Submitted:

15 March 2024

Posted:

15 March 2024

You are already at the latest version

Abstract

Keywords:

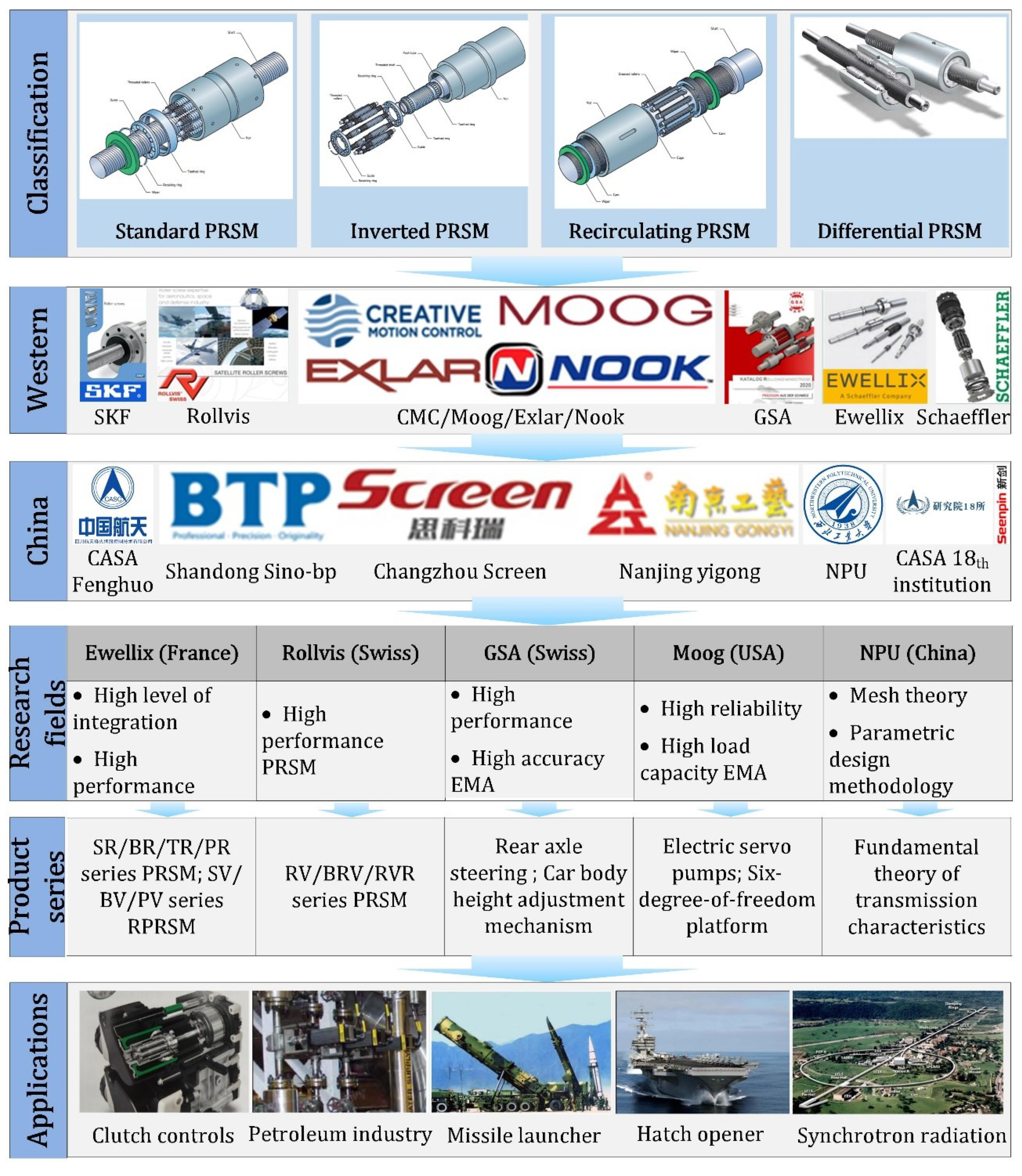

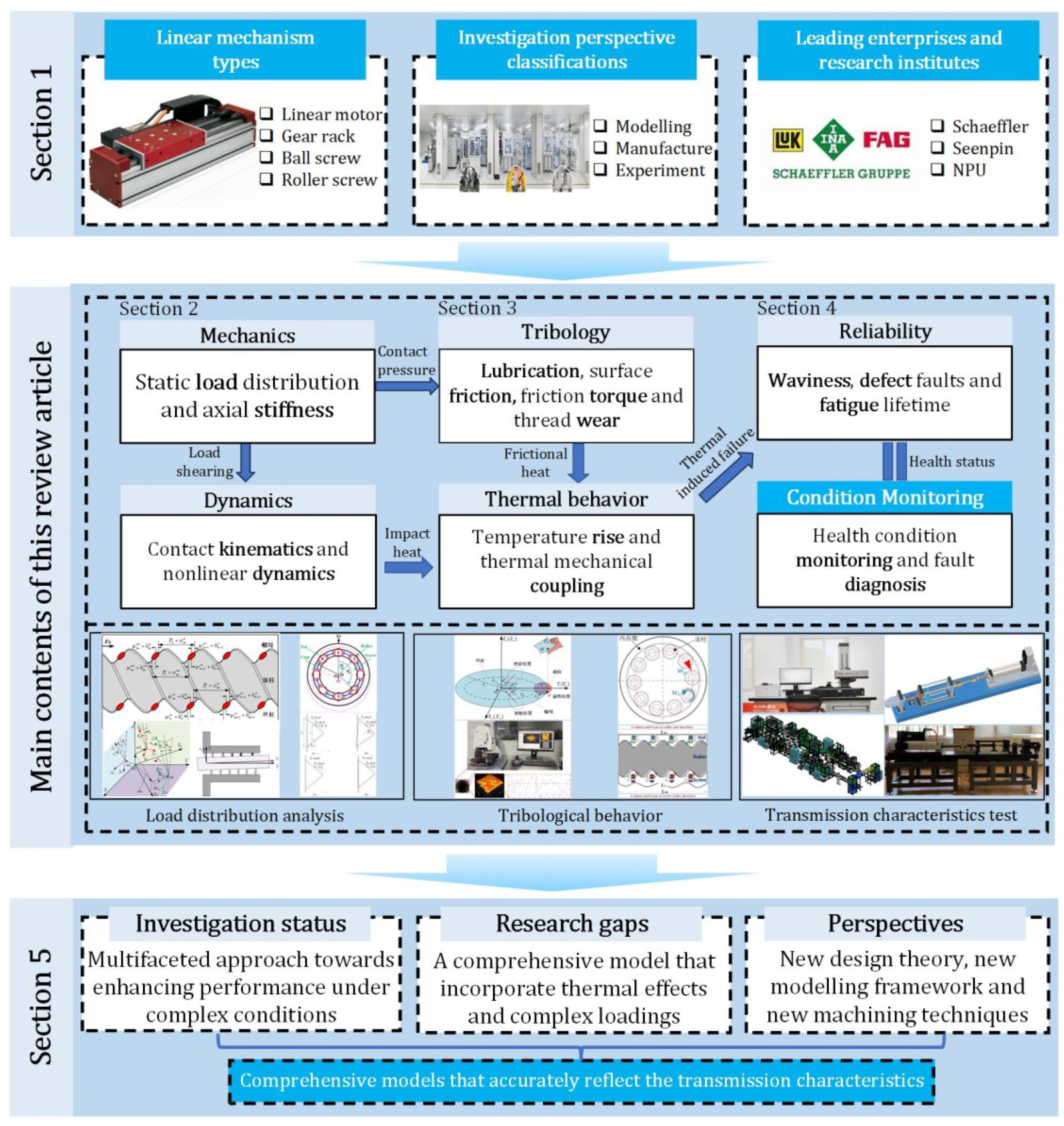

1. Introduction

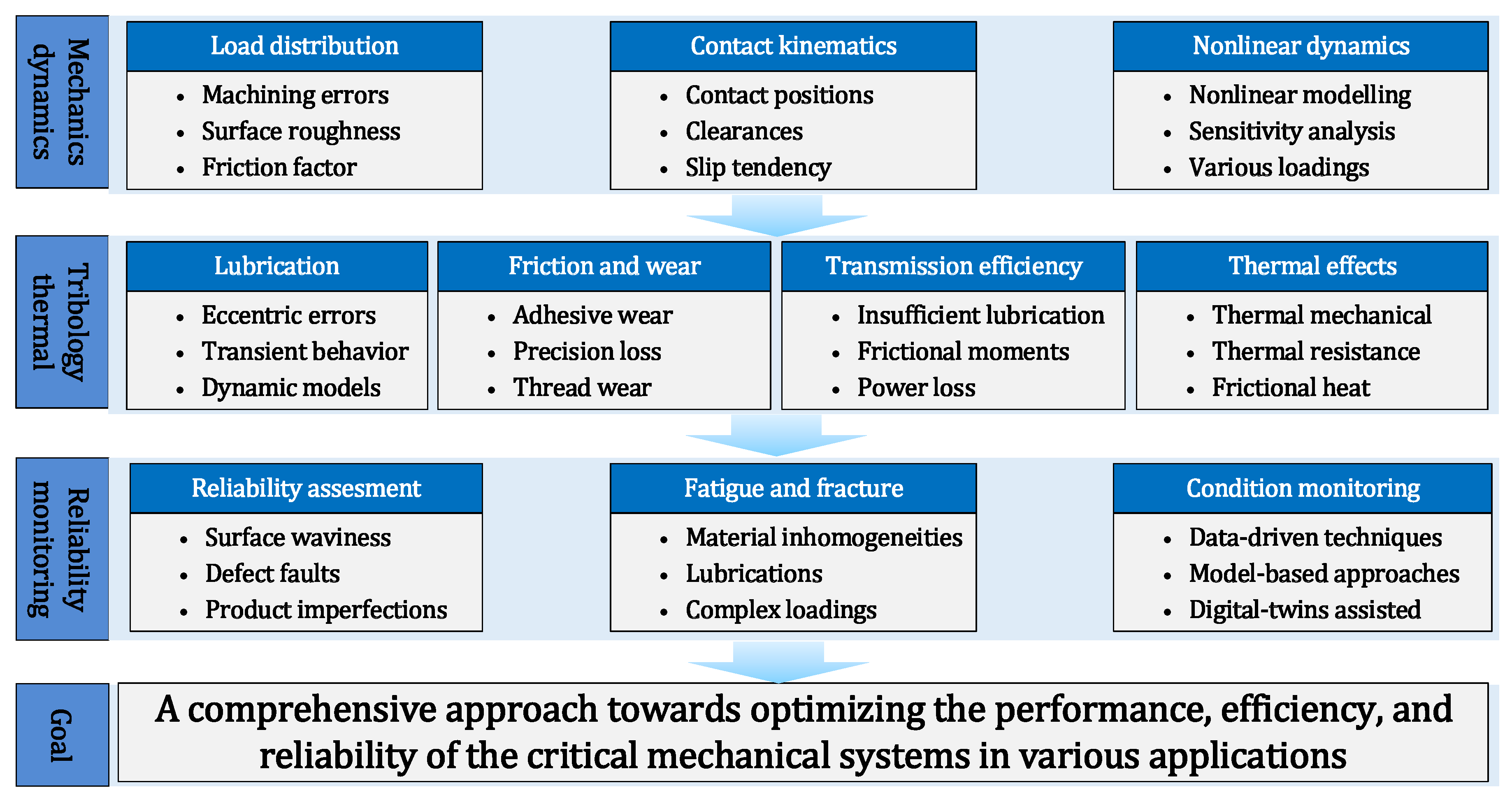

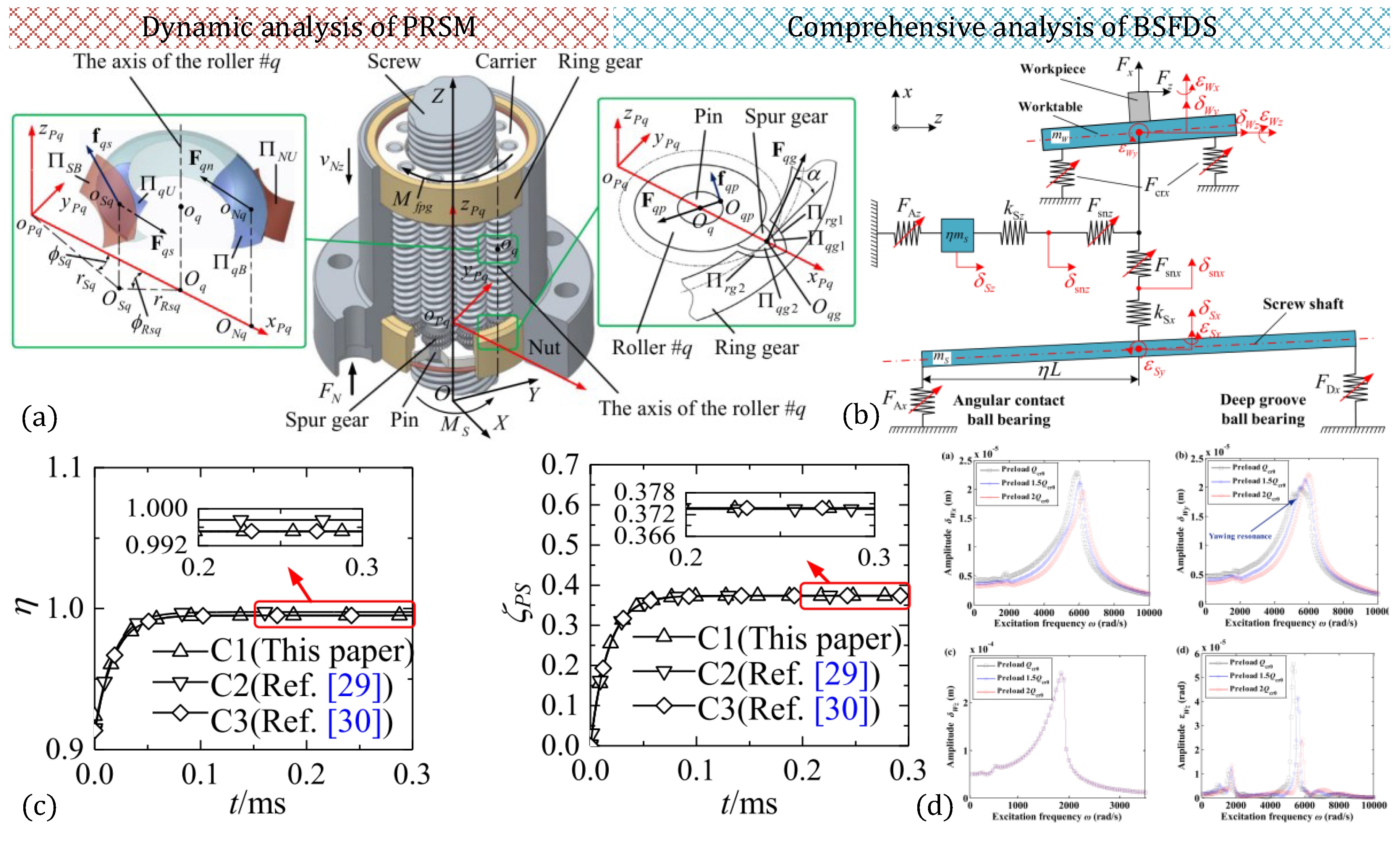

2. Mechanics and Dynamics

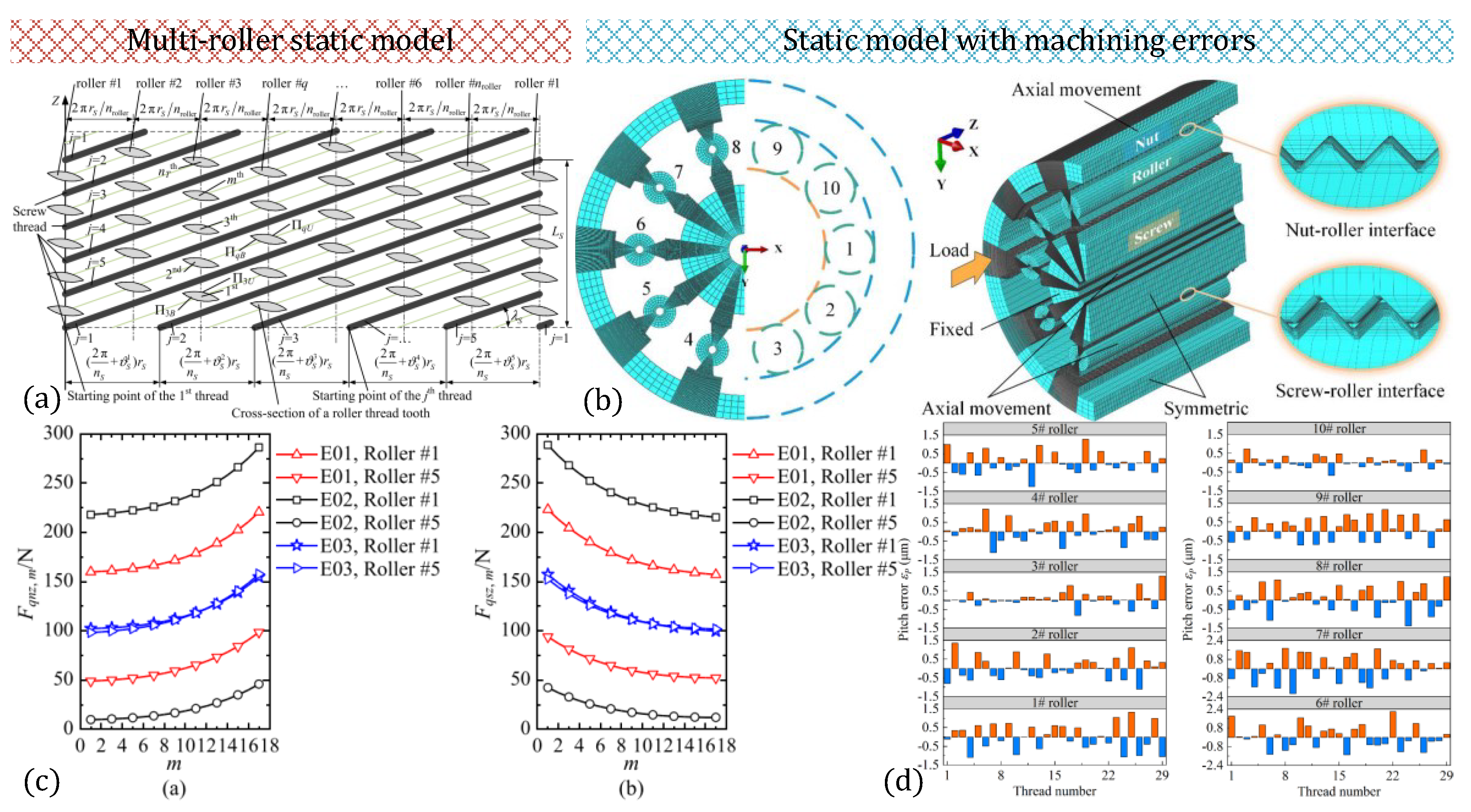

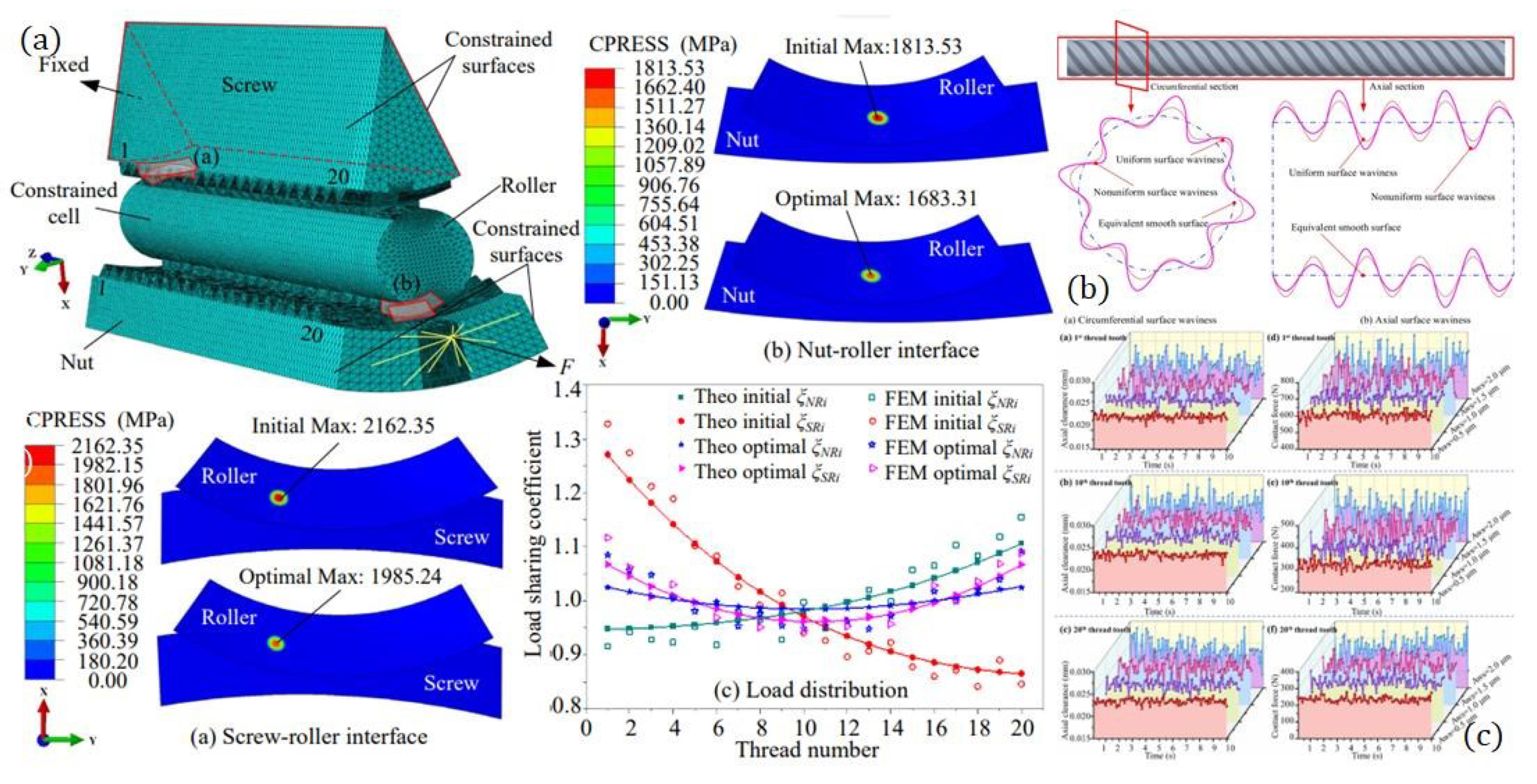

2.1. Static Load Distribution and Axial Stiffness

| Scholar | Method | Merits | Applications |

| Ma et al. [45] | Load deformation model for transmission accuracy | Highlights importance of accounting for elastic deformations for precision and reliability | Enhancing operational accuracy in PRSMs |

| Zhang et al. [46] | Load distribution over threads with pitch deviation | Unveils how pitch deviation affects load distribution and wear depth | Design optimization to mitigate machining errors |

| Du et al. [47] | Fractal model for surface roughness and axial stiffness | Links micro-to-macro performance aspects, offering optimization strategies | Improving load distribution and axial stiffness in PRSMs |

| Fu et al. [49] | Multi-roller static model | Delineates sensitivity of load distribution to component positioning | Enhancing system stiffness and precision |

| Ma et al. [43] | Empirical validation of static stiffness | Corroborates analytical predictions with experimental data | Predicting PRSM behavior under varied conditions |

| Hu et al. [50] | Analytical calculations and machine learning | Demonstrates computational techniques in optimizing PRSM design | Optimizing design for better load distribution among rollers |

| Zhang et al. [51] | Design modifications for uniform load distribution | Recommends recalibrating thread parameters to mitigate axial deformation | Enhancing load uniformity across threads |

| Abevi et al. [52,53] | Static analysis with bars, beams, and nonlinear springs | Provides fresh perspectives on load distribution modelling and system stiffness | Enriching the discourse on PRSM bending behavior |

| Jones and Velinsky [54] | Application of the direct stiffness method | Enables analytical prediction of overall stiffness and load distribution across thread | Advancing optimization of stiffer PRSMs with lower stress |

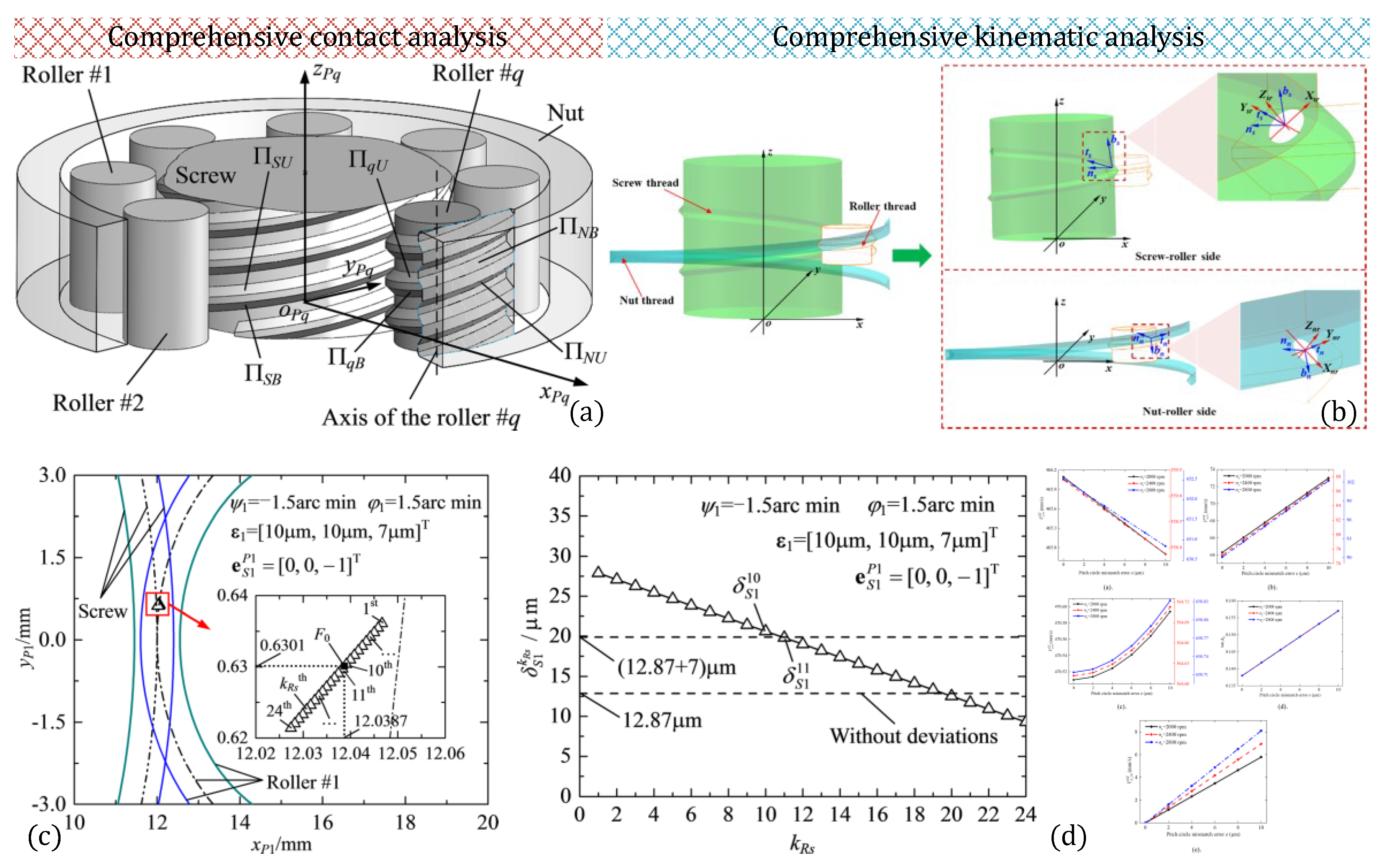

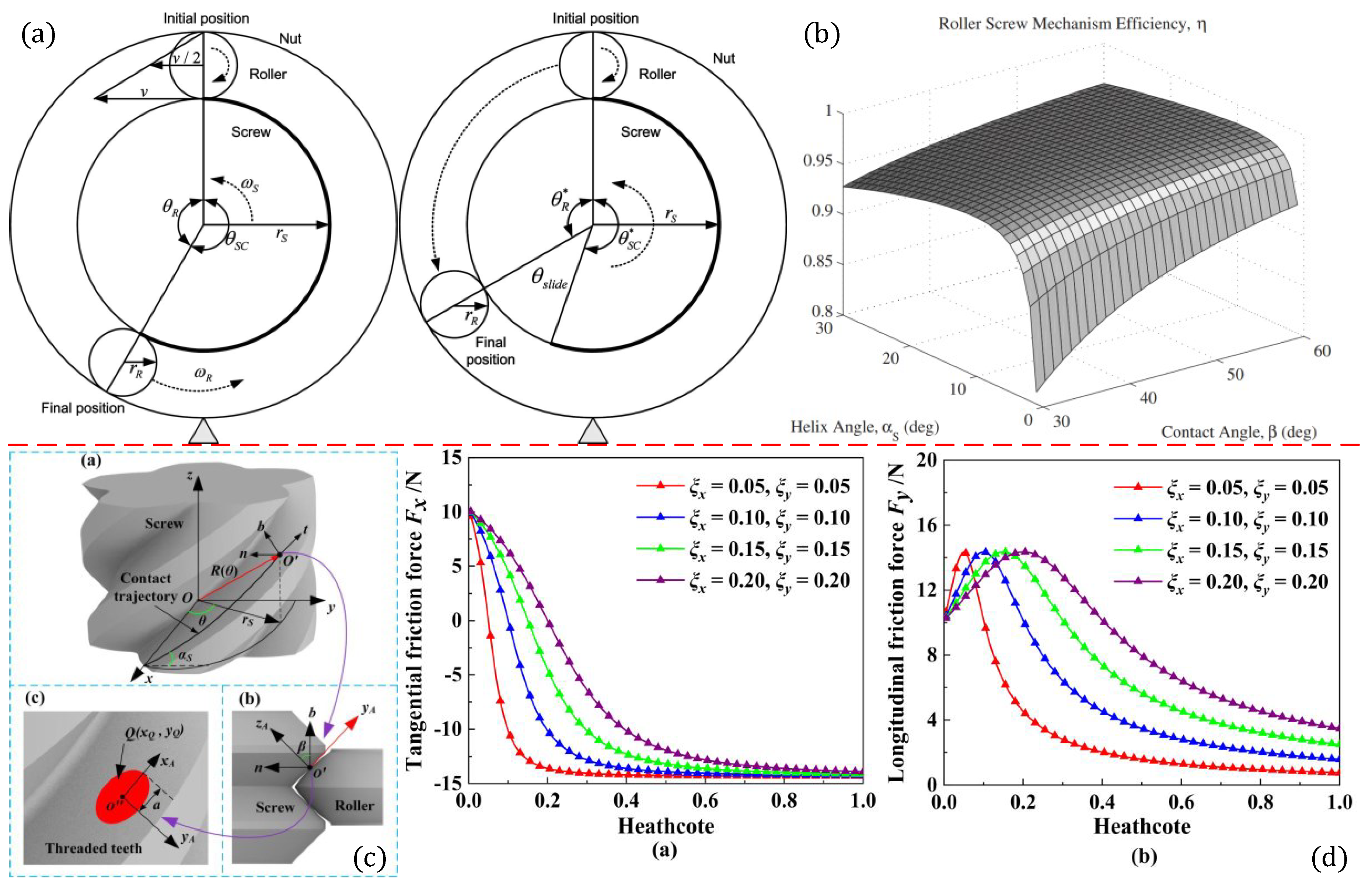

2.2. Contact Kinematics

2.3. Nonlinear Dynamics

3. Tribology and Thermal Behavior

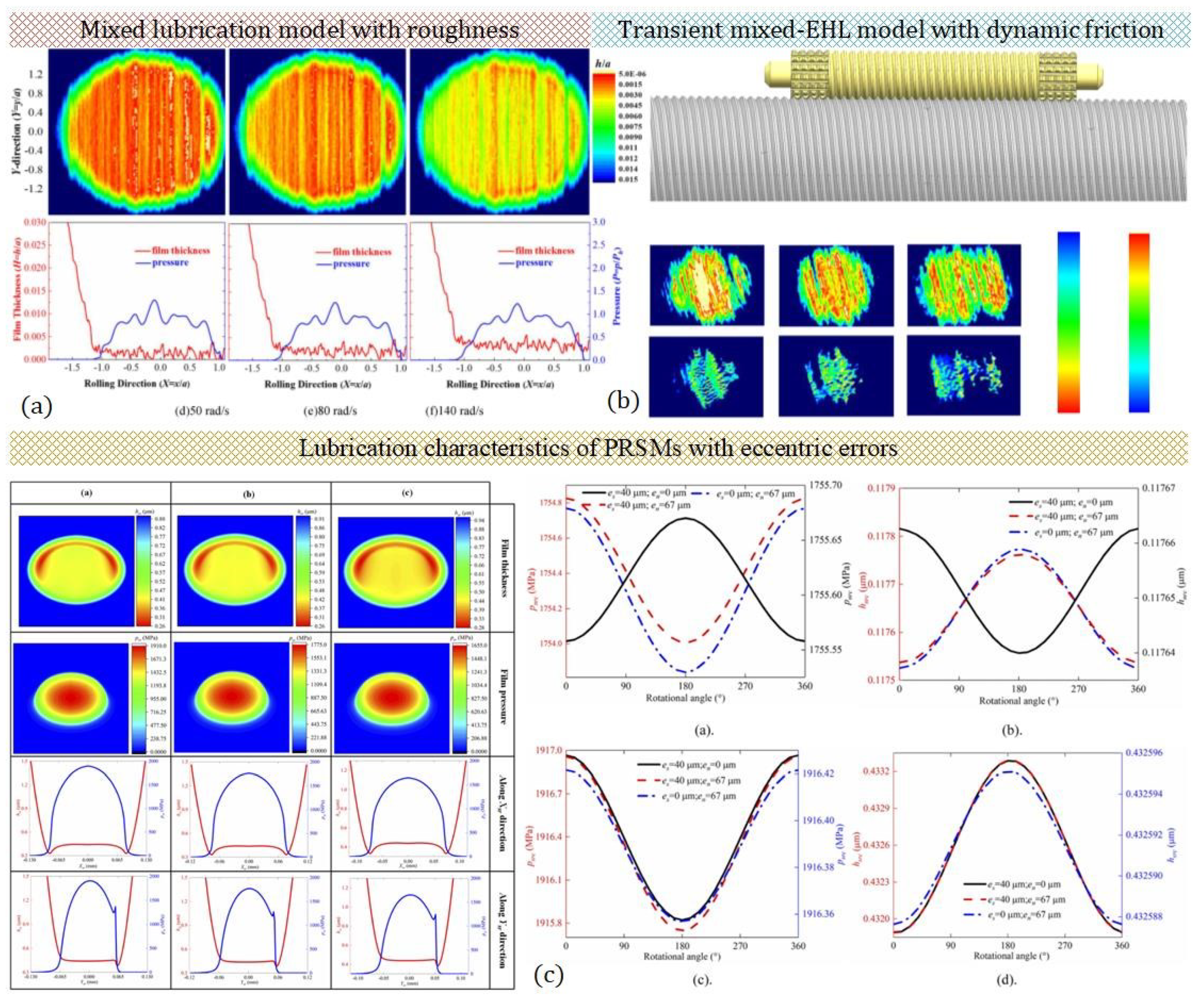

3.1. Elastohydrodynamic Lubrication

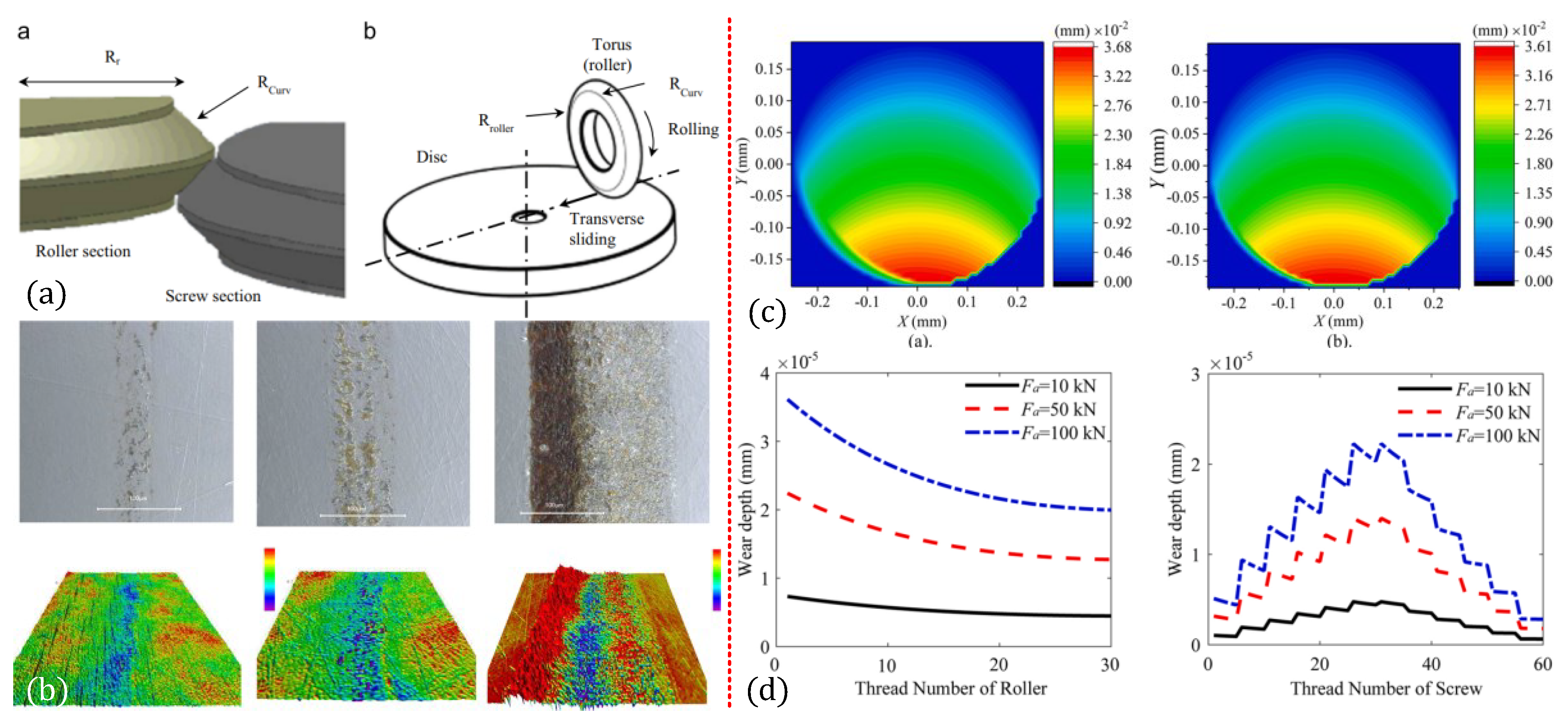

3.2. Surface Friction, Thread Wear and Precision Loss

3.3. Friction Torque, Power Loss and Transmission Efficiency

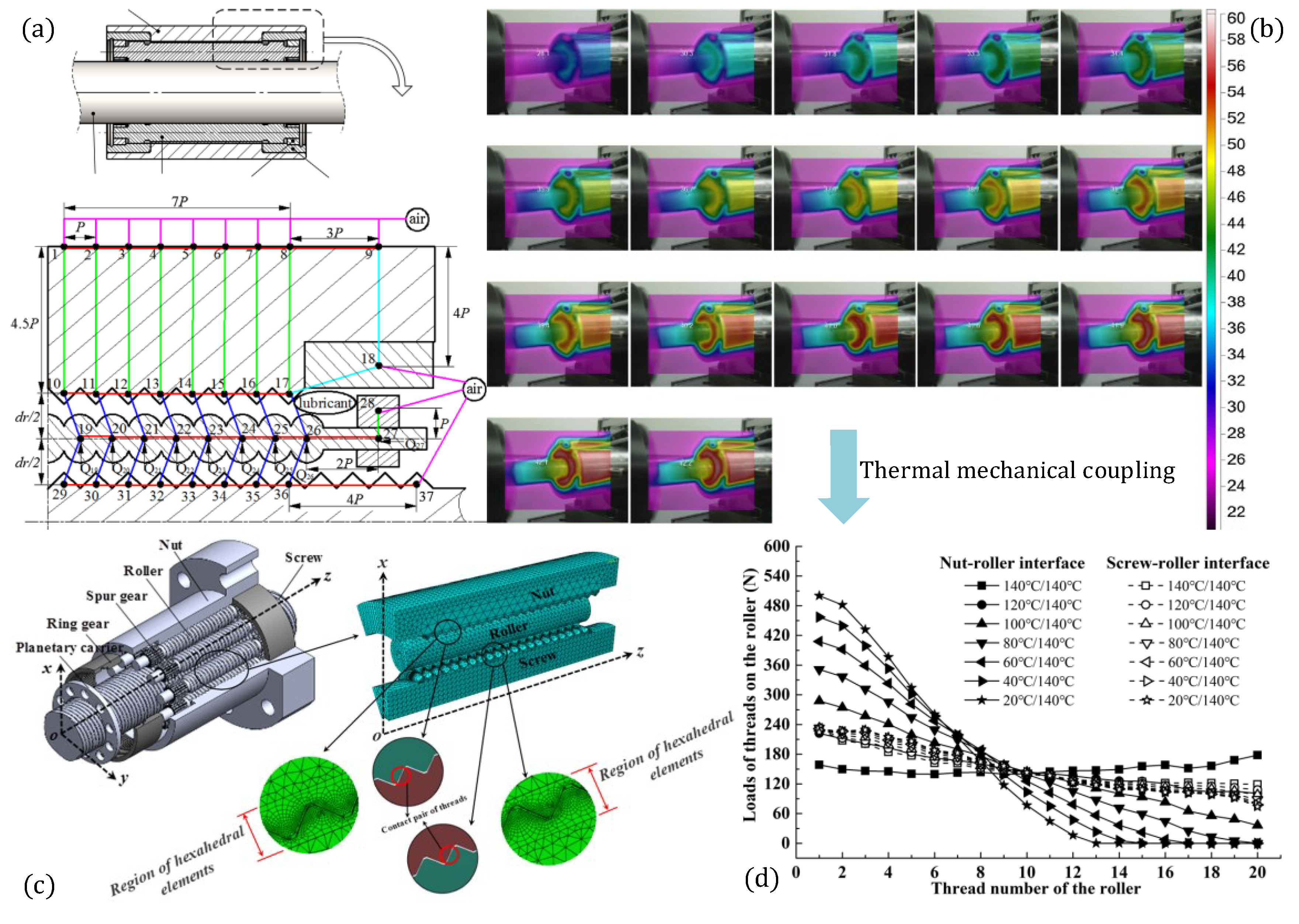

3.4. Temperature Rises and Thermal Mechanical Coupling

4. Reliability and Condition Monitoring

4.1. Waviness, Defect Faults and Reliability Assessments

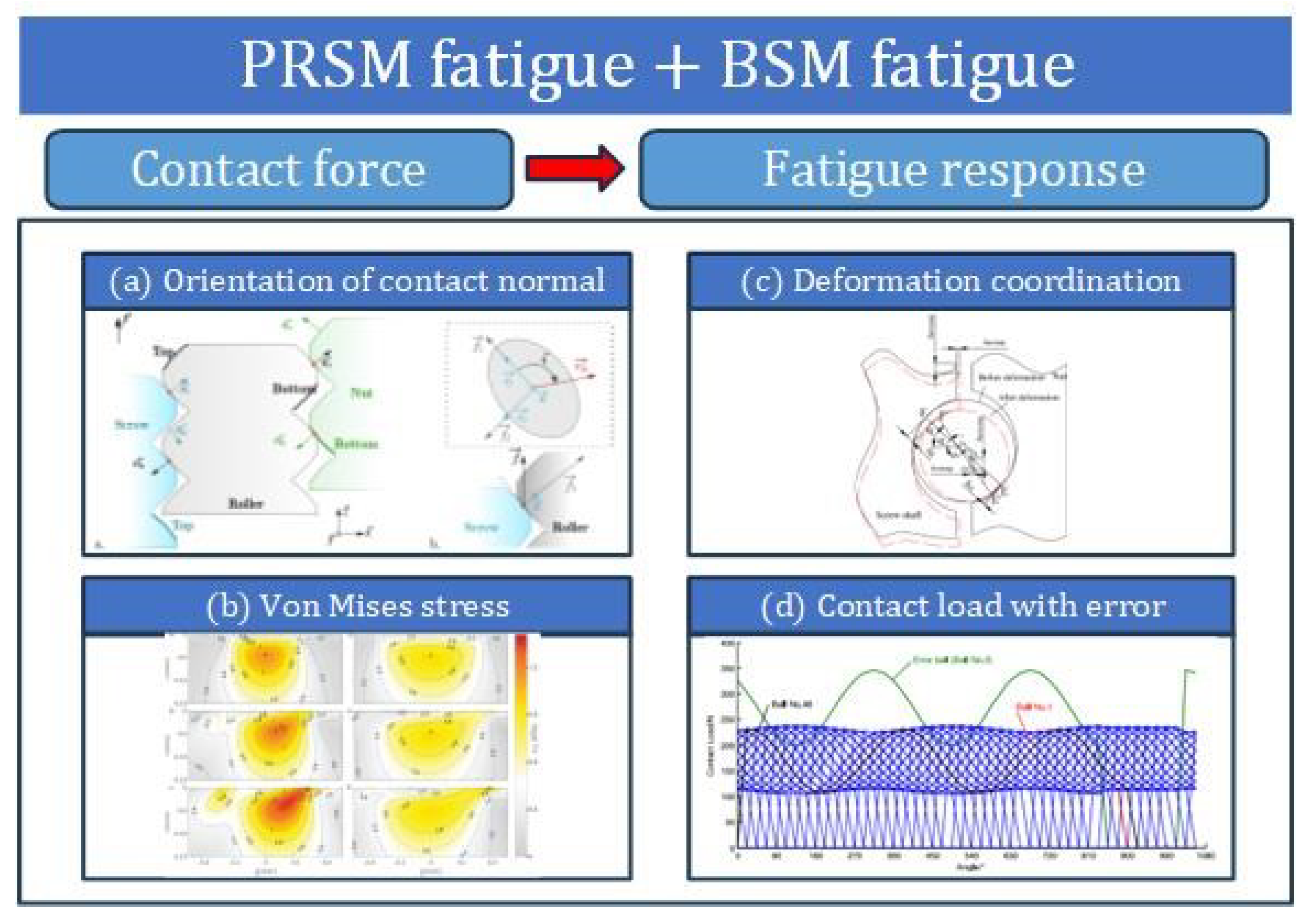

4.2. Fatigue, Surface Fracture and Failure Lifetime

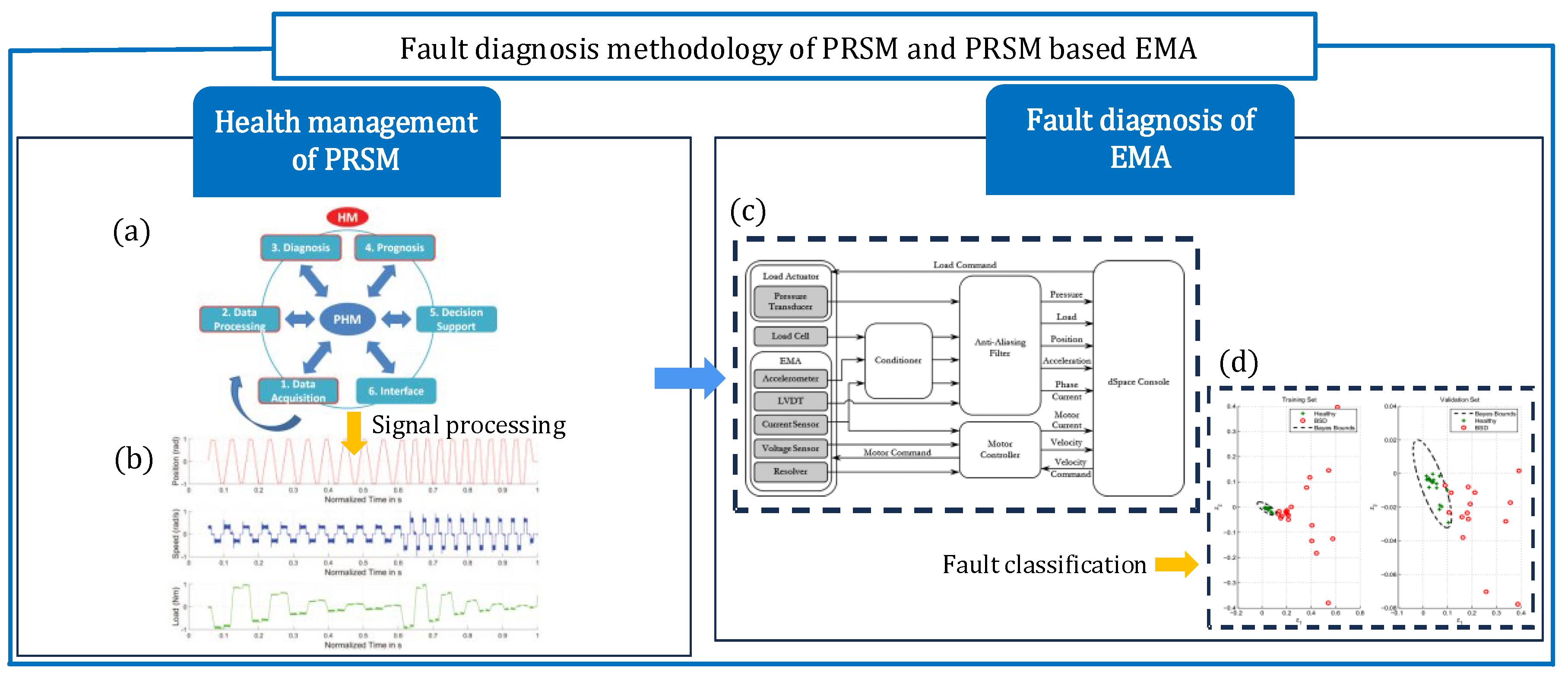

4.3. Health Condition Monitoring and Fault Diagnosis

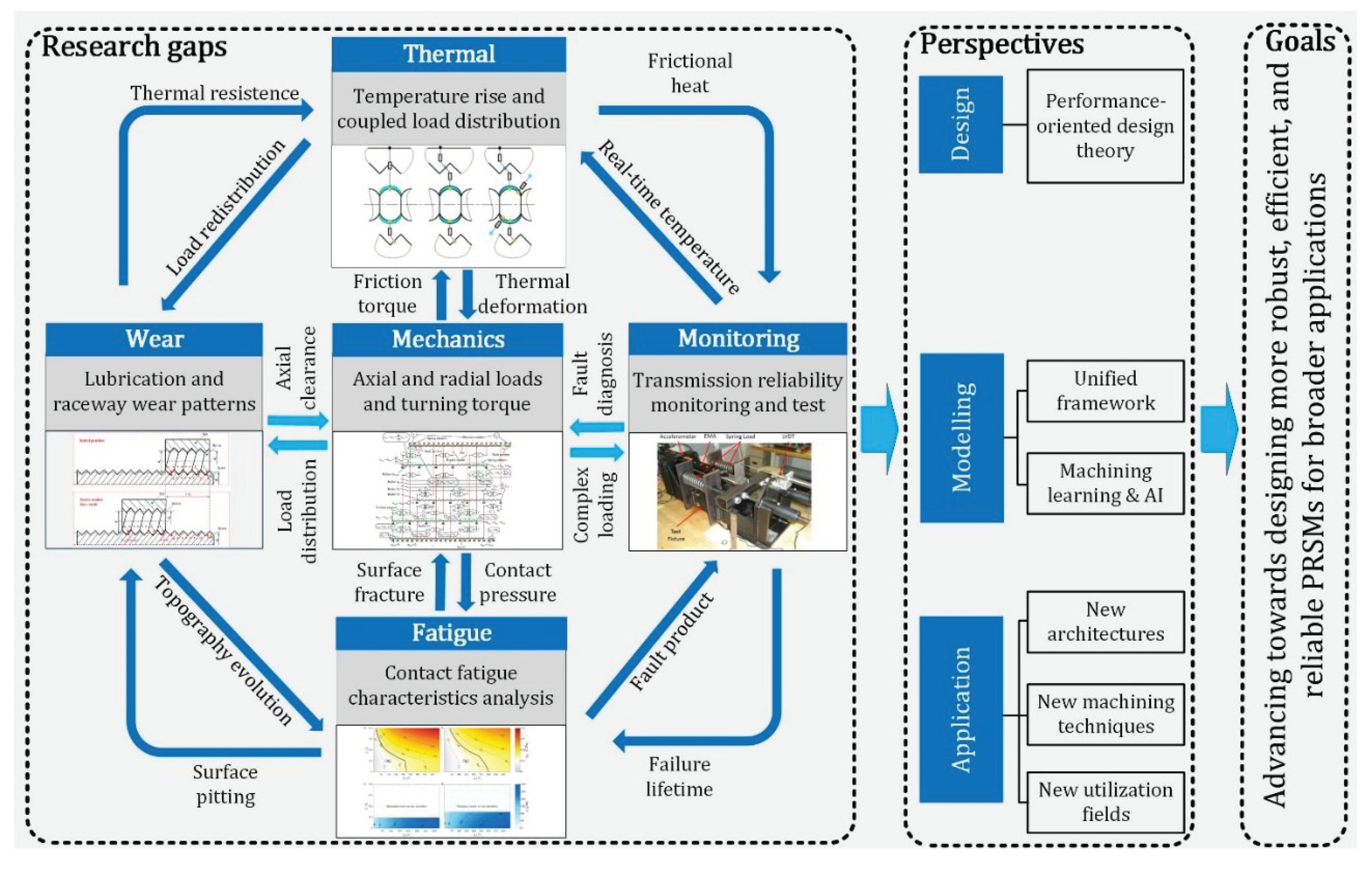

5. Conclusive Remarks and Perspectives

5.1. Summary of Current Investigation Status

5.2. Challenges and Research Perspectives

Acknowledgments

References

- Lemor, P.C. The roller screw, an efficient and reliable mechanical component of electro-mechanical actuators. Proc Iecec, (1996) 215-220.

- Naayagi, R.T. , A Review of More Electric Aircraft Technology. 2013 International Conference on Energy Efficient Technologies for Sustainability (Iceets), (2013).

- Jänker, P.; Claeyssen, F.; Grohmann, B.; Christmann, M.; Lorkowski, T.; LeLetty, R.; Sosniki, O.; Pages, A. New Actuators for Aircraft and Space Applications. Actuator 08, Conference Proceedings, (2008) 346-+.

- Bennett, J.W.; Mecrow, B.C.; Jack, A.G.; Atkinson, D.J. A Prototype Electrical Actuator for Aircraft Flaps. Ieee T Ind Appl 2010, 46, 915–921. [Google Scholar] [CrossRef]

- Rosenberg, G.; Snyder, A.; Weiss, W.; Landis, D.; Geselowitz, D.; Pierce, W. A roller screw drive for implantable blood pumps. Trans Am Soc Artif Intern Organs 1982, 28, 123–6. [Google Scholar]

- Ni, Z.; Wang, T.; Liu, D. Survey on medical robotics. Jixie Gongcheng Xuebao/Journal of Mechanical Engineering 2015, 51, 45–52. [Google Scholar] [CrossRef]

- Kawamoto, Y.; Suda, Y.; Inoue, H.; Kondo, T. , Electro-mechanical suspension system considering energy consumption and vehicle manoeuvre. Vehicle Syst Dyn 2008, 46, 1053–1063. [Google Scholar] [CrossRef]

- Bruno, S.C. , Screw-threaded mechanism, Google Patents 1954. [Google Scholar]

- Bruno, S.C. , Nut and screw devices, Google Patents 1965. [Google Scholar]

- Roantree, W.J. , Differential roller nut, Google Patents 1968. [Google Scholar]

- Saari, O. , Anti-friction nut/screw drive, Google Patents 1986. [Google Scholar]

- Blinov, D.S.; Kolobov, A.Y.; Dikun, E.V. , Prospects of Using Electromechanical Drives Based on Roller Screw Mechanisms in Aerospace Hardware, Xliii Academic Space Conference, Dedicated to the Memory of Academician S P Korolev and Other Outstanding Russian Scientists - Pioneers of Space Exploration 2019, 2171. 2171.

- Okwudire, C.E. , Improved Screw-Nut Interface Model for High-Performance Ball Screw Drives. J Mech Design 2011, 133. [Google Scholar] [CrossRef]

- Okwudire, C.E.; Altintas, Y. , Hybrid Modeling of Ball Screw Drives With Coupled Axial. Torsional, and Lateral Dynamics. J Mech Design 2009, 131. [Google Scholar] [CrossRef]

- Zhao, C.J.; Yu, X.K.; Huang, Q.X.; Ge, S.D.; Gao, X. , Analysis on the load characteristics and coefficient of friction of angular contact ball bearing at high speed. Tribol Int 2015, 87, 50–56. [Google Scholar]

- Chen, Y.J.; Tang, W.C. , Dynamic contact stiffness analysis of a double-nut ball screw based on a quasi-static method. Mech Mach Theory 2014, 73, 76–90. [Google Scholar] [CrossRef]

- Oh, K.J.; Cao, L.; Chung, S.C. , Explicit modeling and investigation of friction torques in double-nut ball screws for the precision design of ball screw feed drives. Tribol Int 2020, 141. [Google Scholar] [CrossRef]

- Zheng, S.C.; Fu, Y.L.; Wang, D.Y.; Pan, J.L.; Li, L.J.; Wang, J.B. , A Novel Planetary Thread Roller Bearing: Design and Analysis of Load Characteristic. J Mech Design 2021, 143. [Google Scholar] [CrossRef]

- Ni, J.A.; Yin, J.H.; Li, D.D.; Liu, J.Q.; Xie, Z.J. , Modeling of contact load distribution of planetary threaded roller bearing based on deformation coordination. Mech Based Des Struc 2023, 51, 5856–5877. [Google Scholar] [CrossRef]

- Pochettino, P.; Ballesio, M.; Gallieni, D.; Gill, S. , Hexapod/Sage III roller screws lifetime and lubrication tests. Esa Sp Publ 1998, 438, 49–54. [Google Scholar]

- Vanthuyne, T. , AN ELECTRICAL THRUST VECTOR CONTROL SYSTEM FOR THE VEGA LAUNCHER, 2009.

- Claeyssen, F.; Jänker, P.; LeLetty, R.; Sosniki, O.; Pages, A.; Magnac, G.; Christmann, M.; Dodds, G. , New Actuators for Aircraft, Space and Military Applications. Actuator, (2010) 324-+.

- Garrison, M.; Steffan, S. , Two-Fault Tolerant Electric Actuation Systems for Space Applications, 42nd AIAA/ASME/SAE/ASEE Joint Propulsion Conference & Exhibit.

- Lepagneul, J.; Tadrist, L.; Mermoz, E.; Linares, J.M. , Axial backlash of planetary roller screw mechanisms: Geometric modelling and Sobol's analysis of design parameters. Cirp Ann-Manuf Techn 2023, 72, 113–116. [Google Scholar] [CrossRef]

- Liu, Y.Q.; Shang, Y.; Wang, J.S. , Mathematical analysis of the meshing performance of planetary roller screws applying different roller thread shapes. Adv Mech Eng 2017, 9. [Google Scholar] [CrossRef]

- Du, X.; Lu, S.Y.; Tang, R.; Li, X.B.; Miao, J.C.; Wu, L.Y.; Yang, Z.; Chen, B.K. , An efficient method for designing high-performance planetary roller screw mechanism with low contact stress. Tribol Int 2023, 187. [Google Scholar] [CrossRef]

- Xiao, Y.L.; Fu, J.; Zhao, Y.S.; Li, F.P.; Chen, K. , Multi-objective optimization of planetary roller screw mechanism based on improved boundary condition. Int J Adv Manuf Tech 2023, 124, 4479–4491. [Google Scholar] [CrossRef]

- Hu, R.; Wei, P.T.; Zhou, P.L.; Liu, H.J.; Du, X.S.; Zhu, C.C. , A roller taper modification method for load distribution optimization of planetary roller screw mechanism. J Adv Mech Des Syst 2022, 16, 1–19. [Google Scholar] [CrossRef]

- Yao, Q.; Zhang, M.C.; Liu, Y.S.; Ma, S.J. , Multi-objective optimization of planetary roller screw mechanism based on improved mathematical modelling. Tribol Int 2021, 161. [Google Scholar] [CrossRef]

- Yao, Q.; Zhang, M.C.; Ma, S.J. , Structural design for planetary roller screw mechanism based on the developed contact modelling. Tribol Int 2022, 171. [Google Scholar] [CrossRef]

- Yao, Q.; Zhang, M.C.; Ma, S.J.; Jiang, Q.S. , Study on multi-level progressive optimization of planetary roller screw mechanism. Tribol Int 2023, 189. [Google Scholar] [CrossRef]

- Guadagno, M.C.; Loss, J.M.; Pearce, J.M. , Open Source 3D-Printable Planetary Roller Screw for Food Processing Applications. Technologies 2021, 9. [Google Scholar] [CrossRef]

- Peng, B.; Luo, Y.; Niu, T.; Baddour, N.; Li, C.S.; Luo, Y.X. , Straightening of the rollers of planetary roller screw - Design of straightening die and experimental validation. J Manuf Process 2023, 92, 42–62. [Google Scholar] [CrossRef]

- Xu, H.W.; Wei, P.T.; Du, X.S.; Hu, R.; Liu, H.J.; Kang, X.H.; Zhu, C.C. , A study of precision grinding of micro-pitch internal thread for planetary roller screw mechanism. J Manuf Process 2023, 106, 35–50. [Google Scholar] [CrossRef]

- Wu, H.L.; Wei, P.T.; Hu, R.; Liu, H.J.; Du, X.S.; Zhou, P.L.; Zhu, C.C. , Study on the relationship between machining errors and transmission accuracy of planetary roller screw mechanism using analytical calculations and machine-learning model. J Comput Des Eng 2023, 10, 398–413. [Google Scholar] [CrossRef]

- Huang, T.; Kang, Y.T.; Du, S.J.; Zhang, Q.; Luo, Z.H.; Tang, Q.; Yang, K.M. , A survey of modeling and control in ball screw feed-drive system. Int J Adv Manuf Tech 2022, 121, 2923–2946. [Google Scholar] [CrossRef]

- Li, C.Y.; Xu, M.T.; Song, W.J.; Zhang, H.Z. , A review of static and dynamic analysis of ball screw feed drives, recirculating linear guideway, and ball screw. Int J Mach Tool Manu 2023, 188. [Google Scholar] [CrossRef]

- Qiao, G.; Liu, G.; Shi, Z.H.; Wang, Y.W.; Ma, S.J.; Lim, T.C. , A review of electromechanical actuators for More/All Electric aircraft systems. P I Mech Eng C-J Mec 2018, 232, 4128–4151. [Google Scholar] [CrossRef]

- Maré, J.C.; Fu, J. , Review on signal-by-wire and power-by-wire actuation for more electric aircraft. Chinese J Aeronaut 2017, 30, 857–870. [Google Scholar] [CrossRef]

- Wu, L.P.; Ma, S.J.; Fu, X.J.; Zhang, J.X.; Liu, G. , A review of planetary roller screw mechanism for development and new trends. P I Mech Eng C-J Mec 2022, 236, 10822–10840. [Google Scholar] [CrossRef]

- Li, X.; Liu, G.; Fu, X.J.; Ma, S.J. , Review on Motion and Load-Bearing Characteristics of the Planetary Roller Screw Mechanism. Machines 2022, 10. [Google Scholar] [CrossRef]

- Cheng, Z.W.; Zu, L.; Zhou, C.G. , Review on errors and transmission characteristics of the planetary roller screw mechanism. P I Mech Eng C-J Mec, (2024).

- Ma, S.J.; Wu, G.Y.; Zhang, J.X.; Liu, G. , Experimental Research on Static Stiffness of the Planetary Roller Screw Mechanism. Matec Web Conf 2020, 306. [Google Scholar]

- Hu, R.; Wei, P.T.; Du, X.S.; Zhou, J.; Liu, H.J.; Liu, G.S.; Zhu, C.C. , Investigation of loaded contact characteristics of planetary roller screw mechanism based on influence coefficient method and machine learning. Adv Eng Inform 2023, 58. [Google Scholar] [CrossRef]

- Ma, S.J.; Cai, W.; Wu, L.P.; Liu, G.; Peng, C. , Modelling of transmission accuracy of a planetary roller screw mechanism considering errors and elastic deformations. Mech Mach Theory 2019, 134, 151–168. [Google Scholar] [CrossRef]

- Zhang, W.J.; Liu, G.; Ma, S.J.; Tong, R.T. , Load distribution over threads of planetary roller screw mechanism with pitch deviation. P I Mech Eng C-J Mec 2019, 233, 4653–4666. [Google Scholar] [CrossRef]

- Du, X.; Chen, B.K.; Liu, R.R.; Li, C.Y. , Research on Fractal Model of Load Distribution and Axial Stiffness of Planetary Roller Screw Mechanism Considering Surface Roughness and Friction Factor. Adv Theor Simul 2022, 5. [Google Scholar] [CrossRef]

- Du, X.; Chen, B.K.; Zheng, Z.D. , Investigation on mechanical behavior of planetary roller screw mechanism with the effects of external loads and machining errors. Tribol Int 2021, 154. [Google Scholar] [CrossRef]

- Fu, X.J.; Li, X.; Ma, S.J.; Gerada, D.; Liu, G.; Gerada, C. , A multi-roller static model of the planetary roller screw mechanism considering load sharing. Tribol Int 2022, 173. [Google Scholar] [CrossRef]

- Hu, R.; Wei, P.T.; Liu, H.J.; Du, X.S.; Zhou, P.L.; Zhu, C.C. , Investigation on load distribution among rollers of planetary roller screw mechanism considering machining errors: Analytical calculation and machine learning approach. Mech Mach Theory 2023, 185. [Google Scholar] [CrossRef]

- Zhang, W.J.; Liu, G.; Tong, R.T.; Ma, S.J. , Load distribution of planetary roller screw mechanism and its improvement approach. P I Mech Eng C-J Mec 2016, 230, 3304–3318. [Google Scholar] [CrossRef]

- Abevi, F.; Daidie, A.; Chaussumier, M.; Sartor, M. , Static Load Distribution and Axial Stiffness in a Planetary Roller Screw Mechanism. J Mech Design 2016, 138. [Google Scholar] [CrossRef]

- Abevi, F.; Daidie, A.; Chaussumier, M.; Orieux, S. , Static Analysis of an Inverted Planetary Roller Screw Mechanism. J Mech Robot 2016, 8. [Google Scholar] [CrossRef]

- Jones, M.H.; Velinsky, S.A. , Stiffness of the Roller Screw Mechanism by the Direct Method. Mech Based Des Struc 2014, 42, 17–34. [Google Scholar] [CrossRef]

- Wang, C.; Zhang, C.X.; Cheng, Q.; Zhang, T.; Shi, W.; Xue, D.Y. , Kinematic modeling of a planetary roller screw mechanism considering runout errors and elastic deformation. Int J Adv Manuf Tech 2023, 124, 4455–4463. [Google Scholar] [CrossRef]

- Fu, X.J.; Liu, G.; Ma, S.J.; Tong, R.T.; Lim, T.C. , A Comprehensive Contact Analysis of Planetary Roller Screw Mechanism. J Mech Design 2017, 139. [Google Scholar] [CrossRef]

- Fu, X.J.; Liu, G.; Ma, S.J.; Tong, R.T.; Lim, T.C. , Kinematic Model of Planetary Roller Screw Mechanism With Run-Out and Position Errors. J Mech Design 2018, 140. [Google Scholar] [CrossRef]

- Hojjat, Y.; Agheli, M.M. , A comprehensive study on capabilities and limitations of roller-screw with emphasis on slip tendency. Mech Mach Theory 2009, 44, 1887–1899. [Google Scholar] [CrossRef]

- Xing, M.C.; Zhang, B.H.; Deng, P.; Xu, J.Q.; Cui, Y. , A comprehensive analysis of contact kinematics for planetary roller screw mechanism. Tribol Int 2023, 179. [Google Scholar] [CrossRef]

- Sandu, S.; Biboulet, N.; Nelias, D.; Abevi, F. , An efficient method for analyzing the roller screw thread geometry. Mech Mach Theory 2018, 126, 243–264. [Google Scholar] [CrossRef]

- Sandu, S.; Biboulet, N.; Nelias, D.; Abevi, F. , Analytical prediction of the geometry of contact ellipses and kinematics in a roller screw versus experimental results. Mech Mach Theory 2019, 131, 115–136. [Google Scholar] [CrossRef]

- Velinsky, S.A.; Chu, B.; Lasky, T.A. , Kinematics and Efficiency Analysis of the Planetary Roller Screw Mechanism. J Mech Design 2009, 131. [Google Scholar] [CrossRef]

- Mamaev, I.M.; Morozov, V.V.; Fedotov, O.V.; Filimonov, V.N. , Harmonic analysis of the kinematic error in a planetary roller screw. Russian Engineering Research 2016, 36, 515–519. [Google Scholar] [CrossRef]

- Acharya, J.; Venkataram, N. , Kinematic Analysis and Thread Profile Modification Study of Planetary Roller Screw Actuator. Mater Today-Proc 2017, 4, 10965–10970. [Google Scholar] [CrossRef]

- Jones, M.H.; Velinsky, S.A. , Contact Kinematics in the Roller Screw Mechanism. J Mech Design 2013, 135. [Google Scholar] [CrossRef]

- Ma, S.J.; Zhang, T.; Liu, G.; Tong, R.T.; Fu, X.J. , Kinematics of Planetary Roller Screw Mechanism considering Helical Directions of Screw and Roller Threads. Math Probl Eng 2015, 2015. [Google Scholar] [CrossRef]

- Jones, M.H.; Velinsky, S.A. , Kinematics of Roller Migration in the Planetary Roller Screw Mechanism. J Mech Design 2012, 134. [Google Scholar] [CrossRef]

- Li, X.; Liu, G.; Fu, X.J.; Ma, S.J. , Lagrange-method-based dynamic analysis of multi-stage planetary roller screw mechanism. Mech Sci 2021, 12, 471–478. [Google Scholar] [CrossRef]

- Xu, M.T.; Zhang, H.Z.; Liu, Z.D.; Li, C.Y.; Zhang, Y.M.; Mu, Y.Z.; Hou, C.M. , A time-dependent dynamic model for ball passage vibration analysis of recirculation ball screw mechanism. Mech Syst Signal Pr 2021, 157. [Google Scholar] [CrossRef]

- Jones, M.H.; Velinsky, S.A.; Lasky, T.A. , Dynamics of the Planetary Roller Screw Mechanism. J Mech Robot 2016, 8. [Google Scholar] [CrossRef]

- Fu, X.J.; Liu, G.; Tong, R.T.; Ma, S.J.; Lim, T.C. , A nonlinear six degrees of freedom dynamic model of planetary roller screw mechanism. Mech Mach Theory 2018, 119, 22–36. [Google Scholar] [CrossRef]

- Fu, X.J.; Liu, G.; Ma, S.J.; Tong, R.T.; Li, X. , An efficient method for the dynamic analysis of planetary roller screw mechanism. Mech Mach Theory 2020, 150. [Google Scholar] [CrossRef]

- Guo, C.; Chen, L.P.; Ding, J.W. , A novel dynamics model of ball-screw feed drives based on theoretical derivations and deep learning. Mech Mach Theory 2019, 141, 196–212. [Google Scholar] [CrossRef]

- Liu, C.; Zhao, C.Y.; Wen, B.C. , Dynamics analysis on the MDOF model of ball screw feed system considering the assembly error of guide rails. Mech Syst Signal Pr 2022, 178. [Google Scholar] [CrossRef]

- Xu, M.T.; Li, C.Y.; Zhang, H.Z.; Liu, Z.D.; Zhang, Y.M. , A comprehensive nonlinear dynamic model for ball screw feed system with rolling joint characteristics. Nonlinear Dynam 2021, 106, 169–210. [Google Scholar] [CrossRef]

- Fu, X.J.; Liu, G.; Li, X.; Ma, S.J.; Qiao, G. , Dynamic Modeling of the Double-Nut Planetary Roller Screw Mechanism Considering Elastic Deformations. J Comput Nonlin Dyn 2021, 16. [Google Scholar] [CrossRef]

- Wu, L.P.; Ma, S.J.; Deng, P.; Huang, Q.Q. , Research on the Modeling of Bending-Torsional Coupling and Vibration Characteristics of Planetary Roller Screw Mechanism. Electronics-Switz 2022, 11. [Google Scholar] [CrossRef]

- Miao, H.H.; Wang, C.Y.; Hao, J.; Li, C.Y.; Xu, M.T.; Liu, Z.D. , Dynamic analysis of the column-spindle system considering the nonlinear characteristics of kinematic joints. Mech Mach Theory 2022, 174. [Google Scholar] [CrossRef]

- Yang, J.C.; Li, C.Y.; Xu, M.T.; Yang, T.Z.; Zhang, Y.M. , Nonlinear dynamic characteristics of ball screw feed system under thermal deformation. Nonlinear Dynam 2022, 107, 1965–1987. [Google Scholar] [CrossRef]

- Liu, Z.D.; Xu, M.T.; Zhang, H.Z.; Li, C.Y.; Yao, G.; Li, Z.Y.; Miao, H.H.; Wang, C.Y.; Zhang, Y.M. , Nonlinear dynamic analysis of variable lead preloaded single nut ball screw considering the variation of working parameters. Nonlinear Dynam 2022, 108, 141–166. [Google Scholar] [CrossRef]

- Xie, Z.J.; Xue, Q.H.; Wu, J.Q.; Gu, L.; Wang, L.Q.; Song, B.Y. , Mixed-lubrication analysis of planetary roller screw. Tribol Int 2019, 140. [Google Scholar] [CrossRef]

- Zhou, G.W.; Zhang, Y.H.; Wang, Z.Z.; Pu, W. , Analysis of transient mixed elastohydrodynamic lubrication in planetary roller screw mechanism. Tribol Int 2021, 163. [Google Scholar] [CrossRef]

- Xing, M.; Zhang, B.; Liu, S.; Cui, Y.; Xu, J.; Deng, P. , Elastohydrodynamic lubrication analysis with eccentric errors for planetary roller screw mechanism. Tribol Int 2024, 109362. [Google Scholar] [CrossRef]

- Cai, W.; Liu, G.; Ma, S.J.; Fu, X.J.; Zhang, J.N.; Niu, M.D. A dynamic separable convolution RCNN for lubrication condition identification of planetary roller screw mechanism. Adv Mech Eng 2022, 14. [Google Scholar] [CrossRef]

- Aurégan, G.; Fridrici, V.; Kapsa, P.; Rodrigues, F. , Experimental simulation of rolling-sliding contact for application to planetary roller screw mechanism. Wear 2015, 332, 1176–1184. [Google Scholar] [CrossRef]

- Xing, M.C.; Zhang, B.H.; Deng, P.; Xu, J.Q.; Cui, Y. , A novel wear prediction model for planetary roller screw based on universal sliding distance model. Tribol Int 2022, 175. [Google Scholar] [CrossRef]

- Ma, S.J.; Wu, L.P.; Fu, X.J.; Li, Y.J.; Liu, G. , Modelling of static contact with friction of threaded surfaces in a planetary roller screw mechanism, Mech Mach Theor 2019, 139, 212–236. [Google Scholar] [CrossRef]

- Aur; eacute; G. gan; Fridrici, V.; Kapsa, P.; Rodrigues, F., Wear Behavior of Martensitic Stainless Steel in Rolling-Sliding Contact for Planetary Roller Screw Mechanism: Study of the WC/C Solution. Tribology Online 2016, 11, 209–217. [Google Scholar] [CrossRef]

- Meng, J.J.; Du, X.; Li, Y.M.; Chen, P.; Xia, F.C.; Wan, L. , A Multiscale Accuracy Degradation Prediction Method of Planetary Roller Screw Mechanism Based on Fractal Theory Considering Thread Surface Roughness. Fractal Fract 2021, 5. [Google Scholar] [CrossRef]

- Meng, J.J.; Du, X.; Zhao, X.; Zheng, J.W.; Wang, D.W.; Wa, L. n, Research on Contact and Wear Characteristics of the Planetary Roller Screw Mechanism with Screw Misalignments. Lubricants 2022, 10. [Google Scholar] [CrossRef]

- Shangjun, M.; Qianjin, X.; Chuangchuang, L.; Jianxin, Z.; Geng, L. , Wear Modelling of the Thread Pair in a Planetary Roller Screw Mechanism, Proceedings of the International Conference of Fluid Power and Mechatronic Control Engineering (ICFPMCE 2022), Atlantis Press 2022, pp. 75–95.

- Cheng, Q.; Qi, B.B.; Liu, Z.F.; Zhang, C.X.; Xue, D.Y. , An accuracy degradation analysis of ball screw mechanism considering time-varying motion and loading working conditions. Mech Mach Theory 2019, 134, 1–23. [Google Scholar] [CrossRef]

- Zhao, J.J.; Lin, M.X.; Song, X.C.; Guo, Q.Z. , Analysis of the precision sustainability of the preload double-nut ball screw with consideration of the raceway wear. P I Mech Eng J-J Eng 2020, 234, 1530–1546. [Google Scholar] [CrossRef]

- Liu, J.L.; Ma, C.; Wang, S.L. , Precision loss modeling method of ball screw pair. Mech Syst Signal Pr 2020, 135. [Google Scholar] [CrossRef]

- Zhou, H.X.; Zhou, C.G.; Feng, H.T.; Ou, Y. , Theoretical and experimental analysis of the preload degradation of double-nut ball screws. Precis Eng 2020, 65, 72–90. [Google Scholar] [CrossRef]

- Zhou, C.G.; Zhou, H.X.; Feng, H.T. , Experimental analysis of the wear coefficient of double-nut ball screws. Wear 2020, 446. [Google Scholar] [CrossRef]

- Zhou, C.G.; Wang, L.D.; Shen, J.W.; Chen, C.H.; Ou, Y.; Feng, H.T. , Wear Characterization of Raceway Surface Profiles of Ball Screws. J Tribol-T Asme 2022, 144. [Google Scholar] [CrossRef]

- Xie, Z.J.; Wang, Y.; Ni, J.A.; Yin, J.H.; Yu, D.; Liu, J.Q. , Friction torque analysis of planetary roller screw based on the creepage theory. Tribol Int 2023, 178. [Google Scholar] [CrossRef]

- Gan, F.J.; Mao, P.C.; Zheng, S.C.; Li, G.L.; Xin, S.P. , Research on Friction Torque Analysis of Planetary Roller Screw Mechanism considering load distribution. Aip Conf Proc 2018, 1955. [Google Scholar]

- Liu, L.; Zhang, C.C.; Guo, Y.Q.; Bian, Y.X.; Fu, Y.L.; Ning, Y.F.; Zhou, J.J. , Friction Torque Analysis and Verification of Planetary Thread Roller Bearing. Actuators 2022, 11. [Google Scholar] [CrossRef]

- Popescu, A.; Houpert, L.; Olaru, D.N. , Four approaches for calculating power losses in an angular contact ball bearing. Mech Mach Theory 2020, 144. [Google Scholar] [CrossRef]

- Fu, J.; Maré, J.C.; Fu, Y.L. , Modelling and simulation of flight control electromechanical actuators with special focus on model architecting, multidisciplinary effects and power flows. Chinese J Aeronaut 2017, 30, 47–65. [Google Scholar] [CrossRef]

- Zheng, S.; Fu, Y.; Zhang, Z.; Zhang, P.; Zhang, W. , Research on Detect Method for Transmission Accuracy and Efficiency of Planetary Roller Screw Pair, 2018 IEEE International Conference on Mechatronics and Automation (ICMA) 2018, pp. 1400–1404.

- Qiao, G.; Liu, G.; Ma, S.J.; Wang, Y.W.; Li, P.; Lim, T.C. , Thermal characteristics analysis and experimental study of the planetary roller screw mechanism. Appl Therm Eng 2019, 149, 1345–1358. [Google Scholar] [CrossRef]

- Lizon, J.L. , Planetary roller screw for cryogenic applications. Proc Spie 2022, 12188. [Google Scholar]

- Du, C.M.; Liu, G.; Qiao, G.; Ma, S.J.; Ca, W. , Transient thermal analysis of standard planetary roller screw mechanism based on finite element method. Adv Mech Eng 2018, 10. [Google Scholar] [CrossRef]

- Ma, S.J.; Liu, G.; Tong, R.T.; Fu, X.J. , A Frictional Heat Model of Planetary Roller Screw Mechanism Considering Load Distribution. Mech Based Des Struc 2015, 43, 164–182. [Google Scholar] [CrossRef]

- Ma, S.J.; Zhang, C.H.; Zhang, T.; Liu, G.; Liu, S.M. , Thermo-mechanical coupling-based finite element analysis of the load distribution of planetary roller screw mechanism. Adv Mech Eng 2018, 10. [Google Scholar] [CrossRef]

- Zhang, L.C.; Ou, Y.; Feng, H.T. , Prediction of the Thermal Elongation of the Ball Screw Mechanism under Various Rotational Speeds. Int J Precis Eng Man 2021, 22, 1221–1228. [Google Scholar] [CrossRef]

- Wang, H.T.; Li, F.H.; Cai, Y.L.; Liu, Y.M.; Yang, Y.W. , Experimental and theoretical analysis of ball screw under thermal effect. Tribol Int 2020, 152. [Google Scholar] [CrossRef]

- Li, T.J.; Wang, M.Z.; Zhang, Y.M.; Zhao, C.Y. , Real-time thermo-mechanical dynamics model of a ball screw system based on a dynamic thermal network. Int J Adv Manuf Tech 2020, 108, 613–624. [Google Scholar] [CrossRef]

- Redmond, M.; Novak, K.; Mireles, V. , Static Ball Bearing Thermal Conductance in Air and Vacuum: Review and Correlation. J Thermophys Heat Tr 2017, 31, 841–846. [Google Scholar] [CrossRef]

- Cheng, J.; Zhou, Z.D.; Feng, Y.X.; Liu, Z.Y.; Zhang, Y.Y. , Thermo-Mechanical Coupling Analysis of the Actuating Mechanism in a High Speed Press. Int J Precis Eng Man 2018, 19, 643–653. [Google Scholar] [CrossRef]

- Ju, X.J.; Lu, J.L.; Jin, H.Y. , Study on heat transfer characteristics and thermal error suppression method of cylindrical giant magnetostrictive actuator for ball screw preload. P I Mech Eng B-J Eng 2021, 235, 782–794. [Google Scholar] [CrossRef]

- Liu, J.; Shi, Z.F.; Shao, Y.M. , Vibration Characteristics of a Ball Bearing Considering Point Lubrication and Nonuniform Surface Waviness. Int J Acoust Vib 2018, 23, 355–361. [Google Scholar] [CrossRef]

- Liu, J.; Shao, Y.M. , Vibration modelling of nonuniform surface waviness in a lubricated roller bearing. J Vib Control 2017, 23, 1115–1132. [Google Scholar] [CrossRef]

- Liu, J.; Wu, H.; Shao, Y.M. , A comparative study of surface waviness models for predicting vibrations of a ball bearing. Sci China Technol Sc 2017, 60, 1841–1852. [Google Scholar] [CrossRef]

- Liu, J.; Pang, R.K.; Xu, Y.J.; Ding, S.Z.; He, Q.B. , Vibration analysis of a single row angular contact ball bearing with the coupling errors including the surface roundness and waviness. Sci China Technol Sc 2020, 63, 943–952. [Google Scholar] [CrossRef]

- Su, S.M.; Cao, H.R.; Zhang, Y.Y. , Dynamic modeling and characteristics analysis of cylindrical roller bearing with the surface texture on raceways. Mech Syst Signal Pr 2021, 158. [Google Scholar] [CrossRef]

- Liu, J.; Li, X.B.; Ding, S.Z.; Pang, R.K. , A time-varying friction moment calculation method of an angular contact ball bearing with the waviness error. Mech Mach Theory 2020, 148. [Google Scholar] [CrossRef]

- Liu, J.; Wang, L.F.; Shi, Z.F. , Dynamic modelling of the defect extension and appearance in a cylindrical roller bearing. Mech Syst Signal Pr 2022, 173. [Google Scholar] [CrossRef]

- Yin, Z.Y.; Yang, Y.; Shen, G.J.; Li, Y.H.; Huang, L.Y.; Hu, N.Q. , Dynamic modeling, analysis, and experimental study of ball screw pairs with nut spalling faults in electromechanical actuators. Mech Syst Signal Pr 2023, 184. [Google Scholar] [CrossRef]

- Yao, Q.; Zhang, M.C.; Jiang, Q.S.; Ma, S.J. , Uncertainty analysis and reliability improvement of planetary roller screw mechanism using active learning Kriging model. Probabilist Eng Mech 2023, 72. [Google Scholar] [CrossRef]

- Du, X.; Wu, L.Y.; Miao, J.C.; Li, X.B.; Shi, Z.X.; Chen, B.K. , Time-varying contact characteristics of the planetary roller screw mechanism considering nonuniform surface waviness. Tribol Int 2023, 187. [Google Scholar] [CrossRef]

- Cai, W.; Liu, G.; Ma, S.; Qiao, G.; Du, C. , Study on jamming mechanism of the planetary roller screw mechanism. Journal of Physics: Conference Series 2019, 1314, 012079. [Google Scholar] [CrossRef]

- El Laithy, M.; Wang, L.; Harvey, T.J.; Vierneusel, B.; Correns, M.; Blass, T. , Further understanding of rolling contact fatigue in rolling element bearings - A review. Tribol Int 2019, 140. [Google Scholar] [CrossRef]

- Moreira, T.M.M.; Godefroid, L.B.; de Faria, G.L.; Silveira, R.A.D. , Computational analysis via FEM of Tirefond screws used in the fastening system of railroads aiming to avoid a recurrent failure case. Eng Fail Anal 2019, 106. [Google Scholar] [CrossRef]

- Kraemer, F.; Klein, M.; Oechsner, M. , Fatigue strength of metric steel screws depending on pre-load and nut type. Eng Fail Anal 2020, 112. [Google Scholar] [CrossRef]

- Wang, M.S.; Jia, X.D.; Lv, W.Y.; Sun, W.H.; Bai, F.X.; Guo, H. , Failure analysis of screw shaft in screw compressor. Eng Fail Anal 2021, 125. [Google Scholar] [CrossRef]

- Kim, Y.C.; Kim, D.H.; Kim, S.W. , Evaluation of the Multiaxial Fatigue Life of Electro-Mechanical Actuator for Aircraft Blade Pitch Control Based on Certification Standards. Aerospace-Basel 2024, 11. [Google Scholar] [CrossRef]

- Lepagneul, J.; Tadrist, L.; Sprauel, J.M.; Linares, J.M. , Fatigue lifespan of a planetary roller-screw mechanism. Mech Mach Theory 2022, 172. [Google Scholar] [CrossRef]

- Zhen, N.; An, Q. , Analysis of stress and fatigue life of ball screw with considering the dimension errors of balls. Int J Mech Sci 2018, 137, 68–76. [Google Scholar] [CrossRef]

- Li, F.K.; Hu, W.P.; Meng, Q.C.; Zhan, Z.X.; Shen, F. , A new damage-mechanics-based model for rolling contact fatigue analysis of cylindrical roller bearing. Tribol Int 2018, 120, 105–114. [Google Scholar] [CrossRef]

- Halme, J.; Andersson, P. , Rolling contact fatigue and wear fundamentals for rolling bearing diagnostics - state of the art. P I Mech Eng J-J Eng 2010, 224, 377–393. [Google Scholar] [CrossRef]

- Vijay, A.; Sadeghi, F. , A crystal plasticity and cohesive element model for rolling contact fatigue of bearing steels. Tribol Int 2022, 173. [Google Scholar] [CrossRef]

- Li, C.; Chen, Z.W.; Chen, X.X.; Liu, Z.T.; Han, X. , Microstructure evolution analysis of aviation bearing in service process based on CPFEM. Eng Fail Anal 2022, 142. [Google Scholar] [CrossRef]

- Raje, N.; Sadeghi, F.; Rateick, R.G.; Hoeprich, M.R. , A numerical model for life scatter in rolling element bearings. J Tribol-T Asme 2008, 130. [Google Scholar] [CrossRef]

- Zhao, J.J.; Jiang, H.K.; Xu, X.R.; Li, Y.F.; Qi, B.B.; Yu, H.W. , Fatigue life prediction of the preload double-nut ball screw under mixed lubrication. Int J Adv Manuf Tech 2023, 124, 4385–4401. [Google Scholar] [CrossRef]

- Liu, G.S.; Wei, P.T.; Liu, H.J.; Du, X.S.; Hu, R.; He, H.L.; Zhou, P.L.; Tan, X.Q. , Transmission accuracy-axial backlash-fatigue life-driven tolerance optimization of planetary roller screw mechanism. J Comput Des Eng 2023, 10, 2401–2421. [Google Scholar] [CrossRef]

- Niu, M.; Ma, S.; Cai, W.; Zhang, J.; Liu, G. , Fault Diagnosis of Planetary Roller Screw Mechanism Based on Bird Swarm Algorithm and Support Vector Machine. Journal of Physics: Conference Series 2020, 1519, 012007. [Google Scholar] [CrossRef]

- Pan, H.Y.; Xu, H.F.; Zheng, J.D.; Tong, J.Y. , Non-parallel bounded support matrix machine and its application in roller bearing fault diagnosis. Inform Sciences 2023, 624, 395–415. [Google Scholar] [CrossRef]

- Zhang, Y.C.; Ji, J.C.; Ren, Z.H.; Ni, Q.; Gu, F.S.; Feng, K.; Yu, K.; Ge, J.; Lei, Z.H.; Liu, Z. , Digital twin-driven partial domain adaptation network for intelligent fault diagnosis of rolling bearing. Reliability Engineering & System Safety 2023, 234. [Google Scholar]

- Shi, Z.F.; Liu, J. , A novel test rig for the investigation of roller-cage impacts of a needle roller bearing. Meas Sci Technol 2023, 34. [Google Scholar] [CrossRef]

- Wang, R.; Ding, X.X.; He, D.; Li, Q.C.; Li, X.; Tang, J.; Huang, W.B. , Shift-Invariant Sparse Filtering for Bearing Weak Fault Signal Denoising. Ieee Sens J 2023, 23, 26096–26106. [Google Scholar] [CrossRef]

- Liu, D.; Cui, L.; Wang, H. , Rotating Machinery Fault Diagnosis Under Time-Varying Speeds: A Review. Ieee Sens J 2023, 23, 29969–29990. [Google Scholar] [CrossRef]

- Zhang, L.; Guo, L.; Gao, H.L.; Dong, D.W.; Fu, G.Q.; Hong, X. , Instance-based ensemble deep transfer learning network: A new intelligent degradation recognition method and its application on ball screw. Mech Syst Signal Pr 2020, 140. [Google Scholar] [CrossRef]

- Zhang, Y.S.; Zhou, C.G.; Nie, C.H.; Feng, H.T. , Remaining useful life prediction of ball screw based on integrating preload and precision. Meas Sci Technol 2024, 35. [Google Scholar] [CrossRef]

- Li, P.; Jia, X.D.; Feng, J.S.; Davari, H.; Qiao, G.; Hwang, Y.; Lee, J. , Prognosability study of ball screw degradation using systematic methodology. Mech Syst Signal Pr 2018, 109, 45–57. [Google Scholar] [CrossRef]

- Han, C.F.; He, H.Q.; Wei, C.C.; Horng, J.H.; Chiu, Y.L.; Hwang, Y.C.; Lin, J.F. , Techniques developed for fault diagnosis of long-range running ball screw drive machine to evaluate lubrication condition. Measurement 2018, 126, 274–288. [Google Scholar] [CrossRef]

- Riaz, N.; Shah, S.I.A.; Rehman, F.; Khan, M.J. , An Intelligent Hybrid Scheme for Identification of Faults in Industrial Ball Screw Linear Motion Systems. Ieee Access 2021, 9, 35136–35150. [Google Scholar] [CrossRef]

- Huang, Y.C.; Hsieh, Y.K. , Applying a support vector machine for hollow ball screw condition-based classification using feature extraction. P I Mech Eng B-J Eng 2022, 236, 1839–1852. [Google Scholar] [CrossRef]

- Giberti, H.; Carnevale, M.; Bocciolone, M. , A Power Recirculating Test Rig for Ball Screws: A New Perspective for Endurance Tests. Machines 2020, 8. [Google Scholar] [CrossRef]

- Zhang, X.C.; Luo, T.J.; Han, T.; Gao, H.L. , A novel performance degradation prognostics approach and its application on ball screw. Measurement 2022, 195. [Google Scholar] [CrossRef]

- Breuneval, R.; Clerc, G.; Nahid-Mobarakeh, B.; Mansouri, B.; Guyamier, A. , Identification of a roller screw for diagnosis of flight control actuator. 2016 Ieee International Conference on Prognostics and Health Management (Icphm), (2016).

- Chirico, A.J.; Kolodziej, J.R. , A Data-Driven Methodology for Fault Detection in Electromechanical Actuators. J Dyn Syst-T Asme 2014, 136. [Google Scholar] [CrossRef]

- Riaz, N.; Shah, S.I.A.; Rehman, F.; Gilani, S.O.; Udin, E. , A Novel 2-D Current Signal-Based Residual Learning With Optimized Softmax to Identify Faults in Ball Screw Actuators. Ieee Access 2020, 8, 115299–115313. [Google Scholar] [CrossRef]

- Zhu, Z.Y.; Wang, L.Z.; Peng, G.L.; Li, S.J. , WDA: An Improved Wasserstein Distance-Based Transfer Learning Fault Diagnosis Method. Sensors-Basel 2021, 21. [Google Scholar] [CrossRef]

- Chang, M.C.; Liou, J.L.; Wei, C.C.; Horng, J.H.; Chiu, Y.L.; Hwang, Y.C.; Lin, J.F. , Fractal Analysis for Vibrational Signals Created in a Ball-Screw Machine Operating in Short- and Long-Range Tribological Tests. J Tribol-T Asme 2013, 135. [Google Scholar] [CrossRef]

- Shan, P.F.; Lv, H.; Yu, L.M.; Ge, H.H.; Li, Y.; Gu, L. , A Multisensor Data Fusion Method for Ball Screw Fault Diagnosis Based on Convolutional Neural Network With Selected Channels. Ieee Sens J 2020, 20, 7896–7905. [Google Scholar] [CrossRef]

- Pandhare, V.; Li, X.; Miller, M.; Jia, X.D.; Lee, J. , Intelligent Diagnostics for Ball Screw Fault Through Indirect Sensing Using Deep Domain Adaptation. Ieee T Instrum Meas 2021, 70. [Google Scholar] [CrossRef]

- Nguyen, T.L.; Ro, S.K.; Park, J.K. , Study of ball screw system preload monitoring during operation based on the motor current and screw-nut vibration. Mech Syst Signal Pr 2019, 131, 18–32. [Google Scholar] [CrossRef]

- Yin, C.; Wang, Y.L.; He, Y.; Liu, L.; Wang, Y.; Yue, G.N. , Early fault diagnosis of ball screws based on 1-D convolution neural network and orthogonal design. P I Mech Eng O-J Ris 2021, 235, 783–797. [Google Scholar] [CrossRef]

- Azamfar, M.; Li, X.; Lee, J. , Intelligent ball screw fault diagnosis using a deep domain adaptation methodology. Mech Mach Theory 2020, 151. [Google Scholar] [CrossRef]

- Di Rito, G.; Luciano, B.; Borgarelli, N.; Nardeschi, M. , Model-Based Condition-Monitoring and Jamming-Tolerant Control of an Electro-Mechanical Flight Actuator with Differential Ball Screws. Actuators 2021, 10. [Google Scholar] [CrossRef]

- Yin, Z.Y.; Yang, Y.; Shen, G.J.; Chen, L.; Hu, N.Q. , Eight-DOF Dynamic Modeling of EMA Mechanical Transmission and Spalling Fault Characteristic Analysis. Actuators 2022, 11. [Google Scholar] [CrossRef]

- Ismail, M.A.A.; Balaban, E.; Windelberg, J. , Spall Fault Quantification Method for Flight Control Electromechanical Actuator. Actuators 2022, 11, 29. [Google Scholar] [CrossRef]

- Butler, Q.; Ziada, Y.; Stephenson, D.; Gadsden, S.A. , Condition Monitoring of Machine Tool Feed Drives: A Review. J Manuf Sci E-T Asme 2022, 144. [Google Scholar] [CrossRef]

| Feature | Linear Motor | Pneumatic Servo System | Hydraulic Servo System | Gear Rack System | Ball Screw Mechanism | Planetary Roller Screw |

| Load Capacity | − | + | ++ | + | + | ++ |

| Rigidity | ± | − | + | + | ± | + |

| Lifespan | + | + | + | + | + | ++ |

| Speed | + | ++ | ± | + | ± | ++ |

| Efficiency | N/A | ± | ± | ++ | ++ | + |

| Friction | − | ± | − | − | − | − |

| Shock Resistance | + | + | ++ | + | ++ | ++ |

| Controllability | Easy | Very Difficult | Difficult | Easy | Easy | Easy |

| Leakage | ✗ | ✓ | ✓ | ✓ | ✗ | ✗ |

| Relative Size | − | + | + | + | ± | − |

| Installation | Simple | Complex | Complex | Simple | Simple | Simple |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).