1. Introduction

With the increasing global energy demand, the exploration and development of oil and gas resources are gradually moving to deep and complex formations; moreover, the demand for drilling complex structural wells, such as large displacement wells, long horizontal wells with large slopes and multibranch wells, is increasing [

1]. Oil-based drilling fluids are often used as the main wellbore working fluids from the open window sidetrack drilling all the way to the completion of the horizontal section to ensure the downhole safety of complex structured wells [

2]. Given the increase in environmental awareness and the strict restriction of environmental regulations, re-placing oil-based drilling fluids using environmentally friendly high-performance weak-gel water-based drilling fluids has achieved a wide consensus worldwide [

3,

4,

5]. Replacing oil-based drilling fluids with water-based drilling fluids faces many realistic engineering complexities, such as the lubrication performance of water-based drilling fluids at the bottom of the well; moreover, this approach cannot easily meet the drilling requirements [

6]. Researchers have developed various environmentally friendly and efficient water-based drilling fluid lubricants to improve the lubrication performance of water-based drilling fluids effectively. Amongst them, modified vegetable oils and fats have been the focus of green lubricant development [

7].

Although vegetable oils are environmentally friendly and renewable, vegetable oil lubricants are less stable in alkaline environments than mineral oil lubricants. Moreover, they are easily hydrolysed and saponified at wellbore temperatures; thus, using vegetable oil lubricants results in drilling fluid foaming, and the continuity of drilling fluid flow cannot be ensured [

8]. The hydrolytically saponified vegetable oil surfactants also cause the weak-gel properties of drilling fluids to deteriorate, affecting the rheology of drilling fluids [

9]. In addition, the cost of vegetable oil lubricants is much higher than that of mineral oil-based lubricants. In the field construction process, the dosage of vegetable oil lubricants usually exceeds 3 v/v% of the liquid volume of drilling fluids, resulting in a high cost of use. If the cost-effectiveness ratio of vegetable oil lubricants is not solved, this type of treatment agent cannot be massively promoted in the field [

10].

Researchers usually esterify vegetable oleic acid to balance the stability and lubrication performance of vegetable oil lubricants in alkaline drilling fluids [

11]. Haseeb et al. [

12] systematically investigated the effects of the length of the lipid-based carbon chain of synthetic ester lubricants and the length of the hydrophobic chain segments of the alcohol group on the lubrication and stabilisation properties of synthetic ester lubricants. The results showed that synthetic esters with different hydrophobic chain segments have good thermal stability. Moreover, no thermal decomposition reaction occurred in the 175–425 °C. The viscosity of all the ester lubricants does not decrease during the shear process, and good rheological stability is maintained. Li W. et al. [

13] investigated the drilling fluid lubricants based on fatty acid methyl ester. A detailed comparison of the properties of fatty acid methyl esters and other vegetable fats and oils showed that the reduction in extreme pressure lubrication of the drilling fluids exceeds 70% in all cases when 2 wt.% fatty acid methyl esters are added to freshwater drilling fluids. Fatty acid methyl ester lubricants also have outstanding lubrication effects in seawater-based drilling fluids. Liu F. et al. [

14] received several hydroxyl groups to the end of vegetable oil fatty acid to form oleic acid-trihydroxypropane polyol ester lubricant. The extreme pressure lubrication reduction rate and filter cake adhesion coefficient reduction rate can reach more than 80% after the ageing process at 150 °C in the base mud. Qian X. et al. [

15] synthesised the environmentally friendly lubricant SMLUB-E by esterification reaction between fatty acid and organic polyol. SMLUB-E has a good lubrication effect in water-based drilling fluid. After being aged at 160 °C in base stock, SMLUB-E has a reduced molecular resistance coefficient from 0.47 to 0.05. Moreover, the reduction rate of extreme pressure lubrication is 89.36%. SMLUB-E was applied in deep horizontal wells of the Taha Oilfield. No downhole failures, such as buttress, stuck drilling and other downhole failures, were observed.

On the basis of ester-based lubricants’ good lubricity, researchers focused on adding lubrication elements of different structures to the lubricants to improve the lubrication effect further under extreme working pressure. The selected lubricant must have strong adsorption to the metal surface to survive in the harsh environment of drilling fluids. The Sinopec Petroleum Engineering Research Institute used the fatty chains of monomers S cross-linked vegetable oil esters to form the sulphurised vegetable oil lubricant SMJH-1 and improve the adsorption density of the lubricant on the surface of the drilling tools [

16]. The friction coefficient reduction rates before and after the ageing of SMJH-1 at a content of 1.0% in the base mud are 91.4% and 90.7%, respectively. The theoretical basis for this result is that the lubricating functional components containing sulphur, phosphorus and other elements can form a protective film with a high strength on the surface of drilling tools and iron reaction under extreme pressure conditions, thereby improving the macroscopic lubrication effect. These lubricants are added with sulphur, phosphorus and other elements to improve the lubrication performance. Under the high-temperature and high-pressure environment at the bottom of the well, these elements cause corrosion to the drilling tools. This phenomenon tends to cause downhole accidents. In addition to chemically reactive extreme pressure lubrication additives, numerous configurations of solid nanomaterials have been used as extreme pressure lubrication promoter materials for lubricants. Liu Y. et al. [

17] added expandable graphite to vegetable oil to form the weak-gel drilling fluid–modified vegetable oil lubricant MVO-3. MVO-3 has excellent dual adsorption characteristics, fluidity and lubrication properties. Modified expandable graphite GIC has a composite lamellar structure with a small surface-to-volume ratio and high ad-sorption capacity. It can form elastic flake expansion in downhole conditions and further generate dense expanded lubricant film by adsorption on a metal surface, thereby obtaining an excellent lubrication effect. Xiao J. et al. [

18] added the hexagonal flake organic borate extreme pressure lubricant GEP-2 to the modified vegetable oil to form the drilling fluid lubricant SDGL-2. SDGL-2 can withstand the temperature of up to 160 °C. When SDGL-2 is added at a dosage of 1.0%, the reductions in the lubricity coefficients of freshwater-based bentonite clay and saltwater-based bentonite clay are 85.33% and 77.51%, respectively, after hot rolling at 160 °C/16 h. The lubricity coefficients of the freshwater-based bentonite clay and saltwater-based bentonite clay are reduced by 1.0%. In addition to the typical modified ester lubricants mentioned above, many commercial ester lubricant products can be found, all of which show good lubrication performance and compatibility with weak-gel drilling fluids in the chamber. However, in the field, the lubricant dosage in the well slurry is consistently higher than 2 v/v%. Reducing the cost of lubricant production and the amount of lubricant in the lubricant is still the main research direction of cost reduction and efficiency of environmentally friendly lubricants.

Ester lubricants have gained considerable attention in the study of weak-gel water-based drilling fluids because these materials have good stability and good lubrication properties in their structure. Suppose ester lubricants can be made with outstand-ing extreme pressure lubrication performance without the addition of expensive inorganic nanomaterials. In that case, the cost of lubricants is expected to be reduced from the production and consumption sides of the lubricant. Thus, ester lubricants can be used on a large scale. Akaighe et al. [

19] found through theoretical analyses and calculations that the horizontal portion of the complex structure wells is mainly controlled by the friction of boundaries and mixing layers. They also found that the lubricant has good stability, strong adsorption capacity on the metal surface and high coverage density. A systematic study of the molecules defines the lubricant ‘head’ that adsorbs on the metal and the lubricant ‘tail’ that is densely arranged to provide a stable lubricant film, thereby providing insight into the optimal molecular structure. The contribution of each head group to the extreme pressure lubrication performance is in the following order: ethyl ester < methyl ester < alcohol < amine. However, the carbon chain length of the tail group has little influence on the lubrication performance. Our group has also spent a long time simulating and applying vegetable oil-modified lubricants. Guo J. et al. [

20] simulated the oil film thickness of vegetable oil lubricants on the surface of drilling tools by adsorption kinetics. Zhang S. et al. [

21] simulated amide-modified vegetable oils and fats via restricted shear. They found that amide polar headgroups can be directionally adsorbed in the shear surface. This finding was confirmed by sub-sequent shear friction wear experiments. The understanding of tribology from other industrial applications can also be used in designing molecules to provide optimal lubrication in weak-gel drilling fluids. Wang W. [

22] modelled the effect of the poly-a-olefin molecular structure on lubrication performance using band pressure–confined shear and concluded that PAO molecules with long side-chains or with a specific form of side-chain distribution can be aligned in a well-ordered manner along the direction of shear to improve extreme pressure lubrication performance under the ultimate pressure of 500 MPa. This model is close to the state of shear friction in horizontal wells and can be used to simulate the lubrication performance of ester lubricants under extreme pressure conditions. The molecular simulation is used to optimise the extreme pressure lubrication performance of ester lubricants through the organic combination of the previous research foundation and the pressure-constrained shear model to obtain high-efficiency lubricants with a reasonable raw material price and low on-site dosage.

2. Simulation and Experiments

2.1. Shear Simulation of Ester Lubricants

- 1.

Structure models

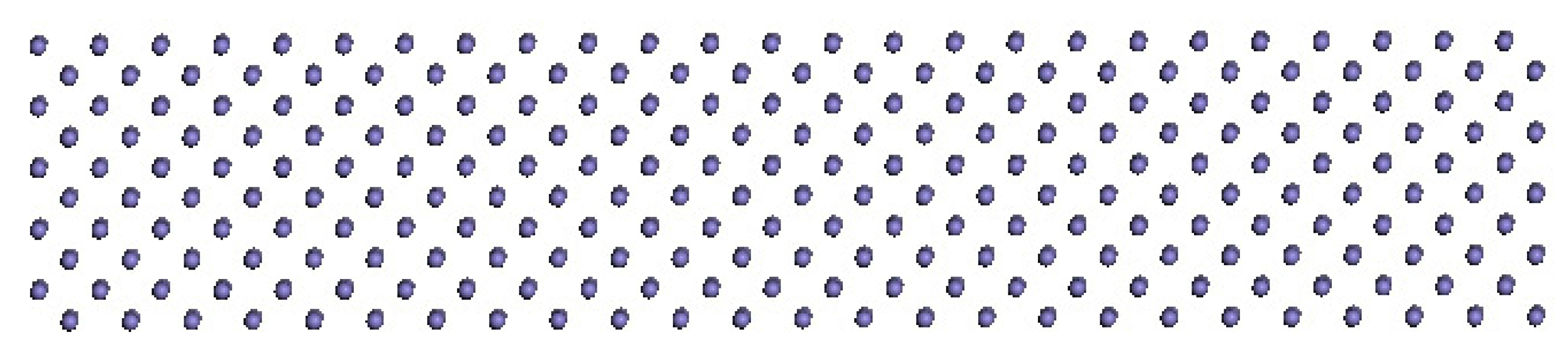

The establishment of a suitable lubricant base oil model has a convincing influence on the accuracy of the molecular dynamics simulation results. The surface of the drilling tools in the drilling process is dominated by iron. The Fe(0 0 1) surface was used as the surface model of the drilling tools to maintain continuity with the previous study [

20,

21]. As shown in

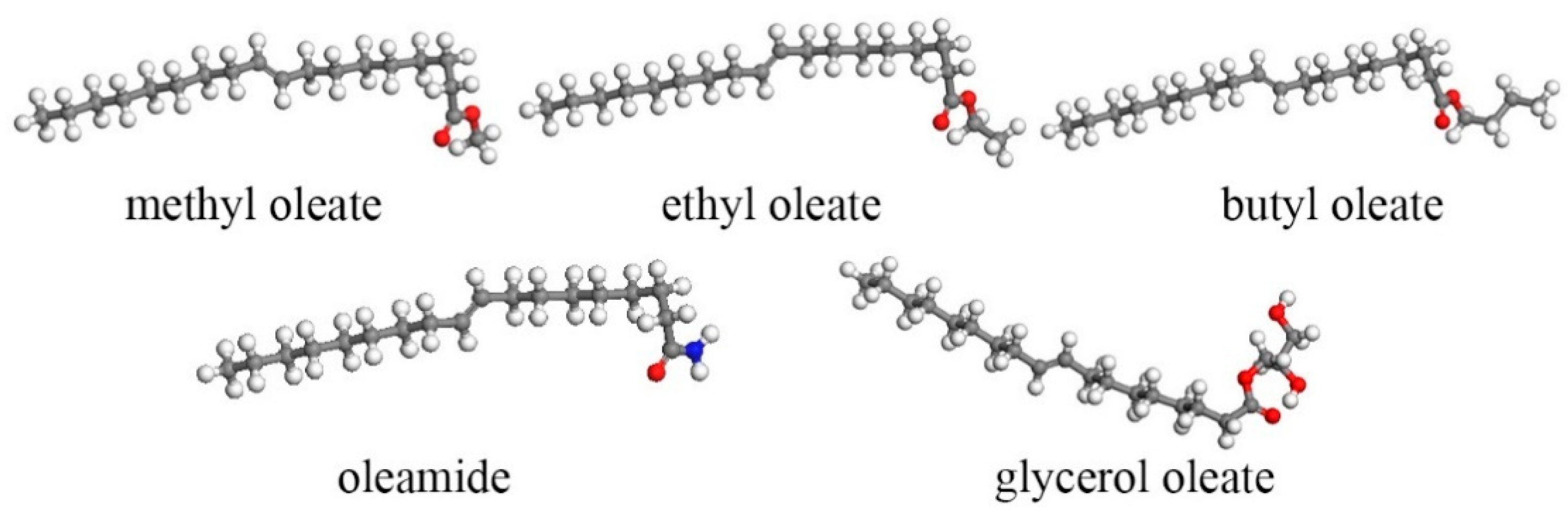

Figure 1, the ‘sandwich model’ of Fe-lubricants-Fe was constructed, with the size of the upper and lower layers of Fe being 80.26 Å × 40.13 Å × 14.4 Å. The single-component structure models of the five lubricants are shown in

Figure 2. They are the same as those of the lubricant base oils.

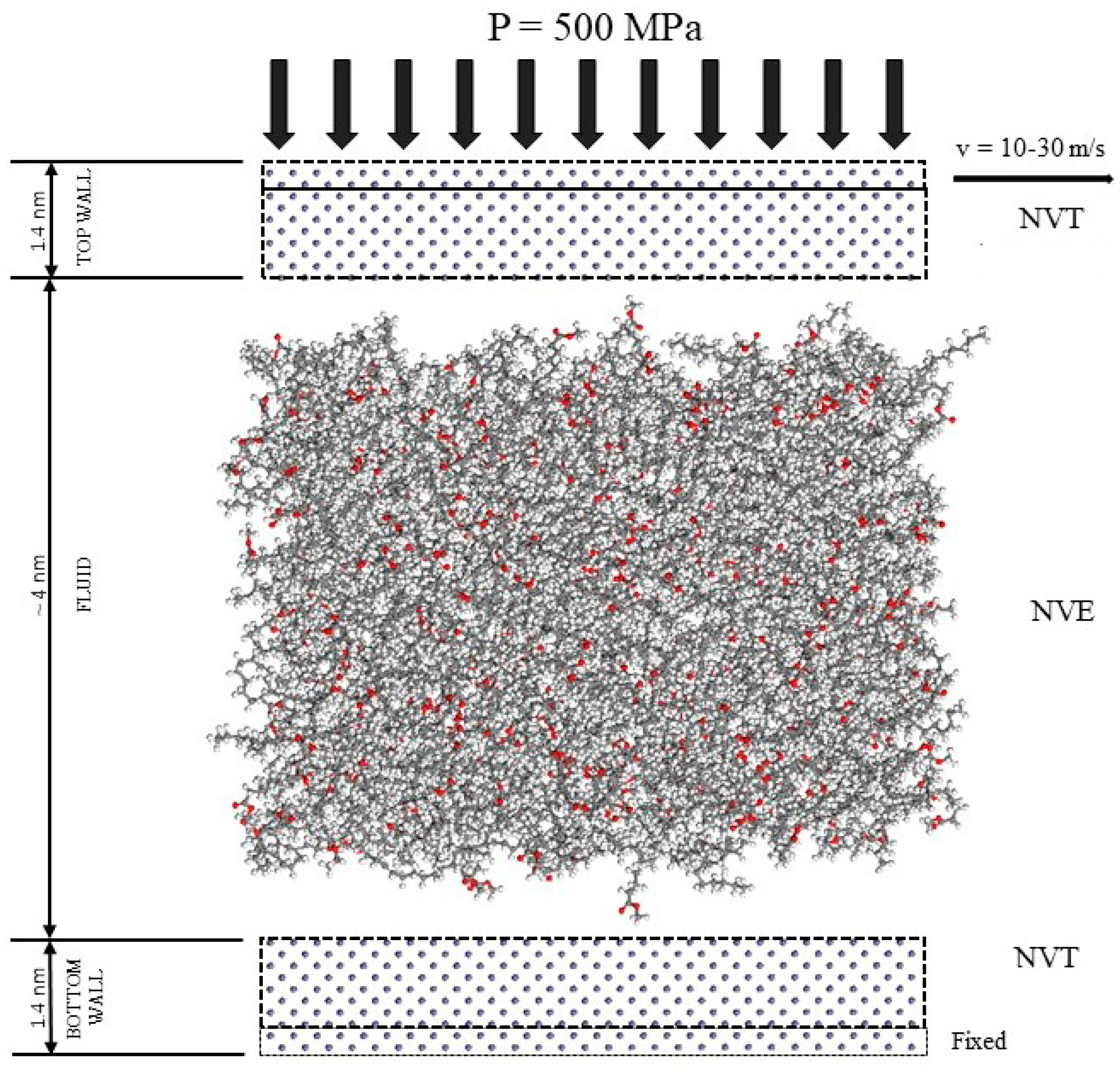

After the lubricant molecules and Fe(0 0 1) surfaces were constructed, the model was optimised in terms of structure and energy with a pcff force field, fine accuracy, an NVT system, a temperature of 298 K, a step size of 1.0 fs and a simulation time of 50 ps. The lubricant system was constructed to contain 200 lubricant molecules. A ‘sandwich model’ was constructed using two layers of Fe(0 0 1) surfaces with the lubricant system. Van der Waals and Coulomb force interactions were calculated using the atom-based and Ewald methods with a truncation radius of 1.55 nm. The initial structure of the ‘sandwich model’ is shown in

Figure 3.

- 2.

Shear simulation of single lubricant structure

After the model was built, the shear simulation was performed according to the following steps:

(1) Structural optimisation: After the establishment of the ‘sandwich model’, the positions of the upper and lower iron layers were fixed, and molecular dynamics simulations were used to optimise the overall structure of the lubricant system in the middle layer.

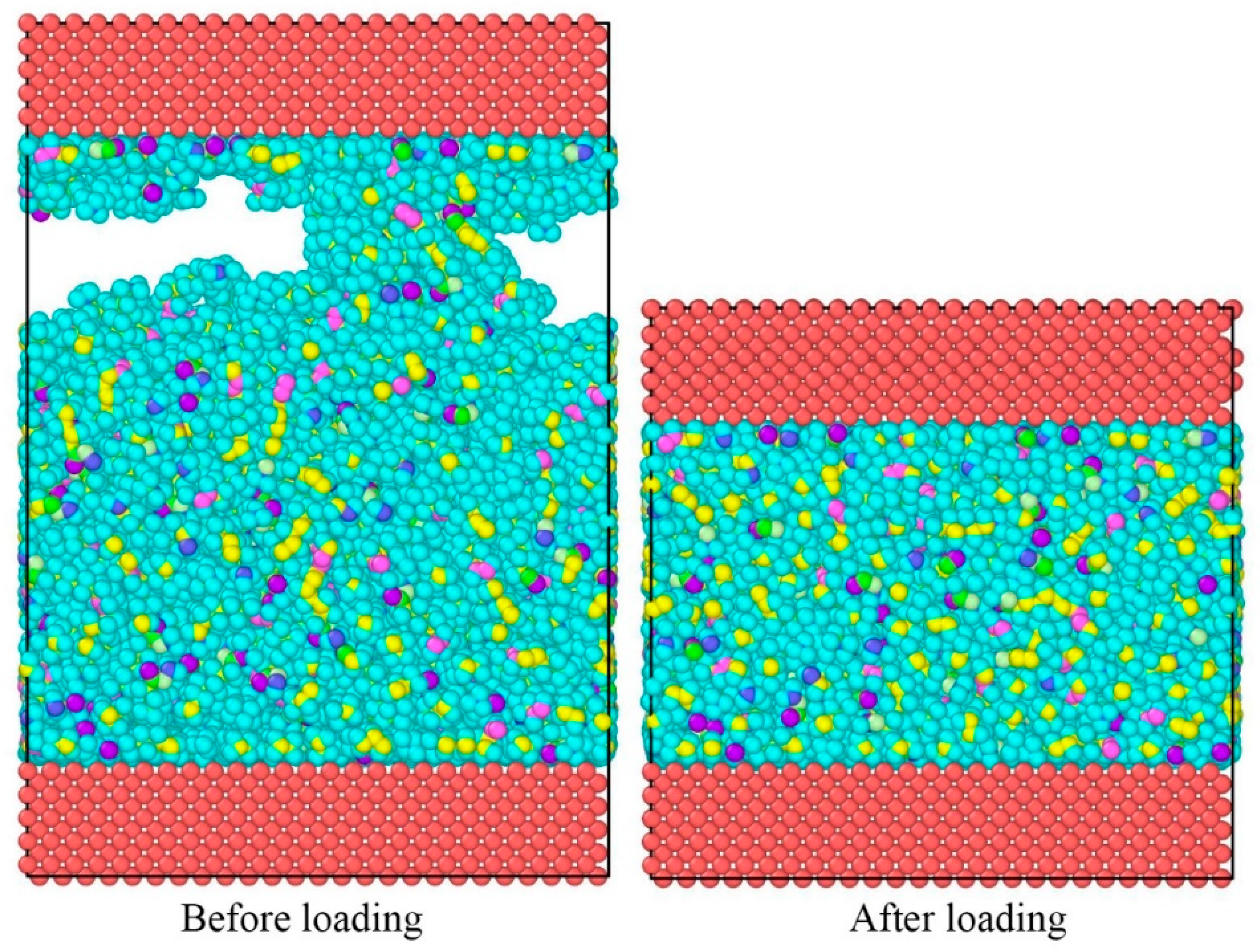

(2) Load process: The simulation system adopted the NVT system, fixed the lower iron wall and applied a pressure of 500 MPa to the upper iron wall. The system’s temperature was set to 298 K, the step size was 1.0 fs, and the simulation time was 50 ps, thereby allowing the system to reach a stable state. The structural changes in the ‘sandwich model’ before and after loading are shown in

Figure 4.

(3) Shear process: After the completion of the load iron wall surface, the system continued using the NVT system, namely, the lubricant system using the NVE system, to simulate the lubricant in the shear process and produce the shear heat phenomenon. The lower iron wall surface was fixed, and the upper iron wall surface of the upper-most layer of iron atoms was set at a speed of 10–30 m/s along the x-axis direction of the shear. The initial temperature of the system was set to 298–398 K. The step size was 1.0 fs, and the simulation time was 2000 ps.

- 3.

Shear simulation for lubricant structure optimization

The optimised oleic acid esters were used as base oils. The oleic acid amides containing amine groups and oleic acid glycerides containing hydroxyl groups were used as the extreme pressure functional components. The base oils were compounded with the extreme pressure agents to form new lubricants. The shear simulations are conducted according to the above method. The effects of different dosages on the performance of the systems were also compared. The extreme pressure lubricant component was preferred, and the extreme pressure lubricant component and base oil were compounded to optimise the structure of the hybrid lubricant through shear simulation under extreme pressure.

2.2. Experimental Materials and Apparatus

The materials used in this study include ethyl oleate, ethyl oleate, butyl oleate, oleic acid amide and monoglyceride oleate from Wuhan Ranabai Pharmaceutical and Chemical Co., Ltd. Anhydrous ethanol was obtained from Tianjin Beilian Fine Chemicals Development Co., Ltd. The apparatuses used include a four-ball friction tester with steel balls (Jinan Hengxu Testing Machine Technology Co., Ltd.), the orthogonal metallurgical microscope PH-M3230 (Jiangxi Phoenix Optical Science and Technology Co., Ltd.), the four-ball friction tester with lever SGW-10G (Jinan Hengxu Testing Machine Technology Co., Ltd.) and 10G (Jinan Hengxu Testing Machine Technology Co., Ltd.).

2.3. Friction and Wear Experiment

The antiwear performance of the lubricant was tested using the SGW-10G, a four-ball friction tester with lever. The four-ball friction test with lever refers to the industry standard SH/T 0189-92 ‘Determination of Anti-wear Performance of Lubricant (four-ball machine method)’. Before the experiment, anhydrous ethanol was used to clean the instrument parts to ensure that the lubricant was not contaminated by impurities on the instrument’s surface. A load of 147 N was applied to the steel balls at room temperature. The temperature of the test chamber was increased to 75 °C, and the top ball was rotated at 1200 r/min for 60 min. The coefficient of friction was measured during the test. At the end of the test, the size of the wear spots on the ball was observed using an orthogonal metallurgical microscope.

2.4. Evaluation of Lubrication Property in Weak-Gel Drilling Fluids

- 1.

Preparation of drilling fluids

(1) Base mud

Water, bentonite and sodium carbonate were mixed according to the mass ratio 400:20:1. They were stirred at 6000 r/min for 30 min, sealed and placed at room temperature for 24 h.

(2) Weak-gel drilling fluid

The composition of the weak-gel drilling fluid formulation was 0.3% polymer FA367, 0.8% polyacrylonitrile-polyacrylamide ammonium composite salt, 1% potassium polyacrylate KPA, 3% of the reduction of filtration loss agent QS-4, 1.5% amphiphilic pressure-bearing plugging agent, 1.5% environmental protection nanoblocking agent YRD-BA01 and 0.2% caustic soda. The aggravating agent barite was mixed in the base mud and aggravated to 1.2 g/m3. The weak-gel drilling fluid was mixed at 6000 r/min for 30 min, sealed and placed at room temperature for 24 h.

- 2.

Evaluation of lubrication performance

(1) Evaluation of extreme pressure lubrication performance

According to the technical indexes and test methods of the Sinopec enterprise standard ‘Technical Requirements of Liquid Lubricant for Water-based Drilling Fluid’ (Q/SH CG0004-2023), FANN 21200 extreme pressure lubrication instrument was used to test the lubrication coefficient of the base mud, with 0.5% lubricant being added to the slurry (the test condition was ageing for 16 h at 120 °C).

(2) Determination of drilling fluid compatibility

The lubricant was added directly into the prepared base mud or polymer drilling fluid and mixed at high speed for 20 min to make the lubricant evenly dispersed. According to the Chinese national standard GB/T 16783-1997 ‘Field Test Procedures for Water-based Drilling Fluids’, the viscosity, filtration loss and rheological parameters of the base mud or polymer drilling fluid were measured to investigate the compatibility of the lubricant with the polymer drilling fluid.

(3) Performance test after long time aging

The lubricant was added into the polymer drilling fluid, stirred well at high speed for 20 min and aged continuously at 120 °C for 7 days. The data of the drilling fluid were tested every day to investigate the effect of the lubricant on the long-time gel performance of the drilling fluid.

4. Conclusions

The conclusions of this work are as follows.

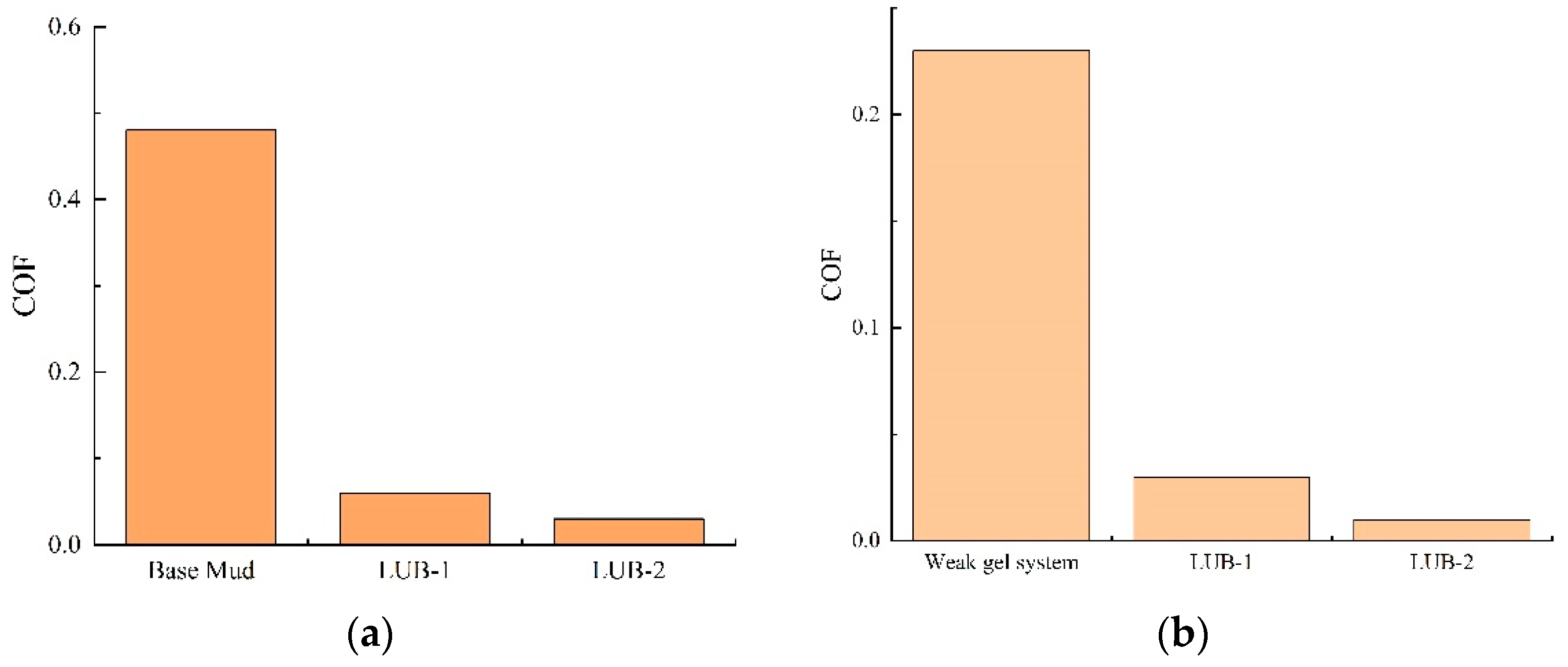

(1) Methyl oleate and oleamide are selected as the base oil of the ester lubricant and the extreme pressure lubricant additive through molecular dynamics shear simulation under extreme pressure. The ratio of oleamide and methyl oleate is optimised, and the ester lubricant LUB-2 is formed when 10% oleamide is added to methyl oleate. LUB-2 can effectively balance the lubricating performance and cost of the lubricant.

(2) The results of the in-house evaluation of the lubricant show that the lubricity coefficient of the drilling fluid is reduced by 95.65% when 0.5% LUB-2 is added to the weak-gel drilling fluid. This reduction is more than the reduction in most of the ester lubricants in the market. The lubricant does not affect the rheological properties of the drilling fluid when 1% LUB-2 is added to it. Moreover, the lubricant does not foam in the drilling fluid. LUB-2 does not hydrolyse and does not foam in the weak-gel drilling fluid with a pH value of 8.0. LUB-2 is not hydrolysed in the weak gel at pH 8.0 and is compatible with the drilling fluid. This feature does not affect the gel performance of the drilling fluid.

(3) The results of the field application show that LUB-2 can reduce the friction resistance by 33% when 1% of LUB-2 is added into the drilling fluid in the field, and the lubrication performance remains unchanged after a total horizontal displacement of 1194 m from the opening of the window side drilling to the completion of the well. Thus, the lubrication effect of the traditional lubricant of 2% is reached. The addition of 10% oleic acid amide to fatty acid methyl ester can greatly improve the economy of ester lubricants and increase the application prospect of ester lubricants.

Figure 1.

The model of Fe(0 0 1).

Figure 1.

The model of Fe(0 0 1).

Figure 2.

The model of component structure models of lubricants.

Figure 2.

The model of component structure models of lubricants.

Figure 3.

Shear simulation of the “sandwich model”.

Figure 3.

Shear simulation of the “sandwich model”.

Figure 4.

Structural changes of the “sandwich model” before and after loading.

Figure 4.

Structural changes of the “sandwich model” before and after loading.

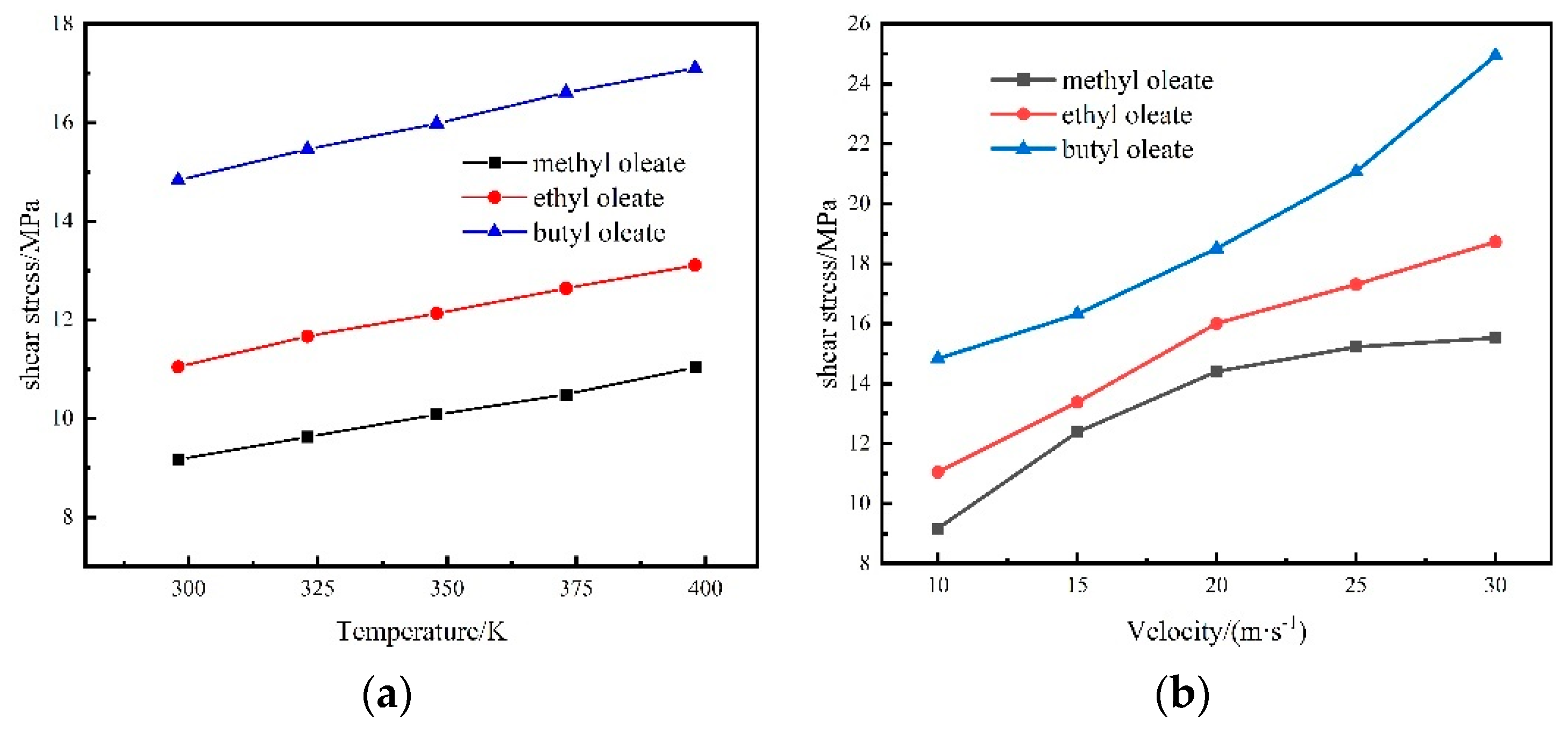

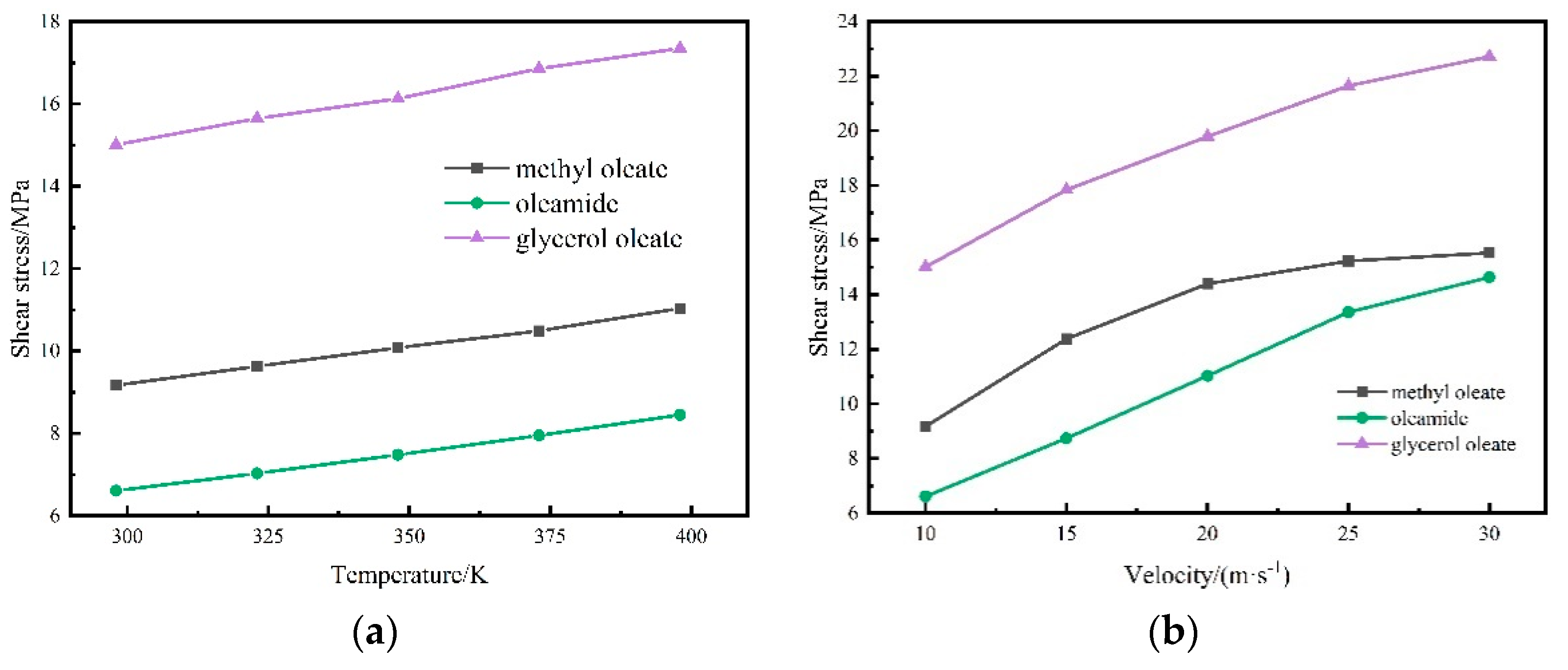

Figure 5.

Average shear stress of base oils under different conditions: (a) Different initial temperatures, (b) Different shear speeds.

Figure 5.

Average shear stress of base oils under different conditions: (a) Different initial temperatures, (b) Different shear speeds.

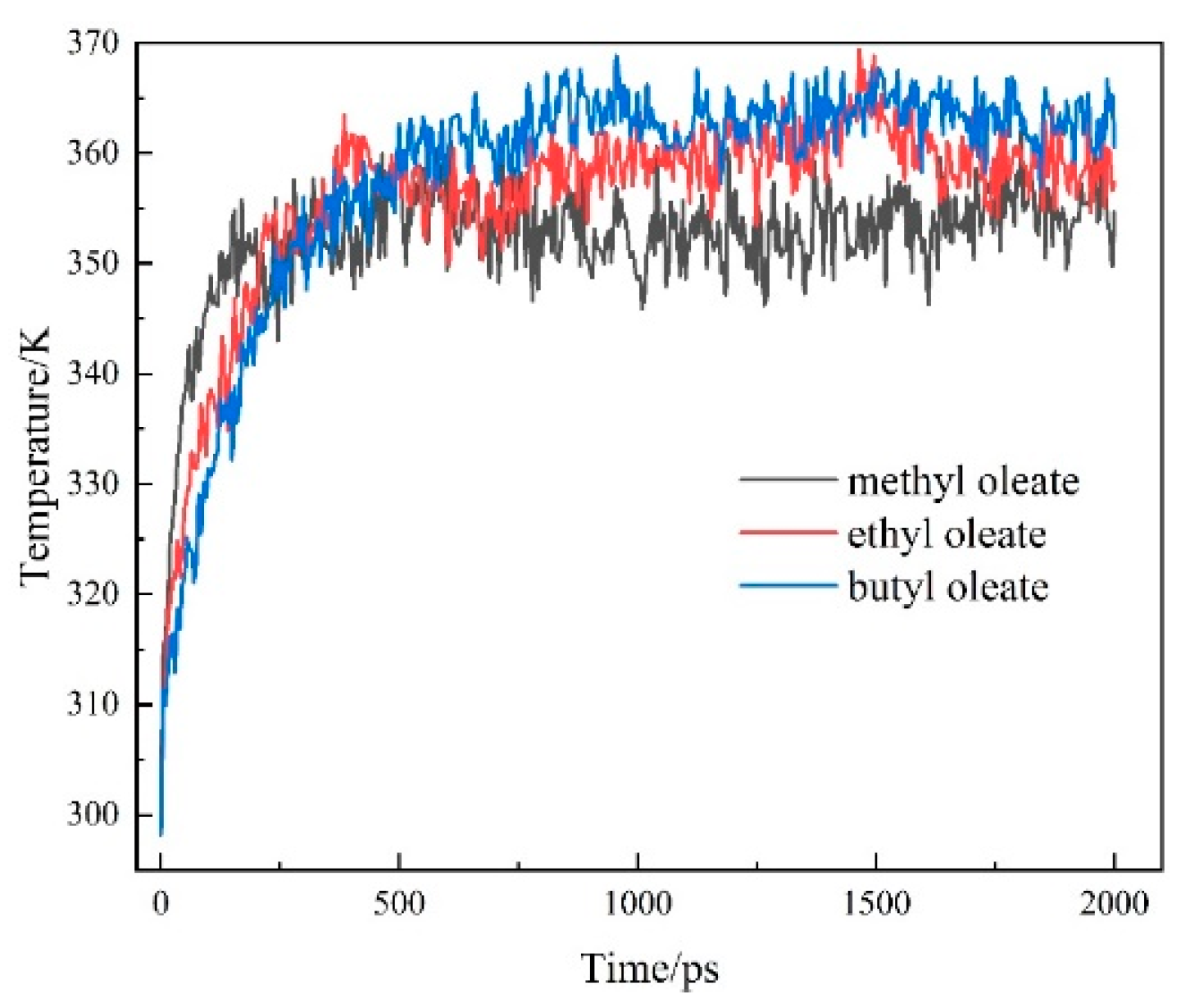

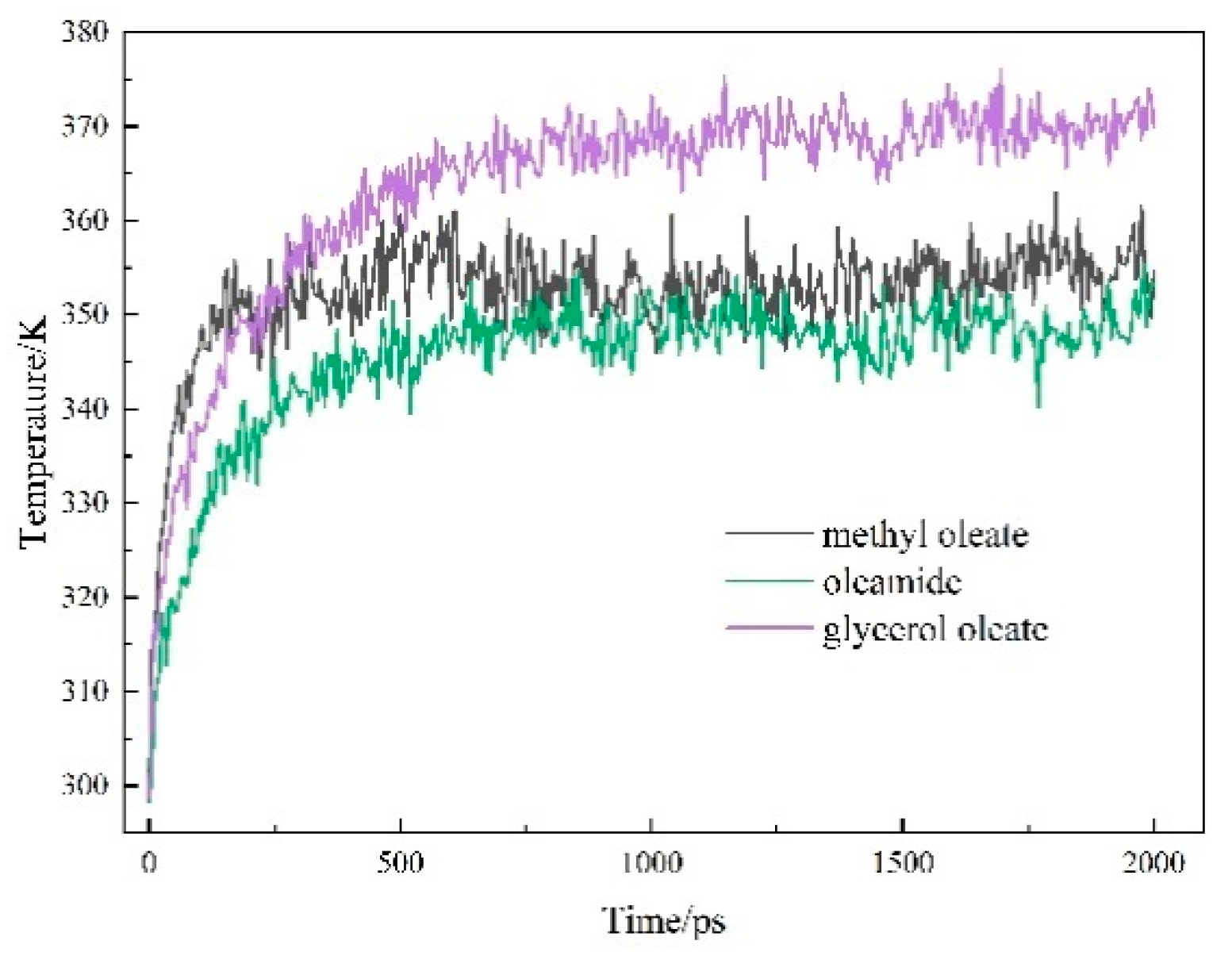

Figure 6.

Variation of mean temperature of ester base oils with shear time.

Figure 6.

Variation of mean temperature of ester base oils with shear time.

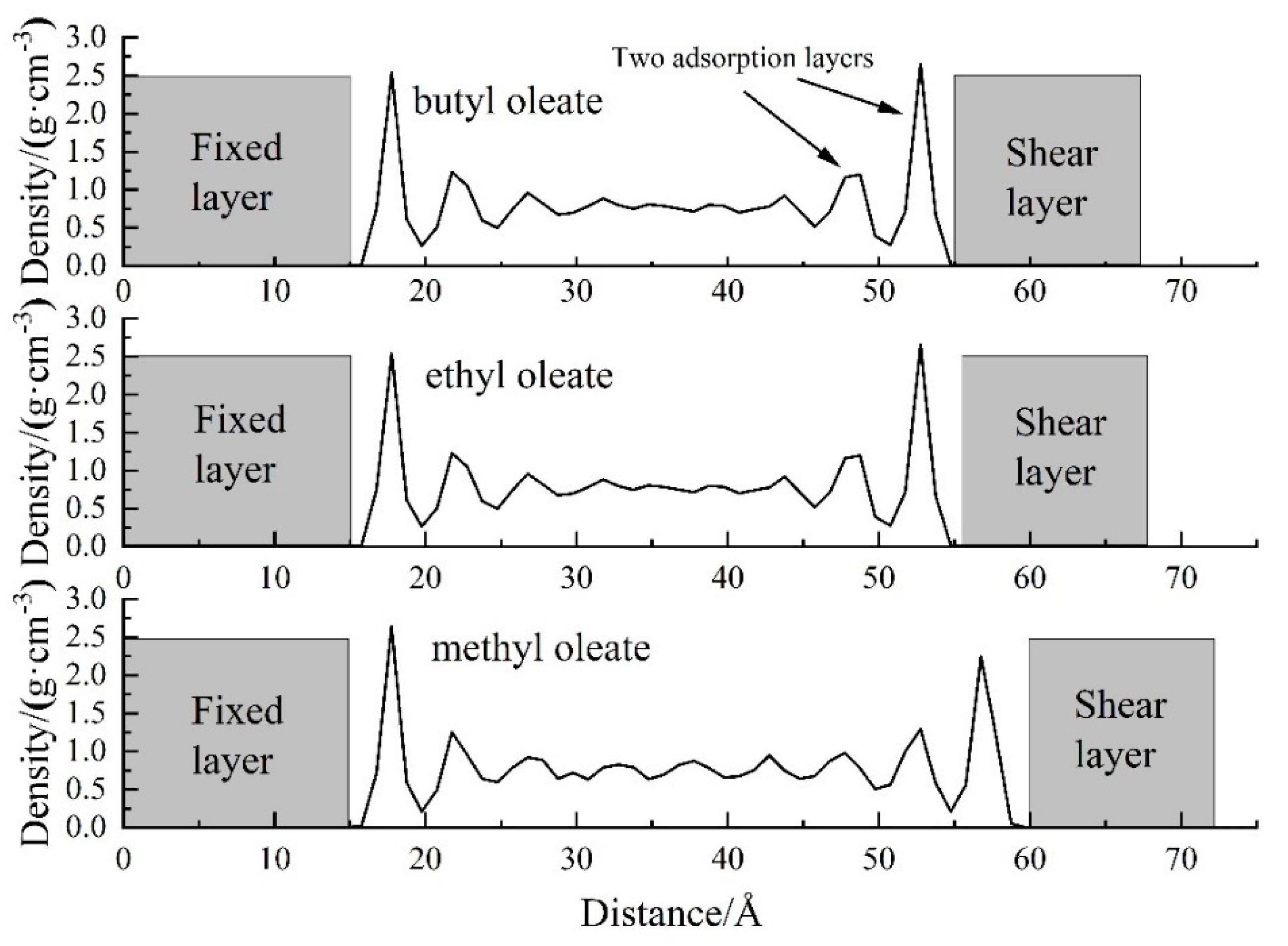

Figure 7.

Density distribution profile of ester lubricants after shearing.

Figure 7.

Density distribution profile of ester lubricants after shearing.

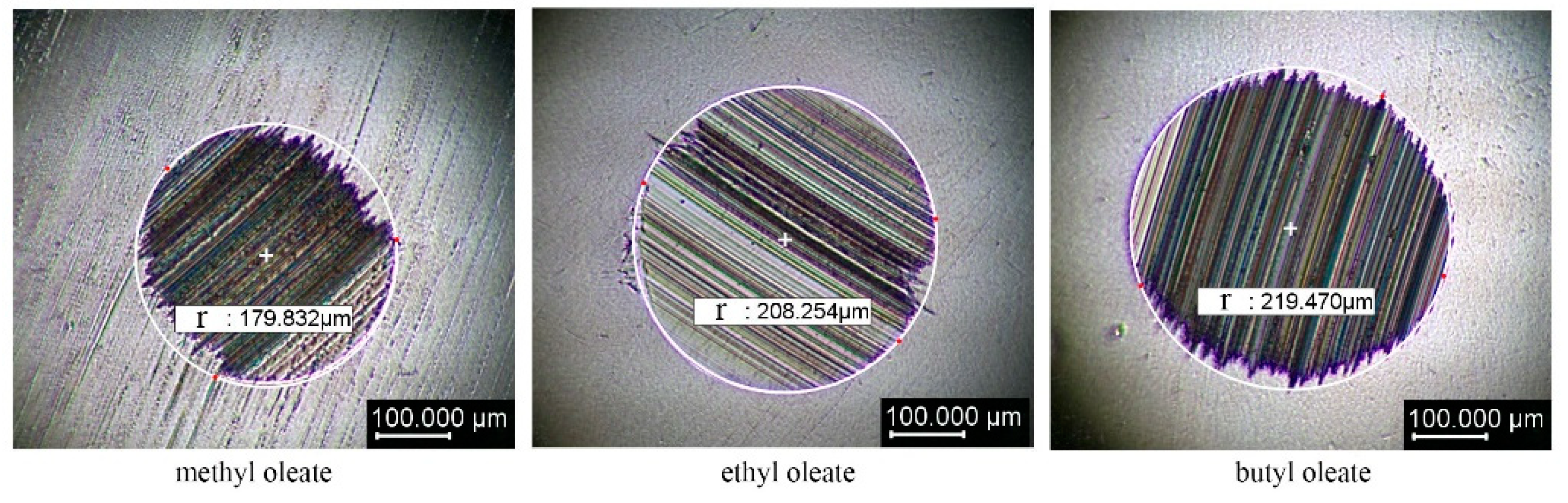

Figure 8.

Friction test wear spot size of ester lubricants.

Figure 8.

Friction test wear spot size of ester lubricants.

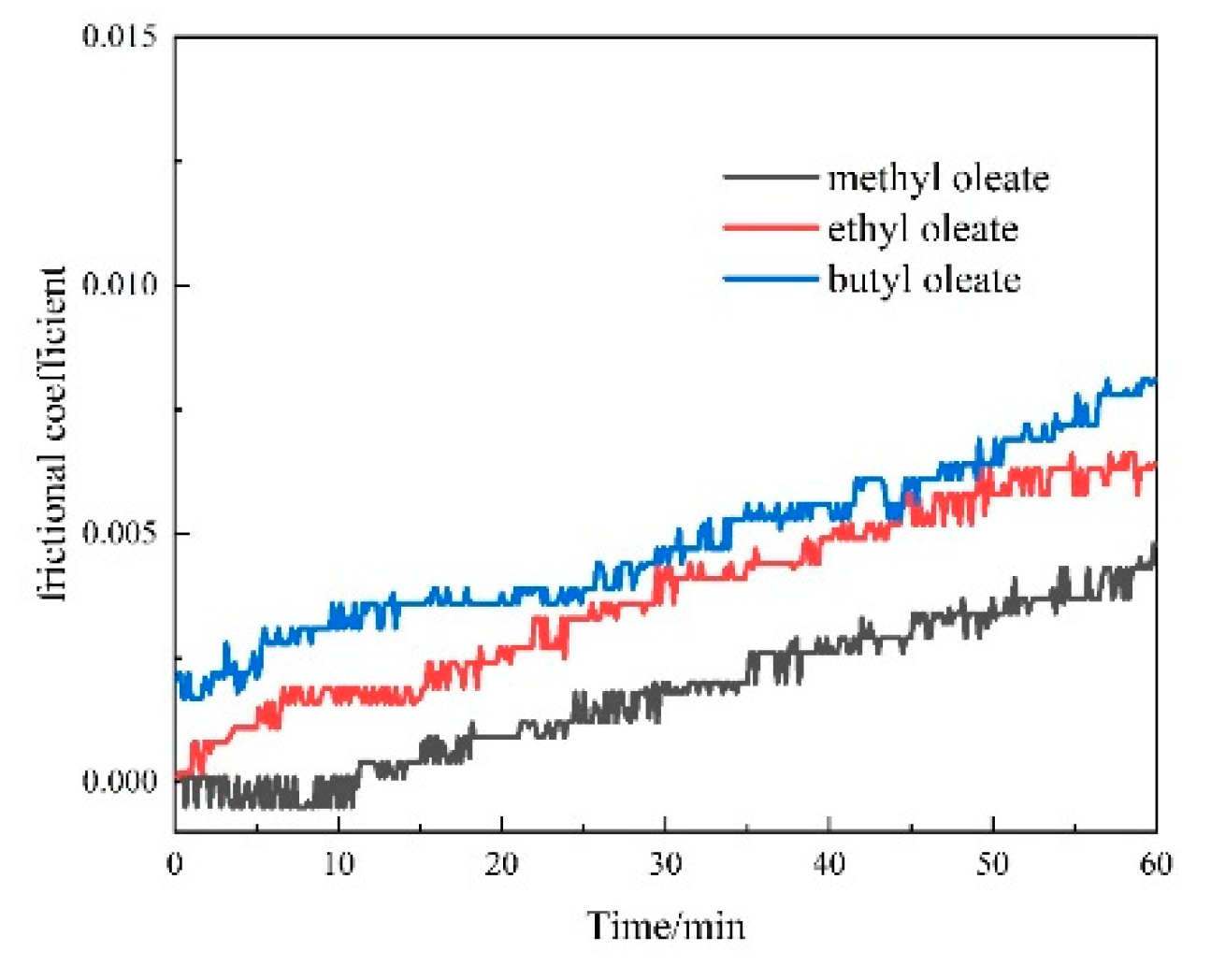

Figure 9.

Coefficient of friction of ester lubricants over time.

Figure 9.

Coefficient of friction of ester lubricants over time.

Figure 10.

Mean shear stresses of extreme pressure functional components: (a) Different initial temperatures, (b) Different shear speeds.

Figure 10.

Mean shear stresses of extreme pressure functional components: (a) Different initial temperatures, (b) Different shear speeds.

Figure 11.

Average shear temperature of extreme pressure lubrication component fluids.

Figure 11.

Average shear temperature of extreme pressure lubrication component fluids.

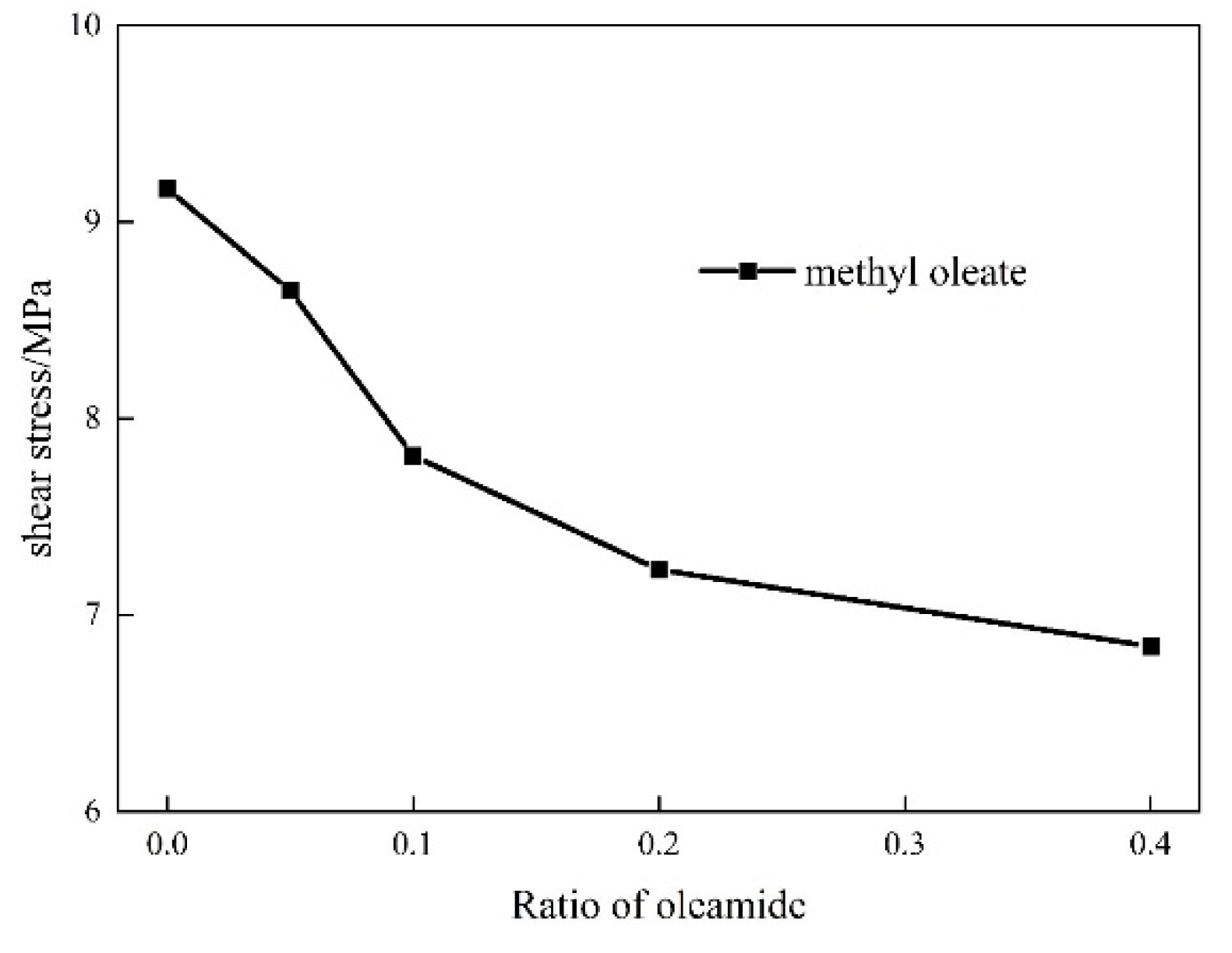

Figure 12.

Average shear stress of two-component mixtures of methyl oleate and oleamide.

Figure 12.

Average shear stress of two-component mixtures of methyl oleate and oleamide.

Figure 13.

Lubricity factor of test system with 0.5% lubricant: (a) Base mud, (b) Weak gel drilling fluid.

Figure 13.

Lubricity factor of test system with 0.5% lubricant: (a) Base mud, (b) Weak gel drilling fluid.

Table 1.

The impact of lubricants on the performance of base mud.

Table 1.

The impact of lubricants on the performance of base mud.

| |

Test Conditions |

AV/

mPa·s |

PV/

mPa·s |

YP/

Pa |

FLAPI / mL |

ρ/

(g·cm-3) |

| Base mud |

before hot rolling |

7.0 |

6.0 |

1.0 |

23.2 |

1.03 |

| 120℃ 16h |

7.5 |

5.5 |

2.0 |

28.4 |

1.03 |

| 0.5% LUB-1 |

before hot rolling |

10.0 |

7.0 |

3.0 |

18.9 |

0.98 |

| 120℃ 16h |

9.0 |

6.5 |

2.5 |

24.5 |

0.95 |

| 0.5% LUB-2 |

before hot rolling |

7.5 |

6.0 |

1.5 |

18.5 |

1.025 |

| 120℃ 16h |

8.5 |

6.5 |

2.0 |

23.9 |

1.02 |

Table 2.

The impact of lubricants on the performance of weak gel drilling fluids.

Table 2.

The impact of lubricants on the performance of weak gel drilling fluids.

| |

Test Conditions |

AV/

mPa·s |

PV/

mPa·s |

YP/

Pa |

FLAPI /

mL |

| Weak-gel drilling fluid |

before hot rolling |

43.0 |

35.0 |

8.0 |

2.8 |

| 120℃ 16h |

36.5 |

32.0 |

4.5 |

3.4 |

| Weak-gel drilling fluid +0.5% LUB-1 |

before hot rolling |

46.0 |

38.5 |

7.5 |

2.6 |

| 120℃ 16h |

38.0 |

34.0 |

4.0 |

3.0 |

| Weak-gel drilling fluid +0.5% LUB-2 |

before hot rolling |

42.0 |

35.0 |

7.0 |

2.4 |

| 120℃ 16h |

34.5 |

31.0 |

3.5 |

3.1 |

Table 3.

The influence of lubricants on the stability of weak gel drilling fluids.

Table 3.

The influence of lubricants on the stability of weak gel drilling fluids.

| Test Conditions |

Gel/ Pa |

AV/ mPa·s |

PV/ mPa·s |

YP/ Pa |

ρ/(g·cm-3) |

| 10 s |

10 min |

| before hot rolling |

3 |

6 |

42.0 |

35.0 |

7.0 |

1.20 |

| Day 1 |

1.5 |

4.5 |

34.5 |

31.0 |

3.5 |

1.19 |

| Day 2 |

1.5 |

4 |

34.0 |

31.0 |

3.0 |

1.19 |

| Day 3 |

1.5 |

4.5 |

34.0 |

30.5 |

3.5 |

1.19 |

| Day 4 |

1.5 |

4.5 |

33.0 |

30.5 |

2.5 |

1.19 |

| Day 5 |

2 |

4 |

33.5 |

30.5 |

3.0 |

1.19 |

| Day 6 |

1.5 |

4 |

33.0 |

30.5 |

2.5 |

1.19 |

| Day 7 |

1.5 |

4 |

33.0 |

30.0 |

3.0 |

1.19 |

Table 4.

Drilling fluid performance in Hua3-01 Well.

Table 4.

Drilling fluid performance in Hua3-01 Well.

Well depth/

m |

AV/

mPa·s |

PV/

mPa·s |

YP/

Pa |

FLHTHP/120℃

|

Drilling resistances/T |

Note |

| 2143 |

47 |

33 |

14 |

14.8 |

14 |

Without Lubricants |

| 2337 |

50 |

35 |

15 |

14.0 |

15 |

Adding 1% LUB-2 |

| 2428 |

47.5 |

33 |

14.5 |

12.8 |

10 |

|

| 2713 |

48.5 |

33 |

14.5 |

14.2 |

10 |

|

| 3160 |

48.5 |

33 |

14.5 |

14.0 |

11 |

|