Submitted:

07 February 2024

Posted:

08 February 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

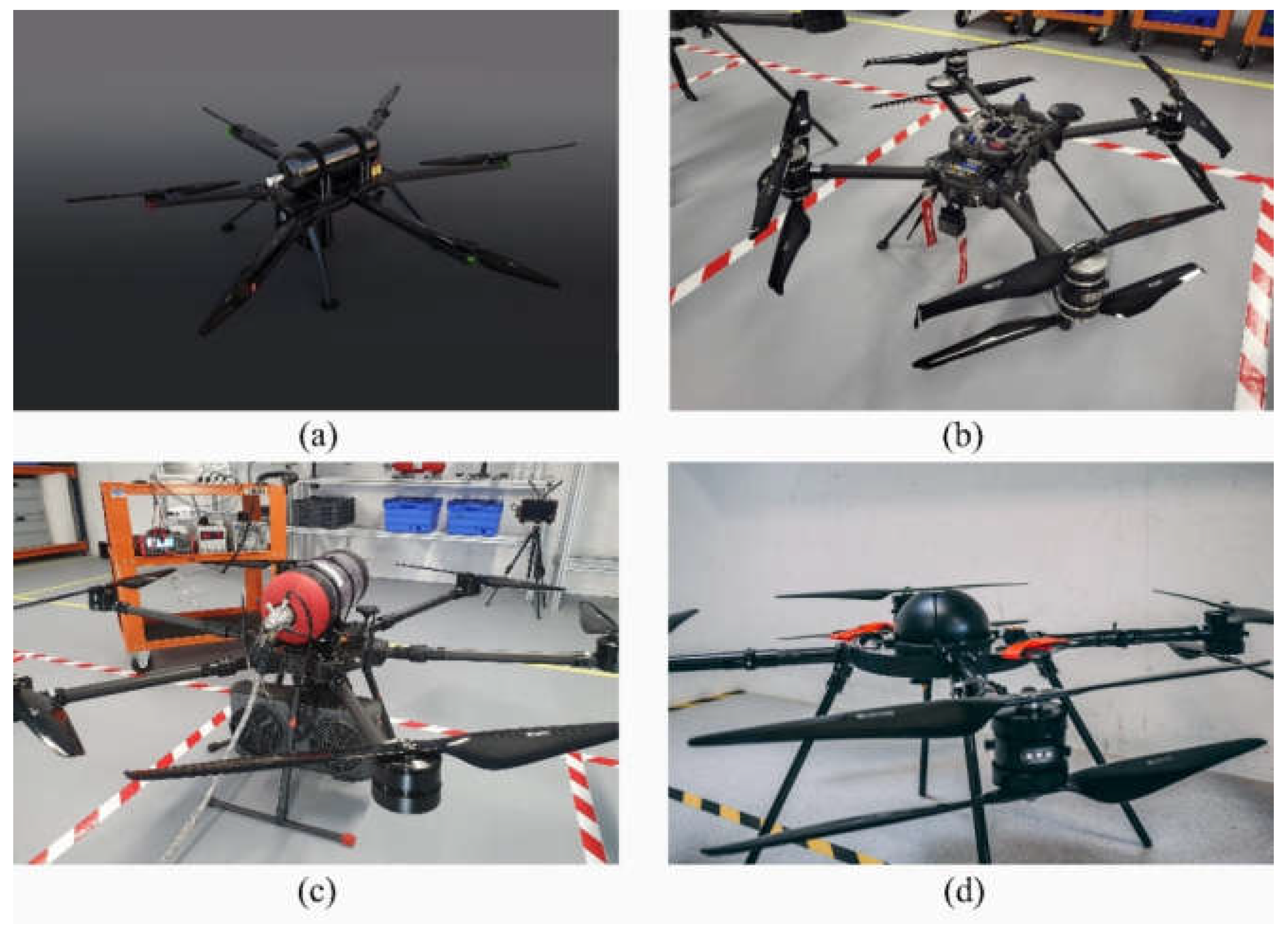

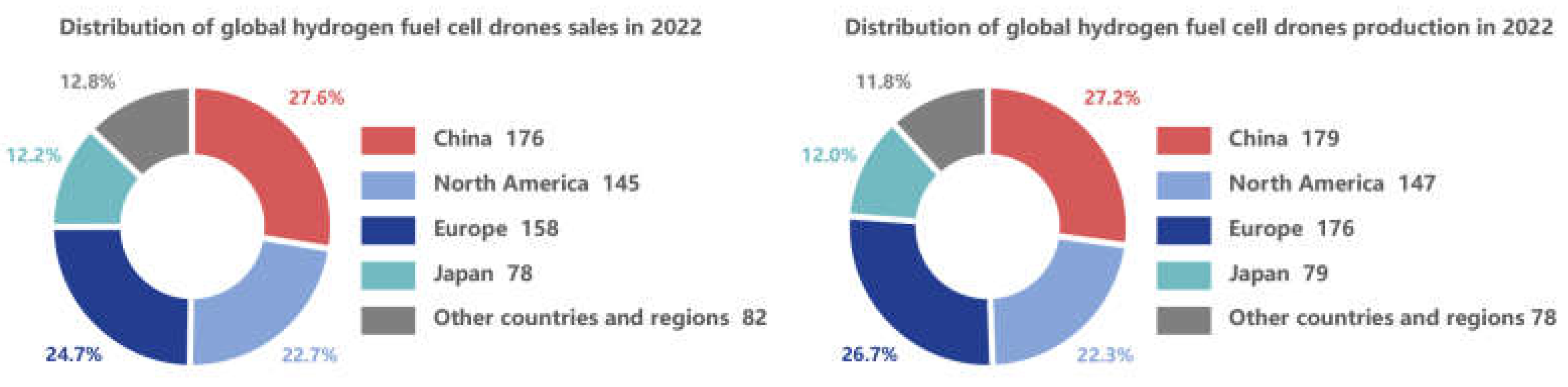

2. Development and Application of of hydrogen fuel cell multi-rotor drones

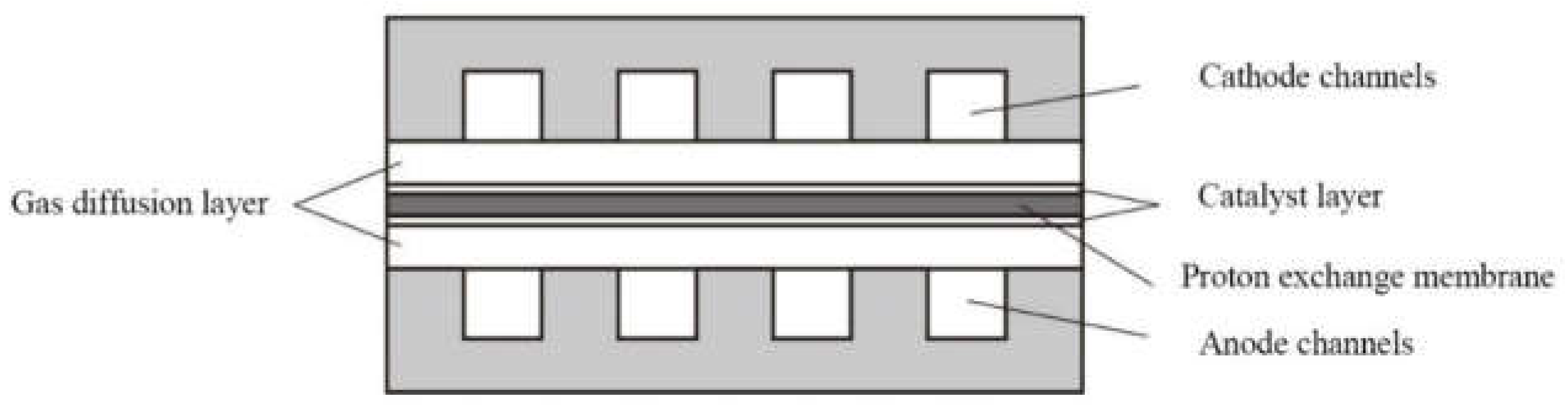

3. Research status of key technologies

3.1. Lightweight design

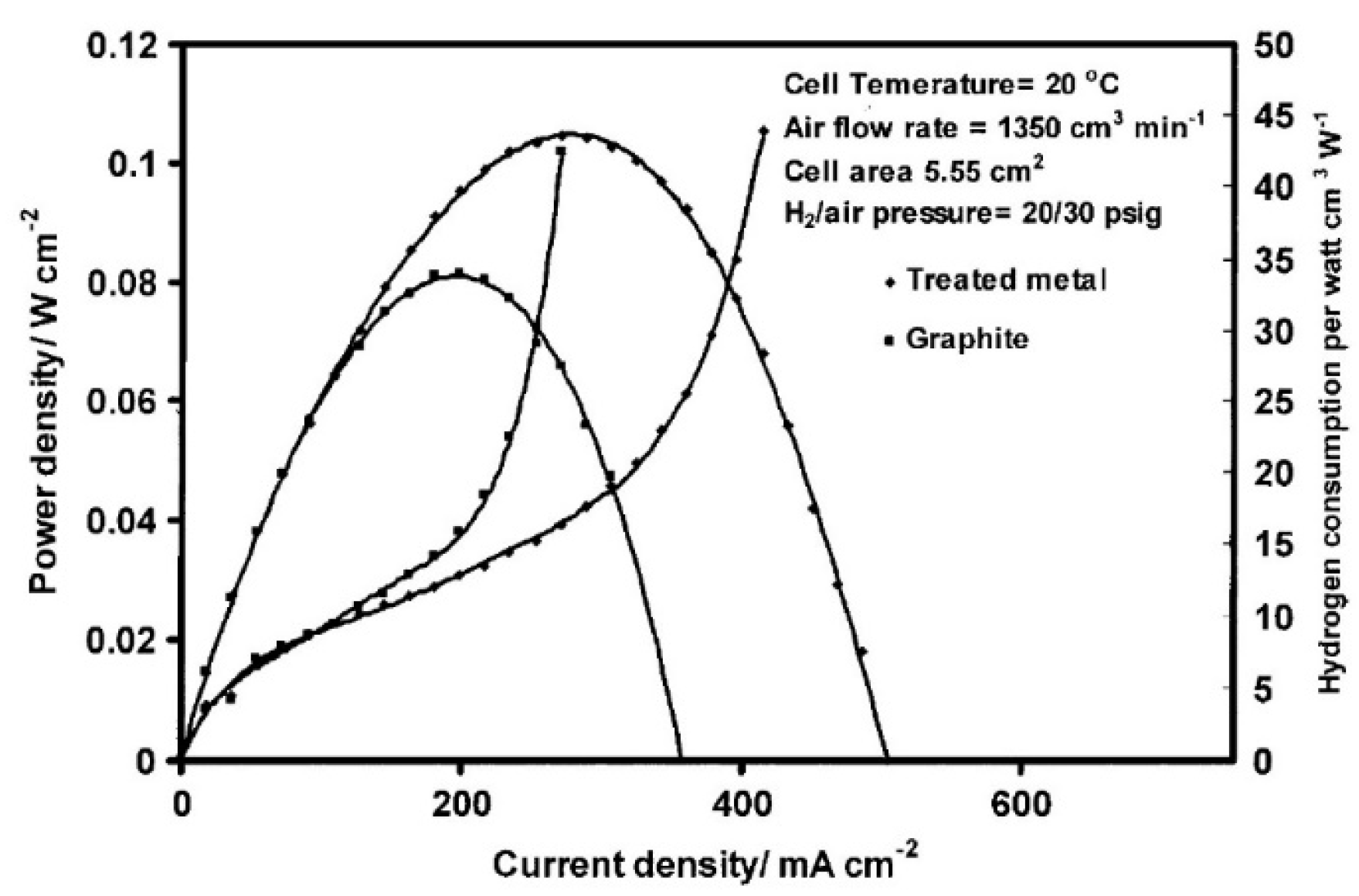

3.1.1. Bipolar plates

3.1.2. High-pressure gas cylinders and hydrogen regulators

3.2. Hydrogen storage methods

3.2.1. Compressed gaseous hydrogen storage methods

3.2.2. Liquid hydrogen storage methods

3.2.3. Solid-state hydrogen storage methods

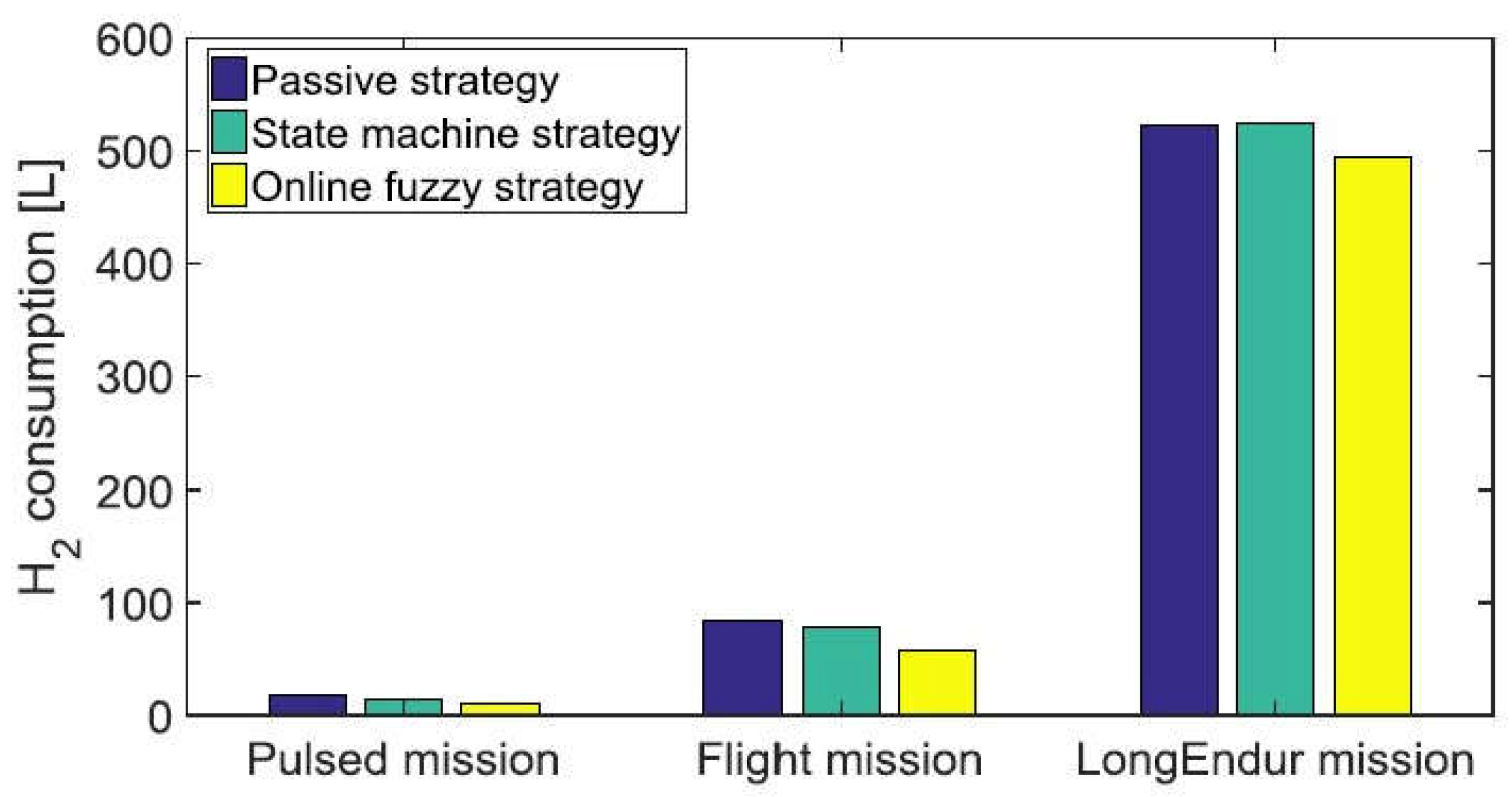

3.3. Energy management strategy

4. Summary and Future Scope

- 1

- Optimization of hydrogen storage methods;

- 2

- Cathode gas filtration system;

- 3

- Auxiliary equipment.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Lee, C.; Kim, S.; Chu, B. A Survey: Flight Mechanism and Mechanical Structure of the UAV. International Journal of Precision Engineering and Manufacturing 2021, 22, 719–743. [Google Scholar] [CrossRef]

- Hassanalian, M.; Abdelkefi, A. Classifications, applications, and design challenges of drones: A review. Progress in Aerospace Sciences 2017, 91, 99–131. [Google Scholar] [CrossRef]

- Arat, H.T.; Sürer, M.G. Experimental investigation of fuel cell usage on an air Vehicle's hybrid propulsion system. International Journal of Hydrogen Energy 2020, 45, 26370–26378. [Google Scholar] [CrossRef]

- Floreano, D.; Wood, R.J. Science, technology and the future of small autonomous drones. Nature 2015, 521, 460–466. [Google Scholar] [CrossRef] [PubMed]

- Mademlis, I.; Mygdalis, V.; Nikolaidis, N.; Montagnuolo, M.; Negro, F.; Messina, A.; Pitas, I. High-Level Multiple-UAV Cinematography Tools for Covering Outdoor Events. Ieee Transactions on Broadcasting 2019, 65, 627–635. [Google Scholar] [CrossRef]

- Ahmed, F.; Mohanta, J.C.; Keshari, A.; Yadav, P.S. Recent Advances in Unmanned Aerial Vehicles: A Review. Arabian Journal for Science and Engineering 2022, 47, 7963–7984. [Google Scholar] [CrossRef] [PubMed]

- Luo, H.; Zhang, P.; Wang, J.J.; Wang, G.Q.; Meng, F.H. Traffic Patrolling Routing Problem with Drones in an Urban Road System. Sensors 2019, 19. [Google Scholar] [CrossRef] [PubMed]

- Humpe, A. Bridge Inspection with an Off-the-Shelf 360 degrees Camera Drone. Drones 2020, 4. [Google Scholar] [CrossRef]

- Chen, C.J.; Huang, Y.Y.; Li, Y.S.; Chen, Y.C.; Chang, C.Y.; Huang, Y.M. Identification of Fruit Tree Pests With Deep Learning on Embedded Drone to Achieve Accurate Pesticide Spraying. Ieee Access 2021, 9, 21986–21997. [Google Scholar] [CrossRef]

- Iost, F.H.; Heldens, W.B.; Kong, Z.D.; de Lange, E.S. Drones: Innovative Technology for Use in Precision Pest Management. Journal of Economic Entomology 2020, 113, 1–25. [Google Scholar] [CrossRef]

- Rejeb, A.; Abdollahi, A.; Rejeb, K.; Treiblmaier, H. Drones in agriculture: A review and bibliometric analysis. Computers and Electronics in Agriculture 2022, 198. [Google Scholar] [CrossRef]

- Hu, P.; Zhang, R.; Yang, J.; Chen, L. Development Status and Key Technologies of Plant Protection UAVs in China: A Review. Drones 2022, 6. [Google Scholar] [CrossRef]

- Yan, Y.H.; Lv, Z.Y.; Yuan, J.B.; Chai, J.G. ANALYSIS OF POWER SOURCE OF MULTIROTOR UAVs. International Journal of Robotics & Automation 2019, 34, 563–571. [Google Scholar] [CrossRef]

- Gong, A.; Verstraete, D. Fuel cell propulsion in small fixed-wing unmanned aerial vehicles: Current status and research needs. International Journal of Hydrogen Energy 2017, 42, 21311–21333. [Google Scholar] [CrossRef]

- Kesselman, S.J.A.f.U.V.S.I. The First 1,000 Commercial UAS Exemptions. 2014, 1-22.

- Apeland, J.; Pavlou, D.G.; Hemmingsen, T. Sensitivity Study of Design Parameters for a Fuel Cell Powered Multirotor Drone. Journal of Intelligent & Robotic Systems 2021, 102. [Google Scholar] [CrossRef]

- Depcik, C.; Cassady, T.; Collicott, B.; Burugupally, S.P.; Li, X.; Alam, S.S.; Arandia, J.R.; Hobeck, J. Comparison of lithium ion Batteries, hydrogen fueled combustion Engines, and a hydrogen fuel cell in powering a small Unmanned Aerial Vehicle. Energy Conversion and Management 2020, 207. [Google Scholar] [CrossRef]

- Pan, Z.F.; An, L.; Wen, C.Y. Recent advances in fuel cells based propulsion systems for unmanned aerial vehicles. Applied Energy 2019, 240, 473–485. [Google Scholar] [CrossRef]

- Belmonte, N.; Staulo, S.; Fiorot, S.; Luetto, C.; Rizzi, P.; Baricco, M. Fuel cell powered octocopter for inspection of mobile cranes: Design, cost analysis and environmental impacts. Applied Energy 2018, 215, 556–565. [Google Scholar] [CrossRef]

- Cai, Q.; Brett, D.J.L.; Browning, D.; Brandon, N.P. A sizing-design methodology for hybrid fuel cell power systems and its application to an unmanned underwater vehicle. Journal of Power Sources 2010, 195, 6559–6569. [Google Scholar] [CrossRef]

- Al Savvaris, Y.X., Konstantinos Malandrakis, Matias Lopez, Antonios Tsourdos. Development of a fuel cell hybrid-powered unmanned aerial vehicle. In Proceedings of the 24th Mediterranean Conference on Control and Automation (MED); 2016.

- Sharaf, O.Z.; Orhan, M.F. An overview of fuel cell technology: Fundamentals and applications. Renewable and Sustainable Energy Reviews 2014, 32, 810–853. [Google Scholar] [CrossRef]

- Tang, A.; Crisci, L.; Bonville, L.; Jankovic, J. An overview of bipolar plates in proton exchange membrane fuel cells. Journal of Renewable and Sustainable Energy 2021, 13. [Google Scholar] [CrossRef]

- Liu, C.Y.; Sung, C.C.J.J.o.P.S. A review of the performance and analysis of proton exchange membrane fuel cell membrane electrode assemblies. 2012, 220, 348-353.

- Zhang, G.; Kandlikar, S.G.J.I.J.o.H.E. A critical review of cooling techniques in proton exchange membrane fuel cell stacks. 2012, 37, 2412-2429.

- Ramezanizadeh, M.; Nazari, M.A.; Ahmadi, M.H.; Chen, L.E. A review on the approaches applied for cooling fuel cells. International Journal of Heat and Mass Transfer 2019, 139, 517–525. [Google Scholar] [CrossRef]

- Graf, C.; Friedrich, K.A.; Vath, A.; Nicoloso, N. Dynamic load and temperature behavior of a PEFC-hybrid-system. Journal of Fuel Cell Science and Technology 2006, 3, 403–409. [Google Scholar] [CrossRef]

- Fluckiger, R.; Tiefenauer, A.; Ruge, M.; Aebi, C.; Wokaun, A.; Buchi, F.N. Thermal analysis and optimization of a portable, edge-air-cooled PEFC stack. Journal of Power Sources 2007, 172, 324–333. [Google Scholar] [CrossRef]

- Zakhvatkin, L.; Schechter, A.; Buri, E.; Avrahami, I. Edge Cooling of a Fuel Cell during Aerial Missions by Ambient Air. Micromachines 2021, 12. [Google Scholar] [CrossRef] [PubMed]

- Kurnia, J.C.; Chaedir, B.A.; Sasmito, A.P.; Shamim, T. Progress on open cathode proton exchange membrane fuel cell: Performance, designs, challenges and future directions. Applied Energy 2021, 283. [Google Scholar] [CrossRef]

- Barrett, S.J.F.C.B. EnergyOr shows off world's first fuel cell multirotor UAV. 2015, 2015, 5-6.

- Bulletin, N.J.F.C. EnergyOr fuel cell multirotor drone in 2 h flight with camera. 2016, 2016, 3-4.

- Horizon launches Hycopter fuel cell multirotor UAV. Fuel Cells Bulletin 2015, 2015. [CrossRef]

- Liu, L.; Cao, X.; Zhang, X.; He, Y. Review of development of light and small scale solar/hydrogen powered unmanned aerial vehicles. Acta Aeronautica et Astronautica Sinica 2019, 41, 623474, (in Chinese with English abstract). [Google Scholar]

- Dutczak, J. Compressed hydrogen storage in contemporary fuel cell propulsion systems of small drones. IOP Conference Series: Materials Science and Engineering 2018, 421. [Google Scholar] [CrossRef]

- Chinese UAV maker MMC flies hydrogen fuel cell drone for 4 h. Fuel Cells Bulletin 2016, 2016, 4–5. [CrossRef]

- Antunes, J. Fly Farther and Longer with FlightWave’s Hydrogen-powered Jupiter-H2 Drone. Available online: https://www.commercialuavnews.com/infrastructure/fly-farther-longer-flightwaves-hydrogen-powered-jupiter-h2-drone (accessed on 25/04/2023).

- Intelligent Energy fuel cells for new ISS UAV. Fuel Cells Bulletin 2020, 2020, 6–6. [CrossRef]

- Loughborough. Intelligent Energy’s 2.4kW Fuel Cell Power module integrated into latest UAV product from ISS Aerospace. Available online: https://www.intelligent-energy.com/news/intelligent-energys-2-4kw-fuel-cell-power-module-integrated-into-latest-uav-product-from-iss-aerospace/ (accessed on 17/03/2023).

- HES multirotor drone, designed and built in US, has 3h flight time. Fuel Cells Bulletin 2018, 2018, 5–5. [CrossRef]

- Skycorp hydrogen fuel cell powered drone with advanced AI. Fuel Cells Bulletin 2018, 5–5.

- Intelligent Energy powers two multirotor UAVs to new records. Fuel Cells Bulletin 2019, 2019, 5–6. [CrossRef]

- Nordic Unmanned in hydrogen drone flight. Fuel Cells Bulletin 2021, 2021, 5–6. [CrossRef]

- FuelCellWorks. MetaVista breaks Guinness world record of multi rotor UAV flight time using Intelligent Energy fuel cell power module. Available online: https://fuelcellsworks.com/news/metavista-breaks-guinness-world-record-of-multi-rotor-uav-flight-time-using-intelligent-energy-fuel-cell-power-module/ (accessed on 16/03/2023).

- Intelligent Energy links up with UAV maker, unveils new module. Fuel Cells Bulletin 2017, 2017. [CrossRef]

- Intelligent Energy unveils 800 W fuel cell for commercial UAVs. Fuel Cells Bulletin 2018, 2018, 6–6. [CrossRef]

- Intelligent Energy launches 2. 4 kW fuel cell module for UAVs. Fuel Cells Bulletin 2019, 2019, 6–6. [Google Scholar] [CrossRef]

- FuelCellsWorks. Unlocking the potential of hydrogen for increased drone capabilities: Intelligent Energy launches new product to provide higher power up to1.6kW for UAVs. Available online: https://fuelcellsworks.com/news/unlocking-the-potential-of-hydrogen-for-increased-drone-capabilities-intelligent-energy-launches-new-product-to-provide-higher-power-up-to-1-6kw-for-uavs/ (accessed on 17/03/2023).

- Intelligent Energy module provides up to 1. 6 kW for UAVs. Fuel Cells Bulletin 2019, 2019, 5–5. [Google Scholar] [CrossRef]

- Barrett, S.J.F.C.B. Intelligent Energy fuel cells power endurance drone for US Army. 2020, 2020, 5-6.

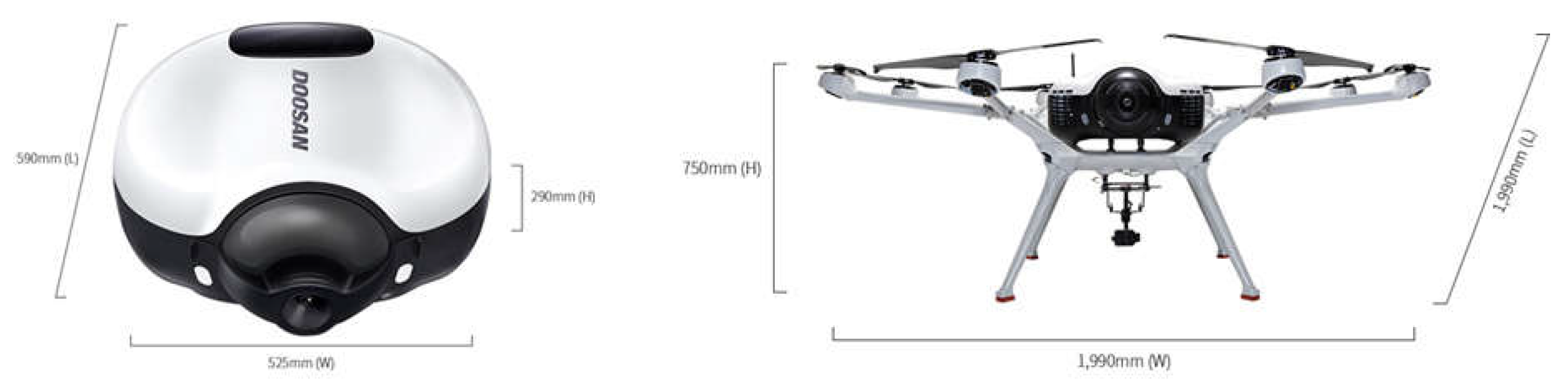

- Doosan sets foot in UAV fuel cell market. Fuel Cells Bulletin 2018, 2018, 6–6. [CrossRef]

- Doosan Mobility Innovation demos fuel cell drone for Africa. Fuel Cells Bulletin 2020, 2020, 6–6. [CrossRef]

- DMI launches modular hydrogen fuel cell power pack for drones. Fuel Cells Bulletin 2020, 2020, 6–6. [CrossRef]

- Chia, A.F.Y.; Min, K.M. Design and Performance Analysis of a Fuel Cell Powered Heavy-Lift Multirotor Drone. In The Proceedings of the 2021 Asia-Pacific International Symposium on Aerospace Technology (APISAT 2021), Volume 1; Lecture Notes in Electrical Engineering; 2003; pp. 269–282. [Google Scholar]

- Barrett, S.J.F.c.b. DMI fuel cell drone delivers face masks to remote Korean islands. 2020, 2020.

- Barrett, S.J.F.c.b. Ballard turnkey fuel cell solutions to power commercial UAVs. 2019, 2019.

- FuelCellWorks. China: world record flight time for hvdrogen fuel cell drone. Available online: https://fuelcellsworks.com/news/china-world-record-flight-time-for-hydrogen-fuel-cell-drone/ (accessed on 24/3/2023).

- Hydrogen fuel cell power system for unmanned aerial vehicles. 2020, GB/T 38954-2020.

- Mohsan, S.A.H.; Othman, N.Q.H.; Li, Y.; Alsharif, M.H.; Khan, M.A. Unmanned aerial vehicles (UAVs): practical aspects, applications, open challenges, security issues, and future trends. Intell Serv Robot 2023, 16, 109–137. [Google Scholar] [CrossRef]

- Tsuchiya, H. Mass production cost of PEM fuel cell by learning curve. International Journal of Hydrogen Energy 2004, 29, 985–990. [Google Scholar] [CrossRef]

- Porstmann, S.; Wannemacher, T.; Drossel, W.G.J.J.o.M.P. A comprehensive comparison of state-of-the-art manufacturing methods for fuel cell bipolar plates including anticipated future industry trends. 2020, 60, 366-383.

- Kim, K.H.; Lim, J.W.; Kim, M.; Dai, G.L.J.C.S. Development of carbon fabric/graphite hybrid bipolar plate for PEMFC. 2013, 98, 103-110.

- Hermann, A.; Chaudhuri, T.; Spagnol, P. Bipolar plates for PEM fuel cells: A review. International Journal of Hydrogen Energy 2005, 30, 1297–1302. [Google Scholar] [CrossRef]

- Marchetti, G.A. Thin graphite bipolar plate with associated gaskets and carbon cloth flow-field for use in an ionomer membrane fuel cell.

- EMANUELSON; C., R.; TAYLOR; A., W.; LUOMA; L., W. SEPARATOR PLATE FOR ELECTROCHEMICAL CELLS. CA1164934A, 1984-04-03.

- Fan, R.; Peng, Y.; Tian, H.; Zheng, J.; Zhang, C. Graphite-Filled Composite Bipolar Plates for Fuel Cells: Material, Structure, and Performance. ACTA PHYSICO-CHIMICA SINICA, 2020; 2009095. (in Chinese with English abstract). [Google Scholar]

- Kuan, H.C.; Ma, C.C.M.; Chen, K.H.; Chen, S.M. Preparation, electrical, mechanical and thermal properties of composite bipolar plate for a fuel cell. Journal of Power Sources 2004, 134, 7–17. [Google Scholar] [CrossRef]

- Muller, A.; Kauranen, P.; von Ganski, A.; Hell, B. Injection moulding of graphite composite bipolar plates. Journal of Power Sources 2006, 154, 467–471. [Google Scholar] [CrossRef]

- Jo, J.; Zhang, X.; Ansari, A. LIGHTWEIGHT PEM FUEL CELL STACK FOR UNMANNED AERIAL VEHICLE. In Proceedings of the ASME Heat Transfer Conference; 2021. [Google Scholar]

- Tawfik, H.; Hung, Y.; Mahajan, D. Metal bipolar plates for PEM fuel cell - A review. Journal of Power Sources 2007, 163, 755–767. [Google Scholar] [CrossRef]

- Hung, Y.; El-Khatib, K.M.; Tawfik, H. Corrosion-resistant lightweight metallic bipolar plates for PEM fuel cells. Journal of Applied Electrochemistry 2005, 35, 445–447. [Google Scholar] [CrossRef]

- DMI, POSCO SPS aim to cut weight of fuel cell drones. Fuel Cells Bulletin 2021, 2021, 6–6. [CrossRef]

- Wang, H.L.; Sweikart, M.A.; Turner, J.A. Stainless steel as bipolar plate material for polymer electrolyte membrane fuel cells. Journal of Power Sources 2003, 115, 243–251. [Google Scholar] [CrossRef]

- Lin, C.H.; Tsai, S.Y. An investigation of coated aluminium bipolar plates for PEMFC. Applied Energy 2012, 100, 87–92. [Google Scholar] [CrossRef]

- Yan, P.F.; Ying, T.; Yang, Y.; Cao, F.Y.; Li, Y.X.; Wang, J.Y.; Zeng, X.Q. Investigation of anodized Ta/Ag coating on magnesium bipolar plate for lightweight proton exchange membrane fuel cells. Corrosion Science 2022, 197. [Google Scholar] [CrossRef]

- Xu, Z.; Qiu, D.; Yi, P.; Peng, L.; Lai, X.J.P.i.N.S.M.I. Towards mass applications: A review on the challenges and developments in metallic bipolar plates for PEMFC - ScienceDirect. 2020, 30, 815-824.

- Dobrovol’skii, Y.A.; Ukshe, A.E.; Levchenko, A.V.; Arkhangel’skii, I.V.; Ionov, S.G.; Avdeev, V.V.; Aldoshin, S.M. Materials for bipolar plates for proton-conducting membrane fuel cells. 2007, 77, 752-765.

- Aukland, N.; Boudina, A.; Eddy, D.S.; Mantese, J.V.; Thompson, M.P.; Wang, S.S. Alloys that form conductive and passivating oxides for proton exchange membrane fuel cell bipolar plates. Journal of Materials Research 2004, 19, 1723–1729. [Google Scholar] [CrossRef]

- Gou, Y.; Jiang, G.; Geng, J.T.; Shao, Z.G. Properties of NbC/a-C:H films on titanium bipolar plates for proton exchange membrane fuel cells. Fuel Cells. [CrossRef]

- Li, T.; Zhang, H.Y.; Wang, Y.; Wu, C.L.; Yan, Y.G.; Chen, Y.G. TiCr transition layer promoting the growth of high-stability TiCrN coating for titanium bipolar plate. Surface & Coatings Technology 2022, 451. [Google Scholar] [CrossRef]

- Wang, Z.D.; Zhang, B.; Gao, K.X.; Liu, R.X. Adjustable TiN coatings deposited with HiPIMS on titanium bipolar plates for PEMFC. International Journal of Hydrogen Energy 2022, 47, 39215–39224. [Google Scholar] [CrossRef]

- Yin, Q.; Zhang, K.; Fu, X.Z.; Wang, X.Z.; Luo, J.L. Rapid coating preparation strategy for chromium nitride coated titanium bipolar plates of proton exchange membrane fuel cells. International Journal of Hydrogen Energy 2022, 47, 31435–31445. [Google Scholar] [CrossRef]

- Zhang, H.B.; Hou, M.; Lin, G.Q.; Han, Z.Y.; Fu, Y.; Sun, S.C.; Shao, Z.G.; Yi, B.L. Performance of Ti-Ag-deposited titanium bipolar plates in simulated unitized regenerative fuel cell (URFC) environment. International Journal of Hydrogen Energy 2011, 36, 5695–5701. [Google Scholar] [CrossRef]

- Wu, S.; Yang, W.; Yan, H.; Zuo, X.; Cao, Z.; Li, H.; Shi, M.; Chen, H. A review of modified metal bipolar plates for proton exchange membrane fuel cells. International Journal of Hydrogen Energy 2021, 46, 8672–8701. [Google Scholar] [CrossRef]

- Gao, P.; Xie, Z.; Ouyng, C.; Wu, X.; Lei, T.; Liu, C.; Huang, Q. Carbon composite coatings on Ti for corrosion protection as bipolar plates of proton exchange membrane fuel cells. Micro & Nano Letters 2018, 13, 931–935. [Google Scholar] [CrossRef]

- Zhang, F.; Zhao, P.C.; Niu, M.; Maddy, J. The survey of key technologies in hydrogen energy storage. International Journal of Hydrogen Energy 2016, 41, 14535–14552. [Google Scholar] [CrossRef]

- Li, M.X.; Bai, Y.F.; Zhang, C.Z.; Song, Y.X.; Jiang, S.F.; Grouset, D.; Zhang, M.J. Review on the research of hydrogen storage system fast refueling in fuel cell vehicle. International Journal of Hydrogen Energy 2019, 44, 10677–10693. [Google Scholar] [CrossRef]

- Barthélémy, H. Hydrogen storage – Industrial prospectives. International Journal of Hydrogen Energy 2012, 37, 17364–17372. [Google Scholar] [CrossRef]

- Zheng, J.; Liu, X.; Xu, P.; Liu, P.; Zhao, Y.; Yang, J. Development of high pressure gaseous hydrogen storage technologies. International Journal of Hydrogen Energy 2012, 37, 1048–1057. [Google Scholar] [CrossRef]

- Rohit, G.; Santosh, M.S.; Kumar, M.N.; Raghavendra, K. Numerical investigation on structural stability and explicit performance of high-pressure hydrogen storage cylinders. International Journal of Hydrogen Energy 2023, 48, 5565–5575. [Google Scholar] [CrossRef]

- Cho, S.M.; Kim, C.; Kim, K.S.; Kim, D.K. Lightweight hydrogen storage cylinder for fuel cell propulsion systems to be applied in drones. International Journal of Pressure Vessels and Piping 2021, 194. [Google Scholar] [CrossRef]

- Cho, S.M.; Kim, K.S.; Kim, W.; Choi, S.J. Application of PET as a non-metallic liner for the 6.8 L type-4 cylinder based on the hydrogen cycling test. International Journal of Hydrogen Energy 2022, 47, 6965–6973. [Google Scholar] [CrossRef]

- Roh, H.S.; Hua, T.Q.; Ahluwalia, R.K. Optimization of carbon fiber usage in Type 4 hydrogen storage tanks for fuel cell automobiles. International Journal of Hydrogen Energy 2013, 38, 12795–12802. [Google Scholar] [CrossRef]

- Alcántar, V.; Aceves, S.M.; Ledesma, E.; Ledesma, S.; Aguilera, E. Optimization of Type 4 composite pressure vessels using genetic algorithms and simulated annealing. International Journal of Hydrogen Energy 2017, 42, 15770–15781. [Google Scholar] [CrossRef]

- Lee, Y.; Park, E.T.; Jeong, J.; Shi, H.; Kim, J.; Kang, B.S.; Song, W. Weight optimization of hydrogen storage vessels for quadcopter UAV using genetic algorithm. International Journal of Hydrogen Energy 2020, 45, 33939–33947. [Google Scholar] [CrossRef]

- Chen, J.X.; Veenstra, M.; Purewal, J.; Hobein, B.; Papasauva, S. Modeling a hydrogen pressure regulator in a fuel cell system with Joule-Thomson effect. International Journal of Hydrogen Energy 2019, 44, 1272–1287. [Google Scholar] [CrossRef]

- The LW351 Series Operating and Service Manual. Available online: https://www.pressure-tech.com/files/124/LW-351%20Series%20-%20O&S%20Manual.pdf (accessed on 07/04/2023).

- Zhang, Y.H.; Jia, Z.C.; Yuan, Z.M.; Yang, T.; Qi, Y.; Zhao, D.L. Development and Application of Hydrogen Storage. Journal of Iron and Steel Research International 2015, 22, 757–770. [Google Scholar] [CrossRef]

- Chen, Y.Z.; Zhao, S.L.; Ma, H.J.; Wang, H.; Hua, L.; Fu, S. Analysis of Hydrogen Embrittlement on Aluminum Alloys for Vehicle-Mounted Hydrogen Storage Tanks: A Review. Metals 2021, 11. [Google Scholar] [CrossRef]

- Niste, V.B.; Tanaka, H.; Ratoi, M.; Sugimura, J. WS2 nanoadditized lubricant for applications affected by hydrogen embrittlement. Rsc Advances 2015, 5, 40678–40687. [Google Scholar] [CrossRef]

- Tarhan, C.; Il, M.A.J.T.J.o.E.S. A study on hydrogen, the clean energy of the future: Hydrogen storage methods. 2021, 40, 102676.

- Moradi, R.; Groth, K.M. Hydrogen storage and delivery: Review of the state of the art technologies and risk and reliability analysis. International Journal of Hydrogen Energy 2019, 44, 12254–12269. [Google Scholar] [CrossRef]

- Stroman, R.O.; Schuette, M.W.; Swider-Lyons, K.; Rodgers, J.A.; Edwards, D.J. Liquid hydrogen fuel system design and demonstration in a small long endurance air vehicle. International Journal of Hydrogen Energy 2014, 39, 11279–11290. [Google Scholar] [CrossRef]

- Yatsenko, E.A.; Goltsman, B.M.; Novikov, Y.V.; Izvarin, A.I.; Platov, I.V.R. Review on modern ways of insulation of reservoirs for liquid hydrogen storage. International Journal of Hydrogen Energy 2022, 47, 41046–41054. [Google Scholar] [CrossRef]

- Osborn, W.; Markmaitree, T.; Shaw, L.L.; Ren, R.M.; Hu, J.Z.; Kwak, J.H.; Yang, Z.G. Solid-State Hydrogen Storage: Storage Capacity, Thermodynamics, and Kinetics. Jom 2009, 61, 45–51. [Google Scholar] [CrossRef]

- Khafidz, N.Z.A.; Yaakob, Z.; Lim, K.L.; Timmiati, S.N. The kinetics of lightweight solid-state hydrogen storage materials: A review. International Journal of Hydrogen Energy 2016, 41, 13131–13151. [Google Scholar] [CrossRef]

- Rimza, T.; Saha, S.; Dhand, C.; Dwivedi, N.; Patel, S.S.; Singh, S.; Kumar, P. Carbon-Based Sorbents for Hydrogen Storage: Challenges and Sustainability at Operating Conditions for Renewable Energy. Chemsuschem 2022, 15. [Google Scholar] [CrossRef]

- Manilov, A.I.; Skryshevsky, V.A. Hydrogen in porous silicon - A review. Materials Science and Engineering B-Advanced Functional Solid-State Materials 2013, 178, 942–955. [Google Scholar] [CrossRef]

- Muduli, R.C.; Kale, P. Silicon nanostructures for solid-state hydrogen storage: A review. International Journal of Hydrogen Energy 2023, 48, 1401–1439. [Google Scholar] [CrossRef]

- Thomas, *!!! REPLACE !!!*; Mark, K.J.D.T. Thomas; Mark, K.J.D.T. Adsorption and desorption of hydrogen on metal–organic framework materials for storage applications: comparison with other nanoporous materials. 2009, 1487-1505.

- Samantaray, S.S.; Putnam, S.T.; Stadie, N.P. Volumetrics of Hydrogen Storage by Physical Adsorption. Inorganics 2021, 9. [Google Scholar] [CrossRef]

- Pedicini, R.; Sacca, A.; Carbone, A.; Passalacqua, E. Hydrogen storage based on polymeric material. International Journal of Hydrogen Energy 2011, 36, 9062–9068. [Google Scholar] [CrossRef]

- Barrett, S.J.F.c.b. First UAV test flight with Cella solid-state hydrogen storage. 2016.

- Kim, H.; Oh, T.H.; Kwon, S. Simple catalyst bed sizing of a NaBH4 hydrogen generator with fast startup for small unmanned aerial vehicles. International Journal of Hydrogen Energy 2016, 41, 1018–1026. [Google Scholar] [CrossRef]

- Kwon, S.M.; Kim, M.J.; Kang, S.; Kim, T. Development of a high-storage-density hydrogen generator using solid-state NaBH4 as a hydrogen source for unmanned aerial vehicles. Applied Energy 2019, 251. [Google Scholar] [CrossRef]

- Salman, M.S.; Rambhujun, N.; Pratthana, C.; Lai, Q.; Aguey-Zinsou, K.F. Solid-state hydrogen storage as a future renewable energy technology. 2021.

- R. O`Hayre, S.-W.C., W. G. Colella, F. B. Prinz. Fuel Cell Fundamentals. 2009.

- Ozbek, E.; Yalin, G.; Ekici, S.; Karakoc, T.H. Evaluation of design methodology, limitations, and iterations of a hydrogen fuelled hybrid fuel cell mini UAV. Energy 2020, 213. [Google Scholar] [CrossRef]

- Erdinc, O.; Uzunoglu, M. Recent trends in PEM fuel cell-powered hybrid systems: Investigation of application areas, design architectures and energy management approaches. Renewable and Sustainable Energy Reviews 2010, 14, 2874–2884. [Google Scholar] [CrossRef]

- Vural, B.; Dusmez, S.; Uzunoglu, M.; Ugur, E.; Akin, B. Fuel Consumption Comparison of Different Battery/Ultracapacitor Hybridization Topologies for Fuel-Cell Vehicles on a Test Bench. IEEE Journal of Emerging and Selected Topics in Power Electronics 2014, 2, 552–561. [Google Scholar] [CrossRef]

- Ustolin, F.; Taccani, R. Fuel cells for airborne usage: Energy storage comparison. International Journal of Hydrogen Energy 2018, 43, 11853–11861. [Google Scholar] [CrossRef]

- Apeland, J.; Pavlou, D.; Hemmingsen, T.J.J.o.A.T. ; Management. Suitability Analysis of Implementing a Fuel Cell on a Multirotor Drone. 2020, 12. [Google Scholar]

- Ahmadi, S.; Bathaee, S.M.T.; Hosseinpour, A.H. Improving fuel economy and performance of a fuel-cell hybrid electric vehicle (fuel-cell, battery, and ultra-capacitor) using optimized energy management strategy. Energy Conversion and Management 2018, 160, 74–84. [Google Scholar] [CrossRef]

- Karunarathne, L.; Economou, J.T.; Knowles, K. Power and energy management system for fuel cell unmanned aerial vehicle. Proceedings of the Institution of Mechanical Engineers Part G-Journal of Aerospace Engineering 2012, 226, 437–454. [Google Scholar] [CrossRef]

- Gang, B.G.; Kwon, S. Design of an energy management technique for high endurance unmanned aerial vehicles powered by fuel and solar cell systems. International Journal of Hydrogen Energy 2018, 43, 9787–9796. [Google Scholar] [CrossRef]

- Xu, L.; Huangfu, Y.; Ma, R.; Xie, R.; Song, Z.; Zhao, D.; Yang, Y.; Wang, Y.; Xu, L. A Comprehensive Review on Fuel Cell UAV Key Technologies: Propulsion System, Management Strategy, and Design Procedure. IEEE Transactions on Transportation Electrification 2022, 8, 4118–4139. [Google Scholar] [CrossRef]

- Apeland, J.; Pavlou, D.; Hemmingsen, T. ; Ieee. In State-of-Technology and Barriers for Adoption of Fuel Cell Powered Multirotor Drones. In Proceedings of the International Conference on Unmanned Aircraft Systems (ICUAS), Athens, GREECE, 2020, Sep 01-04; pp. 1359–1367.

- Zhang, X.; Liu, L.; Dai, Y.; Lu, T. Experimental investigation on the online fuzzy energy management of hybrid fuel cell/battery power system for UAVs. International Journal of Hydrogen Energy 2018, 43, 10094–10103. [Google Scholar] [CrossRef]

- Lei, T.; Min, Z.; Fu, H.; Zhang, X.; Li, W.; Zhang, X. Dynamic balanced energy management strategies for fuel-cell hybrid power system of unmanned air vehicle. Acta Aeronautica et Astronautica Sinica 2020, 41, 15, (in Chinese with English abstract). [Google Scholar]

- Boukoberine, M.N.; Zia, M.F.; Benbouzid, M.; Zhou, Z.; Donateo, T. Hybrid fuel cell powered drones energy management strategy improvement and hydrogen saving using real flight test data. Energy Conversion and Management 2021, 236. [Google Scholar] [CrossRef]

- Boukoberine, M.N.; Donateo, T.; Benbouzid, M. Optimized Energy Management Strategy for Hybrid Fuel Cell Powered Drones in Persistent Missions using Real Flight Test Data. IEEE Transactions on Energy Conversion 2022, 1–1. [Google Scholar] [CrossRef]

- Liu, H.; Yao, Y.; Wang, J.; Qin, Y.; Li, T.J.I.j.o.h.e. A control architecture to coordinate energy management with trajectory tracking control for fuel cell/battery hybrid unmanned aerial vehicles. 2022, 47.

- Yao, Y.; Wang, J.; Zhou, Z.; Li, H.; Liu, H.; Li, T.J.E. Grey Markov prediction-based hierarchical model predictive control energy management for fuel cell/battery hybrid unmanned aerial vehicles. 2023, 262. 262.

- Yan, Y.; Wang, B.; Wang, C.; Zhao, D.; Xiao, C. Adaptive maximum power point tracking based on Kalman filter for hydrogen fuel cell in hybrid unmanned aerial vehicle applications. International Journal of Hydrogen Energy 2023, 48, 25939–25957. [Google Scholar] [CrossRef]

- Zeng, D.; Guo, X.; Guo, K.; Dong, Z.; Yu, X. Design and Management of a Hydrogen Fuel Cell Powered Quadrotor. In Proceedings of the 2023 International Conference on Unmanned Aircraft Systems (ICUAS); 2023; pp. 644–651. [Google Scholar]

| Cylinder types | Materials | Hydrogen storage pressure (Mpa) | Mass percent (%) | Volumetric hydrogen storage density (g/L) |

Service life (a) |

|---|---|---|---|---|---|

| Type Ⅰ | All metal | 17.5–20 | ≈1 | 14.28–17.28 | 15 |

| Type Ⅱ | Metal liner with hoop wrapping |

26.3–30 | ≈1.5 | 14.28–17.28 | 15 |

| Type Ⅲ | Metal liner with full composite wrapping |

30–70 | 2.4-4.1 | 35–40 | 15–20 |

| Type Ⅳ | Plastic liner with full composite wrapping |

>70 | 2.5-5.7 | 38–40 | 15–20 |

| Storage System | Mass Storage Efficiency (%kg H2/kg storage) |

Volumetric Storage Density (kg H2/L storage) |

Gravimetric Storage Energy Density (kWh/kg) |

Volumetric Storage Energy Density (kWh/L) |

|---|---|---|---|---|

| Compressed H2, 300bars | 3.1 | 0.014 | 1.2 | 0.55 |

| Compressed H2, 700bars | 4.8 | 0.033 | 1.9 | 1.30 |

| Cryogenic Liquid H2 | 14.2 | 0.043 | 5.57 | 1.68 |

| Cryo-compression tank (LLNL) | 7.38 | 0.045 | 2.46 | 1.51 |

| Metal hydride (conservative) | 0.65 | 0.028 | 0.26 | 1.12 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).