Submitted:

15 March 2024

Posted:

18 March 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

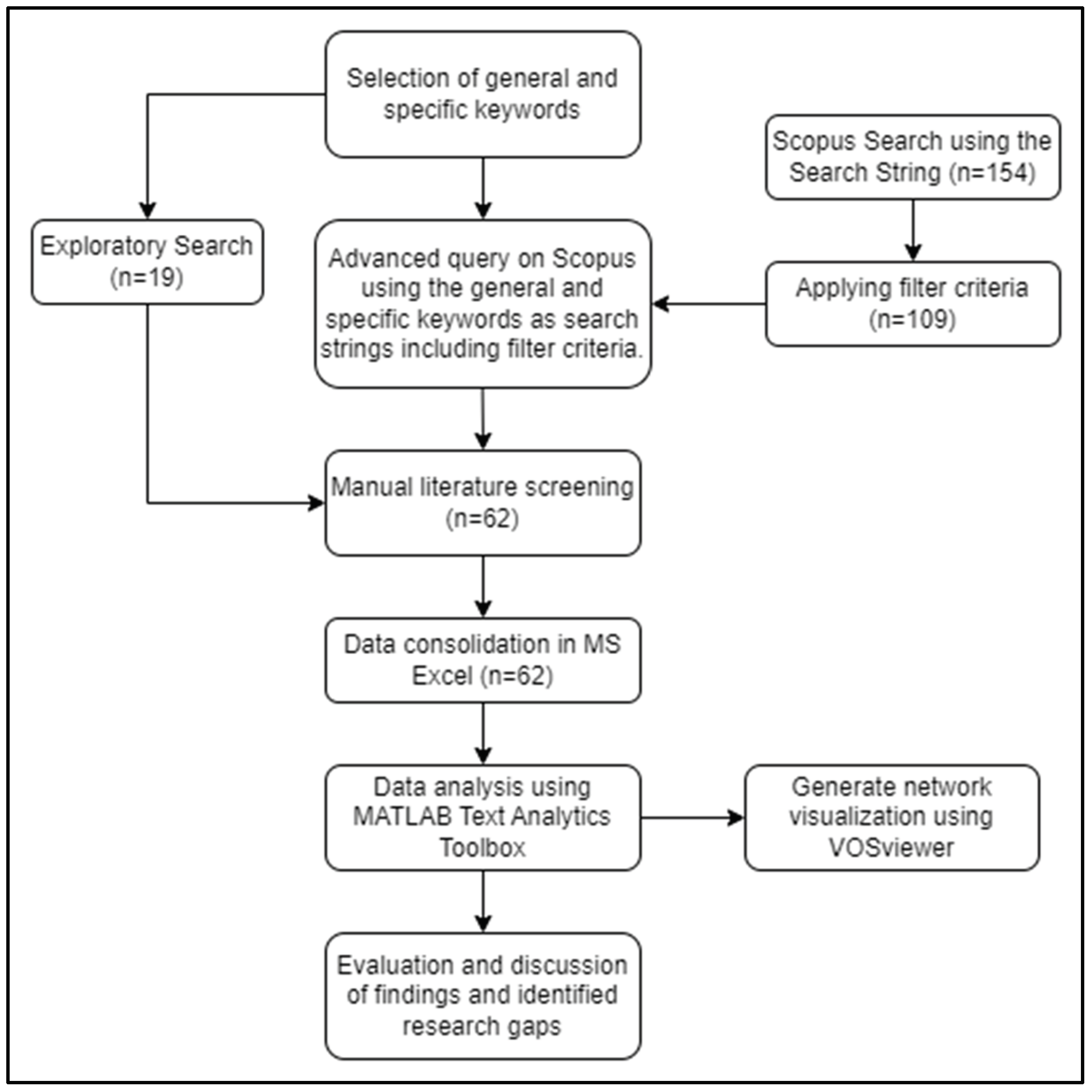

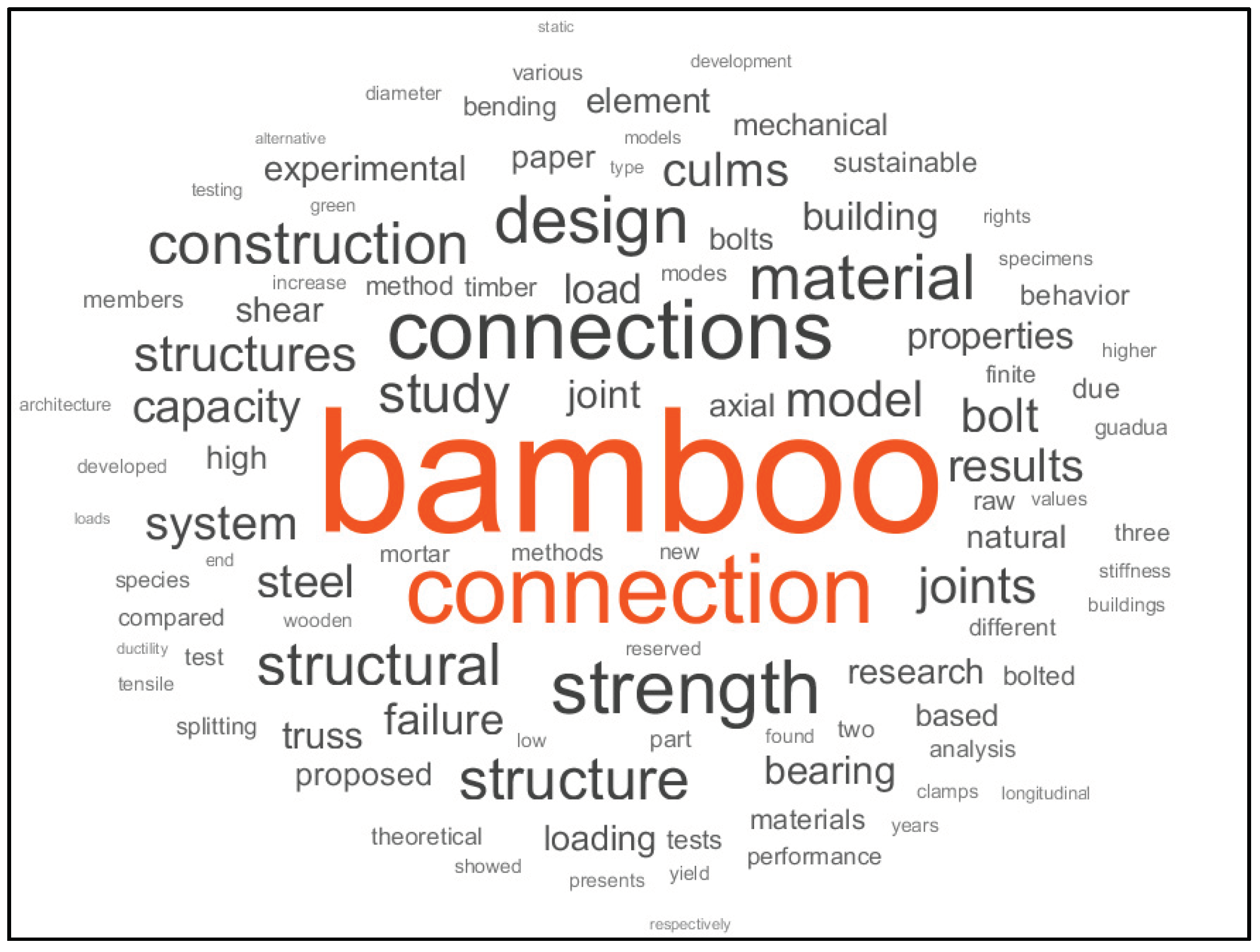

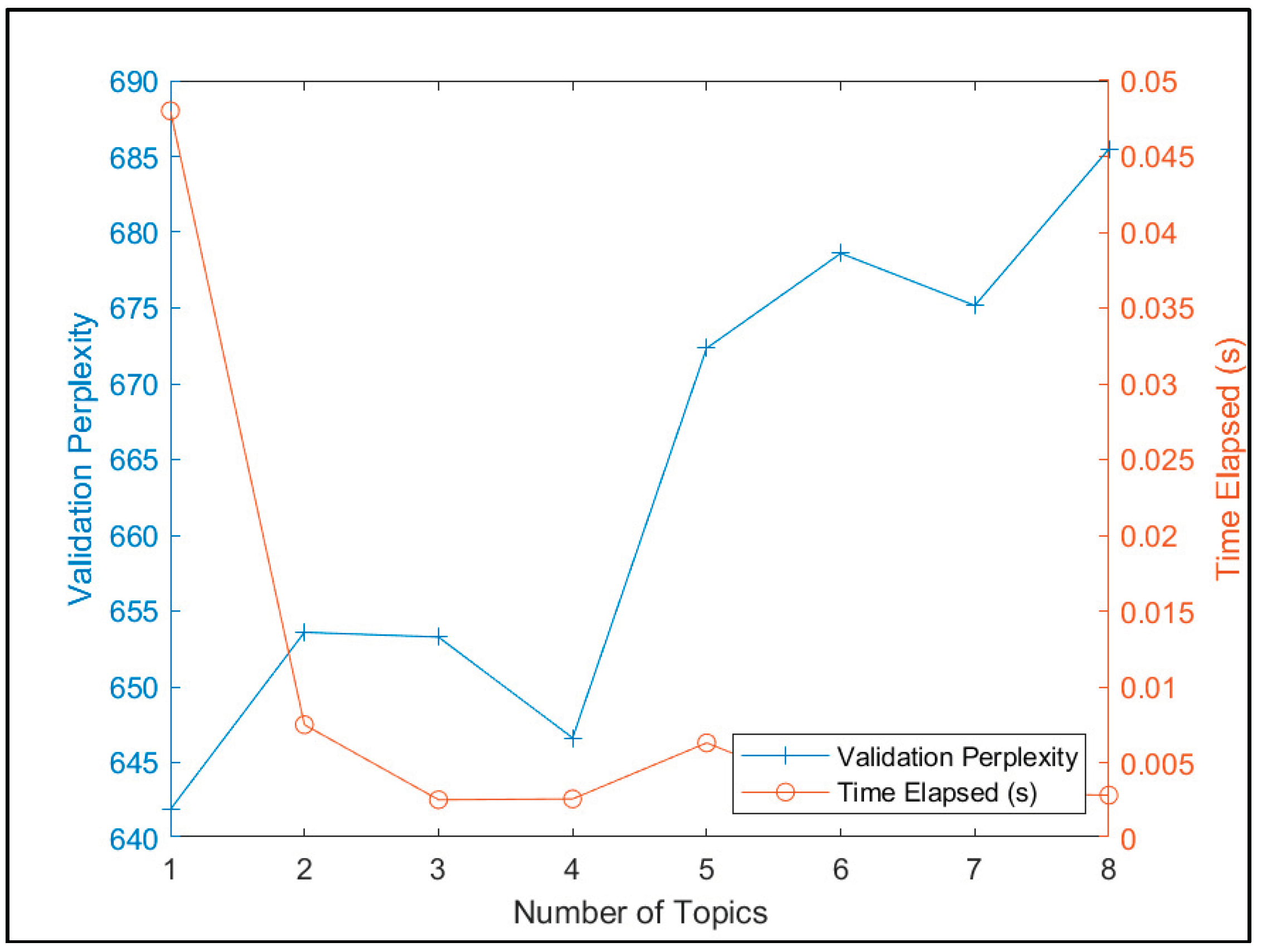

2. Methodology

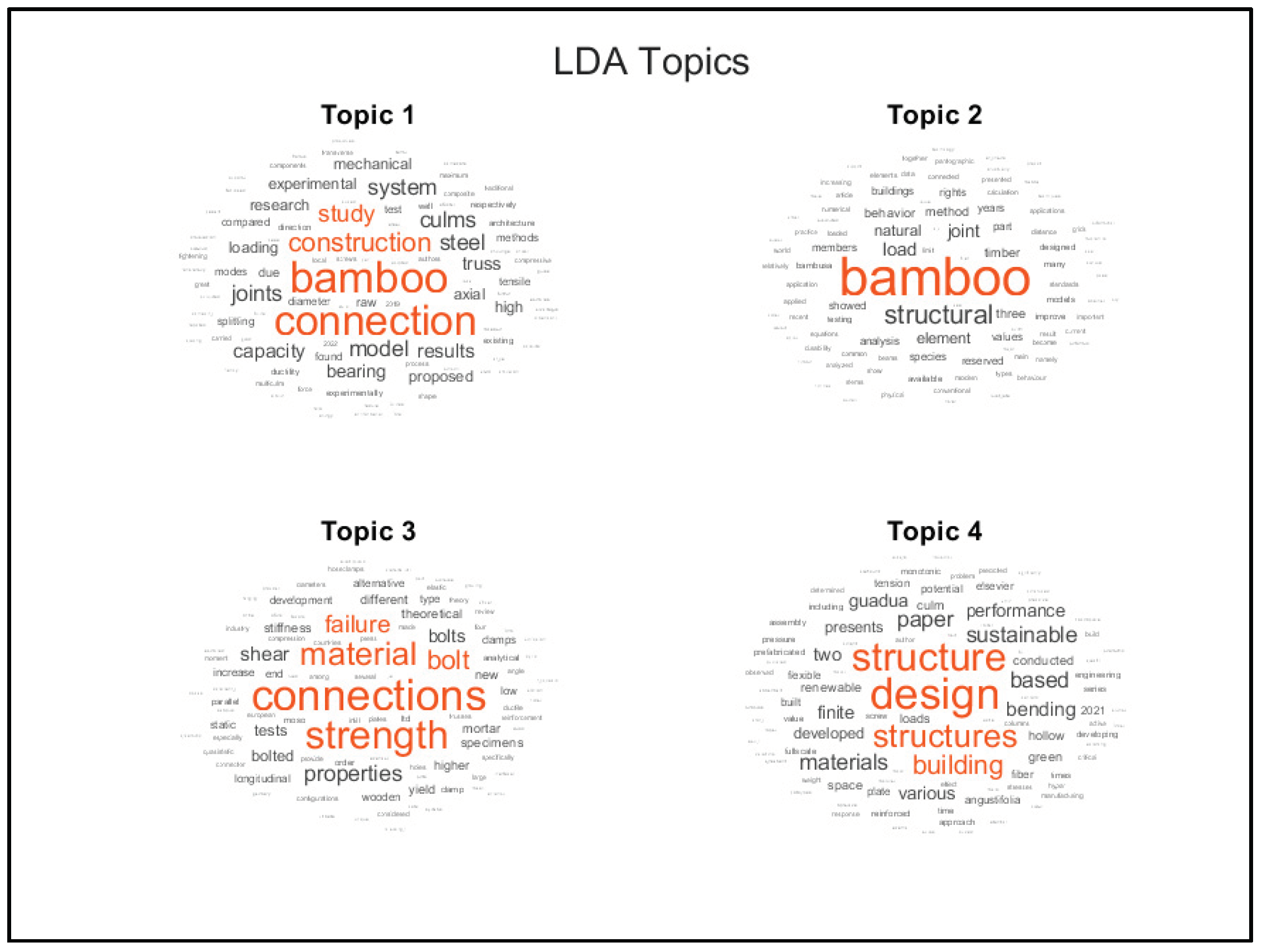

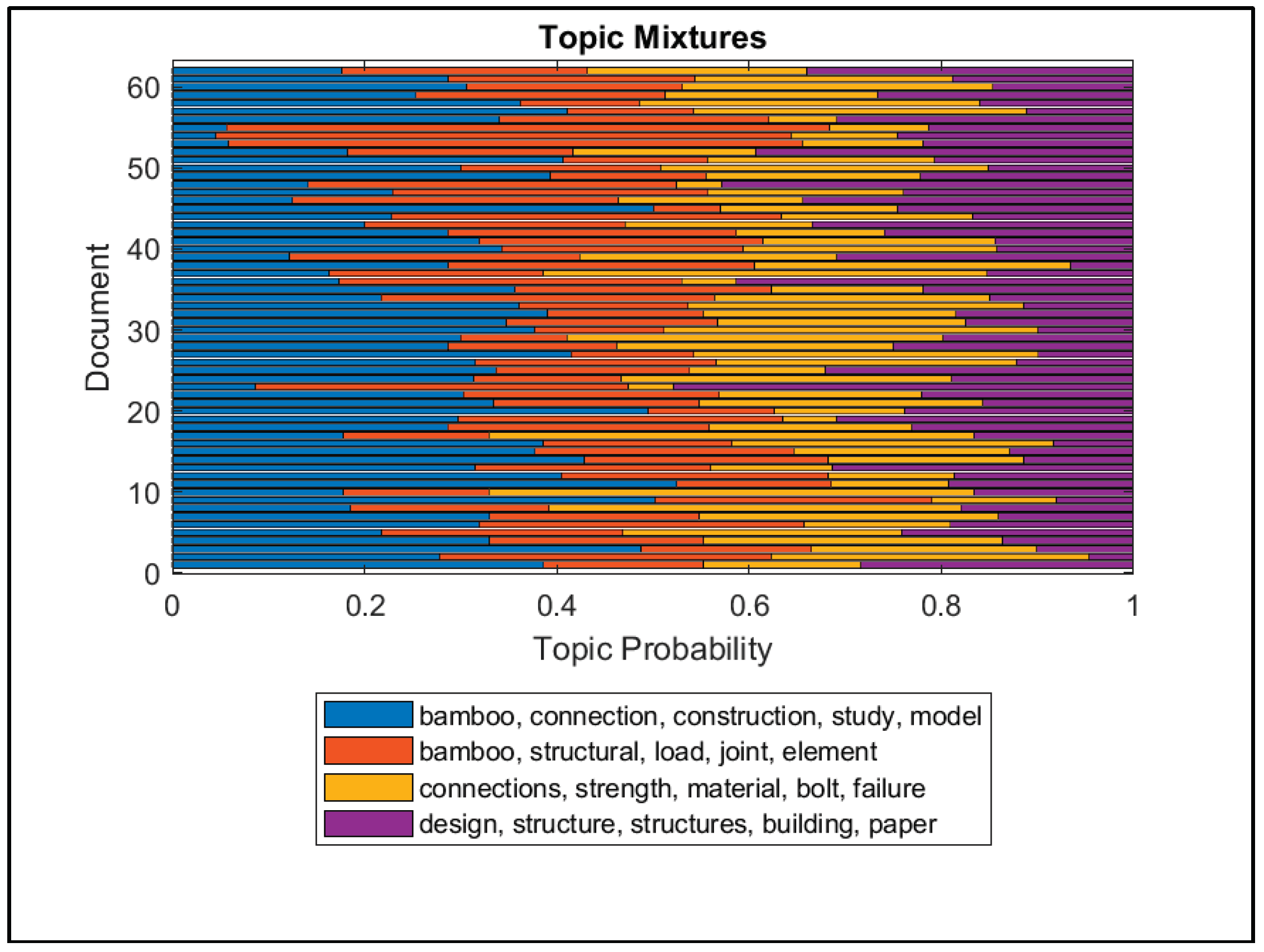

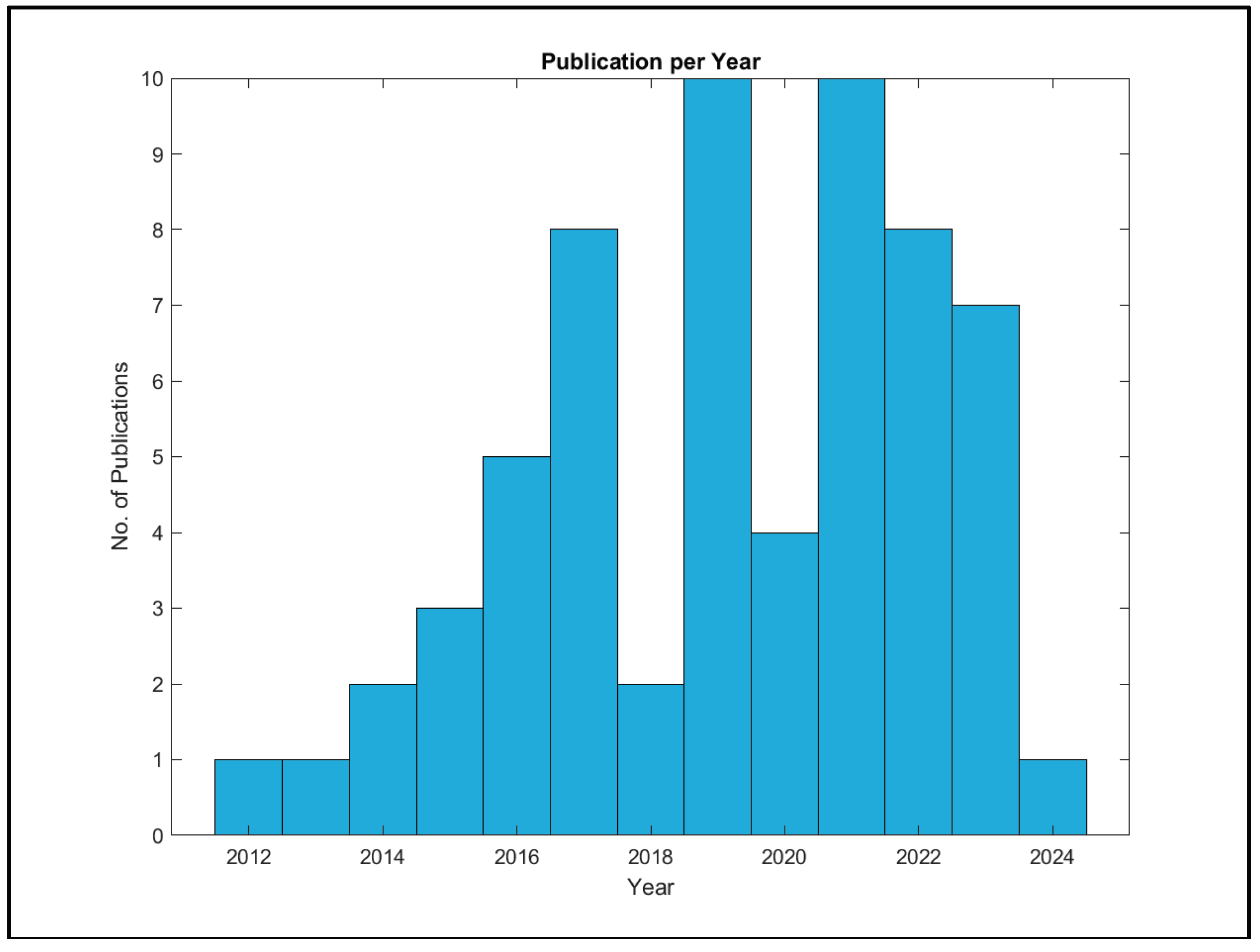

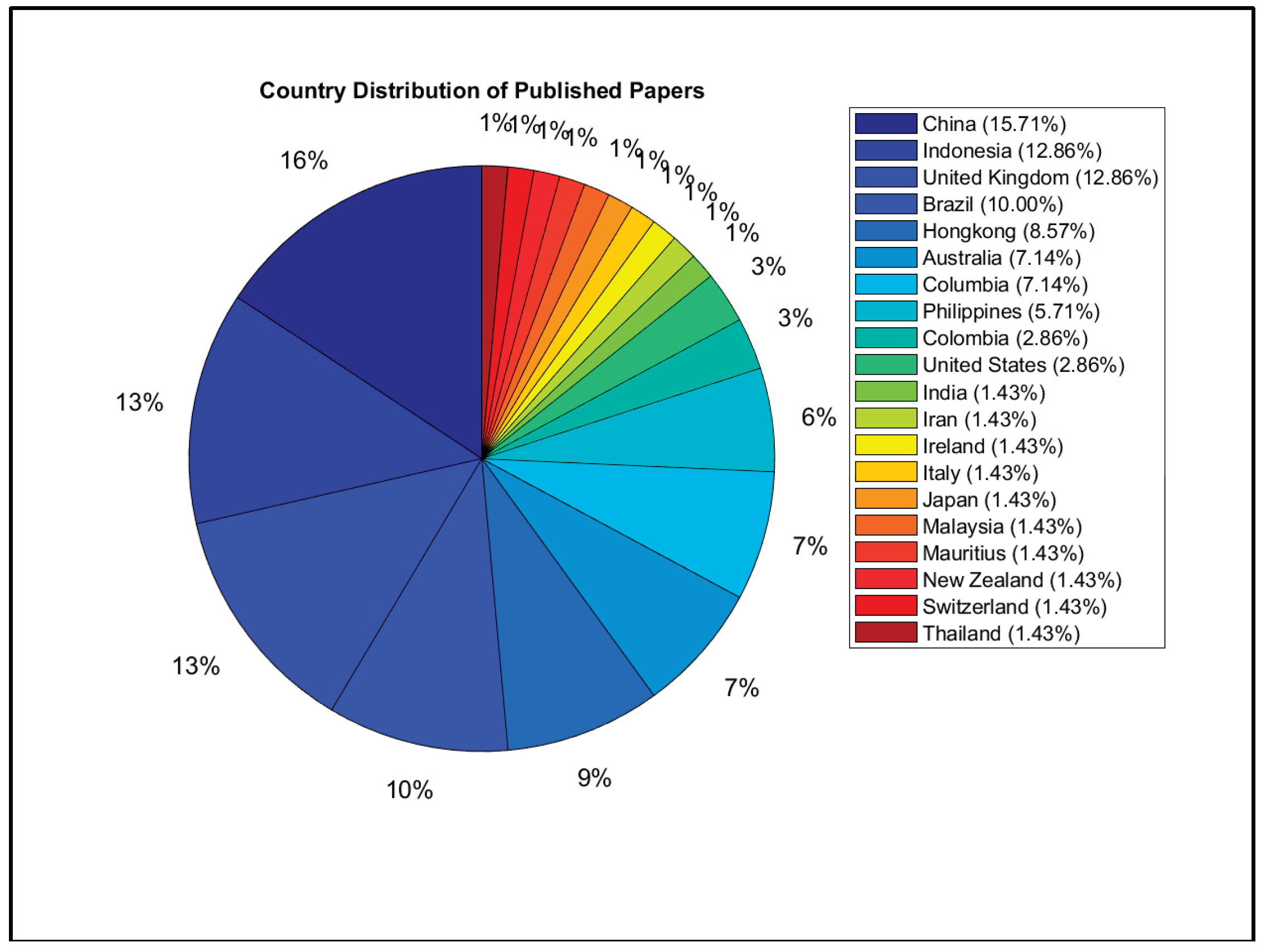

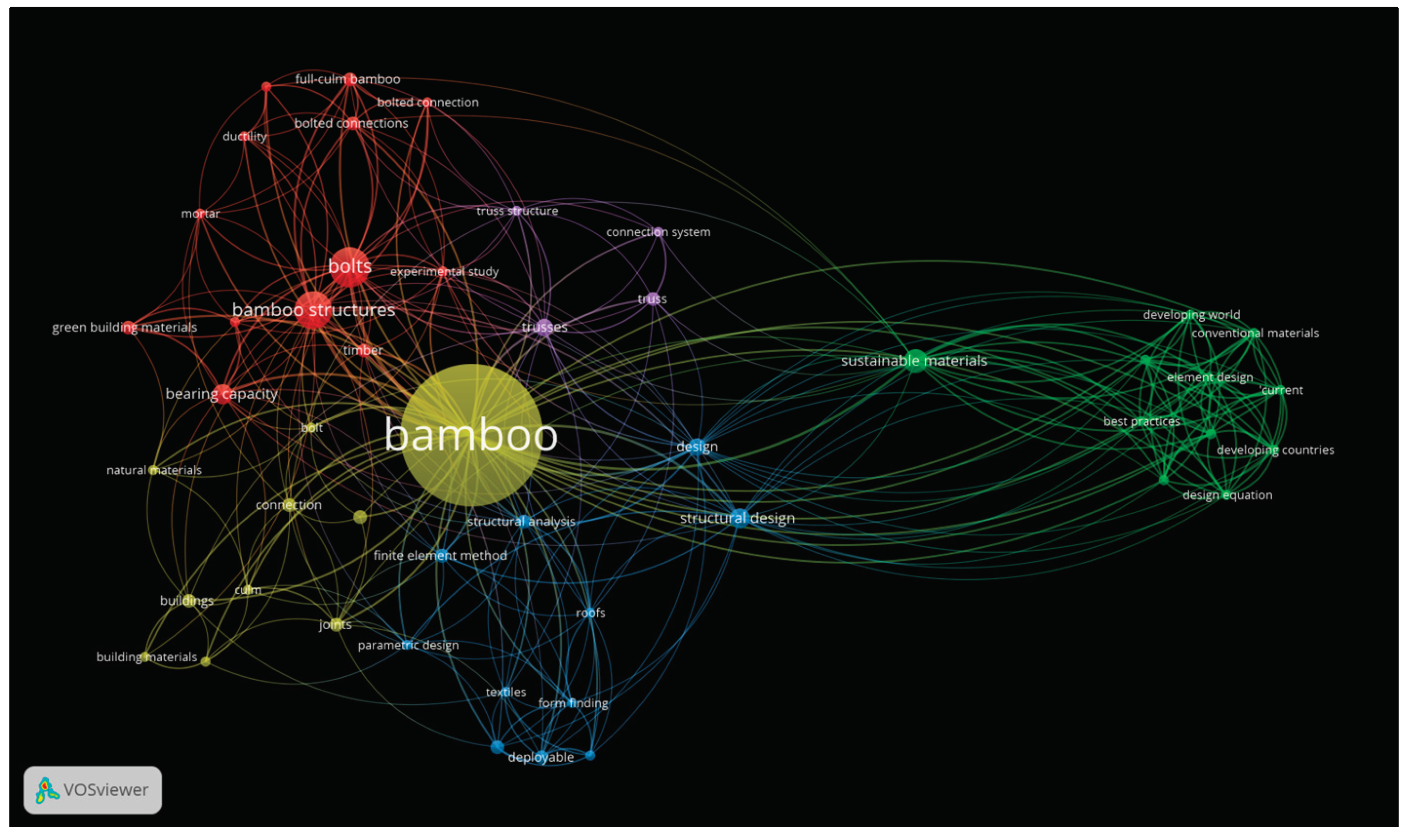

3. Results and Discussion

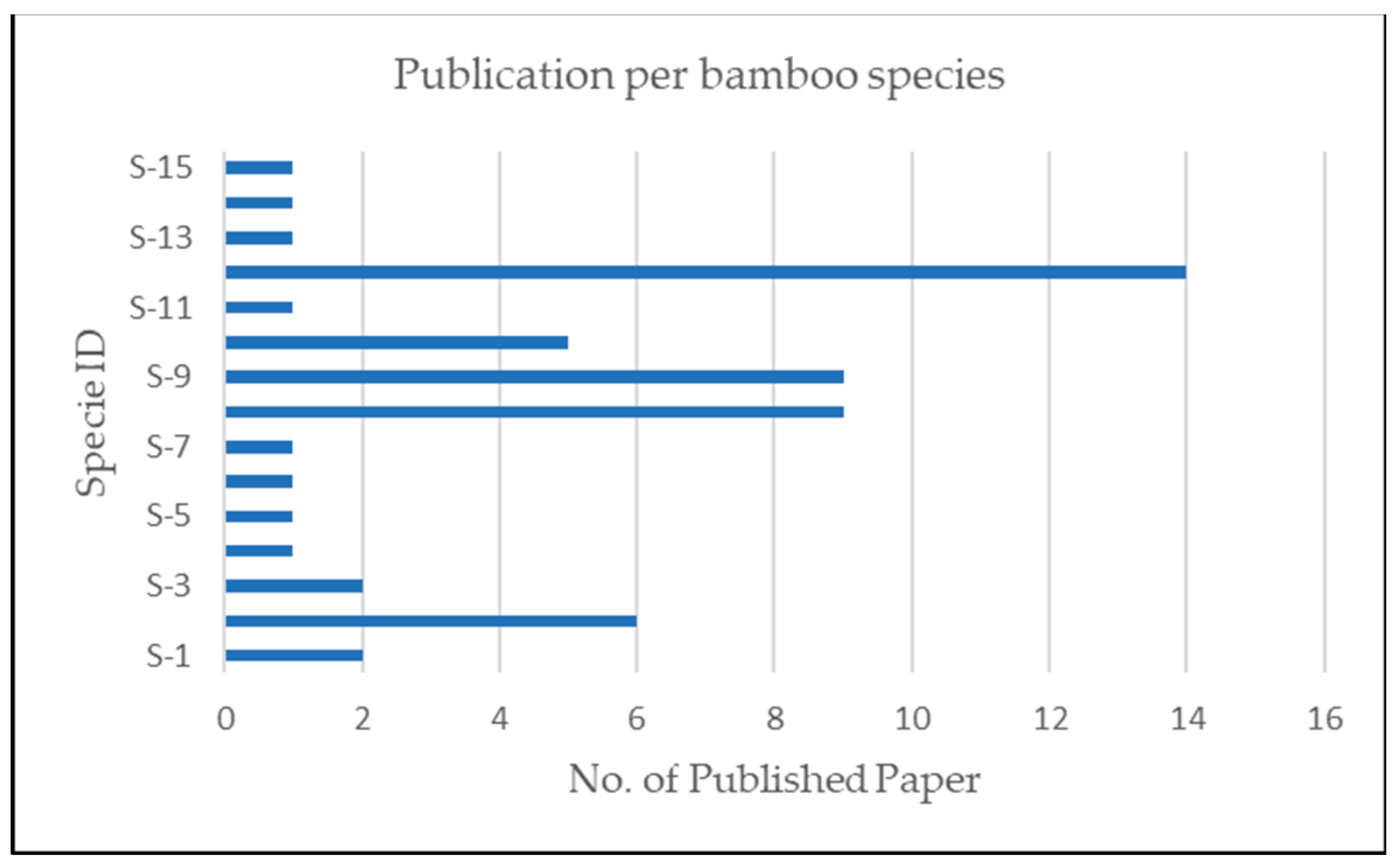

3.1. Bamboo Species

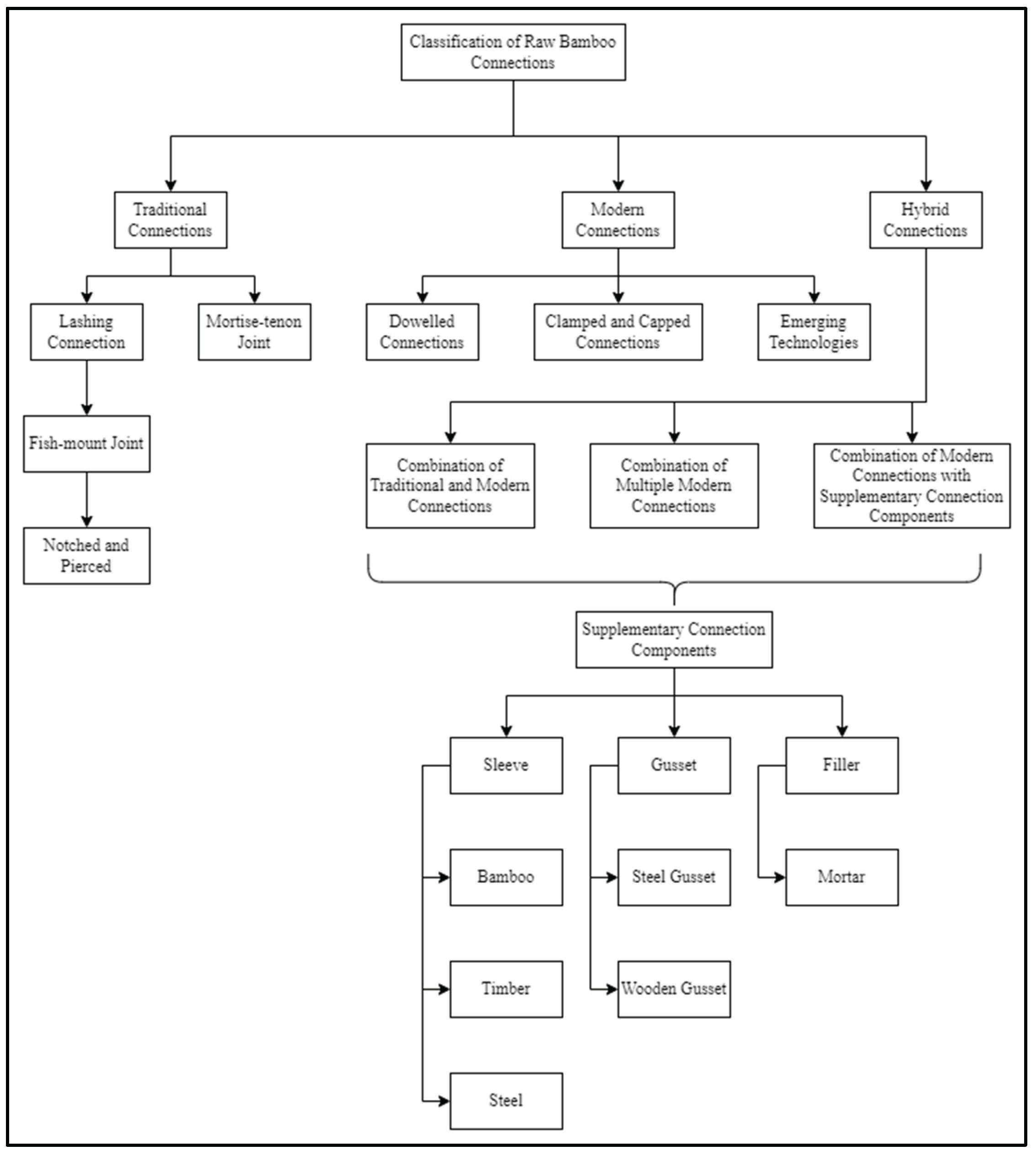

3.2. Classification of Raw Bamboo Connections

3.2.1. Traditional Connections

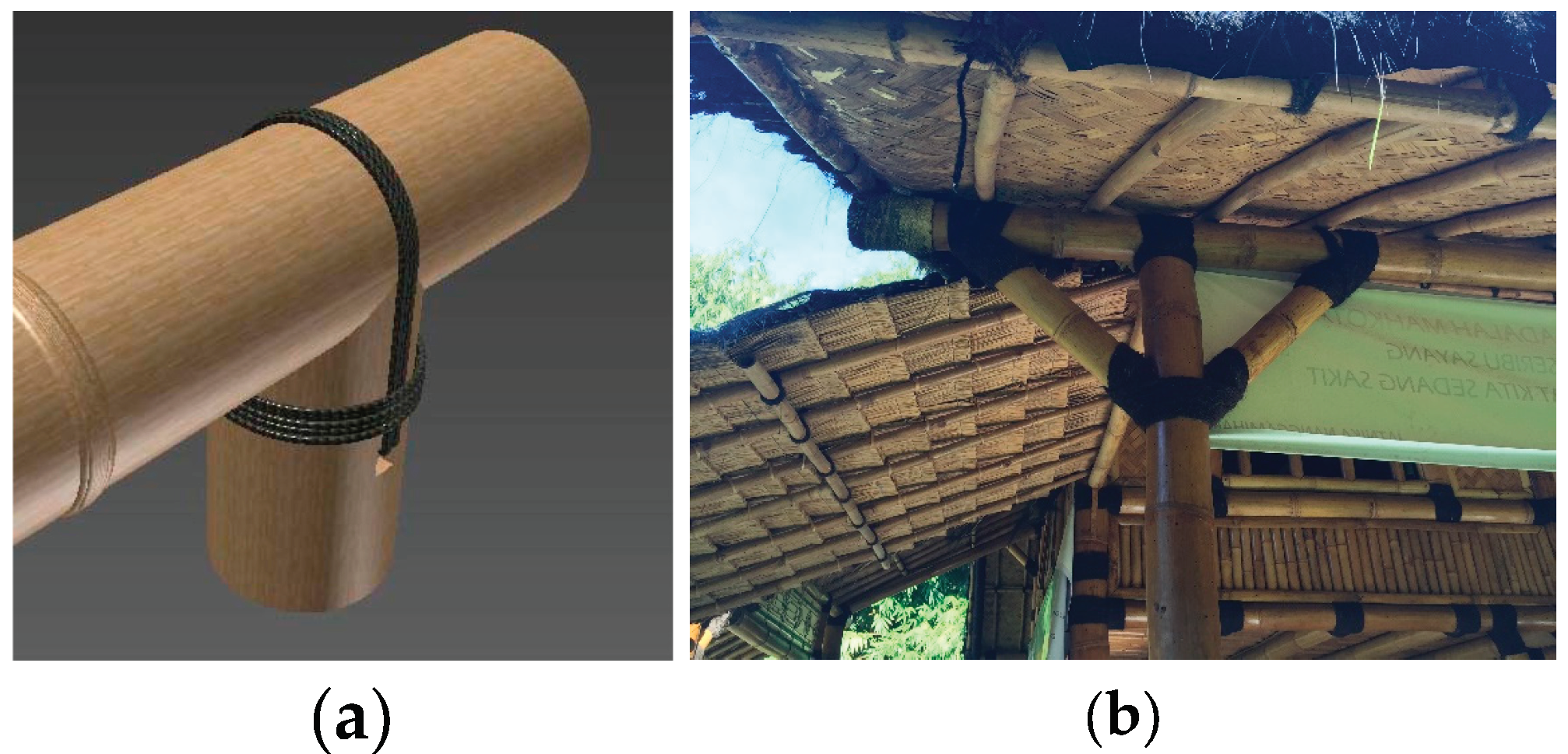

3.2.1.1. Lashing Connections

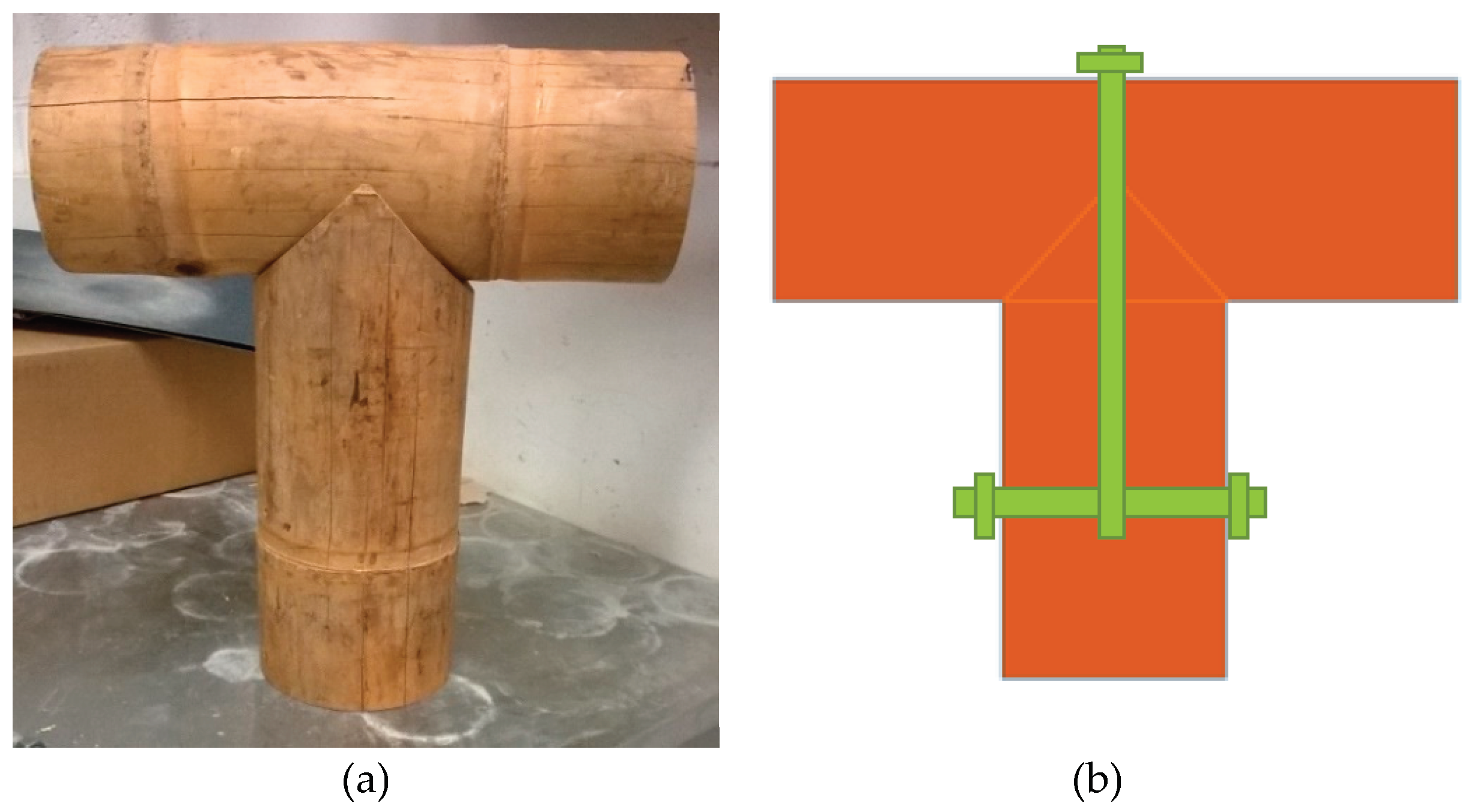

3.2.1.2. Mortise-Tenon Joints

3.2.2. Modern Connections

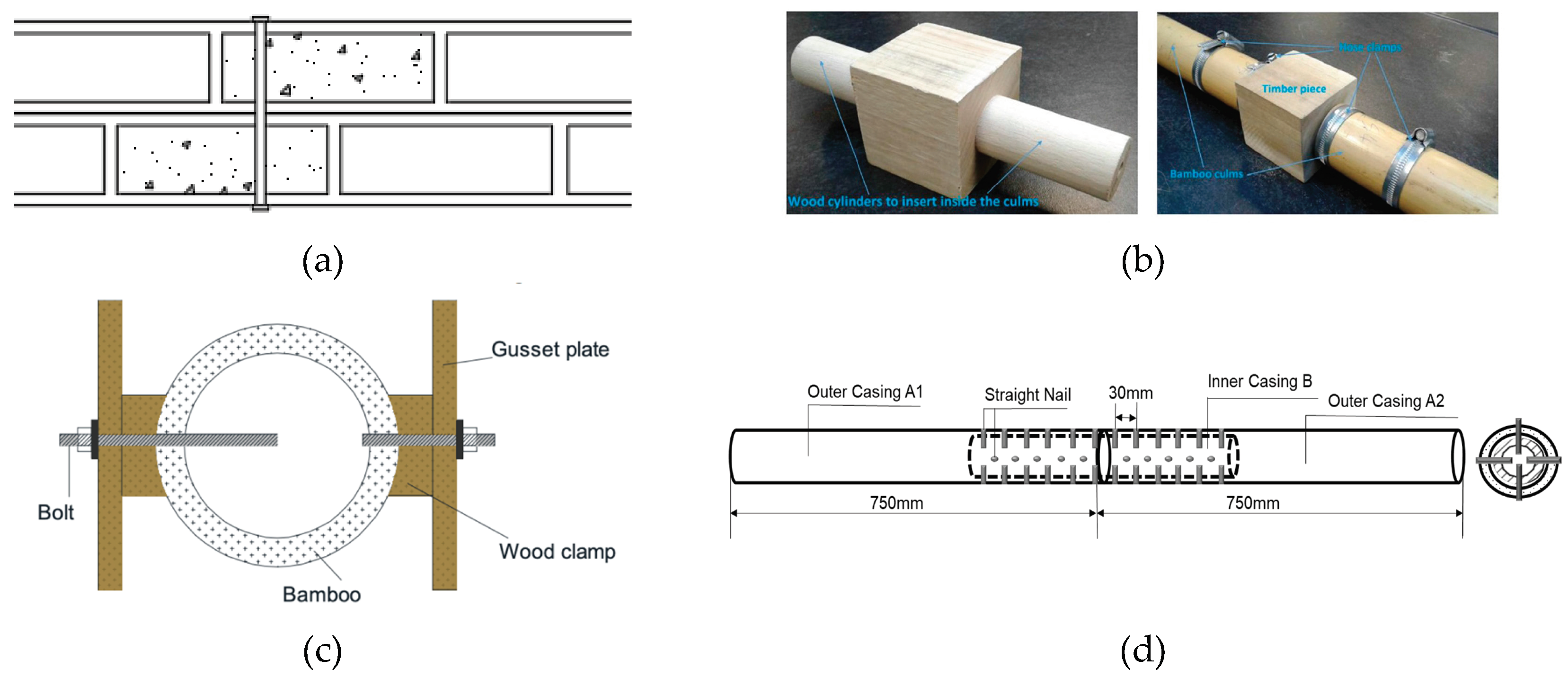

3.2.2.1. Dowelled Connections

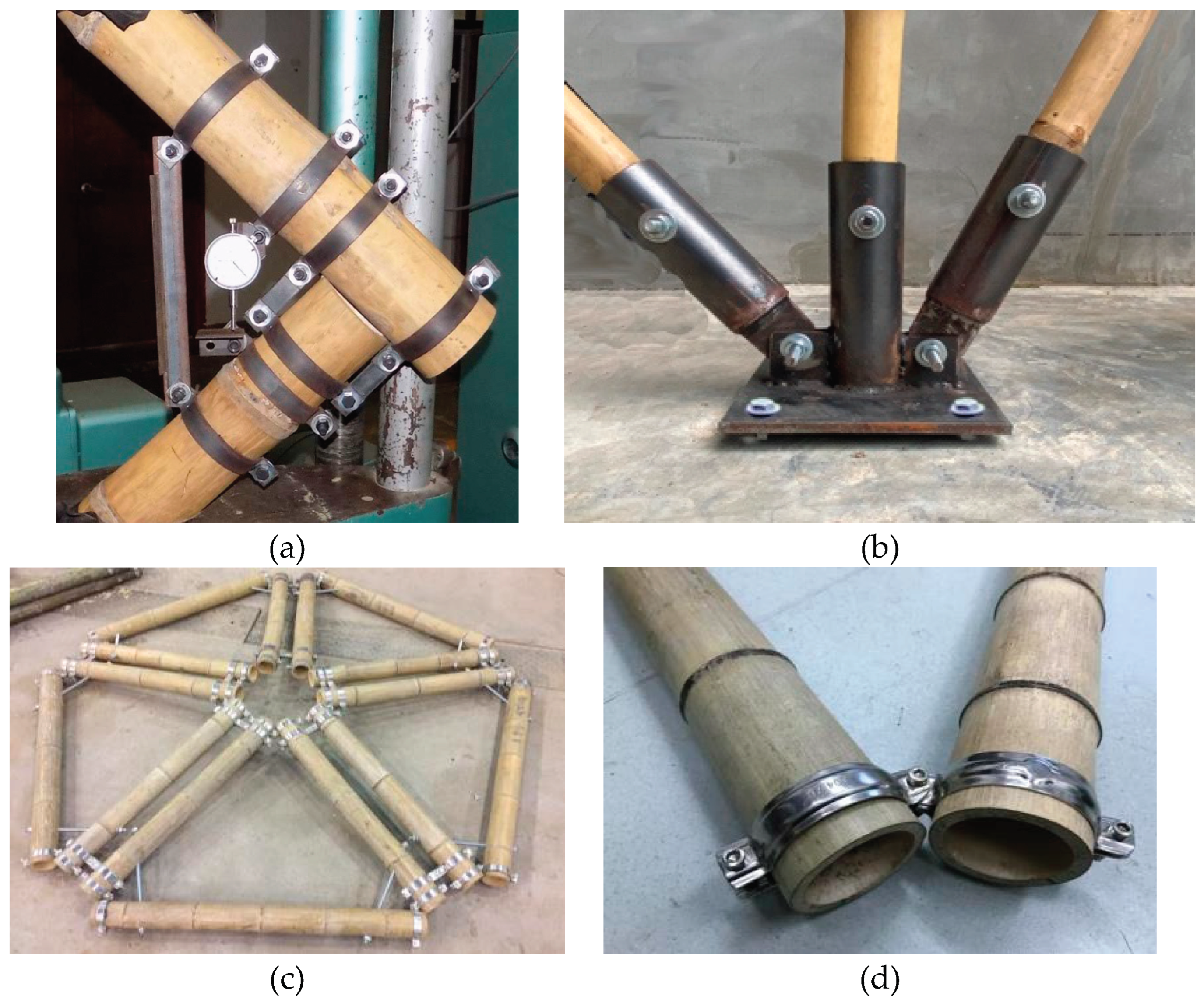

3.2.2.2. Clamped and Capped Connections

3.2.2.3. Emerging Technologies

3.2.3. Hybrid Connections

3.2.3.1. Combination of Traditional and Modern Connections

3.2.3.2. Combination of Multiple Modern Connections

3.2.3.3. Combination of Modern Connections with Supplementary Connection Components

3.3. Codes and Standards for Bamboo

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Yor Maikol, S.M.; Maksimovich, S.V.; Ivanovna, B.G.; Ainur, S. Bamboo Structures for Modern Sustainable Architecture. ISVS E-J. 2020, 7, 27–39. [Google Scholar]

- Escamilla, E.Z.; Habert, G.; Correal Daza, J.F.; Archilla, H.F.; Echeverry Fernández, J.S.; Trujillo, D. Industrial or Traditional Bamboo Construction? Comparative Life Cycle Assessment (LCA) of Bamboo-Based Buildings. Sustainability 2018, 10, 3096. [Google Scholar] [CrossRef]

- Boity, A.; Bhandari, H.; Shukla, S. Bamboo as a Sustainable Building Construction Material. Mater. Today Proc. 2022, 71. [Google Scholar] [CrossRef]

- Chainey, S.; Shijagurumayum, C.; Thokchom, S. Review on the Use of Bamboo as a Construction Material. SAMRIDDHI J. Phys. Sci. Eng. Technol. 2022, 14, 47–51. [Google Scholar] [CrossRef]

- Raj, D.; Agarwal, B. Bamboo as a Building Material. Krishi Sanskriti Publ. 2014, 1, 56–61. [Google Scholar]

- Sikder, A.; Bera, D. Bamboo as a Green Building Material in Construction Industry - a Review. In; 2016.

- Madushan, S.; Buddika, H.A.D.; Bandara, S.; Navaratnam, S.; Abeysuriya, N. Uses of Bamboo for Sustainable Construction a Structural and Durability Perspective a Review. Sustainability 2023, 15, 11137. [Google Scholar] [CrossRef]

- Silverman, E. Can Bamboo Construction Material Replace Timber and Steel? Available online:. Available online: https://blog.bluebeam.com/building-with-bamboo/ (accessed on 12 November 2023).

- Rampal, T.; Goel, M.; Chawra, B.; Taneja, A. ; taneja, payal Potential Use of Bamboo as a Sustainable Material in Construction in India: A Survey of Literature. 2023, 10, 90–103. [CrossRef]

- Rathour, R.; Kumar, H.; Prasad, K.; Anerao, P.; Kumar, M.; Kapley, A.; Pandey, A.; Kumar Awasthi, M.; Singh, L. Multifunctional Applications of Bamboo Crop beyond Environmental Management: An Indian Prospective. Bioengineered 2022, 13, 8893–8914. [Google Scholar] [CrossRef]

- Hildayanti, A. ; Wasilah Optimizing Bamboo as an Alternative Building Material to Respond Global Architectural Challenges. IOP Conf. Ser. Earth Environ. Sci. 2023, 1157, 012011. [Google Scholar] [CrossRef]

- Marketing Indovance Bamboo Benefits as a Mainstream and Sustainable Building Material. Indovance Inc 2022.

- 13. Base Discovering the Fire Resistance of Cement-Bamboo Frame Technology. Build. Sustain. Future Today - BASE.

- 14. Base Going Green: Building Affordable and Disaster-Resilient Houses Using Bamboo. Build. Sustain. Future Today - BASE.

- Shu, B.; Xiao, Z.; Hong, L.; Zhang, S.; Li, C.; Fu, N.; Lu, X. Review on the Application of Bamboo-Based Materials in Construction Engineering. J. Renew. Mater. 2020, 8, 1215–1242. [Google Scholar] [CrossRef]

- Masdar, A.; Suhendro, B.; Siswosukarto, S.; Sulistyo, D. Influence of Bolt Tightening’s Force to the Strength of Connection System of Bamboo Truss Structure with Wooden Clamp. Procedia Eng. 2017, 171, 1370–1376. [Google Scholar] [CrossRef]

- Moran, R.; García, J. Bamboo Joints with Steel Clamps Capable of Transmitting Moment. Constr. Build. Mater. 2019, 216, 249–260. [Google Scholar] [CrossRef]

- Paraskeva, T.; Grigoropoulos, G.; Dimitrakopoulos, E. Design and Experimental Verification of Easily Constructible Bamboo Footbridges for Rural Areas. Eng. Struct. 2017, 143, 540–548. [Google Scholar] [CrossRef]

- Pradhan, N.; Dimitrakopoulos, E.; Paraskeva, T. 2019.

- Villegas, L.; Moran, R.; García, J. Combined Culm-Slat Guadua Bamboo Trusses. Eng. Struct. 2019, 184, 495–504. [Google Scholar] [CrossRef]

- Disén, K.; Clouston, P. Building with Bamboo: A Review of Culm Connection Technology. J. Green Build. 2013, 8, 83–93. [Google Scholar] [CrossRef]

- Trujillo, D.; Jangra, S.; Gibson, J.M. Flexural Properties as a Basis for Bamboo Strength Grading. Proc. Inst. Civ. Eng. - Struct. Build. 2017, 170, 284–294. [Google Scholar] [CrossRef]

- Awaludin, A.; Andriani, V. Bolted Bamboo Joints Reinforced with Fibers. Procedia Eng. 2014, 95. [Google Scholar] [CrossRef]

- Masdar, A.; Suhendro, B.; Siswosukarto, S.; Sulistyo, D. Determinant of Critical Distance of Bolt on Bamboo Connection. J. Teknol. 2014, 69. [Google Scholar] [CrossRef]

- Masdar, A.; Suhendro, B.; Siswosukarto, S.; Sulistyo, D. The Study of Wooden Clamps for Strengthening of Connection on Bamboo Truss Structure. J. Teknol. 2015, 72. [Google Scholar] [CrossRef]

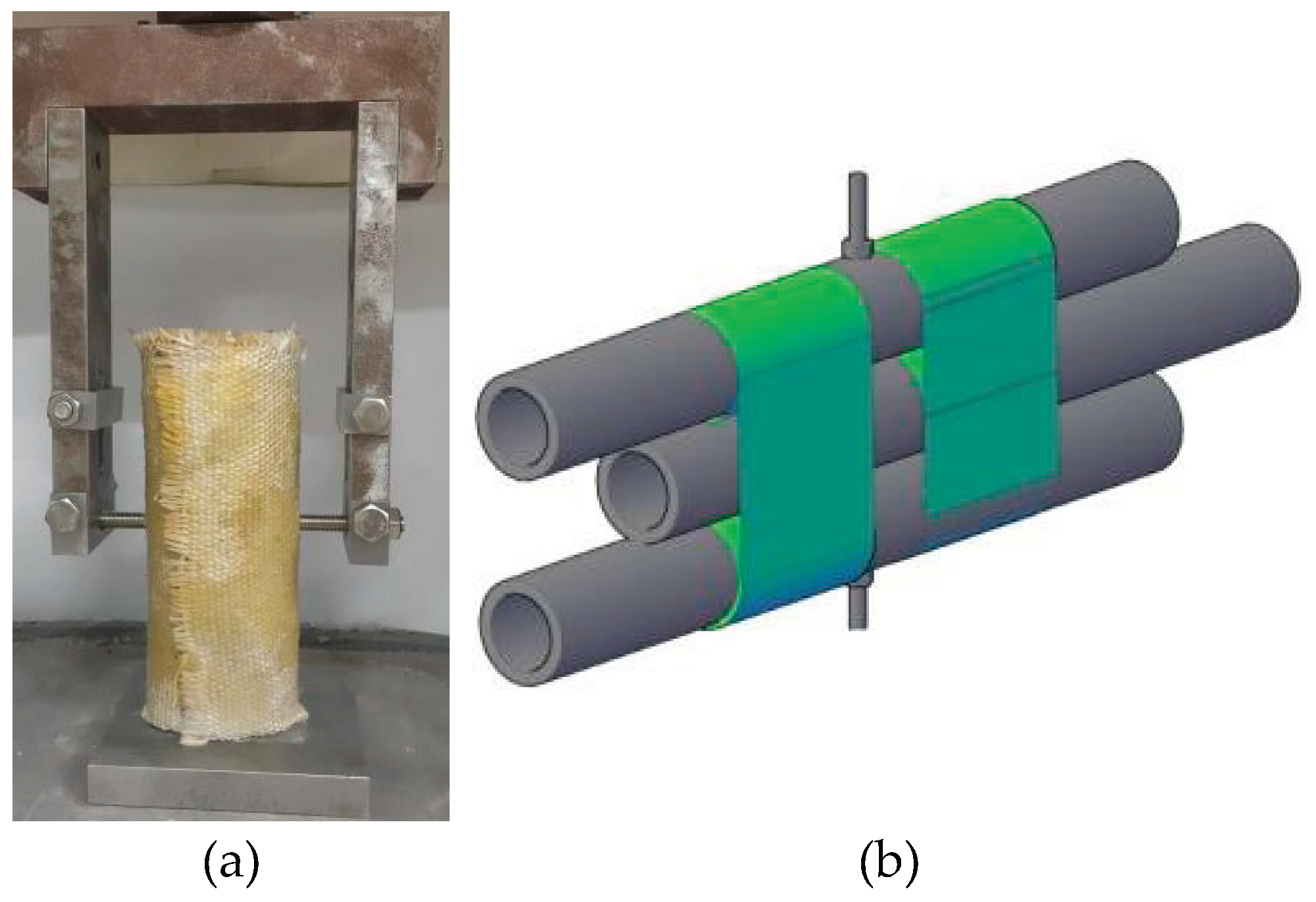

- Paraskeva, T.; Pradhan, N.; Stoura, C.D.; Dimitrakopoulos, E. Monotonic Loading Testing and Characterization of New Multi-Full-Culm Bamboo to Steel Connections. Constr. Build. Mater. 2019, 201, 473–483. [Google Scholar] [CrossRef]

- Ramful, R. Failure Analysis of Bamboo Bolt Connection in Uniaxial Tension by FEM by Considering Fiber Direction. For. Prod. J. 2021, 71, 58–64. [Google Scholar] [CrossRef]

- Iqbal, Q. Scopus: Indexing and Abstracting Database. 2018.

- Dela Cruz, O.; Ongpeng, J. Building Information Modeling on Construction Safety: A Literature Review. In; 2022; pp. 89–102 ISBN 978-3-031-11231-7.

- Adier, M.F.; Sevilla, M.E.; Valerio, D.; Ongpeng, J.M. Bamboo as Sustainable Building Materials: A Systematic Review of Properties, Treatment Methods, and Standards. Buildings 2023, 13. [Google Scholar] [CrossRef]

- The MathWorks Inc. MATLAB R2023b 2023.

- Roque, C.; Lourenço Cardoso, J.; Connell, T.; Schermers, G.; Weber, R. Topic Analysis of Road Safety Inspections Using Latent Dirichlet Allocation: A Case Study of Roadside Safety in Irish Main Roads. Accid. Anal. Prev. 2019, 131, 336–349. [Google Scholar] [CrossRef]

- Osmani, A.; Mohasefi, J.B.; Gharehchopogh, F.S. Enriched Latent Dirichlet Allocation for Sentiment Analysis. Expert Syst. 2020, 37, e12527. [Google Scholar] [CrossRef]

- Liu, W.; Hui, C.; Wang, F.; Wang, M.; Liu, G.; Liu, W.; Hui, C.; Wang, F.; Wang, M.; Liu, G. Review of the Resources and Utilization of Bamboo in China. In Bamboo - Current and Future Prospects; IntechOpen, 2018 ISBN 978-1-78923-231-8.

- van Eck, N. J., W. VOSViewer: Visualizing Scientific Landscapes 2010.

- Savellano, D.; Razal, R. 2022.

- Kaminski, S.; Lawrence, A.; Trujillo, D. Structural Use of Bamboo: Part 1: Introduction to Bamboo. Struct. Eng. 2016, 94, 40–43. [Google Scholar]

- Bacosa, C.J.; Loretero, M. Mechanical Strength of Treated Philippine Bamboo Mortar Infill Joint Connection for Construction. J. Tianjin Univ. Sci. Technol. 2023, 56. [Google Scholar] [CrossRef]

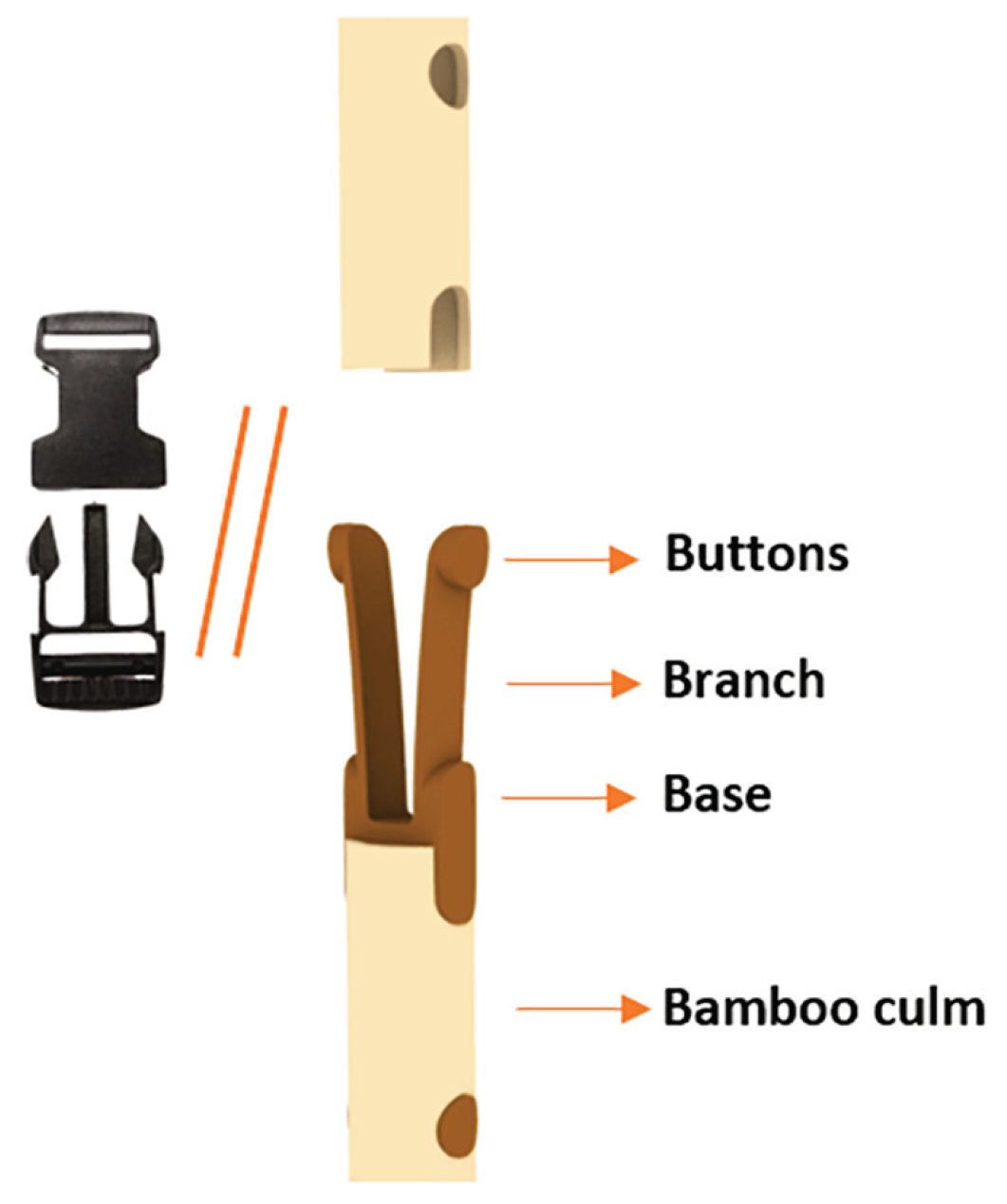

- Masdar, A.; Warman, H.; Masdar, A.D.; Sari, R.; Junnaidy, R. The Experimental Study of Connection System with Bamboo Branch as a Connector for Engineering Design of Bamboo Truss Structure.; 2023; Vol. 2599.

- Pradhan, N.; Paraskeva, T.; Dimitrakopoulos, E. Simulation and Experimental Verification of an Original Full-Scale Bamboo Truss. Eng. Struct. 2022, 256, 113965. [Google Scholar] [CrossRef]

- Pradhan, N.; Paraskeva, T.; Dimitrakopoulos, E. Quasi-Static Reversed Cyclic Testing of Multi-Culm Bamboo Members with Steel Connectors. J. Build. Eng. 2019, 27, 100983. [Google Scholar] [CrossRef]

- Pradhan, N.; Dimitrakopoulos, E.G. Pilot Study on Capacity-Based Design of Multiculm Bamboo Axial Members with Dowel-Type Connections. J. Struct. Eng. 2021. [Google Scholar] [CrossRef]

- Noverma, N.; Yusrianti; Hapsari, O. ; Pribadi, A. Strength Comparison between Bolt and Cendani Bamboo (Bambusa Multiplex) as a Shear Connector. IOP Conf. Ser. Earth Environ. Sci. 2019, 366, 012020. [Google Scholar] [CrossRef]

- Rittironk, S. Pre-Fabricated Connectors Used in Bamboo Frames for Timely-Efficient Construction. Proc. Int. Struct. Eng. Constr. 2022, 9. [Google Scholar] [CrossRef]

- Ramful, R. Evaluation of the Mechanical Properties of Bambusa Bamboo Culms with Metallic Joints through Destructive Testing. J. Green Build. 2018, 13, 1–19. [Google Scholar] [CrossRef]

- Masdar, A.; Noviarti, N.; Suhendro, B.; Siswosukarto, S.; Sulistyo, D. 2019.

- Masdar, A.; Siswosukarto, S.; Noviarti; Suryani, D. Implementation of Connection System of Wooden Plate and Wooden Clamp on Joint Model of Bamboo Truss Structures. Int. J. GEOMATE 2019, 17. [Google Scholar] [CrossRef]

- Oka, G.; Triwiyono, A.; Awaludin, A.; Siswosukarto, S. Experimental and Theoretical Investigation of Bolted Bamboo Joints without Void Filled Material. Appl. Mech. Mater. 2015, 776, 59–65. [Google Scholar] [CrossRef]

- Quintero, M.A.M.; Tam, C.P.T.; Li, H. Structural Analysis of a Guadua Bamboo Bridge in Colombia. Sustain. Struct. 2022, 2. [Google Scholar] [CrossRef]

- Malkowska, D.; Norman, J.; Trujillo, D. Theoretical and Experimental Study on Laterally Loaded Nailed Bamboo Connection. Constr. Build. Mater. 2022. [Google Scholar] [CrossRef]

- Michiels, T.; Lu, L.; Archer, R.; Adriaenssens, S.; Tresserra, G. Design of Three Hypar Roofs Made of Guadua Bamboo Available online:. Available online: https://www.researchgate.net/publication/315978347_Design_of_Three_Hypar_Roofs_Made_of_Guadua_Bamboo (accessed on 6 January 2024).

- Moran, R.; Muñoz, J.; Silva, H.; García, J. A Bamboo Beam-Column Connection Capable to Transmit Moment.; 2017. 28 November.

- García, J.; Benítez, C.; Villegas, L.; Moran, R. Thin Steel Rings as a Feasible Alternative to Connect Bamboo Culms.; 2017. 28 November.

- Trujillo, D.; Malkowska, D. Empirically Derived Connection Design Properties for Guadua Bamboo. Constr. Build. Mater. 2018, 163, 9–20. [Google Scholar] [CrossRef]

- Seixas, M.; Moreira, L.E.; Stoffel, P.; Bina, J. Form Finding and Analysis of an Active Bending-Pantographic Bamboo Space Structure. J. Int. Assoc. Shell Spat. Struct. 2021. [Google Scholar] [CrossRef]

- Seixas, M.; Eustáquio Moreira, L.; Stoffel, P.; Bina, J.; Ripper, J.; Ferreira, J.; Ghavami, K. Analysis of a Self-Supporting Bamboo Structure with Flexible Joints. Int. J. Space Struct. 2021, 36, 137–151. [Google Scholar] [CrossRef]

- Seixas, M.; Eustáquio Moreira, L.; Bina, J.; Ripper, J. Design and Analysis of a Self-Supporting Bamboo Roof Structure with Flexible Connections. J. Int. Assoc. Shell Spat. Struct. 2019, 60, 221. [Google Scholar] [CrossRef]

- Seixas, M.; Bina, J.; Stoffel, P.; Ripper, J.; Eustáquio Moreira, L.; Ghavami, K. Active Bending and Tensile Pantographic Bamboo Hybrid Amphitheater Structure. J. Int. Assoc. Shell Spat. Struct. 2017. [Google Scholar] [CrossRef]

- Seixas, M.; Ripper, J.; Ghavami, K. Prefabricated Bamboo Structure and Textile Canvas Pavilions. J. Int. Assoc. Shell Spat. Struct. 2016, 57, 179–188. [Google Scholar] [CrossRef]

- Malkowska, D.; Trujillo, D.; Toumpanaki, E.; Norman, J. Study of Screwed Bamboo Connection Loaded Parallel to Fibre. Constr. Build. Mater. 2023, 398, 132532. [Google Scholar] [CrossRef]

- Kou, Y.; Tian, L.-M.; Hao, J.; Jin, B.; A, X. Lateral Resistance of the Screwed Connections of Original Bamboo. J. Build. Eng. 2022, 45, 103601. [Google Scholar] [CrossRef]

- Nie, S.; Yu, P.; Huang, Y.; Luo, Y.; Wang, J.; Liu, M.; Elchalakani, M. Experimental Study on Compressive Performance of the Multiple-Culm Bamboo Columns Connected by Bolts. Eng. Struct. 2024, 303, 117525. [Google Scholar] [CrossRef]

- Zhou, Q.; Li, J.; Liu, P.; Fu, F.; Zhu, H.; Chen, H. Study of the Tensile Properties of the Original Bamboo Sleeve Grouting Joints. J. Build. Eng. 2023, 78, 107708. [Google Scholar] [CrossRef]

- Nie, S.; Fu, W.; Wang, H.; Wu, D.; Liu, M.; Wang, J. Experimental Study of Moso Bamboo To-Steel Connections with Embedded Grouting Materials. J. Renew. Mater. 2022, 11. [Google Scholar] [CrossRef]

- Nie, S.; Ran, S.; Wu, D.; Chen, J.; Wang, H.; Wei, Q. Mechanical Properties of Moso Bamboo Connections with External Clamp Steel Plates. J. Renew. Mater. 2021, 10, 487–510. [Google Scholar] [CrossRef]

- Lefevre, B.; West, R.; O’Reilly, P.; Taylor, D. A New Method for Joining Bamboo Culms. Eng. Struct. 2019, 190, 1–8. [Google Scholar] [CrossRef]

- Fu, Y.; Wang, M.Y.; Ge, H.B.; Li, L. Experimental Study of Mechanical Properties of Bamboo’s Joints under Tension and Compression Load. Trans Tech Publ. Ltd. 2012. [Google Scholar] [CrossRef]

- Zhou, H.; Yan, Y.; Su, N.; Fang, C.-H.; Liu, H.; Zhang, X.; Fei, B.; Ma, X. Flexural Properties of Multiple Bamboo Beams with Connection Joints. Forests 2022, 13, 1851. [Google Scholar] [CrossRef]

- van Wassenhove, R.; Laet, L.; Vassilopoulos, A. A 3D Printed Bio-Composite Removable Connection System for Bamboo Spatial Structures. Compos. Struct. 2021, 269, 114047. [Google Scholar] [CrossRef]

- Alami, J.; Afshar, M.A.; Mazloum, A.A. Lateral Performance of a Temporary Bamboo Structure: Design and Experimental Assessment. J. Bamboo Rattan 2021, 20, 34–48. [Google Scholar]

- Hong, C.; Lorenzo, R.; Wu, G.; Corbi, I.; Corbi, O.; Xiong, Z.; Yang, D.; Zhang, H. Review on Connections for Original Bamboo Structures. 2019, 7. 7. [CrossRef]

- Lao, H. Connections for Bamboo Structures. IOP Conf. Ser. Earth Environ. Sci. 2021, 783, 012028. [Google Scholar] [CrossRef]

- Gaffuri, B.A.; Moura, J.D.M.; Barbosa, J.C.; de Medeiros, M.H.F.; Gobbi, A.; Silva, R.D. A Review of the Evolution of Research on Proposals for Bamboo Culms Connections in Structural Systems. BioResources 2023, 18. [Google Scholar] [CrossRef]

- Li, Q.; Ji, X.; Jin, Z.; Xu, J.; Yang, S.; Lv, S. Numerical Simulation of the Shear Capacity of a GFRP-Strengthened Natural Bamboo-Bolt Composite Joint. Polymers 2022, 14, 3024. [Google Scholar] [CrossRef] [PubMed]

- Meng, X.; Yu, J.W.; Zhang, Z.C.; Zhai, J.Q.; Feng, P. Mechanical Properties of Bolted Bamboo Culms Reinforced with FRP Sheets.; 2019. 10 December.

- Hu, C.; Cheng, R.; Cheng, Q.; Liu, J. Study on Behavior of Steel Hoop Connections for Raw Bamboo Members. Materials 2021, 14, 7253. [Google Scholar] [CrossRef]

- Seixas, M.; Eustáquio Moreira, L.; Cardoso, D. A Novel Flexible Joint for Bamboo Structures. J. Int. Assoc. Shell Spat. Struct. 2023, 65. [Google Scholar] [CrossRef]

- Malkowska, D.; Laux, T.; Trujillo, D.; Norman, J. Adaptation of a Wood Theoretical Fracture Model for Predicting Splitting Capacity of Dowelled Connections in Bamboo. Constr. Build. Mater. 2022, 357, 129358. [Google Scholar] [CrossRef]

- Correal, J.; Prada, E.; Suárez, A.; Moreno, D. Bearing Capacity of Bolted-Mortar Infill Connections in Bamboo and Yield Model Formulation. Constr. Build. Mater. 2021, 305, 124597. [Google Scholar] [CrossRef]

- Amede, E.A.; Hailemariama, E.K.; Hailemariam, L.M.; Nuramo, D.A. A Review of Codes and Standards for Bamboo Structural Design. Adv. Mater. Sci. Eng. 2021, 2021, e4788381. [Google Scholar] [CrossRef]

| Scientific Name (Local Name) | Areas Found | Diameter (mm) |

|---|---|---|

| Guadua angustifolia Kunth | South America | 120-160 |

| Dendrocalamus strictus (Calcutta) | Asia | 25-80 |

| Bambusa vulgaris | Africa, Asia, South America | 80-150 |

| Phyllostachys edulis (Moso) | Asia | 120-180 |

| Dendrocalamus asper (Petung) | Asia, South America | 80-200 |

| Bambusa blumeana (Spiny/ThornyBamboo) | Asia, Asia-Pacific | 60-150 |

| Gigantochloa apus | Asia | 40-100 |

| Specie ID | Scientific Name (Local Name) | Reference |

|---|---|---|

| S-1 | Bambusa blumeana (Spiny/Thorny/Ori bamboo) | [38,39] |

| S-2 | Bambusa pervariabilis (Kao Jue) | [18,19,26,40,41,42] |

| S-3 | Bambusa multiplex (Cendani bamboo) | [43,44] |

| S-4 | Bambusa ssp | [45] |

| S-5 | Bambusa vulgaris | [38] |

| S-6 | Dendrocalamus asper (Petung) | [38] |

| S-7 | Dendrocalamus merrillianus Elmer | [38] |

| S-8 | Gigantochloa atroviolacea (Wulung) | [16,23,24,25,39,46,47,48] |

| S-9 | Guadua angustifolia Kunth | [20,49,50,51,52,53,54] |

| S-10 | Phyllostachys aurea | [55,56,57,58,59] |

| S-11 | Phyllostachys bambusoides (Madake) | [27] |

| S-12 | Phyllostachys edulis/Phyllostachys pubescens (Moso) | [18,50,55,57,58,59,60,61,62,63,64,65,66,67], |

| S-13 | Phyllostachys iridescens (Hong) | [68] |

| S-14 | Phyllostachys nigra Boryana | [69] |

| S-15 | Phyllostachys vivax (Kara) | [70] |

| Country | Specie ID | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| S-1 | S-2 | S-3 | S-4 | S-5 | S-6 | S-7 | S-8 | S-9 | S-10 | S-11 | S-12 | S-13 | S-14 | S-15 | |

| Australia | ✓ | ||||||||||||||

| Brazil | ✓ | ||||||||||||||

| Colombia | ✓ | ✓ | |||||||||||||

| China | ✓ | ✓ | |||||||||||||

| Hongkong | ✓ | ✓ | |||||||||||||

| Indonesia | ✓ | ✓ | ✓ | ||||||||||||

| India | |||||||||||||||

| Iran | ✓ | ||||||||||||||

| Ireland | ✓ | ||||||||||||||

| Mauritius | ✓ | ✓ | |||||||||||||

| Philippines | ✓ | ✓ | ✓ | ✓ | |||||||||||

| Switzerland | ✓ | ||||||||||||||

| Thailand | ✓ | ||||||||||||||

| United Kingdom | ✓ | ✓ | |||||||||||||

| United States | ✓ | ||||||||||||||

| Reference | Classification of Raw Bamboo Connections |

|---|---|

| [21] | Traditional Bamboo Connections |

| |

| |

| Modern Bamboo Connections | |

| |

| |

| |

| Emerging Technologies | |

| [71] | Traditional Connection Joints |

| Lashing Joints | |

| Mortise-tenon Joints | |

| Modern Connection Joints | |

| Bolted Joints | |

| Steel Member and Steel Plate Joints | |

| Filler Reinforced Joints | |

| Other Types of Joints | |

| [72] | Traditional Bamboo Connections |

| Friction-tight Lashing | |

| Mortise-tenon Joints | |

| Other Traditional Bamboo Joints | |

| Modern Bamboo Connections | |

| Bolt Joints | |

| Clamp Joints | |

| Other Modern Bamboo Joints | |

| [73] | Use of Metal Connections |

| Bolted Joints | |

| Steel Member Connections and Steel Plate Connections | |

| Reinforced Connections with Fillers | |

| Parameterized Connections | |

| Connections with the use of Wooden Dowels |

| RBC ID | Description | Structure | Number of Culms Connected | Reference | |

|---|---|---|---|---|---|

| only 2 | 2 or more | ||||

| TC-1.1 | Bamboo culms, polyester ropes, and bio-composite rings termed as Hinged Flexible Connection (HFC) | Pantographic bamboo space structure | ✓ | [55] | |

| TC-1.2 | Bamboo culms, polyester ropes, and bio-composite rings termed as Hinged Flexible Connection (HFC) | Self-supporting bamboo structure | ✓ | [56] | |

| TC-1.3 | Bamboo culms, and flexible hinged lashed joints with textile-based techniques (HFC) | Pantographic hybrid amphitheater structure | ✓ | [58] | |

| TC-1.4 | Bamboo culms, and textile moorings | Mobile self-stabilizing structure | ✓ | [57,59] | |

| TC-1.5 | Bamboo culms, polyester ropes, and bio-composite rings termed as Hinged Flexible Connection (HFC) | * | ✓ | [77] | |

| MC-1.1 | Bamboo culms, and steel bolts | * | * | * | [27] |

| MC-1.2 | Bamboo culms, and steel bolts | * | * | * | [24] |

| MC-1.3 | Bamboo culms, and metal pin | * | * | * | [50,78], |

| MC-1.4 | Bamboo culms and bolt | * | ✓ | [48] | |

| MC-1.5 | Bamboo culms, and dowel | * | * | * | [54] |

| MC-2.1 | Bamboo culms, and steel-hose clamps | Temporary bamboo structure | * | * | [70] |

| MC-2.2 | Bamboo culms, and steel-hose clamps (termed as clamp-culm) | Bamboo truss | ✓ | [20] | |

| MC-2.3 | Bamboo culms and steel clamps | Beam-column | ✓ | [17] | |

| MC-2.4 | Bamboo culms and steel clamps | Beam-column | ✓ | [52] | |

| MC-2.5 | Bamboo culms and steel clamps | * | ✓ | [53] | |

| MC-2.6 | Bamboo culms, steel hoop, steel bolts, and NBR pad | * | * | * | [76] |

| MC-3.1 | Bamboo culms, and 3D printed biocomposite removable connection system | Temporary bamboo structure, furniture | ✓ | [69] | |

| HC-1.1 | Bamboo culms, fish-mount, and steel bolts | Hypar roof | ✓ | [51] | |

| HC-2.1 | Bamboo culms, steel bolts, and GFRP | * | * | * | [74] |

| HC-2.2 | Bamboo culms, steel bolts and nuts, and steel cap | Frame-ground | ✓ | [44] | |

| HC-2.3 | Bamboo culms, steel-hose clamps (termed as clamp-culm), and screws | Bamboo truss | ✓ | [20] | |

| HC-2.4 | Bamboo culms, steel-hose clamps (termed as clamp-culm), and through steel bolts | Bamboo truss | ✓ | [20] | |

| HC-2.5 | Bamboo culms, steel clamps, and drywall screws | Beam-column | ✓ | [17] | |

| HC-2.6 | Bambo culms, steel clamps, ad through steel bolts | Beam-column | ✓ | [17] | |

| HC-2.7 | Bamboo culms, steel bolts, and FRP | * | ✓ | [23] | |

| HC-2.8 | Bamboo culms, steel bolts, and natural fiber (ijuk) | * | ✓ | [23] | |

| HC-2.9 | Bamboo culms, steel bolts, and steel hose-clamp | * | * | * | [75] |

| HC-2.10 | Bamboo culms, steel bolts, and GFRP | * | * | * | [75] |

| HC-3.1 | Bamboo culms, bamboo sleeve, steel bolts, and nail | Column | ✓ | [51] | |

| HC-3.2 | Bamboo culms, steel sleeve, steel bolts, screws, and mortar | Slab-wall | ✓ | [63] | |

| HC-3.3 | Bamboo culms, steel bolts, and mortar | Footbridge | ✓ | [49] | |

| HC-3.4 | Bamboo culms, steel bolts, steel gusset plates, and steel hose-clamps | Truss structure for footbridge | ✓ | [19,40,42] | |

| HC-3.5 | Bamboo culms, steel bolts, and steel sleeve | Frame | ✓ | [44] | |

| HC-3.6 | Bamboo culms, bamboo sleeve, steel bolts, and nail | Beams | ✓ | [68] | |

| HC-3.7 | Bamboo culms, steel plate as sleeve, steel bolts, and mortar | * | ✓ | [64] | |

| HC-3.8 | Bamboo culms, steel bolts, and steel plates | * | * | * | [65] |

| HC-3.9 | Bamboo culms, steel bolts, and mortar | * | ✓ | [79] | |

| HC-3.10 | Bamboo culms, steel bolts, and steel gusset plates | * | ✓ | [19] | |

| HC-3.11 | Bamboo culms, steel bolts, steel gusset plates, and steel hose-clamps | * | ✓ | [41] | |

| HC-3.12 | Bamboo culms, steel bolts, steel gusset plates, steel hose-clamps, and mortar | * | ✓ | [41] | |

| HC-3.13 | Bamboo culms, steel bolts, and mortar | * | ✓ | [43] | |

| HC-3.14 | Bamboo culms, Cendani bamboo bolt (as shear connector), and mortar | * | ✓ | [43] | |

| HC-3.15 | Bamboo culms, steel bolts, nuts, and washer, and steel gusset plates | Footbridge | ✓ | [26] | |

| HC-3.16 | Bamboo culms, steel bolts, wooden clamp, and wooden gusset | * | * | * | [16,25,46,47] |

| HC-3.17 | Bamboo culms, steel sleeve, and riveted joint | * | ✓ | [45] | |

| HC-3.18 | Bamboo culms, steel sleeve, and self-drilling metal screw | * | ✓ | [45] | |

| HC-3.19 | Bamboo culms, Ori bamboo bolt (as connector), and mortar | * | ✓ | [39] | |

| HC-3.20 | Bamboo culms, screws, and steel plate | * | * | * | [60] |

| HC-3.21 | Bamboo culms, wood peg (sleeve), and steel hose-clamp | One-storey frame structure | ✓ | [66] | |

| HC-3.22 | Bamboo culms, steel sleeve, mortar, and steel ring | * | ✓ | [67] | |

| HC-3.23 | Bamboo culms, steel bolt, and steel sleeve | * | ✓ | [67] | |

| HC-3.24 | Bamboo culms, steel bolts, and steel plate (as sleeve) | * | ✓ | [67] | |

| RBC ID | Classification of Raw Bamboo Connection | Description |

|---|---|---|

| TC-1 | Traditional | Lashing Connection |

| TC-2 | Traditional | Mortise-tenon Joint |

| MC-1 | Modern | Dowelled Connection |

| MC-2 | Modern | Clamped and Capped Connection |

| MC-3 | Modern | Emerging Technologies |

| HC-1 | Hybrid | Combination of Traditional and Modern Connections |

| HC-2 | Hybrid | Combination of Multiple Modern Connections |

| HC-3 | Hybrid | Combination of Modern Connections and Supports |

| RBC ID | Combinations of Raw Bamboo Connections | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| TC-1 | TC-2 | MC-1 | MC-2 | MC-3 | AS-1.1 | AS-1.2 | AS-1.3 | AS-2.1 | AS-2.2 | AS-3.1 | AS-3.2 | |

| HC-1.1 | ✓ | ✓ | ||||||||||

| HC-2.1 | ✓ | ✓ | ||||||||||

| HC-2.2 | ✓ | ✓ | ||||||||||

| HC-2.3 | ✓ | ✓ | ||||||||||

| HC-2.4 | ✓ | ✓ | ||||||||||

| HC-2.5 | ✓ | ✓ | ||||||||||

| HC-2.6 | ✓ | ✓ | ||||||||||

| HC-2.7 | ✓ | ✓ | ||||||||||

| HC-2.8 | ✓ | ✓ | ||||||||||

| HC-2.9 | ✓ | ✓ | ||||||||||

| HC-2.10 | ✓ | ✓ | ||||||||||

| HC-3.1 | ✓ | ✓ | ||||||||||

| HC-3.2 | ✓ | ✓ | ✓ | |||||||||

| HC-3.3 | ✓ | ✓ | ||||||||||

| HC-3.4 | ✓ | ✓ | ✓ | |||||||||

| HC-3.5 | ✓ | ✓ | ||||||||||

| HC-3.6 | ✓ | ✓ | ||||||||||

| HC-3.7 | ✓ | ✓ | ✓ | |||||||||

| HC-3.8 | ✓ | ✓ | ||||||||||

| HC-3.9 | ✓ | ✓ | ||||||||||

| HC-3.10 | ✓ | ✓ | ||||||||||

| HC-3.11 | ✓ | ✓ | ✓ | |||||||||

| HC-3.12 | ✓ | ✓ | ✓ | ✓ | ||||||||

| HC-3.13 | ✓ | ✓ | ||||||||||

| HC-3.14 | ✓ | ✓ | ||||||||||

| HC-3.15 | ✓ | ✓ | ||||||||||

| HC-3.16 | ✓ | ✓ | ✓ | |||||||||

| HC-3.17 | ✓ | ✓ | ||||||||||

| HC-3.18 | ✓ | ✓ | ||||||||||

| HC-3.19 | ✓ | ✓ | ||||||||||

| HC-3.20 | ✓ | ✓ | ||||||||||

| HC-3.21 | ✓ | ✓ | ||||||||||

| HC-3.22 | ✓ | ✓ | ✓ | |||||||||

| HC-3.23 | ✓ | ✓ | ||||||||||

| HC-3.24 | ✓ | ✓ | ||||||||||

| Codes and 刘Standards | International | National | Country | Reference |

|---|---|---|---|---|

| JG/T 199-2007 | ✓ | China | [63,64,65,74,76] | |

| LY/T 2564-2015 | ✓ | China | [68] | |

| GB/T 228.1-2010 | ✓ | China | [76] | |

| GB/T 1447-2005 | ✓ | China | [74] | |

| GB/T 3098.1-2010 | ✓ | China | [65] | |

| GB/T 3355-2005 | ✓ | China | [74] | |

| GB/T 50005-2017 | ✓ | China | [62,65] | |

| GB/T 50081-2019 | ✓ | China | [63] | |

| GB/T 50448-2015 | ✓ | China | [64] | |

| NSR-10 | ✓ | Colombia | [17,18,20,42,49,51,52,53,54,78,79] | |

| CEN-EN 408 | ✓ | Europe | [23] | |

| EN 383:2007 | ✓ | Europe | [54] | |

| EN 1382:2016 | ✓ | Europe | [54] | |

| EN 1990 | ✓ | Europe | [18,40,42] | |

| EN 1991-1-1 | ✓ | Europe | [18] | |

| EN 1993-1-1 | ✓ | Europe | [17,42,52] | |

| EN 1993-1-4 | ✓ | Europe | [42] | |

| EN 1993-1-8 | ✓ | Europe | [18,42] | |

| EN 1995 | ✓ | Europe | [74] | |

| EN 1995-1-1 | ✓ | Europe | [18,42,54] | |

| EN 12512:2005 | ✓ | Europe | [26] | |

| EN 14358-2016 | ✓ | Europe | [54] | |

| BS EN 12390-3:2009-TC | ✓ | Europe | [26] | |

| BS EN 12390-6:2009-TC | ✓ | Europe | [26] | |

| IS 15912:2012 | ✓ | India | [41] | |

| Iran National Standard No. 2800 | ✓ | Iran | [70] | |

| AWC-TR12 | ✓ | United States | [26,42] | |

| ANSI (2005) | ✓ | United States | [65] | |

| ASTM A240/A240M-12 | ✓ | [26] | ||

| ASTM D1761 | ✓ | [79] | ||

| ASTM D5652 | ✓ | [65] | ||

| ASTM D5764-97a | ✓ | [24,25,26,42,47,54,60,79] | ||

| ASTM F1575-03 | ✓ | [26,39,42,48,60,79] | ||

| ISO 527-1:2019 | ✓ | [69] | ||

| ISO 527-4:2021 | ✓ | [69] | ||

| ISO 10984-2:2009 | ✓ | [54] | ||

| ISO-12122-1:2014 | ✓ | [60] | ||

| ISO 15912:2012 | ✓ | [42] | ||

| ISO 16670:2003 | ✓ | [17,19,23] | ||

| ISO 19624:2018 | ✓ | [42,60] | ||

| ISO/TR 21141:2022 | ✓ | [60] | ||

| ISO 22156:2021 | ✓ | [17,41,42,54,60,62,78,79] | ||

| ISO 22157-1:2004 | ✓ | [16,18,19,20,24,25,26,40,54,62] | ||

| ISO 22157:2019 | ✓ | [16,18,24,26,42,43,47,60,62,63,68,70] | ||

| AC 162 | ✓ | [18] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).