1. Introduction

Surface roughness is a critical determinant of product quality, functionality, and reliability in the manufacturing industry. It quantifies the deviation of a workpiece's actual surface from its ideal form and is influenced by factors such as cutting parameters, tool geometry, material, and machining processes. The complexity of manufacturing intricate geometric parts often involves multiple steps, including boring, milling, roughing, and finishing, with surface roughness needing to meet assembly process specifications post-finishing. Achieving an optimal balance of surface roughness is essential, as it can be neither too low nor too high. Consequently, surface roughness is a vital metric for assessing product quality. Traditionally, quality assurance has relied on periodic sampling and manual inspection, which can lead to significant waste when surface roughness fails to meet standards. Thus, the development of a real-time, accurate surface roughness prediction method is imperative.

Previous research has investigated artificial intelligence (AI) approaches for predicting surface roughness in turning processes. Benardos and Vosniakos [

1] found that AI methods outperformed traditional approaches, while Özel and Karpat [

2] and Palanisamy and Shanmugasundaram [

3] reported that artificial neural networks (ANNs) surpassed regression models and response surface methodologies.

Researchers have also refined input variables to enhance prediction accuracy. For example, in 2010, T. Reddy and C. Reddy [

4] correlated acoustic emission (AE) with surface roughness, Marani et al. [

5] evaluated feed rate and cutting speed in adaptive neuro-fuzzy inference systems (ANFIS), and Lin et al. [

6] demonstrated that ANNs could improve prediction accuracy by incorporating vibration signals. Vasanth et al. [

7] fused cutting force, tool wear, displacement of tool vibration and three cutting parameters to predict the roughness in ANN. Moreover, researchers have improved prediction accuracy by enhancing model capabilities. Pimenov et al. [

8] found that random forests outperformed other models, while Badiger et al. [

9] and Kong et al. [

10] utilized ANNs and machine learning techniques to optimize cutting parameters and feature extraction,respectively. Su et al. [

11] and Lu et al. [

12] applied SVM and GPR, respectively, achieving promising results.

Despite these efforts, existing methods, which primarily rely on traditional statistics, SVM, and ANN, depend heavily on comprehensive training data. The complex machining environment, including the use of cutting coolants, often hinders the acquisition of real surface images, necessitating a reliable and accessible method for initial data collection.

Time domain signal processing methodologies, encompassing statistical functions and advanced techniques, have been extensively investigated for tool condition monitoring in turning processes. Siddhpura and Paurobally [

13] conducted a review of flank wear prediction methods, while Elangovan [

14] enhanced the selection of statistical features from vibration signals using principal component analysis (PCA), achieving a classification accuracy of 91.2% for flank wear. Aghdam et al. [

15] employed the autoregressive moving average (ARMA) model to identify wear-sensitive features based on the dynamics of the tool-holder system, addressing the challenges of identifying random tool wear features in time domain analysis, as noted by Siddhpura and Paurobally [

13], Nath [

16], and Kuntoğlu et al. [

17].

Frequency-domain analysis methods, such as FFT and PSD, have been explored by Fang et al. [

18] and Plaza et al. [

21]. Bhuiyan and Choudhury [

19] utilized the root mean square (RMS) of vibration signals and frequency analysis to assess machine tools under various cutting conditions. Tangjitsitcharoen and Lohasiriwat [

20] differentiated broken chip signals from tool wear using PSD of decomposed cutting force.

Time-frequency domain analysis, including STFT, WT, HHT, and EMD, is widely applied for machinery fault diagnosis. Scheffer and Heyns [

22], Wang et al. [

23,

33,

34], and Segreto et al. [

24] applied wavelet analysis to classify tool wear, achieving high success rates. Gangadhar et al. [

25] used the mean square value of DWT features from vibration signals to classify different worn conditions using a decision tree algorithm. Plaza and López [

26,

27] established criteria for WPT based on vibration and force signals, applying packet reduction criteria such as maximum energy and maximum entropy. Du et al. [

28] combined WPT and WT features, re-extracted using the Relief-F algorithm, to predict tool wear with a mean absolute error of 0.01-0.03mm. Kong et al. [

29] presented a predictive model for tool wear, integrating radial basis function-based principal component analysis and relevance vector machine, with features extracted from time-domain statistical functions, frequency domain parameters, and Daubechies WPT energy using Shannon entropy.

In contrast, the empirical mode decomposition (EMD) has seen limited application in turning tool condition monitoring (TCM). Babouri et al. [

30] combined WT and EMD to detect tool wear, while Li et al. [

31,

32] utilized a meta-learning model based on a fully connected neural network, integrating time-domain statistical functions, frequency domain features, EMD, wavelet analysis, and STFT, achieving a mean absolute error of 0.01-0.03mm in predicting tool wear.

This paper proposes the use of Gaussian Process Regression (GPR) based on vibration signals to accurately predict surface roughness in turning complex-structured workpieces. GPR offers several advantages: it provides uncertainty estimates, is non-parametric and flexible, and has demonstrated higher accuracy and robustness compared to other methods. In turning processes, vibration signals, which are less affected by external noise and easier to install, are analyzed using GPR. This approach leverages the strengths of vibration signals to improve the prediction of surface roughness.

In turning processes, there are various types of signals that can be utilized as inputs for GPR when predicting surface roughness. These signals include commonly used ones such as acoustic emission and cutting force. However, these signals have limitations that can affect their accuracy and applicability in different scenarios. On the other hand, vibration signals possess several advantages. Firstly, vibration sensors can be easily installed without the need to damage the original structure of the machine tool. Secondly, vibration signals are less susceptible to external noise and disturbances, resulting in more reliable and accurate predictions of surface roughness. Therefore, in this paper, GPR is employed to analyze vibration signals from turning complex-structured workpieces.

2. Methodology

The proposed model comprises three primary components: signal acquisition, feature extraction, and surface roughness prediction. The signal acquisition module captures vibration signals in three orthogonal directions from the turning tool throughout the machining process. These signals undergo pre-processing to mitigate noise from extraneous sources. The feature extraction module then extracts parameters from the pre-processed signals, encompassing both time and frequency domains. Time-domain features are derived using statistical measures such as mean, maximum, median, standard deviation (STD), and root mean square (RMS). The frequency domain analysis is facilitated by Welch's method, which transforms the signals from the time domain to the frequency domain, and is further enhanced by a three-level Daubechies Wavelet Packet Transform (WPT). These features are subsequently utilized to construct the surface roughness prediction model.

2.1. Feature Extraction and Correlation

Feature extraction from vibration signals is a pivotal step in preprocessing, aimed at isolating pertinent information that enhances signal quality and processing efficiency. This process encompasses various methodologies, such as statistical characteristics, frequency domain features, time-frequency features, and nonlinear characteristics.

Statistical characteristics involve calculating the mean, variance, standard deviation, and peak values of the vibration signal, which reflect the average vibration level and tool fluctuation. Frequency domain features are derived through Fourier or wavelet transforms, capturing attributes like power spectral density, frequency components, and dominant frequencies, essential for analyzing the frequency composition and distribution of the tool's vibrations.

Welch's method, a prevalent frequency domain feature extraction technique, employs Fourier transform-based signal analysis. It segments the raw vibration data, x(n), into L overlapping subsegments, each containing M data points, resulting in a total of N=LM data points. The jth segment is represented as:

Then a window function w(n) is added to each data segment, and the power spectrum of each segment is calculated. The power spectrum of the jth segment is:

where U is the normalization factor:

Assuming that the power spectra of each segment is approximately uncorre-lated, the power spectral estimate is given by:

The Welch feature extraction method is employed to obtain frequency components and power spectral density, which are instrumental in analyzing the signal's frequency composition and distribution. This method enhances the accuracy of spectral estimation but may introduce information loss and estimation errors during signal segmentation and windowing. Consequently, careful parameter selection and optimization are essential, tailored to the specific application and data characteristics.

Time-frequency domain analysis, including short-time Fourier transform (STFT), wavelet transform (WT), Hilbert-Huang transform (HHT), and empirical mode decomposition (EMD), is extensively applied to nonstationary signals for machinery fault diagnosis. In the context of turning process tool condition monitoring (TCM), WT analysis is particularly prevalent due to its significant reduction in processing time and precise identification of specific frequency contributions.

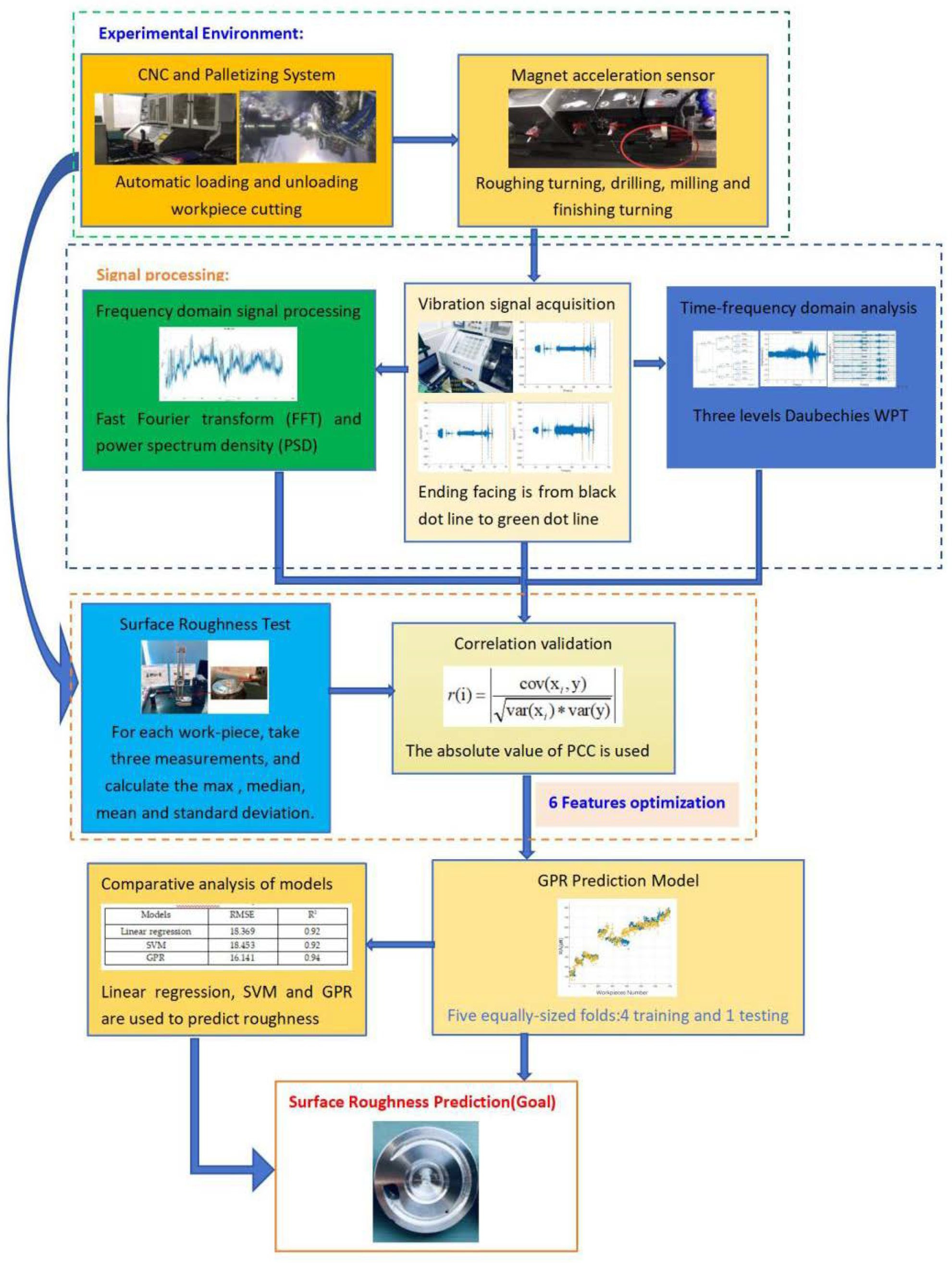

Figure 1.

Surface Roughness Prediction and Signal Processing Workflow.

Figure 1.

Surface Roughness Prediction and Signal Processing Workflow.

To assess the correlation between the statistical properties of time and frequency domain acceleration signals and roughness data, the Pearson correlation coefficient (PCC) is utilized. The PCC ranges from -1 to 1, with a value of 0 indicating no correlation. Negative values denote an inverse relationship, while positive values indicate a direct correlation. In this study, the absolute value of PCC is prioritized, as higher absolute values suggest stronger correlation features. The mathematical equation for PCC is as follows:

Here, is the variable, is the roughness, represents variance and represents covariance. The value of represents the correlation between and .

2.2. Gaussian Process Regression (GPR) Model

To predict surface roughness, a subset of relevant features is selected based on actual requirements and the nature of the problem. These features are then incorporated into a prediction model for tool wear degree, utilizing machine learning algorithms such as Support Vector Machine (SVM), decision trees, and neural networks for modeling and prediction.

Gaussian Process Regression (GPR) is a machine learning algorithm adept at modeling nonlinear relationships between inputs and outputs. It uses the chosen features from signal acquisition and feature extraction modules to predict surface roughness. The Gaussian process, represented by equation (2), is characterized by feature vectors that include parameters such as the time-domain maximum, average, median, and root mean square values.

The mean function, as described by equation (3), represents the expected value of the function.

The covariance function, detailed in equation (4), is a critical component of the GPR model.

The kernel function of GPR, which combines a mean function and a covariance function, typically sets the mean function to zero. The rational quadratic kernel function, as shown in equation (5), is a common choice.

This function's parameters, including the scale factors σ, s, and the proportional mixed factor α, are optimized for the study. The rational quadratic kernel function can be interpreted as a sum of square exponential kernel functions with varying reduction lengths, and it reduces to a square exponential kernel under certain conditions. Its infinite differentiability ensures a smooth function, which is crucial for the GPR model. The optimal parameter solution is determined using an iterative conjugate gradient method.

In essence, a robust prediction model requires accurate signal collection, followed by the optimization and adjustment of feature extraction methods and parameters based on specific vibration signals and tool wear conditions. Additionally, the efficacy of feature extraction and model construction necessitates experimental validation.

4. Signal Processing and Features Optimization

4.1. Time Domain Analysis

The commonly utilized statistical functions in time domain analysis encompass a range of well-established metrics, such as mean, root mean square (RMS), standard deviation (STD), skewness, kurtosis, and crest factor. These functions are instrumental in characterizing the behavior of signals and identifying trends or anomalies within the data.

The time domain analysis involved the examination of signals from both ending facing and cylindrical turning processes, focusing on parameters such as mean, RMS, STD, skewness, kurtosis, and crest factor. The statistical properties were categorized into three distinct groups based on the production timeline: the first group spanned from the 2nd to the 17th day, with approximately 5000 workpieces produced; the second group from the 23rd to the 50th day; and the third group on the 62nd day. Over the 62-day sample period, the analysis revealed fluctuations in amplitude with minimal changes in skewness. The mean value, RMS, and STD decreased in the first group, while the second group showed an increase, and the crest factor and kurtosis exhibited a contrasting trend. The RMS and STD properties were notably similar.

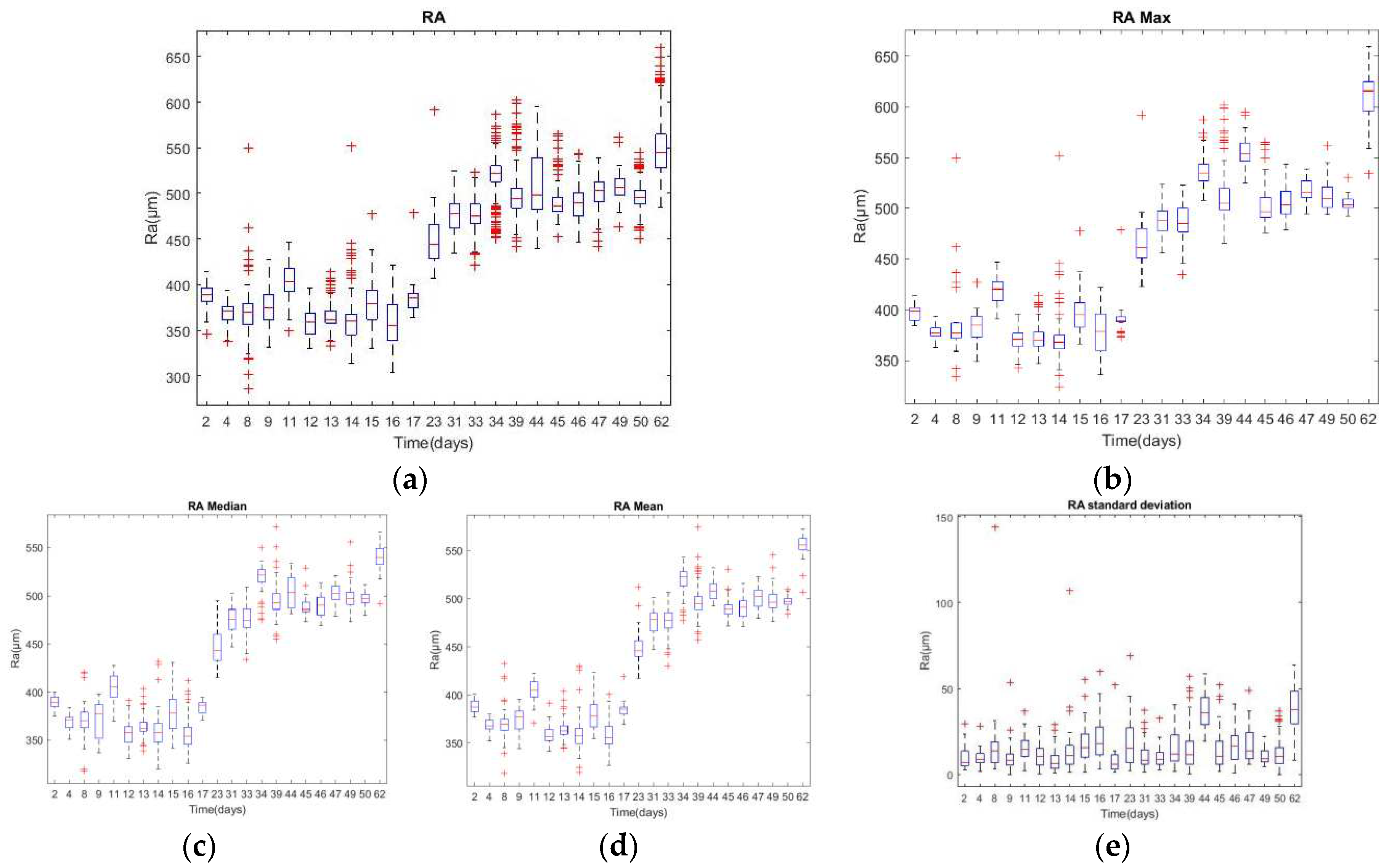

Figure 7(a) presents roughness measurements from three different positions of the 30 workpieces for each day, with

Figure 7(b) to (e) depicting the max, median, mean, and STD of these measurements. The roughness values fluctuate, with some abnormal peaks, but generally trend upwards over time. The roughness can be divided into three groups: the first from the 2nd to the 17th day, with values primarily between 350µm and 450µm; the second from the 23rd to the 50th day, with values around 450µm to 550µm; and the third on the 62nd day, with some workpieces exceeding the desired tolerance of 600µm.

The STD, as shown in

Figure 7(b), occasionally highlighted discrepancies among the roughness measurements.

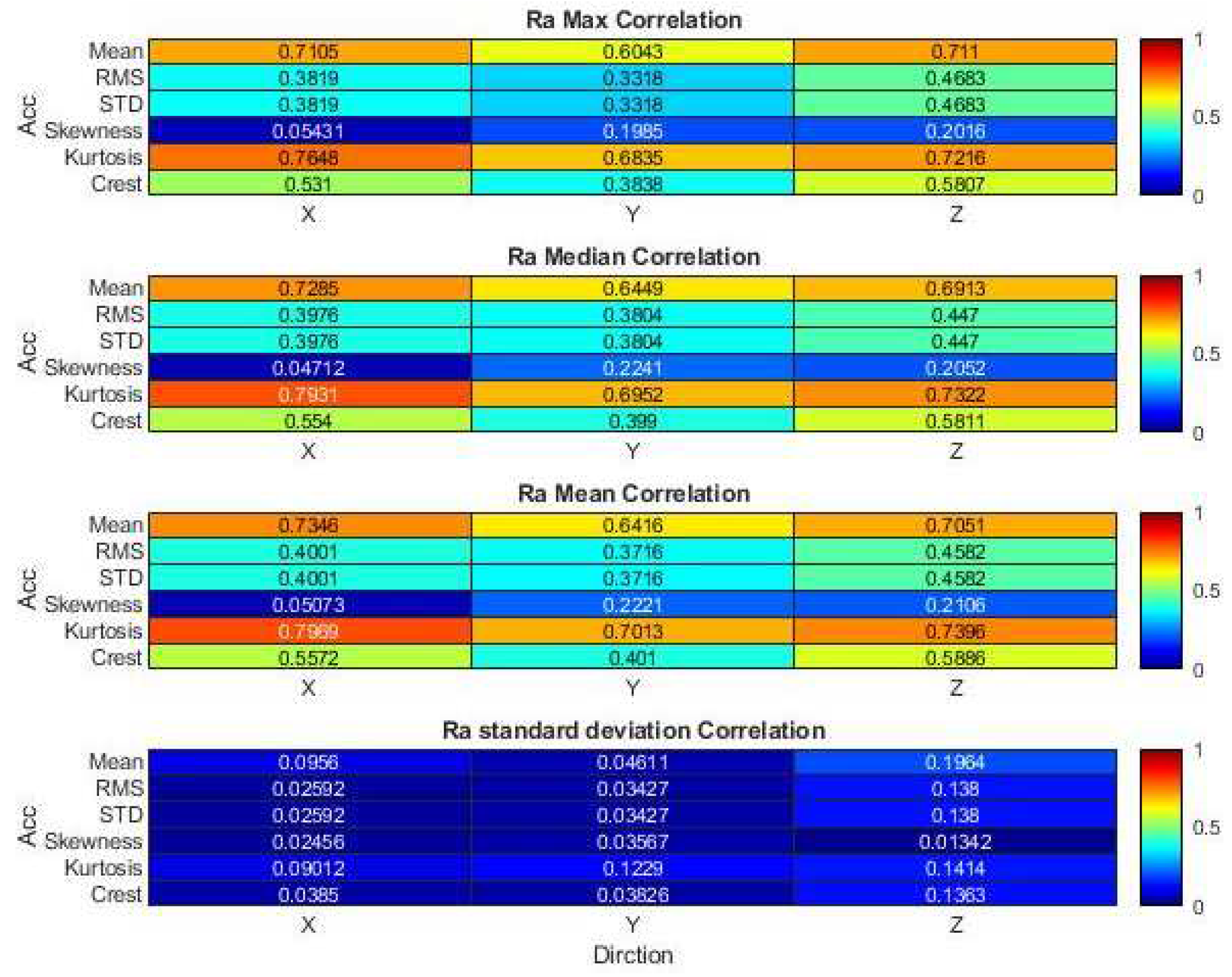

Figure 8's heatmaps illustrate the PCCs between the time domain's statistical properties and roughness metrics. The mean value and kurtosis of the time domain in the X-axis (tangential direction) and Z-axis (feed direction) showed stronger correlations with the max, median, and mean of roughness, with PCC absolute values ranging from 0.70 to 0.79. The kurtosis of the time domain in the X-axis demonstrated the highest correlation with each statistical roughness, with a maximum PCC of 0.7969 for the mean roughness value.

In summary, the mean value of the time domain signals in the X-axis and Z-axis demonstrated consistent performance across both tools, suggesting their potential as relevant features for predicting roughness.

4.2. Frequency Domain Analysis

The Fast Fourier Transform (FFT) is a highly regarded and widely applied technique for processing signals in the frequency domain, harnessing the Fourier Transform (FT) to seamlessly transition signals from the time domain to the frequency domain. The FFT algorithm achieves this by performing a series of multiplications and additions, which markedly decreases the computational burden compared to the traditional DFT. This optimization significantly enhances the efficiency of the DFT computation by minimizing the number of complex operations required.

While the FT is fundamental to signal analysis, it faces a limitation due to its reliance on sinusoidal basis functions. This dependency can impede the precise determination of FT coefficients for non-stationary signals, which lack a constant frequency throughout their duration.

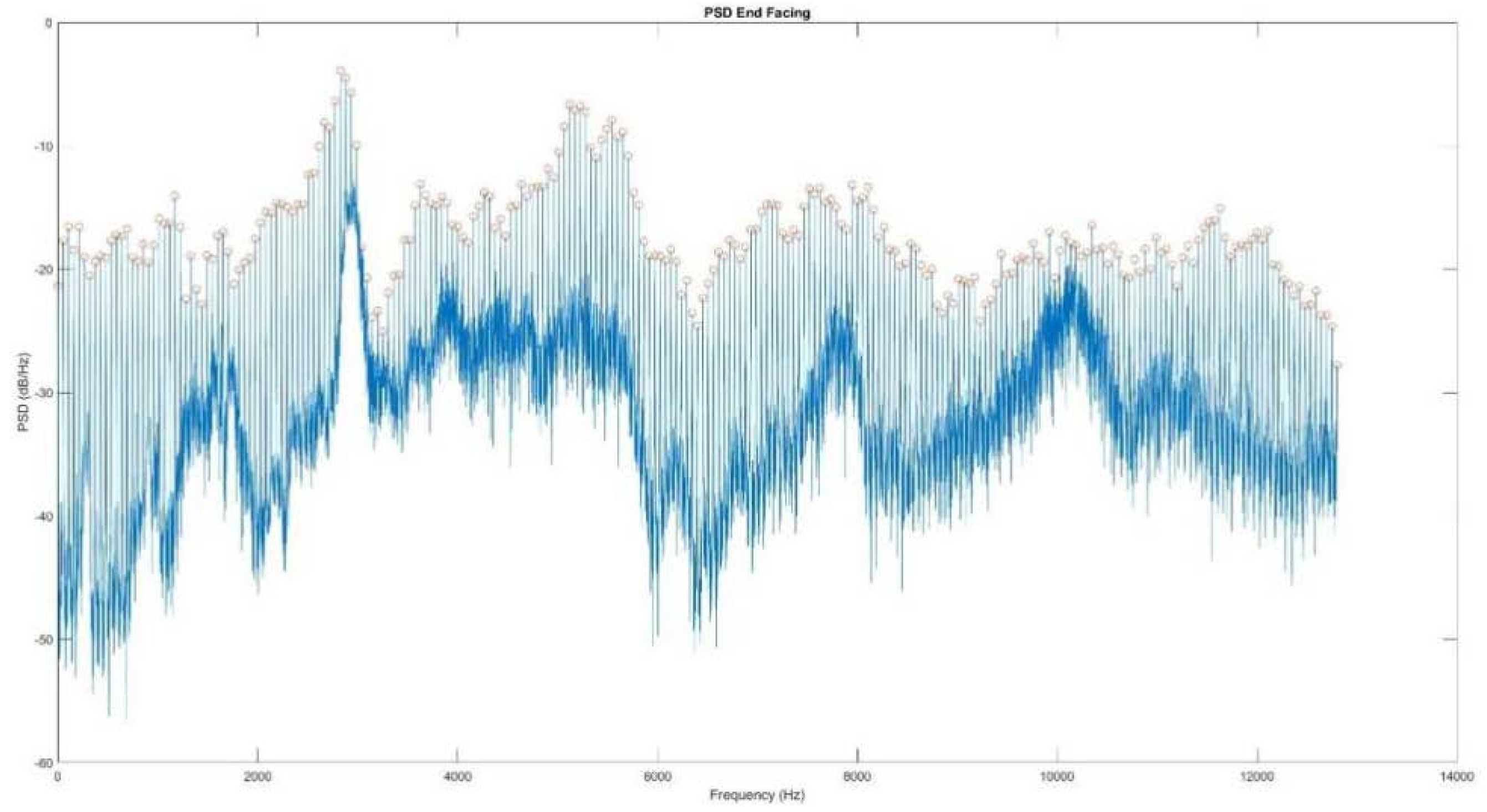

Power Spectral Density (PSD) quantifies the distribution of signal power across various frequency bands. Welch's method enhances PSD analysis by introducing window functions, which effectively mitigate the noise associated with finite data sets, providing a more precise depiction of the signal's power distribution across frequencies.

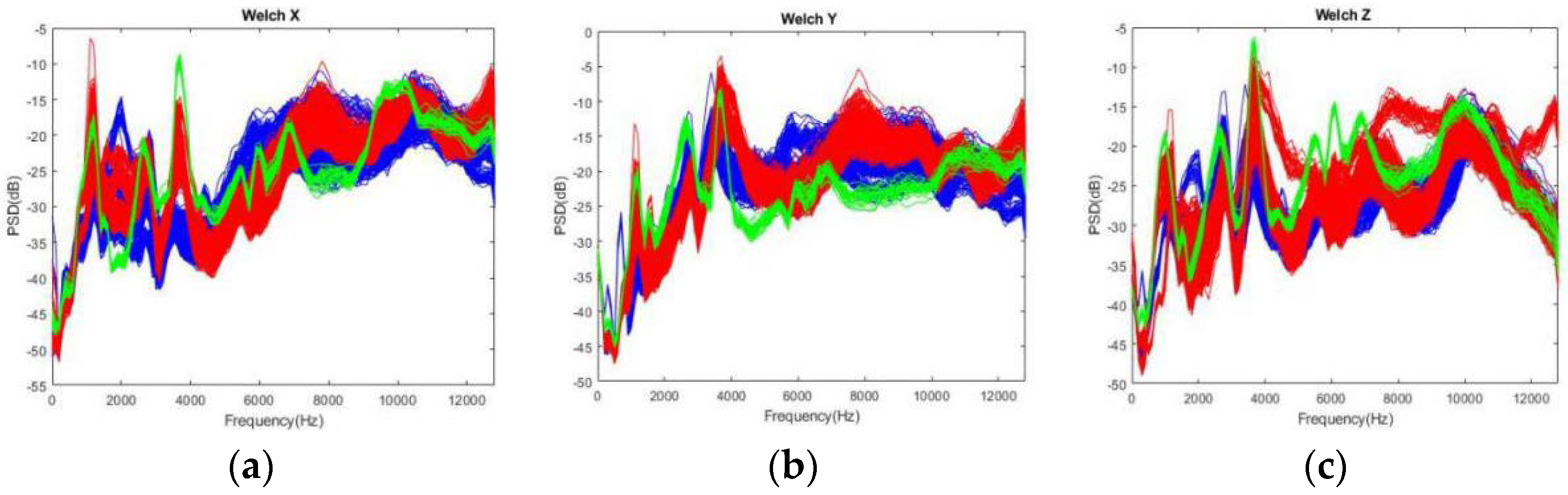

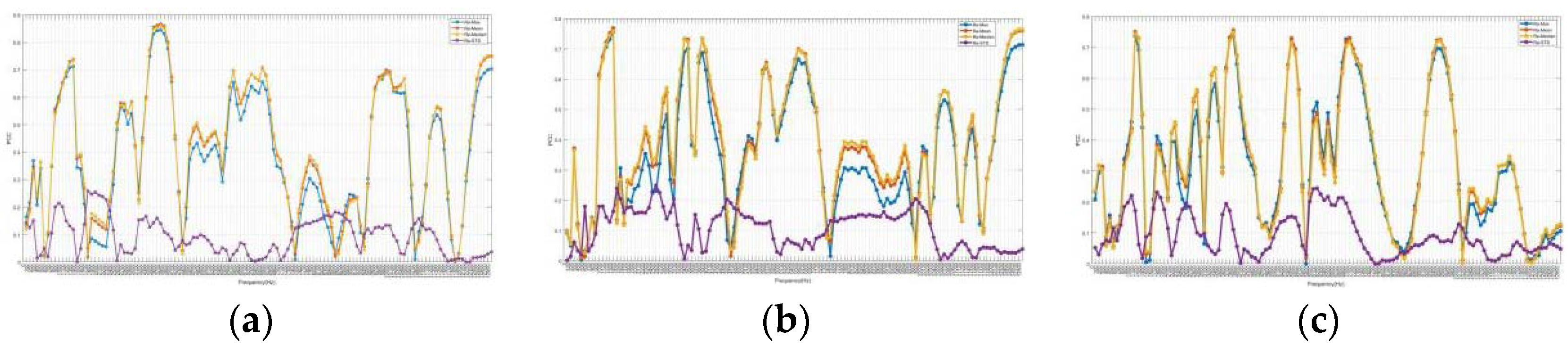

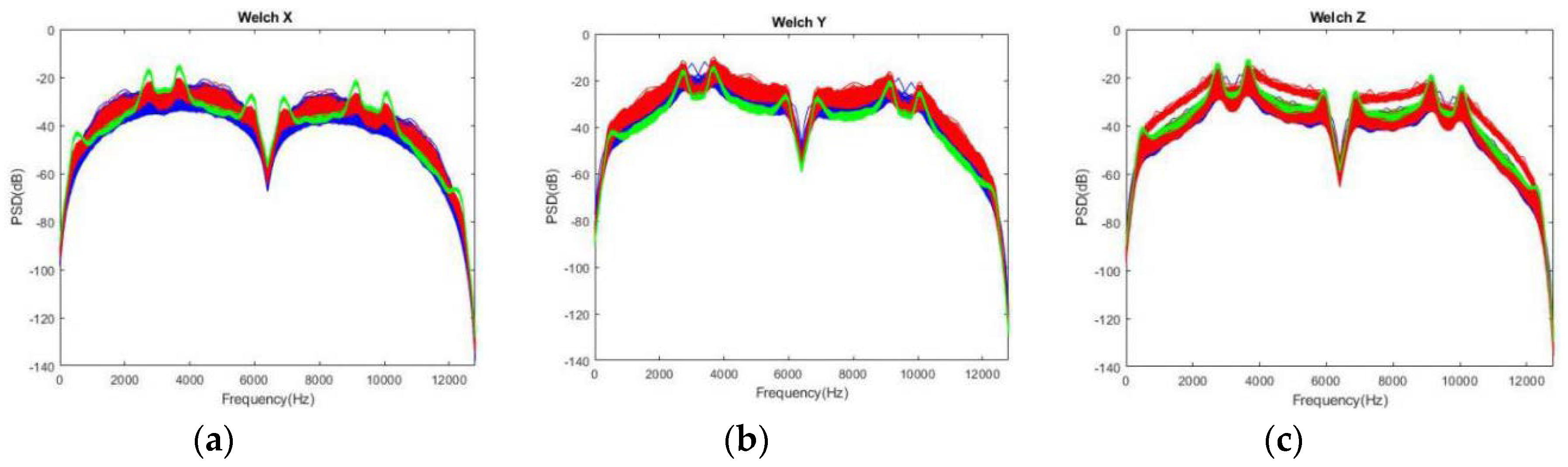

Figure 9 demonstrates the application of Welch's method to analyze the frequency domain of acceleration signals in three orthogonal directions, with a sample rate of 25600 Hz. The data is divided into 256 overlapping segments, each processed with a Hamming window. The PSD is depicted for the three axes—X, Y, and Z—represented in blue, red, and green, respectively. Typically, PSD increases with frequency, with distinct peaks observed around 3700 Hz for the X-axis (

Figure 9a) and Z-axis (

Figure 9c) in Group 1 and 3. The Y-axis (

Figure 9b) for Group 2 exhibits the highest PSD at approximately 3700 Hz.

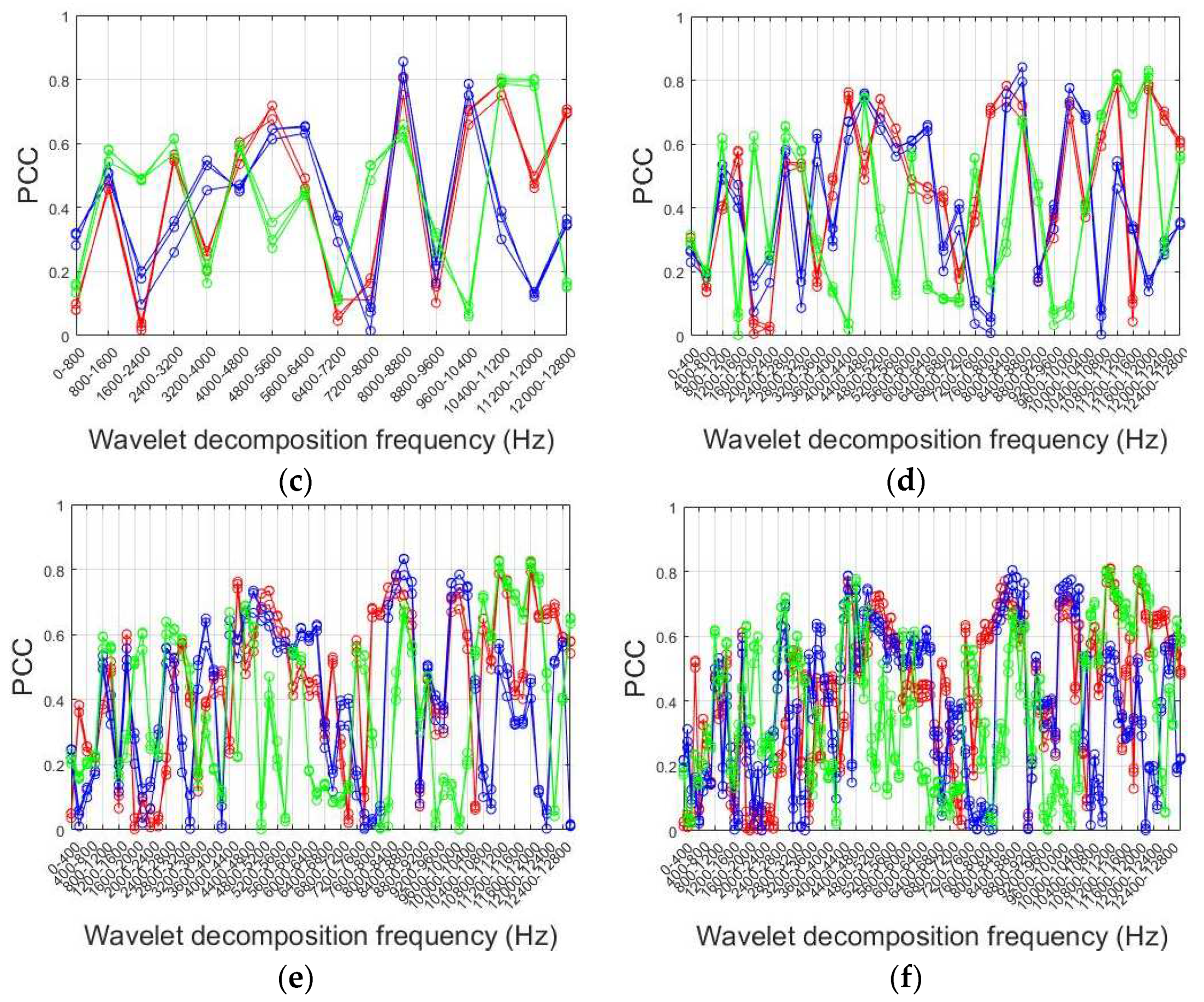

Figure 10 presents the Pearson Correlation Coefficients (PCCs) between the PSD of every 100 frequencies and the statistical roughness, aiding in the selection of relevant frequencies. The blue, red, yellow, and purple curves represent the max, mean, median, and STD of roughness, respectively. The largest PCCs in the X-axis are approximately 0.8446, 0.8674, and 0.8595 for the maximum values, mean values, and median values of roughness, respectively, at 3700 Hz (

Figure 10a). Although these PCCs are not the highest in the Y-axis (

Figure 10b) and Z-axis (

Figure 10c), they still exhibit strong correlations, around 0.67 and 0.72, respectively. The PCCs for mean values, median, and max of roughness are similar, with the median roughness PCC slightly higher. The highest PCCs are around 0.7689 at 1300 Hz for the Y-axis and around 0.7562 at 3800 Hz for the Z-axis. Other significant PCCs are observed around 1200 Hz, 6500 Hz, and 12600 Hz for the X and Y axes. The STD of roughness is less related to the frequency domain.

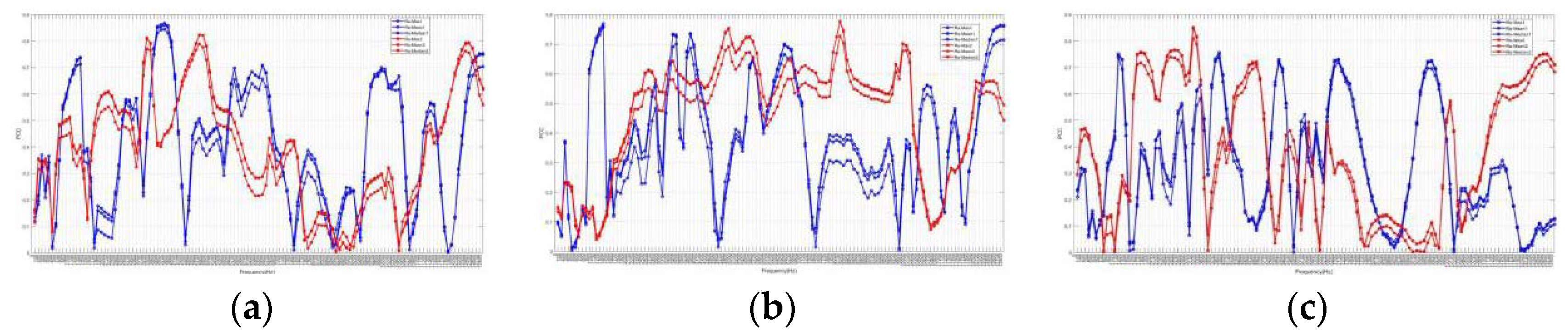

Figure 11 also shows the comparison of PCCs between the frequency domain and roughness for Tool No.1 and No.2. The STD of roughness, which is less related to the frequency domain, is disregarded. The blue and red curves represent Tool No.1 and No.2, respectively. For No.2, the highest PCCs are around 0.8221 at 4700 Hz for the X-axis, 0.7749 at 8100 Hz for the Y-axis, and 0.8511 at 3100 Hz for the Z-axis. The PCCs between the frequency domain and max, mean value, and median of roughness for both tools exhibit similar trends in low frequencies across all three axes. The ranges from 3000 Hz to 4000 Hz generally exhibit steady high PCCs for both tools, especially in the X-axis. The PCCs between the frequency domain and roughness are consistently higher than 0.7 around 12600 Hz for both tools in the X-axis.

Table 3 summarizes the comparison of maximum PCCs for time and frequency domains for both tools. The frequency domain PCCs are superior to those of the time domain for both tools.

In summary, the correlation between the frequency domain and surface roughness outperforms that of the time domain, particularly in the frequency range around 12,600 Hz for the X-axis, where the PCC exceeds 0.7, indicating a strong correlation and suggesting these frequencies as promising features for analysis. While the peaks of PCCs in the frequency domain vary between the two tools, the trends in low frequencies are notably similar.

4.3. Wavelet Packet Transform

Wavelet analysis employs a set of mother wavelets, such as Haar, Daubechies, symlets, Morlets, and coiflets, to decompose signals into their constituent components. The three principal types of wavelet analysis are the continuous wavelet transform (CWT), discrete wavelet transform (DWT), and wavelet packet transform (WPT). A crucial distinction between the short-time Fourier transform (STFT) and wavelet analysis is that STFT breaks down signals into shorter segments using a window function for DFT computation, while wavelet analysis relies on mother wavelets in place of sinusoidal functions. The WPT extends the capabilities of DWT by providing further decomposition of the approximation and detail signals.

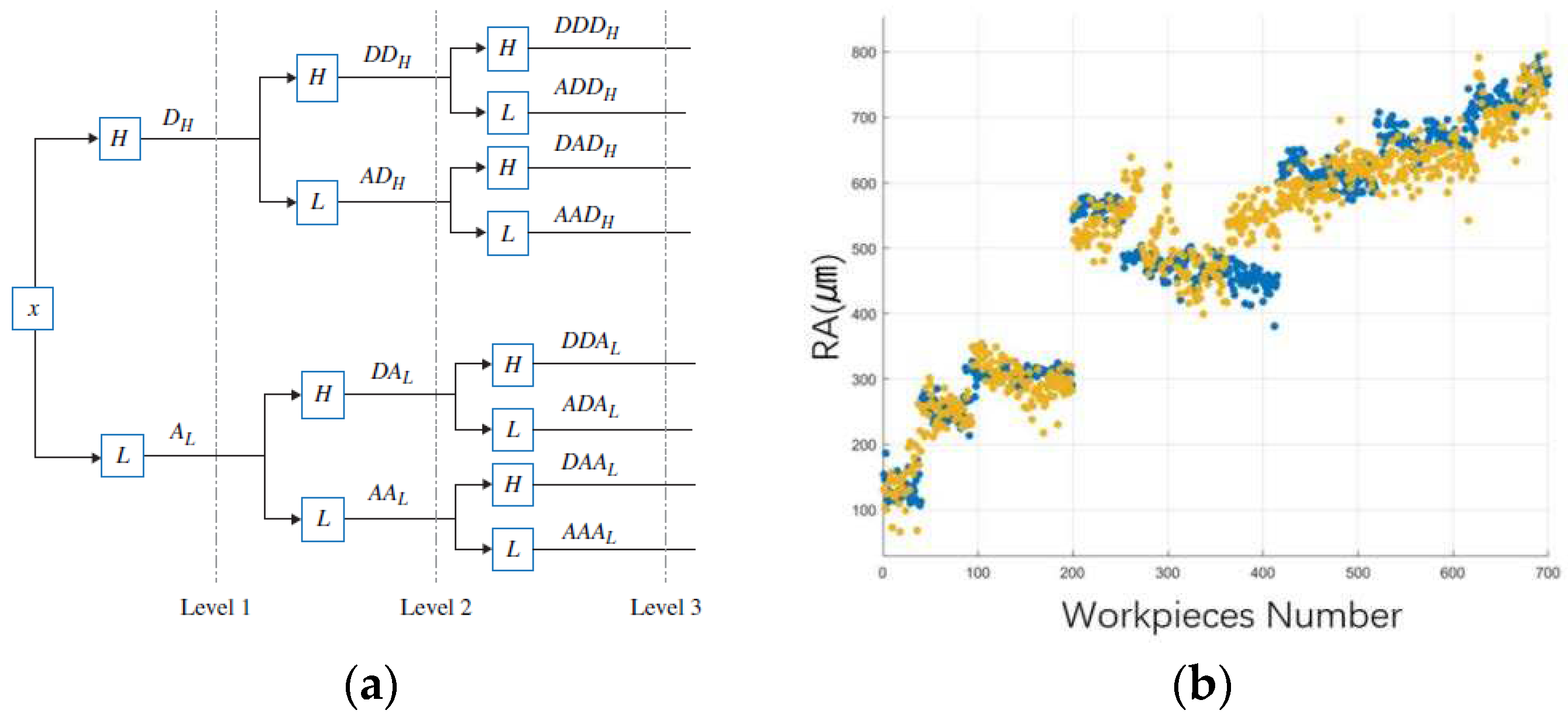

Figure 12 presents a three-level WPT decomposition, where the input signal (x) is initially processed by a low-pass filter to obtain the approximation coefficients (AL) and a high-pass filter to extract the detailed coefficients (DH). This process is recursively applied at subsequent levels.

Figure 13 provides an example of a workpiece's signal decomposition using a three-level Daubechies WPT. The original vibration signals for the X, Y, and Z axes are depicted in

Figure 13(a), (c), and (e), respectively. The corresponding reconstructions of wavelet coefficients are shown in

Figure 13(b), (d), and (f), where larger nodes represent higher-pass wavelet coefficients, indicating regions of greater frequency content.

The PSD results of reconstructed coefficient 3 (frequency range: 3200Hz to 4800Hz) are exemplified in

Figure 14. Blue, red, and green represent Groups 1, 2, and 3, respectively, consistent with

Section 4.1. Notably, there are clear peaks around 3700Hz in the X and Z axes for Group 3, similar to

Figure 9.

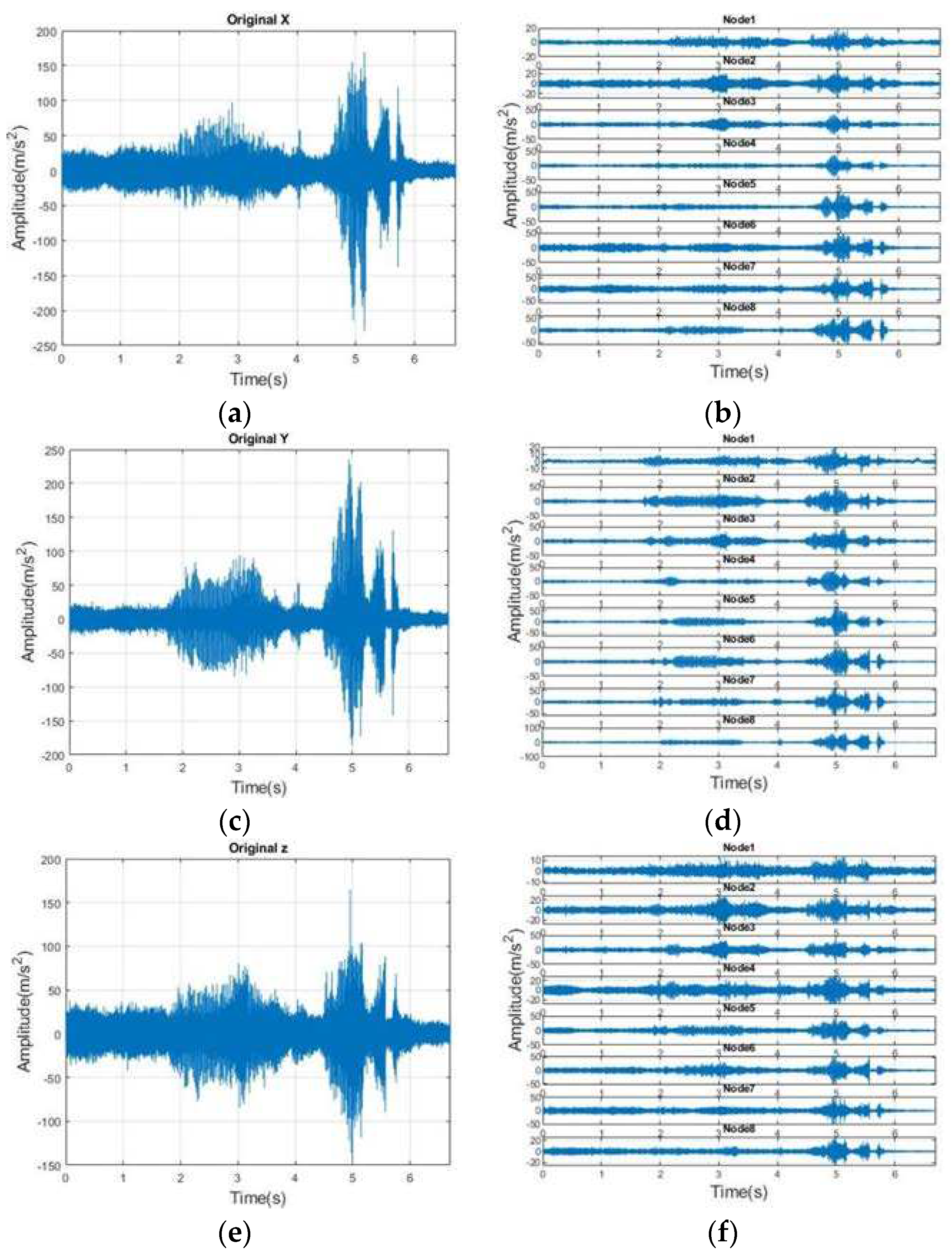

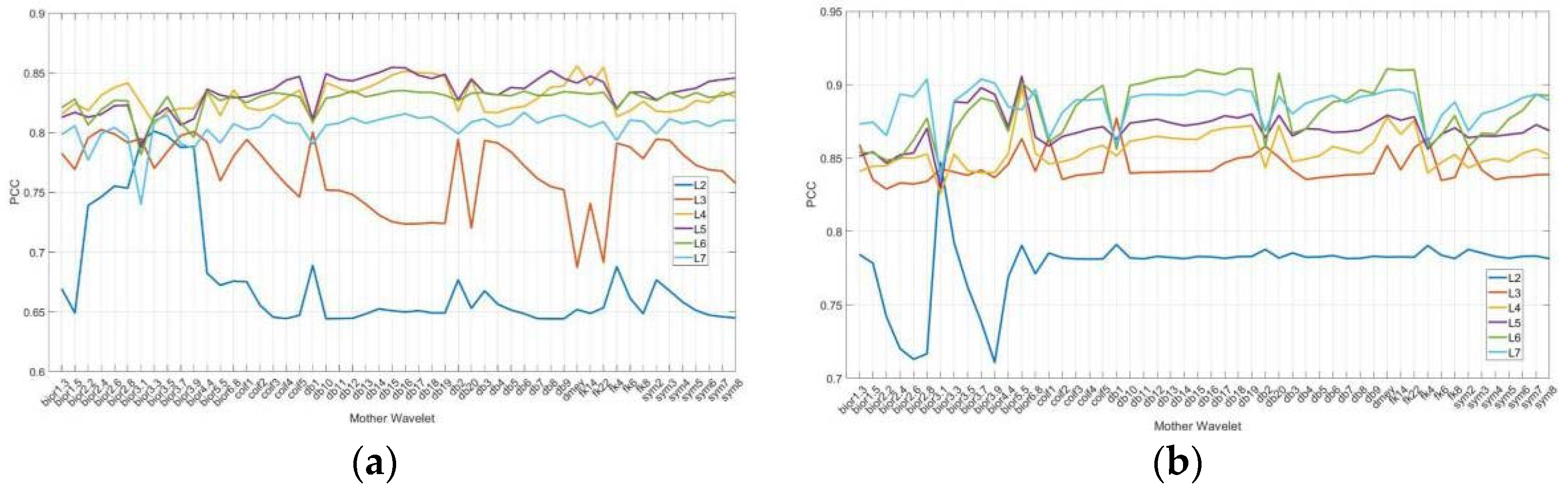

Table 4 lists fifty-two mother wavelet families. Two sets of data are analyzed to determine the optimal performance of PCCs between the energy percentage of these wavelet coefficients and surface roughness, as shown in

Figure 15(a) for Tool No.1 and (b) for Tool No.2. Stability-wise, levels L2 and L3 exhibit variability, and their PCCs are lower than other levels for both tools. The best mother wavelet for Tool No.1 is dmey at level L4 with a PCC of 0.8558 in

Figure 15(a). For Tool No.2, the best mother wavelet is db18 at level L6 with a PCC of 0.9109 in

Figure 15(b).

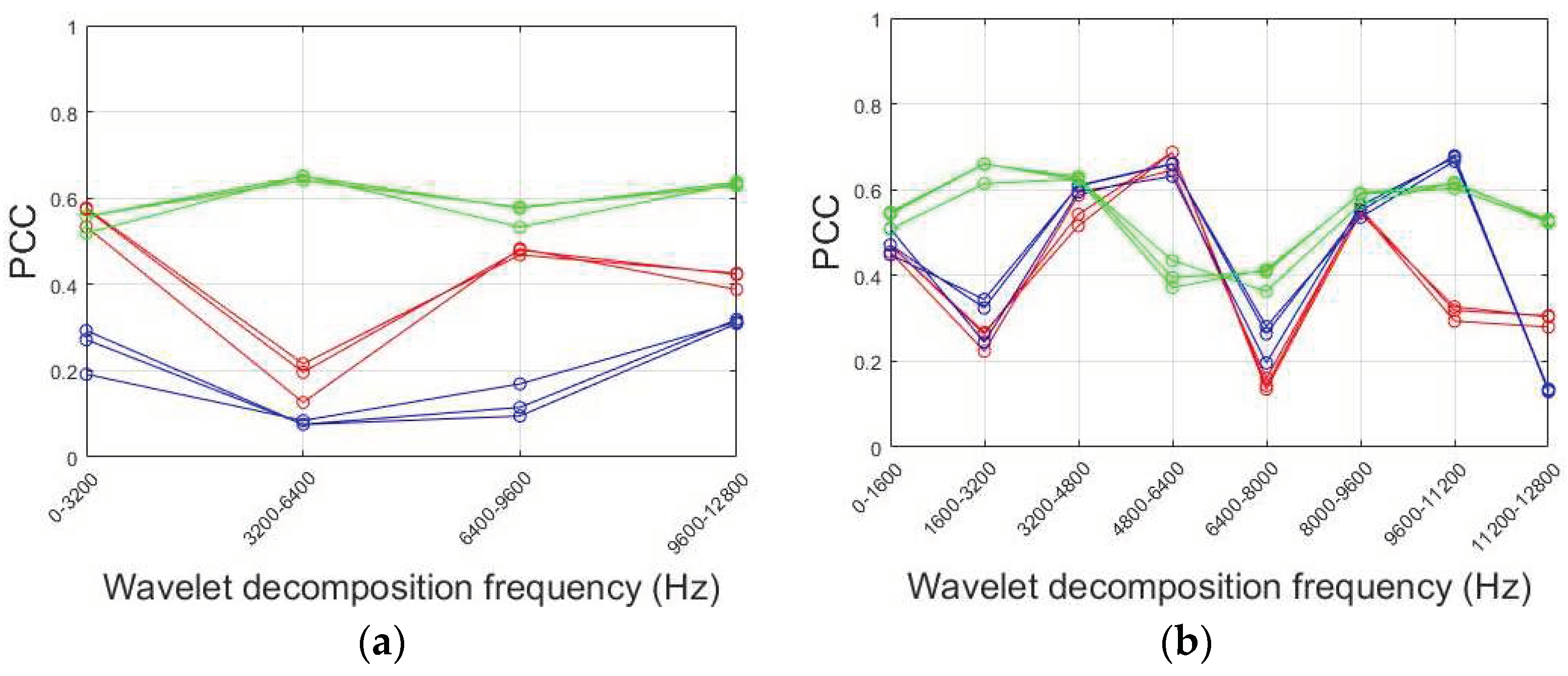

Figure 16 explores the effect of decomposition level (L) on the PCCs between the energy percentage of wavelet decomposition and the roughness of Tool No.1 in three directions. The highest PCC is 0.8558 at 8000Hz to 8800Hz in Y-axis level L4 in

Figure 16(d). Low-pass coefficients of scale functions and high-pass coefficients of wavelet functions fail to filter signals correctly at L2 and L3. Changes in energy percentage at high frequencies are more relevant to roughness at L4, L5, L6, and L7. However, increasing decomposition levels does not improve PCCs, as L7's high-frequency PCC is lower than L5 and L6. There are no significant differences between L5, L6, and L7.

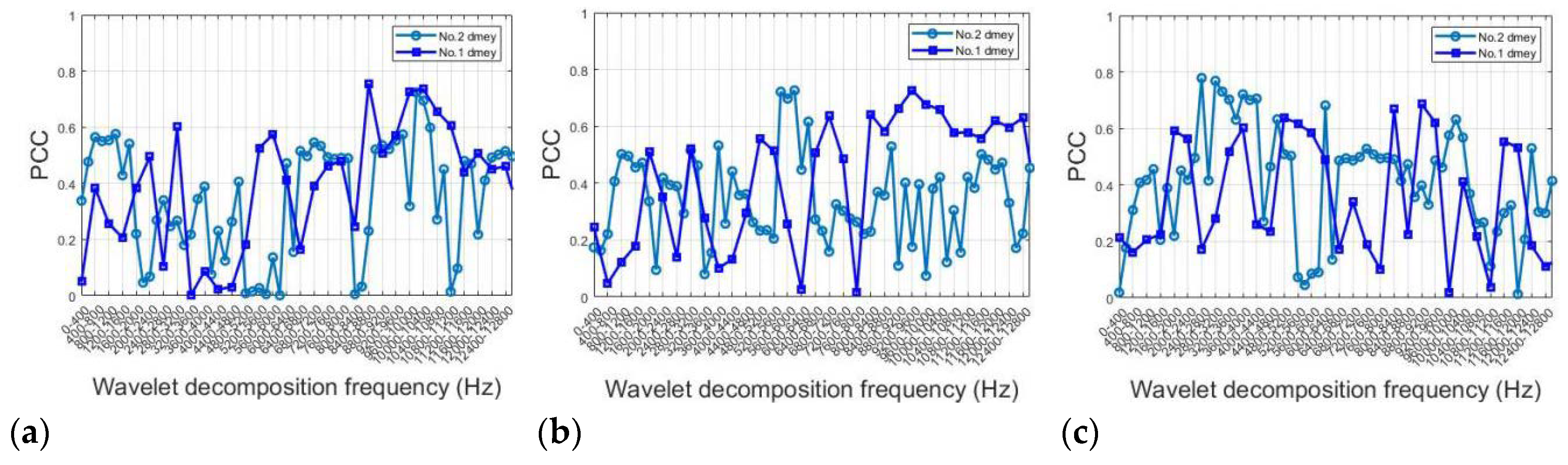

Figure 17 compares the PCCs between the energy of dmey decomposition level L6 and roughness for Tool No.1 and Tool No.2. The blue line represents Tool No.1, and the cyan line represents Tool No.2. PCCs decrease at lower frequencies after WPT in the X-axis, while they increase at higher frequencies. The frequency around 10000Hz in the X-axis is a common feature for both tools, with PCCs around 0.7.

WPT can enhance PCC performance at low and high frequencies, but important features may be filtered during signal decomposition. Increasing decomposition levels does not yield better results, as there are no significant differences between L5, L6, and L7. The best mother wavelet for both tools is dmey.

4.4. Results of GPR Predicts Roughness

To prevent overfitting due to a large number of features, six optimal features with high correlation to roughness were selected as inputs for the Gaussian Process Regression (GPR) model. The dataset was divided into five equally-sized folds, with four folds used for training and one for testing. This cross-validation process was repeated five times, rotating the folds, and the average performance of the model across all folds was calculated to determine the final evaluation model.

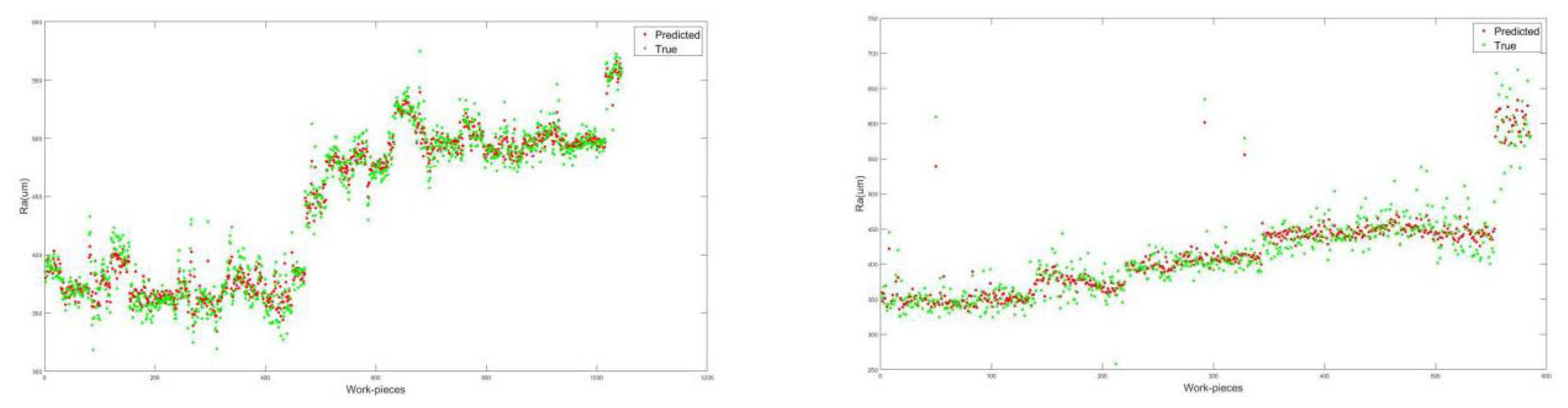

Figure 18 shows that the blue dots represent the surface roughness measurements obtained by the Surftest SJ-210 Surfagauge, while the yellow dots indicate the GPR predicted values. The model's predictions exhibit a strong correlation with the measured results, as demonstrated by an R-squared value of 0.96 and a root-mean-square error (RMSE) of 35 μm.

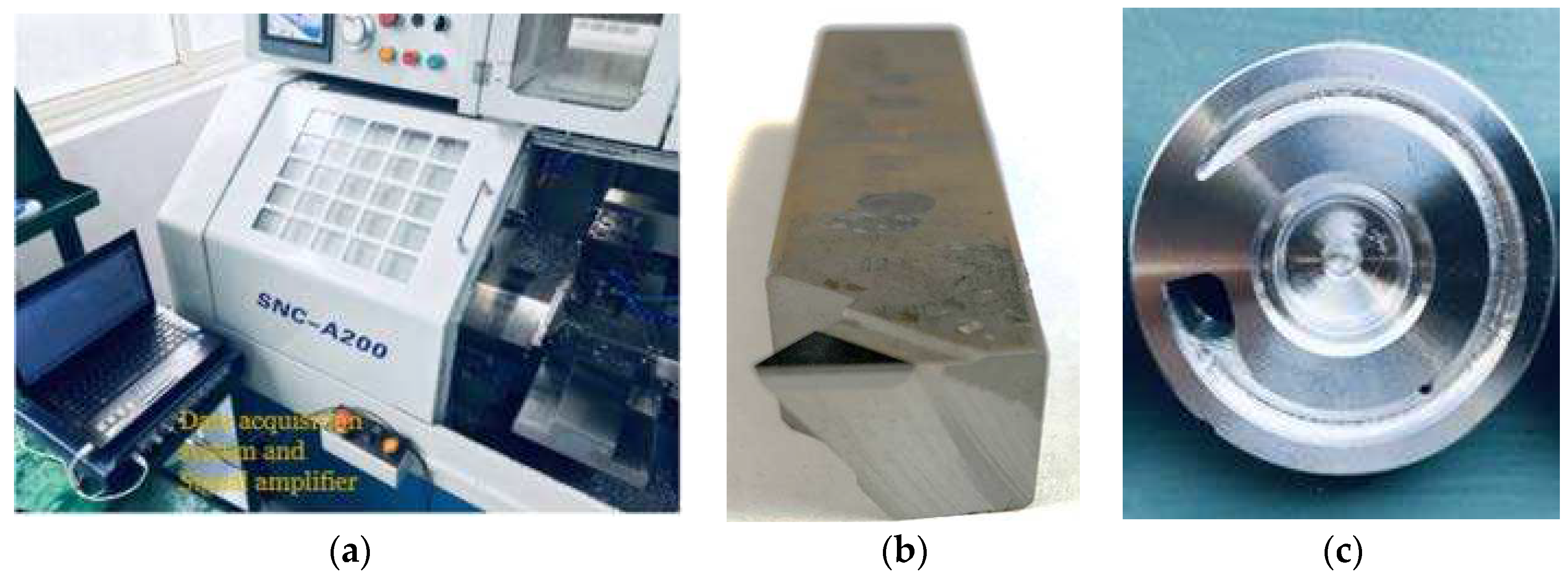

Figure 2.

(a) The CNC machine; (b) The finishing turning tool; (c) Workprice.

Figure 2.

(a) The CNC machine; (b) The finishing turning tool; (c) Workprice.

Figure 3.

Four machine tools with a magnet acceleration sensor.

Figure 3.

Four machine tools with a magnet acceleration sensor.

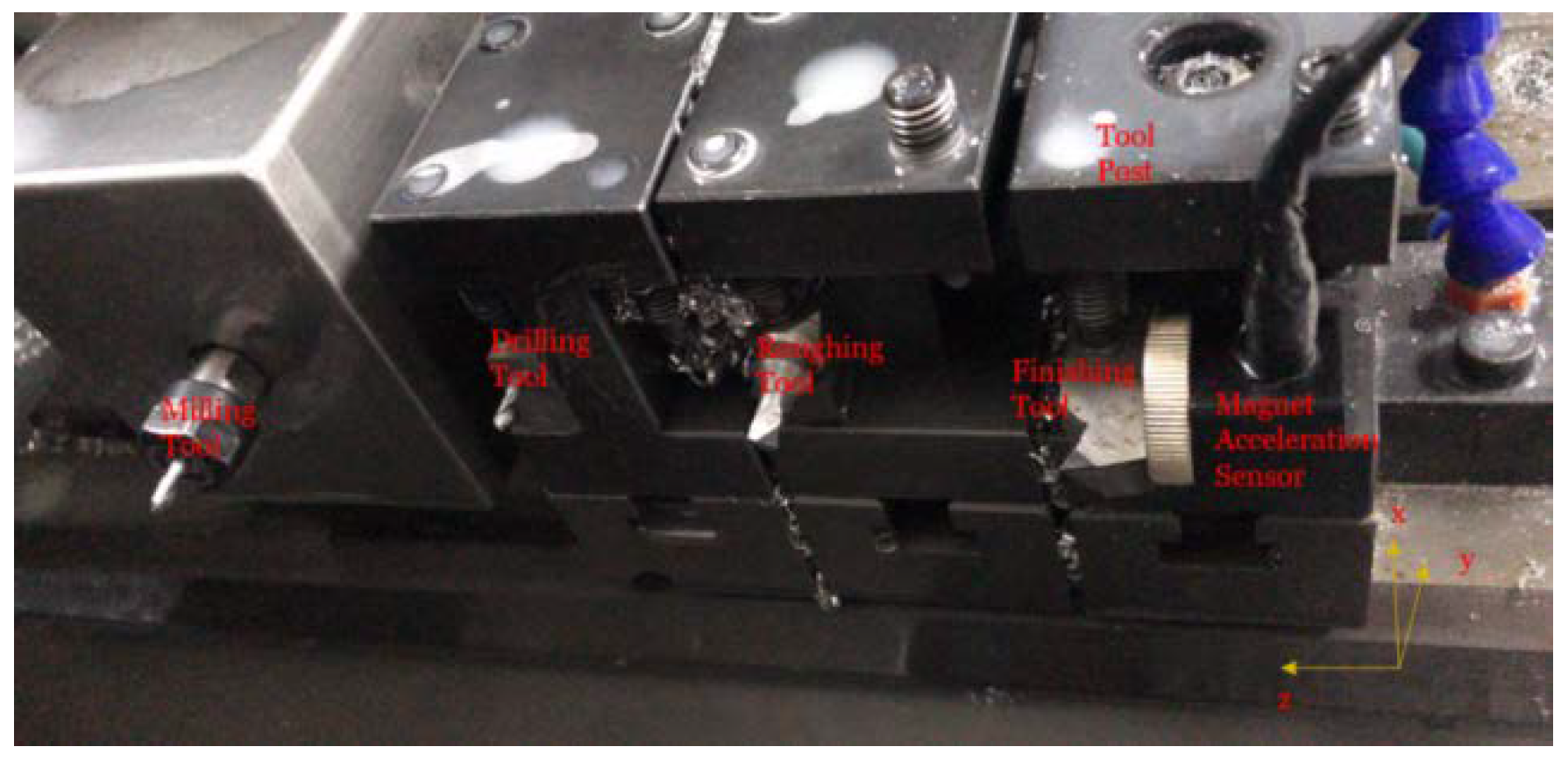

Figure 4.

Surfagauge measures roughness.

Figure 4.

Surfagauge measures roughness.

Figure 5.

Measured three axis acceleration of the tool when cutting one work-piece.

Figure 5.

Measured three axis acceleration of the tool when cutting one work-piece.

Figure 6.

Frequency analysis of finishing turning signals.

Figure 6.

Frequency analysis of finishing turning signals.

Figure 7.

(a)Three times of Ra; (b) Max of Ra; (c) Median of Ra; (d) Mean of Ra; (e) STD of Ra.

Figure 7.

(a)Three times of Ra; (b) Max of Ra; (c) Median of Ra; (d) Mean of Ra; (e) STD of Ra.

Figure 8.

Correlations between statistical properties of time domain and roughness.

Figure 8.

Correlations between statistical properties of time domain and roughness.

Figure 9.

Welch results (a) X-axial; (b) Y-axial; (c) Z-axial.

Figure 9.

Welch results (a) X-axial; (b) Y-axial; (c) Z-axial.

Figure 10.

Correlations between roughness and frequency domain (a)X-axial; (b)Y-axial; (c)Z-axial.

Figure 10.

Correlations between roughness and frequency domain (a)X-axial; (b)Y-axial; (c)Z-axial.

Figure 11.

Comparison PCCs of frequency domain and roughness for No.1 tool with No.2 tool (a)X-axial; (b)Y-axial; (c)Z-axial.

Figure 11.

Comparison PCCs of frequency domain and roughness for No.1 tool with No.2 tool (a)X-axial; (b)Y-axial; (c)Z-axial.

Figure 12.

WPT of three levels decomposition Measured vs predicted roughness by GPR.

Figure 12.

WPT of three levels decomposition Measured vs predicted roughness by GPR.

Figure 13.

An example of the WPT of three levels decomposition.

Figure 13.

An example of the WPT of three levels decomposition.

Figure 14.

An example of PSDs of wavelet coefficient 3 .

Figure 14.

An example of PSDs of wavelet coefficient 3 .

Figure 15.

PCCs between energy of each decomposition level (L) and roughness (a) No.1 tool; (b)No.2 tool.

Figure 15.

PCCs between energy of each decomposition level (L) and roughness (a) No.1 tool; (b)No.2 tool.

Figure 16.

PCCs between energy of each decomposition level (L) and roughness (a) L2; (b) L3; (c) L4; (d) L5; (e) L6; (f) L7.

Figure 16.

PCCs between energy of each decomposition level (L) and roughness (a) L2; (b) L3; (c) L4; (d) L5; (e) L6; (f) L7.

Figure 17.

PCCs between energy of dmey decomposition level (L6) and roughness for No.1 and No.2 tool.

Figure 17.

PCCs between energy of dmey decomposition level (L6) and roughness for No.1 and No.2 tool.

Figure 19.

GPR prediction results for No. 1 tool and No. 2 tool.

Figure 19.

GPR prediction results for No. 1 tool and No. 2 tool.

Table 1.

SYMA CNC Cutting parameters.

Table 1.

SYMA CNC Cutting parameters.

| Cutting Parameters |

Data |

| Depth of cut |

0.06(mm) |

| Spindle speed |

3200(RPM) |

| Feed rate |

0.06 (mm/rev) |

| Tool nose radius |

0.6(mm) |

| Tool overhang length |

13 (mm) |

| Cutting fluid |

With Coolant |

Table 2.

Approximate time duration of each step of cutting.

Table 2.

Approximate time duration of each step of cutting.

| 1 |

8~12 |

Loading |

| 2 |

15~16 |

Moving |

| 3 |

16~20 |

Roughing |

| 4 |

21~23 |

Drilling |

| 5 |

23~25 |

Moving |

| 6 |

25~47 |

Milling |

| 7 |

47~48 |

Moving |

| 8 |

48~53 |

Finishing Turning |

| 9 |

53~58 |

Moving Back |

Table 3.

comparison two tools’ maximum values of PCCs.

Table 3.

comparison two tools’ maximum values of PCCs.

| Tool No. |

Domain |

Parameters |

X |

Y |

Z |

| 1 |

Time |

PCC |

0.7969 |

0.7013 |

0.7396 |

| Property |

Kurtosis |

Kurtosis |

Kurtosis |

| Frequency |

PCC |

0.8674 |

0.7689 |

0.7562 |

| Frequency (Hz) |

3700 |

1300 |

3800 |

| 2 |

Time |

PCC |

0.8267 |

0.2708 |

0.7402 |

| Property |

STD/RMS |

STD/RMS |

STD/RMS |

| Frequency |

PCC |

0.8221 |

0.7749 |

0.8511 |

| Frequency (Hz) |

4700 |

8100 |

3100 |

Table 4.

Fifty-two mother wavelets.

Table 4.

Fifty-two mother wavelets.

| Mother Wavelets Families |

Order |

| Daubechies |

db2, db3, db4, db5, db6, db7, db8, db9, db10, db11, db12,db13, db14, db15, db16, db17, db18, db19, db20 |

| Haar |

Haar |

| Discrete Meyer |

dmey |

| Fejer-Korovkin filters |

fk4, fk6, fk8, fk14, fk22 |

| Coiflets |

coif1,coif2, coif3, coif4, coif5 |

| Symmlets |

sym2, sym3, sym4, sym5, sym6, sym7, sym8 |

| Biorthogonal |

bior1.3, bior1.5, bior2.2, bior2.4, bior2.6, bior2.8, bior3.1, bior3.3, bior3.5, bior3.7, bior3.9, bior4.4, bior5.5, bior6.8. |

Table 5.

Prediction models’s accuracy.

Table 5.

Prediction models’s accuracy.

| Models |

Tool |

RMSE |

R2

|

| Linear regression |

1# |

18.369 |

0.92 |

| 2# |

28.19 |

0.81 |

| SVM |

1# |

18.453 |

0.92 |

| 2# |

27.779 |

0.81 |

| GPR |

1# |

16.141 |

0.94 |

| 2# |

26.682 |

0.83 |