Submitted:

06 February 2024

Posted:

07 February 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

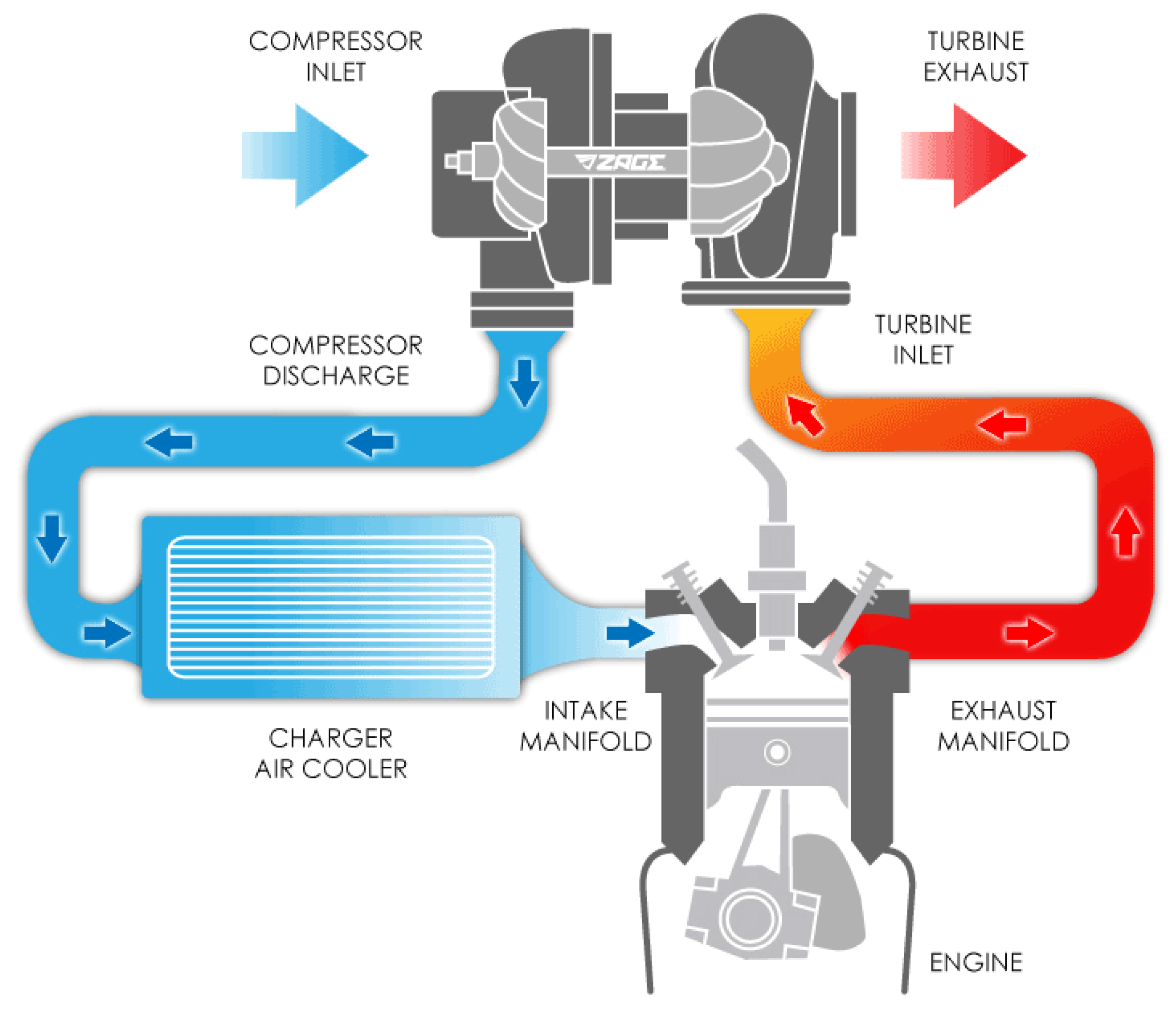

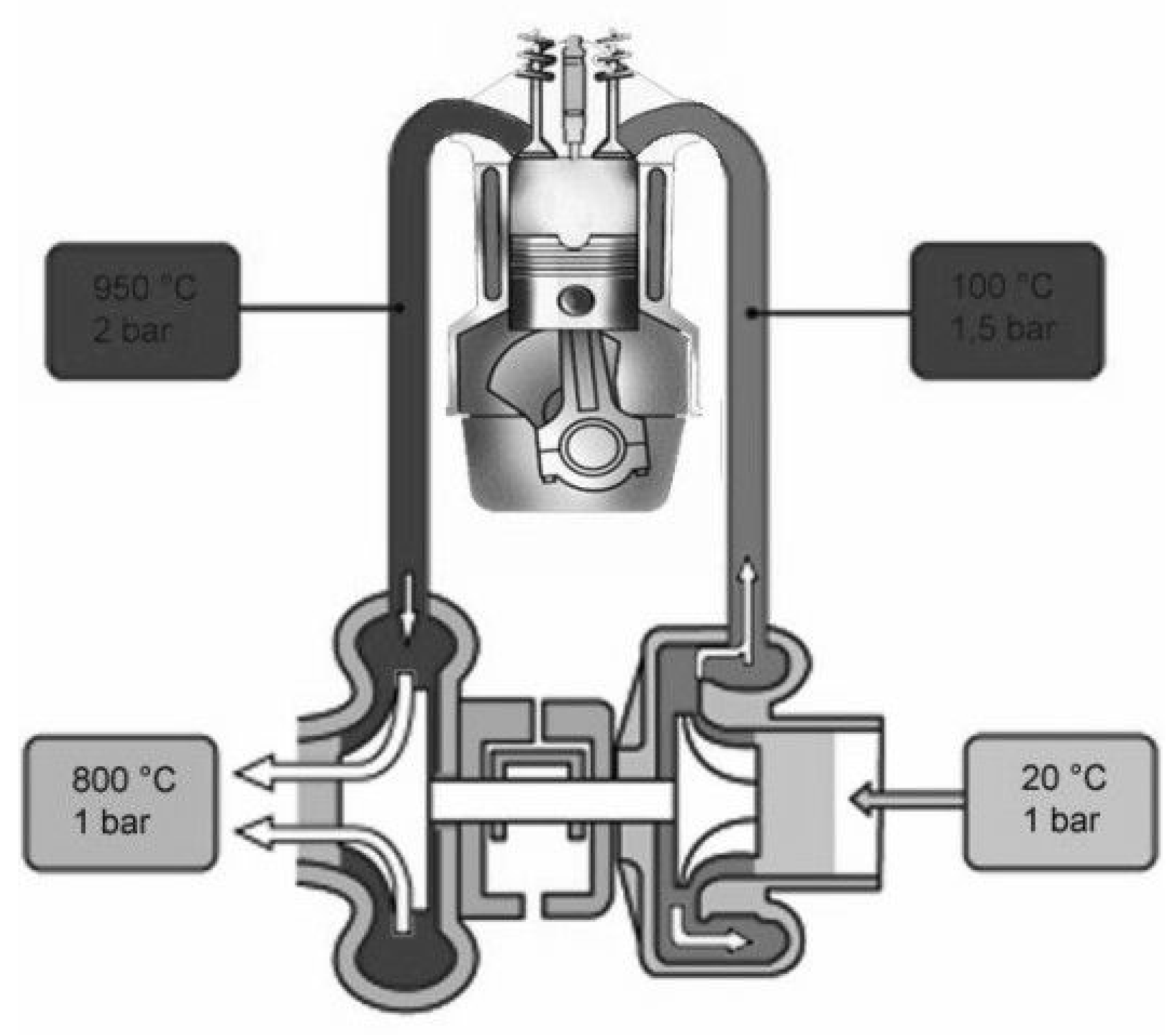

1.1. The Connection between a Turbocharger and a Spark-Ignition Engine

- -

- reducing the compression ratio;

- -

- improving the roadholding by considering the quality of additional accessories (brakes, chassis, suspension) in order to tune the car to the new performances of the engine;

- -

- calibration of the turbocharger (TS unit) with the engine (perfect cooperation of the TS with the other systems and engine units), which requires a significant number of tests be conducted on stands and on the road;

- -

- correction of ignition advance curves;

- -

- use of reinforced pistons;

- -

- use of a more mechanically and thermally resistant cylinder head gasket;

- -

- crankshaft consolidation;

- -

- modification of the intake route;

- -

- modification of the cooling system, in order to obtain a more intense cooling of the upper part of the cylinders and of the cylinder head near the exhaust valve;

- -

- modification of the gas exhaust circuit;

- -

- increasing the capacity of the air filter;

- -

- the lubrication system is improved through the oil flow increase. If necessary, a radiator is inserted in the oil circuit. Forcibly stressed engines require forced cooling of the pistons.

- -

- in the case of a supercharged petrol engine, particular attention must be paid to the study of thermal stresses due to the fact that the motor has a tendency to burn with detonation when stresses upsurge.

- -

- increase of the power per liter (by increasing the dose of the fuel mixture per cycle);

- -

- reduction of noise and chemical pollution;

- -

- reduction of smoke;

- -

- slight reduction in fuel consumption;

- -

- increased silence when evacuating gases;

- -

- improving the operation in terms of altitude;

- -

- reduction of gas dynamic losses;

- -

- increasing the elasticity and adaptability of the engine.

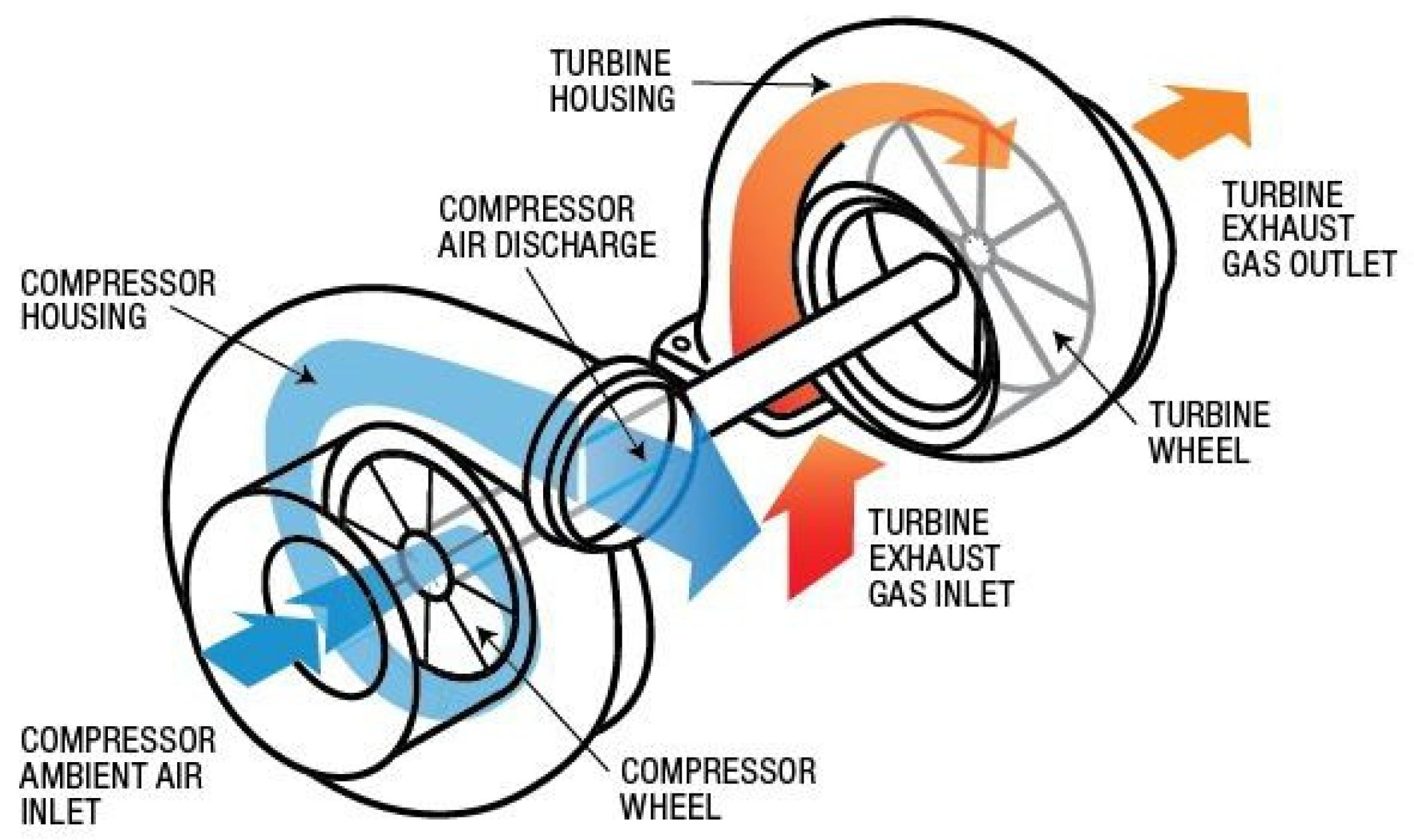

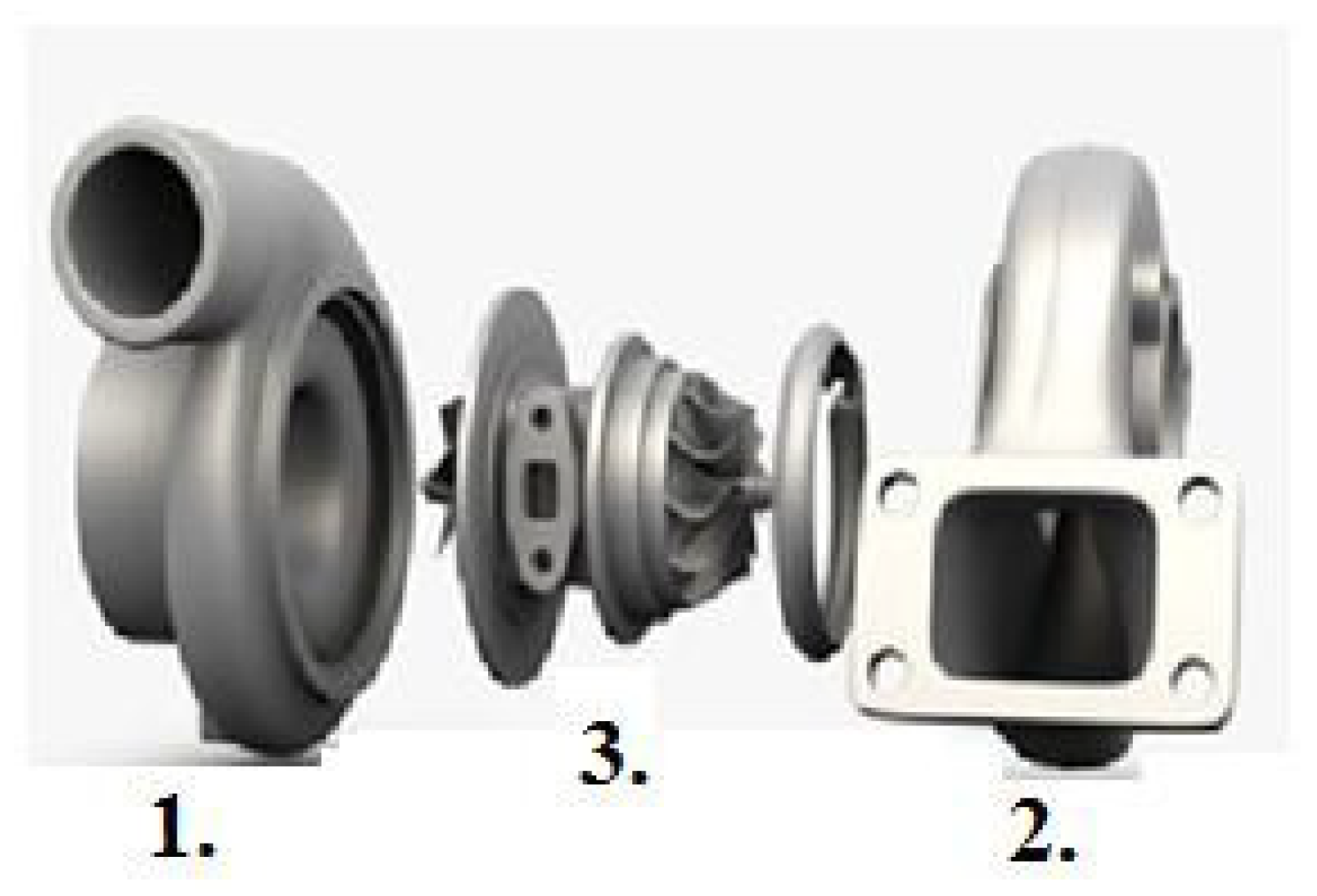

1.2. The Way Turbochargers Work

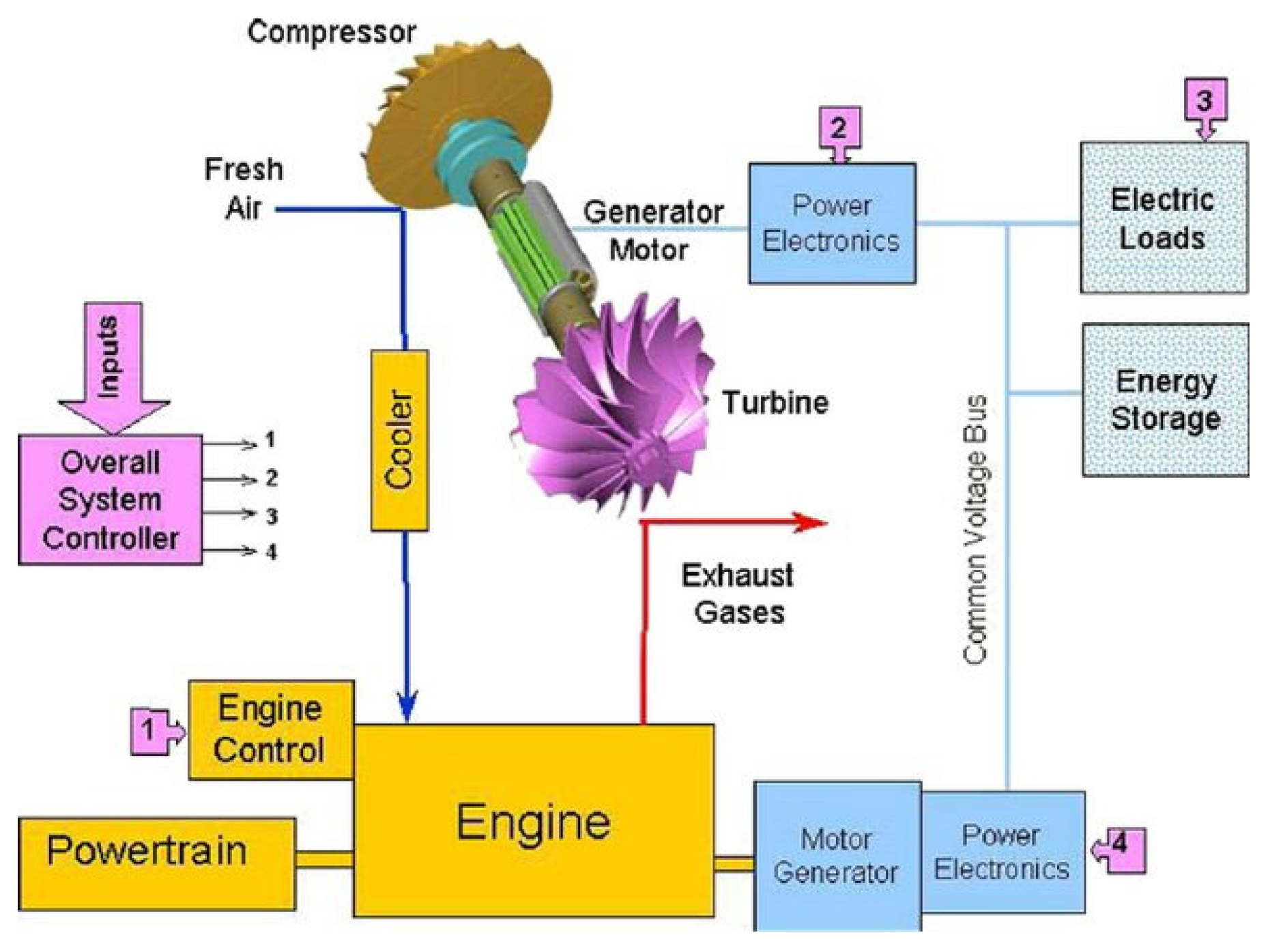

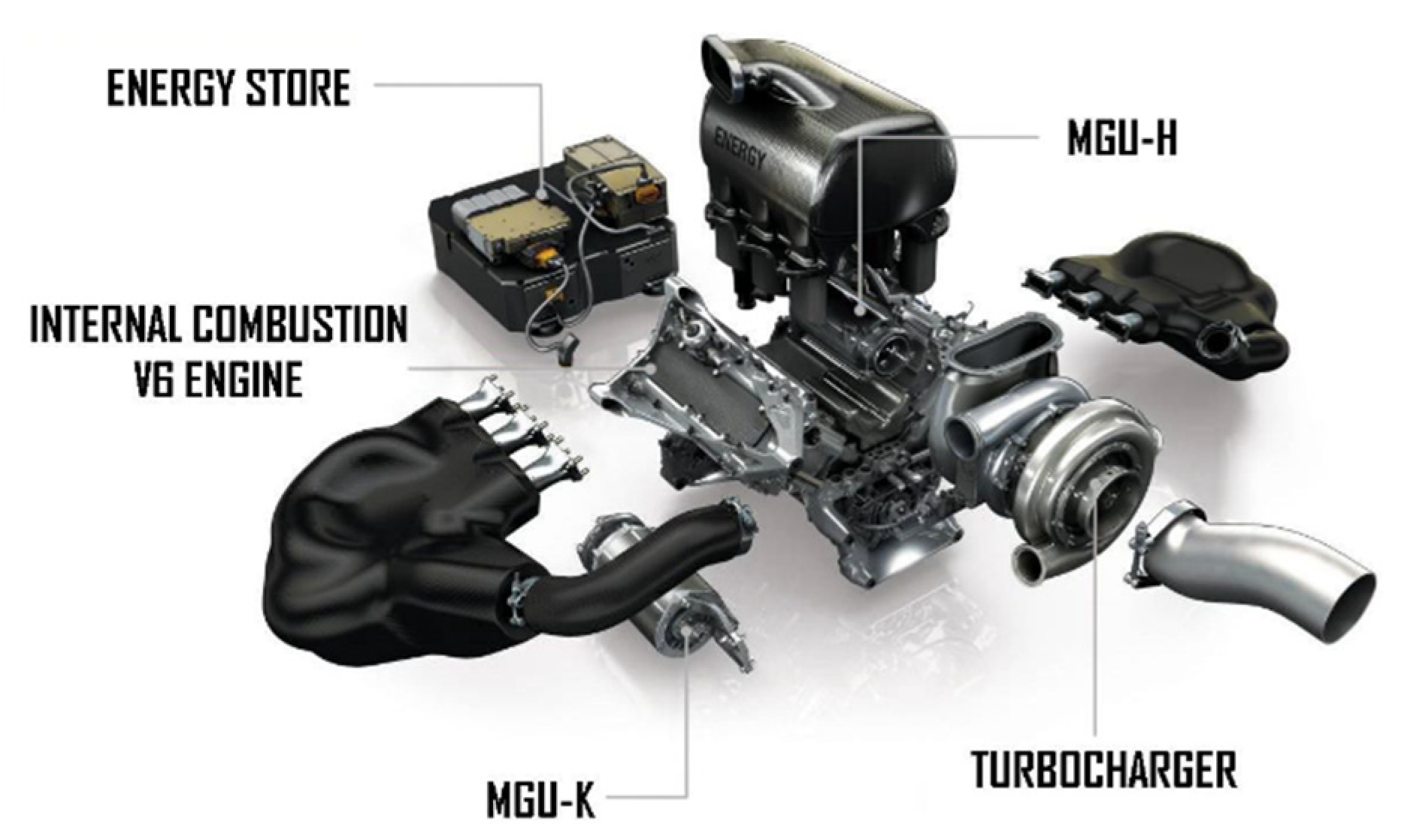

1.3. Hybrid-Electric Turbocharger

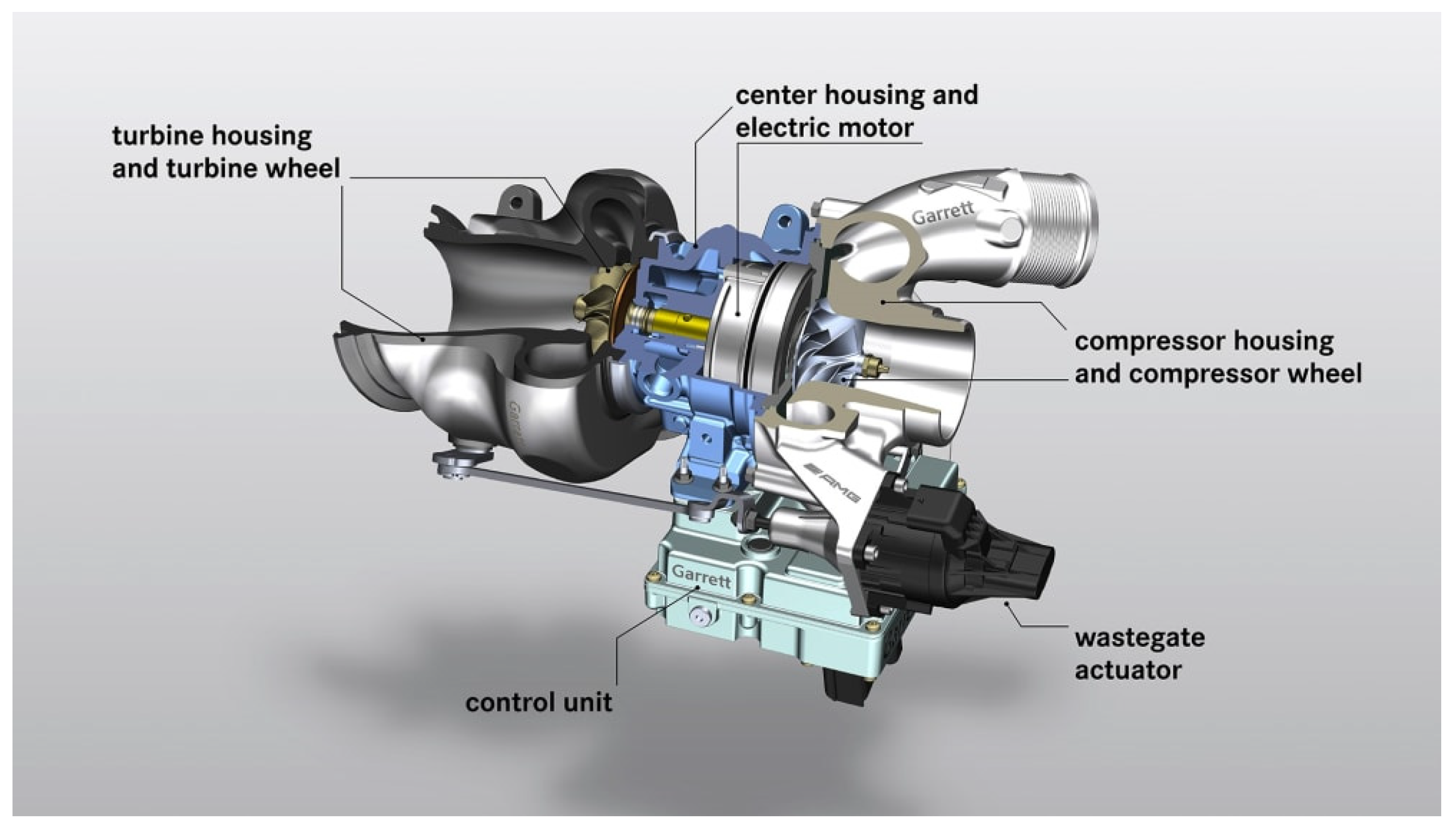

1.4. Electric Drive of the Turbocharger

2. Correlation between HET and Hybrid Vehicles

2.1. Fuel Efficiency and Emissions

2.1.1. Impact of HETs on Fuel Efficiency

2.1.2. Emissions Reduction

2.2. Integration Challenges and Solutions

2.2.1. Technical Challenges

2.2.2. Increased Complexity

2.3. Battery and Energy Management

2.3.1. Synergy with Hybrid Vehicle Battery Systems

2.3.2. Energy Recovery and Efficiency

2.4. Cost-Benefit Analysis

2.4.1. Production Costs

2.4.2. Maintenance Expenses

2.5. Fuel Consumption Savings

3. Materials and Methods

3.1. SWOT Analysis

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| Abbreviation | Definition |

|---|---|

| BTC ECU EV HET MAS MGU-H MGU-K OBD TDC |

Bottom dead center Engine control unit Electric vehicle Hybrid-electric turbocharger Maximum airflow state Motor generator unit - heat Motor generator unit - kinetic On-board diagnostics Top dead center |

References

- Watson, N. Internal Combustion Engines, Chapter Four - Turbocharged Engines. Academic Press, London, UK, 1988. [CrossRef]

- Petrilean, D.C., Irimie, S. I. Operational Influence on the Energetic Efficiency of a Gas Cogenerated Operated Electricity Generator. J EnvironProt Ecol, 17 (4):1464–1471, 2016. [CrossRef]

- Vosniakos, F., Tri, J. Afyllis, J., Prapas, D., Karyda, A., Mentzelou, P., Vasilikiotis, G., Karagiannis, D., Lazou, P., Papastamou, A., Vosniakos, K., Argiriadis, V. Urban Air Pollution Due to Vehicles in Katerini City on Comparison Basis (1999-2006). J EnvironProt Ecol, 9(3):485-493, 2008. https://www.webofscience.com/wos/WOSCC/full-record/000260354500001.

- Turbochargers Working Diagram. https://www.anatomynote.com/industry-and-machinary/industry-scheme/turbo-chargers-working-diagram/ (accessed 02.06.2023).

- Moraal, P. E., Kolmanovsky, I.V. Turbocharger Modeling for Automotive Control Applications. SAE Technical Paper, 1999, 108:1324-1338. [CrossRef]

- Scharf, J., Göcmez, T., Wittler, M., Pischinger, S., Aymanns, R., Steffens, C. Integrating the Turbo Charging System Optimization into the Engine Development. MTZ Worldwide, 2009, 70, 12–19. https://www.osti.gov/etdeweb/biblio/21246534.

- Zhang, Q., Brace, C., Akehurst, S., Burke, R., Capon, G., Smith, L., Garrett, S., Zhang, K. Simulation Study of the Series Sequential Turbocharging for Engine Downsizing and Fuel Efficiency. SAE Technical Papers SAE 2013 World Congress & Exhibition, Montréal, Canada, September 2013, Paper 2. [CrossRef]

- Schweizer, B. Dynamics and Stability of Turbocharger Rotors. Arch Appl Mech, 2010, 80:1017–1043. [CrossRef]

- Mahmoudi, A. R., Khazaee, I., Ghazikhani, M. Simulating the Effects of Turbocharging on the Emission Levels of a Gasoline Engine. Alexandria Engineering Journal, 2017, 56(4):737-748. [CrossRef]

- Martyr, A. J., Plint, M. A. The Design, Building, Modification and Use of Powertrain Test Facilities, Engine testing 4th Edition, Butterworth-Heinemann, London, UK, 2012. https://studylib.net/doc/25751013/a.-j.-martyr--m-a-plint---engine-testing--fourth-edition-...

- Gödeke, H., Prevedel, K. Hybrid Turbocharger with Innovative Electric Motor. MTZ worldwide, 2014, 75(3):26-31. [CrossRef]

- Ono, Y., Shiraishi, K. E., Yamashita, Y. Application of a large hybrid turbocharger for marine electric-power generation. Mitsubishi Heavy Industries Technical Review, 2012, 49(1):29-33. https://api.semanticscholar.org/CorpusID:17325688.

- Dong, H., Zhao, Z., Fu, J., Liu, J., Li, J., Liang, K., Zhou, Q. Experiment and Simulation Investigation on Energy Management of a Gasoline Vehicle and Hybrid Turbocharger Optimization Based on Equivalent Consumption Minimization Strategy. Energy Conversion and Management, 2020, 226, 113518. [CrossRef]

- Shu, G., Liang, Y., Wei, H., Tian, H., Zhao, J., Liu, L. A review of waste heat recovery on two-stroke IC engine aboard ships. Renewable and Sustainable Energy Reviews 2013, 19, 385-401. [CrossRef]

- Gołębiewski, W., Lisowski, M. Analytical Assessment of the Efficiency of the Energy Recovery Process in Decelerating Motion of the Vehicle with Electric or Hybrid Drive in Variable Conditions. IOP Conf. Ser.: Mater. Sci. Eng., 2018, 421(2), 022009. [CrossRef]

- Buchman, M.; Ramanujan, D.; Winter, A. “A Method for Turbocharging Single-Cylinder, Four-Stroke Engines.” SAE International Journal of Engines, 2018, 11(4). [CrossRef]

- Shahed, S. “An Analysis of Assisted Turbocharging with Light Hybrid Powertrain.” SAE Technical Paper 2006-01-0019, 2006. [CrossRef]

- Wang, Y., Biswas, A., Rodriguez, R., Keshavarz-Motamed, Z., Emadi, A. “Hybrid electric vehicle specific engines: State-of-the-art review.” Energy Reports, 2022, 8:832-851. [CrossRef]

- Zhang, Kun; Huang, Xinyu; He, Sai; Deng, Kangyao; Cui, Yi; Luo, Aiqiang. “Study of a Hybrid Modular Exhaust Turbocharging System and Its Application on an 8-cylinder Marine Diesel Engine.” Journal of Mechanical Science and Technology, 2016, 30:2827-2838. [CrossRef]

- Formula Libera - Tecnica. http://www.formulalibera.it/TECNICA.html (accessed 11.06.2023).

- Jain, Achin; Nuesch, Tobias; Nagele, Christian; Lassus, Pedro; Onder, Christopher. Modeling and Control of a Hybrid Electric Vehicle With an Electrically Assisted Turbocharger. IEEE Transactions on Vehicular Technology 2016, 65, 1-1. [CrossRef]

- Lee, T. W., Hong, D. K. Electrical and Mechanical Characteristics of a High-Speed Motor for Electric Turbochargers in Relation to Eccentricity. Energies, 2021, 14(11):3340. [CrossRef]

- Conceptcarz.com - Turbocharging. https://conceptcarz.com/articles/article.aspx?articleID=2536&hcb=1 (11.06.2023).

- Suzuki, T., Hirai, Y., Ikeya, N. Electrically Assisted Turbocharger as an Enabling Technology for Improved Fuel Economy in New European Driving Cycle Operation. 11th International Conference on Turbochargers and Turbocharging 1st Edition, Sawston, UK, 2014, 217-226. [CrossRef]

- Autoentusiastas Classic - F1 2014. http://www.autoentusiastasclassic.com.br/2014/01/f-1-2014-o-que-muda-nos-carros-e-como.html?hcb=1&m=1 (accessed 18.06.2023).

- Chiriac, R.-L., Condrea, O., Anghel, C., “The analysis of a hybrid turbocharger main parameters applied to an internal combustion engine.” IOP Conference Series: Materials Science and Engineering, 1220, 012010, 2022. [CrossRef]

- Chiriac, R.-L., Anghel, C., Condrea, O. “New Hybrid Turbochargers Solutions for Special Military Vehicles with Internal Combustion Engines.” International conference KNOWLEDGE-BASED ORGANIZATION, 26:64-72, 2020. [CrossRef]

- Yin, Y., Mi, J., Zhao, Y., Liu, Z., & Li, P. “Research on E-Boost Technology for Medium-Duty Diesel Engines.” Neiranji Gong-cheng/Chinese Internal Combustion Engine Engineering, 43:94-100, 2022. [CrossRef]

- Wang, Z., Cui, J., Zhang, L., Song, X. Control Strategy for Hybrid Electric Turbocharging System Based on Turbocharger Characteristics. Journal of Clean Energy Technologies, 2015, 3(5):324–328, Oct. 2015. https://www.researchgate.net/publication/298231293_Control_strategy_for_series_hybrid-power_vehicle.

- Tian, Feng, Ren, Guofeng, Zhang, Shumei, & Yang, Lin. “Analysis and Simulation of Hybrid Electric Turbocharger and Application on ICE and HEV.” Lecture Notes in Electrical Engineering, 190, 1193-1200, 2013. [CrossRef]

- Schweizer, B. Dynamics and stability of turbocharger rotors. Arch. Appl. Mech. 2010, 80, 1017–1043. [CrossRef]

- Chasalevris A., Louis J.-C. Evaluation of transient response of turbochargers and turbines using database method for the nonlinear forces of journal bearings, 2019, Lubricants, 7 (9), art. no. 78. [CrossRef]

- Chasalevris, A. An investigation on the dynamics of high-speed systems using nonlinear analytical floating ring bearing models. Int. J. Rotat. Mach. 2016, 7817134. [CrossRef]

- San Andres, L.; Rivadeneira, J.C.; Gjika, K.; Groves, C.; LaRue, G. Rotordynamics of small turbochargers supported on floating ring bearings—highlights in bearing analysis and experimental validation. ASME J. Tribol. 2007, 129, 391–397. [CrossRef]

- Mestemaker, B., Westhoeve, J., and Visser, K., Evaluation of Hybrid Electric Turbocharging for Medium Speed Engines, SAE Technical Paper 2019-24-0188, 2019. [CrossRef]

- D. Zhao, R. Stobart and B. Mason, Real-Time Energy Management of the Electric Turbocharger Based on Explicit Model Predictive Control, IEEE Transactions on Industrial Electronics, 67(4), pp. 3126-3137, 2020. [CrossRef]

- Lee T-W, Hong D-K., Performance Validation of High-Speed Motor for Electric Turbochargers Using Various Test Methods, Electronics, 12(13):293, 2023. [CrossRef]

- Capata R, Sciubba E. Study, Development and Prototyping of a Novel Mild Hybrid Power Train for a City Car: Design of the Turbocharger, Applied Sciences, 11(1):234, 2021. [CrossRef]

- Scheub, J., Zecchetti, D., Habermann, J., Maniar M., Increased Efficiency and Performance with the Electric Turbocharger. MTZ Worldw 82, 74–80, 2021. https://www.springerprofessional.de/en/increased-efficiency-and-performance-with-the-electric-turbochar/19739208.

- Terdich, N., Martinez-Botas, R. F., Romagnoli, A., and Pesiridis, A., “Mild Hybridization via Electrification of the Air System: Electrically Assisted and Variable Geometry Turbocharging Impact on an Off-Road Diesel Engine.” ASME. J. Eng. Gas Turbines Power. 2014; 136(3):031703. [CrossRef]

- Terdich, N., Martinez-Botas, R. F., Howey, D. A., and Copeland, C. D., 2011, “Off-Road Diesel Engine Transient Response Improvement by Electrically Assisted Turbocharging,” 10th International Conference on Engines and Vehicles (ICE2011), Capri, Italy, September 11–15, Paper No. 2011-24-0127. [CrossRef]

- Ibaraki, S., Yamashita, Y., Sumida, K., Ogita, H., and Jinnai, Y., 2006, “Development of the ‘Hybrid Turbo,’ an Electrically Assisted Turbocharger,” Mitsubishi Heavy Ind. Tech. Rev., 43(3):1–5. https://api.semanticscholar.org/CorpusID:39141881.

- Bumby, J., Spooner, E., and Jagiela, M., “Solid Rotor Induction Machines for Use in Electrically-Assisted Turbochargers,” 3rd IET International Conference on Power Electronics, Machines and Drives, Dublin, Ireland, April 4–6, pp. 341–345, 2006. [CrossRef]

- Terdich, N., 2011, Turbocharger Turbine Aerodynamic Performance Improvement by Electrical Assist. Project Progress Report, Imperial College London, London, UK.

- Mihaylov, M.; Stoyanov, I.; Iliev, T. Reduction of the Battery Capacity of Hybrid Electric Vehicle with the Help of Electrically Assisted Turbocharger. E3S Web Conf. 2021, 327, 04003. [CrossRef]

- Capata, R. Experimental Fitting of Redesign Electrified Turbocompressor of a Novel Mild Hybrid Power Train for a City Car. Energies 2021, 14, 6516. [CrossRef]

- Kerviel, A.; Pesyridis, A.; Mohammed, A.; Chalet, D. An Evaluation of Turbocharging and Supercharging Options for High-Efficiency Fuel Cell Electric Vehicles. Appl. Sci. 2018, 8, 2474. [CrossRef]

- Capata, R. “Turbocharged Decoupling and Turbine Electrification Design for Mild-Hybrid Vehicle.” Proceedings of the ASME 2021 International Mechanical Engineering Congress and Exposition. 8A: Energy. Virtual, Online. November 1–5, 2021. [CrossRef]

- Baek, S.; Lee, H.; Lee, K. Fuel efficiency and exhaust characteristics of turbocharged diesel engine equipped with an electric supercharger. Energy 2021, 214, 119049. [CrossRef]

- Zamboni, G.; Moggia, S.; Capobianco, M. Hybrid EGR and turbocharging systems control for low NOX and fuel consumption in an automotive diesel engine. Applied Energy 2016, 165, 839-848. [CrossRef]

- Zi, D.; Zhang, L.; Chen, B.; Zhang, Q. Study of the electric-booster and turbo-generator system and its influence on a 1.5 L gasoline engine. Applied Thermal Engineering 2019, 162, 114236. [CrossRef]

- Dimitriou, P.; Burke, R.; Zhang, Q.; Copeland, C.; Stoffels, H. Electric Turbocharging for Energy Regeneration and Increased Efficiency at Real Driving Conditions. Appl. Sci. 2017, 7, 350. [CrossRef]

- Ekberg, K.; Eriksson, L. Improving Fuel Economy and Acceleration by Electric Turbocharger Control for Heavy Duty Long Haulage. IFAC-PapersOnLine 2017, 50(1):11052-11057. [CrossRef]

- Gödeke, H.; Prevedel, K. Hybrid Turbocharger with Innovative Electric Motor. MTZ Worldw 2014, 75:26–31.

- Baek, S.; Woo, S.; Kim, Y.; Lee, K. Prediction of turbocharged diesel engine performance equipped with an electric super-charger using 1D simulation. Energy 2019, 185:213-228. ISSN 0360-5442. [CrossRef]

- Lei, Y.; Zhou, D.S.; Zhang, H.G. Investigation on performance of a compression-ignition engine with a pressure-wave su-percharger. Energy 2010, 35(1):85-93. [CrossRef]

- Turner, J. W. G., et al. “SuperGen on Ultraboost: Variable-Speed Centrifugal Supercharging as an Enabling Technology for Extreme Engine Downsizing.” SAE International Journal of Engines, 2015, 8(4):1602–15. [CrossRef]

- Katrasˇnik, T.; Rodman, S.; Trenc, F.; Hribernik, A.; Medica, V “Improvement of the Dynamic Characteristic of an Automotive Engine by a Turbocharger Assisted by an Electric Motor.” Journal of Engineering for Gas Turbines and Power, 2003, 125(2):590–595. [CrossRef]

- Ibaraki, S.; Yamashita, Y.; Sumida, K.; Ogita, H.; Jinnai, Y. “Development of the ‘hybrid turbo,’ an electrically assisted tur-bocharger.” Mitsubishi Heavy Industries, Ltd. Technical Review, 43(3), 2006.

- Burke, Richard D. A Numerical Study of the Benefits of Electrically Assisted Boosting Systems. Journal of Engineering for Gas Turbines and Power, 2016, 138(9):092808. [CrossRef]

- Bumby JR, Spooner ES, Carter J, Tennant H, Mego GG, Dellora G, Gstrein W, Sutter H, Wagner J. Electrical Machines for Use in Electrically Assisted Turbochargers. In Second International Conference on Power Electronics, Machines and Drives, 2004, 1:344-349. IET. [CrossRef]

- Bumby, Jim; Crossland, Sue; Carter, Jeff. Electrically Assisted Turbochargers: Their Potential for Energy Recovery. IET-The Institution of Engineering and Technology Hybrid Vehicle Conference 2006. [CrossRef]

- Terdich, Nicola; Martinez-Botas, Ricardo. Experimental Efficiency Characterization of an Electrically Assisted Turbocharger. SAE Technical Paper, 2013, No. 2013-24-0122. [CrossRef]

- Hopmann, Ulrich; Algrain, Marcelo C. Diesel Engine Electric Turbo Compound Technology. SAE Technical Paper, 2003, No. 2003-01-2294. [CrossRef]

- Ibaraki, Seiichi, et al. Development of the Hybrid Turbo, an Electrically Assisted Turbocharger. Mitsubishi Heavy Industries Technical Review, 2006,43(3):1-5. https://www.mhi.co.jp/technology/review/pdf/e582/e582140.pdf.

- Kattwinkel, Thomas; Weiss, Robert; Boeschlin, Jean-Philippe. Mechatronic Solution for Electronic Turbocharger. SAE Technical Paper, 2003, No. 2003-01-0712. [CrossRef]

- Arsie, I., Cricchio, A., Pianese, C., De Cesare, M., & Nesci, W. A Comprehensive Powertrain Model to Evaluate the Benefits of Electric Turbo Compound (ETC) in Reducing CO2 Emissions from Small Diesel Passenger Cars. SAE Technical Paper, 2014, No. 2014-01-1650. [CrossRef]

- Mizushima, Norifumi; Oguma, Mitsuharu. Energy Conversion Analysis for Mild Hybrid Electric Vehicles Equipped with an Electric Supercharged SI Engine via Multi-domain Acausal Modeling. Energy Conversion and Management, 2023, 286:117054. [CrossRef]

- Bumby, Jim; Crossland, Sue; Carter, Jeff. “Electrically Assisted Turbochargers: Their Potential for Energy Recovery.” The Institution of Engineering and Technology Hybrid Vehicle Conference, 2006, pp. 43-52. [CrossRef]

- Bin Mamat, A.M.I.; Martinez-Botas, R.F.; Rajoo, S.; Romagnoli, A.; Petrovic, S. “Waste Heat Recovery Using a Novel High-Performance Low-Pressure Turbine for Electric Turbocompounding in Downsized Gasoline Engines: Experimental and Computational Analysis.” Energy, 2015, 90(1):218-234. [CrossRef]

- Pipitone, E.; Caltabellotta, S.; Sferlazza, A.; Cirrincione, M. “Hybrid Propulsion Efficiency Increment through Exhaust Energy Recovery—Part 2: Numerical Simulation Results.” Energies, 2023; 16(5):2232. [CrossRef]

- Wei, W.; Zhuge, W.; Zhang, Y.; He, Y. “Comparative Study on Electric Turbo-Compounding Systems for Gasoline Engine Exhaust Energy Recovery.” Proceedings of the ASME Turbo Expo 2010: Power for Land, Sea, and Air. Volume 5: Industrial and Cogeneration; Microturbines and Small Turbomachinery; Oil and Gas Applications; Wind Turbine Technology. Glasgow, UK. June 14–18, 2010. pp. 531-539. [CrossRef]

- Chen, Bin; Zhang, Li; Han, Jinlin; Zhang, Qing. “A Combination of Electric Supercharger and Miller Cycle in a Gasoline Engine to Improve Thermal Efficiency Without Performance Degradation.” Case Studies in Thermal Engineering, 2019, 14:100429. [CrossRef]

- Berg, H.P. et al. “Hybrid Turbo Compound Fan Engine: An Eco-Efficient Propulsion System for Aviation.” IOP Conference Series: Materials Science and Engineering, 886, 2020, Article 012010. [CrossRef]

- Inman, S.; El-Gindy, M.; Haworth, D.C. “Hybrid Electric Vehicles Technology and Simulation: Literature Review.” International Journal of Heavy Vehicle Systems, 2003, 10(3):167-187. [CrossRef]

- Pasini, Gianluca; Lutzemberger, Giovanni; Frigo, Stefano; Marelli, Silvia; Ceraolo, Massimo; Gentili, Roberto; Capobianco, Massimo. “Evaluation of an Electric Turbo Compound System for SI Engines: A Numerical Approach.” Applied Energy, 2016, 162:527-540. [CrossRef]

- Eggimann, F.; Frigo, S.; Lutzemberger, G.; Pasini, G. et al. “Numerical Analysis of Electrically Assisted Turbocharger Application on Hybrid Vehicle.” SAE Technical Paper 2021-01-5090, 2021. [CrossRef]

- Carpenter, A.L.; Beechner, T.L.; Tews, B.E.; Yelvington, P.E. “Hybrid-Electric Turbocharger and High-Speed SiC Variable-Frequency Drive Using Sensorless Control Algorithm.” ASME Journal of Engineering for Gas Turbines and Power, 2018; 140(12): 122801. [CrossRef]

- Pipitone, E.; Caltabellotta, S.; Beccari, S.; Lanzafame, R. et al. “Realistic Steady State Performance of an Electric Turbo-Compound Engine for Hybrid Propulsion System.” SAE Technical Paper 2022-24-0015, 2022. [CrossRef]

- Figari, Massimo; Theotokatos, Gerasimos; Coraddu, Andrea; Stoumpos, Sokratis; Mondella, Teresa. “Parametric Investigation and Optimal Selection of the Hybrid Turbocharger System for a Large Marine Four-Stroke Dual-Fuel Engine.” Applied Thermal Engineering, 2022, 208:117991. [CrossRef]

| HET on Thermal Engine | Classic Turbocharger on Thermal Engine | |

|---|---|---|

| Strengths | - Improved engine responsiveness | - Established technology |

| - Enhanced fuel efficiency | - Proven performance in traditional engines | |

| - Contribution to eco-friendly transportation solutions | - Commonly used and understood in the industry | |

| Weaknesses | - Increased complexity in powertrain system | - Turbo lag may be present - Limited efficiency at lower engine speeds |

| - Maintenance challenges and costs - Elevated overall vehicle cost |

- Less energy recovery potential | |

| Opportunities | - Growing market for eco-friendly vehicles | - Continuous improvement and optimization of traditional turbochargers |

| - Opportunities for further refinement in HET integration | - Integration with advanced engine management systems | |

| - Government incentives and fuel efficiency regulations | - Adoption in emerging markets | |

| Threats | - Competition from fully electric vehicles | - Evolving emission standards |

| - Consumer perceptions about hybrid system complexity | - Potential market preference for electric propulsion |

| HET on Thermal Engine | HET on Hybrid Engine | |

|---|---|---|

| Strengths | - Improved engine responsiveness | - Enhanced synergy with hybrid systems |

| - Enhanced fuel efficiency | - Optimized collaboration with electric motor | |

| - Contribution to eco-friendly transportation solutions | - Efficient energy recovery during deceleration | |

| Weaknesses | - Increased complexity in powertrain system | - Technical challenges in coordination with hybrid components |

| - Maintenance challenges and costs - Elevated overall vehicle cost |

- Potential issues in transient response and torque delivery - Specialized training required for technicians |

|

| Opportunities | - Growing market for eco-friendly vehicles | - Integration with advanced hybrid vehicle technologies |

| - Opportunities for further refinement in HET integration | - Advancements in predictive maintenance technologies | |

| - Government incentives and fuel efficiency regulations | - Market demand for fuel-efficient hybrid systems | |

| Threats | - Competition from fully electric vehicles | - Evolving hybrid technology standards |

| - Consumer perceptions about hybrid system complexity | - Potential challenges in market acceptance |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).