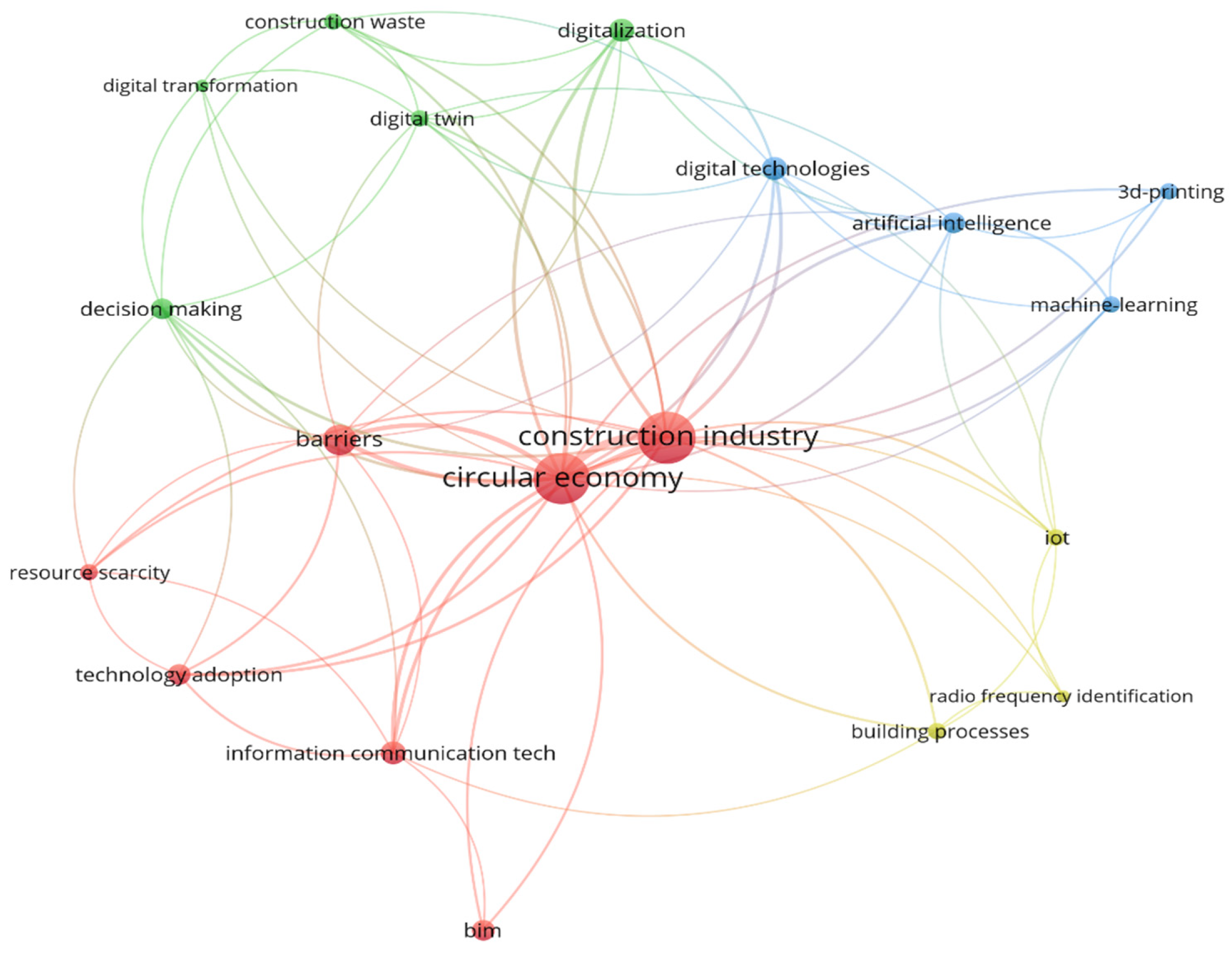

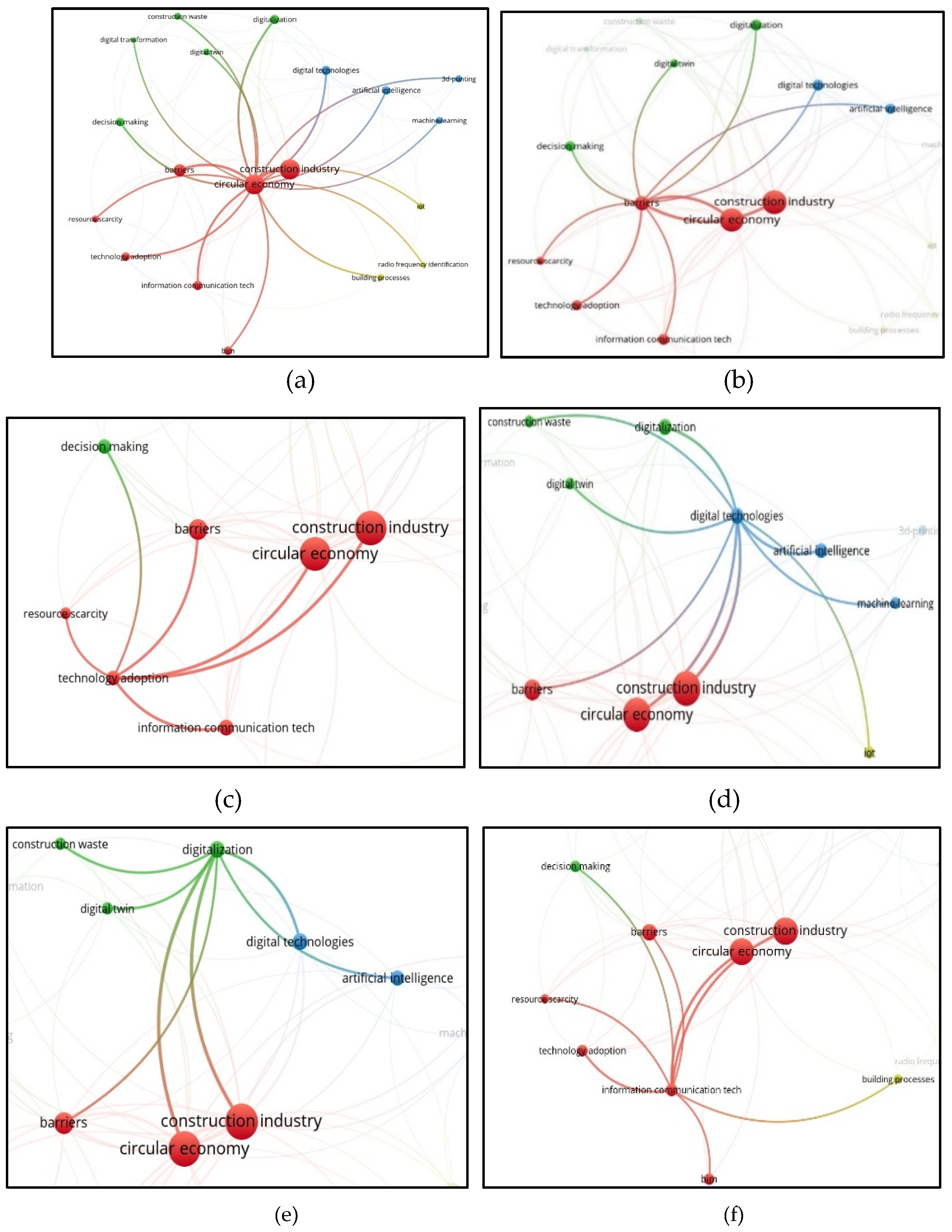

3.3. Barriers to uptake DTs to implement CE in the construction industry

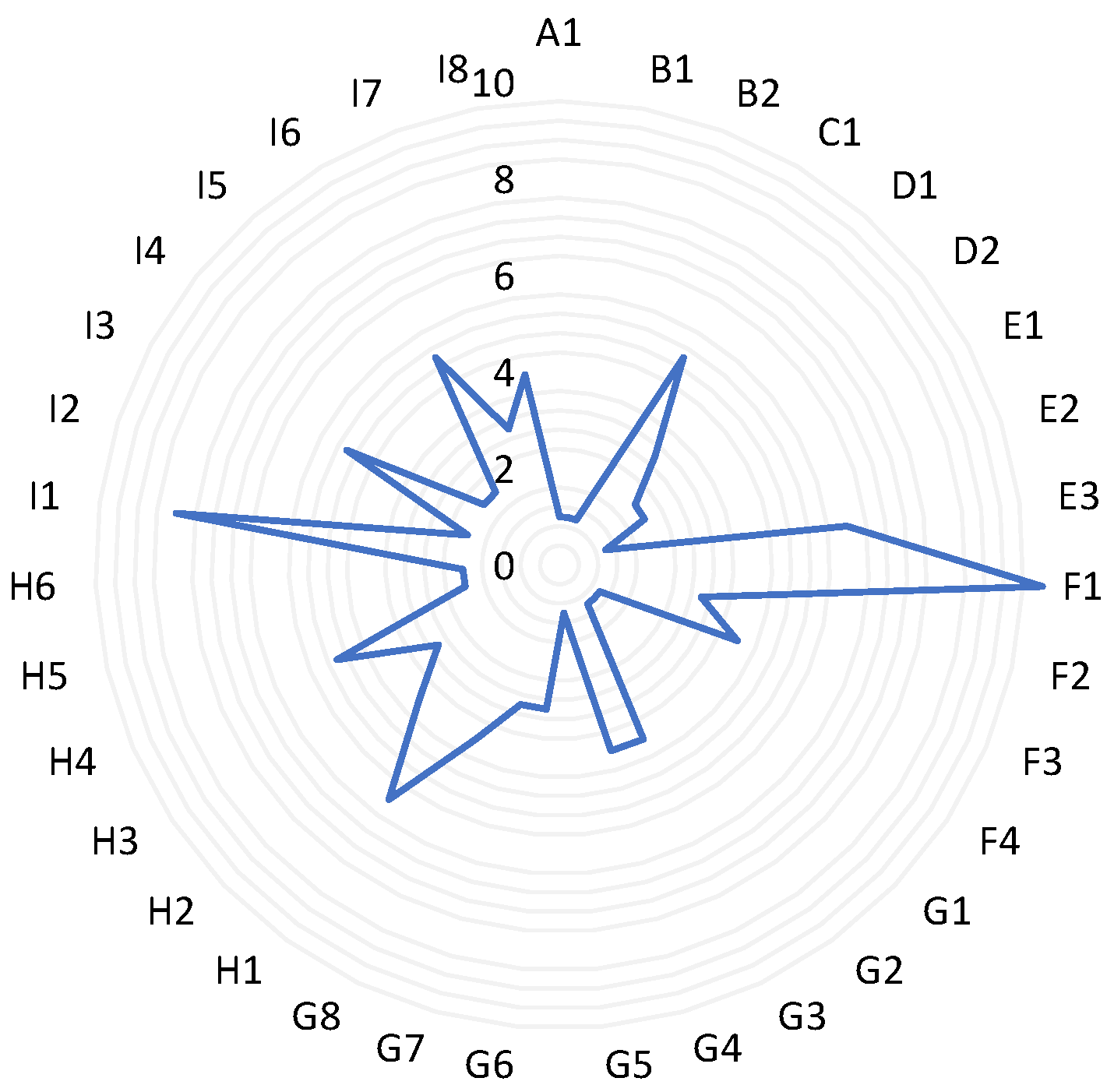

A total of 34 different barriers to adopt DTs to implement CE in the construction industry were identified from the literature, which was further subdivided into nine (09) categories based on their characteristics. Barriers are placed in an order where frequency of each barrier category positioned in ascending order.

Table 2.

Barriers to implement DTs enabled CE.

Table 2.

Barriers to implement DTs enabled CE.

| Barrier Category |

Code |

Barrier |

Reference |

Frequency |

| Infrastructure |

A1 |

Inadequate capacities for infrastructure |

[12] |

1 |

| Organizational |

B1 |

Lack of commitment from Construction Organizations |

[21] |

2 |

| B2 |

Need for new organizational role and training |

[11] |

| Regulatory |

C1 |

Lack of CE regulations |

[1,3,4,9,18] |

5 |

| Standardization |

D1 |

Lack of standardization for DTs |

[3,9,18] |

5 |

| D2 |

Lack of standardization for recovered and reused materials |

[1,8] |

| Investment |

E1 |

Lack of financial resources |

[4,21] |

9 |

| E2 |

Lack of financial incentives |

[21] |

| E3 |

High implementation costs |

[3,9,11,18,22,23] |

| Nature of the Construction Industry |

F1 |

Slow uptake of new technologies in the construction industry |

[3,4,6,7,9,10,12,14,16,18,19,23] |

21 |

| F2 |

Involvement of fragmented parties |

[14,15,19,23] |

| F3 |

Lack of trained workforce |

[7,11,12,22] |

| F4 |

Lack of CE-based knowledge management |

[6] |

| Technological |

G1 |

Disposal of devices (Technology Disposal) |

[3] |

21 |

| G2 |

Elevated power consumption |

[3] |

| G3 |

Sustaining the use of technology |

[2,3,17,23] |

| G4 |

Lack of recognition for DTs |

[10,18,20,22] |

| G5 |

Lack of integrated CDW processes, tools, and practices |

[5] |

| G6 |

Lack of circularity in product design |

[1,5,10] |

| G7 |

Absence of sufficient technologies for reusable, recycled & recovered materials |

[1,5,8] |

| G8 |

Lack of proper information management systems |

[2,5,7,10] |

| Stakeholder |

H1 |

Resistance to change |

[3,4,9,11,20,23] |

23 |

| H2 |

Lack of skills |

[3,9,11,18] |

| H3 |

Lack of awareness |

[4,7,11] |

| H4 |

Lack of commitment from stakeholders |

[3,13,14,16,18,21] |

| H5 |

Cultural Resistance |

[18,23] |

| H6 |

Reluctance to adopt DTs |

[18,23] |

| Data Related |

I1 |

Lack of built-environment related Data |

[3,5,6,7,9,13,20,21] |

31 |

| I2 |

Lack of clarity on the required data |

[22,23] |

| I3 |

Data handling and management |

[3,16,17,21,23] |

| I4 |

Poor quality data |

[3,5] |

| I5 |

Unavailability of web-based database for secondary products |

[5,12] |

| I6 |

Lack of data interoperability |

[9,18,20,21,23] |

| I7 |

Absence of data standardization |

[11,16,23] |

| I8 |

Data security barriers |

[3,4,9,18] |

3.3.1. Infrastructure Barriers

Infrastructure related barriers which impede the adoption of DTs enabled CE in the construction industry are discussed below.

Inadequate capacities for infrastructure: The main obstacles to CE adoption in the construction industry are infrastructure and logistics-related ones, which are, a lack of tracking mechanisms, a lack of expert circular networks, and inadequate facilities for sorting and monitoring systems [12]. Furthermore, the authors added that it is difficult with these barriers in place to control the pattern and product flow of the materials throughout their lifetime, apparently making efficient CE adoption challenging. Also, inadequate capacities for the waste segregation and recycling infrastructure development appears as an apparent barrier which impedes the circular practices in the construction industry.

3.3.2. Organizational Barriers

These barriers are associated with lack of commitment and collaboration from construction organizations, and they hinder the adoption of DTs enabled CE practices. These barriers are discussed below in a detailed manner.

Lack of commitment from construction organizations: Organizational harmonized protocols and processes for data management throughout the value chain in the context of the circular economy are still lacking [21]. The authors also stressed that the lack of regular organizational procedures and data management practices hinders information sharing among stakeholders, which makes the actual application of the CE and material reuse difficult. A lack of harmonization throughout the value chain is hindering the adoption of DTs enabled CE in the construction industry.

Need for new organizational role and training: There is a tremendous need for new professional figures with competency in both information technology and building to aid the development of a suitable path for the uptake of DTs enabled CE in the construction industry [11]. Additionally, to support the professionals in reaching CE, new positions and operators with a variety of responsibilities are required. Specialized training programs are needed to raise the skill levels of operators to the required level for dealing with DTs enabled CE and it is essential for the different supply chain stakeholders to have transversal synergy [11]. There is an urgent need to hire new professionals for new technological-related roles within the organization or provide existing professionals with the necessary training to meet the demands of technology.

3.3.3. Regulatory Barriers

The lack of CE regulations, laws and rules for the adoption of DTs to enable CE in the construction industry are discussed below.

Lack of CE regulations: There are several laws, rules, and conventions that apply to the construction sector, and they differ depending on the jurisdiction. The attainment of circularity in the building industry is impeded by the absence of government involvement in the revision of regulations and norms [4]. Inadequate laws for CE adoption and insufficient CE standards and guidance may be the root cause of regulatory obstacles. The [9] study also added that the construction industry may face regulatory challenges while utilizing modern technologies for CE, including zoning laws, building codes, environmental restrictions, and other regulations. Further the authors have provided additional evidence to bolster their claims by referencing building codes that prohibit the use of specific recycled materials or restrict the application of specific construction techniques, as well as zoning laws that prohibit the construction of specific building types or place restrictions on the location of recycling facilities. Furthermore, there are insufficient markers to plan, execute, and assess CE in construction from an all-encompassing perspective [1]. Regulatory obstacles may need to be addressed in the blockchain's application and execution for circular construction [3,18]. To truly adopt CE principles with the aid of DTs in the construction industry, the government must get involved in revising or amending existing building regulations and norms to comply with CE regulations. Otherwise, the contradictions and inconsistencies in these building regulations and norms could lead to misunderstandings and hinder the adoption of circular practices.

3.3.4. Standardization Barriers

These barriers are related to the lack of standardization which hinders the application of DTs for the CE in the construction industry and they are described below in a detailed manner.

Lack of standardization for DTs: The readiness for change will always provide an underlying conflict between the opposing demands of innovation and standardization. Finding the ideal balance between the competing needs of innovation and standardization can be critical to the construction industry's success in achieving circularity. A lack of standardization has the potential to impede the advancement of DTs by undermining interoperability efforts and creating compatibility, security, and functionality problems. The introduction of DTs, such as Material Passport, Material Databank, and Digital Twin, is being slowed down in the construction industry due to a lack of standardization, as noted by [3]. Integrating CE and BC in construction waste management is hampered by a lack of appropriate standards [18]. Inconsistencies and inefficiencies in the construction value chain may result from the lack of standardization for adopting these technologies, which may ultimately impede their adoption [9]. The construction industry must collaborate with industry organizations to develop and implement standardized protocols covering various aspects of advanced technology adoption [9].

Lack of standardization for recovered and reused materials: Recycled materials may provide uncertainties and practical issues if their performance is not guaranteed to be as intended [8], which may discourage stakeholders from utilizing them in construction projects. Uncertainties among stakeholders may arise from a lack of standards and limited practical guidance regarding the application, efficacy, and durability of recycled materials. Further, the absence of standards for recovered materials is one challenge the building industry faces, making it challenging to modify existing designs [1].

3.3.5. Investment Barriers

These challenges related to the cost, financing, incentives and investment and they are explored below.

Lack of Financial resources: The primary rationale mentioned by construction companies for rejecting new implementations or improvements is a lack of financial resources and support. The primary obstacle to the adoption of digital technology in the building sector is the dearth of green finance and regulations at the corporate and governmental levels [4]. There is no denying that price is the primary factor when purchasing building materials. So, the high cost of retrieving and preserving the materials' residual value at the end of their useful lives obviously makes virgin materials desirable for the new projects [4].

Lack of financial incentives: Efficient reuse of construction materials and a CE will require large-scale data management. Data from existing structures and materials can be labor- and cost-intensive to gather, digitize, and manage [21]. Further the authors underlined that a major obstacle to enabling efficient data management is the absence of financial incentives. It is challenging to develop a business plan for the large-scale reuse of construction materials with the absence of financial incentives from the government or the industry [21].

High Implementation Costs: Using cutting-edge technology for CE in the construction sector can be costly and necessitate large infrastructural, software, and hardware investments. Aside from the cost of hardware and software, there is also a significant financial cost associated with the workforce's lack of knowledge and proficiency with digital technology [22]. The authors have drawn attention to the significant implementation costs associated with the use of BIM, Blockchain, IoT, Artificial Intelligence (AI), Big Data Analytics (BDA), Material Passports, and Extended Reality [3,9,18,22]. Moreover, these knowledge-intensive enabling technologies are associated with high R&D intensity, rapid innovation cycles, and high-skilled employment, all of which result in substantial capital expenditures [11]. Moreover, DTs are becoming a niche area that necessitates convincing a significant number of organizational stakeholders to make investment decisions [23]. The construction industry is burdened by the upfront expenditures associated with its adoption [9,23]. However, the construction industry needs to carefully weigh the implementation's costs and expected advantages to make sure the investment is worthwhile. In the opinion of [11], choosing the truly effective technologies in an assessment of their whole life cycle necessitates the use of life cycle assessment procedures that emphasize the advantages (e.g. material savings) along with the drawbacks (e.g. the high energy consumption of DTs) of employing advanced technologies.

3.3.6. Barriers Associated with Nature of the Construction Industry

These barriers examine the traits of the construction sector, including its lack of labor training, fragmented stakeholder involvement, poor adoption of DTs, and CE-based knowledge management.

Slow uptake of new technologies in the Construction Industry: The construction sector is well known for its slow acceptance of new technologies [12,19,23] and has been the least digitalized in recent decades [7]. Industry appears to be opposing technological advancement rather than waiting for an appropriate application of DTs. Also, the way that existing construction organizations function towards the CE implementation reveals a lack of progress in digitalization [4]. Thus, the construction industry may undergo a radical change if current organizations make a strong transition to digital circularity and encourage digitization across all organizational levels [4,12]. Similarly, as discussed by [6], the construction industry lacks clearly defined indicators for the integration of digital technology and CE. The authors also noted that circularity technologies are still in their infancy within the industry. However, some authors argued that even though DTs have enormous potential, there are not sufficient validated technologies and tools for construction-related CE [10]. The scalability challenges related to the application of blockchain technology for CE in the construction sector were also revealed by [18]. Although several cutting-edge technologies have demonstrated potential in promoting circularity, their scalability and applicability for larger projects or wider adoption may be limited as well [9]. Thus, a thorough approach in terms of both technical and economic factors must be taken into account in order to design scalable solutions to apply CE in the construction industry [9].

Involvement of fragmented parties: Researchers argued that the enormous number and dispersed nature of stakeholders involved in the construction industry act as obstacles to improve construction industry practices [14,15,19,23]. The industry's split structure creates a fragmentation among stakeholders at various project stages and this increases the likelihood of errors and poor interaction among these stakeholders which directly hinders the adoption of DTs enabled CE within the industry.

Lack of trained workforce: The adoption of DTs enabled CE implementation in the construction industry is severely hampered by the lack of skilled people onsite [6,11,22]. Further, stakeholders involved in enabling technologies for the CE implementation need to be highly knowledgeable and qualified [11]. The existing challenge for the organizations is to find extremely skilled and knowledgeable stakeholders to collaborate on DTs enabled CE projects.

Lack of CE-based knowledge management: In their study, [6] found that the industry lacks efficient CE-based knowledge management systems, which makes deployment of DTs enabled CE in the construction industry difficult. It is clear that an organization suffers greatly when CE based knowledge is lacking, and significant time is lost looking for pertinent information rather than finishing tasks with an established goal.

3.3.7. Technological Barriers

These are the barriers caused by technological constraints that restrict the appropriate application of digital technology for the implementation of CE in the construction industry.

isposal of devices (Technology Disposal): Disposal of technology raises issues as it may have a negative effect on sustainability goals and the environment, either directly or indirectly. There are concerns regarding the technology disposal which will directly or indirectly impact the environment and cause negative achievements in sustainability. The effects that IoT devices have during their disposal raise concerns, even though their deployment helps to enable circularity in construction [3]. Further the authors also emphasized the issues with sustainability caused by the manufacture and disposal of Extended Reality technology.

Elevated Power Consumption: The utilization of digital technology to promote circularity raises questions because of the high-power consumption it requires to operate. Blockchain usage necessitates a large computational power [3]. Further, the high electricity consumption of IoT has been highlighted by authors as another negative impact on the environment.

Sustaining the use of technology: These barriers are associated with MPs, BIM, AI, digital twins, IoT, BDA and RFID. MPs are intended to monitor material flows throughout the life cycle of buildings and to record material documentation that will facilitate the recovery of materials for reuse during renovation and demolition phases. However, there is a requirement for manual updates each time a building undergoes modification remains a major barrier to the practical implementation of MPs [23]. Initially, BIM was used to enhance design quality by combining all pertinent data from several disciplines into a single model whereas today, BIM provides a means of smoothly incorporating circular economy concepts into building projects. Concerns have been raised about BIM software's frequent updates and changes to newer file formats, which could eventually render BIM models incompatible [23]. The success of every AI model or project heavily depends on the labelled data known as training data, which is used to teach machine learning algorithms or models to make the right decisions. The AI models are highly susceptible to biases resulting from the training data [23]. Further the authors highlighted that the complexity of the code makes it very challenging to create a rule-based program [17]. Circularity in the construction is expected to be made feasible by DT, which connects real-world data with digital data. Even though, the combination of the DT and CE makes it valuable for the building industry, but the development of DT models is a complex task [3]. The capacity of a system to carry out its intended function over an extended period consistently and without failure is referred to as reliability. Reliability is an important consideration in the context of the IoT, as problems with malfunctioning devices may have serious consequences [3]. BDA has become a key component in producing insightful information for circular construction decision-making. To extract valuable information from a vast amount of data, BDA calls for intensive analysis [3]. One of the existing obstacles in utilizing RFID is the lack of technological and functional knowledge, which determines where the RFID tag should be installed [2]. Further the authors highlighted that RFID tags have shorter service life (15-20 years), when comparing with other construction components. It is also clear that a major gap exists since stakeholders have a limited time on how long they must manage an asset during its useful life. Stakeholders' interest in RFID is significantly curtailed when an asset is transferred to the user after it has been sold or the warranty has ended. Even though DTs pave way for the circularity in the construction, aforementioned issues related to those technologies make it difficult to sustain the benefits from those technologies.

Lack of recognition for DTs: A new paradigm can be adopted more quickly and easily if the necessary technology and information are accessible to advance it [7] DTs were not recognized in the circular construction due to the lack of knowledge and understanding [22]. Further the absence of a strong ICT infrastructure in the construction sector prevents DTs from being used with diligence [20]. Construction organizations are currently rushing to embrace DTs to demonstrate their social responsibility without having a firm grasp and awareness of it. The adoption of CE is hampered by the construction industry's poor ability for technological and eco-innovation as well as its immaturity in enabling DTs and solutions [10,18]. In addition, the authors emphasized that the lack of maturity of CE in the construction industry led to a dearth of investment in tools and technologies necessary for CE adoption. The underappreciation of DTs reflects the double-barreled impact of change aversion on CE adoption [10]. In the modern digital age, being able to recognize the opportunities presented by digital technology has become essential for competitive survival. It is imperative to acknowledge the role of DTs in the construction industry to enable circularity in the construction.

Lack of integrated CDW processes, tools, and practices: Despite the fact that a number of studies have highlighted the potential for digital technology to support integrated construction and demolition waste management (CDW), there are still insufficient integrated CDW procedures, tools, and practices in use. The industry still lacks tools for detecting, categorizing, and certifying salvaged materials [5]. Further the authors added another obstacle to effective CDW management as the complexity of the materials and the composition of the structure (many layers and adjustments throughout its lifecycle).

Lack of circularity in product design: Lack of material alternatives available in the industry inhibits circularity in product design [1]. Further increased supply chain complexity lessens the circularity of product design. Construction circularity is delayed by ineffective green building design development [5]. The practical use of design for deconstruction (DfD) is hindered by a lack of standard spatial geometries and limited visualization in this context [5]. [10] emphasized that there are insufficient technologies available to design for a building materials’ end of life.

Absence of sufficient technologies for reusable, recycled & recovered materials: The current state of recycling technology is immature and stems from a lack of advancement in technology which is necessary for the appropriate recycling of materials [8]. Inadequate material separation, administrative obstacles, and a deficiency in the process for making readily disassembled goods hinder recycling procedures [5]. Complications with material recovery at end of life are another technological barrier to the implementation of CE [1]. Insufficient technological capabilities on the side of managers to recover and reuse resources is a major barrier impeding the circularity [8].

Lack of proper information management system: The absence of an information management system was linked to the lack of transparency and availability of technical data on construction elements which extends the gap to the current modelling tools and material database [5]. Furthermore, there are still insufficient databases and information on constructing, particularly at end of life, due to the restricted number of CE-oriented databases that exist [6]. The limited availability of information that aligns with the end of life has impeded the adoption of digital technology for circular building. A significantly larger quantity of data and information may be needed for circular solutions pertaining to inventory, management, and asset end-of-life [2]. Still, it is difficult to track the recycled materials using trustworthy information systems [10].

3.3.8. Stakeholder Barriers

This set of barriers delves into the stakeholders' unwillingness to adapt, as well as their inadequate engagement, knowledge, and understanding of the use of DTs to enable CE.

Resistance to change: The resistance to change mindset among the stakeholders who are used to traditional construction processes is one of the greatest barriers to the adoption of new technologies for CE in the construction industry [3,4,9,11,20,23]. Construction stakeholders are typically conservative in the context of early acceptance and diffusion of technological innovation [20]. Stakeholders' perceptions are influenced by ease of use and technology acceptance, which discourages them from adopting DTs at this early stage [4]. There is a common problem faced by stakeholders is figuring out how DTs enabled CE may help the construction industry by cutting waste and increasing productivity [9,11]. BIM, GIS and RFID are the contemporary ICT-based decision-making tools which are currently utilized in the construction industry [20]. However, industry stakeholders have not yet widely used IoT, Big data, and blockchain, which are potential means of boosting the practice of CE in the construction sector. [3] also highlighted the extremely low adoption rate of Material Passport and Material Databank among industry stakeholders. As per [23], respondents acknowledged that even if they get BIM models from architects, they still prefer to utilize 2D drawings for their job. Furthermore, some participants in the [23] study highlighted that although new technologies have been implemented in their organization, some colleagues might be hesitant to use them since they have been using the same programs and processes for a long time. In the [11] study, participants highlighted the possibility of losing their professional identity because of the industrialization process made possible by certain technologies. Moreover, with the introduction of digital technology, stakeholders believe that they will be integrated into the industry as technicians, which frequently offers less flexibility and income than the free profession. Stakeholders prefer to adhere with the status quo, as the greater penalties and lack of high-tech expertise associated with project delivery failure [20]. Even though several ICT-based decision support tools have been developed to aid in the implementation of CE, it is difficult to persuade stakeholders that developing innovative CE business models is essential to surviving in the resource-intensive market of the future [20]. A change in the attitudes and behaviors of the participants is necessary for the transition from linear building to DTs enabling circular construction.

Lack of Skills: The advent of digital technology may have created a skills gap in the industry, which could restrict the use of these resources to advance CE in the construction industry [9]. Utilizing DTs for CE in the construction industry demands stakeholders with specific expertise in areas like data handling, programming, and data analysis. The research by [3] makes note of the fact that stakeholders in the construction industry lack the technical know-how knowledge required to create and apply AI models. In addition, the authors confirmed that specific equipment and stakeholder skills are required to reap the full benefits from extended reality technology. Inadequate expertise with digital technology leads to a lack of competency required for managing the technological implementation like blockchain [18]. Further a lack of experience among stakeholders raises concerns about the practical commitments that come with technological progress [11]. Thus, the industry is facing a significant skills gap that needs to be addressed with appropriate solutions.

Lack of Awareness among stakeholders, clients and public: Stakeholder awareness and engagement are the key factors which facilitates a seamless transition from linear construction into a circular one. Lack of understanding among stakeholders and clients is the most significant obstacle impeding the shift to DTs enabled circular construction [4,6]. Stakeholders must become conscious of the environmental impacts created by the construction industry and urge circular principles by changing their disposal-focused and cost-driven perspective. The study conducted by [7] highlighted that public ignores the advantages and practices of CE without sufficient knowledge. Hence, inadequate client and public awareness of CE processes & benefits is one of the reasons why constructions are still adhering to linear construction processes. A lack of awareness about DTs enabled CE in the construction industry can be also interpreted as a kind of deliberate ignorance or a failure to learn or change. It is imperative to raise awareness of DTs enabled CE and demonstrate its advantages for the economy and environment to encourage stakeholders, clients and public to embrace DTs enabled CE practices. Stakeholders, clients and public may lose the chance to produce more circular results if they lack the necessary knowledge and comprehension. It is necessary for the public, clients, and stakeholders to change their viewpoint and admit that they are hindering the implementation of CE. Additionally, stakeholders in the construction industry are not even aware of the advantages that new technologies can provide [7,11].

Lack of commitment from stakeholders: Stakeholders are groups of individuals who have the potential to influence the objectives of an organization, progress, and even its existence. A major obstacle remains to be the absence of cooperation and communication across stakeholders [3,14,18]. Further it is challenging to gather project-related data to support circular construction as the construction industry is so dispersed [3,13]. The inability of many stakeholders to gather, handle, share, and manage data regarding building materials as well as to recognize information's worth in embracing circular principles is an additional barrier to data management [21]. Demanding the construction community's shared commitment in data integration throughout the value chain is one of the greatest barriers [16]. Stakeholders' unwillingness to exchange information amongst themselves and with other parties in the value chain hampers data management and material reuse in the AEC industry [21]. Due to their unwillingness to cooperate, the stakeholders in the AEC industry are unable to support the circular economy. It is obvious that there is a substantial chance of failure when implementing any CE program without significant collaboration from the key stakeholders.

Cultural Resistance: The common values, beliefs, and norms that shape stakeholder's behavior and their work process are referred to as culture. The adoption of new technology within organizations is hampered by existing cultural behavior, which necessitating systemic transformation [23]. Stakeholders must adopt new attitudes and behaviors that modify the construction industry's culture to enable the transition from linear to circular construction. However, such a significant change is challenging to implement, though, in an industry of the economy where supply chain fragmentation and hesitant technology adoption are typical [23]. According to [18], cultural variations in the construction industry also have an impact on the adoption of new technologies like blockchain. It is evident that cultural variances and technological advancements influence one another's growth.

Reluctance to adopt DTs: Employees are unlikely to embrace new technology unless their work environment encourages creativity, cooperation, and a readiness to change. [23] made clear in their study that a full implementation of DTs in daily operations is needed for both digitalization and CE, which are currently limited to pilot projects and the company's corporate vision. [18] state that organizations typically oppose the use of DTs in favor of maintaining the status quo. Organizational resistance makes a company rigid and unable to adjust to internal or external demands for change.

3.3.9. Data Related Barriers

These are the barriers related to lack of quality, quantity, nature and management of construction data. The most significant data related barriers found in the literature are lack of built-environment related data, lack of clarity on the required data, poor data handling & management, poor quality data, unavailability of web-based database for secondary products, lack of data interoperability, absence of data standardization and data security barriers which are discussed below.

Lack of built-environment related data: One of the main concerns regarding the adoption of the DTs enabled CE is the absence of the relevant data from the construction industry. Large volumes of data are required for the efficient operation of advanced technologies like deep learning, BDA, and machine learning [3,5,7,9]. The paucity of datasets makes it challenging to enable AI models for systemic circularity in the construction industry [6]. Further there is still a lack of technology application specifically focused on CE due to the dearth of comprehensive database [7,20]. It is a difficult endeavor to gather project lifecycle data to support circular construction [13]. [6] pointed out that there is still a dearth of data about the end-of-life stage and emphasized how little focus is placed on it. Further the authors stated that data and information for prediction in a CE are not easily accessible everywhere in the world for appropriate demolition auditing. However, lack of documentation of the materials used in construction is a typical occurrence in the industry, but this begs the question of the materials' reusability in the future [5,21]. Additionally, industry lacks critical information for prediction and disassembly, which is imperative for an effective deconstruction process [7]. Data about building materials and supplies are frequently absent, incomplete, inaccessible, or not digitalized, which is one of the major issues of the modern industry [21]. The absence of defined methods for collecting and storing data in the construction sector leads to a lack of data availability, which complicates the adoption of cutting-edge technology [9]. Moreover, ownership, access, privacy, and trust related problems within the industry contribute to dearth of data [5]. There is still plenty of work to be carried out in terms of data collection, data processing and reprocessing to create meaningful information, and ongoing data recording to support decision making [13]. Data is crucial to the application of circular practices throughout the whole life cycle of each construction project. Lack of any kind of data from the project may miss the opportunity to create more circular and profitable outcomes. [7] pointed out that if efforts are not taken to address the data issue, future research on DTs enabled CE may be misdirected.

Lack of clarity on the required data: Uncertainty about the data requirements for circular strategies is another factor contributing to the paucity of built-environment data [22,23]. BIM provides a database for MP generation and facilitates data sharing between project stakeholders to allow CE. However, there are uncertainties regarding data requirements for generating MPs [23]. Due to the lack of completely defined DT standards, data requirements cannot be appropriately specified [22]. More efforts need to be undertaken to critically assess stakeholder’s data requirements to enable them to make informed decisions on CE [23]. Stakeholders lack the expertise required to assess what technologies should be developed and what sort of data they might need to promote circularity in the construction sector. Lack of clarity on the required data barrier must settled down as soon as possible to reap the benefits from the DTs enabled CE implementation.

Data Handling & Management: Data Handling and management of collected data appears to be a prominent barrier to the CE implementation as technologies such as AI, IoT and BDA require and relies on large quantities of data for their functioning. BDA offers a variety of solutions and forecasts for the future by combining all other technologies, including BIM, AI, and IoT [3]. Enabling circularity requires the management of varied data over the whole life cycle. A significant quantity of data is produced at each phase of construction from a broad range of sources, such as sensors, monitoring equipment, and BIM [3]. This leads to challenges in data handling related to accessibility and assessment, which necessitates a substantial time and financial commitment [16–18]. DTs and solutions facilitate the open, transparent, and standardized sharing and connecting of data across the various stakeholders in the supply chain. So, the absence of a proper data management mechanism is a critical problem with DT adoption, especially for MPs [23]. Also, coordinating data management for material reuse without clear standards is challenging in the construction industry [21].

Poor quality data: Data of poor quality is unable to meet the purposes for which it is being used. Low-quality data can erode trust in the information shared due to insufficient coverage, disparate data formats, random collection practices, and monitoring [5]. Additionally, the writers stressed that issues with ownership, access, privacy, and trust in the sector could potentially hinder the acquisition of high-quality data [3] highlighted the need for vast quantities of high-quality data for DTs to operate as intended. The quality of data input influences the BIM outcome [3]. The authors also highlighted how poor construction data quality impedes the use of BDA. Poor quality data leads to inefficiencies in decision making and reduced opportunities for maximizing CE.

Unavailability of web-based database for secondary products: According to circular principles, it is imperative that secondary products have an extended life until they reach a point at which they can no longer be utilized. There is a lack of documentation in the management of used building materials, which raises concerns about their ultimate circularity [5]. Further, inadequate material property information of materials listed on a web-marketplace typically discourages stakeholders from purchasing them. The exchange of usable secondary materials and products is hampered by the lack of an efficient CE web-based waste exchange system [6]. Moreover, reusing secondary materials through marketplaces raises the issue of meeting quality requirements as measuring the physical quality of secondary products is a tedious task and requires expert inquiry [6]. As a result, lack of a web-based database for secondary products deters potential users from considering them for further purposes.

Lack of data interoperability: The transmission of information between the stakeholders along the value chain is hampered by the simple fact that data are frequently kept in disparate repositories, in disparate forms, with differing degrees of ownership and accessibility [21]. It is believed that data transparency is necessary to facilitate interoperability [21]. Naturally, integrating advanced CE technologies with current systems or technologies might be challenging. It is difficult to configure these technologies in a way that ensures process and data interoperability for diverse stakeholders within the industry [9,20].

Additionally, authors pointed out that BIM model versions vary since software is frequently updated and that future compatibility issues may arise with newer file formats [23]. As per [18], a major hindrance to amalgamating concepts such as CE, blockchain, and construction waste management could be their incompatibility. Further the authors added that there is an urging need for a proper system conversion to reap the benefits of blockchain enabled CE [18]. Interoperability and data sharing are difficult to achieve while using various DTs based on disparate languages and standards [23]. Moreover, the authors emphasize how crucial it is to incorporate digital technology into existing systems. A multifaceted strategy involving technical solutions, teamwork, and a long-term outlook is needed to address the issue of lack of interoperability [9]. Ineffective data management can be caused by a lack of technical interoperability, which in turn can slow down the construction industry's practices of reusing materials [21].

Absence of Data Standardization: Inconsistencies and inefficiencies in the construction value chain may result from the lack of standardization for adopting these technologies, which may ultimately impede their adoption [9,11]. The absence of standardization presents a significant obstacle to the construction industry's adoption of cutting-edge technologies for CE. The authors noted that the absence of a national standard for data exchange is becoming an issue for stakeholders [23]. Consequently, these issues with data sharing and administration may be resolved by international data standardization. These requirement for standardization and open interfaces is a major barrier to the construction community's commitment to data availability [16]. The construction industry must collaborate with industry organizations to develop and implement standardized protocols covering various aspects of advanced technology adoption [9].

Data security Barriers: Digitization presents a complicated cyberspace network, making industries vulnerable to cyberattacks despite its apparent benefits. The fragmented nature of the construction sector, where different stakeholders have varying levels of requirements for data privacy and security, has always presented significant hurdles in this regard [9]. The construction industry has witnessed a surge in cyber risks, making the infrastructure for cyber security imperative for all organizations [4]. Nowadays, blockchain is frequently utilized in the construction sector for CE-related solutions, which creates privacy or security concerns as well as legal liabilities [3,18]. Further, [3] stated that high data security is required as complete building data is included in material passports and data banks. Additionally, DT are highly susceptible to privacy issues caused by cyberattacks [3]. Given that these technologies include collecting, storing and exchanging sensitive data, implementing them to promote CE in the construction sector may present significant difficulties [9]. Formulating data privacy and security guidelines and measures to safeguard sensitive data are key areas for future growth in this discipline [9].