8.2. Generating 3D Targets

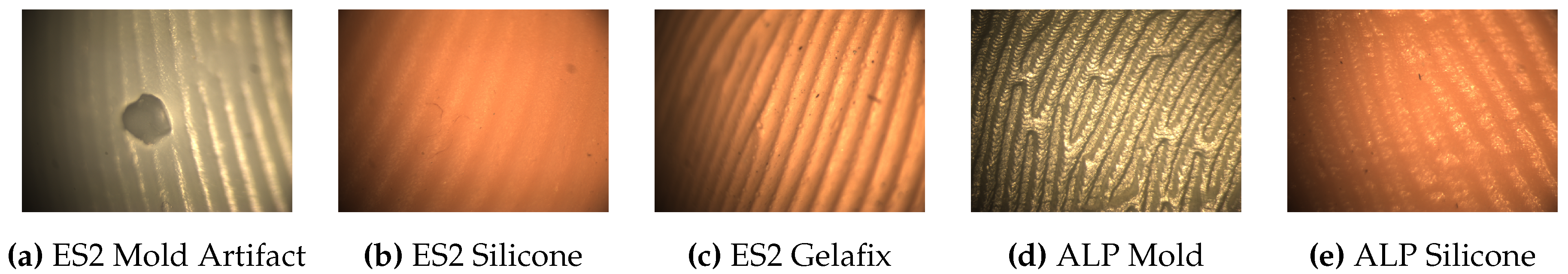

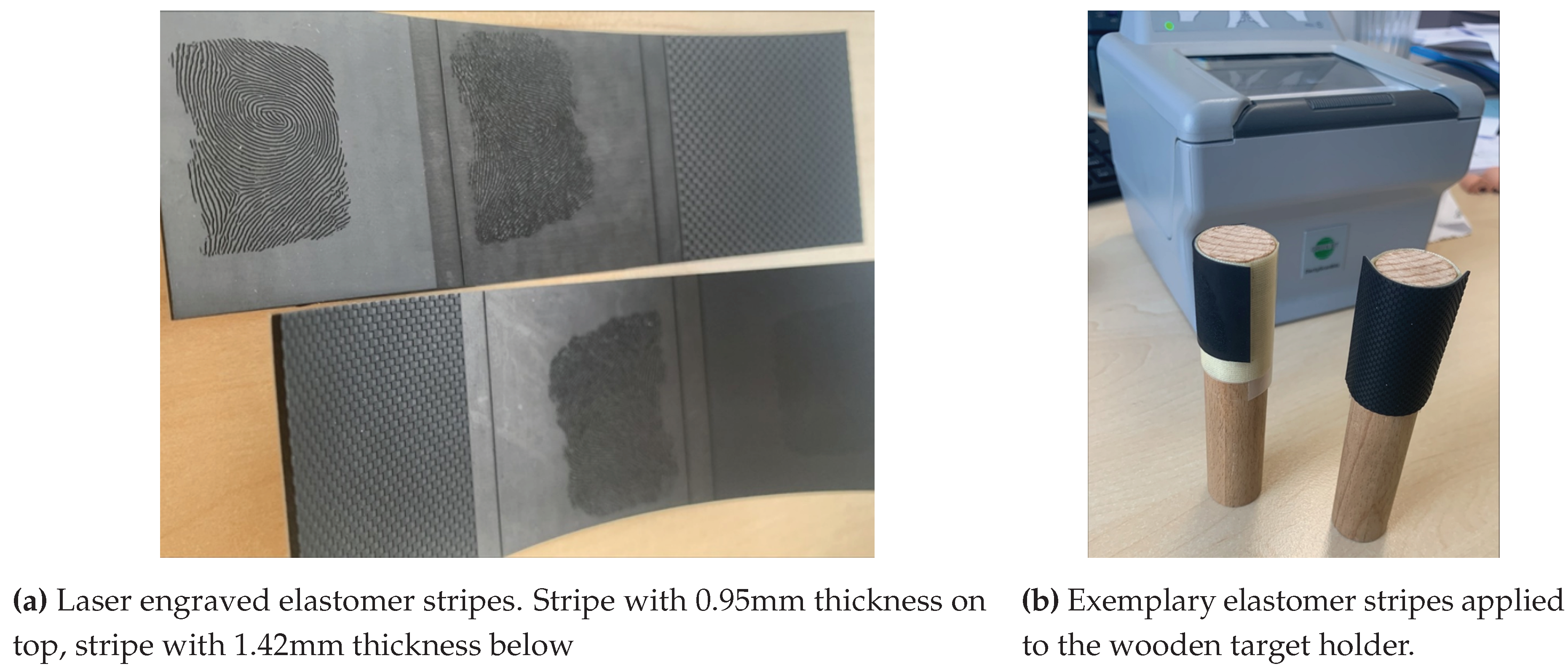

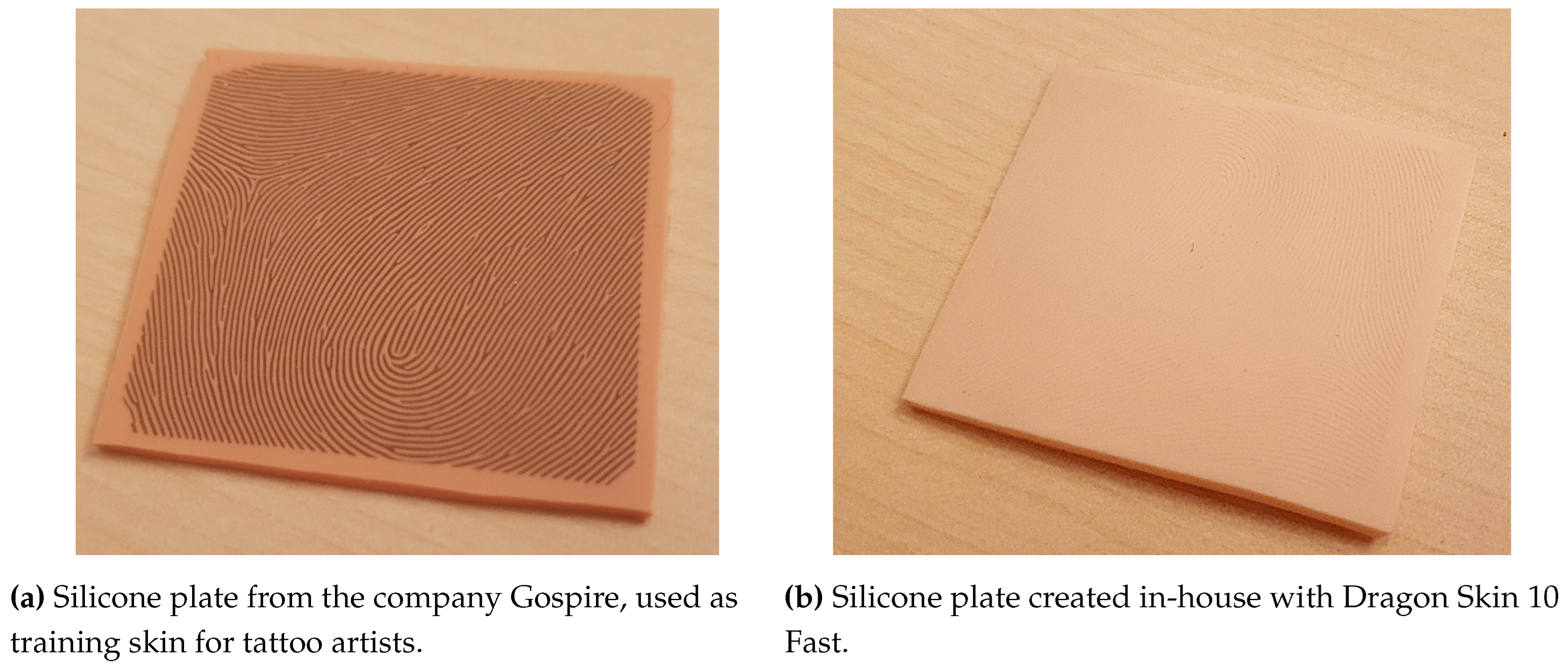

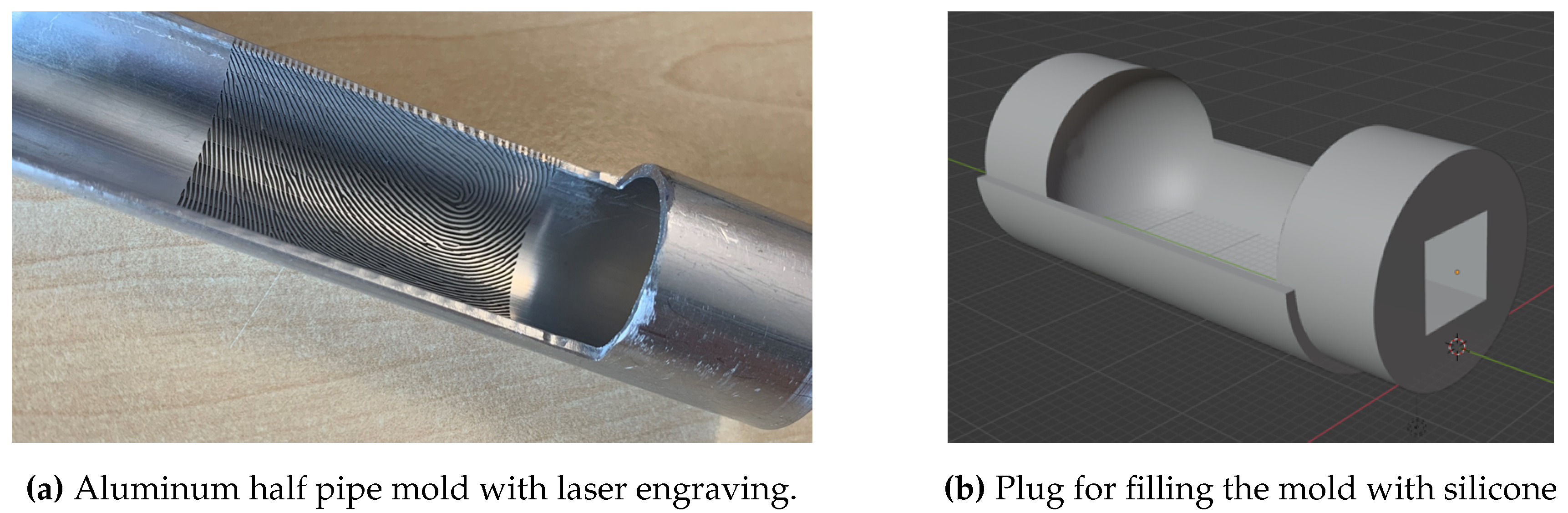

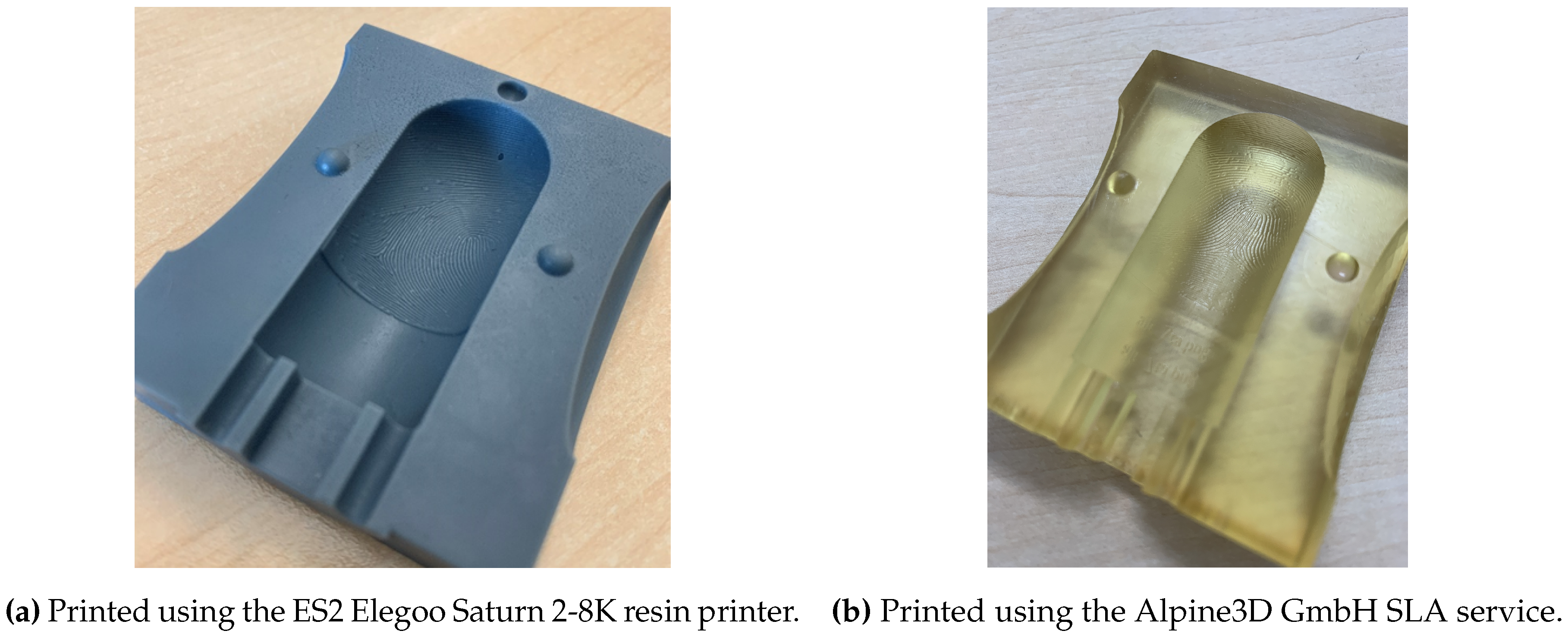

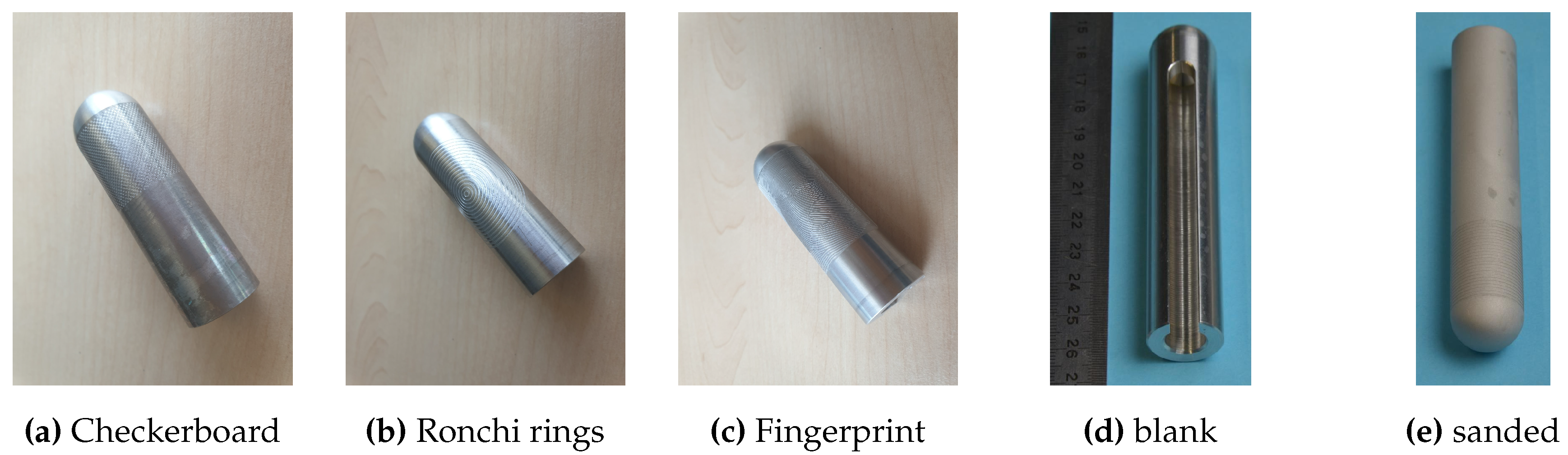

The comparison of manufacturing methodologies for the creation of fingerprint phantoms elucidates distinct advantages and disadvantages inherent in each approach. Direct laser engraving on Laserline EPDM elastomer presents an economically feasible and expedient method. However, resulting phantoms may exhibit inconsistencies in ridge line thickness and stiffness, potentially impeding their compatibility with certain sensors. Conversely, silicone plates engraved with lasers offer uniform ridge thickness and clarity, yet fail to mimic the elasticity of human tissue or the flattening of the finger when rolled over sensors. The use of an aluminum half-pipe mold for silicone phantoms amalgamates the precision of laser engraving with the malleability of silicone, albeit at a higher cost and potential introduction of artifacts. Additionally, 3D printing of resin molds provides unparalleled flexibility in design, accommodating complex features such as minutiae, and the potential for non-cylindrical finger shapes, albeit with the caveat of requiring attention when designing the 3D model of the mold to prevent small artifacts.

Laser-engraved phantom structures in elastomers, along with our in-house manufactured Dragon Skin 10 Fast silicone and commercially available Gospire silicone, exhibit the clearest distinction between ridges and valleys. This determination is based on the evident emergence of well-defined ridges in the measured profiles. Nonetheless, these findings may be influenced by the flat geometry of the materials, contrasting with the cylindrical shape of the other fingerprint phantoms.

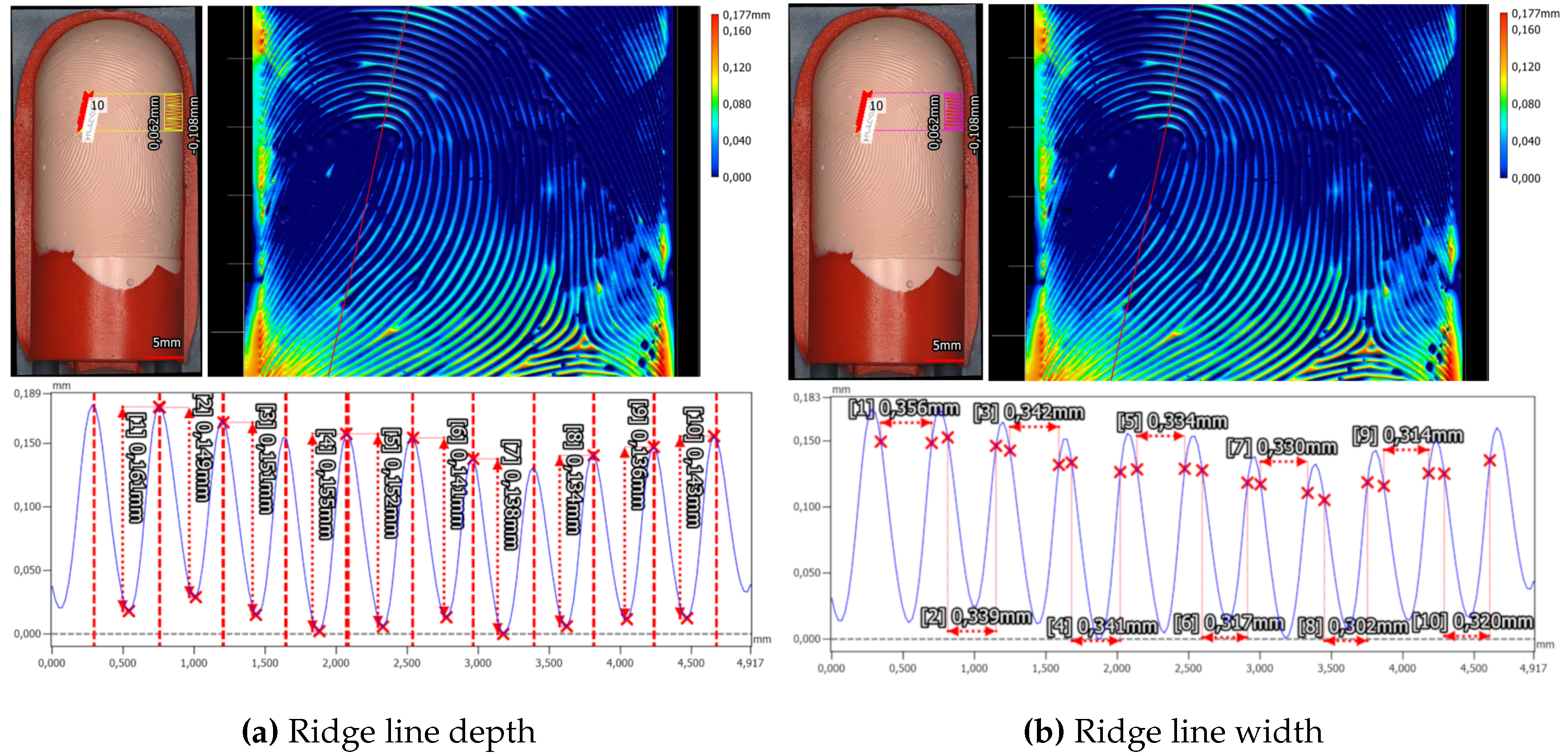

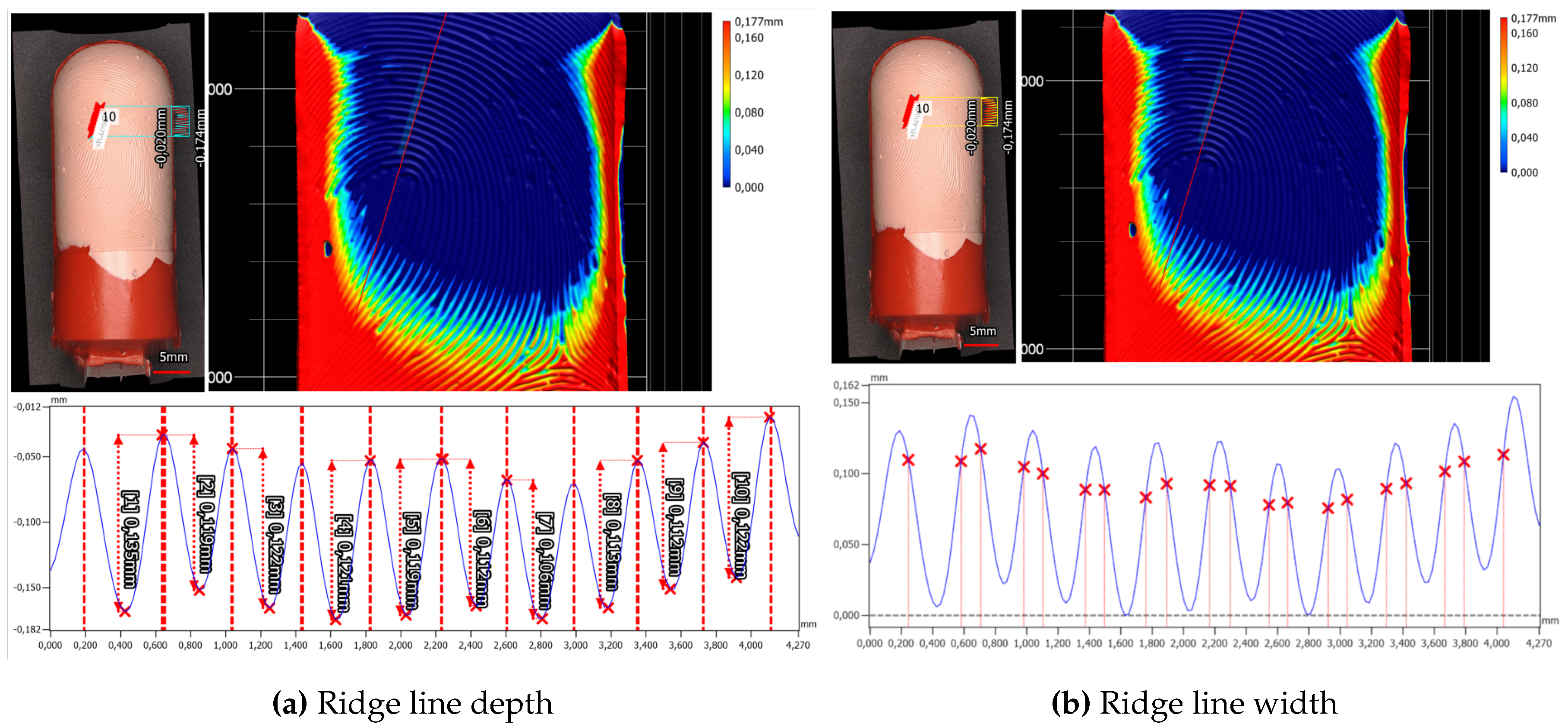

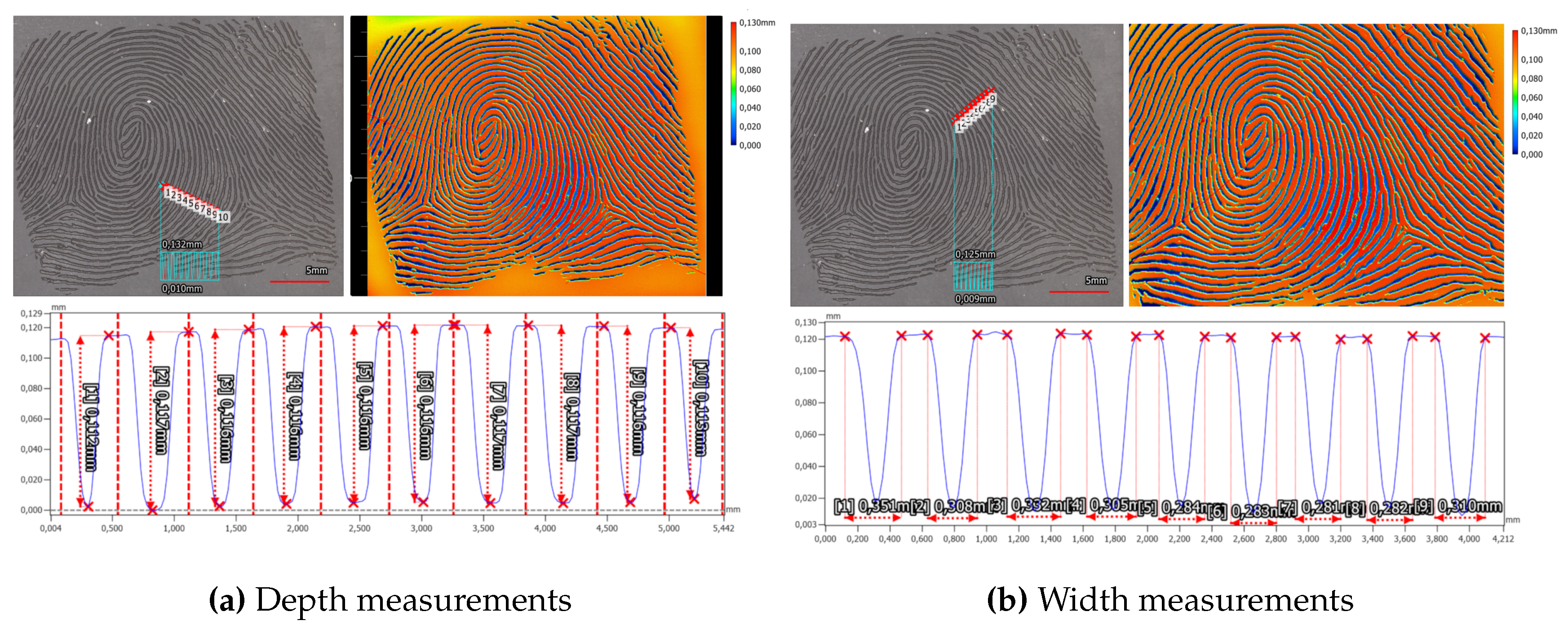

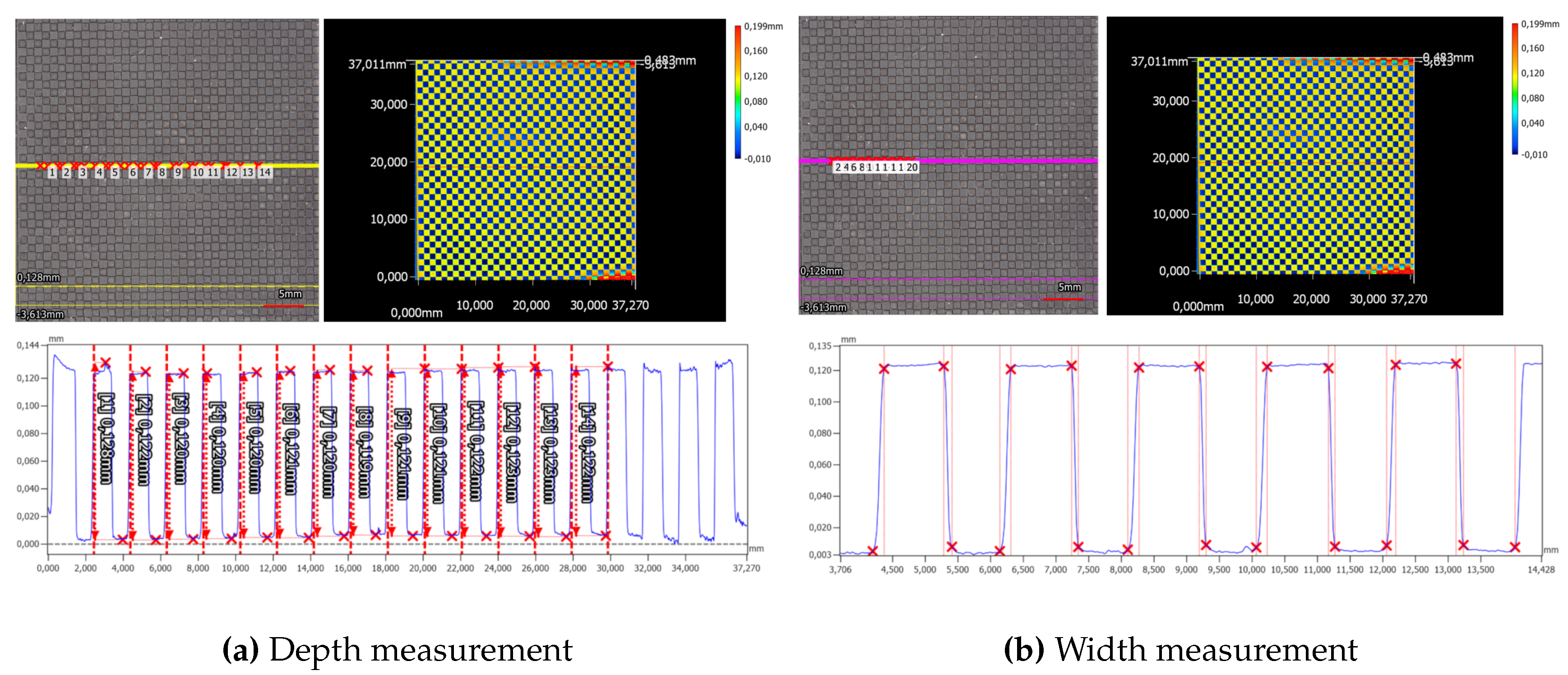

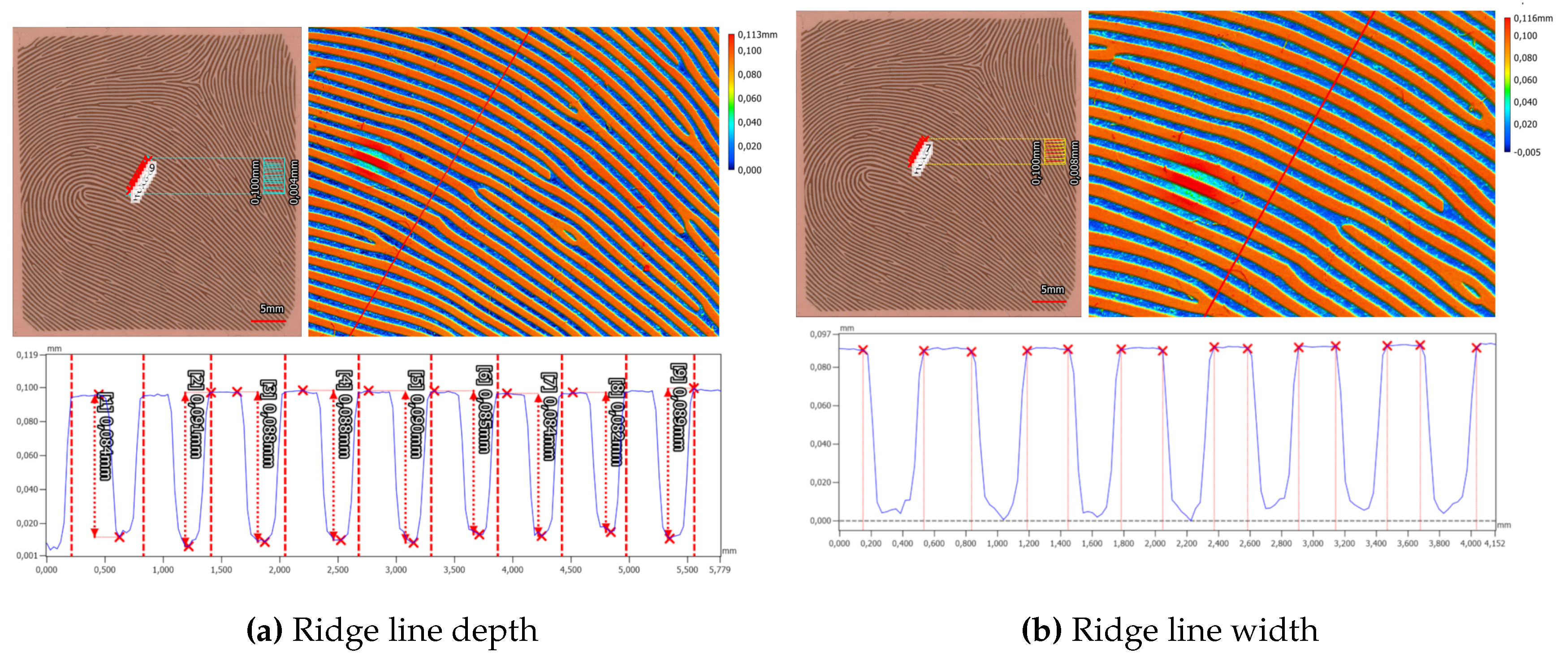

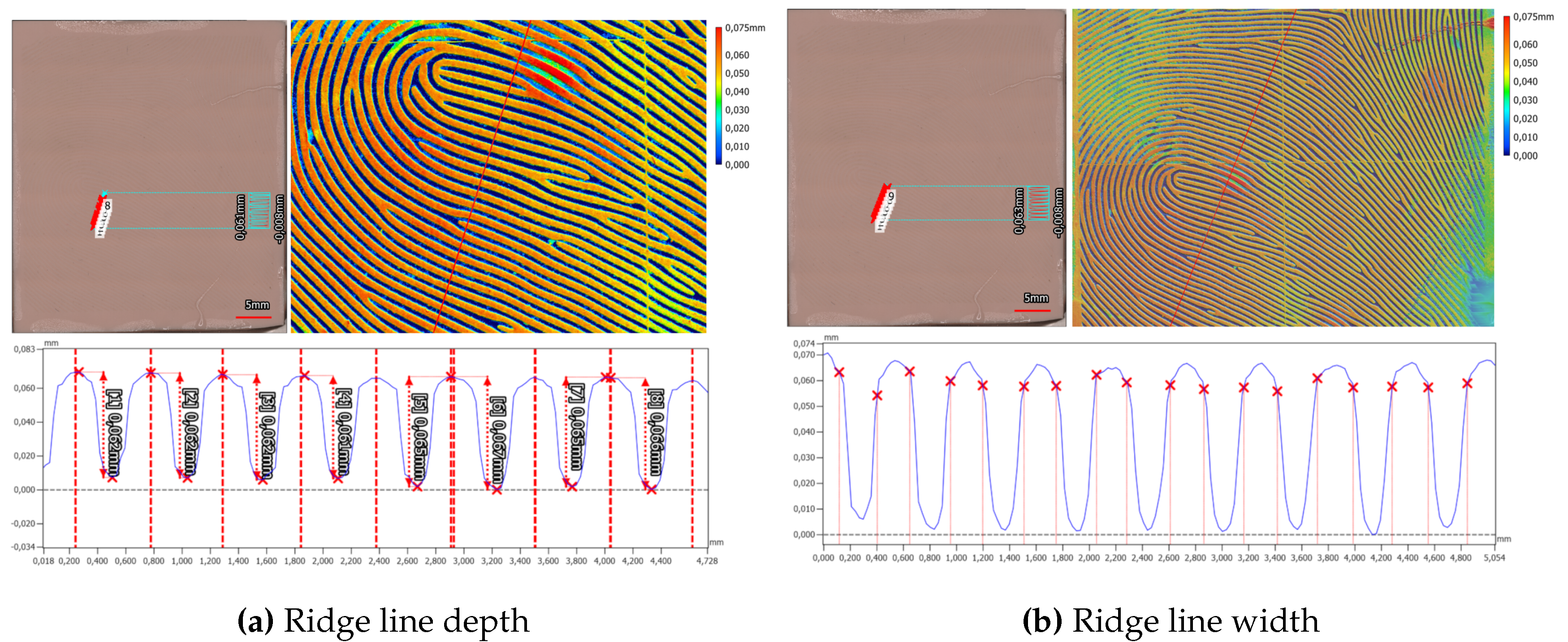

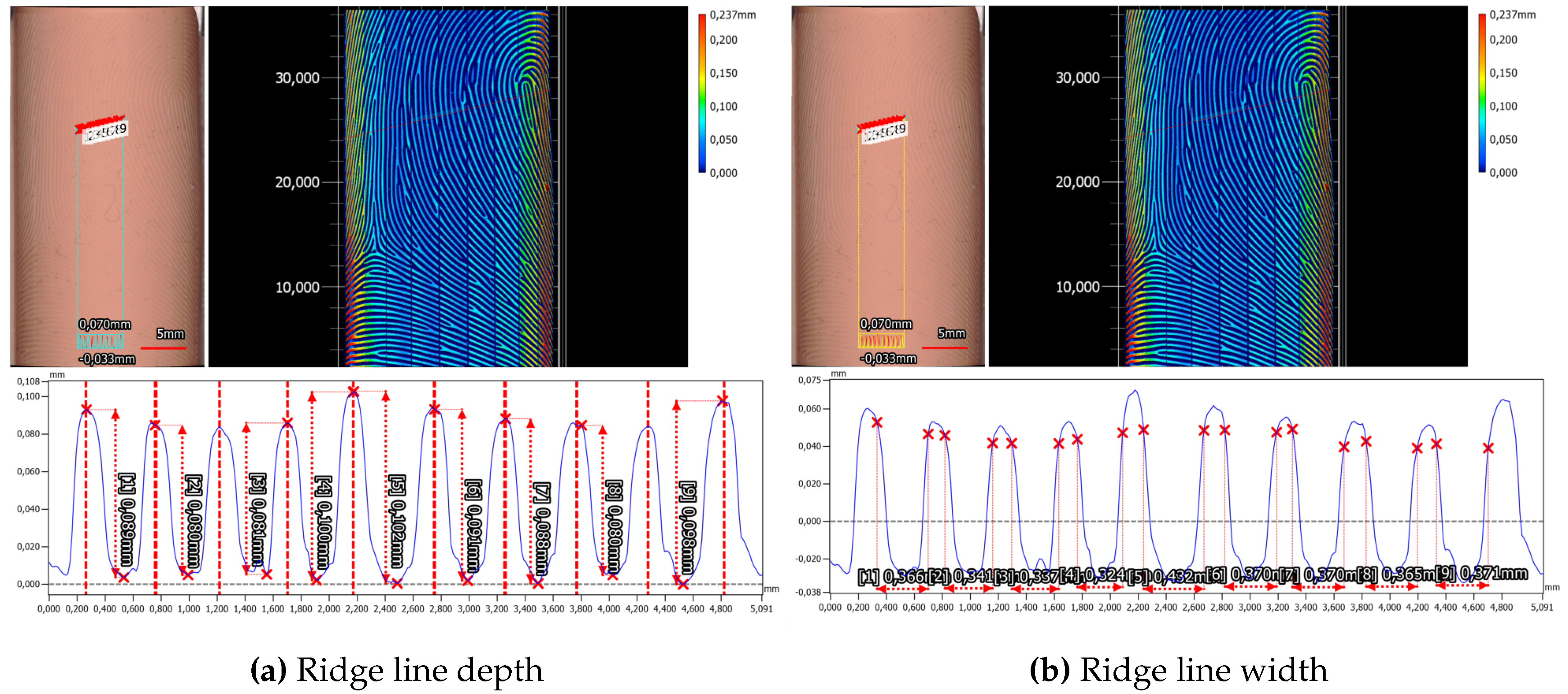

The Dragon Skin 10-based phantoms exhibit a depth range of , whereas those produced using the Alpine 3D 3D-printed mold reach up to for a fresh (Day 0) Gelafix-based fingerprint phantom, fabricated with an in-house 3D resin printer. This height disparity between ridges and valleys is adequate for generating images on contact-based fingerprint scanners. However, it is necessary to assess whether the minimal depth suffices to produce distinguishable structures under varying parameters, such as more applied pressure or the use of even softer materials.

Fingerprint phantoms produced with 3D-printed molds commonly feature narrow and pointed ridges, posing challenges in accurately estimating ridge and valley widths. For rolled fingerprints, the narrow and pointed ridges are not critical, since flattening under pressure increases the contact surface area. Nonetheless, it’s worth noting that this ridge line pattern increases the risk of interrupted ridges, potentially caused by small air bubbles within the material.

Despite the intermediary step involving the creation of negative molds from aluminum master targets, an accurate preservation of the initial structure depth () to the master targets has been achieved (). However, a drawback of this method is the absence of fingerprint structures on the phantom’s fingertip part. The characteristics of the ridges lie somewhere between the phantoms created via laser engraving and casting using 3D-printed resin molds.

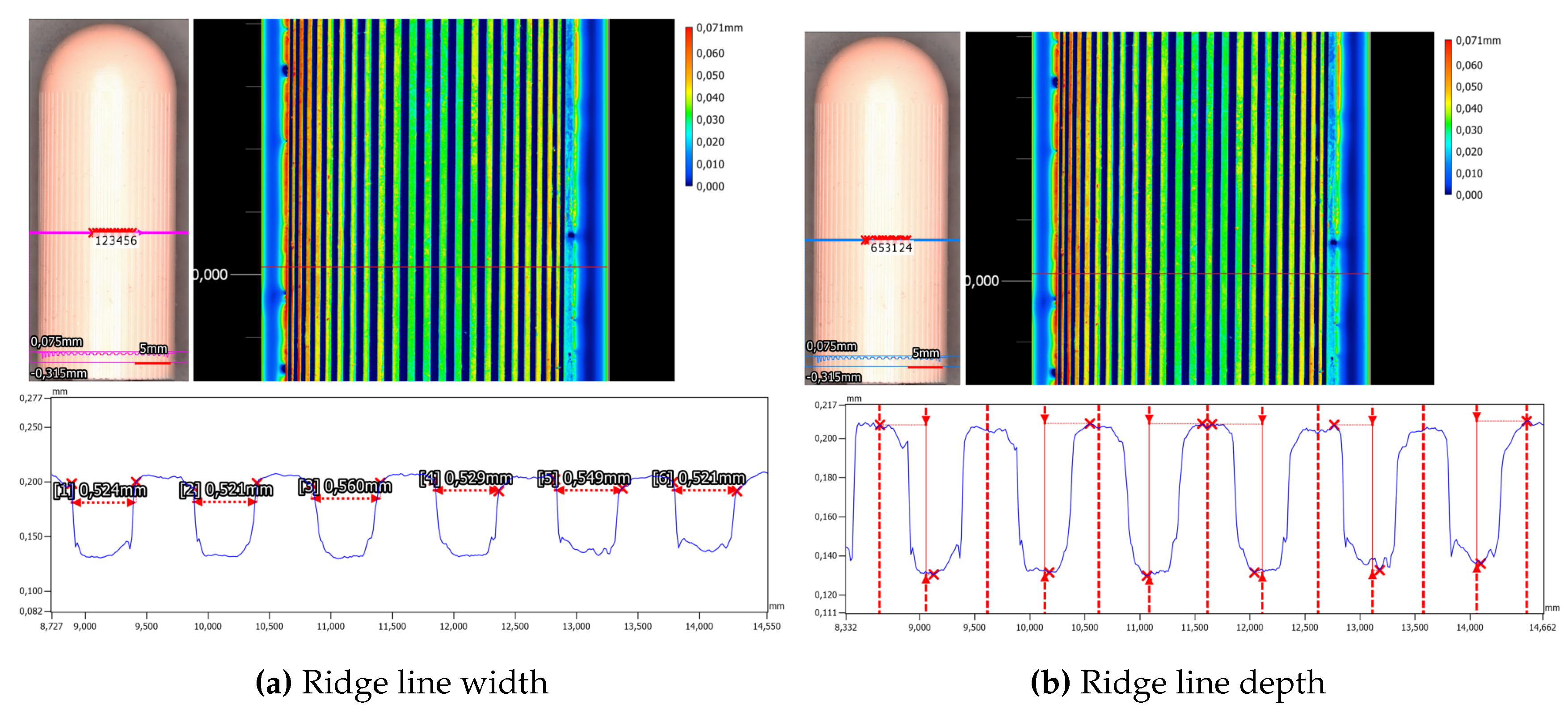

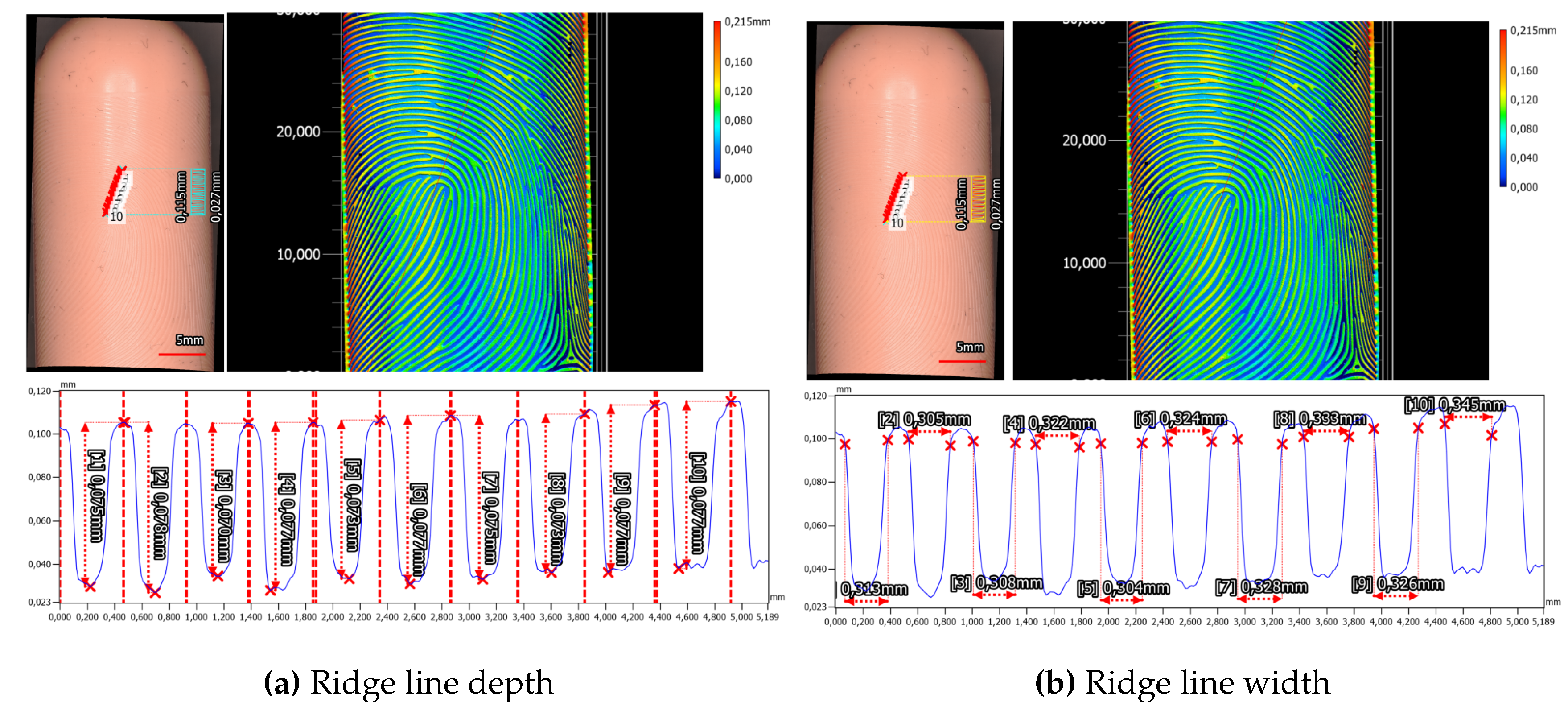

To put the measured results into perspective, a ridge line width in the range of

can be expected for a human fingerprint [

62]. Furthermore, to indicate the magnitude of possible ridge line depths, we measured and evaluated the ridge line depth of a few human fingers, leading to a ridge line depth of

. Overall, in comparison with 3D captures of real fingers, the flatter phantoms created via laser engraving more closely resemble the ridge line shape of real fingerprints.

The effect of skin color is an important consideration in the development of fingerprint phantoms. In our case, the elastomer material is consistently black, while Gelafix can be ordered in different colors, and silicone can be arbitrarily colored using various color pigments.

Notably, pigmentation is not necessary for contact-based recording processes that make use of capacitive, ultrasonic or thermal sensors, because they do not perceive the color. However, in contactless and optical scanner based applications, matching the skin color of the phantom to a wide range of possible skin colors is essential for accurate representation and reliable performance.

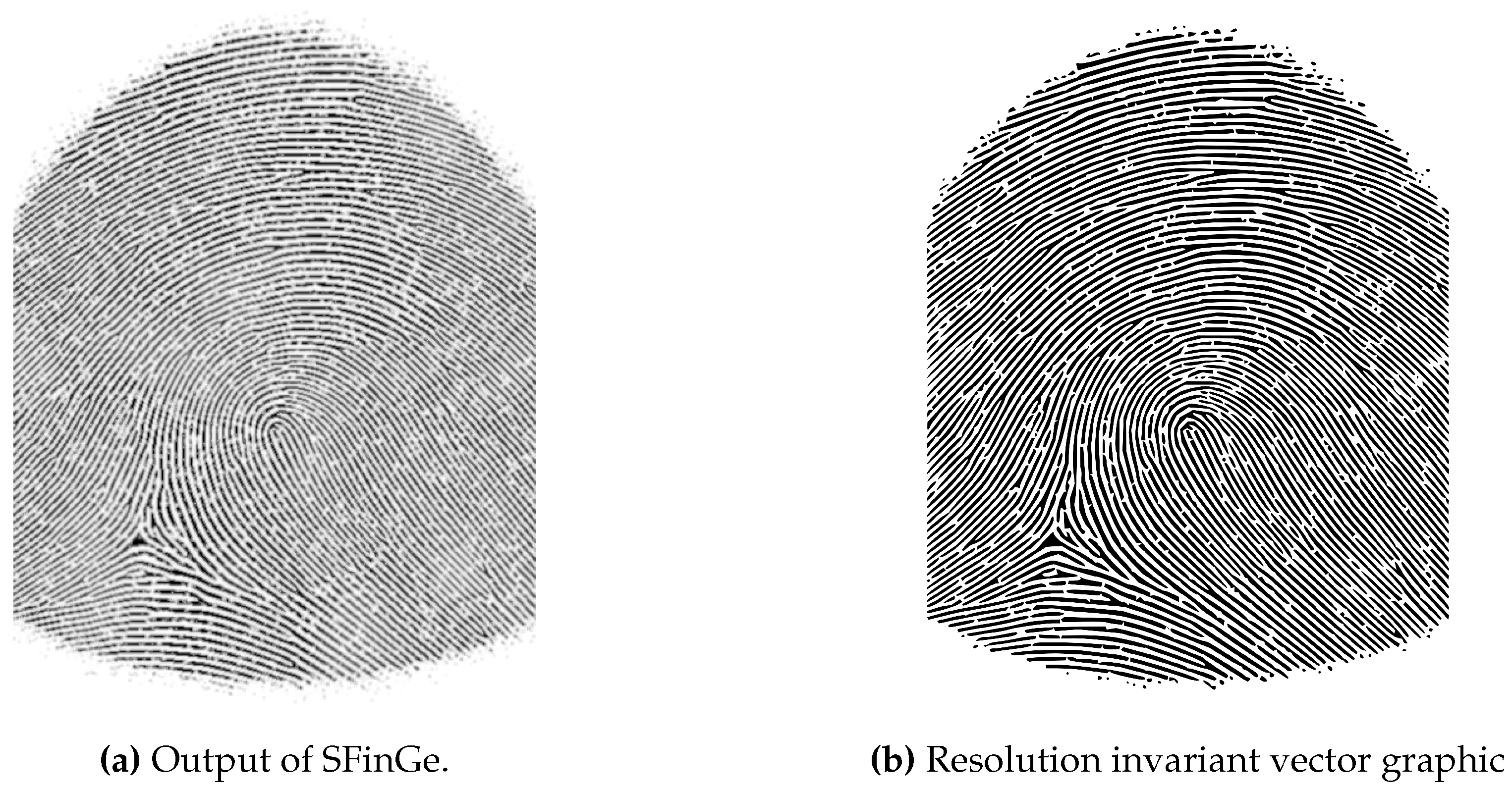

Furthermore, one of the challenges in creating high quality fingerprint phantoms that strongly influences the fidelity of the fingerprint phantoms is the mapping of the fingerprint pattern onto the 3D target shape. There needs to be a balance between realism of the finger shape and repeatability when creating the fingerprint recordings. A complex shape is susceptible to slight changes in the presentation angle and presentation pressure, which change the parts of the fingerprint pattern that are recorded by the contact-based fingerprint sensors and therefore reduces the average fidelity of the target. On the other hand, a too simple of a shape fails to test the real-world recording settings of the fingerprint devices. We struck for a middle ground by using a cylindrical base shape, either creating directly a phantom with this shape, or for the plate-like phantoms, by placing them onto a wooden cylinder. The cylindrical geometry has the advantage that the projection from the 2D to the 3D shape can be done without any projection errors. Additionally, we added a spherical half sphere fingertip for the 3D printed molds to allow for a more life-like shape that could be used for contactless fingerprint scanners.

The scalability of phantom production varies across methodologies. Direct laser engraving on elastomer or silicone plates allows for relatively straightforward upscaling, requiring only the creation of new target plates and fast laser processing. Conversely, 3D printing of resin molds offers extensive flexibility in its scalability due to its adaptability to various finger shapes, though hindered by the molding process and curing time. Meanwhile, CNC machining of aluminum master targets presents a more intricate and time-consuming process, less conducive to large-scale production due to specialized equipment requirements and extended production timelines.

Transitioning to the discussion on the usability of fingerprint phantoms across diverse sensor types, it becomes evident that the efficacy of synthetic phantoms hinges significantly on the manufacturing methodology and material properties. Contactless fingerprint sensors, operating through optical imaging techniques, necessitate phantoms with a realistic finger-like appearance to facilitate fair comparisons across sensors utilizing different pre-processing technologies, like color-based [

63] or learned fingertip segmentation [

64]. While the laser engraved aluminum half-pipe mold and 3D printed resin molds enable the creation of phantoms with lifelike geometry, the latter holds a slight advantage in representing human-like finger phantoms due to its ability to project fingerprint patterns onto rounded fingertip areas.

In contrast, slap recordings, commonly employed for swift and convenient fingerprint capture, pose unique challenges for phantom usability. While the laser engraved silicone plates demonstrate potential for high-quality slap recordings when used in their flat form, issues arise concerning the surface texture and stiffness of Laserline EPDM elastomers. A lot of pressure was required to register an image at the fingerprint sensor. In order to exclude unique difficulties of the GreenBit Dactyscan 84c scanner with the elastomer targets, we tested the Jenetric Livetouch Quattro (2nd gen) Up, Jenetric Livetouch Quattro Integrated Biometrics Five-O as well. For all tested sensors, the same issues arose, rendering the elastomer phantoms ill-suited for such applications.

For rolled recordings, crucial for high-quality fingerprint identification purposes, silicone phantoms stand out as viable options, especially those with a finger-like shape, due to their elasticity, facilitating smooth rolling over sensor surfaces. Although laser engraved plate phantoms can be adapted for rolled recordings by mounting them on a cylindrical, wooden target holder, challenges persist due to the thin silicone layer and reduced surface area exposure. This is exacerbated even more for the Laserline EPDM elastomers plates, because of the same issues as for slap recordings.

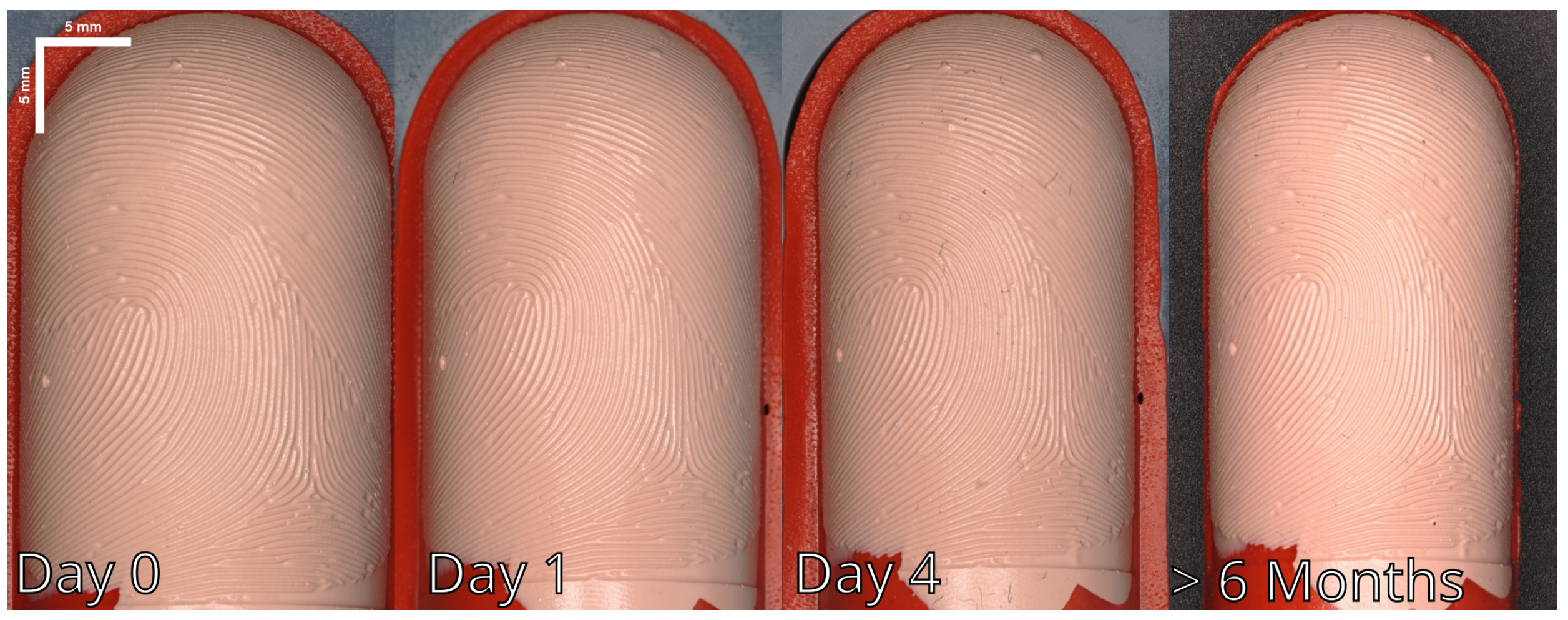

When assessing the durability of fingerprint phantoms, variations primarily arise from the choice of materials. The most pronounced impact of material degradation was observed with Gelafix fillings. As illustrated in

Table 3, they experienced significant shrinkage of over 17%, as well as hardening over time, rendering them unsuitable for high-quality sensor calibration and standardization purposes. Conversely, silicone exhibited minimal shrinkage, below 1%, and maintained its softness even after six months, establishing it as the optimal material for producing reliable and consistent phantoms.

8.3. Fidelity of 3D Targets

The quality of a fingerprint sample can be assessed according to the three aspects character, fidelity and utility, as stated in the ISO/IEC 29794-1:2016. As a measure of the utility of a fingerprint phantom, we used the template comparison score between the generated 2D fingerprint and the rolled fingerprint recording. Since the generated fingerprint patterns that are used for the phantom creation have a high character (i.e. are of good quality for template comparison) as shown by the NFIQ 2 values of

Table 5 and also share those fingerprint patterns over multiple manufacturing methods, we can interpret the differences in measured template comparison scores not only as differences in utility, but also in fidelity. This allows us to interpret the measured template comparison scores as quality indicator of the measured fingerprint phantom.

Furthermore, for the second iteration of the 3D printed resin mold manufactured by the Alpine3D SLA service, we investigated the influence of different finger types on the character and utility (and therefore also fidelity). We used the fingerprint classification scheme introduced by Karu and Jain in [

59], which classifies the fingerprints into arch, tented arch, left loop, right loop and whorl. All generated 2D fingerprints have a NFIQ 2 score between 46 and 59 and can therefore be interpreted as fingerprint with a good visual quality [

65]. Also the fingeprints recorded from rolling the corresponding phantoms on the GreenBit Dactyscan 84c can be considered good quality, because they are in a similar range of 40 to 55. In both cases, the whorl fingerprint pattern was the lowest scoring fingerprint class. This should not be interpreted as a worse performance of the whorl fingerprint class, since the values are calculated only for a single fingerprint pattern. But, since the character for the whorl class is lower than for the other fingerprint classes, we can also expect the utility of the measured samples to be lower. Moreover, we observed a problem with the ridge depth during fingerprint collection. As a result, the end-to-end fidelity scores for the whorl fingerprint class are lower than for the other patterns considering the Idkit (553) and the SourceAFIS (132) matchers. The other fingerprint classes have similar template comparison scores to one another and fall in the range of between 803 and 977 for the Idkit matcher and 245 to 304 for the SourceAFIS matcher. More research is required to investigate whether the lower utility of the whorl fingerprint class is a singular effect due to the combination of a lower character combined with manufacturing problems, or if it is indicative or a finger class depended difference.

Interestingly, we observed a worse performance of the Bozorth3 matcher with the Mindtct Minutiae extractor for the arch and tented arch fingerprint class, even lower than the whorl fingerprint class. For both Idkit as well as FingerNet combined with SourceAFIS, no such effect is visible. Since both other matchers do not agree on the score difference, we assume that this is a matcher inherent effect.

The overall level of the 3D printed resin mold filled with silicone improved from the first in-house experimentation to the second version (31.4% Bozorth3, 34.8% Idkit, 21.5% SourceAFIS). The major difference between the 3D model of the in-house produced sample and the second sample is that the first one has a lower ridge depth on the boundary regions when compared to the center ones. The correction of this, as well as the slower and more precise printing process strongly influences the end-to-end fidelity. Furthermore, the comparison to Gelafix as an alternative filling material revealed that silicone performed better (29.6% Bozorth3, 7.9% Idkit, -0.5% SourceAFIS). We observed a strong shrinking and hardening of the Gelafix material, which also changed its rolling behavior and made it infeasible for durable fingerprint phantom production, which could be the explanation for the worse performance. Nonetheless, Gelafix is a valuable material for fingerprint phantom production in the context of PAD, because it consists mainly of a mixture of water, gelatine and glycerin, which appears human flesh like to contact based fingerprint sensors. The downside of this material is that the phantoms can only be used for a short period of time.

Besides the 3D printed molds, both the laser engraving as well as the CNC machining created phantoms with a very high end-to-end fidelity. Only the elastomer samples are an exception to this, which had the lowest score of all manufacturing methods. This is the case because of the stiffness of the material, which introduced problems creating an image using the contactbased fingerprint scanners.

The intra-class variability scores, which measure the template comparison scores between recordings of one phantom type, confirms the usability of the phantoms for qualifying a fingerprint sensor. Only the elastomer material, as well as the Gelafix filled 3D printed resin mold had scores significantly lower than the other manufacturing methods. This implies that those two materials are not well suited for creating repeatable recordings and overlaps with the insight from the end-to-end fidelity observations. The intra-class variability across different phantom types underlines the conclusions made from the intra-class variability assessment for a single phantom type, highlighting the performance of the laser engraving as a manufacturing methodology and confirming the usability of the 3D printed technology.

Regarding the scaling pre-processing, it should be noted that for the case of very good matching fingerprint recordings that achieve a maximal rating, like those created from CNC machining or laser engraving (except elastomer), the predictive power of the scaling values is lower. This is because even a mismatch in scaling can result in a score that is still capped by the high score, therefore creating a plateau for different scaling values. This is reflected by the zero standard deviation.

Nonetheless, the results of the pre-processing provide an interesting insight: Some phantoms have a non-square optimal scaling value. This is especially prominent for the laser engraving aluminum half pipe mold with silicone filling and the 3D printed resin molds filled with silicone. We suspect that this is the case because the projection from 2D to 3D was done for a static case, meaning that the rolling behavior is expected to follow the rolling of a fixed diameter cylinder. However, since the silicone is soft enough to emulate the realistic rolling behavior of a finger, which deforms under pressure because of the contact with the sensor surface, the contact surface widens. This leads to a stretched fingerprint recording along the rolling direction, which is what we can observe. Furthermore, the phantom created from the Gelafix filling material had a higher stiffness and therefore has a less pronounced difference between the x and y scaling values.

The repeatability of generating fingerprint recordings of the phantoms, although significantly improved when compared to real finger recordings, is still influenced by many factors, including the presentation angle, presentation pressure, and position on the sensor surface. These factors can vary significantly between different user handling the phantoms, and even for the same user, making it difficult to obtain consistent and repeatable results. A robotic arm, on the other hand, could be programmed to follow a precise rolling procedure, ensuring consistent presentation conditions for each recording and eliminating the human factor from the rolling process. This level of precision is essential for obtaining highly repeatable results in fingerprint comparison and more research is required to create this setup.