Submitted:

04 March 2024

Posted:

05 March 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

- (1)

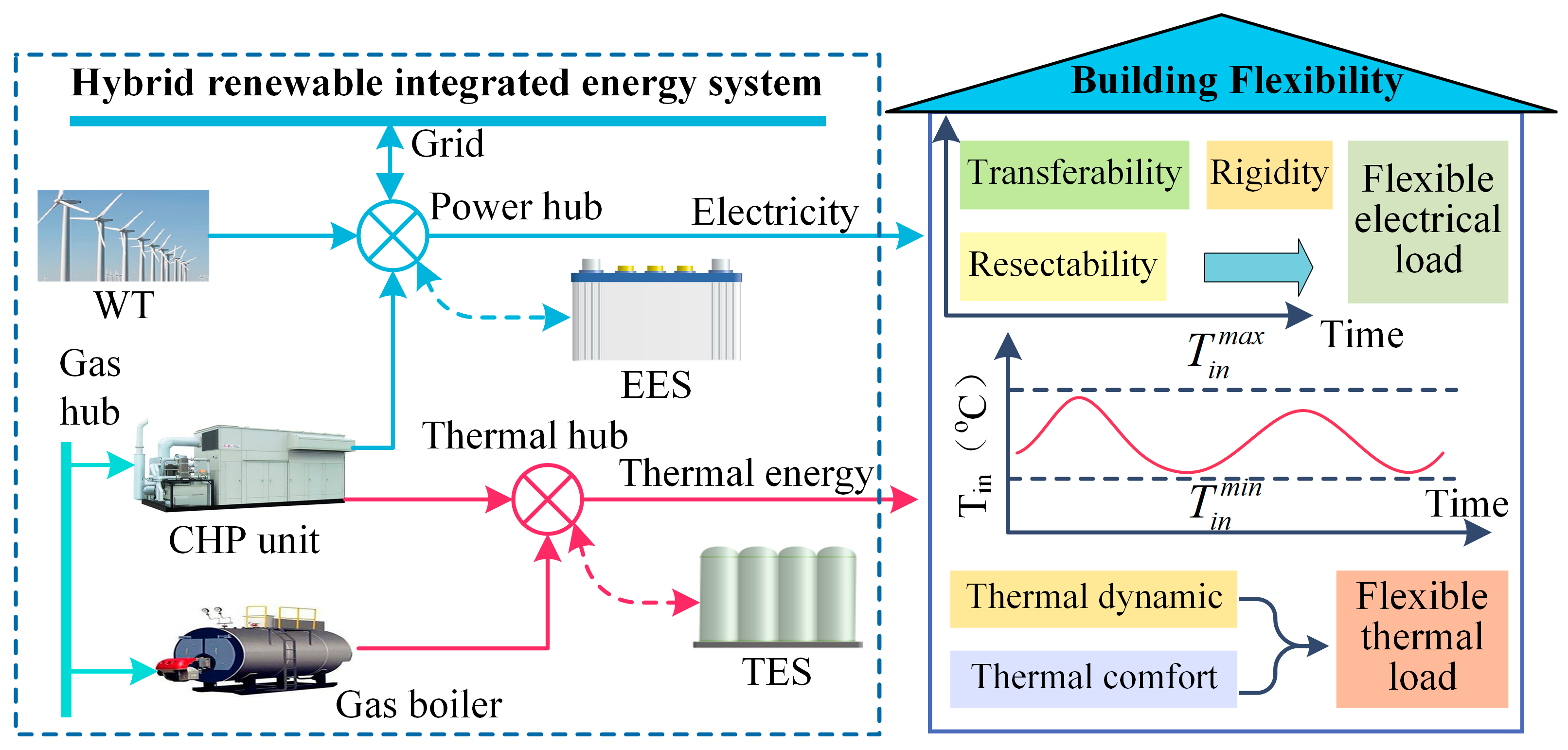

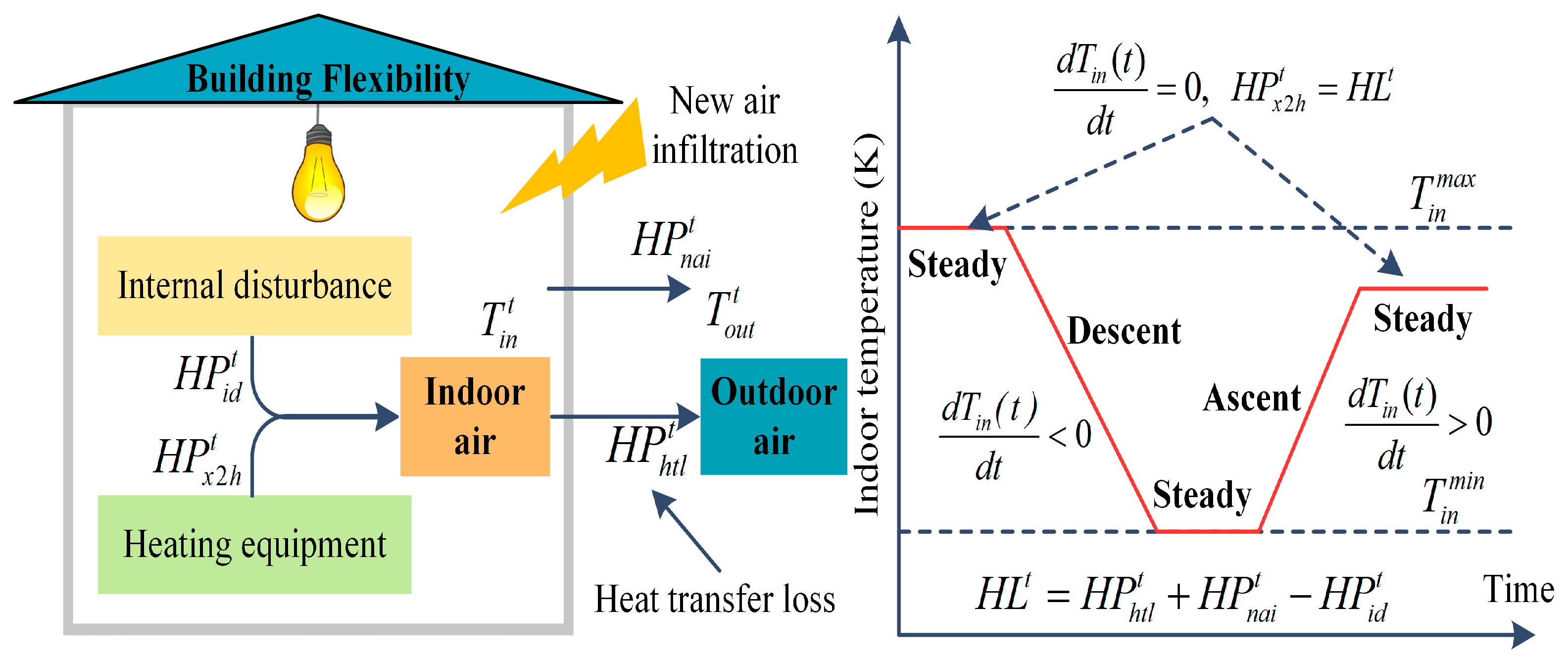

- Unlock the flexible regulation ability of buildings and establish a flexible thermal load regulation model according to the dynamic thermal characteristics and thermal comfort elastic interval of the buildings and a regulation model of the flexible electrical load based on its transferability, resectability, and rigidity.

- (2)

- An operation optimization model, which incorporates multiple flexible load regulations and the variable load of devices, is then developed to improve the operational performance and reduce the entropy of HRIES.

- (3)

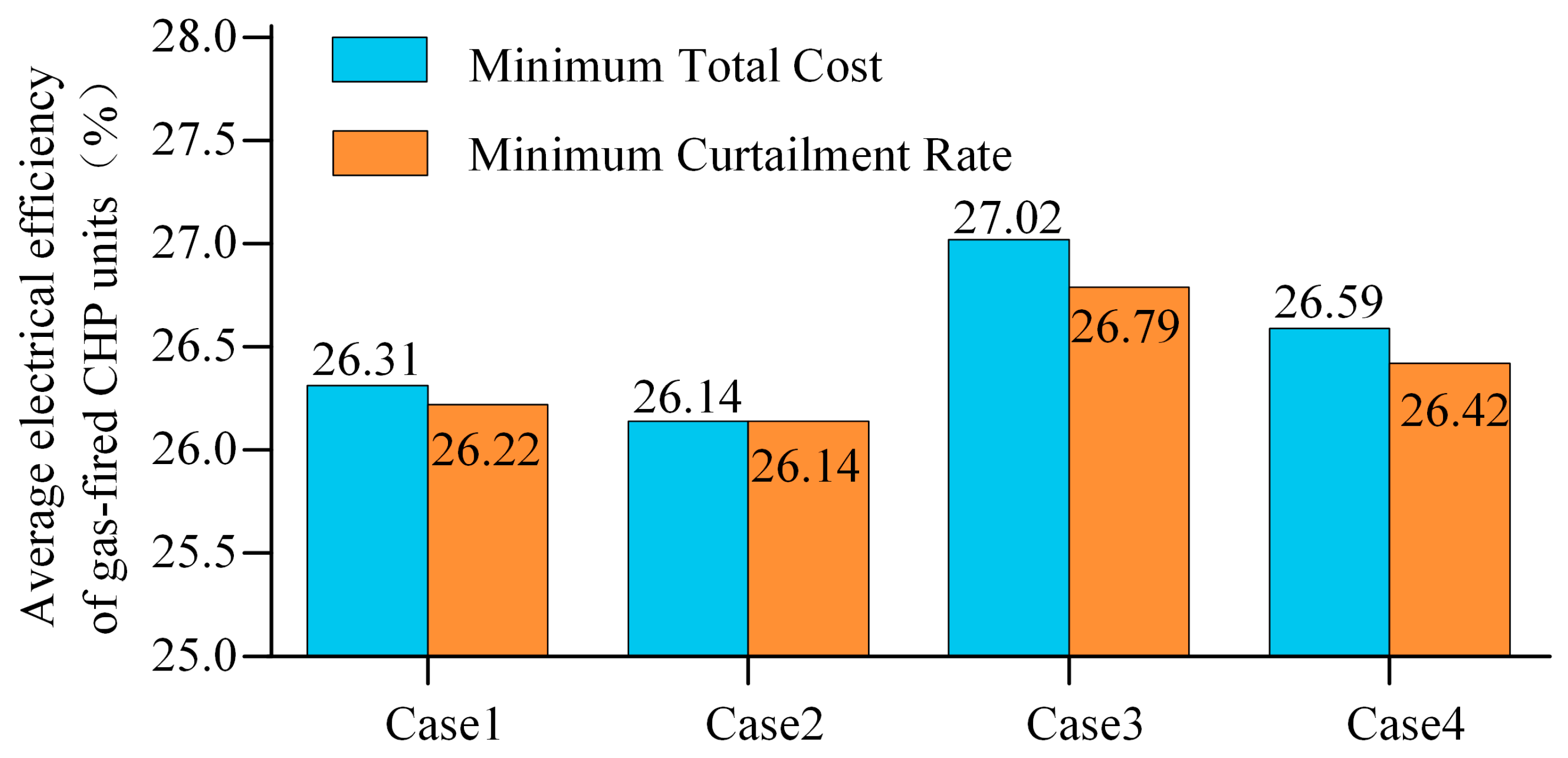

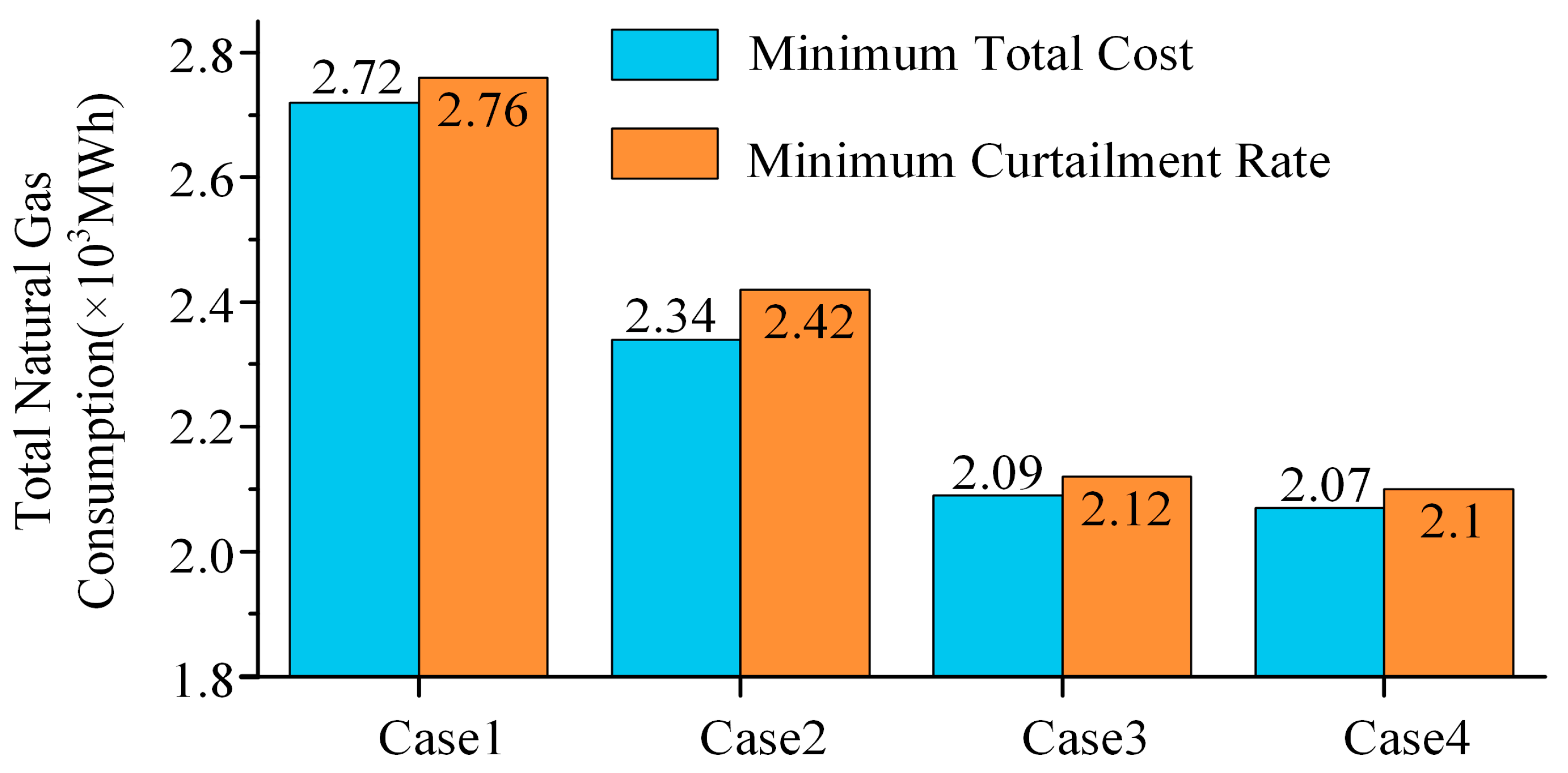

- Comparatively analyze the performance of minimum total cost and renewable energy curtailment rate with various flexible loads. Present the flexible regulation and synergy mechanism of multiple types of flexible loads in improving the average electrical efficiency of the gas CHP units and reducing the renewable energy curtailment rate of HRIES.

2. HRIES with Flexible Buildings

3. Flexible Load Model of Buildings

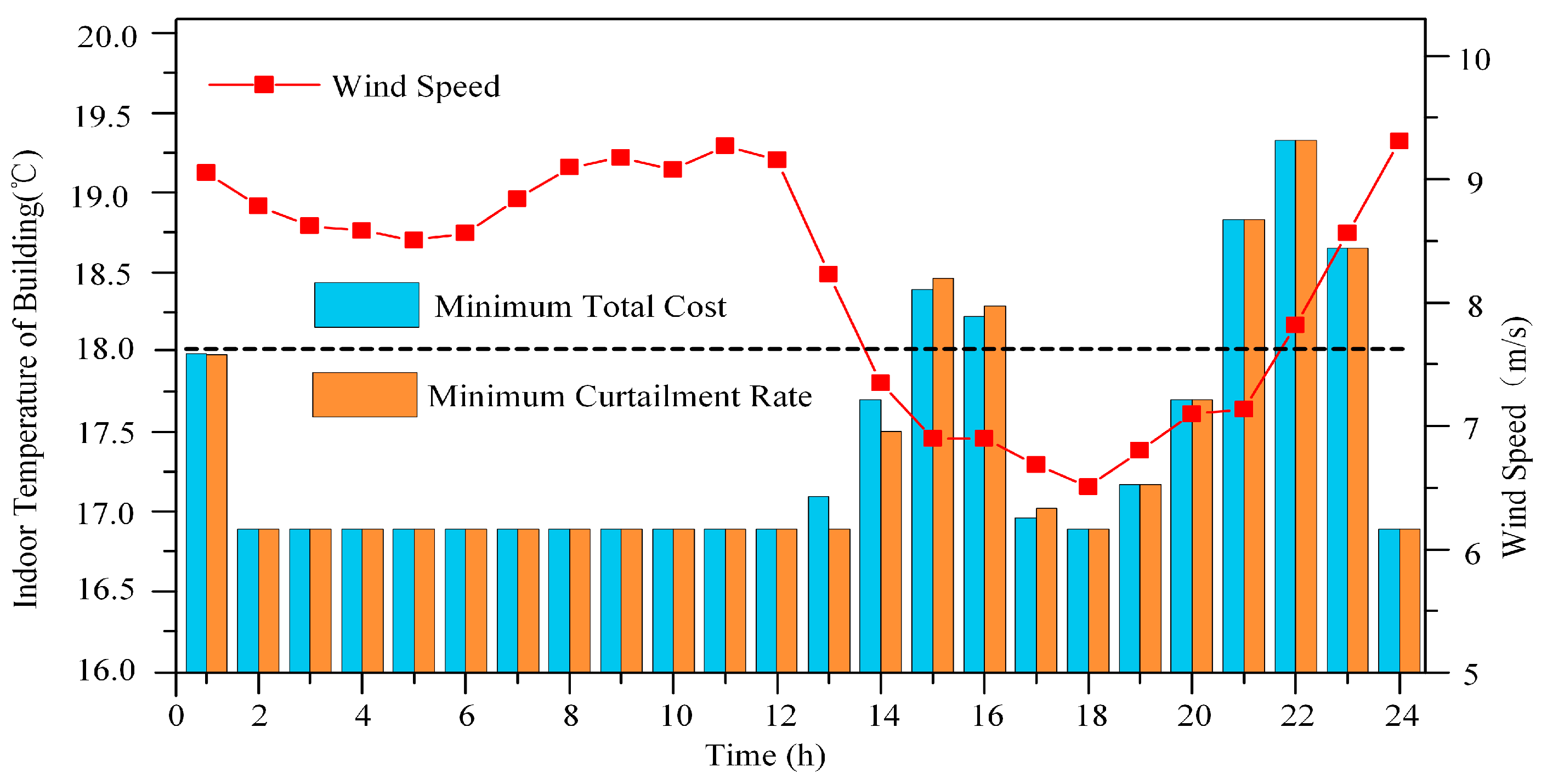

3.1. Flexible Thermal Load Model

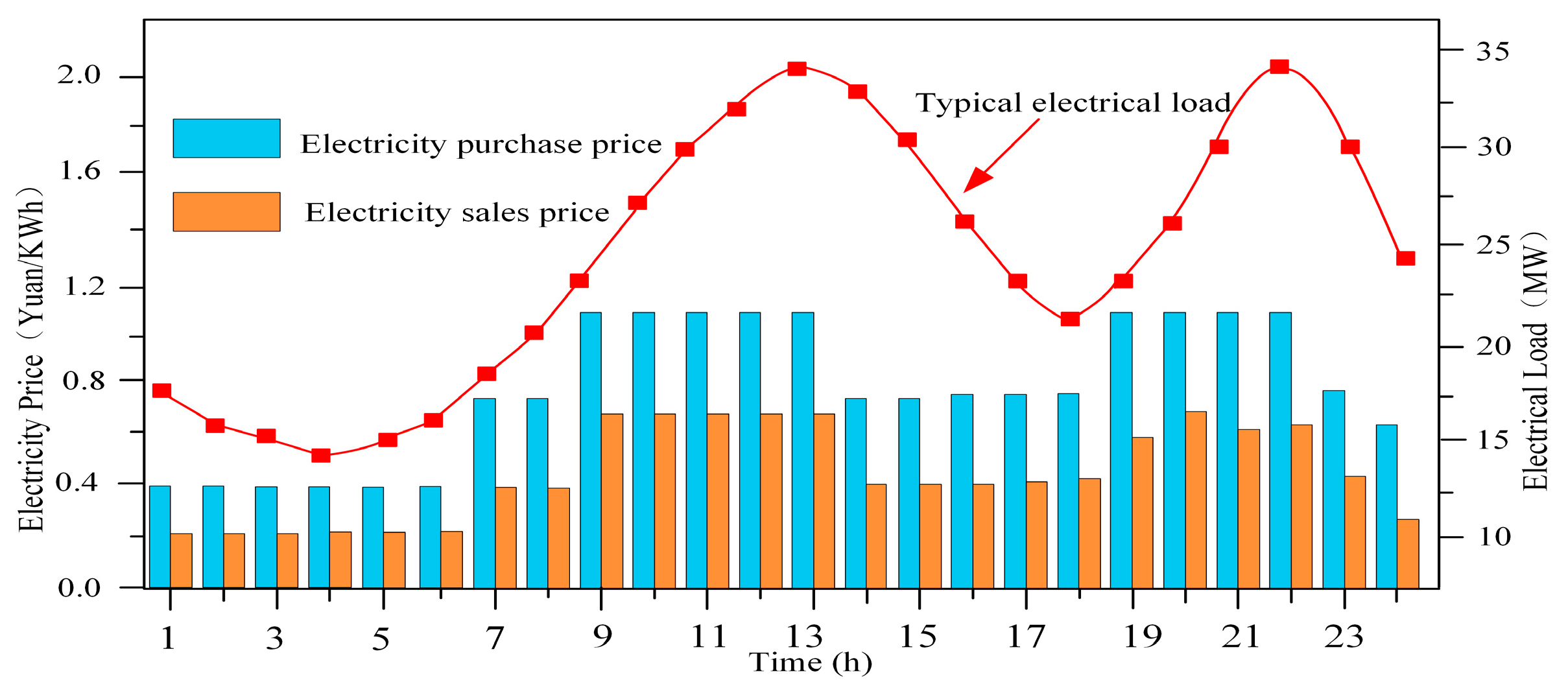

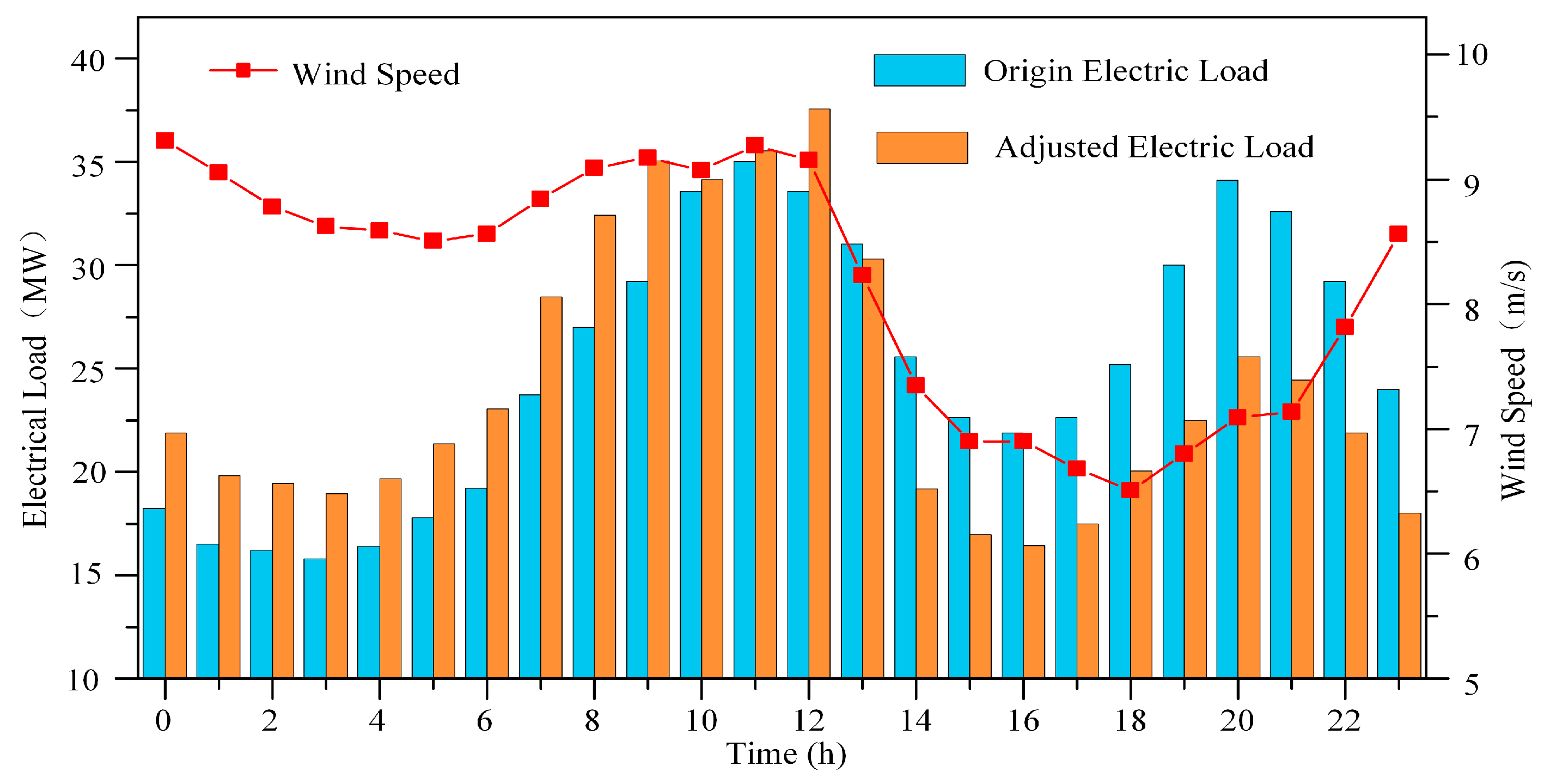

3.2. Flexible Electrical Load Model

4. Optimization Model of Introducing Flexible Load

4.1. Optimization Objectives

4.2. Model Constraints

4.2.1. Device Model Constraints

- (1)

- Wind turbine

- (2)

- Gas CHP units

- (3)

- Gas-fired boiler

- (4)

- Energy storage device

4.2.2. Energy Balance Constraints

4.2.3. Constraints of the Power Grid

4.3. Model Solution

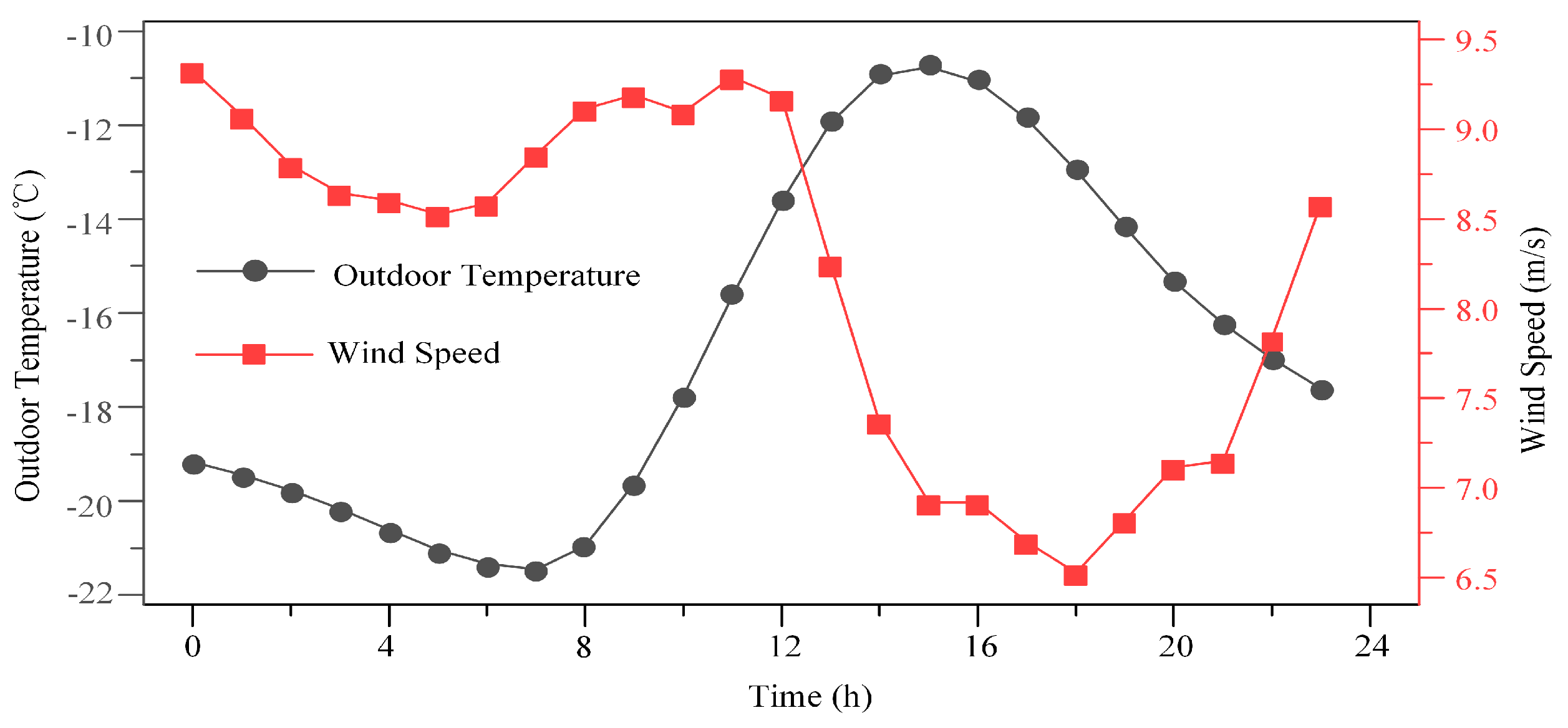

5. Case Study

5.1. Model Solution

5.2. Optimization Results

5.3. Discussion of Results

6. Conclusions

- (1)

- Flexible load increases the compatibility between load and renewable energy output by adjusting the actual load curve of HRIES, thereby increasing the consumption of renewable energy. In addition, flexible load regulation mainly reduces the total cost of HRIES operation by increasing renewable energy consumption.

- (2)

- The flexible heating load reduces the total cost of the system by coordinating the renewable energy consumption during HRIES operation with the increase in the average electrical efficiency of the gas CHP units. Blindly pursuing renewable energy consumption during HRIES operation will reduce the average power efficiency of gas CHP units, which in turn worsens the total cost of the system.

- (3)

- Flexible electrical load and thermal load regulation have a saturation effect in improving the consumption of renewable energy during HRIES operation and a synergistic effect in reducing the total cost of the system, which can reduce the total cost by 0.73%.

- (4)

- If the regulation of flexible electrical and heat loads is considered in the operation optimization of HRIES, the total economic cost of the system will decrease by 15.13%, and the renewable energy curtailment rate will decrease by 12.08%.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Du, Y.; Liu, H.; Huang, H.; Li, X. The carbon emission reduction effect of agricultural policy——Evidence from China. Journal of Cleaner Production 2023, 137005. [Google Scholar] [CrossRef]

- Wen, D.; Aziz, M. Design and analysis of biomass-to-ammonia-to-power as an energy storage method in a renewable multi-generation system. Energy Conversion and Management 2022, 261, 115611. [Google Scholar] [CrossRef]

- Su, Y.; Cheng, H.; Wang, Z.; Yan, J.; Miao, Z.; Gong, A. Analysis and prediction of carbon emission in the large green commercial building: A case study in Dalian, China. Journal of Building Engineering 2023, 68, 106147. [Google Scholar] [CrossRef]

- Huo, T.; Du, Q.; Xu, L.; Shi, Q.; Cong, X.; Cai, W. Timetable and roadmap for achieving carbon peak and carbon neutrality of China's building sector. Energy 2023, 274, 127330. [Google Scholar] [CrossRef]

- Ali, K. A.; Ahmad, M. I.; Yusup, Y. Issues, Impacts, and Mitigations of Carbon Dioxide Emissions in the Building Sector. SUSTAINABILITY 2020, 12(18). [Google Scholar] [CrossRef]

- Ke, Y. Y.; Zhou, L.; Zhu, M. L.; Yang, Y.; Fan, R.; Ma, X. R. Scenario Prediction of Carbon Emission Peak of Urban Residential Buildings in China's Coastal Region: A Case of Fujian Province. SUSTAINABILITY 2023, 15(3). [Google Scholar] [CrossRef]

- Zeng, P. L.; Xu, J.; Zhu, M. C. Demand Response Strategy Based on the Multi-Agent System and Multiple-Load Participation. SUSTAINABILITY 2024, 16(2). [Google Scholar] [CrossRef]

- Al-Rawashdeh, H.; Al-Khashman, O. A.; Al Bdour, J. T.; Gomaa, M. R.; Rezk, H.; Marashli, A.; Arrfou, L. M.; Louzazni, M. Performance Analysis of a Hybrid Renewable-Energy System for Green Buildings to Improve Efficiency and Reduce GHG Emissions with Multiple Scenarios. SUSTAINABILITY 2023, 15(9). [Google Scholar] [CrossRef]

- Reddy, V. J.; Hariram, N. P.; Ghazali, M. F.; Kumarasamy, S. Pathway to Sustainability: An Overview of Renewable Energy Integration in Building Systems. SUSTAINABILITY 2024, 16(2). [Google Scholar] [CrossRef]

- Shi, S. H.; Zhu, N. Challenges and Optimization of Building-Integrated Photovoltaics (BIPV) Windows: A Review. SUSTAINABILITY 2023, 15(22). [Google Scholar] [CrossRef]

- Liu, M.; Wang, S.; Yan, J. Operation scheduling of a coal-fired CHP station integrated with power-to-heat devices with detail CHP unit models by particle swarm optimization algorithm. Energy 2021, 214. [Google Scholar] [CrossRef]

- Turk, A.; Wu, Q.; Zhang, M.; Ostergaard, J. Day-ahead stochastic scheduling of integrated multi-energy system for flexibility synergy and uncertainty balancing. Energy 2020, 196. [Google Scholar] [CrossRef]

- Zeng, Q.; Zhang, B.; Fang, J.; Chen, Z. A bi-level programming for multistage co-expansion planning of the integrated gas and electricity system. Applied Energy 2017, 200, 192–203. [Google Scholar] [CrossRef]

- Wang, H.; Zhang, C.; Li, K.; Ma, X. Game theory-based multi-agent capacity optimization for integrated energy systems with compressed air energy storage. Energy 2021, 221. [Google Scholar] [CrossRef]

- Zhou, Y.; Zhao, P.; Xu, F.; Cui, D.; Ge, W.; Chen, X.; Gu, B. Optimal Dispatch Strategy for a Flexible Integrated Energy Storage System for Wind Power Accommodation. Energies 2020, 13(5). [Google Scholar] [CrossRef]

- Ji, L.; Liang, X.; Xie, Y.; Huang, G.; Wang, B. Optimal design and sensitivity analysis of the stand-alone hybrid energy system with PV and biomass-CHP for remote villages. Energy 2021, 225. [Google Scholar] [CrossRef]

- Li, H.; Wei, Z.; Miao, Q.; Zhao, L.; Sun, B.; Zhang, C. Multi-energy flow cooperative dispatch for generation, storage, and demand in integrated energy systems with dynamic correction. Sustainable Cities and Society 2022, 76. [Google Scholar] [CrossRef]

- Zeng, R.; Guo, B.; Zhang, X.; Li, H.; Zhang, G. Study on thermodynamic performance of SOFC-CCHP system integrating ORC and double-effect ARC. Energy Conversion and Management 2021, 242, 114326. [Google Scholar] [CrossRef]

- Jiang, Y.; Xu, J.; Sun, Y.; Wei, C.; Wang, J.; Liao, S.; Ke, D.; Li, X.; Yang, J.; Peng, X. Coordinated operation of gas-electricity integrated distribution system with multi-CCHP and distributed renewable energy sources. Applied Energy 2018, 211, 237–248. [Google Scholar] [CrossRef]

- Li, Z.; Wu, W.; Shahidehpour, M.; Wang, J.; Zhang, B. Combined Heat and Power Dispatch Considering Pipeline Energy Storage of District Heating Network. Ieee Transactions on Sustainable Energy 2016, 7(1), 12–22. [Google Scholar] [CrossRef]

- Wang, J.; Huo, S.; Yan, R.; Cui, Z. Leveraging heat accumulation of district heating network to improve performances of integrated energy system under source-load uncertainties. Energy 2022, 252. [Google Scholar] [CrossRef]

- Xue, Y.; Shahidehpour, M.; Pan, Z.; Wang, B.; Zhou, Q.; Guo, Q.; Sun, H. Reconfiguration of District Heating Network for Operational Flexibility Enhancement in Power System Unit Commitment. Ieee Transactions on Sustainable Energy 2021, (2), 1161–1173. [Google Scholar] [CrossRef]

- Aluisio, B.; Dicorato, M.; Forte, G.; Litrico, G.; Trovato, M. Integration of heat production and thermal comfort models in microgrid operation planning. Sustainable Energy Grids & Networks 2018, 16, 37–54. [Google Scholar] [CrossRef]

- Yang, X.; Chen, Z.; Huang, X.; Li, R.; Xu, S.; Yang, C. Robust capacity optimization methods for integrated energy systems considering demand response and thermal comfort. Energy 2021, 221. [Google Scholar] [CrossRef]

- Huang, H.; Wang, H.; Hu, Y.-J.; Li, C.; Wang, X. Optimal plan for energy conservation and CO2 emissions reduction of public buildings considering users' behavior: Case of China. Energy 2022, 261. [Google Scholar] [CrossRef]

- Wang, D.; Zhi, Y.-q.; Jia, H.-j.; Hou, K.; Zhang, S.-x.; Du, W.; Wang, X.-d.; Fan, M.-h. Optimal scheduling strategy of district integrated heat and power system with wind power and multiple energy stations considering thermal inertia of buildings under different heating regulation modes. Applied Energy 2019, 240, 341–358. [Google Scholar] [CrossRef]

- Zhang, Y.; Ge, Z.; Yang, Y.; Hao, J.; Xu, L.; Du, X.; Traeholt, C. Carbon reduction and flexibility enhancement of the CHP-based cascade heating system with integrated electric heat pump. Energy Conversion and Management 2023, 280. [Google Scholar] [CrossRef]

- Sun, H.; Sun, X.; Kou, L.; Zhang, B.; Zhu, X. Optimal scheduling of park-level integrated energy system considering ladder-type carbon trading mechanism and flexible load. Energy Reports 2023, 9, 3417–3430. [Google Scholar] [CrossRef]

- Lu, N. An Evaluation of the HVAC Load Potential for Providing Load Balancing Service. IEEE Transactions on Smart Grid 2012, 3(3), 1263–1270. [Google Scholar] [CrossRef]

- Liu, W.; Tian, X.; Yang, D.; Deng, Y. Evaluation of individual thermal sensation at raised indoor temperatures based on skin temperature. Building and Environment 2021, 188. [Google Scholar] [CrossRef]

- Lin, L.; Gu, J.; Wang, L. Optimal Dispatching of Combined Heat-power System Considering Characteristics of Thermal Network and Thermal Comfort Elasticity for Wind Power Accommodation. Dianwang Jishu/Power System Technology 2019, 43(10), 3648–3655. [Google Scholar]

- Yang, H.; Xiong, T.; Qiu, J.; Qiu, D.; Dong, Z. Y. Optimal operation of DES/CCHP based regional multi-energy prosumer with demand response. Applied Energy 2016, 167, 353–365. [Google Scholar] [CrossRef]

- Li, H. Evaluation of a Distributed Energy System Combined With Heating, Cooling and Power Generation Through Multi-Criteria Optimization. In 2003; pp. 277-284. [CrossRef]

| Equipment | Unit Maintenance Cost (Yuan/MWh) | Technical Parameters |

|---|---|---|

| GB | 20 | ICGB = 12 MW; URGB = DRGB = 6 MW/h |

| EES | 83 |

; ; ; |

| HES | 20 |

; ; ; |

| CHP | 20 | ICCHP = 35 MW; URCHP = DRCHP = 12.25 MW/h |

| WT | 68 | ICWT = 50 MW |

| Optimized results |

curtailment rate (%) |

TC (Thousand Yuan) |

MC (Thousand Yuan) |

EC (Thousand Yuan) |

CEC (Thousand Yuan) |

REP (Thousand Yuan) |

| Case 1 | 27.24 | 413.8 | 48.6 | 310.5 | 12.8 | 45.6 |

| Case 2 | 19.06 | 385.6 | 47.6 | 290.3 | 14.1 | 33.6 |

| Case 3 | 22.68 | 382.4 | 45.5 | 282.2 | 15.8 | 38.8 |

| Case 4 | 15.04 | 351.2 | 50.0 | 263.1 | 12.4 | 25.7 |

| Optimized results |

curtailment rate (%) |

TC (Thousand Yuan) |

MC (Thousand Yuan) |

EC (Thousand Yuan) |

CEC (Thousand Yuan) |

REP (Thousand Yuan) |

| Case 1 | 26.73 | 417.6 | 48.6 | 310.5 | 12.8 | 45.7 |

| Case 2 | 19.06 | 385.6 | 47.6 | 290.3 | 14.1 | 33.6 |

| Case 3 | 22.05 | 386.0 | 50.7 | 282.3 | 15.8 | 37.7 |

| Case 4 | 14.65 | 354.2 | 53.7 | 263.1 | 12.4 | 25 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).