherent scenario uncertainty. With such features, this research constitutes a novel contribution to the scientific literature related to strategic decision problems in the context of transportation.

3. Methodology

This section discusses the decision framework proposed for addressing decision problems related to vehicle selections in logistics involving multiple criteria and lifecycle considerations. As discussed before, due to the long-term implications and the relevant financial investment involved and to the substantial uncertainties involved, such decision problems belong to the strategic management level, therefore having a substantial impact on the business performance and on the compliance with future environmental regulations. In addition, the inherent uncertainty related to the dynamic nature of the technological and regulatory context further complicates the decision problem, therefore an appropriate and well-structured decision framework can be a valuable support for the decision makers. According to the above considerations, the decision problem is preliminary structured by identifying the set of technological alternatives and the set of criteria (and related indicators) considered. Such elements are discussed in detail below.

3.1. Technology Alternatives

The current technological scenario of ground transportation involves three main alternatives, namely fossil fuels, electric and hydrogen propelled vehicles. Currently, propulsion systems based on fossil fuels are the most consolidated and spread technology, benefitting of the lowest acquisition cost and highest reliability while rising some fundamental concerns in terms of environmental sustainability due to their emissions of polluting and greenhouse gases. The exhaust gases treatment systems, indeed, ensure the compliance with current environmental regulations, but they are not able to meet the objectives of the EU green deal and related forthcoming regulations. Compared to traditional fossil fuels, electric vehicles do not produce any polluting and greenhouse gases, therefore they are fully ecological, as long as the electric energy is generated from renewable sources. Besides such environmental benefit, however, when the whole lifecycle of the vehicle and its components are considered some environmental concerns still arise about e.g. the disposal of the Li-PO batteries, which up to today do not have a reliable end-of life treatment. In addition, the novelty of electric propulsion technology does not allow to make reliable estimations of the maintenance and operation costs. The third available technology is hydrogen propulsion, employed in HICEVs and FCEVs, with the latter being more competitive from a commercial point view due to the lower complexity and operating cost. Such technology however has a substantially higher acquisition cost, since the Proton-exchange membranes (PEM) employed in such systems are very expensive, with metal catalysts, gas diffusion layers, and bipolar plates accounting for up 70% of their overall cost. Additional problems of FCEVs are related to the limited operating temperature range of PEMs (typically between 20 and 80 ºC) [

51] and to their degradation at high temperatures. Despite their several drawbacks and technological limits, FCEVs are superior to all other mobility technologies from an environmental point of view since they ensure the complete decarbonization of the chain when operated with green hydrogen.

3.2. Decision Criteria

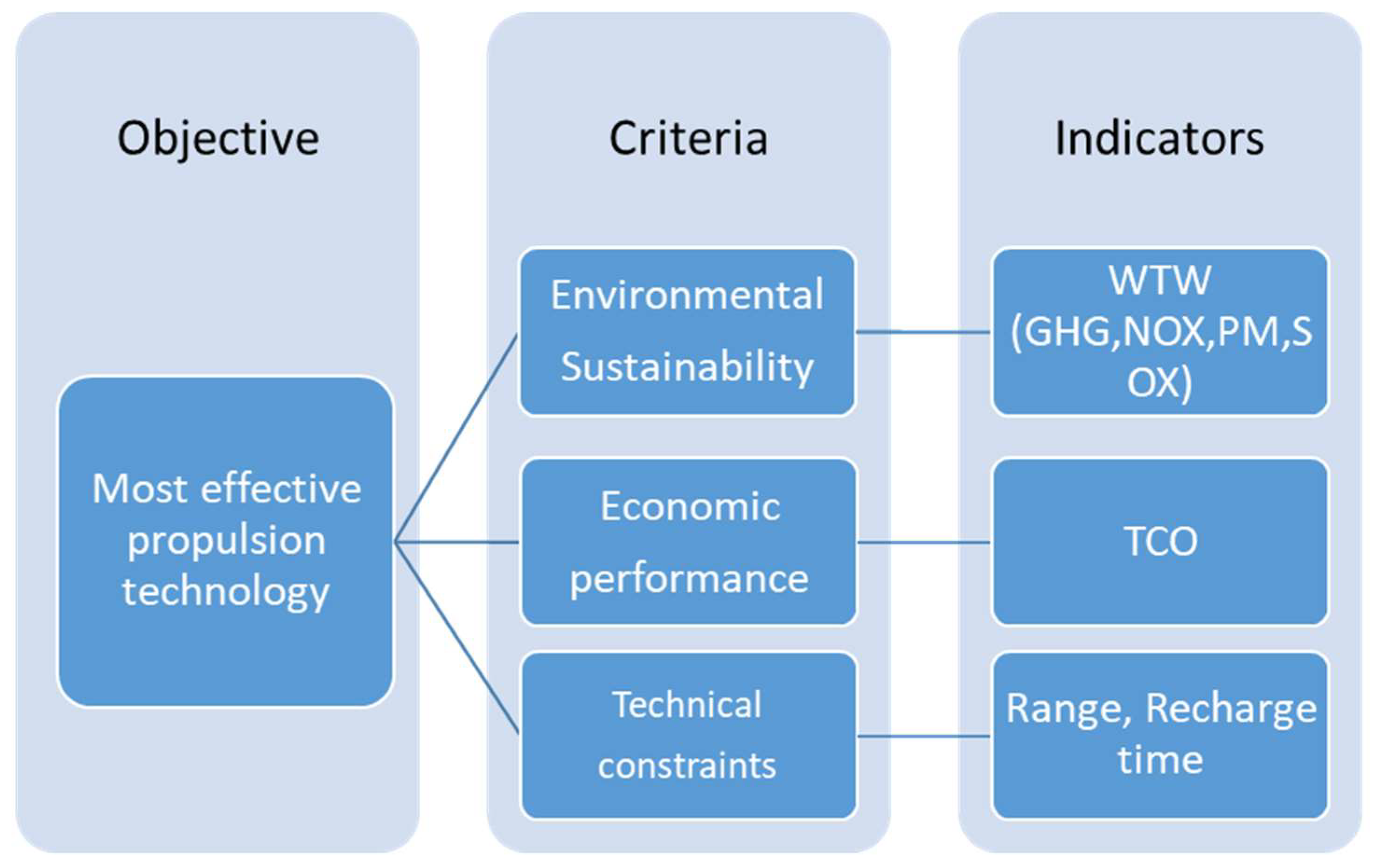

The decision framework proposed relies on the establishment of three decision criteria namely the long-term sustainability (i.e. environmental performance), cost effectiveness (i.e. economic performance) and the technical complexity as given in figure 1. The first two criteria are measured referring to the entire lifecycle of the vehicle and of the energy source, by means of two referenced numerical indicators such as the WTW and the TCO, discussed in detail in the sections below.

Figure 1.

Decision-making criteria for the application of the Topsis.

Figure 1.

Decision-making criteria for the application of the Topsis.

3.2.1. Economic performance

The evaluation of the economic performance of a vehicle has been referred its total cost of ownership (TCO), calculated considering the vehicle capital cost (VCC) and the actualized value of the annual operating costs (AOC) referred to its useful life and average annual vehicle kilometers traveled (VKT).

For fossil fuel powered vehicles, the annual operating cost has been calculated referring to the annual fuel consumption cost (FC), the annual fixed costs related to the insurance (IC) and to the maintenance and repair cost (MC), including ordinary and extraordinary maintenance interventions as well as the cost of consumables (e.g. tires).

The annual fuel consumption cost can thus be evaluated as:

Where fc is the average fuel consumption and fp is the fuel price. For electric vehicles the total annual cost can be calculated as:

Where ECE represents the energy cost of the electric vehicle, calculated as:

Where E

Km is the energy requirement per km and p

kWh is the Energy retail price per kWh. The fixed cost is related to the annual battery leasing fee, average annual insurance cost, annual maintenance and repair cost. The total annual cost of hydrogen vehicles is calculated as:

Where FC

H represents the fuel consumption as a function of the average annual kilometers calculated as:

Where Hkm is the Hydrogen consumption per km and pH is the Hydrogen retail price.

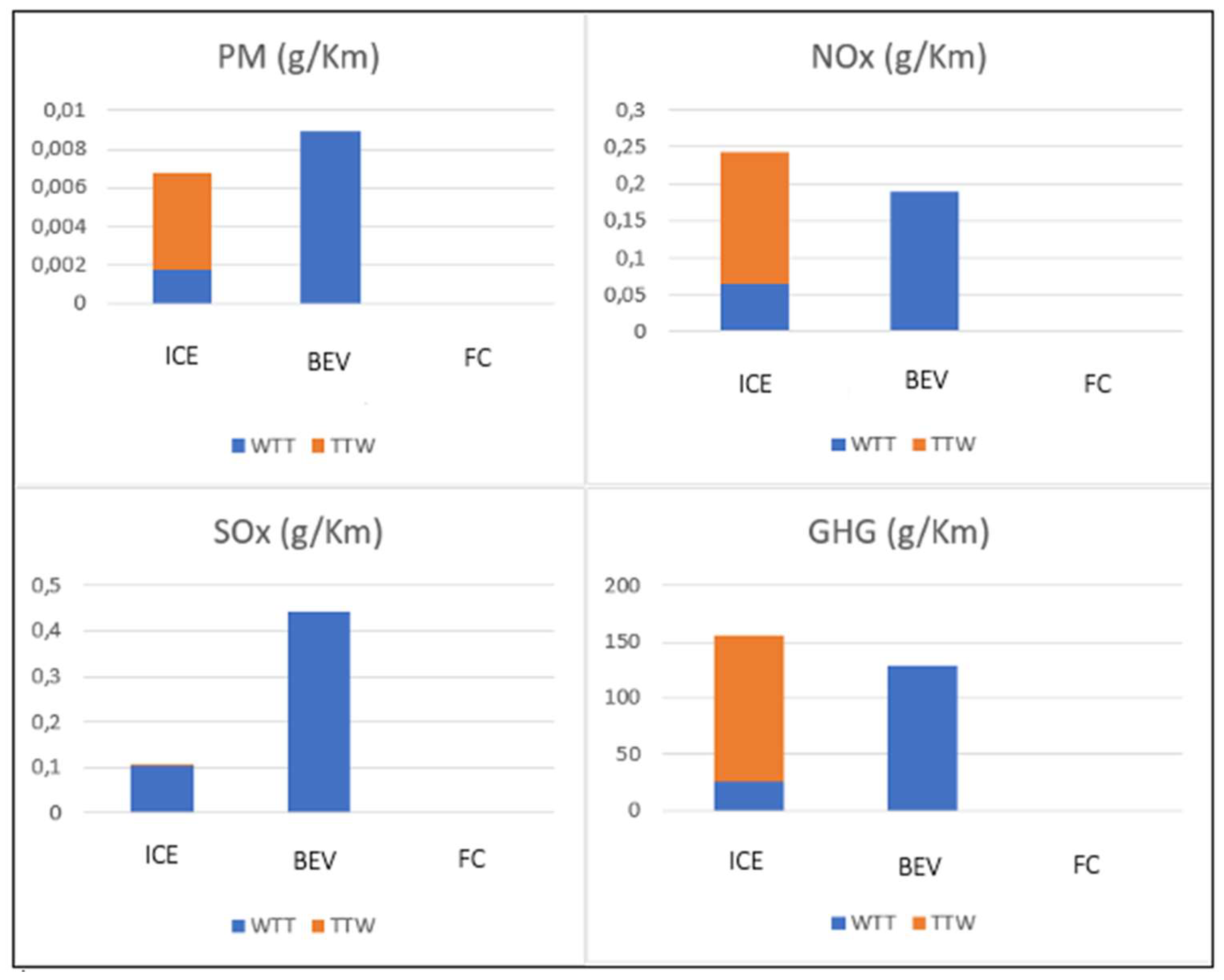

3.2.2. Environmental performance

The sustainability of different propulsion technologies has been evaluated taking into account the lifecycle of the fuel/energy production and utilization according to the well-to-wheel index (WTW) and the related sub-indices: well-to-tank (WTT, from well to tank) and the tank-to-wheel (TTW, from tank to wheel). In particular, The WTT emission index takes into account the pollutant mass emitted in the extraction, chemical processing and transport, while the TTW index takes into account the pollutant mass emitted referred to a reference distance. Finally, the WTW emission index gives the total pollutant emitted from a fuel production pathway and powertrain combination:

Such parameter has been evaluated for both greenhouse gases (CO2, NO2, CH4) and local air pollutants (NOx, SOx, PM). Fore electric vehicles the electric energy produced from is the combination of different pathways that reflect a European mix of sources (named “EU-mix”) considering a forecasted 2030 value where renewables will be almost a quarter of the EU-mix of 2010 [

19]. For hydrogen powered vehicles, only “green” hydrogen has been considered which is the total decarbonization option.

3.2.3. Technical implications: range charging time

This criterion takes into account the impact of the vehicle technology on the fleet management operations. Vehicles based on different propulsion technologies typically achieve a different combination of payload and range and may substantially differ in terms of refueling/recharging time. Such elements must be taken into account during the fleet scheduling and routing process, therefore impacting the overall performance of the fleet. Evaluating this impact at a strategic level is however complicated since it depends on the typology of service performed by the vehicle and on the specific operational context, however such technical limitations can be taken into consideration by the decision maker in the approach proposed, by attributing a specific weight to the criteria. The specific indicators introduced to take into account of the technical limitations of vehicles with different propulsion technologies, are the range and the recharging/refueling time. The range is the distance that can be covered between two subsequent refueling/recharging operations, the replenishment / recharge time is the time required for the energy storage system to reach its full capacity.

3.3. Multi-criteria decision making approach

The decision-making approach adopted in this paper is the well known TOPSIS method, which, involves the initial establishment of the alternatives, the decision criteria, and the weights assigned to each criterion reflecting the decision maker’s preferences. Each alternative is scored according to each criterion, thus obtaining the evaluation matrix which is then normalized according to eq. (9). Finally, the normalized scores are multiplied by the weights according to eq. (10) to obtain for each criterion the related normalized and weighted matrix.

Where: g

ij is the score of the i

th-alternative with respect to criterion j,z

ij is the normalized score, w

j is the weight attributed to criterion j nad u

ij is the weighted normalized score. The ideal A

* and non-ideal A

- solutions are then determined by considering, for each criterion, the best and worst performance offered by the alternatives, respectively, and the Euclidean distance to the best and worst solution is calculated through equations (11) and (12).

The relative distances of the alternatives from the ideal solutions are then calculated through eq. 13.

Finally, the alternatives are classified according to Ci∗: the solutions characterized by the highest Ci∗ value are preferred.

4. Case Study

The proposed methodology has been applied to the practical problem of replacing traditional diesel tractor-trailers with electric or hydrogen propulsion alternatives for a long-haul logistic operator, considering the economic issues as well as long term sustain- ability implications and regulatory compliance. The case considered has a significant industrial relevance, since lightweight electric vehicles for urban distribution are nowadays a consolidated reality, while the long-haul transport represents the biggest challenge for zero emission vehicles, because of the big loads and high daily distance covered (Wentzel., 2020). The target vehicle considered is a tractor with 40 tons capacity, 350 kw power and a maximum range of approx. 500 km. Such features are quite common in traditional long-haul diesel trucks such as the Iveco Stralis truck 500 equipped with a 332 kW Diesel engine, and a gross weight rating (GWR) of 44 tons. Based on publicly available market data, the price of a diesel tractor-trailer is estimated at €135K. An electric truck with similar features is the MAN TGX 4×2 LLS model with a 350 kW electric engine supported by a 270 kWh battery pack. This vehicle however has some substantial technical limitation consisting of only 200 km range and 5-6 hours recharge time with an industrial socket (45 min. with DC fast charging). The overall cost of the semitruck considering inverter, chassis, drivetrain, transmission, electric HVAC and support systems, can be estimated at 330 k€. Recent market evidence, for example, are the Port of Oakland purchase of 10 Peterbilt 579EVs (36 tons GWR, 400 kW Continuous power, 240 km range) at a cost of approximately

$500,000 per semi-truck [

52]. A substantial market change could be the semi-truck recently announced by Tesla with a price of

$180,000 a 500-mile range. Finally, hydrogen propelled trucks with the requested target features have been recently proposed by some manufacturers, although the market is just in an early stage. One of the most advanced products currently available is for example the Hyundai XCIENT a 36 tons GWR vehicle quipped with 2X95 Kw fuel cells and 73kWh energy storage systems coupled an electric motor that develops 350kW power and hydrogen tanks that can store up to 35 kg of H

2 at 350 bar. With such features, the truck has a range of 500 km and an esteemed cost of 385 k€, although it is commercialized exclusively through the Pay-Per-Use model, with an individually calculated flat rate per km. Further assumptions are the FCHV consume hydrogen fuel in the range of 8.3 kg/100km at combined load. Finally, it is assumed that the trucks will be purchased new and kept in service for 10 years, and difference in resale value between a five-year-old zero-emission truck and a diesel truck is ignored. The undiscounted (i.e. with null interest rate) TCO for the three alternatives, calculated according to eq. 1 on the basis of the commercial data reported above is reported in the following table 1,2.

Table 1.

costs for the different alternatives assuming 350 000 kilometres/year.

Table 1.

costs for the different alternatives assuming 350 000 kilometres/year.

| |

Diesel |

HFC |

BEV |

| Truck purchase Cost (€) |

135000 |

330000 |

385000 |

| Energy cons. (kwh/km) |

|

|

1,25 |

| Fuel cons. (lt/100km) |

33 |

8 |

|

| Diesel fuel cost (€/liter) |

1,5 |

|

|

| Energy fuel cost (€/kwh) |

|

|

4,65 |

| H2 fuel cost (€/kg) |

|

4,65 |

|

| Distance traveled (Km) |

350000 |

350000 |

350000 |

| Driver cost (€/Year) |

60000 |

60000 |

60000 |

| Adblue (€/100km) |

0,5 |

|

|

| Tires (€) |

2784 |

2784 |

2784 |

Table 2.

TCO for the different alternatives considering 10 years useful life.

Table 2.

TCO for the different alternatives considering 10 years useful life.

| |

Diesel |

HFC |

BEV |

| Turck Cost |

150000 |

330000 |

385000 |

| fuel cost (€/year) |

1865500 |

1260000 |

1452500 |

| driver cost (€/Year) |

600000 |

600000 |

600000 |

| tires |

27840 |

27840 |

27840 |

| service |

120000 |

165000 |

50000 |

| Total Cost |

2763340 |

2382840 |

2515340 |

Referring to the sustainability criterion, the WTW data adopted for the energy and environmental analysis are based on the elaboration of recent referenced data [

53] and are given in the figures 2 below.

Figure 2.

Comparison index WTW for vehicle electric, traditional and hydrogen.

Figure 2.

Comparison index WTW for vehicle electric, traditional and hydrogen.

After calculating the TCO and having extrapolated the data relating to the WTW analysis from the literature, table 3 is obtained, which contains all the data relating to the criteria which will allow us to apply the Topsis method.

Table 3.

score of the alternatives considered for multicriteria analysis.

Table 3.

score of the alternatives considered for multicriteria analysis.

| Alternatives |

Scores |

| Environmental |

TCO

(€) |

Technical |

| NOx (g/kg) |

PM

(g/kg) |

Sox

(g/kg) |

CO2

(g/kg) |

Range (km) |

Refueling Time (min) |

| Diesel |

0,244 |

0,005 |

0,105 |

156,234 |

2.763.340 |

1250 |

15 |

| Electric |

0,190 |

0,009 |

0,445 |

128,871 |

2.515.340 |

200 |

45 |

| Hydrogen |

0,000 |

0,000 |

0,000 |

0,000 |

2.382.840 |

500 |

15 |

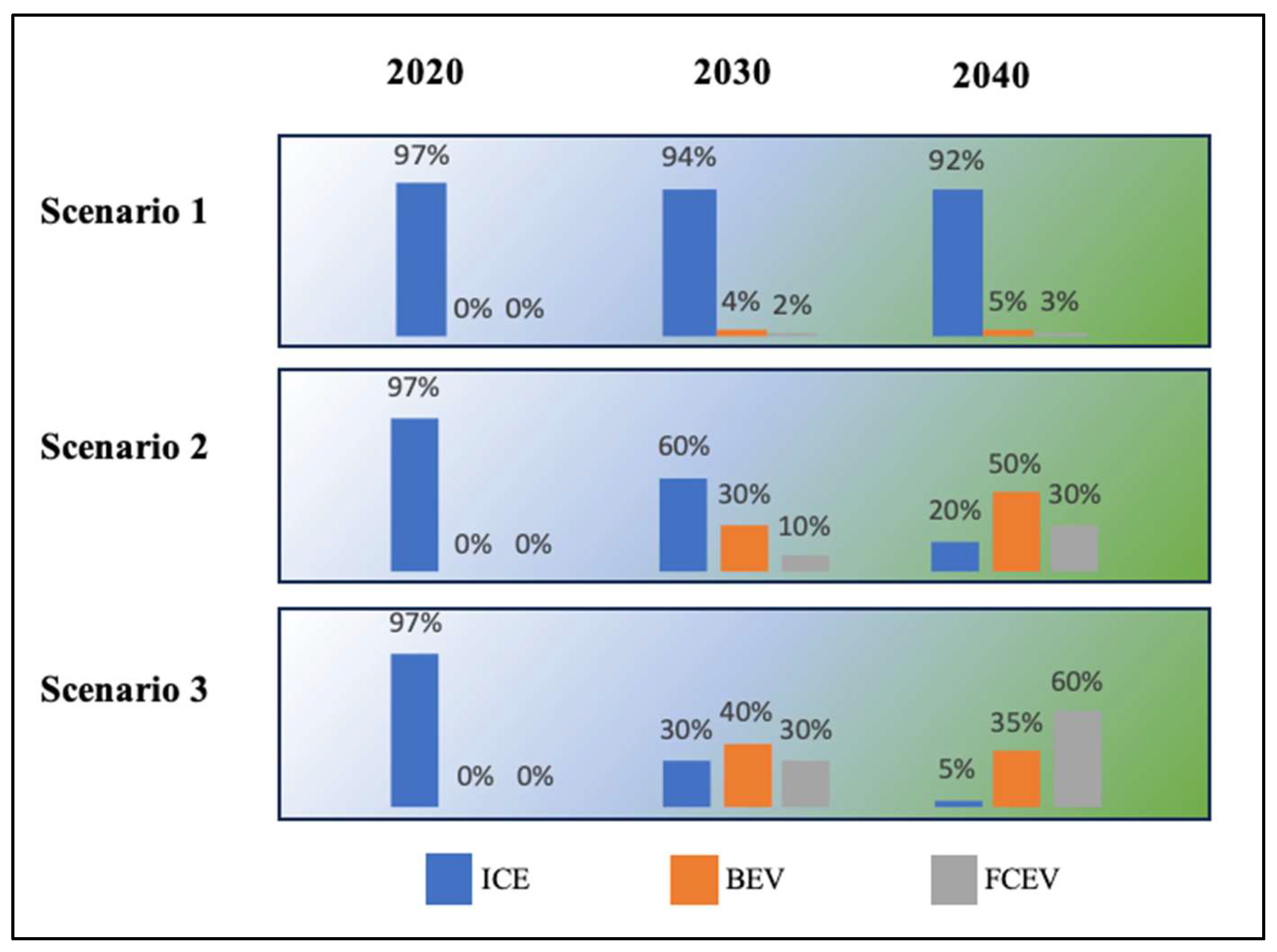

Once the alternatives have been scored according to the criteria considered and corresponding indicators, the decision maker’s preference scheme is introduced by assigning the weights to the criteria. In this step, the scenario uncertainty substantially complicates the weight assignment process, since the outcomes of a long-term strategic decision-making process are significantly influenced by external factors, while the decision maker’s preference scheme is affected by the related uncertainty. In the case study, three different scenarios are considered related to the technological evolution and corresponding environmental regulations. All the scenarios start from the current situation of ZEV penetration in heavy duty transport activities, which is in a very early stage considering that global sales of zero-carbon medium and heavy-duty vehicles reached roughly 0.2% of total sales in 2021 [

54], with China being the largest market. In Europe, the ZEV truck sales witnessed a significant increase over the past years, representing more than 40% of new zero emission heavy duty vehicles registrations in 2020. However, more than 90% of such sales between 2010 and 2015 were represented by buses while more than 97% of registrations in 2020 were battery-electric vehicles, with very limited presence of fuel-cell electric technologies [

55]. Although several electric heavy-duty truck models are currently available on the market, hence, their actual employment in long-haul transportation is still minimal, while hydrogen fuel cell trucks are just appearing on the market although green hydrogen is still considered prohibitively expensive. As a matter of fact, hence, the decarbonization process of long-haul transport activities is still in a preliminary stage, while the share of ZEV in the fleet of long-haul transporters is still negligible. Despite such situation, the targets set by countries in Europe for the phase-out of conventional fuelled trucks across the EU-27 appear very ambitious and to some extent unrealistic. Six Member States (Portugal, Luxembourg, Finland, Denmark, The Netherland, and Austria) have signed a Global Memorandum of Understanding, pledging for 30% of sales of trucks and buses to be zero-emission by 2030 and 100% by 2040. Based on such premises, three scenarios have been formulated concerning different evolutions of the propulsion technologies the first scenario (“Slow Technological Development”) refers to a situation, where the technological developments on hydrogen and electric vehicles/infrastructures, will take longer than expected, and traditional combustion engines will thus maintain their leadership improving their environmental efficiency, while electric and hydrogen vehicles will not enter the market until 2040. The sale of diesel vehicles will not be suspended, and the current scenario will basically persist with minor variations until 2040, while zero emissions, vehicles will finally replace ICE after 2040. The second scenario (“Moderate technological development”) implies a faster transition to battery-powered vehicles until 2030 with a moderate development FCEV propulsion system. The objectives of 30% sales of trucks in 2030 and 100% by 2040 are thus respected, and BEVs will be the most spread solution for long haul transport. The last scenario (“Fast technological development”) concerns a rapid transition to a vehicle fleet dominated by BEV and FCEV by 2030, while subsequently the development of hydrogen will be predominant and by 2040 the market will be dominated by FCEVs with a significant share of BEVs, while ICEs will be totally phased out. In this scenario, the technological evolution is faster where the decarbonization of freight transport is

almost completed in 2040. The three scenarios considered are 483 depicted in figure 3.

Figure 3.

The scenarios considered.

Figure 3.

The scenarios considered.

To represent the preference patterns of the decision maker in the scenarios considered,

Table 4 shows us how the weights were assigned to the different criteria, while

Table 5 shows us how the weights are distributed for each sub-indicator.

Table 4.

Weights attributed to the macro criteria.

Table 4.

Weights attributed to the macro criteria.

| |

Cost |

Environmental |

Technical |

| Scenario 1 |

0,50 |

0,20 |

0.30 |

| Scenario 2 |

0,40 |

0,40 |

0,20 |

| Scenario 3 |

0.40 |

0.50 |

0.10 |

Table 5.

Weights of sub-indicators.

Table 5.

Weights of sub-indicators.

| |

Sustainability |

Cost |

Technical |

| |

Nox |

PM |

SOx |

CO2 |

TCO |

Range |

Refueling Time |

| Scenario 1 |

0,050 |

0,050 |

0,050 |

0,050 |

0,500 |

0,150 |

0,150 |

| Scenario 2 |

0,100 |

0,100 |

0,100 |

0,100 |

0,400 |

0,100 |

0,100 |

| Scenario 3 |

0,125 |

0,125 |

0,125 |

0,125 |

0,400 |

0,050 |

0,050 |

Based on the scores of the alternatives (table 3), the normalized weighted matrix is created in each scenario and the ideal solutions A

* and non-ideal A

- solutions are determined according to eq. 14, 15. The alternatives are finally, classified based on their distance from the extreme solutions. The solutions characterized by the highest C

i*value (eq. 13) are preferred, and the final rank obtained is shown in table 6.

Table 6.

Relative proximity to the ideal point.

Table 6.

Relative proximity to the ideal point.

| |

Scenario 1 |

Scenario 2 |

Scenario 3 |

| Alternative |

C∗ |

Ranking |

C∗ |

Ranking |

C∗ |

Ranking |

| Diesel |

0,511 |

1 |

0,446 |

2 |

0,410 |

2 |

| Battery |

0,404 |

3 |

0,279 |

3 |

0,188 |

3 |

| Hydrogen Fuel Cell |

0,452 |

2 |

0,683 |

1 |

0,841 |

1 |

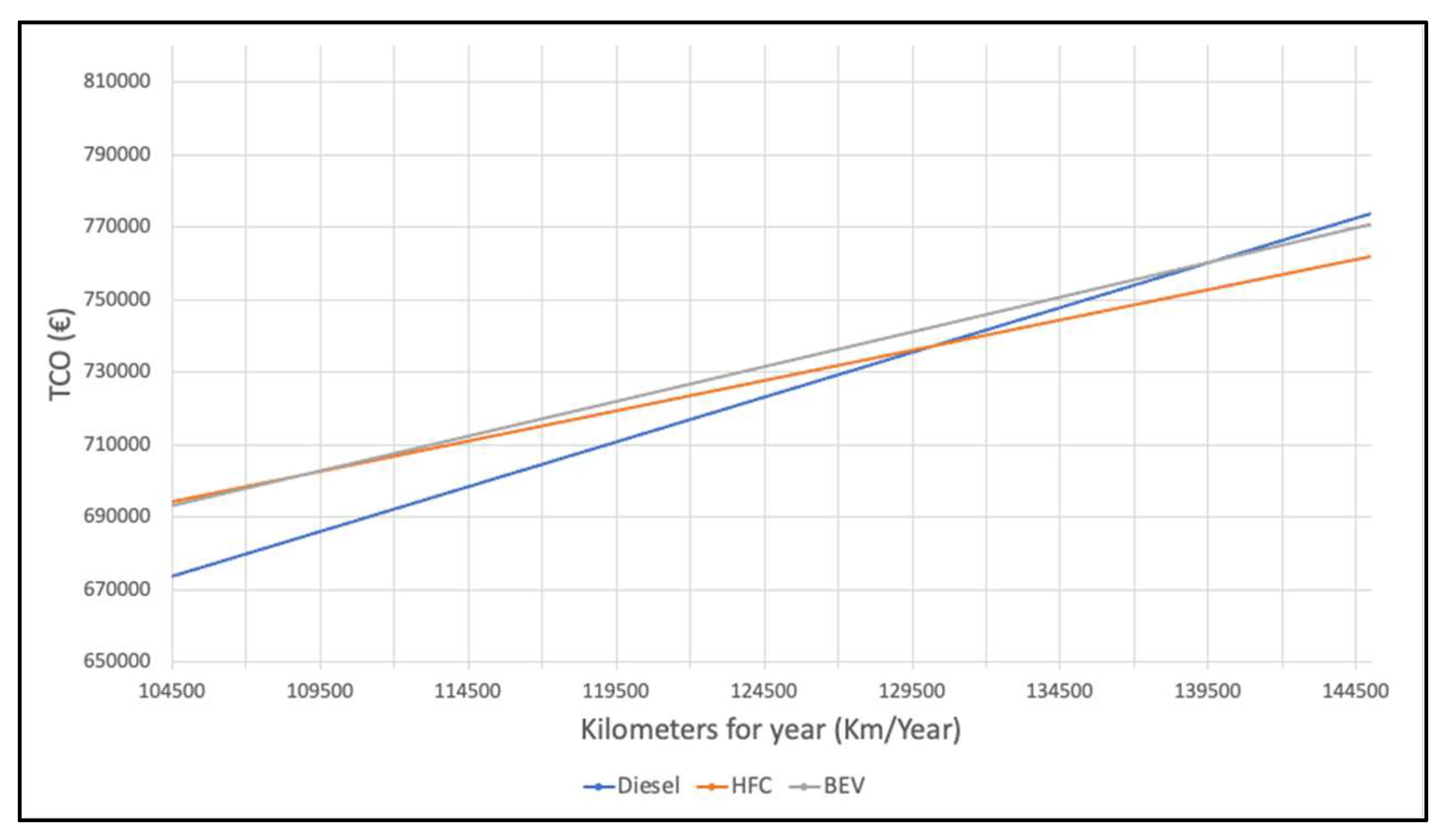

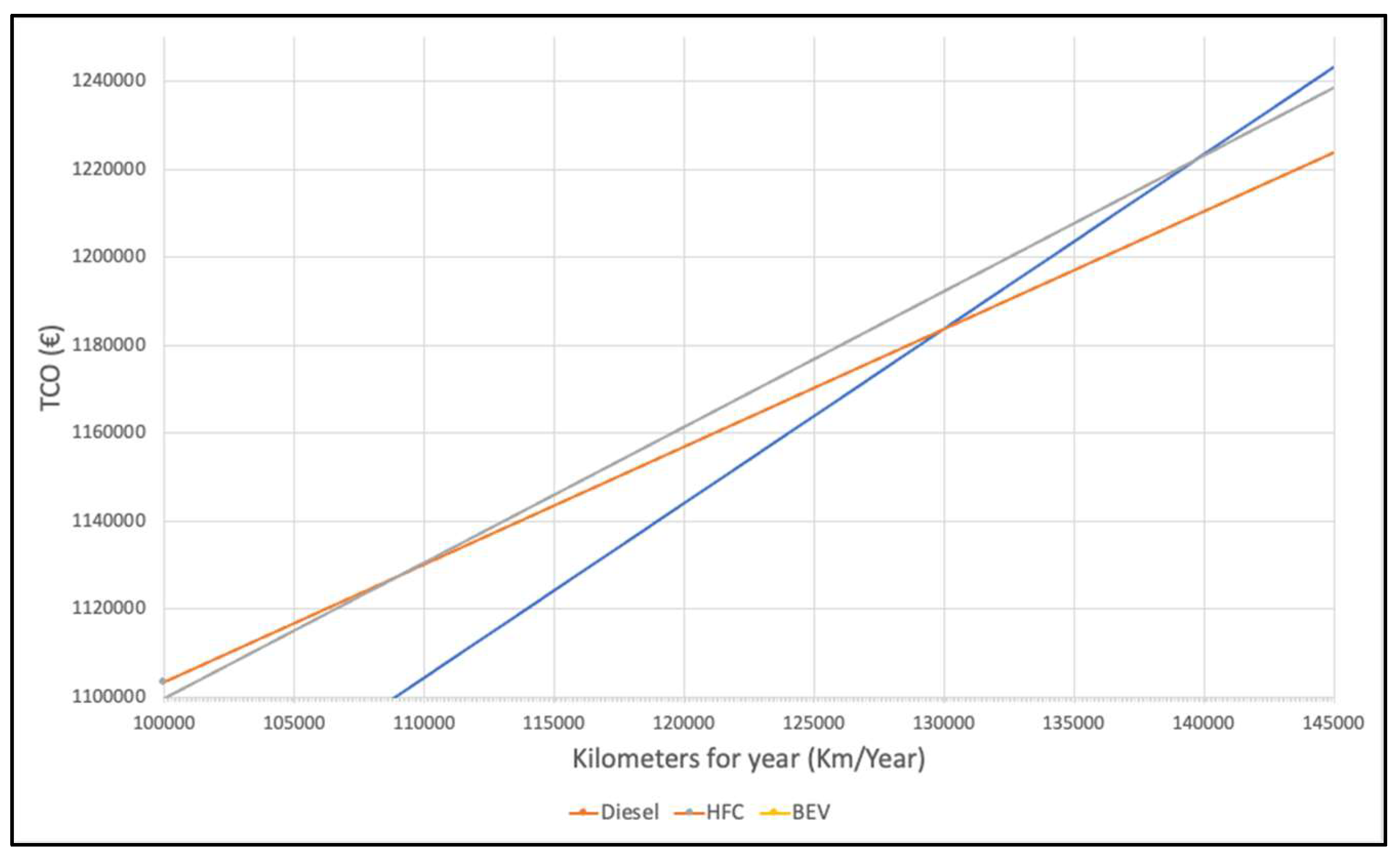

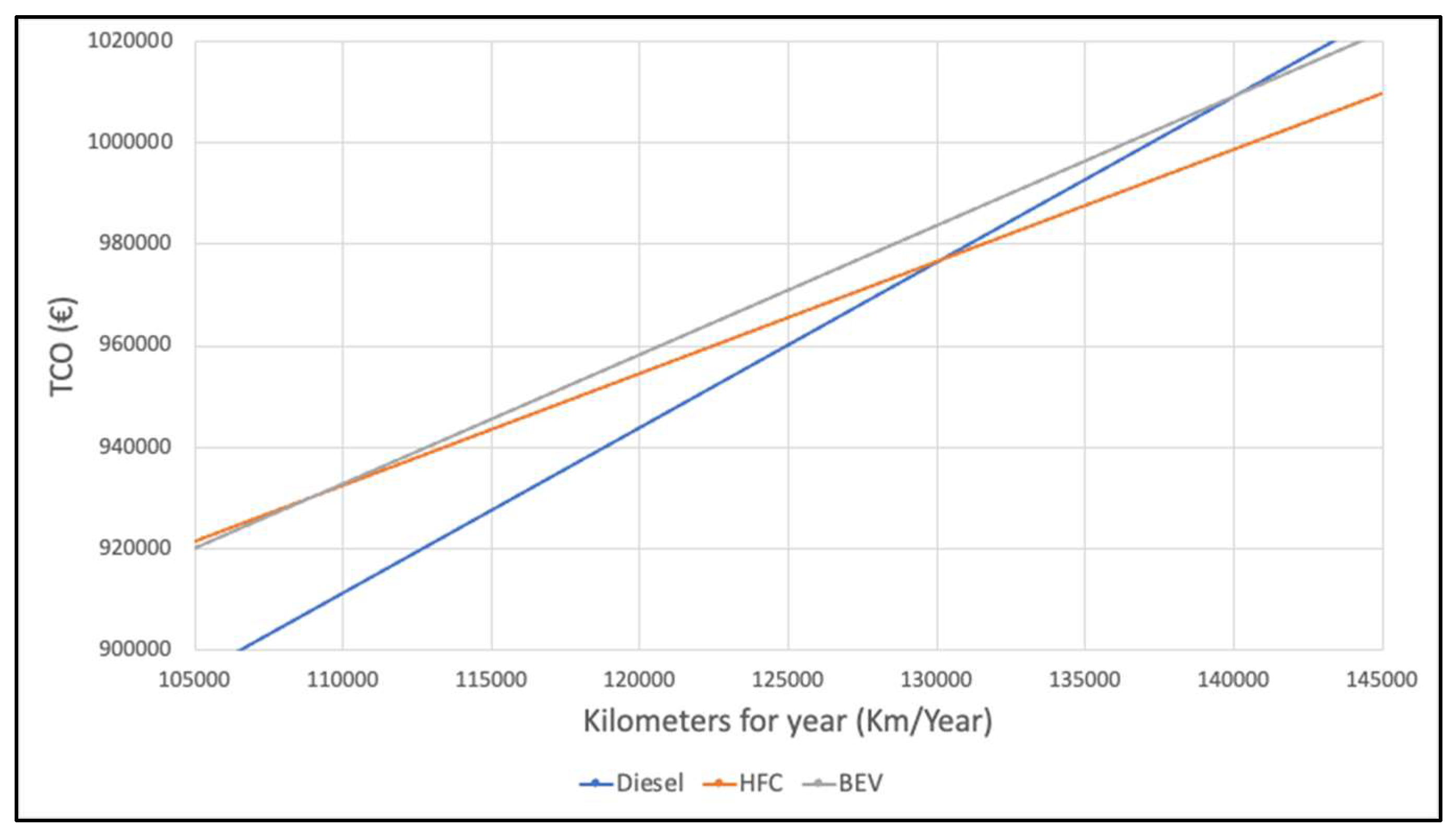

The obtained results show that if the European “green deal” strategy maintains its objective to phase out fossil fueled vehicles by 2040 (scenario 2), the best choice will be the switch towards hydrogen vehicles, since this is the only technology allowing for a complete decarbonization. BEVs are less efficient from an environmental point of view and have a worse operational performance (recharge time and range), therefore they can hardly represent an optimum choice in long-haul transportation. In the slow technological evolution scenario (scenario 1), where the objectives of the green deal are postponed, the decision makers will substantially relay on cost effectiveness, therefore modern ICEs are still the most efficient choice, while the full decarbonization is postponed. The results obtained clearly show how the different sets of weights employed in the scenarios considered influence the ranking of the alternatives. In the slow technological development scenario, the decision maker’s choice will be mainly influenced by the cost criterion, therefore the diesel truck will be on top of the rank, while the choice of hydrogen technology will be preferred in the other scenarios where sustainability criterion assumes a higher weight. It must be however considered that the results obtained are referred to specific service-related assumptions, and significant variation in the related parameters may substantially affect the solutions obtained. In particular the annual truck operational costs depend significantly on the distance covered by the trucks each year, therefore, the TCO calculations are highly sensitive to the choice of the annual vehicle kilometers traveled (VKT) and interest rate. This is shown in Figure, 4,5,6 where the TCO has been evaluated as a function of the VKT and of the interest rate.

Figure 4.

break-even points of the TCO as a function of annual Km travelled (interest rate = 3%).

Figure 4.

break-even points of the TCO as a function of annual Km travelled (interest rate = 3%).

Figure 5.

break-even points of the TCO as a function of annual Km travelled (interest rate = 5%).

Figure 5.

break-even points of the TCO as a function of annual Km travelled (interest rate = 5%).

Figure 6.

break-even points of the TCO as a function of annual Km travelled (interest rate = 8%).

Figure 6.

break-even points of the TCO as a function of annual Km travelled (interest rate = 8%).

Figures 4,5,6 represent the plots of the TCO of different propulsion systems as a function of the annual kilometers travelled, ultimately showing that the TCO is strictly linked to the features of the service operated, while the interest rate does not play a substantial role in the decision problem. In particular, as the annual distance travelled reduces, the ICE vehicles become more convenient, while as the distance increases, first BEVs and subsequently FCEVs become best solutions. In addition, such figures show that variations in the annual kilometers, significantly influence the TCO, thus resulting in raking inversions according to such criterion. Such effect becomes more significant as the interest rate increases.

5. Conclusions

The increased attention towards the environmental situation and the consequent decarbonization strategies undertaken by governments and institutions on a global scale are pushing towards a substantial rethinking of the logistic systems. A fundamental step in such sense will be the transition towards the new mobility technologies based on electricity and hydrogen, and the consequent renewal of the fleet of vehicles currently operated, mostly based on fossil fuels. Considering the dynamical technological landscape and the inherent uncertainty about future scenarios, the choice of the most effective technology is a complex strategic decision problem for logistic operators with significant industrial relevance in the medium/long term. In such context this paper proposes an original multicriteria decision approach based on the TOPSIS method with the merit of integrating economic, environmental, and technical aspects into a comprehensive decision framework. The long-term implications of the economic performance is considered by taking into account the TCO of the vehicles, while the criterion related to the sustainability of the system takes into account the complete lifecycle of the fuel. This is necessary when comparing ZEVs with traditional diesel powertrains. In addition, the decision framework takes into consideration the context uncertainty by involving an integrated scenario analysis. In particular, the decision-maker’s perception about the future scenarios is modelized through a specific preference scheme which substantially influences the optimal choice. The methodology proposed has been validated against a case study referred to the choice of different propulsion technologies for long-haul logistic operations, based on realistic data from commercial vehicles currently available on the market. The results obtained show that the choice of electric propulsion in long haul transport is not convenient in any scenario, thus suggesting that investments from companies in such sector might be at high risk on the long run. Clearly, the final rank of the vehicle technology essentially depends upon the technological developments expected by the decision maker, therefore different subjective perceptions on future scenario might lead decision makers to formulate different preference schemes by attributing different weights. While the methodology proposed explicitly aims at considering the subjective judgment of different decision makers, the results obtained still highlight that the domain of economic profitability for electric vehicles in long-haul transport is actually narrow, which is surely a significant managerial insight. The case study also highlights how robust is the solution obtained against the specific features of the operating scenario considered, and the economic parameters assumed.

Author Contributions

Conceptualization and methodology, S.Q.; validation, A.C.; formal analysis, S.Q. and G.A.; investigation, S.Q.; data curation, S.Q.; writing—original draft preparation, S.Q.; writing—review and editing, G.A.; supervision, R.I, and M.V. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

No new data were created or analyzed in this study. Data sharing is not applicable to this article.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Al-Alawi, B.M.; Bradley, T.H. Total cost of ownership, payback, and consumer preference modeling of plug-in hybrid electric vehicles. Applied Energy 2013, 103, 488–506. [Google Scholar] [CrossRef]

- Offer, G.J.; Howey, D.; Contestabile, M.; Clague, R.; Brandon, N. Comparative analysis of battery electric, hydrogen fuel cell and hybrid vehicles in a future sustainable road transport system. Energy policy 2010, 38, 24–29. [Google Scholar] [CrossRef]

- Zhao, Y.; Pohl, O.; Bhatt, A.I.; Collis, G.E.; Mahon, P.J.; Rüther, T.; Hollenkamp, A.F. A review on battery market trends, second-life reuse, and recycling. Sustainable Chemistry 2021, 2, 167–205. [Google Scholar] [CrossRef]

- Rezvani, Z.; Jansson, J.; Bodin, J. Advances in consumer electric vehicle adoption research: A review and research agenda. Transportation research part D: transport and environment 2015, 34, 122–136. [Google Scholar] [CrossRef]

- Sharma, R.; Manzie, C.; Bessede, M.; Brear, M.; Crawford, R. Conventional, hybrid and electric vehicles for Australian driving conditions–Part 1: Technical and financial analysis. Transportation Research Part C: Emerging Technologies 2012, 25, 238–249. [Google Scholar] [CrossRef]

- Jacobson, M.Z.; Colella, W.; Golden, D. Cleaning the air and improving health with hydrogen fuel-cell vehicles. Science 2005, 308, 1901–1905. [Google Scholar] [CrossRef] [PubMed]

- Thomas, C. Fuel cell and battery electric vehicles compared. international journal of hydrogen energy 2009, 34, 6005–6020. [Google Scholar] [CrossRef]

- Cunanan, C.; Tran, M.K.; Lee, Y.; Kwok, S.; Leung, V.; Fowler, M. A review of heavy-duty vehicle powertrain technologies: Diesel engine vehicles, battery electric vehicles, and hydrogen fuel cell electric vehicles. Clean Technologies 2021, 3, 474–489. [Google Scholar] [CrossRef]

- Shin, J.; Hwang, W.S.; Choi, H. Can hydrogen fuel vehicles be a sustainable alternative on vehicle market? : Comparison of electric and hydrogen fuel cell vehicles. Technological Forecasting and Social Change 2019, 143, 239–248. [Google Scholar] [CrossRef]

- Ni, M.; Leung, M.K.; Leung, D.Y.; Sumathy, K. A review and recent developments in photocatalytic water-splitting using TiO2 for hydrogen production. Renewable and Sustainable Energy Reviews 2007, 11, 401–425. [Google Scholar] [CrossRef]

- da Silva Veras, T.; Mozer, T.S.; da Silva César, A.; et al. Hydrogen: trends, production and characterization of the main process worldwide. International journal of hydrogen energy 2017, 42, 2018–2033. [Google Scholar] [CrossRef]

- Dumortier, J.; Siddiki, S.; Carley, S.; Cisney, J.; Krause, R.M.; Lane, B.W.; Rupp, J.A.; Graham, J.D. Effects of providing total cost of ownership information on consumers’ intent to purchase a hybrid or plug-in electric vehicle. Transportation Research Part A: Policy and Practice 2015, 72, 71–86. [Google Scholar] [CrossRef]

- Contestabile, M.; Offer, G.; Slade, R.; Jaeger, F.; Thoennes, M. Battery electric vehicles, hydrogen fuel cells and biofuels. Which will be the winner? Energy & Environmental Science 2011, 4, 3754–3772. [Google Scholar]

- Wu, G.; Inderbitzin, A.; Bening, C. Total cost of ownership of electric vehicles compared to conventional vehicles: A probabilistic analysis and projection across market segments. Energy Policy 2015, 80, 196–214. [Google Scholar] [CrossRef]

- Davis, B.A.; Figliozzi, M.A. A methodology to evaluate the competitiveness of electric delivery trucks. Transportation Research Part E: Logistics and Transportation Review 2013, 49, 8–23. [Google Scholar] [CrossRef]

- Dablanc, L.; Giuliano, G.; Holliday, K.; O’Brien, T. Best practices in urban freight management: Lessons from an international survey. Transportation Research Record 2013, 2379, 29–38. [Google Scholar] [CrossRef]

- Gilmore, E.A.; Lave, L.B. Comparing resale prices and total cost of ownership for gasoline, hybrid and diesel passenger cars and trucks. Transport Policy 2013, 27, 200–208. [Google Scholar] [CrossRef]

- Al-Alawi, B.M.; Bradley, T.H. Review of hybrid, plug-in hybrid, and electric vehicle marketmodeling studies. Renewable and Sustainable Energy Reviews 2013, 21, 190–203. [Google Scholar] [CrossRef]

- Burke, A.; Sinha, A.K. Technology, Sustainability, and Marketing of Battery Electric and Hydrogen Fuel Cell Medium-Duty and Heavy-Duty Trucks and Buses in 2020-2040 2020.

- Abhyankar, N.; Gopinathan, N.; Khandekar, A.; Karali, N.; Phadke, A.A.; Rajagopal, D. Freight Trucks in India are Primed for Electrification 2022.

- Satterfield, C.; Nigro, N.; Wood, E.; Jensen, J.; Smith, C.; Desai, R.; Ge, Y. Electrification Assessment of Public Vehicles in Washington: A Vehicle-by-Vehicle Assessment of the Electrification Potential for Publicly-Owned Vehicles 2020.

- Wolff, S.; Brönner, M.; Held, M.; Lienkamp, M. Transforming automotive companies into sustainability leaders: A concept for managing current challenges. Journal of Cleaner Production 2020, 276, 124179. [Google Scholar] [CrossRef]

- Liu, D.; Xu, L.; Sadia, U.H.; Wang, H. Evaluating the CO2 emission reduction effect of China’s battery electric vehicle promotion efforts. Atmospheric Pollution Research 2021, 12, 101115. [Google Scholar] [CrossRef]

- Li, M.; Zhang, X.; Li, G. A comparative assessment of battery and fuel cell electric vehicles using a well-to-wheel analysis. Energy 2016, 94, 693–704. [Google Scholar] [CrossRef]

- Gupta, S.; Patil, V.; Himabindu, M.; Ravikrishna, R. Life-cycle analysis of energy and greenhouse gas emissions of automotive fuels in India: Part 1–Tank-to-Wheel analysis. Energy 2016, 96, 684–698. [Google Scholar] [CrossRef]

- Fishburn, P.C. Interdependence and additivity in multivariate, unidimensional expected utility theory. International Economic Review 1967, 8, 335–342. [Google Scholar] [CrossRef]

- Keeney, R.L. Multiplicative utility functions. Operations Research 1974, 22, 22–34. [Google Scholar] [CrossRef]

- Tsoukiàs, A.; Vincke, P. A new axiomatic foundation of partial comparability. Theory and Decision 1995, 39, 79–114. [Google Scholar] [CrossRef]

- Haase, M.; Wulf, C.; Baumann, M.; Ersoy, H.; Koj, J.; Harzendorf, F.; Mesa Estrada, L.S. Multi-criteria decision analysis for prospective sustainability assessment of alternative technologies and fuels for individual motorized transport. Clean Technologies and Environmental Policy 2022, 24, 3171–3197. [Google Scholar] [CrossRef]

- Hamurcu, M.; Eren, T. Electric bus selection with multicriteria decision analysis for green transportation. Sustainability 2020, 12, 2777. [Google Scholar] [CrossRef]

- Geldermann, J.; Rentz, O. Multi-criteria Analysis for Technique Assessment: Case Study from Industrial Coating. Journal of Industrial Ecology 2005, 9, 127–142. [Google Scholar] [CrossRef]

- Hermann, B.G.; Kroeze, C.; Jawjit, W. Assessing environmental performance by combining life cycle assessment, multi-criteria analysis and environmental performance indicators. Journal of cleaner production 2007, 15, 1787–1796. [Google Scholar] [CrossRef]

- Myllyviita, T.; Holma, A.; Antikainen, R.; Lähtinen, K.; Leskinen, P. Assessing environmental impacts of biomass production chains–application of life cycle assessment (LCA) and multi-criteria decision analysis (MCDA). Journal of cleaner production 2012, 29, 238–245. [Google Scholar] [CrossRef]

- Seppälä, J.; Koskela, S.; Melanen, M.; Palperi, M. The Finnish metals industry and the environment. Resources, Conservation and Recycling 2002, 35, 61–76. [Google Scholar] [CrossRef]

- Bouwman, M.E.; Moll, H.C. Environmental analyses of land transportation systems in TheNetherlands. Transportation Research Part D: Transport and Environment 2002, 7, 331–345. [Google Scholar] [CrossRef]

- Elghali, L.; Clift, R.; Sinclair, P.; Panoutsou, C.; Bauen, A. Developing a sustainability framework for the assessment of bioenergy systems. Energy Policy 2007, 35, 6075–6083. [Google Scholar] [CrossRef]

- Zhou, X.; Schoenung, J.M. An integrated impact assessment and weighting methodology: Evaluation of the environmental consequences of computer display technology substitution. Journal of Environmental Management 2007, 83, 1–24. [Google Scholar] [CrossRef] [PubMed]

- Narayanan, D.; Zhang, Y.; Mannan, M.S. Engineering for sustainable development (ESD) in bio-diesel production. Process Safety and Environmental Protection 2007, 85, 349–359. [Google Scholar] [CrossRef]

- Mohamadabadi, H.S.; Tichkowsky, G.; Kumar, A. Development of a multi-criteria assessment model for ranking of renewable and non-renewable transportation fuel vehicles. Energy 2009, 34, 112–125. [Google Scholar] [CrossRef]

- Prado-Lopez, V.; Seager, T.P.; Chester, M.; Laurin, L.; Bernardo, M.; Tylock, S. Stochastic multi-attribute analysis (SMAA) as an interpretation method for comparative life-cycle assessment (LCA). The International Journal of Life Cycle Assessment 2014, 19, 405–416. [Google Scholar] [CrossRef]

- Rogers, K.; Seager, T.P. Environmental decision-making using life cycle impact assessment and stochastic multiattribute decision analysis: a case study on alternative transportation fuels, 2009.

- Tan, R.R.; Culaba, A.B.; Purvis, M.R. POLCAGE 1.0—a possibilistic life-cycle assessment 660 model for evaluating alternative transportation fuels. Environmental Modelling & Software 2004, 661 19, 907–918.

- Kolak, O. I˙. ; Akın, D.; Birbil, S¸.I˙.; Feyziog˘ lu, O.; Noyan, N. Multicriteria sustainability evaluation of transport networks for selected European countries. Lecture Notes in Engineering and Computer Science 2011, 2190, 117–122. [Google Scholar]

- Awasthi, A.; Chauhan, S.S. Using AHP and Dempster–Shafer theory for evaluating sustainable transport solutions. Environmental Modelling & Software 2011, 26, 787–796. [Google Scholar]

- Haghshenas, H.; Vaziri, M. Urban sustainable transportation indicators for global comparison. Ecological Indicators 2012, 15, 115–121. [Google Scholar] [CrossRef]

- Linkov, I.; Burmistrov, D. Model uncertainty and choices made by modelers: Lessons learned from the international atomic energy agency model intercomparisons. Risk Analysis: An International Journal 2003, 23, 1297–1308. [Google Scholar] [CrossRef] [PubMed]

- Leach, M.; Scoones, I.; Stirling, A. Governing epidemics in an age of complexity: Narratives, politics and pathways to sustainability. Global Environmental Change 2010, 20, 369–377. [Google Scholar] [CrossRef]

- Lempert, R.J. Shaping the next one hundred years: new methods for quantitative, long-term policy analysis 2003.

- Wang, Z. , Hao, H., Gao, F., Zhang, Q., Zhang, J., & Zhou, Y. (2019). Multi-attribute decision making on reverse logistics based on DEA-TOPSIS: A study of the Shanghai End-of-life vehicles industry. Journal of cleaner production, 214, 730-737.

- Ulkhaq, M. M., Wijayanti, W. R., Zain, M. S., Baskara, E., & Leonita, W. (2018, March). Combining the AHP and TOPSIS to evaluate car selection. In Proceedings of the 2nd International Conference on High Performance Compilation, Computing and Communications (pp. 112-117).

- Moreno, N.G.; Molina, M.C.; Gervasio, D.; Robles, J.F.P. Approaches to polymer electrolyte membrane fuel cells (PEMFCs) and their cost. Renewable and Sustainable Energy Reviews 2015, 52, 897–906. [Google Scholar] [CrossRef]

- He, G. , Mallapragada, D. S., Bose, A., Heuberger-Austin, C. F., & Gençer, E. (2021). Sector coupling via hydrogen to lower the cost of energy system decarbonization. Energy & Environmental Science, 14(9), 4635-4646.

- Torchio, M. F. , & Santarelli, M. G. (2010). Energy, environmental and economic comparison of different powertrain/fuel options using well-to-wheels assessment, energy and external costs–European market analysis. Energy, 35(10), 4156-4171.

- O’Donovan, A. , Frith, J., & Mckerracher, C. (2018). Electric buses in cities: Driving towards cleaner air and lower CO2. Bloomberg New Energy Finance, 148(8).

- Antwi, S.; Grytli, S.O. Assessing the Drivers of Green Road transport electrification: A case of Europe. Master’s thesis, Høgskolen i Molde-Vitenskapelig høgskole i logistikk, 2022.

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).