1. Introduction

As governments incentivize radical reductions in harmful emissions as overall priority [

1], which as consequence has price increase of carbon to decrease greenhouse gasses [

2], which is unpopular measure as fossil fuels are driving force of marine traffic. From 2008 to 2018 emissions of CO

2 increased by 90% and predictions are that they will further increase [

3]. The main measures to reduce consumption and consequently pollution in the shipbuilding industry are to optimize ship engines, propellers and hull, which are limiting factors, as the efficiency of each part can go so far as to reach limits of maximal efficiency. To overcome that new approach is necessary and as a power system generates all power and pollution, one of the promising solutions is to replace it with a proton exchange membrane fuel cell (PEMFC) in combination with a battery pack. PEMFC-s are electrochemical devices used for the direct conversion of various fuels with hydrogen as an energy carrier to electricity with high efficiency [

4] in comparison to internal combustion engines. Other benefits include generating completely emission-free energy, they are easy to implement on existing systems that use electricity and only byproducts of electrochemical reaction are pure water and heat. With that said PEMFC system is good for long-distance voyages with constant load and for vessels that travel at relatively short distances with power demand variations as shown in this paper, a hybrid system that uses a combination of PEMFC stack and battery package is very effective and has good dynamic load characteristics, which makes it compatible for replacement of classic marine power systems like diesel. To analyze and incorporate such a system into vessels, a numerical model has been developed. Corvus Energy, Toyota and other partners initiated the Corvus Pelican Fuel Cell System which is the result of the H2NOR research project to fast-track the development and production of sustainable and scalable Maritime Hydrogen Fuel Cell Systems. They announced the launch of their ground-breaking, gas-safe marine fuel cell product, the Corvus Pelican Fuel Cell System (FCS). Designed to transform the maritime industry, the new product represents a significant leap forward in safe, clean, and efficient power generation for marine vessels alternative [

5]. Petra et al. in their study [

6] are focused on the possible application of hydrogen-fed PEM fuel cells on board ships. Experimental results confirm that PEM fuel cells, when supported by a suitably sized energy storage system, represent a viable technical solution for zero-emission power generation on board ships. Proton exchange membrane is found to be promising options for maritime applications, once energy efficiency, power capacity and sensitivity to fuel impurities are considered. Currently, power capacity, costs and lifetime of the fuel cell stack are the primary barriers [

7]. CO

2 emissions in the solid oxide fuel cell hybrid system are 5.4% ∼8.8% lower than in the traditional structure for one round trip sail [

8]. Elkafas A. G. et. al. analyzed several issues such as: the main characteristics of fuel cell systems, the available technology suppliers, international policies for fuel cells onboard ships, past and ongoing projects at the international level that aim to assess fuel cell applications in the maritime industry, and the possibility to apply fuel cell systems on different ship types [

9]. In the paper [

10], a system level fidelity model of the fuel cell-fed marine power systems with real-time capabilities is developed. The presented model can be implemented for investigating the system performance for simulator applications, designing high-level controls, sizing and optimization. A two-layer energy management system (EMS) is presented in [

11] to enhance shipping fuel efficiency. The first layer of the EMS optimizes day-ahead power generation plans based on the vessel's next-day cruises, the second layer, dynamically adjusts power splitting decisions based on the output from the first layer. Developments in propulsion and power supply systems and their control strategies have been analyzed [

12] and it has been concluded that a hybrid architecture with advanced control strategies can reduce fuel consumption up to 10-35% while improving noise, maintainability, maneuverability and comfort.

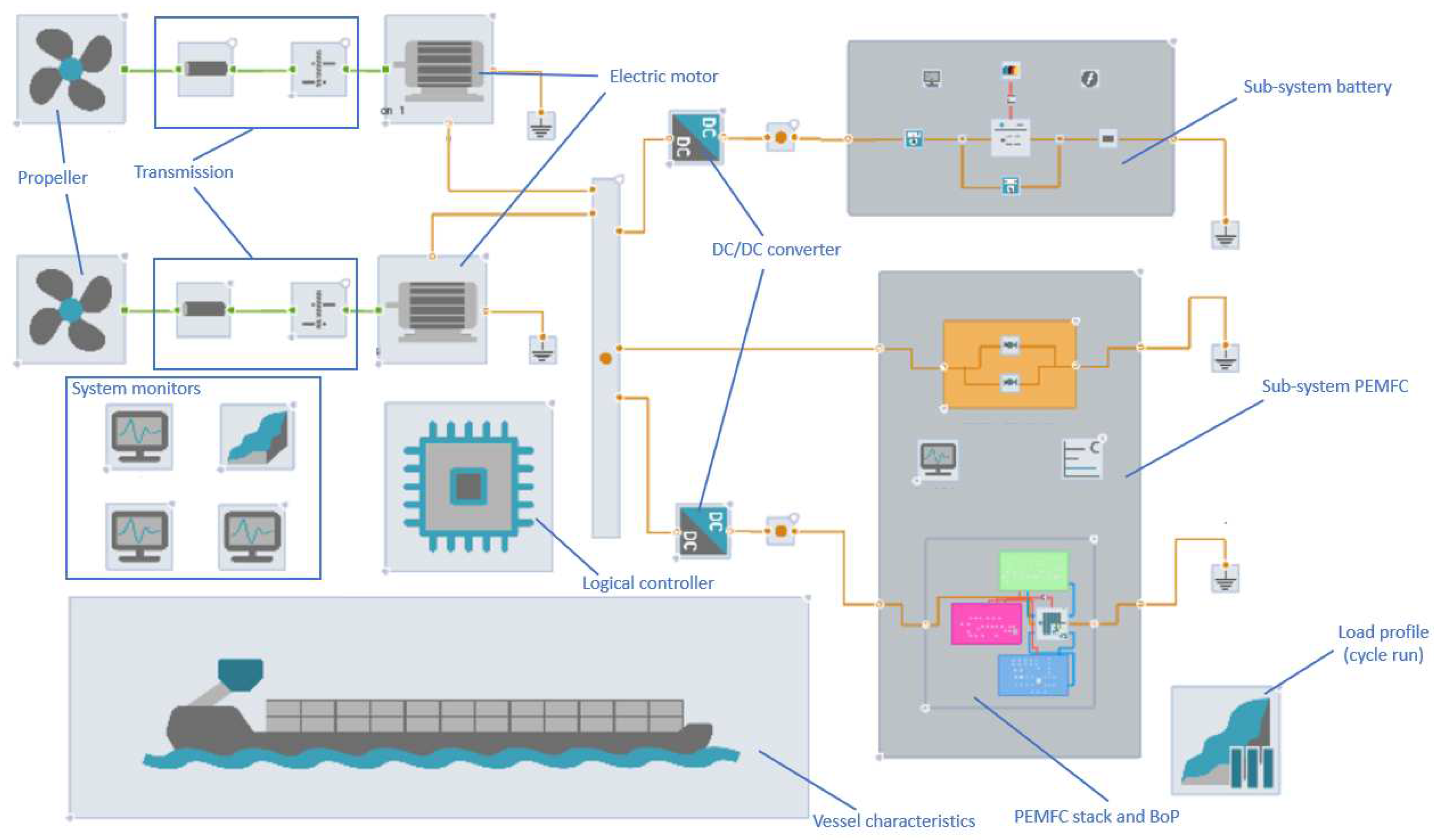

This paper offers detailed insight to the novel hybrid propulsion systems which incorporate system of PEMFC stack with battery pack at known load cycles. Analysis is conducted on catamaran which has previously been in service, and it is considered for refitting from diesel to PEMFC-battery hybrid propulsion system. Goal is to design optimal hybrid system that incorporates PEMFC stack with battery pack for known vessel, analyze fuel consumption and compare it to previous system with diesel engines, with additional benefits as silent drive and eliminated pollution from previously used internal combustion engines running on diesel fuel. Proposed configuration of main components for simulation is shown at

Figure 1.

2. Methodology

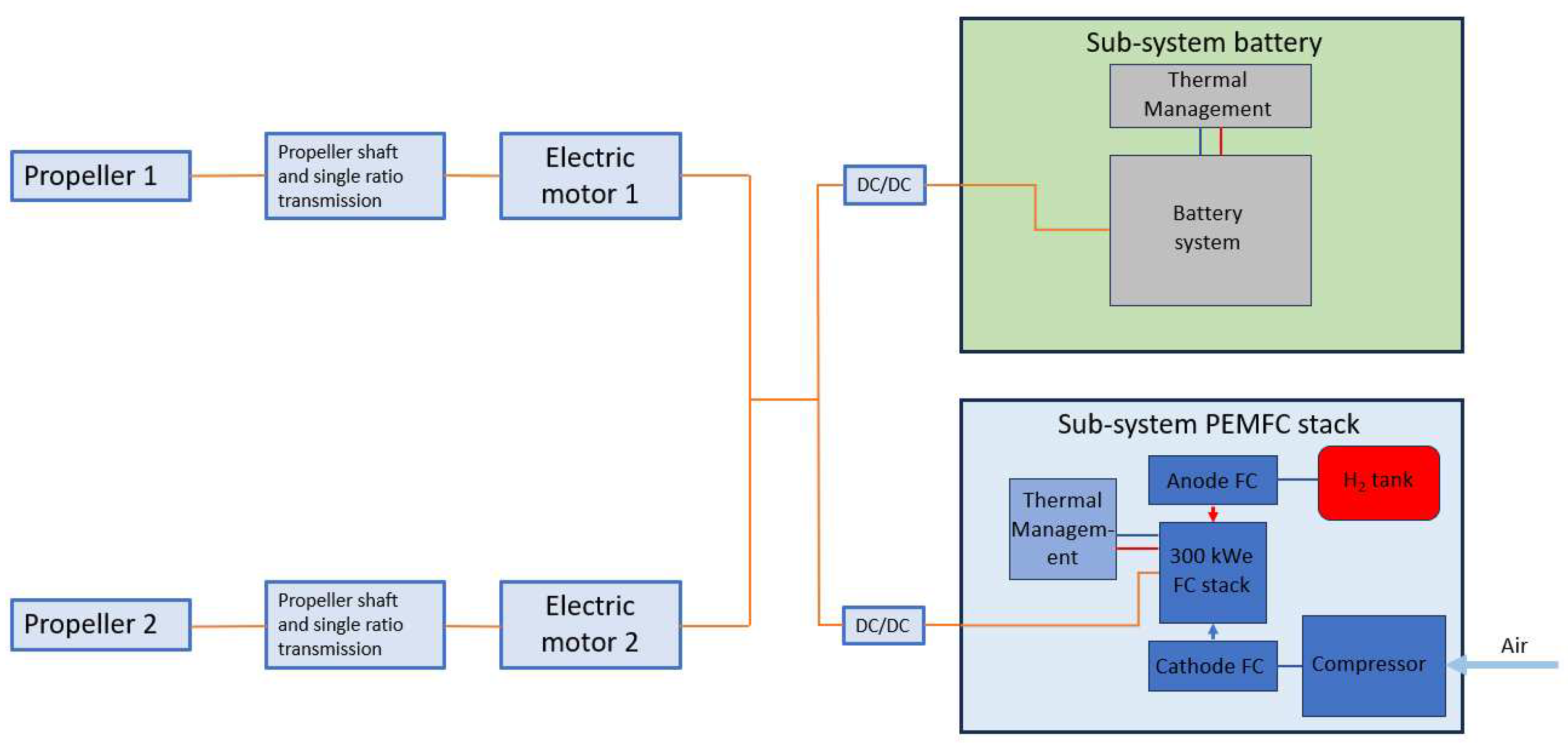

Numerical model is developed with commercial software AVL CRUISE

TM M 2023.1 and it is conceptually developed like on

Figure 1. It consists of three main components, which are PEMFC stack with 300 kWe, battery pack that require unknown power and must be optimized for route shown on

Table 1. and two asynchronous electric motors with maximum power requirement of 300 kW each (600 kW in total).

Additionally, ship resistance is modelled with longitudinal dynamic model to ensure realistic acceleration and velocity of vessel, propeller type is B series, which has numerical background from Wageningen B series tests [

13]. Torque on propellers, which generate load on electric motors (EM) ensures realistic load on power system.

Balance of plant (BoP) include regulation of mass flow rates at cathode and anode side in sub-system of PEMFC that consists of compressor at cathode side with mass flow up to 0.3 kg/s and pump air up to 4 bar from external pressure, which is cooled and circulated through humidifier before PEMFC stack to ensure proper humidity for membrane. Pressure and airflow are controlled via two PID controllers for compressor and control of backpressure valve. Power consumption of compressor is defined as linear and dependent on PEMFC stack load with maximal consumption compared and upscaled from Toyota Mirai PEMFC stack testing [

14]. Anode side consists of large hydrogen tank that stores hydrogen at pressure of 700 bar has enough fuel for six voyages and injection model which manages mixing of hydrogen with water vapor via fuel cell current demand. Recirculation part for unused humid hydrogen is also present which feds it back to system through a Venturi injector, where excess water is removed with water separator to maintain constant humidity. Pressure is controlled with a PID controller which controls Venturi injector opening. Additionally, to address nitrogen buildup due to crossover through membrane, purge valve is periodically opened and releases some of the gas into surroundings. Some unused hydrogen is lost during the process, but in typical operating conditions loss does not exceed 2% of total fuel consumption. Removal of excessive heat is required to maintain stable temperature of 65 °C in PEMFC stack, which is managed with pump, that is controlled with PID control, dependent on load from PEMFC stack. Pump uses up to 4 kW of electric energy. Active components in BoP (compressor at cathode side and pump for thermal management) are simulated as speed-controlled flange and corresponding power consumers. That means that components inside of BoP are controlled indirectly by required current at PEMFC stack and required power consumption is calculated with required mass flow rates. As the system consists of PEMFC stack and battery pack, power split strategy is used to cover for spikes in power demand and insufficient amount of power generated from PEMFC stack at maximum load in correspondence to pre-defined cyclic load profile with variable loads during voyage.

3. Numerical background of fuel cell model

Fuel cell model used in this article is developed and discussed in detail in [

15]. It is a 0-dimensional, thermodynamically consistent electrochemical model for controlling proton exchange membrane fuel cell (PEMFC) performance and then is extended to capture the transport of gases across channels and through the gas diffusion layer (GDL), making it quasi-dimensional. Main property of model is its simplification of the Butler-Volmer equation, which describes the relationship between current and voltage in an electrochemical cell. It assumes a charge transfer coefficient of 0.5, allowing the use of the hyperbolic sine function. This results in equation (2) which is equivalent to Butler-Volmer but significantly easier to work with. Equations are written below:

where

is cathode current, Z is number of electrons transferred in the electrochemical reaction, F is Faraday constant,

and

are the normalized concentrations of oxygen and water, k

B is the Boltzmann constant, T is the temperature,

and

are reaction rate constants, e

0 is the elementary charge and

reaction kinetics overvoltage on the cathode. Based on equation (1), it's possible to derive the expression for the overpotential of reaction kinetics,

for the cathode side. However, analogous derivations can also apply to the anode side. This flexibility enables the model to be effectively utilized both in fuel cell operations and in electrolyzer mode.

The single cell voltage

is defined as:

where

is the thermodynamic potential and

voltage ohmic loss.

Ohmic losses are linked to proton movement across the membrane, significantly influencing ionic conductivity, which is determined with data gathered from literature. With constant properties assumed, ohmic loss exhibits a linear increase with the rise in current density, shaping the medium current's polarization curve slope.,

Transport losses capture the diffusion effects of species going through the channel, GDL, and into the catalyst layer and are modeled via Fick's law of diffusion. These processes outline the limiting current densities, i.e., the current density at which the reactant concentration at the catalyst layer starts to diminish. The transport model's principle is to estimate the reactant concentration at the catalyst layer (

) by multiplying the reactant concentration in the channel (

) by the ratio of the limiting current (I

L) to the current density (I), as follows:

where

is diffusion coefficient and

is GDL width. The electrochemical model introduces five calibration coefficients, each associated with a specific loss mechanism. Since the activation and transport losses are more significant on the cathode side, the parameters for the anode are often considered negligible. Properties of the membrane material, such as density, specific heat capacity, thermal and ionic conductivity, along with water diffusion and electro-osmotic drag coefficients, are sourced from the literature [

16].

4. Developed numerical model

And main components are explained below. First part consists of PEMFC stack, which was explained in detail in previous chapter.

Figure 2.

Main components of developed numerical model in AVL CRUISETM M 2023.1.

Figure 2.

Main components of developed numerical model in AVL CRUISETM M 2023.1.

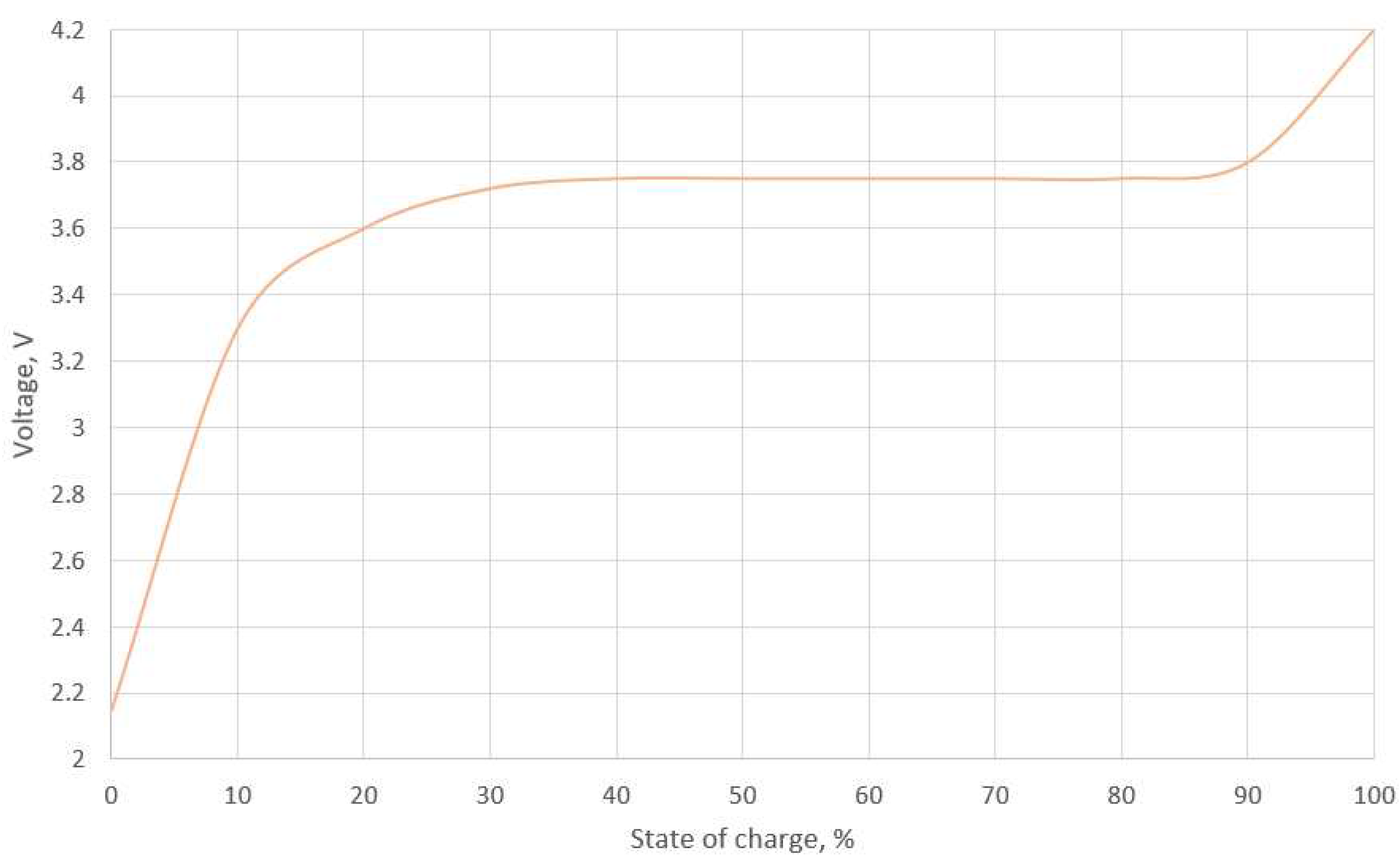

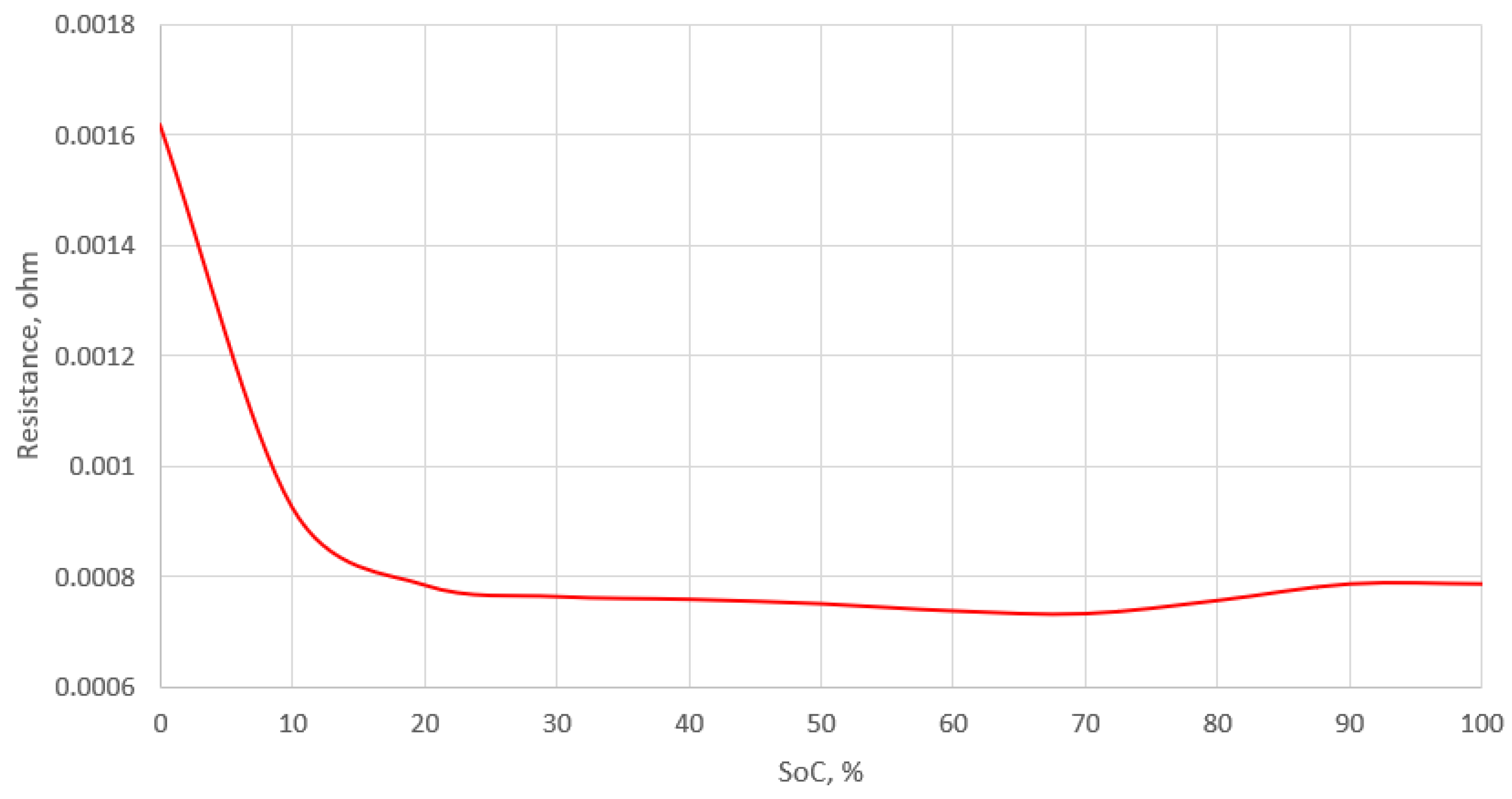

For battery pack equivalent circuit model is used and model consists of controlled voltage source and Ohmic resistance used to describe instantaneous voltage response to current input. In addition, besides the electrical model, thermal model (i.e., a solid wall) is embedded in model to predict the transient thermal behavior of battery. Moreover, multiple battery elements are connected via electrical pins to construct electrical network acting as battery module or battery pack. Open circuit voltage is defined for classic li-ion batteries [

17] as in

Figure 3 Ohmic resistance is taken for temperature of 25 °C and defined as in

Figure 4.

Many combinations of battery packages have been implemented and optimal battery package configuration consists of 110 battery packages connected in parallel with 130 batteries connected in series (total 14300 batteries), each battery have voltage range from 2.5 to 4.2 V, where nominal voltage is 3.7 V and capacity of 8 Ah. Discharge voltage is defined as in

Figure 3. Total combined power of battery pack is 424 kWh with state of charge (SoC) at 100 %. Ohmic losses between each battery for this simulation are neglected, as main goal is to examine required power from auxiliary storage to satisfy required condition.

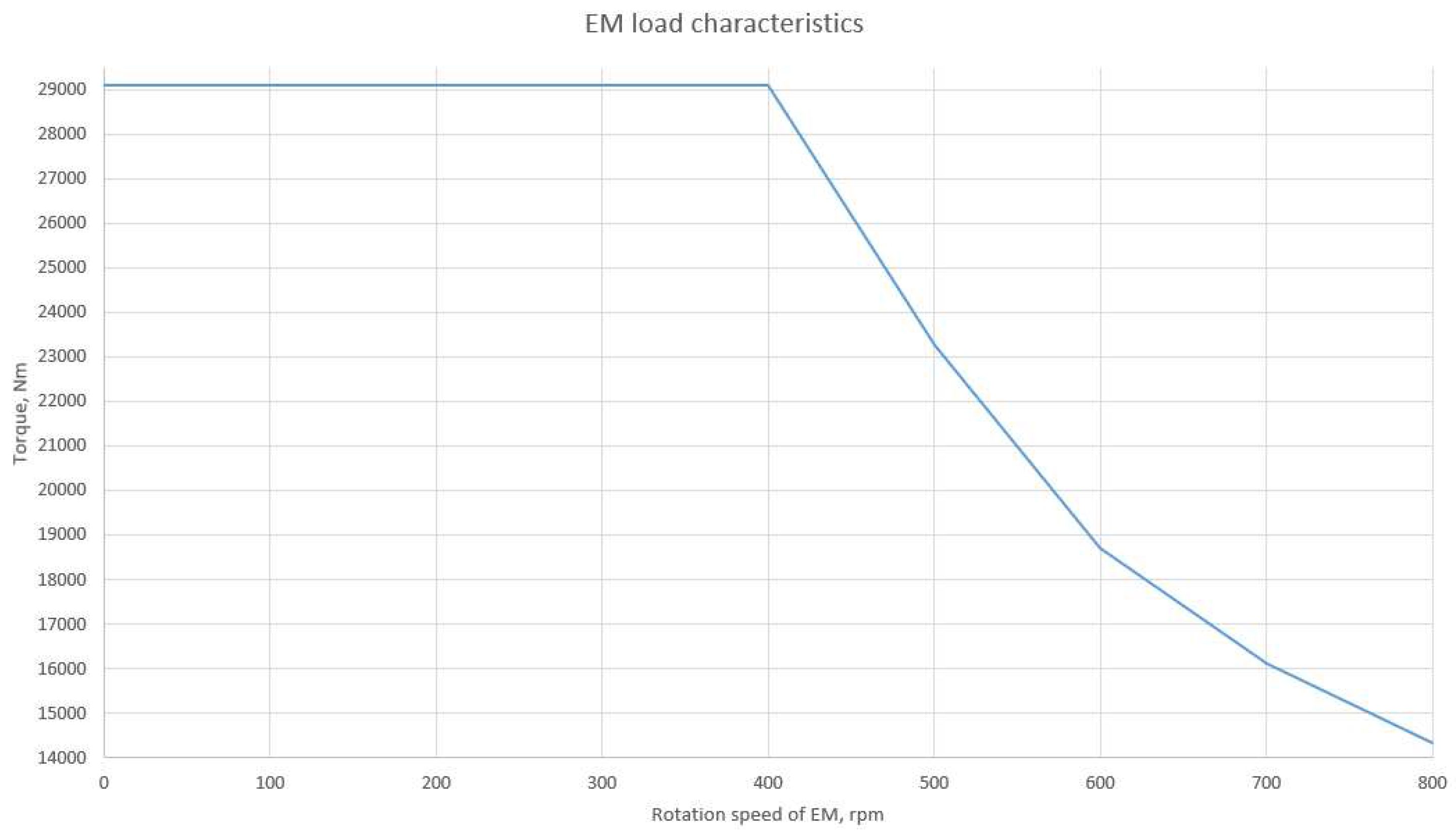

There are two electric motors (EM-s), which are the same defined as asynchronous engines, with demanded maximum power of 300 kW each, or 600 kW in total. They have defined torque for rotation speed, which is shown in

Figure 5 for full spectrum of load. For this simulation spectrum of load is on constant torque, as it is from 0 to 370 rpm.

Propellers that are connected to EM-s are defined as classic B series propellers from [

13], with diameter of 1.5 m, 4 blades, pitch to diameter ratio of 1.2 and disk area coefficient of 0.7. While on full load advance coefficient is 0.73.

The Marine vessel model, which is powered by a fuel cell and a battery is a sophisticated system with multiple interlinked components. Vessel is modeled as longitudinal dynamic model which is designed to calculate various key parameters related to vessel forward and backward movement. Initially, the model defines parameters such are the ship’s mass (80 t), thrust force, external forces, resistance force, initial speed and thrust deduction factor. With that parameters, numerical model calculates ship acceleration with consideration of net forces acting on it, including both the thrust and resistance forces and then dividing them by the ship’s mass. Ship’s velocity is then updated by integrating acceleration over time, starting from an initial velocity value. Furthermore, the position of the ship is determined by integrating velocity over time. Ship’s resistance has been taken from experimentally validated results.

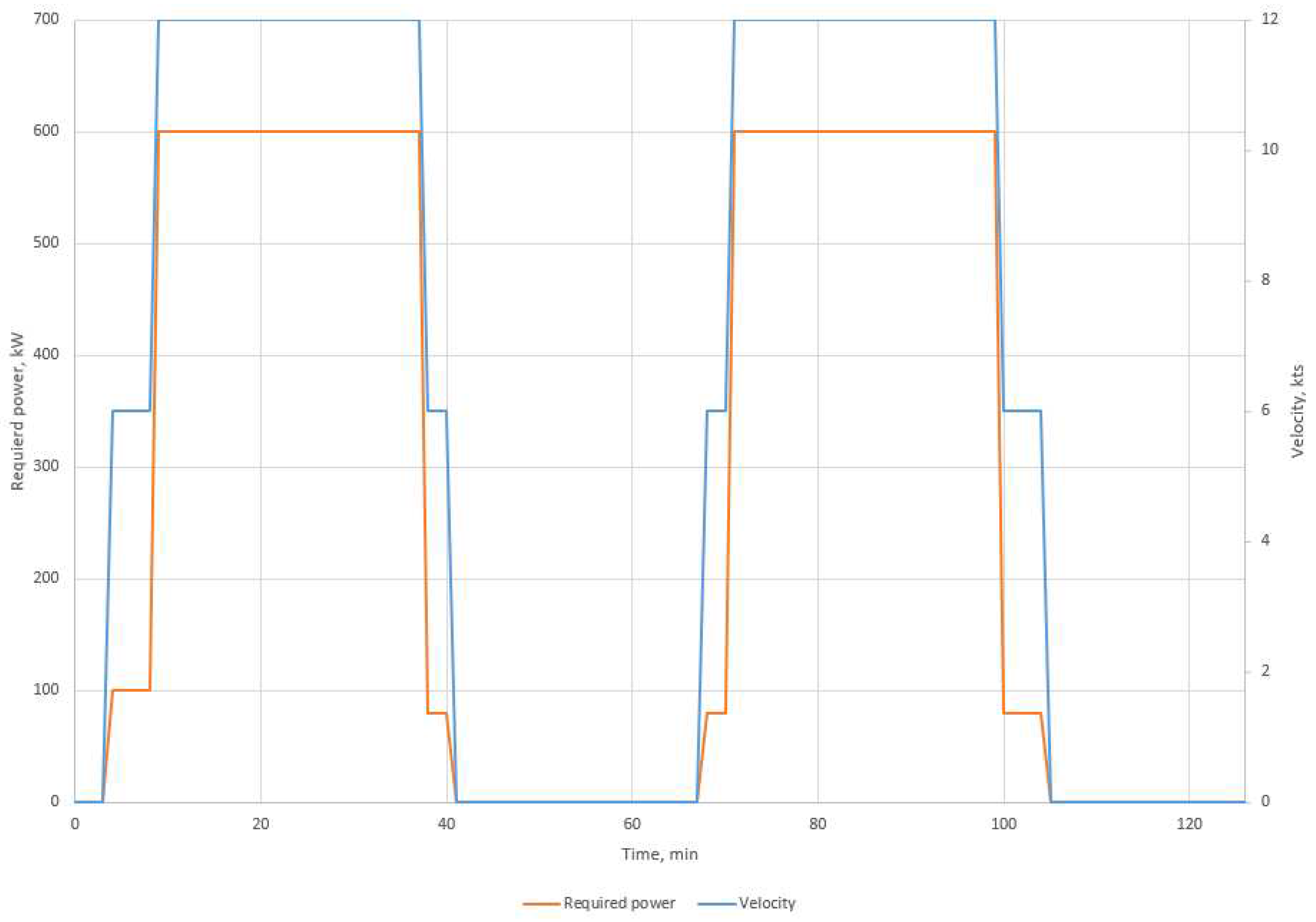

Propeller speed demand is determined by load profile which simulates average cyclical navigation route of 13 nautical miles with load profile presented on

Table 1 and graphically on

Figure 6.

Actual propeller speed is regulated with PID controller, which maintains desired propeller speed with adjustment of EM load based on the comparison between the actual and desired speeds.

In terms of energy storage and management, the system includes battery pack that acts as energy storage, supplying excess power demand that can’t be meet with fuel cell to the EM and other components that require electricity. PEMFC stack is the only source of electricity for battery charging with conversion of chemical energy from hydrogen to electrical energy.

Significant aspects of the system are power demand and voltage regulation. Controller function calculates the total power required for EM, compressor, steering pump and battery charging. Based on this power demand and battery’s SoC, the controller decides PEMFC stack power output. If the power demand is high and battery’s SoC is low, PEMFC operates at its nominal power, utilizing hysteresis mechanism to avoid frequent on-off cycling under certain conditions. The hysteresis mechanism has boundary condition to limit propeller speed to 100 rpm if SoC drop below 20% and holds that limit until SoC reach 30%. The controller also determines the fuel cell’s current demand, considering the voltage limits and whether the fuel cell is on or off. It includes a delay feature to simulate gradual ramping up of current when the fuel cell activates, and a low-pass filter is applied to smooth out any spikes in the output current. Finally, the necessary current from the PEMFC is determined by dividing of calculated power demand by the system voltage. Additionally, stable voltage across the system is maintained by two DC/DC controllers, ensuring efficient and consistent power supply.

5. Results and Discussion

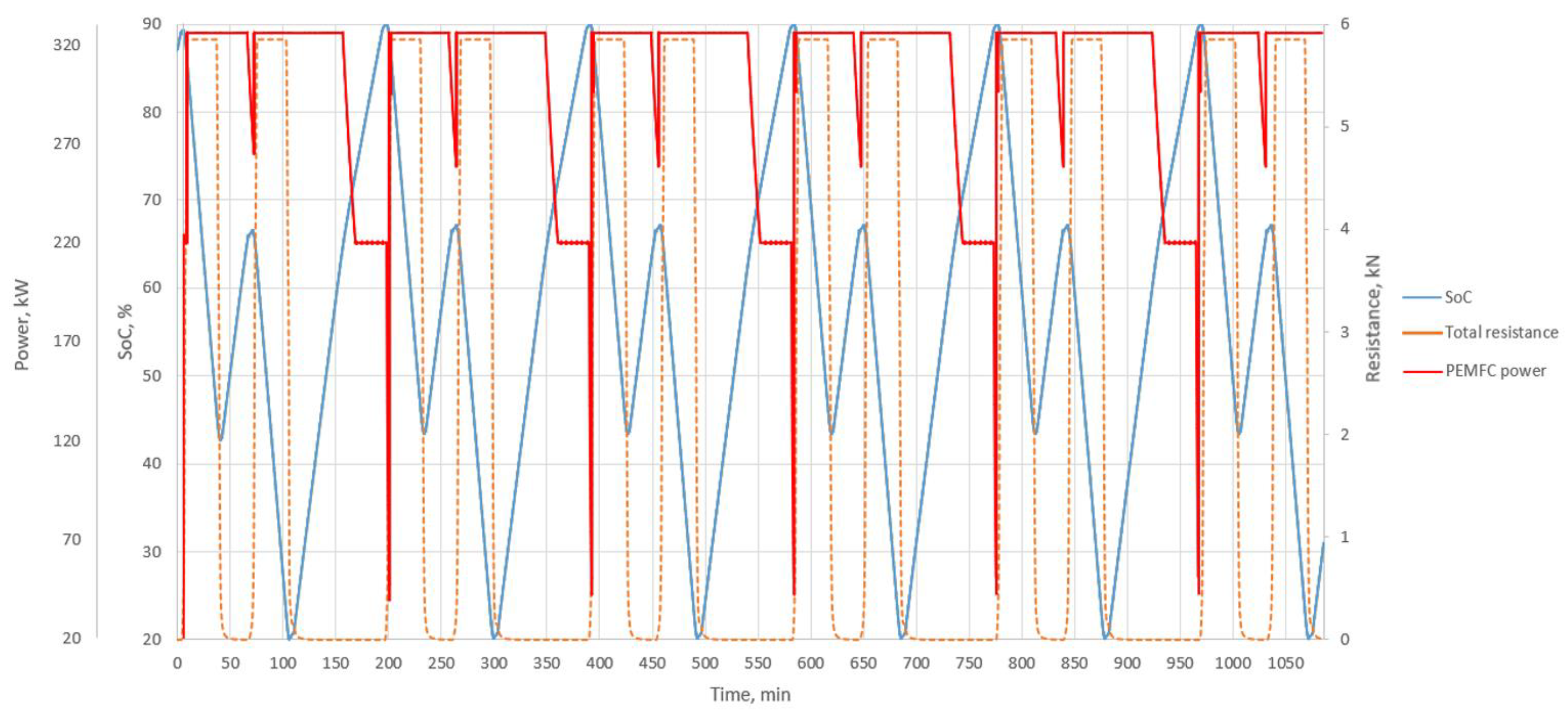

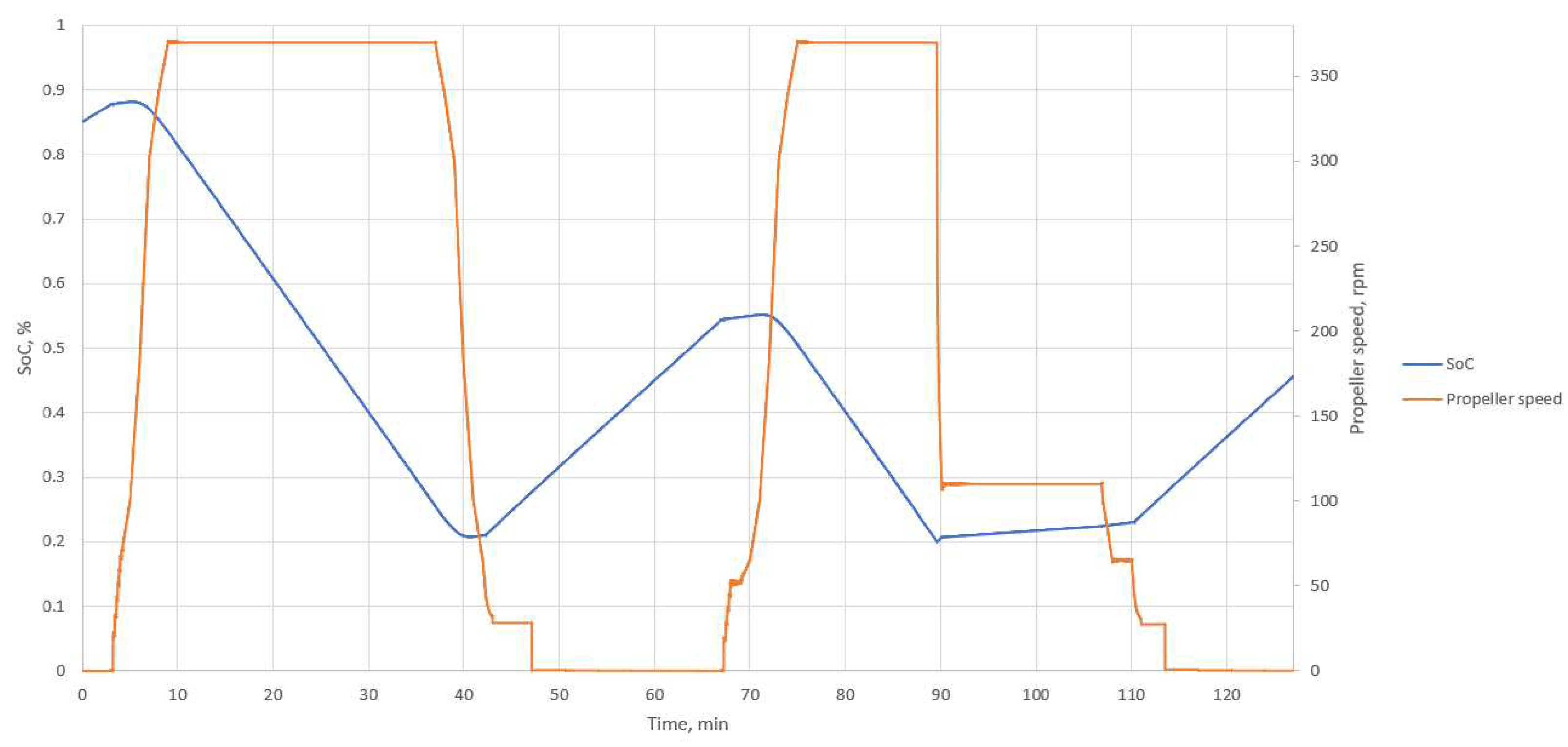

At

Figure 7 the SoC, total resistance of vessel and PEMFC power are shown and all components within system respond to each other with hysteresis mechanism implemented for PEMFC stack, but for this configuration it is not activated. To show hysteresis mechanism there is simulation of one cycle with battery pack of 100 battery packages connected in parallel with 100 batteries connected in series (total 10000 batteries) with total power of 296 kWh and results are shown on

Figure 8, with hysteresis mechanism activated after 89-th minute and kept until end or route, as consequence total distance passed changed from 13.8 nm to 11.6 nm.

The results show that the system with PEMFC stack of 300 kWe and battery pack with 424 kWh with SoC of 87% at start of voyage can replace previous configuration of two diesel engines with output power of 300 kW each and meet all required demands for this route, as shown on

Figure 7, where final SoC is 89.949%. Total consumption for one voyage is 47.45 kg and for 6 voyages with PEMFC as only source of power it is 284.7 kg of hydrogen in comparison to diesel engines, which require 254 kg for one voyage and 1524 kg of diesel for six voyages. Fuel consumption of hybrid system can be reduced with last voyage by 14.6 kg, as it is end of the day, so battery pack can be recharged with outer electric energy supply. For 284.7 kg of hydrogen, the storage capacity required is 7200 l under pressure of 700 bar. All greenhouse gases including CO

2 are removed in comparison to 4886 kg of CO

2 generated from diesel engines.

If the time of ship moored in the harbor increases, battery pack capacity could be reduced and approximation of 2 more minutes in full load increases total consumption of energy up to 3.5 % with increasement of distance traveled from 13 nm to 13.8 nm per voyage. In conclusion that means that realistic power consumption is smaller than in numerical model. As system is 100% electric and compatible with conventional electric energy grid, it is possible to implement system with photovoltaics and plug in charge of batteries, which will as consequence significantly reduce required battery pack power, or it is possible to implement another PEMFC stack as auxiliary or upscaled power system to meet electric energy requirements.

6. Conclusions

The research has shown that repower of existing vessel with PEMFC-Battery hybrid power system increased efficiency and eliminated greenhouse gas emissions compared to previously installed diesel propulsion system. New numerical model of hybrid power system is developed and can be used for different hybrid systems, power demand optimization and as very flexible system for implementation in any electric-dependent power facility with different routes and application. The model will be further developed for BoP optimization in realistic cycles of operation. For further development of numerical model intended improvement would be the system with different output power of PEMFC stack, or a combination of one main and another auxiliary PEMFC stack and implementation of photovoltaics with detailed insight to their power production and possibilities to additionally reduce requirement for batteries.

Author Contributions

Conceptualization, J.P., T.V.; Data curation, J.P.,T.V.,G.R.; Formal analysis, J.P.,T.V.; Funding acquisition, G.R.; Investigation, J.P., T.V., G.R. ; Methodology, J.P., T.V., G.R., Ž.P.; Project administration, G.R.,Ž.P.; Software, J.P., T.V.; Supervision, G.R., Ž.P.; Validation, J.P., T.V., G.R., Ž.P.; Visualization, J.P., T.V.; Writing—original draft, J.P.,T.V.; Writing—review & editing, J.P., T.V., G.R., Ž.P. All authors have read and agreed to the published version of the manuscript.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- T. Vidović, J. Šimunović, G. Radica, and Ž. Penga, “Systematic Overview of Newly Available Technologies in the Green Maritime Sector,” Energies, vol. 16, no. 2. MDPI, Jan. 01, 2023. [CrossRef]

- 2. G. Adamolekun, “Carbon price and firm greenhouse gas emissions,” J Environ Manage, vol. 349, Jan. 2024. [CrossRef]

- 3. “Fourth IMO GHG Study 2020 Full Report”.

- T. Vidović, I. Tolj, G. Radica, and N. B. Ćoko, “Proton-exchange membrane fuel cell balance of plant and per-2 formance simulation for vehicle applications,” vol. 15, 2022. [CrossRef]

- “Marine Power with Toyota Fuel Cell Technology,” https://www.toyota-europe.com/news/2023/marine-power.

- Pietra, M. Gianni, N. Zuliani, S. Malabotti, and R. Taccani, “Experimental characterization of a PEM fuel cell for marine power generation,” in E3S Web of Conferences, EDP Sciences, Jan. 2022. [CrossRef]

- H. Xing, C. Stuart, S. Spence, and H. Chen, “Fuel cell power systems for maritime applications: Progress and perspectives,” Sustainability (Switzerland), vol. 13, no. 3, pp. 1–34, Feb. 2021. [CrossRef]

- J. Il Lee, B. Y. Yoon, and S. W. Cha, “Analysis of solid oxide fuel cell hybrid power system in marine application for CO2 reduction,” Energy Reports, vol. 9, pp. 3072–3081, Dec. 2023. [CrossRef]

- G. Elkafas, M. Rivarolo, E. Gadducci, L. Magistri, and A. F. Massardo, “Fuel Cell Systems for Maritime: A Review of Research Development, Commercial Products, Applications, and Perspectives,” Processes, vol. 11, no. 1. MDPI, Jan. 01, 2023. [CrossRef]

- K. M. Bagherabadi, S. Skjong, J. Bruinsma, and E. Pedersen, “System-level modeling of marine power plant with PEMFC system and battery,” International Journal of Naval Architecture and Ocean Engineering, vol. 14, Jan. 2022. [CrossRef]

- P. Xie, H. Asgharian, J. M. Guerrero, J. C. Vasquez, S. S. Araya, and V. Liso, “A two-layer energy management system for a hybrid electrical passenger ship with multi-PEM fuel cell stack,” Int J Hydrogen Energy, vol. 50, pp. 1005–1019, Jan. 2024. [CrossRef]

- R. D. Geertsma, R. R. Negenborn, K. Visser, and J. J. Hopman, “Design and control of hybrid power and propulsion systems for smart ships: A review of developments,” Applied Energy, vol. 194. Elsevier Ltd, pp. 30–54, 2017. [CrossRef]

- Bernitsas M.M., Ray D., and Kinley P., “KT, KQ and Efficiency Curves for the Wageningen B-Series Propellers”, Accessed: Jan. 31, 2024. [Online]. Available: https://deepblue.lib.umich.edu/bitstream/handle/2027.42/91702/Publication_No_237.pdf?sequence=1&isAllowed=y.

- 14. H. Lohse-Busch et al., “Automotive fuel cell stack and system efficiency and fuel consumption based on vehicle testing on a chassis dynamometer at minus 18 °C to positive 35 °C temperatures,” Int J Hydrogen Energy, vol. 45, no. 1, pp. 861–872, Jan. 2020. [CrossRef]

- Kravos, D. Ritzberger, G. Tavc̆ar, C. Hametner, S. Jakubek, and T. Katras̆nik, “Thermodynamically consistent reduced dimensionality electrochemical model for proton exchange membrane fuel cell performance modelling and control,” J Power Sources, vol. 454, Apr. 2020. [CrossRef]

- T. E. Springer, M. S. Wilson, and S. Gottesfeld, “Modeling and Experimental Diagnostics in Polymer Electrolyte Fuel Cells.”.

- “Li-Ion Voltage Analysis,” https://siliconlightworks.com/li-ion-voltage.

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).