1. Introduction

The current aircraft electrical generation systems can be chopped into 2 kinds of technology: variable speed constant frequency systems and constant speed constant frequency systems [

1,

2]. One technology is the constant speed, constant frequency system commonly denominated by the integrated drive generator (IDG). Most of the civil aircraft use this technology [

2]. It comprises a set continuously variable speed (CVT) gearbox and generator. The integration of a CVT becomes a useful resource in this area since it gives the possibility to offer solutions with constant frequency AC generation systems [

3]. Lower reliability, efficiency, and higher weight are the main drawbacks of [

1,

3].

The growing demand for the electrification of aircraft motivates the development of new solutions. A new trend in research involves exploring the potential of integrating generators within the structure of aircraft turbines, particularly for high-range aircraft, known as aircraft embedded generation systems. In [

4] work, it was verified that inside the low-pressure turbine casing, there exists an enclosed space capable of accommodating a generator without compromising the aerodynamics of the turbine. Some advantages can be depicted over IDG: lighter, more efficient and reliable, less costly and easier integration on aircraft fuselage systems. However, the increase in complexity of designing the turbines can be one drawback.

This work considers an IDG system since it is a mature technology compared to an aircraft-embedded generator system.

Some aircraft power generation systems use synchronous machines with Permanent Magnets (PM) [

1,

4]. Higher power density and efficiency and more compact and lighter due to the lack of slip-ring-based external excitation are some advantages [

5]. Consequently, this work is motivated to research another topology of electric machines to integrate into the IDG solution, considering a possible integration in the embedded generation solution. Indeed, one emerging technology is Flux Switching Machines, more specifically, Doubly Salient Machines being the study focus due to the higher reliability at higher rotor speeds due to its rotor simple design [

6]. Other points can be depicted like a reduction of the vibrations and electromagnetic forces transmitted to PMs due to being placed in stator iron core [

7] and the reduction of the temperature decaying-flux effect in PMs due to the better temperature dissipation [

8].

So, the main goal of this project is to devise a solution suitable for integration into aircraft turbines, designed to endure all atmospheric conditions with utmost reliability, employing a Doubly Salient Permanent Magnet (DSPM) topology.

2. Doubly Salient Permanent Magnet (DSPM) Machine and Methodology of Study Overview

The starting point of this project is the DSPM obtained in [

9], which is presented in

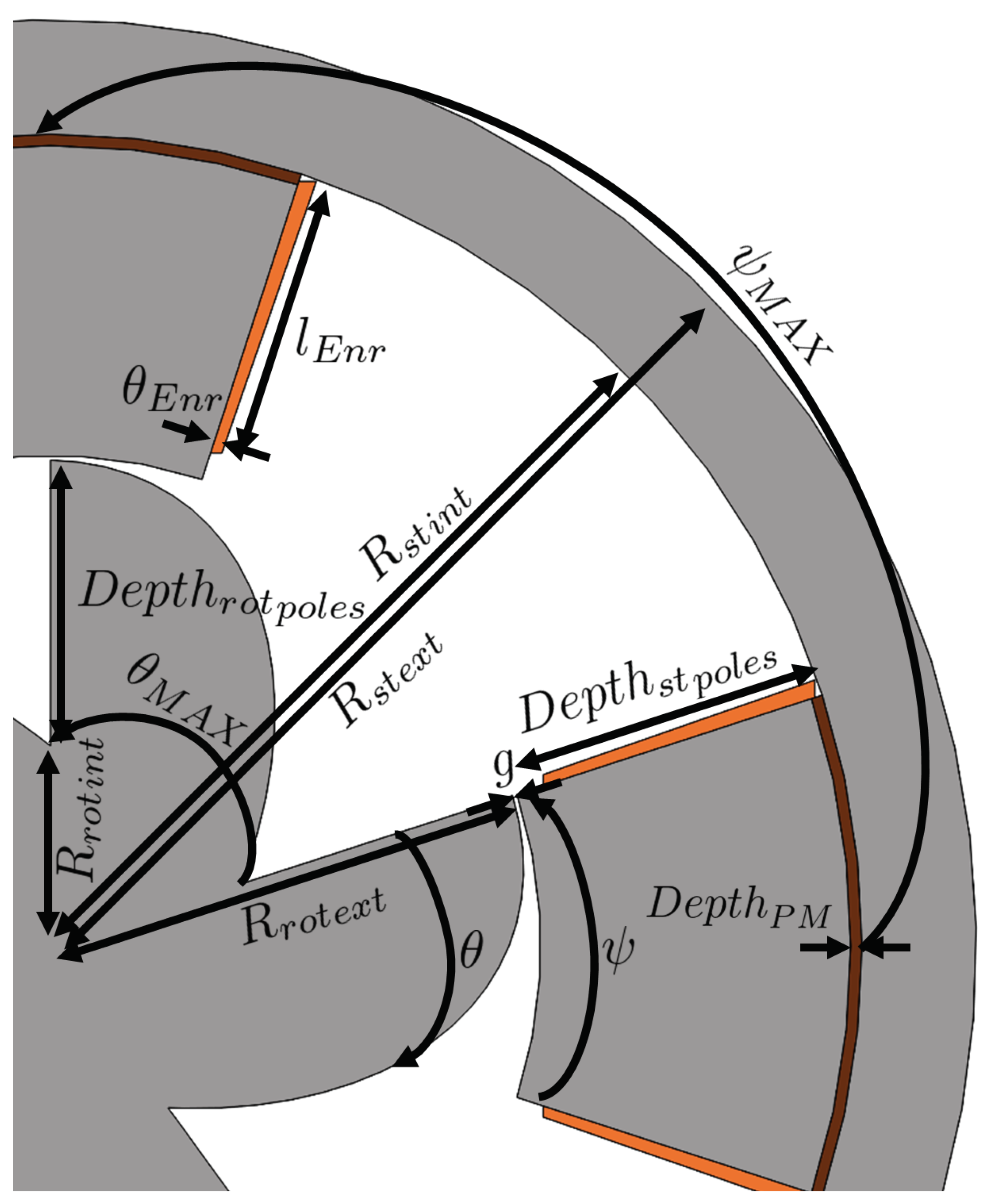

Figure 1. This machine is going to be called now by DSPM S4R5. Also, the methodology used to study the different DSPM geometries will be reviewed. The finite element analysis (FEA) will be our benchmark study of this machine using a distributed-parameters simulation environment finite element method (FEM) program. So, it will be depicted to understand how the FEM models are built. Finally, an overview of the optimization process is presented.

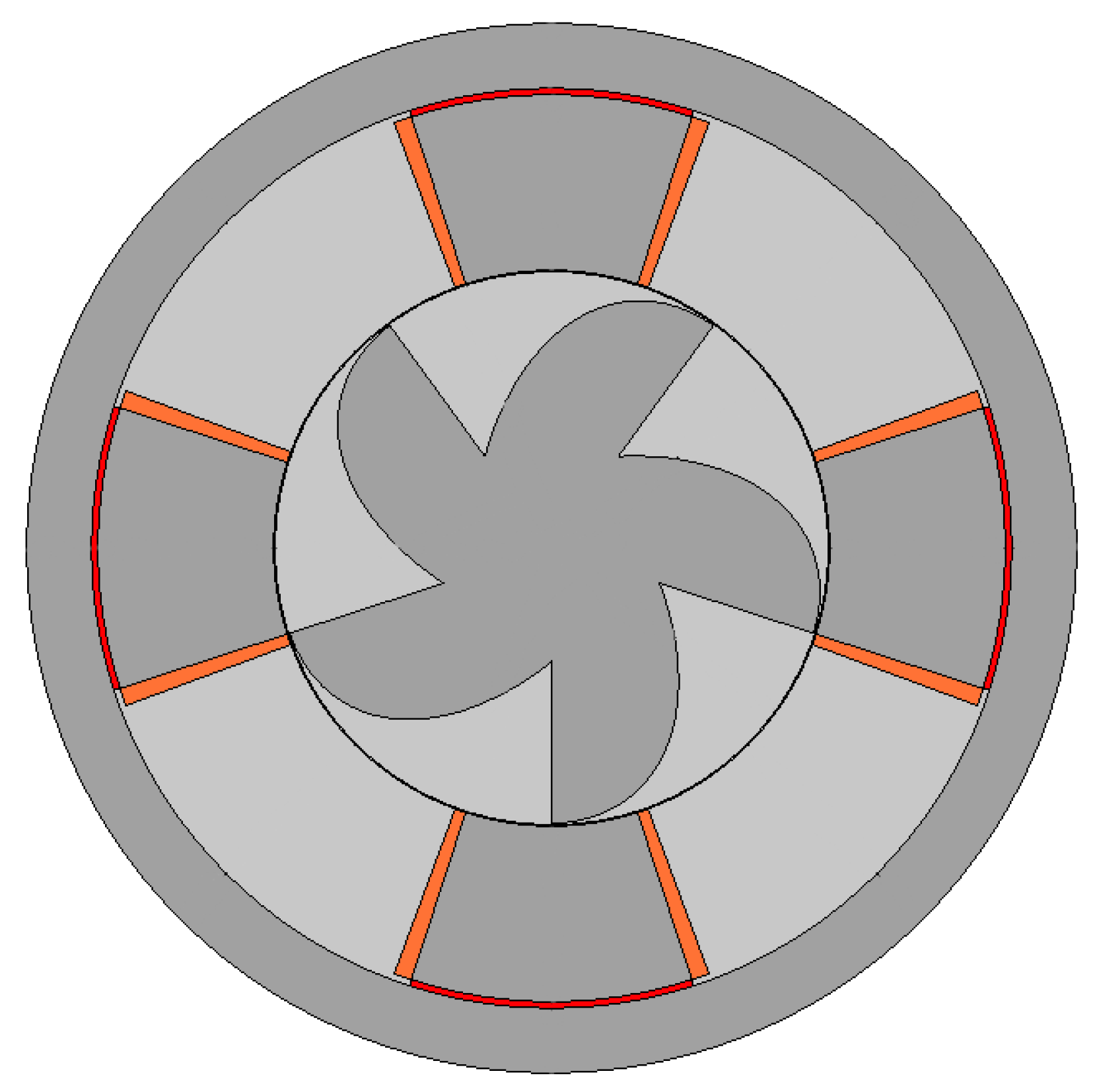

2.1. Geometry

Figure 1 shows the parameters relative to the 2D plot of the DSPM S4R5 geometry.

Table 1 presents the machine dimensions of

Figure 1. The

corresponds to the active length of the machine or stack iron length. The 3D plot is shown in the next Section.

The main geometric feature of the machine dwells on the shape of the rotor teeth, which is given by a quadratic Bézier curve. In a Bézier curve, the initial and final points belong to it, while the intermediate control points (for a quadratic curve only have one intermediate control point) determine the curvature of the curve [

10]. The minimum air gap value considered is 1.6 mm as a minimum mechanical safety margin. The coils have 20 turns each for the initial geometry’s number of turns (

). Nevertheless, during the geometry optimization process, it is assumed 1 turn for the sake of simplicity.

2.2. Materials

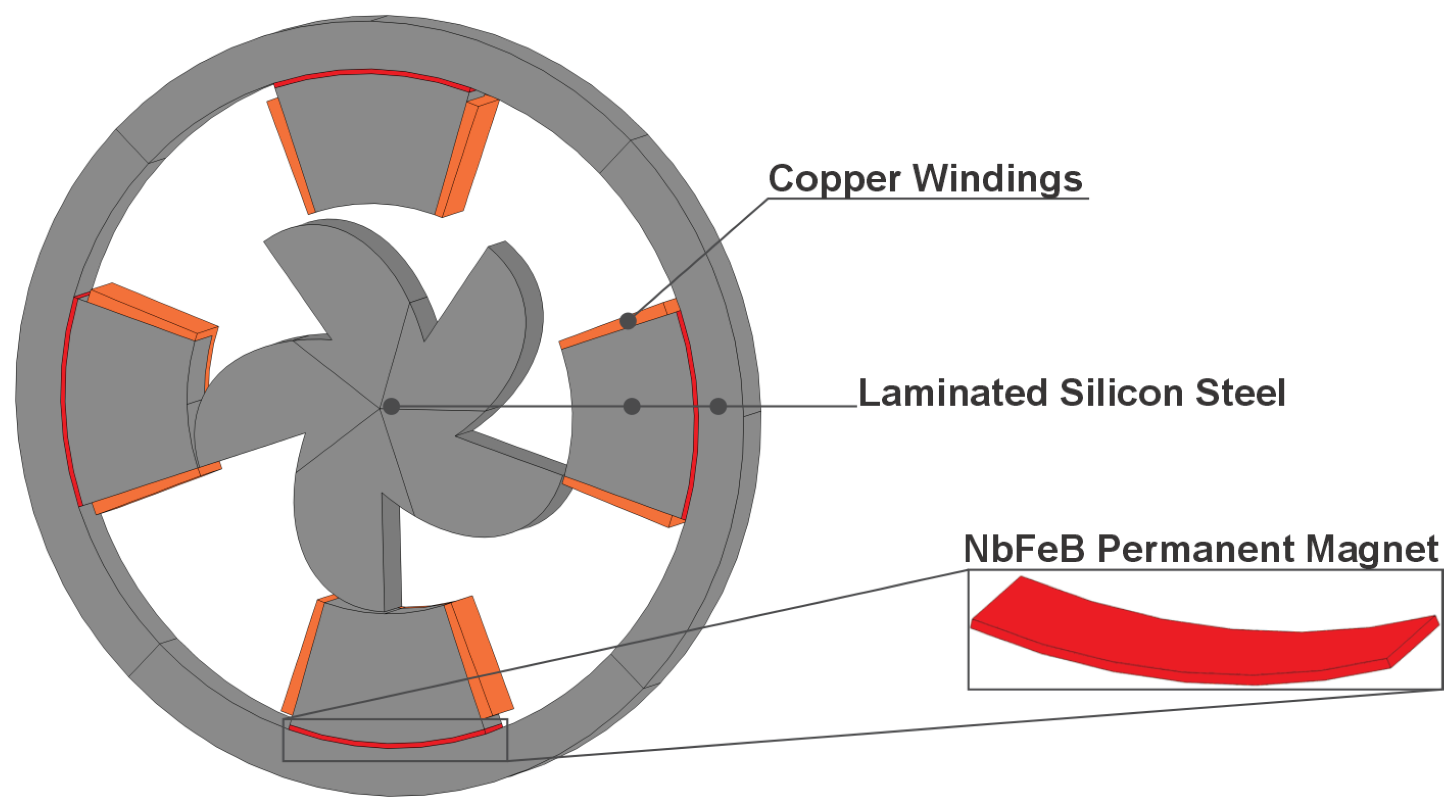

The materials corresponding to the different components of the machine are presented in

Figure 2. The PMs are highlighted in

Figure 2 by zooming on one of them.

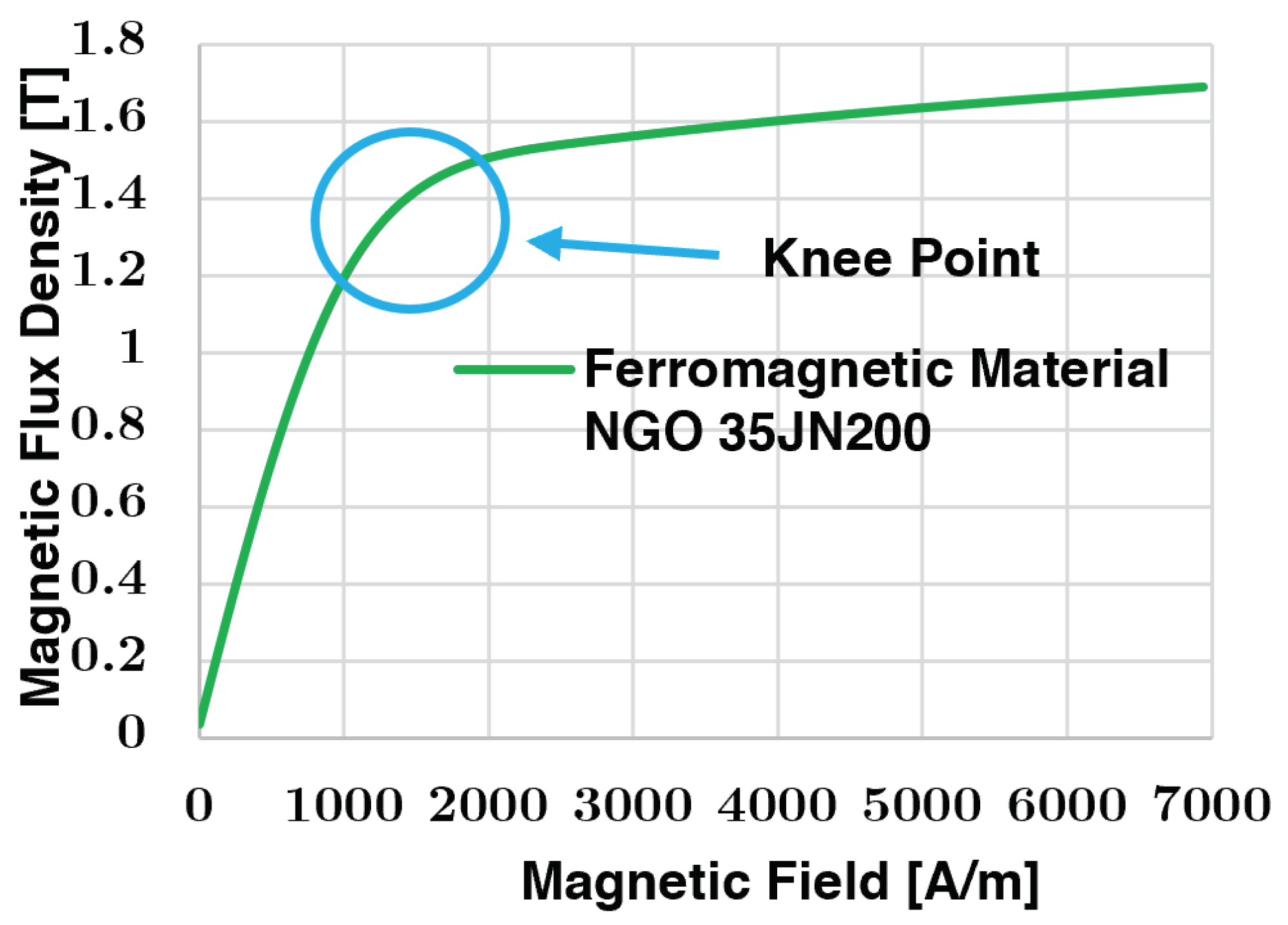

For the iron core, Silicon Steel NGO 35JN200 with a 0.35 mm lamination thickness material is considered. Its density (

) is 7600 kg/m

3 with a B-H characteristic curve presented in

Figure 3 as assumed in [

9] and its electrical conductivity (

) of 1 S/m being considered an isotropic conductivity to reduce computational time.

The NdFeB magnets present a BH curve given by a slope with a remanent flux density () of 1.4 T with a coercive magnetic field of 1.08 MA/m. Their relative magnetic permeability () is around 1.03. The electrical conductivity of the PM is assumed to have a value of 1 S/m to mitigate simulation errors of induced currents. Also, the density of the PMs () is 7600 kg/m3.

The copper windings are considered to have a relative magnetic permeability and relative electrical permittivity similar to the air. However, its electrical conductivity (

) has a value of 60 MS/m.

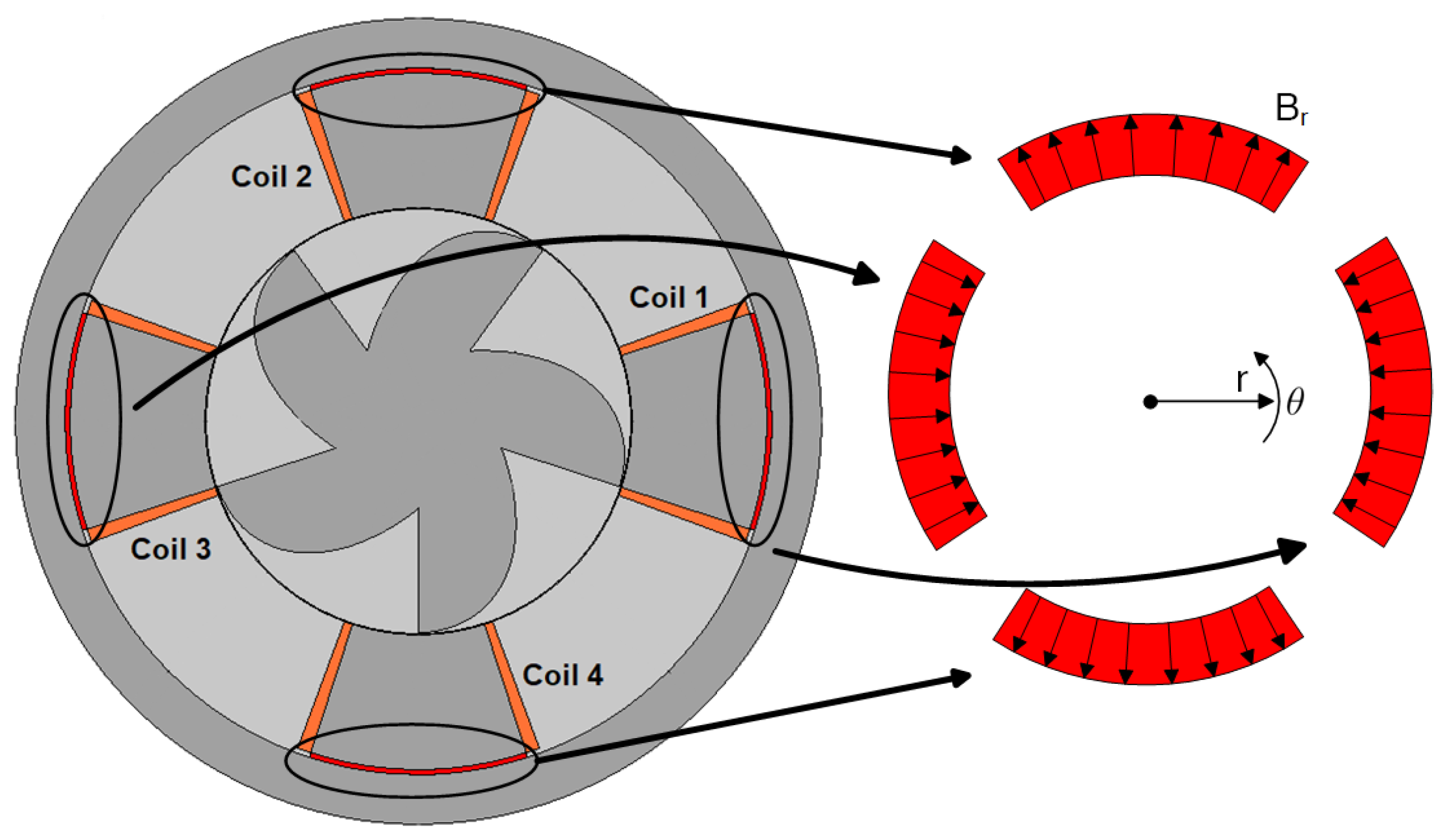

Figure 4 shows the coil numbering and the permanent magnet orientation.

2.3. Generator Specifications

The pretended specifications for this aircraft are based in [

9,

11]. So, the needed electrical apparent power output is at least 90 kVA at a speed of 3000 rpm.

The aircraft load is simulated as a load fed by an AC/DC/AC converter. Therefore, for simplification, the rectifier (AC/DC converter) is considered to have properly dimensioned LC filters to have a 2-level square current wave as phase current during the optimization process.

The assumed value of nominal current density for the coils of 5 [A/mm

2], and a filling factor of 0.5 to ensure the thermal limits and a normal slot factor [

12].

2.4. FEM Study of DSPM S4R5 machine

The equations that govern the FEM models are presented in Equations (

1) and (

2) where

is the magnetic field vector,

is the magnetic flux density vector and

is the current density vector.

The magnetic vector potential equations are considered for the stator side since currents are applied to the coils, and the magnetic scalar potential equations are on the rotor side since the eddy currents in the rotor are neglected.

2.4.1. Magnetic flux and torque calculation

The study of magnetic flux () and torque (T) are relevant since these components relate to the output power, input power and mechanical vibrations, respectively. Therefore, the study process of those quantities considers an angular variation of the rotor position of , which corresponds to an electrical cycle.

Magnetic Flux Calculation

For the 3D model, an FEA is performed assuming a stationary condition, while, for 2D geometries, the FEA considers a time-dependent study since our work verified that the time-dependent study is faster than a stationary one in this condition.

The induced voltage calculation in a stationary situation for 3D geometries is obtained by running the gradient of flux to the position of the rotor since the rotor speed is assumed to be constant. This avoids a time-consuming, time-dependent study.

Electromagnetic Torque Calculation: Arkkio´s Method

The software FEM can perform torque computation through Maxwell’s stress tensor or by Arkkio´s method [

13], characterized by a better precision than normal Maxwell’s stress tensor. Similar to magnetic flux computation, the study of torque will be time-dependent for 2D geometry and stationary for 3D geometry, remembering that the rotor rotates an electrical cycle.

2.4.2. Iron losses determination

Modelling of iron losses

The iron losses model assumed builds on Bertotti’s model where Equation (

3) presents the equation that governs the model. The variables

,f,

,

,

, and

are the iron losses

, the frequency

, the peak value of the signal of the magnetic flux density

and the dimensionless coefficients of hysteresis, eddy current, and excess losses, respectively.

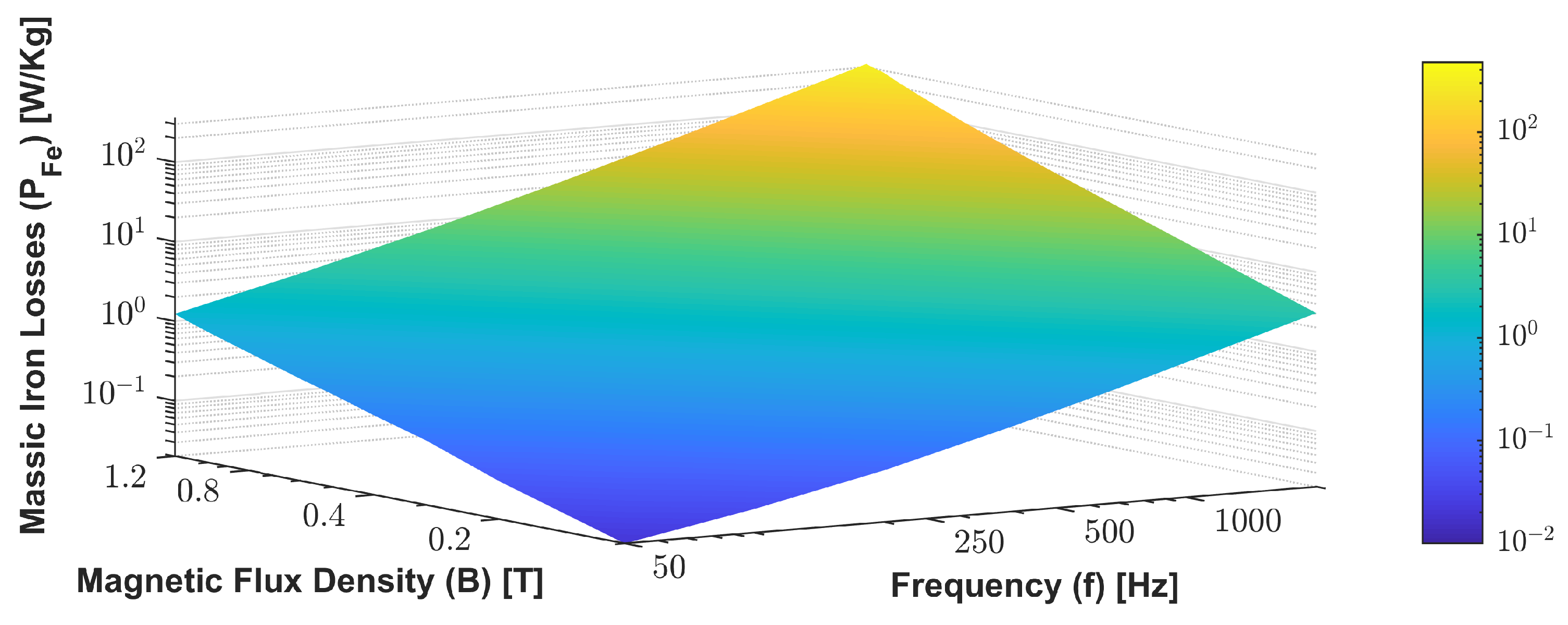

Iron losses’ data map

The majority of power loss data of the Silicon Steel 35JN200 is extracted from the power loss manufacturer´s table. However, the remaining missing data is obtained by extrapolating the manufacturer´s data by fitting that data with the iron losses model Equation (

3). The Berttoti coefficients are obtained by the data fitting for different frequencies.

Figure 5 shows 3D graphs to visualize better the values of losses in iron with the level of induction, as well as the frequency relative to the extrapolation of the range of the most significant harmonic components of the magnetic flux density evolution.

Determination of iron losses

As a first step, acquiring

in the entire mesh, assuming 2 electrical cycles is necessary for accurate FFT computation. With those harmonic values of magnetic flux density, it is possible to obtain the massic losses in the machine´s core by interpolating those values with power loss data shown in

Figure 5. Moreover, the data obtained from FEM software also provides two other matrices, the identification of the elements nodes and the geometric coordinates of them. This allows us to compute the volume of each element either for 2D geometries or 3D geometries. After obtaining the total volume of each element, knowing the value of massic losses in each element and its density, the total value of iron losses is given by Equation (

4) where k is relative to the mesh elements.

,

,

,

are the iron losses in the core

, the massic iron losses in each mesh element

, the volume of each element

and the density of the material that corresponds the element

, respectively.

2.4.3. Electrical Equivalent Circuit Study

The equivalent electric circuit is based on a 1st-order state-space model as shown in Equation (

5), where the state variable is the phase current. The matrices

,

,

,

, and

are the resistance matrix, inductance matrix,

matrix, voltage vector, and current vector, respectively. Those first three matrices are represented in Equation (

6). For the sake of simplicity, the phase current is considered the output variable, and the rotor speed (

) and voltage are considered the input variables. In this analysis, we consider one phase per pole, so a four-phase system.

Firstly, we start to determine the parameters of the equivalent circuit model using the FEM model. The FEM simulation software determines the resistive value of the windings () by the quotient of the product between number of turns in the winding (), the average length of the coil () by the product between and cross-section area of the wire of the winding (). Recalling the axial symmetry in 3D geometry, the resistive value in 3D is multiplied by 2.

Using FEA results, the inductance and

N maps are obtained by the gradient of each phase’s linked flux to the current and rotor position, respectively. Although, taking into account that the study is based on only the phase current of coil 1, the inductance maps obtained will reflect one phase, phase 1, which corresponds to the first column of

. The column vector

is given by the derivative of the linked flux of the coils relative to the rotor position. Equation (

7) show

and

matrices.

Afterward, since it has symmetry between electrical cycles, it is simulated an electric cycle using a stationary study. Visual observation of the linked flux evolution of phase 1 indicates that the maximum and minimum values of linked flux correspond to the location of the d and q axes, respectively. To corroborate the location of the dq axis, one sets out the value of Br to 1.4 T and makes the stationary study once again to obtain torque evolution since the electromagnetic torque is higher when the rotor is aligned with the d-axis than when it is aligned with the q-axis.

2.5. Geometry optimization

Optimization Objectives

The objective functions considered are the minimization of useless torque (

) and the maximization of torque density (

). Since our study focuses on maximizing the output electric power and is made at stationary conditions, the average value of input electromechanical torque is a good gauge for maximization. However, without belittling the minimization of the vibrations transmitted to the PMs, the diminishment of the oscillatory component of the electromechanical torque is also considered. These objectives are shown in Equation (

8).

Design Variables

This work will study the effect of geometric dimensions on electromechanical torque. So, to maximize the freedom degree of the optimization, it will consider almost all geometric independent variables as decision variables as exposed in

Figure 1 which are

,

,

,

,

,

g,

,

,

,

,

,

,

,

and

.

Constraints

According to

Figure 1, it is possible to observe that there are geometrical constraints that cannot be violated so that there are no intersections between the different DSPM machine elements. Therefore, the geometrical constraints are enumerated below.

- 1.

- 2.

- 3.

- 4.

- 5.

- 6.

The limits of the design variables are presented in

Table 2.

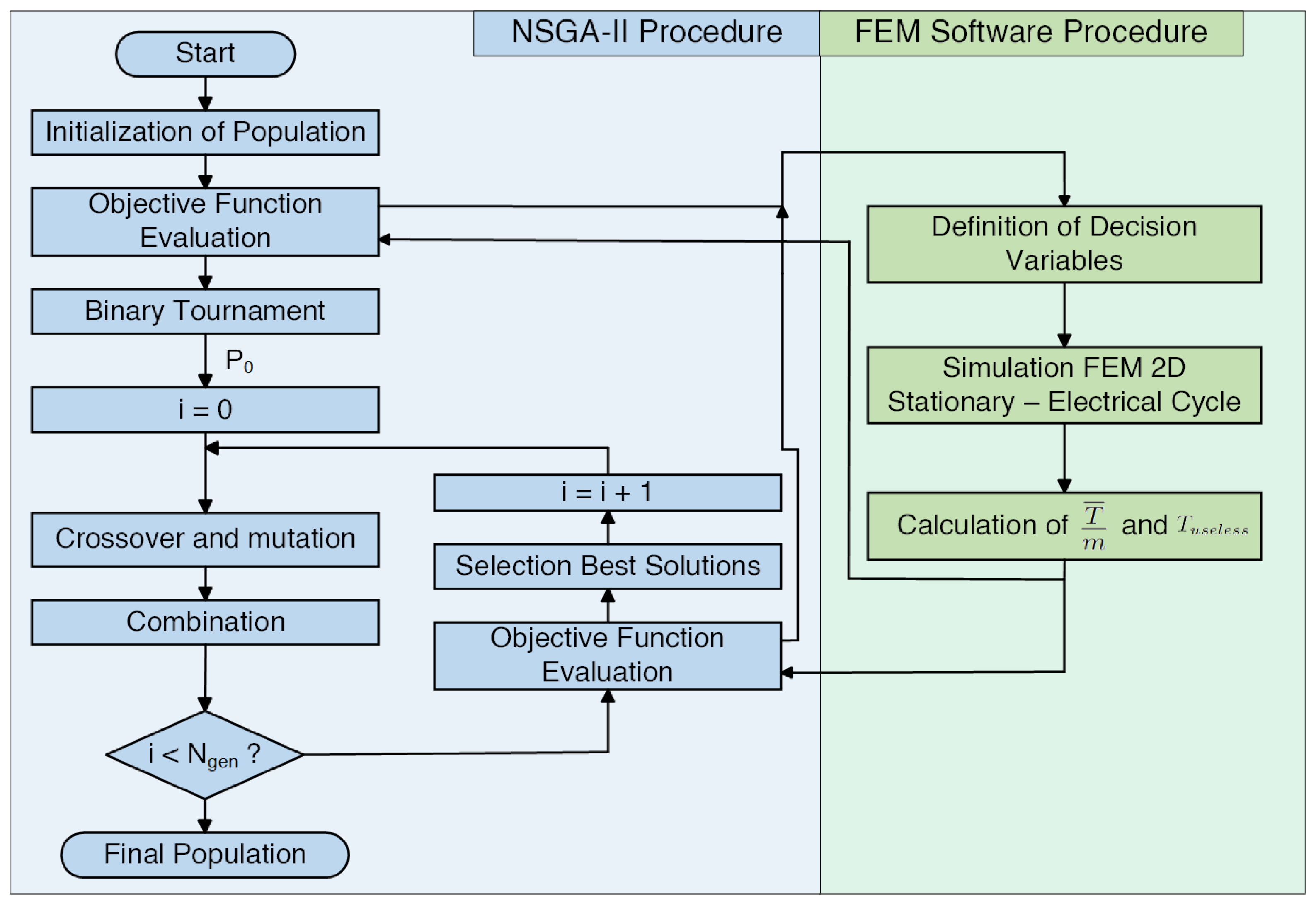

Optimization Program: Genetic Algorithm

To perform the optimization, the NSGA-II (Non-Sorting Dominant Genetic Algorithm) algorithm is used, which is based on the basic idea of the evolution of populations throughout generations, considering a sufficient number of generations to acquire the Pareto front or curve [

14] being briefly described next the optimization algorithm.

Considering the operation principle of the NSGA-II algorithm, the optimization process starts evaluating the constraints violated to study only the valid geometries. The admissible geometries are studied in a stationary study of an electrical cycle, and its results are sorted as described previously to make the next generation. This process is repeated to the next generations until the Pareto curve converges. The number of generations and the number of individuals considered are at least 150 [

15] and 75, respectively.

Figure 6 illustrates a flowchart of the whole process considering the NSGA-II algorithm and electromagnetic study algorithm to visualize the parallelism of the processes in the optimization.

3. Results

3.1. Comparison of flux and torque calculations based on 2D and 3Dgeometries at no load and lumped-parameters study

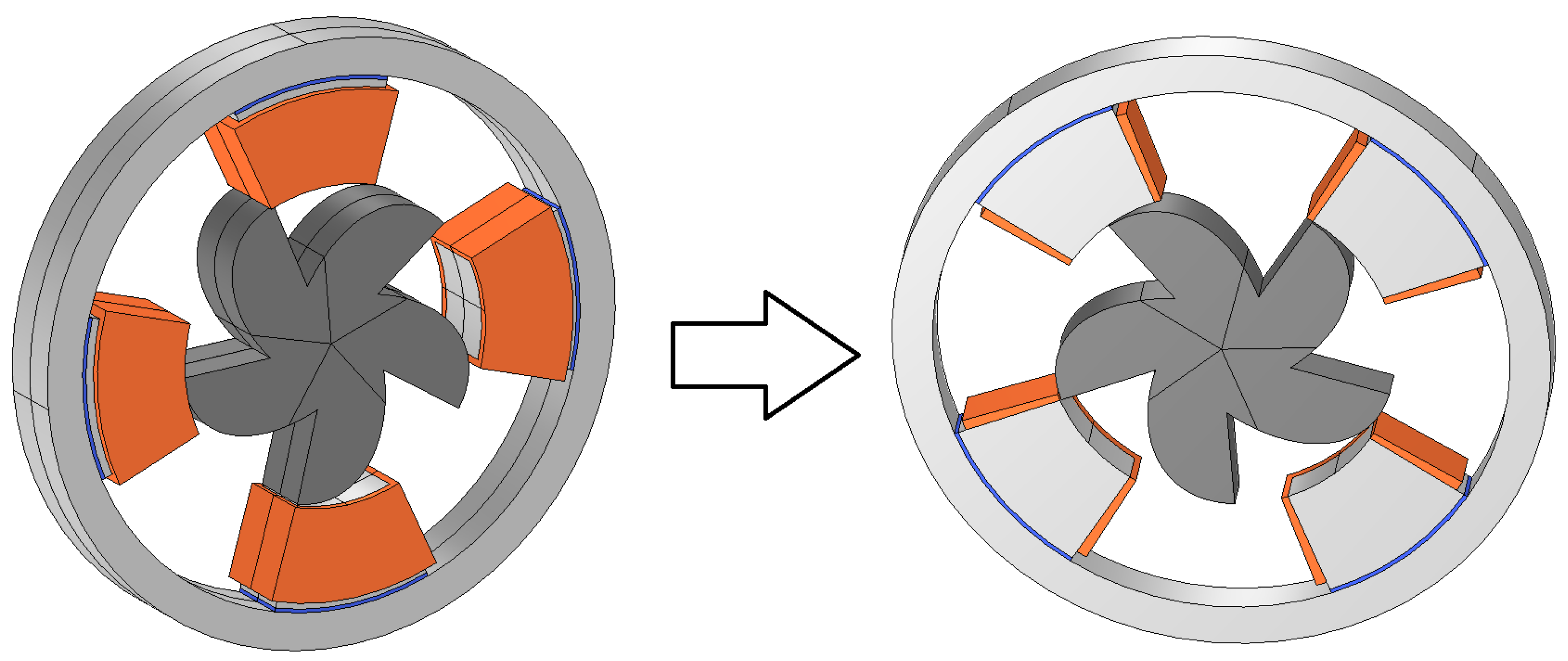

Figure 7 illustrates, on the left side, the DSPM S4R5 and, on the right side, the axial symmetry of the DSPM S4R5 model used to minimize computational time. Yet, the PMs are represented in blue to highlight their visualization. Also,

Figure 8 shows the corresponding 2D geometry.

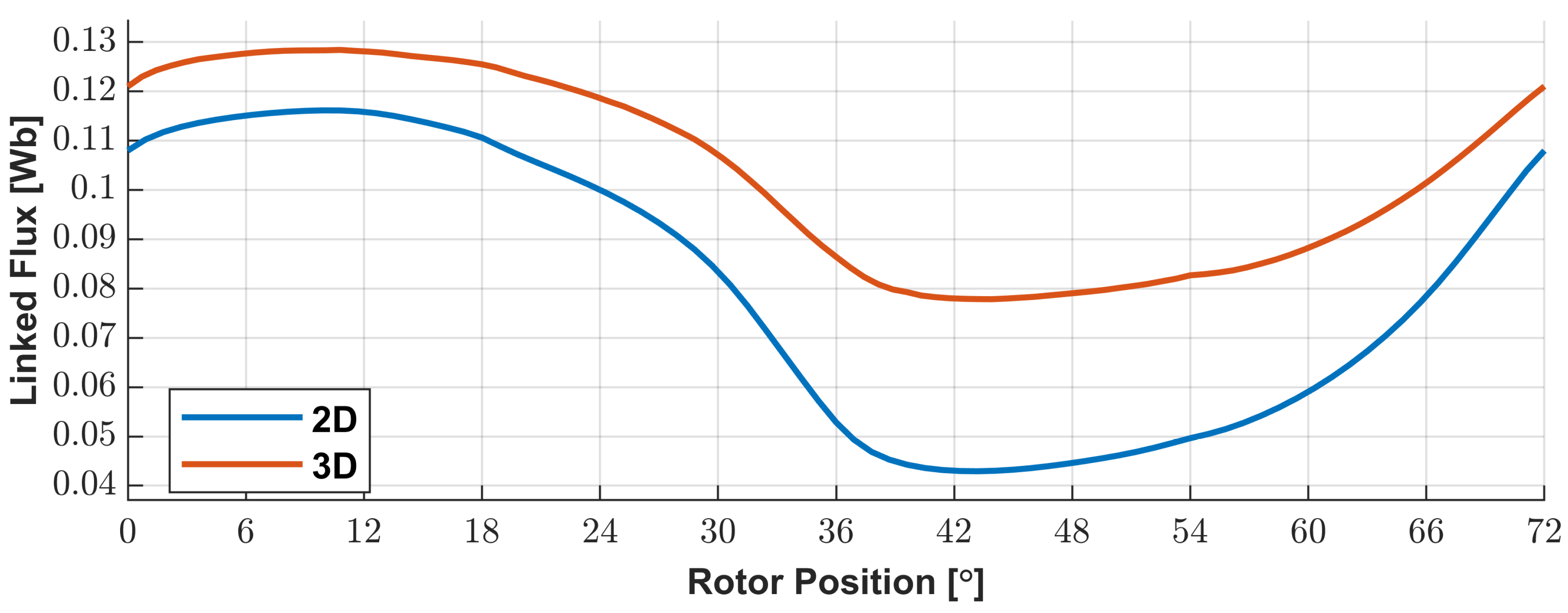

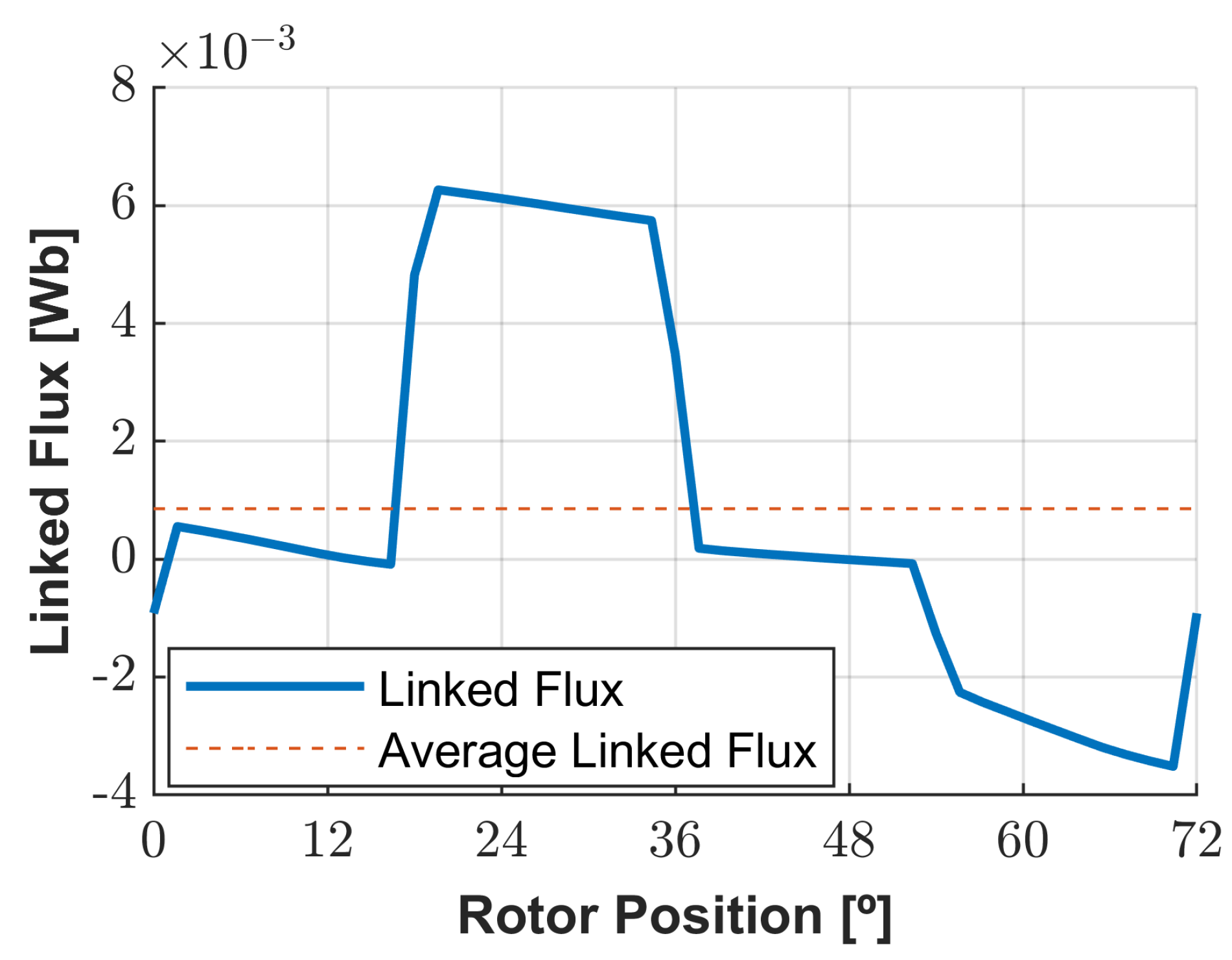

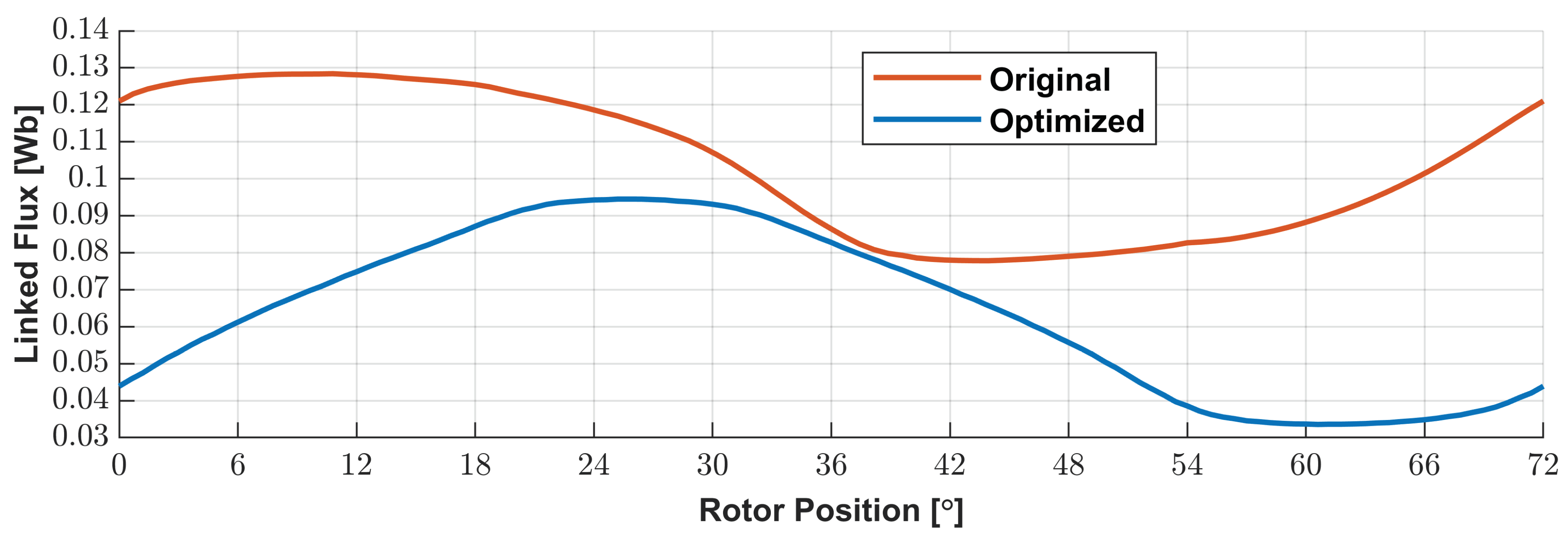

Thus, as verified in

Figure 9, 3D geometry has a higher average and lower peak-to-peak amplitude values of linked flux than its 2D counterpart. As 3D geometry presents lower magnetic reluctance from the standpoints of the PMs, this means a rise in their magnetic load and, in turn, in their total magnetic flux. The constraints imposed on leakage paths by the 2D geometry compel the magnetic flux to cross from the stator into the rotor. In short, the 2D geometry gives more optimistic results in terms of output voltage than the 3D geometry.

To analyze the voltage quality, the linked flux evolution is studied as an image of the induced voltage. So, is performed the computation of the weighted total harmonic distortion (WTHD) of linked flux as shown in

Figure 9. The WTHD is given by Equation (

9) [

17].

The WTHD for 2D geometry is approximately 4.17% and the WTHD for 3D one is approximately 4.25%, thus demonstrating that the 2D geometry has a good approximation to the 3D geometry. This means that the voltage quality can be analyzed by 2D geometry to reduce computational time. Also, the 2D geometry results can be used to analyze the voltage quality supplied by the generator in no-load conditions.

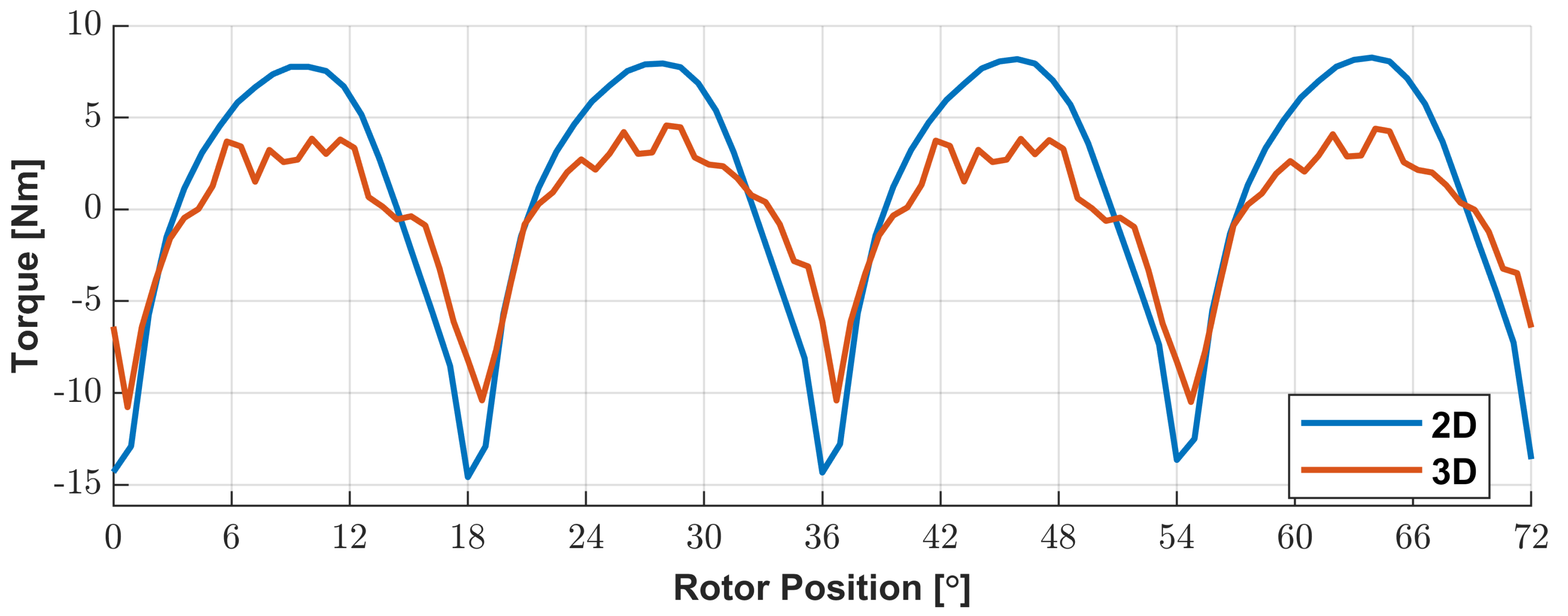

On the other hand, as described in

Section 2.4.1,

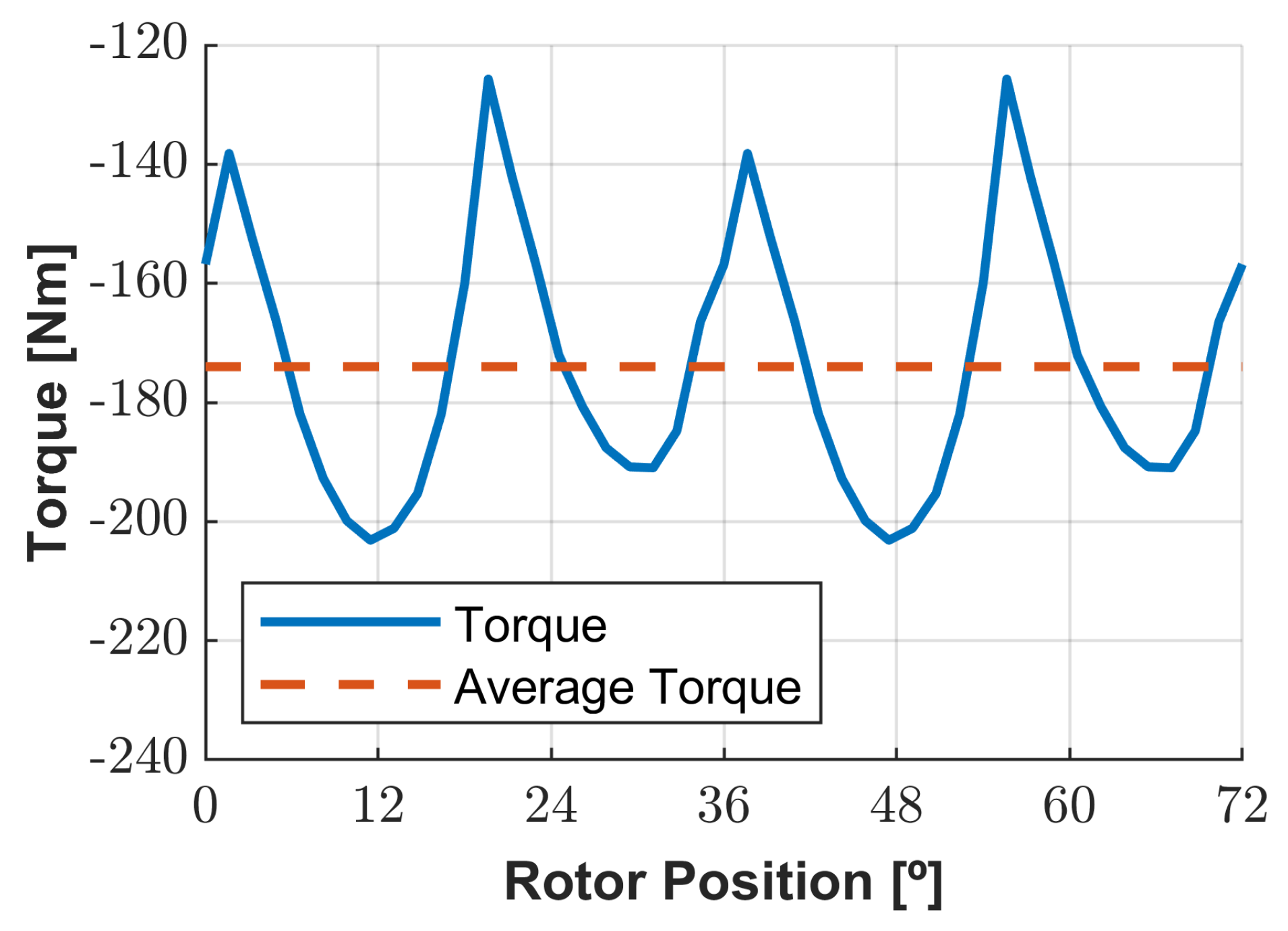

Figure 10 was obtained regarding the electromechanical torque evolution.

The 3D results present a certain unexpected ripple in torque. The torque data was not processed to maintain the peaks since our study verified that smoothing the data imposes a deviation in peaks. The ripple is caused by the inaccuracy given by the mesh and the stationary study. As in 2D geometry, the torque amplitude is higher, which means that 2D geometry gives more conservative results in oscillatory torque than its 3D counterpart. So, 2D can be used in a preliminary design phase. However, if more accuracy is needed in the results, 3D geometry must be used.

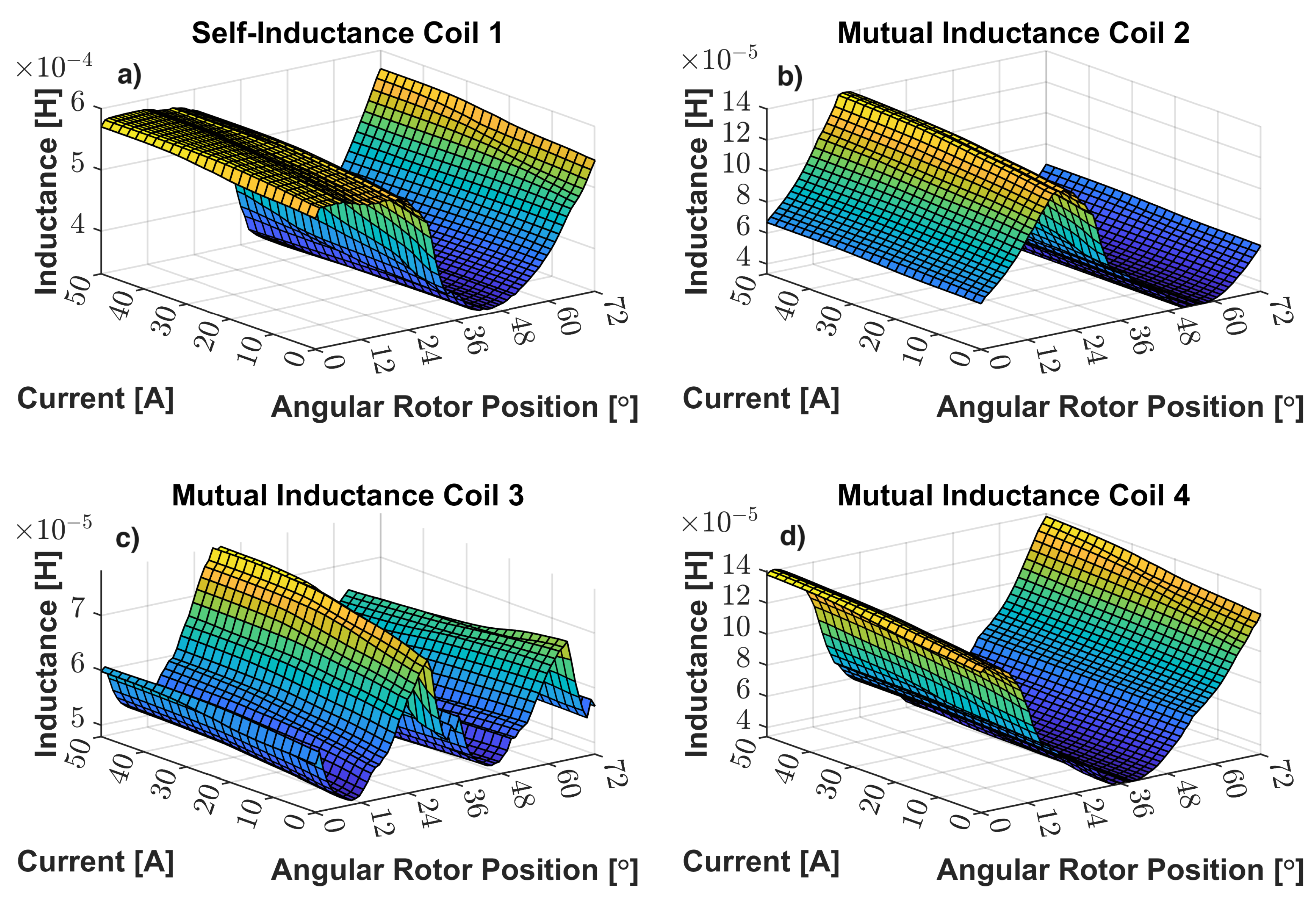

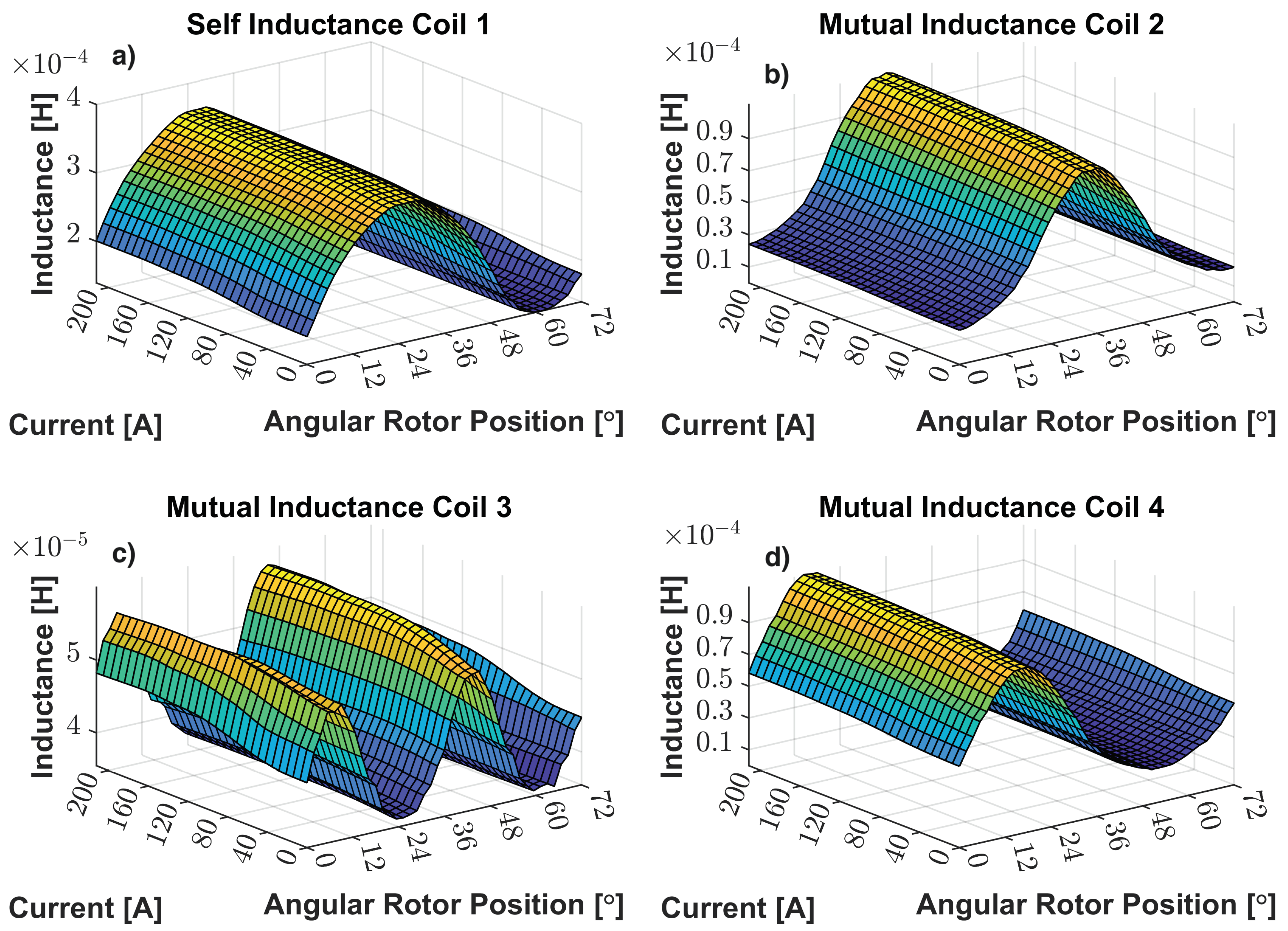

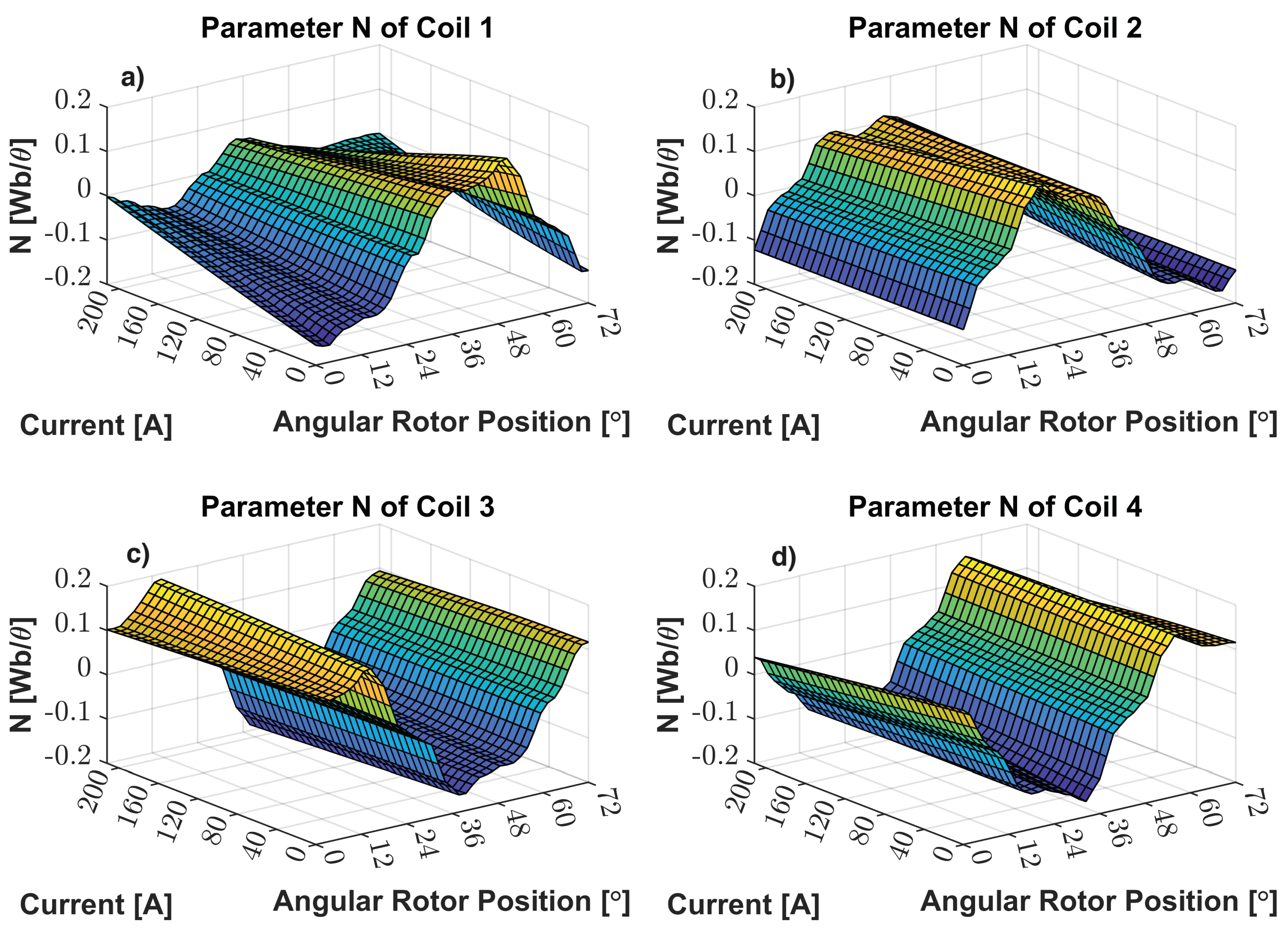

As the study of magnetic flux was already made, it is performed a study of the lumped-element parameters of the equivalent electric model of the machine, as described in

Section 2.4.1. The stator coil resistance is 7.2

.

Figure 11 and

Figure 12 show the preponderance of the effects of the rotor position in inductance fluctuation than the effects of phase current. The peak-to-peak value of 300

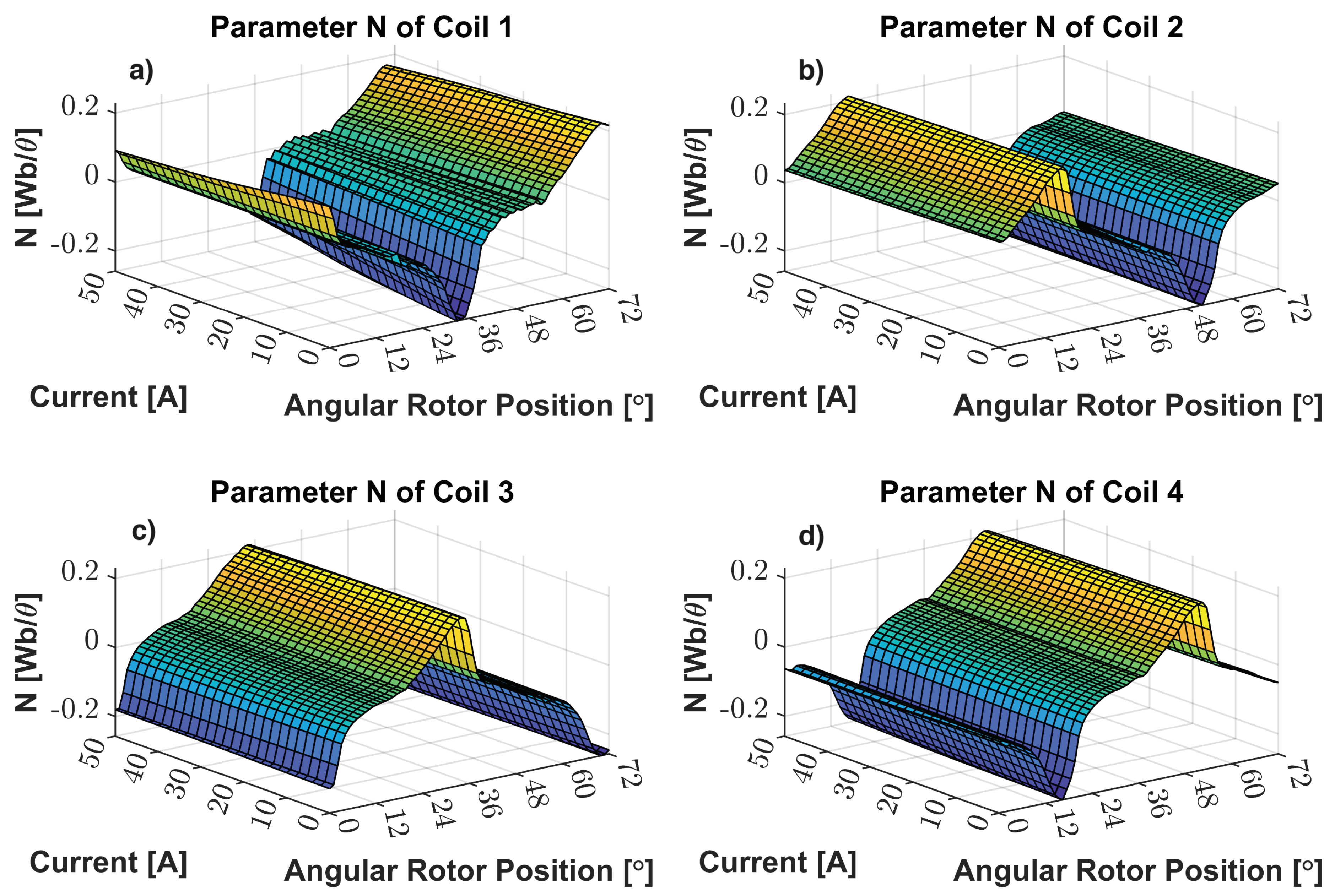

due to the rotor position effect and a neglectable peak-to-peak value due to the phase current effect justifies the previous sentence. Therefore, the core saturation effect is not visible. The self-inductance is about 5 times greater than the adjacent mutual inductances and around 7 times higher than the opposite mutual inductance. The differences between mutual inductance values, either mean or oscillatory values, are given by their geometrical arrangement. Relative to the parameter

N, these maps relate the EMF produced by the DSPM S4R5 machine with rotor position and the current apart from rotor speed as displayed in Equation (

5). Moreover, it is highlighted that the decaying effect due to the current is similar for the

N maps as the linked flux maps.

3.2. Iron losses calculations at no load

The method discussed in

Section 2.4.2 applied to 3D geometries will be our benchmark since the 3D geometry is the most accurate model. Therefore, the loss values obtained for 2D and 3D geometry are 362W and 284W, respectively.

Thus, the 2D geometry results present an oversize of about 45% concerning the most accurate value, 3D geometry. This indicates that the 2D geometry model enables a rough estimation in a preliminary phase of the design of machines with a large diameter-length ratio. Since the discrepancy between the results is so high, the 3D geometry must be used to improve accuracy.

3.3. Phase current shape study

This study is based on the results of [

18,

19,

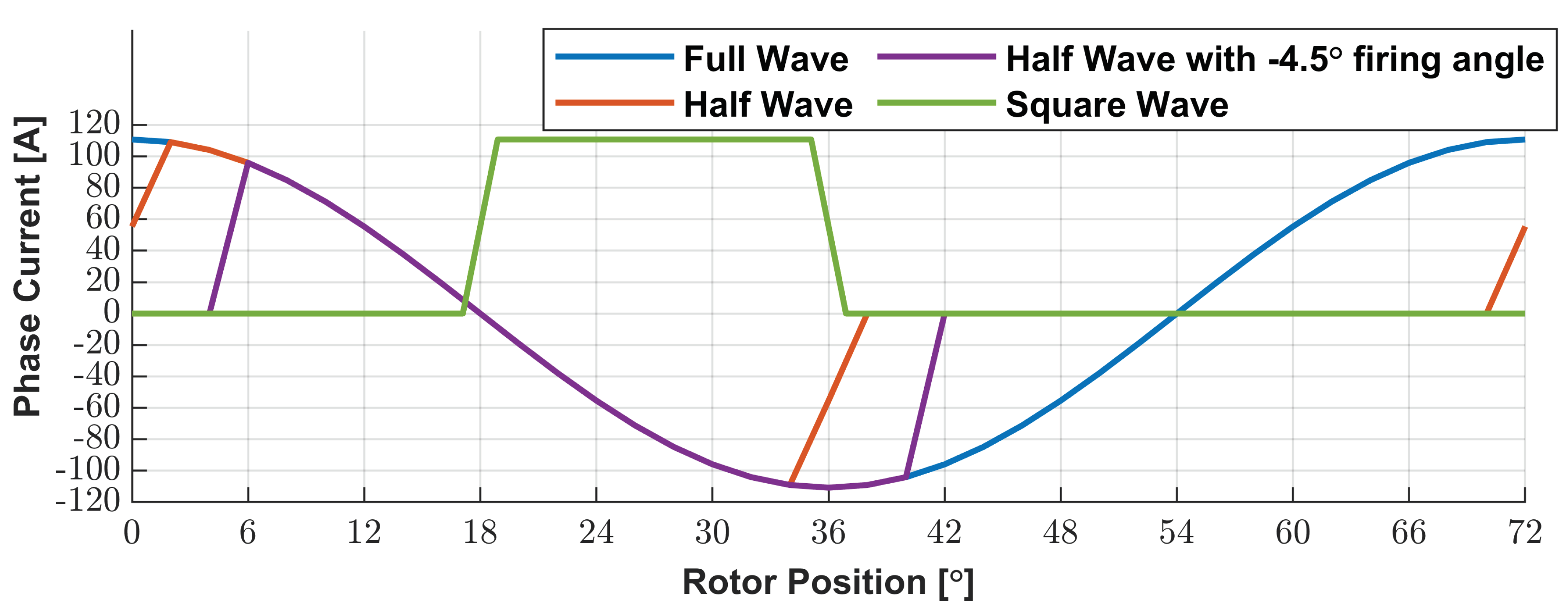

20] being seen four current waveforms as sinusoidal waveform, a square waveform, and two rectified sinusoidal waveforms.

The different kinds of waveforms of current assumed to be studied are shown in

Figure 13 and for only one phase current with an amplitude of 110 [A]. Also, it is highlighted that the number of points considered to acquire the results is enough to represent the fast transitions of the waveforms with the required accuracy. For the sinusoidal waveform, the power angle [

] that provides the biggest torque mean value is 0°.

Most current waveforms in

Figure 13 derive from a cosine wave, where the blue one is the proper one. To replicate a current waveform given by a power electronic converter, the orange and violet lines are the cosine waves considering firing angles. However, as the theory of conventional switched reluctance machine mentions, the higher output power is given when the range given by firing angles is in the interval where the inductance of the machine is decreasing. So, a square wave is obtained (green color).

Table 3 shows the mean reaction torque value results, the standard deviation of the torque to represent the oscillatory torque, and the ratio between them.

The best waveform is the square waveform when imposed at the moment that the misalignment of the rotor and stator poles occurs since it has the lowest ratio. So, the square current waveform will be used in the optimization process. Also, it can be seen that the phase current waveform can significantly improve the electromechanical torque mean value and, in turn, the delivery of active power.

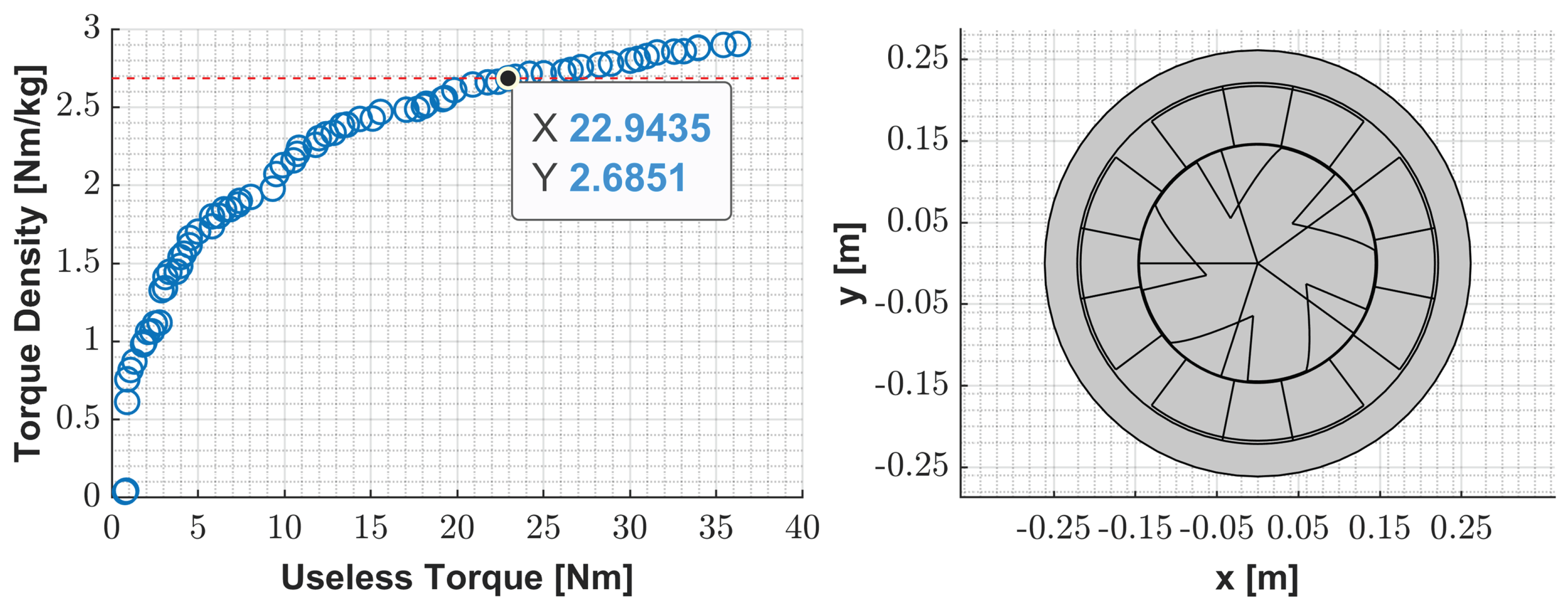

3.4. Optimization of the DSPM S4R5 machine results

The best front obtained by the optimization process is illustrated in the left part of

Figure 14. The selected point is in the middle part of the Pareto curve. The region above the red line represents an output power equal to the minimal power requirements of 90 kW, considering 3000 rpm. The right part of

Figure 14 illustrates the geometry representative of the selected point.

The geometry obtained has a decrease in its total volume concerning the initial geometry of around 35% by a reduction of its radius to about 19.4% relative to the initial geometry. The most relevant difference is the rotor teeth design, which approximates a rectangular shape like the classical machine rotor. The main geometrical parameters of the machine are exposed in

Table 4.

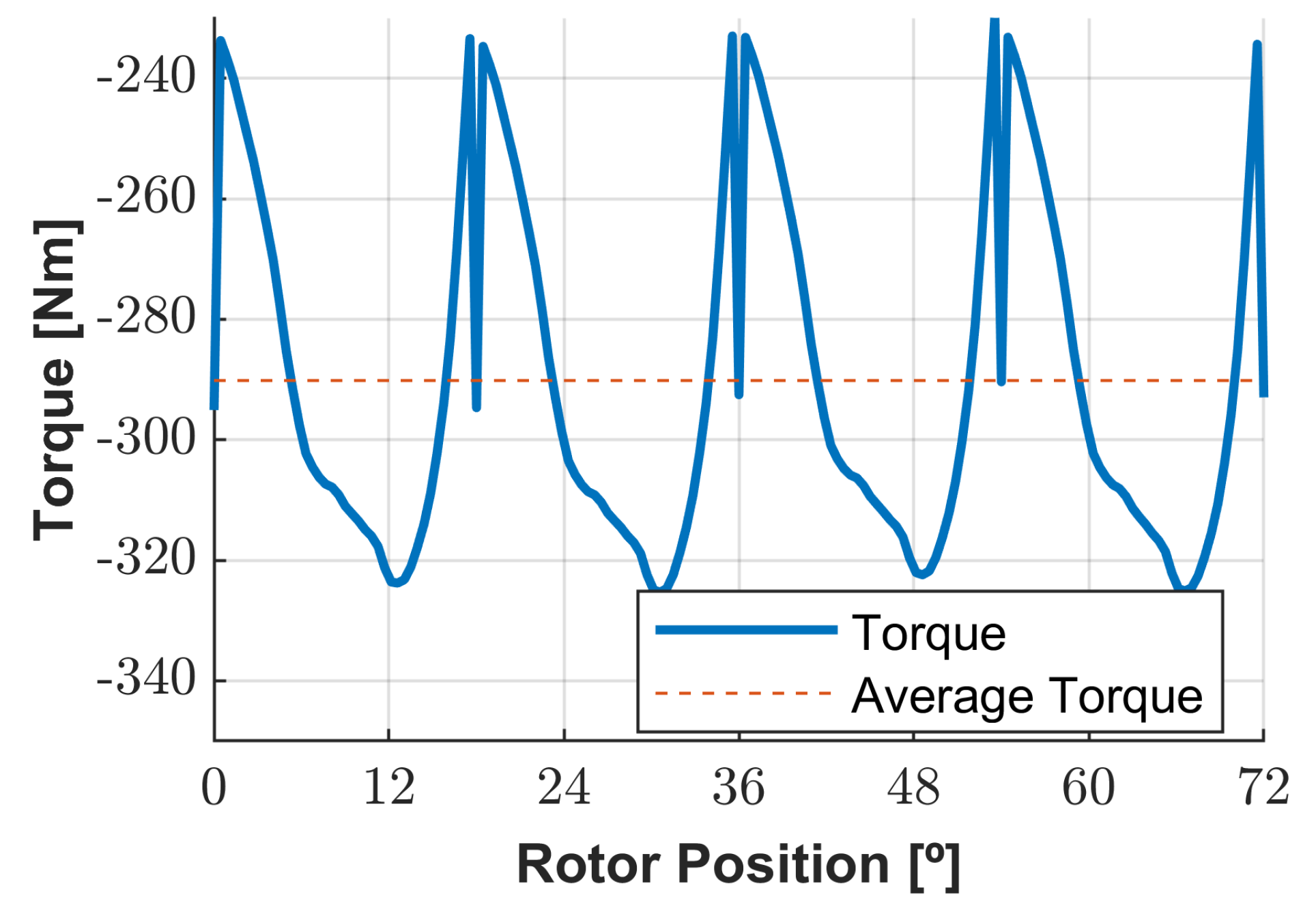

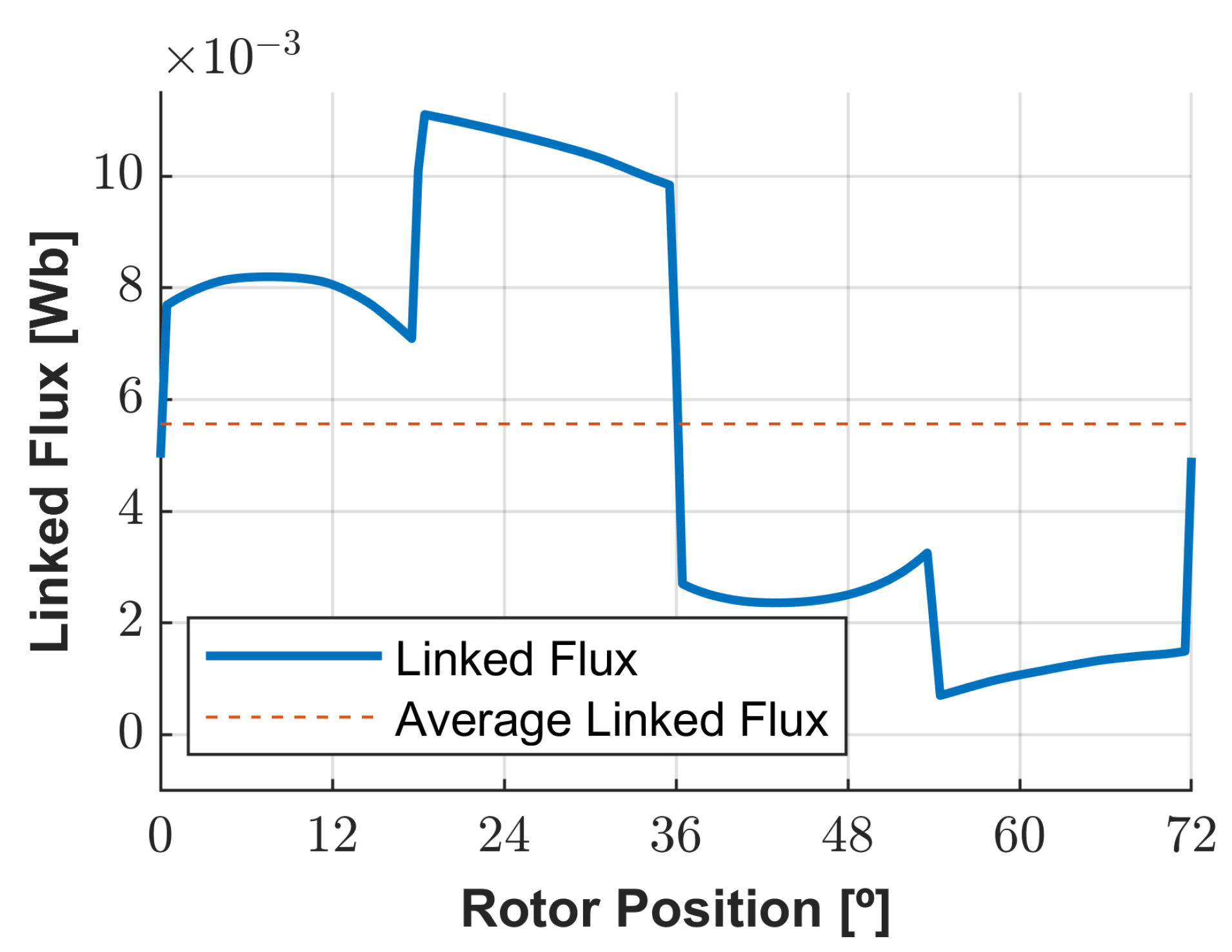

Moreover, to visualize the behavior of this new optimal geometry with nominal load,

Figure 15 and

Figure 16 illustrate the magnetic flux and torque evolution along an electrical cycle for the 3D geometry.

The torque presents a sharp evolution when the stator poles are in almost and right after the alignment, which can impose mechanical stress on the material. However, as the peaks are around 10% of the nominal mean value of the electromechanical torque, the mechanical stress is not harsh. The linked flux evolution presents discontinuity zones due to the imposed switching load currents, translating into voltage peaks.

To obtain more precise results, it is studied the torque and linked flux in the same load condition of the 2D geometry and illustrated in

Figure 17 and

Figure 18 for 3D geometry. This last one is going to be shown in the next Section.

The mean value of linked flux and electromechanical torque decreased. The average value of torque has a decrease of around 46.5%, meaning that the selection of the geometries of the optimization process must take that into account. The average of the electromechanical power is about 47.75 kW. Also, the average value of linked flux decreased its value by 82.8% and the maximum value decreased by about 45%, which indicates the 2D geometry gives errors above 10% compared to 3D geometry for the linked flux values to large diameter-length ratio machines in load conditions.

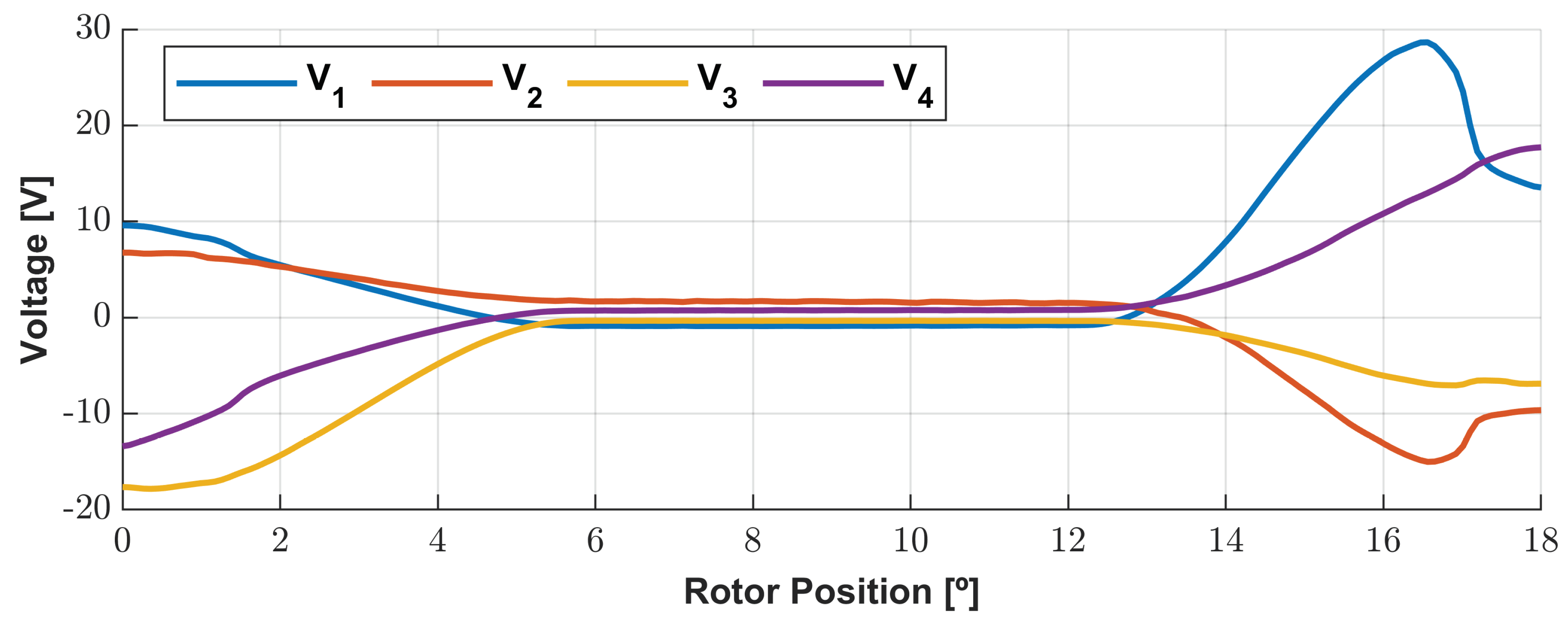

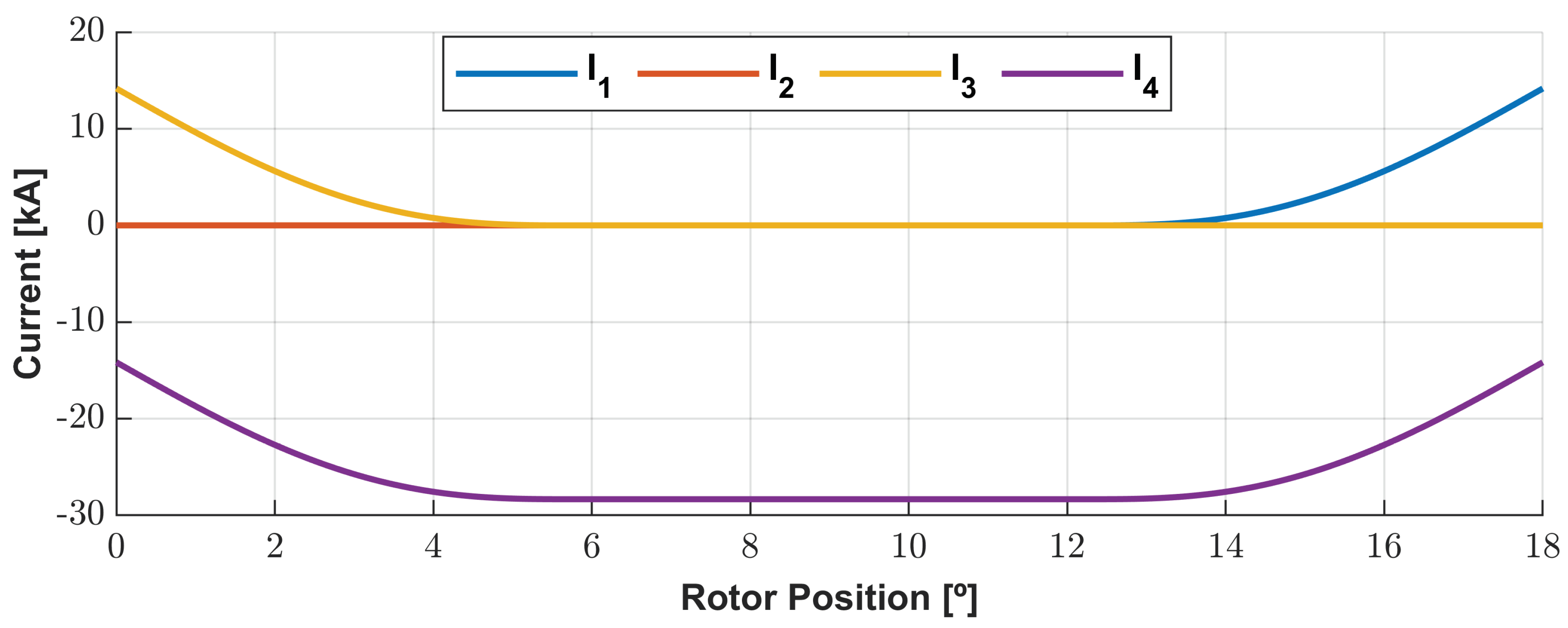

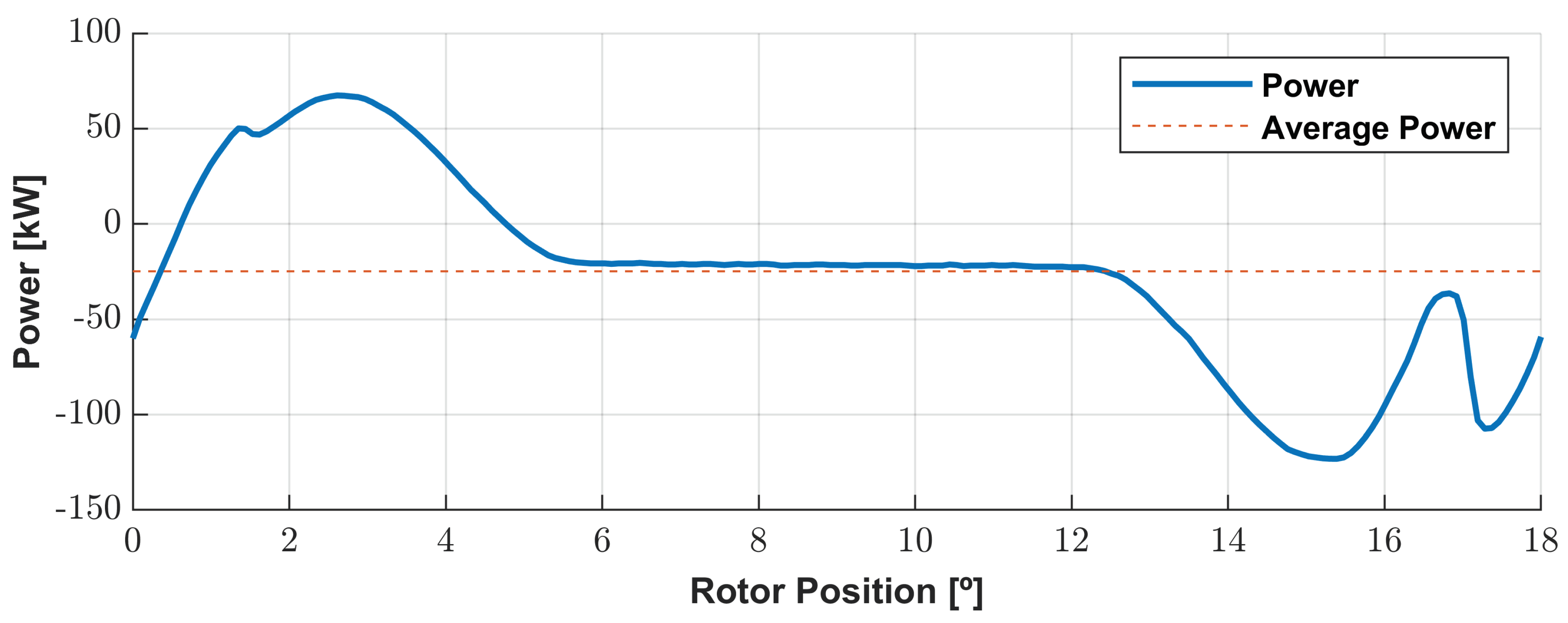

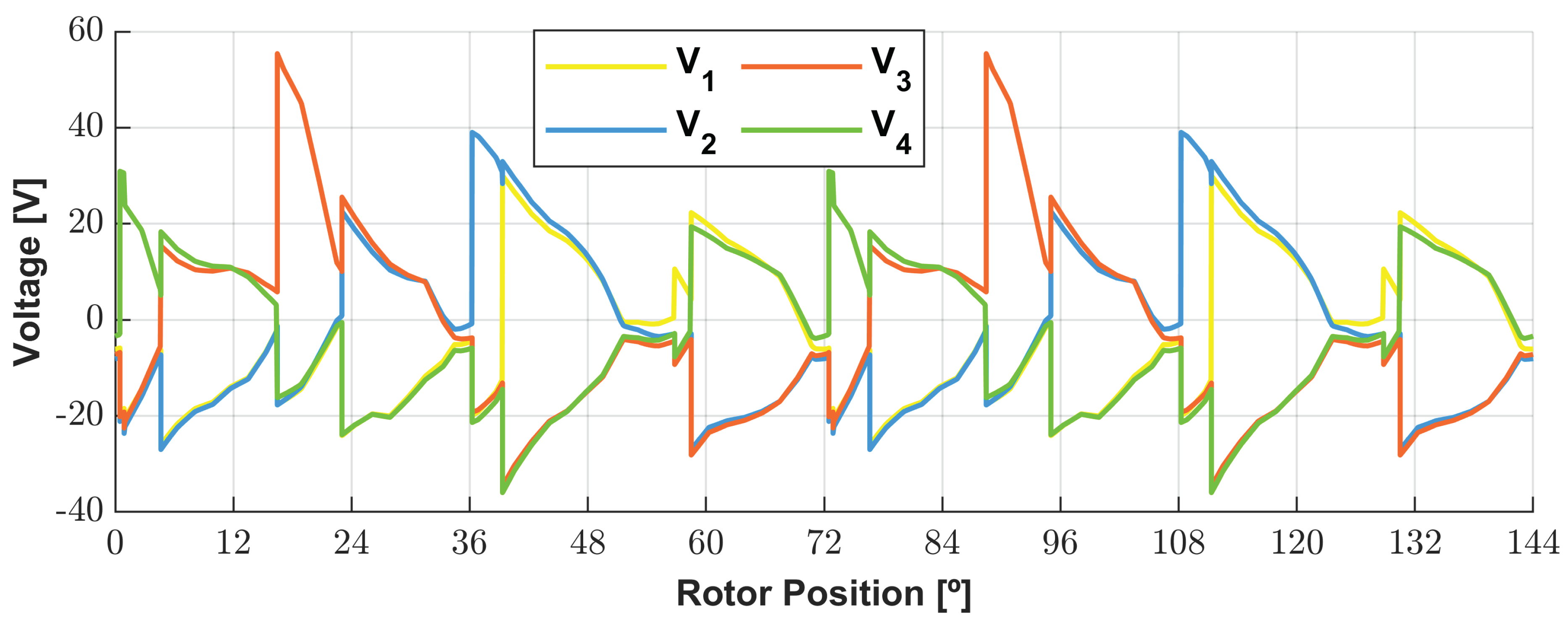

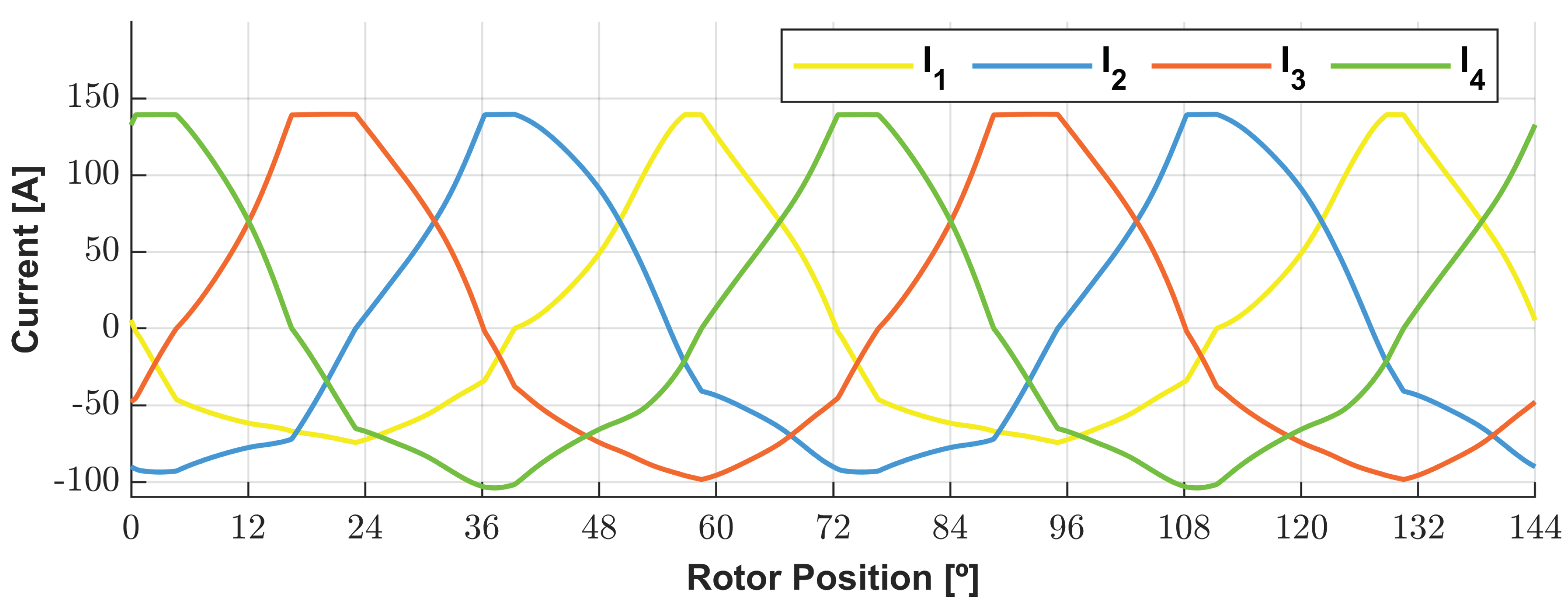

The voltages, currents, and the total electric instantaneous power are presented in

Figure 19,

Figure 20 and

Figure 21. The indexes 1, 2, 3 and 4 shown in the legends are relative to coils 1, 2, 3 and 4. It is recalled that the voltages were obtained without considering the resistive voltage drops of coils since, for 1 turn, these components were around 3 orders of magnitude below the output voltage value.

As visualized in

Figure 18, the voltages are highly distorted as linked flux due to the imposition of pulsed currents. The transient zones of the commutation of the current cause voltage peaks. So, the peaks seen in the power are derived from that fact.

The difference between the average output power and the average input power could occur due to the lack of accuracy of the results. During the work of this dissertation, the torque results were more accurate than the voltage results. So, our benchmark is the electromechanical torque. This indicates that for studying electrical power, it is necessary to use a simpler model, the electric equivalent model of the DSPM S4R5.

Although Joule losses and iron losses can be studied, the machine’s efficiency is given by the quotient of the difference between the total mechanical power and the studied losses by the proper total mechanical power. As visualized in

Figure 20 and

Figure 21, the 4 phases are switched on by a quarter of the electrical period. So, relative to the Joule losses, this means that it can be computed for a single coil, presenting a value of 722 W. The iron losses computed as mentioned in

Section 2.4.2 has a value of 3.05 kW. So, the efficiency of the optimized machine is around 92%, neglecting mechanical losses. This efficiency value is acceptable since the optimization process did not consider this aspect.

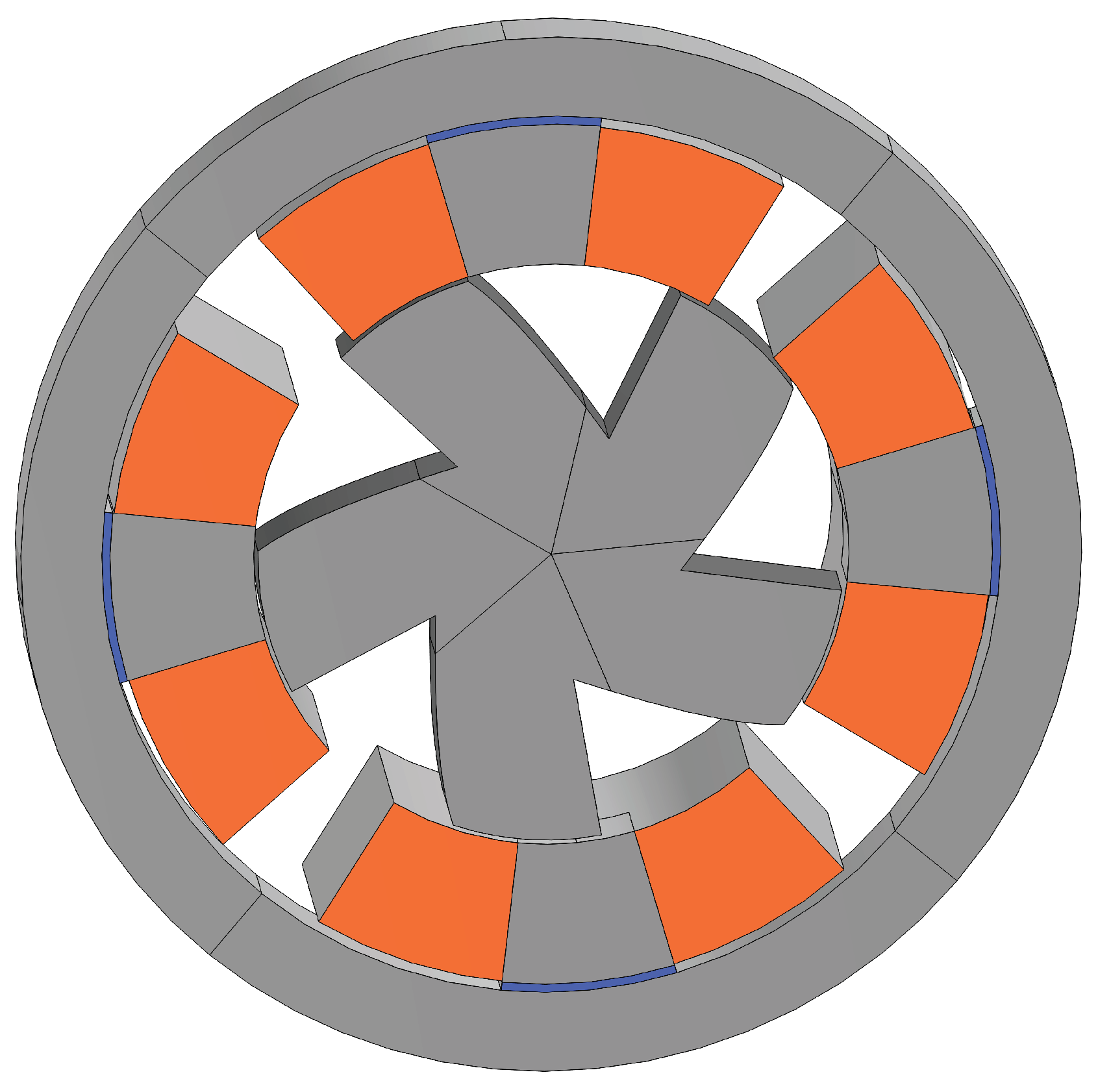

3.5. Comparison of initial and optimized geometries at no load and lumped-parameters study

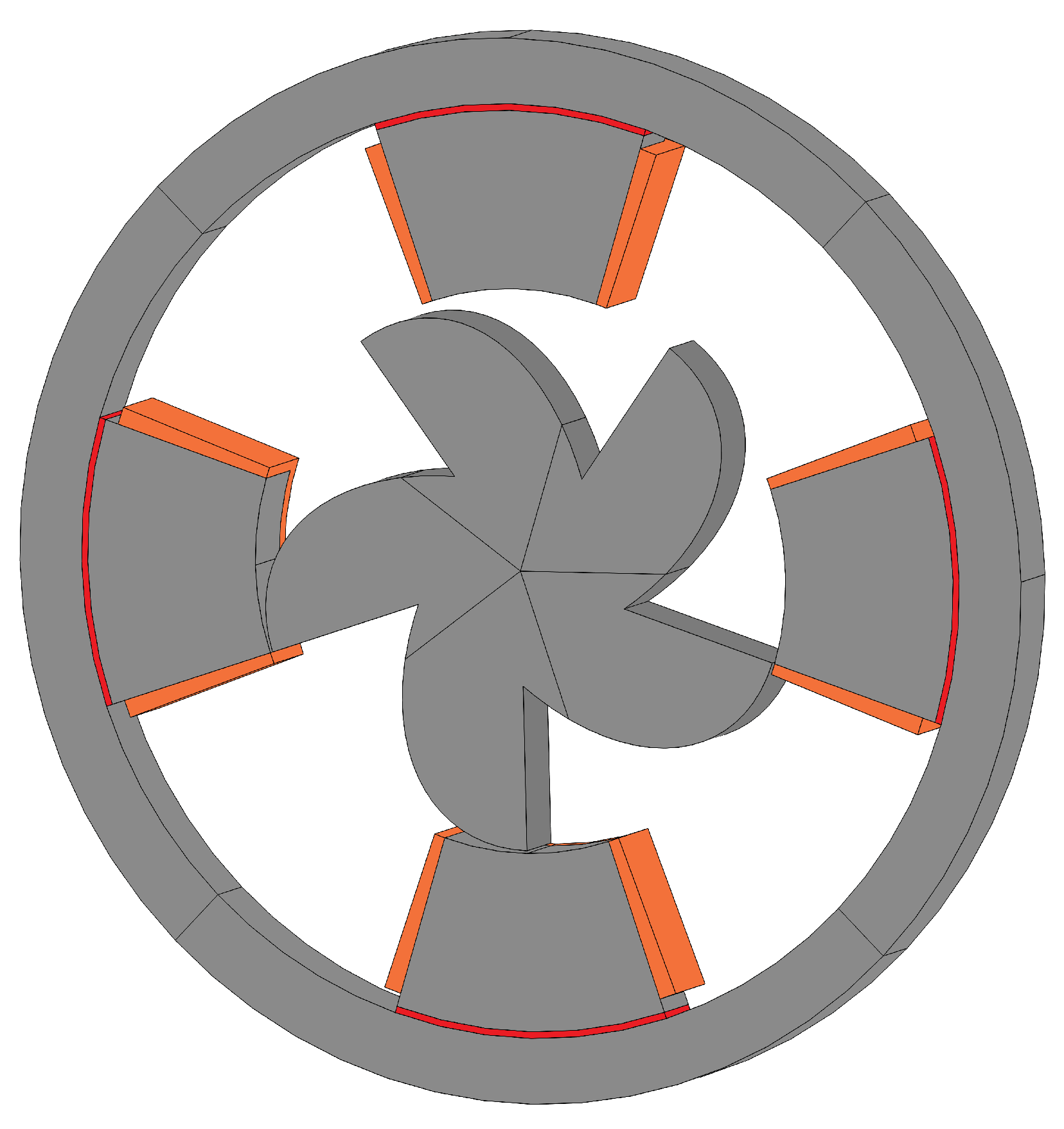

The initial geometry is recalled to visualize the differences to the optimized geometry being the first one illustrated in

Figure 22 and the last in

Figure 23.

Compared with [

9], the number of turns per coil is now assumed to be 20.

Figure 24 shows the evolution of the linked flux for the initial and optimized machines to compare both. The major difference remains in the mean value since the optimized geometry presents a reduction of 42.9% relative to the initial one. Besides that, it is observable that the peak-to-peak value of the optimized geometry is about 60 mWb against 50 mWb. This translates into a higher output voltage considering the same rotor speed for both geometries.

Once more, using the WTHD in linked flux waveform to compare the voltage waveform quality, the WTHD value is 1.1%, against 4.2%. This means that the voltage quality of the optimized DSPM S4R5 machine is greater than the original one.

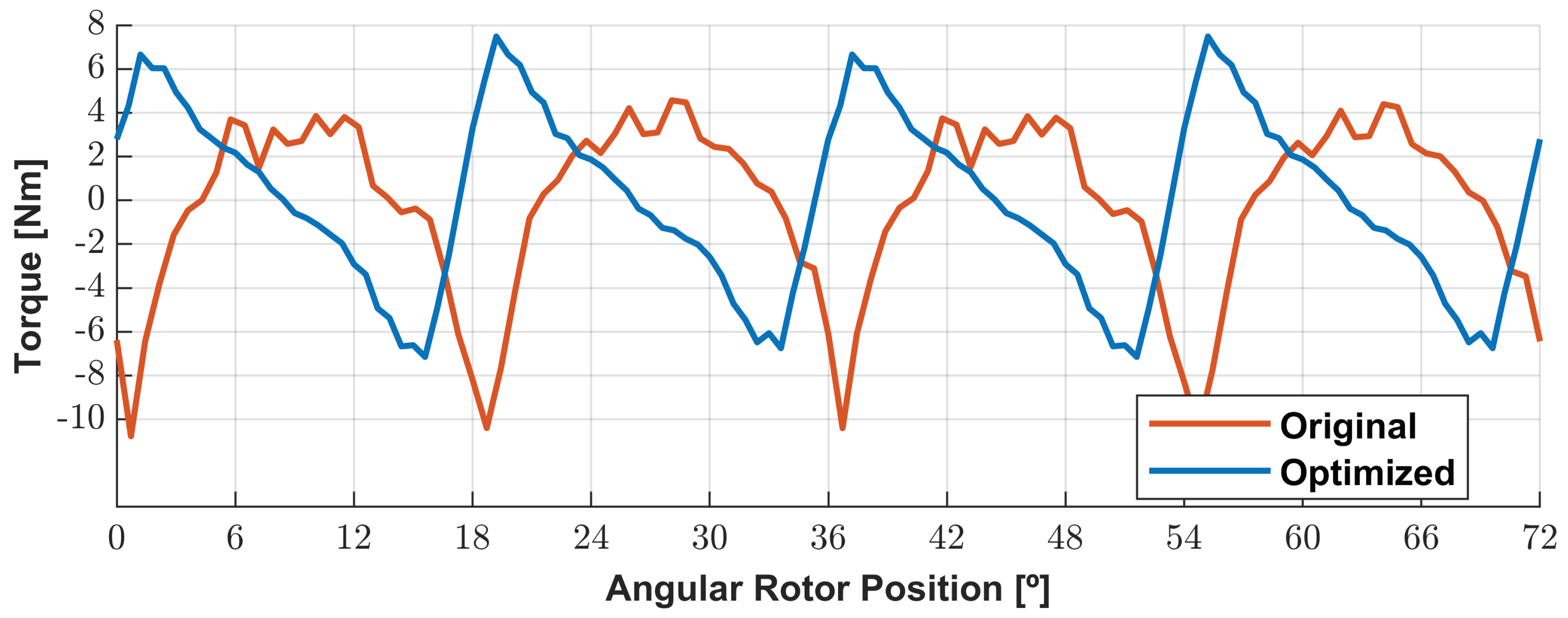

Figure 25 illustrates the electromagnetic torque for the initial and optimized 3D machines for comparison purposes. The evolution in the lower peaks is less rough in the new geometry than in the original one since it has just one abrupt variation in those peaks instead of two as in the initial geometry. This helps minimize the mechanical stress imposed on the shaft. Once more, the results present a significant ripple because they are not filtered since the smoothing would distort the peak values.

For the comparison of iron losses of the original and optimized DSPM S4R5 machines, the iron losses calculation was made by Element Method as described in

Section 2.4.2 obtaining 286W for original geometry and 204W for optimized geometry. Thus, it can be verified that there is a reduction of 28.67% in core losses compared with the original geometry. As the rotor speed of both machines is 3000 rpm, the difference between them, according to Equation (

3), is the magnetic flux density in the core of both machines. Since the harmonic spectrum of linked flux reflects the behavior of each harmonic of magnetic flux density, the WTHD is a measure of the higher harmonic amplitude relative to the fundamental one. So, as the WTHD of the linked flux of the optimized geometry is lower than the original geometry, the decaying of the harmonic components for the optimized geometry is higher than the initial geometry. This means that the main difference between the machines is the lower harmonic component of the optimized one.

The lumped parameters representation of the optimized machine is studied, as referred in

Section 2.4.1 and

Section 3.1. The stator coil resistance has an ohmic value of 0.62

.

Figure 26 and

Figure 27 show each coil’s inductance and

N maps. Once more, the inductance of the machine is higher in the aligned position than in the misaligned position.

Figure 26 shows, for coil 1, its self-inductance and the mutual inductances with coils 2, 3 and 4. By making a comparison between

Figure 11 and

Figure 26, it can be observed that the self and mutual inductances of the optimized machine have lower values than the original one. The superiority of self-inductance over mutual inductance is similar to what was seen in

Section 3 since there is a proportionality of around 4 times greater for the mutual inductance of adjacent phases and around 5 times greater for the inductance of the opposite phase. Once more, the saturation effect is not visible. The

N parameter tends to be a more sinusoidal wave than the initial geometry, as verified by the reduction of the value of WTHD. This is relevant since the higher-order harmonics imply an oversizing of the converter filters. The peak values are similar between the geometries. So, considering constant rotor speed, the induced voltage generated is expected to be the same for both geometries in no-load conditions.

3.6. Loading analysis of the optimized geometry

3.6.1. Aircraft equivalent electrical system

To study the optimized generator in an electric circuit is considered the equivalent circuit of the aircraft, as depicted in [

11]. The generator is modeled by a controlled current source, which is the control signal given by the equivalent electric system. The system’s feedback is given by the voltage measurement of each controlled current source.

3.6.2. Electrical response of the generator with non-commanded AC/DC converter

The simulation of the equivalent electric system of the aircraft studied in [

11] and the equivalent model proceeded in a lumped-parameter circuit software using the methodology described in ??.

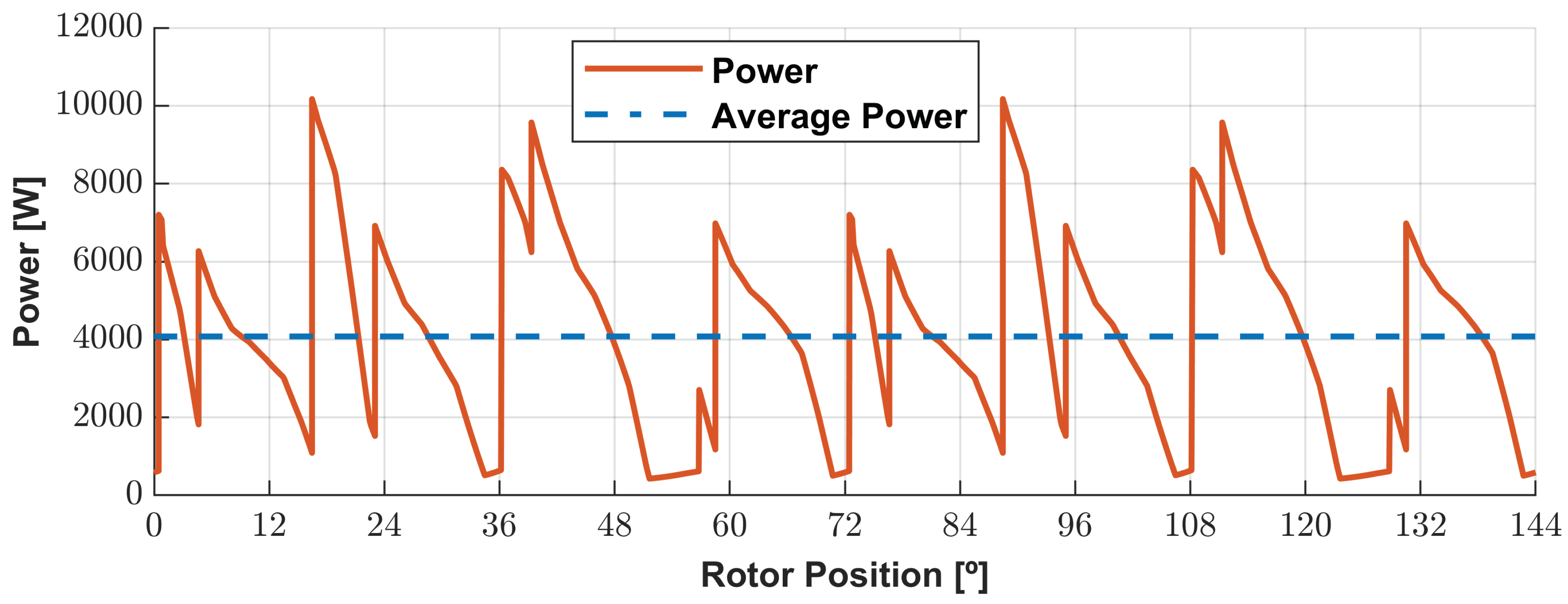

Figure 28 and

Figure 29 illustrates the evolution of the voltages and the currents of each coil. The voltage waveform of each coil is highly distorted from the no-load situation since the AC and DC filters were not properly adjusted to this generator. Also, the voltage waveforms between coils are not symmetrical.

Figure 30 represents the generator output’s instantaneous power evolution. The average output power is around 4 kW, well below the output power obtained in the ideal case. The lack of control implies a degradation of the performance of the generator. Nevertheless, the decaying of the voltage is abrupt just after the peak, implying an abrupt decrease in the output power.

4. Conclusions

This study had two main sections. The first one studied the initial geometry of the DSPM S4R5 in no-load and load conditions, and the second one studied the optimization process and the optimized geometry in load conditions and also viewed the no-load response.

First, the results of the 2D geometry were compared with the 3D geometry to understand what quantities can be studied in 2D. The 2D geometry did not provide accurate results for linked flux, torque, and iron losses. However, since the 2D WTHD had a neglectable deviation concerning the 3D model, the voltage quality can be studied in 2D. Also, the shape of the electromechanical torque evolution has enough accuracy in the 2D geometry study when compared to the 3D one. The overestimation in iron losses of 2D model concerning 3D one can also provide robust results in the design of the machine. In short, the 2D model can be used in the preliminary design phase and the optimization of large diameter-length ratio machines since it gives more robust results.

Finally, regarding the optimized geometry, an optimization process, a study of the 3D geometry in load conditions, a study in no-load conditions, and a study of the electrical response to the aircraft simplified electrical system of [

11] were made. The main conclusions were that the selection of a 2D geometry must be oversized for the electric output power to comply with the requirements; the optimized geometry has better performance in terms of oscillatory torque, induced voltage, WTHD of linked flux, and iron losses.

Author Contributions

Conceptualization, M.N, F.F.d.S and P.J.d.C.B; methodology, M.N, F.F.d.S and P.J.d.C.B; investigation, M.N; writing—original draft preparation, M.N; writing—review and editing, F.F.d.S and P.J.d.C.B; supervision, F.F.d.S and P.J.d.C.B; project administration, P.J.d.C.B; All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by FCT, through IDMEC, under LAETA, project UID/EMS/50022/2020.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Madonna, V.; Giangrande, P.; Galea, M. Electrical power generation in aircraft: Review, challenges, and opportunities. IEEE Transactions on Transportation Electrification 2018, 4, 646–659. [Google Scholar] [CrossRef]

- Wheeler, P.; Bozhko, S. The more electric aircraft: Technology and challenges. IEEE Electrification Magazine 2014, 2, 6–12. [Google Scholar] [CrossRef]

- Lando, J.L. Fixed frequency electrical generation system and corresponding control procedure, 2006. US Patent 7,064, 455.

- Cavagnino, A.; Li, Z.; Tenconi, A.; Vaschetto, S. Integrated generator for more electric engine: Design and testing of a scaled-size prototype. IEEE Transactions on Industry Applications 2013, 49, 2034–2043. [Google Scholar] [CrossRef]

- Rucker, J.E.; Kirtley, J.L.; McCoy, T.J. Design and analysis of a permanent magnet generator for naval applications. IEEE Electric Ship Technologies Symposium, 2005. IEEE, 2005, pp. 451–458.

- Fernando, N.; Nutkani, I.U.; Saha, S.; Niakinezhad, M. Flux switching machines: A review on design and applications. 2017 20th International Conference on Electrical Machines and Systems (ICEMS). IEEE, 2017, pp. 1–6.

- Fernández, D.; Martinez, M.; Reigosa, D.; Guerrero, J.M.; Alvarez, C.M.S.; Briz, F. Permanent magnets aging in variable flux permanent magnet synchronous machines. IEEE Transactions on Industry Applications 2020, 56, 2462–2471. [Google Scholar] [CrossRef]

- Haavisto, M.; Tuominen, S.; Kankaanpää, H.; Paju, M. Time dependence of demagnetization and flux losses occurring in sintered Nd-Fe-B permanent magnets. IEEE Transactions on Magnetics 2010, 46, 3582–3584. [Google Scholar] [CrossRef]

- Esteves, A.N.F. Design and Optimization of an Axial and Solid Double-Inner-Rotor Configuration in PM Flux Switching Generators. Master’s thesis, Instituto Superior Técnico, 2021.

- Reimers, D. Bezier Curves, 2011.

- Silva, J.L.D. Analyses of Solutions for the Attenuation of Cogging Torque in Flux Switching Electrical Generators with Permanent Magnets in the Stator. Master’s thesis, Instituto Superior Técnico, 2016.

- Di Tommaso, A.O.; Genduso, F.; Miceli, R.; Nevoloso, C. Fast procedure for the calculation of maximum slot filling factors in electrical machines. 2017 Twelfth International Conference on Ecological Vehicles and Renewable Energies (EVER). 2017, 1–8. [Google Scholar] [CrossRef]

- Arkkio, A. Analysis of Induction Motors Based on the Numerical Solution of the Magnetic Field and Circuit Equations. PhD thesis, Helsinki University of Technology, Espoo, Finland, 1987.

- Deb, K.; Pratap, A.; Agarwal, S.; Meyarivan, T. A fast and elitist multiobjective genetic algorithm: NSGA-II. IEEE transactions on evolutionary computation 2002, 6, 182–197. [Google Scholar] [CrossRef]

- Gibbs, M.S.; Maier, H.R.; Dandy, G.C.; Nixon, J.B. Minimum number of generations required for convergence of genetic algorithms. 2006 IEEE International Conference on Evolutionary Computation. IEEE, 2006, pp. 565–572.

- Peixoto, I.S.; da Silva, F.F.; Fernandes, J.F.; Vaschetto, S.; Branco, P.C. A Distributed Equivalent-Permeability Model for the 3D Design Optimization of Bulk Superconducting Electromechanical Systems. IEEE Transactions on Applied Superconductivity 2023. [Google Scholar] [CrossRef]

- Barbie, E.; Rabinovici, R.; Kuperman, A. Analytic formulation and optimization of weighted total harmonic distortion in single-phase staircase modulated multilevel inverters. Energy 2020, 199, 117470. [Google Scholar] [CrossRef]

- Chen, H.; Tang, T.; Han, J.; Ait-Ahmed, N.; Machmoum, M.; Zaïm, M.E.H. Current waveforms analysis of toothed pole Doubly Salient Permanent Magnet (DSPM) machine for marine tidal current applications. International Journal of Electrical Power & Energy Systems 2019, 106, 242–253. [Google Scholar]

- Hua, W.; Cheng, M. A new model of vector-controlled doubly-salient permanent magnet motor with skewed rotor. 2008 International Conference on Electrical Machines and Systems. IEEE, 2008, pp. 3026–3031.

- Blaabjerg, F.; Christensen, L.; Rasmussen, P.O.; Oestergaard, L.; Pedersen, P. New advanced control methods for doubly salient permanent magnet motor. IAS’95. Conference Record of the 1995 IEEE Industry Applications Conference Thirtieth IAS Annual Meeting. IEEE, 1995, Vol. 1, pp. 222–230.

Figure 1.

Presentation of the measures relating to 3D geometry of initial concept using a 2D cut plane.

Figure 1.

Presentation of the measures relating to 3D geometry of initial concept using a 2D cut plane.

Figure 2.

Representation of the geometry of the DSPM S4R5 machine to demonstrate which materials are used with a zoom-in PM.

Figure 2.

Representation of the geometry of the DSPM S4R5 machine to demonstrate which materials are used with a zoom-in PM.

Figure 3.

B-H curve of Silicon Steel NGO 35JN200.

Figure 3.

B-H curve of Silicon Steel NGO 35JN200.

Figure 4.

2D plane of DSPM S4R5 for illustration of PM flux direction and coil numbering.

Figure 4.

2D plane of DSPM S4R5 for illustration of PM flux direction and coil numbering.

Figure 5.

Iron losses 3D graphic representation for the frequency and magnetic flux density values range where the most significant harmonics will be present.

Figure 5.

Iron losses 3D graphic representation for the frequency and magnetic flux density values range where the most significant harmonics will be present.

Figure 6.

NSGA-II and FEM procedure for DSPM S4R5 machine optimization. Adapted from [

16].

Figure 6.

NSGA-II and FEM procedure for DSPM S4R5 machine optimization. Adapted from [

16].

Figure 7.

Illustration of 3D complete geometry and a half-cross-cut plane of 3D entire geometry.

Figure 7.

Illustration of 3D complete geometry and a half-cross-cut plane of 3D entire geometry.

Figure 8.

2D Geometric representation of DSPM S4R5.

Figure 8.

2D Geometric representation of DSPM S4R5.

Figure 9.

Linked flux results for 2D geometry and 3D geometry.

Figure 9.

Linked flux results for 2D geometry and 3D geometry.

Figure 10.

Torque results for 2D geometry and 3D geometry.

Figure 10.

Torque results for 2D geometry and 3D geometry.

Figure 11.

Inductance Maps: a) Self Inductance of Coil 1; b) - Mutual Inductance of Coil 2 wrt Phase Current of Coil 1; c) - Inductance of Coil 3 wrt Phase Current of Coil 1; d) - Inductance of Coil 4 wrt Phase Current of Coil 1.

Figure 11.

Inductance Maps: a) Self Inductance of Coil 1; b) - Mutual Inductance of Coil 2 wrt Phase Current of Coil 1; c) - Inductance of Coil 3 wrt Phase Current of Coil 1; d) - Inductance of Coil 4 wrt Phase Current of Coil 1.

Figure 12.

N Parameter Map: a) N of Coil 1; b) - N of Coil 2; c) - N of Coil 3; d) - N of Coil 4.

Figure 12.

N Parameter Map: a) N of Coil 1; b) - N of Coil 2; c) - N of Coil 3; d) - N of Coil 4.

Figure 13.

Different current waveforms to obtain the best current waveform regarding input torque mean value and oscillatory torque.

Figure 13.

Different current waveforms to obtain the best current waveform regarding input torque mean value and oscillatory torque.

Figure 14.

Pareto curve obtained for the optimization process (in left part) and the optimal geometry selected from the point shown in the Pareto curve (in right part).

Figure 14.

Pareto curve obtained for the optimization process (in left part) and the optimal geometry selected from the point shown in the Pareto curve (in right part).

Figure 15.

Torque evolution of the results of optimized DSPM S4R5.

Figure 15.

Torque evolution of the results of optimized DSPM S4R5.

Figure 16.

Magnetic flux evolution of the results of optimized DSPM S4R5.

Figure 16.

Magnetic flux evolution of the results of optimized DSPM S4R5.

Figure 17.

Electromagnetic torque evolution of the 3D geometry of the optimized DSPM S4R5 in same load condition as optimization process.

Figure 17.

Electromagnetic torque evolution of the 3D geometry of the optimized DSPM S4R5 in same load condition as optimization process.

Figure 18.

Magnetic flux evolution of the 3D geometry of the optimized DSPM S4R5 in same load condition as optimization process.

Figure 18.

Magnetic flux evolution of the 3D geometry of the optimized DSPM S4R5 in same load condition as optimization process.

Figure 19.

Evolution of the generator voltages imposed by the ideal phase currents waveforms.

Figure 19.

Evolution of the generator voltages imposed by the ideal phase currents waveforms.

Figure 20.

Evolution of the generator ideal phase currents waveforms.

Figure 20.

Evolution of the generator ideal phase currents waveforms.

Figure 21.

Evolution of the total generator instantaneous power feeding the ideal phase currents waveforms.

Figure 21.

Evolution of the total generator instantaneous power feeding the ideal phase currents waveforms.

Figure 22.

Illustration of the initial 3D geometry.

Figure 22.

Illustration of the initial 3D geometry.

Figure 23.

Illustration of the optimized 3D geometry.

Figure 23.

Illustration of the optimized 3D geometry.

Figure 24.

Linked flux results for initial geometry and optimized geometry for no load condition.

Figure 24.

Linked flux results for initial geometry and optimized geometry for no load condition.

Figure 25.

Torque results for initial geometry and optimized geometry for no load condition.

Figure 25.

Torque results for initial geometry and optimized geometry for no load condition.

Figure 26.

Inductance Maps: a) Self Inductance of Coil 1; b) - Mutual Inductance of Coil 2 wrt Phase Current of Coil 1; c) - Inductance of Coil 3 wrt Phase Current of Coil 1; d) - Inductance of Coil 4 wrt Phase Current of Coil 1.

Figure 26.

Inductance Maps: a) Self Inductance of Coil 1; b) - Mutual Inductance of Coil 2 wrt Phase Current of Coil 1; c) - Inductance of Coil 3 wrt Phase Current of Coil 1; d) - Inductance of Coil 4 wrt Phase Current of Coil 1.

Figure 27.

N Parameter Map: a) N of Coil 1; b) - N of Coil 2; c) - N of Coil 3; d) - N of Coil 4.

Figure 27.

N Parameter Map: a) N of Coil 1; b) - N of Coil 2; c) - N of Coil 3; d) - N of Coil 4.

Figure 28.

Evolution of the generator voltages imposed to the AC/DC converter of the equivalent electric system of aircraft.

Figure 28.

Evolution of the generator voltages imposed to the AC/DC converter of the equivalent electric system of aircraft.

Figure 29.

Evolution of the generator currents feeding the AC/DC converter of the equivalent electric aircraft system.

Figure 29.

Evolution of the generator currents feeding the AC/DC converter of the equivalent electric aircraft system.

Figure 30.

Evolution of the generator output instantaneous power feeding the AC/DC converter of the equivalent electric system of aircraft.

Figure 30.

Evolution of the generator output instantaneous power feeding the AC/DC converter of the equivalent electric system of aircraft.

Table 1.

Geometric Parameters Values.

Table 1.

Geometric Parameters Values.

| Parameter |

Dimension |

|

[mm] |

|

[mm] |

|

[mm] |

|

[mm] |

|

[mm] |

|

[mm] |

|

[mm] |

| g |

[mm] |

|

|

|

|

|

|

|

|

|

[mm] |

|

[rad] |

|

[mm] |

Table 2.

Lower and Upper Limits of Design Variables to optimize DSPM S4R5 machine

Table 2.

Lower and Upper Limits of Design Variables to optimize DSPM S4R5 machine

| Design Variable |

Lower and Upper Limits |

|

[mm] |

|

[mm] |

|

[mm] |

|

[mm] |

|

[mm] |

| g |

[mm] |

|

[rad] |

|

[mm] |

|

[rad] |

|

[rad] |

|

[mm] |

|

[rad] |

|

|

|

|

|

|

Table 3.

Current waveform results in terms of electromagnetic torque mean value and oscillatory torque.

Table 3.

Current waveform results in terms of electromagnetic torque mean value and oscillatory torque.

| Current Waveform |

[Nm] |

[Nm] |

|

| Cosine Wave |

|

|

|

| Half-Cosine |

|

|

|

| Half-Cosine with firing angle |

|

|

|

| Square Wave |

|

|

|

Table 4.

Geometric parameters values of the optimized DSPM S4R5 machine.

Table 4.

Geometric parameters values of the optimized DSPM S4R5 machine.

| Parameter |

Dimension |

|

[mm] |

|

[mm] |

|

[mm] |

|

[mm] |

|

4 [mm] |

| g |

[mm] |

|

[rad] |

|

[mm] |

|

[rad] |

|

[rad] |

|

[mm] |

|

[rad] |

|

|

|

|

|

|

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).