Submitted:

25 March 2024

Posted:

26 March 2024

You are already at the latest version

Abstract

Keywords:

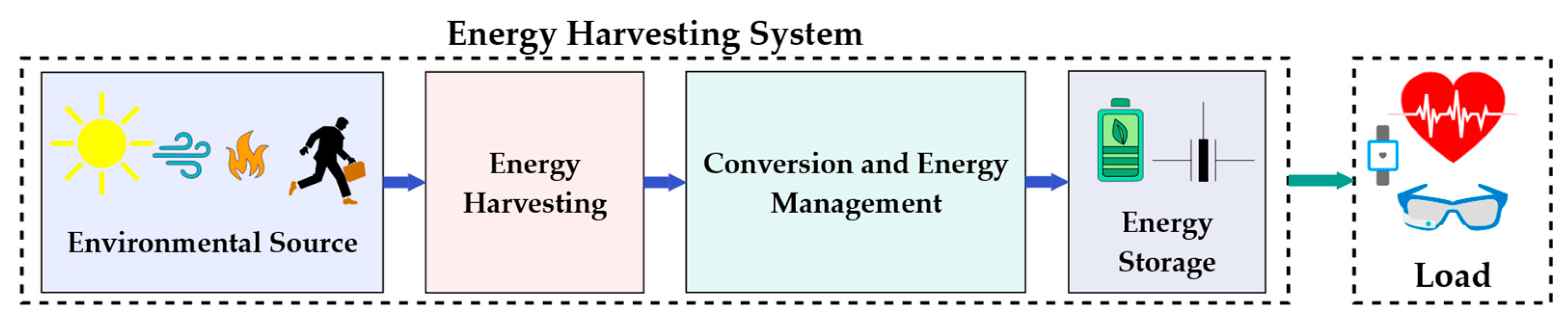

1. Introduction

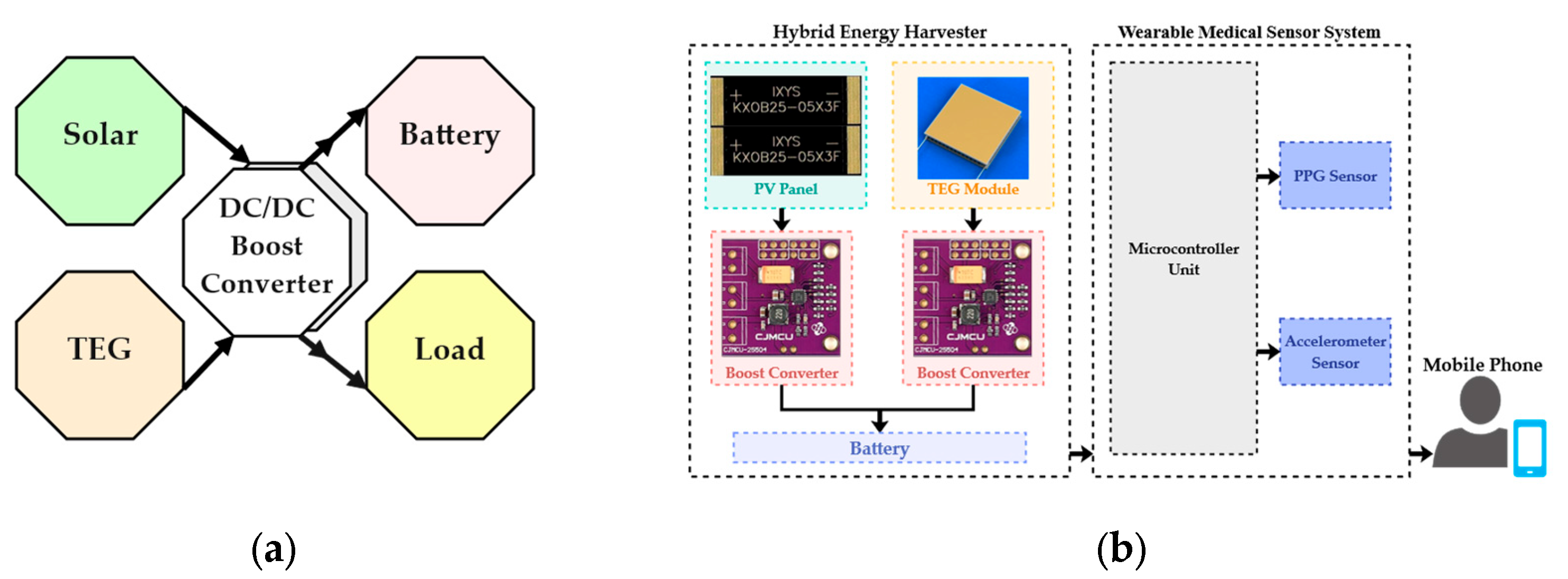

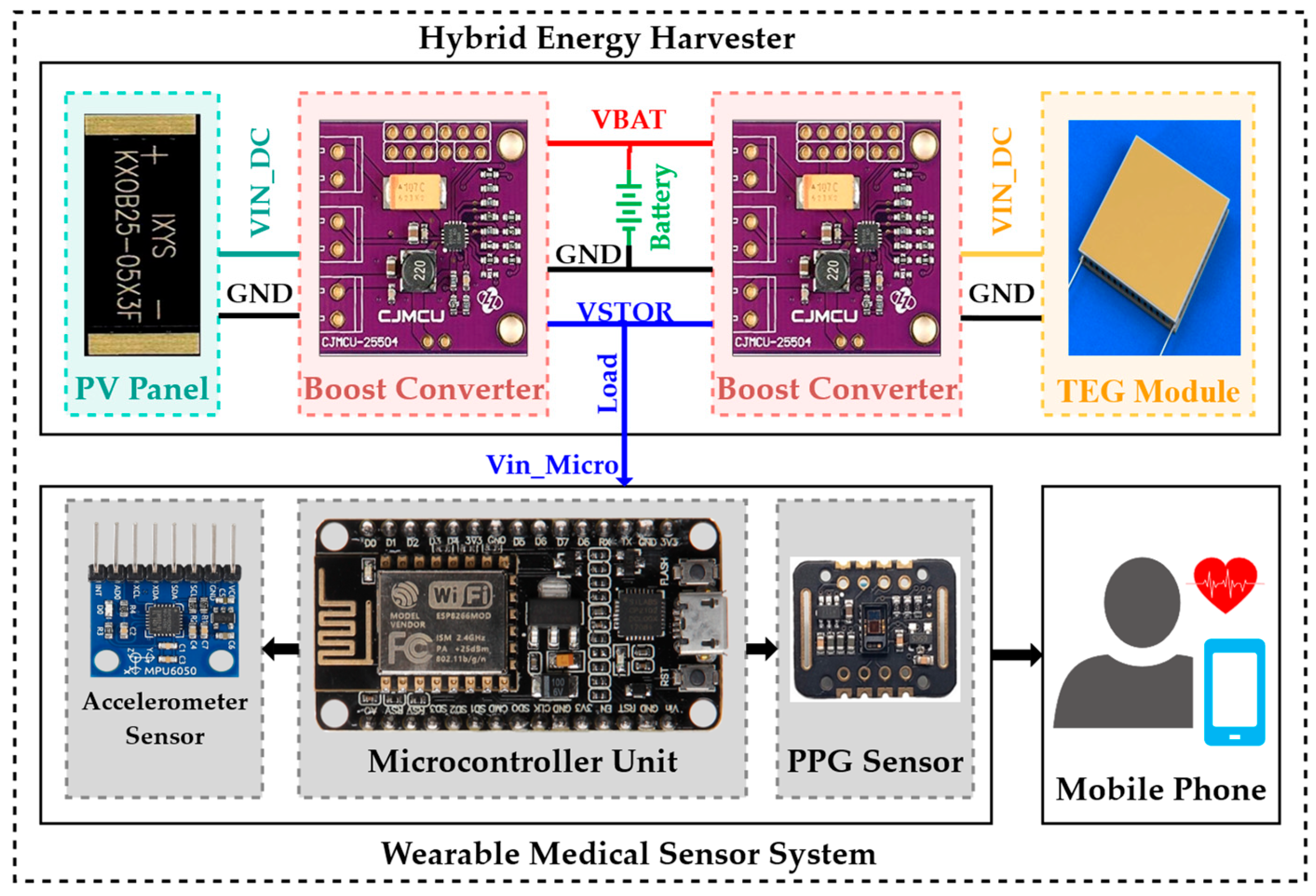

- Designing a double-source hybrid PV/TEG energy harvesting system to achieve MPPT for either input sources, both during battery charging and loading.

- Implementing the harvesting system with two DC/DC boost converters in which both are active and employed simultaneously. The outputs of these converters are paralleled at their two similar circuit nodes: the battery and the load nodes. Consequently, each power source operates with MPPT, as well as they can charge/supply a common battery/load simultaneously or individually.

- Implementing a low-cost, compact form factor, and universal harvesting system compatible with various range of wearable medical devices in different mode of wearability such as wrist/head worn.

- Testing and validating the system in different environmental conditions with the most impact and practical medical sensors such as IMU and PPG with the capability of turning into a self-powered system.

2. Materials and Methods

2.1. Vital Data and Medical Sensors

2.2. Proposed Hybrid Energy Harvesting System, and Hardware Specification

2.2.1. Solar Panel

2.2.2. TEG Module

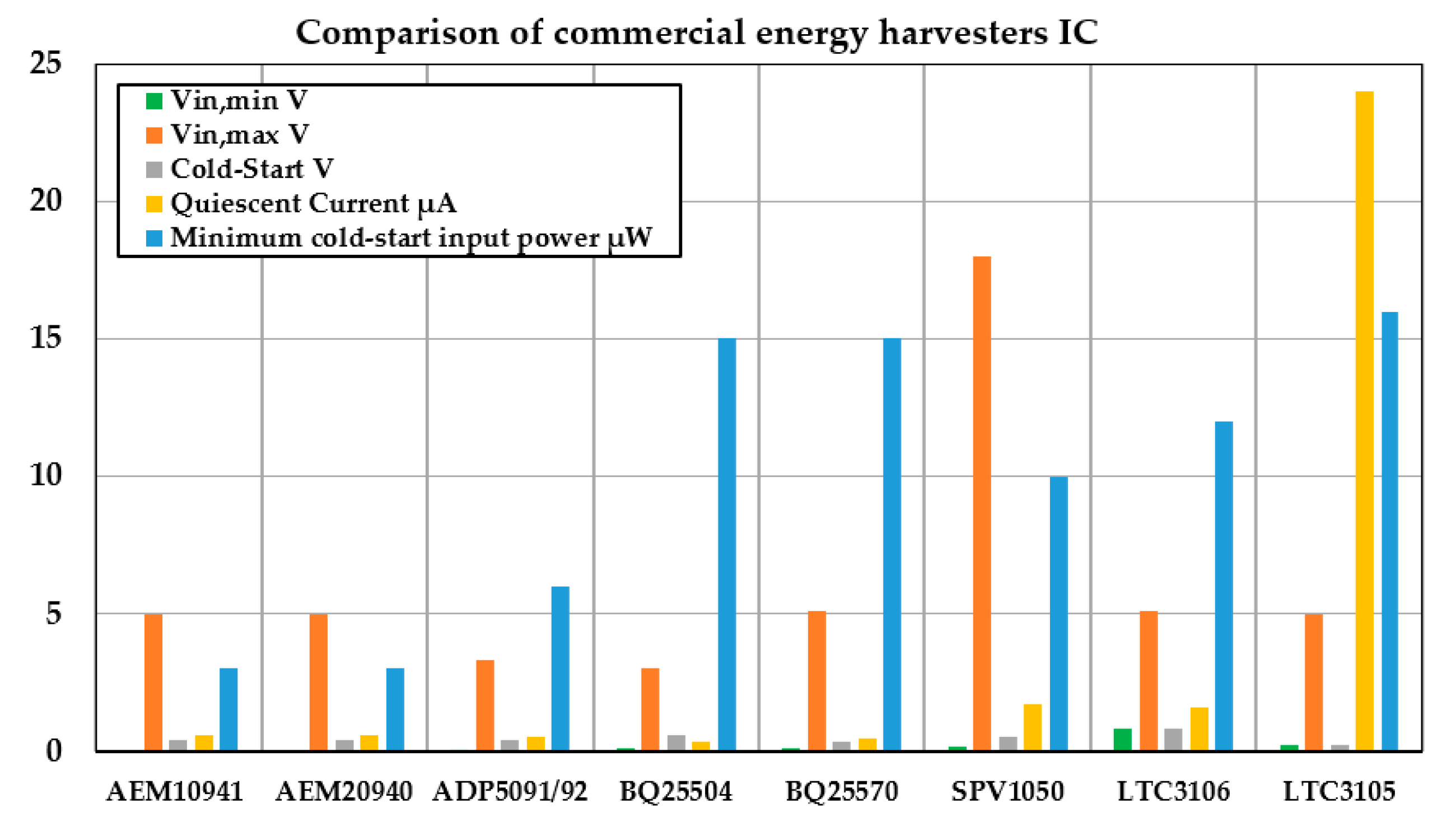

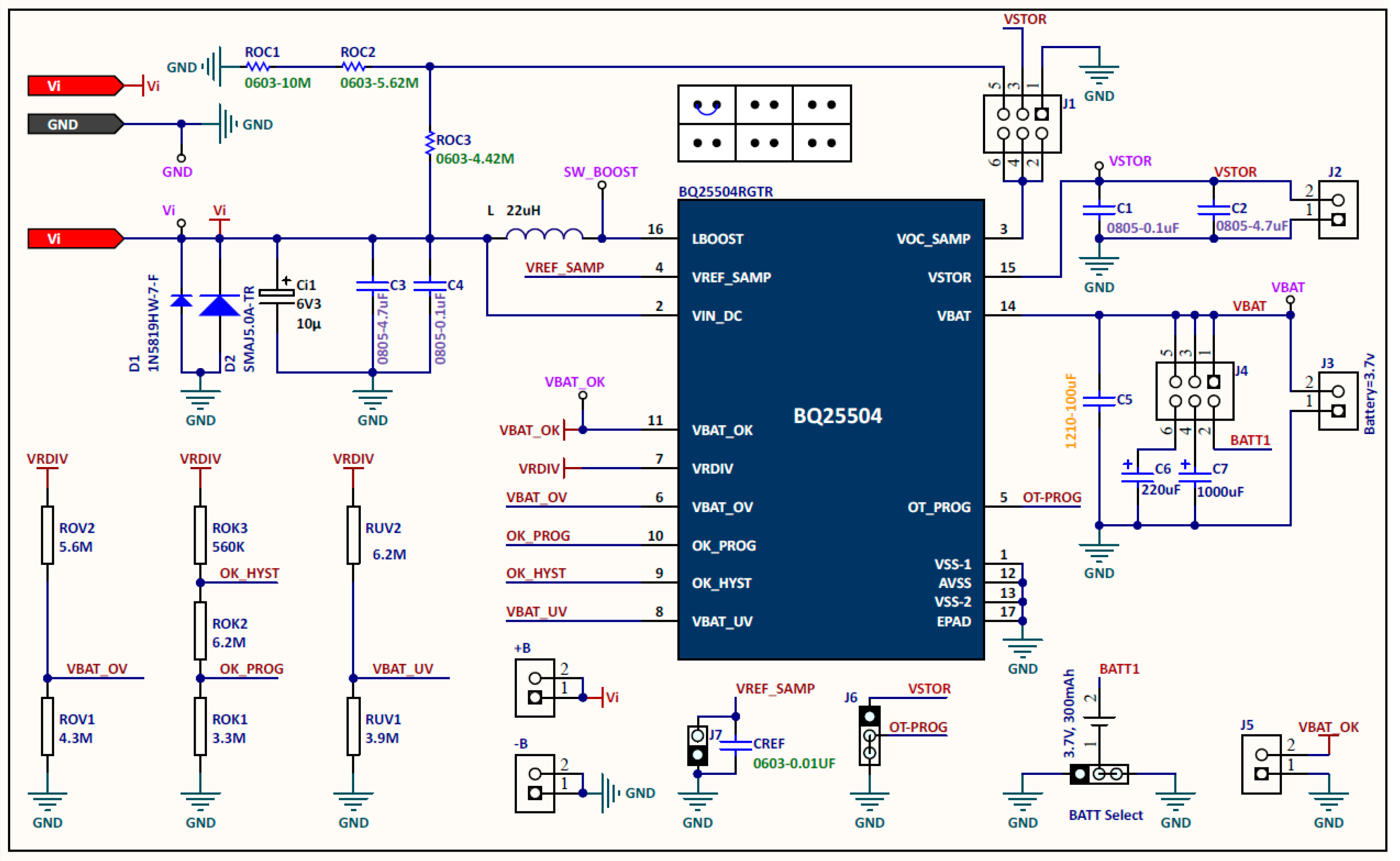

2.2.3. DC/DC Converter and Power Management Unit

2.2.4. Energy Storage Unit

2.3. Proposed Multi-Port Energy Harvesting Circuit

2.3.1. MPPT, Overvoltage, and Undervoltage Protection

3. Experimental Results

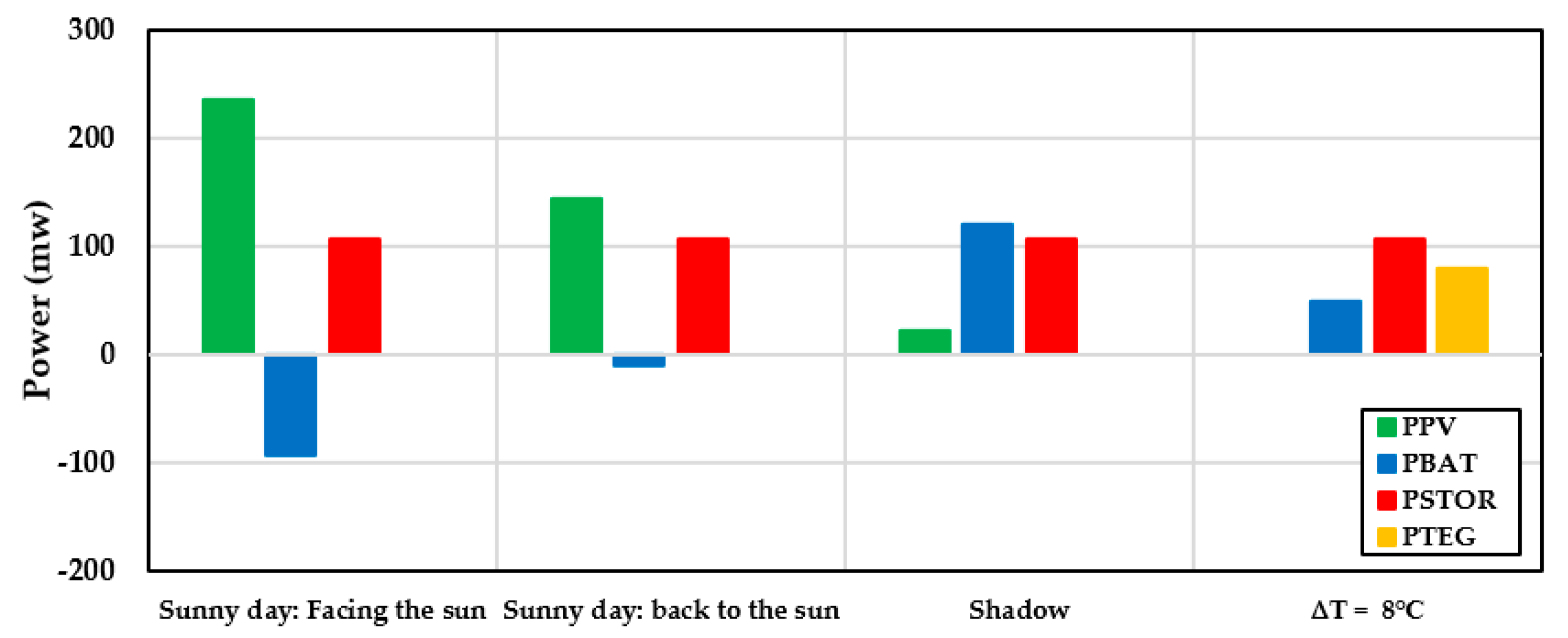

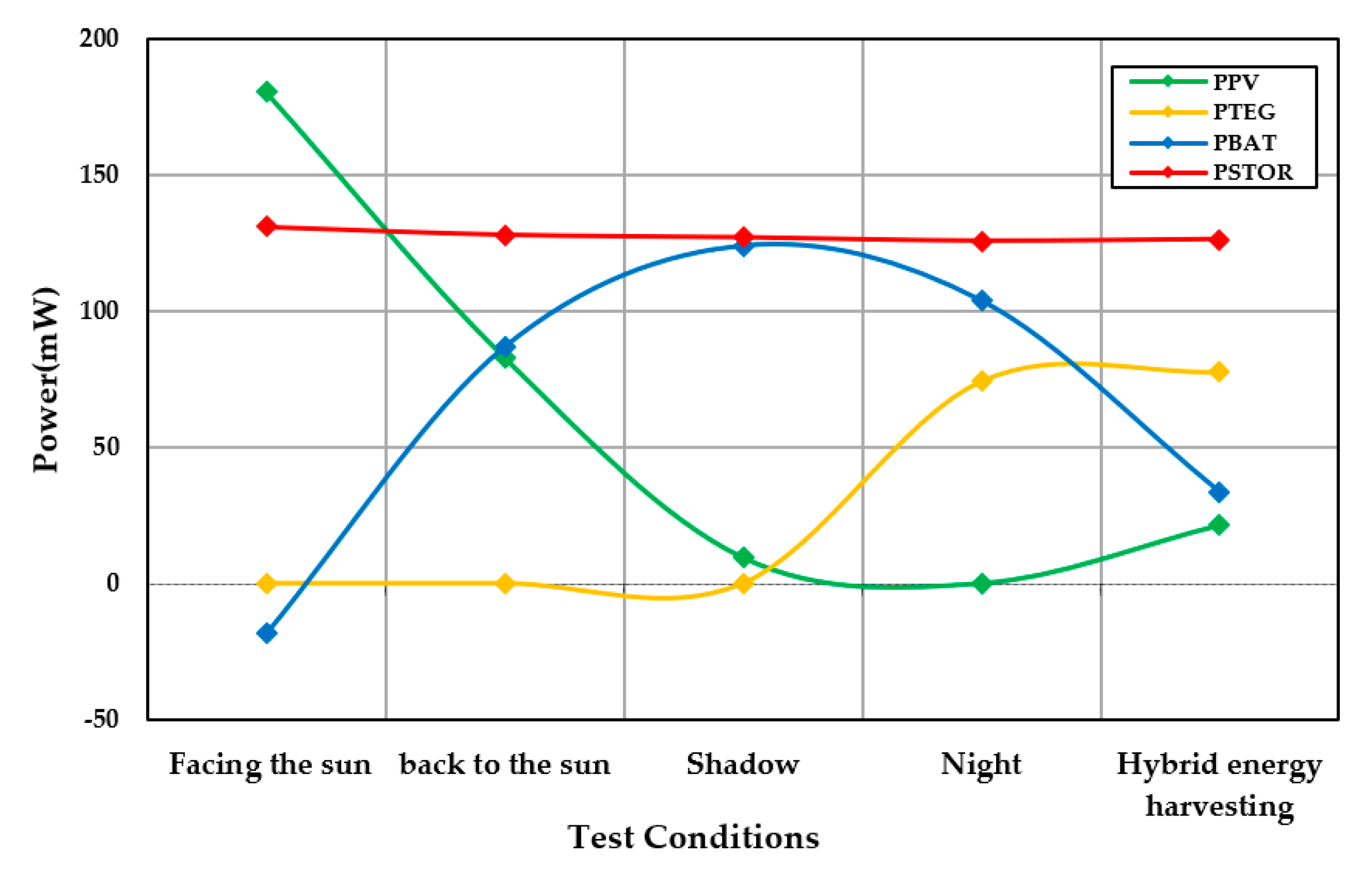

- Sunny day facing the sun,

- Sunny day back to the sun,

- Shady or cloudy conditions.

| Test conditions | Sunny day: facing the sun | Sunny day: back to the sun | ||||

|---|---|---|---|---|---|---|

| 10 min | 1 hour | 2 hours | 10 min | 1 hour | 2 hours | |

| VPV (V) | 2.92 | 2.91 | 2.94 | 2.8 | 2.7 | 2.8 |

| IPV (mA) | 71.2 | 63.4 | 80.1 | 51.7 | 48.5 | 50 |

| PPV (mW) | 207.9 | 184.5 | 235.5 | 144.76 | 131 | 140 |

| VBATT (V) | 3.75 | 3.96 | 3.96 | 3.83 | 3.81 | 4.04 |

| Iavrage (mA)1 | 32.21 | 33.21 | 33.21 | 33.26 | 34.15 | 32.21 |

3.1. The Results of the Hybrid Energy Harvesting System

3.1.1. First Experimental Stage: Wearable Sensor Node

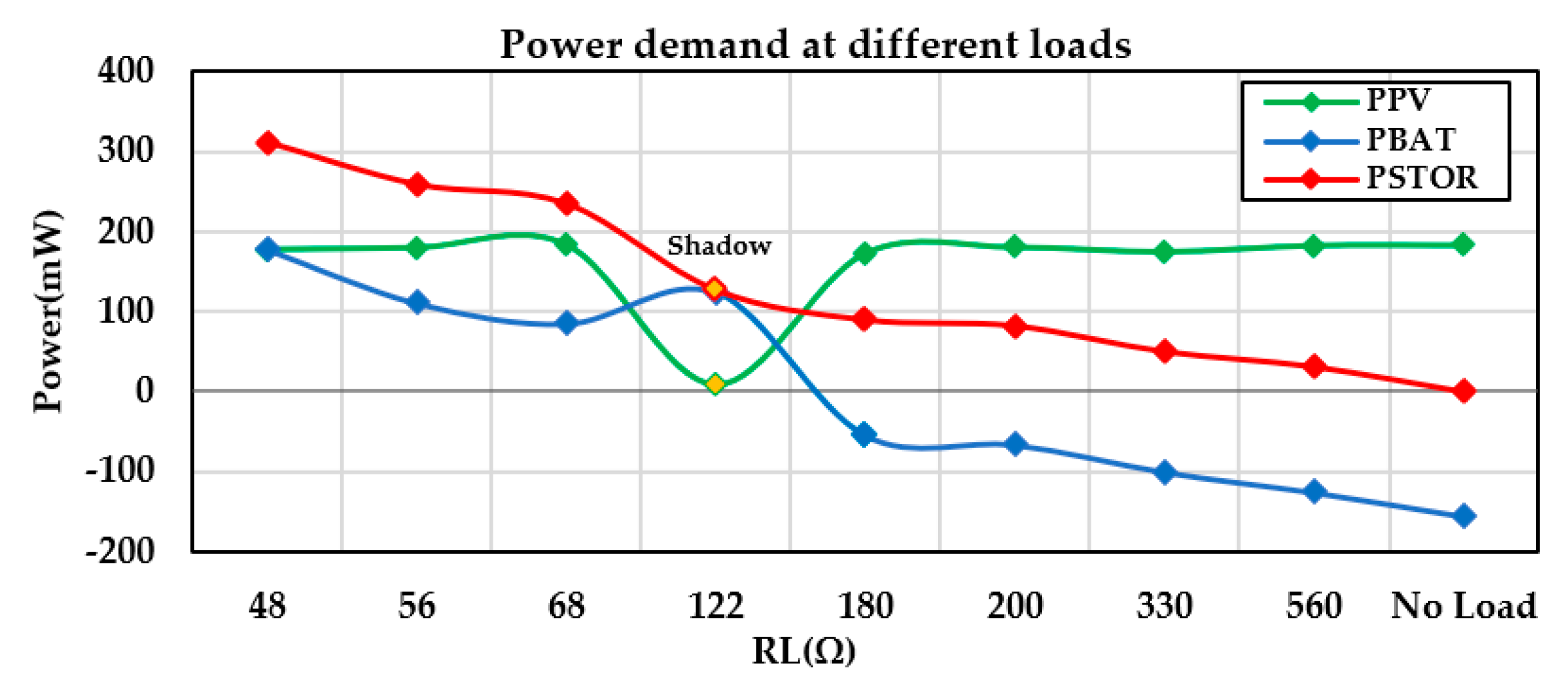

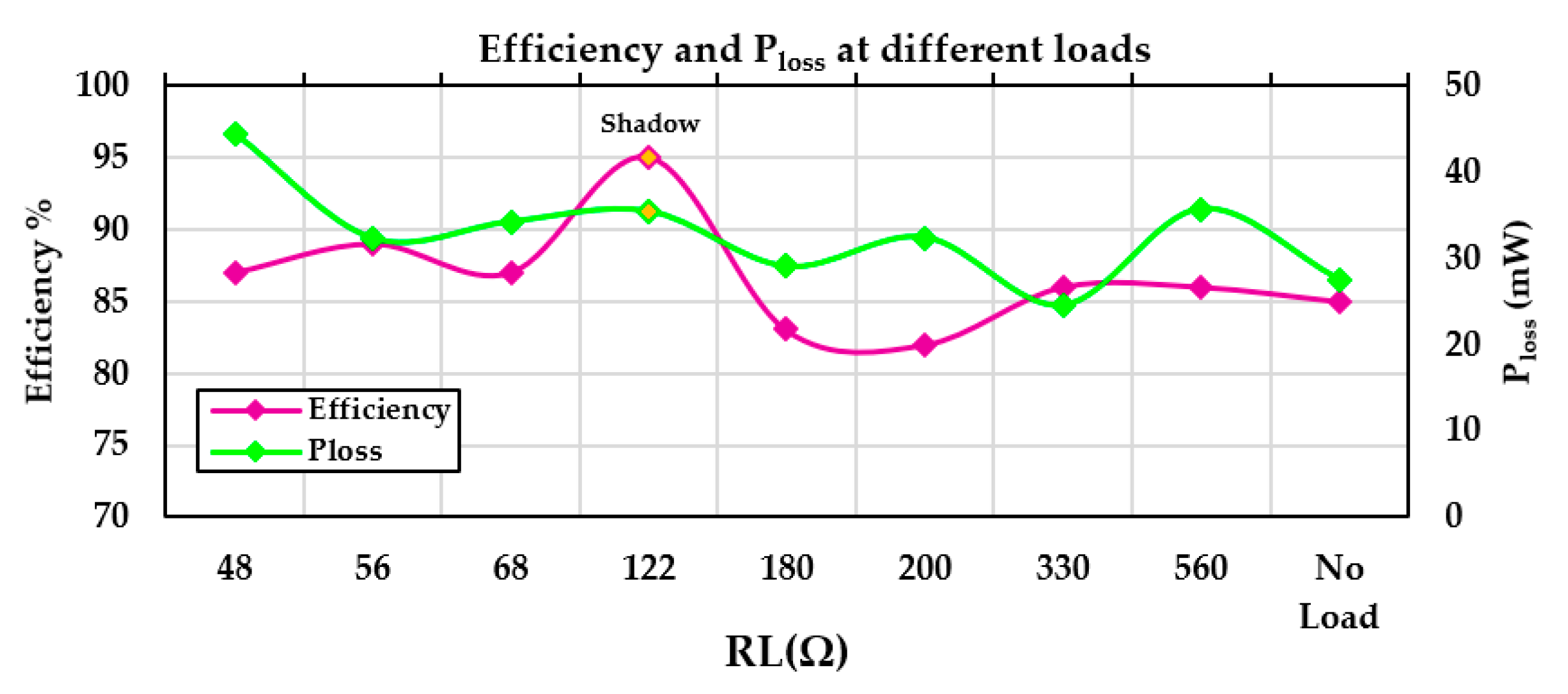

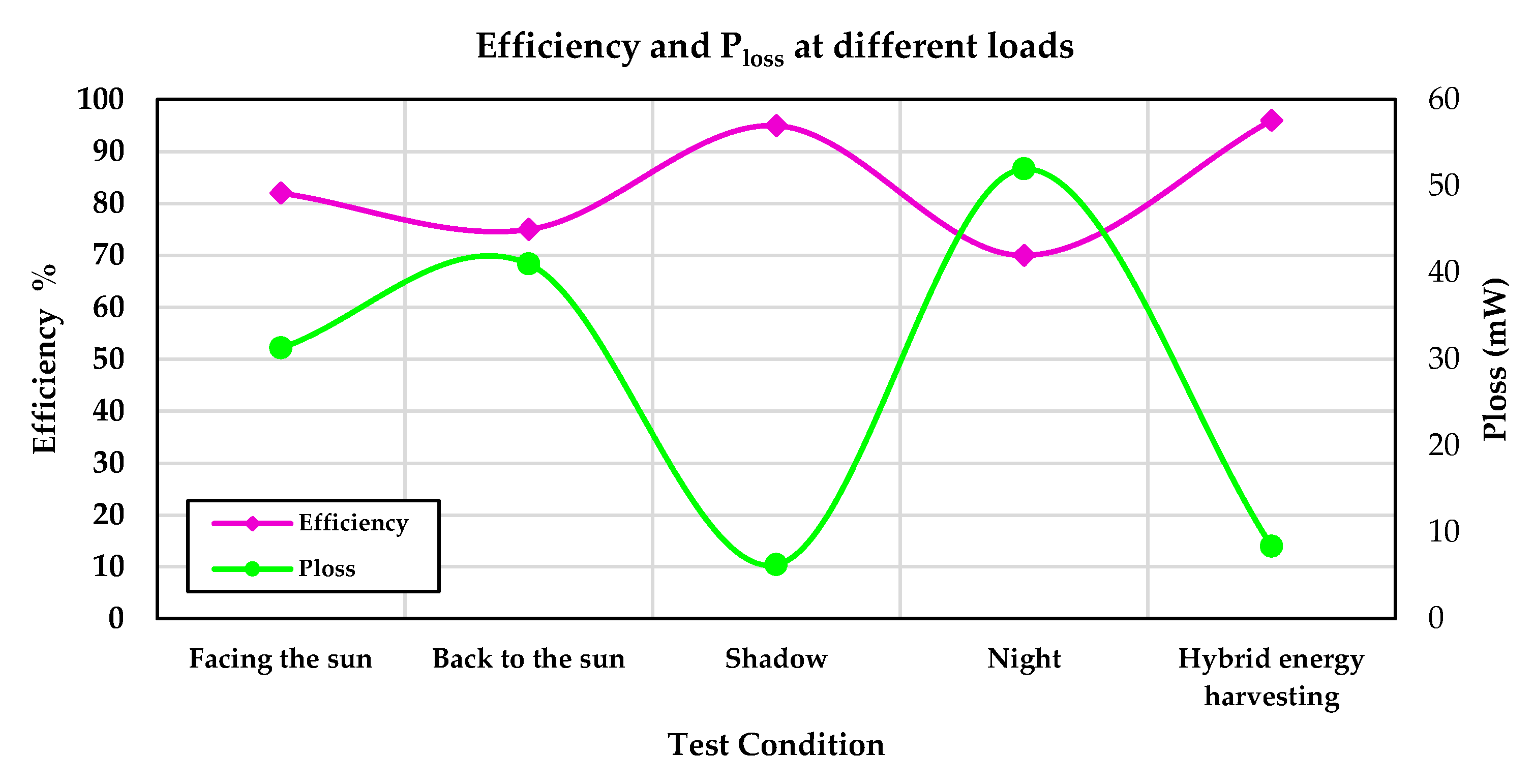

3.1.2. Second Experimental Stage: PV Energy Harvesting System under the Various Resistive Loads

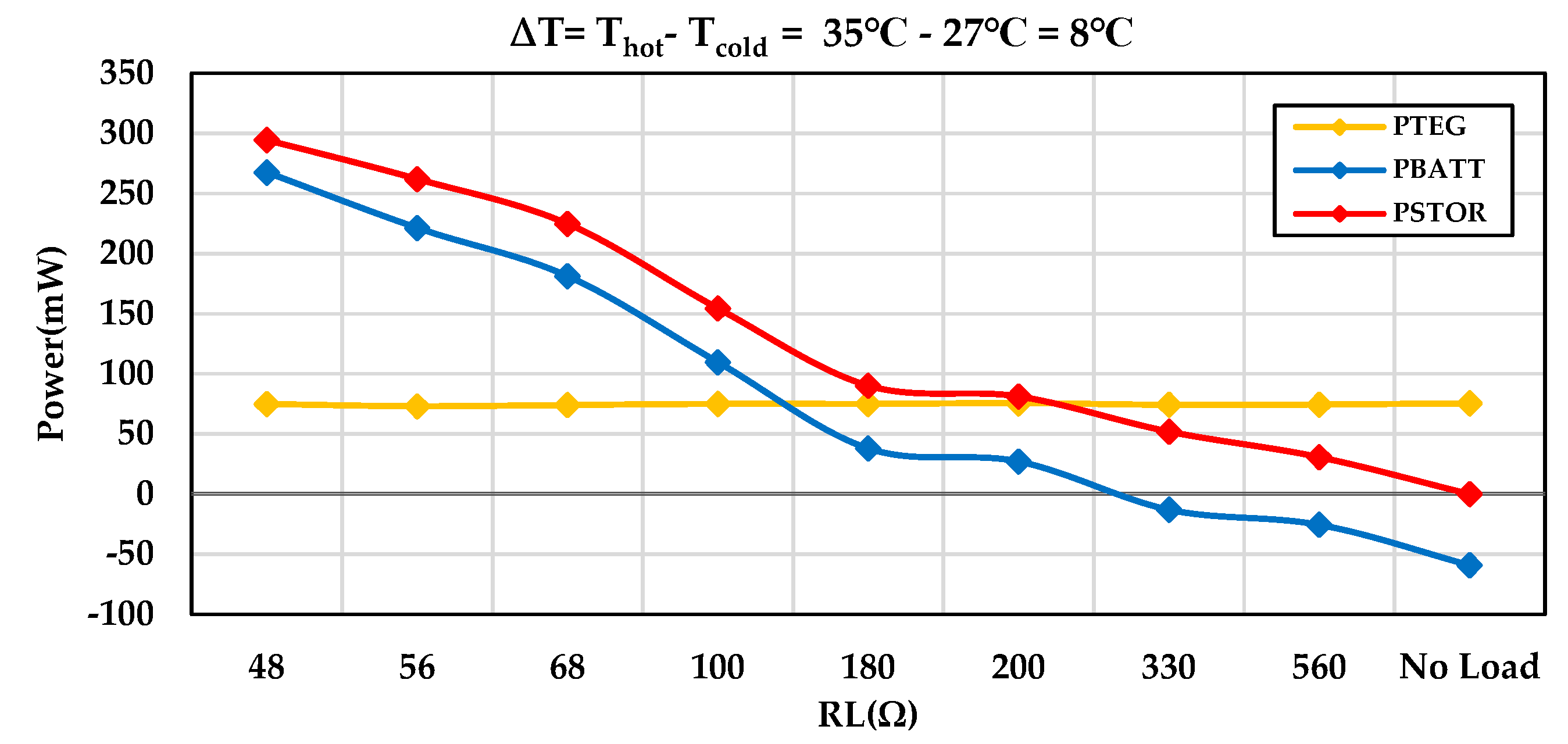

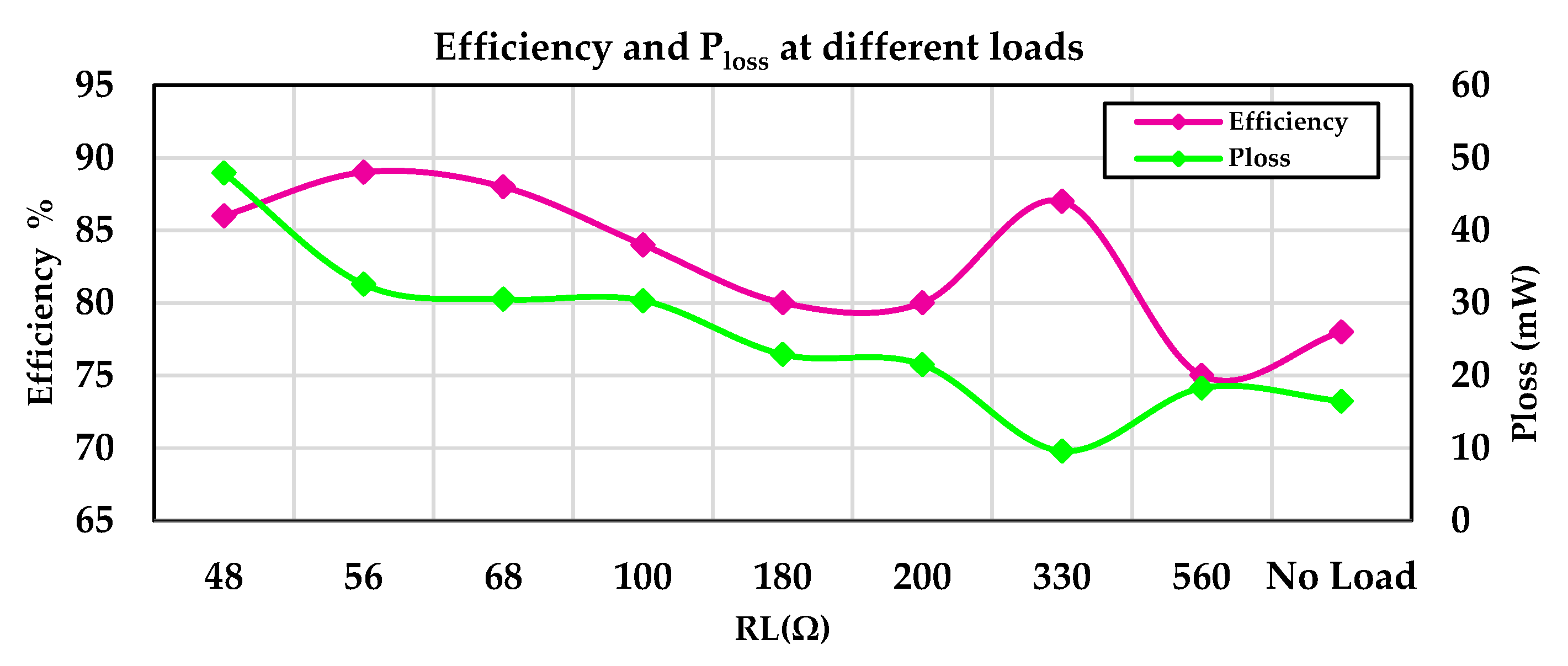

3.1.3. Third Experimental Stage: TEG Energy Harvesting System under the Various Resistive Loads

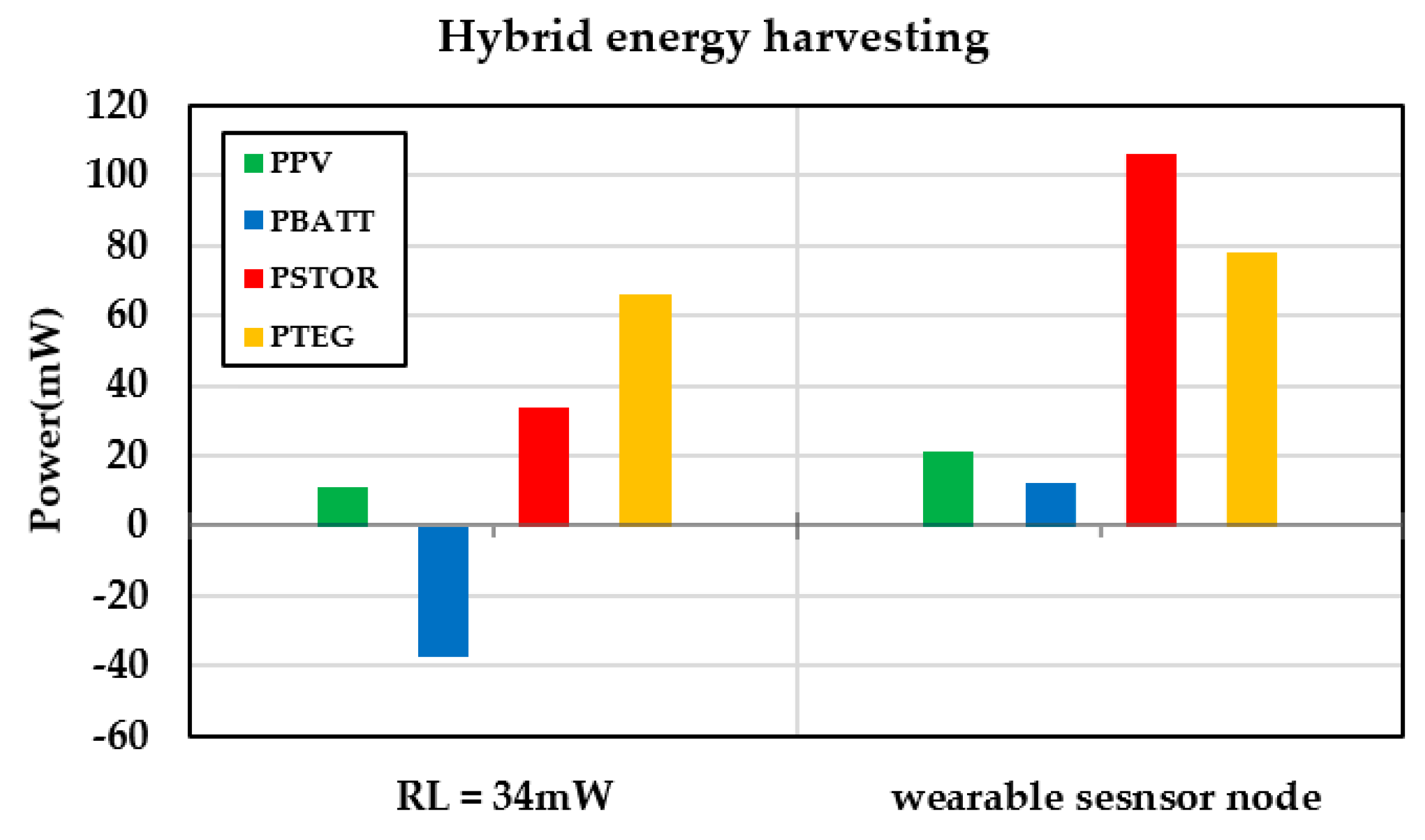

3.1.4. Fourth Experimental Stage: Hybrid Energy Harvesting

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Wearable Devices and Explainable Unsupervised Learning for COVID-19 Detection and MonitoringChong YW, Ismail W, Ko K, Lee CY. Energy harvesting for wearable devices: A review. IEEE Sensors Journal. 2019 Jun 28;19(20):9047-62.

- Cheong SH, Ng YJ, Lau Y, Lau ST. Wearable technology for early detection of COVID-19: A systematic scoping review. Preventive Medicine. 2022, 22, 107170. [Google Scholar]

- Wang WH, Hsu WS. Integrating artificial intelligence and wearable IoT system in long-term care environments. Sensors. 2023, 23, 5913. [Google Scholar] [CrossRef] [PubMed]

- Patil V, Singhal DK, Naik N, Hameed BZ, Shah MJ, Ibrahim S, Smriti K, Chatterjee G, Kale A, Sharma A, Paul R. Factors Affecting the Usage of Wearable Device Technology for Healthcare among Indian Adults: A Cross-Sectional Study. Journal of Clinical Medicine. 2022, 11, 7019. [Google Scholar] [CrossRef] [PubMed]

- Popov VV, Kudryavtseva EV, Kumar Katiyar N, Shishkin A, Stepanov SI, Goel S. Industry 4.0 and digitalisation in healthcare. Materials. 2022 Mar 14;15(6):2140.

- Chong YW, Ismail W, Ko K, Lee CY. Energy harvesting for wearable devices: A review. IEEE Sensors Journal. 2019 Jun 28;19(20):9047-62.

- Damre SS, Shendkar BD, Kulkarni N, Chandre PR, Deshmukh S. Smart Healthcare Wearable Device for Early Disease Detection Using Machine Learning. International Journal of Intelligent Systems and Applications in Engineering. 2024;12(4s):158-66.

- Guk K, Han G, Lim J, Jeong K, Kang T, Lim EK, Jung J. Evolution of wearable devices with real-time disease monitoring for personalized healthcare. Nanomaterials. 2019 May 29;9(6):813.

- Zovko K, Šerić L, Perković T, Belani H, Šolić P. IoT and health monitoring wearable devices as enabling technologies for sustainable enhancement of life quality in smart environments. Journal of Cleaner Production. 2023 Aug 10;413:137506.

- Davies HJ, Williams I, Peters NS, Mandic DP. In-ear spo2: A tool for wearable, unobtrusive monitoring of core blood oxygen saturation. Sensors. 2020 Aug 28;20(17):4879.

- Hussain Z, Sheng QZ, Zhang WE, Ortiz J, Pouriyeh S. Non-invasive techniques for monitoring different aspects of sleep: A comprehensive review. ACM Transactions on Computing for Healthcare (HEALTH). 2022 Mar 3;3(2):1-26.

- Haghi M, Ershadi A, Deserno TM. Recognizing Human Activity of Daily Living Using a Flexible Wearable for 3D Spine Pose Tracking. Sensors. 2023 Feb 12;23(4):2066.

- Bellagente P, Crema C, Depari A, Ferrari P, Flammini A, Lanfranchi G, Lenzi G, Maddiona M, Rinaldi S, Sisinni E, Ziliani G. Remote and non-invasive monitoring of elderly in a smart city context. In2018 IEEE sensors applications symposium (SAS) 2018 Mar 12 (pp. 1-6). IEEE.

- Razavi M, McDonald A, Mehta R, Sasangohar F. Evaluating Mental Stress Among College Students Using Heart Rate and Hand Acceleration Data Collected from Wearable Sensors. arXiv preprint arXiv:2309.11097. 2023 Sep 20.

- Kim J, Khan S, Wu P, Park S, Park H, Yu C, Kim W. Self-charging wearables for continuous health monitoring. Nano Energy. 2021 Jan 1;79:105419.

- Nozariasbmarz A, Collins H, Dsouza K, Polash MH, Hosseini M, Hyland M, Liu J, Malhotra A, Ortiz FM, Mohaddes F, Ramesh VP. Review of wearable thermoelectric energy harvesting: From body temperature to electronic systems. Applied Energy. 2020 Jan 15;258:114069.

- Hesham R, Soltan A, Madian A. Energy harvesting schemes for wearable devices. AEU-International Journal of Electronics and Communications. 2021 Aug 1;138:153888.

- Davies HJ, Bachtiger P, Williams I, Molyneaux PL, Peters NS, Mandic DP. Wearable in-ear PPG: Detailed respiratory variations enable classification of COPD. IEEE Transactions on Biomedical Engineering. 2022 Jan 25;69(7):2390-400.

- Haghi M, Danyali S, Thurow K, Warnecke JM, Wang J, Deserno TM. Hardware prototype for wrist-worn simultaneous monitoring of environmental, behavioral, and physiological parameters. Applied Sciences. 2020 Aug 7;10(16):5470.

- Haghi M, Danyali S, Ayasseh S, Wang J, Aazami R, Deserno TM. Wearable devices in health monitoring from the environmental towards multiple domains: A survey. Sensors. 2021 Mar 18;21(6):2130.

- He Z, Wang K, Zhao Z, Zhang T, Li Y, Wang L. A Wearable Flexible Acceleration Sensor for Monitoring Human Motion. Biosensors. 2022 Aug 10;12(8):620.

- Babar M, Rahman A, Arif F, Jeon G. Energy-harvesting based on internet of things and big data analytics for smart health monitoring. Sustainable Computing: Informatics and Systems. 2018 Dec 1;20:155-64.

- Páez-Montoro A, García-Valderas M, Olías-Ruíz E, López-Ongil C. Solar energy harvesting to improve capabilities of wearable devices. Sensors. 2022 May 23;22(10):3950.

- Proto A, Bibbo D, Cerny M, Vala D, Kasik V, Peter L, Conforto S, Schmid M, Penhaker M. Thermal energy harvesting on the bodily surfaces of arms and legs through a wearable thermo-electric generator. Sensors. 2018 Jun 13;18(6):1927.

- Huet F, Boitier V, Seguier L. Tunable piezoelectric vibration energy harvester with supercapacitors for WSN in an industrial environment. IEEE Sensors Journal. 2022 Jun 28;22(15):15373-84.

- Gljušćić P, Zelenika S, Blažević D, Kamenar E. Kinetic energy harvesting for wearable medical sensors. Sensors. 2019 Nov 12;19(22):4922.

- Sherazi HH, Zorbas D, O’Flynn B. A comprehensive survey on RF energy harvesting: Applications and performance determinants. Sensors. 2022 Apr 13;22(8):2990.

- Mohsen S, Zekry A, Youssef K, Abouelatta M. A self-powered wearable wireless sensor system powered by a hybrid energy harvester for healthcare applications. Wireless Personal Communications. 2021 Feb;116(4):3143-64.

- Bai Y, Jantunen H, Juuti J. Energy harvesting research: the road from single source to multisource. Advanced materials. 2018 Aug;30(34):1707271.

- Shi Y, Wang Y, Mei D, Feng B, Chen Z. Design and fabrication of wearable thermoelectric generator device for heat harvesting. IEEE Robotics and Automation Letters. 2017 Jul 31;3(1):373-8.

- Xiao L, Wu K, Tian X, Luo J. Activity-specific caloric expenditure estimation from kinetic energy harvesting in wearable devices. Pervasive and Mobile Computing. 2020 Sep 1;67:101185.

- Pillatsch P, Yeatman EM, Holmes AS. Real world testing of a piezoelectric rotational energy harvester for human motion. InJournal of Physics: Conference Series 2013 Dec 4 (Vol. 476, No. 1, p. 012010). IOP Publishing.

- Delnavaz A, Voix J. Energy harvesting for in-ear devices using ear canal dynamic motion. IEEE Transactions on Industrial Electronics. 2013 Jan 25;61(1):583-90.

- Li X, Sun Y. WearETE: A scalable wearable e-textile triboelectric energy harvesting system for human motion scavenging. Sensors. 2017 Nov 17;17(11):2649.

- Farooq M, Sazonov E. Segmentation and characterization of chewing bouts by monitoring temporalis muscle using smart glasses with piezoelectric sensor. IEEE journal of biomedical and health informatics. 2016 Dec 14;21(6):1495-503.

- Yu BY, Wang ZH, Ju L, Zhang C, Liu ZG, Tao L, Lu WB. Flexible and wearable hybrid RF and solar energy harvesting system. IEEE Transactions on Antennas and Propagation. 2021 Oct 14;70(3):2223-33.

- Veloo SG, Tiang JJ, Muhammad S, Wong SK. A Hybrid Solar-RF Energy Harvesting System Based on an EM4325-Embedded RFID Tag. Electronics. 2023 Sep 27;12(19):4045.

- J Noh YS, Seo JI, Kim HS, Lee SG. A reconfigurable DC/DC converter for maximum thermoelectric energy harvesting in a battery-powered duty-cycling wireless sensor node. IEEE Journal of Solid-State Circuits. 2022 Mar 7;57(9):2719-30.

- Ali A, Shaukat H, Bibi S, Altabey WA, Noori M, Kouritem SA. Recent progress in Energy Harvesting Systems for wearable technology. Energy Strategy Reviews. 2023 Sep 1;49:101124.

- Tan YK, Panda SK. Energy harvesting from hybrid indoor ambient light and thermal energy sources for enhanced performance of wireless sensor nodes. IEEE Transactions on Industrial Electronics. 2010 Dec 23;58(9):4424-35.

- Carli D, Brunelli D, Benini L, Ruggeri M. An effective multi-source energy harvester for low power applications. In2011 Design, Automation & Test in Europe 2011 Mar 14 (pp. 1-6). IEEE.

- Ngoc-Thang B, Nguyen TM, Truong TT, Nguyen BL, Nguyen TT. A dynamic reconfigurable wearable device to acquire high quality PPG signal and robust heart rate estimate based on deep learning algorithm for smart healthcare system. Biosensors and Bioelectronic.

- Longmore SK, Lui GY, Naik G, Breen PP, Jalaludin B, Gargiulo GD. A comparison of reflective photoplethysmography for detection of heart rate, blood oxygen saturation, and respiration rate at various anatomical locations. Sensors. 2019 Apr 19;19(8):1874.

- MAX30102 Datasheet and Product Info | Analog Devices, High-Sensitivity Pulse Oximeter and Heart-Rate Sensor for Wearable Health. https://www.analog.com/en/products/max30102.html.

- Yang CC, Hsu YL. A review of accelerometry-based wearable motion detectors for physical activity monitoring. Sensors. 2010 Aug 20;10(8):7772-88.

- He Z, Wang K, Zhao Z, Zhang T, Li Y, Wang L. A Wearable Flexible Acceleration Sensor for Monitoring Human Motion. Biosensors. 2022 Aug 10;12(8):620.

- MPU-6050 | TDK InvenSense, TDK InvenSense, Nov. 28, 2022. https://invensense.tdk.com/products/motion-tracking/6-axis/mpu-6050/.

- AEM10941 Solar Energy Harvesting IC, e-peas | Mouser. https://www.mouser.com/new/e-peas/e-peas-aem10941-solar-energy-harvesting-ic/.

- AEM20940 Thermal Energy Harvesting IC, e-peas | Mouser. https://www.mouser.com/new/e-peas/e-peas-aem20940-thermal-energy-harvesting-ic/.

- ADP5091 Datasheet and Product Info | Analog Devices. https://www.analog.com/en/products/adp5091.html.

- BQ25504 data sheet, product information and support | TI.com. https://www.ti.com/product/BQ25504.

- BQ25570 data sheet, product information and support | TI.com. https://www.ti.com/product/BQ25570.

- SPV1050 - STMicroelectronics, STMicroelectronics. https://www.st.com/en/power-management/spv1050.html.

- LTC3105 Datasheet and Product Info | Analog Devices. https://www.analog.com/en/products/ltc3105.html.

- LTC3106 Datasheet and Product Info | Analog Devices. https://www.analog.com/en/products/ltc3106.html.

- Huynh DC, Dunnigan MW. Development and comparison of an improved incremental conductance algorithm for tracking the MPP of a solar PV panel. IEEE transactions on sustainable energy. 2016 Apr 20;7(4):1421-9.

- Guragain DP, Budhathoki RK, Ghimire P. Programmable timer triggered energy harvesting wireless sensor-node using long range radio access technology. International Journal of Electrical & Computer Engineering (2088-8708). 2022 Aug 1;12.

- Magno M, Brunelli D, Sigrist L, Andri R, Cavigelli L, Gomez A, Benini L. InfiniTime: Multi-sensor wearable bracelet with human body harvesting. Sustainable Computing: Informatics and Systems. 2016 Sep 1;11:38-49.

| Energy sources | Power density |

|---|---|

| Ambient light | 100 mW/cm2 (direct sun) 100 μW/cm2 (indoor illumination) |

| Thermoelectric | 60 μW/cm2 |

| Radio frequency | 1 μW/cm2 (ambient) 15 μW (external) |

| Human | 1000 μW/cm2 (biochemical) 4 μW/cm3 (biomechanical - microgenerator) 200 μW/cm3 (biomechanical - piezoelectric) |

| Symbol | Cell Parameter | Typical Ratings1 |

|---|---|---|

| VOC | open circuit voltage | 2.07 V |

| ISC | short circuit current | 19.5 mA |

| Vmpp | voltage at MPP | 1.67 V |

| Impp | current at MPP | 18.4 mA |

| Pmpp | maximum peak power | 30.7 mW |

| H | Solar cell efficiency | 25% |

| Symbol | Parameter | Values at Hot Side Temperature | ||

|---|---|---|---|---|

| 35°C | 55°C | 85°C | ||

| Tcold | Cold Side Temperature, (°C) | 27 | 27 | 27 |

| Optη | Optimum Efficiency, (%) | 0.40 | 1.36 | 2.71 |

| POPT | Optimum Power, (mW) | 20 | 233 | 964 |

| VOPT | Optimum Voltage, (V) | 0.244 | 0.868 | 1.825 |

| VOC | Open Circuit Voltage, (V) | 0.43 | 1.51 | 3.18 |

| ISC | Short Circuit Current, (A) | 0.19 | 0.63 | 1.24 |

| Test Conditions | Indoor | |

|---|---|---|

| 10 min | 1 hour | |

| VTEG (V) | 0.96 | 0.96 |

| ITEG (mA) | 82.2 | 82.2 |

| PTEG (mW) | 78.912 | 78.912 |

| VBATT (V) | 3.93 | 3.92 |

| Iavrage (mA)1 | 32.21 | 33.21 |

| Skin temperature | 35 | 35 |

| Environment temperature | 27 | 27 |

| ref | Energy Source | Sensors deployed | Energy Storage | Area of harvester (mm2) | Power of harvester (mW) | mode of device wearability | Energy Management IC | MCU unit | Circuit Techniques for Hybrid | |

|---|---|---|---|---|---|---|---|---|---|---|

| This work | PV, TEG | PPG, Accelerometer | Battery, 300mAh | Panel = 1840, TEG = 1024 | Panel = 307, TEG = 78.2 at (∆T = 8 °C) | Glasses, Wrist-worn | Two BQ25504 Boost Converter | NodeMCU ESP8266 | energy harvesting from both sources, without diode | |

| [28] | PV, TEG | Tmperature Sensor, pulse oximeter sensor, and accelerometer sensor | Super-capacitor, 50F | Panel = 4320, TEG = 1600 | Panel = 207, TEG = 50 at (∆T = 20 °C) | Wrist-worn | LTC3105 Bosst Converter | ATmega-328p | Power OR-ing. | |

| [30] | TEG | powering a LED | N/A | TEG = 559 | TEG = 0.023 at (∆T = 10 °C) | Wrist-worn | LTC3108 Boost Converter | N/A | __ | |

| [57] | PV | N/A | Battery, CR2025- super-capacitor, 4F | 40000 | 820 | N/A | BQ25570 Buck-Boost Converter | Atmel ATMEGA328P-AU | __ | |

| [58] | PV, TEG | Nano-power accelerometer, a temperature sensor and an analog microphone | Battery, 40mAh | Panel = 3892, TEG = 560 | Panel = 4.42, TEG = 2.62 at (∆T = 16°C) | bracelet | BQ25570 Buck-Boost Converter and LTC3108 Boost Converter | MSP430FR5969 | energy harvesting from both sources, with diode |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).