Submitted:

04 March 2024

Posted:

05 March 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

1.1. Present Contribution

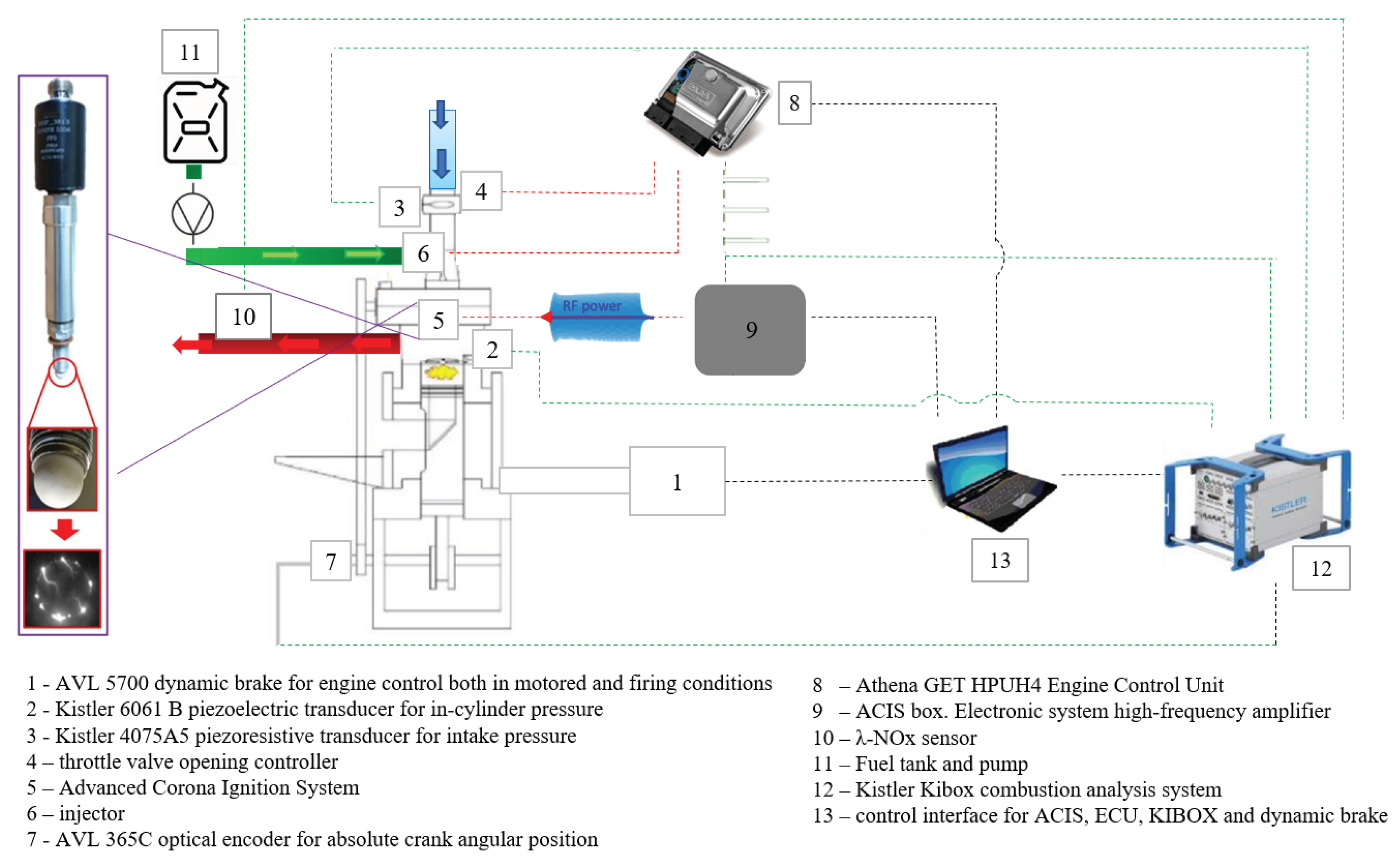

2. Materials and Methods

3. Case Study

4. Results and Discussions

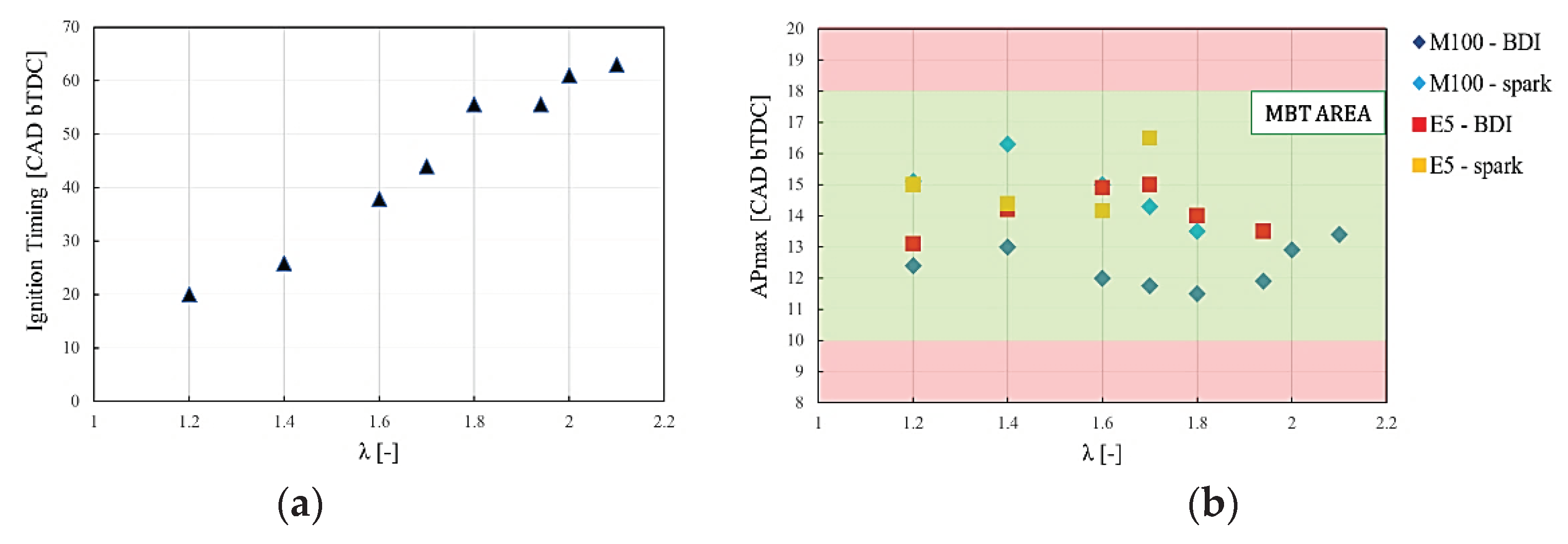

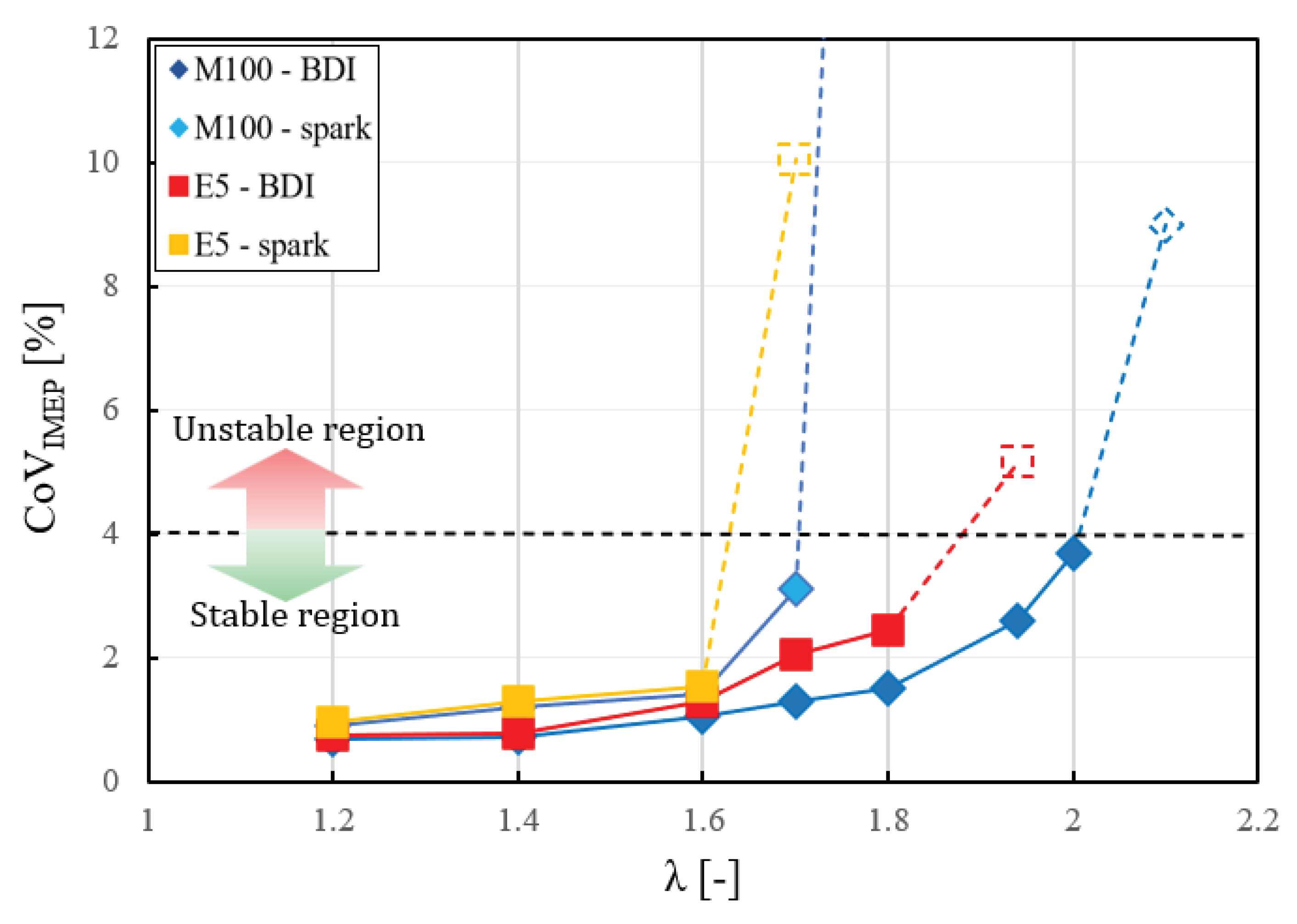

4.1. Combustion Stability

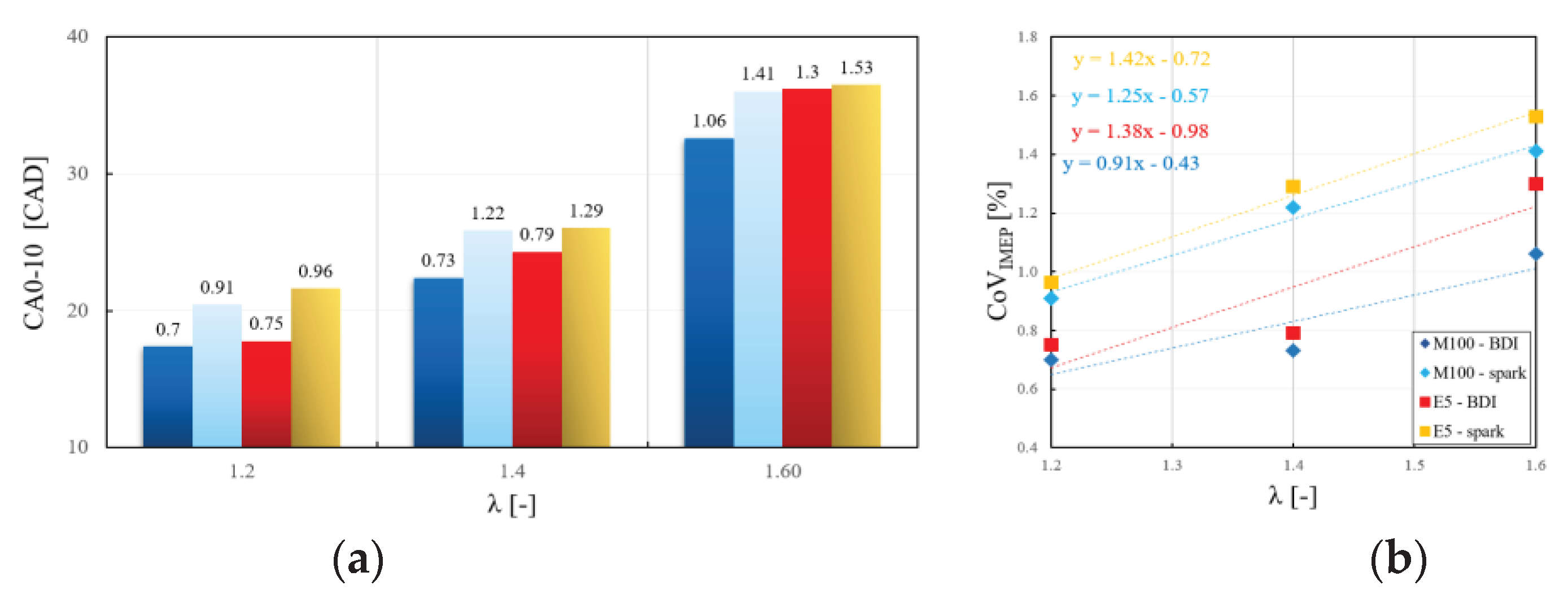

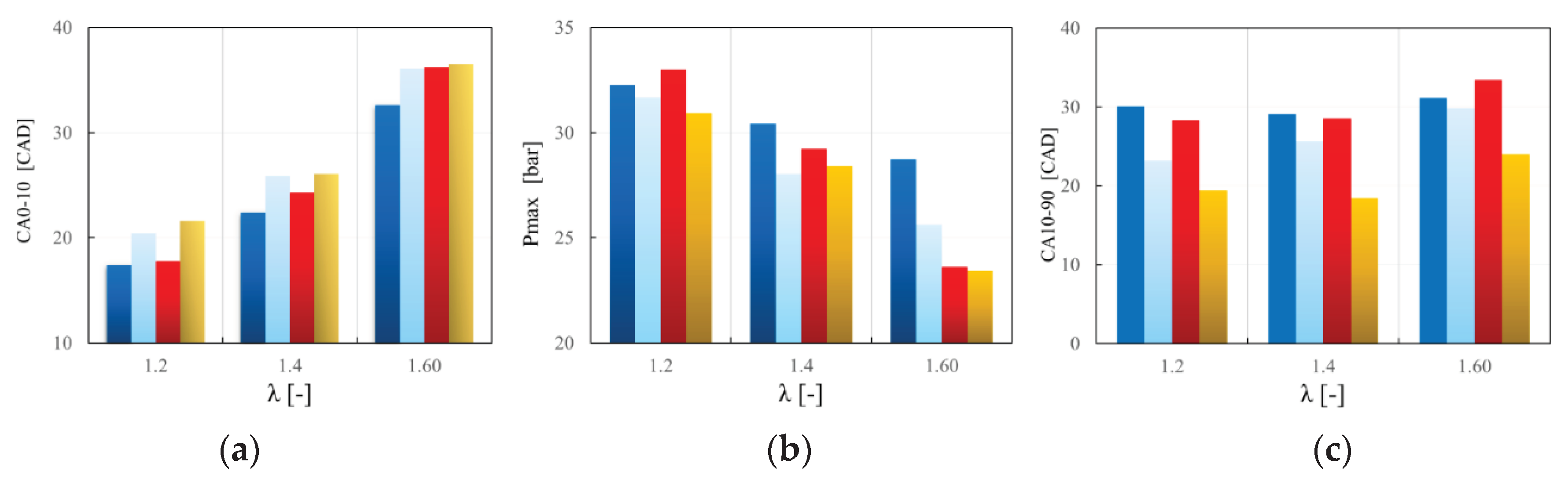

4.2. Combustion Duration

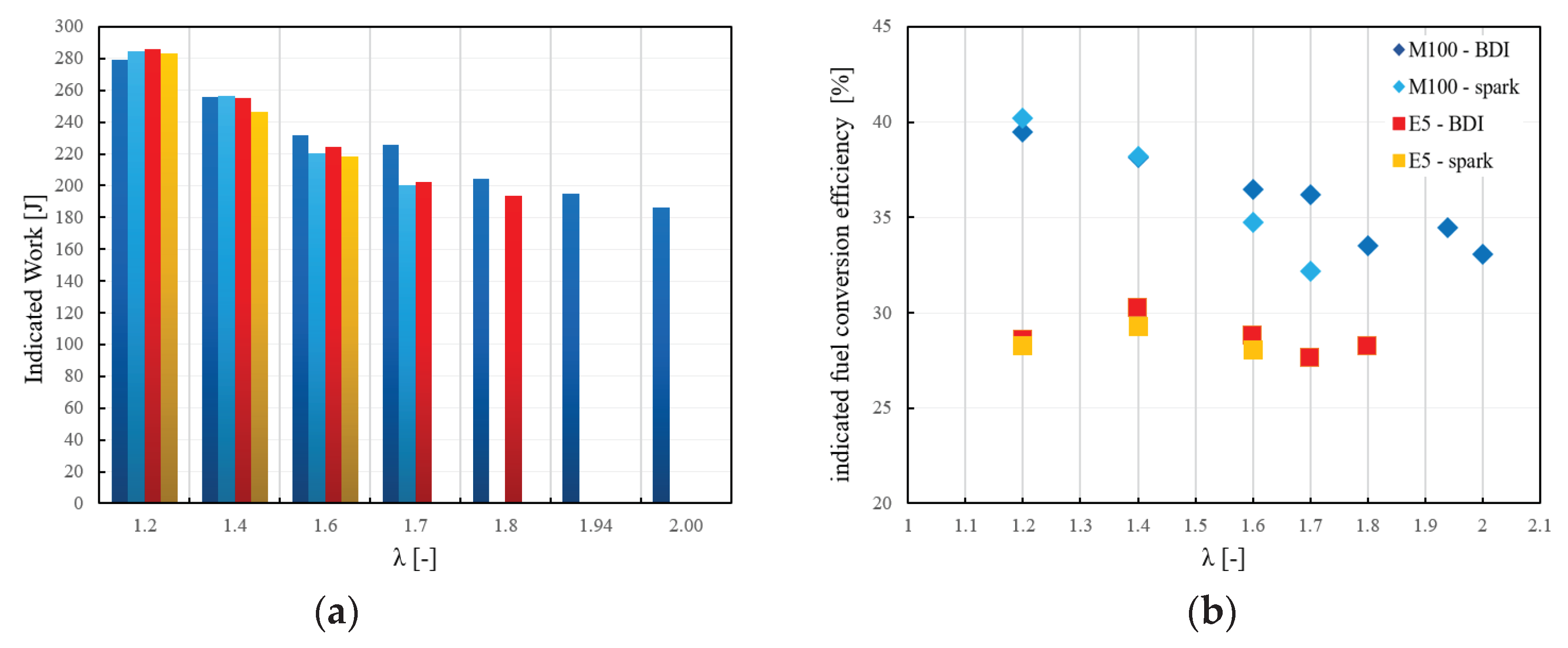

4.3. Indicated Work and Efficiency

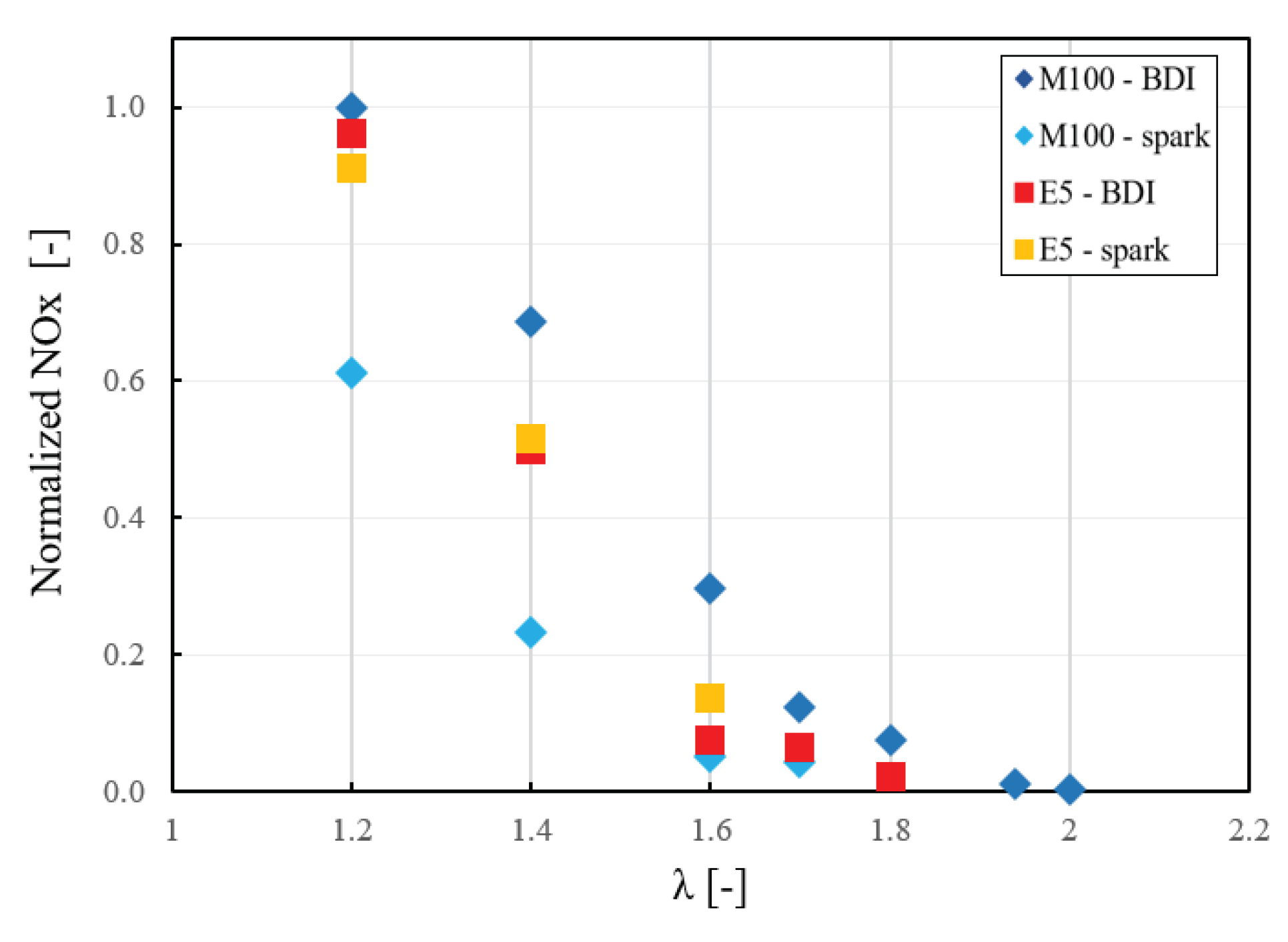

4.4. Nitrogen Oxides Emissions

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| ACIS | Advanced Corona Ignition System |

| APmax | crank angle degree at the maximum in-cylinder pressure |

| aTDC | after the top dead center |

| BDI | barrier discharge igniter |

| CAD | crank angle degree |

| CoV | coefficient of variation |

| E5 | European market gasoline |

| ECU | engine control unit |

| EGR | Exhaust Gas Recirculation |

| ICE | internal combustion engine |

| IMEP | indicated mean effective pressure |

| LTP | Low-Temperature Plasma |

| M100 | methanol |

| MBT | maximum brake torque |

| MON | motor octane number |

| PFI | port fuel injection |

| RF | radio-frequency |

| SI | spark ignition |

| ton | corona activation time |

| Vd | driving voltage |

| λ | relative air-fuel ratio |

References

- Reitz RD, Ogawa H, Payri R,. IJER editorial: the future of the internal combustion engine. Int J Engine Res 2020;21:3–10. [CrossRef]

- Xiumin Yu, “Experimental study on the effects of EGR on combustion and emission of an SI engine with gasoline port injection plus ethanol direct injection”, Fuel, Volume 305, 2021, 121421, ISSN 0016-2361. [CrossRef]

- Zsiga, N.; Voser, C.; Onder, C.; Guzzella, L. Intake Manifold Boosting of Turbocharged Spark-Ignited Engines. Energies 2013, 6, 1746–1763. [Google Scholar] [CrossRef]

- J. Zembi, et al. “Numerical investigation of water injection effects on flame wrinkling and combustion development in a GDI spark ignition optical engine.” SAE Technical Paper, 2021, 2021-01-0465. [CrossRef]

- J. Zembi, et al. “Investigations on the impact of port water injection on soot formation in a DISI engine through CFD simulations and optical methods.” Fuel, 2023, 337, 127170. [CrossRef]

- Ricci, F., Petrucci, L., Cruccolini, V., Discepoli, G., Grimaldi, C. N., & Papi, S. (2020). Investigation of the Lean Stable Limit of a Barrier Discharge Igniter and of a Streamer-Type Corona Igniter at Different Engine Loads in a Single-Cylinder Research Engine. Proceedings, 58(1), 11. [CrossRef]

- James P. Szybist, What fuel properties enable higher thermal efficiency in spark-ignited engines? Progress in Energy and Combustion Science, Volume 82, 2021, 100876, ISSN 03601285. [CrossRef]

- F. Ausfelder and K. Wagemann, “Power-to-Fuels: E-Fuels as an Important Option for a Climate-Friendly Mobility of the Future,” Chemie-Ingenieur-Technik, vol. 92, no. 1–2, pp. 21–30, 2020. [CrossRef]

- L. E. Hombach, L. Doré, K. Heidgen, H. Maas, T. J. Wallington, and G. Walther, “Economic and environmental assessment of current (2015) and future (2030) use of E-fuels in light-duty vehicles in Germany,” J. Clean. Prod., vol. 207, pp. 153–162, 2019. [CrossRef]

- Ballal, Vedant. “Climate change impacts of e-fuels for aviation in Europe under present-day conditions and future policy scenarios.” Fuel 338 (2023): 127316. [CrossRef]

- Puricelli, G. Cardellini, S. Casadei, D. Faedo, A. E. M. van den Oever, and M. Grosso, “A review on biofuels for light-duty vehicles in Europe,” Renew. Sustain. Energy Rev., vol. 137, no. November 2019, p. 110398, 2021. [CrossRef]

- I. Osman, N. Mehta, A. M. Elgarahy, A. Al-Hinai, A. H. Al-Muhtaseb, and D. W. Rooney, Conversion of biomass to biofuels and life cycle assessment: a review, vol. 19, no. 6. Springer International Publishing, 2021. [CrossRef]

- Tian, Zhi. “The effect of methanol production and application in internal combustion engines on emissions in the context of carbon neutrality: A review.” Fuel 320 (2022): 123902. [CrossRef]

- Zhen, X., & Wang, Y. (2015). An overview of methanol as an internal combustion engine fuel. In Renewable and Sustainable Energy Reviews (Vol. 52, pp. 477–493). Elsevier Ltd. [CrossRef]

- Arapatsakos CI, Karkanis AN, Sparis PD. Behavior of a small four-stroke engine using as fuel methanolegasoline mixtures. SAE technical paper No. 2003-32-0024; 2003. [CrossRef]

- Zhen XD. The engine knock analysis – an overview. ApplEnergy 2013; 112:431–9. [CrossRef]

- Celik MB, Ozdalyan B, Alkan F. The use of pure methanol as fuel at high compression ratio in a single cylinder gasoline engine. Fuel 2011; 90:1591–8. [CrossRef]

- Vacca, A., Rossi, E., Cupo, F., Chiodi, M., Kulzer, A. C., Bargende, M., Villforth, J., Unger, T., & Deeg, H. P. (2022). Virtual Development of a Single-Cylinder Engine for High Efficiency by the Adoption of eFuels, Methanol, Pre-Chamber and Millerization. SAE Technical Papers. [CrossRef]

- Dhaliwal B, Yi N, Checkel D. Emissions effects of alternative fuels in light-duty and heavy-duty vehicles. SAE technical paper No. 2000-01-0692; 2000. [CrossRef]

- Anfilatov, A. A., & Chuvashev, A. N. (2020). Effect of methanol use in the engine on the workflow. IOP Conference Series: Materials Science and Engineering, 862(6). [CrossRef]

- Zembi J., Battistoni M., Mariani F. et al. Pressure and Flow Field Effects on Arc Channel Characteristics for a J-type Spark Plug. SAE Technical Papers 2022-01-0436. [CrossRef]

- Zembi J., Mariani F., Grimaldi C., et al. Experimental and Numerical Investigation of the Flow Field Effect on Arc Stretching for a J-type Spark Plug. SAE Technical Papers 2021-24-0020. [CrossRef]

- Abidin, Z. and Chadwell, C., “Parametric Study and Secondary Circuit Model Calibration Using Spark Calorimeter Testing,” SAE Technical Paper 2015-01-0778, 2015. [CrossRef]

- Jung D, Iida N. An investigation of multiple spark discharge using multi-coil ignition system for improving thermal efficiency of lean SI engine operation. Appl. Energy 2018; 212:322–32. [CrossRef]

- Jung D, Sasaki K, Iida N. Effects of increased spark discharge energy and enhanced in-cylinder turbulence level on lean limits and cycle-to-cycle variations of combustion for SI engine operation. Appl Energy 2017;205(August):1467–77. [CrossRef]

- Breden, D.; Karpatne, A.; Suzuki, K.; Raja, L. High-Fidelity Numerical Modeling of Spark Plug Erosion. SAE Tech. Pap. Ser. 2019, 1, 1–12. [Google Scholar] [CrossRef]

- Wyczalek, F.A., Frank, D.L., and Nueman, J.G., “Plasma Jet Ignition of Lean Mixtures,” SAE Technical Paper 750349, 1975. [CrossRef]

- Toulson, E., Schock, H.J., and Attard, W.P., “A Review of Pre-Chamber Initiated Jet Ignition Combustion Systems,” SAE Technical Paper 2010-01-2263, 2010. [CrossRef]

- Mehdi, Ghazanfar, Sara Bonuso, and Maria Grazia De Giorgi. “Plasma assisted Re-ignition of aeroengines under high altitude conditions.” Aerospace 9.2 (2022): 66. [CrossRef]

- Starikovskiy, A. and Aleksandrov, N., “Plasma-Assisted Ignition and Combustion,” Progress in Energy and Combustion Science 39, no. 1 (2013): 61-110. [CrossRef]

- Singleton, D, Pendleton, S, Gundersen, M. The role of non-thermal transient plasma for enhanced flame ignition in C2H4-air. J Phys D Appl Phys 2001; 44: 022001. [CrossRef]

- S. M. Starikovskaia. “Plasma assisted ignition and combustion. “ J Phys D Appl Phys 2006;39 (16):R265–99. [CrossRef]

- J. Zembi, et al. “Modeling of thermal and kinetic processes in non-equilibrium plasma ignition applied to a lean combustion engine.” Applied Thermal Engineering, 2021, 197, 117377. [CrossRef]

- Starikovskii A. Plasma supported combustion. Proc Combust Inst 2005;30(2): 2405–17. [CrossRef]

- Breden, D., Idicheria, C. A., Keum, S., Najt, P. M., & Raja, L. L. (2019). Modeling of a Dielectric-Barrier Discharge-Based Cold Plasma Combustion Ignition System. IEEE Transactions on Plasma Science, 47(1), 410–418. [CrossRef]

- Idicheria, C. A., Yun, H., & Najt, P. M. (n.d.). 1.3 An Advanced Ignition System for High Efficiency Engines. 40–54. [CrossRef]

- Cruccolini, V., Discepoli, G., Ricci, F., Petrucci, L., Grimaldi, C., Papi, S., & Dal Re, M. (2020). Comparative Analysis between a Barrier Discharge Igniter and a Streamer-Type Radio-Frequency Corona Igniter in an Optically Accessible Engine in Lean Operating Conditions. SAE Technical Papers, 202-01-0276. [CrossRef]

- Martinelli R., Ricci F., et.al, Lean Combustion Analysis of a Plasma-Assisted Ignition System in a Single Cylinder Engine fueled with E85, SAE Technical Papers, 2022-24-0034. [CrossRef]

- Starikovskaia, S. M. (2014). Plasma-assisted ignition and combustion: Nanosecond discharges and development of kinetic mechanisms. Journal of Physics D: Applied Physics, 47(35). [CrossRef]

- Starikovskaia, S. M. (2006). Plasma assisted ignition and combustion. Journal of Physics D: Applied Physics, 39(16). [CrossRef]

- Irimescu, A., Tornatore, C., Marchitto, L., and Merola, S.S., “Compression Ratio and Blow-by Rates Estimation Based on Motored Pressure Trace Analysis for an Optical Spark Ignition Engine,” Appl. Therm. Eng. 61(2):101-109, 2013. [CrossRef]

- Ricci, F., Discepoli, G., Cruccolini, V., Petrucci, L., Papi, S., di Giuseppe, A., & Grimaldi, C. N. (2021). Energy characterization of an innovative non-equilibrium plasma ignition system based on the dielectric barrier discharge via pressure-rise calorimetry. Energy Conversion and Management, 244(April), 114458. [CrossRef]

- Discepoli, G., Cruccolini, V., Dal Re, M., Zembi, J., Battistoni, M., Mariani, F., & Grimaldi, C. N. (2018). Experimental assessment of spark and corona igniters energy release. Energy Procedia, 148, 1262-1269. [CrossRef]

- Ricci, F., Cruccolini, V., Discepoli, G., Petrucci, L., Grimaldi, C., & Papi, S. (2021). Luminosity and Thermal Energy Measurement and Comparison of a Dielectric Barrier Discharge in an Optical Pressure-Based Calorimeter at Engine Relevant Conditions. SAE Technical Paper Series, 1, 1–11. [CrossRef]

- Zembi, J., Ricci, F., & Grimaldi, C. (2021). Numerical Simulation of the Early Flame Development Produced by a Barrier Discharge Igniter in an Optical Access Engine. SAE Technical Papers, 2021-24-0011. [CrossRef]

- Ricci, F., Zembi, J., Battistoni, M., Grimaldi, C., Discepoli, G., & Petrucci, L. (2019). Experimental and Numerical Investigations of the Early Flame Development Produced by a Corona Igniter. SAE Technical Papers, 2019-24-0231. [CrossRef]

- Discepoli, G., Cruccolini, V., Ricci, F., di Giuseppe, A., Papi, S., & Grimaldi, C. N. (2020). Experimental characterization of the thermal energy released by a Radio-Frequency Corona Igniter in nitrogen and air. Applied Energy, 263(February), 114617. [CrossRef]

- Petrucci, Luca. “A Development of a New Image Analysis Technique for Detecting the Flame Front Evolution in Spark Ignition Engine under Lean Condition.” Vehicles 4.1 (2022): 145-166. [CrossRef]

- Ricci, F., Martinelli, R., Petrucci, L., Discepoli, G., Nazareno, C., & Papi, S. (n.d.). Streamers Variability Investigation of a Radio- Frequency Corona Discharge in an Optical Access Engine at Different Speeds and Loads. Doi: E3S Web of Conferences. [CrossRef]

- Cruccolini, V., Discepoli, G., Ricci, F., Grimaldi, C. N., & di Giuseppe, A. (2020). Optical and Energetic Investigation of an Advanced Corona Ignition System in a Pressure-Based Calorimeter. E3S Web of Conferences, 197. [CrossRef]

- Cruccolini, V., Grimaldi, C. N., Discepoli, G., Ricci, F., Petrucci, L., & Papi, S. (2020). An optical method to characterize streamer variability and streamer-to-flame transition for radio-frequency corona discharges. Applied Sciences (Switzerland), 10(7), 1–20. [CrossRef]

- Cimarello, A.; Grimaldi, C.N.; Mariani, F.; Battistoni, M.; Dal Re, M. Analysis of RF Corona Ignition in Lean Operating Conditions Using an Optical Access Engine. SAE Tech. Pap. 2017, 2017-01-0673. [CrossRef]

- Germane, Geoff J., Carl G. Wood, and Clay C. Hess. Lean combustion in spark-ignited internal combustion engines-a review. Vol. 31. October, 1983. [CrossRef]

- Wu, Bin. “Comparison of lean burn characteristics of an SI engine fueled with methanol and gasoline under idle condition.” Applied Thermal Engineering 95 (2016): 264-270. [CrossRef]

- Eliasson, B.; Kogelschatz, U. Nonequilibrium volume plasma chemical processing. IEEE Trans. Plasma Sci.1991, 19, 1063–1077. [CrossRef]

- Masurier, J-B.. “Ozone applied to the homogeneous charge compression ignition engine to control alcohol fuels combustion.” Applied Energy 160 (2015): 566-580. [CrossRef]

| Displaced volume | 500 cc |

| Stroke | 88 mm |

| Bore | 85 mm |

| Connecting Rod | 139 mm |

| Compression ratio | 8.8:1 |

| Number of Valves | 4 |

| Exhaust Valve Open | 13 CAD bBDC |

| Exhaust Valve Close | 25 CAD aTDC |

| Inlet Valve Open | 20 CAD bTDC |

| Intake Valve Close | 24 CAD aBDC |

| Properties | Gasoline (E5) | Methanol (M100) |

|---|---|---|

| C/H ratio [-] | 0.54 | 0.25 |

| O/C ratio [-] | 0.03 | 1 |

| Density [kg/m3] | 761.42 | 792 |

| Lower heating value [MJ/kg] | 44 | 19.93 |

| Heat of vaporization [kJ/kg] | 349 | 1160 |

| Stoichiometric air-to-fuel ratio | 14.7 | 6.4 |

| Research octane number (RON) | 95-98 | 109 |

| Autoignition temperature [K] | 536-853 | 738 |

| Adiabatic Flame Temperature [°C] | 2002 | 1870 |

| Laminar flame speed at the normal temperature and pressure, λ = 1 (cm/s) | 28 | 42 |

| Flammability limit in air (λ) | 0.26–1.60 | 0.23–1.81 |

| λ | 1.2 | 1.4 | 1.6 | 1.7 | 1.8 | 1.9 | 2.0 | 2.1 |

|---|---|---|---|---|---|---|---|---|

| Combination Igniter-Fuel | BDI-M100 BDI-E5 SPARK-M100 SPARK-E5 |

BDI-M100 BDI-E5 SPARK-M100 SPARK-E5 |

BDI-M100 BDI-E5 SPARK-M100 SPARK-E5 |

BDI-M100 BDI-E5 SPARK-M100 |

BDI-M100 BDI-E5 SPARK-M100 |

BDI-M100 BDI-E5 |

BDI-M100 | BDI-M100 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).