Submitted:

18 February 2024

Posted:

19 February 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

1.1. Logistics Center Site Selection

1.2. Multi-data fusion

2. Modeling multi-objective node selection

2.1. Multi-objective node selection model

2.2. Restrictive condition

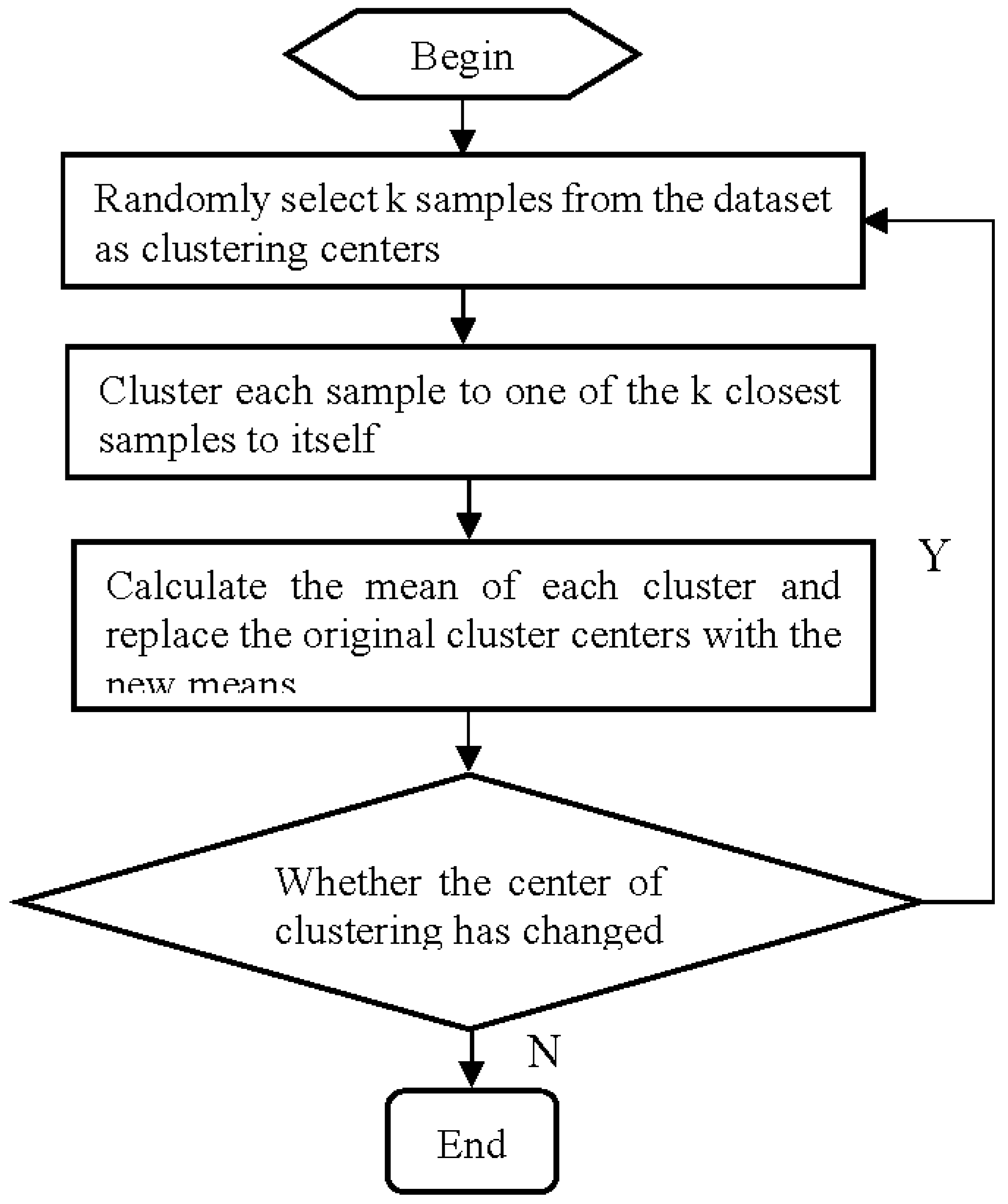

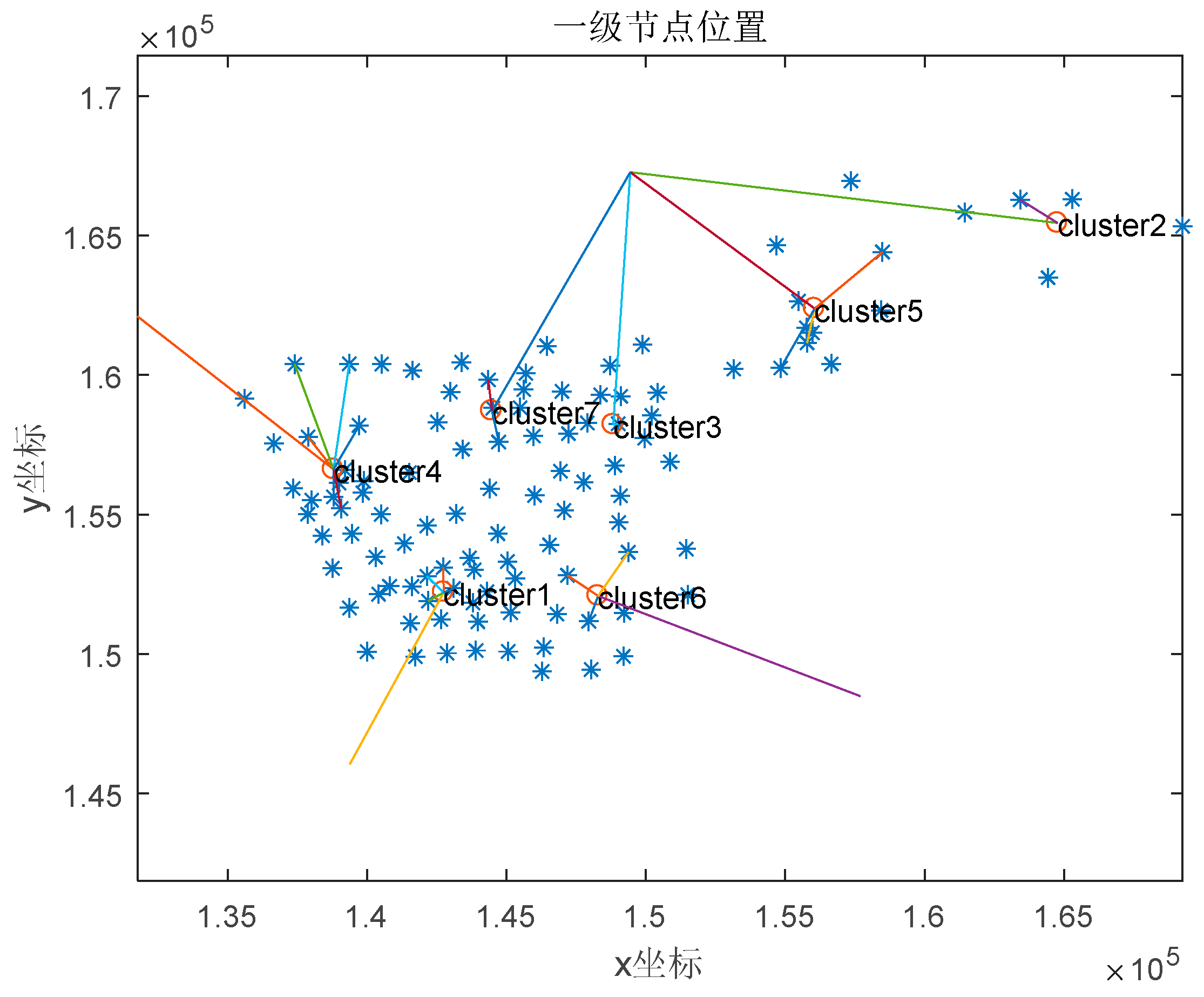

3. Preferred first-level node identification based on cluster analysis

3.1. Cluster analysis algorithms

3.2. Cluster analysis results test

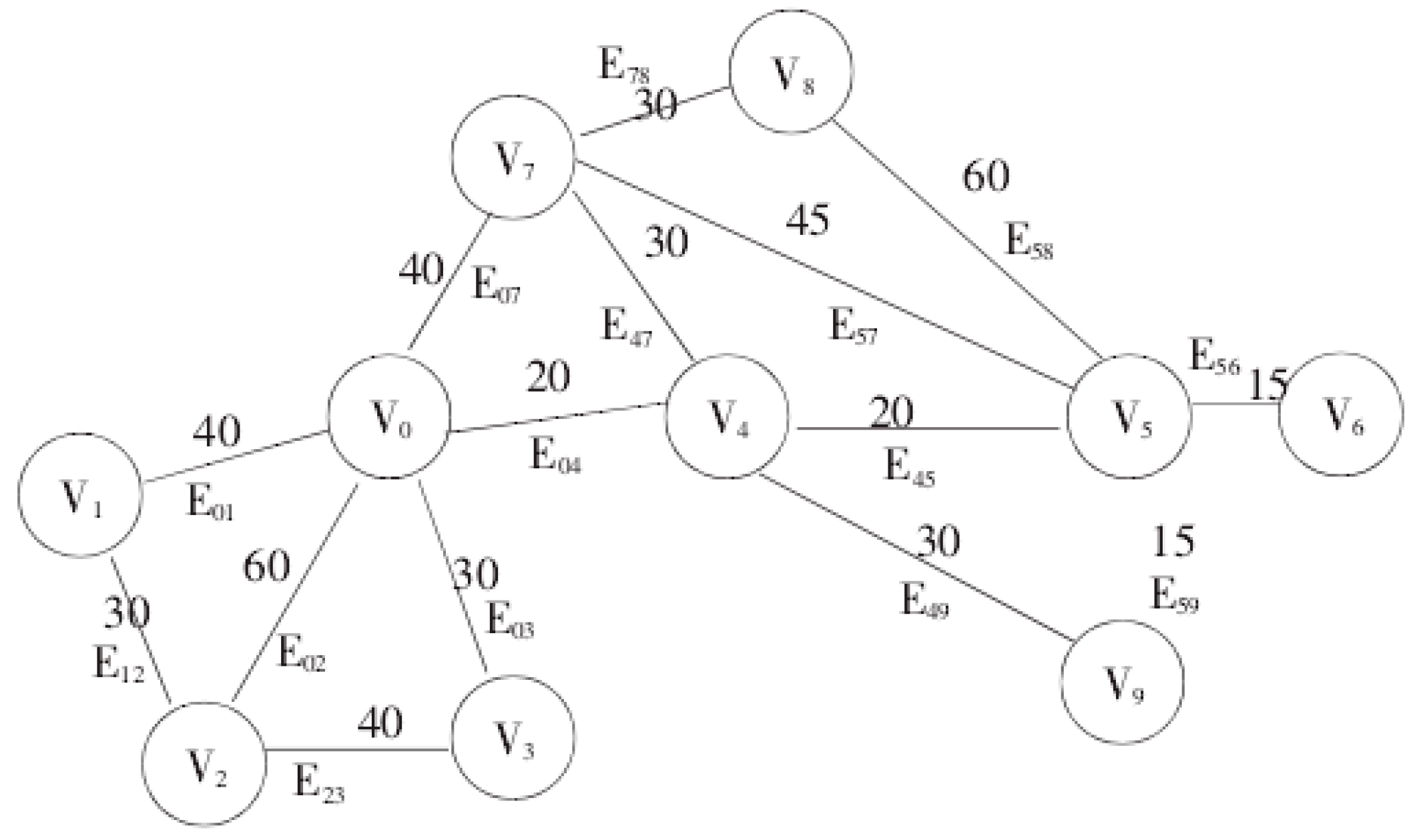

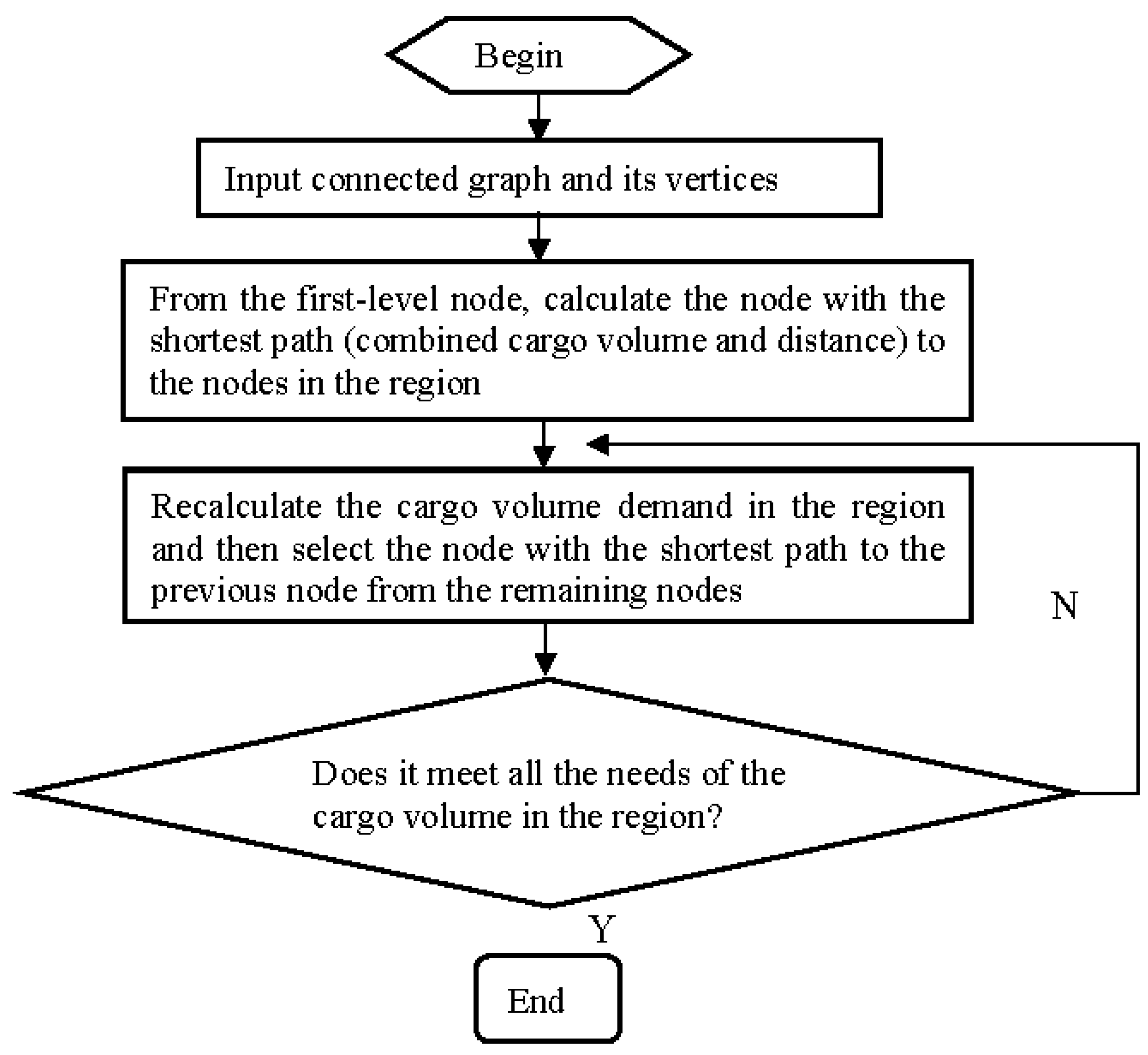

4. Selection of secondary node identification based on greedy algorithm

5. Example and result analysis

5.1. Selection of underground logistics nodes

| Level 1 node number | Freight volume/t | Transit rate | Position coordinate | |

|---|---|---|---|---|

| X | Y | |||

| I-1 | 44549.12 | 0.1949 | 142746.9 | 152213.7 |

| I-2 | 13254.41 | 0.189 | 164769.5 | 165451.4 |

| I-3 | 31508.57 | 0.1888 | 148832.7 | 158220.1 |

| I-4 | 31094.69 | 0.1888 | 138800.1 | 156621.5 |

| I-5 | 28393.75 | 0.1818 | 156051.9 | 162385.7 |

| I-6 | 29472.58 | 0.1802 | 148284.2 | 152085.8 |

| I-7 | 19674.26 | 0.1759 | 144477.2 | 158718.5 |

| Node number | Approaching node | Freight volume/t | Position coordinate | Node number | Approaching node | Freight volume/t | Position coordinate | |||

|---|---|---|---|---|---|---|---|---|---|---|

| X | Y | X | Y | |||||||

| II-1 | 811 | 500.95 | 143105.67 | 152346.13 | II-29 | 859 | 237.997 | 139712.38 | 158196.62 | |

| II-2 | 811 | 499.3 | 143005.54 | 152357.19 | II-30 | 869 | 231.447 | 137403.37 | 160390.60 | |

| II-3 | 819 | 478.205 | 142735.81 | 153102.05 | II-31 | 868 | 278.97 | 139355.42 | 160403.74 | |

| II-4 | 819 | 412.385 | 142734.58 | 153100.82 | II-32 | 869 | 227.177 | 145960.34 | 157813.24 | |

| II-5 | 819 | 392.17 | 142733.35 | 153099.59 | II-33 | 845 | 226.562 | 139062.69 | 155216.00 | |

| II-6 | 819 | 337.825 | 142730.59 | 153096.83 | II-34 | 859 | 211.112 | 139712.38 | 158196.62 | |

| II-7 | 819 | 336.925 | 142727.83 | 153094.07 | II-35 | 887 | 204.432 | 155779.18 | 161153.63 | |

| II-8 | 817 | 328.8 | 142147.44 | 152788.09 | II-36 | 887 | 204.202 | 155972.26 | 161519.38 | |

| II-9 | 817 | 311.925 | 143839.80 | 153020.83 | II-37 | 894 | 202.802 | 158485.91 | 164411.95 | |

| II-10 | 807 | 299.115 | 142199.94 | 151897.77 | II-38 | 894 | 196.537 | 154679.32 | 164648.90 | |

| II-11 | 817 | 286.42 | 142733.35 | 153099.59 | II-39 | 886 | 194.062 | 154828.66 | 160253.62 | |

| II-12 | 811 | 279.64 | 143106.67 | 152356.13 | II-40 | 894 | 191.002 | 158429.82 | 162320.97 | |

| II-13 | 811 | 272.69 | 143146.67 | 151356.13 | II-41 | 886 | 182.712 | 156649.10 | 160401.30 | |

| II-14 | 899 | 265.59 | 165295.96 | 166307.48 | II-42 | 894 | 173.282 | 155475.94 | 162649.70 | |

| II-15 | 899 | 262.93 | 157354.70 | 166956.66 | II-43 | 826 | 173.012 | 136654.80 | 157552.12 | |

| II-16 | 899 | 258.065 | 163428.02 | 166293.35 | II-44 | 826 | 171.227 | 139712.38 | 158196.62 | |

| II-17 | 872 | 256.29 | 145961.77 | 157814.67 | II-45 | 805 | 168.927 | 142526.33 | 158311.54 | |

| II-18 | 872 | 243.59 | 147221.06 | 157904.41 | II-46 | 826 | 167.215 | 144511.24 | 158818.60 | |

| II-19 | 872 | 263.135 | 149007.88 | 158255.23 | II-47 | 826 | 165.815 | 135605.67 | 159147.49 | |

| II-20 | 872 | 250.325 | 147900.64 | 158283.67 | II-48 | 805 | 159.55 | 142989.12 | 159395.66 | |

| II-21 | 872 | 237.63 | 150211.94 | 158547.64 | II-49 | 822 | 157.075 | 144347.43 | 159827.39 | |

| II-22 | 872 | 230.85 | 145488.59 | 158833.25 | II-50 | 826 | 154.015 | 143383.79 | 160462.05 | |

| II-23 | 872 | 223.9 | 148375.72 | 159294.26 | II-51 | 856 | 145.725 | 141628.28 | 160162.22 | |

| II-24 | 872 | 216.8 | 149100.78 | 159241.67 | II-52 | 864 | 279.56 | 140521.56 | 160395.32 | |

| II-25 | 872 | 245.78 | 140522.99 | 160396.75 | II-53 | 864 | 338.67 | 137403.37 | 160390.60 | |

| II-26 | 848 | 345.47 | 138792.09 | 155636.76 | II-54 | 864 | 217.89 | 139355.42 | 160403.74 | |

| II-27 | 848 | 217.65 | 139841.39 | 155777.27 | II-55 | 856 | 457.32 | 145960.34 | 157813.24 | |

| II-28 | 857 | 407.68 | 137888.25 | 157780.23 | ||||||

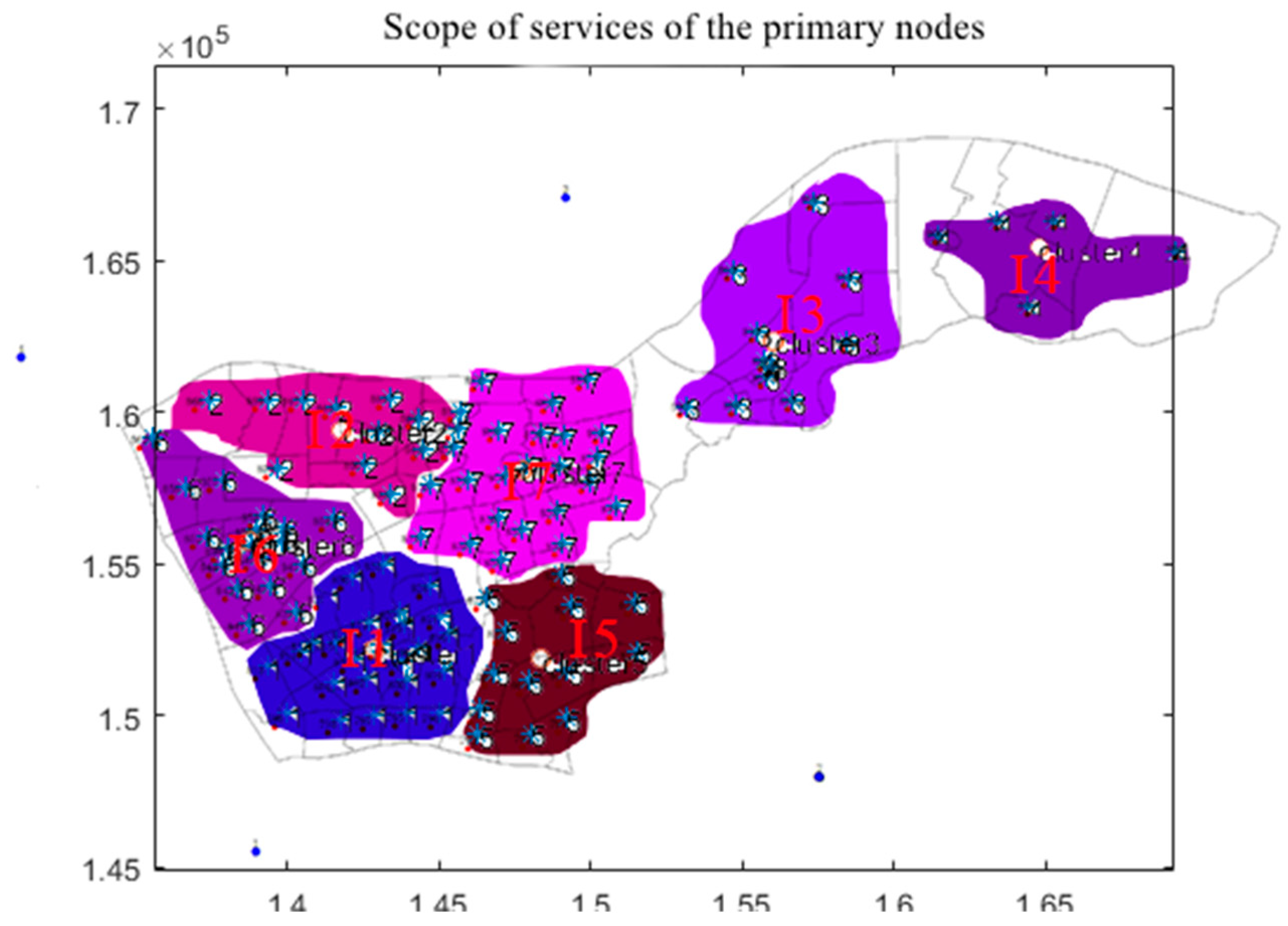

5.2. Scope of nodal services

| primary node | Contains secondary nodes | Includes service area centers |

|---|---|---|

| I-1 | II-1~II-13 | 793、795、796、797、798、800、801、802、804、806、807、809、810、811、813、814、815、816、817、818、819、820、821、823、827、828、830、833 |

| I-2 | II-14~II-16 | 892、896、897、899、900 |

| I-3 | II-17~II25 | 832、836、837、838、839、840、871、872、873、874、876、877、879、880、882、884 |

| I-4 | II-25~II-32 | 841、842、843、844、845、846、847、848、849、850、851 852、853、854、857、858、859、862、867、868、869 |

| I-5 | II-33~II-40 | 885、886、887、888、889、890、891、893、894、895、898 |

| I-6 | II-41~II-48 | 791、792、794、799、803、805、808、812、822、824、825、826、829、831 |

| I-7 | II-48~II-55 | 834、835、855、856、860、861、863、864、865、866、870、875、878、881、883 |

5.3. Analysis of results

6. Conclusions

References

- ÇAKMAK E, ÖNDEN İ, ACAR A Z, et al. Analyzing the location of city logistics centers in Istanbul by integrating Geographic Information Systems with Binary Particle Swarm Optimization algorithm[J/OL]. Case Studies on Transport Policy, 2021: 59-67. [CrossRef]

- ÖNDEN İ, ELDEMIR F. A multi-criteria spatial approach for determination of the logistics center locations in metropolitan areas[J/OL]. Research in Transportation Business & Management, 2022: 100734. [CrossRef]

- WU J, LIU X, LI Y, et al. A Two-Stage Model with an Improved Clustering Algorithm for a Distribution Center Location Problem under Uncertainty[J/OL]. Mathematics, 2022, 10(14): 2519. [CrossRef]

- KHAIRUNISSA M, LEE H. Hybrid Metaheuristic-Based Spatial Modeling and Analysis of Logistics Distribution Center[J/OL]. ISPRS International Journal of Geo-Information, 2021: 5. [CrossRef]

- HUANG Y, WANG X, CHEN H. Location Selection for Regional Logistics Center Based on Particle Swarm Optimization[J/OL]. Sustainability, 2022: 16409. [CrossRef]

- YAN L, GRIFOLL M, FENG H, et al. Optimization of Urban Distribution Centres: A Multi-Stage Dynamic Location Approach[J/OL]. Sustainability, 2022: 4135. [CrossRef]

- LI J, YANG Y H, LEI H, et al. Solving Logistics Distribution Center Location with Improved Cuckoo Search Algorithm[J/OL]. International Journal of Computational Intelligence Systems, 2020: 676. [CrossRef]

- JENG-SHYANG PAN J S P, JENG-SHYANG PAN Z F, ZONGLIN FU C C H, et al. Rafflesia Optimization Algorithm Applied in the Logistics Distribution Centers Location Problem[J/OL]. Internet Technology Journal, 2022: 1541-1555.

- DUPAS R, DESCHAMPS J C, TANIGUCHI E, et al. Optimizing the location selection of urban consolidation centers with sustainability considerations in the city of Bordeaux[J/OL]. Research in Transportation Business & Management, 2023: 100943. [CrossRef]

- RAO C, GOH M, ZHAO Y, et al. Location selection of city logistics centers under sustainability[J/OL]. Transportation Research Part D: Transport and Environment, 2015: 29-44. [CrossRef]

- KAINZ W, HOCHMAIR H, JIAO H, et al. Using Large-Scale Truck Trajectory Data to Explore the Location of Sustainable Urban Logistics Centres—The Case of Wuhan[J]. [CrossRef]

- ZHANG S, CHEN N, SHE N, et al. Location optimization of a competitive distribution center for urban cold chain logistics in terms of low-carbon emissions[J/OL]. Computers & Industrial Engineering, 2021: 107120. arXiv:10.1016/j.cie.2021.107120.

- LI X, ZHOU K. Multi-objective cold chain logistic distribution center location based on carbon emission.[J/OL]. Environmental Science and Pollution Research, 2021: 32396-32404. [CrossRef]

- TAOUKTSIS X, ZIKOPOULOS C. A decision-making tool for the determination of the distribution center location in a humanitarian logistics network[J].

- CHANG K H, CHIANG Y C, CHANG T Y. Simultaneous Location and Vehicle Fleet Sizing of Relief Goods Distribution Centers and Vehicle Routing for Post-Disaster Logistics[J/OL]. SSRN Electronic Journal, 2022. [CrossRef]

- Zengxi Feng, Gangting Li, Wenjing Wang, Lutong Zhang, Weipeng Xiang, Xin He, Maoqiang Zhang, Na Wei. Emergency logistics centers site selection by multi-criteria decision-making and GIS[J]. International Journal of Disaster Risk Reduction, Volume 96, 2023:103921. [CrossRef]

- ZHANG B, LI Z, SONG F, et al. Discrimination of black tea fermentation degree based on multi-data fusion of near-infrared spectroscopy and machine vision[J/OL]. Journal of Food Measurement and Characterization, 2023: 4149-4160.

- CHEN C, CHEN Q, LI G, et al. A novel multi-source data fusion method based on Bayesian inference for accurate estimation of chlorophyll-a concentration over eutrophic lakes[J/OL]. Environmental Modelling & Software, 2021: 105057.

- LI Y, CHEN Y, CHEN Y, et al. Fast Deployable Real-Time Bioelectric Dissolved Oxygen Sensor Based on a Multi-Source Data Fusion Approach[Z/OL]. (2023-06). [CrossRef]

- JIANG H, DENG J, CHEN Q. Monitoring of simultaneous saccharification and fermentation of ethanol by multi-source data deep fusion strategy based on near-infrared spectra and electronic nose signals[J]. [CrossRef]

- ZHANG Yi, HUANG Jiaming, LIN Hongwei, et al. Voltage sag interactive platform of provincial power grid based on multi-source data fusion [J]. Electric Power Automation Equipment, 2023,43(03):196-203.

- LIU Q, DONG M, SUN P, et al. All-parameter Calibration Method of On-orbit Multi-view Dynamic Photogrammetry System[J/OL]. Optics Express, 2023: 11471.

- SHI Y, YUAN H, XIONG C, et al. Improving performance: A collaborative strategy for the multi-data fusion of electronic nose and hyperspectral to track the quality difference of rice[J/OL]. Sensors and Actuators B: Chemical, 2021: 129546. [CrossRef]

- ZOU J, ZHENG H, WANG F. Real-Time Target Detection System for Intelligent Vehicles Based on Multi-Source Data Fusion[J/OL]. Sensors, 2023: 1823. [CrossRef]

- JIAO H, SONG W, CAO P, et al. Prediction method of coal mine gas occurrence law based on multi-source data fusion[J/OL]. Heliyon, 2023: e17117.

- SHI Y, REN C, YAN Z, et al. Improving soil moisture retrieval from GNSS-interferometric reflectometry: parameters optimization and data fusion via neural network[J/OL]. International Journal of Remote Sensing, 2021: 9085-9108. [CrossRef]

- LI X, LI Z, QIU H, et al. Soil carbon content prediction using multi-source data feature fusion of deep learning based on spectral and hyperspectral images[J/OL]. Chemosphere, 2023: 139161.

- FENG J, QIN D, LIU Y, et al. Real-time estimation of road slope based on multiple models and multiple data fusion[J/OL]. Measurement, 2021: 109609.

- Ye Xiao, Xingchen Li, Jiangjin Yin, Wei Liang, Yupeng Hu. Adaptive multi-source data fusion vessel trajectory prediction model for intelligent maritime traffic[J/OL]. Knowledge-Based Systems, 2023:110799.

- LI Y, JIANG W, SHI Z, et al. A Soft Sensor Model of Sintering Process Quality Index Based on Multi-Source Data Fusion[J]. [CrossRef]

- JIANG Y, LI C, SUN L, et al. A deep learning algorithm for multi-source data fusion to predict water quality of urban sewer networks[J/OL]. Journal of Cleaner Production, 2021: 128533. [CrossRef]

- WANG B, LI Z, XU Z, et al. Digital twin modeling for structural strength monitoring via transfer learning-based multi-source data fusion[J].

- WANG S, LI W. GeoAI in terrain analysis: Enabling multi-source deep learning and data fusion for natural feature detection[J/OL]. Computers, Environment and Urban Systems, 2021: 101715.

- YANG N, YANG L, DU X, et al. Blockchain based Trusted Execution Environment Architecture Analysis for Multi - source Data Fusion Scenario[Z/OL]//Research Square - Research Square,Research Square - Research Square. (2023-04).

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).