1. Introduction

1.1. Background

In the fully mechanized Cut-to-Length (CTL) harvesting method, stems are bucked into logs in the forest, facilitating the development of relatively lightweight forest machines and appropriate tree-cutting methods for these machines [

1]. These machines include either tracked or wheeled harvesters and tracked or wheeled forwarders [

2,

3,

4]. Modern wheeled harvesters, manufactured by the forest machine manufacturers like Ponsse in Vieremä and John Deere in Joensuu in Finland, use cranes with a reach of around 10 meters [

5,

6,

7]. This reach allows for selective thinning, preserving the best trees for future growth, thereby enhancing the overall value of trees and forests. This approach ensures that both trees and forests increase in value, and high-quality timber can be obtained during later thinnings or final felling. Additionally, the CTL method is gaining social acceptance as a harvesting method for nature conservation management in sustainable forestry due to its smaller ecological footprint, profitability in harvesting small stands, and the benefits of selective thinning [

8,

9,

10].

The CTL method facilitates the operations of wood procurement of forest industry in tree plantations for several benefits compared to tree-length method [

1,

11,

12]. Firstly, wood harvesting is more profitable because fewer machines are required at the harvesting site [

13]. Typically, a machine fleet consists of a harvester and a forwarder where the harvester fells, delimbs, measures and cuts trees for wood assortments according to market needs. After cutting, a forwarder performs forest hauling of the separately stacked timber assortments to a storage on roadside. Secondly, the CTL method requires a little storage area on the roadside because the bucking has already been done in the forest and there is no need for a special machine for this work phase. Typically, timber transport takes place rather soon after the logs have been hauled by forwarder to the roadside [

14]. This possibility keeps the storage area at a manageable size. Timber trucks can be equipped with cranes for loading and unloading the logs to perform long-distance transport either to terminals, railway stations or to production plants. Thirdly, because the stems have already been cut optimally in the forest the sawmill can sort the logs into separate batches according to their diameters before the sawing process even begins [

15]. These kinds of batches can be sawn at a higher line speed because all the logs being fed into the saw are in the same diameter class, meaning that the saw’s settings do not have to be changed for each log separately.

As mentioned above, trees are delimbed and cut to logs in the forest. For this reason, the mass of leaves and needles, as well as branches and the crown - all of which contain vital nutrients - remain in the forest [

5]. This ensures, particularly in nutritionally deprived soil, that growing trees left standing or planted seedlings will get enough nutrition from the forest soil. At ecologically fragile harvesting locations, the harvester also lays down a carpet made from branches and the tops of delimbed stems over which the forwarder drives. When it comes to damages to the environment such as tire tracks or broken trees, the CTL method also exerts significantly less environmental impact than the tree-length method [

16,

17,

18]. Therefore, the CTL is seen as an environmentally friendly method [

5].

1.2. Timber Harvesting Productivity Studies on Eucalyptus Plantations

In South America, the tree-length method as a harvesting method is gradually being replaced by the CTL method. In recent years, the CTL method has also become the most important of the mechanized harvesting methods used in Brazil [

19]. The competition of land use is high between eucalyptus cultivation areas and agriculture in Brazil. Due to this reason, a significant portion of tree plantations have been established on steep slope terrains. The impact of terrain slope has been considered in several productivity studies of eucalyptus plantation harvesting [

2,

4,

20,

21,

22]. These studies have found that a small increase in slope practically has little effect on logging productivity, but the impact on productivity only appears on particularly steep slopes. In these conditions, the productivity of tracked harvesters designed for logging remains more stable compared to cutting machines built directly on the base of an excavator [

22].

In previous productivity assessments of eucalyptus plantation wood harvesting, the emphasis has been on the characteristics of the harvesting machine and particularly the impact of the harvesting conditions. The studies have compared the costs and productivity of tree-length and CTL methods on eucalyptus plantations [

23,

24]. Despite slightly lower productivity, the CTL method has been found to be a competitive method in terms of costs, especially if logging residues are to be left on the site [

23,

24]. On the other hand, logging residues as whole wood or small logs may be harvested for energy wood, which is economically valuable fuel, which is compensating low productivity [

25,

26].

Tree species of eucalyptus plantations have also been a focus of productivity studies. Within the Eucalyptus genus (Eucalyptus spp.), there exists a numerous of different eucalyptus species, but in commercial timber plantations, mainly nine species are utilized. It has been observed that the species has a statistically significant effect on harvesting productivity [

22]. When the impact of the stem form of eucalyptus on harvesting productivity was studied, productivity was lower on trees with thick branches and on trees with a curved or crooked eucalyptus compared to good quality trees [

27].

Eucalyptus plantations can be regenerated either by planting or naturally using stumps, allowing one or more stems to sprout from the same stump. The highest harvesting productivity levels have been achieved with planted single-stem trees, and harvesting of naturally regenerated single-stem trees has been found to be the next most productive [

27]. On the other hand, a skilled harvester operator can handle single- and double-stemmed eucalyptus trees with the same productivity; the productivity difference has been observed only among less skilled operators [

28]. As the planting spacing increases in eucalyptus plantations, harvesting productivity also rises [

21]. Similarly, pre-harvest chainsaw felling [

2] and initial thinning [

29] enhance the harvesting productivity of eucalyptus on its final felling.

The productivity of eucalyptus plantation harvesting has been extensively studied in the native regions of eucalyptus in Australia [

24,

29,

30], as well as notably in South Africa [

22,

27,

28], and Brazil [

19,

21,

31,

32]. Studies have also been conducted in California [

23] and the Iberian Peninsula [

2]. However, productivity of pine plantations has more seldom been a focus of previous studies [

28,

33]. In

Table 1 the average productivity figures comparable for this study have been compiled from some previous studies, where the average volume of tree size, however, varies considerably.

Eucalyptus trees are typically debarked during the processing of the stem immediately after the felling phase in the tree cutting cycle, as the bark adheres tightly to the stem when it dries. The degree of debarking has been found to impact harvesting productivity [

23]. In most of the presented studies, stems were likely debarked, which naturally increased the time required for harvesting.

1.3. Harvesting on Slope Terrain Forests

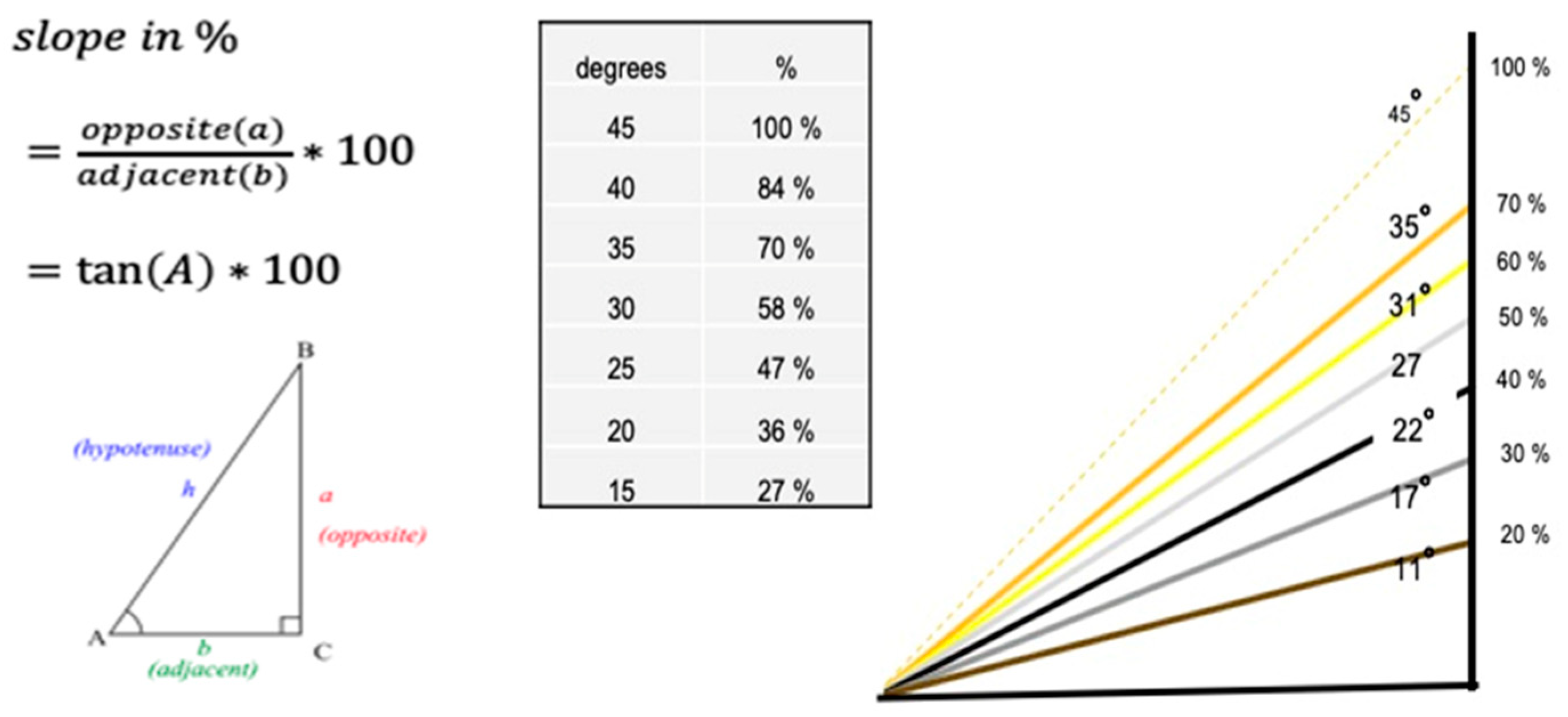

On slope terrain forests, harvesting conditions such as inclination, lateral inclination, topsoil type, weather, and steepness must be considered. When steepness of slope terrain is being discussed, two different scales can be utilized: Steepness in degrees and steepness in percentage. The relationship between these terms is depicted in

Figure 1. In steep slope terrain, the concepts of average and operational slope are also used. The average slope steepness value ignores short steep sections on the slope. To obtain the operational slope, the angle on-site is monitored by the operator at the beginning and during the operation. Depending on the terrain, the maximum usable slope for harvesting can be up to 30 – 35 degrees, corresponding to 17 – 20 percent (

Figure 1).

Machine operators can operate on steep slopes with traction assisted harvesting machines, which consists of wheeled harvesters and forwarders, including a winch, seat levelling system, reversing camera, tracks in all bogies, steel cable, inclinometer, etc. [

34,

35,

36]. When traction assistance is used, it is possible to work with the same CTL harvesting chain as on flat terrain, although anchoring times have a negative effect on the productivity of harvesting (

Figure 2). In slope terrain traction assistance is also necessary for safety reasons during both cutting and forwarding [

37,

38,

39]. The use of winch-based traction assistance causes additional work phases such as attaching and removing the anchoring, but during the actual cutting work or loading work, the operator can work regardless of the use of the winch, as the system automatically adjusts the speed of the winch in relation to the driving speed of forest machine.

Typically, the work with winch assistance amounted machines are done downhill direction. The limiting factor in this case is the operative winch cable length (330 – 340 m). The winch assistance weights about 1900 kg, which is installed in front of the engine of harvester and on the rear frame of forwarder. The winch is attached to the top of the slope on a stump, a tree, or another machine. The cable is 14.5 mm thick and allows a tensile strength of 20 t. With winch assistance, a pulling power of 0 – 7 t can be achieved in cutting machines and a pulling power of 0 – 10 t in forwarders [

40].

If the slope is steep, the risk for loss of traction increases and consequently the risk of getting stuck also increases. Therefore, changes in the harvesting conditions like weather must be taken account of more carefully in advance. In addition, the logs may slide downhill if they are left parallel to slope. Therefore, there is a need to stack logs in perpendicular direction in slope terrains. It is also possible that stacks need to be supported in some way.

From the forwarding point of view load space is typically on the uphill side when there is no risk of logs sliding away from the load space. There is also a risk to reverse forwarder to too steep terrain when the load space is on downhill side, and it is not possible to use traction assistance system. However, a decision of the forwarding direction should be made by following the local circumstances, not selecting “automatically” the traditional way of downhill direction.

In addition to technical issues, harvesting staff must be well educated for work with a winch system. In this respect, planning of the anchoring zone should be done in advance and finalized on harvesting site, where the difference of the average and absolute (operational) slope is important to notice for a determination of maximum degree of slope. The maximum slope in case of traction assistance is always the operational slope. In addition, the selection of anchor stump is fundamental to the safety of the operation and should be carried out in accordance with all recommended technical criteria. In addition, to establish a safe working method, both the operator and the planning staff must be familiar with the local conditions and tree species [

39].

In addition to environmental characteristics, the efficiency of harvesting is influenced by the manner in which trees are felled around the harvester’s workplace. The operator plays a crucial role in determining the direction in which trees are felled in relation to the strip road, the positioning of the harvester in relation to the trees to be felled, the size of the piles made from the trees, and the angle at which the piles are placed in relation to the strip road for forwarding. These variables, referred to as the cutting method, have been empirically shown to impact both the productivity and the quality of the harvesting operation [

41]. Despite extensive research on the productivity of eucalyptus plantation timber harvesting and documentation of the employed cutting method, the detailed cutting method has not been systematically adopted as a classifying variable in the dataset. A notable challenge in such studies is finding machine operators capable of working with different cutting methods with consistent efficiency.

1.4. Aims of Study

The main aim of the research was to find out the most productive CTL cutting methods on flat terrain and slope terrain. In both terrains, two cutting methods were compared, which differed from each other in terms of sideway cutting methods. In addition, on flat terrain, the efficiency of the forward cutting method was studied in relation to the above-mentioned methods. Comparisons of the alternative CTL methods were made by using statistical tests. Conclusions for the relative efficiency of the methods were based on productivity results of the methods that were affected by the following factors:

eucalyptus and pine species,

average size of trees (m3) and density (trees/ha) in forest,

sideways felling at edge of harvesting front,

sideways felling inside the harvesting front,

forward felling in the middle of the harvesting front,

harvesting with the traction assistance on slope terrains,

use of winch assistance.

Possible effects of these factors were considered in the discussion section to find out how they may affect the results of the most productive CTL methods.

2. Material and Methods

2.1. Material

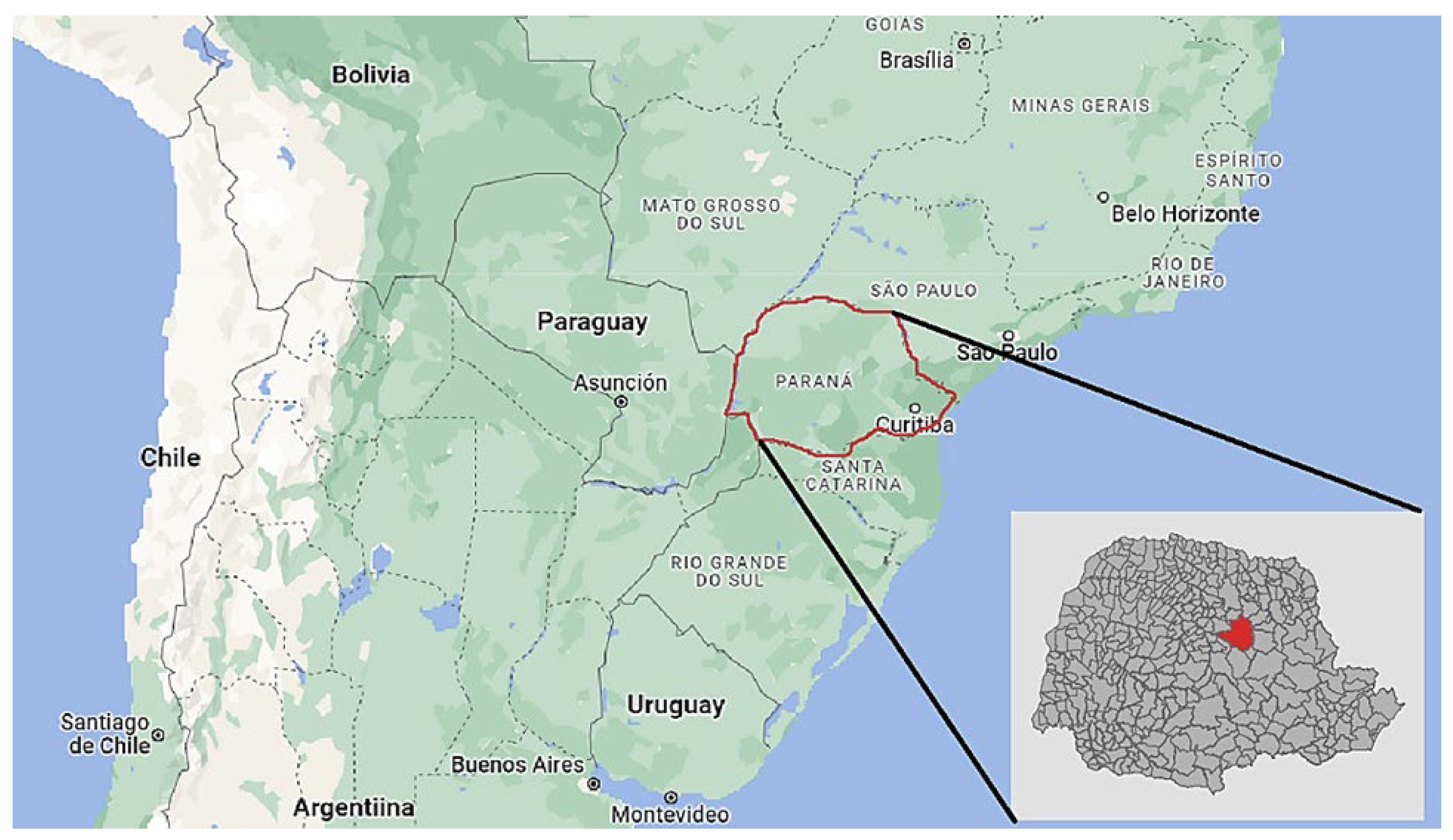

The material was collected in 2022 from three tree plantations. The plantations located in the state of Paraná, in southern Brazil near the border of Argentina and Paraguay (

Figure 3).

The work study focused on two forest machines with which the harvesting study operations were performed (

Table 2). In this way, it was possible to minimize the impact of forest machine characteristics on productivity. The harvester was a Ponsse Ergo wheeled harvester. The forwarder, Ponsse Elephant King, was suited for forest hauling with its 20-tonne load carrying capacity. In practical tests of the study, the forest machines were equipped with the Ponsse Syncrowinch winch system [

40]. Both machines were powered by the same efficient diesel engine and the machines were also equipped with tracks.

In the context of work study, it is also worth describing the harvester head as one of the harvesting fleet components. When talking about machines for harvesting chain, it means the selection of harvesting chain components (harvester – forwarder – harvester head) so that their features match the features of forest and trees to be harvested as suitable as possible. There are many criteria which may be evaluated when making the selection of the harvesting chain components, but the most important selection criteria are average size of trees (m

3/ha) in area to be harvested and density of trees in a forest plantation (trees/ha) to be harvested [

32]. Eucalyptus forest is an example that has a high density. Further, the average size of trees may be quite “middle-size” like 0.2 – 0.3 m

3 allowing use of smaller harvester heads from the category of harvester heads (

Table 1). In this case the harvester was equipped with the H7 Euca harvester head developed specifically for processing of eucalyptus trees.

There were four forest stands for comparisons of the CTL methods (

Table 3). The main characteristics varying between the stands were the degree of slope and tree species. The terrain was categorized into two classes: flat and slope. In the stands representing slope’s harvesting methods, the average slope was 10–15% higher than in flat terrains’ harvesting methods. When looking at the slope, the operative slope of the machine’s working point must be distinguished from the average slope of forest stand (

Figure 1). Further, due to the gradually steepening shape of the slopes, slope terrains’ harvesting methods were partly worked on operative slopes significantly higher than the average slope. Therefore, the cutting methods needed harvesting-assisting equipment on slope terrain which affected time consumption, productivity, performance, and profitability of the human-machine systems. In this study, steepness in percentage is employed.

The type of tree species varied between the stands. The main tree species in pine plantations was loblolly pine (Pinus taeda), and in eucalyptus plantations it was Sydney’s eucalyptus (Eucalyptus saligna). The tree species differed considerably in their stem shape. The average tree diameter at the breast height (205 – 210 mm) in pine plantations was larger than in eucalyptus plantations (178 – 184 mm). In contrast, the average heights of eucalyptus plantations (21.3 – 22.1 m) were significantly higher than the average heights of pine plantations (13.3 – 15.1 m). In other words, pine trees were relatively conical in their stem shape, and the eucalyptus trees were narrow. The pines were also smaller than the eucalyptus trees in their average volume per tree (m3). In addition, the thick branches of pine trees extended lower as compared to eucalyptus stems.

The spatial distribution of trees in the stands was even since the trees were planted in rows. The tree planting density in eucalyptus plantations was 1 650 trees/ha, while in pine plantations it was a little lower, 1350 trees/ha. The density of stands at the moment of cutting corresponded to the planting density, because these short-rotation forests were not thinned during the growing rotation.

2.2. Cutting and Forwarding Methods in Harvesting

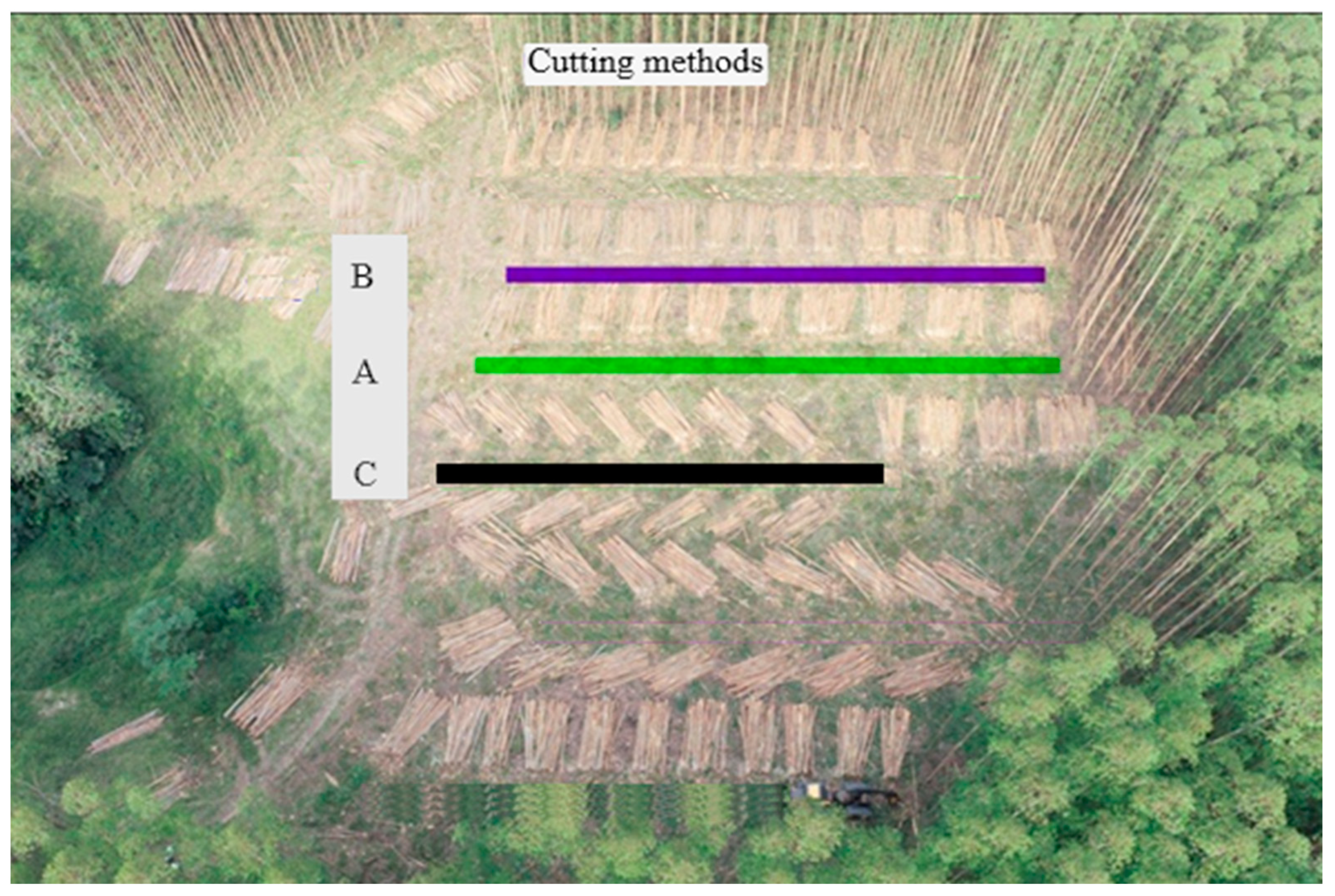

Figure 4 describes three different cutting methods that were used in flat terrain. In this respect, two sideways (A and B) and one forward felling (C) cutting methods were compared to each other. On slope terrain, two cutting methods (D and E) applied methods A and B, where in addition to the cutting methods, a winch assistance for the harvester and forwarder was utilized in the study stands.

Table 4 consists of the average size of trees (m

3) in the samples of harvesting methods on flat terrain, which is a main variable for productivity of harvesting. Three cutting methods are also described more specifically for analysis.

The study layout of cutting and forwarding methods is presented in

Table 5. A total of 17 harvesting samples were prepared as the data sets of four stands on flat and slope terrains.

Table 5 also depicts abbreviations of forwarding methods after respective cutting method. There A means sideways felling at the edge of harvesting front, B as sideways felling inside the harvesting front, C as forward felling in the middle of the harvesting front. D means sideways felling at edge of harvesting front with traction assistance, E as sideways felling inside the harvesting front with traction assistance. AL means forwarding after sideways felling at edge of harvesting front, BL as forwarding after sideways felling inside the harvesting front, CL as forwarding after forward felling in the middle of the harvesting front, DL as forwarding after sideways felling at edge of harvesting front with traction assistance and EL as forwarding after sideways felling inside the harvesting front with traction assistance.

In addition, to be an efficient harvesting method, machine operators must be educated for the harvesting methods, and they must be able to work fluently with the models [

41]. In this study, two study operators represented a local forest industry company and forest machines, and one operator represented a Finnish forest machine manufacturer. The harvester operator of a forest industry company had worked as a forest machine operator for seven years. The test operator of forwarder had a remarkable 34 years of work experience as a forest machine operator. The Finnish forest machine manufacturer’s test operator was the same for both harvester and forwarder. He had worked as a forest machine operator for nine years, and then, for eight years as an operator trainer for a forest machine manufacturer. This test operator had a total of 17 years of work experience.

2.3. Analysis Methods

The work study was applied in the analysis of harvesting [

42], in which work was observed visually using video material. The time study material of the harvesting work was processed using a video analysis tool developed for the research. The output data of cut trees were collected with the automatic measuring system of the harvester. In the beginning of analysis, time distributions of work phases of cutting cycles were calculated for the cutting methods. Then, the time consumption analysis of work phases was evaluated more precisely with the help of statistical analysis [

43]. First, the normal distribution of samples from time study data was examined with the Kolmogorov-Smirnov test (K-S). It was found that the distributions of variables of some samples differed statistically from the normal distribution. Therefore, it was decided to use the non-parametric tests in the statistical analysis. Statistical differences between the samples were examined with the Kruskal-Wallis’s test (K-W) and the Mann-Whitney U-test (M-W).

After the time-consumption analysis of the cutting methods, productivity analysis was implemented by using the same analysis methods. Cutting productivity was examined by average calculations and statistical tests at the forest stand level using the cutting cycle times that also included the work phases of “driving to the working point” and “the additional auxiliary times”. Since the number of working breaks (interruptions) in the data varied, the comparison of cutting methods was performed using the effective-hour productivity (m3/E0h).

Further effort was made to identify the differences between harvesting methods by testing the time consumptions of loading cycle of forwarder. The same tests were used in the analysis, (K-W and M-W), because it was found that the distributions of variables of samples differed statistically from the normal distribution. For example, on the slope terrain, loading cycle times of forwarder were tested in DL, (K-S, p = 0.004) and in EL, (K-S, p = 0.012).

3. Results

3.1. Time Consumption of Cutting Cycles

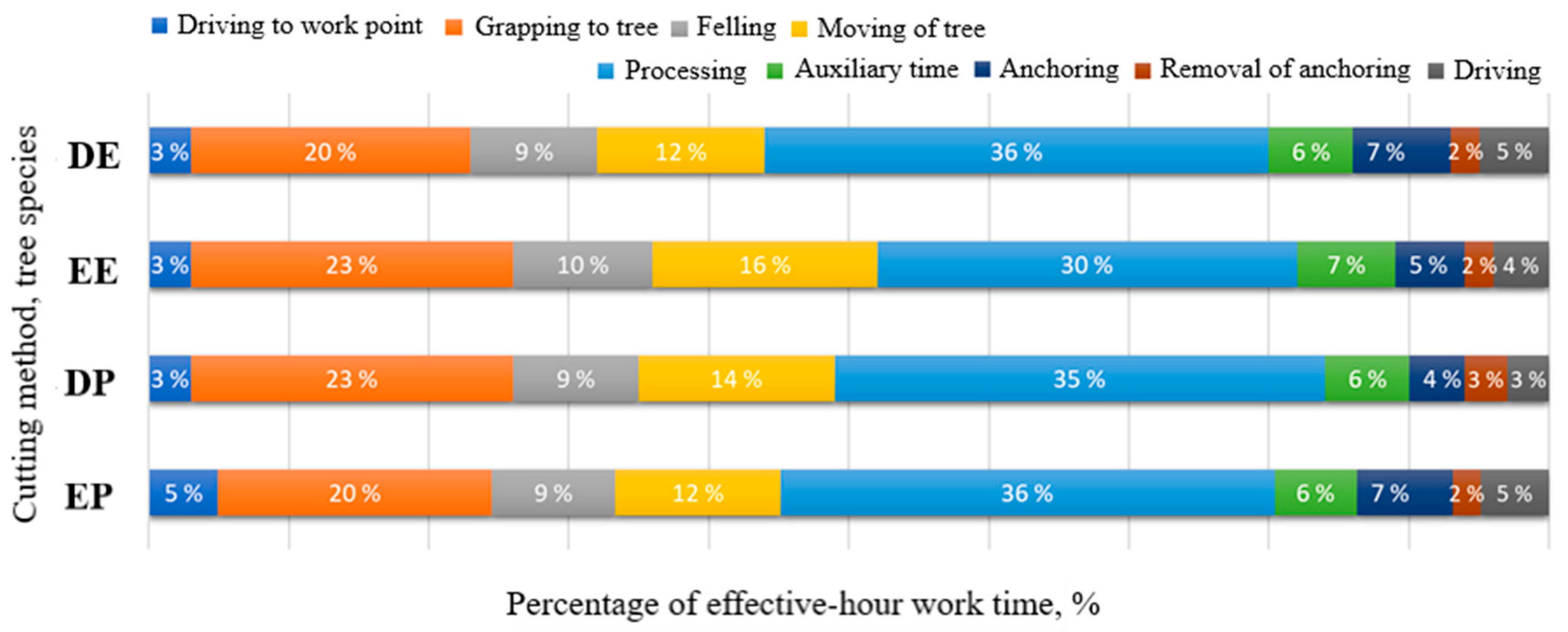

Figure 5 and

Figure 6 show average time consumptions of work phases of cutting methods as percentage shares for flat and slope terrains at forest stand level. In data of the flat terrain (

Figure 5), the average time consumption of grabbing a tree (23 – 24%) in cutting eucalyptus would seem to be slightly lower compared to cutting of pine (25 – 31%). On the other hand, the share of processing time seemed to be higher in eucalyptus cutting (41 – 46%) compared to pine cutting (28 – 38%). In addition, the time distributions of work phases of cutting cycles were also slightly different between the cutting methods, (1 – 4%).

The time consumption was also analyzed on slope terrain in groups formed by the cutting methods and tree species (

Figure 6). The effect of tree species on the time consumption of the work phases would seem to decrease when moving from flat terrain to a slope terrain. Omitting pine stands’ processing phase, this difference was caused by increased total time consumption of the cutting cycle because of anchoring phases. Further, only a minor difference was observed in the processing time when it is compared between eucalyptus (30 – 36%) and pine (35 – 36%). In addition, the time consumption of moving grabble to tree (20 – 23%) in eucalyptus is very similar compared to pine as are all time distributions of cutting cycles between the cutting methods.

3.5. Time Consumption Analysis of Loading Cycle of Forwarder

There was a statistically significant difference in total time consumptions in the loading cycles (K-W, p<0.000). In a pairwise comparison, the loading cycle methods AL and CL (M-W, p=0.023) and the methods BL and CL (M-W, p<0.000) caused statistically significant differences in time consumption of the loading cycles. On the other hand, no statistically significant difference was observed between the loading cycles in the methods AL and BL. In addition, a statistically significant difference was observed in the average time consumption of loading cycles between flat and sloped terrain (M-W, p=0.006). On the other hand, the average time consumption of loading cycles did not differ statistically significantly between eucalyptus and pine loading. Furthermore, in contrast to cutting cycles, a statistically significant difference between the operators was observed in loading cycles (M-W, p<0.000).

Table 6 presents average time consumption values of loading cycles, which is presented separately for flat and slope terrains. A statistically significant difference in time consumptions of the loading cycles of pine was observed in the data of operator 2 (K-W, p<0.000) on flat terrain, where the loading times of the CL method was 25.4–13.4% lower than loading times of other methods (

Table 6). On the other hand, the statistical difference between the methods DL and EL was observed in slope terrain (M-W, p=0.013), even though the position of the stacks along the logging trail was similar between the methods.

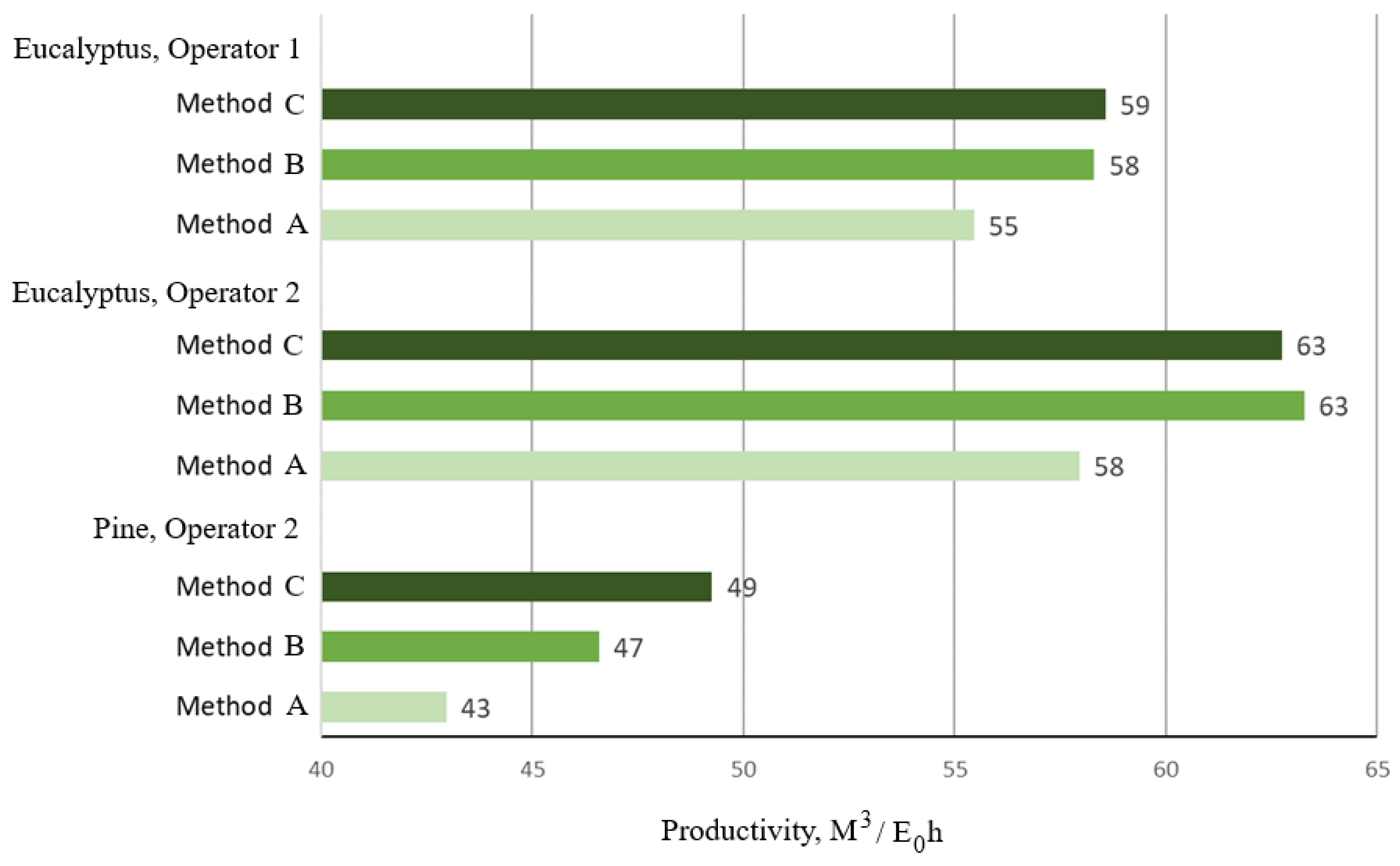

3.4. Effective Hour Productivity of Cutting Methods on Flat Terrain

The productivity of the cutting methods was considered in respect to tree species and operators. When average productivity of cutting methods was compared between tree species, the cutting of eucalyptus was more productive (20 – 35%) compared to the cutting of pine. The productivity differences caused by the operators were, on the other hand, significantly smaller (5 – 9%) regarding the cutting methods.

More precise analysis shows that sideways felling at the edge of harvesting front (Method A) was the least productive method in the samples of flat terrain for all tree species and operators (

Figure 7). The sideways felling inside the harvesting front (Method B) and the forward felling in the middle of the harvesting front (Method C) were found to be statistically significantly more productive than method A on the flat terrain. On the other hand, the mutual difference between methods B and C was not very clear, especially in eucalyptus stands. In eucalyptus stands, method C was 7 – 8% more productive than method A. Method B was correspondingly 5 – 8% more productive than method A. In pine stands, the methods differed clearly. Method C had the highest productivity, and Method A had the lowest productivity. Method C was found to be up to 14% more productive than method A. Method B was 9% more productive than method A.

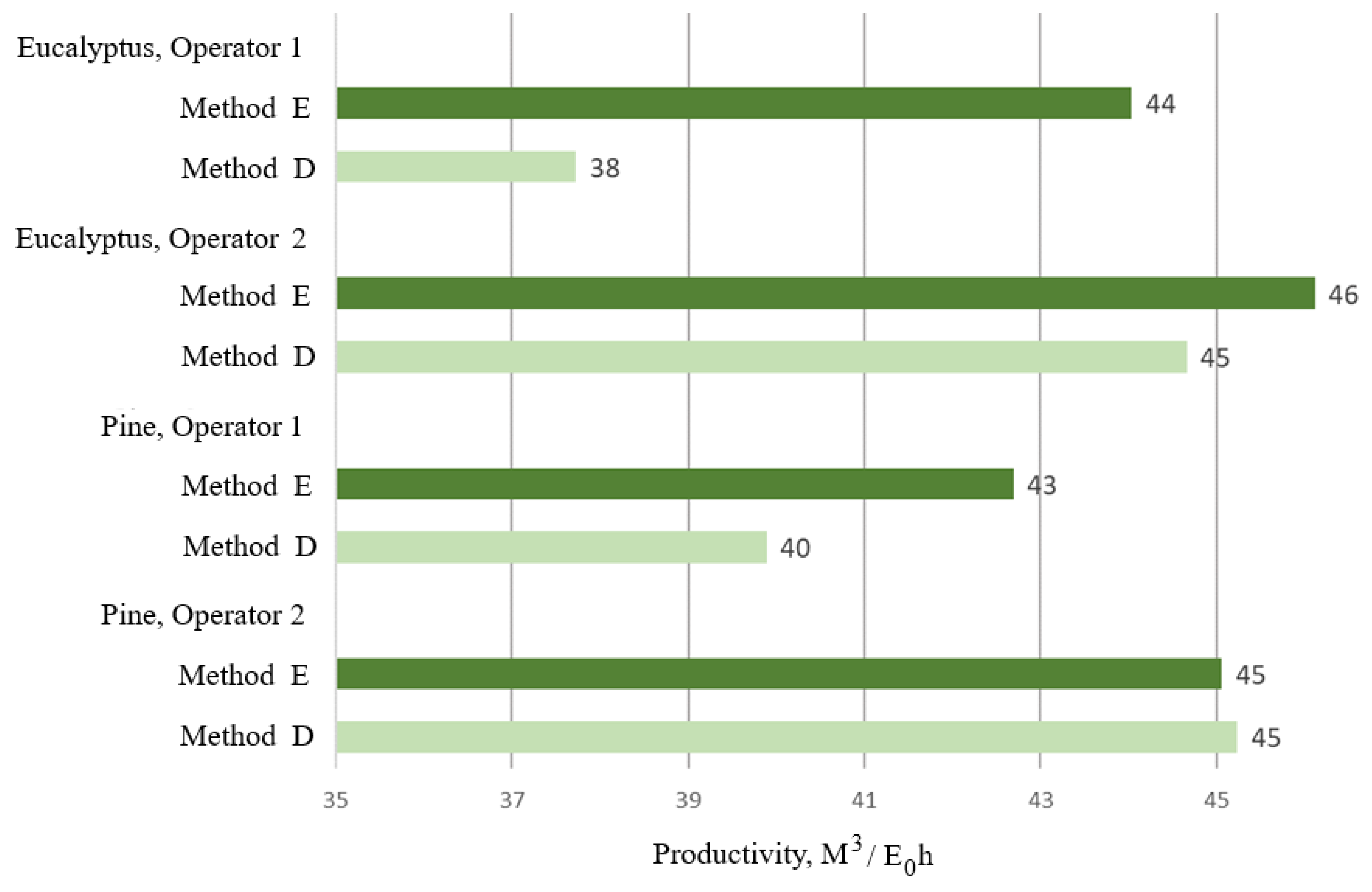

3.5. Effective Hour Productivity of Cutting Methods with Traction Assistance

In the slope terrain stands the average productivity differences between tree species did not differ as clearly as in the flat terrain stands when the results were calculated by the cutting method. Eucalyptus cutting was 0 – 5% more productive compared to pine cutting, due to the cutting method and the operator. The differences caused by the operators were larger (2 – 16 %) when the results were calculated by the cutting method.

Whereas on flat terrain a clear difference in the effective-hour productivity was observed between two different sideways cutting methods (method A vs. method B), on slope terrain the differences of cutting methods D and E were not completely unambiguous (

Figure 8). The cutting method E was clearly more productive than the method D in the data of cutting work of the operator 1. In eucalyptus stands, the productivity difference in favor of the method E was 16% and in pine stands it was 8%. However, similar differences were not observed in the cutting work of operator 2. In eucalyptus stands, only a small difference (2%) between the methods D and E was observed in data of the operator 2. In pine stands, the effective-hour productivity of the methods seemed to be equal in the cutting work.

3.6. Productivity Analysis of Cutting Cycles by Statistical Tests

When analyzing the productivity of cutting cycles in the entire material, a statistically significant difference between the cutting methods was observed (K-W, p=0.005). In a pairwise comparison, methods A and B (M-W, p=0.033) and methods A and C (M-W, p=0.002) differed statistically from each other. On the other hand, no statistical difference was observed between methods B and C. In the entire material, the effect of variables on productivity was also analyzed. It was observed that the productivity of cutting cycles differed statistically significantly in a pairwise comparison between eucalyptus and pine study stands (M-W, p<0.000) and flat and sloping terrain (M-W, p<0.000). On the other hand, no statistically significant difference was observed between harvester operators (M-W, p=0.257).

An average productivity calculation of the cutting methods on flat and slope terrain is presented in

Table 7. The average productivity of method A was generally lower than methods B and C in both datasets of operators. Further, the productivity of cutting methods was higher on flat terrain in eucalyptus forests, however the situation was opposite i.e. the productivity of cutting methods was higher on slope terrain in pine forests.

Table 7 also shows that the average productivity did not differ statistically significantly between different cutting methods on flat stands. On the other hand, the statistically significant difference between cutting methods D and E was observed in both eucalyptus and pine stands on slope terrain (M-W, p = 0.030). This statistical difference was observed in the data of operator 1, where method E was 7.0 – 7.7 m

3/h more productive than method D, depending on the tree species.

4. Discussion

4.1. Productivity Comparison of Cut-to-Length Harvesting Methods

There has been quite a little research on the harvesting methods of tree plantations with CTL wheel machines.

Table 1 describes well previous productivity studies for tree plantations. In addition, the stands were very dense at the final cutting, which could have caused difficulties in productivity comparisons in respect to Nordic harvesting conditions. Since comparative information seems to be available rather scarcely, we proceed in the examination of the results via the harvesting conditions of tree plantations.

When the productivity of this study is compared with previous results, it is noticed that the productivity is on considerably higher level. If the average size of the stem is about 0.3 m

3, then the cutting productivity has been about 20 m

3/E

0h in previous studies, while in this study it was 45 m

3/E

0h in pine cuttings and 55 m

3/E

0h in eucalyptus cuttings. The power of the harvesters in comparison may has an effect on the results [

44]. The engine power of track-based harvesters is generally lower compared to the power of the harvester used in this study (205 kW). For example, in the material of Strandgard et al. [

30], the power of the harvesters varied between 104–224 kW. On the other hand, Seixas & Batista’s [

19] study found no significant difference in the productivity of wheeled harvesters and tracked harvesters when they worked in similar conditions. In Nordic studies, another significant factor causing differences is the operators’ experience [

41]. The test operators of this study can be considered very experienced with 17 and 34 years of work experience, while in the material of Strandgard et al. [

30], the operators’ experience varied between 1 and 20 years of work.

Regarding cutting methods, the time distributions of the work phases provided weakly unambiguous information about the impact of the cutting method on efficiency of wood harvesting methods. Further, tree species did not explain the time distribution differences. Acuna et al. [

29] have concluded that the tree density of the stands can influence productivity. This characteristic affected indirectly in this study because trees of forest stands grew in denser positions compared to the cited reference materials.

4.2. Productivity Comparison between Flat and Slope Terrains

A previous study has already confirmed the notion that winch-assisted wood harvesting is significantly more productive than traditional slope harvesting methods (such as manual felling and short-distance transportation using cable cars) [

39]. However, productivity values for winch-assisted harvesting have been considered indicative. Therefore, the importance of further research on the topic has been emphasized in order to achieve a sufficient understanding of the profitability of winch-assisted harvesting in varying conditions. This research contributes to the presented further research needs and increases the understanding of the productivity of the winch-assisted CTL method for harvesting in tree plantations.

When cutting methods on a slope terrain with winch assistance was compared to cutting methods on flat terrain where winch assistance was not used, productivity was found to decrease by an average of 11.26 m

3/E

0h when winch assistance was used. In previous studies comparing harvesting productivity without winch assistance and with winch assistance, winch assistance was found to decrease productivity clearly [

45]. The use of winch assistance was found to decrease productivity by up to 36 m

3/E

0h [

46]. Based on previous studies, the use of winch assistance is justified mainly in conditions where mechanized wood harvesting would not otherwise be possible or if soil impacts want to be avoided [

17,

39]. On the other hand, winch assistance has been found to increase the power of the forest machine so that the driving speed and the load of forwarder can be increased [

36]. This should be taken into account in future studies when thinking about the impact of additional work phases of anchoring on productivity.

Winch assistance has been shown in a previous study to enable a safe and efficient alternative to conventional methods for wood harvesting on steep slopes [

39]. The results achieved in this study support and complement the previous rather limited research data on the time consumption and productivity of winch-assisted wood harvesting. Based on the results, it can be concluded that the winch assistance enables the use of forest machines developed for the CTL method in steep terrains. With the harvesting productivity remaining at a good level thanks to the winch support, forestry can be practiced even more efficiently in areas where harvesting costs were previously thought to be too high. In addition, the winch assistance was found to offer useful opportunities for managing the environmental impact of harvesting on sloped areas that are prone to erosion. This study did not focus on the safety aspects of harvesting work, but the improvement of work safety is obvious if winch assistance can be used to replace manual harvesting work [

37,

39].

The most significant work phases that reduce the productivity of winch-assisted harvesting are related to the attachment of the winch assist [

39]. Additional work phases that increase the effective working time for harvesting have been reported in previous studies to take 10–23% of the effective working time [

34,

35,

36]. In this study, the average share of additional work phases from the effective working time was 12% for the cutting methods and 16% for forwarding. The results correspond to the percentage of time required for anchoring the winch support in previous studies, but it is important to note that the percentage of additional work phases depends strongly on the effective work time of the entire work cycle and its distribution to the work phases. For example, in forwarding the length of the driving distance and the number of stacks processed in cutting are variables that cause variation in the distribution of effective working time between studies.

The forest machines were equipped with the Ponsse Syncrowinch winch system [

40]. When anchoring the winch and removing the anchoring are considered, the work phases mentioned above took significantly less time in this study than in previous studies, an average of 4.4 minutes. In previous studies, the average winch attachment times varied between 21.6 and 23.3 minutes [

34,

35,

36]. The longer time of the additional work phases may be explained by the different winch systems used in other studies, because the work phases required to anchoring them and their removing are probably not completely comparable to the method used in this study.

In this study, information was collected only on the average slope of the harvesting stands. However, the operative inclination of the stands varied between different working points of machines, but no research data was collected of this variation. The operational slope of the working point probably has some effect on harvesting productivity even when winch assistance is in use, but previous research does not give an unequivocal answer to that issue [

34,

39].

4.3. Validity of Data and Methods

According to Harstela [

47], when collecting representing time research data, one should try to control the conditions by choosing research sites with the most uniform quality possible. As a research environment, tree plantations are of uniform quality compared to, for example, Nordic forests. Despite this, the average size of the stem was found to vary significantly between different cutting methods (

Table 4), which may reduce the reliability of the results at the study stand level. It may be a matter of chance, which is impossible to influence by selection of research samples. It should be noted that the outliers in the data may also significantly disturb statistical comparisons [

3]. One option would have been to remove outliers from the data. However, a better option was to collect a sufficiently large data set so that the impact of abnormal findings is reduced. Therefore, the material of this study was large enough to compare productivity variations at the stand level. On the other hand, when the harvesting conditions are rather uniform the number of outliers should be minimal.

In the actual comparative time study, for increasing validity, there should be at least three operators, each of whom would work with all the studied methods in all study environments. Contrary to the original plan of the study, however, the number of test operators had to be reduced from three operators to two. The productivity difference between the operators examined in the study was 2.21 m

3/h in favor of operator 2. This difference may be considered as a greater influence on productivity than was assumed when preparing the study layout. In other words, operator-specific choices and habits during harvesting may have an impact on the results of the study [

41]. On the other hand, the variability caused by the equipment was minimized by using the same machines and adjusting the speed of the boom to a constant for both operators. In addition, it should be noticed that harvesting conditions and tree size may also affect the productivity difference between operators.

The influence of the operators on the variation in the study material could hardly be fully controlled. The simplest method to control the operator effect would be to use average operators [

47]. The test operators in the study were used to working with the old method and were very good at that. Even if the operators learned the new methods quickly, it is very possible that getting used to the old method still influenced the results [

3]. When choosing the operators, it was assumed that they had a similar motivation and attitude towards new wood harvesting methods and the research situation. In the end, however, evaluation of motivation is uncertain, which makes the selection of test operators a very challenging task. Test operators are also generally more motivated and enthusiastic at the beginning of the research when work productivity is higher. For this reason, the advice has been that the results of the first two research days have been recommended to be removed from the data. However, there were not enough financial resources for removing data in this study. Instead of removing the data, by giving the study operators enough training time on the cutting methods of the study, the remove of the material can be avoided.

Manual time study like this, in which work is observed visually using video footage, has become a common method of time study in wood harvesting studies, although automatic time study has become more common recently [

48,

49,

50]. With an automatic time study the division of work phases could not have been carried out to the extent required. Particularly, measuring special work phases such as the time consumption of winch anchoring required the collection of video material for the study.

It should be noted that in manual time study, the measurement accuracy is always limited, because it is based on the observation made by the work researcher [

48]. However, the characteristics of the time study tool used in the study made it possible to separate the work phases with sufficient accuracy from the video. It was also possible to quickly correct observation errors made by the researcher. However, in a manual time study, the effect of the researcher’s skills and experience on the results cannot be completely eliminated [

51,

52]. In particular, three-dimensional visualization of distances and movements from video material was a challenge. The movements of the grapple device in the lateral direction could be detected accurately, but it was more difficult to observe the movements of the grapple device in the depth direction because the video material was shot from above.

The time distributions of the work phases provided weakly unambiguous information about the impact of the cutting method on efficiency of harvesting methods, especially for comparisons of them at flat terrain and slope terrain conditions. Therefore, productivity analysis by statistical methods was necessary. The quantitative statistical methods used in the study have already been successfully applied in many previous studies e.g., [

41,

48]. Even if the research methods are established, statistical testing is almost always accompanied by uncertainty. When evaluating the reliability of the results, it must be noted that the study used a significance level of at least 5% (p<0.05) in the interpretation of statistical tests and finding the differences.

4.4. Future Studies

The case studies of harvesting methods consisted of both cutting of trees and loading of logs to load space. However, both methods could be analyzed more precisely. The reason for that was that time study data of cutting was more precise than the data of loading of logs to load space. In other words, results of cutting were at the stand and tree level, while results of forwarding were at the loading cycle level. When looking at the average loading times of forwarder between the time study units, a clear line in favor of cutting methods A or B was not observed despite some statistical differences. This analysis could be expanded to tree level (spatial stack level) for considerations of flat and slope terrains more precisely. Further, a productivity analysis of forwarder-operator systems could be implemented if precise work phase data collected from work cycles of interests.

Although the study only measured quantitative outputs, the outputs are always qualitative as well, which could be considered more precisely in the future. Since the logs of the study stands ended up as raw material for the fiber industry, the importance of product quality was not really emphasized in the research setting. In addition, the effect of harvesting on the quality of the environment could be emphasized, as some of the research sites were in erosion-sensitive slope areas. Although the quality of the environment was not actually measured in the study, indirect interpretations of the impact of the harvesting operation on the soil can be made from the video recordings. The machines and work methods used in the study were not found to cause significant wear and tear on the soil, which supports the use of a harvesting chain equipped with winch assistance and tracks in harvesting on slopes.

5. Conclusions

The layout and material of the study can be considered good for reaching the main goal of the study. In the study harvesting conditions, the sideways felling inside the harvesting front was the best suited and the most productive (63 m3/E0h) for harvesting on both flat and slope terrain. It was found that winch assistance has a negative effect on harvesting productivity (11 m3/E0h). Despite this necessity, the winch assistance system examined in the study enabled sufficiently productive cutting even on steep slopes (45 m3/E0h), while at the same time being an environmentally sustainable solution for harvesting on erosion-sensitive slopes. As a method that increases work safety, it also has a positive effect on the perspective of the social sustainability of working life. The significant variation of the average size of trees (m3) between the time study units partly reduced the validity of the research material or at least made it difficult to draw conclusions. Therefore, in further studies, it would be useful to model productivity as a function of tree size and make more precise comparisons in respect to harvesting conditions.

Author Contributions

Conceptualization, methodology and writing T.P. and A.P; formal analysis, A.P.; software, A.L.; writing—review and editing, H.O. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data is unavailable due to privacy restrictions.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Lundbäck, M.; Häggström, C.; Nordfjell, T. Worldwide trends in methods for harvesting and extracting industrial roundwood. Int. J. For. Eng. 2021, 32, 202–215. [Google Scholar] [CrossRef]

- Spinelli, R.; Owende, P.; Ward, S. Productivity and cost of CTL harvesting of Eucalyptus globulus stands using excavator-based harvesters. For. Prod. J. 2002, 52, 67–77. [Google Scholar]

- Palander, T.; Bergroth, J.; Kärhä, K. Excavator technology for increasing the efficiency of energy wood and pulp wood harvesting. Biomass Bioenergy 2012, 40, 120–126. [Google Scholar] [CrossRef]

- Ackerman, P.; Martin, C.; Brewer, J.; Ackerman, S. Effect of slope on productivity and cost of Eucalyptus pulpwood harvesting using single-grip purpose-built and excavator-based harvesters. Int. J. For. Eng. 2018, 29, 74–82. [Google Scholar] [CrossRef]

- Anon 2023a. Ponsse. The cut-to-length method. https://www.ponsse.com/en/cut-to-length.

- Anon 2023b. John Deere Worldwide. https://www.deere.com/assets/pdfs/common/our-company/about/jd-world-locations-8-27-20.pdf.

- Eriksson, M.; Lindroos, O. Productivity of harvesters and forwarders in CTL operations in northern Sweden based on large follow-up datasets. Int. J. For. Eng. 2014, 25, 179–200. [Google Scholar] [CrossRef]

- Kuuluvainen, T.; Grenfell, R. Natural disturbance emulation in boreal forest ecosystem management — theories, strategies, and a comparison with conventional even-aged management. Can. J. For. Res. 2012, 42, 1185–1203. [Google Scholar] [CrossRef]

- Grönlund, Ö.; Erlandsson, E.; Djupström, L.B.; Bergström, D.; Eliasson, L. Nature conservation management in voluntary set-aside forests in Sweden: practices, incentives and barriers. Scand. J. For. Res. 2020, 35, 196–107. [Google Scholar] [CrossRef]

- Fernandez-Lacruz, F.; Grönlund, Ö.; Johannesson, T.; Djupström, L.B.; Söderberg, J.; Eliasson, L. Harvester time consumption in nature conservation management operations. Int. J. For. Eng. 2023, 34, 112–116. [Google Scholar] [CrossRef]

- McEwan, A.; Marchi, E.; Spinelli, R.; Brink, M. Past, present and future of industrial plantation forestry and implication on future timber harvesting technology. J. For. Res. 2020, 31, 339–351. [Google Scholar] [CrossRef]

- Spinelli, R.; Magagnotti, N.; De Francesco, F.; Kovác, B.; Heger, P.; Heilig, D.; Heil, B.; Kovács, G.; Zemánek, T. Cut-to-Length Harvesting Options for the Integrated Harvesting of the European Industrial Poplar Plantations. Forests 2022, 13, 1478. [Google Scholar] [CrossRef]

- Zhang, F.; Johnson, D.M.; Wang, J.; Yu, C. Cost, energy use and ghg emissions for forest biomass harvesting operations. Energy 2016, 114, 1053–1062. [Google Scholar] [CrossRef]

- Adebayo, A.; Han, H.S.; Johnson, L. Productivity and cost of cut-to-length and whole-tree harvesting in a mixed-conifer stand. For. Prod. J. 2007, 57, 59–69. [Google Scholar]

- Fuentealba, S.; Pradenas, L.; Linfati, R.; Ferland, J.A. Forest harvest and sawmills: An integrated tactical planning model. Comput. Electron. Agric. 2019, 156, 275–281. [Google Scholar] [CrossRef]

- Labelle, E.R.; Lemmer, K.J. Selected Environmental Impacts of Forest Harvesting Operations with Varying Degree of Mechanization. Croat. J. For. Eng. 2017, 40, 239–257. [Google Scholar] [CrossRef]

- Garren, A.M.; Bolding, M.C.; Aust, W.M.; Moura, A.C.; Barrett, S.M. Soil disturbance effects from tethered forwarding on steep slopes in Brazilian eucalyptus plantations. Forests 2019, 10, 721. [Google Scholar] [CrossRef]

- Labelle, E.R.; Hansson, L.; Högbom, L.; Jourgholami, M.; Laschi, A. Strategies to Mitigate the Effects of Soil Physical Disturbances Caused by Forest Machinery: a Comprehensive Review. Curr. For. Rep. 2022, 8, 20–37. [Google Scholar] [CrossRef]

- Seixas, F.; Batista, J. Technical and economical comparison between wheel harvesters and excavators. Sci. For. 2014, 24, 185–191. [Google Scholar]

- Simoes, D.; Fenner, P.T. Influence of relief in productivity and costs of harvester. Scientia Forestalis 2010, 38, 107–114. [Google Scholar]

- Da Silva Leite, E.; Minette, L.J.; Fernandes, H.C.; de Souza, A.P.; do Amaral, E.J.; das Graça Lacerda, E. Desempenho do harvester na colheita de eucalipto em diferentes espaçamentos e declividades (Harvester performance on eucalyptus crops in different spacing and slopes). Rev. Arvore. 2014, 38, 1–7. [Google Scholar] [CrossRef]

- Norihiro, J.; Ackerman, P.; Spong, B.D.; Längin, D. Productivity Model for Cut-to-Length Harvester Operation in South African Eucalyptus Pulpwood Plantations. Croat. J. For. Eng. 2018, 39, 1–13. [Google Scholar]

- Hartsough, B.; Cooper, D. Cut-to-length harvesting of short-rotation Eucalyptus. For. Prod. J. 1999, 49, 69–75. [Google Scholar]

- Strandgard, M.; Mitchell, R.; Wiedemann, J. Comparison of Productivity, Cost and Chip Quality of Four Balanced Harvest Systems Operating in a Eucalyptus globulus Plantation in Western Australia. Croat. J. For. Eng. 2019, 40, 39–48. [Google Scholar]

- Ghaffariyan, M.R.; Dupuis, E. Analysing the Impact of Harvesting Methods on the Quantity of Harvesting Residues: An Australian Case Study. Forests 2021, 12, 1212. [Google Scholar] [CrossRef]

- Spinelli, R.; Magagnotti, N.; Lombardini, C. Low-Investment Fully Mechanized Harvesting of Short-Rotation Poplar (populus spp.) Plantations. Forests 2020, 11, 502. [Google Scholar] [CrossRef]

- Ramantswana, M.; McEwan, A.; Steenkamp, J. A comparison between excavator-based harvester productivity in coppiced and planted Eucalyptus grandis compartments in KwaZulu-Natal, South Africa. Southern Forests: A Journal of Forest Science 2013, 75, 239–246. [Google Scholar] [CrossRef]

- McEwan, A.; Magagnotti, N.; Spinelli, R. The effects of number of stems per stool on cutting productivity in coppiced Eucalyptus plantations. Silva Fenn. 2016, 50, 1448. [Google Scholar] [CrossRef]

- Acuna, M.; Strandgard, M.; Wiedemann, J.; Mitchell, R. Impacts of Early Thinning of a Eucalyptus globulus Labill. Pulplog Plantation in Western Australia on Economic Profitability and Harvester Productivity. Forests 2017, 8, 415. [Google Scholar] [CrossRef]

- Strandgard, M.; Mitchell, R.; Acuna, M. General productivity model for single grip harvesters in Australian eucalypt plantations. Aust. For. 2016, 79, 1–6. [Google Scholar] [CrossRef]

- Tarnowsky, C.; Schneider, P.; Machado, C. Productivity and costs of processor working in stands of Eucalyptus grandis. Sci. For. 1999, 2, 103–111. [Google Scholar] [CrossRef]

- Martins, R.J.; Seixas, F.; Stape, J.L. Technical and economical evaluation of a harvester, working under different spacing and planting arrangement conditions in eucalypts plantations. Sci. For. 2009, 37, 253–263. [Google Scholar]

- Ackerman, P.; Williams, C.; Ackerman, S.; Nati, C. Diesel Consumption and Carbon Balance in South African Pine Clear-Felling CTL Operations: A Preliminary Case Study. Croat. J. For. Eng. 2017, 38, 65–72. [Google Scholar]

- Brandtner, N. Produktivitätsevaluierung des seilgestützten Harvesters John Deere 1170E. MS Thesis, University of Natural Resources and Life Sciences, Vienna, Austria, 2018; 49p. [Google Scholar]

- Holzfeind, T.; Stampfer, K.; Holzleitner, F. Productivity, setup time and costs of a winch-assisted forwarder. J. For. Res. 2018, 23, 196–203. [Google Scholar] [CrossRef]

- Strimbu, V.; Boswell, B. Adverse skidding using a Tigercat 635E assisted by a T-winch; FPInnovations: Pointe-Claire, QC, Canada, 2018. [Google Scholar]

- Garland, J.; Belart, F.; Crawford, R.; Chung, W.; Cushing, T.; Fitzgerald, S. Safety in steep slope logging operations. J. Agromed. 2019, 24, 138–145. [Google Scholar] [CrossRef]

- Holzleitner, F.; Kastner, M.; Stampfer, K.; Höller, N.; Kanzian, C. Monitoring Cable Tensile Forces of Winch-Assist Harvester and Forwarder Operations in Steep Terrain. Forests 2018, 9, 53. [Google Scholar] [CrossRef]

- Holzfeind, T.; Visser, R.; Chung, W.; Holzleitner, F.; Erbe, G. Development and Benefits of Winch-Assist Harvesting. Curr. For. Rep. 2020, 6, 201–209. [Google Scholar] [CrossRef]

- Anon 2023c. Ponsse Synchrowinch. https://www.ponsse.com/synchrowinch#/.

- Ovaskainen, H. Timber harvester operators’ working technique in first thinning and the importance of cognitive abilities on work productivity; Monograph No. 79 in Dissertationes Forestales; University of Eastern Finland: Joensuu, Finland, 2009; 62p. [Google Scholar]

- Niebel, B.W. Motion and time study; Irwin: Homewood, Illinois, USA, 1993; 850p. [Google Scholar]

- Hollander, M.; Wolfe, D.A. Nonparametric statistical methods; John Wiley and Sons: New York, USA, 1973. [Google Scholar]

- Spinelli, R.; Hartsough, B.; Magagnotti, N. Productivity standards for harvesters and processors in Italy. For. Prod. J. 2010, 60, 226–235. [Google Scholar] [CrossRef]

- Petitmermet, J.; Sessions, J.; Bailey, J.; Zamora-Cristales, R. Cost and productivity of tethered cut-to-length Systems in a dry-Forest Fuel-Reduction Treatment: a case study. For. Sci. 2019, 65, 581–592. [Google Scholar] [CrossRef]

- Green, P.; Chung, W.; Leshchinsky, B.; Belart, F.; Sessions, J.; Fitzgerald, S. Insight into the productivity, cost and soil impacts of cable assisted harvester-forwarder thinning in Western Oregon. For. Sci. 2019, 66, 82–96. [Google Scholar] [CrossRef]

- Harstela, P. Work studies in forestry; Silva Carelica 18; University of Joensuu, Faculty of Forestry: Joensuu, Finland, 1991; 41p. [Google Scholar]

- Nuutinen, Y. Possibilities to use automatic and manual timing in time studies on harvester operations; Monograph No. 156 in Dissertationes Forestales; University of Eastern Finland: Joensuu, Finland, 2013; 68p. [Google Scholar]

- Palander, T.; Nuutinen, Y.; Kariniemi, A.; Väätäinen, K. Automatic time study method for recording work phase times of timber harvesting. For. Sci. 2013, 59, 472–483. [Google Scholar] [CrossRef]

- Olivera, A.; Visser, R.; Acuna, M.; Morgenroth, J. Automatic GNSS-enabled harvester data collection as a tool to evaluate factors affecting harvester productivity in a Eucalyptus spp. harvesting operation in Uruguay. Int. J. For. Eng. 2016, 27, 15–28. [Google Scholar] [CrossRef]

- Nuutinen, Y.; Väätäinen, K.; Heinonen, J.; Asikainen, A.; Röser, D. The Accuracy of Manually Recorded Time Study Data for Harvester Operation Shown via Simulator Screen. Silva Fenn. 2008, 42, 63–72. [Google Scholar] [CrossRef]

- Palander, T.; Ovaskainen, H.; Tikkanen, L. An Adaptive Work Study Method for Identifying the Human Factors that Influence the Performance of a Human-Machine System. For. Sci. 2012, 58, 377–389. [Google Scholar] [CrossRef]

Figure 1.

The relationship between degrees of inclination and percentage of slope terrain.

Figure 1.

The relationship between degrees of inclination and percentage of slope terrain.

Figure 2.

Ponsse Ergo harvester with Ponsse Syncrowinch winch assistance has been anchored to the stump.

Figure 2.

Ponsse Ergo harvester with Ponsse Syncrowinch winch assistance has been anchored to the stump.

Figure 3.

Stands located in the state of Parana in southern Brazil.

Figure 3.

Stands located in the state of Parana in southern Brazil.

Figure 4.

Two sideways (A, B) and one forward felling (C) cutting method on flat terrain.

Figure 4.

Two sideways (A, B) and one forward felling (C) cutting method on flat terrain.

Figure 5.

Effect of cutting method and tree species on percentages of time consumptions (m3/E0h) on flat terrain. A = sideways felling at edge of harvesting front, B = sideways felling inside the harvesting front, C = forward felling in the middle of the harvesting front, E = Eucalyptus, P = Pine.

Figure 5.

Effect of cutting method and tree species on percentages of time consumptions (m3/E0h) on flat terrain. A = sideways felling at edge of harvesting front, B = sideways felling inside the harvesting front, C = forward felling in the middle of the harvesting front, E = Eucalyptus, P = Pine.

Figure 6.

Effect of cutting method and tree species on time consumptions (m3/E0h) on slope terrain. D = sideways felling at edge of harvesting front with traction assistance, E = sideways felling inside the harvesting front with traction assistance.

Figure 6.

Effect of cutting method and tree species on time consumptions (m3/E0h) on slope terrain. D = sideways felling at edge of harvesting front with traction assistance, E = sideways felling inside the harvesting front with traction assistance.

Figure 7.

Average effective-hour productivity of cutting methods in stands on flat terrain. Method A = sideways felling at edge of harvesting front. Method B = sideways felling inside the harvesting front. Method C = forward felling in the middle of the harvesting front.

Figure 7.

Average effective-hour productivity of cutting methods in stands on flat terrain. Method A = sideways felling at edge of harvesting front. Method B = sideways felling inside the harvesting front. Method C = forward felling in the middle of the harvesting front.

Figure 8.

Effective-hour productivity of cutting methods D and E on slope terrain. Method D = sideways felling at edge of harvesting front with traction assistance. Method E = sideways felling inside the harvesting front with traction assistance.

Figure 8.

Effective-hour productivity of cutting methods D and E on slope terrain. Method D = sideways felling at edge of harvesting front with traction assistance. Method E = sideways felling inside the harvesting front with traction assistance.

Table 1.

Productivity studies of CTL method from tree plantations. EH = Excavator-based harvester, WH = Wheeled harvester.

Table 1.

Productivity studies of CTL method from tree plantations. EH = Excavator-based harvester, WH = Wheeled harvester.

| Authors of Study |

Year |

HarvesterModel |

Species |

Country |

Tree Size (m3) |

Productivity (m3/h) |

| Spinelli et al. |

2002 |

EH |

Eucalyptus spp. |

Spain, Portugal |

0.11–0.26 |

5–14 |

| Martins et al. |

2009 |

WH |

Eucalyptus spp. |

Brazil |

0.25 |

17 |

| Magagnotti et al. |

2012 |

WH |

Eucalyptus spp. |

Portugal |

0.09 |

8.8 |

| Ramatswana et al. |

2013 |

EH |

Eucalyptus spp. |

South-Africa |

0.21 |

16.1 |

| Seixas and Batista |

2014 |

WH |

Eucalyptus spp. |

Brasilia |

0.29 |

19.1 |

| MacEwan et al |

2016 |

EH |

Eucalyptus spp. |

South-Africa |

0.47 |

24.8 |

| Ackerman et al. |

2017 |

EH |

Pinus spp. |

South-Africa |

1.05 |

54.13 |

| Brewer et al. |

2018 |

WH |

Pinus spp. |

South-Afrika |

1.12–1.33 |

84.3–100.8 |

| Norhiro et al. |

2018 |

EH |

Eucalyptus spp. |

South-Africa |

0.12–0.38 |

13.8–27.5 |

Table 2.

Technical characteristics of the forest machines in the study.

Table 2.

Technical characteristics of the forest machines in the study.

| Characteristic |

Ponsse Ergo H7 C5

Harvester |

Ponsse Elephant King

Forwarder |

| Operating mass (with accessories), kg |

24 650 |

23 900 |

| Engine power, kW |

205 |

205 |

| Traction force, KN |

195 |

240 |

| Engine torque, rpm |

1 100 |

1 100 |

| Boom reach, m |

9.5 |

10.0 |

| Wheels, " |

26.5" |

26.5" |

| Tracks |

Yes |

Yes |

| Year of manufacturing |

2016 |

2016 |

| Operating hours, h |

22 235 |

20 459 |

Table 3.

Characteristics of four stands for comparisons of CTL harvesting methods.

Table 3.

Characteristics of four stands for comparisons of CTL harvesting methods.

| Characteristic |

1 |

2 |

3 |

4 |

| The main tree species |

Eucalyptus saligna |

Pinus taeda |

Eucalyptus saligna |

Pinus taeda |

| Slope of terrain, % |

17.5 |

22.5 |

7.5 |

7.5 |

| Number of trees, trees/ha |

1650 |

1350 |

1650 |

1350 |

| Diameter at dbh1.3, mm |

184 |

205 |

178 |

210 |

| Tree length, m |

21.3 |

13.3 |

22.1 |

15.1 |

| Tree volume, m3

|

0.416 |

0.315 |

0.386 |

0.366 |

Table 4.

The average size of trees (m3) in samples of cutting methods on flat terrain: A = sideways felling at the edge of harvesting front, B = sideways felling inside the harvesting front, C = forward felling in the middle of the harvesting front, E = Eucalyptus, P = Pine, 1 = Operator 1, 2 = Operator 2.

Table 4.

The average size of trees (m3) in samples of cutting methods on flat terrain: A = sideways felling at the edge of harvesting front, B = sideways felling inside the harvesting front, C = forward felling in the middle of the harvesting front, E = Eucalyptus, P = Pine, 1 = Operator 1, 2 = Operator 2.

Tree Species/

Operator |

A |

B |

C |

| |

m3

|

|

| E1 |

0.414 |

0.319 |

0.436 |

| E2 |

0.413 |

0.418 |

0.432 |

| P2 |

0.290 |

0.287 |

0.351 |

Table 5.

Study layout of the cutting and forwarding methods.

Table 5.

Study layout of the cutting and forwarding methods.

| Terrain |

Tree Species |

Cutting Method |

Forwarding Method |

Traction Assistance |

| Flat |

Eucalyptus |

A |

B |

C |

AL |

BL |

CL |

No |

| Flat |

Pine |

A |

B |

C |

AL |

BL |

CL |

No |

| Slope |

Eucalyptus |

D |

E |

- |

DL |

EL |

|

Yes |

| Slope |

Pine |

D |

E |

- |

DL |

EL |

|

Yes |

Table 6.

The average time consumption of the loading cycle (s) and testing of statistical differences between loading regarding factors of them on flat and slope terrains. AL = Forest hauling after sideways felling at edge of harvesting front, BL = Forest hauling after sideways felling inside the harvesting front, CL = Forest hauling after forward felling in the middle of the harvesting front, DL = Forest hauling after sideways felling at edge of harvesting front with traction assistance, EL = Forest hauling after sideways felling inside the harvesting front with traction assistance, E = Eucalyptus, P = Pine, 1 = Operator 1, 2 = Operator 2, K-W = Kruskal-Wallis test, M-W = Mann-Whitney U-test.

Table 6.

The average time consumption of the loading cycle (s) and testing of statistical differences between loading regarding factors of them on flat and slope terrains. AL = Forest hauling after sideways felling at edge of harvesting front, BL = Forest hauling after sideways felling inside the harvesting front, CL = Forest hauling after forward felling in the middle of the harvesting front, DL = Forest hauling after sideways felling at edge of harvesting front with traction assistance, EL = Forest hauling after sideways felling inside the harvesting front with traction assistance, E = Eucalyptus, P = Pine, 1 = Operator 1, 2 = Operator 2, K-W = Kruskal-Wallis test, M-W = Mann-Whitney U-test.

| Species, |

Flat Terrain, s

|

|

Slope Terrain, s

|

| Operator |

AL |

BL |

CL |

K-W |

|

DL |

EL |

M-W |

| E 1 |

18.6 |

17.9 |

17.7 |

0.638 |

|

18.2 |

20.8 |

0.013* |

| E 2 |

21.8 |

22.9 |

22.9 |

0.550 |

|

26.0 |

26.4 |

0.883 |

| P 1 |

17.6 |

18.7 |

16.4 |

0.147 |

|

- |

18.4 |

- |

| P 2 |

22.4 |

26.0 |

19.4 |

0.000* |

|

- |

22.7 |

- |

Table 7.

Average productivities of cutting methods and statistical differences between them: A = sideways felling at edge of harvesting front, B = sideways felling inside the harvesting front, C = forward felling in the middle of the harvesting front, D = sideways felling at edge of harvesting front with traction assistance, E = sideways felling inside the harvesting front with traction assistance, E = Eucalyptus, P = Pine, 1 = Operator 1, 2 = Operator 2, K-W = Kruskal-Wallis test, M-W = Mann-Whitney U-test.

Table 7.

Average productivities of cutting methods and statistical differences between them: A = sideways felling at edge of harvesting front, B = sideways felling inside the harvesting front, C = forward felling in the middle of the harvesting front, D = sideways felling at edge of harvesting front with traction assistance, E = sideways felling inside the harvesting front with traction assistance, E = Eucalyptus, P = Pine, 1 = Operator 1, 2 = Operator 2, K-W = Kruskal-Wallis test, M-W = Mann-Whitney U-test.

| Species, |

Flat Terrain, s

|

Slope Terrain, s

|

| Operator |

A |

B |

C |

K-W |

D |

E |

M-W |

| E1 |

58.1 |

64.8 |

62.1 |

0.149 |

46.1 |

53.8 |

0.030* |

| E2 |

66.3 |

64.0 |

63.9 |

0.716 |

57.9 |

56.0 |

0.615 |

| P1 |

- |

- |

- |

- |

51.7 |

58.7 |

0.030* |

| P2 |

49.3 |

53.6 |

53.8 |

0.730 |

55.1 |

57.7 |

0.325 |

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).