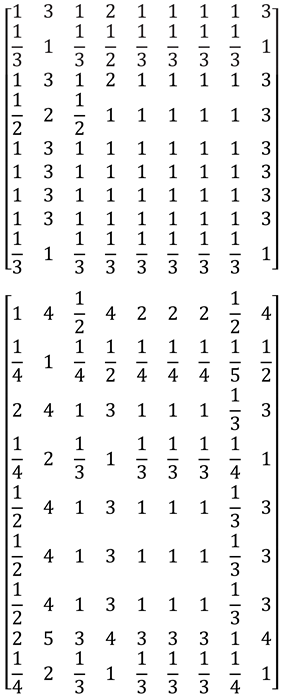

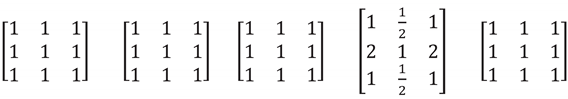

2.1.2. Theoretical basis and principles of indicator system architecture

The establishment of an indicator system is a prerequisite for evaluating the health status of drainage networks. There are many factors that affect the health of drainage networks, and they are interrelated. There are many factors that need to be considered. To ensure that the selected indicators can comprehensively reflect the health status of drainage networks, the following principles need to be noted:

1. Systematic principle

The health status of the drainage network involves a wide range of aspects. When evaluating, it is important to not only pay attention to the characteristics of the pipeline itself, but also to the current operation status, social environment, and maintenance of the network. Therefore, when selecting indicators, it is necessary to consider all aspects in a balanced manner, and each indicator should be independent of each other and have inherent connections, which can comprehensively reflect the health status of the drainage network.

2. Objectivity principle

The evaluation indicators selected for evaluating the health status of drainage networks should be able to be qualitatively or quantitatively described, that is, the evaluation results of the indicators can be objectively measured by objective data, avoiding the influence of subjective factors on the evaluation results as much as possible, making the evaluation results more accurate and authentic.

3. Principle of scientificity

The main purpose of evaluating the health status of drainage networks is to comprehensively evaluate the health status of drainage networks, providing a basis for later pipeline inspection, rectification, and maintenance. Therefore, comprehensive analysis should be conducted on the basis of fully considering the operational requirements of the pipeline network, scientifically and reasonably selecting indicators, constructing an indicator system, and ensuring that the selected indicators can truly reflect the actual health status of the drainage network.

4. Principle of representativeness

The evaluation indicators for the health status of drainage networks should be representative, which means reducing the number of indicators as much as possible while fully reflecting the health status, ensuring that there is no overlap between indicators, and the content should be as independent as possible to avoid complexity.

5. Feasibility principle

When selecting indicators, special attention should be paid to the availability and difficulty of obtaining indicator data. The selected indicators should not only be easy for researchers to analyze and calculate, but also for construction units, maintenance units, administrative authorities, and even the public to understand and master. The original data of indicators should be as easily accessible from existing data as possible to ensure the practicality of evaluation.

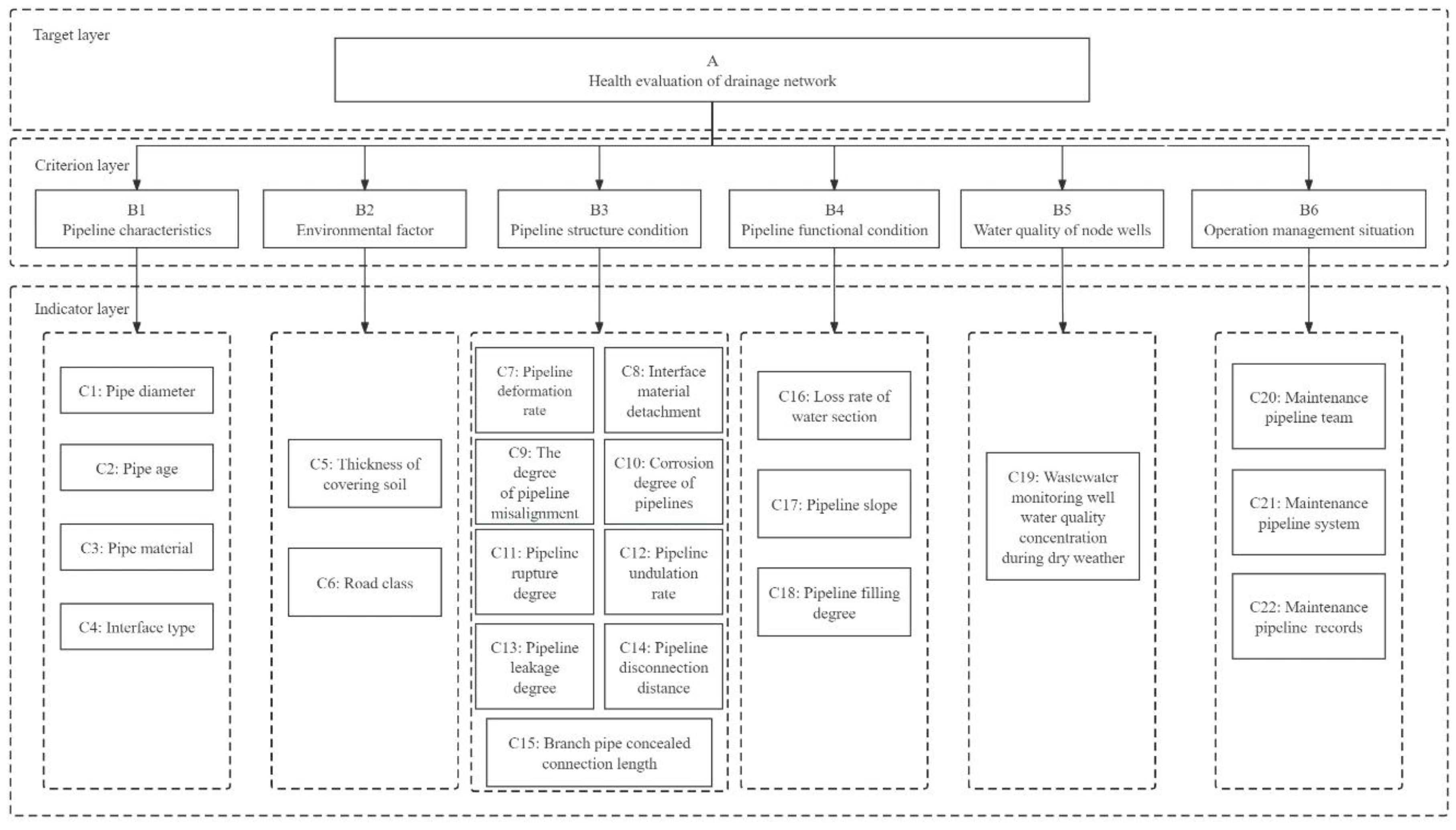

2.1.3. Indicator screening and system construction

Selecting scientifically reasonable evaluation indicators is a necessary prerequisite to ensure the accuracy and reliability of evaluation results. Based on the requirements of evaluating the health status of drainage networks and the feasibility of obtaining indicator data, this article takes the evaluation of the health status of drainage networks as the target layer. Based on the investigation, rectification, and later operation and maintenance of the pipeline network, select the criteria layer and indicator layer indicators in sequence. From the perspective of the hierarchical structure characteristics of health evaluation indicators for drainage networks, the indicator system includes bottom level diagnostic indicators and intermediate transition indicators. The health status of the drainage network can be comprehensively reflected through the evaluation results of various levels of indicators.

This article selects six criteria layer indicators: pipeline characteristics, environmental factors, pipeline structure condition, pipeline function condition, water quality of node wells, and operation management situation, and selects appropriate indicators as the indicator layer indicators.

1. Pipeline characteristics

The diameter, age, pipe material, and interface form of the drainage network are the basis for the health status of the drainage network. The size of the pipe diameter in the drainage network plays a decisive role in the water flow velocity and head loss within the network. The smaller the pipe diameter, the thinner the pipe wall, and the poorer the impact resistance. The pipe age refers to the service life of the drainage network, and the longer the pipe age, the greater the possibility of defects. The construction methods of different pipes are different, and their material characteristics determine their advantages and disadvantages. For example, plastic pipes such as HDPE have lower roughness coefficient, faster water flow rate, and stronger corrosion resistance compared to reinforced concrete pipes. However, they also have the disadvantage of poor external pressure resistance. The interface is the midpoint at which the pipeline bears stress. Once it is misaligned or disconnected, it can lead to external water intrusion, which is also an important factor affecting the health of the pipeline network.

2. Environmental factors

The drainage pipeline is buried underground and has openness, which is influenced by various natural conditions and human factors. The thickness of soil cover and road grade are two important environmental factors. The distance from the top of the outer wall of the pipeline to the ground is the thickness of the pipeline’s soil cover. According to the "Outdoor Drainage Design Standard (GB50014-2021)", the burial depth of the pipeline is determined by factors such as pipe strength, external loads, soil freezing depth, and soil properties. The minimum soil cover depth under sidewalks should be 0.6m, and under roadways it should be 0.7m. For existing pipelines, the deeper they are buried, the less they are affected by external factors, the higher their safety, but the higher their construction costs. The health condition of buried drainage pipes is closely related to external ground loads. Generally speaking, the higher the road level, the greater the traffic flow, the greater the ground load, and the higher the likelihood of pipeline damage. However, the ground load on drainage pipelines is generally difficult to calculate, so road grades are used to classify the external load on pipelines [

5].

3. Pipeline structure condition

The health of pipeline structure is based on the relative concept of pipeline structural defects, indicating the integrity of the internal structure of the pipeline. It has a decisive impact on the infiltration of external water and is also a decisive factor in whether the drainage network needs to be repaired. The indicators for measuring the structural condition of pipelines include pipeline deformation rate, interface material detachment, degree of pipeline misalignment, degree of pipeline corrosion, degree of pipeline rupture, pipeline undulation rate, degree of pipeline leakage, pipeline disconnection distance, and concealed connection length of branch pipes, totaling 9 items.

4. Pipeline functional condition

Pipeline functional health is based on the relative concept of pipeline functional defects, expressing the water transmission capacity of pipelines. It is mainly divided into three indicators: pipeline water loss rate, pipeline slope, and pipeline fullness. The loss rate of pipeline water section refers to the loss ratio of the current water section compared to the intact state caused by sedimentation, residual walls, dam roots, hard scaling, obstacles, tree roots and foreign objects that affect the flow in the pipeline. The slope of a pipeline refers to the ratio of the height difference between the starting and ending ends to the length of the pipeline. The drainage pipe is mainly gravity flow, and the slope of the pipeline is an important factor affecting the flow velocity and sedimentation conditions inside the pipe. The pipeline filling degree refers to the ratio of the water depth inside the pipeline to the pipe diameter, which has a certain impact on the pipeline load.

5. Water quality of node wells

The water quality of the node well is mainly determined by the water concentration of the sewage monitoring well during dry days, in order to determine the collection effect of the sewage pipeline network and the situation of external water intrusion.

6. Operation management situation

The operation and management of the drainage network includes three indicators: management team, management system, and management records.

The evaluation index system for the health status of the drainage network is shown in

Figure 1.

2.1.4. Index scoring method construction

This article combines the evaluation methods of domestic and foreign scholars on the standardized performance indicators of drainage networks [80–82], existing standards in China, such as the Technical Regulations for Testing and Evaluation of Urban Drainage Pipelines (CJJ181-2012), and quantitative scoring suggestions from relevant experts in the field for qualitative indicators in health condition evaluation, to develop a scoring method. The maximum score for the health evaluation index layer of the drainage network is 100 points. The scoring method for the 22 evaluation indicators is as follows:

1. Pipe diameter: According to the drainage design specifications, the minimum pipe diameter for outdoor sewage pipe networks is DN300. As the amount of sewage increases and the pipe diameter increases, the probability of pipe damage gradually decreases. This article selects DN300 and DN800 as the dividing lines for pipe diameters. A pipe diameter not less than DN800 is defined as 90, DN600 ≤ pipe diameter<DN800 is defined as 80, DN400 ≤ pipe diameter<DN600 is defined as 70, DN300 ≤ pipe diameter<DN400 is defined as 60, and a pipe diameter less than DN300 is defined as 0.

2. Pipe age: The water delivery performance of the pipeline decreases with the increase of pipe age. At present, about 10% of the total length of urban sewage pipelines in China are over 30 years old, and the damage rate of such pipelines is extremely high [83]. This article selects 5 years and 30 years as the dividing line for pipe age, with 90 points for pipes less than 5 years, 80 points for pipes less than 5 years ≤ pipe age<10 years, 70 points for pipes less than 10 years ≤ pipe age<20 years, 60 points for pipes less than 20 years ≤ pipe age<30 years, and 0 points for pipes greater than or equal to 30 years.

3. Pipes: Taking into account the corrosion resistance, compressive and seismic resistance of pipes, steel plastic pipes are defined as 90 points, ductile iron pipes are defined as 80 points, plastic pipes such as HDPE are defined as 70 points, and concrete pipes are defined as 60 points.

4. Interface form: Based on the adaptive performance of different interface forms in geological settlement, flexible interfaces such as plug-in rubber rings are defined as 90 points, prefabricated sleeve asbestos cement (or asphalt mortar) interfaces are defined as 80 points, cement mortar plastering interfaces are defined as 70 points, and cast-in-place concrete sleeve interfaces are defined as 60 points.

5. Soil cover thickness: If the minimum burial depth thickness recommended by the specifications is met, 100 points will be given, otherwise 0 points will be given.

6. Road level: Based on traffic type, capacity, and volume, the impact of roads on pipelines is divided into four levels. Pipelines laid under green belts and sidewalks are defined as 90 points, pipelines laid under branch roads are defined as 80 points, pipelines laid under secondary roads and slow lanes are defined as 70 points, pipelines laid on main roads and under fast lanes are defined as 60 points.

7. Pipeline deformation rate: Full score for no deformation, defined as 80 points for deformation not exceeding 5% of pipeline diameter, 60 points for deformation ranging from 5% to 15% of pipeline diameter, 40 points for deformation ranging from 15% to 25% of pipeline diameter, and 0 points for deformation greater than 25% of pipeline diameter.

8. Interface material detachment: If the interface material does not detach, it will receive a full score. If the interface material is visible above the horizontal centerline in the pipeline, it will receive a score of 60 points. If the interface material is visible below the horizontal centerline in the pipeline, it will receive a score of 0 points.

9. Degree of pipeline misalignment: If no misalignment occurs, the score is full. If the deviation between the two adjacent pipe orifices is not more than 0.5 times the thickness of the pipe wall, it is defined as 90 points. If the deviation is 0.5-1 times the thickness of the pipe wall, it is defined as 60 points. If the deviation is 1-2 times the thickness of the pipe wall, it is defined as 40 points. If the deviation is more than 2 times the thickness of the pipe wall, it is defined as 0 points.

10. Degree of pipeline corrosion: Full score for no corrosion, defined as slight surface peeling, and defined as concave and convex surfaces on the pipe wall as 90 points. Surface peeling exposing coarse aggregate or steel bars is defined as 60 points, and complete exposure of coarse aggregate or steel bars is defined as 0 points.

11. Degree of pipeline rupture: No rupture is given a full score. According to the level of pipeline structural rupture, slight fine cracks or peeling on the pipeline wall are defined as 90 points. Cracks on the pipeline wall that are not affected by the shape of the pipeline and do not fall off are defined as 60 points. The circumferential coverage range of fragments left at the location where the pipeline wall ruptures or falls off is defined as 40 points, with an arc length of 60 ° or less. Collapse with a circumferential coverage range greater than 60 ° at the location of pipeline rupture is defined as 0 points.

12. Pipeline undulation rate: If there is no undulation, it is a full score. The undulation rate is the ratio of the pipeline undulation height to the pipe diameter. A undulation rate of less than or equal to 20% is defined as 90 points, 20% < undulation rate ≤ 35% is 60 points, 35% < undulation rate ≤ 50% is 40 points, and a undulation rate greater than 50% is 0 points.

13. Pipeline leakage degree: Full score for no leakage, 90 points for drip leakage, 60 points for line leakage, 40 points for water surface area less than or equal to 1/3 of the pipeline cross-section when leakage occurs, and 0 points for water surface area greater than 1/3 of the pipeline cross-section when leakage occurs.

14. Pipeline disconnection distance: If there is no disconnection, the score is full. When there is a small amount of soil squeezed into the end of the pipeline, it is defined as 80 points. If the disconnection distance is not greater than 2cm, it is 60 points. If the disconnection distance is 2-5cm, it is 40 points. If the disconnection distance is greater than 5cm, it is 0 points.

15. Branch pipe concealed connection length: If there is no branch pipe concealed connection, it is full score. When the distance between the concealed connection branch and the main pipe is not more than 10% of the diameter of the main pipe, it is defined as 90 points. When the distance between the concealed connection branch and the main pipe is 10% to 20%, it is defined as 60 points. When the distance between the concealed connection branch and the main pipe is greater than 20%, it is defined as 40 points.

16. Loss rate of water flow section: Full score for intact water flow section. When the water flow loss rate of the pipeline is less than 15%, it is defined as 80 points. When the loss rate is between 15% and 25%, it is 60 points. When the loss rate is between 25% and 50%, it is 40 points. When the loss rate is greater than 50%, it is 0 points.

17. Pipeline Slope: When the pipeline slope meets the minimum slope requirements in the outdoor drainage design specifications, it is considered full score. Otherwise, it is considered 0 point.

18. Pipeline filling degree: When the filling degree is not greater than the maximum design filling degree in the outdoor drainage design specification, it is full score; otherwise, it is 0 point.

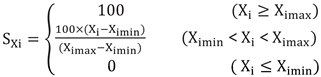

19. Sewage monitoring well dry day water quality concentration: Set up a high line Ximax and a low line Ximin for evaluating the dry day water quality concentration of the sewage monitoring well. The scoring method is as follows: Xi represents the measured values of various water quality indicators in the sewage monitoring well during dry days, SXi represents the scores of each water quality indicator, and SW represents the scores of the sewage monitoring well during dry days.

(n represents the number of water quality indicators, i represents different water quality indicators) (2.4)

20. Operation and Maintenance Status: The indicators of operation and maintenance status include the management team, management system, and management records. If the regional requirements are met, a full score will be given for each item. If there is no corresponding content, it will be 0 points.

This article aims to evaluate the health status of the entire regional sewage pipeline network, not limited to individual sewage pipe sections. Therefore, sewage pipelines are divided based on roads for evaluation, and the overall pipeline score is obtained by weighting the average length of individual pipe sections.

The score of the evaluation criteria for the health status of the drainage network is the sum of the corresponding indicator scores and their weights, and the total score is the sum of the product of the indicator scores and their weights for each criterion layer.