Submitted:

16 February 2024

Posted:

19 February 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Materials and Methods

2.1. Measurement Methods and Model Selection

2.1.1. Production Scale Index

2.1.2. Location Gini Coefficient

2.1.3. Location Quotient

2.1.4. Coefficient of Variation

2.1.5. Moran’s Index

2.1.6. Spatial econometric model

2.2. Data sources

3. Results

3.1. Temporal and Spatial Characteristics of Cotton Production Agglomeration in China

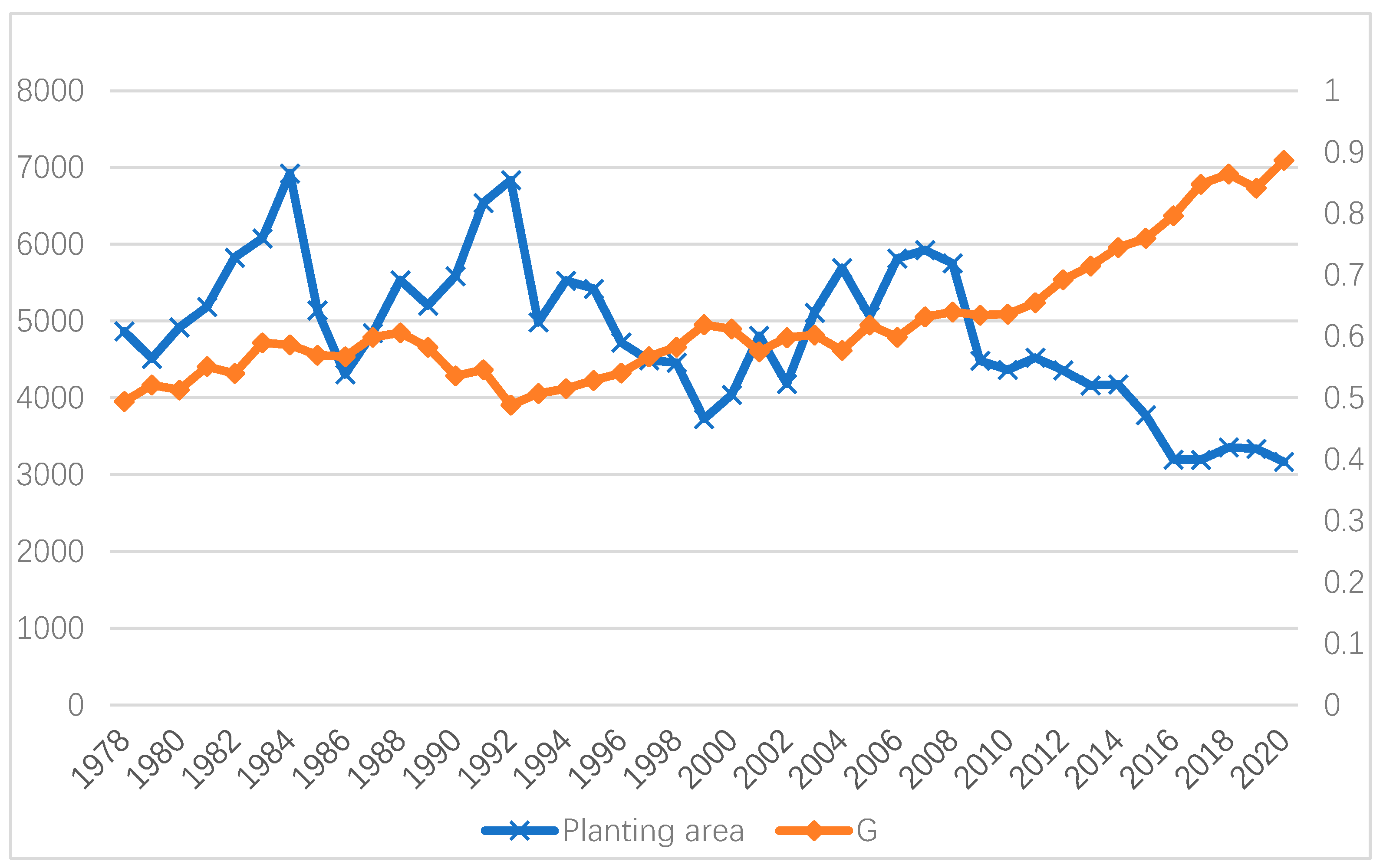

3.1.1. The level of cotton production agglomeration shows stage-based dynamic changes over time, generally exhibiting an upward trend.

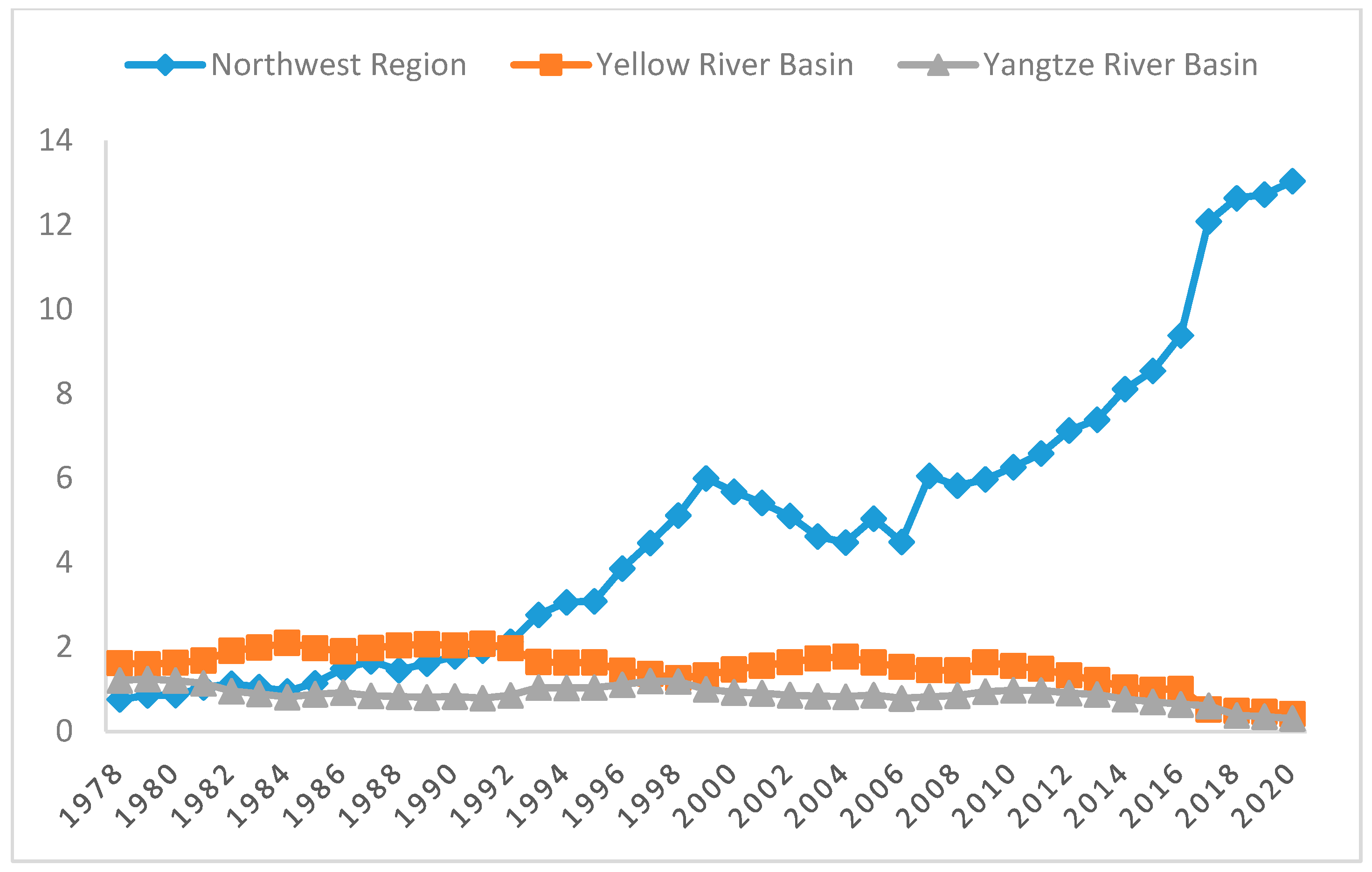

3.1.2. The regional gradient pattern of cotton production agglomeration is evident and dynamically changing

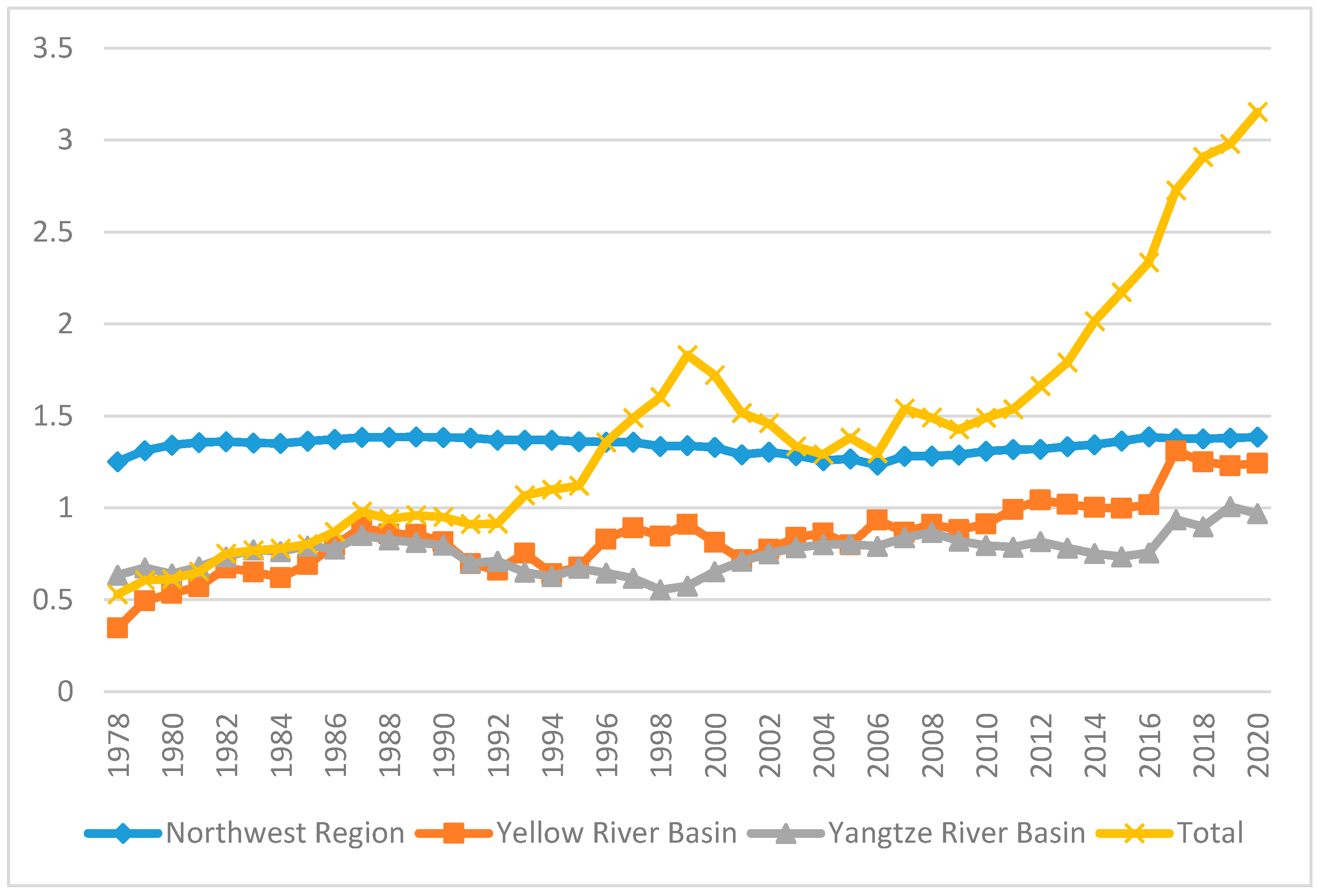

3.1.3. The disparity in cotton production agglomeration levels among the main cotton-producing provinces is evident, and this gap is gradually widening

| 1978 | 1990 | 2000 | 2010 | 2020 | |

| Northwest Region | |||||

| Xinjiang | 1.533 | 3.877 | 11.544 | 11.148 | 21.056 |

| Gansu | 0.094 | 0.043 | 0.359 | 0.436 | 0.223 |

| Yellow River Basin | |||||

| Tianjin | 0.833 | 0.825 | 1.093 | 4.097 | 0.983 |

| Hebei | 1.898 | 2.752 | 1.317 | 2.423 | 1.236 |

| Shanxi | 1.669 | 0.861 | 0.412 | 0.567 | 0.016 |

| Liaoning | 0.639 | 0.140 | 0.079 | 0.004 | 0.000 |

| Shandong | 1.802 | 3.438 | 1.973 | 2.573 | 0.694 |

| Henan | 1.722 | 1.838 | 2.294 | 1.191 | 0.058 |

| Shaanxi | 1.482 | 0.614 | 0.256 | 0.442 | 0.009 |

| Yangtze River Basin | |||||

| Jiangsu | 2.121 | 1.839 | 1.437 | 1.123 | 0.059 |

| Zhejiang | 0.562 | 0.416 | 0.289 | 0.304 | 0.126 |

| Anhui | 1.258 | 0.936 | 1.325 | 1.382 | 0.307 |

| Jiangxi | 0.618 | 0.324 | 0.472 | 0.531 | 0.328 |

| Hubei | 2.307 | 1.644 | 1.622 | 2.180 | 0.860 |

| Hunan | 0.668 | 0.396 | 0.706 | 0.774 | 0.374 |

| Sichuan | 0.705 | 0.264 | 0.282 | 0.062 | 0.012 |

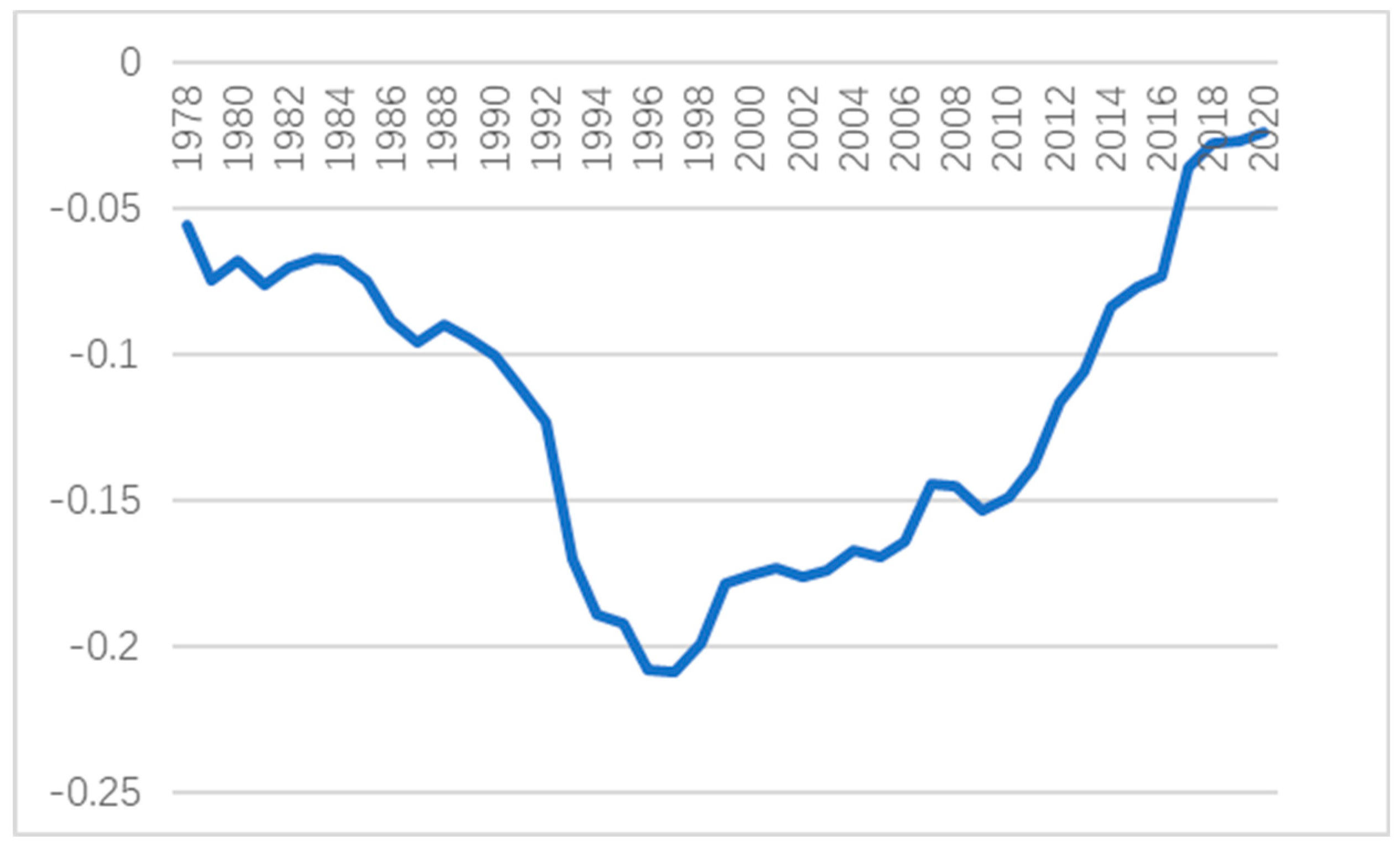

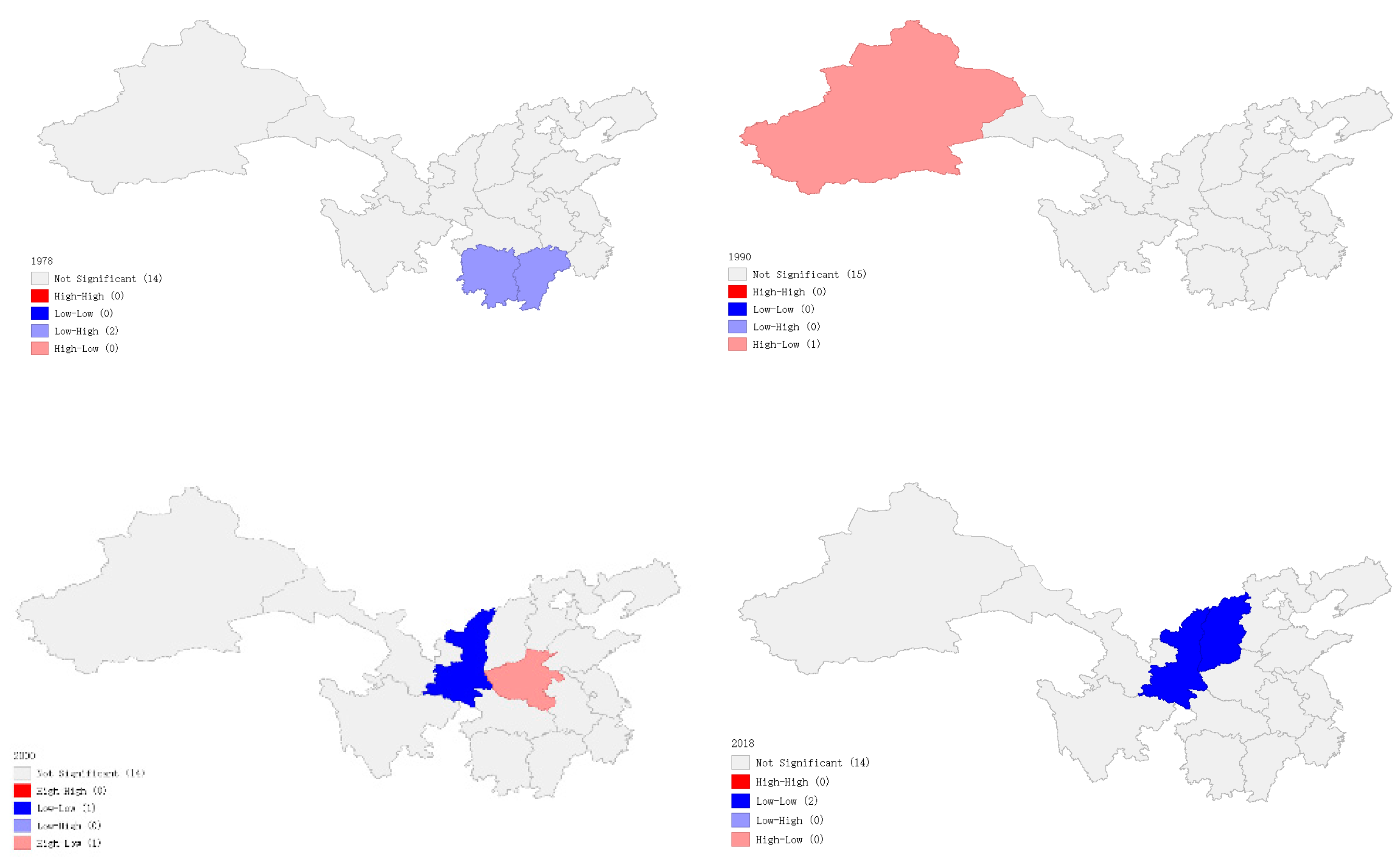

3.2. Spatial autocorrelation analysis

3.3. Empirical analysis of influencing factors

3.3.1. Theoretical analysis and variable selection

- Theoretical analysis

- 2.

- Variable Selection

| Variable Type | Variable Name | Variable Definition | Variable Symbol |

| Agricultural Resources | Agricultural Land Quantity | Area of grain cultivation in each region | grain |

| Agricultural labor | Number of people employed in agriculture, forestry, animal husbandry, and fishery in each region | employ | |

| Infrastructure | Transportation Cost | Transportation network density=total road transportation distance/Administrative area of the region | trans |

| Technological Level | Production per Unit Area | Cotton yield per unit area = Cotton production / Cotton cultivation area | tech |

| Policy | Temporary Storage Policy | Dummy variable, 01 variable | policy1 |

| Cotton Target Price Subsidy Policy | Dummy variable, 01 variable | policy2 | |

| Substitute Industrial Products | Synthetic Fiber Production | Production of chemical fibers in each region | fiber |

| Foreign Trade | Openness Degree | Trade dependence = (Total import and export trade volume * Average exchange rate of the year) / Gross regional product | open |

3.3.2. Analysis of Empirical Results

- Testing the Applicability of Spatial Econometric Models

| Test Form | Indicator | Statistic |

| Spatial error LM test | LM-error | 63.473*** |

| Spatial error RLM test | RLM-error | 35.319*** |

| Spatial lag LM test | LM-lag | 39.333*** |

| Spatial lag RLM test | RLM-lag | 11.179*** |

| Spatial lag LR test | LR-sar | 590.85*** |

| Spatial error LR test | LR-sem | 469.74*** |

| Spatial lag Wald test | Wald-sar | 956.69*** |

| Spatial error Wald test | Wald-sem | 632.35*** |

| Hausman Test | Hausman | 55.18*** |

- 2.

- Model Estimation Results

| Variable | Individual time fixed effects | Variable | Individual time fixed effects |

| Main | W*x | ||

| grain | -0.000 | W*grain | -0.001*** |

| (-1.31) | (-4.45) | ||

| employ | 0.000*** | W*employ | 0.000*** |

| (11.00) | (6.08) | ||

| trans | -0.072*** | W*trans | 0.008 |

| (-7.70) | (0.21) | ||

| tech | 0.000*** | W*tech | 0.000*** |

| (4.53) | (3.79) | ||

| policy1 | 0.030** | W*policy1 | 0.072 |

| (2.41) | (1.32) | ||

| policy2 | 0.031*** | W*policy2 | 0.256*** |

| (4.23) | (8.43) | ||

| fiber | -0.012*** | W*fiber | -0.112*** |

| (-5.37) | (-10.90) | ||

| open | 0.007** | W*open | 0.070*** |

| (2.32) | (3.69) | ||

| rho | -0.227** | ||

| (-2.21) | |||

| sigma2_e | 0.001*** | ||

| (18.86) | |||

| Obs | 688 | ||

| Adj.R-sq | 0.672 |

| Direct effect | Indirect effect | Total effect | |

| grain | -0.000 | -0.001*** | -0.001*** |

| (-0.86) | (-4.17) | (-4.01) | |

| employ | 0.000*** | 0.000*** | 0.000*** |

| (10.19) | (4.50) | (6.33) | |

| trans | -0.073*** | 0.023 | -0.050 |

| (-7.53) | (0.71) | (-1.59) | |

| tech | 0.000*** | 0.000*** | 0.000*** |

| (4.61) | (3.63) | (4.70) | |

| policy1 | 0.028** | 0.057 | 0.085* |

| (2.41) | (1.26) | (1.71) | |

| policy2 | 0.026*** | 0.214*** | 0.240*** |

| (3.38) | (7.29) | (7.64) | |

| fiber | -0.010*** | -0.094*** | -0.104*** |

| (-4.41) | (-7.56) | (-7.46) | |

| open | 0.006** | 0.060*** | 0.065*** |

| (1.97) | (3.15) | (3.31) |

- 3.

- Analysis of Estimation Results

4. Discussion

5. Conclusions

- From 1978 to 2020, China’s cotton production agglomeration level exhibited dynamic changes over time, showing an overall upward trend. Specifically, there were fluctuations and increases from 1978 to 1988, fluctuations and decreases from 1988 to 1992, a steady upward trend from 1992 to 1999, significant fluctuations from 1999 to 2009, and rapid increases from 2009 to 2020.

- China’s cotton production agglomeration demonstrates a dynamic regional gradient pattern change. From 1978 to 1981, the pattern was “Yellow River Basin Cotton Area > Yangtze River Basin Cotton Area > Northwest Cotton Area”, from 1981 to 1992, it changed to “Yellow River Basin Cotton Area > Northwest Cotton Area > Yangtze River Basin Cotton Area”, and from 1992 to 2020, it became “Northwest Cotton Area > Yellow River Basin Cotton Area > Yangtze River Basin Cotton Area”.

- There is a significant gap in cotton production agglomeration levels among the main producing provinces, and this gap has been widening year by year. The differences in cotton production levels in the Yellow River Basin Cotton Area have expanded, while the differences in the Yangtze River Basin Cotton Area have increased to a lesser extent. The difference in the Northwest region has shown a higher overall magnitude of change compared to the other two regions.

- There is spatial correlation in cotton production among the main producing provinces, and the overall trend shows a “U” shape. The agglomeration pattern of national cotton production has shifted from “low-high agglomeration “ and “high-low agglomeration “ to “low-low agglomeration “, indicating a low-level convergence.

- Spatial econometric empirical results indicate that, apart from agricultural resources, transportation costs, technological levels, policies, substitute industrial products, and foreign trade are all important factors affecting changes in cotton production agglomeration. Among them, technological levels, target price subsidy policies, substitute industrial products, and foreign trade not only impact cotton production agglomeration in the local area but also have spillover effects on adjacent areas through geographic transmission.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Qin, Z.C.; Ning, X. The development trend and policy optimization of China’s cotton industry since China’s accession into WTO. Reform 2020, 9, 104–117. [Google Scholar]

- Xiao, W.D. Geographic agglomeration of plantations in China: spatial and temporal characteristics, changing trends and influencing factors. Chinese Rural Economy 2012, 5, 19–31. [Google Scholar]

- Jia, X.M.; Ling, P. Degree of agriculture concentration and agricultural economic growth: Empirical test spatial layout changes of 12 types of crops in China. Journal of China Agricultural University 2014, 1, 209–217. [Google Scholar]

- Zhu, Q.R. Analysis of Production Layout of Main Cotton Producing Areas in China. Chinese Rural Economy 2009, 4, 31–38. [Google Scholar]

- Zhu, H.Y. The underlying cause for the concentration of China’s cotton production in Xinjiang. Geographical Research 2013, 4, 744–754. [Google Scholar]

- Ma, C.Y.; Mai, S.; Yao, J. Spatio-temporal changes of cotton production in China from 1950 to 2015. Acta Geographica Sinica 2020, 8, 1699–1710. [Google Scholar]

- Pan, X.B. Studies on the spatial distribution and variation of cotton production in counties of China based on GIS. Scientia Agricultura Sinica 2003, 4, 382–386. [Google Scholar]

- Yu, Y.W.; Yu, G.X.; Wei, J.Z. Analysis of spatial distribution and influencing factors of cotton production layout in Xinjiang under the backdrop of supply side reform. Journal of Arid Land Resources and Environment 2019, 05, 74–80. [Google Scholar]

- Wang, R.Y.; Song, Y.L. Research on the evolution and influencing factors of China’s cotton production layout from the perspective of industrial chain. Resource Development & Market 2022, 3, 337–343+384. [Google Scholar]

- Zhao, Y.M.; Qin, Y.J. Study on the optimization path of cotton industry chain in Xinjiang—Analysis on the background of cotton target price reform. Price: Theory & Practice 2019, 12, 47–50. [Google Scholar]

- Wei, J.Z.; Liu, W.Z. Theoretical Analysis of the Impact of Cotton Subsidy Policy on the Distribution of Benefits in the Cotton Industry Chain. Journal of Agrotechnical Economics 2014, 5, 81–88. [Google Scholar]

- Jie, M.S.; Xue, Y.; Xue, L. Study on cotton production’s spatial distribution, changes and influencing factors in China. Research of Agricultural Modernization 2015, 3, 387–393. [Google Scholar]

- Tan, X.Y.; Zhang, X.H.; You, L.Z. A study on the impact of natural factors and policy interventions on the dynamic of cotton production. Journal of Agrotechnical Economics 2020, 4, 79–93. [Google Scholar]

- Zhong, F.N.; Hu, X.M. Study on Regional Patterns of Cotton Production and Influencing Factors in China. Journal of Agrotechnical Economics 2008, 1, 4–9. [Google Scholar]

- Cheng, W.M.; Wang, L.; Chen, B. Study on improving quality and increasing efficiency of characteristic industries in ethnic minority areas under the strategy of vitalizing rural areas: Take Xinjiang cotton industry as an example. Guizhou Ethnic Studies 2019, 6, 166–171. [Google Scholar]

- Wang, L.; Wang, J.F. Planting decisions of cotton farmers in a high risk and high cost background. Journal of South China Agricultural University(Social Science Edition) 2013, 4, 80–86. [Google Scholar]

- Zhai, X.L.; Li, R. Price subsidy and its policy matching: taking cotton industry as an example. Reform 2015, 10, 89–100. [Google Scholar]

- Xiao, S.X.; Liu, X.H. Analysis of Factors Influencing Cotton Planting Area - A Survey Based on Xinjiang, Henan, Jiangsu and Shandong Provinces. Journal of Agrotechnical Economics 2008, 4, 79–84. [Google Scholar]

- Zhong, F.N.; Hu, X.M. An economic analysis of cotton farmers’ cotton sowing area decisions in China. Chinese Rural Economy 2008, 6, 39–45. [Google Scholar]

- Tan, Y.W. A case study on China’s cotton production fluctuation. Journal of South China Agricultural University(Social Science Edition) 2005, 1, 1–5. [Google Scholar]

- Du, M. Analysis of factors affecting the returns of cotton planting by farmers in China. Issues in Agricultural Economy 2005, 12, 54–60. [Google Scholar]

- Yao, C.S.; Li, Z.T.; Wang, W.; Liao, Y.Q.; Zhang, X.Z. Geographical agglomeration characteristic and spatial evolution mechanism of aquaculture industry in China. Economic Geography 2016, 36, 118–127. [Google Scholar]

- Zhao, J.W.; Chen, Y.F.; Yu, L.; Yin, C.B. Spatial-temporal characteristics and affecting factors of swine breeding industry in China. Economic Geography 2019, 39, 180–189. [Google Scholar]

- Yang, C. Study on the Changes of Production Layout and Location Optimization of Major Grain Crops in China. Ph.D. Thesis, Zhejiang University, Hangzhou, China, 2009. [Google Scholar]

- Duan, Y.B. Exploring the Logic and Path of National Governance under the Coupling of System and Policy. Contemporary World and Socialism 2023, 3, 151–156. [Google Scholar]

- Du, Z.X.; Xiao, W.D. China’s Agricultural Trade and the Transformation of Agricultural Development Mode under the Perspective of Globalization. Intertrade 2011, 8, 27–35. [Google Scholar]

- LeSage, J.P.; Pace, R.K. Introduction to Spatial Econometrics, 1sted. New York: Chapman and Hall/CRC,2009.

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).