1. Introduction

This study was inspired by the work of Javorski [

1], who first characterized the dynamic behavior of a ceiling-mounted basketball goal using an impact hammer and a fixed-location accelerometer, and then compared that empirical analysis to a theoretical finite element analysis. Empirical vibration measurements were taken at fourteen nodes, ten of which were on the frame supporting the basketball rim and backboard. Only four nodes were measured on the backboard, at the corners of the backboard, and none on the rim itself. Overall, 36 frequency response functions were measured, and this study concentrated mostly on structural vibrations between 2 and 10 Hz. Thus, this important study was focused more on the structural support of the backboard and rim rather than the elastic vibrations of the backboard and rim themselves.

ANSYS was chosen as our finite element package of choice for two major reasons. The first reason was that bundled education on this package was available online through Cornell University [

2]. MAE-141 taught the conceptual foundations of finite element analysis, MAE-142 taught ANSYS mechanical concepts and implementation, MAE 143 taught elasticity applications, and MAE-144 taught beam and shell applications. Most importantly, the final module in this bundle, MAE-145, taught vibration applications, which was very helpful. Each of these five modules contained lecture materials, quizzes, and a comprehensive hands-on student project. The second reason was the free ANSYS 2024R1 Student Edition [

3].

Another important source to get us pointed in the right direction was the basketball rim and backboard modeled in ANSYS by Tickoo [

4]. Tickoo’s modeling did not use the precise dimensions as specified by the NCAA [

5] or Gared [

6]. However, he did get us started using DesignModeler within ANSYS for creating our geometry. We followed his lead of first creating the toroidal rim. Secondly, we followed his process of creating a new offset plane, followed by sketching a rectangle (saw icon), then extruding that rectangle from the offset plane to the toroidal rim to create the top of the mount. Finally, we followed his process of creating yet another new offset plane, followed by sketching yet another rectangle (saw icon), then extruding that rectangle from that second new plane to create the back of the mount. The use of ANSYS to study plate vibrations by Nkounhawa, et-al., [

7] and Guguloth, et-al., [

8] were also very helpful.

2. Materials and Methods

We first launched ANSYS Workbench 2024R1, then double-clicked on MODAL under Analysis Systems in Workbench. This caused the MODAL cell to be displayed in the project schematic window. We then right-clicked on Geometry within MODAL and selected DesignModeler Geometry from the menu. We did use English units because all of the dimensions of the basketball rim, mount, and backboard are specified in inches in the United States.

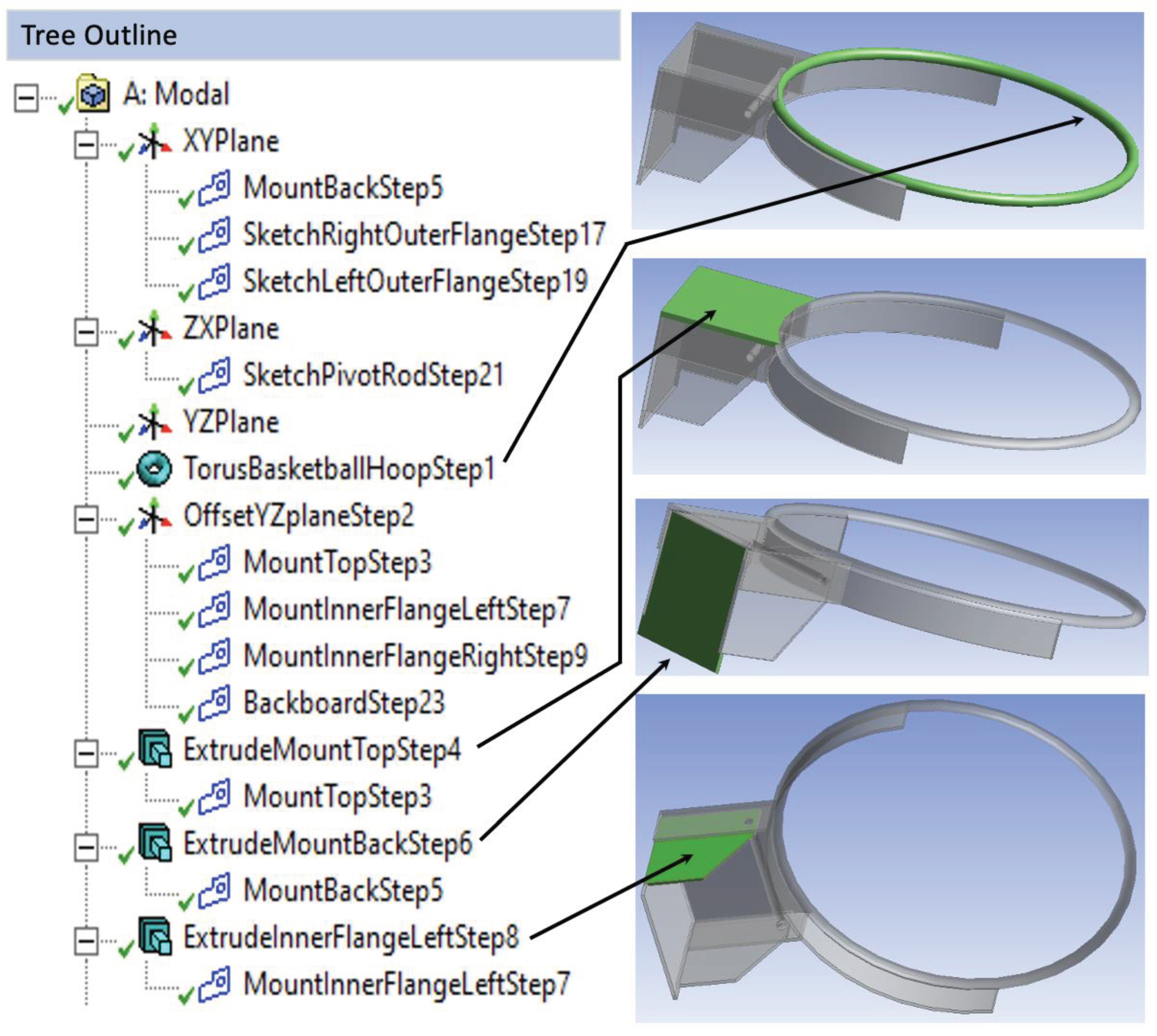

Figure 1,

Figure 2 and

Figure 3 define how we established the geometry for the rim, its mount, the backboard, and the aluminum frame.

As shown in

Figure 1, step 1 was to create the toroidal rim. For this, we used the toroid listed in the create-primitives section. Step 2 was used to create an offset-YZ plane, followed by sketching a rectangle (saw icon) in step 3, then extruding that rectangle from the offset-YZ plane to the toroidal rim to create the top of the mount, step 4.

Steps 2-4 began a repetitive process in

Figure 1,

Figure 2 and

Figure 3 of sketching a geometry (typically a rectangle) and extruding that geometry, and creating a new plane when needed. For example, the rectangle used to create the back of the mount was defined in step 5, then that rectangle was extruded to create the back of the mount in step 6. Finally, in

Figure 1, a rectangle was sketched in step 7 and extruded in step 8 to create the left inner mount flange.

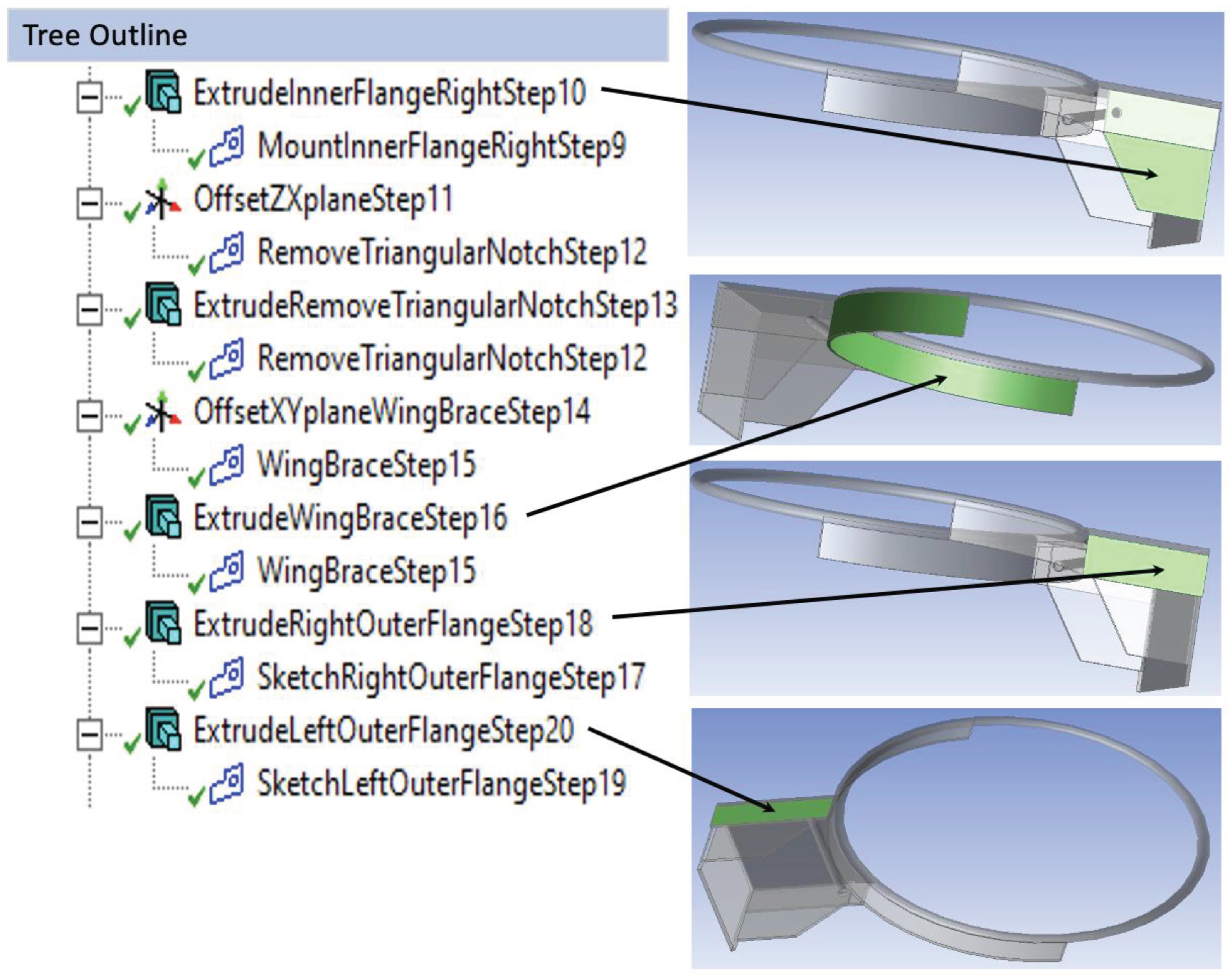

In

Figure 2, a rectangle was sketched in step 9 and extruded in step 10 to create the right inner mount flange. In step 11, an offset-ZX plane was created, then a sketch of a triangular cutout was made in step 12. In step 13, this triangular cutout was extruded as a material removal, to finalize the five-sided inner flanges. In step 14, a horizontal offset-XY plane was created, then a pair of concentric semicircles were connected at their ends in sketch step 15 before being extruded in step 16 to create the wing brace which attached to the rim. This was followed by sketching a rectangle in step 17 and extruding it in step 18 for form the right outer flange. Then a matching rectangle was created in step 18 and extruded in step 19 to form the left outer flange.

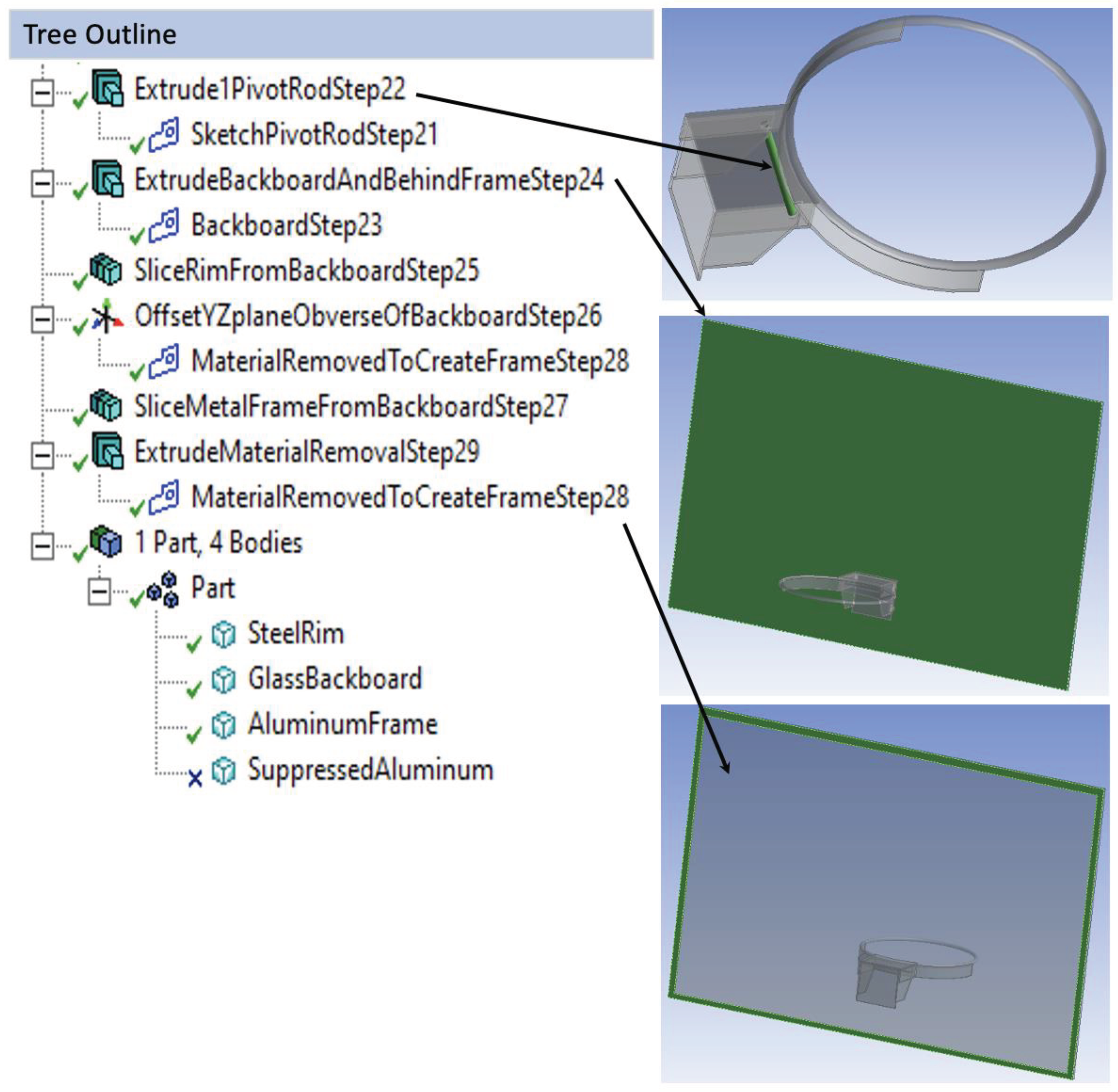

In

Figure 3, a circle was sketched in step 21 and then extruded in step 22 to form the pivot rod of the break-away release mechanism. This completed the geometric definition of the rim and its mount. Next came a rectangular sketch of the backboard in step 23, and the extrusion of that backboard and its frame in step 24. Step 25 utilized the slice function to separate the rim and its mount from the backboard so that the rim and mount could be declared to be made of steel. Specifically, we used slice – select face – generate. The rim-mound subassembly was then reunited with the backboard by the use of form-new-part to create an assembly of the individual component parts, as shown in

Figure 3.

When the backboard was extruded, its thickness was declared to be the thickness of the tempered glass and the thickness of the aluminum frame behind the tempered glass. In step 26, an offset-YZ plane was created so that the metal frame could be sliced from the obverse side of the backboard in step 27. This allowed the backboard to be declared to be made of tempered glass and the metal frame to be made of aluminum. At this point, the metal frame was a rectangle the same width and height of the backboard. To make the aluminum frame into a border frame, a second slightly smaller rectangle was created in step 28 and extruded as a slice in step 29, to remove unwanted aluminum. This concluded the geometry definition with one part comprising four bodies, the steel rim, the glass backboard, the aluminum border frame, and the material removed from the solid piece of aluminum to make the aluminum border frame. The material removed to create the aluminum border frame was then suppressed to take it out of the analysis; hence the “x” next to it at the bottom-left of

Figure 3.

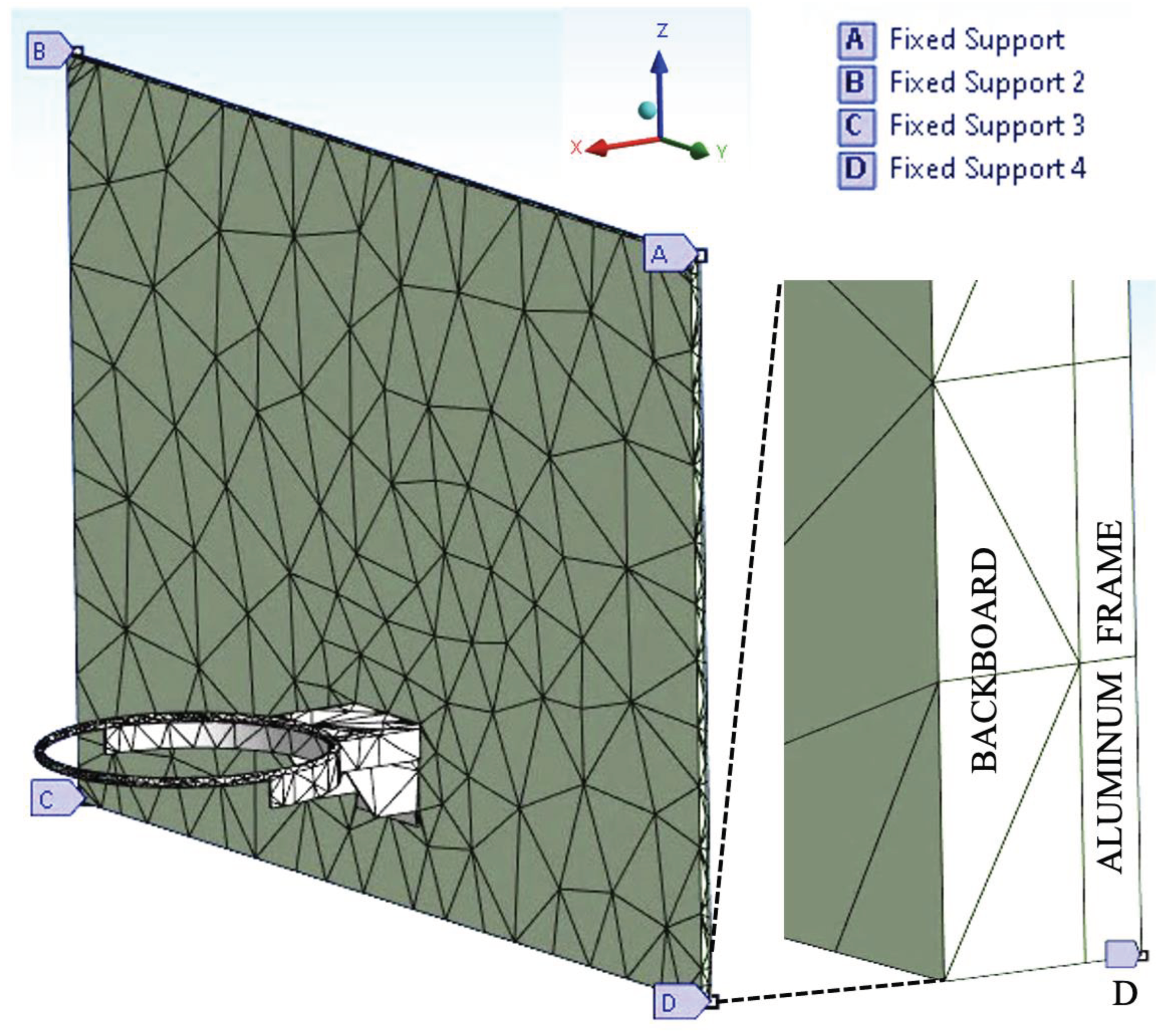

The next step was to exit Geometry and enter Model within the MODAL cell. Once in Model, the mesh seen in

Figure 5 was created. All mesh parameters were set to program default.

After the mesh was created, four fixed support conditions were applied, one to each of the four outer corner vertices of the aluminum frame behind the backboard, as shown in

Figure 4. The zoom showing the location of fixed support “D” at an outer corner is equally applicable of fixed supports “A,” “B,” and “C.” The choice of the four fixed support conditions was based on our previously published mode shapes [

9].

With the help of the “Details of Mesh” feature of ANSYS,

Figure 4 was summarized in

Table 1. Because elements are not shared between individual parts, the sum of the elements by individual parts equaled the total (4,618) number of elements.

At this point, the finite element model was ready for the calculation of theoretical mode shapes and frequencies, as shown in

Figure 5,

Figure 6,

Figure 7,

Figure 8 and

Figure 9.

Figure 5,

Figure 6,

Figure 7 and

Figure 8 compared our previously published empirically measured frequencies [

9] with the theoretical output of this ANSYS finite element analysis, as tabulated in

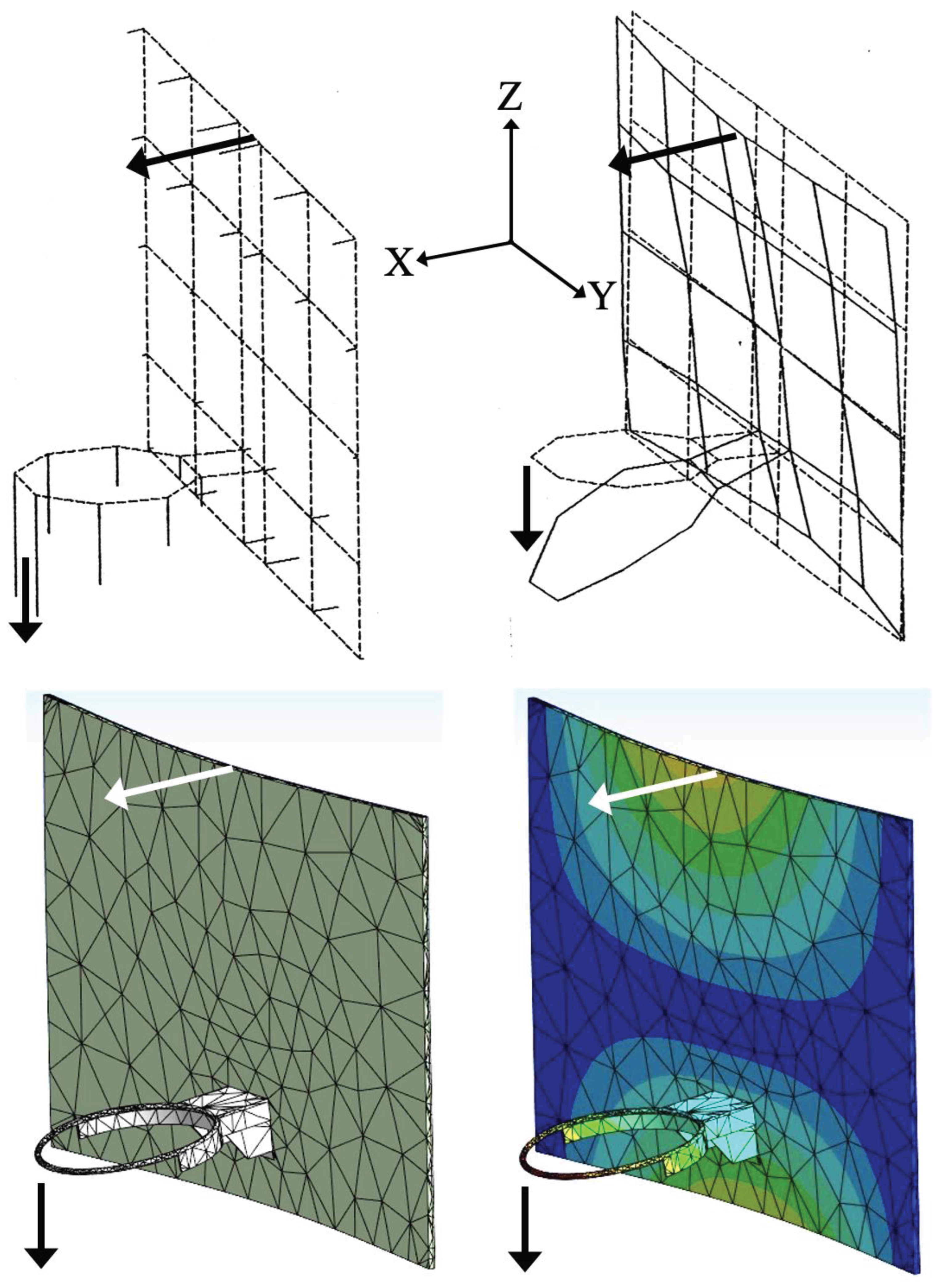

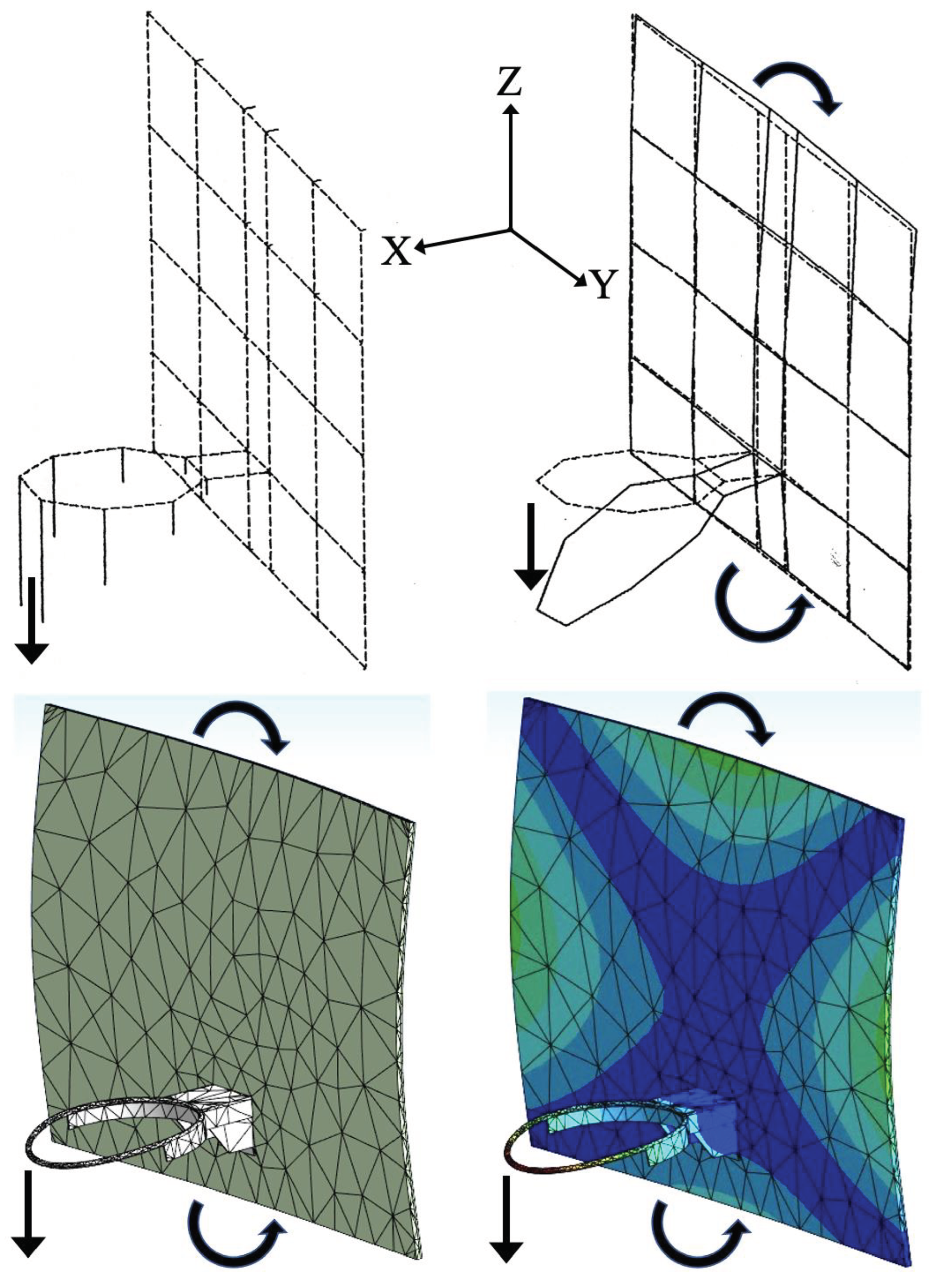

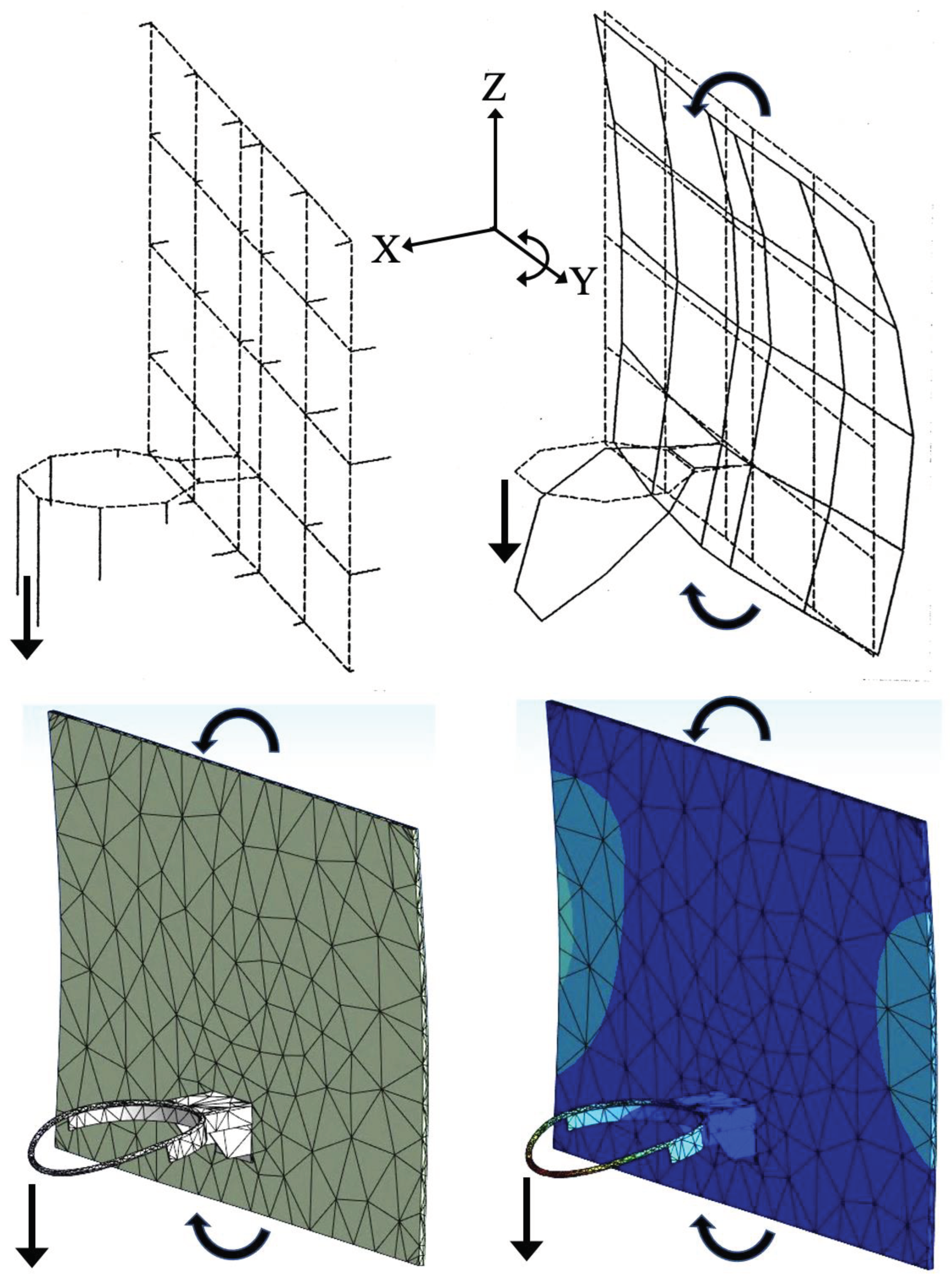

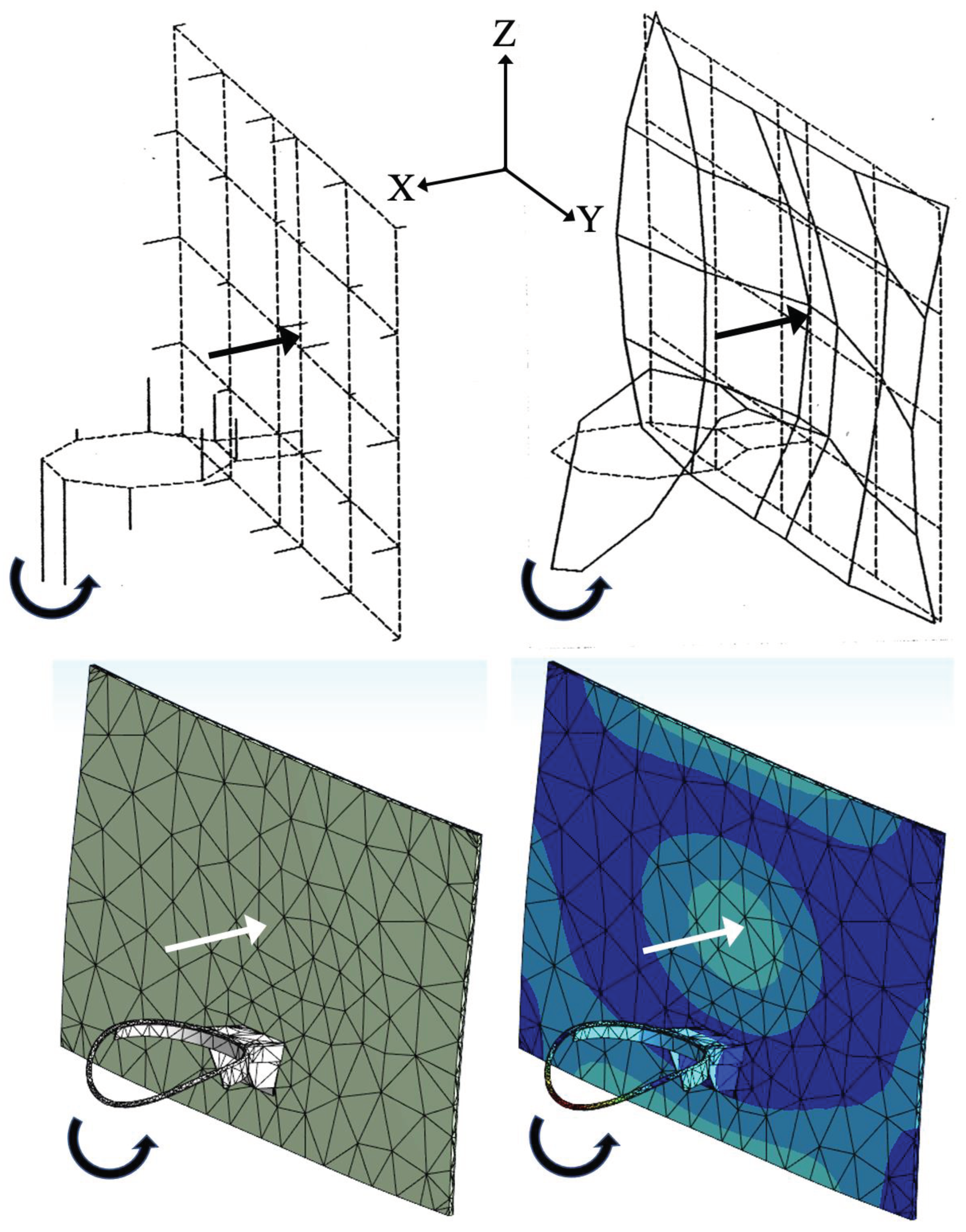

Table 2. The bold arrows in

Figure 5,

Figure 6,

Figure 7,

Figure 8 and

Figure 9 represent eigenvectors, which explain the relative motions seen in the respective figures.

Figure 5 exhibited an in-phase rocking motion of the rim and backboard, which was indicative of a lower-frequency mode.

Figure 8 was interesting because both the empirical modal analysis and the theoretical finite element analysis showed that the steel rim was flexing. As the mount and inner portion of the rim flexed upward, the outer portion of the rim flexed downward, and visa-versa. The characteristic oscillating central bulge in the backboard plate prominent in

Figure 9 can also be found in [

10,

11,

12,

13].

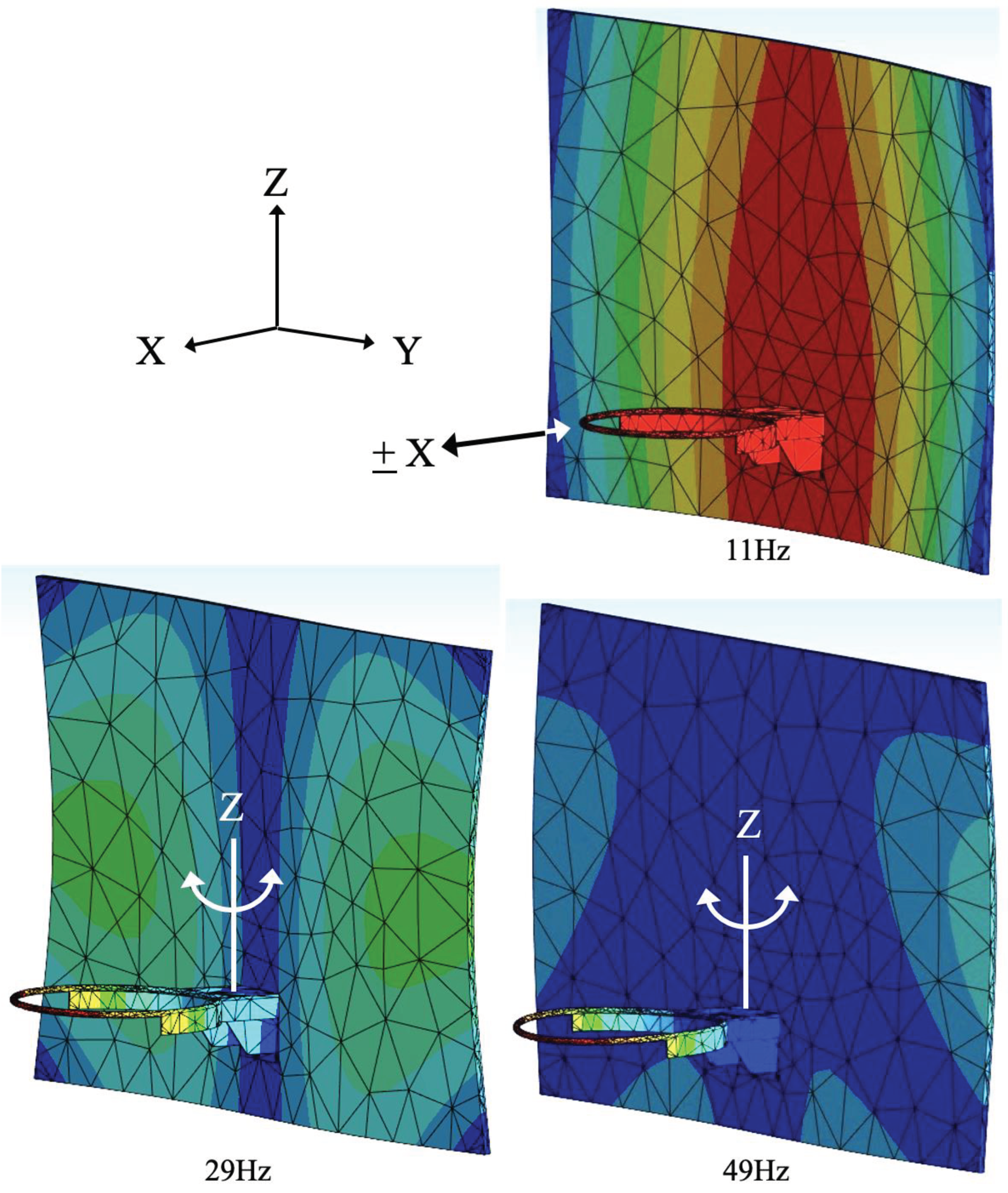

Figure 5,

Figure 6,

Figure 7 and

Figure 8 all showed that the basketball rim was oscillating perpendicular to the XY (horizontal) plane. As stated in [

9], the fixed-location accelerometer used in the empirical modal analysis was at the outer end of the rim and pointed in the vertical Z direction, so the accelerometer would be primarily sensitive to motion perpendicular to the horizontal XY plane. Thus, it is understandable that the theoretical finite element modes shown in

Figure 9, below, were missed by the empirical modal analysis because the theoretical motion of the rim in each mode in

Figure 9 was entirely within the XY plane.

The missed mode at 11 Hz comprised a piston-motion of the rim and mount in the

+ X direction. The missed modes at 29 Hz and 49 Hz comprised the reciprocating rotational motion of the rim and mount about the Z-axis. The missed mode at 29 Hz had previously perplexed the authors’ empirical modal analysis [

9] as that was a common mode of vibrations in plates [

11,

12,

13]. But we now understand that the lack of vertical motion of the rim in

Figure 9 meant that any signal from the vertically-oriented accelerometer could have easily been overlooked as noise.

3. Discussion and Conclusions

This paper gives a process of creating a geometry, mesh, and boundary conditions for a basketball rim, mount, backboard, and border frame, for the purpose of theoretical finite element analysis. Four empirical modes of vibration compared favorably with this theoretical finite element analysis.

There are many possible designs of rims, backboards, and frames which meet NCAA standards, so this study is not comprehensive across the sport of basketball. However, our efforts of finite element analysis did match four empirically measured mode shapes and frequencies of our previously published data. Also, we showed the potential need for a triaxial accelerometer for any future empirical modal analysis efforts involving basketball rims and backboards.

Author Contributions

Conceptualization, K.P.N.; methodology, D.W.; validation, K.P.N., D.W. and T.W.; formal analysis, D.W. and T.W.; investigation, D.W. and T.W.; writing—original draft preparation, D.W.; writing—review and editing, K.P.N., D.W. and T.W.; visualization, K.P.N. and D.W.; supervision, K.P.N.; project administration, K.P.N. All authors have read and agreed to the published version of the manuscript.