Submitted:

03 February 2024

Posted:

07 February 2024

You are already at the latest version

Abstract

Keywords:

Introduction

Inaccuracies in Model Structure

Digital Data Issues

Risk Management of Transportation Simulation in WSCs

Partial Optimization of WSC Network Models

Reducing Inaccuracies in Dynamics by Right Model

Accuracy of Spatial data in GIS for WSC Modelling

- -

- A dataset fulfilling the requirements is not available or is too expensive,

- -

- Collecting the required data independently is too laborious or expensive,

- -

- Data processing capacity is insufficient with regard to the high spatial resolution, or

- -

- The importance of spatial information is low in relation to the needs.

Discussion

Prospects in Near Future

- -

- Plenty of manual work in different ERP systems,

- -

- Scattered Data in separated parts of WSC and not easily available for analysis and actions,

- -

- Lack of resources for development of WSC and its DDMs of DSS in ERP systems,

- -

- Old and rigid standards, codes and network platforms.

- -

- Faster collaboration through better access to standardized data,

- -

- Local data is easier to use than before,

- -

- Many of the manual tasks have been automated,

- -

- User experience has been improved through user friendly solutions,

- -

- Communication is more efficient by mobile tools,

- -

- International standardized data format is comparable for additional analysis.

Cloud Platform-Based ERP and DDM for Collaboration and Group Decision Making of WSC

Conclusions

Conflicts of Interest

Human and Animal Rights

References

- Papers of particular interest, published recently, have been highlighted as:.

- Of importance.

- Of major importance.

- Gavilanes Montoya AV, Castillo Vizuete DD, Marcu MV. Exploring the Role of ICTs and Communication Flows in the Forest Sector. Sustainability. 2023;15(14):10973. [CrossRef]

- •Palander, T. Outsourcing Issues of Wood Supply Chain Management in the Forest Industry. For Sci. 2022;68(5-6):521–532. This document introduces thoroughly the current state of outsourcing in forest supply chains e.g., both wood procurement chain and wood supply chain. [CrossRef]

- Palander T, Hecker M, Forss E, Toivonen M. Cultural Differences Influencing the Use of ICT and Forest Technology in German and Finnish Foresters’ Work. Research Notes. 2002;136:1–24. https://www.researchgate.net/scientific-contributions/Mari-Toivonen-2010673451.

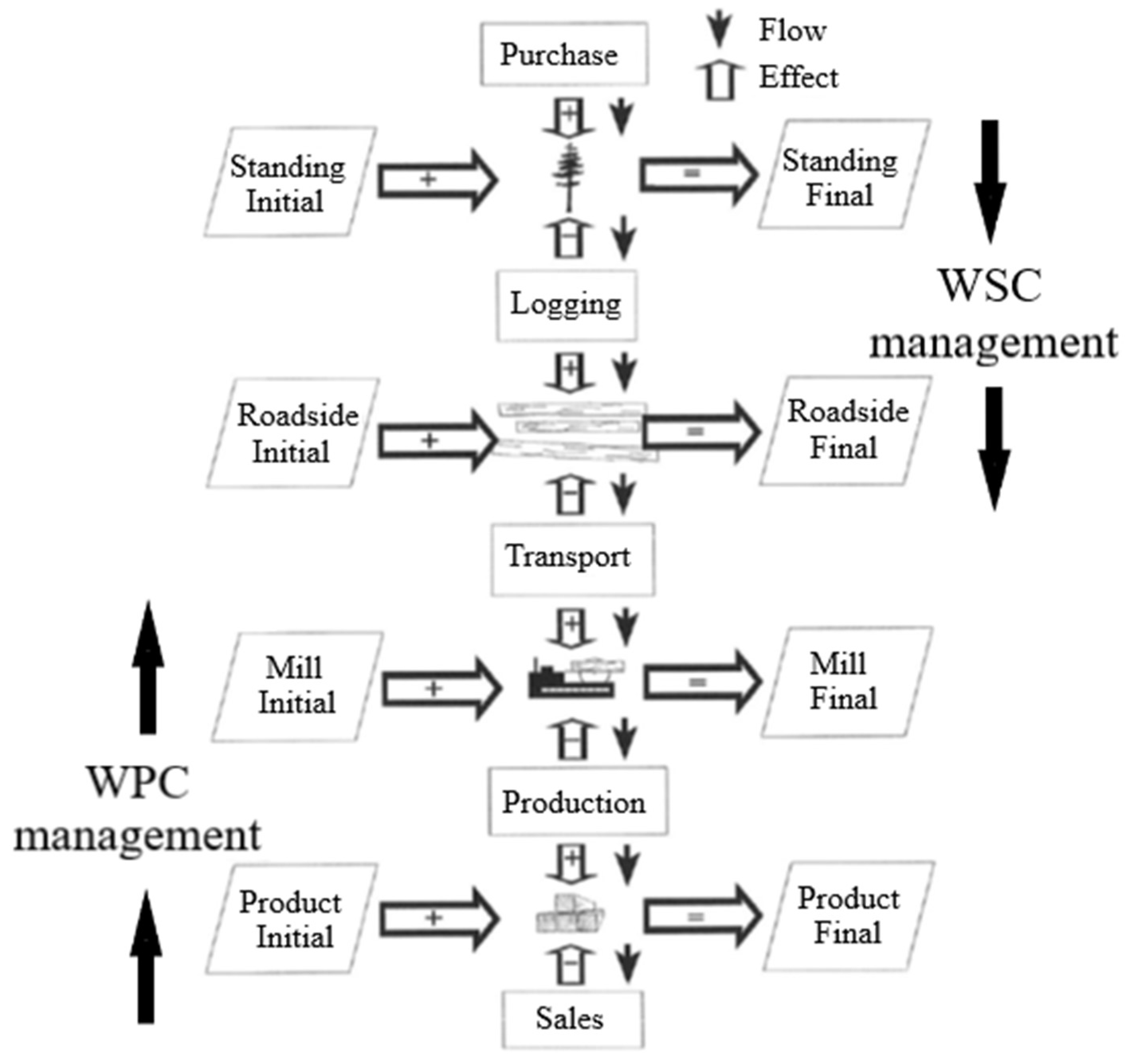

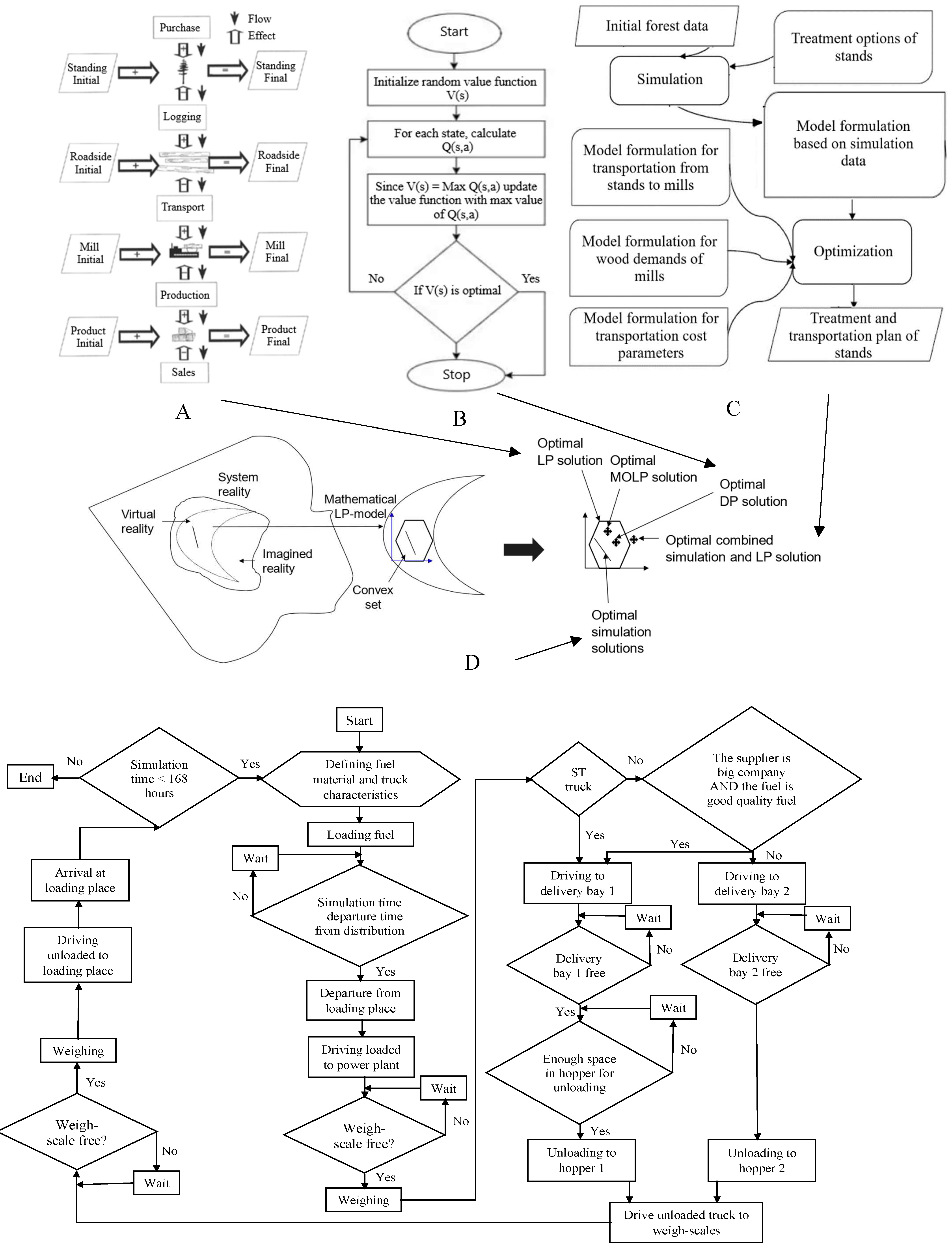

- •Palander T. Tactical Models of Wood-Procurement Teams for Geographically Decentralized Group Decision Making. D.Sc. Thesis. University of Eastern Finland, Finland. 1998. Comprehensive analysis of dynamics of wood procurement of forest industry issues supporting the translation of knowledge from static models into dynamic logistics network assessments which is more appealing to forest supply chain stakeholders.

- Anon 2022. Finnish Sawmills Association. https://woodfromfinland.fi/why-finnish-wood/.

- Palander T. Data-Driven Internal Carbon Pricing Mechanism for Improving Wood Procurement in Integrated Energy and Material Production. Energies. 2023;16(8):3473. [CrossRef]

- •Scholz J, De Meyer A, Marques AS, Pinho TM, Boaventura-Cunha J, Van Orshoven J, Rosset C, Künzi J, Jaakola K, Nummila K. Digital Technologies for Forest Supply Chain Optimization: Existing Solutions and Future Trends. Environ Manage. 2018;62:1108–1133. This paper deals with digital technologies in forest-based supply chains which integrate multiple process data collection tools. [CrossRef]

- ••Cambero C, Sowlati T. Assessment and optimization of forest biomass supply chains from economic, social and environmental perspectives – A review of literature. Renew Sustain Energy Rev. 2014;36:62–73, https://doi.org/10.1016/j.rser.2014.04.041. This paper is useful for forest supply chain modelers aiming to provide assessments of the impacts of renewable and sustainable energy options: it can be used to identify those models for which basic data are at present lacking. [CrossRef]

- Kogler C, Rauch P. A discrete-event simulation model to test multimodal strategies for a greener and more resilient wood supply. Can J For Res. 2019;49(10):1298–1310.

- Rauch, P. Stochastic simulation of forest fuel sourcing models under risk. Scand J For Res. 2010;25(6):574–584.

- van Oijen M.Bayesian Methods for Quantifying and Reducing Uncertainty and Error in Forest Models. Curr For Rep. 2017;3:269–280. [CrossRef]

- D’Amours S, Rönnqvist M, Weintraub A. Using operational research for supply chain planning in the forest products industry. INFOR: Information Systems and Operational Research. 2008;46(4):265–281.

- Rönnqvist M. Optimization in forestry. Math Program. 2003;97(1-2):267–284.

- Bravo MDL, Naim MM, Potter A. Key issues of the upstream segment of biofuels supply chains: a qualitative analysis. Logist Res. 2012;5(1-2):21–31.

- De Meyer A, Cattrysse D, Van Orshoven J. A generic mathematical model to optimize strategic and tactical decisions in biomass-based supply chains (OPTIMASS). Eur J Oper Res. 2015;245(1):247–264.

- Wee HM, Yang WH, Chou CW, Padilan MV. Renewable energy supply chains, performance, application barriers and strategies for further development. Renew Sustain Energy Rev. 2012;16:5451–5465.

- Palander T, Haavikko H, Kärhä K. Towards sustainable wood procurement in forest industry — The energy efficiency of larger and heavier vehicles in Finland. Renew Sustain Energy Rev. 2018;96:100–118.

- Jonkman J. Bridging process engineering and supply chain design for agro-food processing chains. D.Sc. Thesis. University of Wageningen, Nederland. 2018. 132 p. ISBN 978-94-6343-338-9. [CrossRef]

- Palander T, Toivonen M, Laukkanen S. GroupWare and group decision support systems for wood procurement organisation. A review. Silva Fenn. 2002;36(2):585–600. [CrossRef]

- Yu T, Wang X. Real-Time Data Analytics in Internet of Things Systems. In: Tian YC, Levy DC, (eds). Handbook of Real-Time Computing. Springer, Singapore. 2022. [CrossRef]

- Rossit DA, Olivera A, Céspedes VV, Broz D. A Big Data approach to forestry harvesting productivity. Computers and Electronics in Agriculture. 2019;161:29–52. [CrossRef]

- Palander T, Ovaskainen H, Tikkanen L. An Adaptive Work Study Method for Identifying the Human Factors that Influence the Performance of a Human-Machine System. For Sci. 2012;58(4);377–389. [CrossRef]

- Palander T, Nuutinen Y, Kariniemi A, Väätäinen K. Automatic Time Study Method for Recording Work Phase Times of Timber Harvesting. For Sci. 2013;59(4):472–483. [CrossRef]

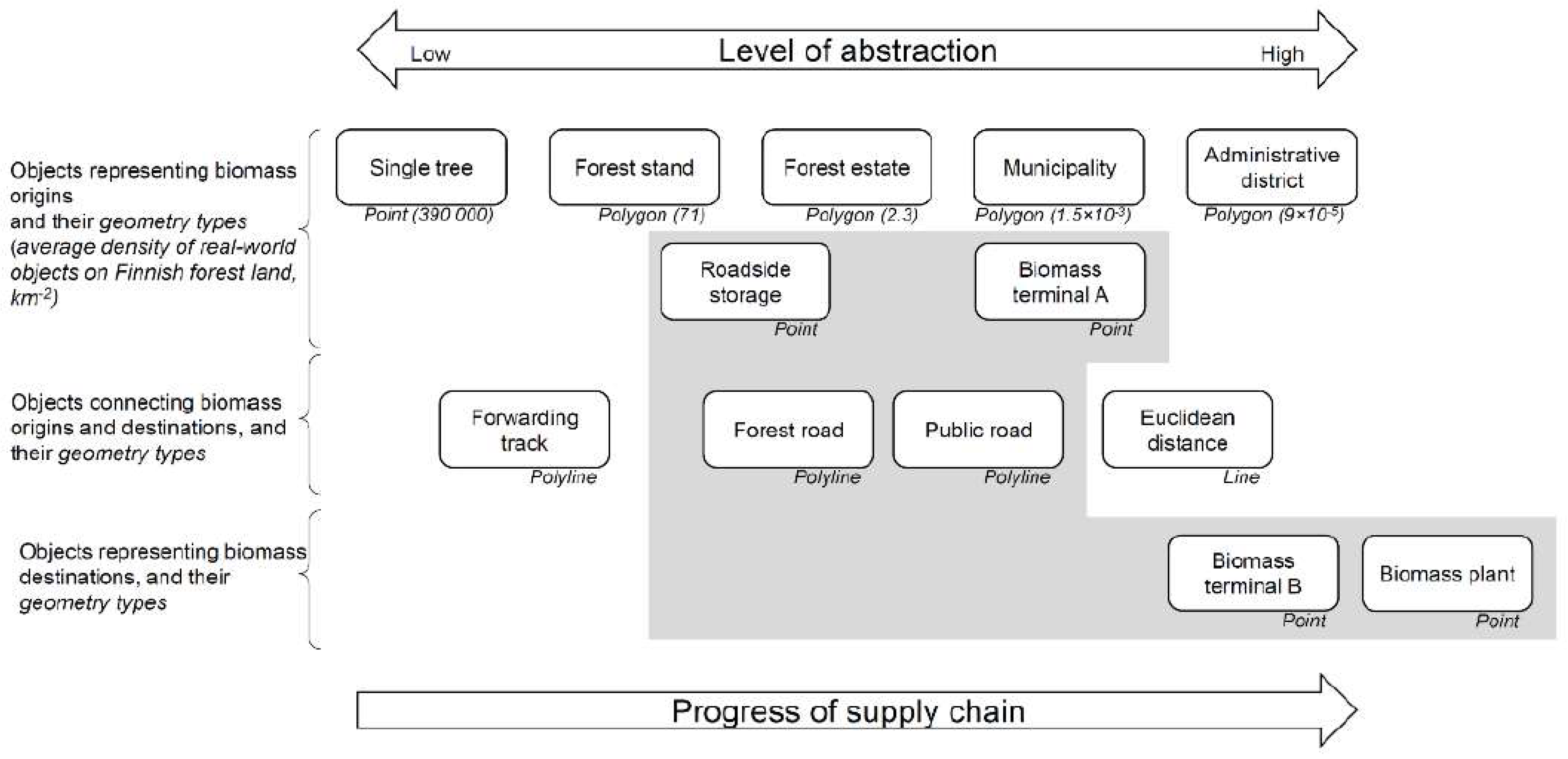

- ••Korpinen, O-J. 2021. Spatial forest biomass supply chain analysis in Finland. Dissertationes Forestales 323. The paper is describing broadly the GIS based data management concepts for biomass supply chain and presenting various examples with current GIS-data alternatives. [CrossRef]

- Kankare V, Vauhkonen J, Tanhuanpää T, Holopainen M, Vastaranta M, Joensuu M, Krooks A, Hyyppä J, Hyyppä H, Alho P, Viitala R. Accuracy in estimation of timber assortments and stem distribution – A comparison of airborne and terrestrial laser scanning techniques. ISPRS J Photogramm Remote Sens. 2014;97:89–97. [CrossRef]

- Sanz, B. 2022. Methods for supporting digital timber trade. Dissertationes Forestales 326. [CrossRef]

- Rodrigue J-P. The Geography of Transport Systems, Fifth edition. Routledge, New York. 2020.

- ••Nayak S, Patgiri R, Waikhom L, Ahmed A. A review on edge analytics: Issues, challenges, opportunities, promises, future directions, and applications. Digital Communications and Networks 2022. This article introduces state-of-the-art of edge devices, edge computing, and edge analytics to analyze data and to solve many problems and applications in agriculture and industry. [CrossRef]

- Ott M, Shin W, Bourassa N, Wilde T, Ceballos S, Romanus M, Bates N. Global Experiences with HPC Operational Data Measurement, Collection and Analysis, in 2020 IEEE International Conference on Cluster Computing (CLUSTER), Kobe, Japan. 2020. pp. 499–508. [CrossRef]

- •Palander T, Takkinen J. Data-driven modeling of CO2 emission-allowance compensation for wood-purchasing optimization toward carbon–neutral forest industry. Optim Eng. 2022;23:2091–2110. In this work, prescriptive data analytics of data-driven modelling support tactical and strategic decision making for WSC management in practice. [CrossRef]

- Rossi, B. 2014. IT operations analytics: Changing the IT perspective. Information Age. https://www.information-age.com/it-operations-analytics-changing-it-perspective-29336/. 2933. [Google Scholar]

- Bellman, R. Dynamic Programming Treatment of the Travelling Salesman Problem. J Assoc Comput Mach. 1962;9:61–63. [CrossRef]

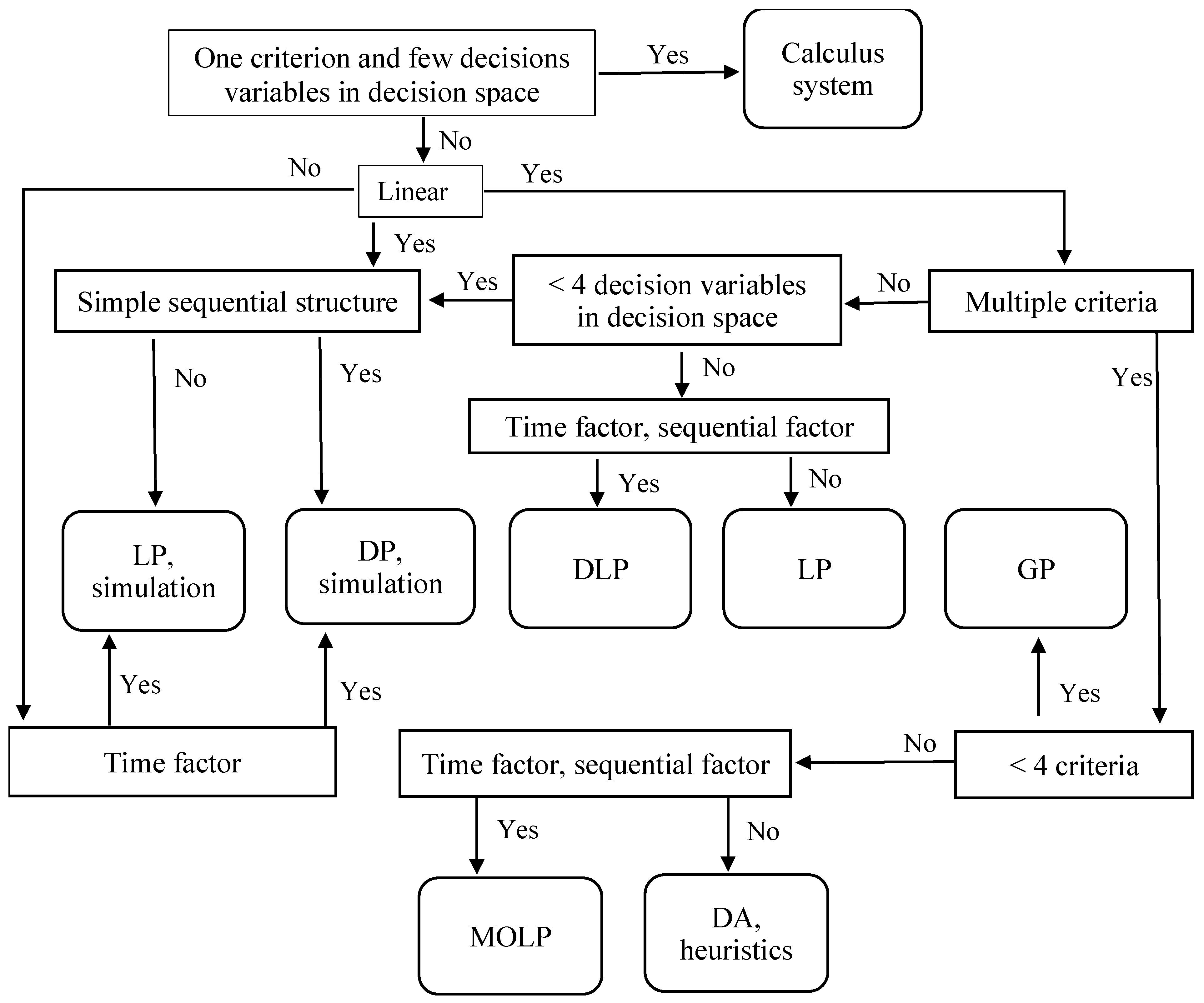

- Palander, T. Local Factors and Time-Variable Parameters in Tactical Planning Models: A Tool for Adaptive Timber Procurement Planning. Scan J For Res. 1995;10:370–382. [CrossRef]

- Beaudoin D, LeBel L, Soussi MA. Discrete event simulation to improve log yard operations. INFOR Inf Syst Oper Res. 2016;50(4):175–185.

- •Kogler, C; Rauch. P Lead time and quality driven transport strategies for the wood supply chain. Res Transp Bus Manag. 2023;47:100946. In this work, predictive data analytics of data-driven modelling predict future trends, forecast inventory levels, and manage available resources.

- Palander T, Vesa L. Data-Driven Optimization of Forestry and Wood Procurement toward Carbon-Neutral Logistics of Forest Industry. Forests. 2022;13(5):759. [CrossRef]

- NewVantage Partners. Data and AI Leadership Executive Survey 2022. https://c6abb8db-514c-4f5b-b5a1-fc710f1e464e.filesusr.com/ugd/e5361a_2f859f3457f24cff9b2f8a2bf54f82b7.pdf.

- Palander T, Kainulainen J, Koskinen R. A computer-supported group decision-making system for timber procurement planning in Finland. Scan J For Res. 2005;20(6):514–520. [CrossRef]

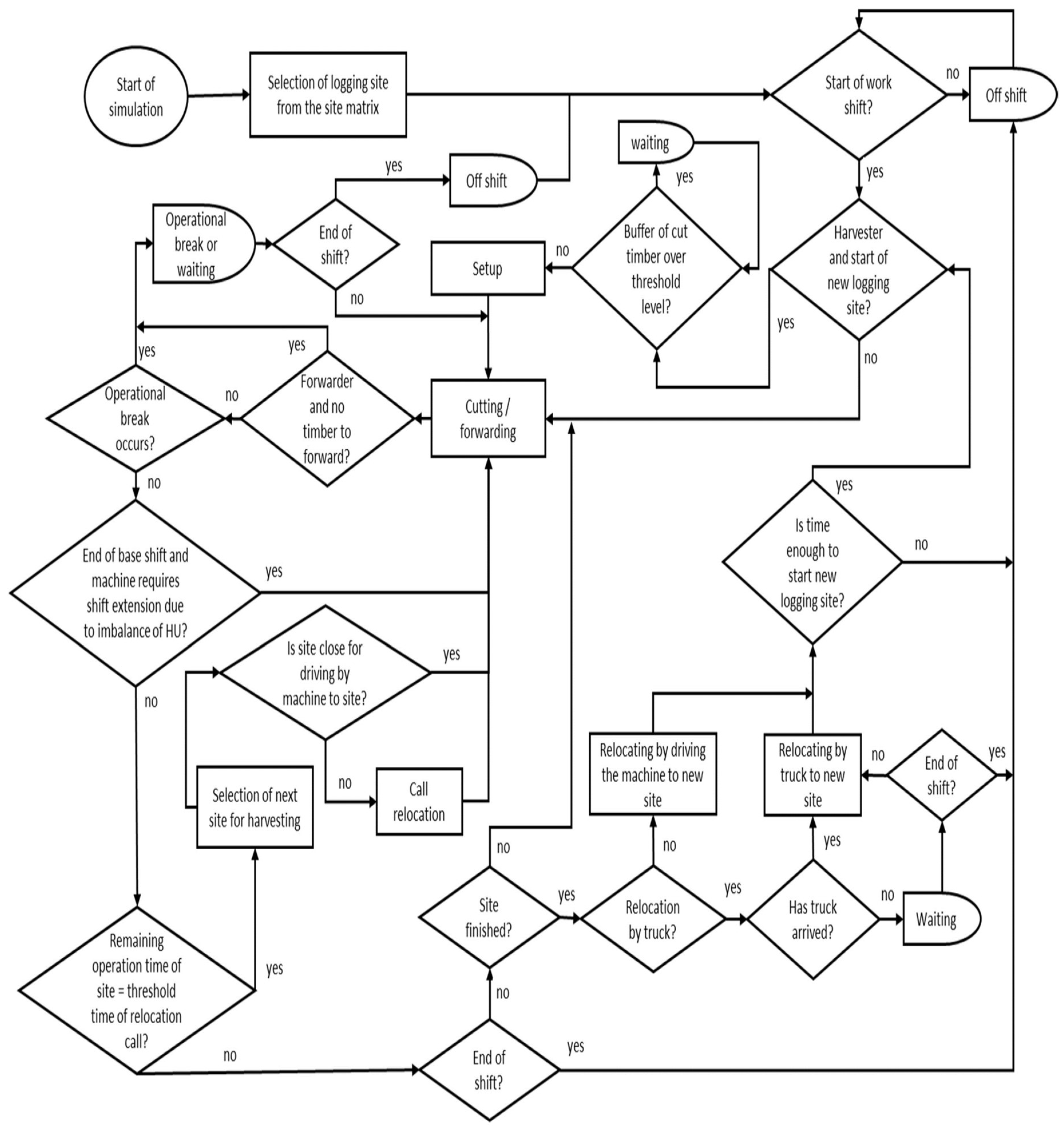

- Väätäinen K, Hyvönen P, Kankaanhuhta V, Laitila J, Hirvelä H. The Impact of Fleet Size, Harvesting Site Reserve, and Timing of Machine Relocations on the Performance Indicators of Mechanized CTL Harvesting in Finland. Forests. 2021;12(10):1328. [CrossRef]

- Asikainen A, Stampfer K, Talbot B, Belbo H. Simulation of skyline systems in Norwegian conditions. In: OSCAR proceedings from the 2010 Nordic Baltic conference on forest operations. Eds. Belbo H, Rapport 12/2010. Report from Norwegian Forest and Landscape institute. pp. 87–88. https://nibio.brage.unit.no/nibio-xmlui/bitstream/handle/11250/2673095/SoL-Rapport-2010-12-s87-88.pdf?sequence=1&isAllowed=y.

- Kennedy JOS. Dynamic Programming: Applications to Agriculture and Natural Resources. Elsevier Applied Science. 1986.

- Palander T. Influence of local factors and time-varying parameters on total costs of timber procurement. Thesis for the degree of Licentiate of Science in Agriculture and Forestry. University of Eastern Finland. 1994.

- Dykstra, DP. Mathematical programming for natural resource management. New York: McGraw-Hill Book Company. 1984.

- Palander, TS. Dynamic Analysis of Interest Rate and Logging Factors in Reducing Saw Timber Procurement Costs. Int J For Eng. 1995;7(1):29–40. [CrossRef]

- Lappi J, Lempinen R. A linear programming algorithm and software for forest-level planning problems including factories. Scan J For Res. 2014;29:178–184.

- Korhonen, KT. Finland. Assessment of Wood Availability and Use. In: Vidal, C., Alberdi, I., Hernandez, L. and Redmond, J. (ed.) National Forest Inventories. Gewerbestrasse 11, 6330 Cham, Switzerland: Springer International Publishing Switzerland. 2016. pp. 369–384. ISBN 978-3-319-44014-9.

- Hyvönen P, Lempinen R, Lappi J, Laitila J, Packalen T. Joining up optimisation of wood supply chains with forest management: a case study of North Karelia in Finland. Forestry: J For Res. 2020;93(1):163–177. [CrossRef]

- Acuna, M. Timber and Biomass Transport Optimization: A Review of Planning Issues, Solution Techniques and Decision Support Tools. Croat J For Eng. 2017;38(2):279–290.

- ••Acuna M, Sessions J, Zamora R. Boston K, Brown M, Reza Ghaffariyan M. Methods to Manage and Optimize Forest Biomass Supply Chains: a Review. Curr For Rep. 2019;5:124–141. https://doi.org/10.1007/s40725-019-00093-4. This review introduces a major modeling development in management of biomass supply chains by means of operations analysis for complex process-based models of forest logistics. [CrossRef]

- Väätäinen K, Laitila J, Anttila P, Kilpeläinen A, Asikainen A. The influence of gross vehicle weight (GVW) and transport distance on timber trucking performance indicators – Discrete event simulation case study in Central Finland. Int J For Eng. 2020;31(2):156–170. [CrossRef]

- Kogler C, Rauch P. Discrete event simulation of multimodal and unimodal transportation in the wood supply chain: a literature review. Silva Fenn. 2018;52(4):9984.

- Kogler C, Schimpfhuber S, Eichberger C, Rauch P. Benchmarking Procurement Cost Saving Strategies for Wood Supply Chains. Forests. 2021;12:1086. [CrossRef]

- Shahi S, Pulkki R. Supply Chain Network Optimization of the Canadian Forest Products Industry: A Critical Review. Am J Ind Bus Manag. 2013;3(7):631–643. [CrossRef]

- Kogler C, Stenitzer A, Rauch P. Simulating Combined Self-Loading Truck and Semitrailer Truck Transport in the Wood Supply Chain. Forests. 2020;11(12):1245.

- Laubscher R, van der Merwe J, Liebenberg J, Herbst P. Dynamic simulation of aortic valve stenosis using a lumped parameter cardiovascular system model with flow regime dependent valve pressure loss characteristics. Med Eng Phys. 2022;106:103838.

- Frisk M, Göthe-Lundgren M, Jörnsten K, Rönnqvist M. Cost Allocation in Collaborative Forest Transportation. Eur J Oper Res. 2010;205:448–458.

- Palander, T. A model to estimate benefits from log drying for supply chains in wood procurement. Conference: 2nd World Symposium on Logistics in Forest Sector, IUFRO and Wood Logistics Network At: Växjö, Sverige, Volume: Supply Chain Management for Paper and Timber Industries. 2001. [CrossRef]

- Korpinen O-J, Aalto M, Kc R, Tokola T, Ranta T. Utilisation of Spatial Data in Energy Biomass Supply Chain Research—A Review. Energies. 2023;16(2):893. [CrossRef]

- Palander, T. A local DLP-GIS-LP system for geographically decentralized wood procurement planning and decision making. Silva Fenn. 1997;31(2):179–192.

- ••de Smith MJ, Goodchild MF, Longley P. Geospatial Analysis: A comprehensive guide to principles, techniques and software tools. 6th Edition. The Winchelsea Press, Edinburgh. 2018. Book is a comprehensive guide for advanced modelers of WSCs, which provides all needed terminology, techniques and software tools for geospatial analysis.

- Pourabdollah A, Morley J, Feldman S, Jackson M. Towards an Authoritative OpenStreetMap: Conflating OSM and OS OpenData National Maps’ Road Network. ISPRS Int J Geo-Inf. 2013;2(3):704–728. [CrossRef]

- Mäkisara K, Katila M, Peräsaari J. The multi-source national forest inventory of Finland - methods and results 2015. Natural resources and bioeconomy studies 8/2019. Natural Resources Institute Finland, Helsinki. 2019. http://urn.fi/URN:ISBN:978-952-326-712-1.

- Tuominen S, Pitkänen T, Balazs A, Kangas A. Improving Finnish Multi-Source National Forest Inventory by 3D aerial imaging. Silva Fenn. 2017;51(4):7743. [CrossRef]

- Finnish Forest Centre. Paikkatietoaineistot. 2023. [in Finnish] https://www.metsakeskus.fi/fi/avoin-metsa-ja-luontotieto/aineistot-paikkatieto-ohjelmille/paikkatietoaineistot. Accessed 17 Aug 2023.

- Strandström, M. Timber harvesting and long-distance transportation of roundwood 2019. Metsäteho result series 9. 2021. https://www.metsateho.fi/timber-harvesting-and-long-distance-transportation-of-roundwood-2019/. Accessed 9 Sep 2021.

- Finnish Transport Infrastructure Agency. Digiroad – National road and street database. 2023. https://vayla.fi/en/transport-network/data/digiroad. Accessed 17 Aug 2023.

- Venäläinen P, Nousiainen M. Yksityistietiedon tietolajit - Nykytila, suositukset määritelmiksi ja kehittämistarpeet. [in Finnish] Metsätehon raportti 261. 2021. https://www.metsateho.fi/yksityisteiden-tietolajikuvaukset-ja-kehittamistarpeet-paivitetty/. Accessed 17 Aug 2023.

- Finnish Transport Infrastructure Agency. Maps and charts - A summary of Finnish Transport Infrastructure Agency’s maps. 2023. https://vayla.fi/en/transport-network/data/maps-charts. Accessed 17 Aug 2023.

- •Waga K. Unpaved forest road quality assessment using airborne LiDAR data. Dissertationes Forestales 316. 2021. https://doi.org/10.14214/df.316. The paper describes data needs and problems related to forest roads and provide discussion, how quality of unpaved roads could be monitored and maintained. [CrossRef]

- Nevalainen P, Salmivaara A, Ala-Ilomäki J, Launiainen S, Hiedanpää J, Finér L, Pahikkala T, Heikkonen J. Estimating the Rut Depth by UAV Photogrammetry. Remote Sens. 2017;9:279–1304. [CrossRef]

- Jaakkola, A. Low-cost Mobile Laser Scanning and its feasibility for Environmental Mapping. D.Sc. Thesis. Aalto University publication series doctoral dissertations 65. 2015. ISBN:978-952-60-6198-6.

- Metsäteho.fi. Konenäkö tunnisti tiestön ongelmapaikkoja. [Machine vision identified problem areas on the road]. Metsätehon tiedote 13. 2020. https://www.metsateho.fi/konenako-tunnisti-tieston-ongelmapaikkoja/. Accessed 17 Aug 2023.

- Vaisala. Thermal Mapping - Observation-based temperature profiles of your entire road network. 2023. https://www.vaisala.com/sites/default/files/documents/WEA-GT-eBook-Intelligent-Year-Round-Road-Maintenance-B211807EN-D.pdf. Accessed 17 Aug 2023.

- Chen H, Chiang RHL, Storey VC. Business Intelligence and Analytics: From Big Data to Big Impact. MIS Q. 2012;36(4):1165–88. [CrossRef]

- Singh, J.; Singh, S.; Kumari, M. Role of ICT in supply chain management. J Interdiscip Cycle Res. 2020;12:992.

- Zhang X, Wang J, Vance J, Wang Y, Wu J, Hartley D. Data Analytics for Enhancement of Forest and Biomass Supply Chain Management. Curr For Rep. 2020;6:129–142.

- Müller F, Jaeger D, Hanewinkel M. Digitization in wood supply–A review on how Industry 4.0 will change the forest value chain. Comput Electron Agric. 2019;162:206–218.

- He Z, Turner P. A Systematic Review on Technologies and Industry 4.0 in the Forest Supply Chain: A Framework Identifying Challenges and Opportunities. Logistics. 2021;5:88.

- John Deere. Operator assistance. https://www.deere.com/en/technology-products/forestry-and-logging-technology/operator-assistance-technology/. Accessed 17 Aug 2023.

- LogForce. Available online at: https://www.logforce.fi/. Accessed 8 Aug 2023.

- WoodForce. Available online at: https://www.woodforce.fi/tuotteen-esittely/. Accessed 8 Aug 2023.

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).