1. Introduction

Mayonnaise is one of the oldest and most widely used acidic condiments in the world, which is used to enhance the texture and flavor of food. It is a classic oil-in-water (O/W) colloidal structure containing 65%–80% oil, typically formed by slowly mixing egg yolk (EY) with oil along with vinegar for pH adjustment and other ingredients such as salt, sugar, and mustard [

1].

EY functions as an emulsifier in mayonnaise, containing low-density lipoprotein, high-density lipoprotein, phospholipids, and unbound proteins, which help in forming granular micro-oil particles and preventing coagulation, thereby imparting the desired texture [

2,

3]. Although EY is an excellent emulsifier with strong emulsifying properties, it has disadvantages such as high cholesterol content, potential contamination with

Salmonella, and high cost. Furthermore, the global trend toward health, environmental preservation, and animal ethics, along with the growing vegan market, highlights the need for plant-based emulsifiers [

4]. Consequently, research is actively underway to explore and develop emulsifiers that can replace EY in mayonnaise production [

5,

6]. Constant research efforts are being done to develop mayonnaise with plant-based ingredients such as wheat protein mayonnaise [

7], soy milk mayonnaise [

8], pea mayonnaise [

9], chickpea, faba bean, lentil mayonnaise [

10], aquafaba mayonnaise [

11], and clover sprouts mayonnaise [

12].

Soybeans, comprising 40% protein, 15% monosaccharides, 15% dietary fiber, 20% oil, and 10% other components, serve as a high-quality protein source with low cholesterol and lactose levels, making them suitable as a substitute for animal ingredients [

13]. The principal storage proteins in soy, glycinin and β-conglycinin, account for >80% of its protein content, with β-conglycinin known to have remarkable structural stability at oil–water interfaces [

14]. However, soybeans have a drawback of high-fat content (20%). It has been reported that soy milk made from full-fat soybean powder presents challenges in completely substituting EY in mayonnaise production [

8]. Soybean powder has been indicated to have lower emulsifying qualities than soy protein isolates [

15]. Studies have also shown that the removal of fat from mustard, soy, and flaxseed powders increases water and oil absorption capacity, foamability, and emulsifying properties, thereby enhancing the functional characteristics of the powders [

16]. Fat removal appears to be one strategy to enhance the functional qualities of soybean powder for use as an emulsifying agent.

The primary method for removing fats from soybeans is organic solvent extraction, typically using hexane. Although this method is efficient in oil extraction and solubility, concerns about residual hexane and high flammability raise environmental and safety issues. Supercritical fluid extraction using carbon dioxide as a solvent is harmless to humans and facilitates the separation of solvent and solute, making it an environmentally friendly and safe alternative to traditional organic solvent extraction [

17,

18]. Studies have demonstrated that supercritical processing can produce soy protein with low denaturation and superior nutritional, functional, and biodegradable qualities (49%–50% protein concentration) [

19]. Although defatted soybean powder processed with supercritical treatment has been established to have better functional properties in terms of moisture and oil absorption, emulsification, and foaming than hexane-treated defatted soybean powder [

20], research on the quality characteristics of mayonnaise made with supercritically treated defatted soybean powder is lacking.

The aim of this study was to make vegan mayonnaise using soybean powder. Mayonnaise was prepared using full-fat control soybean flour (CSF), defatted soybean flour treated with supercritical fluid (DSF-SC), and EY. Their emulsifying and qualitative attributes were examined. This study aimed to assess the potential for quality enhancement of vegan mayonnaise using supercritical treatment.

2. Materials and Methods

2.1. Materials and Chemicals

Soybean flour (Always Green Co., Icheon, Korea), soybean oil (Ottogi Co., Seoul, Korea), EY (Edentown Co., Ltd., Incheon, Korea), white sugar (CJ, Seoul, Korea), sea salt (Sinsong Co., Seoul, Korea), mustard powder (World Spice Co., Ltd., Turkey), and brewed vinegar (Ottogi Co., Seoul, Korea) were purchased. All other chemicals used were analytical grade reagents.

2.2. Supercritical Carbon Dioxide (SC-CO2) Processing

For the defatting of soybean flour, a SC-CO2extraction system (Ilshin Autoclave Co. Ltd., Daejeon, Korea) was used. The system consists of an extraction vessel, separation vessel, high-pressure pump, and a CO2 storage tank. Five hundred grams of soybean flour was added in the extraction vessel and connected to the extractor. The extraction was conducted at 45°C and 40 MPa for 10 h, after which the supercritical CO2 was separated into gaseous CO2 and oil through a micrometering valve in the separation vessel. The defatted soybean flour was kept at −18°C for experimental use.

2.3. Proximate Composition Analysis

The proximate composition of the CSF, DSF-SC, and EY was analyzed according to the AOAC method [

21]. Moisture content was ascertained using atmospheric pressure drying at 105°C, and ash was evaluated by direct ashing at 550°C. The auto Kjeldahl method was utilized for crude protein, while Soxhlet extraction method was used for assessing crude fat.

2.4. Plant-Based Mayonnaise Preparation

The recipe for mayonnaise was displayed in

Table S1. For the preparation, CSF or DSF-SC was added to purified water and mixed at 400 rpm on a hot plate at 90°C for 30 min, followed by the addition of salt, mustard powder, and sugar and stirring until crystals dissolved using a direct driven digital stirrer (PL-SS41D, Poonglim, Korea) at 700 rpm. For EY, salt, mustard powder, and sugar were added to the purified water and stirred at 700rpm. The stirred sample was emulsified at 1000 rpm by gradually adding soybean oil, followed by brewed vinegar. Then secondary emulsification was performed at 2000 rpm to prepare the mayonnaise.

2.5. Color and pH Measurements

The color of the mayonnaise was measured using a colorimeter (Minolta CT-310, Osaka, Japan) calibrated with a standard white plate (L = 93.6, a = 0.31, b = 0.32). Each sample was placed in a petri dish (60 × 15 mm; SPL Life Science Co., Pochen, Korea) and measured three or more times, with results provided as L (lightness), a (−: greenness; +: redness), and b (−: blueness; +: yellowness) values.

The pH was measured by adding 20 g of plant-based mayonnaise to a 50 mL conical tube (SPL Life Science Co., Pochen, Korea) and measured three or more times with a pH meter (Model 735P, Istek, Seoul, Korea), with the average value reported.

2.6. Confocal Laser Scanning Microscope

The microstructure of the plant-based mayonnaise was compared using a confocal laser scanning microscope (CLSM; FV1000 MPE, Olympus America, Inc., Melville, NY). Each sample (1 g) was stained with 10μL of 0.1% Nile red and 10μL of 0.1% Nile blue. Activation of Nile blue and Nile red occurred at the Ar laser 488 nm and the He–Ne laser 633 nm, respectively.

2.7. Particle Size Analysis

The particle size was measured using a laser-based particle size analyzer, Mastersizer 3000 (Malvern Instruments Ltd., Malvern, Worcestershire, UK), following the method of Metri-Ojeda et al. [

22]. The refractive index of the emulsion oil droplets was 1.456 and that of the continuous phase was 1.33. The droplet size was expressed as the volume mean diameter (d

4,3, μm) and calculated as follows:

Equation (1)

where n

i is the number of droplets with the same diameter and d

i is the particle size.

2.8. Measurement of Physical and Thermal Stability

The emulsifying capacity of the plant-based mayonnaise was determined by centrifuging 25 g of the sample in a 50 mL conical tube at 3000 ×g for 30 min using a centrifuge (Hanil, FLETAS) and expressed as a percentage of the emulsified height over the total height.

Emulsion stability (thermal stability) was assessed by shaking the plant-based mayonnaise in a shaking water bath (Baths WSB shaking water bath) at 185 rpm for 1 h at 90°C, followed by centrifugation at 3000 ×g for 30 min.

2.9. Viscosity Measurement

The viscosity of the plant-based mayonnaise was determined using a Brookfield viscometer (DV Ⅱ+, Brookfield engineering labs, MA, USA). The spindle used was LV4, and the spindle speed was 20 rpm. The experiment was performed for three or more times.

2.10. Texture Analysis

The texture of the plant-based mayonnaise was measured using a texture analyzer (TA-XT Express, England) with a 20-mm-diameter cylinder probe in a two-bite compression test. The parameters were as follows: pretest speed 1.0 (mm/s), test speed 1.0 (mm/s), posttest speed 1.0 (mm/s), test distance 3.0 (mm), and trigger force 3.0 (g). The force-distance curve obtained was analyzed using Texture Expert software. The experiment was performed for three or more times.

2.11. Sensory Evaluation

Sensory evaluation of the plant-based mayonnaise samples was conducted with 20 undergraduate and graduate students from Gyeongsang National University. Participants were given mayonnaise samples along with plain crackers (IVY, Haitai Co., Ltd., Seoul, Korea). Evaluation criteria included appearance, aroma, taste, texture, and overall satisfaction, rated on a nine-point scale (1 = “dislike extremely,” 9 = “like extremely”). Samples were assigned random three-digit numbers and tasted in random order. Water was provided between samples for accurate taste evaluation.

2.12. Statistical Analysis

Experimental data were presented as mean ± standard deviation from three or more repeated trials. Data were analyzed using SPSS 12.0 (SPSS, Inc., Chicago, IL, USA) and subjected to analysis of variance with p < 0.05 regarded as statistical significant, followed by Duncan’s multiple range test to verify significance.

3. Results and Discussion

3.1. Proximate Composition Analysis

The moisture, ash, crude protein, and crude fat contents of each emulsifier used in the mayonnaise were listed in

Table S2. The moisture content is a critical factor for the long-term stability of the product. The moisture contents of the emulsifiers were found to be CSF (7.41% ± 0.65%), DSF-SC (3.30% ± 0.08%), and EY (3.48% ± 0.24%), with DSF-SC showing a 55.47% decrease compared to CSF. It is considered safe to store with moisture content below 12% [

23]. The moisture content of flaxseed and hexane-defatted flaxseed were found to be 7.94% ± 0.33% and 9.37% ± 0.40%, respectively, suggesting an increase in moisture with hexane treatment [

24]. Supercritical carbon dioxide defatting appears to be a technique that can reduce the moisture content of powders. Ash content, indicating the mineral content per emulsifier, was noted for CSF (5.41% ± 0.29%), DSF-SC (6.26% ± 0.14%), and EY (3.94% ± 0.21%).

The crude fat content of the emulsifiers was 18.95% ± 0.95% for CSF, 0.51% ± 0.37% for DSF-SC, and 54.27% ± 0.56% for EY samples, with DSF-SC showing approximately 97.31% decrease compared to CSF. The crude fat in mustard, flaxseed, and soybean seed meal powders was reported to be 7.26% ± 0.16%, 4.77% ± 0.35%, and 1.20% ± 0.42%, respectively [

16]. Supercritical carbon dioxide treatment emerges to be an effective technology for defatting soybean powder. However, the crude protein content in soybean powder rose from CSF (38.66% ± 0.66%) to DSF-SC (48.93% ± 0.82%) by approximately 26.56% after supercritical carbon dioxide treatment. The increase in protein content in defatted pumpkin seeds has been previously reported due to the relative increase in other components following fat removal [

25]. It has been reported that the surface of the soybean oil body is centered around triacylglycerols, surrounded by a phospholipid layer, facilitating the creation of an O/W emulsion system without any emulsifier or high-pressure homogenization [

26]. The high crude protein and low crude fat content of DSF-SC are anticipated to have a positive impact on emulsification and stability during mayonnaise production.

3.2. Color and pH of Mayonnaise

The findings of the color measurement of mayonnaise were displayed in

Table 1. The L* values, which indicates brightness, were measured for mayonnaises containing CSF (73.2–76.55), DSF-SC (79.43–81.96), and EY (77.53–83.22), with DSF-SC mayonnaise showing L* values close to those of EY mayonnaise. The L* values of the emulsion could be impacted by the amount of emulsifier supplied, and it has been observed that as the size of oil droplets reduces, light scattering rises, causing color of the emulsion to change from gray to bright white [

27]. This suggests that the degree of emulsification in mayonnaise affects the L* value. As the amount of each emulsifier (in CSF, DSF-SC, EY mayonnaise) increased, the a* and b* values tended to rise (

p < 0.05). Mayonnaise prepared with the same amount of emulsifiers (in CSF, DSF-SC, EY samples) exhibited significantly higher a* and b* values of CSF mayonnaise (

p < 0.05). These colorimetric findings revealed that the natural color of the emulsifier affects the color of the mayonnaise [

28].

The pH of mayonnaise is a crucial parameter that influences its shelf life, viscosity, and elasticity by reducing microbial risks [

29]. Generally, the pH of mayonnaise is thought to be in the range of 3.0–4.5 [

30]. The pH measurement results for mayonnaise were shown in

Table S3. CSF mayonnaise (3.82–4.34), DSF-SC mayonnaise (3.61–4.16), and EY mayonnaise (4.17–4.67) exhibited an increasing trend in pH values as the amount of emulsifier increased (

p < 0.05). Mayonnaise made with DSF-SC showed a lower pH than that made with CSF. The lower pH of DSF-SC mayonnaise compared with CSF mayonnaise suggested potential improvements in the safety and stability of mayonnaise.

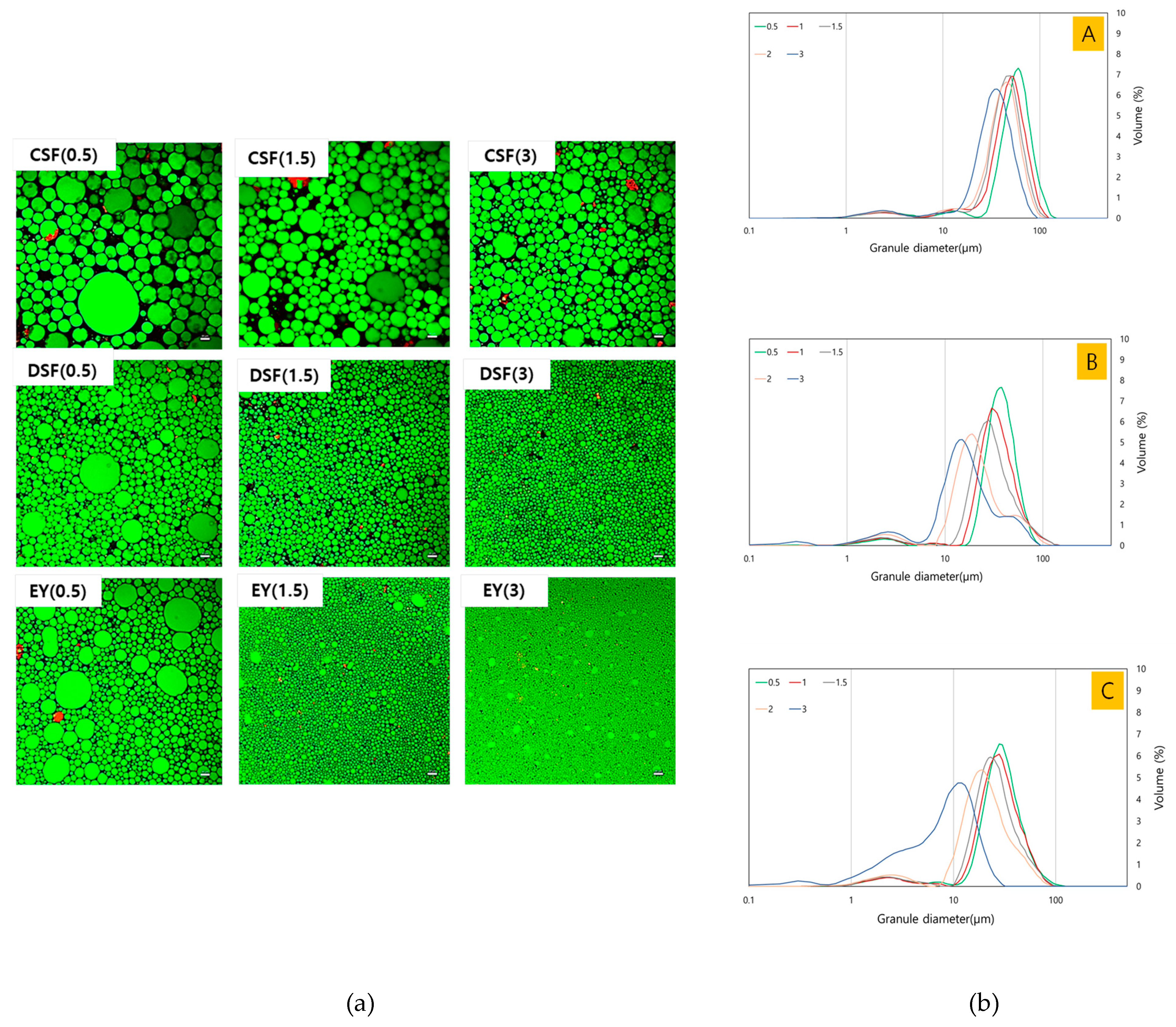

3.3. Microstructures of Mayonnaise

Mayonnaise is an O/W emulsion, typically comprising 60%–70% oil by total volume. The green fluorescence on the surface of the dispersed droplets indicates protein adsorption, and the red fluorescence in the discontinuous phase suggests the creation of an O/W emulsion [

31]. The microstructure of mayonnaise is determined by various parameters such as the type and amount of emulsifier used, as well as the manufacturing process, which affect factors such as the size of fat particles and moisture in the microstructure [

32]. Microstructural observations of mayonnaise were displayed in

Figure 1. Both EY and plant-based mayonnaise exhibited finely dispersed spherical oil droplets in the aqueous medium. These findings suggested that soybean powder could function as an active filler in emulsion formation, surrounding the oil droplets and creating a gel network. The small droplet size in mayonnaise implied higher stability of the emulsifier [

8]. Mayonnaise prepared with CSF and DSF-SC displayed comparatively larger oil droplets than EY mayonnaise. However, at the same concentration of emulsifier, mayonnaise made with DSF-SC showed oil droplet sizes closer to those of EY mayonnaise, and a trend was observed where the diameter of the oil droplets decreased and became more uniform as the amount of emulsifier increased. The increase in the emulsifier stabilized the oil–water interface area and generated smaller droplets.

Changes in the droplet size observed through CLSM were consistent with the droplet size distribution and d

4,3 results. The droplet size distribution and d

4,3 of CSF, DSF-SC, and EY mayonnaises were shown in

Figure 1. All the prepared mayonnaises showed a monomodal distribution. The droplet size distribution for all mayonnaises prepared with CSF, DSF-SC, and EY showed a trend of decreasing peak height and widening peak width as the concentration of the emulsifier rose. This result is similar to studies, in which an increase in the amount of insoluble soy peptide aggregates led to lower peak heights and wider peak widths in droplet size distribution [

33]. The d

4,3 of mayonnaise samples containing CSF (33.01–53.35), DSF-SC (12.02–35.84), and EY (8.3–28.98) considerably decreased as the concentration of emulsifier increased (

p < 0.05) (

Table S4). The d

4,3 of DSF-SC mayonnaise showed droplet sizes closer to d

4,3 value of EY mayonnaise than that of CSF mayonnaise. With the same emulsifier concentration, DSF-SC mayonnaise had smaller d

4,3 values than CSF mayonnaise, indicating that DSF-SC effectively adsorbed at the oil–water interface, aiding in the creation of stable droplets. DSF-SC is anticipated to be effective in forming soy protein gel networks and is expected to substitute EY in the production of plant-based mayonnaise [

34].

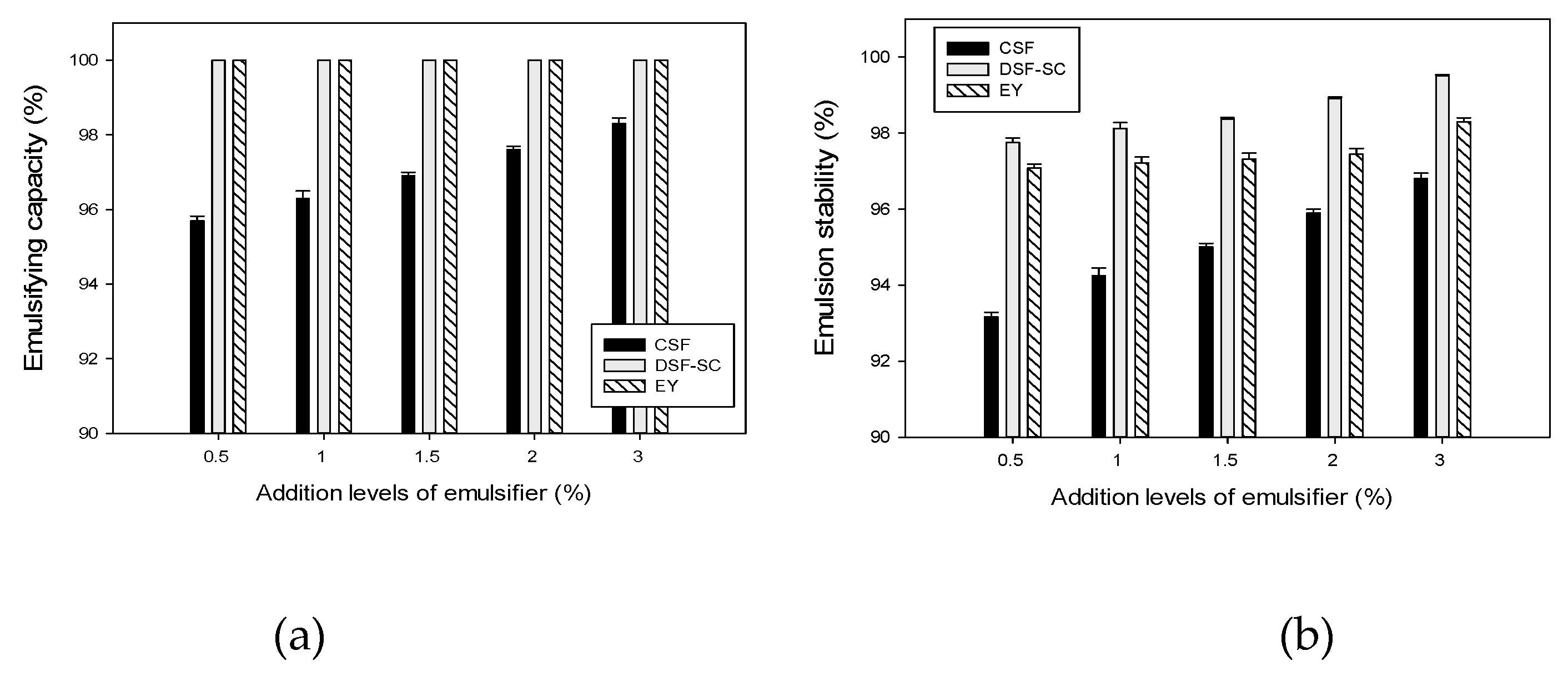

3.4. Emulsion Capacity and Stability

The emulsion capability and stability of plant-based mayonnaise prepared with CSF and DSF-SC and egg-based mayonnaise prepared with EY were demonstrated in

Figure 2. Emulsion capacity refers to phase separation due to the density difference between the dispersed and continuous phases, which causes the rise of oil globules [

35]. Maintaining the quality of emulsified foods like mayonnaise necessitates a high emulsion capacity, which is impacted by variables including applied pressure, vibrations, temperature variations, and the kind and concentration of emulsifiers [

11]. The emulsion capacity tests showed that mayonnaise made with DSF-SC and EY had an emulsion capacity of 100%, indicating stable emulsification, whereas mayonnaise made with CSF showed a capacity of about 95.7%–98.3%. Similar findings of no phase separation were reported in mayonnaise studies using chickpea protein, faba bean protein, and lentil protein emulsifiers [

36]. In addition, a similar increase in emulsion stability was observed in mustard, soy, and flaxseed emulsions after defatting, attributed to the high oil absorption capacity of the defatted meal [

16]. Emulsifiers such as proteins and polysaccharides increase viscosity by creating strong and adequate intermolecular interactions between oil droplets, thereby reducing the movement of oil droplets and eventually improving stability [

37]. Thus, the increased protein content in DSF-SC appears to enhance the oil absorption capacity of DSF-SC and consequently stabilized the mayonnaise.

In O/W emulsion systems such as mayonnaise, temperature increase can disrupt the structure, resulting in oil exudation, thereby lowering emulsion stability [

38]. The emulsion stability of mayonnaise made with CSF was 93.1%–96.8% that of DSF-SC mayonnaise was 97.75%–99.51%, and the emulsion stability of EY mayonnaise was 97.08%–98.3%, showing a decrease in all mayonnaise stability compared to their emulsion capacity. An increasing trend in emulsion stability was observed with increased content of emulsifiers, indicating that the size of fat globules in mayonnaise directly impacted its stability. Increased oil droplet diameter can cause defects like phase separation and sedimentation, which can be separated by gravity [

39]. Increased addition of emulsifier appears to promote protein adsorption on oil droplets, efficiently preventing emulsion coagulation. Among the three types, mayonnaise with DSF-SC showed the highest emulsion stability at the same emulsifier concentration. DSF-SC, which has a larger protein concentration than CSF, appears to exhibit higher hydrophobicity, improving adsorption capacity at the droplet surface and thereby boosting emulsion capability. In clover protein mayonnaise, higher emulsion capacity and stability were reported compared to EY mayonnaise, and increasing clover protein substitution was found to enhance the stability of the mayonnaise [

12]. Similarly, The mayonnaise containing wheat germ protein exhibited higher emulsion capacity and stability than the control group, consistent with the findings of this study [

40].

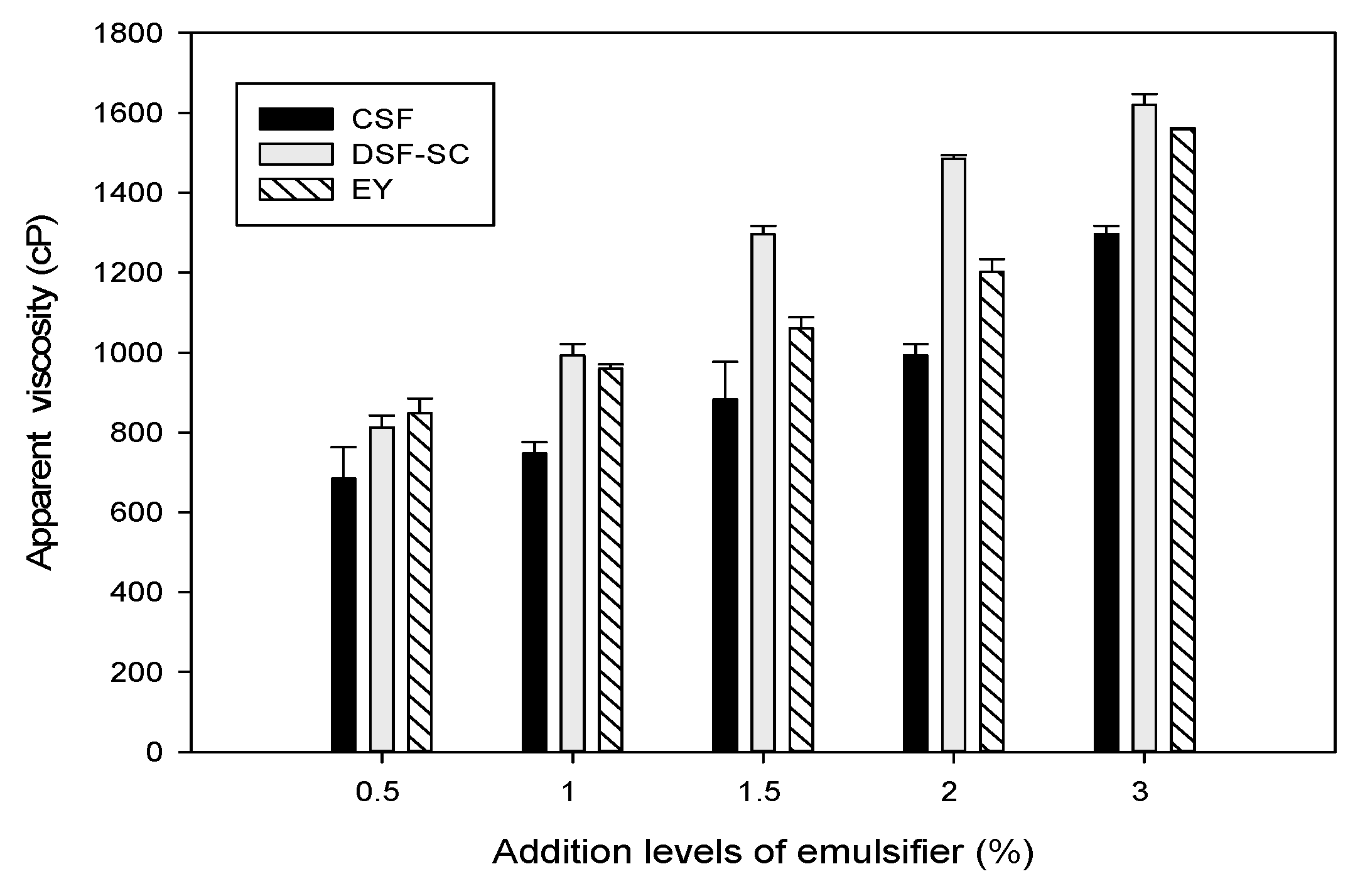

3.5. Texture and Viscosity

The texture parameters of the mayonnaise are presented in

Table 2. Hardness represents the resistance of a material to compression, similar to the force needed to compress food between the molars. Gumminess is generally related to the product’s elasticity or “springiness” and reflects the characteristics during chewing and swallowing [

41]. The cohesiveness of mayonnaise, which indicates the internal binding strength of a food matrix and the degree to which it can deform before breaking, was found to be independent of the content of emulsifier. Similar findings have been reported where the oil-to-aquafaba ratio in mayonnaise production was unrelated to cohesiveness [

42]. As the amount of emulsifier in all mayonnaises increased, hardness and gumminess significantly increased, with the mayonnaise made with CSF exhibiting the lowest values at the same emulsifier concentration. At 0.5% and 1% emulsifier addition, the hardness and gumminess of EY mayonnaise were higher than those of DSF-SC, but at 2% and 3%, DSF-SC mayonnaise showed higher values than EY mayonnaise. This trend was comparable to the viscosity measurements (

Figure 3). The viscosity results showed that after adding 1.5% emulsifier, DSF-SC mayonnaise exhibited the highest values. Earlier studies have reported that changes in the content of protein, emulsifier, or oil in mayonnaise can influence its hardness, and the viscosity of mayonnaise can partially impact the degree of hardness and gumminess [

5]. The increased viscosity of DSF-SC mayonnaise, with a higher total protein content than CSF mayonnaise, appears to influence its hardness and gumminess. Emulsifiers, by their nature, can increase the stability of O/W emulsion systems by improving the interactions within the structure and decreasing fluidity [

43]. When >2% emulsifier is added to mayonnaise, the viscosity was increased in DSF-SC mayonnaise and formed a stable O/W emulsion, with cohesiveness being reduced than that of EY mayonnaise. Thus, DSF-SC might function as an efficient emulsifier through potent electrostatic interactions.

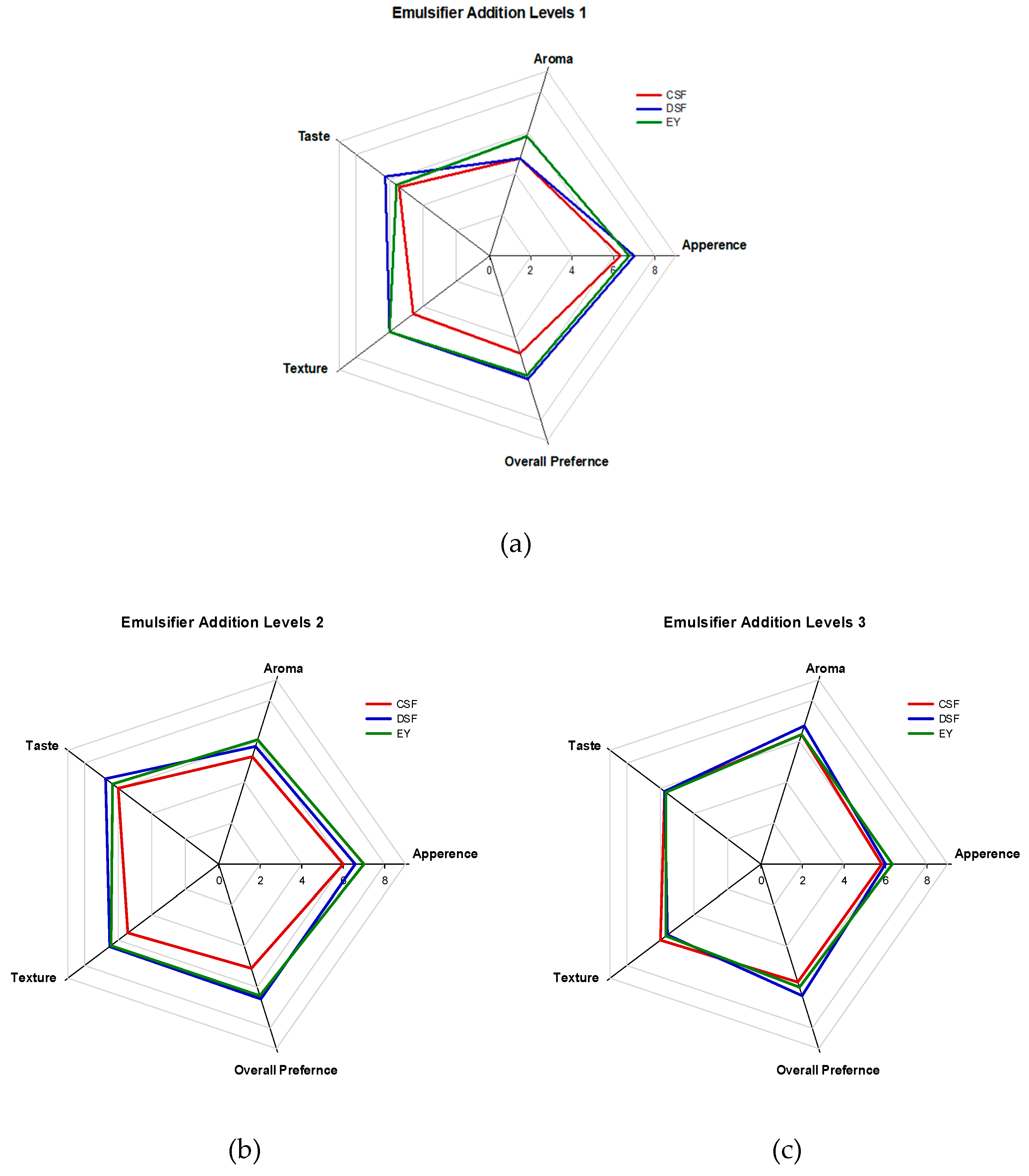

3.6. Sensory Evaluation

For ready-to-eat products such as mayonnaise, sensory acceptability is one of the most crucial factors. The most significant sensory characteristic for food emulsions is overall appearance, which is impacted by the combined effects of texture and color [44]. The sensory evaluation results for mayonnaise samples prepared with different emulsifiers and their concentrations were shown in

Figure 4. The appearance preference for plant-based mayonnaises prepared with CSF and DSF-SC showed a decreasing trend with an increase in the amount of emulsifier, whereas the aroma preference increased. In terms of taste and texture preference, mayonnaise with 2% DSF-SC concentration exhibited the highest values, whereas the addition of 3% DSF-SC negatively affected the taste and texture of the mayonnaise. In terms of overall preference, mayonnaise produced with DSF-SC and EY was rated higher than that made with CSF, with both receiving higher scores at 2% emulsifier addition. Therefore, the potential of DSF-SC as an EY substitute emulsifier in mayonnaise appears promising.

4. Conclusions

This study assesses the capacity of DSF-SC in improving the quality of plant-based mayonnaise and replacing animal-derived emulsifiers such as EY. Supercritical carbon dioxide treatment significantly reduced fat while increasing protein content in soybean powder. DSF-SC mayonnaise exhibited fat particle characteristics similar to EY mayonnaise and demonstrated smaller, more homogeneous fat particles than CSF mayonnaise with increasing emulsifier content, suggesting higher emulsification capability and stability. Furthermore, DSF-SC mayonnaise demonstrated higher firmness and viscosity values, suggesting its potential as an emulsifier in various food products. In sensory assessments, particularly at 2% emulsifier concentration, DSF-SC and EY mayonnaises were rated highly, with 2% DSF-SC mayonnaise receiving the highest overall preference. This study demonstrates the viability of DSF-SC as a plant-based emulsifier in vegan mayonnaise, contributing to food development that aligns with health, environment, and vegan market demands. It also offers a foundation for sustainable, plant-based food product development without sacrificing flavor or texture. Long-term storage stability experiments should be performed in the future to further clarify commercial applicability of DSF-SC.

Supplementary Materials

The following supporting information can be downloaded at the website of this paper posted on

Preprints.org. Table S1: Mayonnaise Recipes Varying Emulsifiers and Additive Amounts; Table S2: Comparison of Proximate Composition in CSF, DSF-SC and Egg yolk: Moisture, Crude Fat, Crude Fiber, and Crude Protein Content; Table S3: pH Measurement of Mayonnaise with Different Emulsifier Additions: CSF, DSF-SC, and EY; Table S4: Particle Size Analysis of Mayonnaise with Different Emulsifier Additions.

Author Contributions

Conceptualization, C.-Y.H, K.-Y. L, and S.-G.C.; methodology, C.-Y.H., K.-Y.L.; software, C.E.P.; validation, C.-Y.H, and S.-G.C.; formal analysis, C.-Y.H, and K.-Y.L; investigation, C.-Y.H..; resources, C.-Y.H., S.-G.C.; data curation, C.-Y.H, and K.-Y.L; writing—original draft preparation, C.-Y.H, K.-Y.L, and S.-G.C; writing—review and editing, C.-Y.H, K.-Y.L, and S.-G.C.; visualization, C.-Y.H., C.E.P and K.-Y.L. ; supervision, S.-G.C.; project administration, S.-G.C.; Funding acquisition, S.-G.C. All authors have read and agreed to the published version of the manuscript.

Funding

This research was supported by the Korea Basic Science Institute (National Research Facilities and Equipment Center; Grant No. 2022R1A6C101B724), funded by the Ministry of Education, Republic of Korea. Additionally, it received funding from the High Value-added Food Technology Development Program, supported by the Korea Institute of Planning and Evaluation for Technology in Food, Agriculture, and Forestry (IPET), Republic of Korea (Project No. 121011-03-2-HD020).

Data Availability Statement

Data is contained within the article.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Laca, A.; Sáenz, M.; Paredes, B.; Díaz, M. Rheological properties, stability and sensory evaluation of low-cholesterol mayonnaises prepared using egg yolk granules as emulsifying agent. J. Food Eng. 2010, 97, 243–252. [Google Scholar] [CrossRef]

- Moros, J.; Franco, J.; Gallegos, C. Rheological properties of cholesterol-reduced, yolk-stabilized mayonnaise. J. Am. Oil Chem. Soc. 2002, 79, 837–843. [Google Scholar] [CrossRef]

- Depree, J.; Savage, G. Physical and flavour stability of mayonnaise. Trends Food Sci. Technol. 2001, 12, 157–163. [Google Scholar] [CrossRef]

- Gumus, C.E.; Decker, E.A.; McClements, D.J. Impact of legume protein type and location on lipid oxidation in fish oil-in-water emulsions: Lentil, pea, and faba bean proteins. Food Res. Int. 2017, 100, 175–185. [Google Scholar] [CrossRef]

- Nikzade, V.; Tehrani, M.M.; Saadatmand-Tarzjan, M. Optimization of low-cholesterol–low-fat mayonnaise formulation: Effect of using soy milk and some stabilizer by a mixture design approach. Food Hydrocoll. 2012, 28, 344–352. [Google Scholar] [CrossRef]

- Smittle, R. Microbiological safety of mayonnaise, salad dressings, and sauces produced in the United States: a review. J. Food Prot. 2000, 63, 1144–1153. [Google Scholar] [CrossRef] [PubMed]

- Herald, T.J.; Abugoush, M.; Aramouni, F. Physical and sensory properties of egg yolk and egg yolk substitutes in a model mayonnaise system. J. Texture Stud. 2009, 40, 692–709. [Google Scholar] [CrossRef]

- Rahmati, K.; Mazaheri Tehrani, M.; Daneshvar, K. Soy milk as an emulsifier in mayonnaise: physico-chemical, stability and sensory evaluation. J. Food Sci. Technol. 2014, 51, 3341–3347. [Google Scholar] [CrossRef]

- Rudra, S.G.; Hanan, E.; Sagar, V.; Bhardwaj, R.; Basu, S.; Sharma, V. Manufacturing of mayonnaise with pea pod powder as a functional ingredient. J. Food Meas. Charact. 2020, 14, 2402–2413. [Google Scholar] [CrossRef]

- Armaforte, E.; Hopper, L.; Stevenson, G. Preliminary investigation on the effect of proteins of different leguminous species (Cicer arietinum, Vicia faba and Lens culinarius) on the texture and sensory properties of egg-free mayonnaise. Lwt 2021, 136, 110341. [Google Scholar] [CrossRef]

- 1Kim, J.; Kim, J.; Jeong, S.; Kim, M.; Park, S.; Kim, I.; Nam, I.; Park, J.; Moon, K.-D. The quality characteristics of plant-based garlic mayonnaise using chickpea aquafaba with different ultrasonic treatment time. Korean J. Food Preserv. 2022, 29, 381–394. [Google Scholar]

- Mirsadeghi Darabi, D.; Ariaii, P.; Safari, R.; Ahmadi, M. Effect of clover sprouts protein hydrolysates as an egg substitute on physicochemical and sensory properties of mayonnaise. Food Sci. Nutr. 2022, 10, 253–263. [Google Scholar] [CrossRef]

- Preece, K.; Hooshyar, N.; Zuidam, N. Whole soybean protein extraction processes: A review. Innov. Food Sci. Emerg. Technol. 2017, 43, 163–172. [Google Scholar] [CrossRef]

- Matsumura, Y.; Sirison, J.; Ishi, T.; Matsumiya, K. Soybean lipophilic proteins—Origin and functional properties as affected by interaction with storage proteins. Curr. Opin. Colloid Interface Sci. 2017, 28, 120–128. [Google Scholar] [CrossRef]

- MCWATTERS, K.H.; CHERRY, J.P. Emulsification, foaming and protein solubility properties of defatted soybean, peanut, field pea and pecan flours. J. Food Sci. 1977, 42, 1444–1447. [Google Scholar] [CrossRef]

- Rani, R.; Badwaik, L.S. Functional properties of oilseed cakes and defatted meals of mustard, soybean and flaxseed. Waste Biomass Valorization 2021, 1–9. [Google Scholar] [CrossRef]

- Sahena, F.; Zaidul, I.; Jinap, S.; Karim, A.; Abbas, K.; Norulaini, N.; Omar, A. Application of supercritical CO2 in lipid extraction–A review. J. Food Eng. 2009, 95, 240–253. [Google Scholar] [CrossRef]

- Lim, G.-B.; Lee, S.-Y.; Lee, E.-K.; Haam, S.-J.; Kim, W.-S. Separation of astaxanthin from red yeast Phaffia rhodozyma by supercritical carbon dioxide extraction. Biochem. Eng. J.

- Russin, T.A.; Boye, J.I.; Arcand, Y.; Rajamohamed, S.H. Alternative techniques for defatting soy: a practical review. Food Bioprocess Technol. 2011, 4, 200–223. [Google Scholar] [CrossRef]

- Kang, S.-W.; Rahman, M.S.; Kim, A.-N.; Lee, K.-Y.; Park, C.-Y.; Kerr, W.L.; Choi, S.-G. Comparative study of the quality characteristics of defatted soy flour treated by supercritical carbon dioxide and organic solvent. J. Food Sci. Technol. 2017, 54, 2485–2493. [Google Scholar] [CrossRef]

- Aoac. Association of official analytical chemist. In Official methods of analysis; AOAC Gaithersburg: MD, USA, 2000. [Google Scholar]

- Metri-Ojeda, J.; Ramírez-Rodrigues, M.; Rosas-Ordoñez, L.; Baigts-Allende, D. Development and Characterization of a Low-Fat Mayonnaise Salad Dressing Based on Arthrospira platensis Protein Concentrate and Sodium Alginate. Appl. Sci. 2022, 12, 7456. [Google Scholar] [CrossRef]

- Tirgar, M.; Silcock, P.; Carne, A.; Birch, E.J. Effect of extraction method on functional properties of flaxseed protein concentrates. Food Chem. 2017, 215, 417–424. [Google Scholar] [CrossRef] [PubMed]

- Rodríguez-Miranda, J.; Hernández-Santos, B.; Herman-Lara, E.; Vivar-Vera, M.A.; Carmona-García, R.; Gómez-Aldapa, C.A.; Martínez-Sánchez, C.E. Physicochemical and functional properties of whole and defatted meals from M exican (C ucurbita pepo) pumpkin seeds. Int. J. Food Sci. Technol. 2012, 47, 2297–2303. [Google Scholar] [CrossRef]

- Wang, W.; Wang, M.; Xu, C.; Liu, Z.; Gu, L.; Ma, J.; Jiang, L.; Jiang, Z.; Hou, J. Effects of soybean oil body as a milk fat substitute on ice cream: Physicochemical, sensory and digestive properties. Foods 2022, 11, 1504. [Google Scholar] [CrossRef] [PubMed]

- Worrasinchai, S.; Suphantharika, M.; Pinjai, S.; Jamnong, P. β-Glucan prepared from spent brewer’s yeast as a fat replacer in mayonnaise. Food Hydrocoll. 2006, 20, 68–78. [Google Scholar] [CrossRef]

- Flamminii, F.; Di Mattia, C.D.; Sacchetti, G.; Neri, L.; Mastrocola, D.; Pittia, P. Physical and sensory properties of mayonnaise enriched with encapsulated olive leaf phenolic extracts. Foods 2020, 9, 997. [Google Scholar] [CrossRef]

- Thakur, K.; Kapoor, S.; Kapoor, A.; Aggarwal, P.; Kumar, V.; Tyagi, S.K. Tomato seed oil enriched mayonnaise: structural, rheological, and biochemical characterization. J. Food Sci. Technol. 2023, 1–11. [Google Scholar] [CrossRef] [PubMed]

- Ma, Z.; Boye, J.I. Advances in the design and production of reduced-fat and reduced-cholesterol salad dressing and mayonnaise: a review. Food Bioprocess Technol. 2013, 6, 648–670. [Google Scholar] [CrossRef]

- Liu, X.; Guo, J.; Wan, Z.-L.; Liu, Y.-Y.; Ruan, Q.-J.; Yang, X.-Q. Wheat gluten-stabilized high internal phase emulsions as mayonnaise replacers. Food Hydrocoll. 2018, 77, 168–175. [Google Scholar] [CrossRef]

- Mun, S.; Kim, Y.-L.; Kang, C.-G.; Park, K.-H.; Shim, J.-Y.; Kim, Y.-R. Development of reduced-fat mayonnaise using 4αGTase-modified rice starch and xanthan gum. Int. J. Biol. Macromol. 2009, 44, 400–407. [Google Scholar] [CrossRef]

- Jing, X.; Cai, Y.; Liu, T.; Chen, B.; Zhao, Q.; Deng, X.; Zhao, M. Formation, texture, and stability of yolk-free mayonnaise: Effect of soy peptide aggregates concentration. Food Chem. 2023, 403, 134337. [Google Scholar] [CrossRef]

- Muttakin, S.; Kim, M.S.; Lee, D.-U. Tailoring physicochemical and sensorial properties of defatted soybean flour using jet-milling technology. Food Chem. 2015, 187, 106–111. [Google Scholar] [CrossRef] [PubMed]

- McClements, D.J. Biopolymers in food emulsions. In Modern Biopolymer Science; Elsevier: Amsterdam, The Netherlands; pp. 129–166.

- Alu’datt, M.H.; Rababah, T.; Alhamad, M.N.; Ereifej, K.; Gammoh, S.; Kubow, S.; Tawalbeh, D. Preparation of mayonnaise from extracted plant protein isolates of chickpea, broad bean and lupin flour: Chemical, physiochemical, nutritional and therapeutic properties. J. Food Sci. Technol. 2017, 54, 1395–1405. [Google Scholar] [CrossRef] [PubMed]

- Ladjal-Ettoumi, Y.; Boudries, H.; Chibane, M.; Romero, A. Pea, chickpea and lentil protein isolates: Physicochemical characterization and emulsifying properties. Food Biophys. 2016, 11, 43–51. [Google Scholar] [CrossRef]

- Huang, L.; Wang, T.; Han, Z.; Meng, Y.; Lu, X. Effect of egg yolk freezing on properties of mayonnaise. Food Hydrocoll. 2016, 56, 311–317. [Google Scholar] [CrossRef]

- McClements, D.J. Encapsulation, protection, and release of hydrophilic active components: Potential and limitations of colloidal delivery systems. Adv. Colloid Interface Sci. 2015, 219, 27–53. [Google Scholar] [CrossRef] [PubMed]

- Rahbari, M.; Aalami, M.; Maghsoudlou, Y.; Kashaninejad, M. Evaluation of physicochemical and sensory properties of mayonnaise containing wheat germ protein isolate and xanthan gum. Res. Innov. Food Sci. Technol. 2013, 2, 1–16. [Google Scholar]

- Chandra, M.; Shamasundar, B. Texture profile analysis and functional properties of gelatin from the skin of three species of fresh water fish. Int. J. Food Prop. 2015, 18, 572–584. [Google Scholar] [CrossRef]

- Raikos, V.; Hayes, H.; Ni, H. Aquafaba from commercially canned chickpeas as potential egg replacer for the development of vegan mayonnaise: Recipe optimisation and storage stability. Int. J. Food Sci. Technol. 2020, 55, 1935–1942. [Google Scholar] [CrossRef]

- Zhang, F.; Cai, X.; Ding, L.; Wang, S. Effect of pH, ionic strength, chitosan deacetylation on the stability and rheological properties of O/W emulsions formulated with chitosan/casein complexes. Food Hydrocoll. 2021, 111, 106211. [Google Scholar] [CrossRef]

- McClements, D.J.; Demetriades, K. An integrated approach to the development of reduced-fat food emulsions. Crit. Rev. Food Sci. Nutr. 1998, 38, 511–536. [Google Scholar] [CrossRef]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).