Submitted:

06 February 2024

Posted:

06 February 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

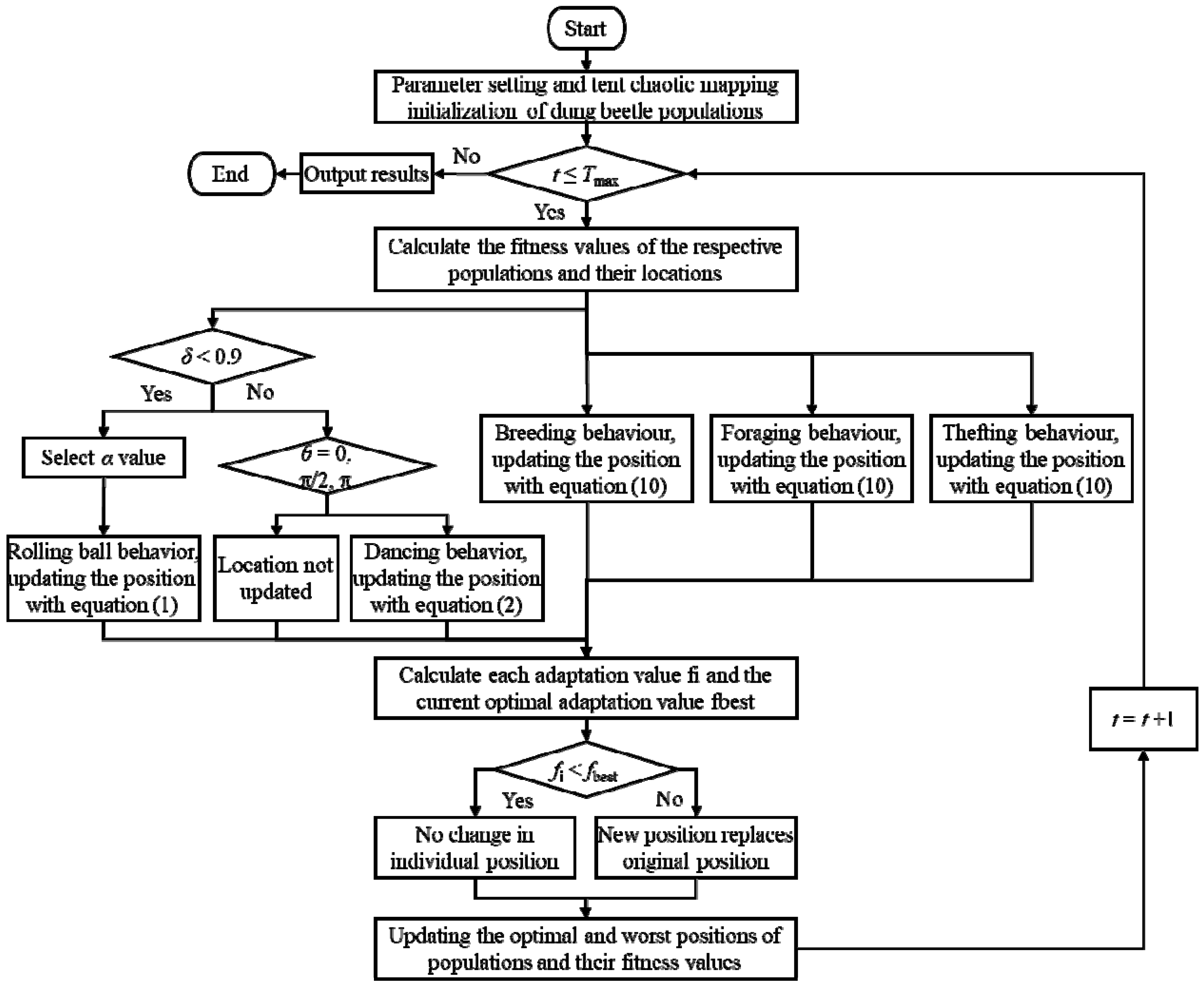

2. Methodology

2.1. The Standard DBO Algorithm

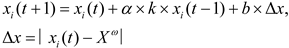

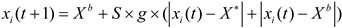

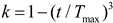

2.1.1. Ball-Rolling Behavior

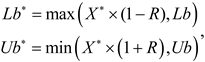

2.1.2. Dancing Behavior

2.1.3. Foraging Behavior

2.1.4. Stealing Behavior

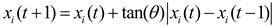

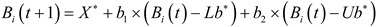

2.1.5. Breeding Behavior

2.2. Multi-Strategy Improved DBO Algorithm

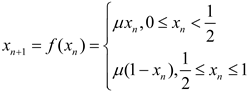

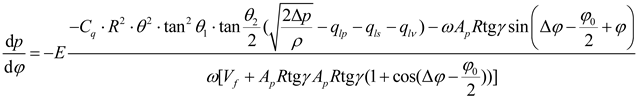

2.2.1. Tent Chaotic Mapping

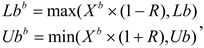

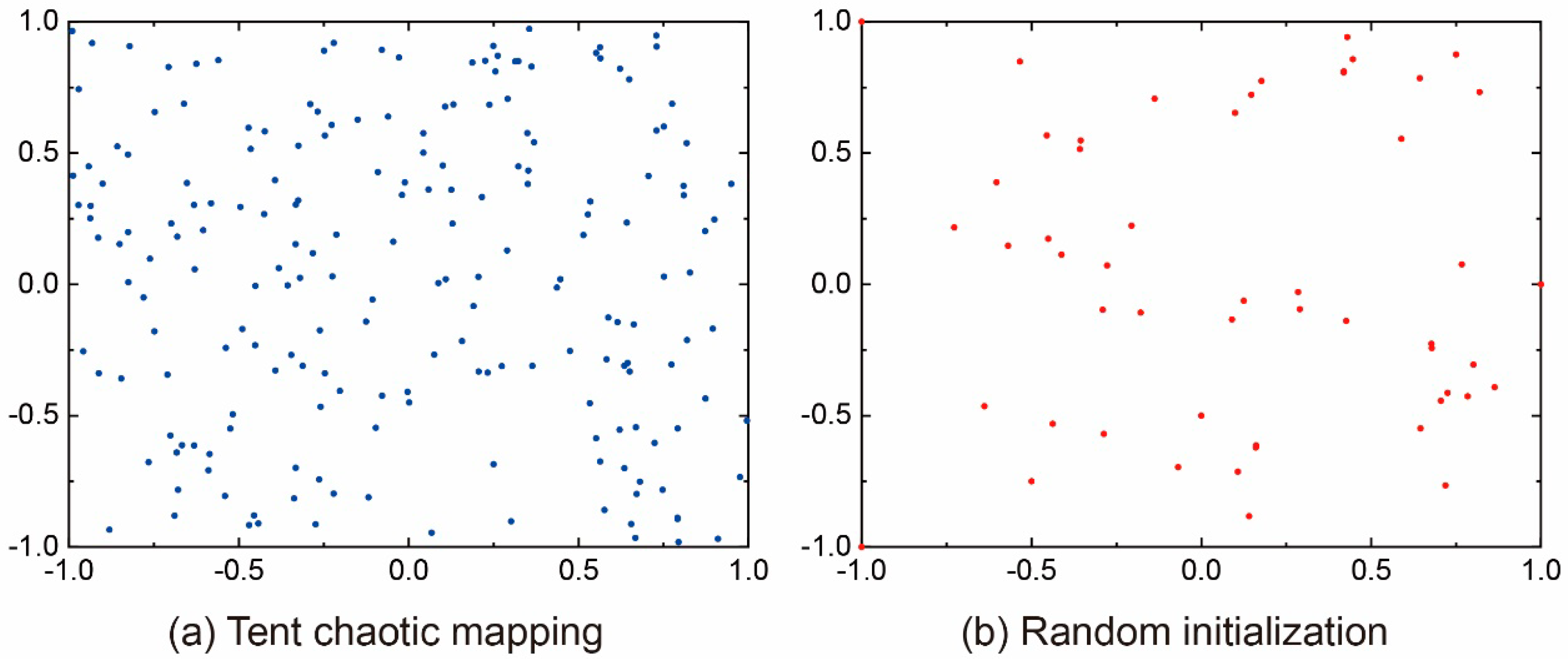

2.2.2. Gold Sine Strategy

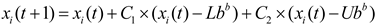

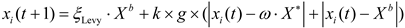

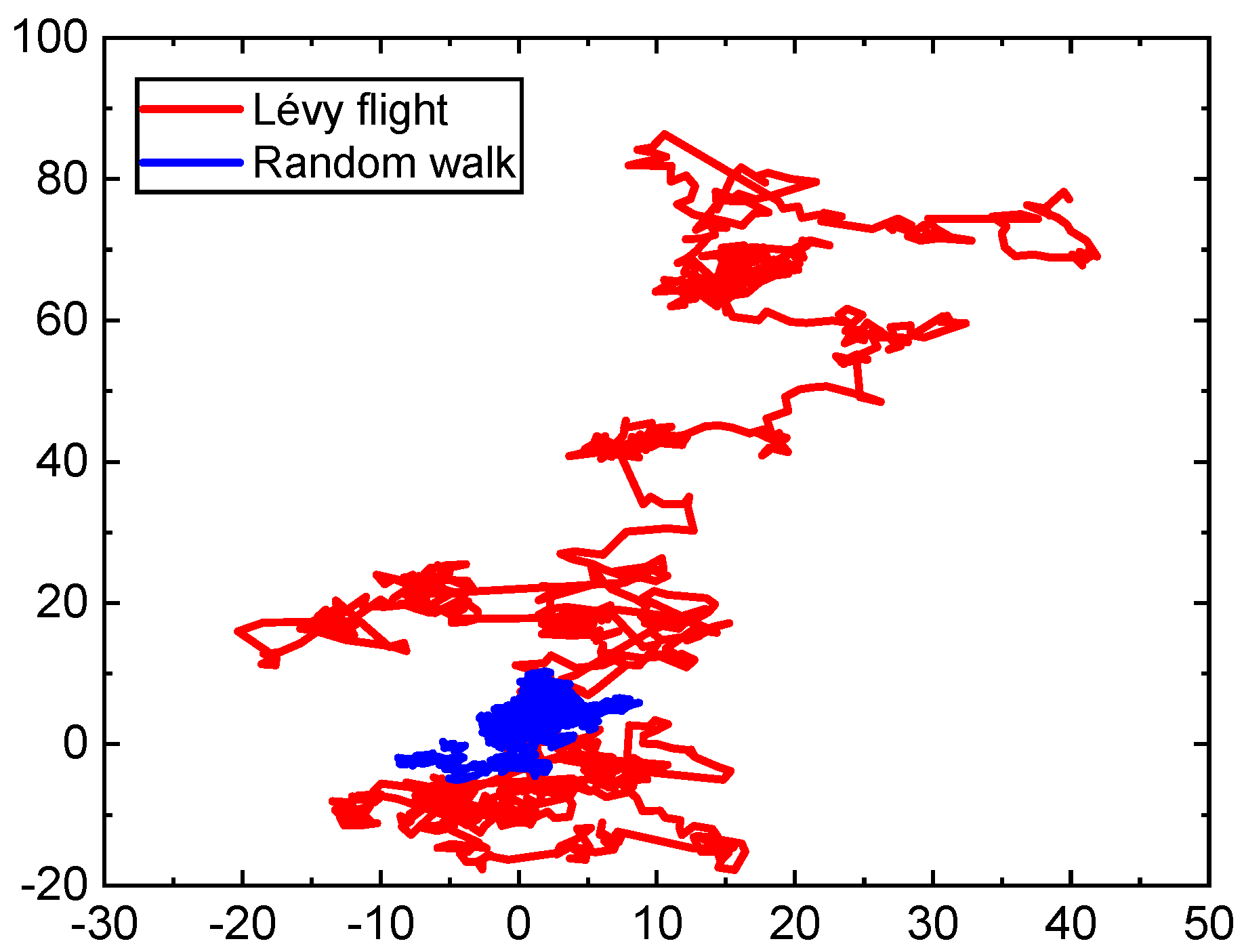

2.2.3. Lévy Flight Strategy

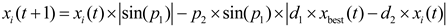

3. Experiment Results and Discussions

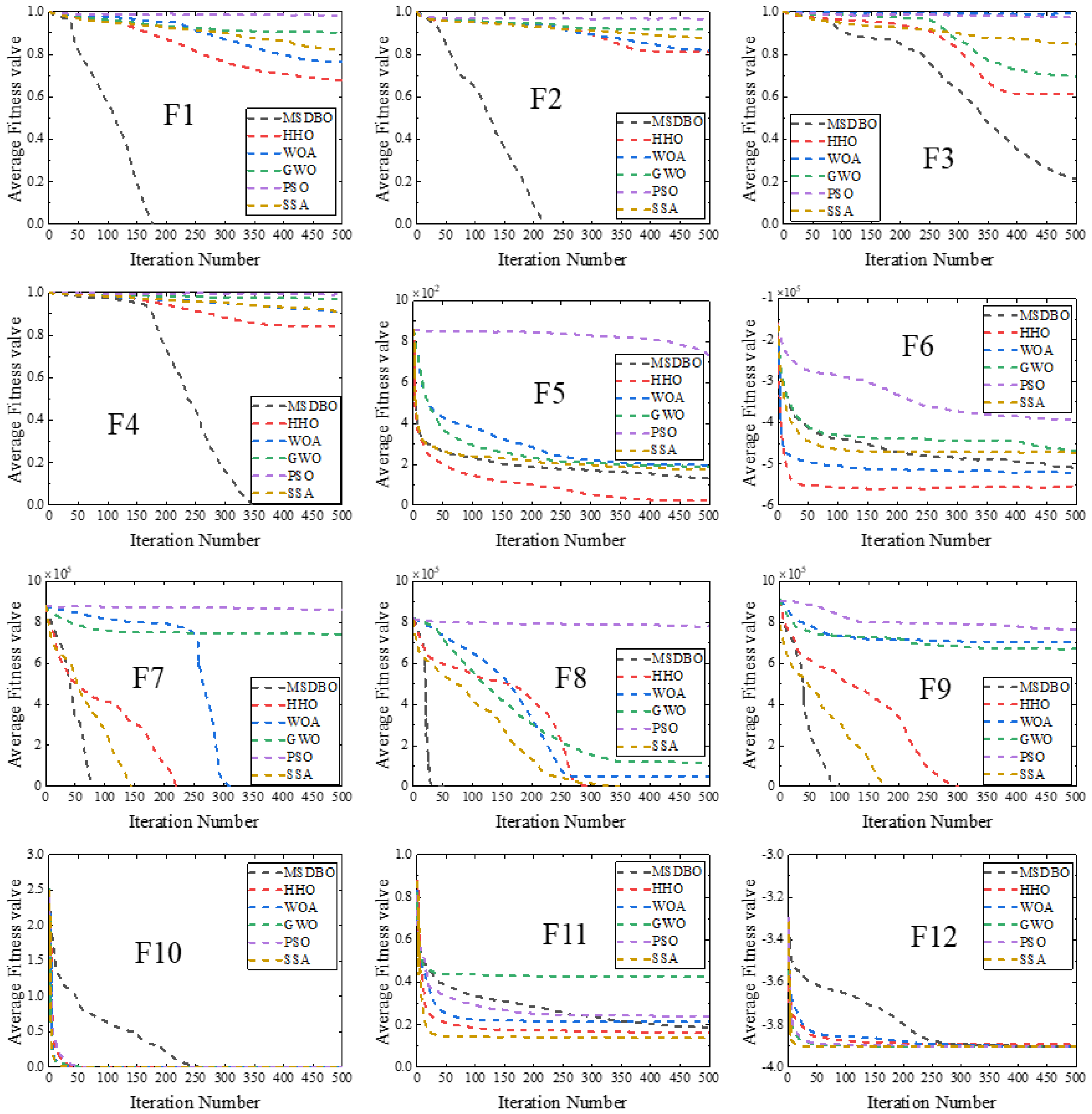

3.1. Numerical Experiment

3.1.1. Environment of Experimental

3.1.2. Parameter Configurations

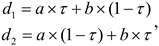

3.1.3. Benchmark Functions

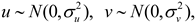

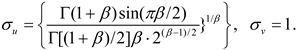

3.1.4. Comparation and Analysis

3.2. Engineering Experiment

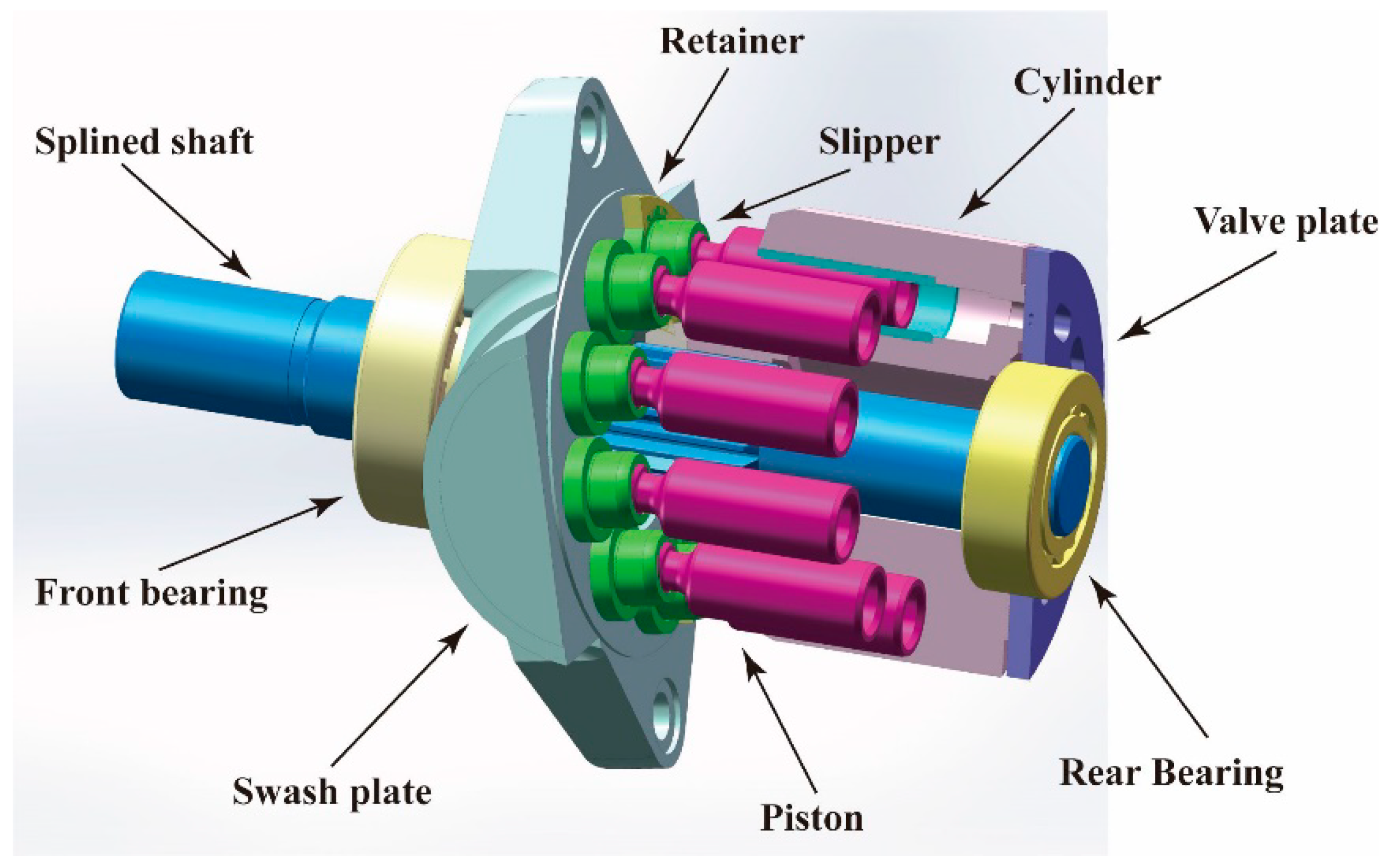

3.2.1. Theoretical Modeling of Axial Piston Pump

- A.

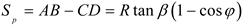

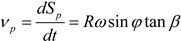

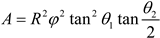

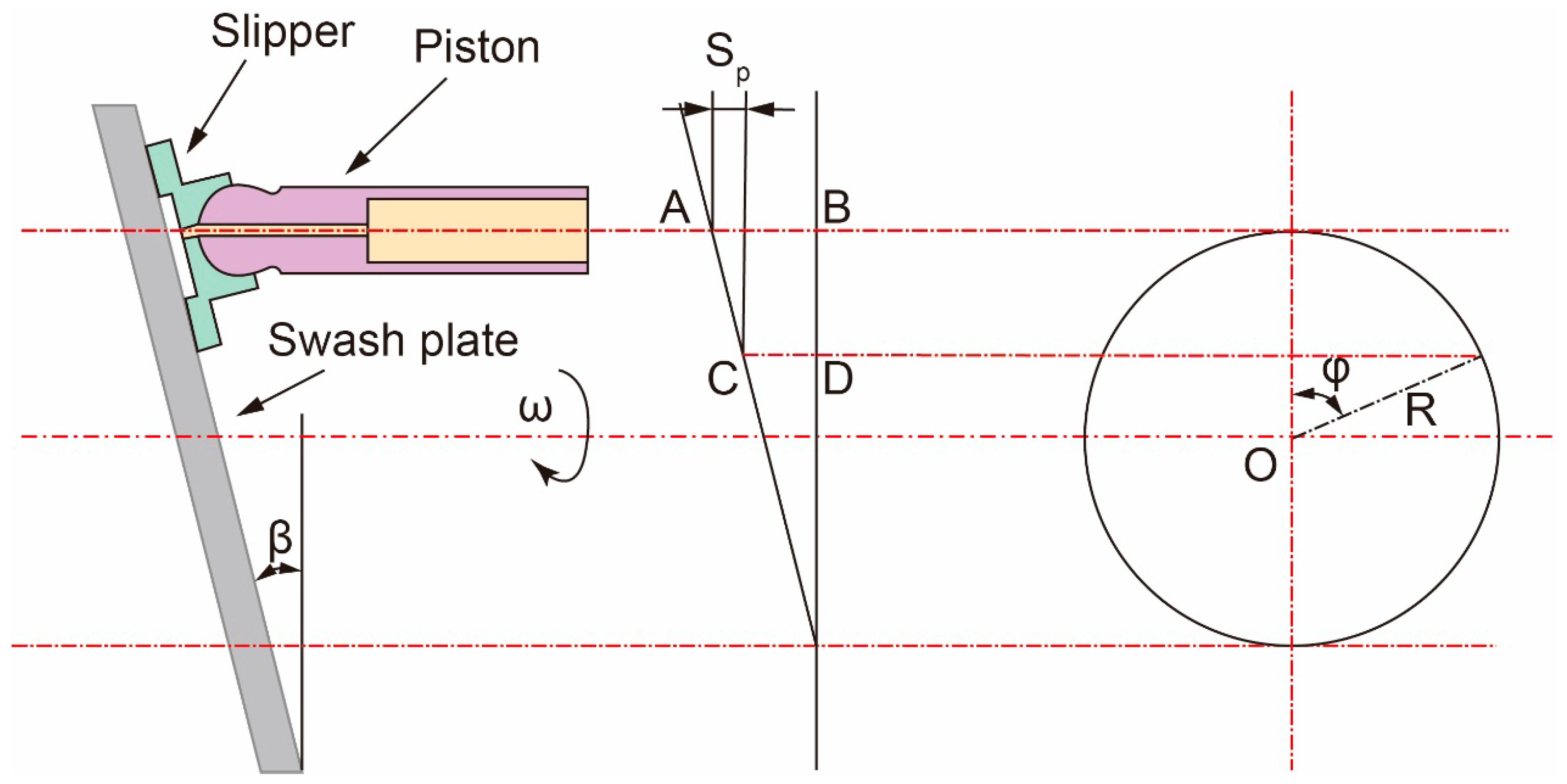

- Kinematic model

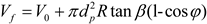

- B.

- Leakage flow

- (1)

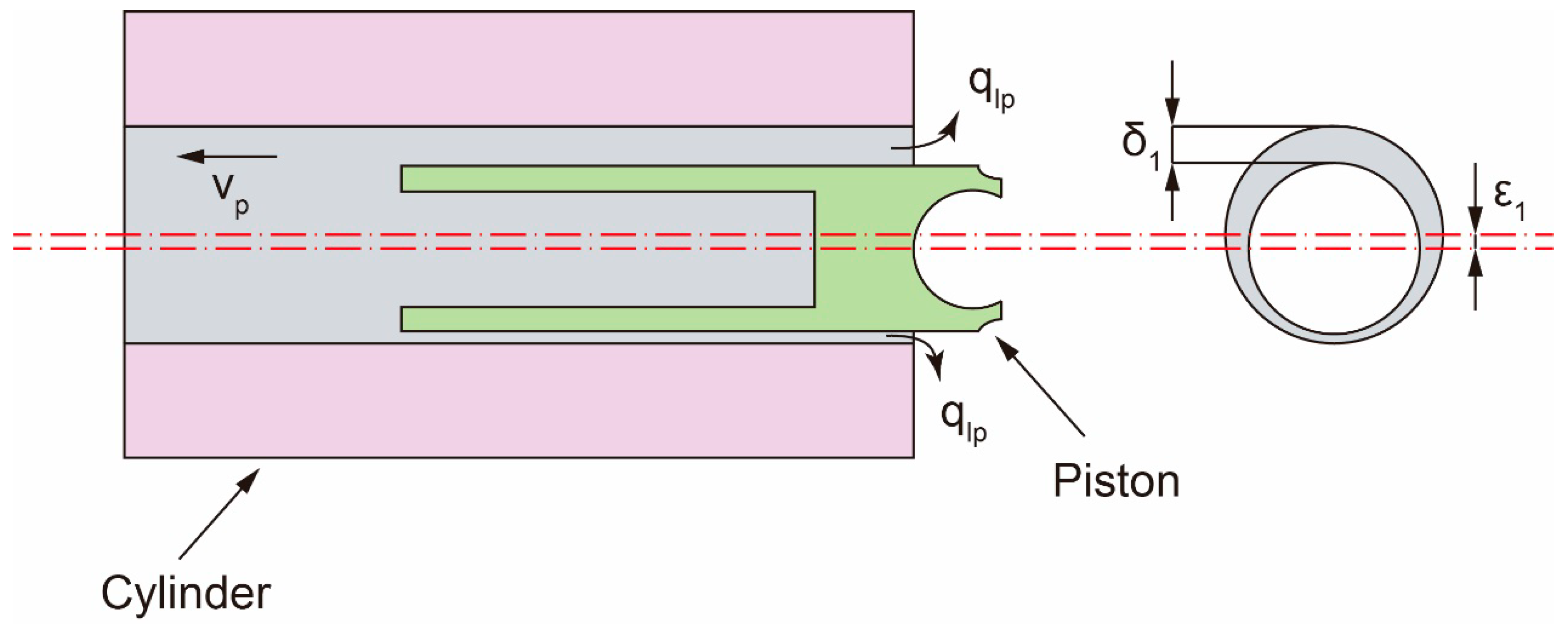

- Piston/cylinder pair

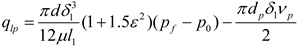

- (2)

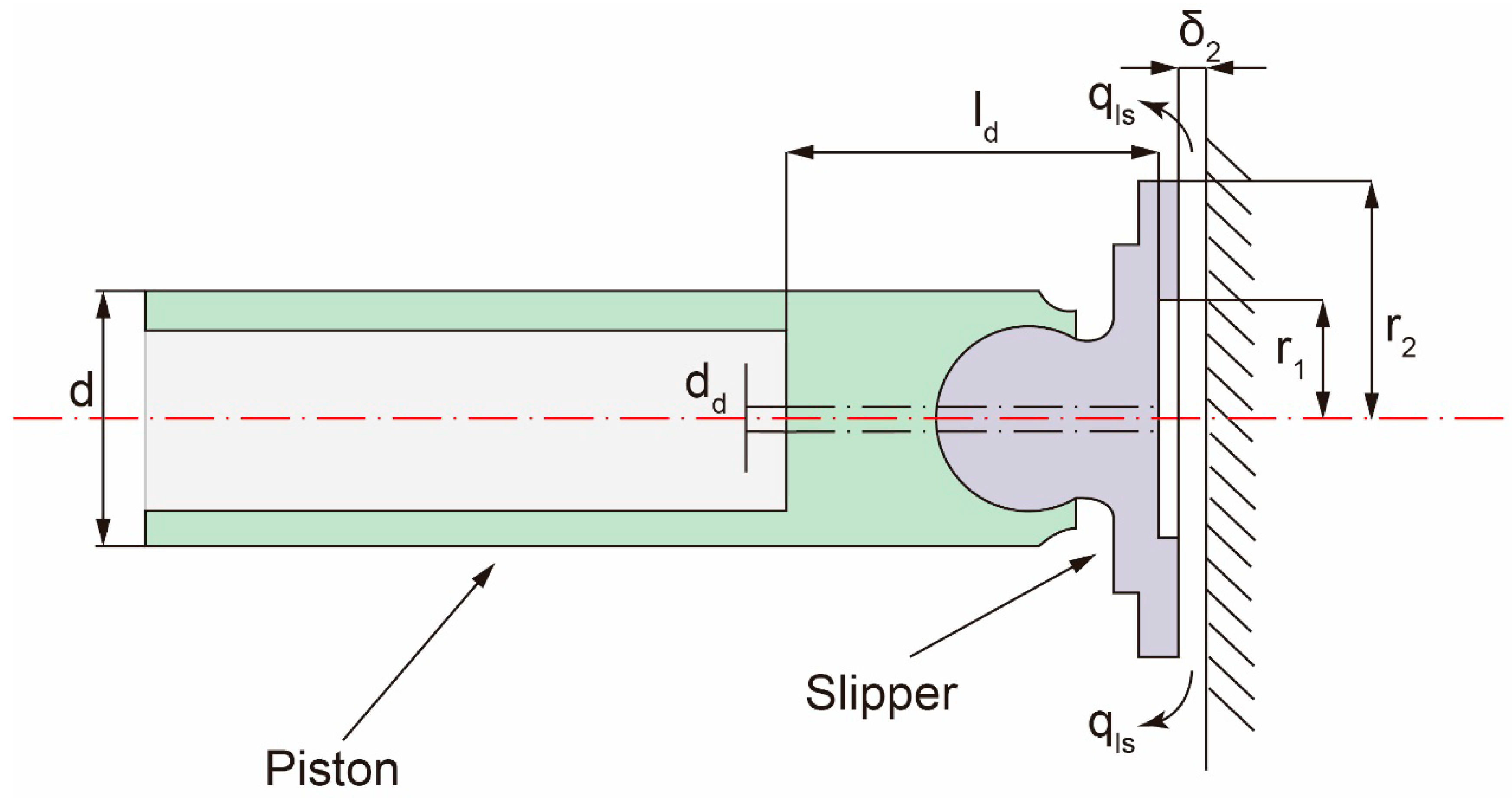

- Piston/slipper pair

- (3)

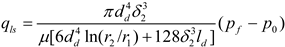

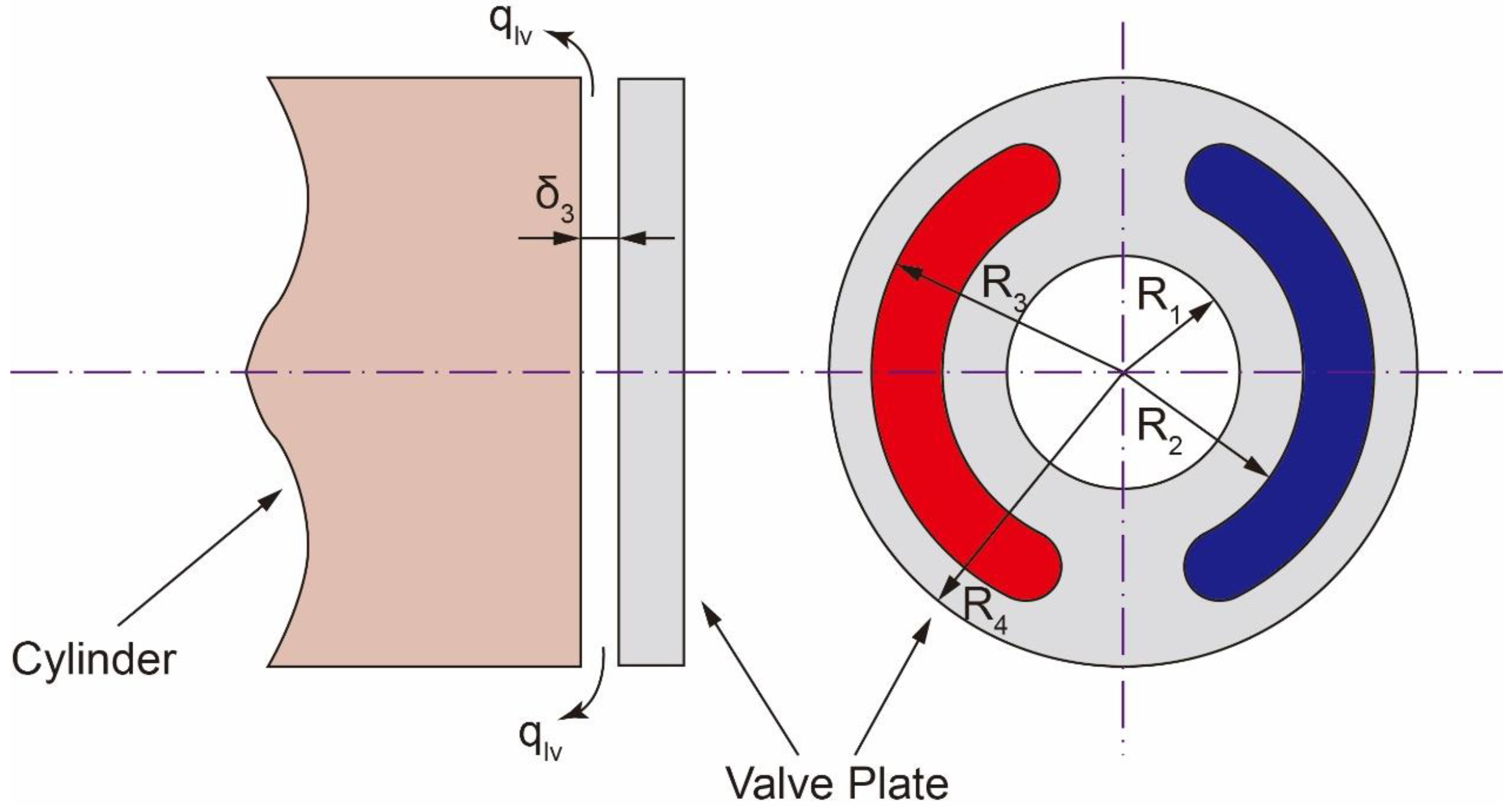

- Cylinder/Valve Plate Pairs

- C.

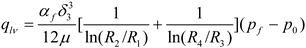

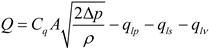

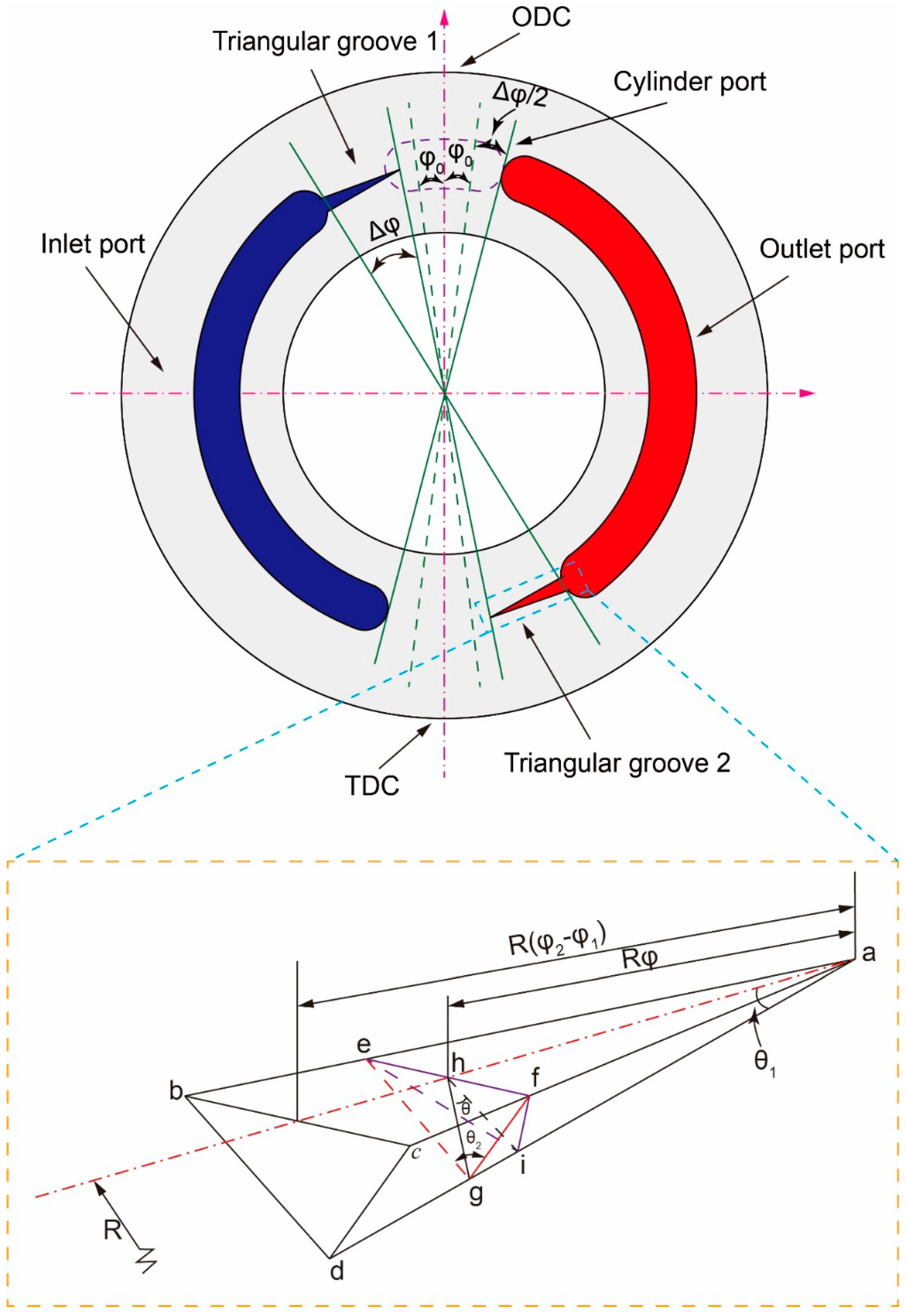

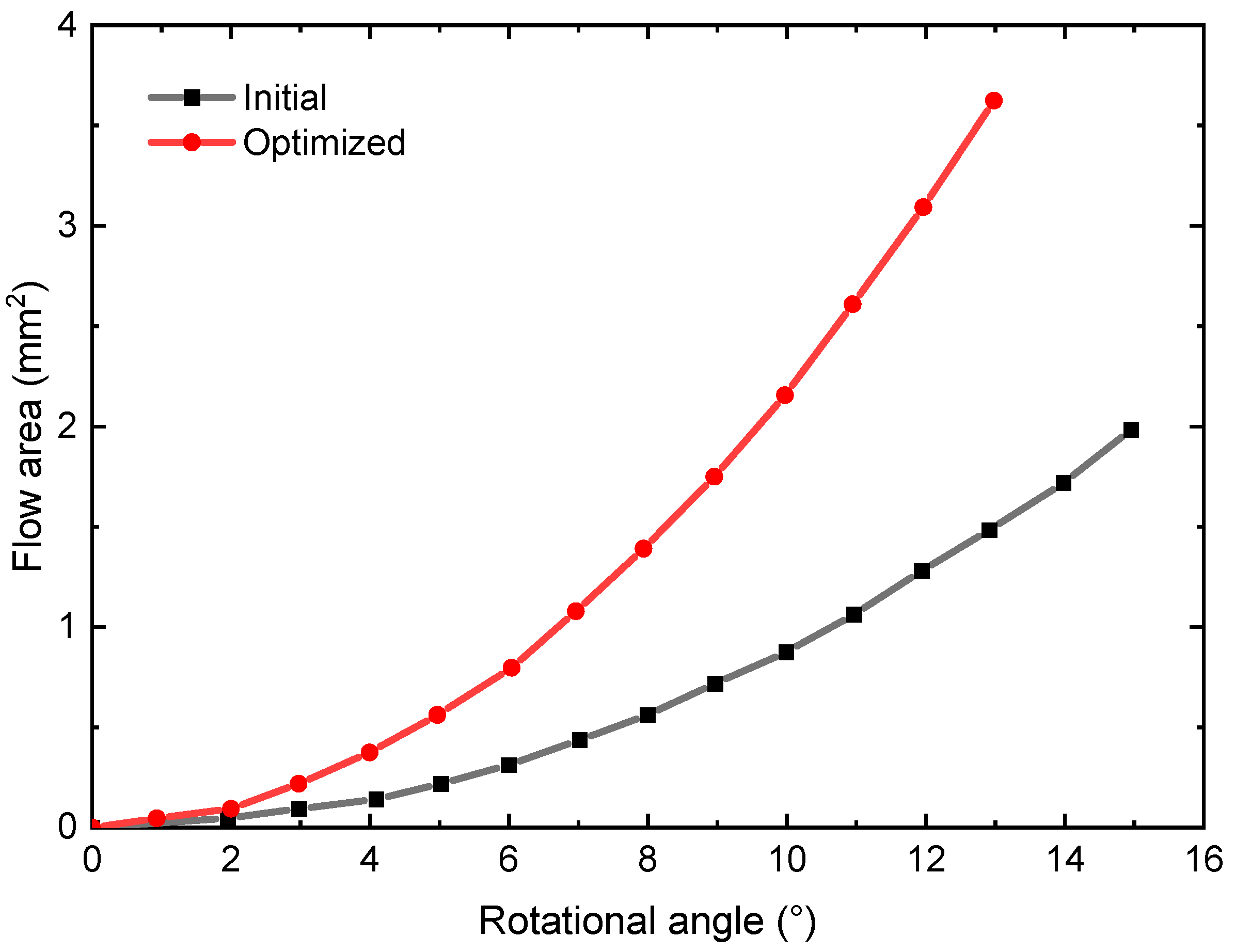

- Valve plate

- D.

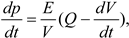

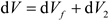

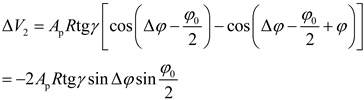

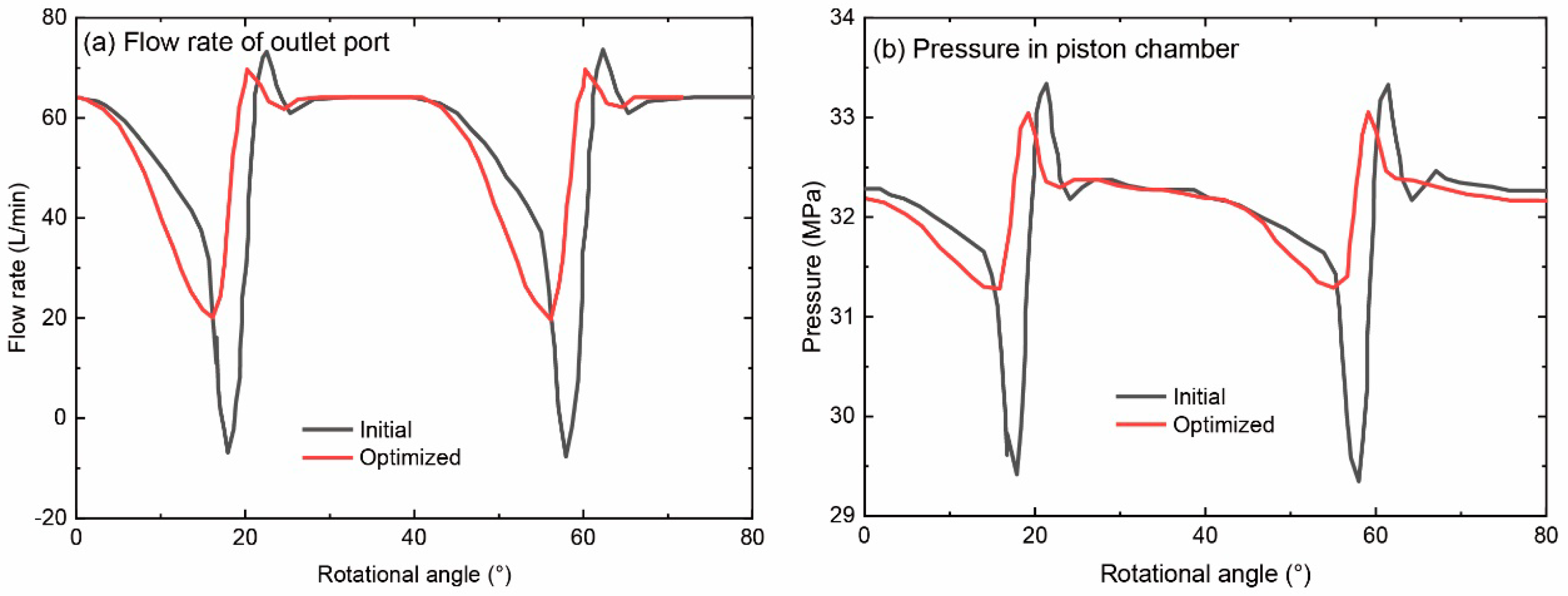

- Piston chamber pressure

3.2.2. Model Validation and Parametric Study

- A.

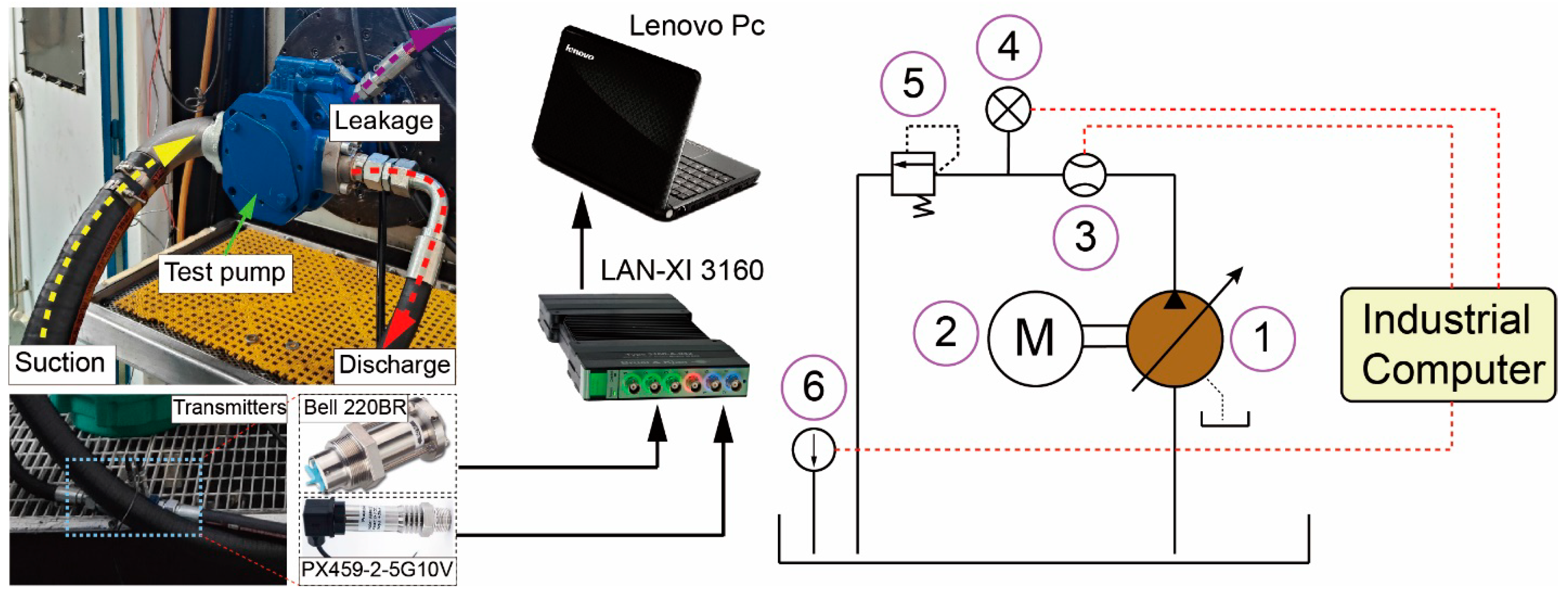

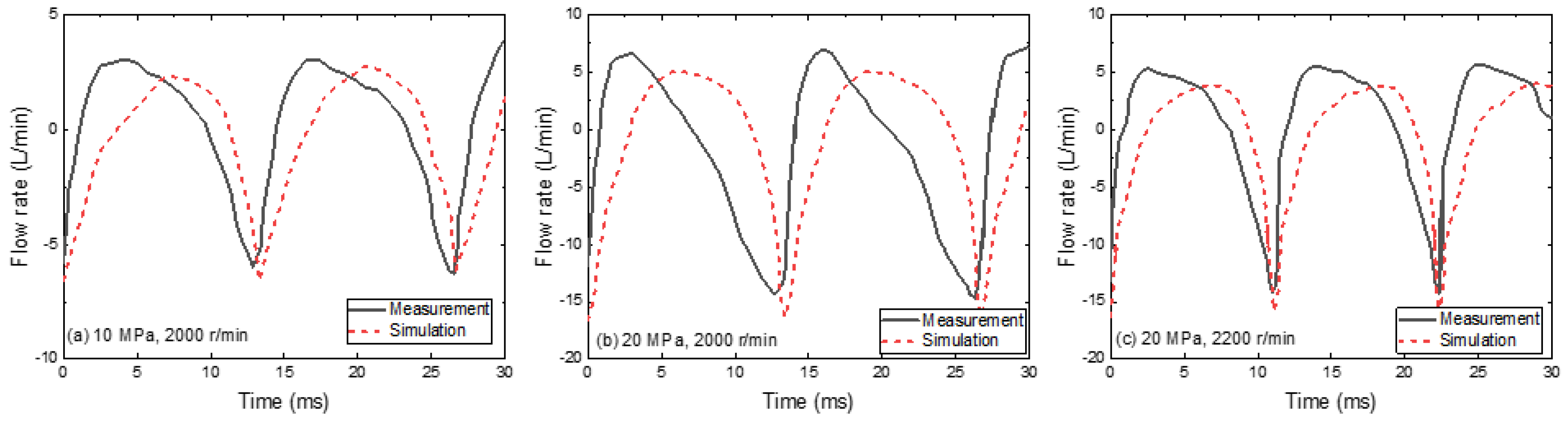

- Measurement and validation

- B.

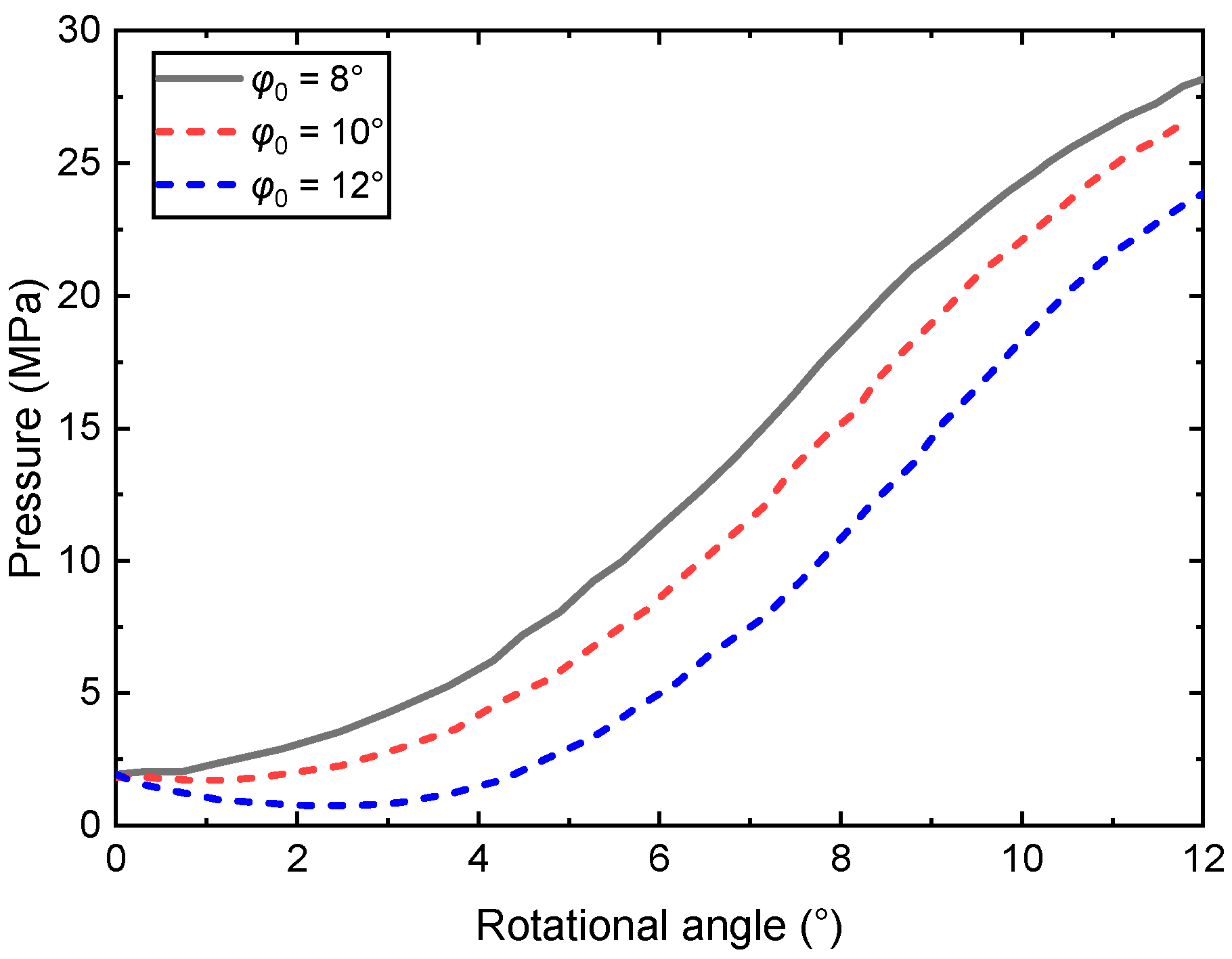

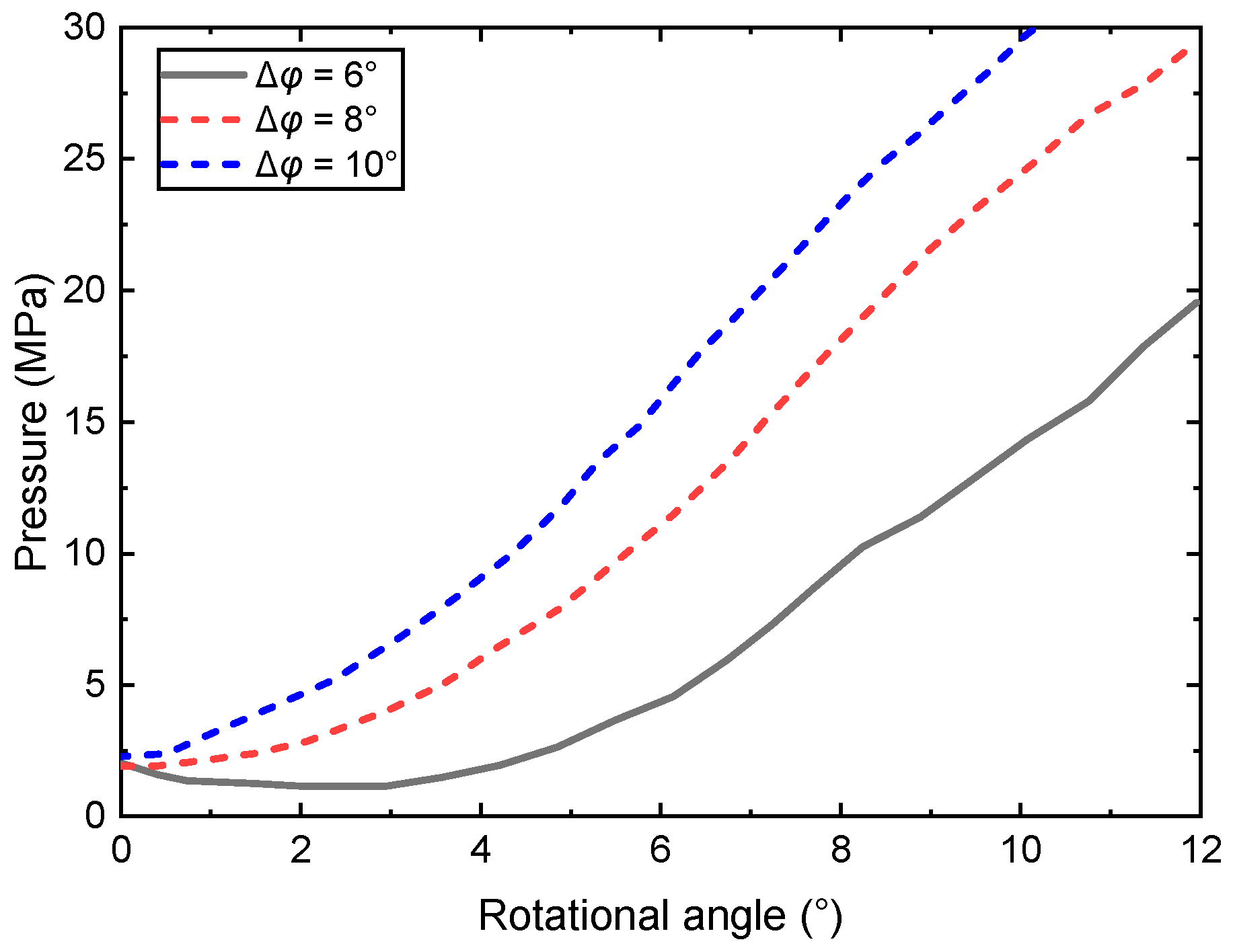

- The effect of close angle

- C.

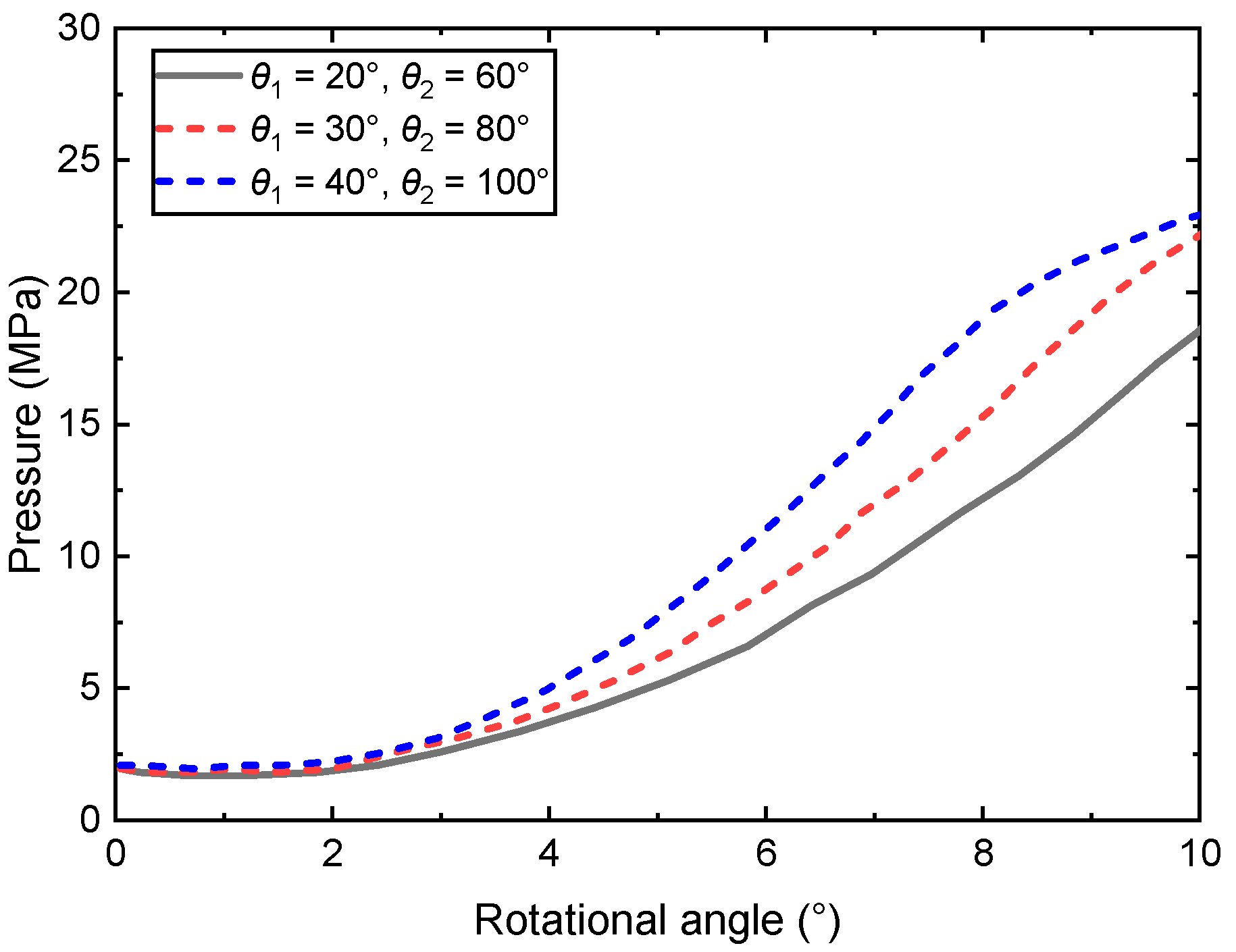

- The effect of cross angle

- D.

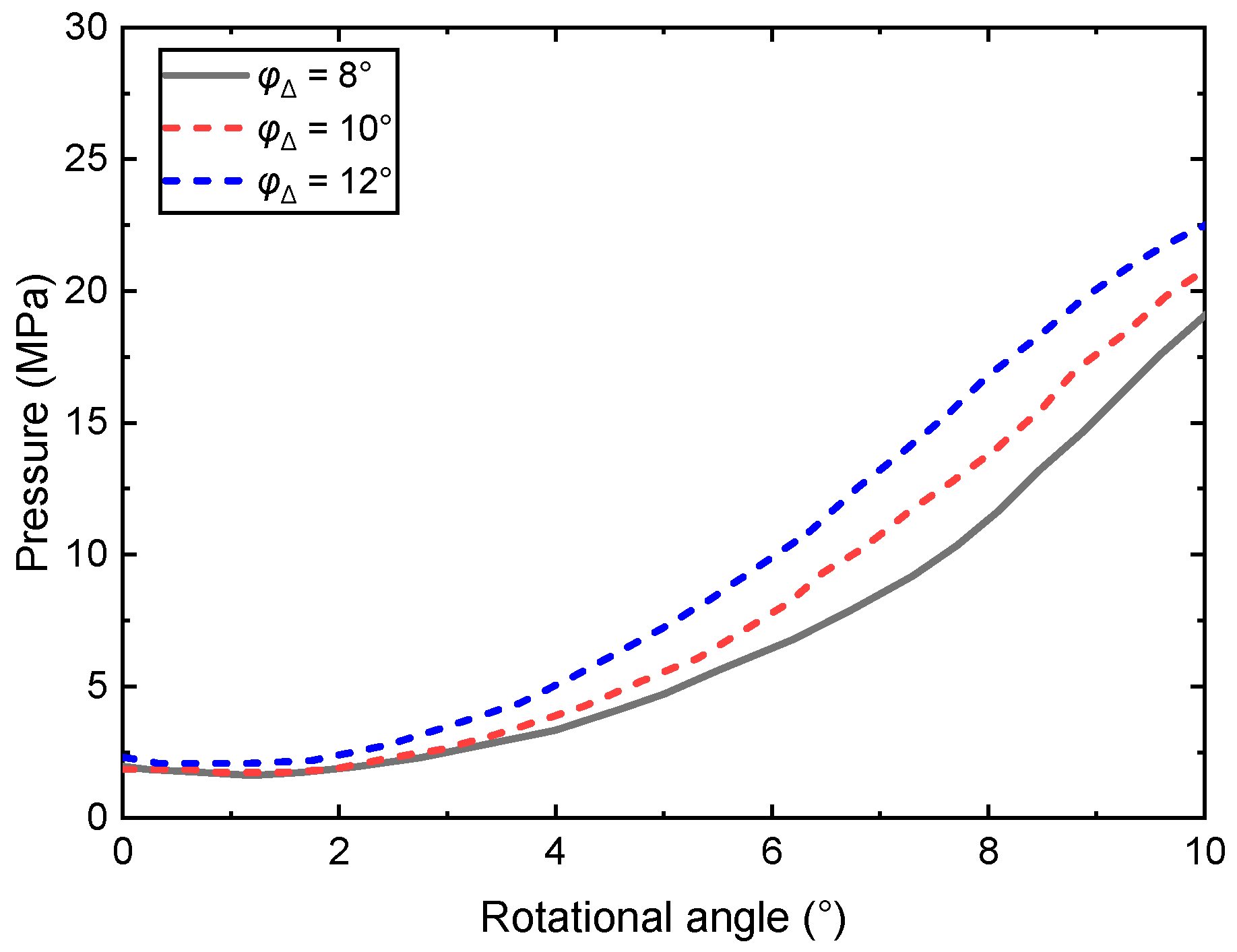

- The effect of the triangular groove size

- E.

- The effect of wrap angle

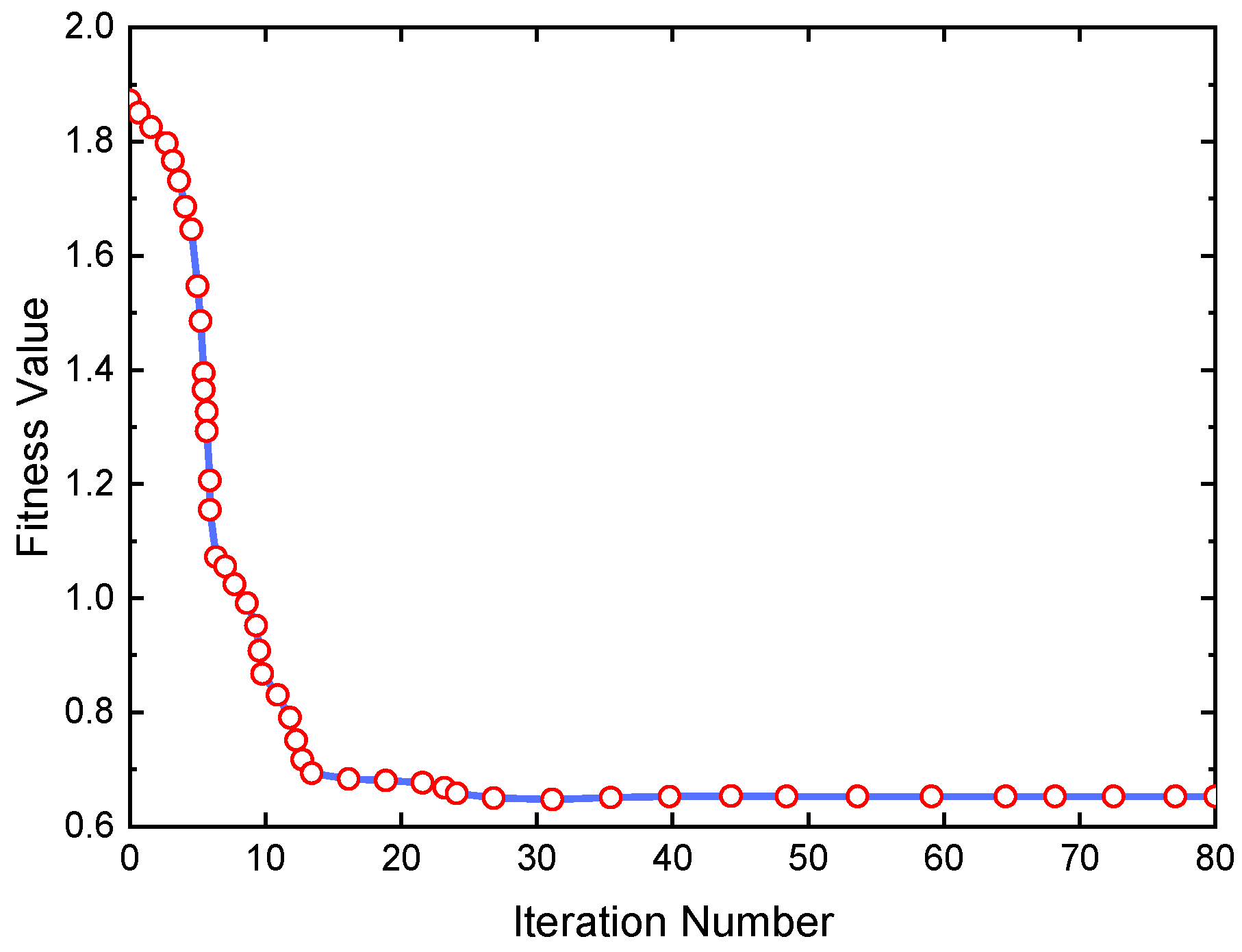

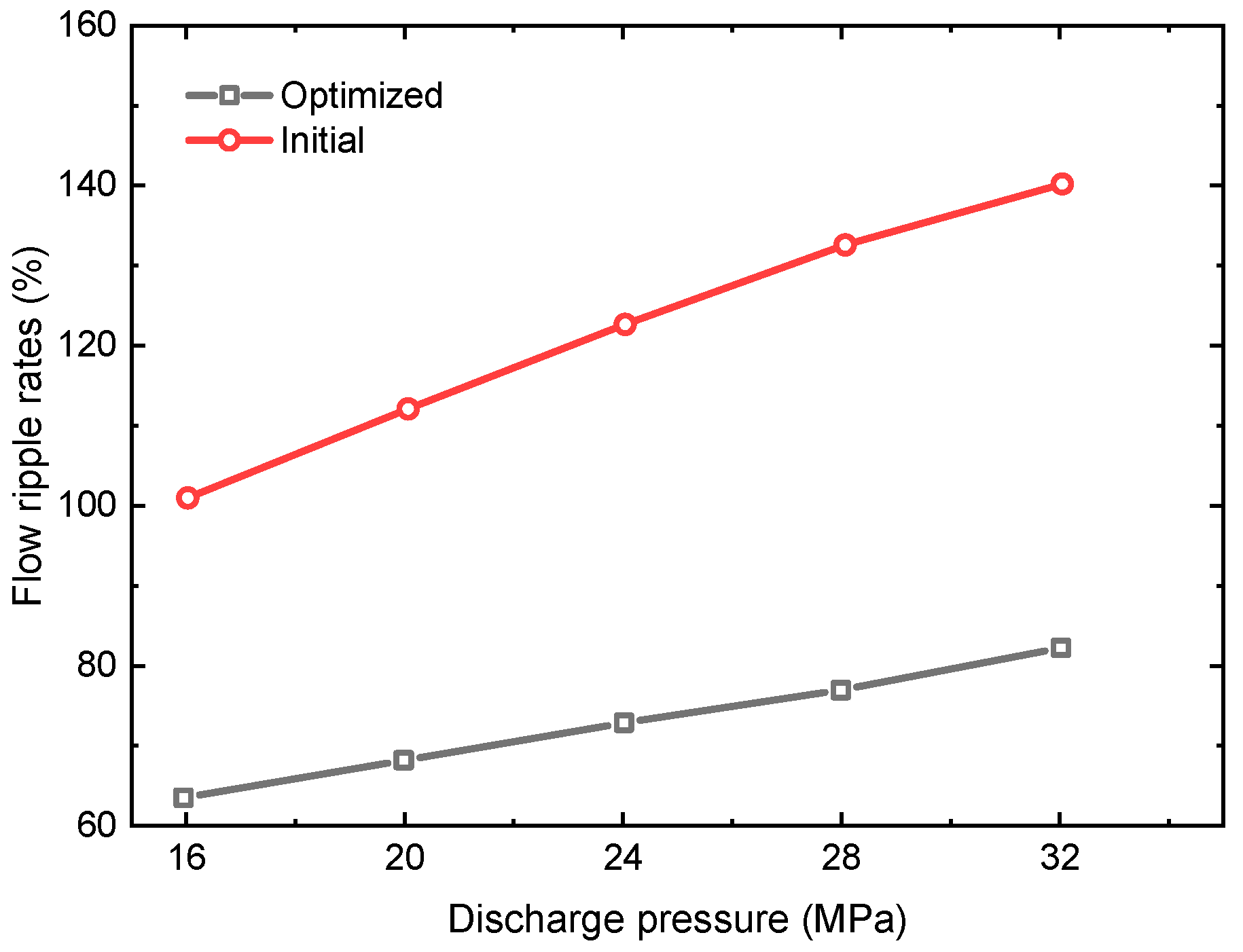

3.3. Valve Plate Optimization Based on MSDBO

3.3.1. Optimization Procedure

3.3.2. Optimization Results

4. Conclusions

Funding

Data Availability Statement

Conflicts of Interest

References

- Kumar A, Nadeem M, Banka H. Nature inspired optimization algorithms: a comprehensive overview[J]. Evolving Systems, 2023, 14(1): 141-156. [CrossRef]

- Sachan R, Singh K. Nature-Inspired Optimization Algorithms: Research Direction and Survey[M]. 2021. [CrossRef]

- Xue J, Shen B. Dung beetle optimizer: a new meta-heuristic algorithm for global optimization[J]. The Journal of Supercomputing, 2023, 79(7): 7305-7336. [CrossRef]

- Heryanto, A. Priyadi, A. Soeprijanto, et al. Optimization of DG Placement in Real Distribution System as a Solution for Increasing the Quality of the System Using GA Algorithms[C]//2021 6th IEEE International Conference on Recent Advances and Innovations in Engineering (ICRAIE): Vol. 6. 2021: 1-4. [CrossRef]

- Gad A G. Particle Swarm Optimization Algorithm and Its Applications: A Systematic Review[J]. Archives of Computational Methods in Engineering, 2022, 29(5): 2531-2561. [CrossRef]

- S. Jaiswal, Y. R. Sood, A. Maheshwari, et al. Dung Beetle Optimizer Algorithm Based OPF Solution considering Renewable Energy Sources[C]//2023 International Conference on Computer, Electronics & Electrical Engineering & their Applications (IC2E3). 2023: 1-6. [CrossRef]

- Shen Q, Zhang D, Xie M, et al. Multi-Strategy Enhanced Dung Beetle Optimizer and Its Application in Three-Dimensional UAV Path Planning[J]. Symmetry, 2023, 15(7). [CrossRef]

- Hu T, Zhang H, Zhou J. Prediction of the Debonding Failure of Beams Strengthened with FRP through Machine Learning Models[J]. Buildings, 2023, 13(3). [CrossRef]

- W. Zilong, S. Peng. A Multi-Strategy Dung Beetle Optimization Algorithm for Optimizing Constrained Engineering Problems[J]. IEEE Access, 2023, 11: 98805-98817. [CrossRef]

- Lu Z, Zhang J. An Enhanced Dung Beetle Optimization Algorithm for Global Optimization[J]. Current Journal of Applied Science and Technology, 2023, 42: 9-22. [CrossRef]

- S. Li, J. Li. Chaotic dung beetle optimization algorithm based on adaptive t-Distribution[C]//2023 IEEE 3rd International Conference on Information Technology, Big Data and Artificial Intelligence (ICIBA): Vol. 3. 2023: 925-933. [CrossRef]

- Zhang R, Zhu Y. Predicting the Mechanical Properties of Heat-Treated Woods Using Optimization-Algorithm-Based BPNN[J]. Forests, 2023, 14(5). [CrossRef]

- Lu Z, Zhang J. An Enhanced Dung Beetle Optimization Algorithm for Global Optimization[J]. Current Journal of Applied Science and Technology, 2023, 42: 9-22. [CrossRef]

- Liu Q, Li N, Jia H, et al. A Hybrid Arithmetic Optimization and Golden Sine Algorithm for Solving Industrial Engineering Design Problems[J]. Mathematics, 2022, 10(9). [CrossRef]

- Noah D. Manring. Fluid Power Pumps and Motors: Analysis, Design and Control[M]. McGraw-Hill Professional, 2013.

- Tang S, Zhu Y, Yuan S, et al. Intelligent Diagnosis towards Hydraulic Axial Piston Pump Using a Novel Integrated CNN Model[J]. Sensors, 2020, 20(24). [CrossRef]

- Xu B, Ye S, Zhang J, et al. Flow ripple reduction of an axial piston pump by a combination of cross-angle and pressure relief grooves: Analysis and optimization[J]. Journal of Mechanical Science and Technology, 2016, 30(6): 2531-2545. [CrossRef]

- Ye S G, Zhang J H, Xu B. Noise Reduction of an Axial Piston Pump by Valve Plate Optimization[J]. Chinese Journal of Mechanical Engineering, 2018, 31(1): 57. [CrossRef]

- Lyu F, Ye S, Zhang J, et al. Theoretical and Simulation Investigations on Flow Ripple Reduction of Axial Piston Pumps Using Nonuniform Distribution of Pistons[J]. Journal of Dynamic Systems, Measurement, and Control, 2020, 143(041008). [CrossRef]

- Zhang J, Xia S, Ye S, et al. Experimental investigation on the noise reduction of an axial piston pump using free-layer damping material treatment[J]. Applied Acoustics, 2018, 139: 1-7. [CrossRef]

- Danes L, Vacca A. A Tandem Axial-Piston Unit Based Strategy for the Reduction of Noise Sources in Hydraulic Systems[J]. Energies, 2020, 13(20). [CrossRef]

- Fiebig W. NOISE CONTROL OF FLUID POWER UNITS[M]. 2016.

- Fiebig W, Rosikowski P. Reduction of Noise Emission of Hydraulic Power Units[C]//STRYCZEK J, WARZYŃSKA U. Advances in Hydraulic and Pneumatic Drives and Control 2020. Cham: Springer International Publishing, 2021: 241-251. [CrossRef]

- Xu B, Sun Y hui, Zhang J hui, et al. A new design method for the transition region of the valve plate for an axial piston pump[J]. Journal of Zhejiang University-SCIENCE A, 2015, 16(3): 229-240. [CrossRef]

- Zhou J, Jing C, Bao Q, et al. Novel study on the pressure pulsation of the axial piston machines with even number of pistons[J]. The Journal of Engineering, 2020, 2020: 932-935. [CrossRef]

- Pan Y, Li Y, Liang D. The influence of dynamic swash plate vibration on outlet flow ripple in constant power variable-displacement piston pump[J]. Proceedings of the Institution of Mechanical Engineers, Part C: Journal of Mechanical Engineering Science, 2019, 233(14): 4914-4933. [CrossRef]

- Ye S G, Zhang J H, Xu B. Noise Reduction of an Axial Piston Pump by Valve Plate Optimization[J]. Chinese Journal of Mechanical Engineering, 2018, 31(1): 57. [CrossRef]

- Dacke M, Baird E, Byrne M, et al. Dung Beetles Use the Milky Way for Orientation[J]. Current Biology, 2013, 23(4): 298-300. [CrossRef]

- Byrne M, Dacke M, Nordström P, et al. Visual cues used by ball-rolling dung beetles for orientation[J]. Journal of Comparative Physiology A, 2003, 189(6): 411-418.

- Baird E, Byrne M, Smolka J, et al. The Dung Beetle Dance: An Orientation Behaviour?[J]. PloS one, 2012, 7: e30211. [CrossRef]

- Chang Z, Luo J, Zhang Y, et al. A mixed strategy improved dung beetle optimization algorithm and its application[M]. 2023. [CrossRef]

- Pervaiz S, Bangyal W, Ashraf A, et al. Comparative Research Directions of Population Initialization Techniques using PSO Algorithm[J]. Intelligent Automation & Soft Computing, 2022, 32: 1427-1444. [CrossRef]

- Agushaka J O, Ezugwu A E, Abualigah L, et al. Efficient Initialization Methods for Population-Based Metaheuristic Algorithms: A Comparative Study[J]. Archives of Computational Methods in Engineering, 2023, 30(3): 1727-1787. [CrossRef]

- Rauf H T, Gao J, Almadhor A, et al. Multi population-based chaotic differential evolution for multi-modal and multi-objective optimization problems[J]. Applied Soft Computing, 2023, 132: 109909. [CrossRef]

- L. Shen, L. Xu, R. Wei, et al. Multi-swarm Optimization with Chaotic Mapping for Dynamic Optimization Problems[C]//2015 8th International Symposium on Computational Intelligence and Design (ISCID): Vol. 2. 2015: 132-137. [CrossRef]

- Li Y, He Y, Yu W. A hybrid control strategy based on CSA and ELM for uncertain nonlinear chaotic system[J]. Journal of Algorithms & Computational Technology, 2020, 14: 1748302620922500. [CrossRef]

- Naskar P K, Bhattacharyya S, Nandy D, et al. A robust image encryption scheme using chaotic tent map and cellular automata[J]. Nonlinear Dynamics, 2020, 100(3): 2877-2898. [CrossRef]

- Zhu F, Li G, Tang H, et al. Dung beetle optimization algorithm based on quantum computing and multi-strategy fusion for solving engineering problems[J]. Expert Systems with Applications, 2024, 236: 121219. [CrossRef]

- Han M, Du Z, Zhu H, et al. Golden-Sine dynamic marine predator algorithm for addressing engineering design optimization[J]. Expert Systems with Applications, 2022, 210: 118460. [CrossRef]

- J. Zhang, J. S. Wang. Improved Whale Optimization Algorithm Based on Nonlinear Adaptive Weight and Golden Sine Operator[J]. IEEE Access, 2020, 8: 77013-77048. [CrossRef]

- Cui Y, Shi R, Dong J. CLTSA: A Novel Tunicate Swarm Algorithm Based on Chaotic-Lévy Flight Strategy for Solving Optimization Problems[J]. Mathematics, 2022, 10(18): 3405. [CrossRef]

- Kaidi W, Khishe M, Mohammadi M. Dynamic Levy Flight Chimp Optimization[J]. Knowledge-Based Systems, 2022, 235: 107625. [CrossRef]

- Lu X li, He G. QPSO algorithm based on Lévy flight and its application in fuzzy portfolio[J]. Applied Soft Computing, 2021, 99: 106894. [CrossRef]

- Rezaei H, Bozorg-Haddad O, Chu X. Grey wolf optimization (GWO) algorithm[J]. Advanced optimization by nature-inspired algorithms, 2018: 81-91. [CrossRef]

- Xue J, Shen B. A novel swarm intelligence optimization approach: sparrow search algorithm[J]. Systems science & control engineering, 2020, 8(1): 22-34. [CrossRef]

- Kaur G, Arora S. Chaotic whale optimization algorithm[J]. Journal of Computational Design and Engineering, 2018, 5(3): 275-284. [CrossRef]

- Heidari A A, Mirjalili S, Faris H, et al. Harris hawks optimization: Algorithm and applications[J]. Future generation computer systems, 2019, 97: 849-872. [CrossRef]

- Abualigah L, Diabat A, Mirjalili S, et al. The Arithmetic Optimization Algorithm[J]. Computer Methods in Applied Mechanics and Engineering, 2021, 376: 113609. [CrossRef]

- Guo S, Chen J, Lu Y, et al. Hydraulic piston pump in civil aircraft: Current status, future directions and critical technologies[J]. Chinese Journal of Aeronautics, 2020, 33(1): 16-30. [CrossRef]

- Chao Q, Xu Z, Tao J, et al. Capped piston: A promising design to reduce compressibility effects, pressure ripple and cavitation for high-speed and high-pressure axial piston pumps[J]. Alexandria Engineering Journal, 2023, 62: 509-521. [CrossRef]

- Chen Y, Zhang J, Xu B, et al. Multi-objective optimization of micron-scale surface textures for the cylinder/valve plate interface in axial piston pumps[J]. Tribology International, 2019, 138: 316-329. [CrossRef]

- Pan Y, Li Y, Liang D. The influence of dynamic swash plate vibration on outlet flow ripple in constant power variable-displacement piston pump[J]. Proceedings of the Institution of Mechanical Engineers, Part C: Journal of Mechanical Engineering Science, 2019, 233(14): 4914-4933. [CrossRef]

| Algorithm | Parameters |

|---|---|

| PSO | C1 = C2 = 1.8, ωmax = 0.95, ωmin = 0.6 |

| GWO | amax = 1.8, amin = 0.5 |

| WOA | b = 1.2 |

| HHO | P = 0.8, J ∈ [0,2] |

| SSA | ST = 0.9, PD = 0.3, SD = 0.3 |

| MSDBO | K = λ = 0.1, b = 0.5, S=0.7 |

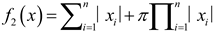

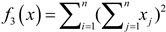

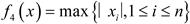

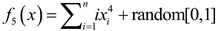

| Name | Functions | Dimensionality | Range | Optimum value |

|---|---|---|---|---|

| F1 |  |

30 | [-100,100] | 0 |

| F2 |  |

30 | [-10,10] | 0 |

| F3 |  |

30 | [-100,100] | 0 |

| F4 |  |

30 | [-100,100] | 0 |

| F5 |  |

30 | [1.28,1.28] | 0 |

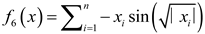

| F6 |  |

30 | [-500,500] | -419n |

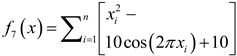

| F7 |  |

30 | [5.12,5.12] | 0 |

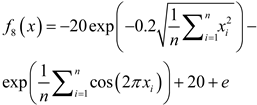

| F8 |  |

30 | [-32,32] | 0 |

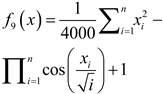

| F9 |  |

30 | [-600,600] | 0 |

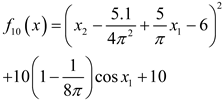

| F10 |  |

2 | [-5,5] | 0.398 |

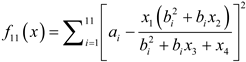

| F11 |  |

4 | [-5,5] | 0.000307 |

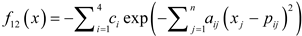

| F12 |  |

3 | [0,1] | -3.86 |

| Algorithm | F1 | F2 | ||||

|---|---|---|---|---|---|---|

| Best | Mean | Std | Best | Mean | Std | |

| PSO | 1.234E+00 | 3.821E+00 | 2.109E+00 | 5.672E+00 | 6.327E+00 | 1.219E+00 |

| GWO | 2.568E-28 | 1.921E-26 | 2.334E-26 | 3.421E-17 | 1.295E-16 | 9.781E-17 |

| WOA | 1.793E-84 | 3.921E-72 | 1.498E-71 | 3.245E-57 | 3.796E-51 | 1.831E-50 |

| HHO | 1.962E-112 | 9.281E-90 | 6.553E-89 | 1.184E-59 | 4.762E-50 | 2.038E-49 |

| SSA | 3.827E-161 | 6.724E-54 | 4.276E-53 | 2.731E-52 | 8.294E-31 | 4.104E-30 |

| MSDBO | 0.000E+00 | 0.000E+00 | 0.000E+00 | 0.000E+00 | 0.000E+00 | 0.000E+00 |

| Algorithm | F3 | F4 | ||||

| Best | Mean | Std | Best | Mean | Std | |

| PSO | 2.543E+01 | 4.448E+02 | 1.977E+02 | 4.638E+00 | 6.024E+00 | 7.941E-01 |

| GWO | 9.549E-09 | 2.991E-05 | 7.416E-05 | 3.306E-07 | 2.178E-06 | 2.093E-06 |

| WOA | 5.223E+04 | 1.282E+05 | 3.942E+04 | 7.404E-01 | 1.489E+02 | 8.970E+01 |

| HHO | 9.276E-98 | 8.346E-74 | 4.236E-73 | 1.311E-56 | 4.614E-48 | 2.149E-47 |

| SSA | 0.000E+00 | 4.002E-27 | 2.244E-26 | 7.161E-83 | 5.424E-28 | 2.613E-27 |

| MSDBO | 0.000E+00 | 1.488E-176 | 0.000E+00 | 0.000E+00 | 0.000E+00 | 0.000E+00 |

| Algorithm | F5 | F6 | ||||

| Best | Mean | Std | Best | Mean | Std | |

| PSO | 4.086E+00 | 4.959E+01 | 3.918E+01 | 2.300E+03 | 1.759E+03 | 4.146E+02 |

| GWO | 5.766E-04 | 6.546E-03 | 3.513E-03 | 2.368E+03 | 1.833E+03 | 2.787E+02 |

| WOA | 5.421E-04 | 7.473E-03 | 9.186E-03 | 3.771E+03 | 3.195E+03 | 5.493E+02 |

| HHO | 1.646E-05 | 4.419E-04 | 4.890E-04 | 3.771E+03 | 3.759E+03 | 5.622E+01 |

| SSA | 1.267E-04 | 5.031E-03 | 4.179E-03 | 2.958E+03 | 2.538E+03 | 1.799E+02 |

| MSDBO | 8.136E-05 | 2.505E-03 | 1.601E-03 | 3.708E+03 | 3.081E+03 | 5.943E+02 |

| Algorithm | F7 | F8 | ||||

| Best | Mean | Std | Best | Mean | Std | |

| PSO | 2.708E+01 | 4.857E+01 | 1.106E+01 | 5.619E-01 | 8.193E-01 | 1.120E-01 |

| GWO | 0.000E+00 | 7.470E+00 | 1.104E+01 | 2.251E-13 | 3.000E-13 | 5.112E-14 |

| WOA | 0.000E+00 | 8.526E-15 | 5.394E-14 | 4.398E-14 | 1.332E-15 | 1.252E-14 |

| HHO | 0.000E+00 | 0.000E+00 | 0.000E+00 | 1.332E-15 | 1.332E-15 | 0.000E+00 |

| SSA | 0.000E+00 | 0.000E+00 | 0.000E+00 | 1.332E-15 | 1.332E-15 | 0.000E+00 |

| MSDBO | 0.000E+00 | 0.000E+00 | 0.000E+00 | 1.332E-15 | 1.332E-15 | 0.000E+00 |

| Algorithm | F9 | F10 | ||||

| Best | Mean | Std | Best | Mean | Std | |

| PSO | 1.632E-01 | 3.645E-01 | 1.330E-01 | 3.979E-01 | 3.979E-01 | 0.000E+00 |

| GWO | 0.000E+00 | 1.445E-02 | 2.182E-02 | 3.979E-01 | 3.979E-01 | 2.923E-06 |

| WOA | 0.000E+00 | 3.327E-02 | 1.277E-01 | 3.979E-01 | 3.979E-01 | 2.912E-05 |

| HHO | 0.000E+00 | 0.000E+00 | 0.000E+00 | 3.979E-01 | 3.979E-01 | 1.975E-05 |

| SSA | 0.000E+00 | 0.000E+00 | 0.000E+00 | 3.979E-01 | 3.979E-01 | 0.000E+00 |

| MSDBO | 0.000E+00 | 0.000E+00 | 0.000E+00 | 3.979E-01 | 3.979E-01 | 2.215E-05 |

| Algorithm | F11 | F12 | ||||

| Best | Mean | Std | Best | Mean | Std | |

| PSO | 2.011E-03 | 2.721E-03 | 3.327E-04 | 3.863E+00 | 3.863E+00 | 6.120E-15 |

| GWO | 9.225E-04 | 1.516E-02 | 2.509E-02 | 3.863E+00 | 3.862E+00 | 6.219E-03 |

| WOA | 9.396E-04 | 2.168E-03 | 1.359E-03 | 3.863E+00 | 3.853E+00 | 5.175E-02 |

| HHO | 9.261E-04 | 1.326E-03 | 1.013E-03 | 3.863E+00 | 3.858E+00 | 9.003E-03 |

| SSA | 9.225E-04 | 1.059E-03 | 4.731E-04 | 3.863E+00 | 3.863E+00 | 6.912E-15 |

| MSDBO | 9.225E-04 | 1.629E-03 | 1.002E-03 | 3.863E+00 | 3.858E+00 | 7.797E-03 |

| Function | PSO | GWO | WOA | HHO | SSA | DBO |

|---|---|---|---|---|---|---|

|

2.012E-16 | 2.012E-16 | 2.012E-16 | 2.012E-16 | 2.012E-16 | 2.012E-16 |

|

2.012E-16 | 2.012E-16 | 2.012E-16 | 2.012E-16 | 2.012E-16 | 2.012E-16 |

|

5.476E-16 | 5.476E-16 | 5.476E-16 | 5.476E-16 | 5.476E-16 | 5.476E-16 |

|

2.012E-16 | 2.012E-16 | 2.012E-16 | 2.012E-16 | 2.012E-16 | 2.012E-16 |

|

1.462E-14 | 1.022E-08 | 1.408E-03 | 8.216E-11 | 6.509E-03 | 1.028E-01 |

|

3.959E-13 | 1.447E-13 | 9.160E-02 | 7.529E-14 | 2.213E-04 | 1.692E-04 |

|

2.012E-16 | 7.337E-16 | 3.378E-01 | N/A | N/A | 8.376E-02 |

|

2.012E-16 | 1.888E-16 | 1.965E-10 | N/A | N/A | N/A |

|

2.012E-16 | 1.040E-04 | 8.376E-02 | N/A | N/A | 3.378E-01 |

|

2.012E-16 | 4.372E-07 | 1.689E-02 | 9.821E-03 | 2.012E-16 | 2.012E-16 |

|

5.843E-09 | 3.492E-02 | 4.468E-03 | 2.877E-01 | 3.594E-11 | 1.342E-04 |

|

2.012E-16 | 1.427E-06 | 1.665E-03 | 3.423E-01 | 2.012E-16 | 4.046E-05 |

| W/L/E | 12/0/0 | 12/0/0 | 9/3/0 | 7/2/3 | 9/0/3 | 8/3/1 |

| Parameter | Valve |

|---|---|

| Volume modulus E | 1.1×109 Pa |

| Flow coefficient Cq | 0.7 |

| Fluid density ρ | 875 kg/m3 |

| Diameter of the piston d | 18 mm |

| Radius of the pitch circle R | 34 mm |

| Close angle φ0 | 14.9° |

| Rotational speed ω | 178 rad/s |

| Dead volume V0s | 0.74×10-5 m2 |

| Swashplate angle γ???Width angle θ1 | 13° |

| Depth angle θ2 | 50° |

| Cross angle Δφ | 15° |

| Warp angle φΔ | 0° |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).