1. Introduction

The European Green Deal has set ambitious targets: climate neutrality by 2050 & reducing transport related greenhouse gas emissions by 90% by 2050. The Sustainable and Smart Mobility Strategy lays the foundation for how the EU transport system can achieve its green and digital transformation. One measure which has been identified to reduce transport emissions is a shift to inland waterway transport (IWT). IWT can reduce negative impacts from road transport, such as emissions, noise, and congestion costs [

1,

2]. Over several years, the European Commission has been promoting shifts from road freight transport to more sustainable modes. Nonetheless, these alternative modes currently account for only a limited portion of transport activities across most European regions [

3]. IWT has a limited network density and is dependent on multimodal transport, with pre-carriage and on-carriage often carried out by road due to the high road network density for collection and delivery [

4,

5]. As containers are mostly standardized and usually used as an equipment for multimodal transports, it is essential to enable and facilitate their transport on inland waterways. While the transport of containers is already common on rivers, such as the Rhine, there are hardly any container transports carried out on the Danube [

6]. Thus, enabling container transports on the Danube could on the one hand promote multimodality and on the other hand increase the usage of the Danube significantly by attracting new customers [

7].

To enable efficient multimodal transport a continuous and resilient infrastructure for the involved transport modes is required [

8,

9]. For IWT this means that there are minimum fairway parameters, such a minimum fairway depth and width, which are needed, to ensure an economic viable transport and a resilient infrastructure [

10]. The IWT infrastructure faces two main challenges, which hamper the deployment of this minimum fairway parameters. Firstly, as a natural resource, inland waterways have uneven riverbeds, which means that the fairway depth of the river can vary throughout the course of the river and throughout a year. This could be a cause for the development of bottlenecks for inland navigation [

11]. To maintain a water depth of 2,5m throughout the year maintenance works, such as continuous dredging works, to remove surplus sediment on the rivers are essential. Secondly, there have been increasingly frequent periods of low water in recent years. Low water means that a river does not carry enough water due to metrological conditions, e.g. droughts. Periods of low water often last for several months and massively hinder inland navigation, as the resulting shallower fairway depth means that ships can bear less cargo. This leads to delayed, unreliable and uneconomical transports [

10].

One possibility to improve the navigability on inland rivers in low water periods is to adapt the current available ship designs to the increasingly frequent low water conditions. Few studies have addressed this issue.

The study from Obidike [

12] investigates the possibility for improvement of cargo transport within the European inland water ways by exploring the design and optimization of a pushed barge capable of coping with the events of shallow water while also maintaining a plausible solution in normal water conditions. The proposed vessel is optimized with the aim of minimizing the overall light ship weight through structural weight reduction by a careful assessment of the vessel‘s main dimensions and hull structure while conforming to structural, economic and production constraints [

12]. Sha et al. [

13] present a new design for a 3000 tonnes dead weight barge. Alternate stern shapes are examined using CFD software SHIPFLOW. The hull form is modal tested. The propeller geometry is optimized for the given engine and a suitable gear box. The proposed design is then investigated for its manoeuvring ability in shallow waters. The hydrodynamic sway forces yaw moments and nominal wake distribution for port and starboard propellers during manoeuvring motion are estimated by CFD software SHIPFLOW. The barge’s directional stability performance is investigated for twin-propeller twin –rudder configuration [

13]. Radojčić et al. [

14] addresses key aspects for the design of contemporary, shallow draught IW vessels for the transport of dry cargo (containers and bulk cargo). Most of the logic that is presented is applicable to the design of river vessels for any river, but the material that is presented is focused on vessels for the Danube and its tributaries. And Backalov et. al [

15] investigates the possibilities for improvement of container transport on the Danube by means of an innovative and unconventional container vessel design. The proposed design differs from standard European inland ships of the same capacity by shallow draught and increased breadth.

Our paper follows the aim of identifying new barge options for an improved navigability in fluctuating water conditions. To focus on fluctuating water levels rather than on low water levels was a decision based on the fact that vessels, which are built specifically for low water, are in most cases less cost-effective at sufficient fairway depth. Therefore, we agreed on designing barge designs for fluctuating water levels. The research questions, which guide this paper are the following:

(RQ1): Which design options effectively enhance navigability for container barges on the Danube River?

(RQ2) How do these improvements compare in terms of stability and sightlines assessment?

This paper is structured as follows.

Section 2 focuses on the methodology.

Section 3, which presents the new barge designs in detail, followed by an in-depth analysis of the barge designs, including the analysis of the sightlines and a stability analysis. In

Section 4, the results are discussed, and further research needs are identified.

2. Materials and Methods

Our approach to developing and evaluating new barge design options for the fluctuating water conditions on the Rhine-Main-Danube corridor involved a systematic four-step process.

First, we embarked on a comprehensive data collection phase, meticulously gathering information on the infrastructure along the corridor. This included detailed data on locks, bridges and ports, which was essential to understand the operational constraints and navigational challenges faced by barges. Through extensive desktop research and literature review, we synthesised this data to gain insight into the specific requirements and constraints of the waterway.

We then engaged in detailed discussions to establish the precise parameters of the barge's intended operation. This crucial step involved defining the specific waterways the barge would navigate and identifying the types of goods it would carry. With a view to seamlessly integrate inland water transport into existing logistics chains it is essential for the barges to be able to carry 45’ pallet-wide high-cube units (dimensions: 13,716mx2,55mx2,896m), as these are the predominant types for road and rail transport in mainland Europe. By aligning our design objectives with the unique requirements of the waterway and cargo, we ensured that the resulting barge designs would be optimally suited to their intended purpose.

With a clear understanding of the operational context and design objectives, we proceeded to analyse the existing barge options for container transport on the Danube. This comparative analysis provided valuable insights into the strengths and limitations of current designs and laid the groundwork for the development of innovative solutions. Based on this analysis, we conceptualised and designed a series of new barge prototypes equipped to navigate safely and economically through fluctuating water levels. To the determination of the lightship weight all barge types have been modelled with the structural 3D CAD software SOLIDWORKS according to the dimensions derived from the longitudinal strength assessment. As building material conventional grade A shipbuilding steel has been assumed, with the following material properties [

16]: Relative density: 7,8 t/m³; Yield strength: 235 N/mm² All hydrostatic calculations (floating position under different loading conditions, stability, bending moments) have been performed with the naval architecture software Delftship [

17].

To achieve acceptably comparable results, the preliminary dimensioning for all barge versions has been carried out using the software GLRulesND (Version 2.950, Edition 2014). Based on the preliminary results for the thickness of bottom, bilge, and side plating as well as dimensions of bottom and side girders the main sections for all barge versions have been drawn up. The structural design has been further refined by assessing the individual moments of inertia and section moduli of the cross sections of the different barge versions against the bending moments resulting from a standardised load distribution at a draught of 2,70 m. The structural design has been carried out for all barge version for grade A shipbuilding steel. With a view to as far as possible achieve directly comparable results for lightship weights and draughts at different loading conditions of the various barge versions we endeavoured to keep the safety factor between the maximum permissible bending moment and the actually given bending moment in a range between 2,15 and 2,3.

In the final stage of our approach, we carried out an in-depth assessment of the identified design options, examining their stability, line of sight requirements and suitability of construction materials. We also carefully evaluated key nautical factors such as draught and air draft to ensure compatibility with the dynamic water conditions of the Danube. This rigorous evaluation process enabled us to refine and prioritise the design options based on their feasibility, performance and potential to improve navigational efficiency and safety.

By rigorously following this systematic approach, we not only developed a diverse range of innovative barge designs, but also laid the foundation for informed decision-making regarding their implementation and deployment in real-world scenarios. It has to be noted that the barge designs have not been optimized from a hydrodynamic perspective as the focus was placed on the optimization of the cargo capacity.

3. Results and Discussion

Generally, there is minimal room for enhancing or refining barge dimensions to efficiently utilize current infrastructure on the Danube. Regrettably, the existing infrastructure lacks a coherent size framework. For instance, locks that are 24 meters wide can accommodate two vessels that are 11.75 meters wide each, whereas to accommodate three barges in the larger 34-meter-wide locks on the Danube, the maximum width of such barges would be capped at 11.16 meters. Therefore, for all further considerations on barge design therefore the following limits have been applied as these dimensions are considered to be an acceptable compromise between lock utilization and sufficient flexibility with a view to the accommodation of 45’ high-cube containers.

The chapters below describe the new barge designs one by one, addressing various characteristics, such as sight lines, stability, and capacity of each barge.

3.1. Design Design Options

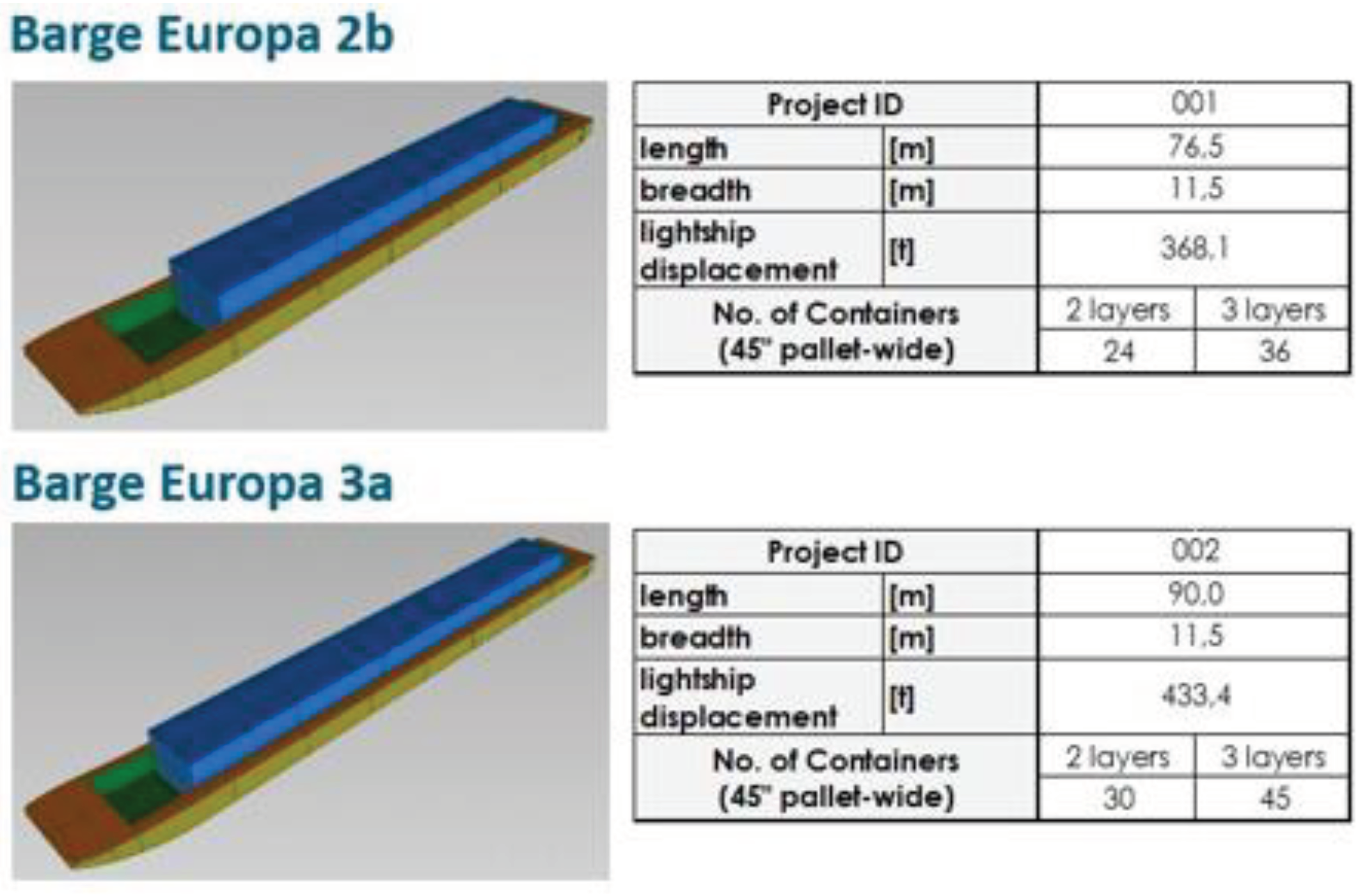

Based on the Europe 2b (001 Europa 2b) and Europe 3a (002 Europa 3a) barges, six new barge designs were developed. The Europa 2b barge can be regarded as a prototypical example of a utilitarian vessel within the realm of European inland navigation. For the analysis of design options for new barges within the IW-NET project it serves as a benchmark for comparison purposes. Many barges of this type or with slightly varied main dimensions can be found in operation on the European inland waterways for a wide range of different cargoes (bulk, containers, high and heavy etc.). The Europa 3a a larger version of the Europa 2b barge and also serves as a benchmark for comparison purposes for the new barge designs.

Figure 1 shows the CAD models and details of the Europa 2a and Europa 2b barge designs, which are used as a basis for the new barge designs created.

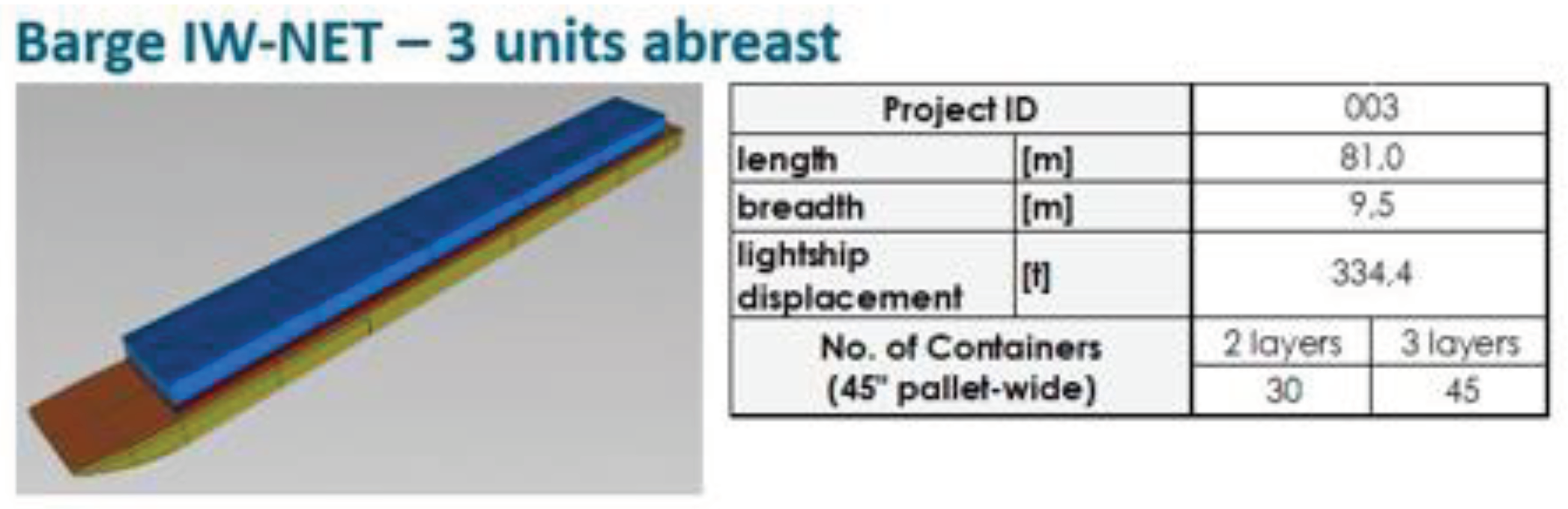

The general idea behind the design of the “

IW-NET – 3 units abreast” barge is to tightly fit the principal geometry of the Europa 2b and Europa 3a barges around a container stack of 3 by 5 by 2 45’ high-cube containers; i.e. in particular to reduce the width of the barge to the width necessary for the cargo hold and two side decks in accordance with the applicable statutory technical requirements and to fit a bow and a stern section similar to the Europa barges to the cargo hold lengthwise.

Figure 2 shows the IW-NET – 3 units abreast barge design.

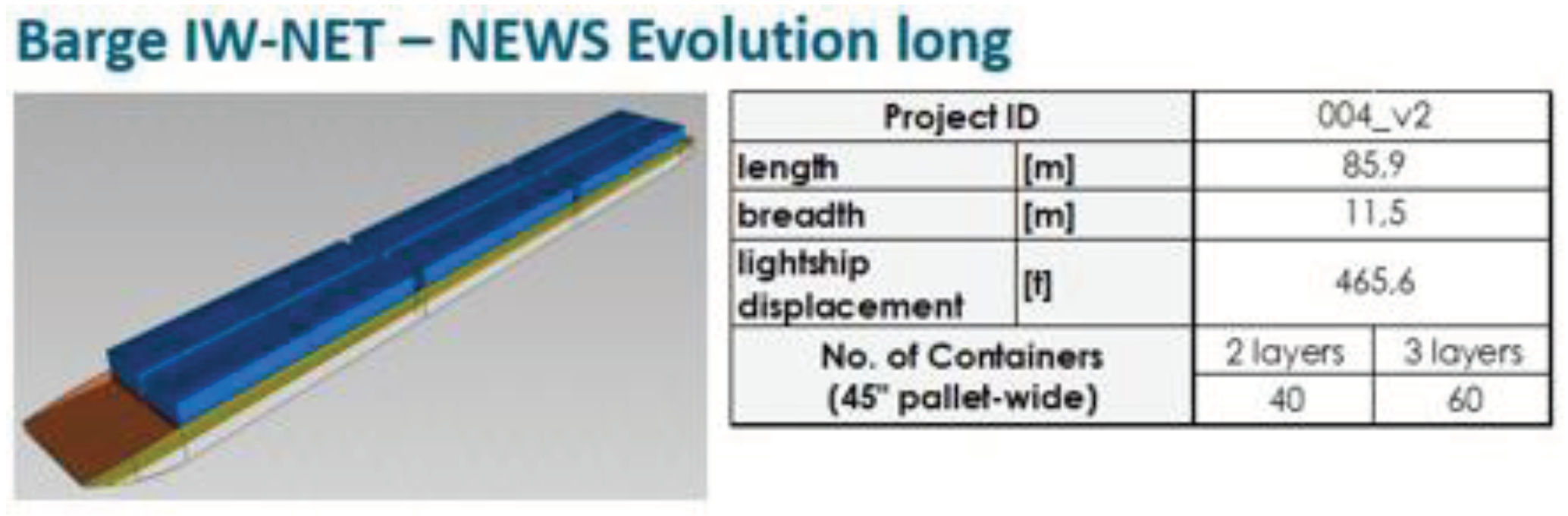

The general idea of

004 IW-NET NEWS Evolution barge design, which is presented in

Figure 3, is to optimise existing barge designs (namely Europa 2b and Europa 3a) for container transport by replacing the two side decks with a center walkway and to create container bays in order to fit four rows of (ISO-) containers abreast. The need to accommodate in particular 45’ high-cube pallet-wide containers in order to facilitate integration of inland navigation into logistics chains in mainland Europe (i.e. in particular pre- and post-run by road or rail instead of seagoing vessel) is also taken account.

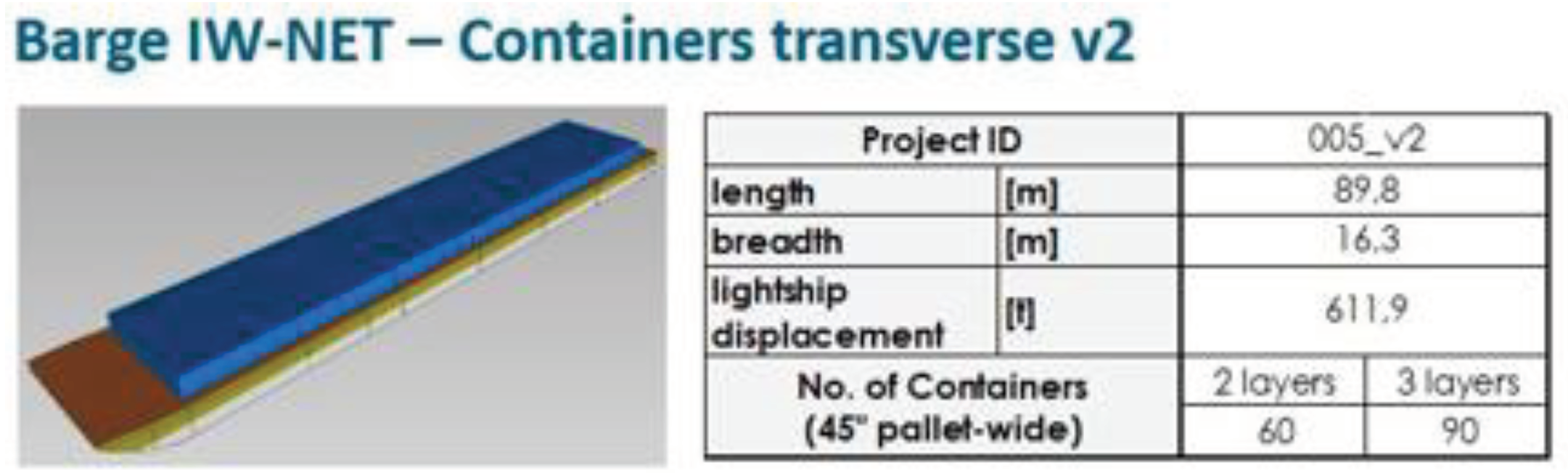

The

005 IW-NET containers transverse design (see

Figure 4) is the result of an attempt at “thinking out of the box”. Instead of the usual lengthwise placement of the containers in this design option for the containers are arranged transverse to the longitudinal center plane. Naturally, this results in a much broader barge, which does not fit into the usual convoy patterns etc. However, it was nevertheless considered worthwhile to include this option in the analysis. With a view to the breadth of the barge it would not be possible to pass the locks on the upper Danube (upstream of Regensburg) an on the Main-Danube-Canal. Considering the low grade of compatibility of this barge for convoy formations the basic design might be converted into a self-propelled motor cargo vessel.

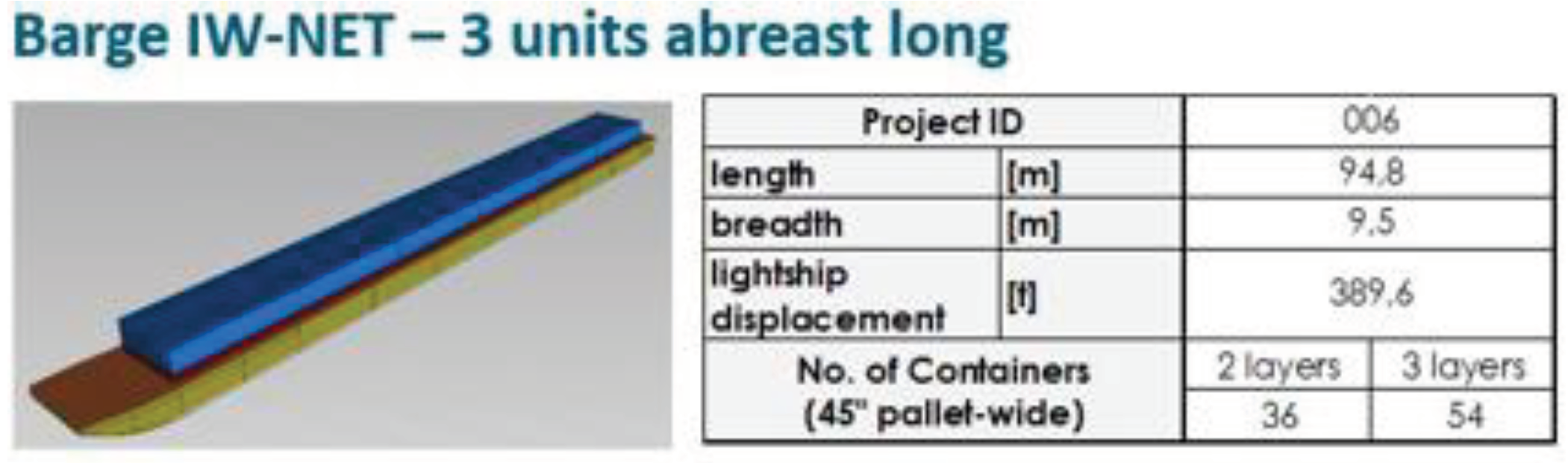

This version, i.e.,

006 IW-NET 3 units abreast long, which is shown in

Figure 5 is a variation of the IW-NET 3 units abreast barge, lengthened to accommodate an additional stack of containers.

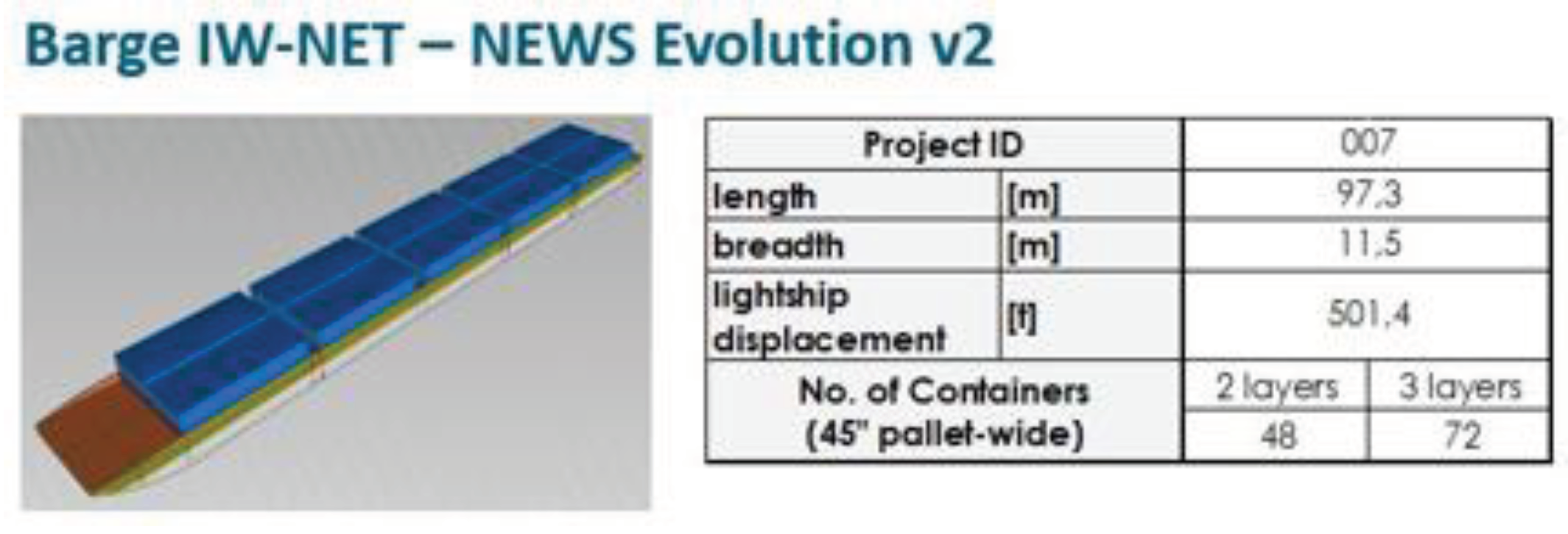

The variation called

007 IW-Net NEWS Evolution long of the IW-NET NEWS Evolution barge has been designed with six instead of ten container bays, however, the individual container bays can accommodate two lengths of 45’ high cube containers instead of just one. This variation therefore provides higher flexibility for other container types, for example being capable of receiving three lengths of 30’ containers or four lengths of 20’ containers in the container bays. The CAD model with details is presented in

Figure 6

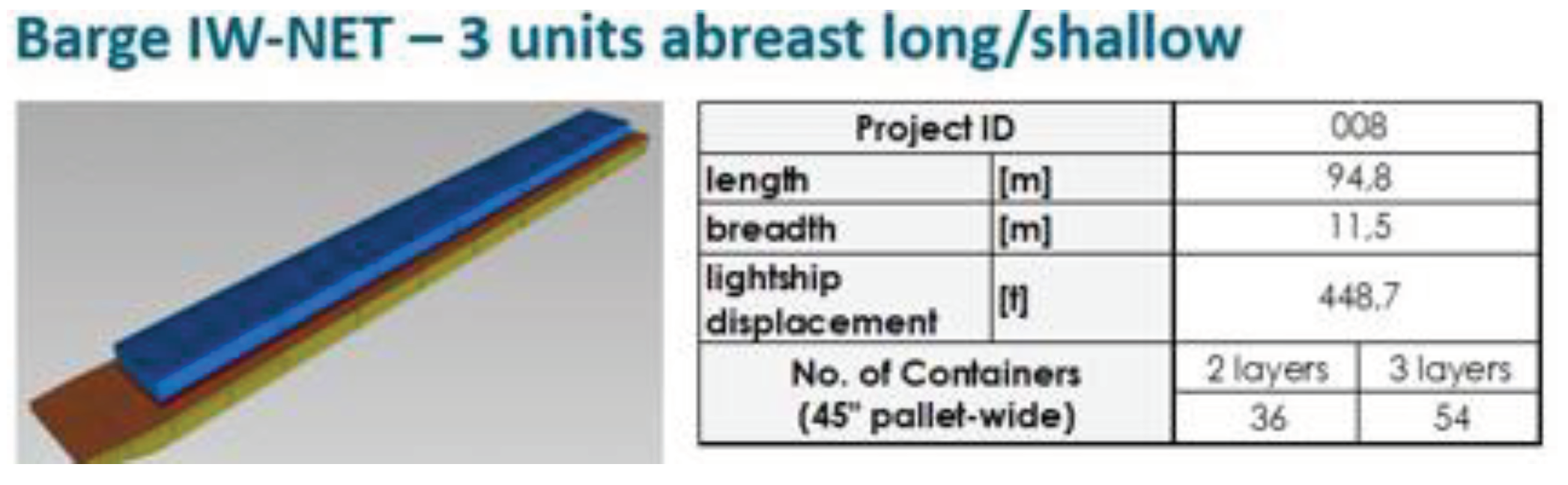

008 IW-NET 3 units abreast long-shallow (see

Figure 7) is a further variation of the IW-NET 3 units abreast barge, which keeps the container hold of the “long” variation while at the same time increasing the breadth to 11,45 m (instead of 9,50 m). The changes provide additional buoyancy, thus improving the shallow water capabilities, and more favourable stability characteristics than the other two variations.

In the following sub-sections, the modeled barge design will be further evaluated and assessed regarding their stability and the given sightlines.

3.2. Analysis of Sightlines

A sufficiently unobstructed view from the wheelhouse / the helmsman’s positions is essential for safety of navigation on inland waterways. For non-motorized barges the provisions of the European Standard for Technical Requirements for Inland Waterway Vessels (ES-TRIN) are not applicable as they are not equipped with a wheelhouse, however, operational limits as defined in the navigational police regulations have to be taken into account. Most navigational police regulations for the European inland waterway network are at least based on the European Code for Inland Waterways (CEVNI) of the UNECE Inland Water Transport Committee [

18] there-fore this set of rules has been used as a benchmark for the assessment of sightlines. Article 1.07 of the CEVNI requires that the “load […] of the vessel shall not restrict the direct view at a distance of more than 350 m in front of the vessel.” This means that a direct sightline from the helmsman’s position to a point not farther than 350 m in front of the bow of the vessel or convoy on the surface of the water must be present.

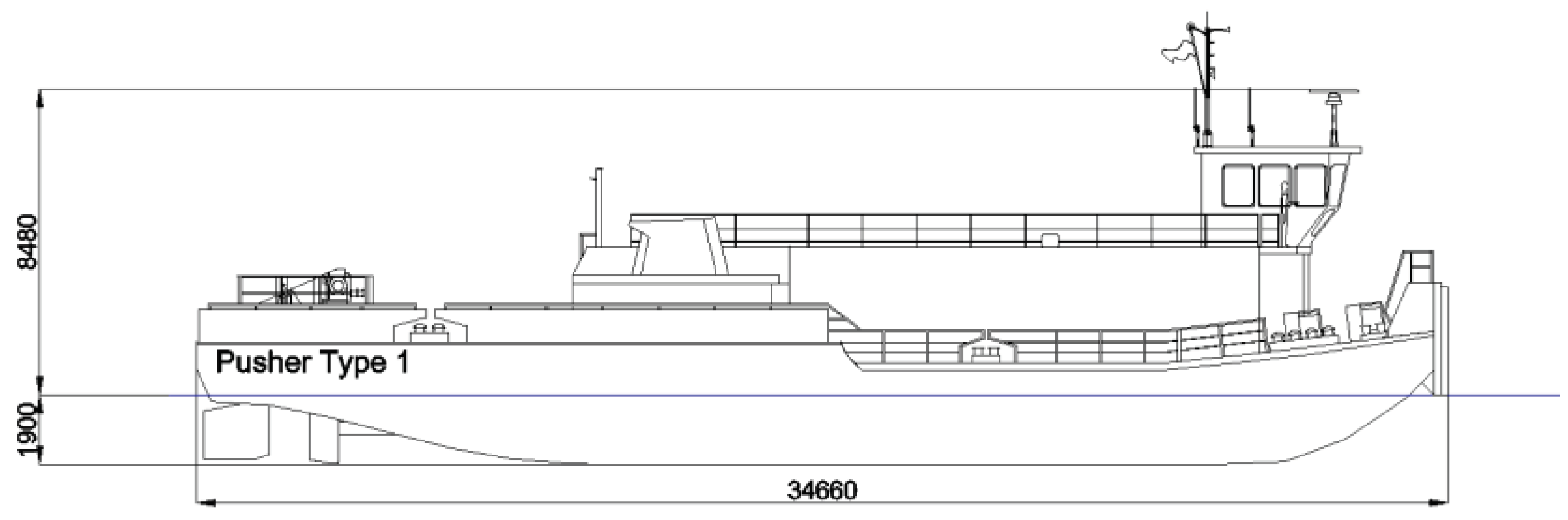

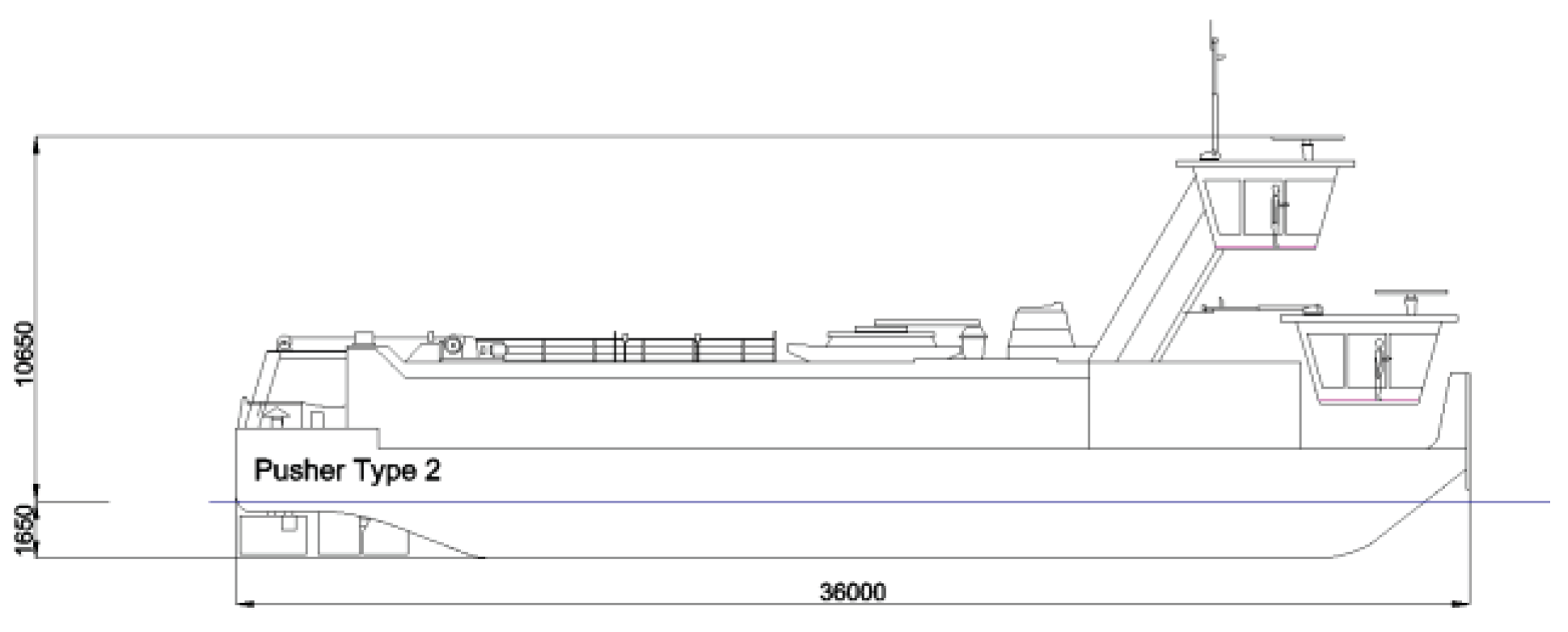

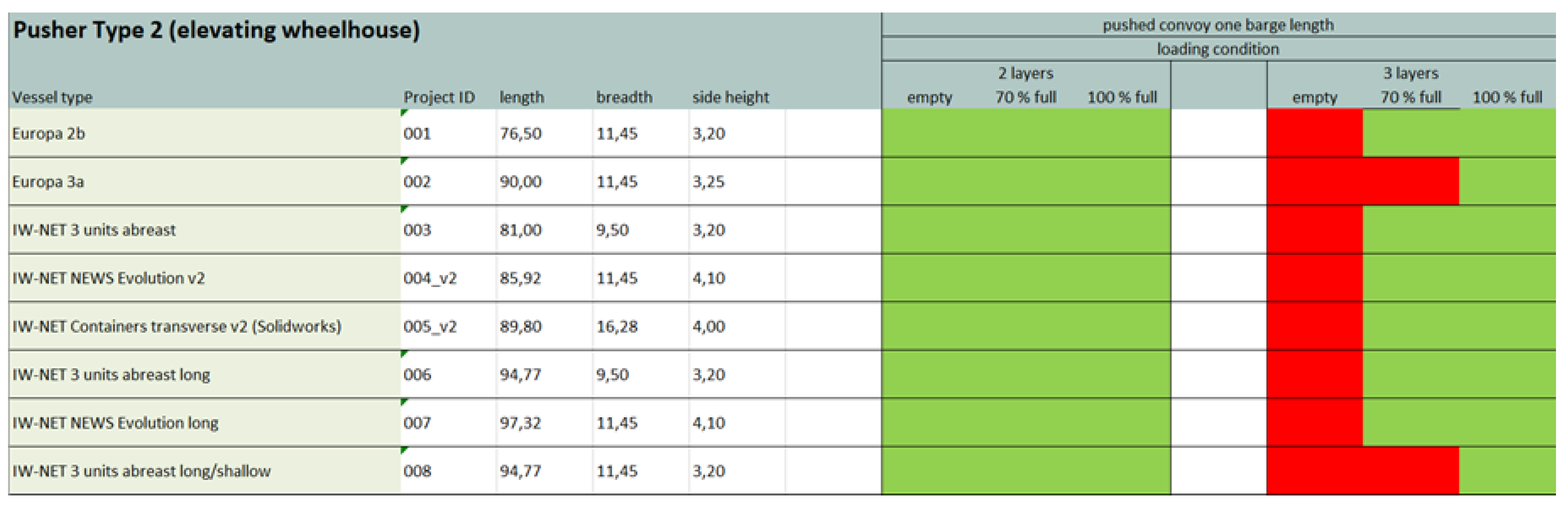

To cover a realistic range of possible pusher vessels two different types which are typical for Danube navigation have been taken into consideration for the assessment of sightlines – the main difference between the two versions is that type 1 has a fixed wheelhouse while type 2 is equipped with an elevating wheelhouse which can be lifted to provide more favourable visibility for high cargoes.

Figure [M1] 9. Pusher type 2 – elevating wheelhouse.

Figure 8.

Pusher type 1 – fixed wheelhouse.

Figure 8.

Pusher type 1 – fixed wheelhouse.

Figure 9.

Pusher type 2 – elevating wheelhouse.

Figure 9.

Pusher type 2 – elevating wheelhouse.

The analysis has been carried out under the assumption that for all considered loading conditions the barges are floating on level trim and for convoy formations with only one barge length. In line with the initial thoughts on barge design it has furthermore been assumed that the load consists of 45’ high-cube containers, which certainly have a considerable impact on the sightlines.

For all combinations of pushers and barges three different loading conditions for the containers have been considered: (1) all containers empty, (2) all containers loaded to 70% of the permissible maximum load and (3) all containers loaded to the maximum permissible load. The sightlines have been assessed geometrically, assuming a height of eye of 1,65 m above the wheelhouse floor at the steering position [

19]. The assessment shows that pushers with a fixed wheelhouse will mostly not be suitable to be used for the transport of 45’ high-cube containers. In general, sightlines in compliance with the applicable rules can only be demonstrated for one layer of containers. For two layers of containers compliance with the applicable rules can mainly be demonstrated for maximum load only. The detailed analysis is presented in

Figure 10.

As

Figure 11 reveals, the situation is much more favorable for pushers with elevating wheelhouses as two layers of containers can be carried within the applicable legal framework in all standard loading conditions assessed in this study. For a three layers transport in most pusher/barge combinations compliance can be demonstrated for containers with 70 % of the maximum load.

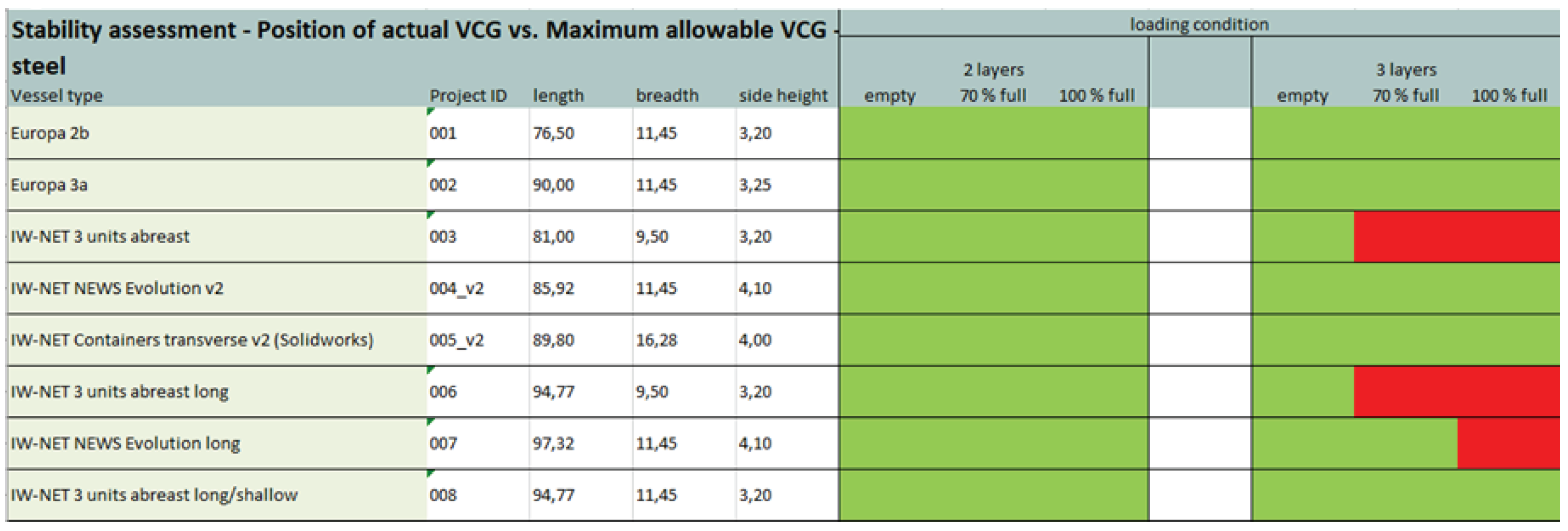

3.3. Stability Analysis

Both, technical requirements (ES-TRIN) and navigational police regulations (CEVNI) address the issue of stability of inland navigation vessels carrying containers. The provisions of Article 1.07 No. 5 of CEVNI focus on the individual operational situation and require a stability check prior to loading and unloading as well as prior to departure. The responsibility for such stability checks lies with the boat master. Exemptions from per-forming stability checks apply to certain loading configurations which are always deemed inherently stable. Regarding the technical characteristics of an inland navigation vessel the ES-TRIN sets out a range of provisions in Chapter 27 concerning limit conditions and methods of calculation for the transport of non-secured and secured containers, taking into account the hydrostatic characteristics of the hull (mainly depending on the shape of the hull and the weight distribution), the loading situation and the heeling moments to be considered. For the purpose of this study, it was decided to assess the stability of the different barge designs under the conditions set out in Article 27.02 of ES-TRIN (non-secured containers) and for six standard loading conditions:

- (1)

2 layers of 45’ high-cube containers empty.

- (2)

2 layers of 45’ high-cube containers 70 % full

- (3)

2 layers of 45’ high-cube containers 100 % full

- (4)

3 layers of 45’ high-cube containers empty.

- (5)

3 layers of 45’ high-cube containers 70 % full

- (6)

3 layers of 45’ high-cube containers 100 % full

For each loading condition the calculation delivers a maximum allowable vertical center of gravity (VCG) that must be met to ensure compliance with the requirements of Article 27.02 of ES-TRIN. The actual VCG of each loading condition is assessed against the maximum allowable VCG.It can be shown that most of the loading conditions comply with the statutory requirements, the only exceptions being the 9,50 m wide barge versions in the short and long variants for three layers of loaded containers (70 % and 100 %) and the long version of the NEWS Evolution barge for three layers of fully loaded containers.

When comparing loading scenarios, it's important to note that the results discussed are based on standardised conditions. Optimising the loading situation for individual cases may give better results, especially when considering the transport of three layers of containers. Only high-cube containers were considered for the standardised loading conditions. However, by using standard height containers, the total load height for three layers could be reduced by approximately 1.20 metres, which would improve visibility and the vertical centre of gravity of the load, thereby increasing stability. In addition, the use of a pusher with a longer operating range for the lifting wheelhouse could further improve sightlines compared to the pusher type analysed in this study.

Looking at the overall assessment of the different design options, it's clear that there is no single optimal solution. Barge design must always be tailored to the specific application and the operator's requirements, considering the available infrastructure in the intended navigation area.

Nevertheless, there's considerable room for improvement compared to the current barge types (001 Europa 2b and 002 Europa 3a), especially when it comes to accommodating the 45' high-cube pallet-wide containers commonly used in European road and rail transport. It's estimated that a minimum of 30 45' containers per barge is required to achieve competitive freight rates on the Danube corridor. While standard Europe 2b barges fall short of this capacity, Europe 3a barges barely meet it. Conversely, all new design options meet or exceed this threshold.

With low water resistance as the primary consideration, the 005 IW-NET Containers transverse version appears to be the most favourable design. However, this design has operational drawbacks that need to be carefully considered. Considering other factors such as stability, traffic safety and unobstructed views from the wheelhouse, the best design choice can only be made on an individual basis, taking into account specific transport routes, port facilities and available pusher tugs.

4. Conclusions

One goal of our study was to identify design options, which enhance the navigability of container barges on the Danube River. We identified in total six new barge designs, which fit to the boundaries we decided on (i.e., the barges should serve the Danube stretch between Enns, Austria and Giurgiu, Romania; they should be optimized to carry 45’ pallet-wide high-cube containers used for intermodal transport; barges should not exceed the dimensions of 97,50 m x 11,45 m). The new barge designs are able to foster up 90 45’ pallet-wide high-cube containers in three layers, compared to a traditional Europa 2a barge, which is able to carry only up to 45 containers in three layers. Nevertheless, after assessing stability and sightlines of each barge designs, we observed that a three layers transport is not feasible in each case. A two layers transport is in most cases possible. There is hardly a general answer, which can be given regarding the best suitable barge design for transporting 45’ pallet-wide high-cube containers. For this reason, each transport situation needs to be evaluated separately, to determine the best suitable barge design for this specific transport situation.

The study contributes to the theoretical understanding by identifying six new barge designs tailored for enhanced navigability on the Danube River, specifically optimized for transporting 45’ pallet-wide high-cube containers within defined boundaries. Our study provides practical contributions by offering stakeholders involved in container transport along the Danube River viable barge designs optimized for specific operational requirements. The identification of feasible designs, along with considerations of stability and sightlines, furthermore, enables practical enhancements in barge design aimed at improving efficiency and safety in container transport operations on the Danube.

As limitations of our study there could be named the geographical scope, which limits the generalizability of the results for other rivers. Another limitation concerns the container type. The study focused solely on 45’ pallet-wide high cube containers, omitting other possible container types. Further research on this topic could imply broadening the geographical scope and the utilization of other possible container types. Other fields for further research would be investigating the operational feasibility of the fix new barge designs developed or utilizing dynamic simulation modeling techniques to simulate various loading scenarios.

Author Contributions

Conceptualization, L.H. and B.D.-B.; methodology, B.B..; software, R.K..; validation, B.B. and R.K..; formal analysis, B.B. and R.K..; investigation, L.H and B.B.; resources, B.B. and R.K..; data curation, B.B. and R.K.; writing—original draft preparation, L.H. and B.D.-B.; writing—review and editing, L.H. and B.D.-B.; visualization, B.B.; supervision, L.-M.P.-E.; project administration, L.-M.P.-E.; funding acquisition, L.-M.P.-E. All authors have read and agreed to the published version of the manuscript.

Funding

This research is part of the IW-NET project and has received funding from the European Union’s Horizon 2020 research and innovation programme under grant agreement No 861377.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

In this section, please provide details regarding where data supporting reported results can be found, including links to publicly archived datasets analyzed or generated during the study. Please refer to suggested Data Availability Statements in section “MDPI Research Data Policies” at

https://www.mdpi.com/ethics. If the study did not report any data, you might add “Not applicable” here.

Conflicts of Interest

The authors declare no conflict of interest.

References

- European Commission. Communication from the Commission to the European Parliament, the European Council, the Council, the European economic and social Comittee and the Comittee of the regions: The European Green Deal, 2019. Available online: https://eur-lex.europa.eu/resource.html?uri=cellar:b828d165-1c22-11ea-8c1f-01aa75ed71a1.0002.02/DOC_1&format=PDF.

- European Commission. Sustainable and Smart Mobility Strategy – putting European transport on track for the future: COM(2020) 789 final, 2020. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX%3A52020DC0789 (accessed on 12 August 2022).

- Jacobs, K. Inland waterway transport in the EU, 2022. Available online: https://www.europarl.europa.eu/thinktank/en/document/EPRS_BRI(2022)698918.

- Tavasszy, L.A.; Behdani, B.; Konings, R. Intermodality and Synchromodality. SSRN Journal 2015. [Google Scholar] [CrossRef]

- Blauwens, G.; Vandaele, N.; van de Voorde, E.; Vernimmen, B.; Witlox, F. Towards a Modal Shift in Freight Transport? A Business Logistics Analysis of Some Policy Measures. Transport Reviews 2006, 26, 239–251. [Google Scholar] [CrossRef]

- CCNR. “Act now!” on low water and effects on Rhine navigation. Available online: https://www.ccr-zkr.org/files/documents/workshops/wrshp261119/ien20_06en.pdf (accessed on 24 November 2020).

- Kawasaki, T.; Matsuda, T. Containerization of bulk trades: A case study of US-Asia wood pulp transport. Maritime Economics & Logistics 2015, 17, 179–197. [Google Scholar]

- Bian, Z.; Bai, Y.; Douglas, W.S.; Maher, A.; Liu, X. Multi-year planning for optimal navigation channel dredging and dredged material management. Transportation Research Part E: Logistics and Transportation Review 2022, 159, 102618. [Google Scholar] [CrossRef]

- Islam, D.M.Z. Prospects for European sustainable rail freight transport during economic austerity. Benchmarking: An International Journal 2018, 25, 2783–2805. [Google Scholar] [CrossRef]

- Hoffmann, M.; Haselbauer, K.; Haberl, A.; Blab, R.; Simoner, M.; Hartl, T. Performance based Waterway Management - Transport Market and Competitiveness. In Life-Cycle of Structural Systems: Design, Assessment, Maintenance and Management; Hitoshi, Furuta/Dan M., Frangopol/Mitsuyoshi, Akiyama, Ed., 2014; pp 365–366, ISBN 9781138001206.

- Beuthe, M.; Jourquin, B.; Urbain, N.; Lingemann, I.; Ubbels, B. Climate Change Impacts on Transport on the Rhine and Danube: A multimodal approach. Transportation Research Part D: Transport and Environment 2014, 27, 6–11. [Google Scholar] [CrossRef]

- Obidike, V.E. Development of a pushed barge with optimum performance on shallow draughts; Schiffstechnik Buchloh GmbH u., Co. KG, Germany, 2021.

-

Feasibility study and design of shallow draught ore carriers for inland, waterways, Sha, O.P.; Pallencar, S.; Viswanath, N.; Misra, S.C.,; Eds. First International Conference IDS 2013, Peru, 2013.

- Radojčić, D.; Simić, A.; Momčilović, N.; Motok, M.; Friedhoff, B. Design of Contemporary Inland Waterway Vessels: The Case of the Danube River, 1st ed., 2021, ISBN 978-3-030-77324-3.

- Bačkalov, I.; Kalajdzic, M.; Momčilović, N.; Rudaković, S. A study of an unconventional container vessel concept for the Danube. Proceedings of PRADS 2016 2016. [Google Scholar]

- GNEE. Shipbuilding Steel. Available online: https://de.coldrolledsteels.com/shipbuilding-steel-plate/bv-grade-a-shipbuilding-steel-length-3000mm.html (accessed on 16 March 2024).

- Delftship. Naval Architecture software. Available online: http://www.delftship.net/ (accessed on 14 March 2024).

- United Nations Economic Commission for Europe. European Code for Inland Waterways, Sixth revised edition; United Nations: New York, Geneva, 2021; ISBN 978-92-1-005865-0. [Google Scholar]

- CESNI. European Standard laying down Technical Requirements for Inland Navigation vessels, 2021/1; United Nations, 2021.

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).