Submitted:

20 February 2024

Posted:

23 February 2024

You are already at the latest version

Abstract

Keywords:

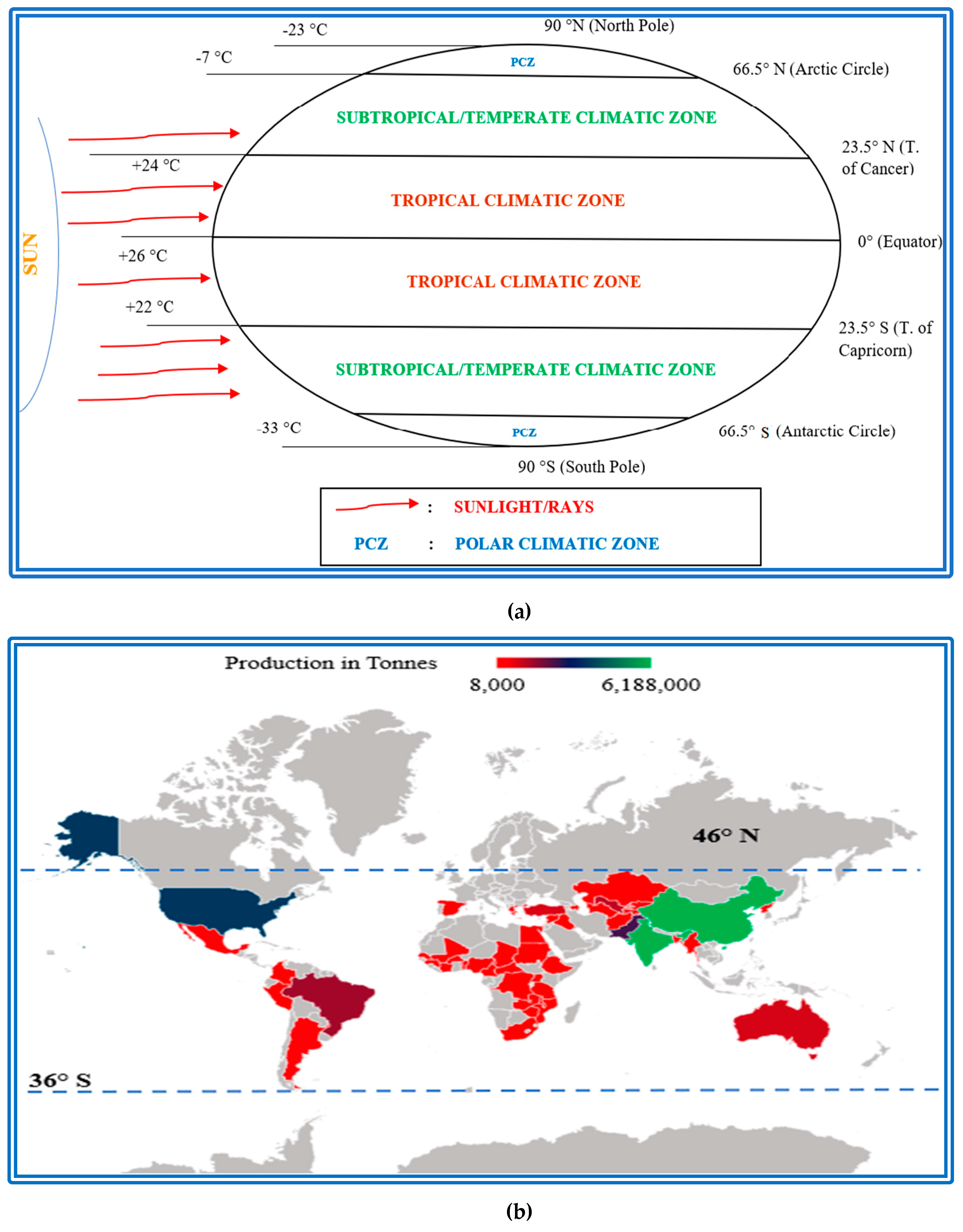

1. Introduction

2. Key Sustainability Issues in Conventional Cotton Farming

3. Technological Evolutions and Advancements in Cotton Agronomy

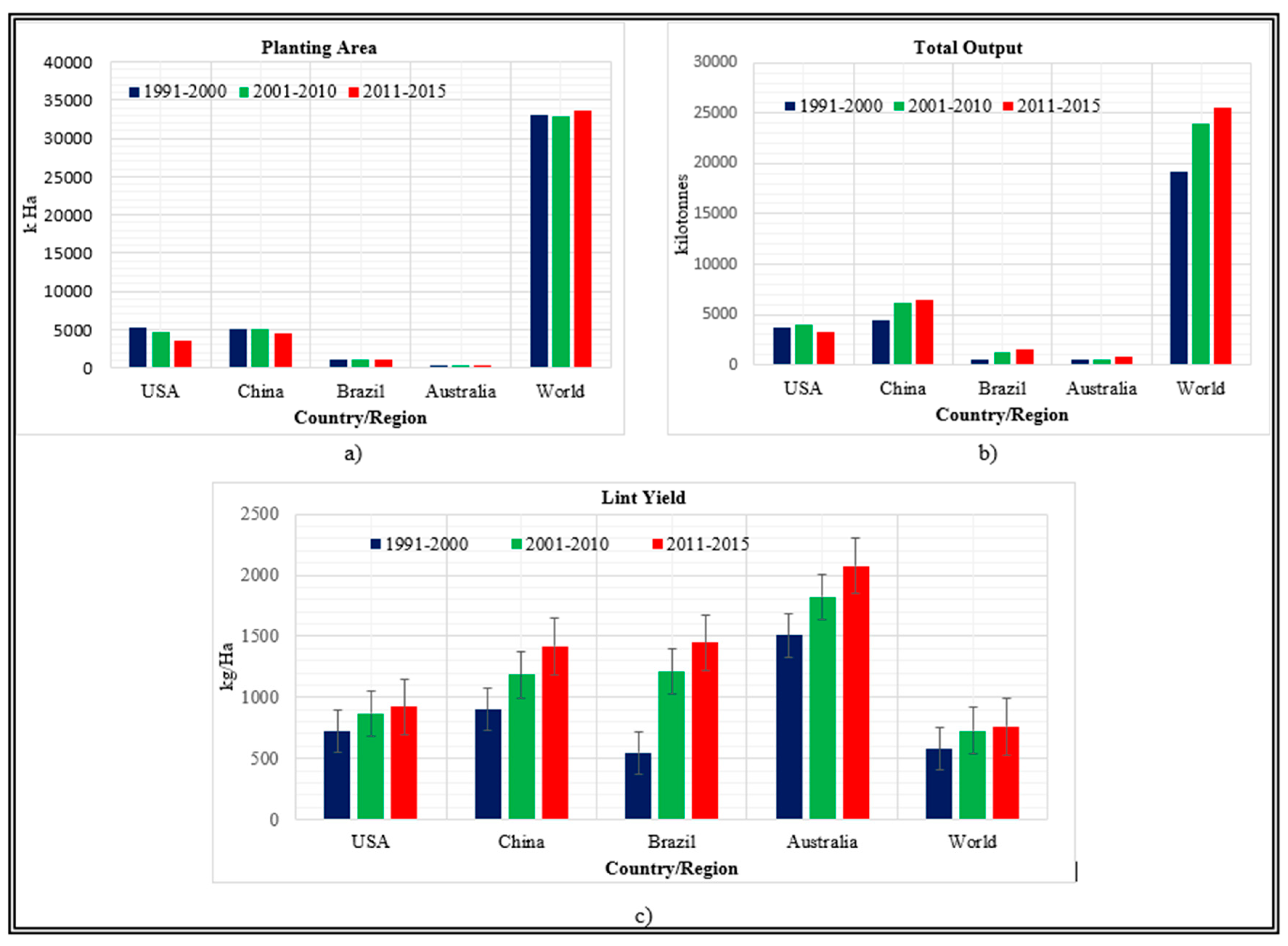

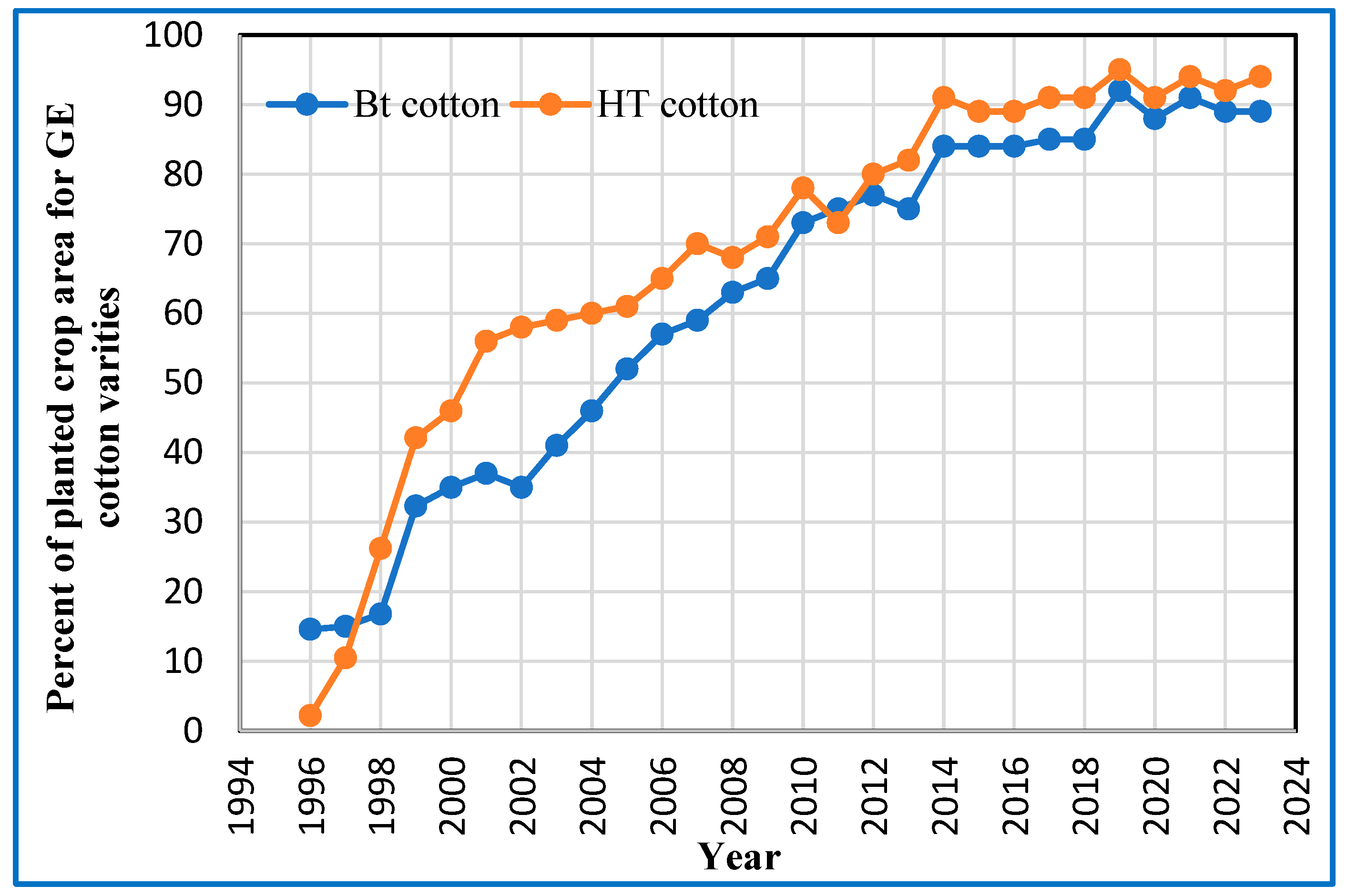

3.1. New Cotton Cultivars/Hybrids Developments

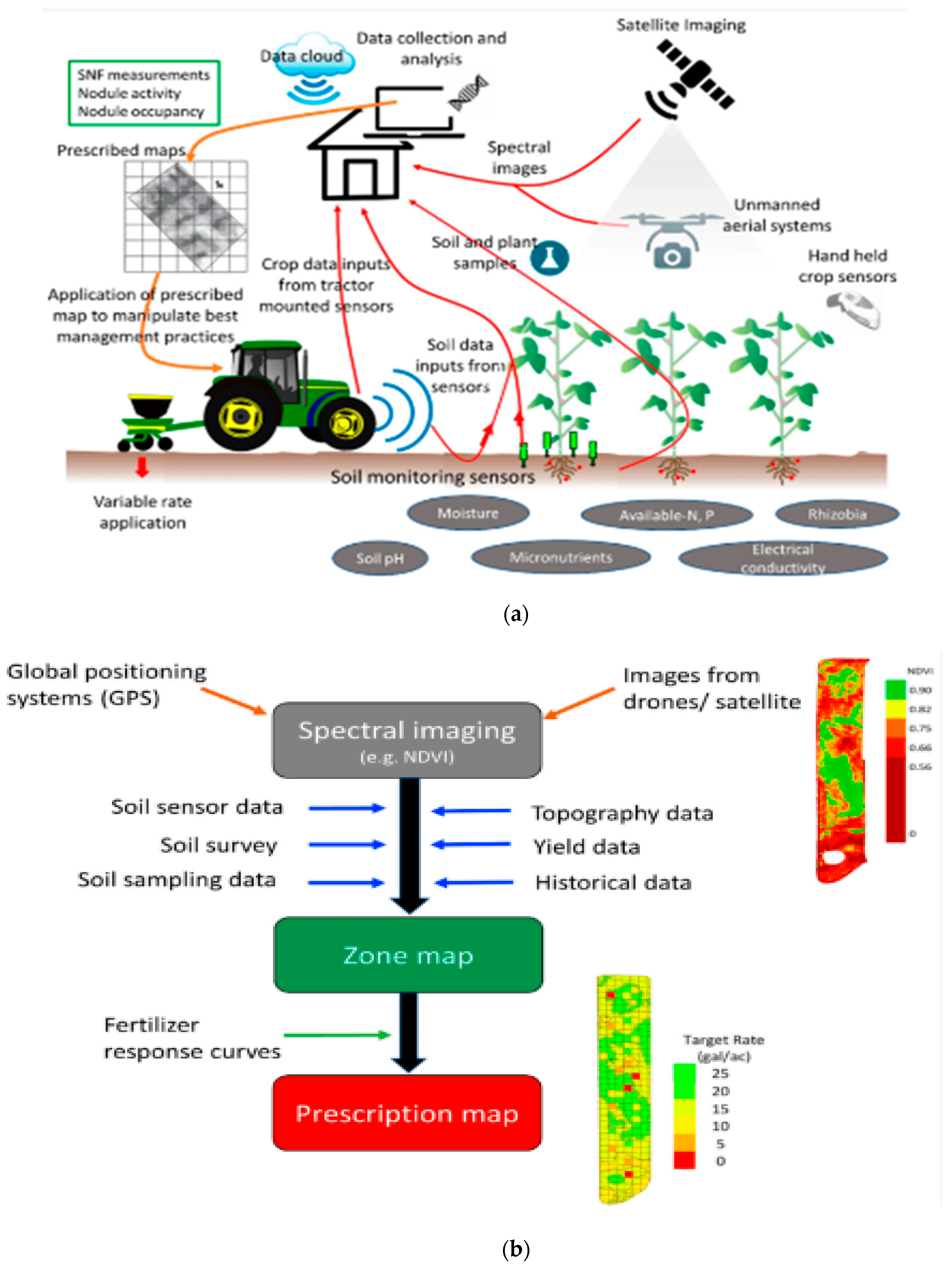

3.2. Precision Agriculture Techniques

3.3. UAV Inspections and Remote Sensing Techniques

3.4. Effective Water Management Strategies

Plastic Film Mulching

Drip and Center Pivot Irrigation and Fertigation Methods

3.5. Advancements in Mechanical Harvesting and General Crop Management Technologies

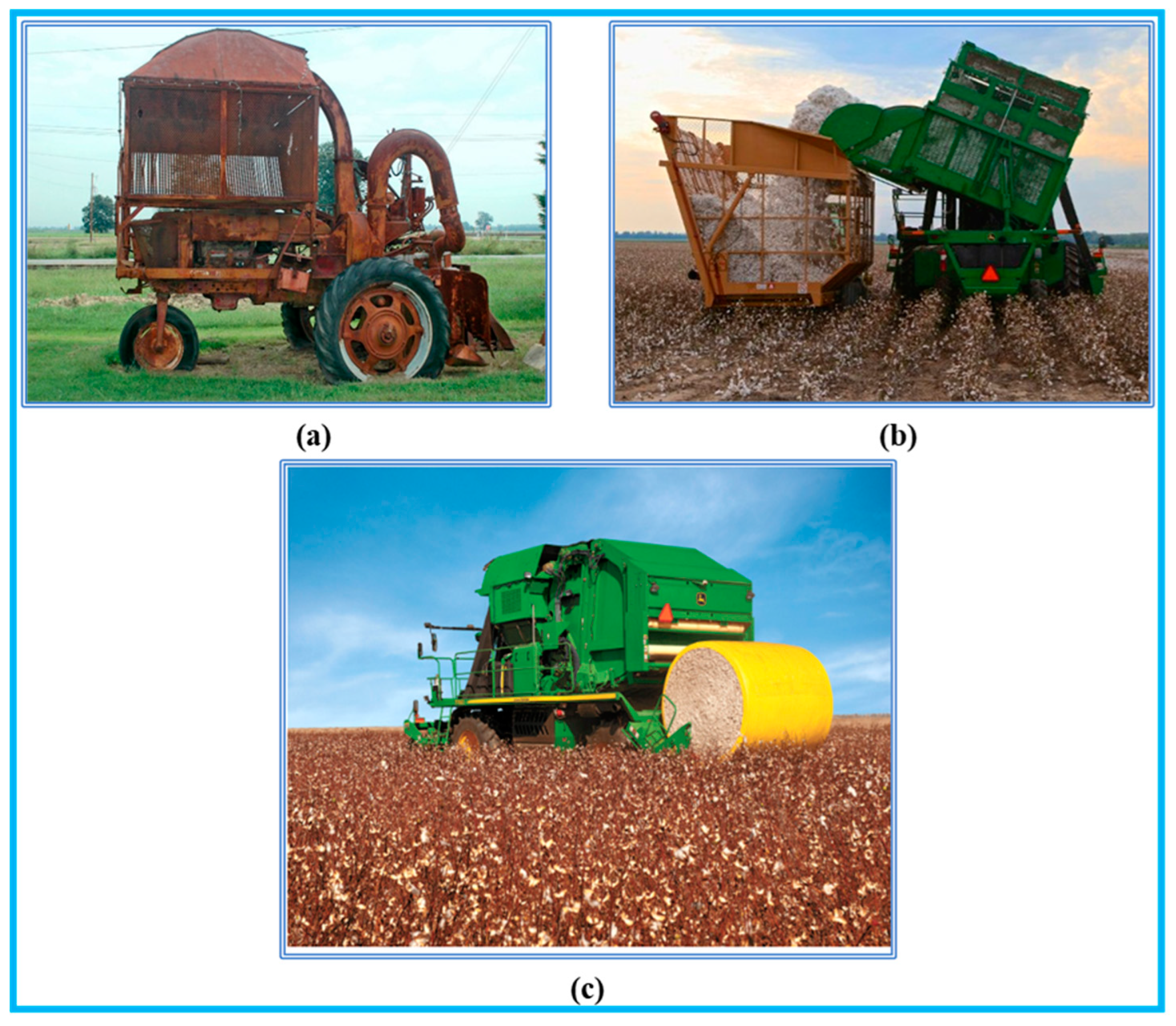

Heavy-Duty (Stripper And Picker) Harvesters

3.6. Multipurpose Robotic Platforms for Phenotyping, Spaying, Weeding, and Harvesting

3.7. Organic Cotton Production and High Plant Density (Close Planting) Techniques

Organic Cotton Production

High-Density Planting Technique

3.8. Sowing and Plant Stand Establishment Techniques

Flat-Sowing Technique

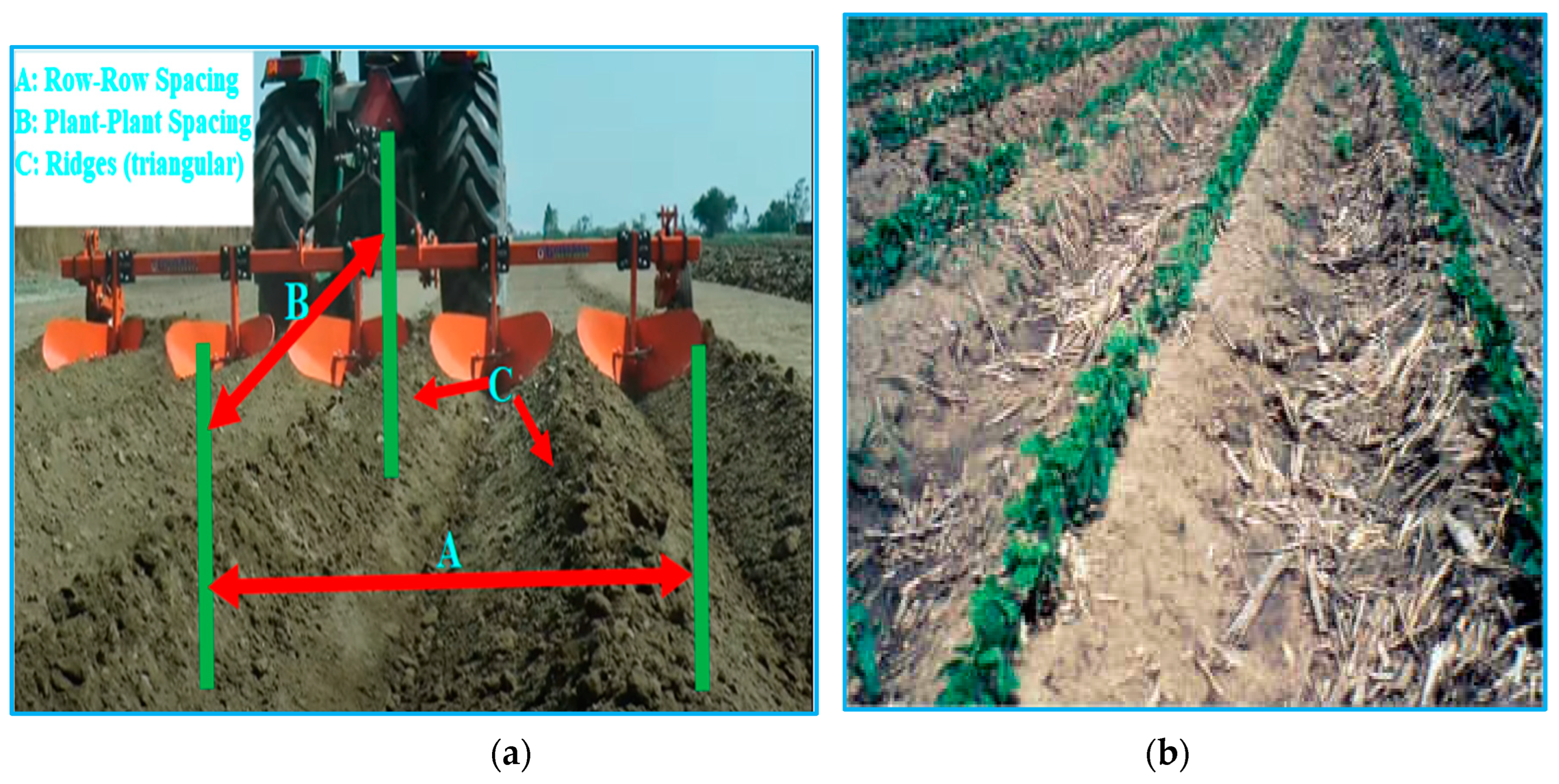

Ridge-Planting Technique

Early Planting Aided by Transplantation

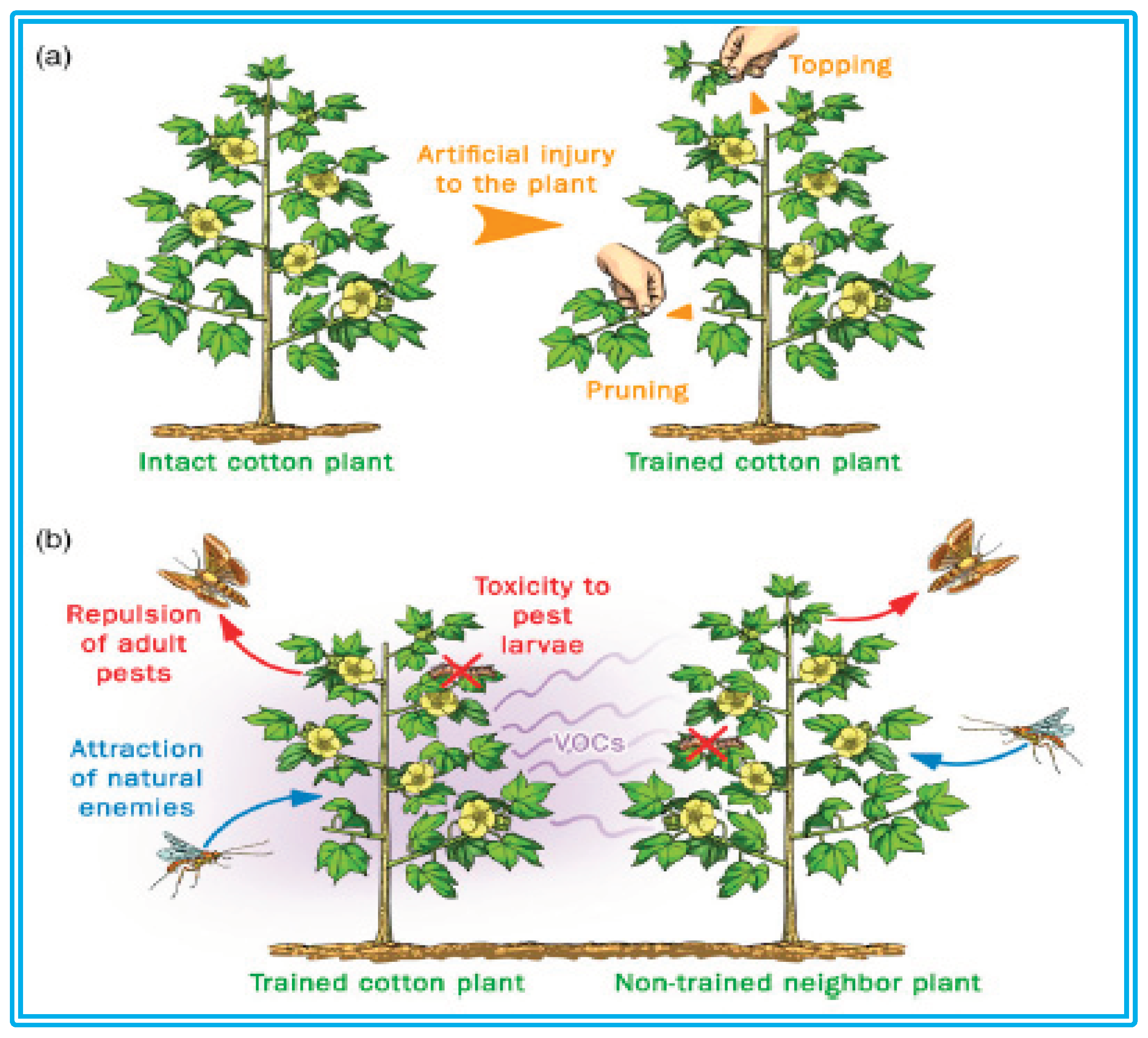

3.9. Chemical and Mechanical Growth Regulation/Topping

Chemical Topping

Mechanical Topping

| Change | Key Benefits | Challenges | Prospects | Region of adoption/use |

|---|---|---|---|---|

| Plastic mulching |

|

|

China, US[31,49]. | |

| Fertigation technique |

|

|

|

US, China, Australia[51,52]. |

| GM crop/New hybrids |

|

|

|

US, India, China, Australia, some African Countries[29,30,33,34,35,36]. |

| Heavy-duty mechanical harvesters |

|

|

US, Australia, Israel, Brazil[2,24,59]. | |

| Multipurpose robotic platforms |

|

|

|

US, Australia, Israel, partly China[24,59]. |

| Drip/center-pivot irrigation technology |

|

|

|

US, China, Australia, Israel[39,40,41,51,52]. |

| Organic cotton cultivation technique |

|

Tanzania, India, China, Turkey, US[62]. | ||

| High-density planting technique |

|

|

China, US, Brazil Mexico Australia, India[31,63]. | |

| Plastic film mulching combined with drip irrigation and fertigation |

|

|

|

US, China[31,48,49]. |

| Flat-sowing technique |

|

|

|

US, Pakistan, India, and rest of the world (ROW)[64,68]. |

| Ridge-planting technique |

|

Pakistan, USA India, ROW[64,77,78,79]. | ||

| Chemical topping |

|

|

|

USA, Australia, China, Pakistan[88,95,96]. |

| Mono-seeding/Single-seed planting |

|

China[85] | ||

| Early planting assisted by transplanting |

|

|

Pakistan, China, India; Iran[82,83,84]. |

4. Summary and Projections

5. Conclusions

6. Electronic Supplementary Information

Author Contributions

Acknowledgments

Conflict of Interest

Disclaimer

Data Availability/Electronic Supplementary Information

References

- Zhang X, Zhang Z, Zhou R, Wang Q, Wang L. 2020. Ratooning annual cotton (Gossypium spp.) for perennial utilization of heterosis. Front. Plant Sci. 11:554970. [CrossRef]

- Adeleke AA. 2023. A review of plastic contamination challenges and mitigation efforts in cotton and textile milling industries. AgriEngineering, 5(1), 193-217. [CrossRef]

- Radhakrishnan S. 2017. Sustainable cotton production. In: Sustainable Fibres and Textiles, (ed. Muthu SS). Elsevier, pp. 21–67.

- WWF. N.d. Available online: https://www.worldwildlife.org/industries/cotton (accessed on 25 October 2023).

- USDA. 2019. Cotton sector at a glance. Washington, DC: USDA National Agricultural Statistics Service. Available online: https://www.ers.usda.gov/topics/crops/cotton-wool/cotton-sector-at-a-glance/(Reviewed on 22 Sept. 2020).

- Adeleke AA, Hardin IV RG, Pelletier MG. Design of a plastic removal system for a cotton gin module feeder. In Proceedings of the Beltwide Cotton Conferences, Virtual, 5–7 January 2021.

- Yang Z, Tang J, Yu M, Zhang Y, Abbas A, Wang S, Bagadeem S. Sustainable cotton production through increased competitiveness: analysis of comparative advantage and influencing factors of cotton production in Xinjiang, China. Agronomy 2022, 12(10), 2239. [CrossRef]

- Reller A, Gerstenberg J. 1997: Weisses gold, wohin? Stand und aussichten der baumwollnutzung. [CrossRef]

- WWF. 1999. The impact of cotton on fresh water resources and ecosystems. 1999. Available online: http://d2ou- vy59p0dg6k.cloudfront.net/downloads/impact_long.pdf (accessed on 25 October 2023).

- Zhou RY. (2016). Method of producing hybrid seeds for annual cotton by cultivating perennially. US Patent, US9265206B2.

- Zhang T, Xuan L, Mao Y, Hu Y. Cotton heterosis and hybrid cultivar development. Theor Appl Genet. 2023 Mar 31;136(4):89. [CrossRef]

- Wang J, Du G, Tian J, Jiang C, Zhang Y, Zhang W. Mulched drip irrigation increases cotton yield and water use efficiency via improving fine root plasticity. Agricultural Water Management. 2021 Sep 01; 255. [CrossRef]

- Blaise D, Manikandan A, Desouza ND, Bhargavi B, Somasundaram J. Intercropping and mulching in rain-dependent cotton can improve soil structure and reduce erosion. Environmental Advances. 2021 Jul 01;4. [CrossRef]

- Iqbal R, Habib-ur-Rahman M, Raza MAS, Waqas M, Ikram MR, et al. Assessing the potential of partial root zone drying and mulching for improving the productivity of cotton under arid climate. Environ Sci Pollut Res 28, 66223–41 (2021). [CrossRef]

- McKinion JM, Jenkins JN, Akins D, Turner SB, Willers JL, Jallas E, Whisler FD. Analysis of a precision agriculture approach to cotton production. Computers and Electronics in Agriculture. 2001 Oct 01;32(3). [CrossRef]

- Neupane J, Guo W, West CP, Zhang F, Lin Z. (2021). Effects of irrigation rates on cotton yield as affected by soil physical properties and topography in the southern high plains. PLoS ONE 16(10): e0258496. [CrossRef]

- Sui R, Thomasson, JA, Ge Y. Development of sensor systems for precision agriculture in cotton. Int J Agric & Biol Eng, 2012; 5(4).

- Hardin IV RG, Searcy SW. 2010. Autonomous module builder. National Cotton Council Beltwide Cotton Conference. CD ROM pp. 558-69.

- Han X, Thomasson JA, Wang T, Swaminathan V. Autonomous mobile ground control point improves accuracy of agricultural remote sensing through collaboration with UAV. Inventions 2020, 5, 12. [CrossRef]

- Wang Y, Ji C. Study on discrimination of mature cotton in early scenes. Acta Agricultural Jiangxi 2007, vol. 18, no. 6, pp. 141-143.

- Wang M, Wei J, Yuan J, Xu K. A research for intelligent cotton picking robot based on machine vision. 2008 International Conference on Information and Automation, Changsha, China, 2008, pp. 800-3. -3. [CrossRef]

- Deere and Company. 2014. Products: CP690 Cotton picker. Available online: http://www.deere.com/en_US/products/equipment/cotton_harvesting/cp690_cotton_picker/cp690_cotton_picker.page? (accessed on 26 October 2023).

- Willcutt MH. 2011. New cotton harvesters benefit growers. Resource: Eng. Tech. Sust. World 18(5):22–23.

- Maja JM, Polak M, Burce ME, Barnes E. CHAP: Cotton-harvesting autonomous platform. AgriEngineering 2021, 3, 199-217. [CrossRef]

- O’Neill C, McCann M, Syam U. 2023. America is using up its groundwater like there’s no tomorrow. (ed. Umi Syam): The New York Times. 2023. (accessed on November 4, 2023). Available online: https://www.nytimes.com/interactive/2023/08/28/climate/groundwater-drying-climate-change.html.

- Wanjura JD, Parnell CB, Shaw BW, Capareda SC. Source testing of particulate matter emissions from cotton harvesters–system design. In Proceedings of the Beltwide Cotton Conferences, San Antonio, Texas, 3-6 January 2006.

- CottonWorks. N.d.(b). Sustainable cotton production. (accessed on November 4, 2023). Available online: https://cottonworks.com/en/topics/sustainability/cotton-sustainability/cotton-sustainability-basics/.

- Blaise D, Venugopalan M., Raju A. 2014. Introduction of Bt cotton hybrids in India: Did it change the agronomy? Indian J. of Agronomy, 59, pp. 1-20.

- Venugopalan MV, Sankaranarayanan K, Blaise D, Nalayini P, Prahraj CS, Gangaiah B. 2009. Bt cotton (Gossypium sp.) in India and its agronomic requirements - a review. Indian Journal of Agronomy 54(4): 343–360.

- Drishti (N.d). India’s cotton story. (accessed on November 4, 2023). Available online: https://www.drishtiias.com/printpdf/india-s-cotton-story.

- Feng L, Dai J, Tian L, Zhang H, Li W, Dong H. 2017. Review of the technology for high-yielding and efficient cotton cultivation in the northwest inland cotton-growing region of China. Field Crops Research, 208, pp. 18-26. [CrossRef]

- James, C. 2006. Global status of commercialized biotech/GMCrops: 2006. ISAAA Briefs No. 35, International Service for the Acquisition of Agri-biotech Applications, Ithaca, NY.

- USDA. (N.d.). Recent trends in GE adoption. Available online: https://www.ers.usda.gov/data-products/adoption-of-genetically-engineered-crops-in-the-u-s/recent-trends-in-ge-adoption(accessed on November 4, 2023).

- Pray C, Ma D, Huang J, Qiao F. 2001. Impact of Bt cotton in China. World Development, 29(5), pp. 813-825. [CrossRef]

- ICAC. 2009. Biotech cotton and technology fee. ICAC Recorder, 27(1): 4–8.

- ISAA. 2019. Brief 55: Global status of commercialized biotech/GM crops: 2019. (accessed on November 5, 2023). Available online: https://www.isaaa.org/resources/publications/briefs/55/.

- Thilakarathna MS, Raizada MN. Challenges in using precision agriculture to optimize symbiotic nitrogen fixation in legumes: Progress, Limitations, and Future Improvements Needed in Diagnostic Testing. Agronomy. 2018; 8(5):78. Agronomy. [CrossRef]

- Xu W, Chen P, Zhan Y, Chen S, Zhan L, Lan Y. 2021. Cotton yield estimation model based on machine learning using time series UAV remote sensing data. Intl. J. Appl. Earth Observation and Geoinf. 104, pp. 102511-. [CrossRef]

- Duke HR, Sadler EJ. 1992. Linear move irrigation system for fertilizer management research. In: Proc. Int. Exposition and Tech. Conf. Irrig. Assoc., Fairfax, VA, pp. 72–81.

- McCann IR, Stark JC. 1993. Method and apparatus for variable application of irrigation water and chemicals. US Patent 5,246,164, September 21, 1993.

- Camp CR, Sadler EJ. 1994. Center pivot irrigation system for site-specific water and nutrient management. ASAE Pap. 94-1586, ASAE, St. Joseph, MI. [CrossRef]

- Yeom J, Jung J, Chang A, Maeda M, Landivar J. 2018. Automated open cotton boll detection for yield estimation using unmanned aircraft vehicle (UAV) data. Remote Sensing. 10(12):1895. [CrossRef]

- Sun S, Li C, Paterson AH, Jiang Y, Xu R, Robertson JS, Snider JL, Chee PW. 2018. In-field high throughput phenotyping and cotton plant growth analysis using LIDAR. Front. Plant Sci., 9. [CrossRef]

- Großkinsky DK, Pieruschka R, Svensgaard J, Rascher U, Christensen S, Schurr U, et al. 2015. Phenotyping in the fields: dissecting the genetics of quantitative traits and digital farming. New Phytol. 207, pp. 950–52. [CrossRef]

- Wu, J. Wu, J., Wen, S., Lan, Y. et al. Estimation of cotton canopy parameters based on unmanned aerial vehicle (UAV) oblique photography. Plant Methods 18, 129 (2022). [CrossRef]

- Hardin IV RG, Huang Y, Poe R. Detecting plastic trash in a cotton field with a UAV. In Proceedings of the Beltwide Cotton Conferences, San Antonio, TX, USA, Jan. 3-5, 2018.

- Zhai Z, Chen X, Zhang R, Qiu F, Meng Q, Yang J, Wang H. 2022. Evaluation of residual plastic film pollution in pre-sowing cotton field using UAV imaging and semantic segmentation. Front. Plant Sci., 13, 91191. [CrossRef]

- Mandal DK, Mandal C, Venugopalan MV. 2005. Sustainability of cotton cultivation in shrink-swell soils in central India. Agricultural Systems, 84(1), pp. 55-75. [CrossRef]

- Fereres E, Goldhamer D. 1991. Plastic mulch increases cotton yield, reduces need for preseason irrigation. Calif Agr, 45(3), pp. 25-28. [CrossRef]

- Dong HZ, Mao SC, Zhang WF, Chen DH. 2014. The theory for optimization of cotton boll cultivation and its development. Sci. Agric. Sin., 47, pp. 441-451. (in Chinese with English abstract).

- Goebel TS, Lascano R. 2019. Rainwater use by cotton under subsurface drip and center pivot irrigation. Agric. Water Mangt. 215:1-7. [CrossRef]

- Okasha AM, Deraz N, Elmetwalli AH, Elsayed S, Falah MW, Farooque AA, Yaseen ZM. Effects of irrigation method and water flow rate on irrigation performance, Soil Salinity, Yield, and Water Productivity of Cauliflower. Agriculture. 2022; 12(8):1164. [CrossRef]

- Bell S, Koc AB, Maja JM, Payero J, Khalilian A, Marshall M. 2022. Development of an automated linear move fertigation system for cotton using active remote sensing. AgriEngineering, 4, pp. 320-334. [CrossRef]

- Ran J, Ren Y, Guo W, Hu C, Wang X. 2023. Aging characteristics of drip irrigation belt in Xinjiang cotton fields and their effects on its recovery and recycling. Sci Rep 13, 16948 (2023). [CrossRef]

- Liang J. 2015. Xinjiang integration of water and fertilizer technology application present situation and the development countermeasures. Xinjiang Agric. Reclam. Technol., 38 (1), pp. 38-40.

- Certi-PIK. (accessed on November 4, 2023). Available online: https://certipik.com/2017/10/23/a-look-at-the-history-of-cotton-pickers-and-the-advancement-of-cotton-harvester-parts/.

- Bennett JMcL, Woodhouse NP, Keller T, Jensen TA, Antille DL. 2015. Advances in cotton harvesting technology: a review and implications for the John Deere round baler cotton picker. J. Cotton Sci, 19, pp. 225-249.

- EOA. (accessed on November 4, 2023). Available online: https://encyclopediaofarkansas.net/entries/john-daniel-rust-2272/.

- Barnes E, Morgan G, Hake K, Devine J, Kurtz R, Ibendahl G, Sharda A, Rains G, Snider J, Maja JM, et al. Opportunities for robotic systems and automation in cotton production. AgriEngineering. 2021; 3(2):339-362. [CrossRef]

- Alish-o‘g‘li MK, Khusanovna MZ. 2022. Research cotton mechanization in Asian countries. JournalNX, 8(3), pp. 22-30. Available online: https://oarepo.org/index.php/oa/article/view/598/593. [CrossRef]

- Lamm RD, Slaughter DC, Gilles DK. 2002. Precision weed control system for cotton. Trans. ASAE, 45(1), pp. 231-238. [CrossRef]

- Cotton Australia. Organic Cotton. (N.d.). (accessed on November 4, 2023). Available online: https://cottonaustralia.com.au/organic-cotton.

- Khadi BM. 2022. High density planting system–next revolution in cotton farming in India. World Cotton Research Conference 7, Cairo, Egypt, October 5, 2022. 2022. (accessed on November 4, 2023). Available online: https://www.atpbr.com/doc/webinar/Webinar-19-PPT.pdf.

- Farooq O, Mubeen K, Khan AA, Ahmad S, 2020. Modern concepts and techniques for better cotton production. In: Cotton Production and Uses. S Ahmad, M Hasanuzzaman (Eds.). Springer, Singapore. [CrossRef]

- Krause U, Koch HJ, Maerlaender B. 2009. Soil properties effecting yield formation in sugar beet under ridge and flat cultivation. Eur J Agron 31(1):20–28. [CrossRef]

- Bayer Group. 2019. Optimum cotton planting conditions and seed placement. 2019. Available online: https://www.cropscience.bayer.us/articles/dad/optimum-cotton-planting-conditions-and-seed-placement (accessed on 26 January 2024).

- Silvertooth JC. 2000. Planting methods and soil temperature. Arizona Cotton Comments. Available online: https://ag.arizona.edu/crop/cotton/comments/jan2000cc.html (accessed on 26 January 2024).

- Cotton Farming. 2015. Want to save money? Plant on flat beds. Available online: https://www.cottonfarming.com/special-report/want-to-save-money-plant-on-flat-beds/ (accessed on 26 January 2024).

- Ahmad N, Arshad M, Shahid MA. 2009. Bed-furrow system to replace conventional flood irrigation in Pakistan. In: Proceedings of 59 IEC meeting and 20 ICID conference held at New Delhi, India, pp 6–11.

- Iftikhar T, Babar LK, Zahoor S, Khan NG. 2010. Impact of land pattern and hydrological properties of soil on cotton yield. Pak J Bot 42:3023–3028.

- Sayre KD. 2000. Effects of tillage, crop residue retention and nitrogen management on the performance of bed-planted, furrow irrigated spring wheat in northwest Mexico. Presented at the 15th conference of the international soil tillage research organization, 2–7 July 2000, Fort Worth, TX. 2–7 July.

- Hobbs PR, Gupta RK. 2003. Resource conserving technologies for wheat in rice–wheat systems. In: Ladha JK, Hill J, Gupta RK, Duxbury J, Buresh RJ (eds). Improving the productivity and sustainability of rice–wheat systems: issues and impact, vol. 65, paper 7, ASA special publications. ASA, Madison, WI, pp 149–171.

- Kumar N, Upadhyay G, Choudhary S, Patel B, Naresh S, Chhokar RS, Gill SC. 2023. Resource Conserving Mechanization Technologies for Dryland Agriculture. In: Naorem, A., Machiwal, D. (eds.). Enhancing resilience of dryland agriculture under changing climate. Springer, Singapore. [CrossRef]

- JPlovesCOTTON LLC. N.d. Available online: https://hundredpercentcotton.com/cotton/cotton-101-planting/ (accessed on 26 January 2024).

- Boquet DJ. 2005. Cotton in ultra- narrow row spacing: plant density and nitrogen fertilizer rates. Agron J 97:279–287. [CrossRef]

- Jahedi MB, Vazin F, Ramezani MR. 2013. Effect of row spacing on the yield of cotton cultivars. Cer Agron Moldova 46:31–38. [CrossRef]

- Cropwatch. N.d. Ridge Plant. Available online: https://cropwatch.unl.edu/tillage/ridge (accessed on 27 January 2024).

- Gürsoy S, Sessiz A, Karademir E, Karademir C, Kolay B, Urgun M, Malhi SS. 2011. Effects of ridge and conventional tillage systems on soil properties and cotton growth. Int J Plant Prod 5 (3):227–236. [CrossRef]

- Hussain T, Jehanzeb, Tariq M, Siddiqui BN. 2003. Effect of different irrigation levels on the yield and yield components of cotton (Gossypium hirsutum L.) under two sowing methods. J Biol Sci 3:655–659.

- Ali M, Ali L, Sattar M, Ali MA (2012) Response of seed cotton yield to various plant populations and planting methods. J Agric Res 48:134–137.

- Ahmad S, Iqbal M, Muhammad T, Mehmood A, Ahmad S, Hasanuzzaman M. 2018. Cotton productivity enhanced through transplanting and early sowing. Acta Sci Biol Sci 40, e34610. [CrossRef]

- Kumar R, Sharma SK, Yadav S. 2015. Effect of transplanting date on growth and yield of Bt cotton. Indian Journal of Agricultural Sciences, 85(11), 1453–1457.

- Li X, Zhang Y, Wang L. 2016. Effects of transplanting date on cotton yield and quality. Field Crops Research, 190, 29–36.

- Yan Y, Liang C, Hou Z. 2018. Influence of transplanting date on cotton yield and fiber quality. Journal of Cotton Research, 1(1), 1–8.

- Kong X, Li X, Lu H, Li Z, Xu S, Li W, Zhang Y, Zhang H, Dong H. 2018. Monoseeding improves stand establishment through regulation of apical hook formation and hypocotyl elongation in cotton. Field Crops Research, 222:50-58. [CrossRef]

- Lv Q, Chi B, He N, Zhang D, Dai J, Zhang Y, Dong H. 2023. Cotton-based rotation, intercropping, and alternate intercropping increase yields by improving root–shoot relations. Agronomy. 13(2):413. [CrossRef]

- Aydin I, Arslan S. 2018. Mechanical properties of cotton shoots for topping. Industrial Crops and Products., 112:396-401. [CrossRef]

- Wu Y, Tang J, Tian J, Du M, Gou L, Zhang Y, Zhang W. 2023. Different concentrations of chemical topping agents affect cotton yield and quality by regulating plant architecture. Agronomy, 13(7):1741. [CrossRef]

- Dai J, Li W, Zhang D, Tang W, Li Z, Lu H, Kong X, Luo Z, Xu S, Xin C, Dong H. 2017. Competitive yield and economic benefits of cotton achieved through a combination of extensive pruning and a reduced nitrogen rate at high plant density. Field Crops Res., 209, 65–72. [CrossRef]

- Byrd S. 2019. Plant growth regulators in cotton. Available online: https://extension.okstate.edu/fact-sheets/plant-growth-regulators-in-cotton.html (accessed on 28 January 2024).

- Llandres AL, Almohamad R, Brévault T, Renou A, Téréta I, Jean J, Goebel F-R. 2018. Plant training for induced defense against insect pests: a promising tool for integrated pest management in cotton. Pest Manag Sci., 74(9), 2004-2012. [CrossRef]

- Xu S, Zuo W, Chen M, Sui L, Dong H, Jiu, X, Zhang W. 2017. Effect of drip irrigation amount on the agronomic traits and yield of cotton grown with a chemical topping in northern Xinjiang, China. Cotton Sci., 29, 345–355.

- Zhao Q, Zhou C, Zhang J, Li S, Yun Y, Tian X. 2011. Effect of Chemical Detopping on the Canopy and Yield of Cotton (Gossypium hirsutum) in South Xinjiang. Cotton Sci., 23, 329–333.

- Mishra PK, Sharma A, Prakash A. 2023. Current research and development in cotton harvesters: A review with application to Indian cotton production systems. Heliyon, 9: 1-16. [CrossRef]

- Vistro R, Chachar QI, Charchar SD, Charchar NA, Laghari A, Vitro S, Kumbhar I. 2017. Impact of plant growth regulators on the growth and yield of cotton. Intl. J. Agric. Tech, 13(3), 353-362.

- Abro GH, Syed TS, Unar MA, Zhang MS. 2004. Effect of application of plant growth regulator and micronutrients on insect pest infestation and yield components of cotton. J. of Entomology, 1(1):12-16. [CrossRef]

- Chen L, Hou J, Hu XL, Zhang JZ, Wang HD. 2022. Environmental Behaviors of Plant Growth Regulators in Soil: A Review. 43(1):11-25. [CrossRef]

- Paudel KP, Lohr L, Cabrera, M. 2005. Residue management systems and their implications for production efficiency. Renewable Agriculture and Food Systems, 21(2):124-133. [CrossRef]

- Gencsoylu, I. 2009. Effect of plant growth regulators on agronomic characteristics, lint quality, pests, and predators in Cotton. J of Plant Growth Regulator 28:147-153. [CrossRef]

- Tian JS, Zhang XY, Zhang WF, Li JF, Yang YL, Heng YD, et al. 2018. Fiber damage of machine-harvested cotton before ginning and after lint cleaning. J. Intgr. Agric. 17, 1120–1127. [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).