1. Introduction

The concept of animal welfare is emerging as an increasingly important aspect of sustainable food systems (United Nations Environment Programme, 2019; Coghlan et al., 2021). In many countries, increasing consumer concern for animal welfare is driving retailer commitments and government legislation that aim to improve the lives of animals farmed for food (Alonso et al., 2020; Albalat et al., 2022; Wahltinez et al., 2022; Wickens, 2022). These policies are increasingly targeted at aquatic animals in particular (Ashley, 2007; Stien et al., 2020; Crump et al., 2022). By scale, fish constitute one of the most numerous groups of farmed animals, exceeding even the number of farmed chickens and pigs and behind only farmed invertebrates (Romero Waldhorn and Autric, 2022; Klaura et al., 2023; Mood et al., 2023). As such, initiatives that aim to improve the lives of farmed fish can cause large overall benefits in the lives of animals.

Fish welfare interventions typically target one of three periods during the lives of farmed fish. Interventions can target the welfare of fish during breeding (the breeding stock or the juveniles) (Grimsrud et al., 2013; Tørud et al., 2019), the welfare of fish on-farm during the grow-out period (Pettersen et al., 2014; Stien et al., 2020), or the welfare of fish at slaughter (Lines and Spence, 2012; European Commission, 2017; Clemente et al., 2023).

One tractable way to improve the welfare of fish at slaughter is to stun fish before slaughter. Stunning involves rendering fish insensible, thus reducing the amount of suffering experienced by the fish when killed (Lines and Spence, 2012). Fish farming industries in many countries have made progress in implementing stunning before slaughter. However, one of the largest finfish farming industries that has not yet made significant progress in implementing stunning before slaughter is the European sea bass and sea bream farming industry.

In Europe, sea bass and sea bream are farmed along the Mediterranean coast. The countries with the highest production of sea bass and sea bream are Türkiye, Greece, Spain, and Italy (

Table 1). Türkiye and Greece each have several hundred farms, while Spain and Italy have only 24 farms each. The farms in Türkiye and Spain tend to have larger production volumes per farm, while the industries in Greece and Italy tend to be dispersed with farms having smaller production volumes.

Before turning to the details of humane slaughter, it helps to give a brief overview of the industry structure in these four countries. In Türkiye, 257,000 t of sea bass and sea bream are produced by 237 mostly large-scale sea cage farms and 173 mostly small-scale earthen pond farms (Çoban et al., 2020). In Türkiye, there are fish farms along the western and southern coastlines with the Mediterranean and the northern coastline with the Black Sea. In Greece, 100,000 t of sea bass and sea bream are produced by 347 sea cage farms (European Commission, n.d.). The eastern coastline appears to be more important, with many farms clustered within just a few hundred kilometres of Athens. Sea bass and sea bream farms in Greece are farmed using inshore floating sea cages (Pavlidis and Mylonas, 2011). In Spain and Italy, the farms are located along the length of the countries’ coastlines with the Mediterranean. In Spain, 35,000 t of sea bass and sea bream are produced by 24 sea cage farms (Fishcount, 2017; Nielsen et al., 2021). In Italy, 14,000 t of sea bass and sea bream are produced by 24 sea cage farms. This equates to an average production per farm of 250 t (Italy - Eurofish.dk, n.d.; Hofherr et al., 2015; WWF, 2021). Spanish and Italian farms also mostly use floating sea cages, though a minority of production takes place in wetlands/brackish water (Nielsen et al., 2021).

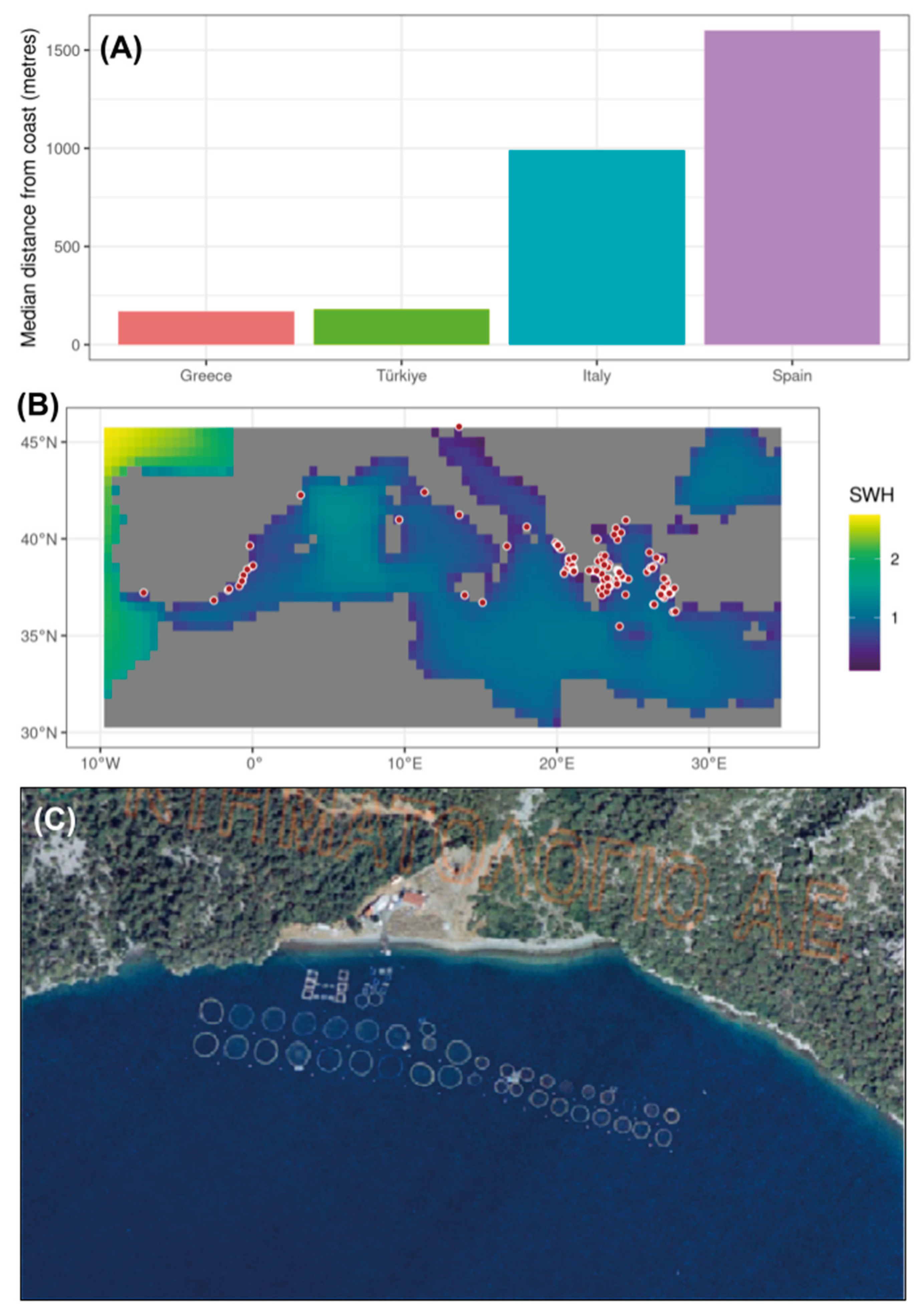

When it comes to distance from shore, these four countries can be divided into two pairs (

Figure 1A). Greece and Türkiye tend to have fish farms very close to the shoreline. Half of Greece’s fish farms are located within 170 metres of the shoreline, while half of Türkiye’s fish farms are located within 180 metres of the coastline (Hofherr et al., 2015). In contrast, Italy and Spain tend to have fish farms much further from the shoreline. Half of all fish farms in Italy are located within 990 metres from the coastline, while half of Spain’s fish farms are located within 1,600 metres of the shoreline (Hofherr et al., 2015). The distance from shoreline determines the geographical and wave dynamics of farms, which in turn influences the technology and equipment that farmers can adopt. We discuss this point further below.

In the remainder of this article, we examine the technological options for humane slaughter of sea bass and sea bream, before turning to a discussion of the industry perspectives, economic details, and engineering aspects associated with implementing humane slaughter in the European sea bass and sea bream industry.

2. Humane Slaughter of Sea Bass and Sea Bream

2.1. Electrical Stunning before Slaughter

Today, almost all sea bass and sea bream are slaughtered by live chilling in ice or ice slurry, followed by a gill cut (European Commission, 2017). During live chilling, fish generally remain conscious for between 5 and 40 minutes and display signs of suffering, including vigorous escape attempts (Van De Vis et al., 2003; Simitzis et al., 2013; Zampacavallo et al., 2015; de la Rosa et al., 2021). Brain activity continues even after fish become immobile (Lines and Spence, 2012).

During slaughter, animal welfare can be improved by stunning. Electrical stunning involves rendering fish unconscious using an electric current. Studies indicate that electrical stunning causes sea bass and sea bream to immediately become unconscious and lose sensibility (Giuffrida et al., 2007; Lambooij et al., 2007; Zampacavallo et al., 2015) (Panel on Animal Health and Welfare, 2009). It is important that stunning parameters (e.g. current and duration) are carefully selected, especially with reference to the method of electrical stunning, the handling method, and the subsequent killing method. Greater efficacy is generally achieved with higher currents and a longer duration (Robb et al., 2002; Lines et al., 2003; Jung-Schroers et al., 2020).

Electrical stunning can involve one of two methods: in-water and in-air. For in-water electrical stunning, fish are transported to a tank in batches using brailing and then exposed to the electrical field. Alternatively, fish can be captured using a pump and passed along a channel through which an electrical current is generated (Lines et al., 2003). In-air stunning is also possible but introduces the requirement to dewater the fish prior to stunning. Currently, producers of electrical stunning equipment for sea bass and sea bream include the UK-based company Ace Aquatec (in-water stunning), the Norway-based company Optimar (dry stunning), and the Türkiye-based company Smilefish.

The other major category of fish stunning is percussive slaughter. Percussive slaughter is not recommended for small fish, which includes sea bass and sea bream. This is because percussive stunning requires accuracy to be consistently maintained over time, which is difficult for small fish in a commercial setting (de la Rosa et al., 2021).

2.2. Current Uptake of Humane Slaughter

Many Mediterranean sea bass and sea bream producers have expressed an interest in implementing electrical stunning. Currently, progress appears relatively promising in Spain, Greece, and Türkiye, with Italy appearing less promising.

In Spain and Greece, the major producer Avramar intends to implement electrical stunning this decade. Specifically, Avramar has publicly committed to implementing, by 2027, electrical stunning for 100% of its production in Spain and 50% of its production in Greece. Currently, Avramar has electrical stunning installed on two of its farms in Greece (Avramar, 2023). Likewise, the producer Philosofish has begun installing on its harvest vessels electrical stunners produced by Ace Aquatec (The Fish Site, 2023).

In Türkiye, a study conducted by the NGO Future for Fish provides insight into the status of electrical stunning at Turkish fish farms (Future for Fish, 2023). In collaboration with academic advisors, Future for Fish contacted and visited numerous aquaculture companies, accounting for 76% of sea bass and sea bream production in Türkiye. A key finding showed that the majority (90 percent) of Turkish aquaculture companies already have electrical stunning systems. Companies with electrical stunning systems do not always use those systems; only around 40% of companies use electrical stunning for over 95% of the harvesting process. The primary driver of Turkish farmers’ adoption of electrical stunning systems is demand from customers (e.g. retailers in the UK and the Netherlands). Turkish fish farmers tend to use electrical stunning systems that are produced and sold in Türkiye, by companies such as Smilefish. Such systems have not been evaluated scientifically for their efficacy in successfully and consistently stunning fish.

In Italy, a survey of 21 sea bass and sea bream farms found that none of the surveyed farms have adopted electrical stunning (Clemente et al., 2023). The slaughter methods used by the surveyed farms were "thermal shock" (20 farms) and "asphyxia in air" (one farm).

3. Industry Perspectives and Implementation of Humane Slaughter

3.1. Industry Perspectives

The most detailed information about industry perspectives on humane fish slaughter in Türkiye comes from the recent stakeholder survey conducted by Future for Fish (Future for Fish, 2023). The main challenge with electrical stunning systems in Türkiye is the initial installation aboard harvest vessels. The research also found other valuable insights. Implementing electrical stunning in operations leads to a decrease in labour due to “better organisation and occupational safety on harvest ships”, better product quality, and possibly a longer shelf life. Fish producers believe that electrical stunning is more challenging for sea bass in particular, due to the fish getting stuck in the fish pumps leading to haemorrhages on their skin. A similar survey was conducted in Italy, but the negligible uptake of electrical stunning in the Italian sea bass and sea bream industry means that the survey did not produce detailed information about farmers’ views on those species (Clemente et al., 2023).

3.2. Economic Costs and Funding

To our knowledge, there are three main manufacturers of electrical stunning equipment for European aquaculture: Ace Aquatec (United Kingdom), Optimar (Norway), and Smilefish (Türkiye). Surveys of manufacturers reveal that installing an in-water electrical stunner aboard a harvest vessel would cost a farmer somewhere in the vicinity of 150,000 €, though stunners produced by Smilefish may cost a different amount (European Commission, 2017). This cost excludes expenses associated with any necessary modification to ships.

When it comes to making the investment necessary to purchase electrical stunning equipment, company size emerges as a critical factor (European Commission, 2017). Larger enterprises, with more resources, may integrate stunning equipment more seamlessly, while smaller companies might face greater challenges, indicating a need for tailored strategies. A stakeholder consultation conducted by the European Parliament’s Committee on Fisheries found that European fish farmers most often mention investment funds as the main obstacle to adopting new techniques, followed by justification of need (Pavlidis et al., 2023). Direct funding is mentioned as one of the most useful tools for mitigating potential impacts when transitioning to new fish welfare requirements..

Funding through the European Maritime Fisheries and Aquaculture Fund offers support, with specific budgets allocated for animal health and welfare improvements (e.g. 4M € for Italy, 8M € for Spain, and 560,000 € for Greece). A considerable portion of the funds allocated during the 2014 - 2020 period for aquaculture innovation remained unused. A lack of transparency in grants hitherto makes it difficult to assess how much money was used on animal welfare improvements. There are however known examples of the previous budget being used for a sea bream and sea bass stunning pilot in Spain. In general, transparency in funding allocation is a concern, with unclear information on recipients and purposes.

3.3. Engineering Aspects

The physical, economic, and geographical details of sea bass and sea bream farms vary by country (

Figure 1). Therefore, it is reasonable to expect that some countries will have an easier time than others in implementing electrical stunning. Spain in particular appears to have farms located in areas of the ocean with large waves, which could mean that air entering the fish pumps could be an engineering challenge in that country (

Figure 1B). Size differences of fish can also cause the design sizes of pumps to be exceeded, likely leading to fish suffering and damaged product (Future for Fish, 2023).

The difficulty of installing new stunning equipment onboard vessels depends on the space available on the vessel, the type of vessel, and the installation requirements for the stunning equipment. Research and data on the types of vessels being used is scarce. Vessel types include platforms, workboats, and larger wellboats. All vessel types have been observed used for harvesting operations. Platforms are floating barges equipped with outboard engines and a crane. Workboats are larger, better equipped vessels ranging from 12 to 30 metres (Paleo et al., 2000). For larger, workboat-type vessels, installation of stunning equipment and fish pumps should not pose large problems. Equipment can be installed on deck or, for in-water stunners beneath deck. For smaller platform vessels, the limited deck space and the lack of below-deck area pose problems for installing a stunner and pump system. The pre-existing power on smaller vessels might not be enough to power both the crane and stunning system.

The study by Future for Fish found that 60% of interviewed farmers mentioned that stunning works faster than live chilling, meaning that stunning equipment may actually offer advantages for the harvest rate and associated labour requirements (Future for Fish, 2023). For some types of systems adding electrical stunning led to a slower harvest. Other technical obstacles include malfunctions in the equipment, long waiting times for spare parts and increased operating costs.

4. Discussion

As consumers develop an appreciation for animal welfare and its role as a component of sustainable food production, the priority placed on animal welfare by producers will only increase. In this report, we have examined the trajectory towards stunning before slaughter in European sea bass and sea bream aquaculture. The current progress towards installing electrical stunners aboard harvest vessels provides optimism, but succeeding in this policy goal will require concerted action by stakeholders throughout the supply chain (McAfee et al., 2019).

Sea bass and sea bream producers have expressed an interest in installing electrical stunners where this is economically attractive, and some producers have begun to do so (Avramar, 2023; Future for Fish, 2023; The Fish Site, 2023). However, success is greatest when there is a clear demand from retailers for stunned fish (Future for Fish, 2023). This mirrors the dynamic in other agricultural sectors like poultry and pork, where demand from retailers drives improvements in on-farm practices (Scrinis et al., 2017; Peacock and Mendez, 2020). As such, retailers have an important responsibility to ensure that their procurement policies account for consumers’ increasing demand for animal welfare.

Likewise, producers are likely to respond to clear signals from government, whether at the national or the EU level. The EU is home to some of the world’s most progressive pieces of animal welfare legislation, though legislation for the welfare of fish specifically has been lagging behind (McCulloch, 2018; Giménez-Candela et al., 2020). Nevertheless, the EU has expressed interest in legislation that would make stunning before slaughter mandatory for fish farmers (Dullaghan, 2023). The EU is also exploring the possibility of applying EU farm animal welfare legislation to imported meat products, which could have important repercussions for producers in Türkiye who export their product to EU Member States (Dullaghan, 2023). When particular higher-welfare practices become mandatory, this can help ensure that all producers within a country have access to the same markets (Carey et al., 2017, 2020; Department for Environment, Food and Rural Affairs, 2017). It can be useful for governments or other stakeholders to support farmers in the transition to higher-welfare practices by providing funding and other support, a strategy used successfully when installing CCTV in slaughterhouses in Great Britain (Department for Environment, Food and Rural Affairs, 2017; Springlea, 2022). As such, support from stakeholders throughout the supply chain can drive collective action to improve the lives of animals used for food.

Acknowledgements

Figure 1B is generated using Copernicus Climate Change Service information. Neither the European Commission nor ECMWF is responsible for any use that may be made of the Copernicus information or data it contains.

References

- Albalat, A., Zacarias, S., Coates, C. J., Neil, D. M., and Planellas, S. R. (2022). Welfare in Farmed Decapod Crustaceans, With Particular Reference to Penaeus vannamei. Frontiers in Marine Science 9. [CrossRef]

- Alonso, M. E., González-Montaña, J. R., and Lomillos, J. M. (2020). Consumers’ Concerns and Perceptions of Farm Animal Welfare. Animals (Basel) 10. [CrossRef]

- Ashley, P. J. (2007). Fish welfare: Current issues in aquaculture. Appl. Anim. Behav. Sci. 104, 199–235. [CrossRef]

- Avramar (2023). Responsible aquaculture. Avramar. Available at: https://avramar.eu/story/sustainability/ [Accessed January 11, 2024].

- Carey, R., Parker, C., and Scrinis, G. (2017). Capturing the meaning of “free range”: The contest between producers, supermarkets and consumers for the higher welfare egg label in Australia. J. Rural Stud. 54, 266–275. [CrossRef]

- Carey, R., Parker, C., and Scrinis, G. (2020). How free is sow stall free? Incremental regulatory reform and industry co-optation of activism. Law Policy 42, 284–309. [CrossRef]

- Clawson, G., Kuempel, C. D., Frazier, M., Blasco, G., Cottrell, R. S., Froehlich, H. E., et al. (2022). Mapping the spatial distribution of global mariculture production. Aquaculture 553, 738066. [CrossRef]

- Clemente, G. A., Tolini, C., Boscarino, A., Lorenzi, V., Dal Lago, T. L., Benedetti, D., et al. (2023). Farmed fish welfare during slaughter in Italy: survey on stunning and killing methods and indicators of unconsciousness. Frontiers in Veterinary Science 10. [CrossRef]

- Çoban, D., Didem Demircan, M., and Tosun, D. D. eds. (2020). Marine Aquaculture in Turkey: Advances and Management. Turkish Marine Research Foundation.

- Coghlan, S., Coghlan, B. J., Capon, A., and Singer, P. (2021). A bolder One Health: expanding the moral circle to optimize health for all. One Health Outlook 3, 21. [CrossRef]

- Crump, A., Browning, H., Schnell, A. K., Burn, C., and Birch, J. (2022). Invertebrate sentience and sustainable seafood. Nat Food 3, 884–886. [CrossRef]

- de la Rosa, I., Castro, P. L., and Ginés, R. (2021). Twenty Years of Research in Seabass and Seabream Welfare during Slaughter. Animals (Basel) 11. [CrossRef]

- Department for Environment, Food and Rural Affairs (2017). Improving animal welfare: Closed Circuit Television (CCTV) in Slaughterhouses: Impact Assessment. Department for Environment, Food and Rural Affairs. Available at: https://consult.defra.gov.uk/farm-animal-welfare/cctv-in-slaughterhouses/supporting_documents/CCTV%20internal%20impact%20assessment%20%20final.pdf.

- Dullaghan, N. (2023). EU Farmed Fish Policy Reform Roadmap. Rethink Priorities Available at: https://rethinkpriorities.org/publications/eu-farmed-fish-policy-reform-roadmap-brief.

- European Commission (2017). Welfare of farmed fish: Common practices during transport and at slaughter. European Commission Available at: https://publications.europa.eu/resource/cellar/facddd32-cda6-11e7-a5d5-01aa75ed71a1.0001.01/DOC_1.

- European Commission (n.d.). Eurostat. Available at: https://ec.europa.eu/eurostat/data/database [Accessed March 2022].

- Fishcount (2017). Estimated numbers of individuals in aquaculture production (FAO) of fish species (2017). Fishcount. Available at: http://fishcount.org.uk/studydatascreens2/2017/numbers-of-farmed-fish-B0-2017.php.

- Future for Fish (2023). Electrical Stunning System: Türkiye Review. Future for Fish Available at: https://futureforfish.org/wp-content/uploads/2024/01/ELECTRICAL-STUNNING-SYSTEM-REPORT-TURKIYE.pdf.

- Giménez-Candela, M., Saraiva, J. L., and Bauer, H. (2020). The legal protection of farmed fish in Europe – analysing the range of EU legislation and the impact of international animal welfare standards for the fishes in European aquaculture. Derecho Animal Forum of Animal Law Studies 11, 65. [CrossRef]

- Giuffrida, A., Pennisi, L., Ziino, G., Fortino, L., Valvo, G., Marino, S., et al. (2007). Influence of slaughtering method on some aspects of quality of gilthead seabream and smoked rainbow trout. Vet. Res. Commun. 31, 437–446. [CrossRef]

- Grimsrud, K. M., Nielsen, H. M., Navrud, S., and Olesen, I. (2013). Households’ willingness-to-pay for improved fish welfare in breeding programs for farmed Atlantic salmon. Aquaculture 372-375, 19–27. [CrossRef]

- Hersbach, H., Bell, B., Berrisford, P., Biavati, G., Horányi A., Muñoz Sabater, J., et al. (2023). ERA5 monthly averaged data on single levels from 1940 to present. Copernicus Climate Change Service (C3S) Climate Data Store (CDS). [CrossRef]

- Hofherr, J., Natale, F., and Trujillo, P. (2015). Is lack of space a limiting factor for the development of aquaculture in EU coastal areas? Ocean Coast. Manag. 116, 27–36. [CrossRef]

- Italy - Eurofish.dk (n.d.). Available at: https://www.eurofish.dk/italy [Accessed November 11, 2021].

- Jung-Schroers, V., Hildebrandt, U., Retter, K., Esser, K.-H., Hellmann, J., Kleingeld, D. W., et al. (2020). Is humane slaughtering of rainbow trout achieved in conventional production chains in Germany? Results of a pilot field and laboratory study. BMC Vet. Res. 16, 197. [CrossRef]

- Klaura, J., Breeman, G., and Scherer, L. (2023). Animal lives embodied in food loss and waste. Sustainable Production and Consumption 43, 308–318. [CrossRef]

- Lambooij, B., Gerritzen, M. A., Reimert, H., Burggraaf, D., André, G., and Van De Vis, H. (2007). Evaluation of electrical stunning of sea bass (Dicentrarchus labrax) in seawater and killing by chilling: welfare aspects, product quality and possibilities for implementation. Aquaculture Research 39, 50–58. [CrossRef]

- Lines, J. A., Robb, D. H., Kestin, S. C., Crook, S. C., and Benson, T. (2003). Electric stunning: a humane slaughter method for trout. Aquacult. Eng. 28, 141–154. [CrossRef]

- Lines, J. A., and Spence, J. (2012). Safeguarding the welfare of farmed fish at harvest. Fish Physiol. Biochem. 38, 153–162. [CrossRef]

- McAfee, D., Doubleday, Z. A., Geiger, N., and Connell, S. D. (2019). Everyone Loves a Success Story: Optimism Inspires Conservation Engagement. Bioscience 69, 274–281. [CrossRef]

- McCulloch, S. P. (2018). Brexit and Animal Protection: Legal and Political Context and a Framework to Assess Impacts on Animal Welfare. Animals (Basel) 8. [CrossRef]

- Mood, A., Lara, E., Boyland, N. K., and Brooke, P. (2023). Estimating global numbers of farmed fishes killed for food annually from 1990 to 2019. Anim. Welf. 32, e12. [CrossRef]

- Nielsen, R., Guillen, J., and Virtanen, J. (2021). Scientific, Technical and Economic Committee for Fisheries (STECF) - The EU Aquaculture Sector – Economic report 2020 (STECF-20-12). European Commission Available at: https://stecf.jrc.ec.europa.eu/documents/43805/2783239/STECF+20-12+-+EU+Aquaculture+economics.pdf/ef242822-3343-43f4-b0a3-dfad889dd52c?version=1.0.

- Paleo, J. D. B., Muir, J., and Turner, R. (2000). Offshore mariculture: Workboats. : Série B. Etudes et …. Available at: http://om.ciheam.org/om/pdf/b30/00600659.pdf.

- Panel on Animal Health and Welfare (2009). Species-specific welfare aspects of the main systems of stunning and killing of farmed fish: Rainbow Trout. The EFSA Journal. [CrossRef]

- Pavlidis, M. A., and Mylonas, C. C. eds. (2011). Sea bream: biology and aquaculture of gilthead sea bream and other species. Ames, Iowa: Wiley-Blackwell.

- Pavlidis, M., Papaharisis, L., Jung-Schroers, M. A. D. S., Kristiansen, T., Theodoridi, A., and Lourido, F. O. (2023). Animal welfare of farmed fish. PECH Committee Available at: https://www.europarl.europa.eu/thinktank/en/document/IPOL_STU(2023)747257.

- Peacock, J., and Mendez, S. (2020). Measuring Better Chicken Commitment–Compliant Chicken Supply. [CrossRef]

- Pettersen, J. M., Bracke, M. B. M., Midtlyng, P. J., Folkedal, O., Stien, L. H., Steffenak, H., et al. (2014). Salmon welfare index model 2.0: an extended model for overall welfare assessment of caged Atlantic salmon, based on a review of selected welfare indicators and intended for fish health professionals. Rev. Aquac. 6, 162–179. [CrossRef]

- Robb, D. H. F., O’ Callaghan, M., Lines, J. A., and Kestin, S. C. (2002). Electrical stunning of rainbow trout (Oncorhynchus mykiss): factors that affect stun duration. Aquaculture 205, 359–371.

- Romero Waldhorn, D., and Autric, E. (2022). Shrimp: The animals most commonly used and killed for food production. [CrossRef]

- Scrinis, G., Parker, C., and Carey, R. (2017). The caged chicken or the free-range egg? The regulatory and market dynamics of layer-hen welfare in the UK, Australia and the USA. J. Agric. Environ. Ethics 30, 783–808. [CrossRef]

- Simitzis, P. E., Tsopelakos, A., Charismiadou, M. A., Batzina, A., Deligeorgis, S. G., and Miliou, H. (2013). Comparison of the effects of six stunning/killing procedures on flesh quality of sea bass (Dicentrarchus labrax,Linnaeus 1758) and evaluation of clove oil anaesthesia followed by chilling on ice/water slurry for potential implementation in aquaculture. Aquac. Res. [CrossRef]

- Springlea, R. (2022). CCTV cameras in slaughterhouses: Modest benefits for animal welfare. Animal Ask. Available at: https://www.animalask.org/post/cctv-cameras-in-slaughterhouses-modest-benefits-for-animal-welfare.

- Stien, L. H., Bracke, M., Noble, C., and Kristiansen, T. S. (2020). “Assessing Fish Welfare in Aquaculture,” in The Welfare of Fish, eds. T. S. Kristiansen, A. Fernö, M. A. Pavlidis, and H. van de Vis (Cham: Springer International Publishing), 303–321.

- The Fish Site (2023). Philosofish commits to electrical stunners. The Fish Site. Available at: https://thefishsite.com/articles/philosofish-commits-to-electrical-stunners [Accessed January 11, 2024].

- Tørud, B., Jensen, B. B., Gåsnes, S., Grønbech, S., and Gismervik, K. (2019). Animal welfare in fish hatcheries - SMÅFISKVEL. Norwegian Veterinary Institute Available at: https://dyrevern.no/app/uploads/2019/12/Animal-welfare-in-fish-hatcheries-SMAFISKVEL.pdf.

- United Nations Environment Programme (2019). Why is Animal Welfare Important for Sustainable Consumption and Production? United Nations Available at: https://www.unep.org/resources/perspective-series/issue-no-34-why-animal-welfare-important-sustainable-consumption-and.

- Van De Vis, H., Kestin, S., Robb, D., Oehlenschläger, J., Lambooij, B., Münkner, W., et al. (2003). Is humane slaughter of fish possible for industry? Aquac. Res. 34, 211–220.

- Wahltinez, S. J., Stacy, N. I., Hadfield, C. A., Harms, C. A., Lewbart, G. A., Newton, A. L., et al. (2022). Perspective: Opportunities for advancing aquatic invertebrate welfare. Front Vet Sci 9, 973376. [CrossRef]

- Wickens, S. (2022). Review of the evidence of sentience in cephalopod molluscs and decapod crustaceans. Anim. Welf. 31, 155–156. [CrossRef]

- WWF (2021). SEA BASS AND SEA BREAM SUPPLY CHAIN STUDY: FROM TURKEY TO EUROPE. Available at: https://www.fishforward.eu/wp-content/uploads/2021/07/WWF_supply_chain_study_2021_seabass_seabream.pdf [Accessed December 6, 2021].

- Zampacavallo, G., Parisi, G., Mecatti, M., Lupi, P., Giorgi, G., and Poli, B. M. (2015). Evaluation of different methods of stunning/killing sea bass (Dicentrarchus labrax) by tissue stress/quality indicators. J. Food Sci. Technol. 52, 2585–2597. [CrossRef]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).