1. Introduction

The SC is a vast, heterogeneous, and complex system where its complexity varies based on the industry, product type, and geographical scope of operations. The fish industry is an example of this system due to the nature of the product, the diverse range of stakeholders involved, and the quality and authenticity requirements.

The FSC aims to track and trace the fish lifecycle from origin to the end customer [

1]. FSC face several challenges that impact their ability to provide reliable information about the fish product’s quality and the authenticity [

2]. FSC stakeholders, including harvesters, suppliers, manufacturers, distributors, consumers, and regulatory or governmental authorities demand proper chain of custody traceability [

3]. Effective approaches are being developed to ensure FSC traceability, quality control, and product authenticity. BC can address these challenges; however, it still requires more collaborated research efforts to prove its appropriateness in terms of performance and behavior, especially when used in a combination with other technologies [

4].

BC is a DLT that can be used as a decentralized database that supports the essential SC system requirements, including visibility, provenance, security, and traceability [

5,

6]. New technological advancements, such as Big Data, AI, and Internet of Things (IoT), integrated with BC-based seafoodSC, can offer significant advantages and create an agile and effective ecosystem [

7], revolutionizing how smart cities manage their perishable food supplies and enhance seafood safety measures [

8]. Adopting BC technology in SC solutions is crucial for highly perishable products such as fish. To this end, we propose a BC-based FSC framework integrated with QAT technology, that supports species identification, fish quality monitoring, and freshness assessment. The framework is described as a layered architecture, intending not only to track and trace the fish from source to destination but also to monitor fish quality and authenticity along the different stages of the chain. We aim to assist ongoing research in implementing effective FSC with the combination of BC, AI, and IoT technological advancements.

The main contributions of this paper are as follows:

Proposing a BC-based FSC framework that can be described as a layered architecture and consisting of: a SC layer, an IoT layer, and a BC layer for better traceability.

Integrating QAT technology into the BC-based FSC to automate species identification and freshness assessment. The QAT hand-held device can identify fish quality and evaluate its freshness level on-site through its integrated AI architecture.

Leveraging BC and smart contracts deployed over the Ethereum to enhance system efficiency and transparency. Automating FSC processes can be facilitated through smart contracts implementation. As an illustrative example, we introduce the smart contract of a Harvester stakeholder, providing insights into its business logic, implementation, testing, and validation processes, which can serve as a reference for smart contracts development for other stakeholders.

2. Related Work

BC is an ideal architecture for SC applications that require distributed databases, which allow all participants to access and update information while maintaining data consistency and security, in addition to decentralizing computation and management. BC supports several key features, including data immutability, decentralization, transparency, data signatures, consensus, and smart contracts [

9]. All product details are collected using IoT devices and sensors, then validated, secured, and recorded on a distributed ledger and shared among system actors in order to protect the product integrity and stakeholders’ sensitive data [

1]. Adopting BC in the FSC has been extensively explored in the literature. Notable surveys by [

1,

10,

11,

12], have covered various aspects, including existing research, benefits, design requirements, industrial demands, challenges, technological integration, and more.

The authors of [

13] reviewed and investigated many corporate initiatives related to BC applications, including WWF-New Zealand, Pacifical and Atato, OpenSC, Bumble Bee Foods, and Fishcoin. The study has culminated in a set of recommendations that promote BC technology to develop national and international SC.

Numerous research studies have delved into BC integration within the domain of fisheries and seafood SC (

Table 1). Several compelling reasons underlie this particular focus, including:

Inherent fish products attributes, characterized by high perishability and sensitivity to temperature fluctuations.

Multifaceted challenges faced by the fishing and aquaculture sectors, encompassing the preservation of product quality, safety assurance, and adherence to sustainability standards.

Intricate issues associated with identifying and preventing IUU activities, along with fraudulent practice mitigation.

For instance, the authors of [

14] presented a seafood SC case study that explored the importance of information continuity, traceability, accessibility, bridging between the information flow and physical flow, and fraud prevention. The authors of [

15] introduced a monitoring system for frozen shellfish cold storage that uses BC, Wireless Sensor Network (WSN), and K-means and Support Vector Machine (SVM) classification techniques. The aim was to improve transparency and trust while monitoring cold storage conditions quality parameters for frozen shellfish. The authors of [

16] studied a provenance BC-based FSC to improve marine conservation and fisheries. They discussed how BC technology can improve trust issues by supporting transparency in the FSC. The authors of [

17] studied the feasibility of BC adopting in the SC for the fishery sector considering different locations in Atlantic Canada as a case study. They examined IoT sensors attached to ocean buoys for data generation and collection. The authors of [

18] proposed a fish provenance and quality tracking system for trusted data sharing among different FSC parties.

The authors of [

19] studied the United Nations Sustainable Development Goals to reshape the BC-based food SC by focusing on Thai fish industry. The authors of [

20] introduced a framework for the SC to enhance the fishery sector in developing markets. This framework incorporates the use of BC, satellite imagery, and IoT technologies. The authors of [

21] proposed a BC-based fish traceability solution for handling both wild-caught fish and farmed fishery SC aiming to prevent fraudulent activities. The authors of[

22] discussed a framework that combined BC, IoT, Cloud Computing, and AI technologies to implement SC. They investigated a tuna FSC in Thailand as an empirical study to identify the different aspects of the approach.

3. BC-Based FSC Framework Architecture

In this section, we discuss the layered architecture of the proposed BC-based FSC framework, which consists of SC layer, BC layer, and IoT layer, and should work as a whole to provide better traceability and data transparency. The goal is to track and trace the fish product throughout its different stages starting from harvesting to manufacturing, packaging, shipping, distribution, and ending with delivery to the final customer, in addition to monitoring fish quality and authenticity along the different stages of the chain. The proposed framework is designed using the Ethereum platform and smart contracts using Solidity.

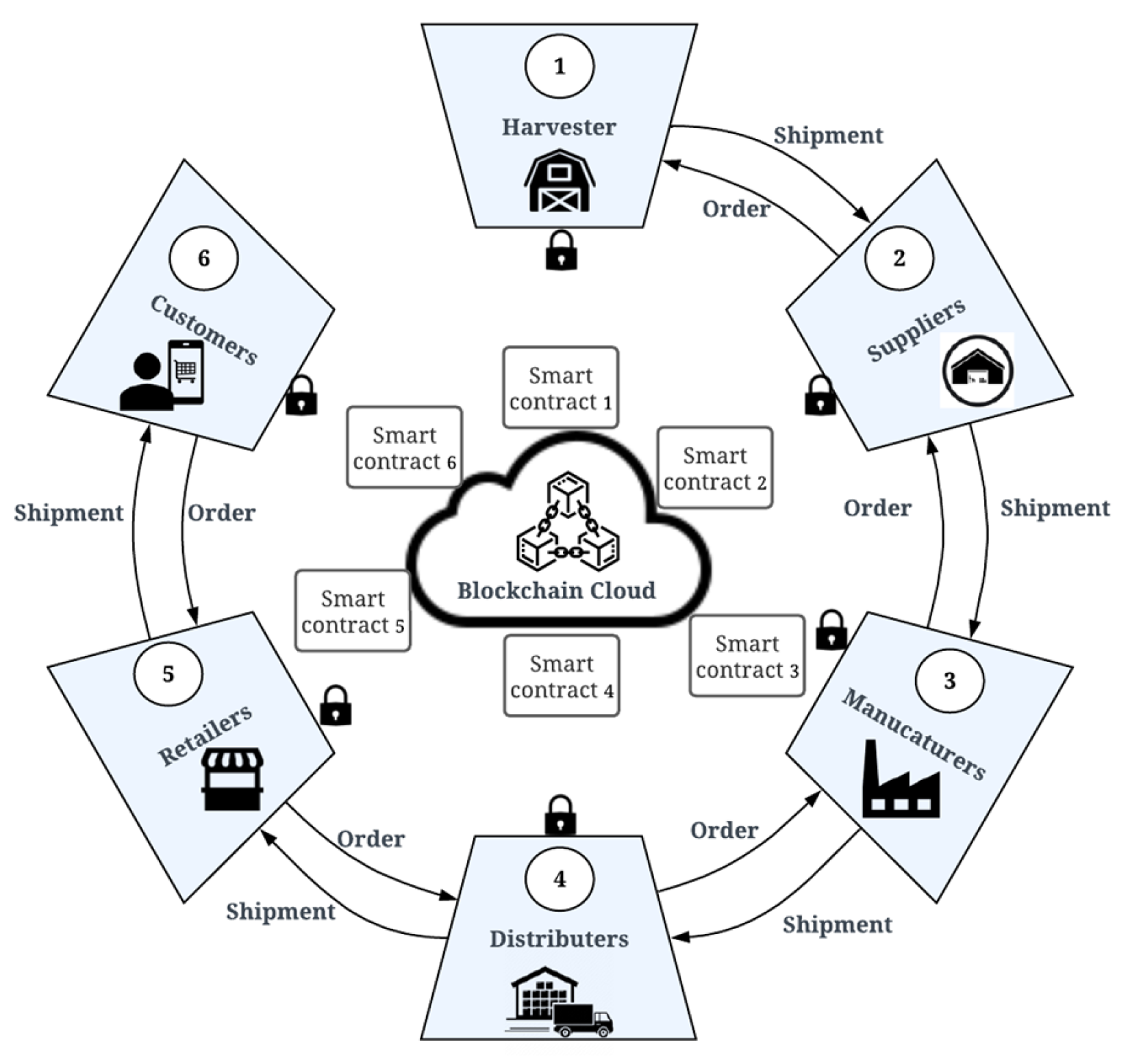

3.1. SC LAYER

The SC layer consists of the system actors, which play the role of system participants communicating and transacting over the network while the fish product physically flows from one stage to the other, starting at the Harvester, to Supplier, Manufacturer, Distributor, Retailer, and up to the Customer (

Figure 1).

The system actors are mainly the stakeholders that are controlling the fish’s physical flow in addition to the following key roles:

Real-time monitoring and reporting

Traceability management and documentation

Ensuring compliance with regulations

Collaboration with certification bodies and inspection agencies for safety and quality assessment

Establishing a clear chain of custody for the fish products

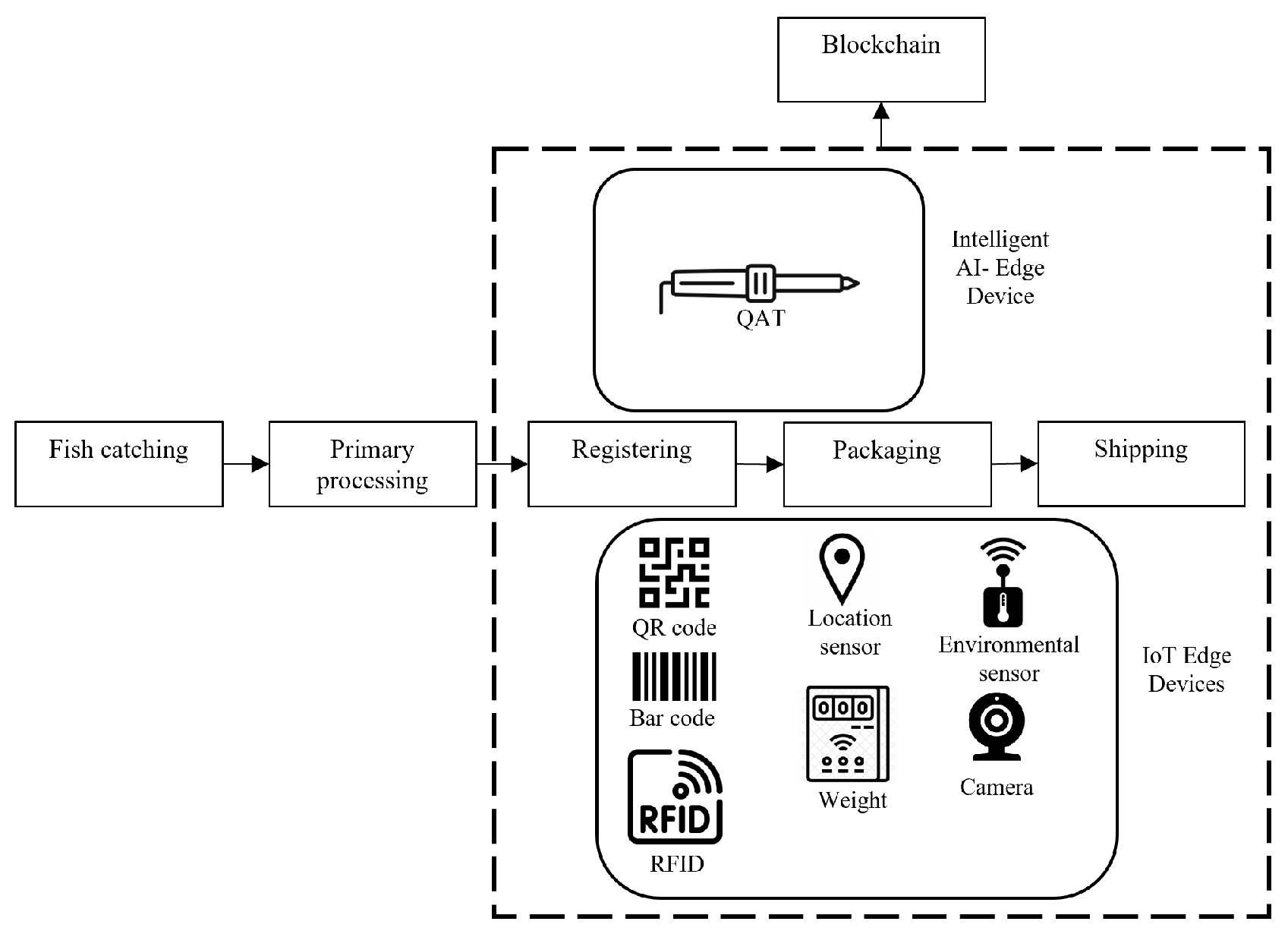

3.1.1. IoT LAYER

The IoT layer consists of IoT edge devices connected to the Internet, scattered across the different stages of the SC, and usually placed strategically to collect and exchange real-time track and trace data. Examples of IoT edge devices include environmental sensors such as temperature, humidity, water quality, scanning machines for QR and Bar codes, Radio Frequency (RFID), and cameras. Other intelligent AI-edge devices, such as QAT, can be integrated and used for species identification and freshness assessment.

3.1.2. BC LAYER

Exchanged transactions over the BC network collect information related to the SC activities. These transactions are encrypted and controlled by smart contracts and distributed to the involved entities so they can permanently recorded on the immune shared ledger. Recording transactions in the BC makes a system more transparent, reliable, and, most importantly, eliminates the need for central authority.

One of the critical elements in BC-based system design is smart contracts. Smart contracts are responsible for connecting business logic and processing SC activity execution [

23]. Smart contracts can be defined as event-driven programs stored in the BC database that can be executed autonomously on the selected BC platform. Smart contracts will be triggered when SC activities change states. Each of the actors has its own contract, and the interactions between them are defined and automated through these contracts, which are able to communicate through their individual Ethereum addresses and application programming interfaces (API) (

Figure 1).

4. Big Data and AI Integration through QAT Technology

Big Data and AI are seamlessly integrated to process vast amounts of information, such as environmental data, shipping routes, and product quality metrics [

24]. This synergy empowers stakeholders to make data-driven decisions, ensuring fish quality and safety towards enhancing the sustainability of the seafood industry. Fish is a highly perishable food that requires effective quality control and freshness monitoring approaches throughout production, storage, and transportation. The QAT technology can be used to evaluate fish freshness and species identification on-site and draw conclusions about fish quality and safety [

25]. The QAT technology is a proprietary hand-held device technology proposed and developed by SafetySpect Inc. [

26].

In the following, we demonstrate prevalent methods for species identification and fish fillet freshness evaluation, elucidate the discourse concerning the significance of QAT technology in the proposed BC-based FSC, and provide a concise overview of its ML methodology.

4.1. Prevalent Methods

Current prevalent methods for identifying fish fillet species include visual examinations, DNA bar-coding, and real-time PCR. Multiple technologies are available to evaluate the raw fish fillet freshness, including:

Sensory techniques: employing visuals, such as color and texture, smell, and touch to gauge attributes such as firmness and water-retention capacity

TVB-N: evaluating volatile gases, such as ammonia, dimethylamine, and trimethylamine [

27], along with gas sensors or "electronic noses" for volatile compounds [

28]

ELISA: identifying specific compounds via antigen-antibody reactions [

29]

TVC: microbiological tests to pinpoint spoilage organism growth [

30]

Tests involving Nucleotide/Adenosine Triphosphate (ATP) and the K-value [

31]

Electrical attributes examination [

32]

Imaging with RGB photos for freshness categorization

Methods involving fluorescence/reflectance spectroscopy [

33]

Some of these techniques, such as TVB-N, ELISA, TVC, and Nucleotide tests, are better aligned with research purposes. While, sensory evaluations and electrical properties are more tailored for industrial applications; however, each method presents its own set of challenges, which may include high costs, labor-intensive procedures,expert handling requirements, potential harm to the fish specimen, or limitations in precision. Optical spectroscopic approaches, such as QAT technology introduced for the proposed BC-based FSC, offer potential solutions to these challenges.

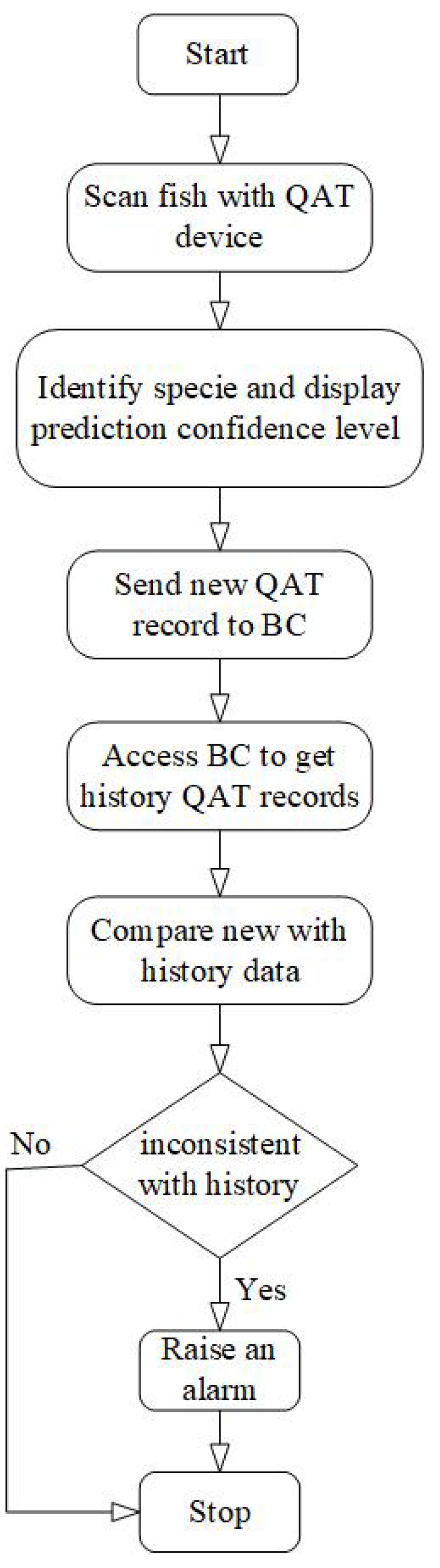

4.2. QAT Technology

We can monitor fish species identity and assess quality as frequently as required by integrating QAT technology at the IoT layer in the proposed BC-based FSC framework (

Figure 2). The QAT technology’s innovativeness is three-fold: 1) hardware design and manufacturing have allowed for the manufacturing of a miniaturized prototype that fits in the hand of an unskilled worker and is equipped with custom-designed illumination, 2) it employs fusion AI to integrate three spectroscopy modes, combining them to outperform each one individually [

34], and 3) we have developed a novel AI architecture that transcends the challenge of achieving high classification accuracy comparable to lab testing, particularly when dealing with numerous data classes. This architecture involves training specialized classification models for groups of similar fish. These models are subsequently invoked as needed by the global model, resulting in a significant enhancement in classification performance.

This technology can revolutionize the FSC, allowing stakeholders to use a hand-held device that can be instantly connected to an IoT-enabled BC network for non-destructive species detection and freshness assessment.

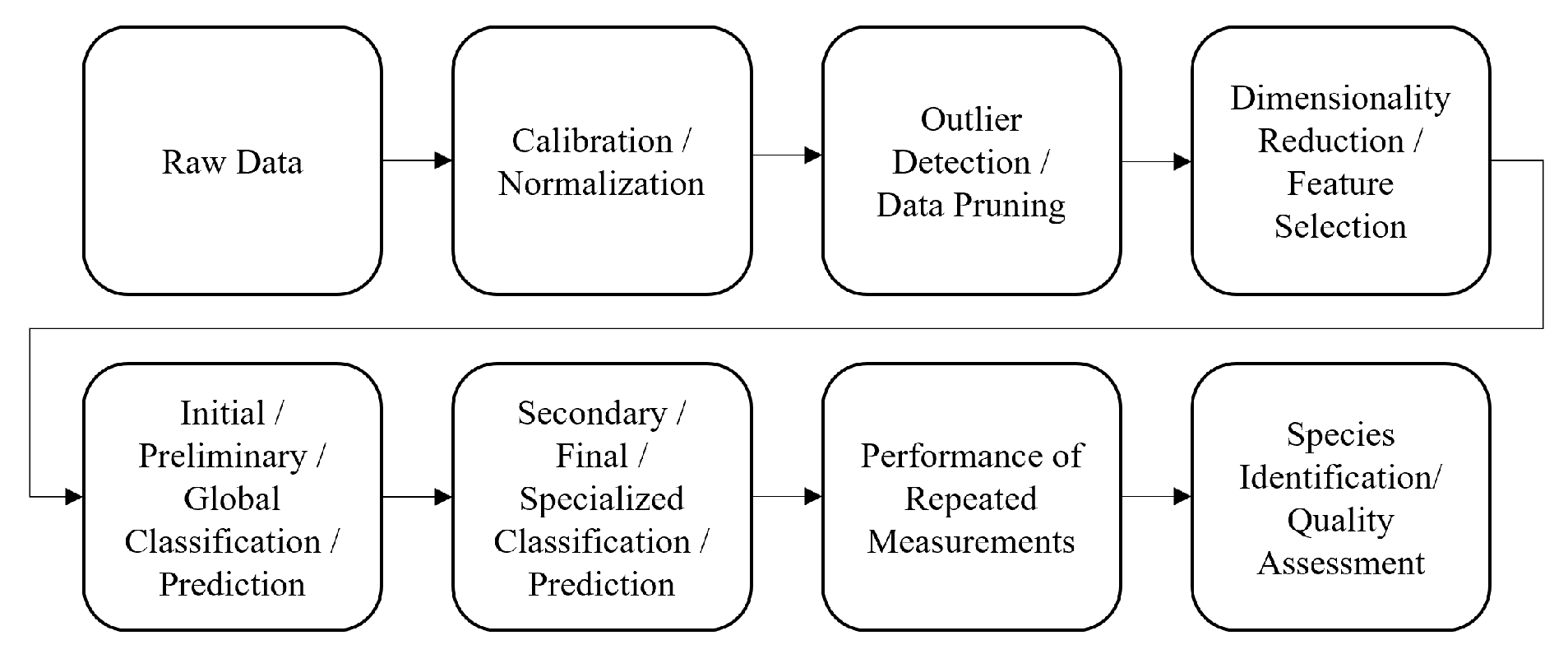

The QAT device’s ML methodology is depicted in

Figure 3. Linear and quadratic discriminant analysis, Decision Trees (DT), Random Forests (RF), Naive Bayes (NB), SVM, Logistic Regression (LR), and stacking ensemble ML classification algorithms have been used to train and test the data [

35].

The collected data was initially checked visually for quality, such as noise, saturation, and consistency. The spectra were normalized using techniques such as area-under-the-curve and min-max to finally select the best-performing normalization method. Data augmentation techniques were used to generate a larger dataset by adding random noise arrays to the spectra and shifting the original spectra vertically in both directions. All spectra were interpolated to integer values of wavelengths in nanometers so that the trained models are usable even if the wavelength values of future device versions change. Analysis techniques, including PCA and PLS, were used to reduce dimensionality in other cases. Feature/spectra from the modes were concatenated to fuse spectroscopy modes.

We evaluated the improvement in accuracy by: 1) fusing the three modes of spectroscopy: fluor, VNIR, and SWIR), 2) using each mode (fluor, VNIR, and SWIR) individually, and 3) pairing two modes (fluor-VNIR, fluor-SWIR, and VNIR-SWIR). The results revealed that the fluor mode is more effective in species identification while SWIR performs better for freshness assessment. The expected results represent the predicted species identity and freshness grade in addition to its respective level of confidence.

As the output of the device, fish species names will be reported as mandated by the FDA, using the list of common seafood names [

36], and fish freshness grade will be reported based on the index followed by the industry [

37]. For example, the QAT device is used to scan a fish fillet, then outputs, “Wild Atlantic Salmon – 98% confidence, Grade 9 freshness – 94% confidence”. The predicted species will be compared to the previous scan outputs and a discrepancy will be flagged. Fish has a natural rate of decay even when kept at mandated temperatures and atmospheric conditions. Therefore, at each node of the SC, the freshness of a fillet is allowed to be within an acceptable range depending on the distance from the previous node. A warning will be displayed if the predicted freshness grade has a larger-than-expected degradation from the last SC node.

5. Smart Contract Implementation

Smart contracts enable FSC process automation by providing a secure, transparent, and efficient way to execute and enforce agreements among stakeholders [

23]. FSC processes can be automated using smart contracts, in which each function automatically triggers an action, when specific conditions are met [

38].

This section’s emphasis is discussing smart contract implementation for the proposed BC-based FSC. The framework consists of six smart contracts, each belonging to one actor: smart contract 1 for Harvester, smart contract 2 for Supplier, smart contract 3 for Manufacturer, smart contract 4 for Distributor, smart contract 5 for Retailer, and smart contract 6 for Customer (

Figure 1). Each function in each smart contract is allowed to be executed by registered and authorized entities only [

7]. We implement, assess, and validate smart contract 1 for the Harvester actor to control the interaction between the Harvester and the Supplier. Smart contracts 2 through 6 can be similarly implemented to facilitate purchase agreements between two successive stakeholders.

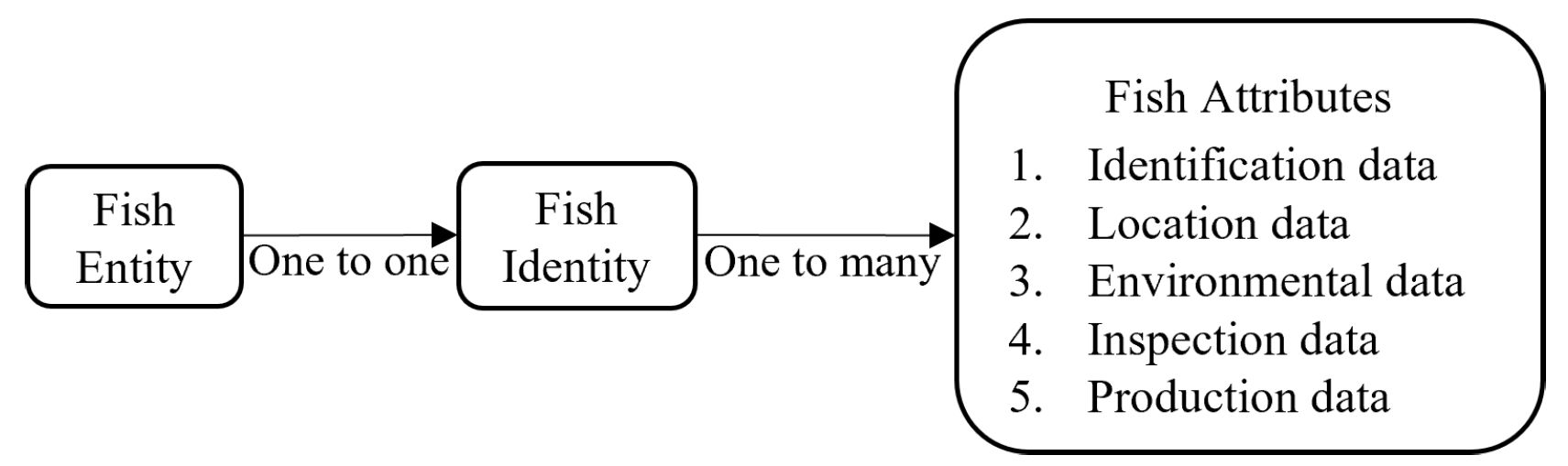

The Harvester stage consists of several essential steps: fish catching, primary processing, registering, packaging, and shipping (

Figure 4). This stage is crucial to ensure the quality, traceability, and sustainability of the fish that will eventually reach consumers. QR code and Bar code readers, RFID, environmental sensors, locations, weight devices, and cameras are examples of IoT edge devices that can be integrated into the BC-based FSC. Each fish entity is defined using a set of attributes that can be categorized into: 1) Identification data, such as fish ID and fish name; 2) Location data which represents each catch location’s GPS coordinates; 3) Environmental data such as temperature, humidity, and other environmental and water quality parameters; 4) Inspection data which considers QAT device output, such as freshness level and species identification; and 5) Production data which primarily related to applied processing methods, packaging, and labeling (

Figure 5).

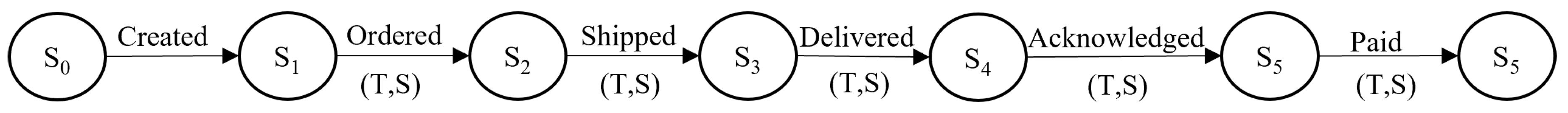

Contract execution can be represented by the execution model state chart found in

Figure 6 where T is defined as the timestamp and S is the status. The sequence of states captures the various events that occur during the interaction between the Harvester and the consecutive stages. The states, including "Created," "Ordered," "Shipped," "Delivered," "Acknowledged," and "Paid,", represent the states following event occurrences, which can be defined as follows:

Created: This state is defined as the initial state when a fish item is first created.

Ordered: The product advances to the "Ordered" state when a customer places an order for the fish.

Shipped: The order progresses to the "Shipped" state once processed and dispatched for delivery.

Delivered: The state transitions to "Delivered" once successfully delivered to the customer.

Acknowledged: The state transitions to "Acknowledged" when the customer acknowledges receipt of the delivery.

Paid: The state transitions to "Paid" once the payment for the order has been successfully completed.

Real-world situations may introduce further complexities, such as order cancellations, returns, and refunds. These complexities can be accommodated by incorporating additional states and transitions into the chart [

39]. This sequence of states can be applied to smart contracts 2 through 6, aligning with a buyer-seller interaction scenario.

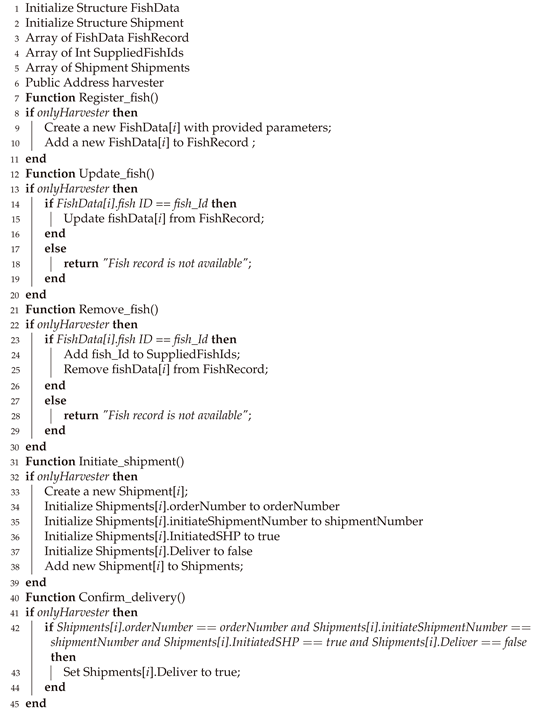

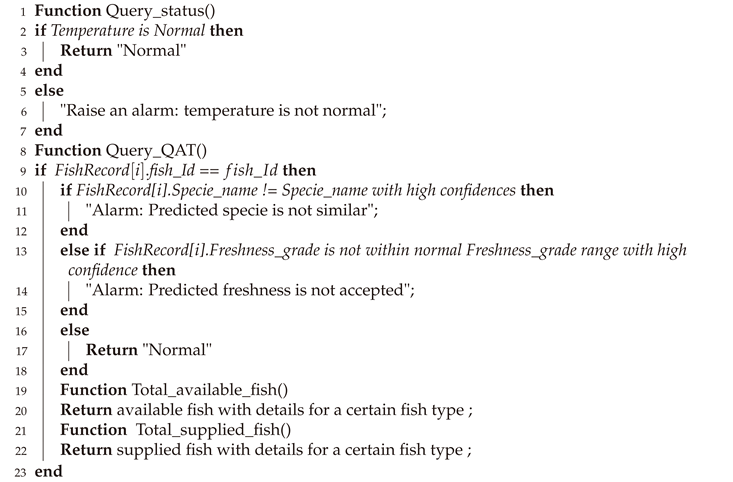

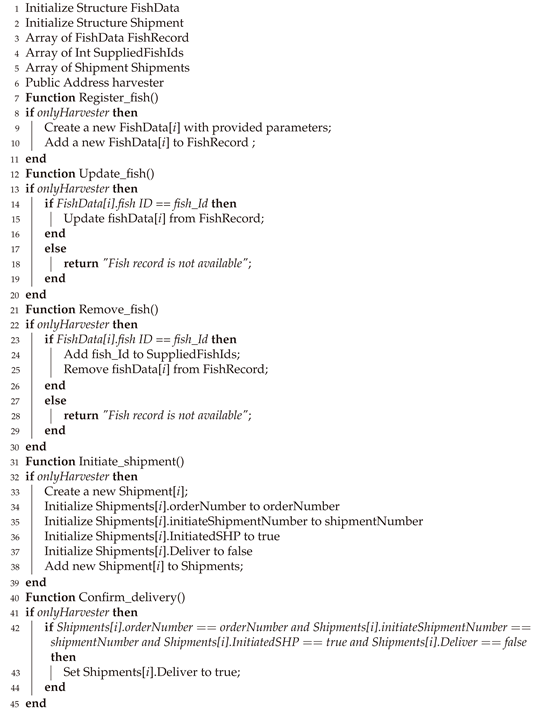

Smart contract 1 consists of the following key functions:

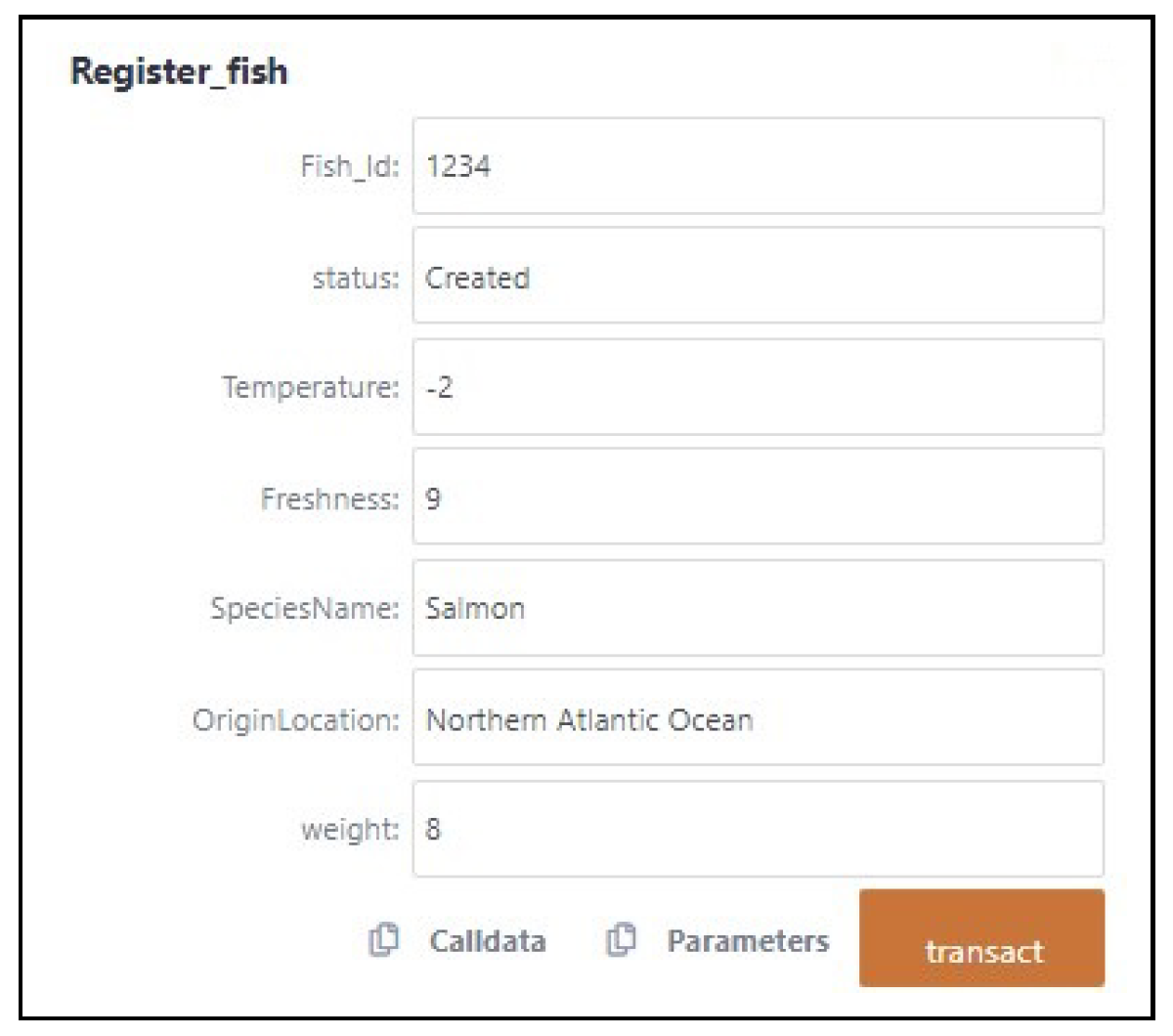

Register_fish(): A new record for a raw fish instance is created. Parameters include identification data such as fish id, fish descriptor, timestamp, status, location, and weight.

Update_fish(): The status of the raw fish will be updated periodically based on sensors’ readings. Parameters include environmental and inspection data.

Remove_fish(): This function removes the product instance record once the fish is supplied.

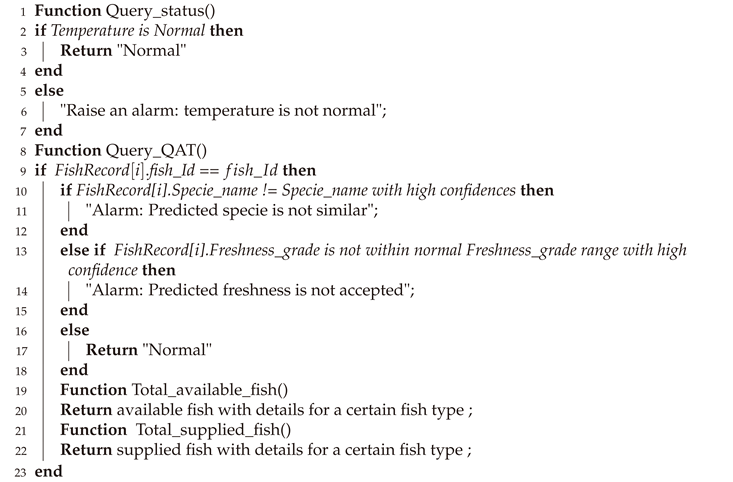

Query_status(): A view function that queries the environmental sensors by retrieving sensors’ readings.

Query_QAT(): A view function that queries the species identity and freshness level by retrieving the QAT device’s output.

Total_available_fish(): A view function that counts the total number of available fish records for a certain fish type. Parameters include fish ID, fish name, and quantity.

Total_supplied_fish(): A view function that retrieves the supplied fish with details.

Initiate_shipment():The shipment should be initialized once the harvester receives an order for raw fish. Parameters include harvester id, fish id, fish quantity, weight, received order number, and shipment number.

Confirm_delivery(): The harvester should confirm delivery upon receipt. Parameters include harvester id, fish id, order number, and shipment number.

Smart contract 1 has two types of functions: payable and non-payable. Payable function transfers some Ether to the contract upon execution. Non-payable function, also called view function, does not involve any Ether payment during execution. This type of function is employed within a contract solely for reading or performing actions that do not alter the contract’s state variables and do not require Ether payments to the contract. Examples of non-payable functions can be querying the contract’s state or conducting computations. Register_fish(), Update_fish(), Supply_fish(), Initiate_shipment(), and Confirm_delivery() are payable functions in smart contract 1, while Query_status(), Query_QAT(), Total_available_fish(), and Total_supplied_fish() are non-payable functions. Algorithms 1 and 2 explain the logic behind the payable and non-payable functions of smart contract 1, respectively.

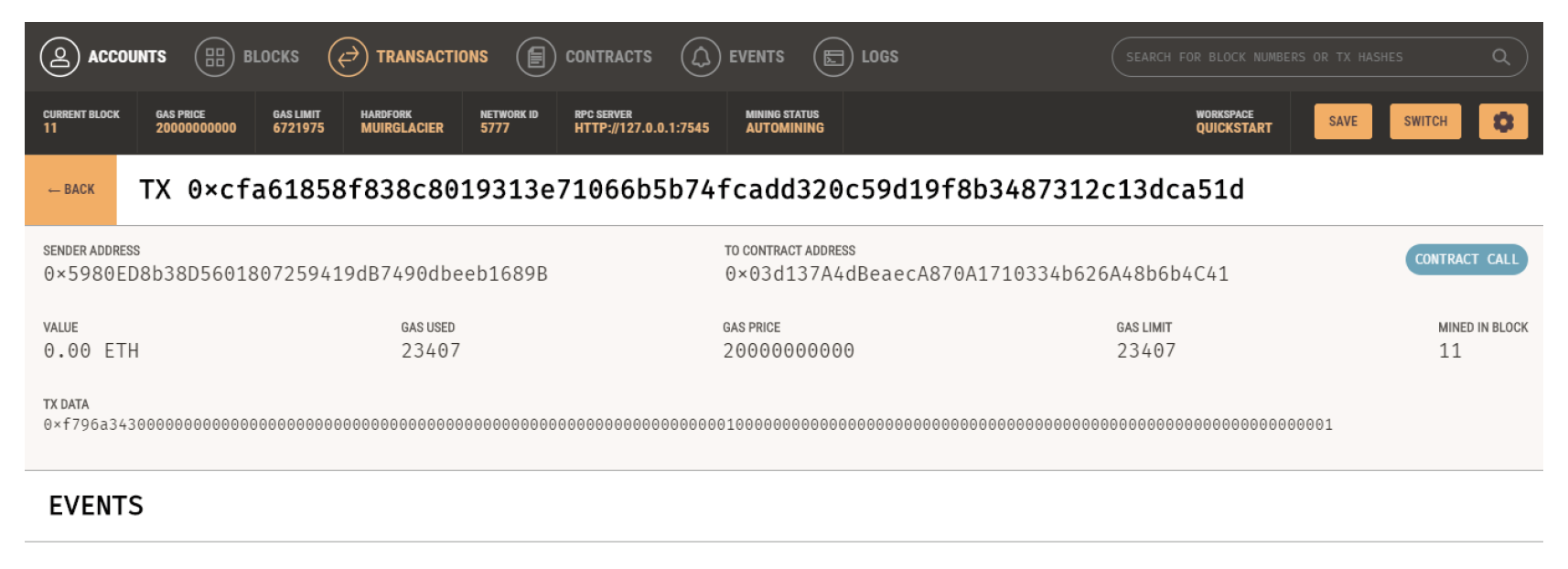

6. Smart Contract Results

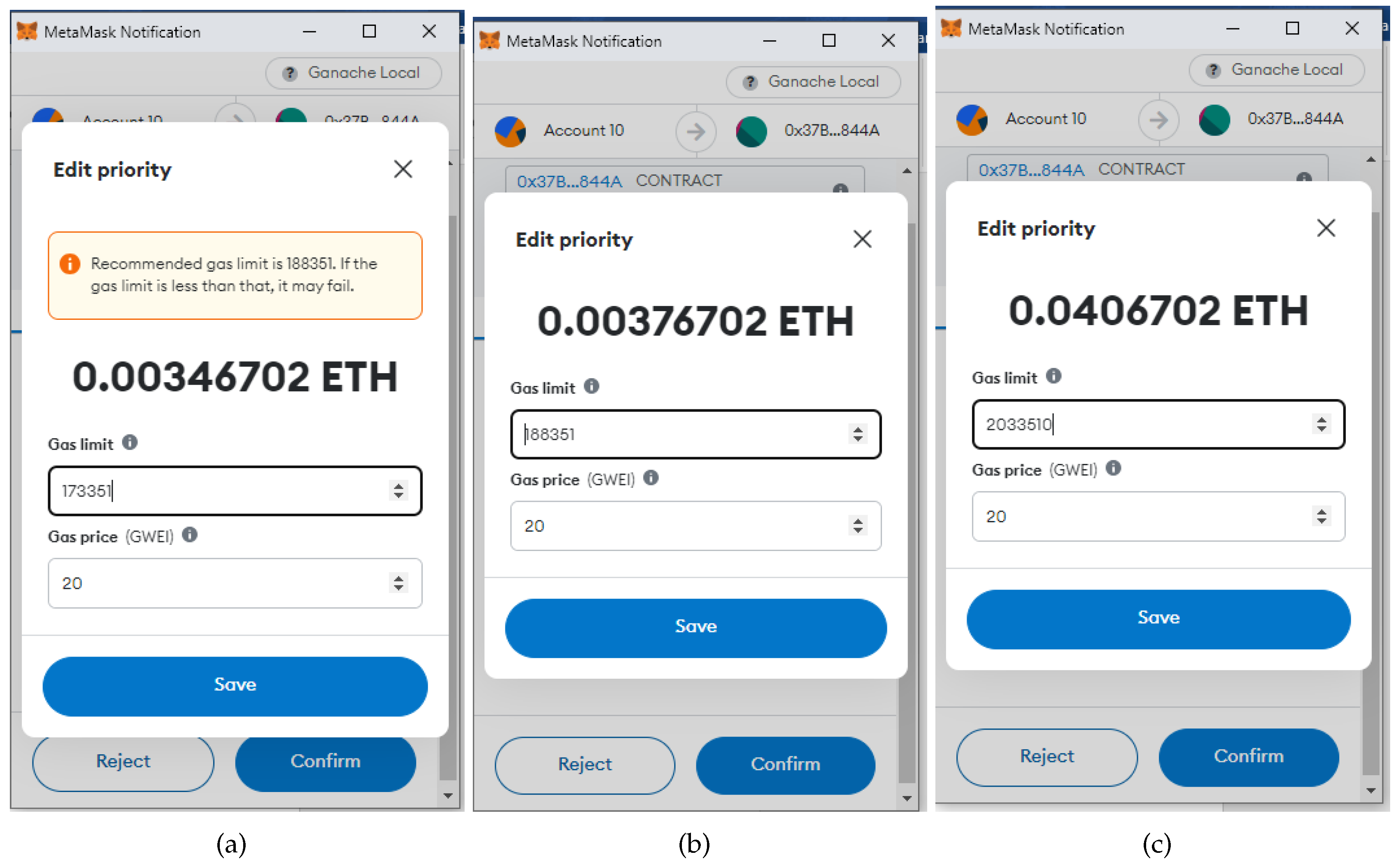

This section demonstrates the results of smart contract 1 in detail. We use Remix IDE web, connected with Metamask wallet and Ganache for the development of smart contract 1. Remix IDE offers a robust environment for deploying smart contracts, conducting testing, and assessing responses, providing feedback for each transaction and incorporating features for exception handling.

We create and run unit tests for the Harvester actor to step through smart contract 1 execution. Each function in smart contract 1 is called by initiating a transaction directed to its designated address, including the requisite input parameters. Smart contract execution uses gas as the unit to estimate cost [

40]. The amount of gas varies according to the type and number of operations, which affect the cost [

41].

Table 2 lists transaction cost and execution cost of each payable function in gwei unit, as well as gas cost in USD for a realistic estimation. Two sets of results are provided: environment recommended gas and customized gas. Transaction cost usually exceeds execution cost since it encompasses both the cost associated with executing contract functions and the cost of contract deployment. The recommended execution option has a lower price than the fast execution option; however, opting for fast execution significantly reduces the transaction confirmation delay and enhances the likelihood of a block being successfully mined. Gas price determines how quickly a transaction will be processed since miners prioritize transactions with higher gas prices [

42].

The amount of gas consumed by a smart contract function typically depends on the complexity of the opcodes or instructions within that function. Each opcode has a predefined gas cost associated with it, and the total gas cost of a transaction is the sum of the gas costs for all opcodes executed during that transaction [

43], which encourages developers to implement efficient and optimized processes to reduce gas costs. This practice helps manage transaction expenses and contributes to the overall security and performance of the BC network, which is essential for transparent and efficient traceability in the SC.

Table 3 lists the execution cost of non-payable functions. Non-payable functions, which are usually read-only operations querying the contract’s state and do not involve interactions with external entities or smart contracts, have lower execution costs than payable functions, which involve external interactions or changes in the contract state. For example, when we contrast the non-payable function with the highest execution cost, Query_QAT(), against the payable function with the lowest execution cost, Update_fish_status(), it becomes evident that the latter costs 3.4 times more.

|

Algorithm 1: Payable functions of smart contract 1 |

|

|

Algorithm 2: Non-payable functions of smart contract 1 |

|

Three scenarios for identifying the gas limit is demonstrated in

Figure 7. We set the gas limit to a value lower than the gas limit recommended by the environment in the first one. Transaction confirmation consistently fails in this case. We set the gas limit value to the recommended gas value in the second scenario and observe that transaction verification succeeds, but with some delay. We select a higher value of gas limit than the recommended value in the third scenario and observe that transaction confirmation is much faster.

All contract functions have been tested successfully.

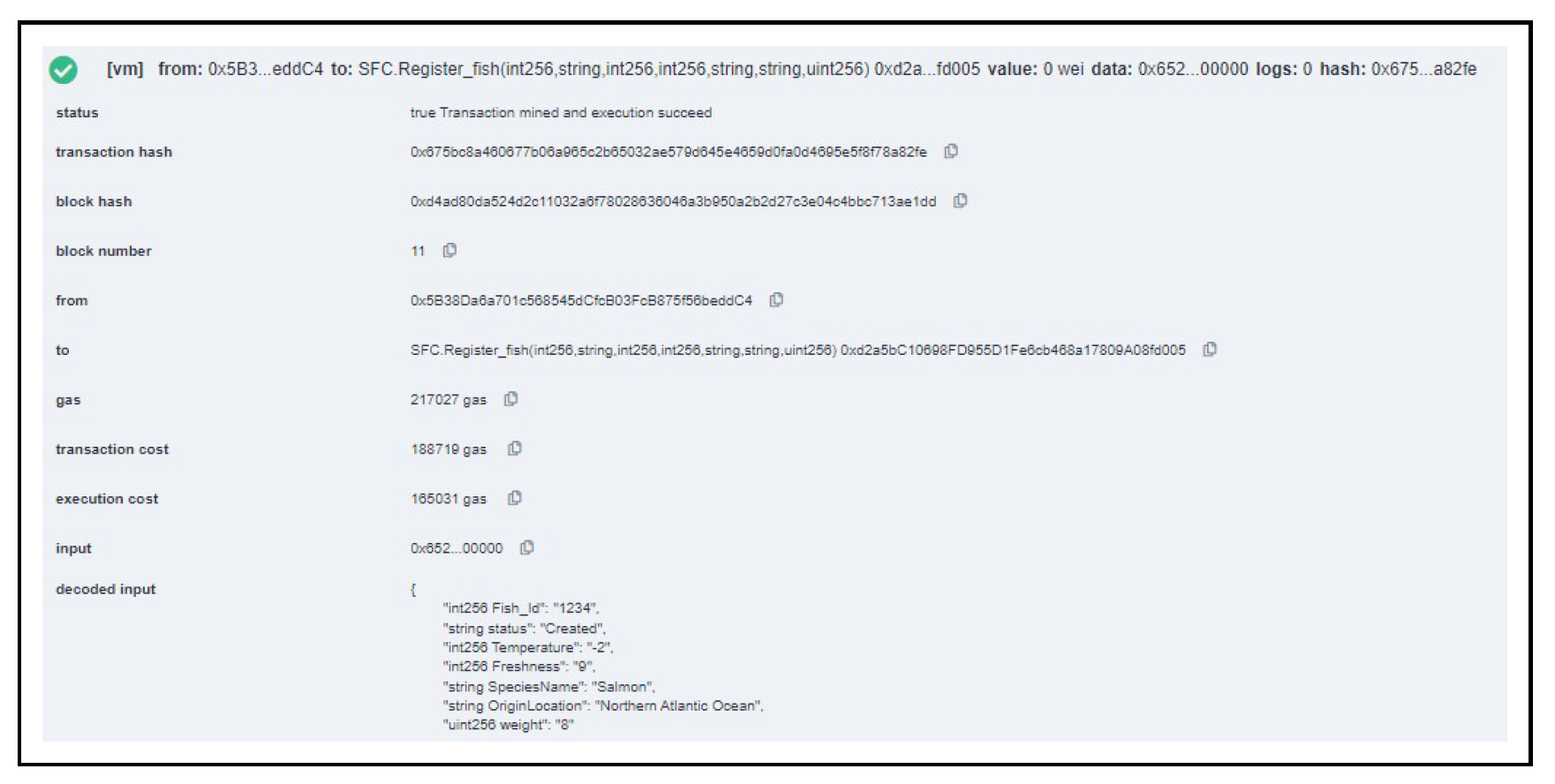

Figure 8 depicts the creation of one fish instance by inputting a set of initial parameters to the Register_fish() function, while

Figure 9 represents the log after the function Register_fish() successfully transacts.

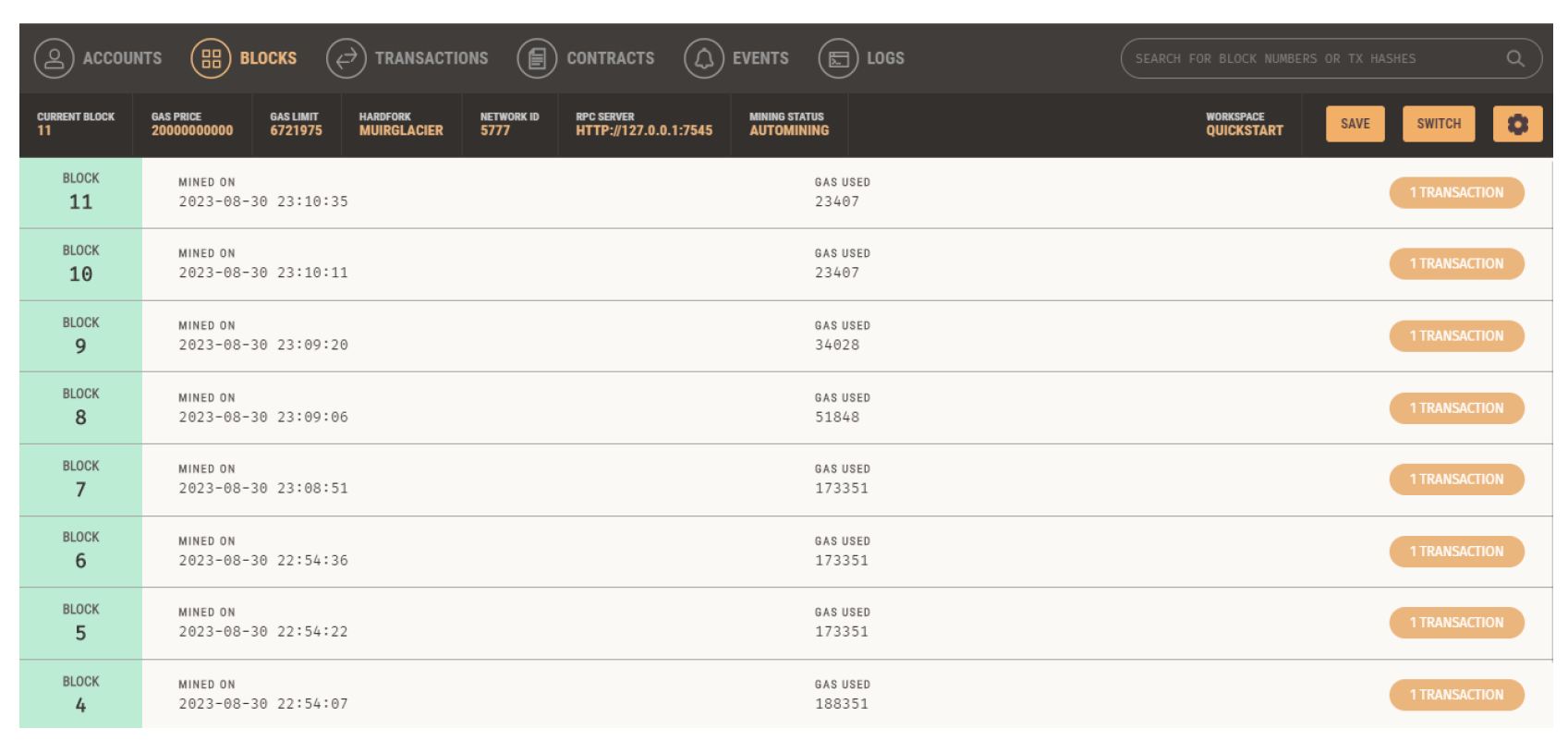

From Ganache, one can observe an example of recorded blocks in

Figure 10, while

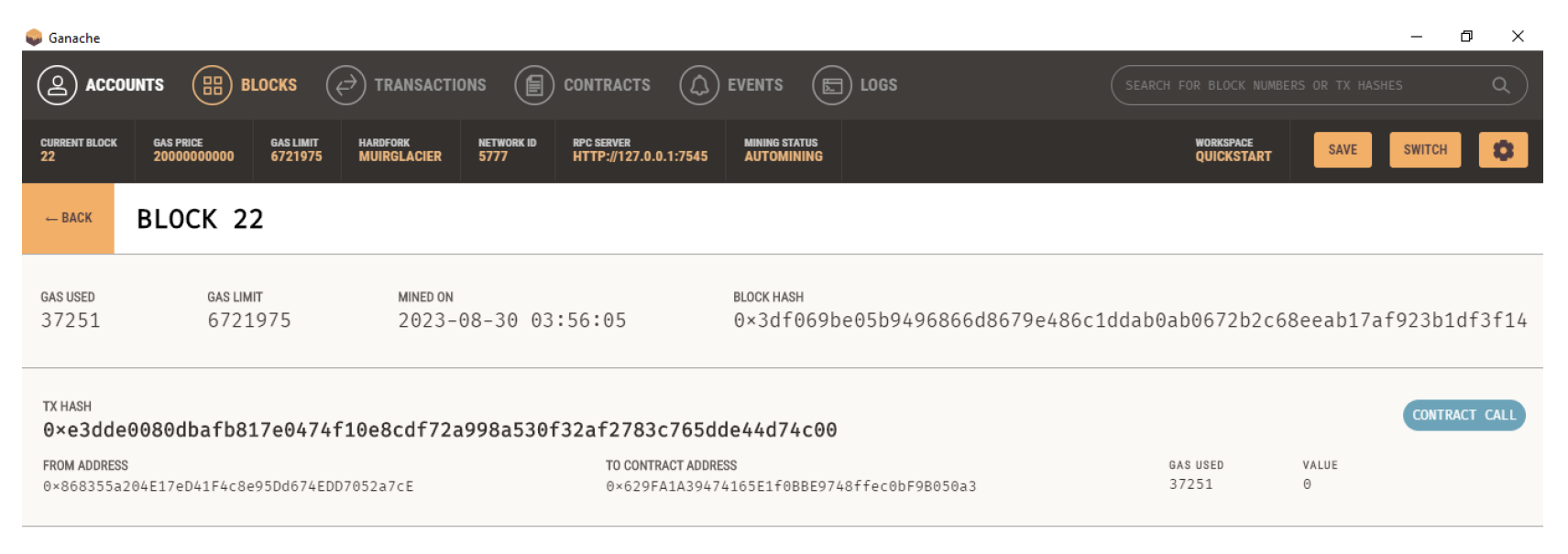

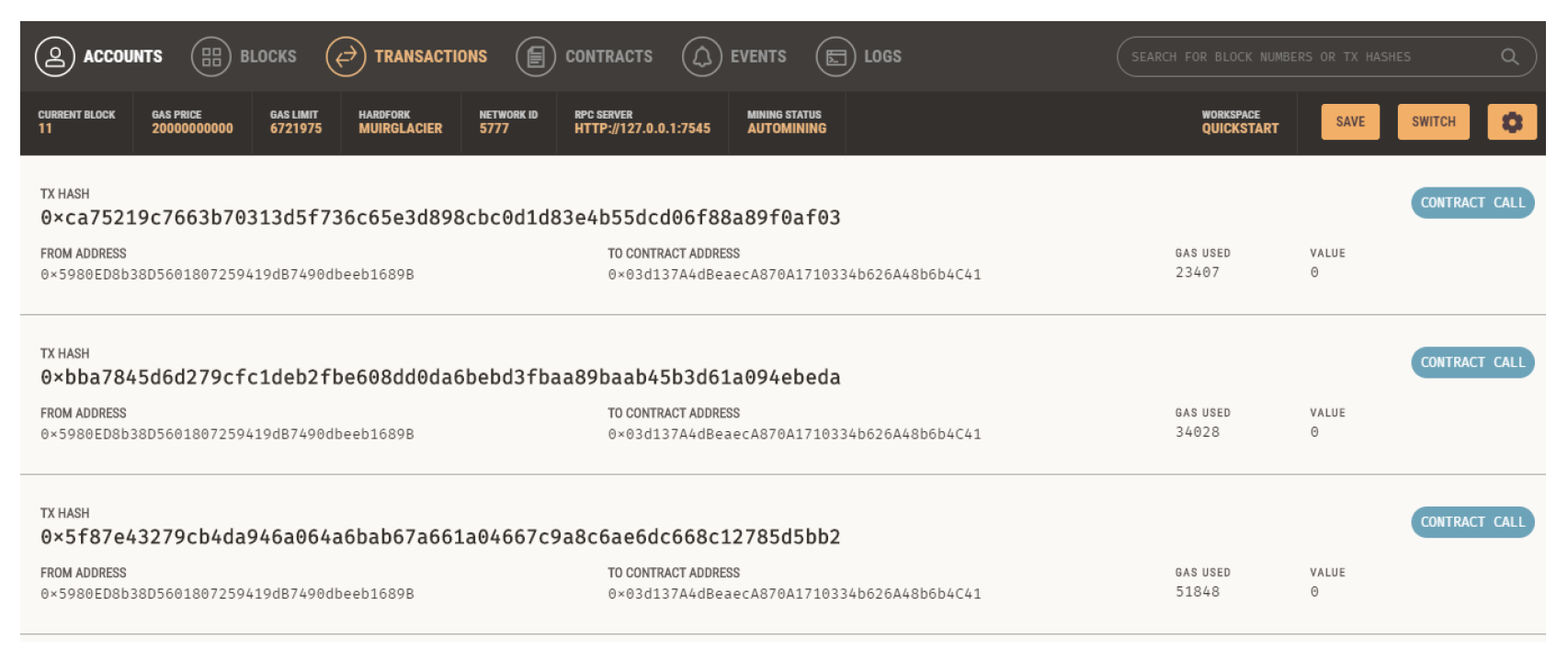

Figure 11 illustrates an example of a newly created block. Transactions stored in the form of a Merkle tree in a block can be observed from the transactions section in Ganache, as demonstrated in

Figure 12, with the presentation of a single transaction in

Figure 13.

7. Conclusions

The FSC aims to track and trace the fish lifecycle, starting from its origin and extending to the end consumer. BC supports the essential FSC requirements, including visibility, provenance, security, and traceability. The integration of Big Data, AI, and IoT technologies plays a pivotal role in maintaining fish quality and authenticity in modern FSC systems. This paper proposed a layered BC-based FSC framework integrated with QAT technology that supports fish quality monitoring and freshness assessment. QAT technology is developed using Big Data and an innovative AI architecture in the form of a hand-held device that can be deployed by stakeholders at any of the chain stages to detect the fish species identity and assess its quality. We leverage BC and smart contracts features to implement and validate the proposed framework over the Ethereum platform.

Data Availability Statement

All data supporting the findings of this study are available upon request due to privacy restrictions.

Acknowledgments

This work was partially funded by National Oceanic and Atmospheric Administration (NOAA) Small Business Innovation Research (SBIR), grant number NA21OAR0210305.

Conflicts of Interest

All authors declare that they have no conflict of interest.

References

- Ismail, S.; Reza, H.; Salameh, K.; Kashani Zadeh, H.; Vasefi, F. Toward an Intelligent Blockchain IoT-Enabled Fish Supply Chain: A Review and Conceptual Framework. Sensors 2023, 23. [Google Scholar] [CrossRef] [PubMed]

- Surana, A.; Kumara*, S.; Greaves, M.; Raghavan, U.N. Supply-chain networks: a complex adaptive systems perspective. International Journal of Production Research 2005, 43, 4235–4265. [Google Scholar] [CrossRef]

- Sunny, J.; Undralla, N.; Madhusudanan Pillai, V. Supply chain transparency through blockchain-based traceability: An overview with demonstration. Computers & Industrial Engineering 2020, 150, 106895. [Google Scholar] [CrossRef]

- Ferreira, J.C.; Martins, A.L.; Tokkozhina, U.; Helgheim, B.I. Fish Control Process and Traceability for Value Creation Using Blockchain Technology. Innovations in Bio-Inspired Computing and Applications; Abraham, A., Madureira, A.M., Kaklauskas, A., Gandhi, N., Bajaj, A., Muda, A.K., Kriksciuniene, D., Ferreira, J.C., Eds.; Springer International Publishing: Cham, 2022; pp. 761–773. [Google Scholar]

- Ismail, S.; Reza, H.; Zadeh, H.K.; Vasefi, F. A Blockchain-based IoT Security Solution Using Multichain. 2023 IEEE 13th Annual Computing and Communication Workshop and Conference (CCWC), 2023, pp. 1105–1111. [CrossRef]

- Ismail, S.; Reza, H. Security Challenges of Blockchain-Based Supply Chain Systems. 2022 IEEE 13th Annual Ubiquitous Computing, Electronics & Mobile Communication Conference (UEMCON), 2022, pp. 1–6.

- Gohil, D.; Thakker, S.V. Blockchain-integrated technologies for solving supply chain challenges. Modern Supply Chain Research and Applications 2021, 3, 78–97. [Google Scholar] [CrossRef]

- Ullah, Z.; Naeem, M.; Coronato, A.; Ribino, P.; De Pietro, G. Blockchain applications in sustainable smart cities. Sustainable Cities and Society, 2023; 104697. [Google Scholar]

- Shahid, A.; Almogren, A.; Javaid, N.; Al-Zahrani, F.A.; Zuair, M.; Alam, M. Blockchain-Based Agri-Food Supply Chain: A Complete Solution. IEEE Access 2020, 8, 69230–69243. [Google Scholar] [CrossRef]

- Callinan, C.; Vega, A.; Clohessy, T.; Heaslip, G. Blockchain adoption factors, enablers, and barriers in fisheries supply chain: preliminary findings from a systematic literature review. The Journal of The British Blockchain Association 2022, 32437. [Google Scholar] [CrossRef]

- Tokkozhina, U.; Martins, A.L.; Ferreira, J.C.; Casaca, A. Traceable Distribution of Fish Products: State of the Art of Blockchain Technology Applications to Fish Supply Chains. International Conference on Intelligent Transport Systems. Springer, 2022, pp. 89–100.

- Tolentino-Zondervan, F.; Ngoc, P.T.A.; Roskam, J.L. Use cases and future prospects of blockchain applications in global fishery and aquaculture value chains. Aquaculture 2023, 565, 739158. [Google Scholar] [CrossRef]

- Blaha, F.; Katafono, K. Blockchain application in seafood value chains. FAO Fisheries and Aquaculture Circular 2020, pp. I—-43.

- Aich, S.; Chakraborty, S.; Sain, M.; Lee, H.i.; Kim, H.C. A Review on Benefits of IoT Integrated Blockchain based Supply Chain Management Implementations across Different Sectors with Case Study. 2019 21st International Conference on Advanced Communication Technology (ICACT), 2019, pp. 138–141. [CrossRef]

- Feng, H.; Wang, W.; Chen, B.; Zhang, X. Evaluation on Frozen Shellfish Quality by Blockchain Based Multi-Sensors Monitoring and SVM Algorithm During Cold Storage. IEEE Access 2020, 8, 54361–54370. [Google Scholar] [CrossRef]

- Howson, P. Building trust and equity in marine conservation and fisheries supply chain management with blockchain. Marine Policy 2020, 115, 103873. [Google Scholar] [CrossRef]

- Mondragon, A.E.C.; Mondragon, C.E.C.; Coronado, E.S. Feasibility of Internet of Things and Agnostic Blockchain Technology Solutions: A Case in the Fisheries Supply Chain. 2020 IEEE 7th International Conference on Industrial Engineering and Applications (ICIEA), 2020, pp. 504–508. [CrossRef]

- Wang, X.; Yu, G.; Liu, R.P.; Zhang, J.; Wu, Q.; Su, S.; He, Y.; Zhang, Z.; Yu, L.; Liu, T.; Zhang, W.; Loneragan, P.; Dutkiewicz, E.; Poole, E.; Paton, N. Blockchain-Enabled Fish Provenance and Quality Tracking System. IEEE Internet of Things Journal 2021, 1. [Google Scholar] [CrossRef]

- Tsolakis, N.; Niedenzu, D.; Simonetto, M.; Dora, M.; Kumar, M. Supply network design to address United Nations Sustainable Development Goals: A case study of blockchain implementation in Thai fish industry. Journal of Business Research 2021, 131, 495–519. [Google Scholar] [CrossRef]

- Sengupta, T.; Narayanamurthy, G.; Moser, R.; Pereira, V.; Bhattacharjee, D. Disruptive technologies for achieving supply chain resilience in COVID-19 era: An implementation case study of satellite imagery and blockchain technologies in fish supply chain. Information Systems Frontiers 2021, 1–17. [Google Scholar] [CrossRef] [PubMed]

- Patro, P.K.; Jayaraman, R.; Salah, K.; Yaqoob, I. Blockchain-based traceability for the fishery supply chain. IEEE Access 2022, 10, 81134–81154. [Google Scholar] [CrossRef]

- Tsolakis, N.; Schumacher, R.; Dora, M.; Kumar, M. Artificial intelligence and blockchain implementation in supply chains: a pathway to sustainability and data monetisation? Annals of Operations Research 2023, 327, 157–210. [Google Scholar] [CrossRef] [PubMed]

- Chang, S.E.; Chen, Y.C.; Lu, M.F. Supply chain re-engineering using blockchain technology: A case of smart contract based tracking process. Technological Forecasting and Social Change 2019, 144, 1–11. [Google Scholar] [CrossRef]

- Philipp, R.; Prause, G.; Gerlitz, L. Blockchain and smart contracts for entrepreneurial collaboration in maritime supply chains. Transport and Telecommunication 2019, 20, 365–378. [Google Scholar] [CrossRef]

- Vasefi, F.; Barton, K.E.; Zadeh, H.K.; Ismail, S.S.; Reza, H. System and method for assessing product, 2023. US Patent App. 18/228,246.

- .

- Malle, P.; Poumeyrol, M. A new chemical criterion for the quality control of fish: trimethylamine/total volatile basic nitrogen (%). Journal of food protection 1989, 52, 419–423. [Google Scholar] [CrossRef]

- Olafsdottir, G.; Martinsdóttir, E.; Oehlenschläger, J.; Dalgaard, P.; Jensen, B.; Undeland, I.; Mackie, I.; Henehan, G.; Nielsen, J.; Nilsen, H. Methods to evaluate fish freshness in research and industry. Trends in food science & technology 1997, 8, 258–265. [Google Scholar]

- Sakamoto, S.; Putalun, W.; Vimolmangkang, S.; Phoolcharoen, W.; Shoyama, Y.; Tanaka, H.; Morimoto, S. Correction to: Enzyme-linked immunosorbent assay for the quantitative/qualitative analysis of plant secondary metabolites. Journal of natural medicines 2018, 72, 43–43. [Google Scholar] [CrossRef]

- Ohashi, E.; Okamoto, M.; Ozawa, A.; Fujita, T. Characterization of common squid using several freshness indicators. Journal of Food Science 1991, 56, 161–163. [Google Scholar] [CrossRef]

- Hattula, T. Adenosine triphosphate breakdown products as a freshness indicator of some fish species and fish products; Technical Research Centre of Finland, 1997.

- Martinsen, Ø.G.; Grimnes, S.; Mirtaheri, P. Non-invasive measurements of post-mortem changes in dielectric properties of haddock muscle–a pilot study. Journal of food engineering 2000, 43, 189–192. [Google Scholar] [CrossRef]

- Franceschelli, L.; Berardinelli, A.; Dabbou, S.; Ragni, L.; Tartagni, M. Sensing technology for fish freshness and safety: A review. Sensors 2021, 21, 1373. [Google Scholar] [CrossRef]

- Qin, J.; Vasefi, F.; Hellberg, R.S.; Akhbardeh, A.; Isaacs, R.B.; Yilmaz, A.G.; Hwang, C.; Baek, I.; Schmidt, W.F.; Kim, M.S. Detection of fish fillet substitution and mislabeling using multimode hyperspectral imaging techniques. Food Control 2020, 114, 107234. [Google Scholar] [CrossRef]

- Kashani Zadeh, H.; Hardy, M.; Sueker, M.; Li, Y.; Tzouchas, A.; MacKinnon, N.; Bearman, G.; Haughey, S.A.; Akhbardeh, A.; Baek, I.; others. Rapid Assessment of Fish Freshness for Multiple Supply-Chain Nodes Using Multi-Mode Spectroscopy and Fusion-Based Artificial Intelligence. Sensors 2023, 23, 5149. [Google Scholar] [CrossRef] [PubMed]

- FDA Seafood List Updates for 2022. https://www.fda.gov/, 2022 (accessed August 23, 2023).

- Huss, H.H. Fresh fish–quality and quality changes: a training manual prepared for the FAO/DANIDA Training Programme on Fish Technology and Quality Control; Number 29, Food & Agriculture Org., 1988.

- Prause, G. Smart contracts for smart supply chains. IFAC-PapersOnLine 2019, 52, 2501–2506. [Google Scholar] [CrossRef]

- Qin, P.; Tan, W.; Guo, J.; Shen, B. Intelligible description language contract (IDLC)–A novel smart contract model. Information Systems Frontiers 2021, 1–18. [Google Scholar] [CrossRef]

- Turjo, M.D.; Khan, M.M.; Kaur, M.; Zaguia, A. Smart supply chain management using the blockchain and smart contract. Scientific programming 2021, 2021, 1–12. [Google Scholar] [CrossRef]

- Panda, S.K.; Satapathy, S.C. An investigation into smart contract deployment on Ethereum platform using Web3. js and solidity using blockchain. Data Engineering and Intelligent Computing: Proceedings of ICICC 2020. Springer, 2021, pp. 549–561.

- Haque, B.; Hasan, R.; Zihad, O.M. SmartOil: Blockchain and smart contract-based oil supply chain management. IET Blockchain 2021, 1, 95–104. [Google Scholar] [CrossRef]

- Marchesi, L.; Marchesi, M.; Destefanis, G.; Barabino, G.; Tigano, D. Design patterns for gas optimization in ethereum. 2020 IEEE International Workshop on Blockchain Oriented Software Engineering (IWBOSE). IEEE, 2020, pp. 9–15.

9. Biography Section

SHEREEN ISMAIL is currently a Ph.D. candidate and graduate research assistant (GRA) at University of North Dakota, USA. She completed her MSc in Computer Engineering and Networks from the University of Jordan, Amman, Jordan, and BSc in Computer Engineering from the same university. She taught undergraduate level at the American University of Ras Al-Khaimah , Al-Zaytoonah University of Jordan, and Applied Science University of Jordan. Her research focuses on Wireless Networks, and Cybersecurity.

Muhammad Nouman received Bachelors degree in Computer Science from the Federal Urdu University of Arts, Science and Technology (FUUAST), Islamabad, Pakistan, in 2019. Currently, he is pursuing a Masters degree in Computer Science from the Communication over Sensors (ComSens) Research Laboratory, Department of Computer Science, COMSATS University Islamabad, Pakistan. His research interests include Computer Networks, Wireless Sensor Networks, Blockchain, and Machine Learning.

HASSAN REZA is a Professor of Software Engineering at the University of North Dakota and affiliated faculty with North Dakota State University and UND Biomedical Engineering. He has served as a technical member for the Center of Excellence for Unmanned Aircraft Systems (UAS) since its inception and the UND Research Institute for Autonomous Systems (RIAS). He has been involved as PI or Co-PI for projects involving

$ 15 million in funding from DOD, NIH, NASA, NSF, NASA-EPSCore, and Rockwell Collins. His areas of expertise include Architectural Modelling of Data/Software Intensive Systems, Model-Based Engineering of Cyber-Physical Systems (Avionic and Medical Systems), Software Testing, and the Engineering of Safety/Security Critical Systems.

Fartash Vasefi His award-winning work has ranged from research in electrical and optical engineering to translational cancer diagnostics applications. Dr. Vasefi is especially interested in commercially adoptable technologies that use innovative optical imaging and image processing systems. Dr. Vasefi received his doctorate degree in Biomedical Engineering from Simon Fraser University. During this time, he received multiple international and Canadian awards from SPIE, the Canadian Institute of Health Research, and Mathematics of Information Technology and Complex Systems Institutions. His publications include 65 conference papers, 30 journal articles, and multiple patents. As CTO at SafetySpect Inc., Dr. Vasefi manages internal personnel coordination, contract manufacturers, academic collaborators, software developers, and strategic partners to bring a visionary new medical device to market under quality system requirements.

Hossein Kashani Zadeh is an assistant professor at the University of North Dakota and the Data Science manager at SafetySpect Inc where he is working on identifying species and assessing freshness of seafood and other food products using multi-mode spectroscopy and machine learning. He also studies food residue contamination detection using fluorescence imaging and detection of pathogens in plants using hyperspectral, RGB and IR imaging systems mounting on unmanned aerial vehicles and image processing techniques. Prior to that, he served as an expert in structural analysis and testing of aircraft engines at Pratt & Whitney for 10 years improving technology readiness level of tip clearance analysis. His academic research in numerical simulation of metal forming processes started with tube hydroforming and later led to the development of a material model to simulate and optimize metal powder compaction.

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

SHEREEN ISMAIL is currently a Ph.D. candidate and graduate research assistant (GRA) at University of North Dakota, USA. She completed her MSc in Computer Engineering and Networks from the University of Jordan, Amman, Jordan, and BSc in Computer Engineering from the same university. She taught undergraduate level at the American University of Ras Al-Khaimah , Al-Zaytoonah University of Jordan, and Applied Science University of Jordan. Her research focuses on Wireless Networks, and Cybersecurity.

SHEREEN ISMAIL is currently a Ph.D. candidate and graduate research assistant (GRA) at University of North Dakota, USA. She completed her MSc in Computer Engineering and Networks from the University of Jordan, Amman, Jordan, and BSc in Computer Engineering from the same university. She taught undergraduate level at the American University of Ras Al-Khaimah , Al-Zaytoonah University of Jordan, and Applied Science University of Jordan. Her research focuses on Wireless Networks, and Cybersecurity. Muhammad Nouman received Bachelors degree in Computer Science from the Federal Urdu University of Arts, Science and Technology (FUUAST), Islamabad, Pakistan, in 2019. Currently, he is pursuing a Masters degree in Computer Science from the Communication over Sensors (ComSens) Research Laboratory, Department of Computer Science, COMSATS University Islamabad, Pakistan. His research interests include Computer Networks, Wireless Sensor Networks, Blockchain, and Machine Learning.

Muhammad Nouman received Bachelors degree in Computer Science from the Federal Urdu University of Arts, Science and Technology (FUUAST), Islamabad, Pakistan, in 2019. Currently, he is pursuing a Masters degree in Computer Science from the Communication over Sensors (ComSens) Research Laboratory, Department of Computer Science, COMSATS University Islamabad, Pakistan. His research interests include Computer Networks, Wireless Sensor Networks, Blockchain, and Machine Learning. HASSAN REZA is a Professor of Software Engineering at the University of North Dakota and affiliated faculty with North Dakota State University and UND Biomedical Engineering. He has served as a technical member for the Center of Excellence for Unmanned Aircraft Systems (UAS) since its inception and the UND Research Institute for Autonomous Systems (RIAS). He has been involved as PI or Co-PI for projects involving $ 15 million in funding from DOD, NIH, NASA, NSF, NASA-EPSCore, and Rockwell Collins. His areas of expertise include Architectural Modelling of Data/Software Intensive Systems, Model-Based Engineering of Cyber-Physical Systems (Avionic and Medical Systems), Software Testing, and the Engineering of Safety/Security Critical Systems.

HASSAN REZA is a Professor of Software Engineering at the University of North Dakota and affiliated faculty with North Dakota State University and UND Biomedical Engineering. He has served as a technical member for the Center of Excellence for Unmanned Aircraft Systems (UAS) since its inception and the UND Research Institute for Autonomous Systems (RIAS). He has been involved as PI or Co-PI for projects involving $ 15 million in funding from DOD, NIH, NASA, NSF, NASA-EPSCore, and Rockwell Collins. His areas of expertise include Architectural Modelling of Data/Software Intensive Systems, Model-Based Engineering of Cyber-Physical Systems (Avionic and Medical Systems), Software Testing, and the Engineering of Safety/Security Critical Systems. Fartash Vasefi His award-winning work has ranged from research in electrical and optical engineering to translational cancer diagnostics applications. Dr. Vasefi is especially interested in commercially adoptable technologies that use innovative optical imaging and image processing systems. Dr. Vasefi received his doctorate degree in Biomedical Engineering from Simon Fraser University. During this time, he received multiple international and Canadian awards from SPIE, the Canadian Institute of Health Research, and Mathematics of Information Technology and Complex Systems Institutions. His publications include 65 conference papers, 30 journal articles, and multiple patents. As CTO at SafetySpect Inc., Dr. Vasefi manages internal personnel coordination, contract manufacturers, academic collaborators, software developers, and strategic partners to bring a visionary new medical device to market under quality system requirements.

Fartash Vasefi His award-winning work has ranged from research in electrical and optical engineering to translational cancer diagnostics applications. Dr. Vasefi is especially interested in commercially adoptable technologies that use innovative optical imaging and image processing systems. Dr. Vasefi received his doctorate degree in Biomedical Engineering from Simon Fraser University. During this time, he received multiple international and Canadian awards from SPIE, the Canadian Institute of Health Research, and Mathematics of Information Technology and Complex Systems Institutions. His publications include 65 conference papers, 30 journal articles, and multiple patents. As CTO at SafetySpect Inc., Dr. Vasefi manages internal personnel coordination, contract manufacturers, academic collaborators, software developers, and strategic partners to bring a visionary new medical device to market under quality system requirements. Hossein Kashani Zadeh is an assistant professor at the University of North Dakota and the Data Science manager at SafetySpect Inc where he is working on identifying species and assessing freshness of seafood and other food products using multi-mode spectroscopy and machine learning. He also studies food residue contamination detection using fluorescence imaging and detection of pathogens in plants using hyperspectral, RGB and IR imaging systems mounting on unmanned aerial vehicles and image processing techniques. Prior to that, he served as an expert in structural analysis and testing of aircraft engines at Pratt & Whitney for 10 years improving technology readiness level of tip clearance analysis. His academic research in numerical simulation of metal forming processes started with tube hydroforming and later led to the development of a material model to simulate and optimize metal powder compaction.

Hossein Kashani Zadeh is an assistant professor at the University of North Dakota and the Data Science manager at SafetySpect Inc where he is working on identifying species and assessing freshness of seafood and other food products using multi-mode spectroscopy and machine learning. He also studies food residue contamination detection using fluorescence imaging and detection of pathogens in plants using hyperspectral, RGB and IR imaging systems mounting on unmanned aerial vehicles and image processing techniques. Prior to that, he served as an expert in structural analysis and testing of aircraft engines at Pratt & Whitney for 10 years improving technology readiness level of tip clearance analysis. His academic research in numerical simulation of metal forming processes started with tube hydroforming and later led to the development of a material model to simulate and optimize metal powder compaction.