Submitted:

13 March 2024

Posted:

13 March 2024

You are already at the latest version

Abstract

Keywords:

Introduction

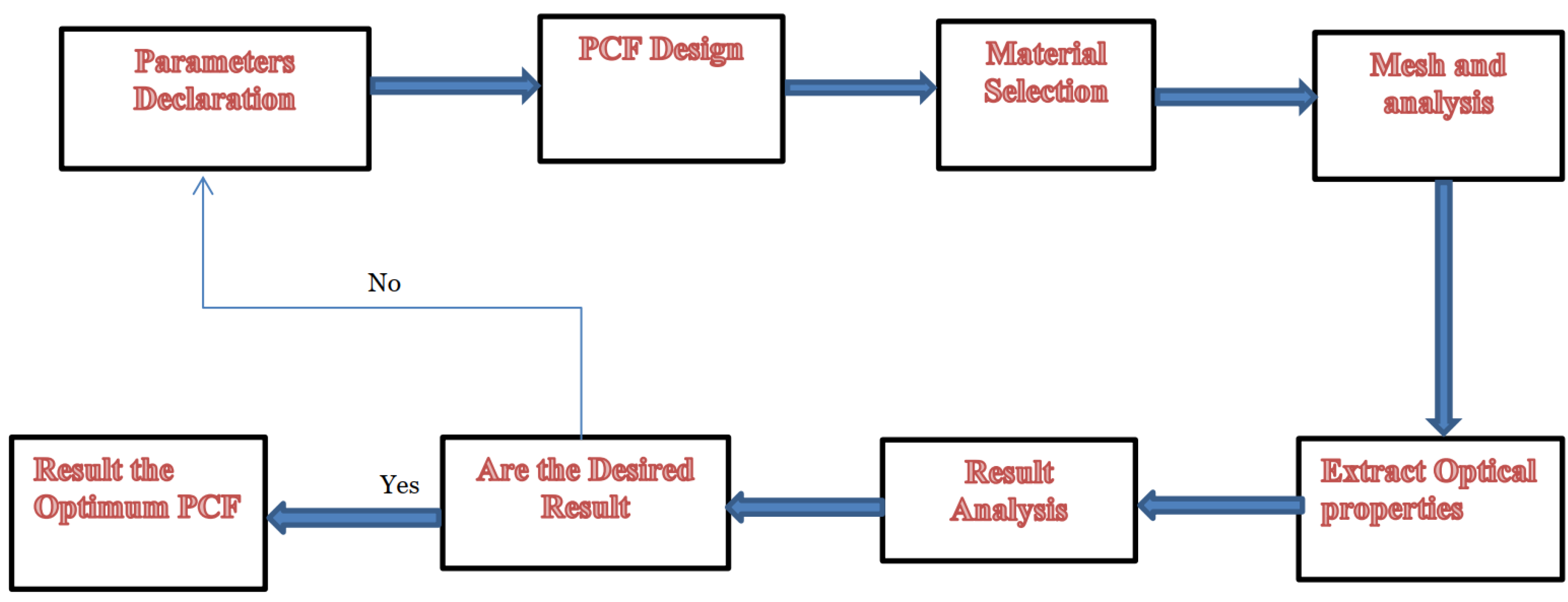

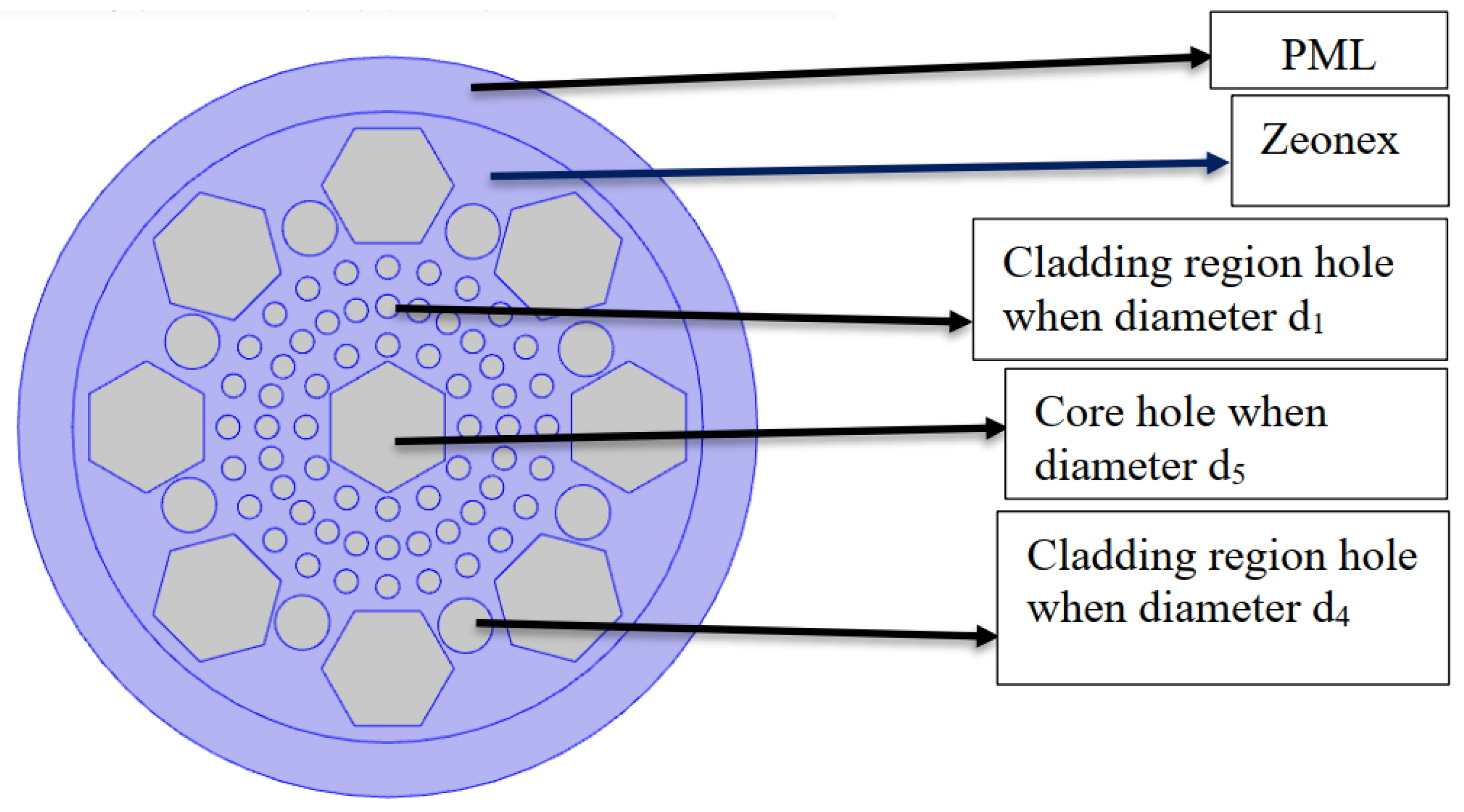

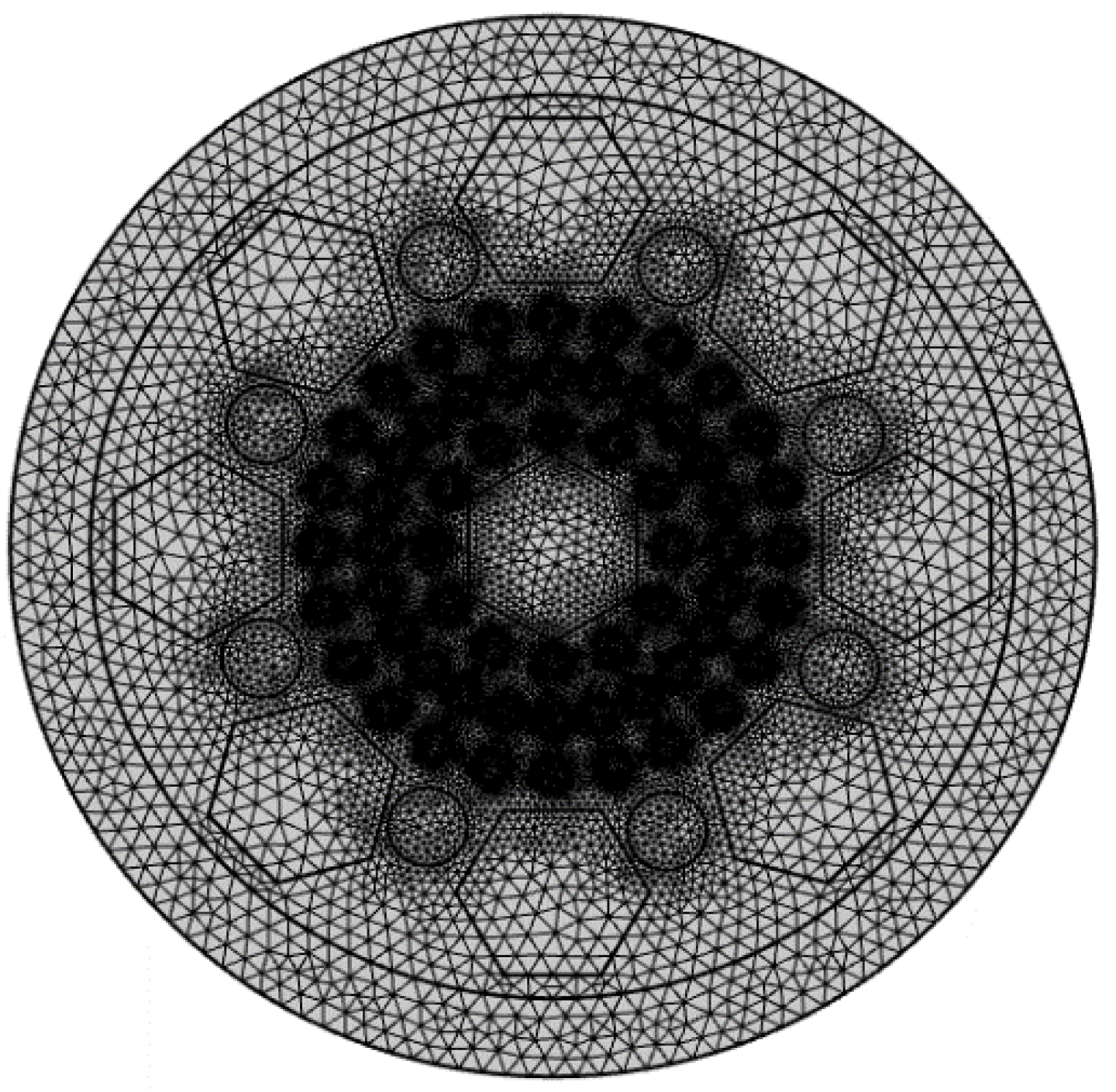

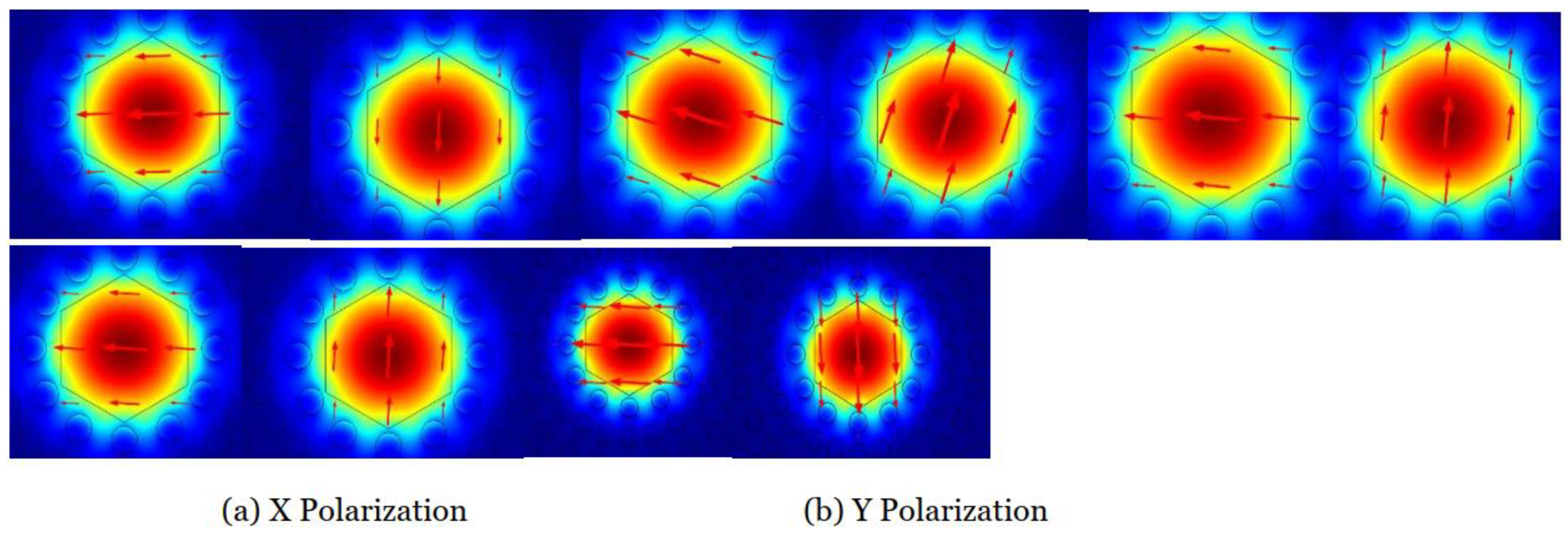

Design of the Proposed Sensor

Mathematical Analysis

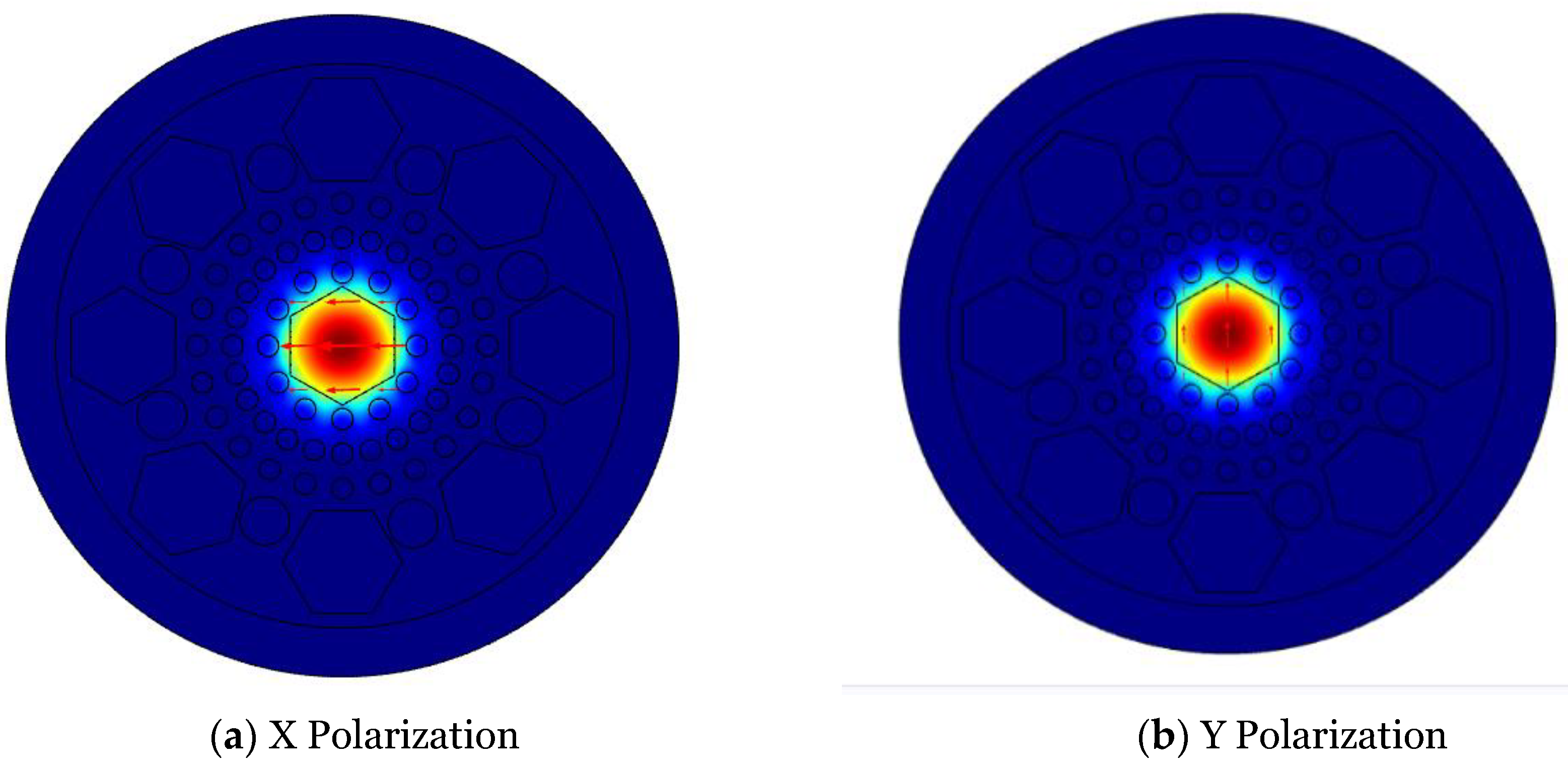

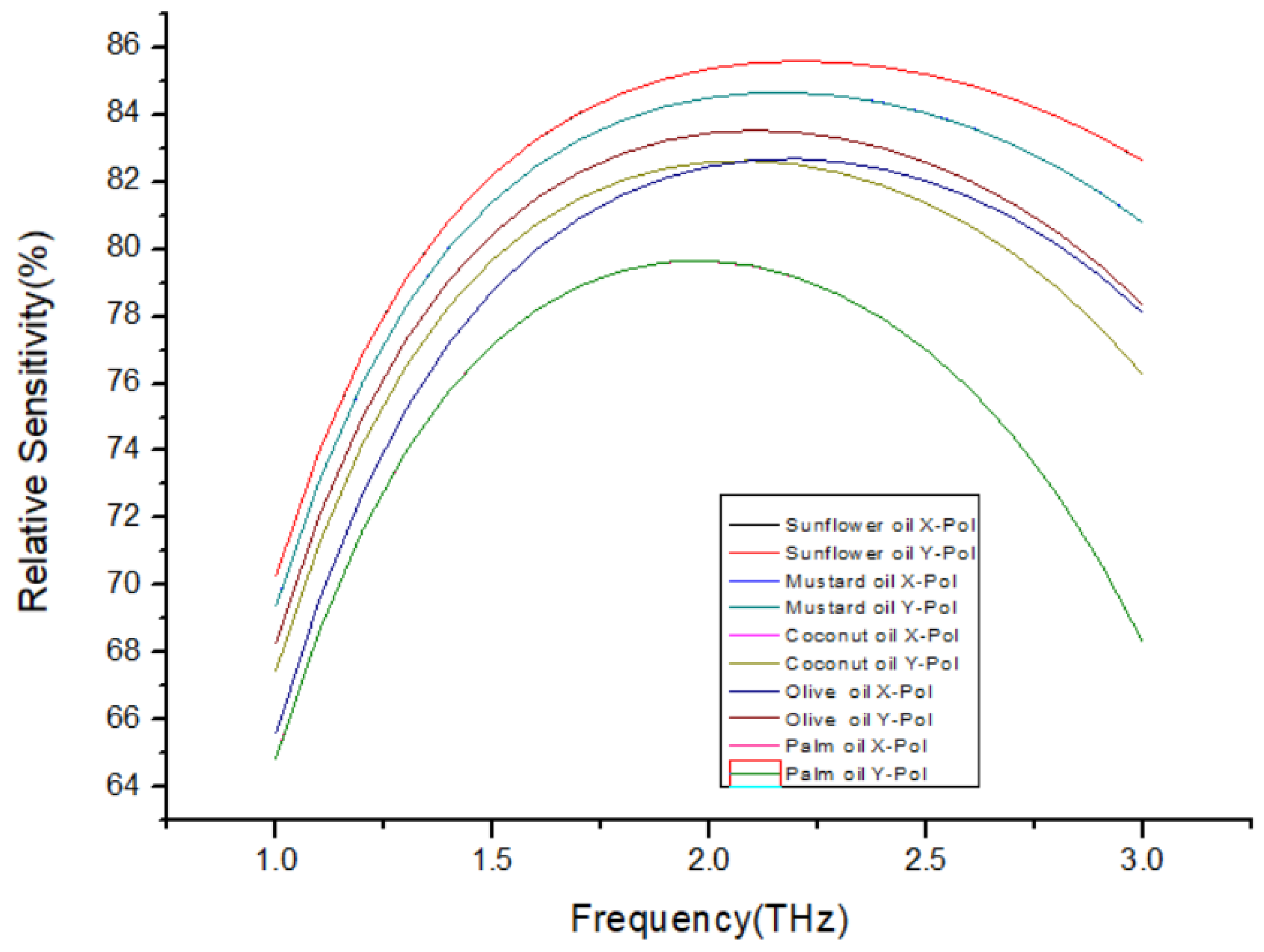

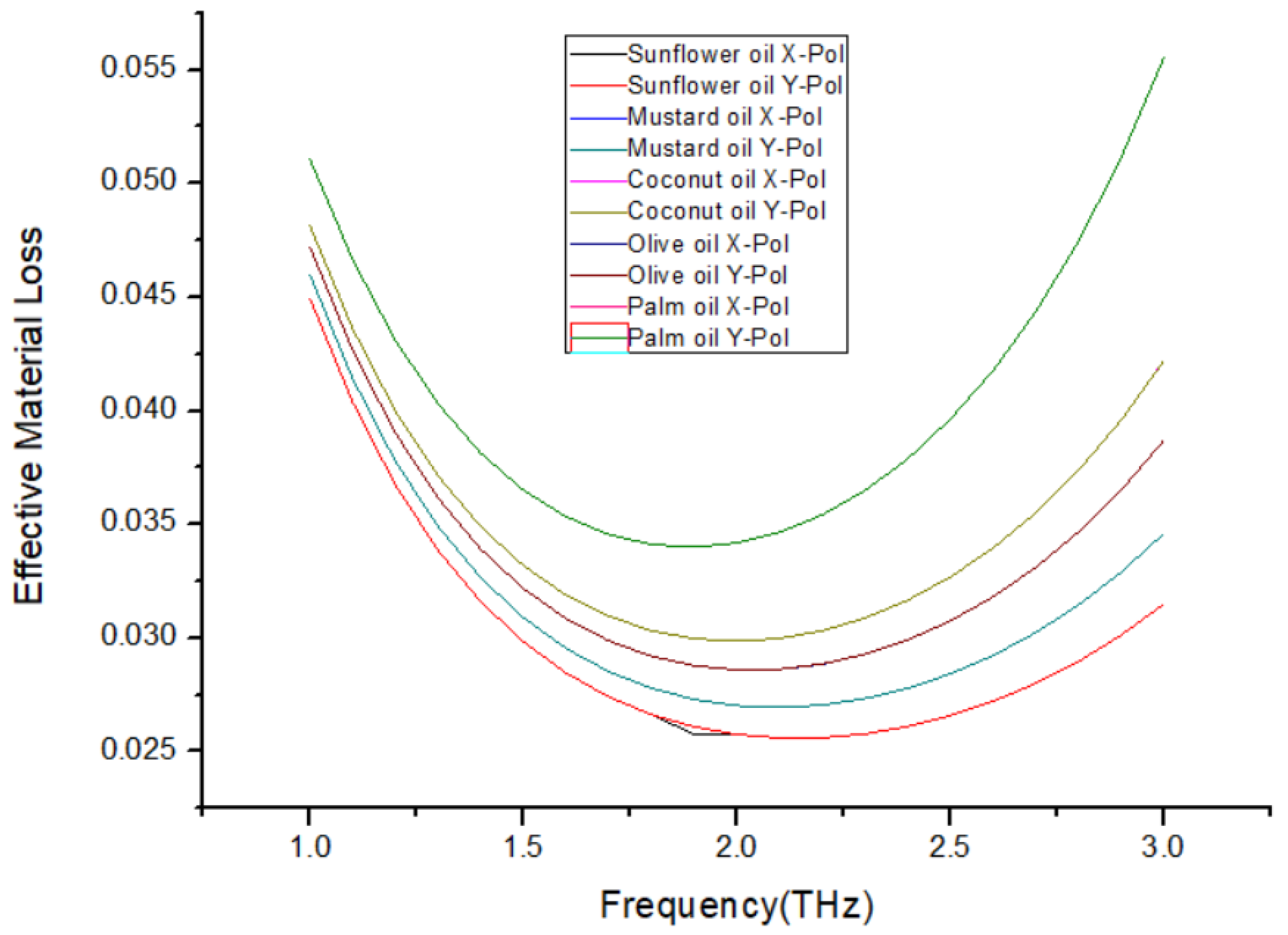

Simulation Results and Discussion

Conclusions

References

- Hossain, B.; Kříž, J.; Dhasarathan, V.; Rahaman, E. Photonic crystal fiber (PhCF) for petrochemical sensing. Front. Phys. 2023, 10, . [CrossRef]

- Paul, B.K.; Ahmed, K.; Vigneswaran, D.; Ahmed, F.; Roy, S.; Abbott, D. Quasi-Photonic Crystal Fiber-Based Spectroscopic Chemical Sensor in the Terahertz Spectrum: Design and Analysis. IEEE Sensors J. 2018, 18, 9948–9954, . [CrossRef]

- Fard, A.P.; Makouei, S.; Danishvar, M.; Danishvar, S. The Design of a Photonic Crystal Fiber for Hydrogen Cyanide Gas Detection. Photonics 2024, 11, 178, . [CrossRef]

- Md. Nazmul Islam, Kusay Faisal Al-tabatabaie , Md. Ahasan Habib, Sheikh Sharif Iqbal, Khurram Karim Qureshi and Eid M. Al-Mutairi, Design of a Hollow-Core Photonic Crystal Fiber Based Edible Oil Sensor, Crystals 2022, 12, 1362. [CrossRef]

- Johny, J.; Prabhu, R.; Fung, W.K. Investigation of structural parameter dependence of confinement losses in PCF–FBG sensor for oil and gas sensing applications. Opt. Quantum Electron. 2016, 48, 1–9, . [CrossRef]

- Ferdous, A.H.M.I., Anower, M.S. and Habib, M.A., 2021. A hybrid structured PCF for fuel adulteration detection in terahertz regime. Sens Bio-Sensing Res 33: 100438. [CrossRef]

- Ferdous, A.I., Anower, M.S., Musha, A., Habib, M.A. and Shobug, M.A., 2022. A heptagonal PCF-based oil sensor to detect fuel adulteration using terahertz spectrum. Sensing and Bio-Sensing Research, 36, p.100485.

- Liu, S.; Liu, J.; Li, Y.; Zhang, J. THz sensor based on dual-core PCF with defect core in detecting adulteration of olive oil. Opt. Quantum Electron. 2021, 53, 1–10, . [CrossRef]

- Ferdous, A.H.M.I., Anower, M.S. and Habib, M.A., 2021. A hybrid structured PCF for fuel adulteration detection in terahertz regime. Sens Bio-Sensing Res 33: 100438. [CrossRef]

- Paul, A.K. Design and analysis of photonic crystal fiber plasmonic refractive Index sensor for condition monitoring of transformer oil. OSA Contin. 2020, 3, 2253–2263, . [CrossRef]

- Wang, Y.; Ma, G.; Zheng, D.; Liao, W.; Jiang, J.; Qin, W. Detection of Dissolved Acetylene in Power Transformer Oil Based on Photonic Crystal Fiber. IEEE Sensors J. 2020, 20, 10981–10988, . [CrossRef]

- Islam, S.; Ferdous, A.H.M.I.; Tamilselvi, M.; Swarna, M.; Anitha, G.; Hasan, M.; Rashid, T.H.M.S.; Sayed, R.; Ahammad, S.H.; Rashed, A.N.Z.; et al. Highly sensitive hybrid structured based dodecagonal core with double layer hexagonal cladding photonic crystal fiber for food oil health sensing. J. Opt. 2023, 1–15, . [CrossRef]

- Ferdous, A.H.M.I.; Sarker, P.; Hasan, G.; Islam, A.; Musha, A.; Anwer, T.M.K.; Ahammad, S.H.; Rashed, A.N.Z.; Eid, M.M.A.; Hossain, M. Design of a Terahertz Regime-Based Surface Plasmon Hybrid Photonic Crystal Fiber Edible Oil Biosensor. Plasmonics 2023, 18, 1923–1932, . [CrossRef]

- Rahman, M.; Mou, F.A.; Bhuiyan, M.I.H.; Islam, M.R. Photonic crystal fiber based terahertz sensor for cholesterol detection in human blood and liquid foodstuffs. Sens. Bio-Sensing Res. 2020, 29, 100356, . [CrossRef]

- Geng, Y.; Wang, L.; Xu, Y.; Kumar, A.G.; Tan, X.; Li, X. Wavelength multiplexing of four-wave mixing based fiber temperature sensor with oil-filled photonic crystal fiber. Opt. Express 2018, 26, 27907–27916, . [CrossRef]

- Bulbul, A.A.-M.; Rashed, A.N.Z.; El-Hageen, H.M.; Alatwi, A.M. Design and numerical analysis of an extremely sensitive PCF-based sensor for detecting kerosene adulteration in petrol and diesel. Alex. Eng. J. 2021, 60, 5419–5430, . [CrossRef]

- Hossen, R.; Hossain, S.; Ahmed, S.; Sayduzzaman, M.; Sultana, M.; Naima, R.L.; Sen, S. Design and performance analysis of alcohols sensing using photonic crystal fiber in terahertz spectrum. Phys. Open 2023, 17, . [CrossRef]

- Sen, S.; Shafi, A.A.; Sikder, A.S.; Hossain, S.; Azad, M.M. Zeonex based decagonal photonic crystal fiber (D-PCF) in the terahertz (THz) band for chemical sensing applications. Sens. Bio-Sensing Res. 2020, 31, 100393, . [CrossRef]

- Almawgani, A.H.M.; Alhamss, D.N.; Taya, S.A.; Hindi, A.T.; Upadhyay, A.; Singh, S.; Colak, I.; Pal, A.; Patel, S.K. Identification of four detrimental chemicals using square-core photonic crystal fiber in the regime of THz. J. Appl. Phys. 2023, 133, . [CrossRef]

- Rifat, A.A.; Ahmed, R.; Yetisen, A.K.; Butt, H.; Sabouri, A.; Mahdiraji, G.A.; Yun, S.H.; Adikan, F.M. Photonic crystal fiber based plasmonic sensors. Sensors Actuators B: Chem. 2017, 243, 311–325, . [CrossRef]

- Islam, S.; Sultana, J.; Dinovitser, A.; Ahmed, K.; Ng, B.W.-H.; Abbott, D. Sensing of toxic chemicals using polarized photonic crystal fiber in the terahertz regime. Opt. Commun. 2018, 426, 341–347, . [CrossRef]

- Hossain, S.; Hossen, R.; Alvi, S.T.; Sen, S.; Amin, A.; Hossain, M. Design and numerical analysis of a novel photonic crystal fiber based chemicals sensor in the THz regime. Phys. Open 2023, 17, 100168. [CrossRef]

- Leon, J.B.M.; Abedin, S.; Kabir, A. A photonic crystal fiber for liquid sensing application with high sensitivity, birefringence and low confinement loss. Sensors Int. 2021, 2, 100061, . [CrossRef]

- El Wakf, A.M.; Hassan, H.A.; Gharib, N.S. Osteoprotective effect of soybean and sesame oils in ovariectomized rats via estrogen-like mechanism. Cytotechnology 2013, 66, 335–343, . [CrossRef]

- Fusaro, M.; Mereu, M.C.; Aghi, A.; Lervasi, G.; Gallieni, M. Vitamin K and bone. Clin. Cases Miner. Bone Metab. 2017, 14, 200–206. https://doi.org10.11138/ccmbm/2017.14.1.200.

- Fusaro, M.; Mereu, M.C.; Aghi, A.; Lervasi, G.; Gallieni, M. Vitamin K and bone. Clin. Cases Miner. Bone Metab. 2017, 14, 200–206. https://doi.org10.11138/ccmbm/2017.14.1.200.

- E Berger, M.; Smesny, S.; Kim, S.-W.; Davey, C.G.; Rice, S.; Sarnyai, Z.; Schlögelhofer, M.; Schäfer, M.R.; Berk, M.; McGorry, P.D.; et al. Omega-6 to omega-3 polyunsaturated fatty acid ratio and subsequent mood disorders in young people with at-risk mental states: a 7-year longitudinal study. Transl. Psychiatry 2017, 7, e1220, . [CrossRef]

- Islam, A.; Islam, M.R.; Siraz, S.; Rahman, M.; Anzum, M.S.; Noor, F. Wheel structured Zeonex-based photonic crystal fiber sensor in THz regime for sensing milk. Appl. Phys. A 2021, 127, 1–13, . [CrossRef]

- Reza, M.S.; Habib, M.A. Extremely sensitive chemical sensor for terahertz regime based on hollow-core photonic crystal fiber. Ukranian J. Phys. Opt. 2020, 21, 8–14.

- Md. Nazmul Islam, Kusay Faisal Al-tabatabaie , Md. Ahasan Habib, Sheikh Sharif Iqbal, Khurram Karim Qureshi and Eid M. Al-Mutairi, Design of a Hollow-Core Photonic Crystal Fiber Based Edible Oil Sensor, Crystals 2022, 12, 1362. [CrossRef]

- JAKEYA SULTANA,1 MD. SAIFUL ISLAM,1,* KAWSAR AHMED,2 ALEX DINOVITSER,1BRIAN W.-H. NG,1 AND DEREK ABBOTT1, Terahertz detection of alcohol using a photonic, codes: (060.2370) Fiber optics sensors; (060.2420) Fibers, polarization-maintaining; (060.2330) Fiber optics communications;

- Md. Shadidul Islam a, Bikash Kumar Paul a,b, Kawsar Ahmed a,b,*,Sayed Asaduzzaman a,b,c, Md. Ibadul Islam a, Sawrab Chowdhury a, Shuvo Sen a, Liquid-infiltrated photonic crystal fiber for sensing purpose: Design and analysis, Alexandria Engineering Journal (2017).

- Jabin, A.; Rana, J.; Al-Zahrani, F.A.; Paul, B.K.; Ahmed, K.; Bui, F.M. Novel Detection of Diesel Adulteration Using Silver-Coated Surface Plasmon Resonance Sensor. Plasmonics 2022, 17, 467–478, . [CrossRef]

- Habib, M.A.; Anower, M.S.; Hasan, M.R. Ultrahigh birefringence and extremely low loss slotted core microstructure fiber in terahertz regime. Curr. Opt. Photonics 2017, 1, 567–572. [CrossRef]

- Agrež, V.; Petkovšek, R. Gain switch laser based on micro-structured Yb-doped active fiber. Opt. Express 2014, 22, 5558–5563, . [CrossRef]

- Wang, Y.; Ma, G.-M.; Zheng, D.; Qin, W.-Q.; Jiang, J.; Zhou, H.-Y.; Yan, C. Transformer oil-dissolved acetylene detection with photonic crystal fiber loop ringdown spectroscopy. Sensors Actuators B: Chem. 2021, 346, . [CrossRef]

- Pawar, A.Y.; Sonawane, D.D.; Erande, K.B.; Derle, D.V. Terahertz technology and its applications. Drug Inven. Today 2013, 5, 157–163, . [CrossRef]

- Habib, M.A.; Anower, M.S. Low loss highly birefringent porous core fifiber for single-mode terahertz wave guidance. Curr. Opt. Photonics 2018, 2, 215–220.

- Szentpáli, B.; Fürjes, P.; Bársony, I. THz Detection by Thermopile Antenna. Procedia Comput. Sci. 2011, 7, 156–157, . [CrossRef]

- Sultana, J.; Islam, S.; Ahmed, K.; Dinovitser, A.; Ng, B.W.-H.; Abbott, D. Terahertz detection of alcohol using a photonic crystal fiber sensor. Appl. Opt. 2018, 57, 2426–2433, . [CrossRef]

- Yakasai, P.E. Abas, S.F. Kaijage, W. Caesarendra, F. Begum, Proposal for a quadelliptical photonic crystal fiber for terahertz wave guidance and sensing chemical warfare liquids, in: Photonics, MDPI, 2019 Jul 8 (Vol. 6, No. 3, p. 78).

- Liu, Z.; Tam, H.Y. Fabrication and sensing applications of special microstructured optical fifibers. Sel. Top. Opt. Fiber Technol. Appl. 2017.

- Liu, Z.; Wu, C.; Tse, M.L.V.; Tam, H.Y. Fabrication, Characterization, and Sensing Applications of a High-Birefringence SuspendedCore Fiber. J. Light. Technol. 2014, 32, 2113–2122. Available online: https://opg.optica.org/jlt/abstract.cfm?URI=jlt-32-11-2113 (accessed on 12 September 2022).

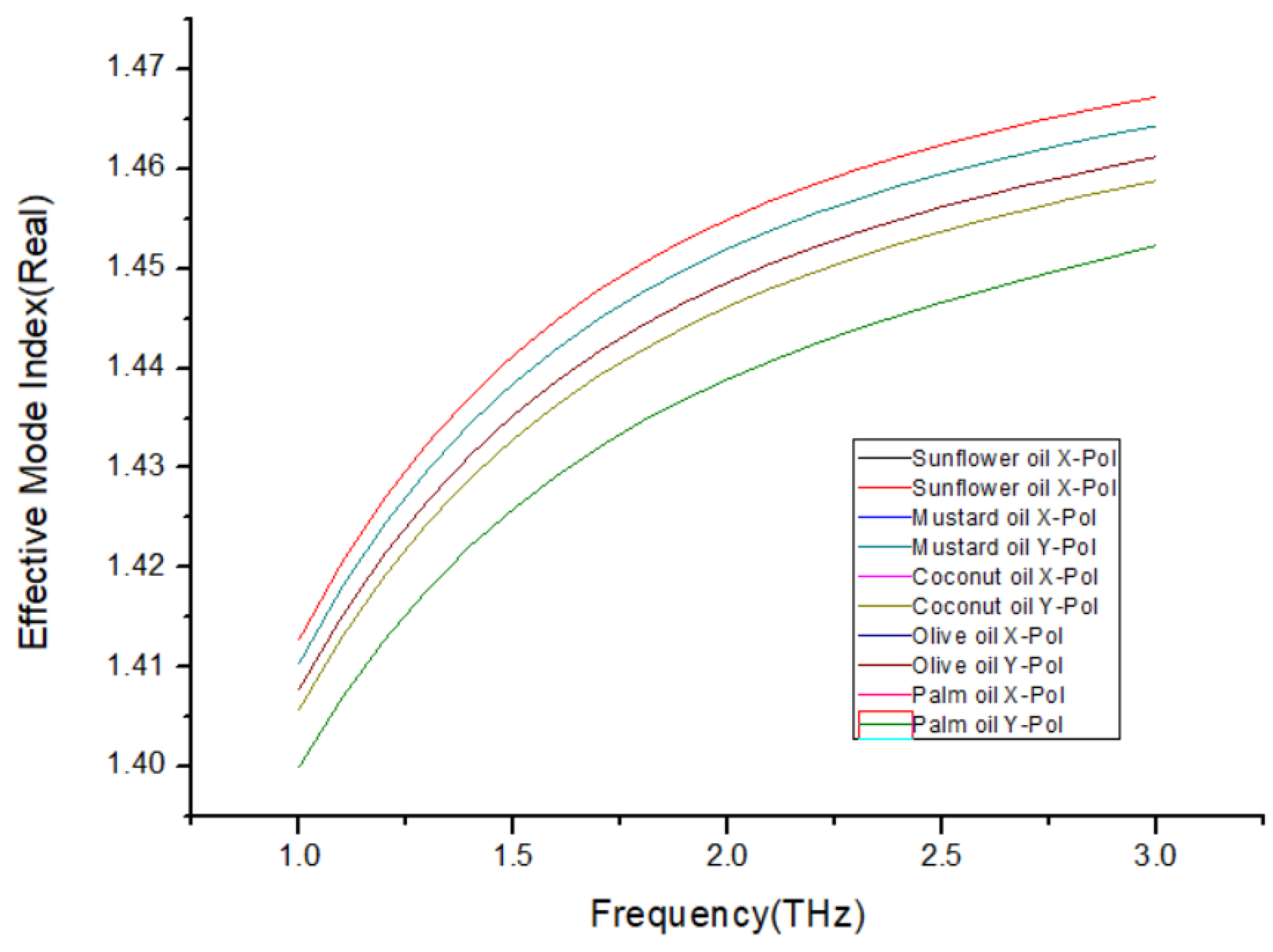

| Oil Type | Refractive Index |

| Sunflower oil | 1.4735 |

| Mustard oil | 1.4760 |

| Coconut oil | 1.463 |

| Olive oil | 1.466 |

| Palm oil | 1.454 |

| Ref: | Finalized frequency(f) / wavelength(λ) | Sensing Sample | Relative Sensitivity | Effective Area | Effective Material Loss | Confinement Loss (dB/m) |

|---|---|---|---|---|---|---|

| [2] | f=1.3 THz | Ethanol, Benzene, Water | 78.8%, 77.8%, and 69.7% | – | 0.0501 cm−1 | 2.19×10-10 |

| [28] | f=2.0 THz | camel and cow milk | 81.16% ,81.32% | – | 0.033 cm−1,0.032824 cm−1 | 8.675 × 10-18 cm−1,.435 × 10-18 cm−1 |

| [31] | f=1.0 THz | Ethanol | 68.87% | - | – | 7.79 × 10−12 cm−1 |

| [32] | λ =1.33 µm | Ethanol, Water and Benzene | 53.22%, 48.19% and 55.56% | 93,800 um2 | 0.03301 cm−1 | - |

| [23] | λ=0.6[um]-1.3[um] | Human Mucosa and Glucose | 47.31% and 47.59% | - | - | - |

| [18] | f=1.0 THz | Ethanol, Benzene, water | 78.56%, 79.76%, 77.51% | - | - | 6.02 × 10-8 dB/m,5.80 × 10-8 8 dB/m, 5.74 × 10-8 dB/m |

| [3] | λ=1.533 µm | Hydrogencyanide gas | 65.13% | - | - | 1.5 × 10-3 dB/m |

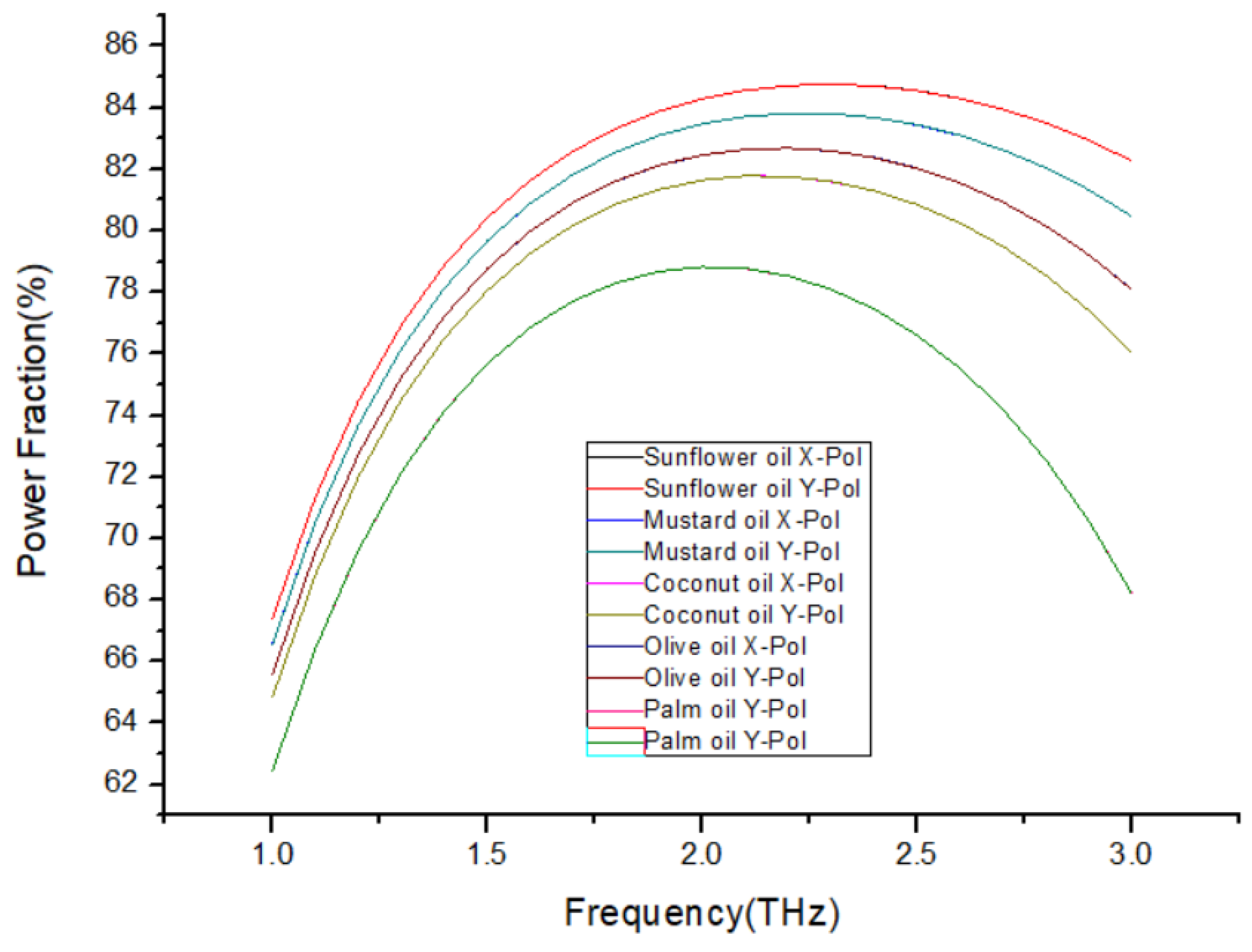

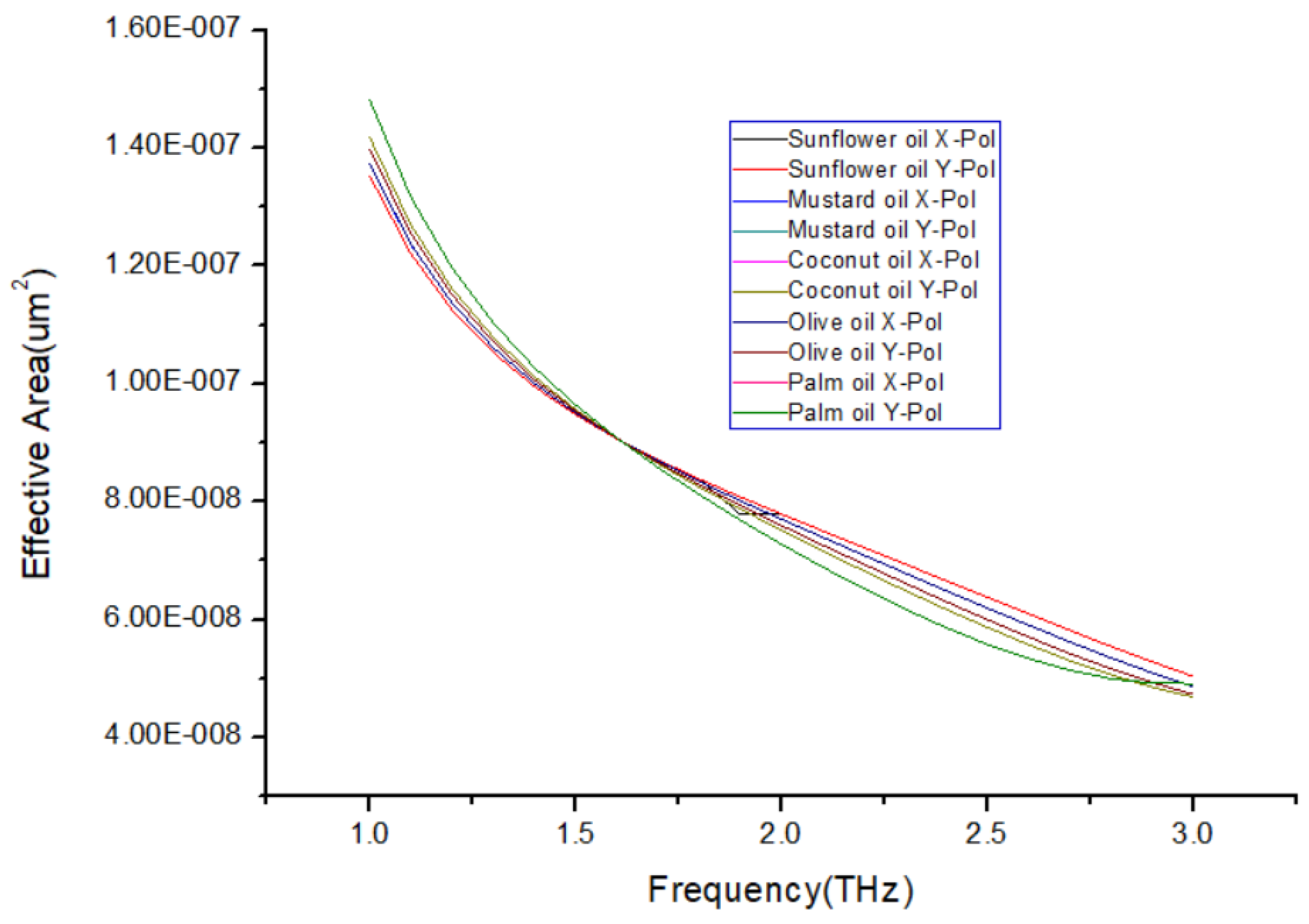

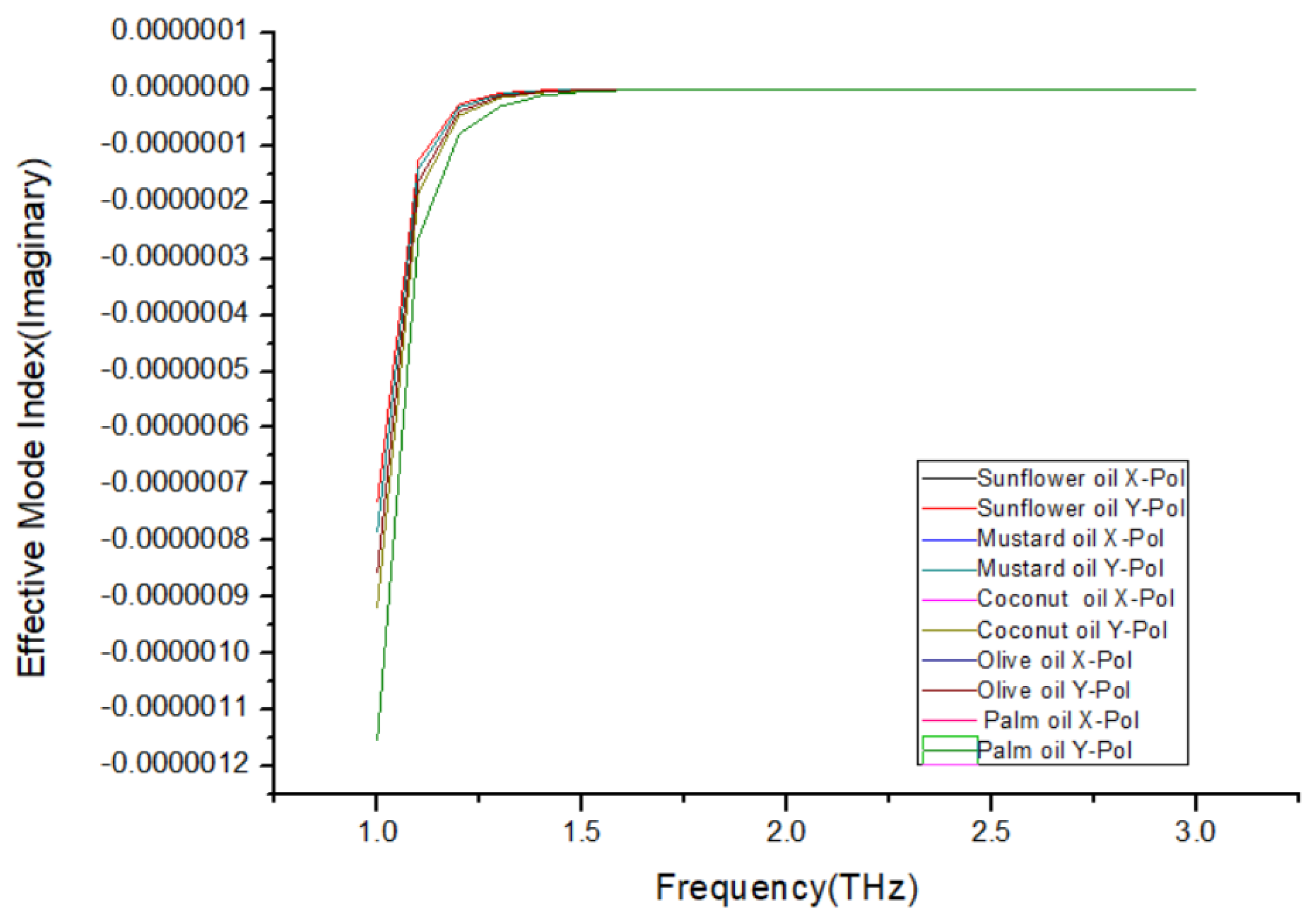

| This work 2024 | f=2.2 THz | sunflower oil, mustard oil, coconut oil, olive oil and palm oil | 85.591%, 84.648%, 82.625%, 82.683%, and 79.161%, | 7.22×10-8 um2, 7.09 ×10-8 um2, 6.83×10-8 um2,7.09 ×10-8 um2, 6.5231 ×10-8 um2. | 0.02561 cm-1, 0.027054 cm-1, 0.030322 cm-1, 0.028854 cm-1 ,0.035427cm-1 | 1.55 ×10-8 dB/m, 1.63×10-8 dB/m, 1.31×10-8 dB/m, 1.99×10-8 dB/m, 4.0345×10-8 dB/m, |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).