1. Introduction

Nowadays, Brazil is the main producer and exporter of crude coffee, throughout the world. The National Supply Company (CONAB) of Brazil indicated that the 2022 harvest produced 50,920 thousand bags of 60 kilograms, being 27% of robusta coffee (

Coffea canephora) and 73% of arabica coffee (

Coffea arabica L.) [

1]. At the year of 2021, 21.5 million of bags were consumed in Brazil, representing an increment of 1.39% when compared to the year of 2020. Brazil is the second coffee consumer at the entire world, behind United States of America [

2].

Regarding the coffee production chain, roasted and milled coffee remains as the product with greater impact on company revenues, reaching 81.4 % of the total income. Eighty two percent of the coffee producing industry in Brazil is made up of micro and small companies, with 70% operating exclusively in the family economy [

3]. It is estimated that the sector's sales in 2021 reached R

$ 15.2 billion and that adherence to quality seals has grown 51% in the last 5 years. Thus, coffee production is a solid and important activity in Brazil and at countries near the Equator Line, which provides a more suitable environment to produce coffee, in quantity and in quality manner.

Coffee, which began its consumption as a simple stimulant drink, has today become a complex drink appreciated in different approaches, which drives an entire value chain. With the increasing demand for grains with higher quality, in 1991, the Brazilian Specialty Coffee Association (BSCA) was founded, with the aim of disseminating technical improvement throughout the specialty coffee chain in search of sustainable development.

Being that said, coffee growers are increasingly searching for production techniques to increment the coffee quality [

4]. High quality coffees, called specials, consider the differentiated sensorial attributes of these grains, which are free of impurities and defects, classifiable with scores above 80 points, in a scale from 0 to 100. In addition, its production must respect environmental, economic, and social sustainability criteria throughout production process [

5]. However, production of special coffees, mostly those with score between 80 to 83 points are still a challenge, because in addition to the higher production cost and effort of the coffee producer, these grains, most of the time, are commercialized for the price of coffee commodities, not attending its potential and sustainable aspects. This trend may occur due to lack of information for the coffee producers and by the coffee traders.

To conceptualize sustainability, it requires more than a single action. It includes wide and multidimensional concepts of three variables, called the Tripod of Sustainability [

6]. This Tripod involves the social, environmental, and economic aspects of the coffee production. The social aspect includes the power for society, equality, and social improvements. The environmental aspect seeks the maintenance of biodiversity, ecosystem integrity and climate, whilst the economic aspects is the institution's growth in an efficient manner. Therefore, sustainability is achieved when we can act in a way that integrates the tripod. And the tripod is required for several certificates, such as 4C, Rainforest Alliance, Fair Trade, Organic coffee, among others.

When relating the production of specialty coffees to sustainable production, it is worth highlighting that the sustainable production system aims to guarantee equality and social improvements, the maintenance of biodiversity, ecosystem integrity, climate, and the economic growth of the institution in an efficient and inseparable way [

6]. Because of the consumers choice, a coffee may need to be produced focused more on one of the three aspects: economic, social, or environmental. However, they are indissociable.

One alternative to reduce the impact of price variations on the production of specialty coffees is the installation of a roasting facility for a coffee grower or for an association of several coffee growers. In addition to increase the product value, parameters can be evaluated during its processing, aiming a better use of the raw material and inputs, without reducing its quality. Being that said, the first step is to study the roasting profiles of the coffee [

7].

Roasting profiles or roasting curves express the variation in temperature during the processing time, until the desired color of the grains is achieved. In this process, the cellular structure of the grains is altered, releasing water and aromatic compounds. As it develops, sugars and amino acids react and produce melanoidins, which are responsible for the darkening of the grain. As roasting continues, the grain absorbs energy and triggers reactions such as caramelization and pyrolysis, changing its chemical composition [

8,

9]. These alterations are noted in the sensory evaluation of the coffee beverage.

Some reactions, such as the Maillard reaction, Strecker degradation, and breakdown of amino acids are responsible for these alterations [

9]. Light roast gives sweet, cocoa, and nutty aromas, whereas a dark roast produces burnt/acrid, ashy/sooty, sour, pungent, coffee, and roasted aromas [

8].

Being that stated, the purpose of this study was to analyze, recognize and establish parameters that determine the roasting process of specialty coffee grains, which can guarantee greater use of raw materials and inputs in roasting facilities, without compromising the coffee beverage quality, pursuing a higher sustainability of the coffee produced.

2. Materials and Methods

The work was conducted in a post-harvest coffee laboratory, in the city of Alegre, at the state of Espírito Santo, country Brazil. Arabica coffee beans (Coffea arabica L.) were used, grown at different properties within the ‘Matas de Minas’ and ‘Caparaó’ region. The coffee grains were purchased from eight coffee producers of familiar production, with scores between 80 to 83 points, using the SCA (Specialty Coffee Association) methodology.

Before the roasting process, the coffee grain was classified according to their subcategory, and only grains from sieves 16 (sixteen) and above were used in the research. This procedure is indispensable, because standardization regarding the grain size is an important parameter to obtain a homogenized roast. Furthermore, all defects were removed prior to roasting, to prevent its influence. It is known that defects impact at the roasting profile, decreasing the quality of this process.

Afterwards, coffee samples of 300 g were roasted in a rotating cylindrical roaster. It possesses a flow control of the liquefied petroleum gas (LPG), performed by a manometer coupled to the roaster. The roasting profile was developed and fixed by the authors, as described ahead. The first roasting step: between 0 and 4 minutes of the roasting process, the liquefied petroleum gas pressure was maintained at 1 mbar; the second roasting step: between 5 and 8 minutes, the liquefied petroleum gas pressure was increased to 5 mbar; the third and last roasting step: from 9 minutes onwards, the liquefied petroleum gas was increased to 7 mbar, maintained at this level until the complete roasting, depending on the determined color.

It was used four levels of roasting, specified by the Agtron scale, according to the color of the grains. The scales #22.36; #33.64; #40.05; and #59.92. They are called light, medium light, medium, and dark, respectively. Thus, for each coffee purchased, they were roasted at these four levels; thus, thirty-two roasts of coffees were carried out.

The fuel rate used was calculated based on the standardization of the roasting profile and their respective roasting times. To measure the mass before and after roasting, a high precision scale of 0.01g precision was used. All samples were weighed before and after roasting, to measure the weight loss.

After roasting, sensory analysis was carried out by certified specialty coffee evaluators using the methodology developed by the Specialty Coffee Association – SCA [

10]. To analyze the quality of the coffee beverage, a sensory profile was carried out by three Q-graders, at roasting levels #40.05, ideal for cupping according to SCA [

10], and #33.64, to comparison. The two levels were chosen because they are commonly used commercially. The other two roast levels (#22.36 and #59.92) were not analyzed regarding they sensory characteristics.

The results were analyzed using Sisvar software [

11]. Analysis of Variance (ANOVA) was applied with three tests: the first one to analyze the roasting time data; the second to analyze the weight loss; and the third test to analyze the coffee beverage quality. The factorial scheme used was 4x2 (4 roasting profiles and 2 post-harvest processing, the two roasting levels, #33.64 and # 40.05). A regression and Tukey test was also carried out at a 5% probability level to analyze the results of roasting time, weight loss and quality of the coffee beverage as a function of the interaction between post-harvest processing and the roasting point.

3. Results and Discussion

Roasting is a process of heat and mass transfer, which the roaster provides heat to the coffee grain. The heat is generated from the combustion of the fuel, in the present work, liquefied petroleum gas (LPG). Afterwards, coffee grain is heated, and volatile compounds are generated and lost to the environment, in other words, mass is transferred from grain to the environment. Finally, the roasting time affects the amount of heat and mass transfer throughout the process, producing coffee with different chemical composition, and different sensorial profiles.

Regarding the roasting time, it was verified that there is at least one mean time that presents a statistical difference.

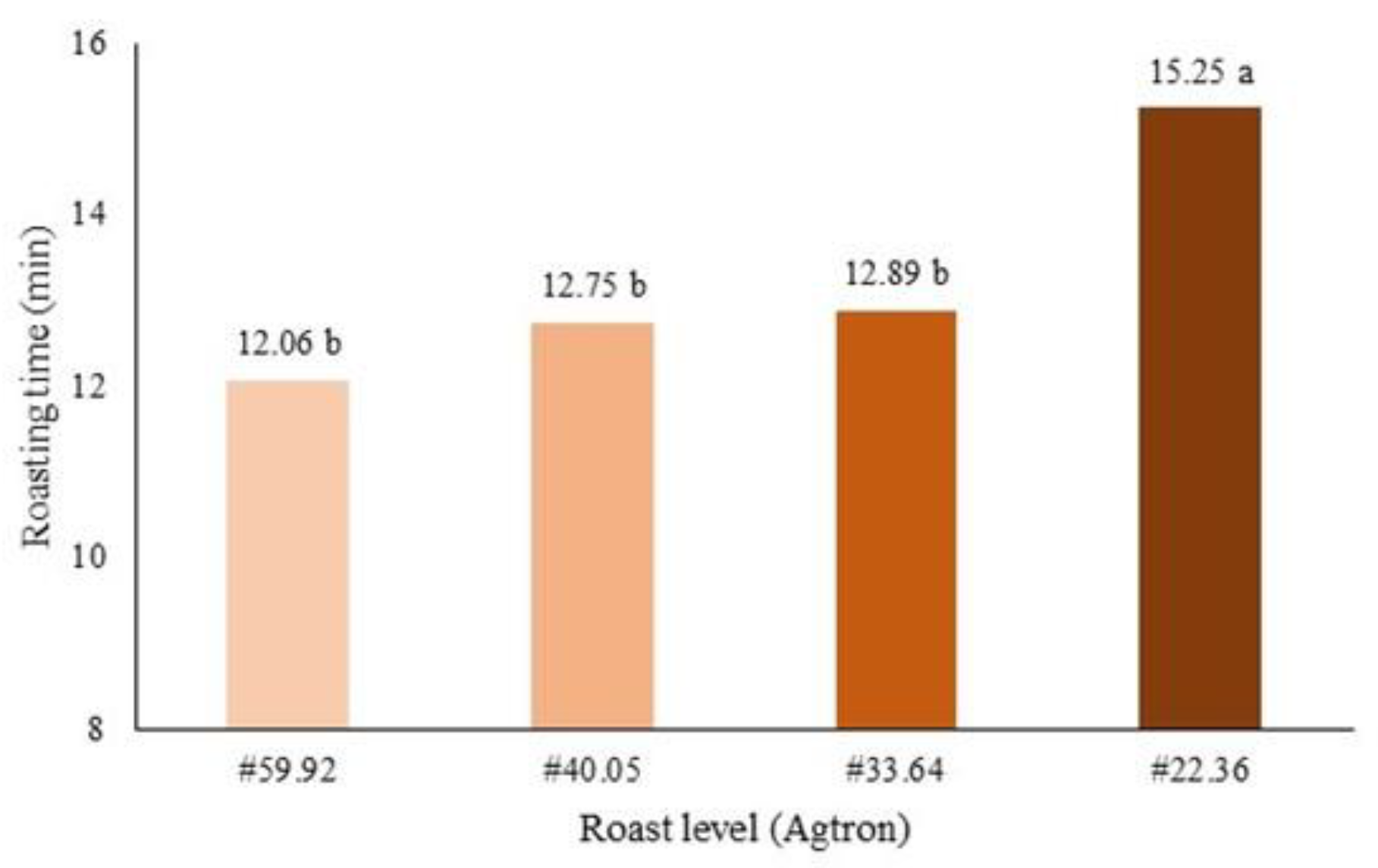

Figure 1 presents a comparison between roasting time depending on color (#Agtron) for all roasts used in the present work.

Statistically, the roast levels #59.92, #40.05, and #33.64 do not differ from each other. However, roast degree #22.36 differed from the others, presenting higher roasting time. Similar result was reported in previous work, which analyzed three different roasting time (fast, medium and slow) and three different roasting levels (light, medium and dark roasts), concluding that only dark roast differed from the remaining roast levels [

12]. These authors used a starting temperature of 120 ºC and the roasting time was controlled by the gas flow to the gas burner: 90% fast, 60% medium and 40% slow, in percentage of maximal flow. And used different flow during roasting procedure: 0 to 5 minutes with high flow and from 5 minutes on with low flow.

Thus, since the flame temperature was constant in all roasting profiles, the energy consumption is greater for darker roasts, with greater consumption of liquefied petroleum gas (LPG). This trend was expected, since darker roasts requires both or one of the following features: increased roasting time, and thus higher energy consumption; or higher fuel consumption. Because at the present work the gas pressure was increased throughout roasting, darker roasts required more roasting time and fuel consumption.

However, the non-differentiation of roasting time at lighter roasting levels, despite not being expected, can be understood as positive, as it indicates that it is possible to vary the color of the beans, using a similar energy consumption. According to this result, the person responsible to roast the coffee has more flexibility to choose the ideal roasting point according to the coffee samples and the desired market to commercialize the product. This trend allows a higher sustainability of the coffee roasting procedure because different coffee roasts can be performed in a similar energy consumption, attending different market share. An increased market share provides more flexibility and stability to the coffee producers, becoming more economical sustainable.

Finally, with the results shown in

Figure 1, it can be inferred that reducing roasting time makes the process more sustainable. For example, the roast level #40.05, there is a reduction in the excessive heat exposure by the person responsible to roast. Furthermore, there is a reduction in consumption of liquefied petroleum gas input, which is derived from fossil fuel, launching less carbon dioxide to the environment, decreasing the features that increments the worldwide temperature globe. On the other hand, the consumers choice must be accounted for the roast level choice. For instance, darker roasts can be preferred regarding health issues [

13,

14] or because of local culture, when compared to lighter roasts.

Intake of the dark roast coffee beverage most effectively improved the antioxidant status of erythrocytes [

13]. Furthermore, administration of the coffee beverage rich in N-methylpyridinium led to a significant body weight reduction in pre-obese subjects [

13]. Regular consumption of a dark roast coffee blend has a beneficial protective effect on human DNA integrity in both, men and women [

14].

Weight loss throughout the roasting procedure is mainly due to loss of moisture and volatile compounds, as stated before. Coffee grain, at the beginning of the roasting possess around 12-12.5% of moisture, in dry basis, and around 3-5% of moisture after the roast, in dry basis. This loss affects the final weight and the color of the grain, depending on the roasting time and number of chemical reactions, such as Maillard.

Along with moisture content, other chemical composition is altered according to roasting levels. Ether extract is around 10.39 ± 0.30 %, 10.47 ± 0.19 % and 10.65 ± 0.22 %, respectively for light, medium and dark roasts; crude protein is around 13.05 ± 0.14 %, 12.36 ± 0.24 % and 11.10 ± 0.06 %, respectively for light, medium and dark roasts; crude fiber is around 24.24 ± 0.47 %, 28.31 ± 0.31 % and 28.40 ± 0.42 %, respectively for light, medium and dark roasts; ash content is around 3.95 ± 0.26 %, 3.89 ± 0.08 % and 4.10 ± 0.17 %, respectively for light, medium and dark roasts; and nitrogen-free extract is 48.37 %, 44.97 % and 45.76 %, respectively for light, medium and dark roasts [

15].

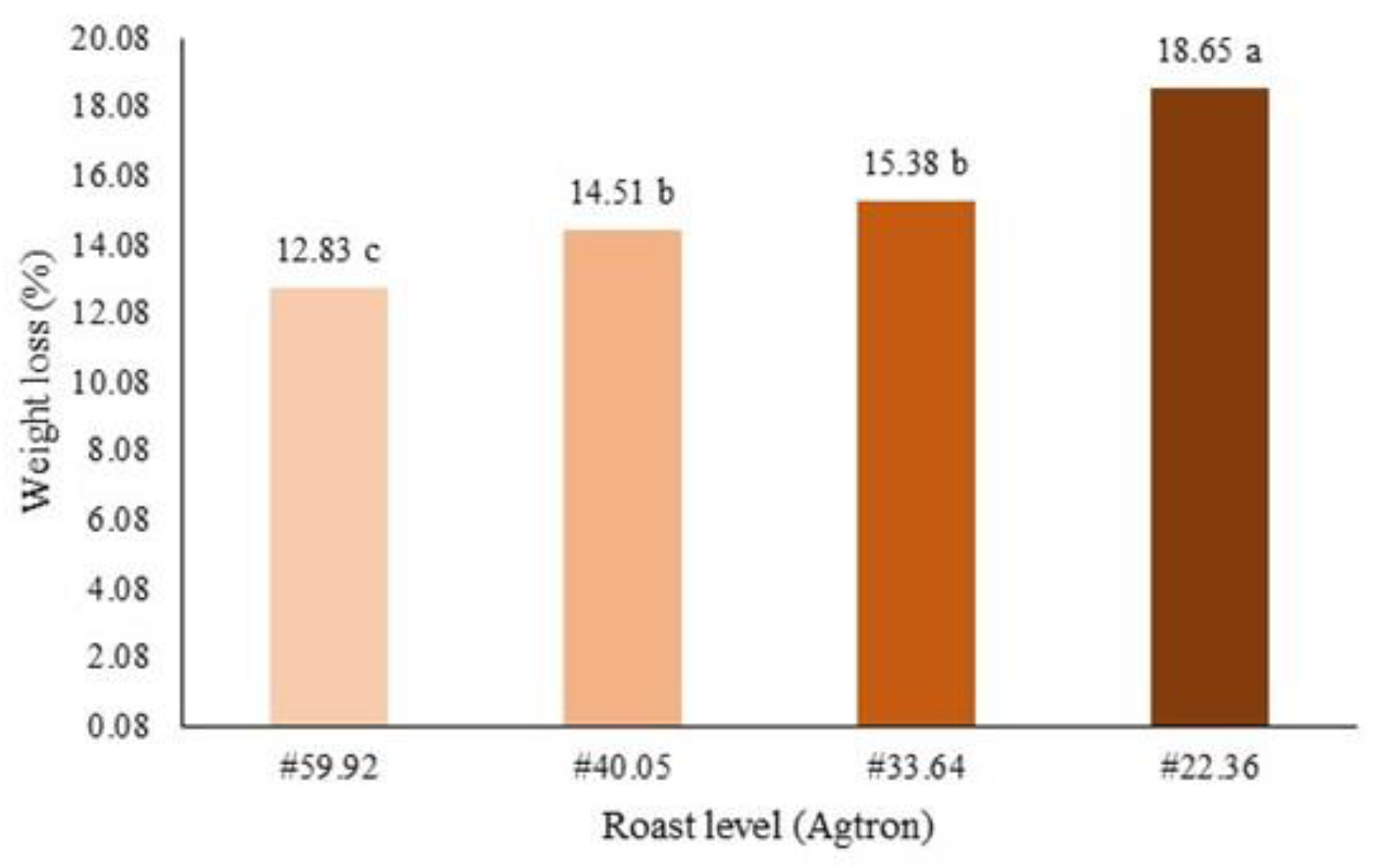

Regarding weight loss, according to

Figure 2, there is a mean weight loss that presents a statistical difference according to the degree of roasting of the coffee, at a significance level of 5%.

Previous work [

16], evaluating the yield of the raw material, verified that the weight loss of the grains, in four levels of roasting, is an important variable and presented a loss between 16 and 21%, respectively. These authors used Agtron scale, with roasting levels of #65, #55, #45 and #35. This study corroborates with the results in the present work, which darker roasting leads to greater loss of mass of the grains. This trend is expected, because darker roasts, which requires higher roasting time, leads to an increase of moisture loss and other chemical compounds, such as volatile and dry matter.

From the more than 1000 volatile compounds produced during the roasting process, reports state that no more than 20 to 30 volatile compounds are responsible for the coffee aroma and taste [

17]. Some of them are sulfur compounds, such as sulfides and thiols, particularly 2-furfurylthiol; Strecker aldehydes, such as methylpropanal, 2-methylbutanal, and 3-methylbutana; and α-Dicarbonyls such as 2,3-butanedione and 2,3-pentanedione [

17]. Includes pyrazines, furans and derivatives, ketones, phenolic compounds [

18]. Also includes, terpenes, pyrazole, pyridines, acids, pyrroles, and alcohols [

19].

Previous research evaluated the weight loss of four different roasting degrees (light, medium, medium-dark and dark), and concluded that they are significantly different from each other [

17]. These authors reported an average weight loss of 11.89 %, 14.08 %, 17.34 % and 19.29 %, respectively for light, medium, medium-dark and dark roast levels. According to

Figure 2, it can be observed that treatments #40.05 and #33.64 do not differ from each other in relation to weight loss. This was not expected; however, it is a positive trend. Weight of the coffee is used to commercialize, as packages of 250g, 500g, 1kg, or even 60kg of roasted coffee. Similar weight loss can be used in different roasting levels, to different consumers/market, increasing the profitability of the coffee producers. The roasting method used in the present work was different, in which we altered the gas pressure throughout roasting, which interferes at the roasting temperature, and thus, the final roasting. On the other hand, the previous work indicated solely the initial temperature to start the roasting, with constant gas pressure [

17]. These authors used an initial temperature of 75 ºC to insert coffee at the roasting chamber, and later retrieving coffee when different temperatures were reached: 187 °C (light roast), 202 °C (medium roast), 217 °C (medium-dark roast), and 225 °C (dark roast). This trend indicates that the parameters used to initiate and terminate the roasting process impacts the weight loss of coffee and final roasting level.

Higher roasting time provides elevated weight loss due to the evaporation of moisture from the grains [

20,

21,

22]. Four different roasting time (16, 18, 20 and 22 minutes) and two particle sizes (medium and fine) were analyzed for the preference of coffee consumers from Paraná state, Brazil. These authors reported that coffee beans roasted for 20 minutes was preferred, and particle size did not affect the consumers choice [

20], and the weight loss was, respectively, 10.60 %, 11.25 %, 18.65 % and 22.78 % for 16, 18, 20 and 22 minutes of roasting process. Weight loss was 10.5, 13.4 and 19.4 % for three different roasting intensities (200-240 ºC, 5-12 minutes) [

21] and 15.85 % and 18.74 % for medium light (SCA #65) and moderately dark (SCA #45) [

22], respectively.

In addition to moisture loss, coffee grains suffer a disruption in their cellular structure due to the elevated temperatures used during roasting process, releasing aromatic compounds produced through chemical reactions [

8]. Rapid roasting, using higher temperature and lower roasting time led to considerable differences in aroma formation, when compared to slow roasting [

8].

Furthermore, volatile compounds, such as carbon dioxide, are also lost during roasting, impacting directly at weight loss. Previous work indicated that at fixed roasting speed, an increase of degassing rates and total amount of weight losses occurs with roast degree [

12]. These authors used degassing rates between 73 to 126 h

-1, for a total roasting time of approximately 7 to 8 minutes.

As stated, regarding the analysis of roasting time, the non-significant variation of weight loss between roasts #40.05 and #33.64 can be considered positive, as it demonstrates greater flexibility to determine the best roasting profile, considering the sensory characteristics of the coffee, without a decrease in coffee yield.

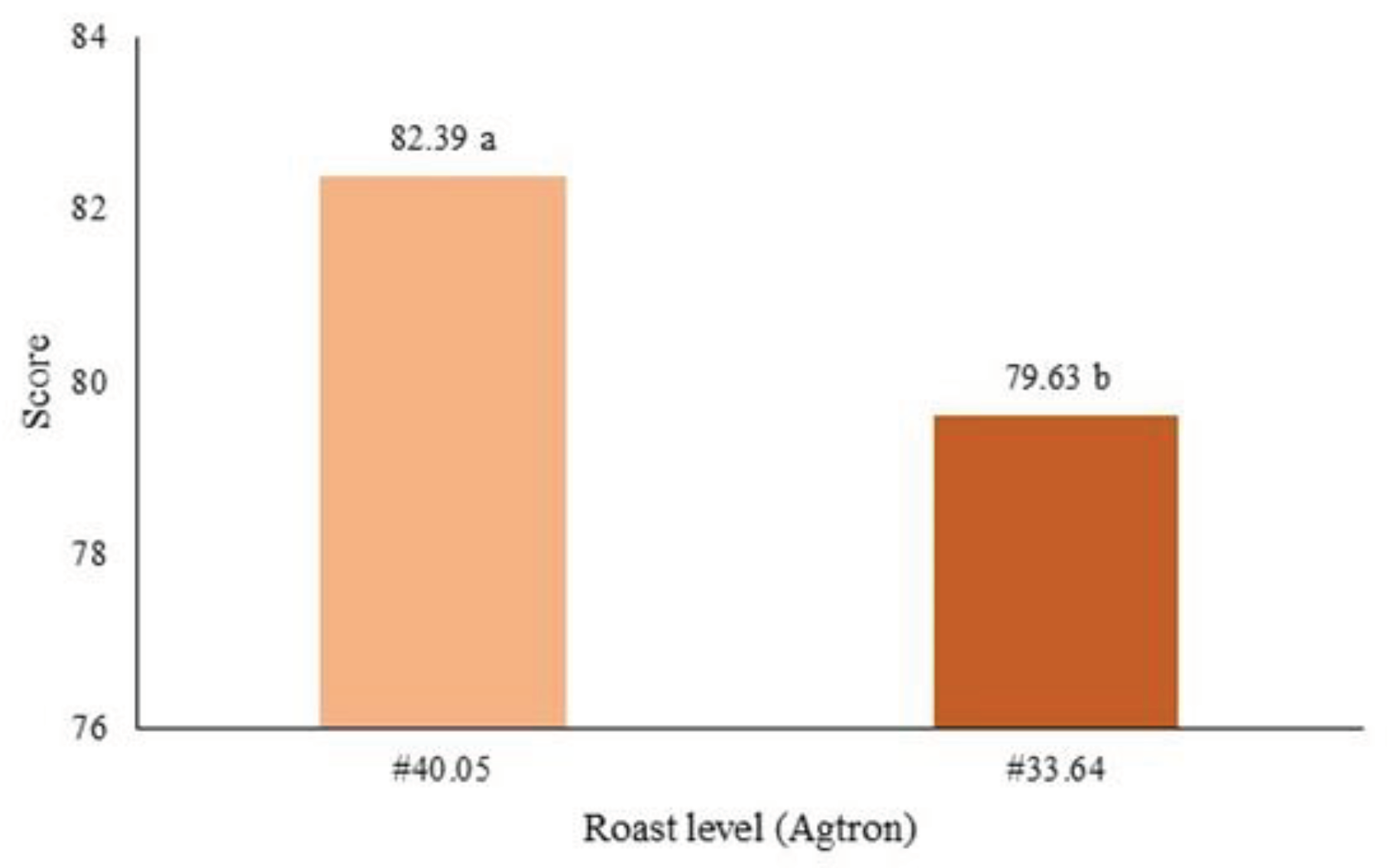

Data regarding the statistical analysis related to the sensory analysis of coffee is presented in

Table 1. According to the SCA methodology, specific roasting standards are required, thus, this analysis was accomplished for samples #40.05 and #33.64.

It was verified, at a significance level of 5%, that there is at least one mean value of sensorial score that presents statistical difference, as a function of the four levels of roasting studied (

Table 1).

Previous work [

22] reported that, for roasting of nine samples (soft/light, hard/light, river/light, soft/express, hard/express, river/espresso, soft/dark, hard/dark, and river/dark) of the coffee drink (

Coffea arabica L.), darker roasts had maximum intensity and longer duration of the bitter and burnt taste. The samples roasted in the light level showed lower intensity of these tastes [

17]. Furthermore, smoke/acrid aroma, tobacco flavor, woody flavor and rubber flavor are common descriptors of darker roasted coffees [

24]. These studies confirm the results shown in

Figure 3, since the higher the roasting level, the lower the quality perception of specialty coffees, which can be validated from the sensory reports of each coffee in the two Agtron scales, #40.05 and #33.64.

This result is important, since a minor difference in the roasting level leads to an important variation in sensory analysis, and thus a significant difference in value of the coffee. Samples roasted at #40.05 level is classified as special coffee (>80 points), and the same sample, roasted at #33.64, is not a special coffee (<80 points). Thus, we can conclude that the roast at level #40.05 has the potential to provide higher quality coffees, with lower energy and time consumption to roast. On the other hand, the acceptability depends on the target market, which due to cultural and/or preference, a darker roast may be preferred.

Previous work [

25], studying the composition of the volatiles of two gourmet coffees and one soft coffee as a function of the degree of roasting, found that roasting significantly affects the sensory results of coffees. Thus, it can be inferred that the flexibility pointed out in the results presented in

Figure 1 and

Figure 2 is considered a positive aspect in the roasting process. This trend is due to the possibility of producing coffees with different sensory profiles (

Figure 3).

Table 2 presents a general comparison between roasting levels and roasting time, gas consumption, weight loss and coffee beverage quality.

It was noted that, when roasting for a longer period (#33.64), compared to #40.05, coffee is no longer classified as a specialty coffee, with a score of 79.63. This result indicates that, even having the flexibility with respect to the roasting time and the weight loss for the intermediate roasts studied, the process must be made with cautious. Because the financial losses may also be originated in the decrease of the coffee beverage quality due to poorly executed or poorly planned roasting. The roasting process must be controlled because it has an influence on the quality of the beverage, since during this process modifications and formation of different chemical components that contribute to the final aroma of the drink occur [

17,

26].

The roaster used in the research, according to the manufacturer's data, for a 12-minute roast, it consumes 0.32 kg of gas per kg of coffee. Thus, comparing the roast degree # 40.05 (standard used for specialty coffee) with the roast degree #22.36 (most used for commodities coffee), the first one has a gas consumption of 0.34 kg per coffee kg, whilst the second presented a gas consumption of 0.41 kg per coffee kg. This leads to an increase in gas consumption of 20.59 %.

As previously stated, the weight loss after roasting of the samples roasted at #40.05 yields about 4% more raw material when compared to a roasting scale of #22.36. Therefore, the roaster facility that chooses the specialty coffee market, will have a greater economic sustainability when compared to the profiles of commodity coffees and darker roasts.

The present study points out that the industrialization of specialty coffees is feasible according to sustainable ideals. To do so, the entrepreneur must acknowledge and control each phase of this process, such as roasting time and roasting profile, which are determinant to achieve higher quality of the product. In addition to the variables mentioned, the evaluation of weight loss can contribute to the profitability of the company.