1. Introduction

Dental implants are a widely used option for oral rehabilitation when one or more natural teeth are missing. Although implants have a high survival rate, marginal bone loss frequently occurs. This compromises the long-term prognosis of implants since early marginal bone loss seems to increase the risk of peri-implantitis. Moreover, excessive bone loss may lead to soft tissue recession, implant exposure and esthetic problems[

1].

Traditionally an implant was defined successful when less than 1.5 mm of bone were lost during the first year of function and less than 0.2 mm annually thereafter. However, this is difficult to accept, especially in the esthetic area where a bone loss even lower than 1.5 mm could dramatically affect the esthetic outcome of our restorations. For this reason, many researches in the last years had focused their attention on the best options to preserve the buccal bone plate and soft tissues especially in the esthetic zone[

2]. The sub-crestal placement of the implant shoulder was proposed to obtain a more comfortable prosthetic emergence profile and improve soft tissue esthetic results. Unfortunately, after the connection of the abutment and placement of the final prosthesis, a “physiological” adaptation of the bone was observed around two-piece implants, both horizontally and vertically. This increased loss may be caused by the bacterial colonization of the micro-gap[

2].

Implant-supported prostheses can be either screw- or cement-retained. They have traditionally been composed of an implant, an abutment and a screw that joins both pieces providing structural integrity to the restoration. This type of dental restoration is known as implant-supported, directly attached or direct-to-implant restoration. Screw-retained ones are popular because they are easily retrieved for maintenance. In the traditional implant prosthesis, the prosthetic screw was intentionally designed as the weakest link within the system. Precisely, in this type of restoration a punctual excessive occlusal force (overload) or the succession of moderate loads over time (fatigue) can lead the screw to mechanical failure and, as a consequence, to the failure of the dental restoration[

3,

4,

5]. However, it may be seen as an advantage the fact that, in case of any mechanical stress challenging the prosthesis, the screw would take up the stress without endangering the bone-implant interface[

6].

The topic under study is of great relevance because some of the most common complications in implant prosthodontics have been mechanical complications. Abutment screw loosening has been reported as the most common prosthetic complication, which has been associated with preceding the more challenging abutment screw or even implant fracture[

7,

8]

The incidence of abutment screw fracture has been examined by certain authors, such as Katsavochristou and Koumoulis. These authors concluded that the incidence of screw loosening falls within the range of 7% to 11%. Interestingly, the occurrence of abutment screw fracture remains much lower, specifically at 0.6%[

7]. Due to the lack of standardized study designs and the great diversity of implant prosthetic components, data should be taken with caution, but should be utilized for further evaluation of each implant system individually.

We already know that the etiology of mechanical failures is rather multifactorial and includes both, patient and mechanical, parameters: such as the crown height, type of the implant connection, the direction of the load, cusp inclination, size of the occlusal table, and implant angulation[

7,

9].

Several authors have investigated the most common mechanical complications in single dental implants, as well as how complication rates are influenced by various clinical factors. For Lee et al.[

10] the incidence of mechanical complications was 18.1%. The rates of occurrence of abutment screw loosening [ASL], abutment screw fracture [ASF], and ceramic fracture [CF], repeated ASL, and repeated CF were 12.7%, 1.4%, 4.1%, 1.8%, and 0.9%, respectively. Excessive or parafunctional mastication dynamics (e.g., high occlusal force, bruxism, and clenching) and anatomic characteristics (e.g., alveolar bone resorption, presence of the inferior alveolar nerve or maxillary sinus floor, and bone quality) can cause occlusal overloading and/or non-axial loading, increasing the risk of mechanical complications in the posterior region.

Mechanical complications continue to be reported in the literature, and their clinical management can be often very challenging for the clinician while there is no consensus on the ideal management[

7]. Rescuing the fragment of a fractured abutment screw without damaging the remaining implant components has found to be often not possible. If this is not achieved, it may be necessary to remove the implant.

Moreover, in the early days of implant dentistry, and with this kind of restorations, healing abutments were disconnected and reconnected several times, for example, during impression taking, fitting of the restoration and then for its placement. As it was considered inevitable, little attention was paid[

1]. Repeated disconnection and connection of theses abutments result in a negative bone response that manifests as bone loss at the marginal ridge level, accompanied by apical soft tissue migration[

11].

In order to overcome these problems, prosthetic procedures were modified and the “one-abutment one-time” protocol was introduced. This protocol included the placement of the permanent abutment immediately after implant placement, hereby eliminating the need for multiple implant–abutment disconnections[

1,

11]. As a result, the fragile soft tissue seal around an implant is not disrupted, obtaining stability of soft tissue dimensions[

11,

12]and marginal bone is expected to be maximally preserved[

1,

11].

That is how, alternatively to the two pieces restorations, the use of a Multi/Unit abutment (also known as transmucosal or transepithelial abutment) between implant and abutment is an increasingly common practice that brings numerous advantages from a clinical point of view. Firstly, it allows the possibility of mounting the transepithelial abutment immediately after implant placement, avoiding the need to remove it later. This allows working at the tissue level rather than the bone level during the next visit to the clinic.[

13]. Secondly, it allows to decide both the prosthetic emergence and height even once the implant is inserted, selecting the transepithelial component that best suits each case[

14]. Thirdly, the transepithelial component favors sealing at the level of the implant platform[

14].

As a consequence of some of the advantages mentioned above, several studies assure a lower crestal bone loss for restorations using a transepithelial component compared to direct-to-implant restorations[

1,

2,

14,

15]. With this kind of transepithelial abutment, “one-abutment one-time” protocol can be followed, and therefore benefit from the advantages that it brings. Although its use has shown great advantages when used for the rehabilitation of multiple implants, their use in single-unit implants is less common and few articles have been found regarding this topic.

However, evaluating stress distribution clinically in the implant-supported prostheses is problematic. Therefore, finite element analysis (FEA) has been widely used for the mechanical testing of dental implants[

16,

17]. This method reflects the complexity of clinical conditions and has benefits over many analysis methods[

17,

18,

19]. Data from FEA studies could be carefully extrapolated to the daily clinical practice to improve understanding of different scenarios, offering a suitable degree of reliability and accuracy without the risk and expense of implantation.[

20].

This method has been used as a tool to predict, for example, stresses in the peri-implant region and in the components of implant-supported restorations. Mathematically, FEA depends on using numerical techniques in solving partial differential equations that govern the simulation problem. With FEA, the structures are to be converted into meshes using a computer software. The resulting models consist of elements, nodes, and pre-defined boundary conditions. During the simulation, the loads are to be applied on specific nodes or elements specified by the user and then the displacement and stresses will be evaluated as a result for running the simulation analysis. The FEA has been applied in many aspects of implant dentistry such as the shape and design of restorations, crowns or dental implants[

20].

It is necessary to understand the biomechanics of implant-supported restorations in order to design correctly a FEA. In implant dentistry, as we have already said, the abutment is usually connected to the implant by a retention screw. A tightening preload must be applied through this screw to prevent loosening of this implant-abutment connection[

16,

21]. This preload is positively correlated with the screw-tightening torque, but only 10% of the torque is converted into the preload; the remaining 90% is used to overcome the friction between the surfaces of the joint of the components. The preload is the tension generated in the screw and the complementary clamping force between the head of the screw and the abutment. It is maintained by friction between the abutment-screw thread and the internal thread of the implant. When the abutment screw is tightened, a compressive force is generated along the interface between the abutment screw thread and the internal thread of the implant. Increasing the torque can increase the stability of the abutment-to-screw joint. The preload needs to be higher than the occlusal force to achieve a stable screw joint and to avoid screw loosening. Optimum preload should induce a force in the screw joint that is 75% of the yield strength of the screw[

16]. However, excessive preloads can create screw stresses that exceed the yield limit of the material, resulting in plastic deformation of the screw threads and, hence, screw loosening or even fracture of this screw. The higher stresses created by excessive preloads can accelerate fatigue failure[

21].

Screw loosening or fracture of screws is indeed a significant concern in implant-supported restorations. Achieving the right preload is crucial to prevent these complications and ensure long-term success[

16]. Making sure we follow the torque specifications set by the manufacturer is critical to avoiding problems and ensuring optimal operation. This recommended torque varies among implant manufacturers, ranging from 18Ncm to 45Ncm. Inadequate tightening may result in joint separation and screw failure through fatigue, loosening, or even fracture[

21].

The comprehensive relationship of the direction of load, center of rotation, and stress distribution on the implant restoration simultaneously has been barely investigated. Understanding the loading point and direction of load is critical for designing implant prostheses that can withstand functional forces while minimizing stress concentration. Some author such as Kim et al.[

9] have researched the correlation between the stress level and various directions of the load on the occlusal surface in a FE study. The stress level was increased as the direction of the vector changes from the center of the implant connection[

9].

Therefore, to complement the clinical studies that evaluate the clinical performance of single implant restorations and to begin to gather evidence regarding the mechanical behavior of this type of restorations when we incorporate a transepithelial component, this study assesses the impact of using a transepithelial component versus a direct implant-supported restoration on the fatigue behavior of single dental implants. This study is carried out by using the Finite Element Method (FEM) and was experimentally validated. To the best of our knowledge, this is the first time an experiment has been conducted to analyze the biomechanical advantages of using intermediate abutments in the rehabilitation of single-unit implants.

2. Materials and Methods

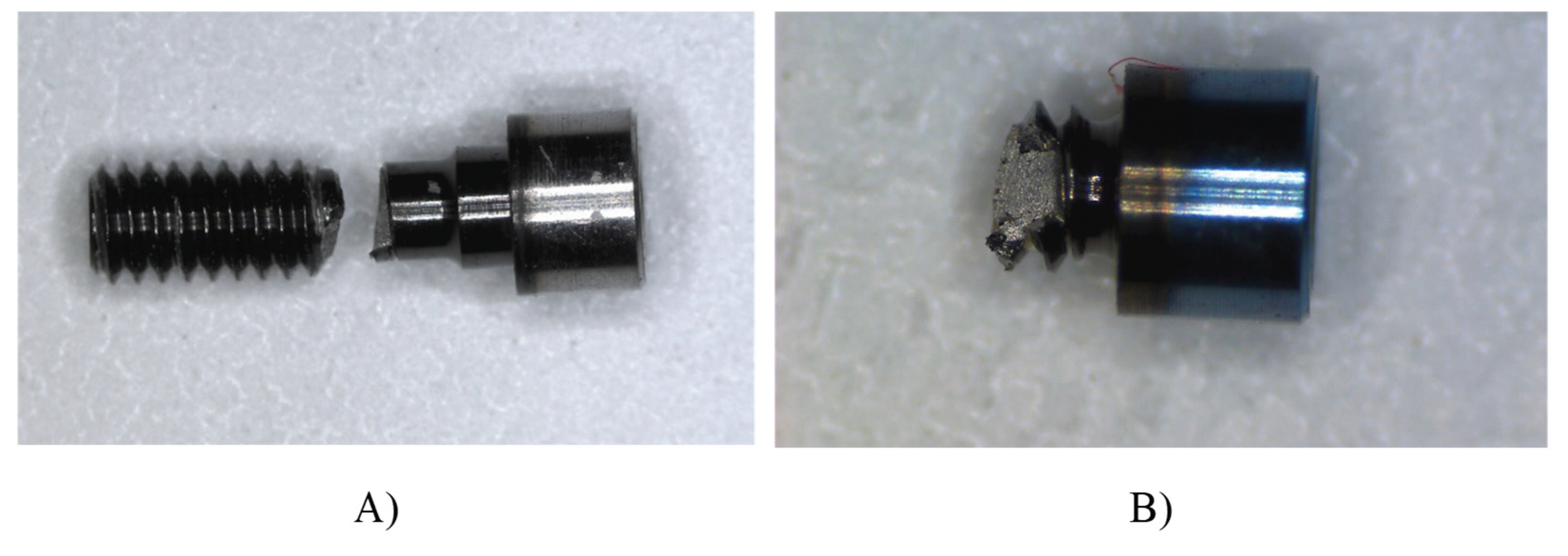

An IIPSCA4513 Interna Plus implant of 4.5mm diameter and 13mm length was selected. Two implants were inserted in cortical bone yuxtacrestally, that is, leaving implant-abutment platform at bone level. In the first case, an INPPTU44 abutment was mounted. The post was attached to the implant by means of the INTTUH screw tightened at 35Ncm. In the second case studied, a INTMIPU20 transepithelial abutment was mounted on the implant, tightened at 35Ncm. A CPMIUPU abutment was mounted on top, being joined to the assembly by means of the TTMIR prosthetic screw, tightened at 20Ncm. The implants, abutments and transepithelial bodies are made of pure grade 4 titanium (Ti CP4) while the screws (including the one that comes with the transepithelial) are made of Ti6Al4V extra low interstitials (ELI) (Ti Gr 5) with the chemical composition indicated in

Table 1.

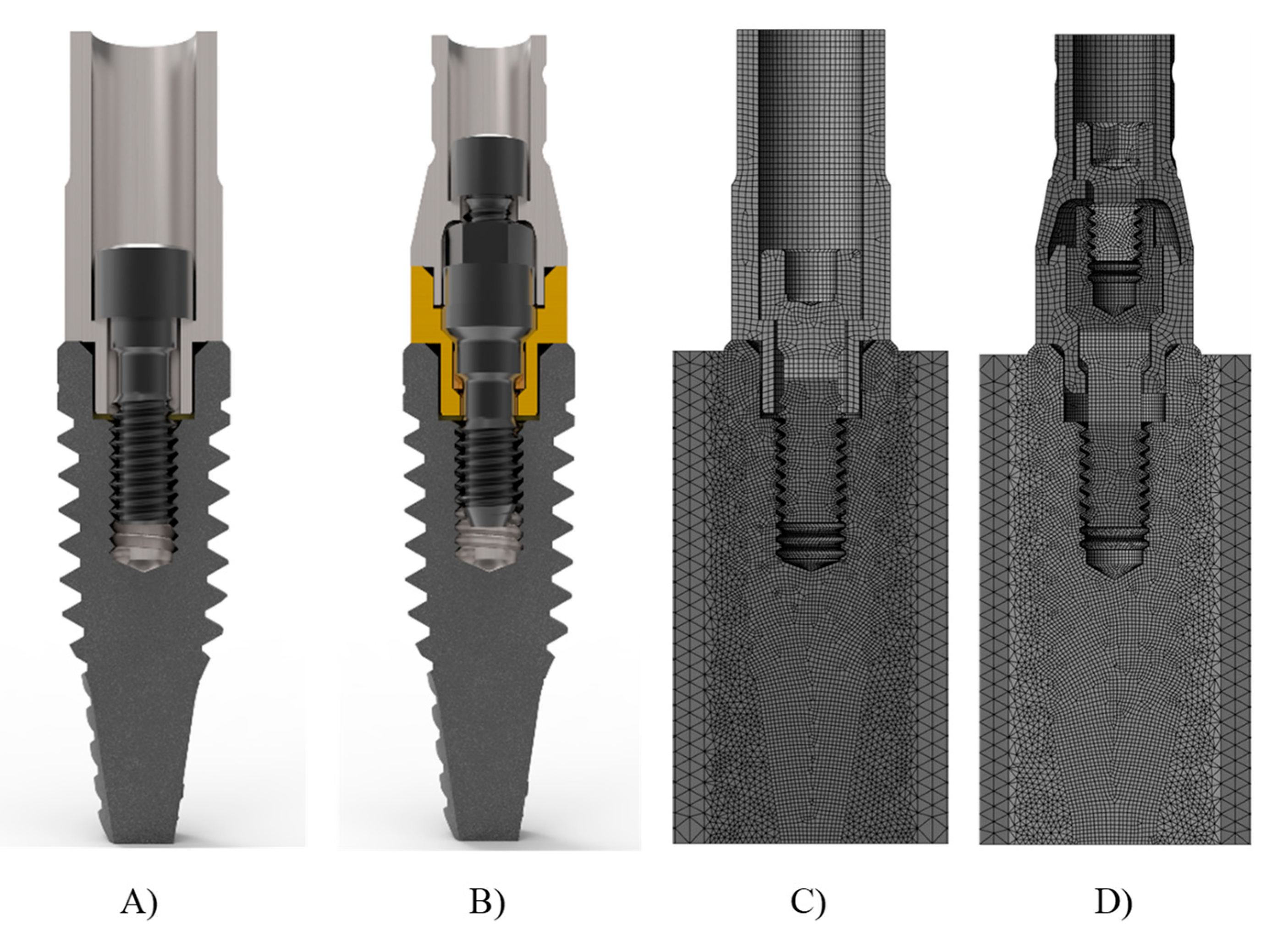

Figure 1A and B show the 3D models of the two dental restorations used in the study. FE analyses have been performed in Ansys Workbench

® 19R1. A (cyclic) chewing force is simulated with an inclination of 30° with respect to the vertical, as indicated in ISO 14801[

22].

In general, two types of loads have been applied in many studies, vertically and 30° obliquely[

9]

In order to consider a more severe case, and possibly also more realistic, the load has been applied at 10.5mm height from the implant abutment connection (IAC)[

23].

The stress level of the implant increases with increasing crown height, which appears to be a more critical factor than the crown-implant ratio. This is related to the class I lever effect. The fulcrum, load arm, and effort arm should be considered carefully to understand the stress distribution of the implant restoration[

9].

Taking advantage of the symmetry of both load and model geometry, only half restoration has been modeled and consequently, half of the preload and external load has been applied. The threads of the screws and the internal thread of the implant have been modeled as cylindrical threads instead of helical since this simplification does not imply an error greater than 3.5%[

24].

Figure 1C and D show the mesh of the two models under study, with a total of 2.7M DoF. Both titanium materials have been modeled as linear elastic with E=103GPa, v=0.35 for CP4 and v=0.31 for GR5 while cortical bone was modelled, also as linear elastic, with E=13 GPa, v=0.37. Contacts have been defined as frictional contacts with friction coefficient of 0.17 for screw-implant, screw-post and screw-transepithelial contacts and 0.21 for implant-post, implant-transepithelial and transepithelial-cylinder contacts[

25].

The FEA performed consist of two or three load steps, depending on the case under study. First, the screw preload corresponding to the recommended tightening torque is applied by means of a pretension section. In the case of direct-to-implant restoration, this is done in the first load step. In the case of transepithelial-supported restoration, a first load step will be necessary to preload the implant screw and a second load step to preload the prosthetic screw on the transepithelial component. This preload is calculated using the Motosh formula[

24] and results in 814N (direct to implant), 688N (transepithelial) and 572N (prosthetic screw over transepithelial). In a similar study the preload of 825 N as a body force was applied on the upper part of the shank of the abutment screw, where the elongation of the screw was expected with tightening

.

Once the screw preloads have been applied, a final loading step is used to apply the masticatory load with values from 0 to 400N.The simulated bite forces employed in our finite element study were up to 400N as it has been seen in other similar studies[

26].

From the FEA, contact reactions at the screw head were obtained: axial force, transverse force and bending moment. These forces, once transferred to the critical section, the first thread in contact, have been used to calculate the nominal stress in this section. Since the load cycle determined by the ISO14801[

22] varies sinusoidally from the maximum load and the 10% of this load, the nominal stress value at these two values of the load cycle were recorded. With both nominal stress values obtained, the effective fatigue stress is determined to later compare its behavior under a succession of masticatory loads.

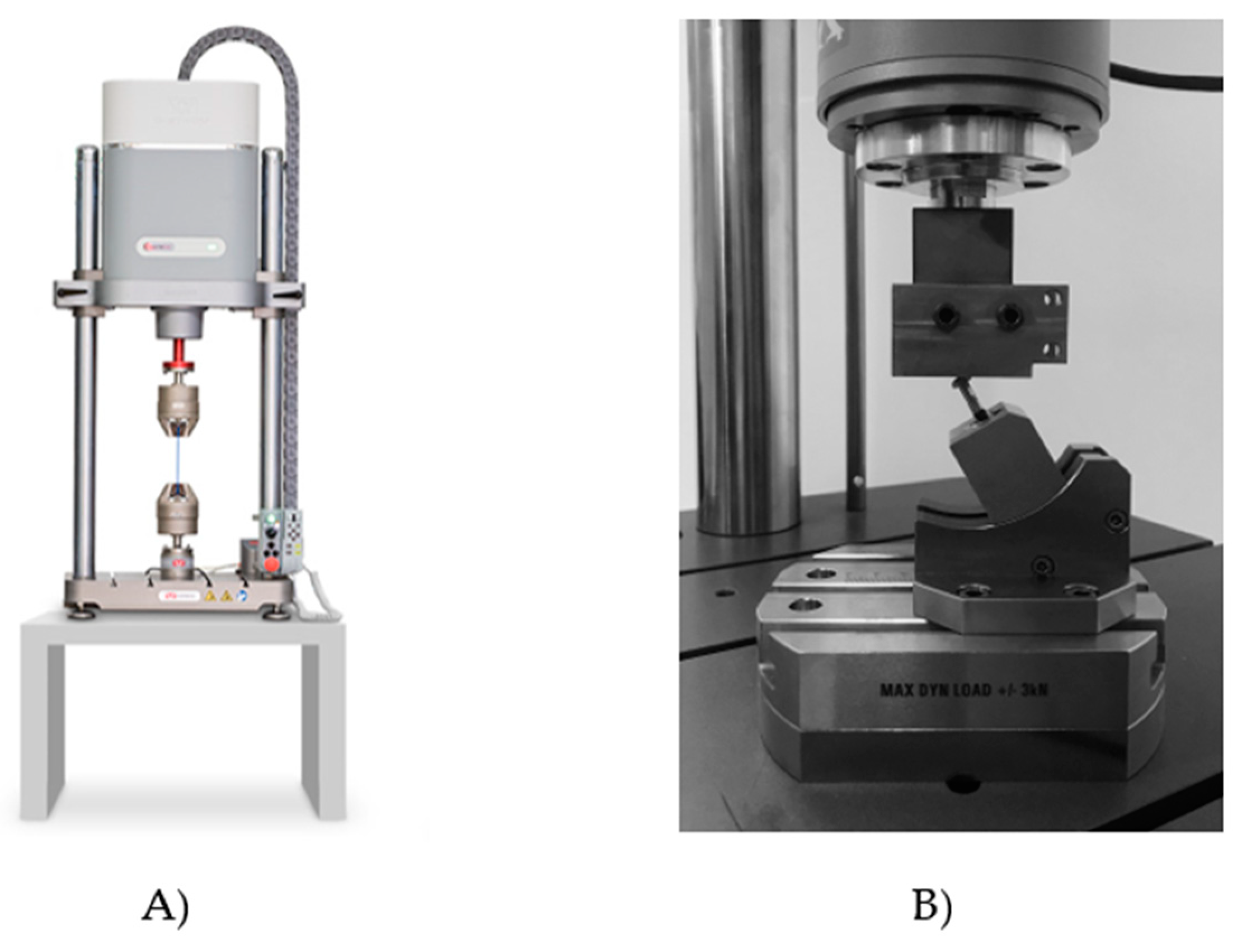

Finally, in order to verify that the breakages are produced by the site assumed by the FEM, a cyclic load has been applied to three samples of each of the two dental restorations under study: the direct-to-implant and the transepithelial-supported restorations. The load was applied until a breakage of the dental restoration was detected and the component on which the breakage occurred was identified. The tests were performed on an INSTRON E 3000 Electropuls fatigue bench mounted with a DYNACELLTM 2527-153 load cell with a load range of ±5-kN. The setup is the same as explained in the FE analysis modeling, except for the specimen holder, that in this case is made of steel rather than cortical bone. Moreover, in order to facilitate a correct load application, a hemispherical device has been added over the abutment to ensure that the load is applied at 10.5 mm from the height of the implant platform, as is done in the FEA.

Figure 2A show a direct tension fatigue machine with standard fixtures for testing material specimens and

Figure 2B show specific set-up for conducting tests on dental restorations.

4. Discussion

In this study, we investigate how the use of a transepithelial component compares to a direct implant-supported restoration in terms of fatigue behavior. Given that one of the most common complications in single-unit restorations on implants is screw loosening or even fracture, it is intriguing to analyze force distribution when adding an intermediate component. Additionally, investigating whether using a transepithelial abutment can prevent the dreaded fracture of the direct implant-to-screw connection, which could render the implant nonfunctional, is of significant interest.

We have demonstrated that the component most likely to fracture is the screw of the intermediate abutment. In such cases, removing the fractured fragment or, in the worst scenario, the intermediate abutment itself is sufficient. Importantly, the implant remains uncompromised.

Considering the significance of preload in preserving the structural and interfacial integrity of the implant abutment assembly, Honório et al.[

21] conducted a study to evaluate the impact of varying preloads on the stress experienced by the retention screw and the microgap width of the internal conical connection. They employed Finite Element Analysis (FEA) with a well-established model for preload assessment. This research sheds light on optimizing preload to enhance the performance and longevity of dental implant components. When the screw-tightening torque was increased from 20 Ncm to 30 Ncm, it led to higher stresses in the abutment screw throughout various phases: before, during, and after occlusal loads. However, this higher torque also had some interesting effects such as smaller microgaps. The higher torque also increased the occlusal load required to bridge the internal implant space. This could potentially help reduce bacterial leakage. Interestingly, the study found that the maximum stress in the abutment screw occurred at its neck on the distal surface. This suggests that the screw is more likely to fail in this specific region[

21]. This is consistent with the results obtained in our study.

Furthermore, FEA can be used for sensitivity analysis to study the effects of varying material and geometrical parameters such as coefficient of friction, screw diameter, screw design, and length of the implant fixture. Within the range of loads (10N - 280N) tested in this FEA study, the gap sizes, especially those within the bridging zone, may not be large enough for the invasion of bacteria, the size of which can reach 6µm. Therefore, further studies are needed to correlate interfacial gap opening and bacterial microleakage[

21].

Jung et al.[

16] investigated in a FE study the effects of abutment screw preload in two different implant connection systems. Six 3D finite element models were created based on various conditions: EO, External hexagonal connection system with preload only; EN, External hexagonal connection system with occlusal load only (no preload); EP, External hexagonal system with both preload and occlusal load; IO, Internal hexagonal system with preload only; IN, Internal hexagonal system with occlusal load only and IP, Internal hexagonal system with both preload and occlusal load. An 11.3-degree oblique load (100 N) was applied to the crown’s occlusal surface for models with occlusal load and a preload of 825 N was applied to the abutment screw in models. The abutment screw experienced the greatest increase in von Mises stress values under occlusal load. Stress values ranged from 104.5 MPa (model EN) to 850 MPa (model EP) and from 37 MPa (model IN) to 674 MPa (model IP). Following the implant, the abutment showed the next highest stress levels. This study highlights the importance of considering preload conditions and connection system designs when evaluating the biomechanical behavior of dental implants. Understanding stress distribution patterns can contribute to the long-term success of implant-supported restorations[

16]. Regardless of the conditions of occlusal load, the models with preload showed higher stress values than the models without preload in both external and internal connection systems. It seems essential to consider including the preload condition in finite element analysis. Preload applied to the abutment screw influences the stress level in the implant system and bone.

Verri et al.[

17] carried out a similar FE study to analyze the stress distributions of single implant-supported prostheses with different connections (external hexagon EH, internal hexagon IH, or Morse taper MT) in the anterior region of the maxilla, while varying the inclination of the applied load (0, 30, and 60 degrees) and the surgical technique for implant placement (monocortical/conventional, bicortical, and bicortical with nasal floor elevation)[

17].

In this study conducted by Verri et al. EH implants exhibited higher stress levels on the fixation screw and implant, ranging from 100 to 600 MPa. However, these stress values did not necessarily affect implant viability. The stress primarily indicated a mechanical tendency for issues like screw loosening or failure, rather than posing a biological risk. The study found that the worst situations occurred under 60-degree loading. It’s important to note that implants in clinical practice are typically not subjected to such large oblique forces. Internal connection implants showed a tendency toward implant-related problems. However, the amount of stress required to loosen the fixation screw of an EH implant should be less than the stress needed to fracture titanium. This observation might explain why EH implants are sometimes associated with more biomechanical issues than IC implants[

17].

4.1. Impact of the Design of the Restoration

Whether prosthetic restorations supported by implants of different sizes and diameters placed adjacent should be separate or splinted is unclear. While splinted restorations may offer advantages in stress distribution, individual patient factors and clinical realities play a significant role. The restoration designs can change stress levels in adjacent implants of different lengths and diameters. Kul et al.[

19] analyzed the stress and strain distribution around short and standard implants in the posterior mandible with splinted and separate crowns. Practical clinical considerations from the results of this study include the importance of an optimal and stable implant-abutment connection that plays a crucial role in the long-term success of dental implants, because the stress is reduced. Oblique loads (loads applied at an angle) have a greater moment effect than purely vertical loads. As the angle between the direction of the oblique load and the implant axis increases, the moment effect becomes more pronounced. These oblique loads can significantly influence stress distribution in implant-supported restorations. If a standard implant and a short implant are placed adjacent and restored with splinted crowns, the implants, abutments, and screws may be damaged; therefore, adjacent splinted implants should be of similar size. However, the perfect fit of the implant-abutment junction reduces stress, even in this adverse situations[

19].

Other variables to take into account during the manufacture of our restorations are: retention system (usually either screw or cement retained) and the type of restorative material used, that can also affect the stress distribution. For many years, metal-ceramic prostheses have been considered by some clinicians to be the gold standard of rehabilitation with an implant supported prosthesis. However, currently, there is increasing demand for metal-free restorations as a more esthetic rehabilitative treatment option, such as zirconia. Lemos et al.[

27] evaluated different implant-abutment connections, retention systems, and restorative materials in single crowns Using 3D FEA. There was a higher concentration of stress in the fixation screw for the cemented prostheses in the external hexagon implants, independent of the restorative materials used (increasing the risk of screw loosening/fracture). And, it should be taken into account that in the event of screw loosening, the solution is more complex than in screwed ones. Therefore, the combination of external hexagon implant and cement-retained prosthesis should be avoided[

27].

Metal-ceramic and zirconia monolithic implant-supported single crowns had similar biomechanical behaviors in the bone tissue, implants, and their components. For Lemos et al., the similarities between the metal-ceramic and zirconia monolithic prostheses may be attributed to similar mechanical properties which may contribute to the sharing of stress across structures[

27].

However, other authors such as Punmil et al.[

28] think differently regarding the influence of the material on the transmission of loads. The comparative 3D FEA study of stress distribution in implant, screw, Ti-base, abutment, and restorative crown between the different customized abutment types has not been evaluated, and the proper abutment type selection for the implant supported single crown is still an ambiguous issue. Therefore, Punmil et al.[

28] introduced a study to investigate stress distribution with 3D FEA on the implant, screw, Ti-base, abutment, hybrid-abutment-crown, and restorative crown among different abutment types as follows: customized titanium abutment, customized titanium hybrid-abutment-crown, customized zirconia abutment with Ti-base, and customized zirconia hybrid abutment-crown with Ti-base. For all groups, oblique loading tends to generate higher stress values compared to purely vertical loads. Clinicians should avoid excessive oblique forces to prevent stress-related complications. They concluded that the choice of abutment type significantly impacts stress distribution in implant-supported restorations. The presence of a titanium base within a zirconia abutment improves stress distribution. Titanium has the ability to absorb stress, contributing to overall stability. This combination is a favorable option for implant-supported crowns. A customized titanium hybrid-abutment-crown created stress concentration at screw and this abutment type should be used cautiously and maintained regularly. In addition, a customized zirconia hybrid-abutment-crown with titanium base made stress concentration at implant and this abutment type should be maintenance regularly. A thoughtful selection of abutment materials and diligent maintenance are crucial for successful implant restorations[

28].

4.2. Impact of Intermediate Abutments

In relation to the use of intermediate abutments, Zincir et al.[

18] compared the stress and strain values of the direct to implant system with the conventional angled multiunit abutment-implant connection system used in “all on four” rehabilitations, in the implant parts and surrounding bone using FEM. In the context of axial and oblique forces, they found that direct to implant systems exhibit greater stress accumulation in bone, prosthesis screws, and implants when compared to multiunit abutment-implant connection systems[

18]. These results are in line with those reported in this study.

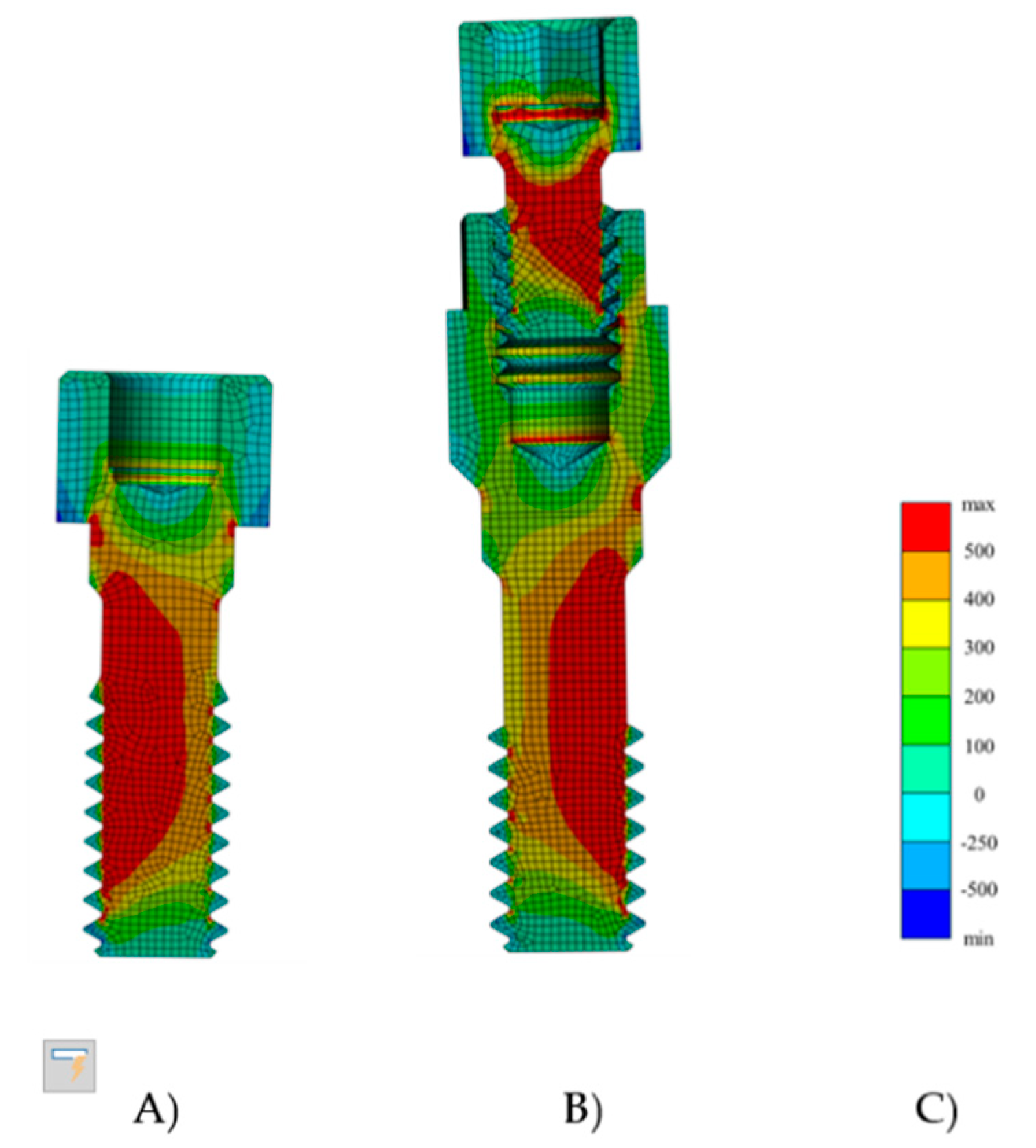

As seen in the stress map of the screws of the two dental restorations (

Figure 3) in the case of transepithelial-supported restorations, in the event of an overload, the top screw would be the one that breaks. This prevents the rest of the restoration from being damaged.

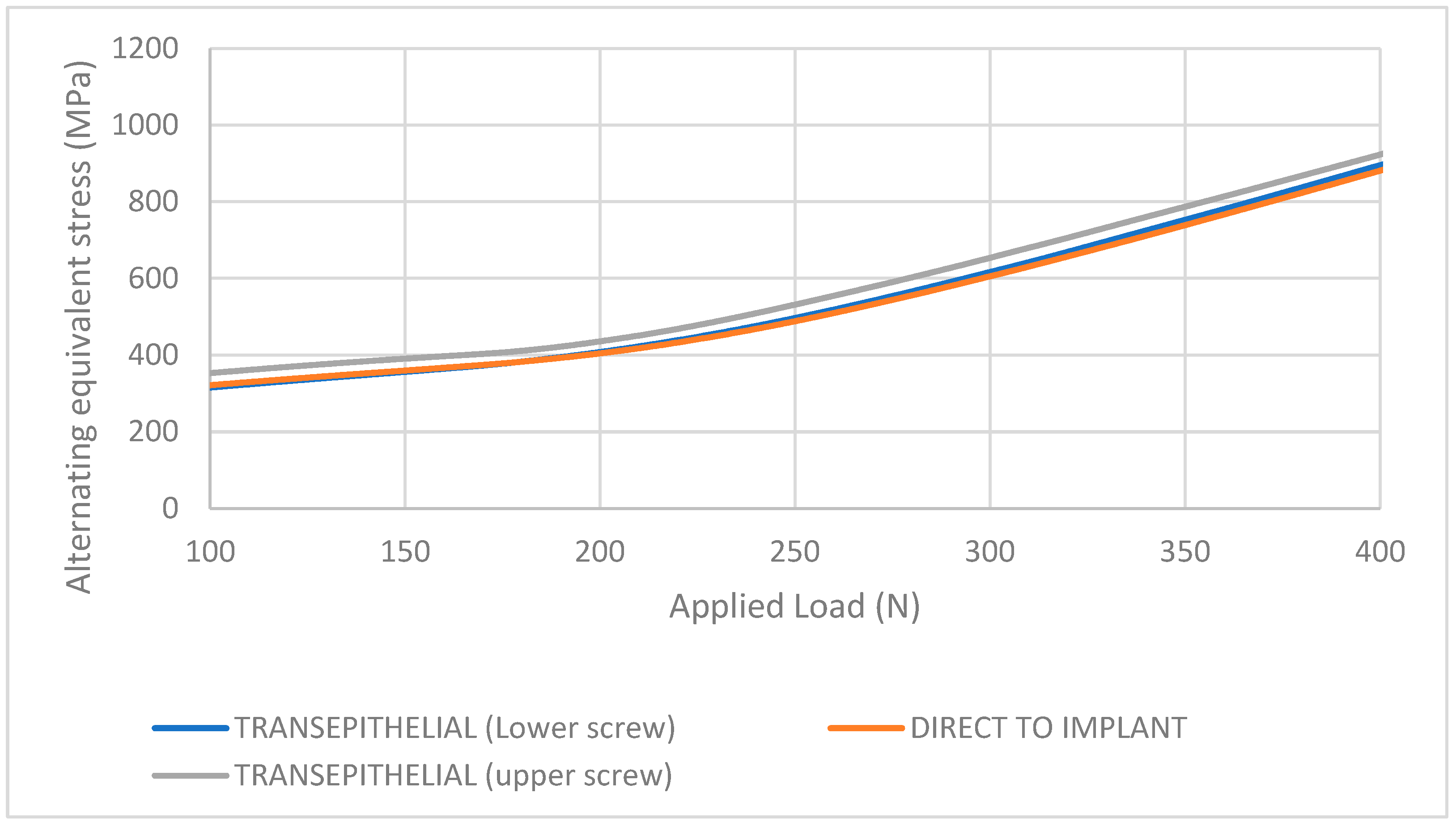

It is worth mentioning that the stress level of the upper screw (

Figure 4) indicates that the fatigue life of the screw of the intermediate abutment would be slightly lower than in the case of direct-to-implant restoration. However, it should be noted that the difference is minimal, so this reduction in fatigue life may not be relevant in the patient’s mouth. In any case, the fact that the upper prosthetic screw acts as a fuse, as mentioned above, serves to protect the rest of the dental restoration. It is beneficial that, in the event of a fracture, it is the abutment screw that usually suffers from it, as we have seen in this study

. Furthermore, in case of needing repair, this would be done at the tissue level; that is, replacing the upper screw and, at most, also the abutment, without touching the implant abutment connection or the bone surrounding it. Therefore, these advantages far outweigh the minimal reduction in fatigue life mentioned above.

However, there are additional potential benefits. Even if the screw does not break, when screw loosening occurs, we are aware of biological implications. The microgap at the implant interface permits fluid passage independently of the implant system. Functional rocking effects and screw loosening may contribute to increased leakage. Moreover, the clinical phenomenon of bleeding and malodor characteristic of anaerobic bacteria on the removal of abutments or healing screws may be the result of, in part, the effects of microleakage[

29].

When the implant-abutment interface is positioned at the alveolar bone level, it leads to persistent peri-implant inflammation and significant bone loss. This suggests that the inflammatory stimulus originates precisely at the implant-abutment interface, and there exists a direct relationship between the extent of inflammation and the magnitude of alveolar bone loss[

30].

Abutment screw loosening, as we have already said, is a common mechanical complication in dental implants. It occurs primarily because the abutment screw is the weakest part of the implant system. Stable connections between implant components are crucial for treatment success. A review by Goodacre et al.[

31] revealed that screw loosening occurs in 8% of cases, and this figure can rise to 45% in single crowns. Additionally, abutment screw loosening may lead to other complications, including screw fracture, marginal gap, peri-implantitis, microbial leakage, crown loosening, and patient discomfort[

32].

To mitigate this, it is essential to ensure optimal component fit, minimize abutment micromovement, reduce prosthetic misfit, optimize prosthetic design and occlusion, and maintain sustained preload[

29].

The use of an intermediate abutment in single implant restorations offers several advantages. Firstly, the implant-abutment interface remains better sealed, avoiding disconnection during prosthesis fabrication. This inherently reduces contamination and minimizes microleakage around the implant platform. Additionally, as mechanical overload primarily affects the abutment screw, it is more likely to loosen. Importantly, this loosening occurs away from the bone crest, mitigating potential biological complications and preventing marginal bone loss.

Although the use of intermediate abutments has been more commonly accepted in multiple implants, it is not as common in single implants. Not all commercial implant manufacturers offer this possibility yet. However, following the results of this study, we can emphasize that, among the other advantages already described of using an intermediate abutment, in the event of a fracture of the abutment screw, it would be possible to remove it and put in a new one. Or, worst case scenario, when trying to rescue the fragment of the screw the abutment could be damaged, but not the implant. And, in the event of screw loosening, it will not happen at the implant-abutment interface. Consequently, there may be a reduction in biological complications related to microfiltrations, although research and further investigation are essential for advancing our understanding and addressing unanswered questions

Limitations of the study: Finite Element Analysis (FEA) has its limitations, and critical considerations are necessary when interpreting its results. FEA relies on input material properties, which may not perfectly mimic real-world conditions. Variations in material behavior can impact simulation outcomes. Clinicians should be cautious when directly applying FEA findings to clinical practice because it is a virtual model and cannot fully replicate the complexities of biological tissues. Clinical validation is essential to confirm the observed biomechanical effects. However, FEA provides valuable insights and its findings should be complemented by empirical evidence from clinical studies.

Practical clinical applications: With the results obtained in this study, we can affirm that the use of intermediate abutments may be beneficial when rehabilitating our single-unit implants. The use of these abutments has been relatively common in multiple implant rehabilitations but, until now, not so much in single-unit implants. The biomechanical advantages that their use can provide seem to be proven.

Future research directions: Future studies that incorporate even more sophisticated models are essential. These studies would allow for a comprehensive evaluation, for example, of the impact of simulating the preload condition in the abutment screw during advanced Finite Element Analysis (FEA) applications. By considering these factors, researchers can gain deeper insights into the behavior of implant-supported restorations and enhance clinical outcomes.

It should be taken into account that this study has been limited to analyzing the mechanical behavior of a specific transepithelial abutment model. There are transepithelial abutments with different prosthetic emergences and it is possible these different prosthetic platforms have influence on the behavior of the prosthetic screw (the upper screw). This study is proposed as a future line of the current research.