Submitted:

20 March 2024

Posted:

20 March 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

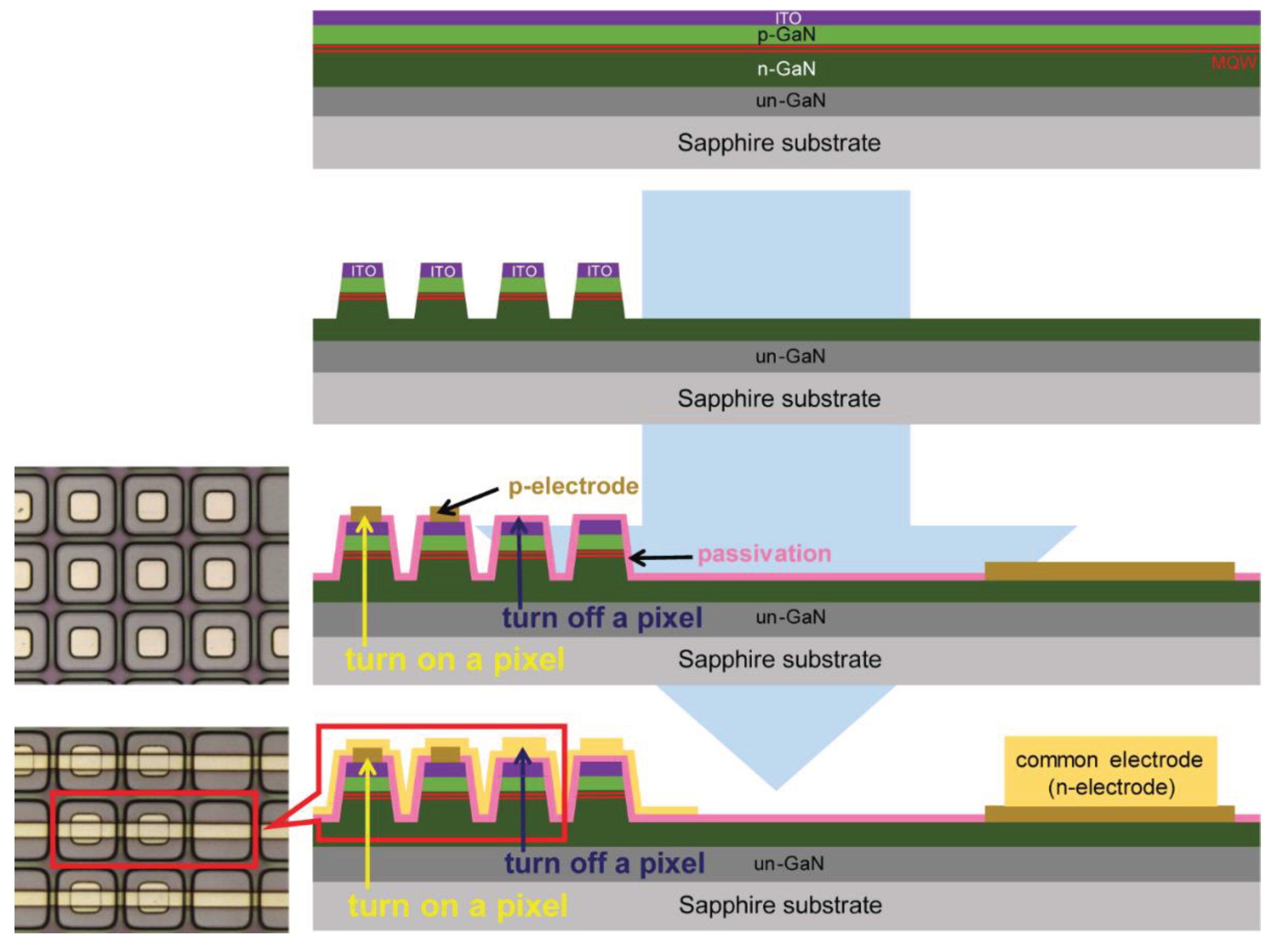

2. Experimental Section

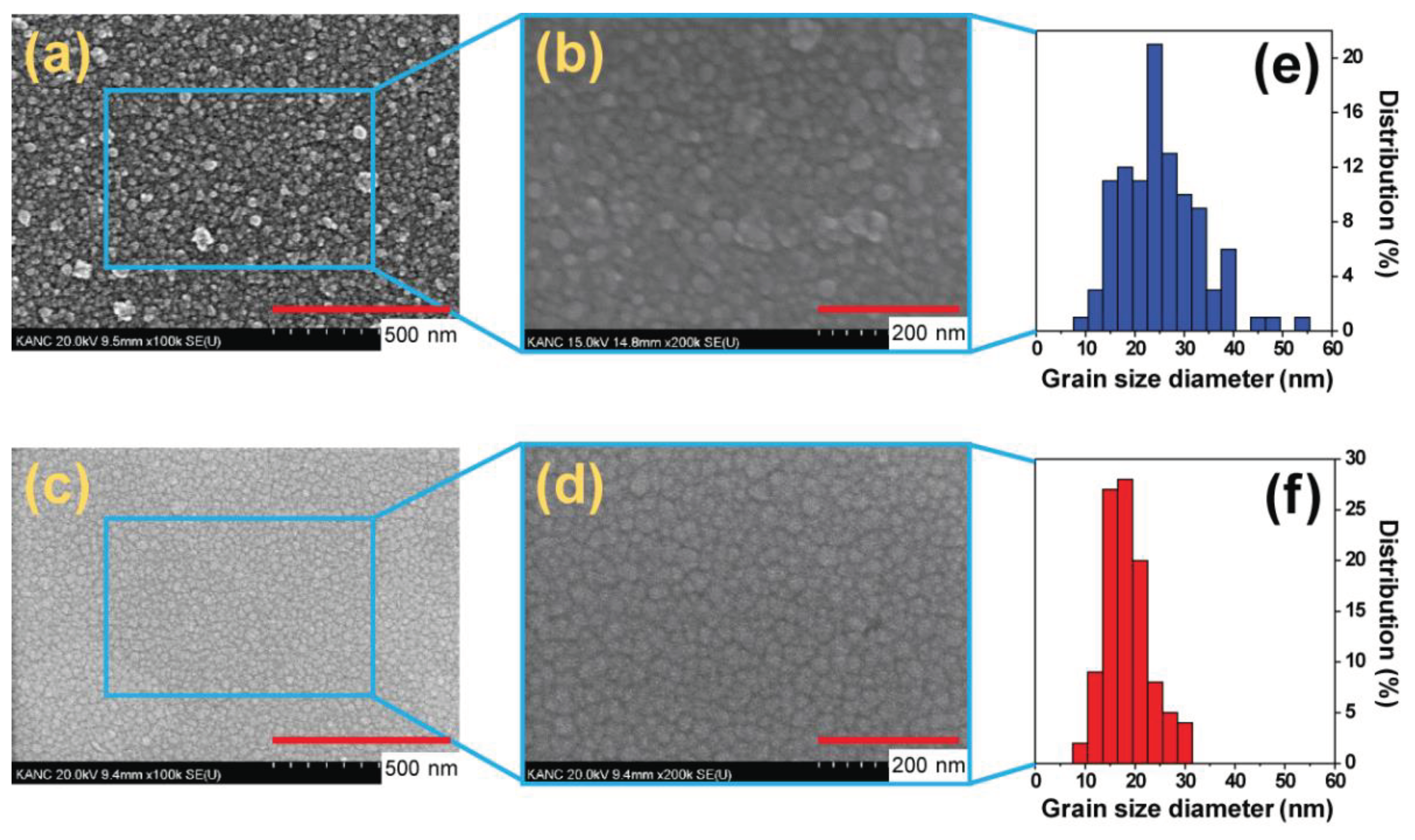

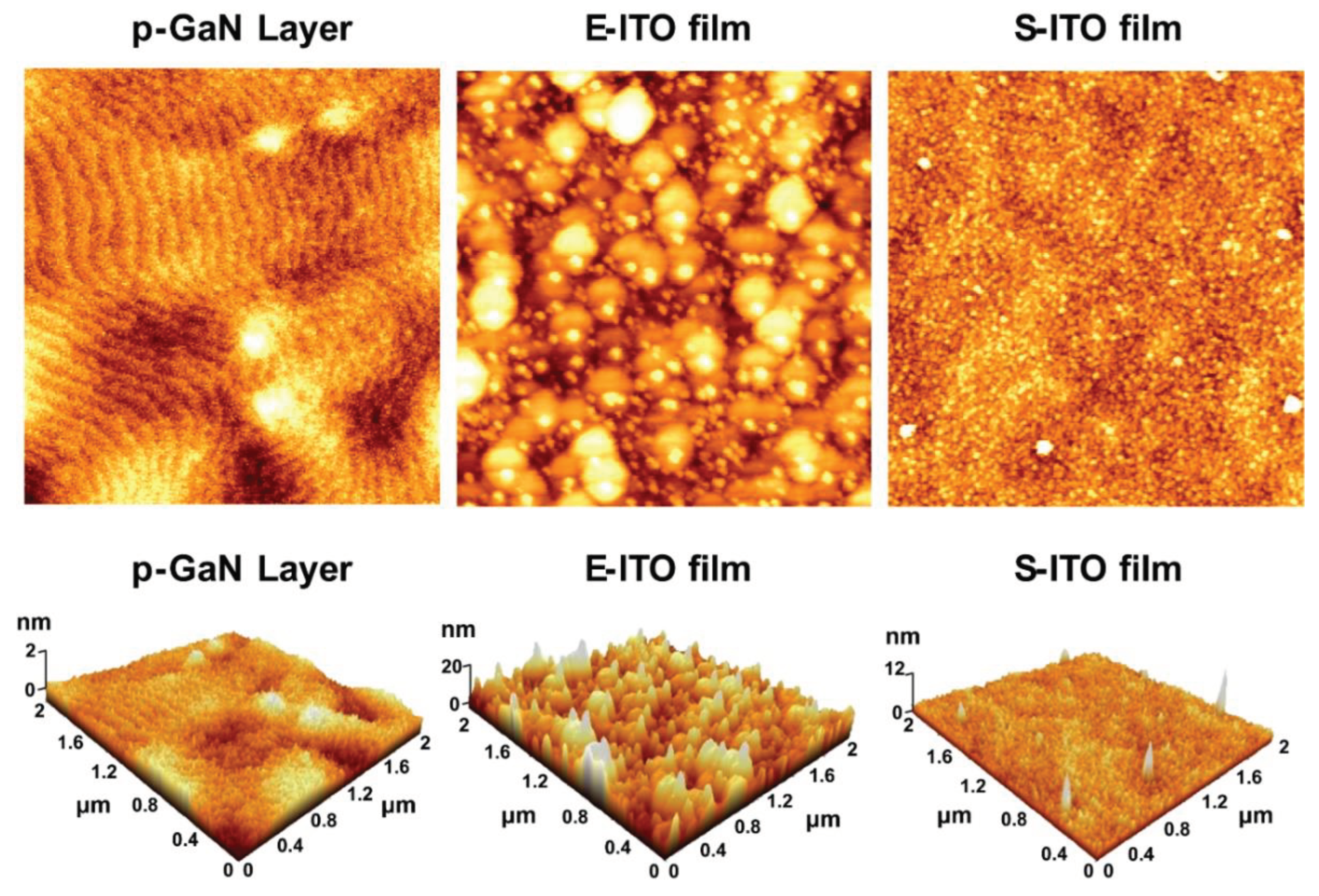

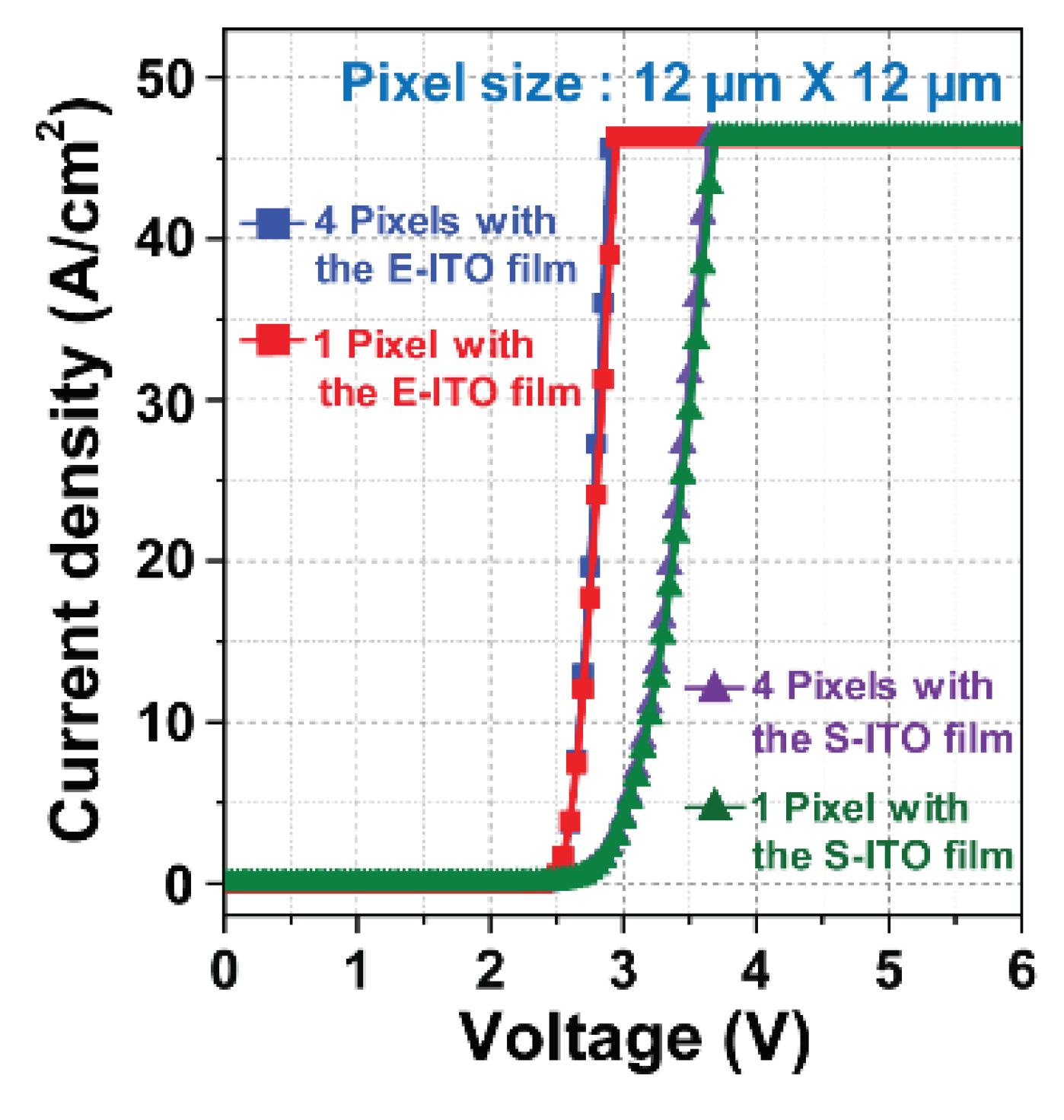

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Huang, Y.; Hsiang, E.-L.; Deng, M.-Y.; Wu, S.-T. Mini-LED, Micro-LED and OLED displays: present status and future perspectives. Light. Sci. Appl. 2020, 9, 1–16 . [CrossRef]

- Chen, Z.; Yan, S.; Danesh, C. MicroLED technologies and applications: characteristics, fabrication, progress, and challenges. J. Phys. D: Appl. Phys. 2020, 54, 123001 . [CrossRef]

- Wu, T.; Sher, C.-W.; Lin, Y.; Lee, C.-F.; Liang, S.; Lu, Y.; Chen, S.-W.H.; Guo, W.; Kuo, H.-C.; Chen, Z. Mini-LED and Micro-LED: Promising Candidates for the Next Generation Display Technology. Appl. Sci. 2018, 8, 1557 . [CrossRef]

- Lin, J.Y.; Jiang, H.X. Development of microLED. Appl. Phys. Lett. 2020, 116, 100502 . [CrossRef]

- Qi, L.; Zhang, X.; Chong, W.C.; Li, P.; Lau, K.M. 848 ppi high-brightness active-matrix micro-LED micro-display using GaN-on-Si epi-wafers towards mass production. Opt. Express 2021, 29, 10580-10591.

- Lu, S.; Li, J.; Huang, K.; Liu, G.; Zhou, Y.; Cai, D.; Zhang, R.; Kang, J. Designs of InGaN micro-LED structure for improving quantum efficiency at low current density. Nanoscale Res. Lett. 2021, 16, 99.

- Xiong, J.; Hsiang, E.-L.; He, Z.; Zhan, T.; Wu, S.-T. Augmented reality and virtual reality displays: emerging technologies and future perspectives. Light. Sci. Appl. 2021, 10, 1–30 . [CrossRef]

- Bae, J.; Shin, Y.; Yoo, H.; Choi, Y.; Lim, J.; Jeon, D.; Kim, I.; Han, M.; Lee, S. Quantum dot-integrated GaN light-emitting diodes with resolution beyond the retinal limit. Nat. Commun. 2022, 13, 1–9 . [CrossRef]

- Jin, S.X.; Li, J.; Li, J.Z.; Lin, J.Y.; Jiang, H.X. GaN microdisk light emitting diodes. Appl. Phys. Lett. 2000, 76, 631–633 . [CrossRef]

- Day, J.; Li, J.; Lie, D.Y.C.; Bradford, C.; Lin, J.Y.; Jiang, H.X. III-Nitride full-scale high-resolution microdisplays. Appl. Phys. Lett. 2011, 99, 031116 . [CrossRef]

- Liu, Y.; Feng, F.; Zhang, K.; Jiang, F.; Chan, K.-W.; Kwok, H.S.; Liu, Z. Analysis of size dependence and the behavior under ultrahigh current density injection condition of GaN-based Micro-LEDs with pixel size down to 3 μm. J. Phys. D: Appl. Phys. 2022, 55, 315107.

- Chen, J.; Brewer, W.D. Ohmic contacts on P-GaN. Adv. Electron. Mater. 2015, 1, 1500113.

- Zahir, N.H.; Talik, N.A.; Harun, H.N.; Kamarundzaman, A.; Tunmee, S.; Nakajima, H.; Chanlek, N.; Shuhaimi, A.; Abd Majid, W.H. Improved performance of InGaN/GaN LED by optimizing the properties of the bulk and interface of ITO on p-GaN. Appl. Surf. Sci. 2021, 540, 148406.

- Horng, R.-H.; Wuu, D.-S.; Lien, Y.-C.; Lan, W.-H. Low-resistance and high-transparency Ni/indium tin oxide ohmic contacts to p-type GaN. Appl. Phys. Lett. 2001, 79, 2925–2927 . [CrossRef]

- Sheremet, V.; Genç, M.; Elçi, M.; Aydınlı, A.; Altuntaş, I.; Ding, K.; Avrutin, V.; Özgür, .; Morkoç, H. The role of ITO resistivity on current spreading and leakage in InGaN/GaN light emitting diodes. Superlattices Microstruct. 2017, 111, 1177–1194 . [CrossRef]

- Zhanghu, M.; Hyun, B.-R.; Jiang, F.; Liu, Z. Ultra-bright green InGaN micro-LEDs with brightness over 10M nits. Opt. Express 2022, 30, 10119–10125 . [CrossRef]

- Leonard, J.T.; Cohen, D.A.; Yonkee, B.P.; Farrell, R.M.; DenBaars, S.P.; Speck, J.S.; Nakamura, S. Smooth e-beam-deposited tin-doped indium oxide for III-nitride vertical-cavity surface-emitting laser intracavity contacts. J. Appl. Phys. 2015, 118, 145304 . [CrossRef]

- Gandrothula, S.; Kamikawa, T.; Shapturenka, P.; Anderson, R.; Wong, M.; Zhang, H.; Speck, J.S.; Nakamura, S.; Denbaars, S.P. Optical and electrical characterizations of micro-LEDs grown on lower defect density epitaxial layers. Appl. Phys. Lett. 2021, 119, 142103 . [CrossRef]

- Fallah, H.R.; Ghasemi, M.; Hassanzadeh, A.; Steki, H. The effect of annealing on structural, electrical and optical properties of nanostructured ITO films prepared by e-beam evaporation. Mater. Res. Bull. 2007, 42, 487–496 . [CrossRef]

- Tuna, O.; Selamet, Y.; Aygun, G.; Ozyuzer, L. High quality ITO thin films grown by dc and RF sputtering without oxygen. J. Phys. D Appl. Phys. 2010, 43, 43 . [CrossRef]

- Ghorannevis, Z.; Akbarnejad, E.; Ghoranneviss, M. Structural and morphological properties of ITO thin films grown by magnetron sputtering. J. Theor. Appl. Phys. 2015, 9, 285–290 . [CrossRef]

- Zuev, D.A.; Lotin, A.A.; Novodvorsky, O.A.; Lebedev, F.V.; Khramova, O.D.; Petuhov, I.A.; Putilin, P.N.; Shatohin, A.N.; Rumyanzeva, M.N.; Gaskov, A.M. Pulsed laser deposition of ITO thin films and their characteristics. Semiconductors 2012, 46, 410–413 . [CrossRef]

- Socol, M.; Preda, N.; Rasoga, O.; Costas, A.; Stanculescu, A.; Breazu, C.; Gherendi, F.; Socol, G. Pulsed Laser Deposition of Indium Tin Oxide Thin Films on Nanopatterned Glass Substrates. Coatings 2018, 9, 19 . [CrossRef]

- Cho, H.; Yun, Y.-H. Characterization of indium tin oxide (ITO) thin films prepared by a sol–gel spin coating process. Ceram. Int. 2011, 37, 615–619 . [CrossRef]

- Hammad, T.M. Effect of annealing on electrical, structural, and optical properties of sol-gel ITO thin films. Phys. Status Solidi A 2009, 206, 2128–2132.

- Marikkannu, S.; Sanjeeviraja, C.; Piraman, S.; Ayeshamariam, A. Studies on the structural, optical, and electrical properties of jet-nebulized spray pyrolysis ITO thin films. J. Mater. Sci. Mater. Electron. 2015, 26, 2531–2537 . [CrossRef]

- Aouaj, M.A.; Diaz, R.; Belayachi, A.; Rueda, F.; Abd-Lefdil, M. Comparative study of ITO and FTO thin films grown by spray pyrolysis. Mater. Res. Bull. 2009, 44, 1458–1461 . [CrossRef]

- Hsu, S.-C.; Wuu, D.-S.; Zheng, X.; Horng, R.-H. Electron-Beam and Sputter-Deposited Indium–Tin Oxide Omnidirectional Reflectors for High-Power Wafer-Bonded AlGaInP Light-Emitting Diodes. J. Electrochem. Soc. 2009, 156, H281–G27 . [CrossRef]

- Shakiba, M.; Kosarian, A.; Farshidi, E. Effects of processing parameters on crystalline structure and optoelectronic behavior of DC sputtered ITO thin film. J. Mater. Sci. Mater. Electron. 2016, 28, 787–797 . [CrossRef]

- Liu, Z.; Lin, C.-H.; Hyun, B.-R.; Sher, C.-W.; Lv, Z.; Luo, B.; Jiang, F.; Wu, T.; Ho, C.-H.; Kuo, H.-C.; et al. Micro-light-emitting diodes with quantum dots in display technology. Light. Sci. Appl. 2020, 9, 1–23 . [CrossRef]

- Lin, Y.-S.; Li, C.N.; Chang, Y.-C.; Tseng, C.-L.; Shen, C.-H. Improved output power and low forward voltage for GaN-based light emitting diodes with an annealed ITO transparent conducting layer. J. Mater. Sci: Mater. Electron. 2016, 27, 6265–6270.

- Visher, G.S. Grain Size Distributions and Depositional Processes. J. Sediment. Res. 1969, 39 . [CrossRef]

- Son, K.J.; Kim, T.K.; Cha, Y.-J.; Oh, S.K.; You, S.-J.; Ryou, J.-H.; Kwak, J.S. Impact of plasma electron flux on plasma damage-free sputtering of ultrathin tin-doped indium oxide contact layer on p-GaN for InGaN/GaN light-emitting diodes. Adv. Sci. 2018, 5, 1700637.

- Tian, L.; Cheng, G.; Zheng, R.; Tian, K.; Yan, X.; Hu, Z.; Wang, H. Effect of sputtering deposition process of indium tin oxynitride on surface damage of gallium nitride film. Superlattices Microstruct. 2017, 109, 750–757 . [CrossRef]

- Foster, G.M.; Koehler, A.; Ebrish, M.; Gallagher, J.; Anderson, T.; Noesges, B.; Brillson, L.; Gunning, B.; Hobart, K.D.; Kub, F. Recovery from plasma etching-induced nitrogen vacancies in p-type gallium nitride using UV/O3 treatments. Appl. Phys. Lett. 2020, 117, 082103 . [CrossRef]

- Gîrgel, I.; Edwards, P.R.; Le Boulbar, E.; Coulon, P.-M.; Sahonta, S.-L.; Allsopp, D.W.E.; Martin, R.W.; Humphreys, C.J.; Shields, P.A. Investigation of indium gallium nitride facet-dependent nonpolar growth rates and composition for core–shell light-emitting diodes. J. Nanophotonics 2016, 10, 016010 . [CrossRef]

- Bi, Z.; Gustafsson, A.; Lenrick, F.; Lindgren, D.; Hultin, O.; Wallenberg, L.R.; Ohlsson, B.J.; Monemar, B.; Samuelson, L. High In-content InGaN nano-pyramids: Tuning crystal homogeneity by optimized nucleation of GaN seeds. J. Appl. Phys. 2018, 123 . [CrossRef]

- Senawiratne, J.; Chatterjee, A.; Detchprohm, T.; Zhao, W.; Li, Y.; Zhu, M.; Xia, Y.; Li, X.; Plawsky, J.; Wetzel, C. Junction temperature, spectral shift, and efficiency in GaInN-based blue and green light emitting diodes. Thin Solid Films 2010, 518, 1732–1736.

- Kim, K.; Schmidt, M.C.; Sato, H.; Wu, F.; Fellows, N.; Saito, M.; Fujito, K.; Speck, J.S.; Nakamura, S.; DenBaars, S.P. Improved electroluminescence on nonpolar m -plane InGaN/GaN quantum wells LEDs. Phys. Status solidi (RRL) – Rapid Res. Lett. 2007, 1, 125–127 . [CrossRef]

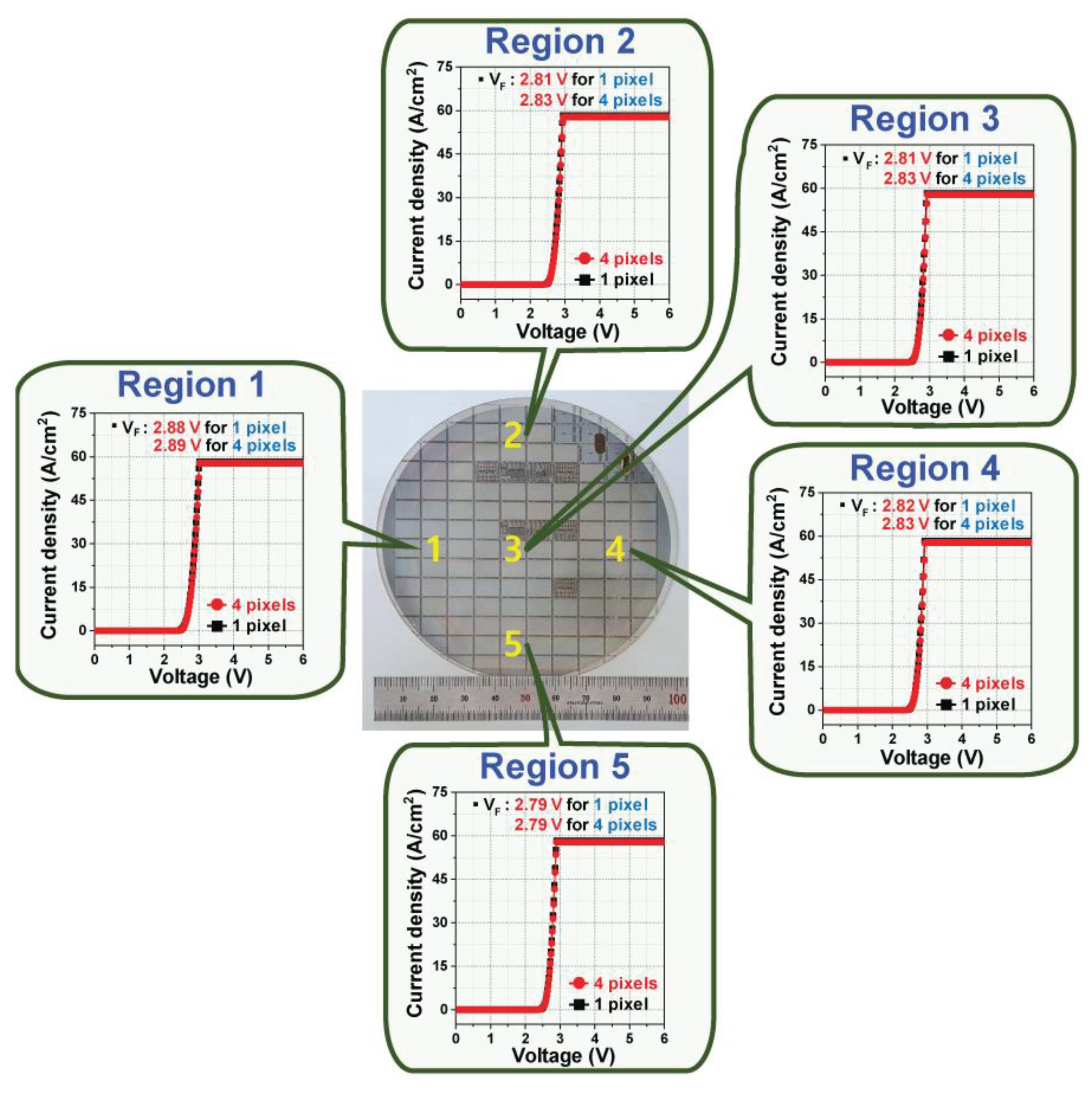

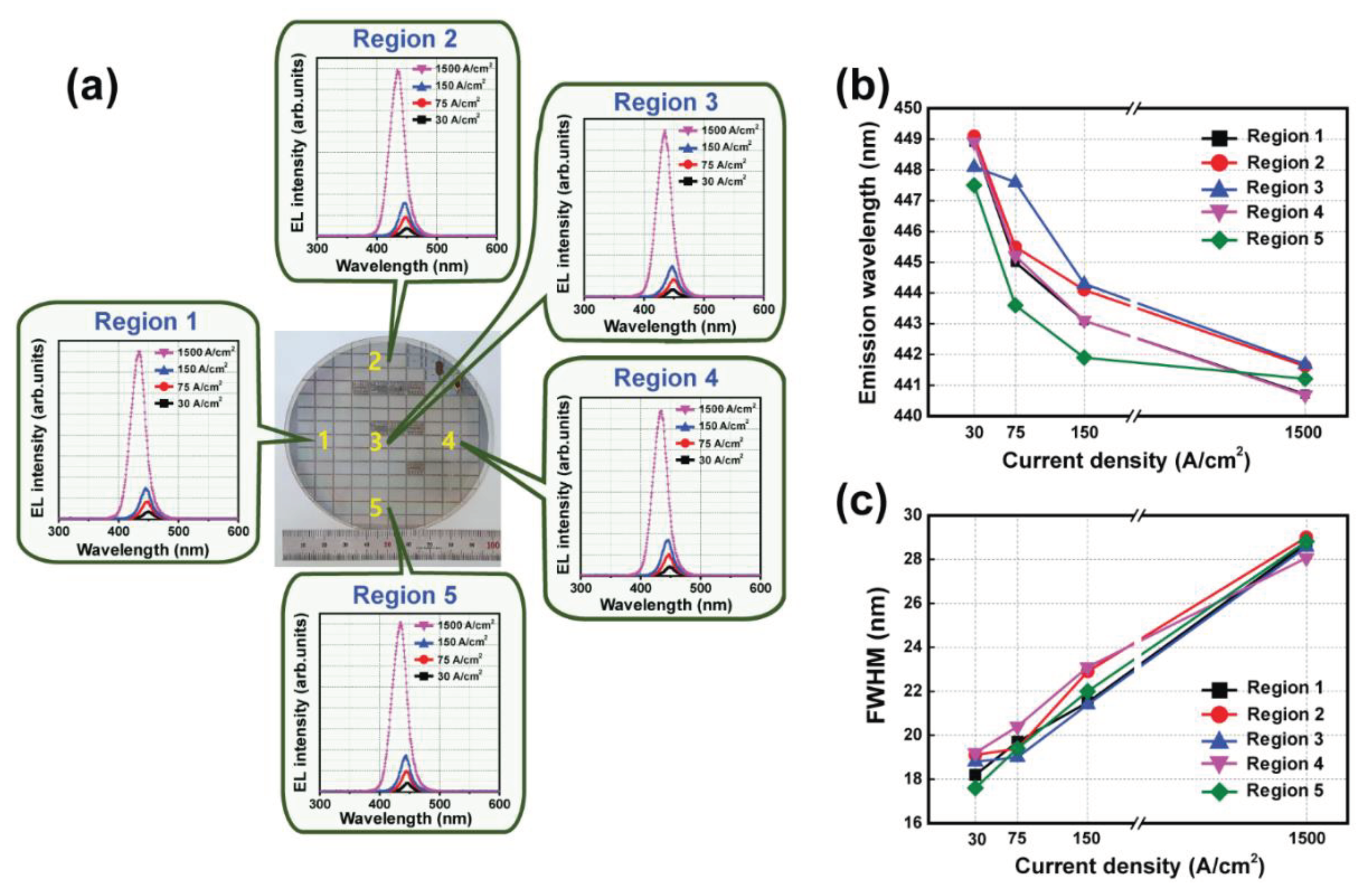

| Position | EL property | Current density | |||

|---|---|---|---|---|---|

| 30 A/cm2 | 75 A/cm2 | 150 A/cm2 | 1500 A/cm2 | ||

| Region 1 | Emission wavelength [nm] | 448.9 | 445.0 | 443.1 | 440.7 |

| FWHM [nm] | 18.2 | 19.7 | 21.5 | 28.7 | |

| Region 2 | Emission wavelength [nm] | 449.1 | 445.5 | 444.1 | 441.6 |

| FWHM [nm] | 19.1 | 19.4 | 22.9 | 29.0 | |

| Region 3 | Emission wavelength [nm] | 448.1 | 447.6 | 444.3 | 441.7 |

| FWHM [nm] | 18.8 | 19.0 | 21.4 | 28.6 | |

| Region 4 | Emission wavelength [nm] | 448.9 | 445.2 | 443.1 | 440.7 |

| FWHM [nm] | 19.2 | 20.4 | 23.1 | 28.1 | |

| Region 5 | Emission wavelength [nm] | 447.5 | 443.6 | 441.9 | 441.2 |

| FWHM [nm] | 17.6 | 19.4 | 22.0 | 28.8 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).