Submitted:

20 March 2024

Posted:

21 March 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Materials and Methods

2.1. Colony

2.2. Diet Formulation

| Parameter | Initial Substrates | Young Larvae | |||

|---|---|---|---|---|---|

| D1i | D2 | D3 | D4 | ||

| Dry Matter | 278.0 | 304.1 | 255.8 | 245.2 | 302.6 |

| Organic matter | 239.2 | 284.6 | 238.5 | 230.2 | - |

| Crude Proteins | 40.1 | 20.1 | 81.5 | 121.8 | 112.9 |

| Crude Fat | 14.9 | 9.4 | 34.4 | 54.3 | 31.8 |

| Ash | 38.8 | 19.5 | 17.3 | 15.0 | 50.6 |

| Crude Fiber | 14.0 | 36.1 | 24.7 | - | 29.8 |

| Neutral detergent fiber | 48.1 | 68.8 | 85.1 | - | 43.8 |

| Acid detergent fiber | 22.9 | 59.0 | 35.5 | - | 37.6 |

| Acid detergent lignin | 7.60 | 18.7 | 12.5 | - | 7.2 |

| N-Free extractive ii | 612.53 | 720.39 | 382.94 | 220.41 | 77.4 |

| Starch | 94.1 | 135.3 | 51.9 | 6.1 | - |

2.3. Experimental Design

2.4. Larvae Growth

2.5. Chemical Analysis and Utilization of Substrate Nutrients

2.6. Substrate Temperature and Accumulated Degree Hours

2.7. Statistical Analysis

3. Results

3.1. Larvae Gowth

3.2. Larvae Chemical Composition

3.3. Substrates Chemical Composition

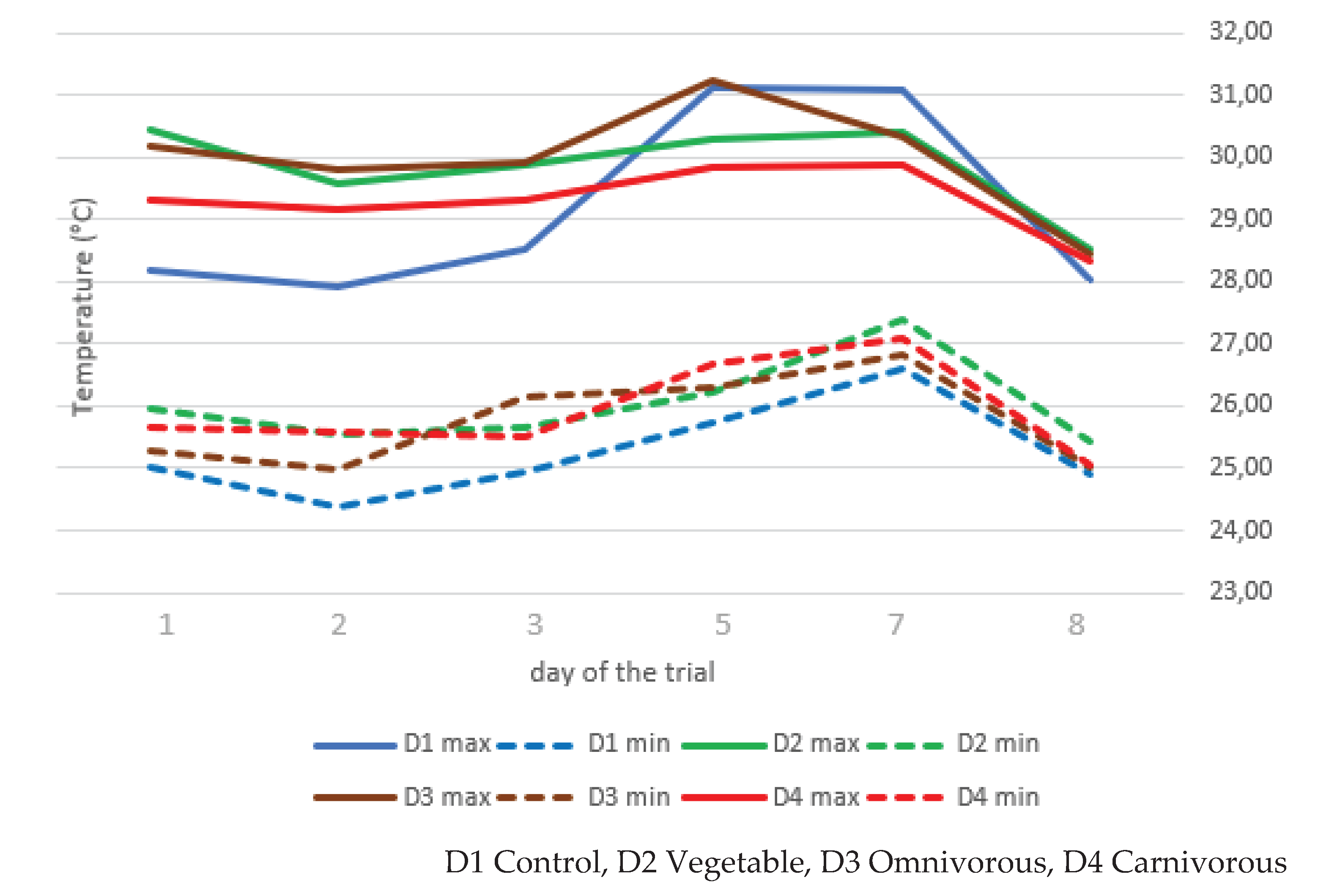

3.4. Substrate Temperature

3.5. Accumulated Degree Hours

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Acknowledgments

Conflicts of Interest

References

- Ambaye, T.G.; Rene, E.R.; Nizami, A.-S.; Dupont, C.; Vaccari, M.; Van Hullebusch, E.D. Beneficial Role of Biochar Addition on the Anaerobic Digestion of Food Waste: A Systematic and Critical Review of the Operational Parameters and Mechanisms. Journal of Environmental Management 2021, 290, 112537. [Google Scholar] [CrossRef] [PubMed]

- FAO, IFAD, UNICEF, WFP and WHO. 2023 In Brief to The State of Food Security and Nutrition in the World 2023Urbanization, Agrifood Systems Transformation and Healthy Diets across the Rural–Urban Continuum.; FAO; IFAD; UNICEF; WFP; WHO; Rome, FAO., 2023; ISBN 978-92-5-137952-3.

- Food and Agriculture Organization of the United Nations,The State of Food Security and Nutriion in the World。 Trasforming Food Systems for Food Security, Improved Nutrition and Affordable Healthy Diets for All “ FAO Rome, 2021. [CrossRef]

- FAO, IFAD, UNICEF, WFP and WHO. 2022. The State of Food Security and Nutrition in the World 2022. Repurposing Food and Agricultural Policies to Make Healthy Diets More Affordable.; FAO: Rome, FAO, 2022. [Google Scholar] [CrossRef]

- Food and Agriculture Organisation Water for Sustainable Food and Agriculture Water for Sustainable Food and Agriculture; 2017; ISBN 9789251099773.

- Clapp, J.; Moseley, W.G.; Burlingame, B.; Termine, P. Viewpoint: The Case for a Six-Dimensional Food Security Framework. Food Policy 2022, 106, 102164. [Google Scholar] [CrossRef]

- United Nations Environment Programme (2021). Food Waste Index Report 2021. Nairobi ISBN 978928073 8513.

- OECD; Food and Agriculture Organization of the United Nations OECD-FAO Agricultural Outlook 2023-2032; OECD-FAO Agricultural Outlook; OECD, 2023; ISBN 978-92-64-61933-3.

- Awasthi, S.K.; Sarsaiya, S.; Awasthi, M.K.; Liu, T.; Zhao, J.; Kumar, S.; Zhang, Z. Changes in Global Trends in Food Waste Composting: Research Challenges and Opportunities. Bioresource Technology 2020, 299, 122555. [Google Scholar] [CrossRef] [PubMed]

- Tiwary, A.; Williams, I.D.; Pant, D.C.; Kishore, V.V.N. Assessment and Mitigation of the Environmental Burdens to Air from Land Applied Food-Based Digestate. Environmental Pollution 2015, 203, 262–270. [Google Scholar] [CrossRef]

- Pham, T.P.T.; Kaushik, R.; Parshetti, G.K.; Mahmood, R.; Balasubramanian, R. Food Waste-to-Energy Conversion Technologies: Current Status and Future Directions. Waste Management 2015, 38, 399–408. [Google Scholar] [CrossRef]

- Salomone, R.; Saija, G.; Mondello, G.; Giannetto, A.; Fasulo, S.; Savastano, D. Environmental Impact of Food Waste Bioconversion by Insects: Application of Life Cycle Assessment to Process Using Hermetia Illucens. Journal of Cleaner Production 2017, 140, 890–905. [Google Scholar] [CrossRef]

- Siddiqui, S.A.; Ristow, B.; Rahayu, T.; Putra, N.S.; Widya Yuwono, N.; Nisa’, K.; Mategeko, B.; Smetana, S.; Saki, M.; Nawaz, A.; et al. Black Soldier Fly Larvae (BSFL) and Their Affinity for Organic Waste Processing. Waste Management 2022, 140, 1–13. [Google Scholar] [CrossRef]

- Diener, S.; Zurbrügg, C.; Tockner, K. Conversion of Organic Material by Black Soldier Fly Larvae: Establishing Optimal Feeding Rates. Waste Manag Res 2009, 27, 603–610. [Google Scholar] [CrossRef]

- Surendra, K.C.; Tomberlin, J.K.; Van Huis, A.; Cammack, J.A.; Heckmann, L.-H.L.; Khanal, S.K. Rethinking Organic Wastes Bioconversion: Evaluating the Potential of the Black Soldier Fly (Hermetia Illucens (L.)) (Diptera: Stratiomyidae) (BSF). Waste Management 2020, 117, 58–80. [Google Scholar] [CrossRef]

- Tomberlin, J.K.; Van Huis, A. Black Soldier Fly from Pest to ‘Crown Jewel’ of the Insects as Feed Industry: An Historical Perspective. JIFF 2020, 6, 1–4. [Google Scholar] [CrossRef]

- Lalander, C.; Ermolaev, E.; Wiklicky, V.; Vinnerås, B. Process Efficiency and Ventilation Requirement in Black Soldier Fly Larvae Composting of Substrates with High Water Content. Science of The Total Environment 2020, 729, 138968. [Google Scholar] [CrossRef] [PubMed]

- Spranghers, T.; Ottoboni, M.; Klootwijk, C.; Ovyn, A.; Deboosere, S.; De Meulenaer, B.; Michiels, J.; Eeckhout, M.; De Clercq, P.; De Smet, S. Nutritional Composition of Black Soldier Fly ( Hermetia Illucens ) Prepupae Reared on Different Organic Waste Substrates. J Sci Food Agric 2017, 97, 2594–2600. [Google Scholar] [CrossRef] [PubMed]

- Rumpold, B.A.; Schlüter, O.K. Nutritional Composition and Safety Aspects of Edible Insects. Mol. Nutr. Food Res. 2013, 57, 802–823. [Google Scholar] [CrossRef] [PubMed]

- Makkar, H.P.S.; Tran, G.; Heuzé, V.; Ankers, P. State-of-the-Art on Use of Insects as Animal Feed. Animal Feed Science and Technology 2014, 197, 1–33. [Google Scholar] [CrossRef]

- Lalander, C.; Diener, S.; Zurbrügg, C.; Vinnerås, B. Effects of Feedstock on Larval Development and Process Efficiency in Waste Treatment with Black Soldier Fly (Hermetia Illucens). Journal of Cleaner Production 2019, 208, 211–219. [Google Scholar] [CrossRef]

- Scala, A.; Cammack, J.A.; Salvia, R.; Scieuzo, C.; Franco, A.; Bufo, S.A.; Tomberlin, J.K.; Falabella, P. Rearing Substrate Impacts Growth and Macronutrient Composition of Hermetia Illucens (L.) (Diptera: Stratiomyidae) Larvae Produced at an Industrial Scale. Sci Rep 2020, 10, 19448. [Google Scholar] [CrossRef]

- Bellezza Oddon, S.; Biasato, I.; Resconi, A.; Gasco, L. Determination of Lipid Requirements in Black Soldier Fly through Semi-Purified Diets. Sci Rep 2022, 12, 10922. [Google Scholar] [CrossRef]

- Georgescu, B.; Boaru, A.M.; Muntean, L.; Sima, N.; Struți, D.I.; Păpuc, T.A.; Georgescu, C. Modulating the Fatty Acid Profiles of Hermetia Illucens Larvae Fats by Dietary Enrichment with Different Oilseeds: A Sustainable Way for Future Use in Feed and Food. Insects 2022, 13, 801. [Google Scholar] [CrossRef] [PubMed]

- Barragán-Fonseca, K.Y.; Barragán-Fonseca, K.B.; Verschoor, G.; Van Loon, J.J.; Dicke, M. Insects for Peace. Current Opinion in Insect Science 2020, 40, 85–93. [Google Scholar] [CrossRef] [PubMed]

- Leppla, N.C. Rearing of Insects Second Edi.; Elsevier Inc., 2009; ISBN 9780123741448.

- Palma, L.; Ceballos, S.J.; Johnson, P.C.; Niemeier, D.; Pitesky, M.; VanderGheynst, J.S. Cultivation of Black Soldier Fly Larvae on Almond Byproducts: Impacts of Aeration and Moisture on Larvae Growth and Composition. J Sci Food Agric 2018, 98, 5893–5900. [Google Scholar] [CrossRef]

- Singh, A.; Kumari, K. An Inclusive Approach for Organic Waste Treatment and Valorisation Using Black Soldier Fly Larvae: A Review. Journal of Environmental Management 2019, 251, 109569. [Google Scholar] [CrossRef]

- Lemke, N.B.; Dickerson, A.J.; Tomberlin, J.K. No Neonates without Adults: A Review of Adult Black Soldier Fly Biology, Hermetia Illucens (Diptera: Stratiomyidae). BioEssays 2023, 45, 2200162. [Google Scholar] [CrossRef]

- Meneguz, M. , Miranda C.D., Cammack J.A. and J.K. Tomberlin Adult Behaviour as the next Frontier Fo Optimising Industrial Production of Clack Soldie Fly Hermetia Illucens (L.) (Diptera: Stratiomydae).

- Chia, S.Y.; Tanga, C.M.; Khamis, F.M.; Mohamed, S.A.; Salifu, D.; Sevgan, S.; Fiaboe, K.K.M.; Niassy, S.; Van Loon, J.J.A.; Dicke, M.; et al. Threshold Temperatures and Thermal Requirements of Black Soldier Fly Hermetia Illucens: Implications for Mass Production. PLoS ONE 2018, 13, e0206097. [Google Scholar] [CrossRef]

- Harnden, L.M.; Tomberlin, J.K. Effects of Temperature and Diet on Black Soldier Fly, Hermetia Illucens (L.) (Diptera: Stratiomyidae), Development. Forensic Science International 2016, 266, 109–116. [Google Scholar] [CrossRef]

- European Commission, E. (2001). REGULATION (EC) No 999/2001 OF THE EUROPEAN 608 PARLIAMENT AND OF THE COUNCIL of Laying down Rules for the Prevention, Control and Eradication of Certain Transmissible Spongiform Encephalopathies Https://Eur-Lex.Europa.Eu/Legalcontent/EN/ALL/?uri=CELEX%3A32001R09991. 22 May.

- Regulation (EC) No 1069/2009 of the European Parliament and of the Council of Laying down Health Rules as Regards Animal by-Products and Derived Products Not Intended for Human Consumption and Repealing Regulation (EC) No 1774/2002 (Animal by-Products Regulation). 21 October.

- Commission Regulation (EU) No 142/2011 of Implementing Regulation (EC) No 1069/2009 of the European Parliament and of the Council Laying down Health Rules as Regards Animal by-Products and Derived Products Not Intended for Human Consumption and Implementing Council Directive 97/78/EC as Regards Certain Samples and Items Exempt from Veterinary Checks at the Border under That DirectiveText with EEA Relevance. 25 February.

- Oonincx, D.G.A.B.; Van Broekhoven, S.; Van Huis, A.; Van Loon, J.J.A. Feed Conversion, Survival and Development, and Composition of Four Insect Species on Diets Composed of Food By-Products. PLoS ONE 2015, 10, e0144601. [Google Scholar] [CrossRef]

- Dortmans, B.; Diener, S.; Verstappen, B.; Zurbrügg, C. Black Soldier Fly Biowaste Processing.

- Nguyen, T.T.X.; Tomberlin, J.K.; Vanlaerhoven, S. Influence of Resources on <I>Hermetia Illucens</I> (Diptera: Stratiomyidae) Larval Development. jnl. med. entom. 2013, 50, 898–906. [Google Scholar] [CrossRef]

- AOAC Official Method 981.10 Crude Protein in Meat.

- Janssen, R.H.; Vincken, J.-P.; Van Den Broek, L.A.M.; Fogliano, V.; Lakemond, C.M.M. Nitrogen-to-Protein Conversion Factors for Three Edible Insects: Tenebrio Molitor, Alphitobius Diaperinus, and Hermetia Illucens. J. Agric. Food Chem. 2017, 65, 2275–2278. [Google Scholar] [CrossRef] [PubMed]

- AOAC: Official Methods of Analysis (Volume 1) (15th ed.), Assoc. Off. Anal. Chem., Arlington, VA (1990).

- Standardization of Analytical Methodology for Feeds: Proceedings of a Workshop Held in Ottawa, Canada, 12 - 14 March 1979; Pigden, W.J., Ed.; International Development Research Centre: Ottawa, 1980; ISBN 978-0-88936-217-8.

- Holmes, L. Role of Abiotic Factors on the Development and Life History of the Black Soldier Fly, Hermetia Illucens (L.) (Diptera: Stratiomyidae).

- Van Huis, A.; Oonincx, D.G.A.B. The Environmental Sustainability of Insects as Food and Feed. A Review. Agron. Sustain. Dev. 2017, 37, 43. [Google Scholar] [CrossRef]

- Tschirner, M.; Simon, A. Influence of Different Growing Substrates and Processing on the Nutrient Composition of Black Soldier Fly Larvae Destined for Animal Feed. JIFF 2015, 1, 249–259. [Google Scholar] [CrossRef]

- Rebora, M.; Salerno, G.; Piersanti, S.; Saitta, V.; Morelli Venturi, D.; Li, C.; Gorb, S. The Armoured Cuticle of the Black Soldier Fly Hermetia Illucens. Sci Rep 2023, 13, 22101. [Google Scholar] [CrossRef]

- Nguyen, T.T.X.; Tomberlin, J.K.; Vanlaerhoven, S. Ability of Black Soldier Fly (Diptera: Stratiomyidae) Larvae to Recycle Food Waste. Environmental Entomology 2015, 44, 406–410. [Google Scholar] [CrossRef] [PubMed]

- Gold, M.; Egger, J.; Scheidegger, A.; Zurbrügg, C.; Bruno, D.; Bonelli, M.; Tettamanti, G.; Casartelli, M.; Schmitt, E.; Kerkaert, B.; et al. Estimating Black Soldier Fly Larvae Biowaste Conversion Performance by Simulation of Midgut Digestion. Waste Management 2020, 112, 40–51. [Google Scholar] [CrossRef] [PubMed]

- Barragan-Fonseca, K.B.; Dicke, M.; Van Loon, J.J.A. Influence of Larval Density and Dietary Nutrient Concentration on Performance, Body Protein, and Fat Contents of Black Soldier Fly Larvae ( Hermetia Illucens ). Entomologia Exp Applicata 2018, 166, 761–770. [Google Scholar] [CrossRef] [PubMed]

- Park,H.BlackSoldierFlyLarvaeManual2016https://scholarworks.umass.edu/sustainableumass_studentshowcase/14.

- Tomberlin, J.K.; Adler, P.H.; Myers, H.M. Development of the Black Soldier Fly (Diptera: Stratiomyidae) in Relation to Temperature. ENVIRONMENTAL ENTOMOLOGY 2009, 38. [Google Scholar] [CrossRef] [PubMed]

- Meneguz, M.; Schiavone, A.; Gai, F.; Dama, A.; Lussiana, C.; Renna, M.; Gasco, L. Effect of Rearing Substrate on Growth Performance, Waste Reduction Efficiency and Chemical Composition of Black Soldier Fly ( Hermetia illucens ) Larvae. J Sci Food Agric 2018, 98, 5776–5784. [Google Scholar] [CrossRef]

- Shumo, M.; Khamis, F.; Tanga, C.; Fiaboe, K.; Subramanian, S.; Ekesi, S.; Van Huis, A.; Borgemeister, C. Influence of Temperature on Selected Life-History Traits of Black Soldier Fly (Hermetia Illucens) Reared on Two Common Urban Organic Waste Streams in Kenya. Animals 2019, 9, 79. [Google Scholar] [CrossRef] [PubMed]

- Ribeiro, N.; Costa, R.; Ameixa, O.M.C.C. The Influence of Non-Optimal Rearing Conditions and Substrates on the Performance of the Black Soldier Fly (Hermetia Illucens). Insects 2022, 13, 639. [Google Scholar] [CrossRef]

- McEachern, T. Determining Heat Production of Black Solderi Fly Larvae, Hermitia Illucens, to Design Rearing Structures at Livestock Facilities. 2018. [CrossRef]

- Li, C.; Addeo, N.F.; Rusch, T.W.; Tarone, A.M.; Tomberlin, J.K. Black Soldier Fly (Diptera: Stratiomyidae) Larval Heat Generation and Management. Insect Science 2023, 30, 964–974. [Google Scholar] [CrossRef]

| Parameter | D1i | D2 | D3 | D4 | p-Value |

|---|---|---|---|---|---|

| Larval biomass (g)ii | 376.9±34.603A | 278.0±49.558B | 335.1±19.274AB | 305.9±24.212AB | p<0.01 |

| Residual biomass (g) | 380.1±22.533AB | 476.8±±53.485B | 313.5±14.925A | 304.7±26.268A | p<0.01 |

| larvae weight (g) | 0.16±0.024A | 0.10±0.011B | 0.12±0.006B | 0.11±0.014B | p<0.01 |

| Larvae lenght (cm) | 1.75±0.182Aa | 1.40±0.097Bb | 1.46±0.081ABb | 1.43±0.111ABb | p<0.01 |

| Growth rate (%) | 1.60±0.389A | 0.82±0.139B | 1.03±0.074B | 0.94±0.176B | p<0.01 |

| Substrate reduction (%) | 82.72±1.024B | 77.41±2.847A | 84.32±0.746B | 84.77±1.313B | p<0.01 |

| Dry Matter larvae (%) | 37.05±7.132AB | 26.82±5.273B | 35.11±5.504AB | 44.43±3.952A | p<0.01 |

| Larvae meal yield (g DM) | 138.56±21.924B | 76.31±29.348A | 117.52±18.292AB | 135.40±8.242B | p<0.01 |

| Black soldier fly larvae | |||||

|---|---|---|---|---|---|

| Parameter | D1i | D2 | D3 | D4 | p-Value |

| Crude Protein | 28.1±0.494ab | 27.3±3.475a | 28.8±3.467ab | 33.0±0.679b | p<0.05 |

| Crude Fat | 26.1±1.184b | 9.7±1.998a | 30.29±2.530b | 25.59±6.976b | p<0.01 |

| Ash | 15.3±0.284c | 10.8±1.385b | 6.1±0.787a | 4.6±0.211a | p<0.01 |

| Crude Fiber | 6.2±0.335ab | 9.1±0.378c | 6.5±0.177b | 5.8±0.297a | p<0.01 |

| Neutral detergent fiber | 12.8±4.427 | 16.3±3.433 | 12.7±2.398 | 11.5±1.254 | p<0.21 |

| Acid detergent fiber | 8.9±0.666 | 15.1±2.638 | 12.9±5.333 | 13.9±5.133 | p<0.18 |

| Acid detergent lignin | 1.1±0.076 | 2.34±0.268 | 2.5±1.087 | 2.1±1.037 | p<0.10 |

| Non-Free extractive ii | 24.3±0.704a | 43.1±4.786c | 28.2±3.492ab | 31.0±7.043b | p<0.01 |

| Degradation (%) | |||||

|---|---|---|---|---|---|

| Parameter | D1 | D2 | D3 | D4 | p-Value |

| DM | 45.90±4.52A | 58.36±4.29B | 60.51±2.02B | 57.72±2.40B | p<0.01 |

| OM | 50.81±4.31A | 58.99±4.18B | 61.33±2.27B | 59.18±2.64B | p<0.01 |

| CP | 54.38±5.78Aa | 63.69±5.76ABb | 71.78±3.71Bb | 59.91±2.32Aab | p<0.01 |

| CF | 96.41±1.89B | 89.90±3.38B | 91.05±3.24B | 64.01±5.70A | p<0.01 |

| Ash | 15.84±9.71A | 49.16±5.82B | 49.32±4.86B | 34.69±3.82B | p<0.01 |

| Starch | 42.45±4.36B | 34.59±12.62B | 40.35±5.45B | 98.06±0.37A | p<0.01 |

| NFE | 49.59±4.55A | 61.44±4.60B | 43.61±3.79A | 52.68±3.67Ab | p<0.01 |

| Temperature | D1 | D2 | D3 | D4 | p-Value |

|---|---|---|---|---|---|

| MAX | 3359.5±177.686 | 3430.24±187.64 | 3455.98±139.40 | 3314.7±104.66 | p=0.27 |

| MIN | 2568.4±101.98 | 2713.1±121.02 | 2646.6±64.06 | 2690.1±69.47 | p=0.10 |

| MEANS | 2964±136.32 | 3071.7±149.78 | 3051.3±98.14 | 3002.4±82.94 | p=0..29 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).